LNG (liquefied natural gas) liquid dome fragment same-mould manufacturing and staged folding method

A staged, liquid dome technology, applied in ship construction, ship parts, ships, etc., can solve problems such as difficult to meet the precision requirements of liquid dome segments, verticality deviation of pump tower installation, large joint deviation, etc., to avoid The effects of cutting and repairing work, ensuring construction quality, and ensuring butt joint accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

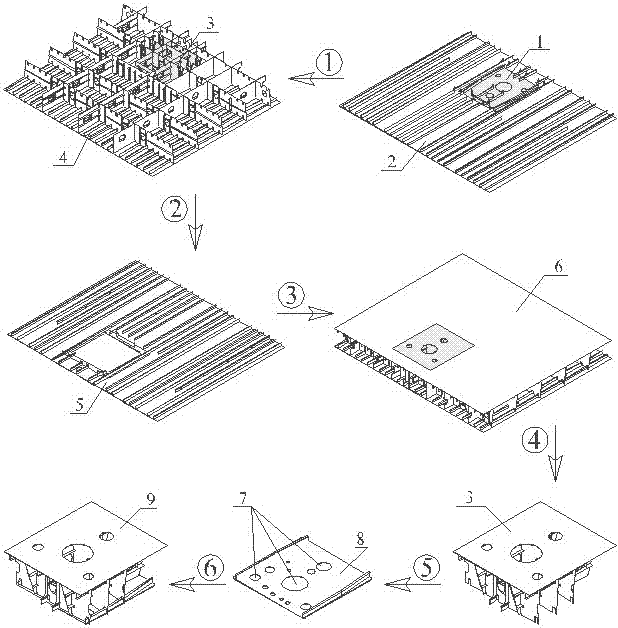

[0023] Such as figure 1 , figure 2 and image 3 As shown, the LNG liquid dome of the present embodiment is manufactured in segments and in stages, and the method is closed in stages, and the method includes the following steps:

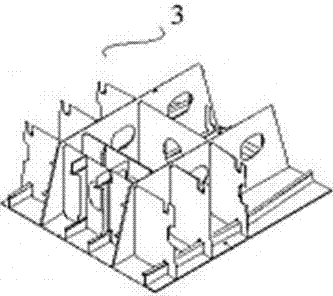

[0024] The first step is reverse manufacturing: take liquid dome segmented well deck 1 and deck segment 6’s well deck 2 as the same base, and adopt synchronous scribing, assembly and welding to produce reverse liquid dome fragment 3 and deck fragment 4,

[0025] The second step, normal closure: After the anti-state fragments are combined, turn over to the inner deck 5, and use the inner deck 5 as the base to normal close the same tire (note: the vacant inner deck at the liquid dome segment is temporarily replaced by slats ), the liquid dome segment 3 and the deck segment 6 are obtained. After the completion of the two segments, go to the overall painting and assembly,

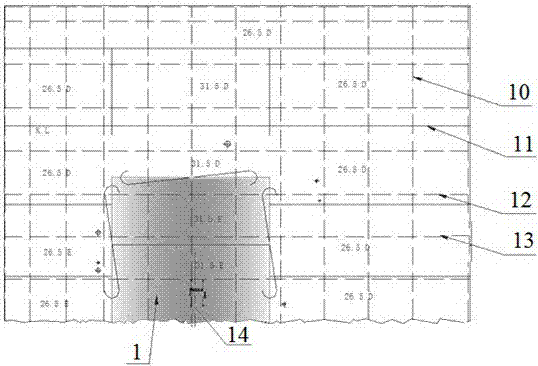

[0026] The third step, data measurement: after the dock is installed, the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com