Automatic packaging box stacking machine capable of achieving selective stacking

An optional, box-packing technology, applied in the stacking of objects, de-stacking, transportation and packaging of objects, etc., can solve the problems of low steering efficiency and insufficient steering, and achieve high steering efficiency, reliable steering, and palletizing. Provides the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

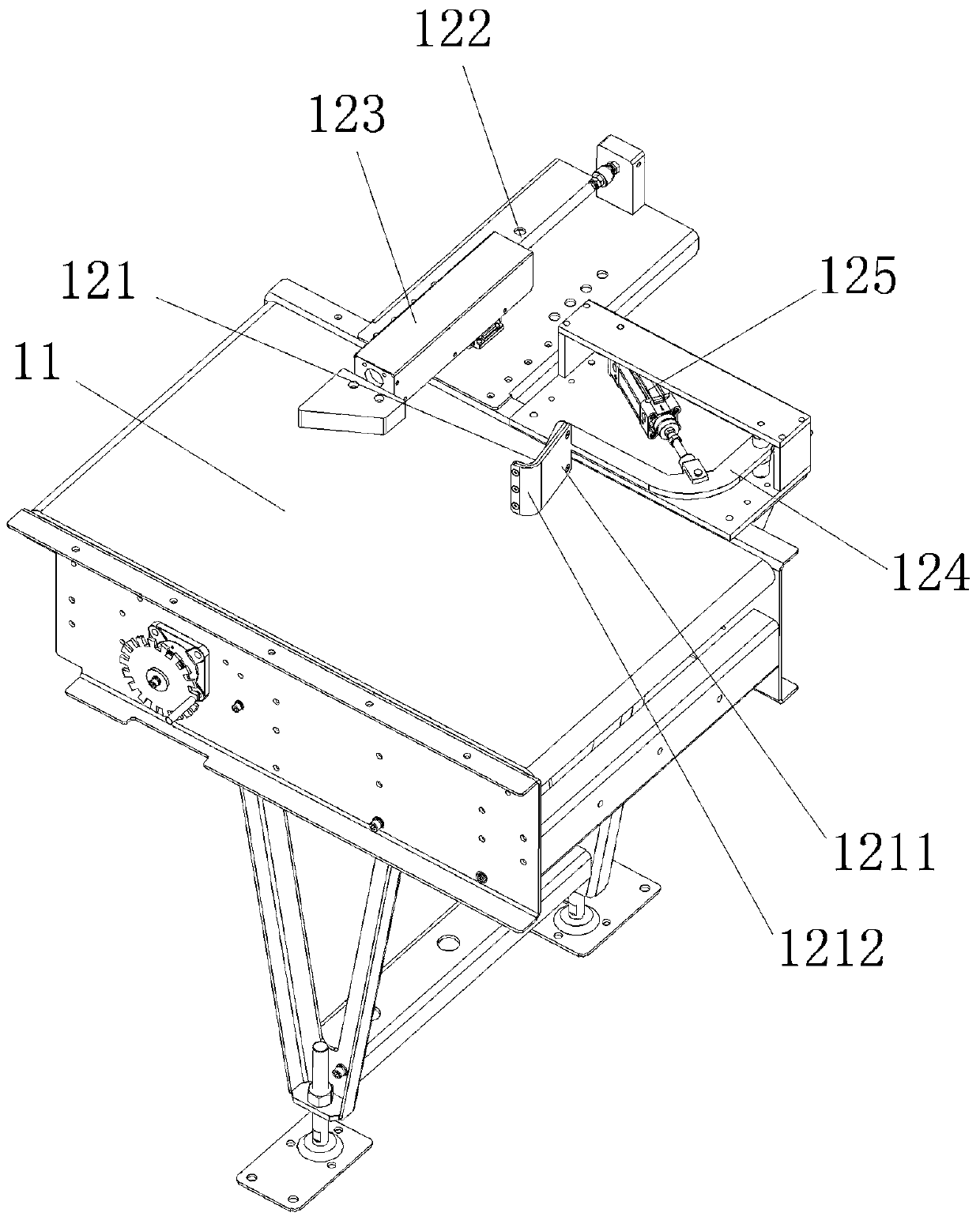

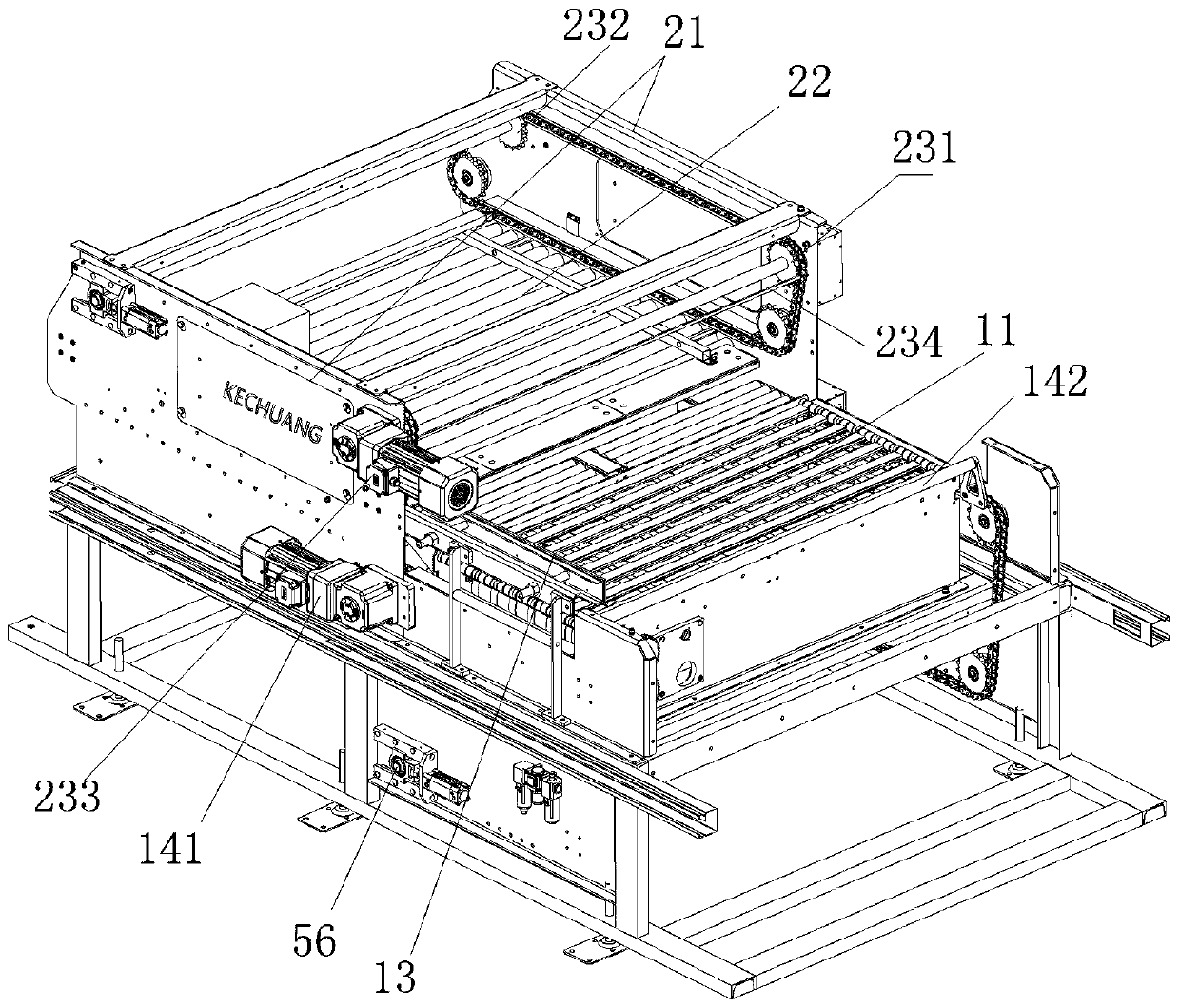

[0032] figure 1 It is the first embodiment of the present invention. In this embodiment, the feeding conveying device 11 adopts a conveyor belt, and several groups of conveying rollers are arranged at the docking position of the end of the feeding conveying device 11 and the grouping push mechanism, so that the pusher rod 142 can move in a circular motion. Pass through the gap between the conveyor rollers. A detection sensor is provided at a suitable position of the feed conveying device 11. When the packing box needs to be turned to be transported to the position of the detection sensor, the control system controls the pre-steering baffle 121 and the righting stopper 123 to stretch out, and the pre-steering baffle 121 passes through its lateral direction. The blocking part 1211 blocks a corner of the packaging box. Under the forward thrust of the feeding conveying device 11, the packaging box rotates and pre-steers around the blocked angle, and most of the steering is less th...

