Patents

Literature

610results about How to "Sports reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

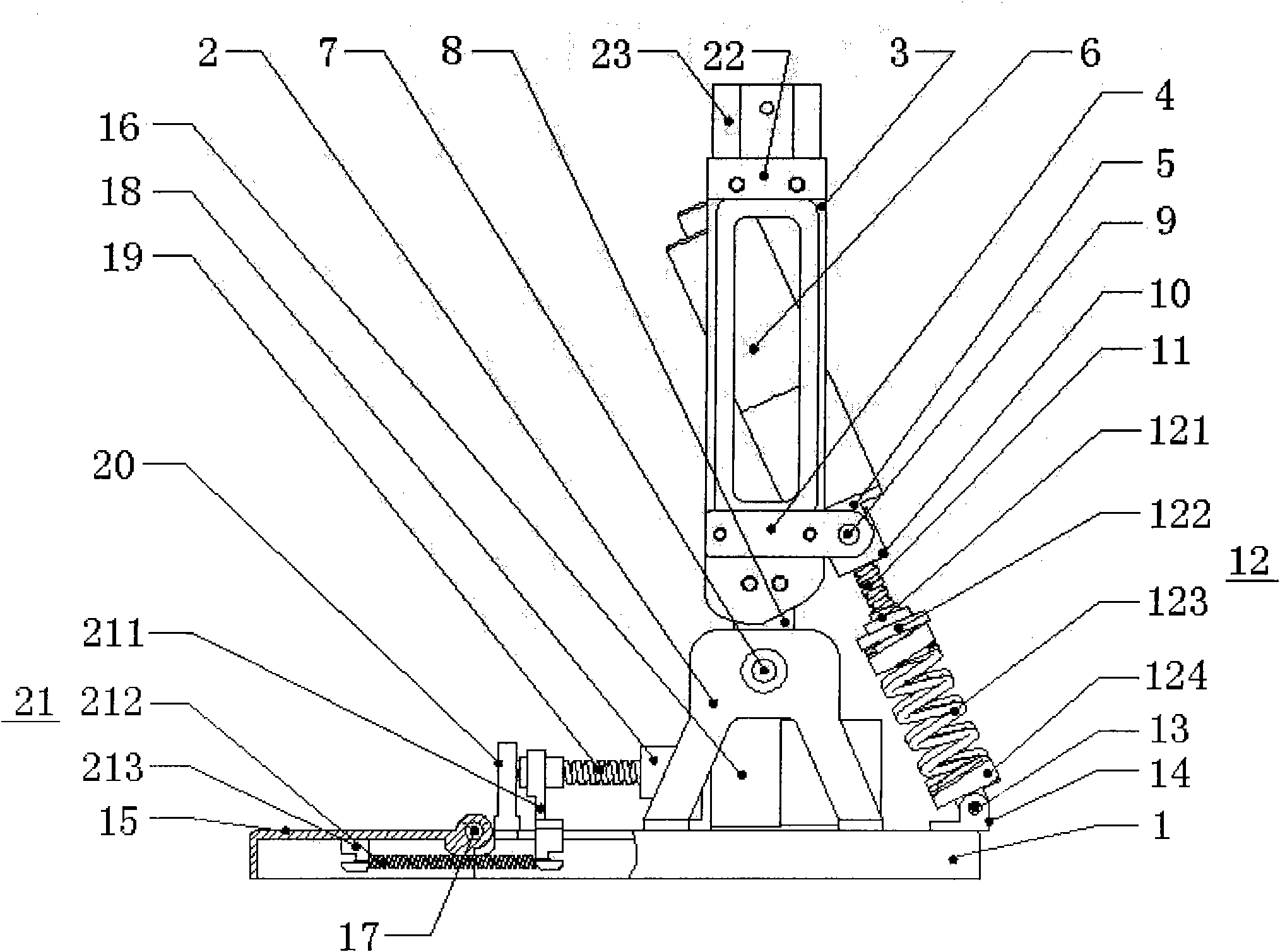

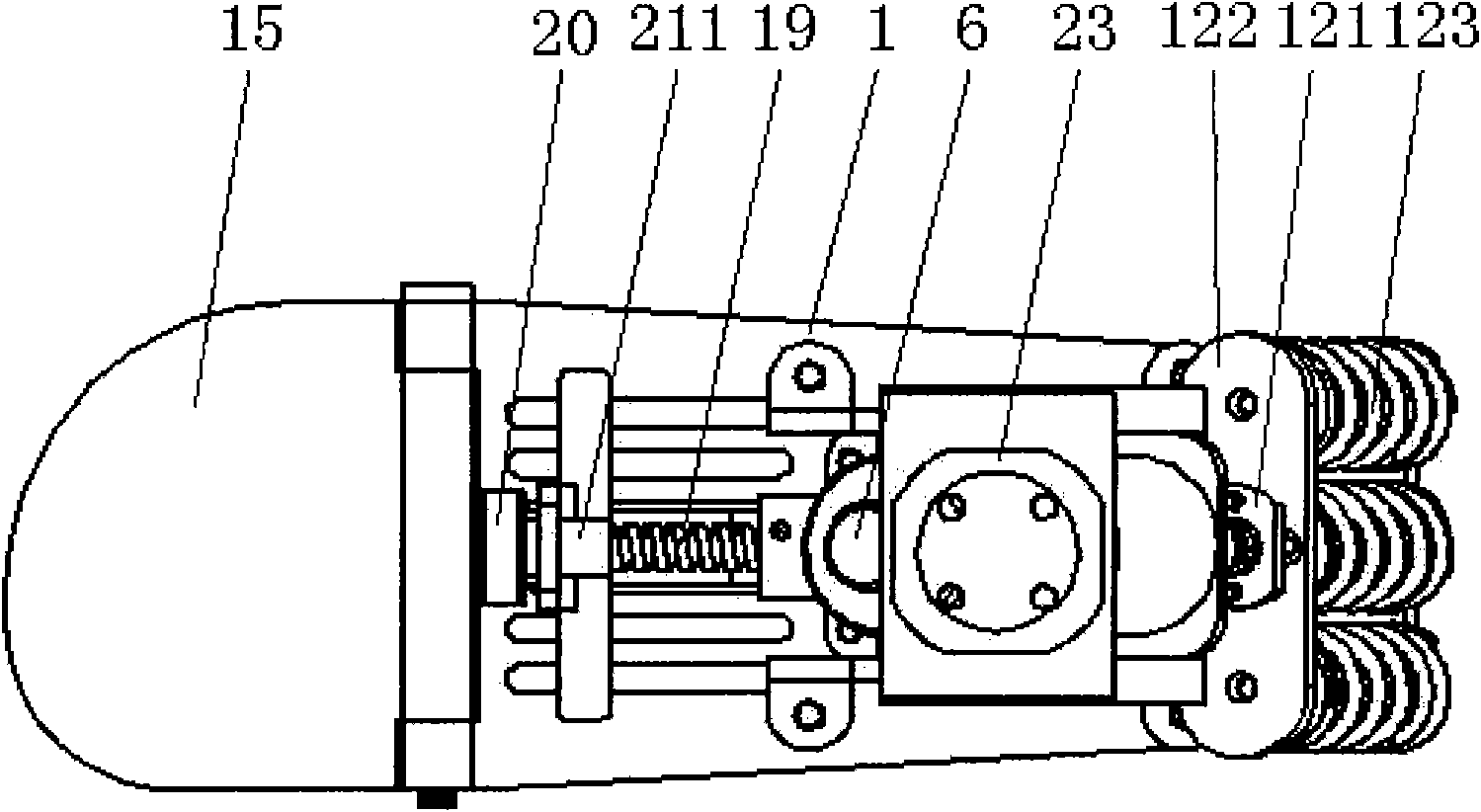

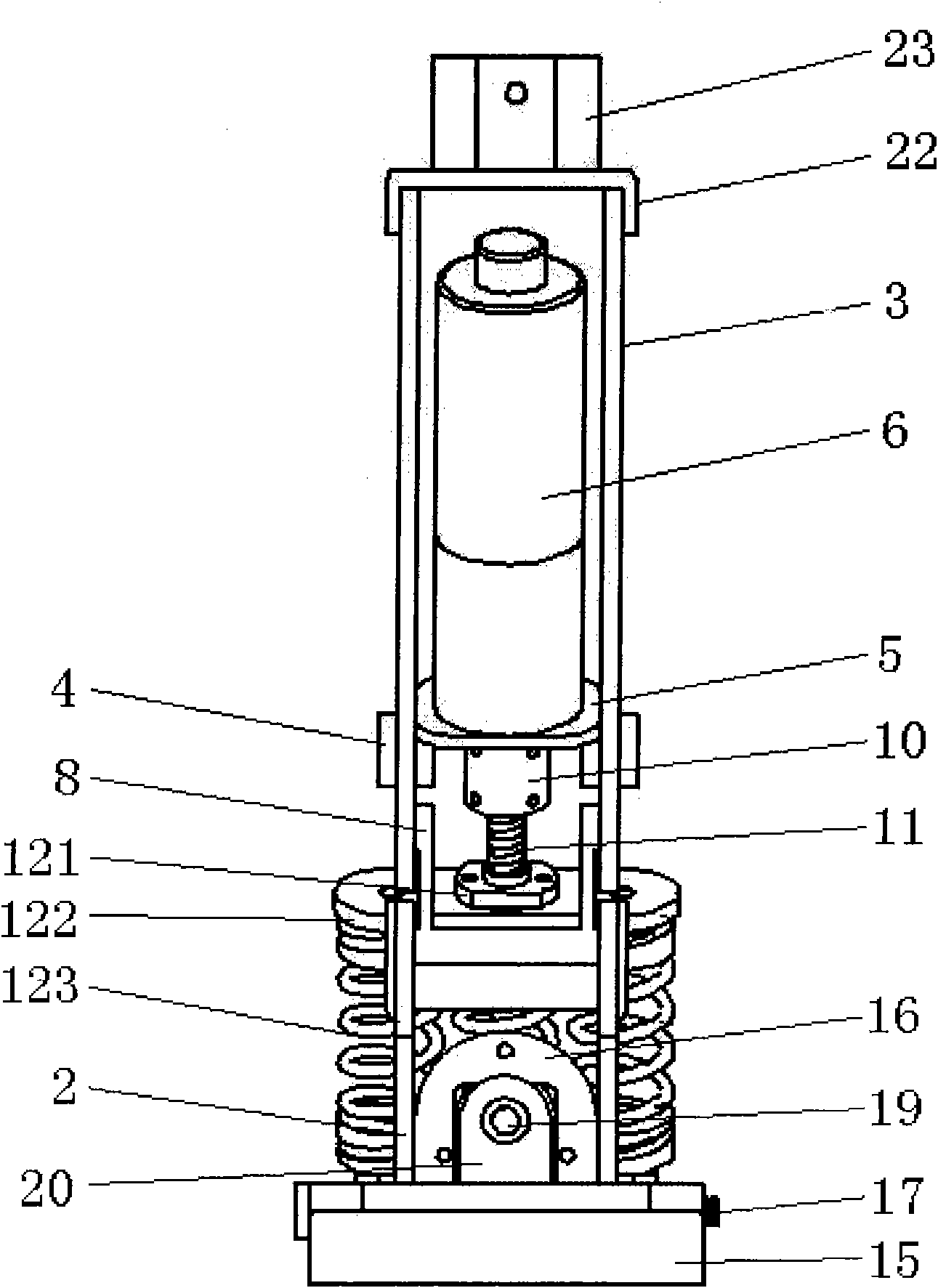

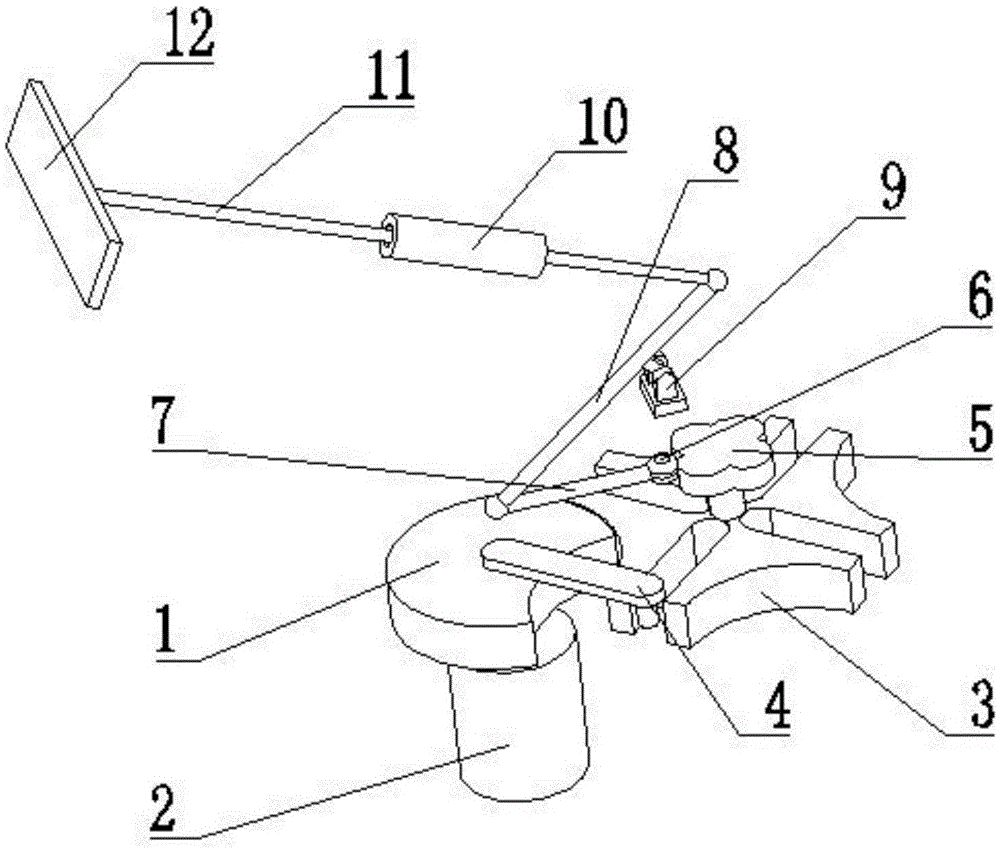

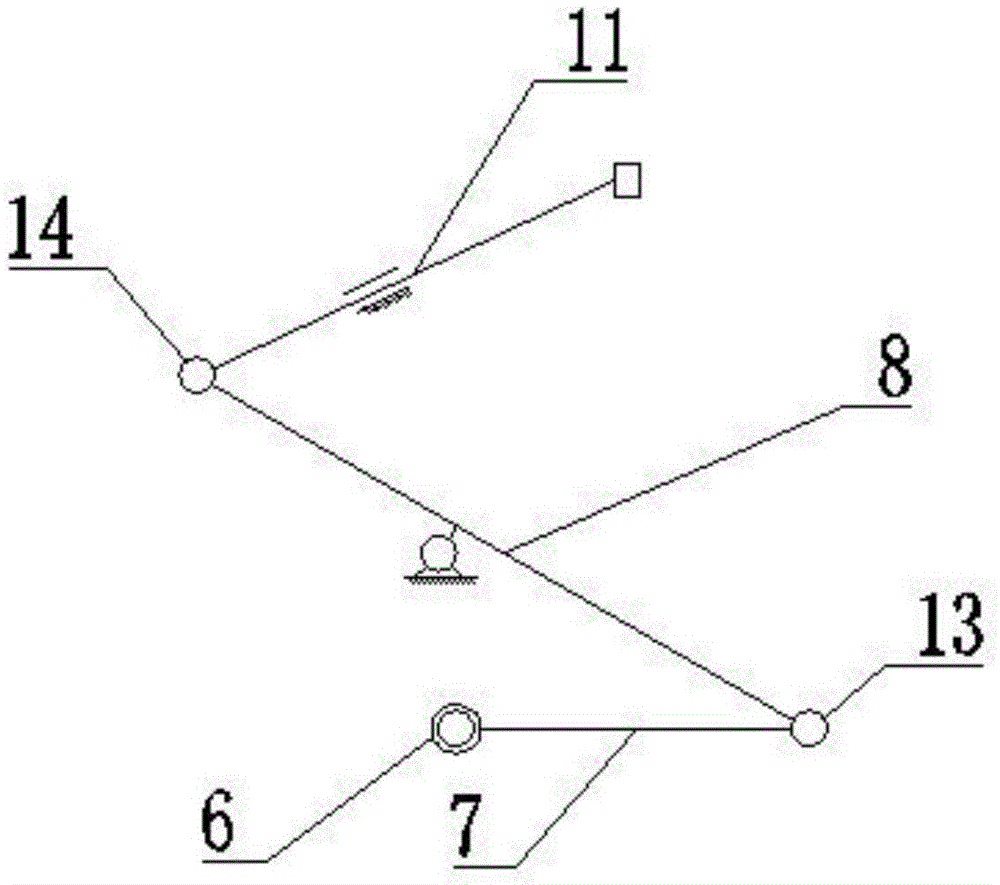

Dynamic below-knee artificial limb containing flexible dynamic ankle joints and toe joints

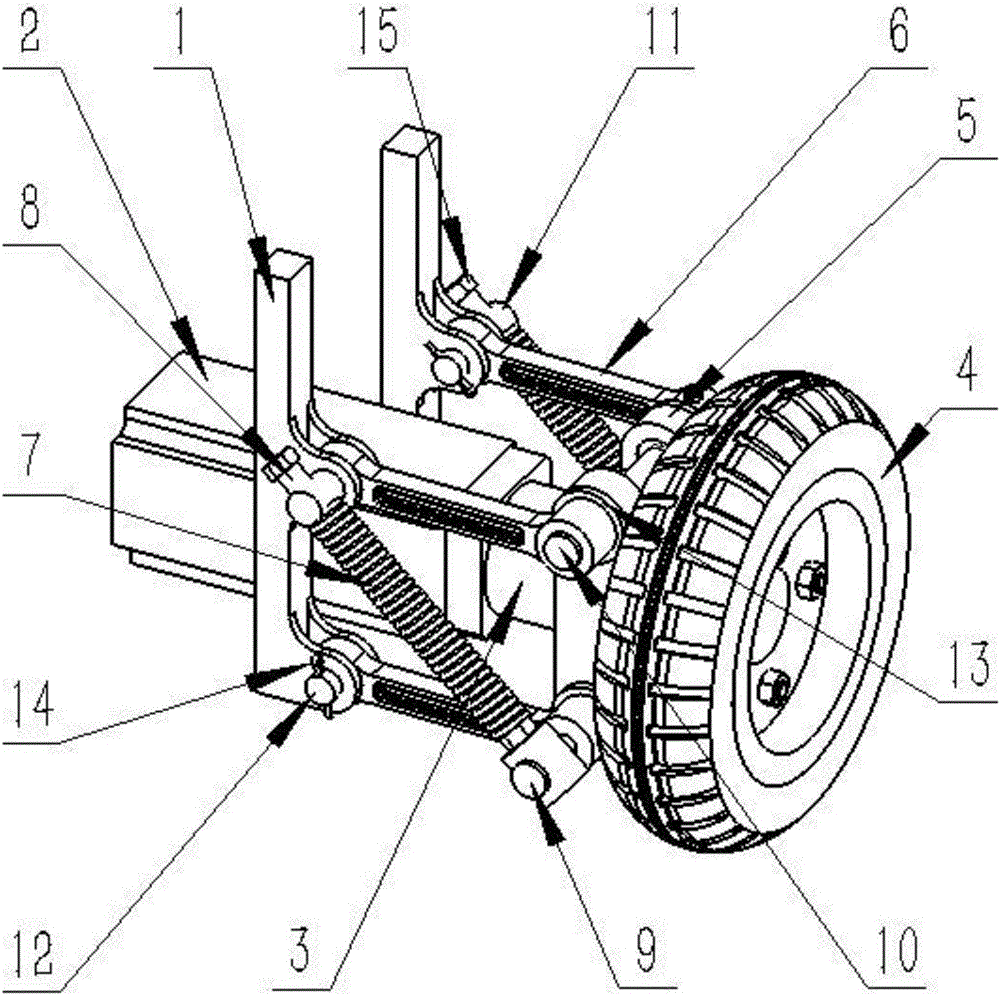

The invention relates to a dynamic below-knee artificial limb containing flexible dynamic ankle joints and toe joints, which is characterized by comprising an ankle joint moving mechanism and a toe joint moving mechanism, wherein the ankle joint moving mechanism comprises a back sole, an ankle joint supporting frame, shank baffle plates and an ankle joint motor; the ankle joint supporting frame is fixed at the upper part of the back sole, and the upper end of the ankle joint supporting frame is articulated with an ankle joint shaft connecting frame connected between two shank baffle plates; the ankle joint motor is fixedly connected between the two shank baffle plates, the output end of the ankle joint motor is fixedly connected with one end of an ankle joint screw through a shaft coupling, and the other end of the screw is connected with the back sole through an ankle joint spring mechanism; the toe joint moving mechanism comprises a front sole and a toe joint motor, wherein the front sole is articulated with the back sole, and the toe joint motor is fixedly connected with the back sole; an output shaft of the toe joint motor is fixedly connected with one end of a toe joint screw through a shaft coupling, and the other end of the screw is articulated with a toe joint screw fixing frame; and the toe joint screw is connected with the front sole through a toe joint spring mechanism. The dynamic below-knee artificial limb can be widely applied to the researches on the flexible dynamic joints of artificial limbs and serves the handicapped.

Owner:PEKING UNIV

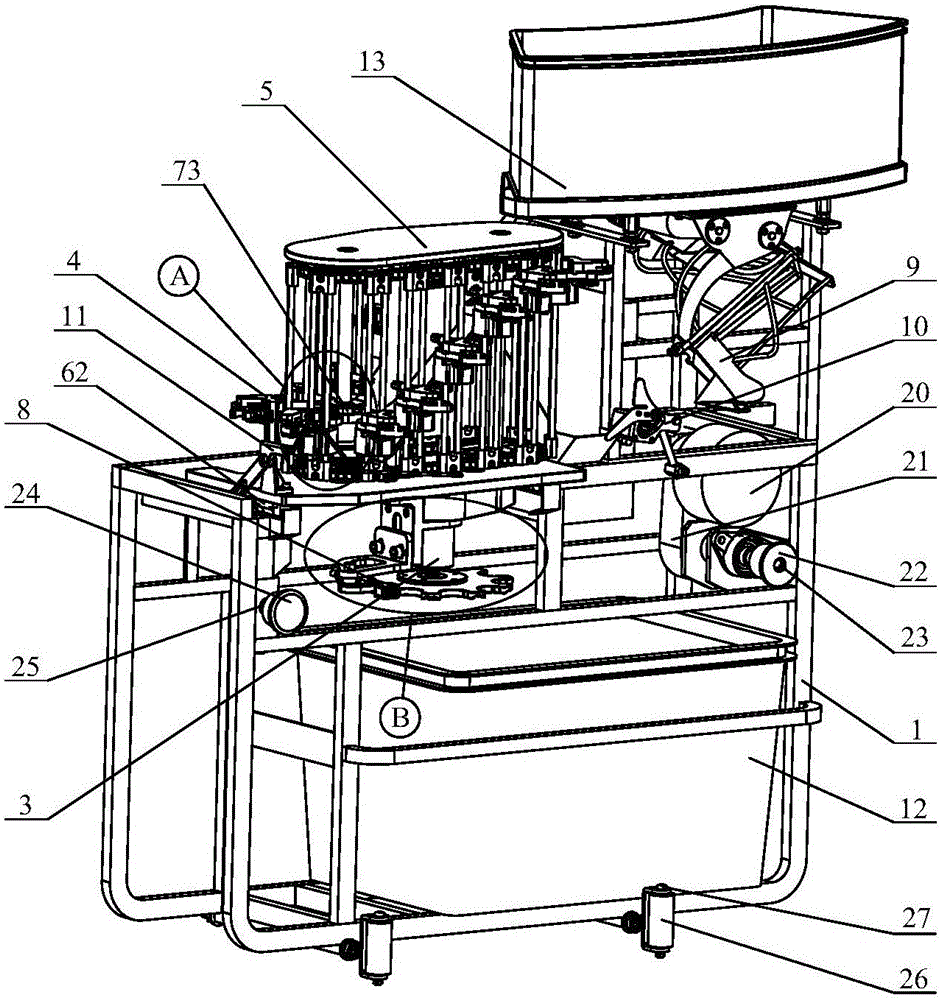

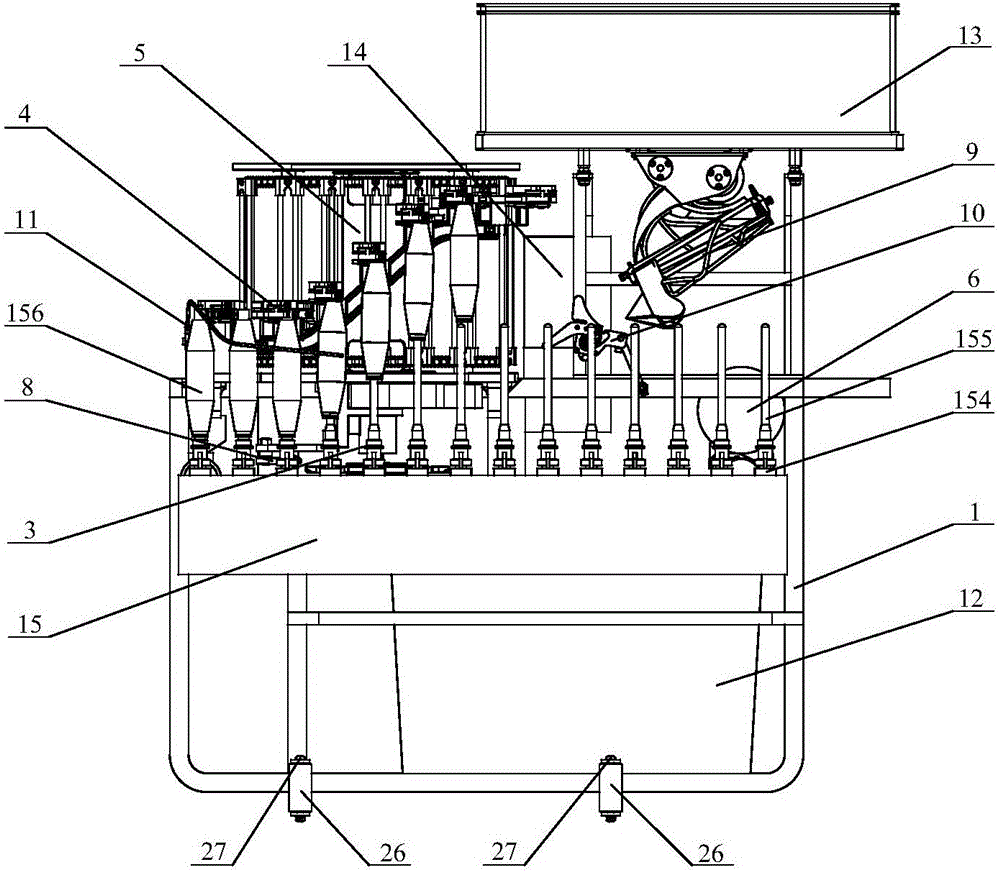

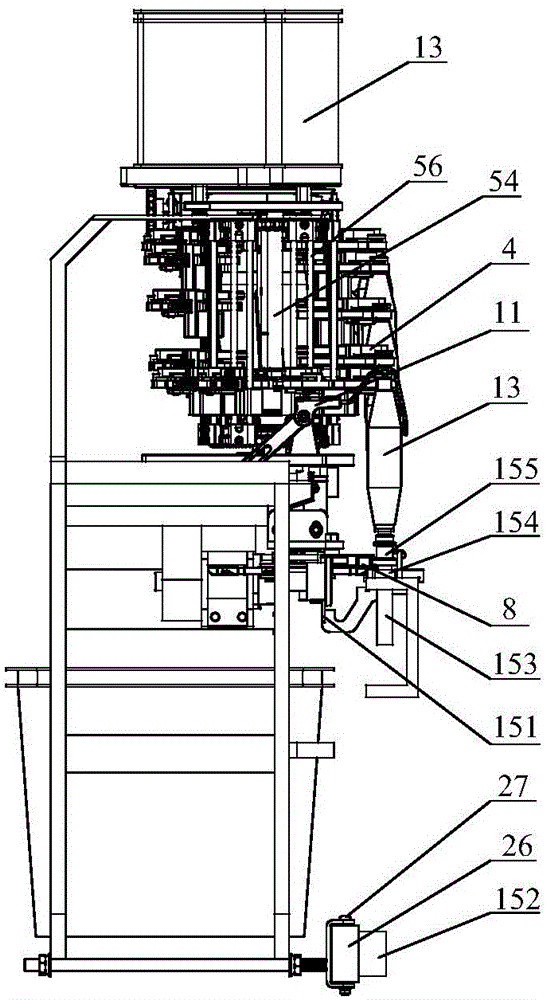

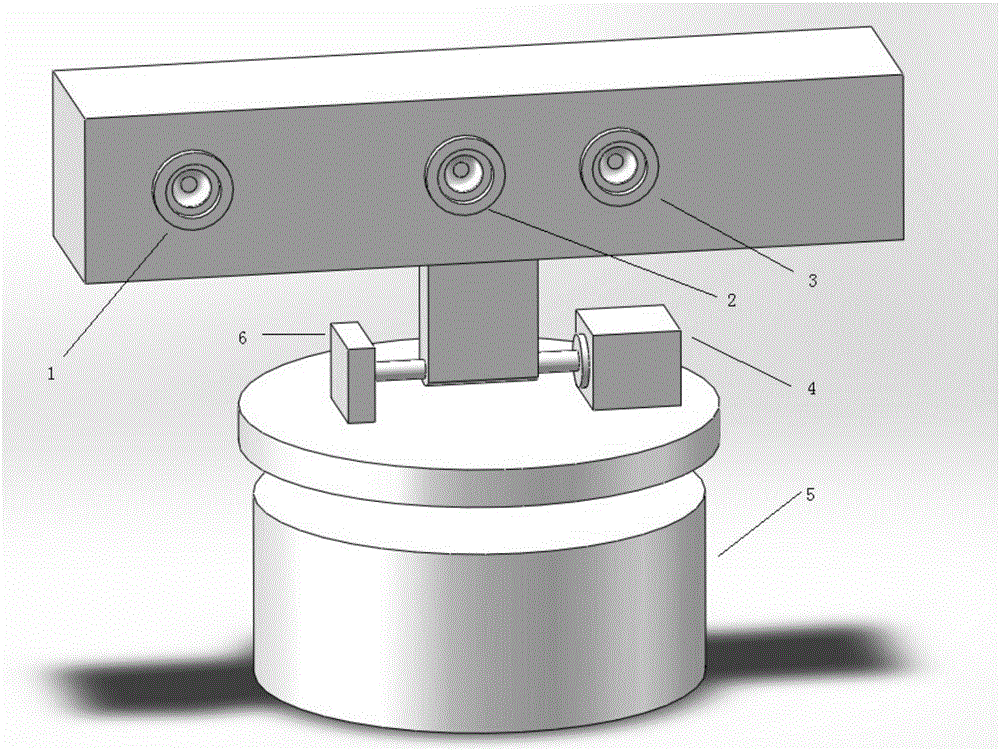

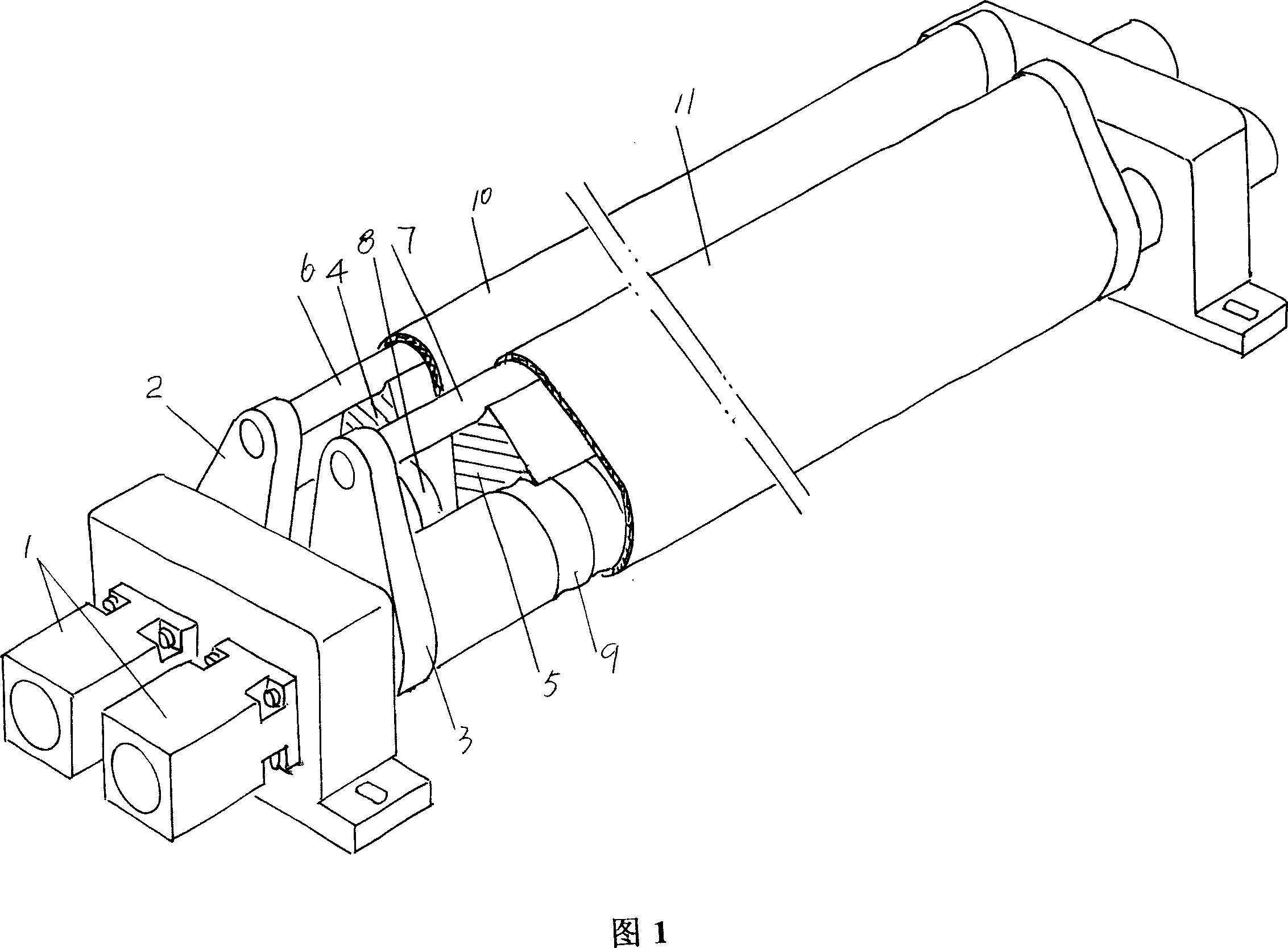

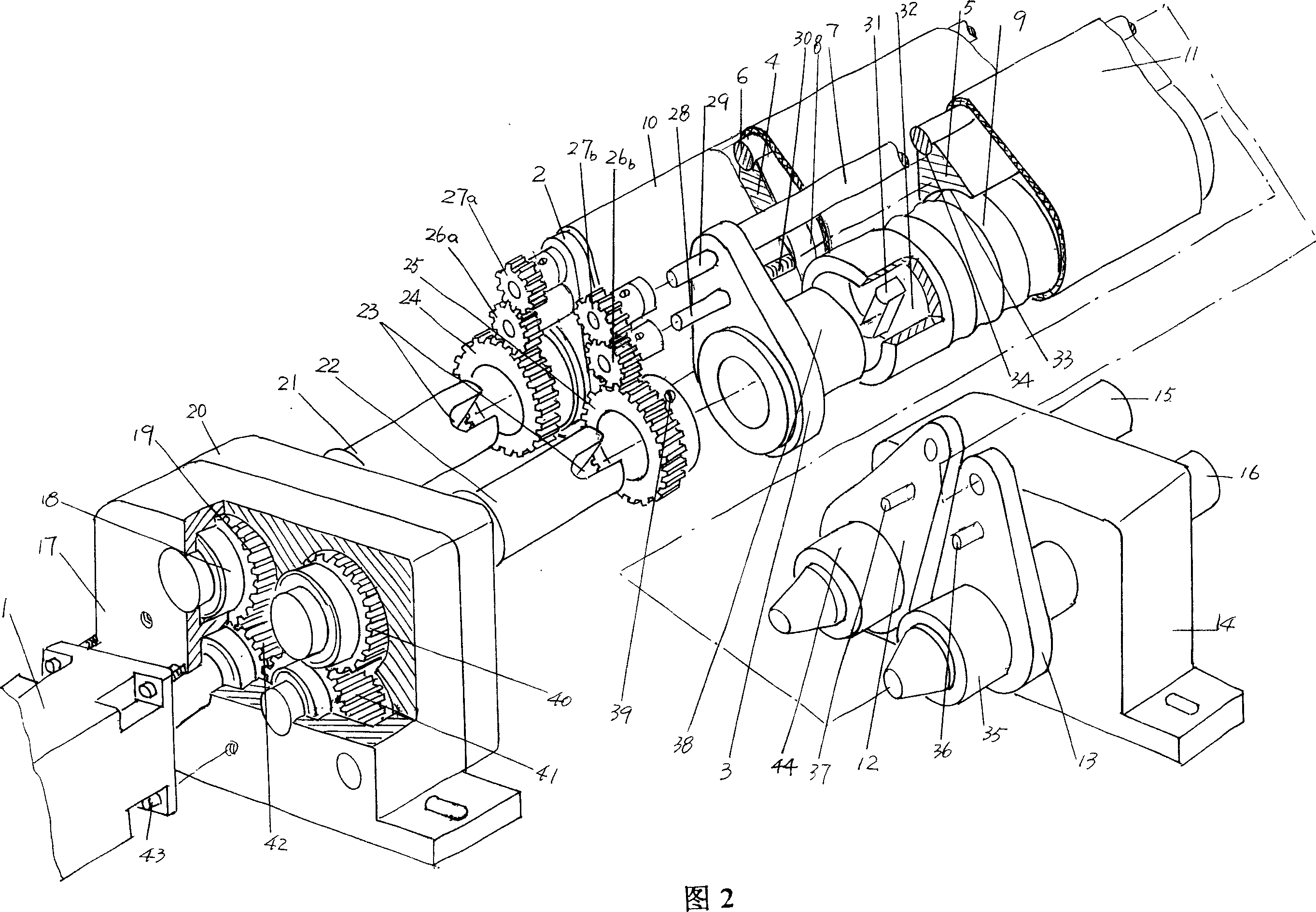

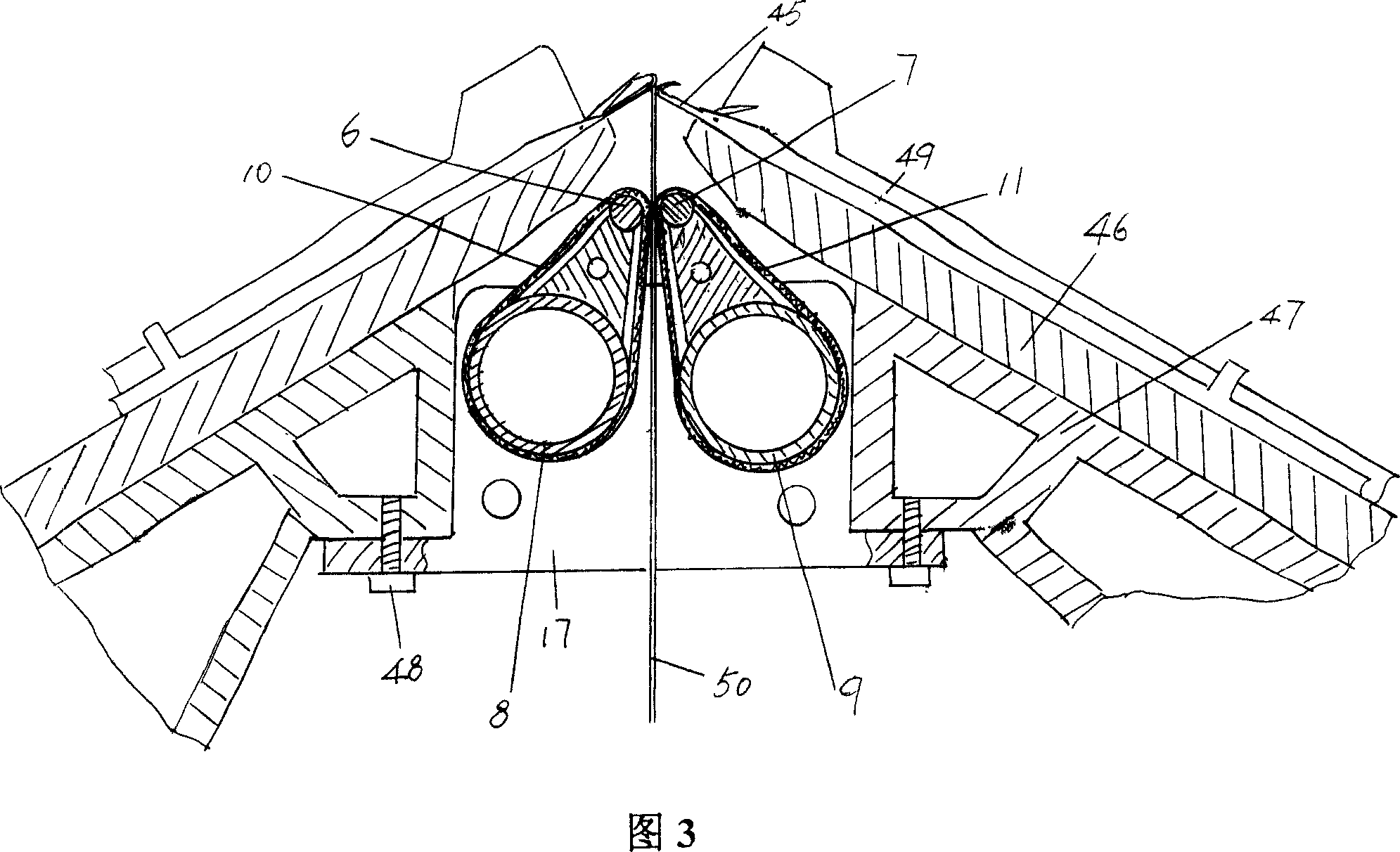

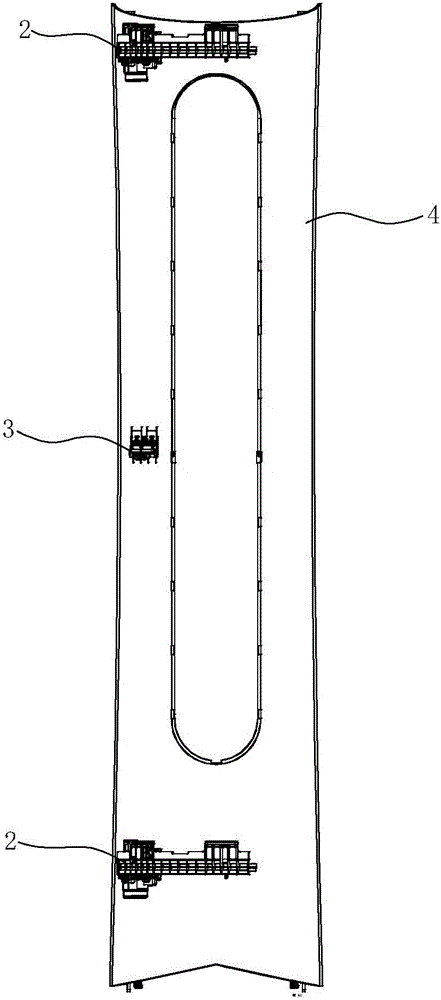

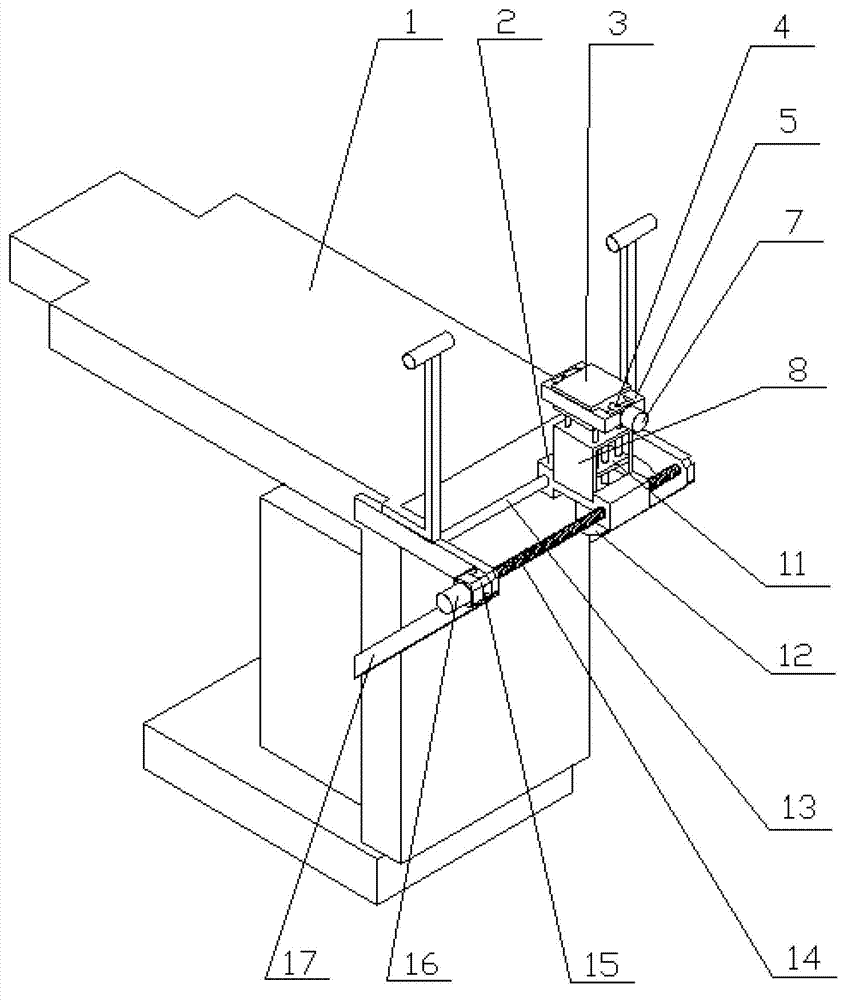

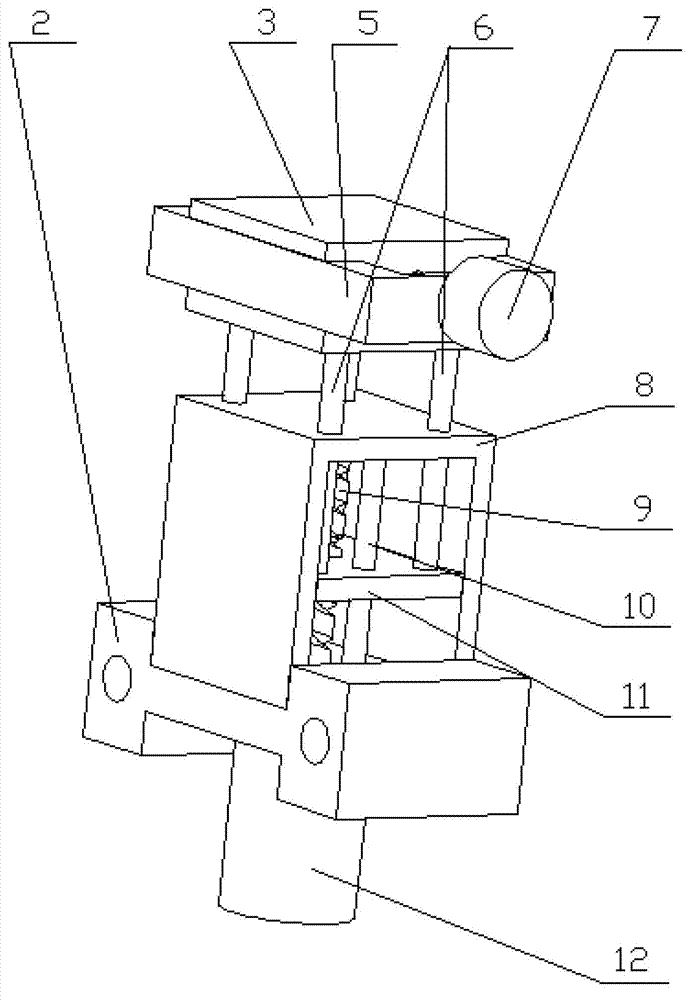

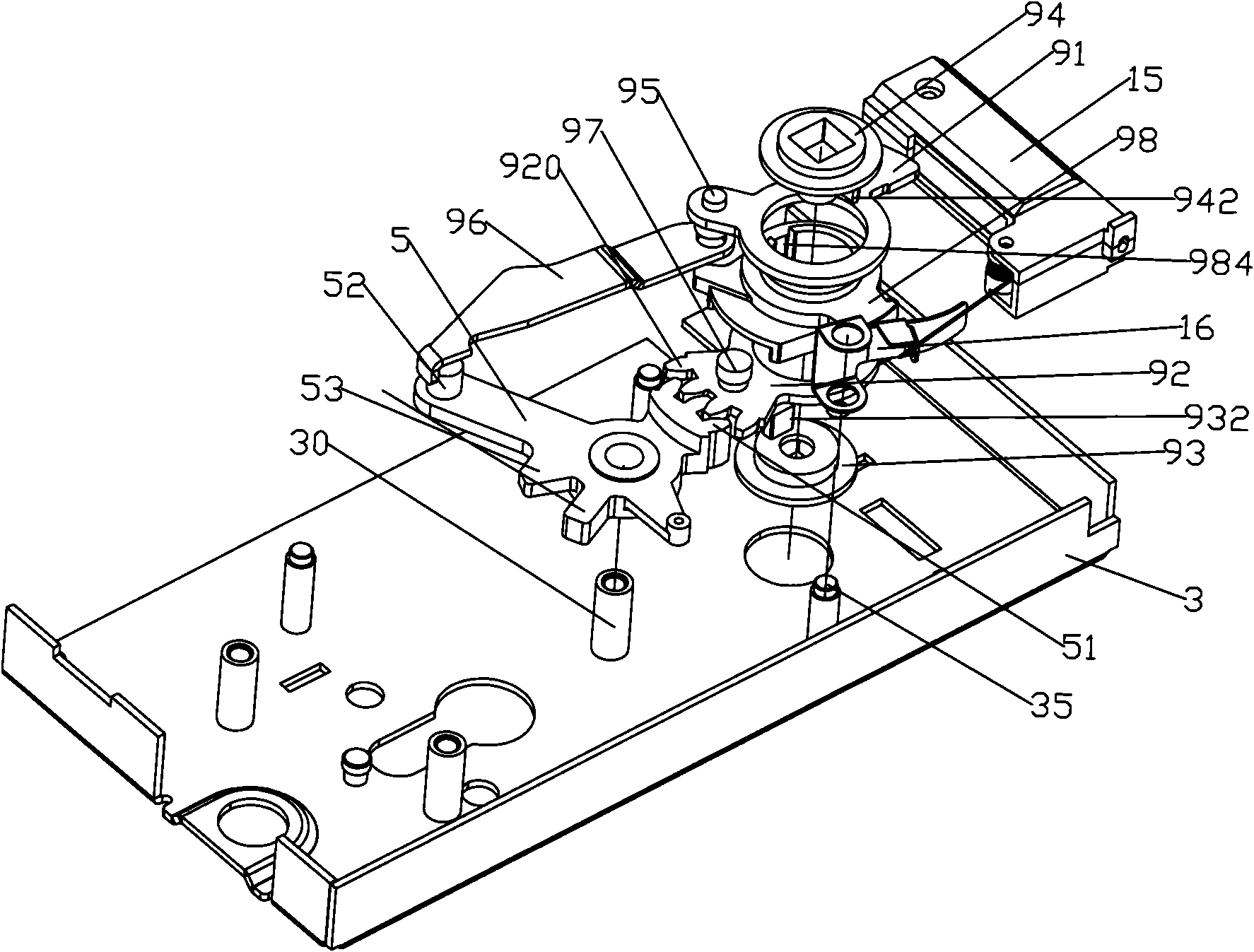

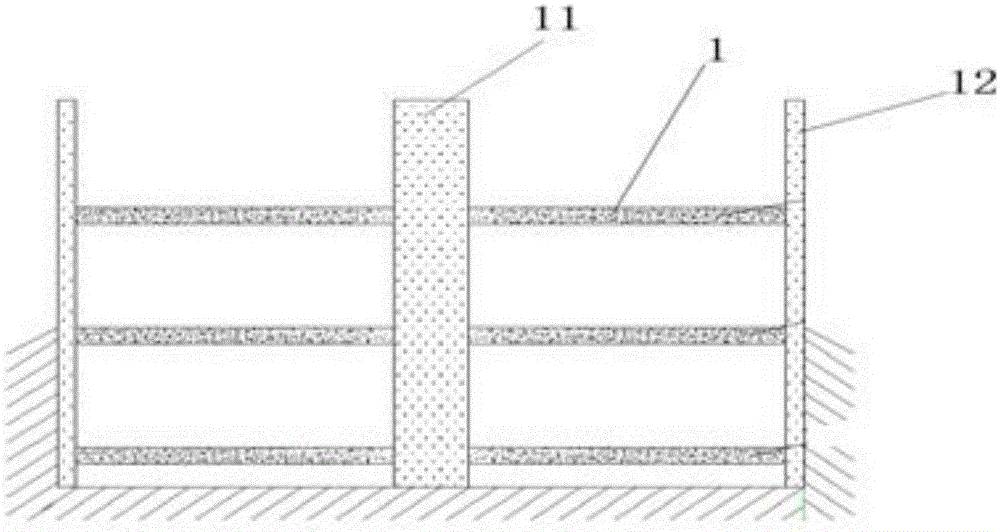

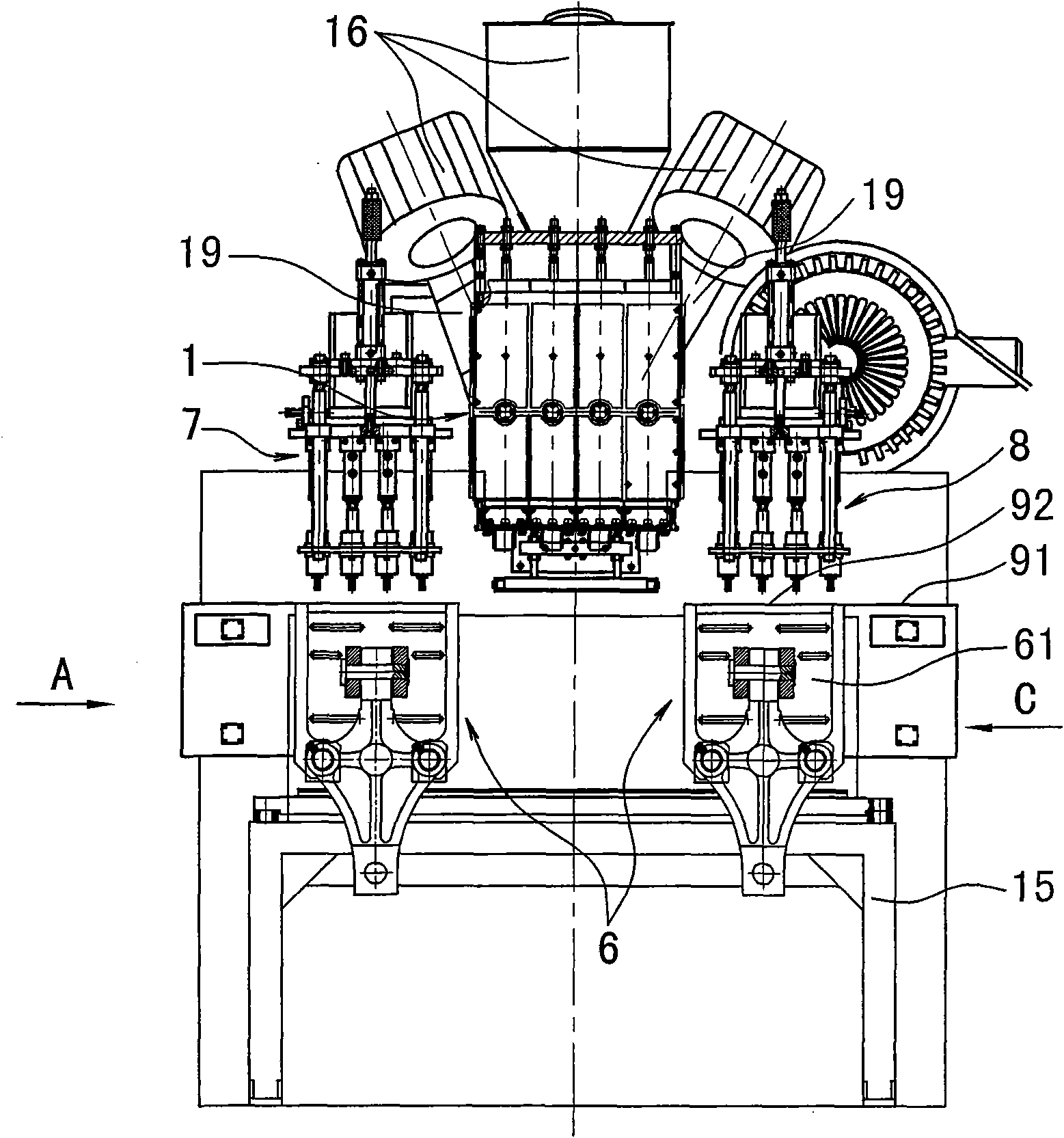

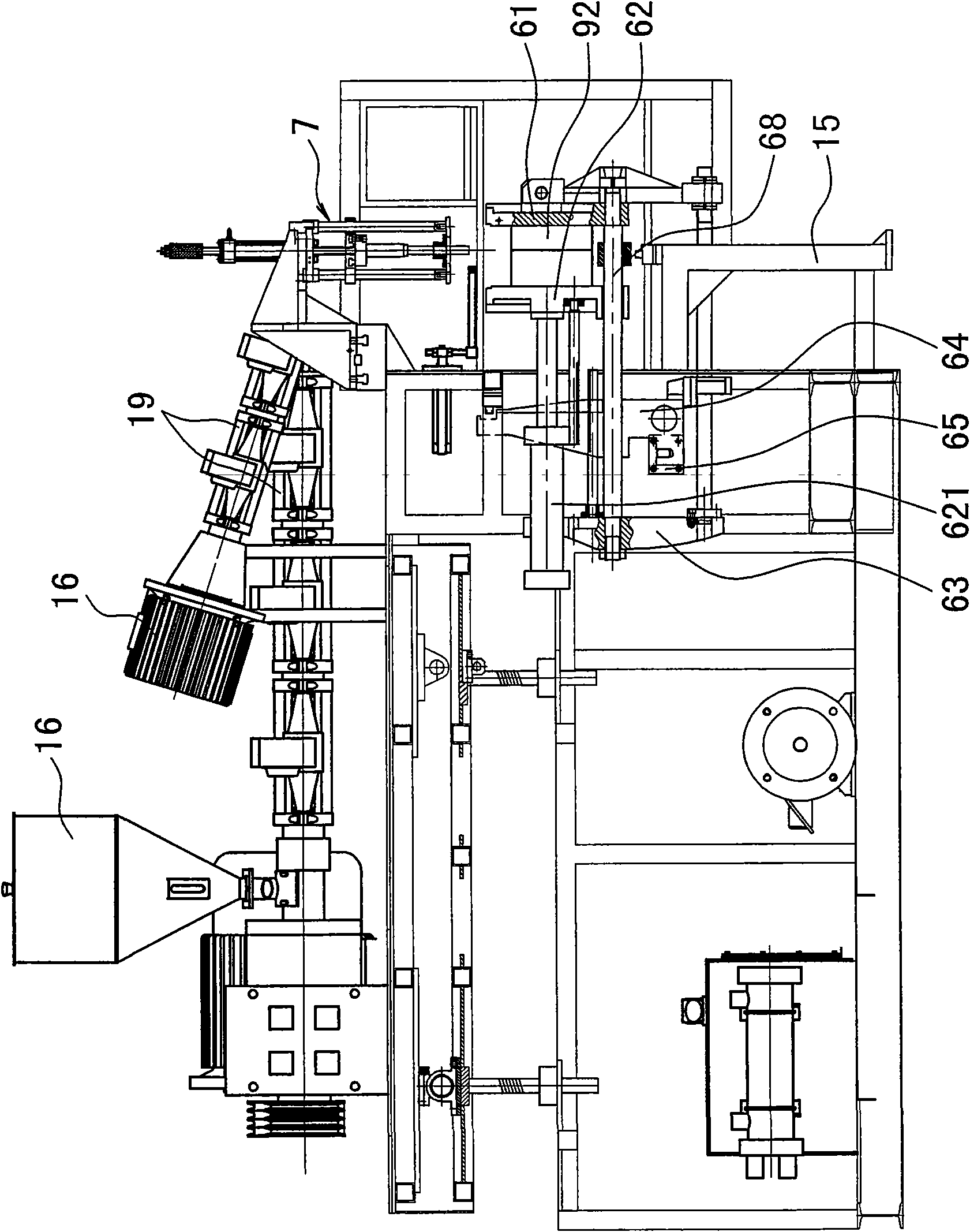

Vertical shaft type ring spinning automatic yarn falling device