Embodiment 2

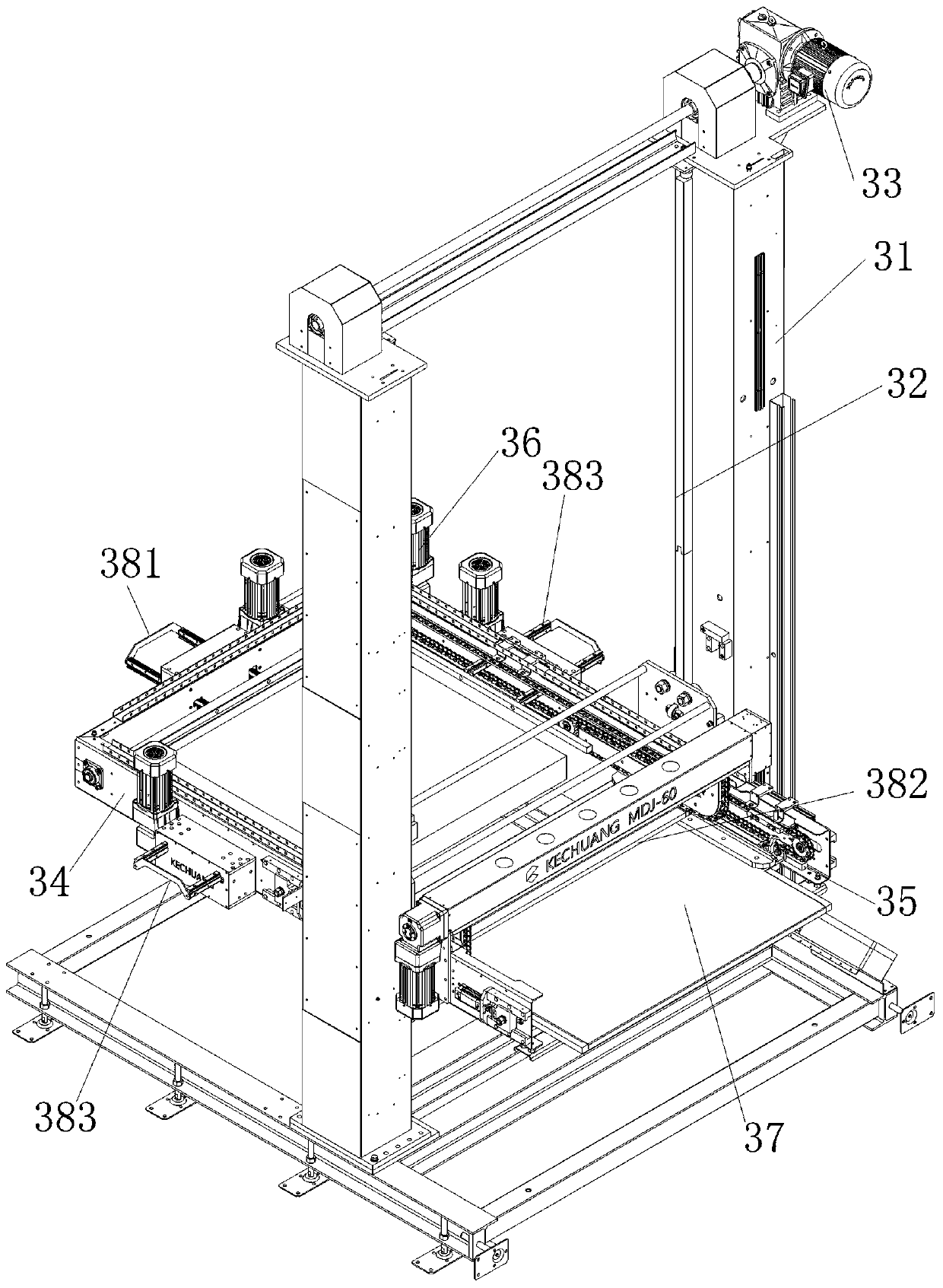

[0044] In embodiment two, the basic structure is the same as in embodiment one, and all conveying devices in embodiment two use conveying rollers. In the sorting steering device and the grouping pushing mechanism of the first embodiment, the pushing box motor 141 and the pushing motor 233 are directly connected with the sprocket shaft 56, while in the second embodiment, they are connected by a belt. Both the pushing box transmission mechanism and the layer pushing mechanism in the second embodiment adopt belt transmission, and the pushing box lever 142 and the layer pushing rod 234 are all positioned on the belt. The driving mechanism of the conveying trolley in the gantry palletizing mechanism also adopts a belt drive, and the conveying trolley 37 both sides are connected with the belt by means of a fixed plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com