The invention discloses a vertical shaft type ring spinning automatic yarn falling device, and belongs to the technical field of ring spinning yarn falling devices. The device comprises a frame, a base, a motor, a traveling mechanism, a positioning mechanism, a pre-loosening mechanism, a yarn falling transmission mechanism and a manipulator. By the matching between the positioning mechanism and the yarn falling transmission mechanism, the manipulator can be positioned relative to a caught bobbin when the frame moves forwards; and by the matching between the yarn falling transmission mechanism and the manipulator, horizontal revolving and vertical motion of the manipulator and a function of opening and closing the manipulator are realized, so that the aim of vertically pulling out the bobbin from a spindle blade is comprehensively fulfilled. The device adopts a yarn falling mode that the tops of yarns are in contact with the bobbin, so that the yarns cannot be damaged; the bobbin can be continuously pulled out, and the yarn falling efficiency is high; by the matching between the yarn falling transmission mechanism and the pre-loosening mechanism, before the manipulator upwards pulls out the bobbin, the bobbin and the spindle blade relatively rotate to realize loosening, so that the pre-loosening effect is good; complicated sensing control is not needed, the volume is small, and the weight is light; and when the vertical shaft type ring spinning automatic yarn falling device is used, the existing ring spinning machine does not need to be improved.

Owner:TSINGHUA UNIV +1

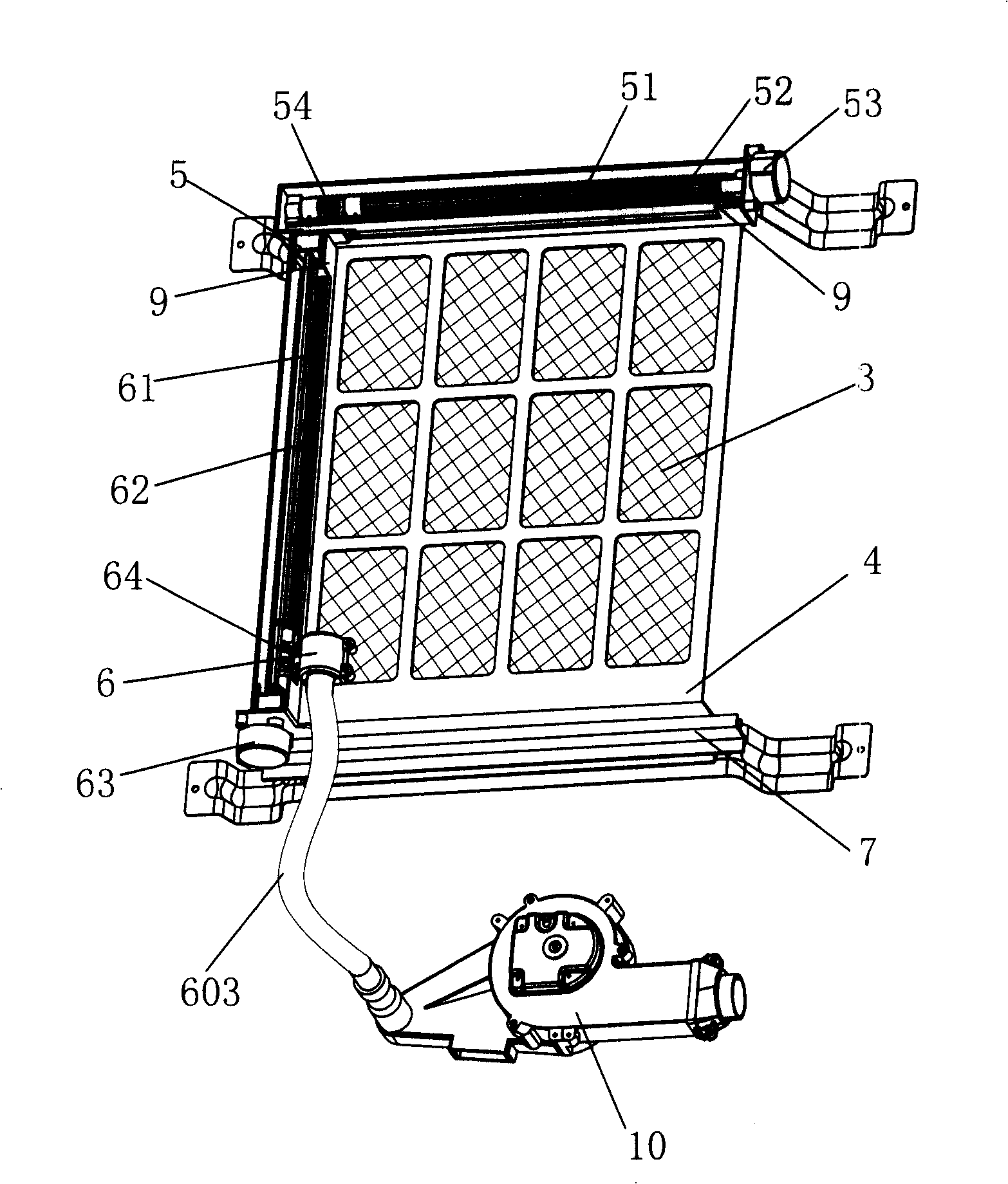

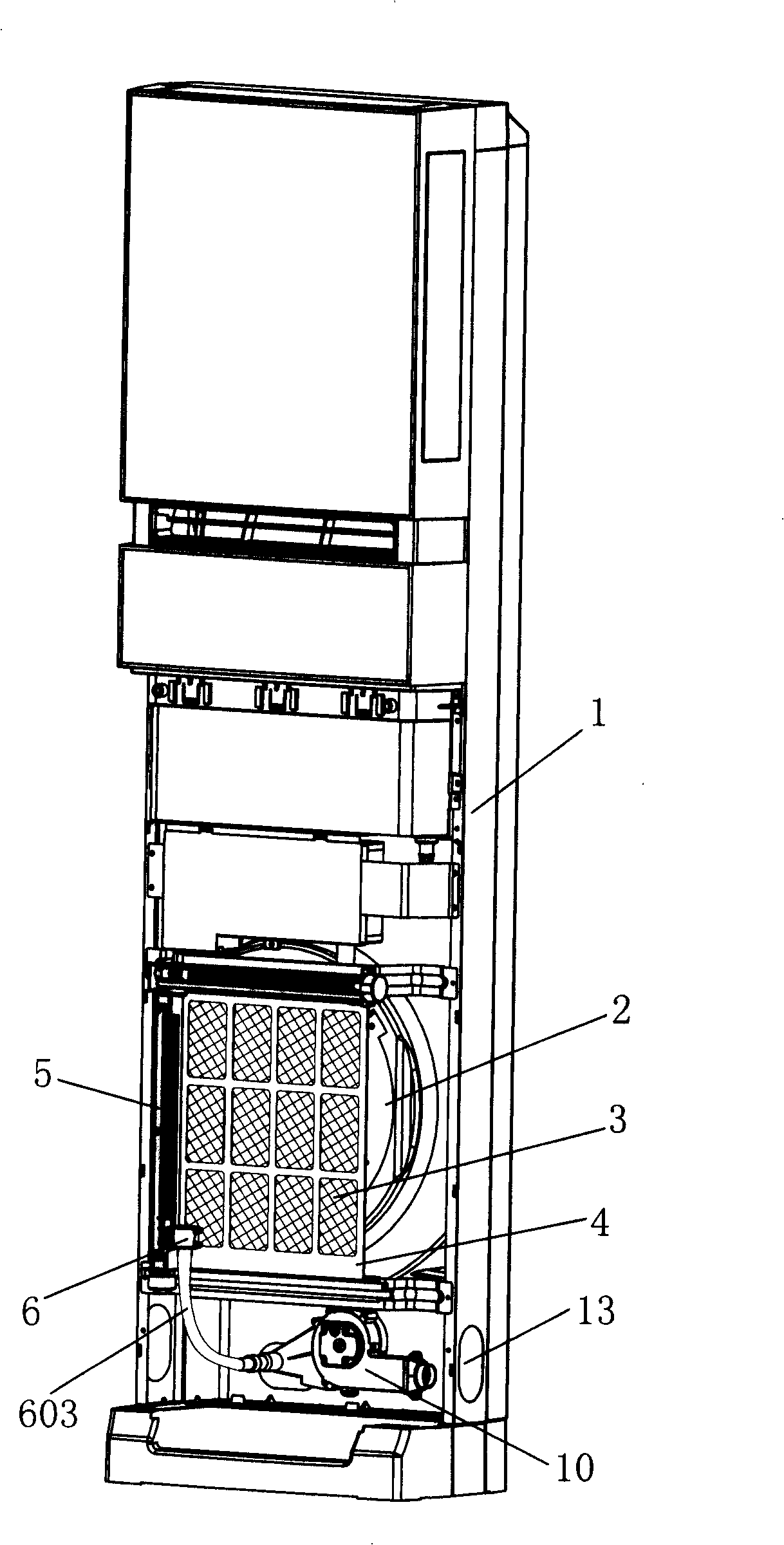

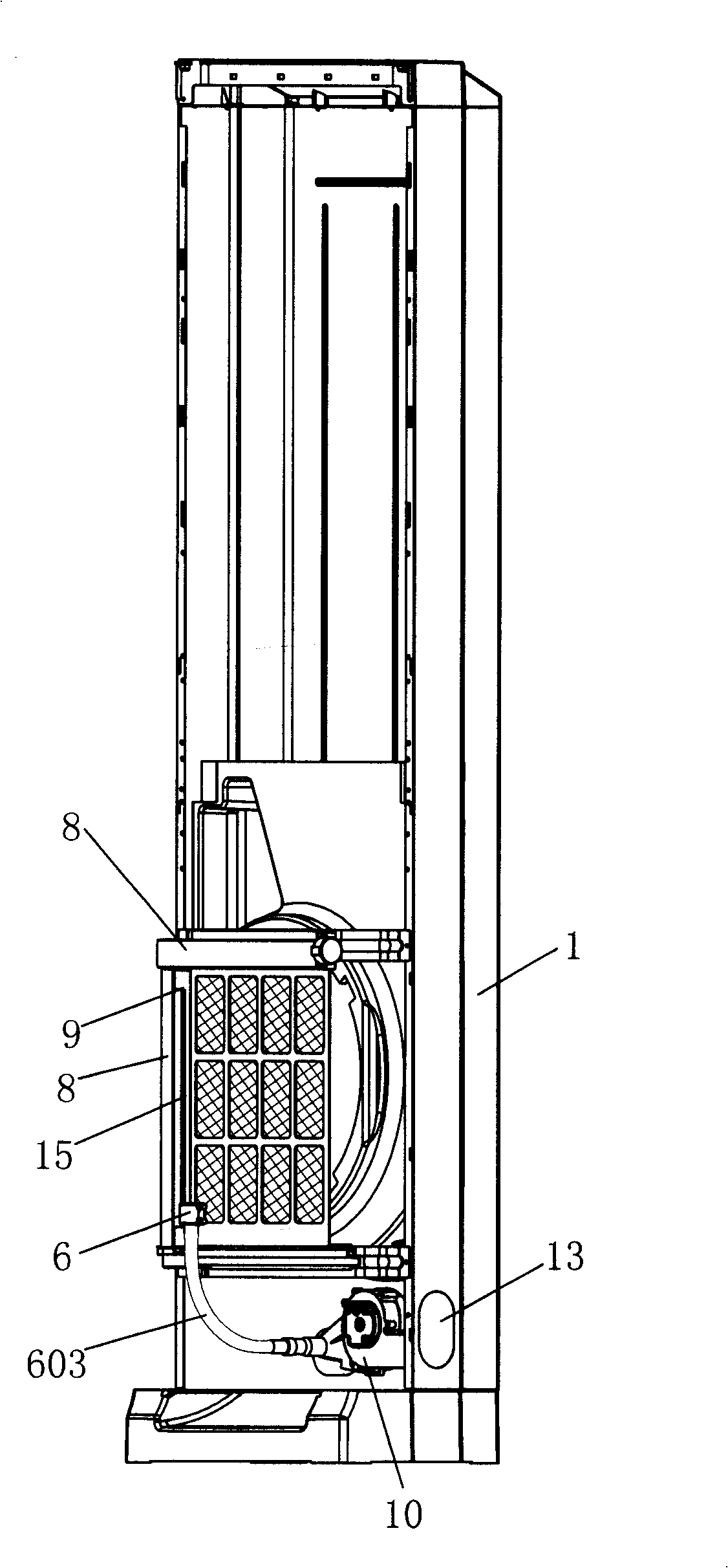

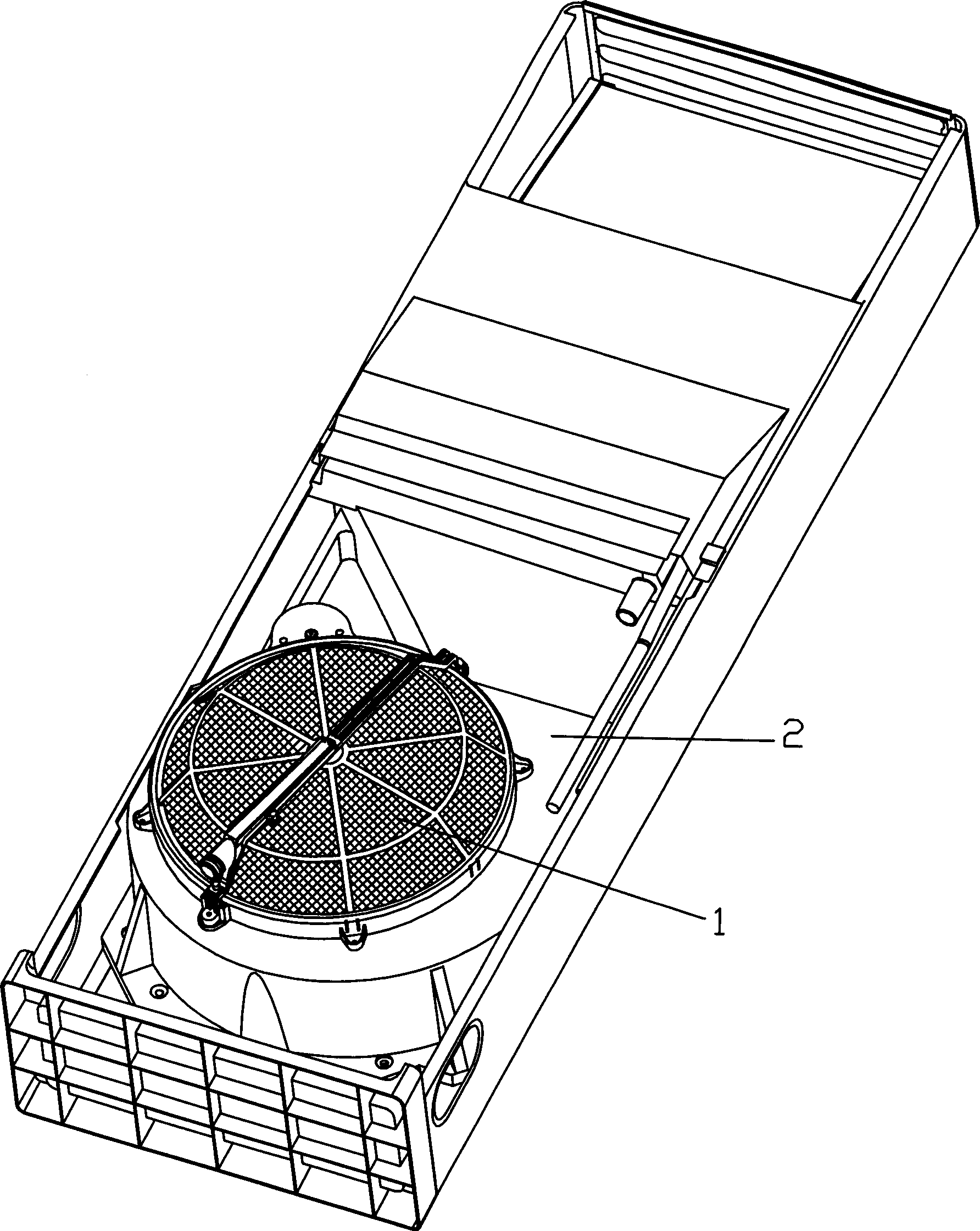

Cabinet air-conditioner dust gauze self-cleaning device and operation method thereof

ActiveCN101270913ASports reliableLow costLighting and heating apparatusSpace heating and ventilation detailsAirflowEngineering

The invention discloses a cabinet-type air-conditioning strainer mesh self-cleaning device and the working methods, wherein the device consists of a suction nozzle mechanism and a strainer mesh mechanism; the strainer mesh mechanism is fixed outside the scroll casing of the air passage and consists of a strainer mesh and a strainer mesh frame; the suction nozzle mechanism is attached to the side of the strainer mesh facing outward, and consists of main body arranged on the strainer mesh and a suction nozzle arranged on the main body, wherein the main body is driven by a drive mechanism to slide between the left and the right sides of the strainer mesh along the track, and the suction nozzle is driven by another drive mechanism to slide between the top and bottom sides of the strainer mesh along the main body; the suction nozzle is provided with a dust absorption port and a brush, and is connected with the vacuum cleaner arranged in the air-conditioning through a connecting passage; the brush adjacent to the dust absorption port cleans the strainer mesh first, and then the connecting passage of the vacuum cleaner produces negative pressure high speed air flow by way of the suction nozzle, and the air flow keeps sucking the dust at the dust absorption port. The invention is characterized by reliable operation, low costs, wide ranged of dust absorption and good effect of dust cleaning.

Owner:HAIER GRP CORP +1

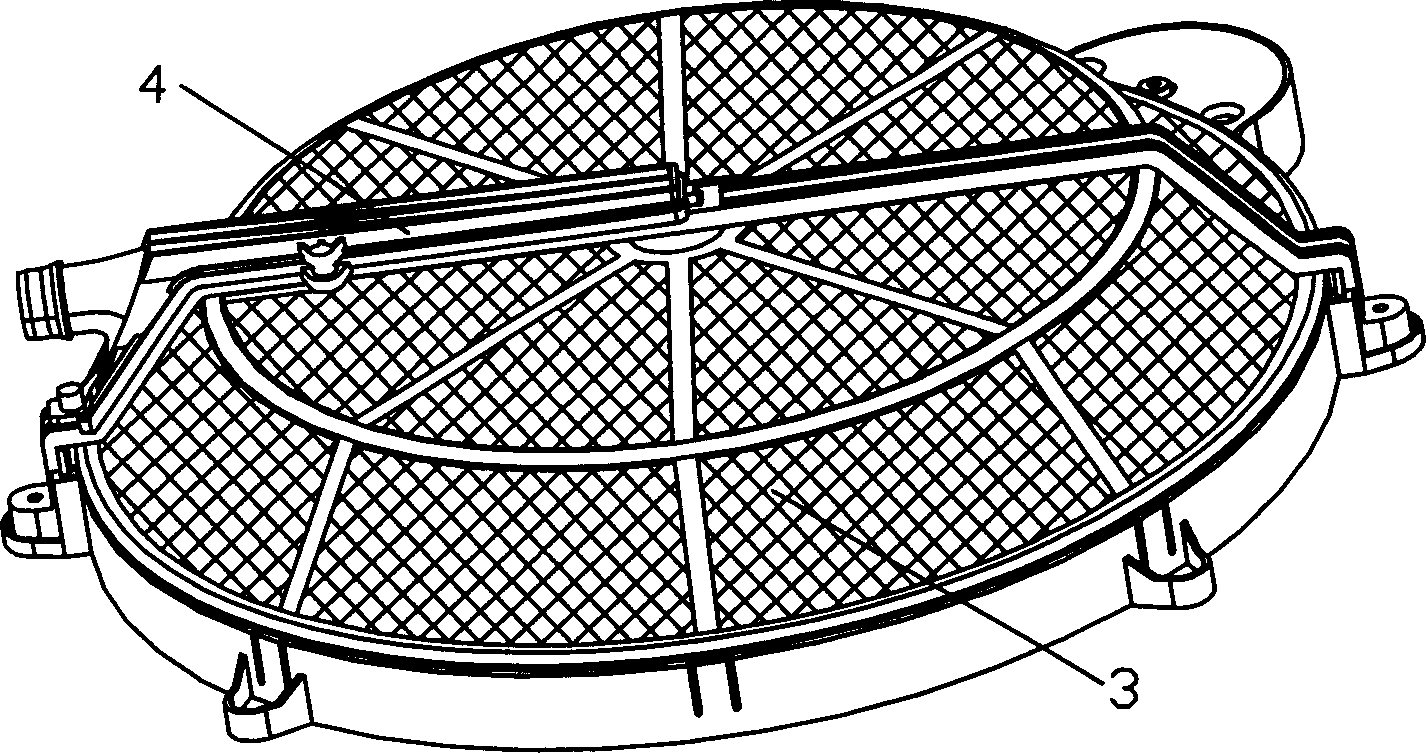

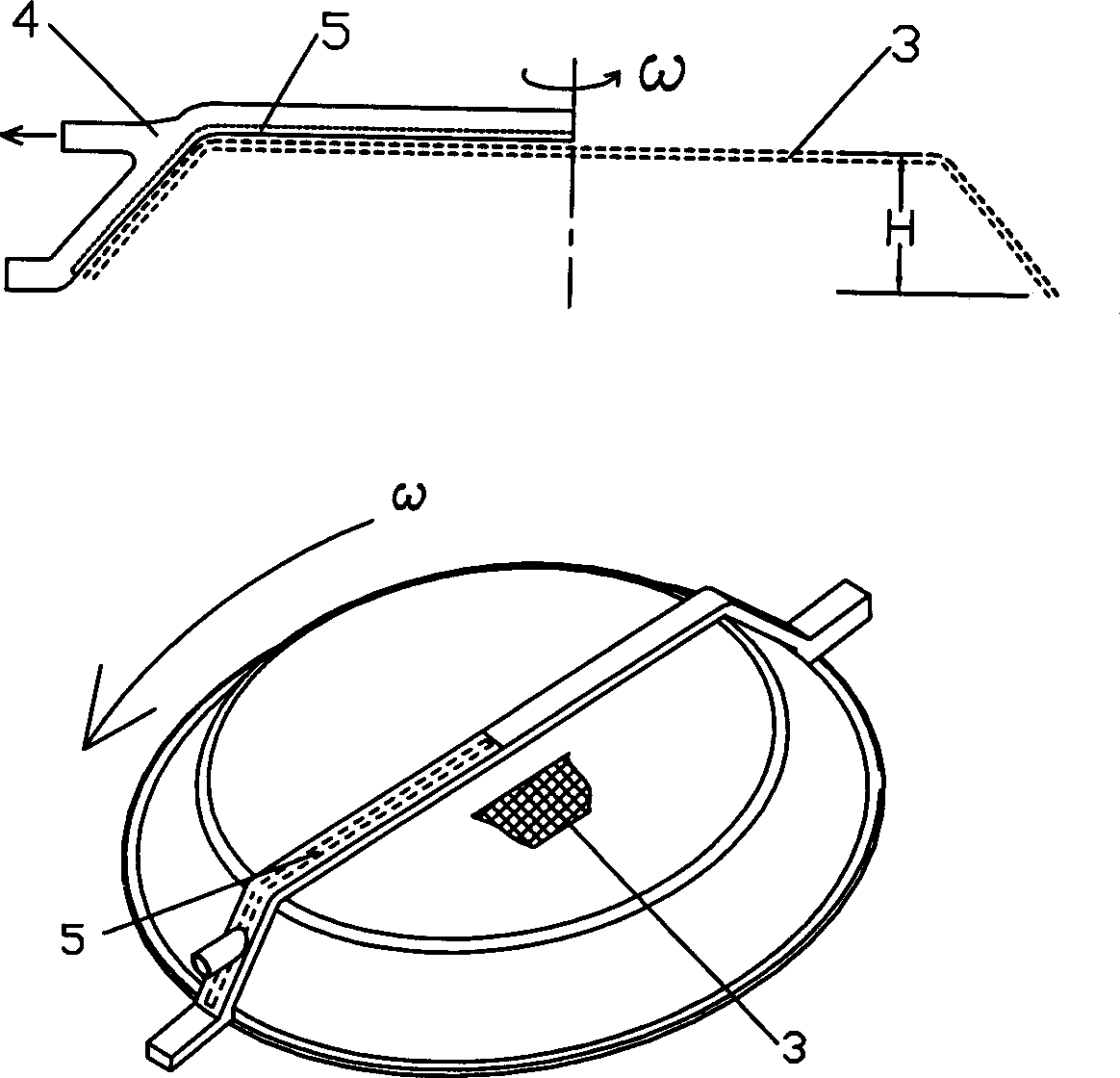

Self-purging unit for filter screen of air conditionner

ActiveCN1873339ASimple structureSports reliableLighting and heating apparatusSpace heating and ventilation detailsAerospace engineeringNozzle

The present invention relates to an automatic cleaning device capable of automatically cleaning air filter screen positioned on air inlet side of air conditioner indoor machine. It includes suction nozzle mechanism and filter screen mechanism. The filter screen mechanism includes base seat, filter screen, filter screen bracket, motor and its rotation drive mechanism, and the suction nozzle mechanism includes suction nozzle and suction nozzle supporting frame. Said invention also provides the connection mode of all the above-mentioned components and concrete working principle and operation method of said air conditioner filter screen automatic cleaning device.

Owner:MIDEA GRP CO LTD

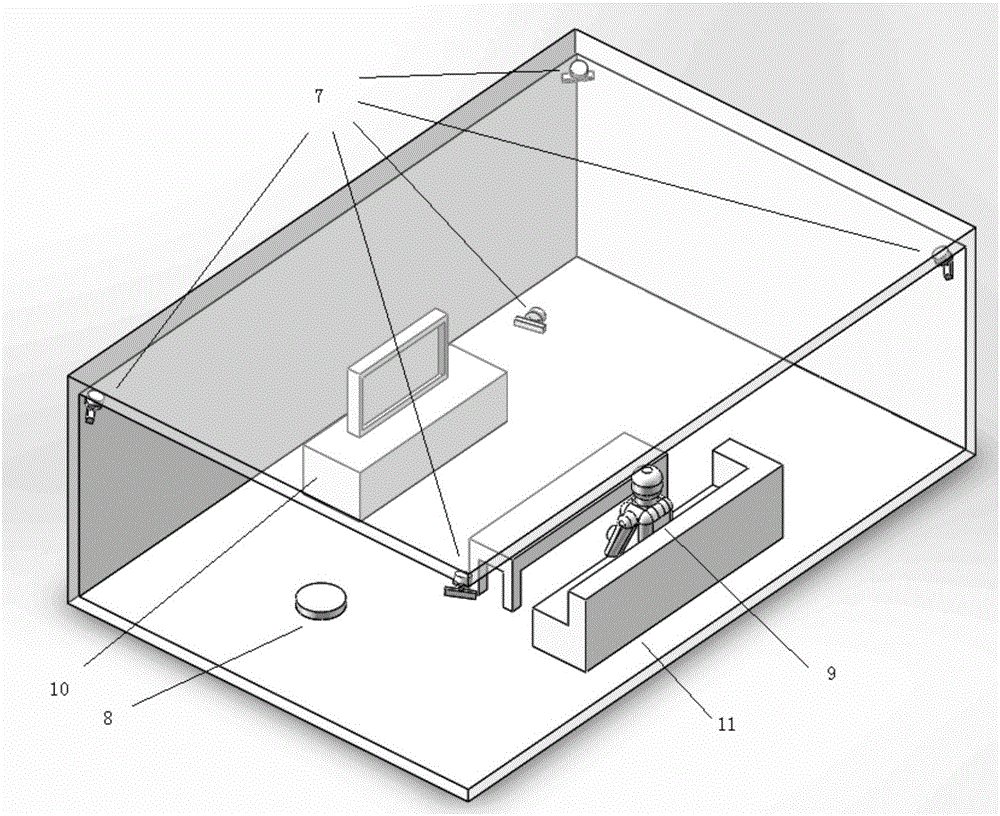

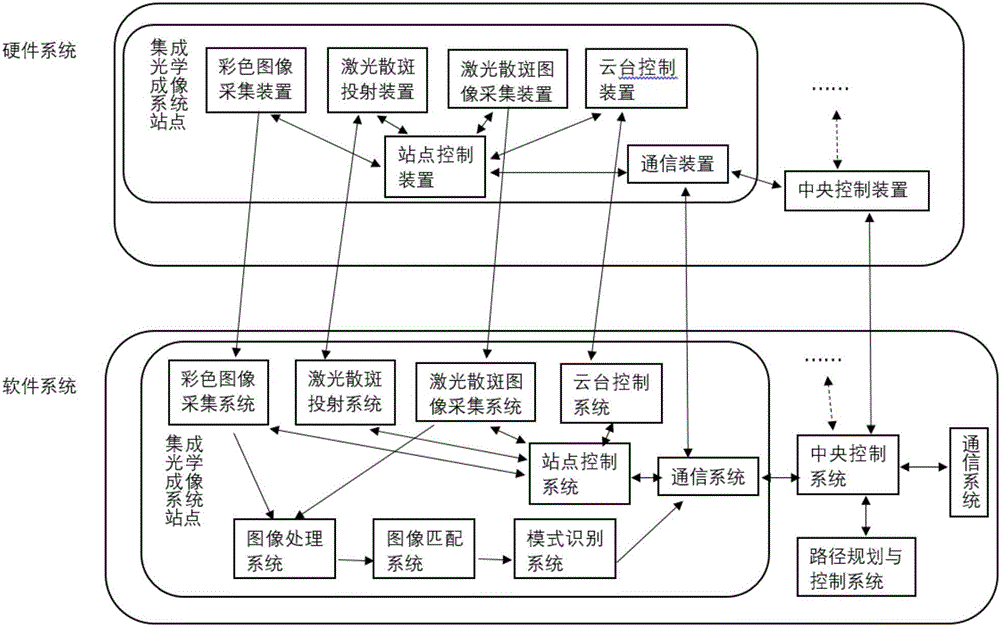

Automatic high-precision indoor rapid positioning method

InactiveCN106802658AExpand indoor positioning coverageImprove image processing capabilitiesPosition/course control in two dimensionsColor imageSoftware system

The invention discloses an automatic high-precision indoor rapid positioning method. A positioning system comprises a hardware system and a software system, the hardware system comprises a color image acquisition apparatus, a laser speckle projection apparatus, a laser speckle image acquisition apparatus, a holder control apparatus, a communication apparatus, and a central control apparatus, and the software system comprises a laser speckle projection system, a color image and laser speckle image acquisition system, an image processing system, an image matching system, a mode recognition system, a holder control system, a central control system, and a path planning and control system. According to the scheme of the method, software and hardware are combined, an indoor positioning device accomplishes intelligence and systematization of the whole process of personal / household service robot characteristic information acquisition and input, indoor object image acquisition and matching recognition, indoor object positioning, path planning, and robot motion control, and methods of indoor positioning and path planning and control are more accurate and efficient.

Owner:XIAMEN UNIV

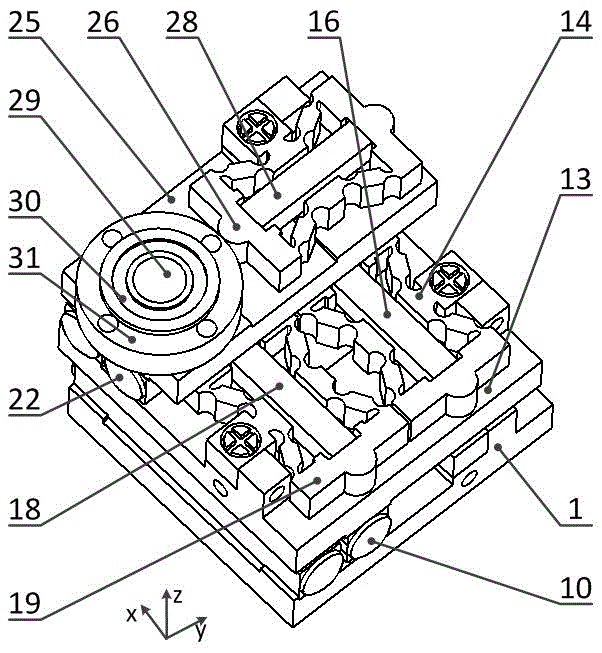

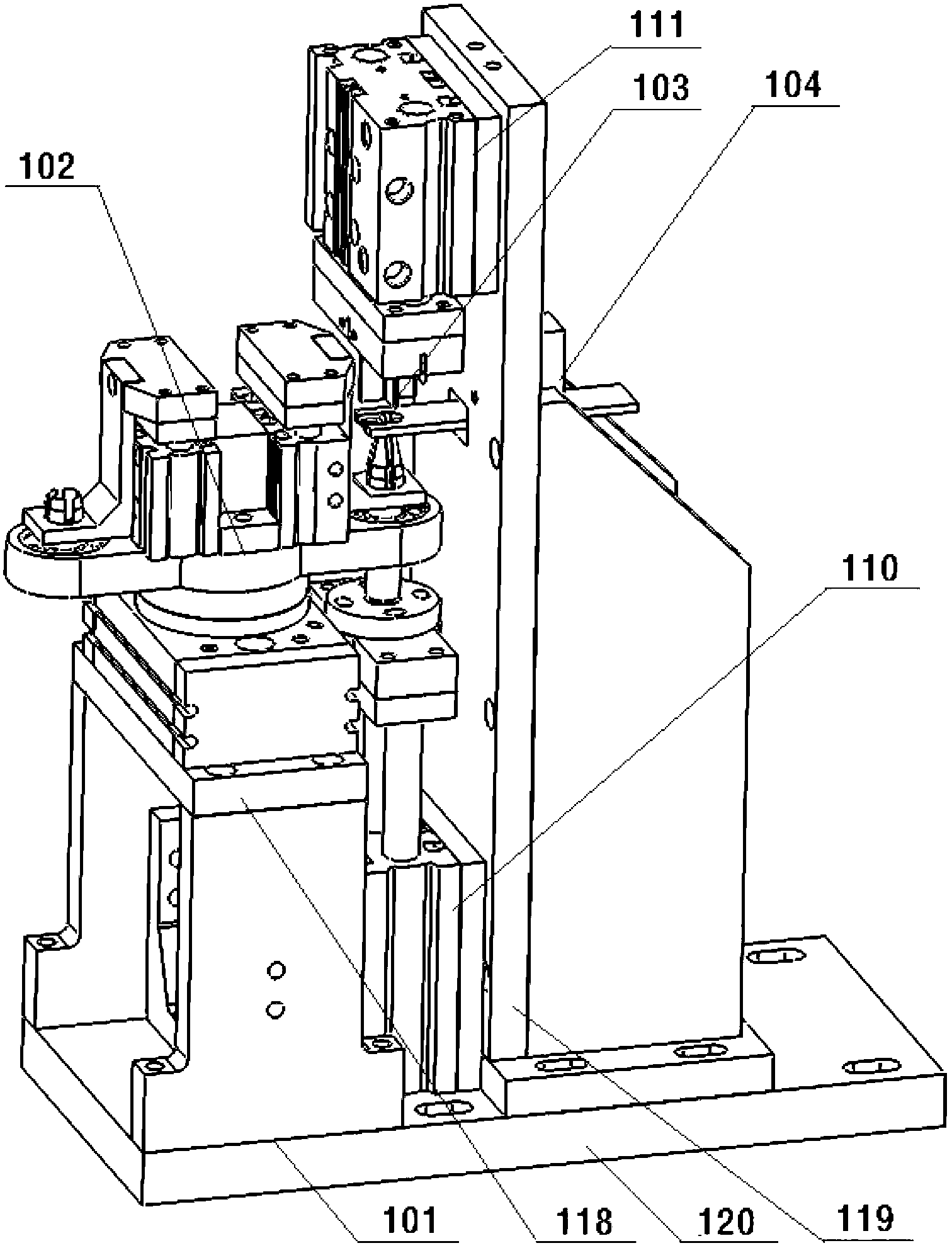

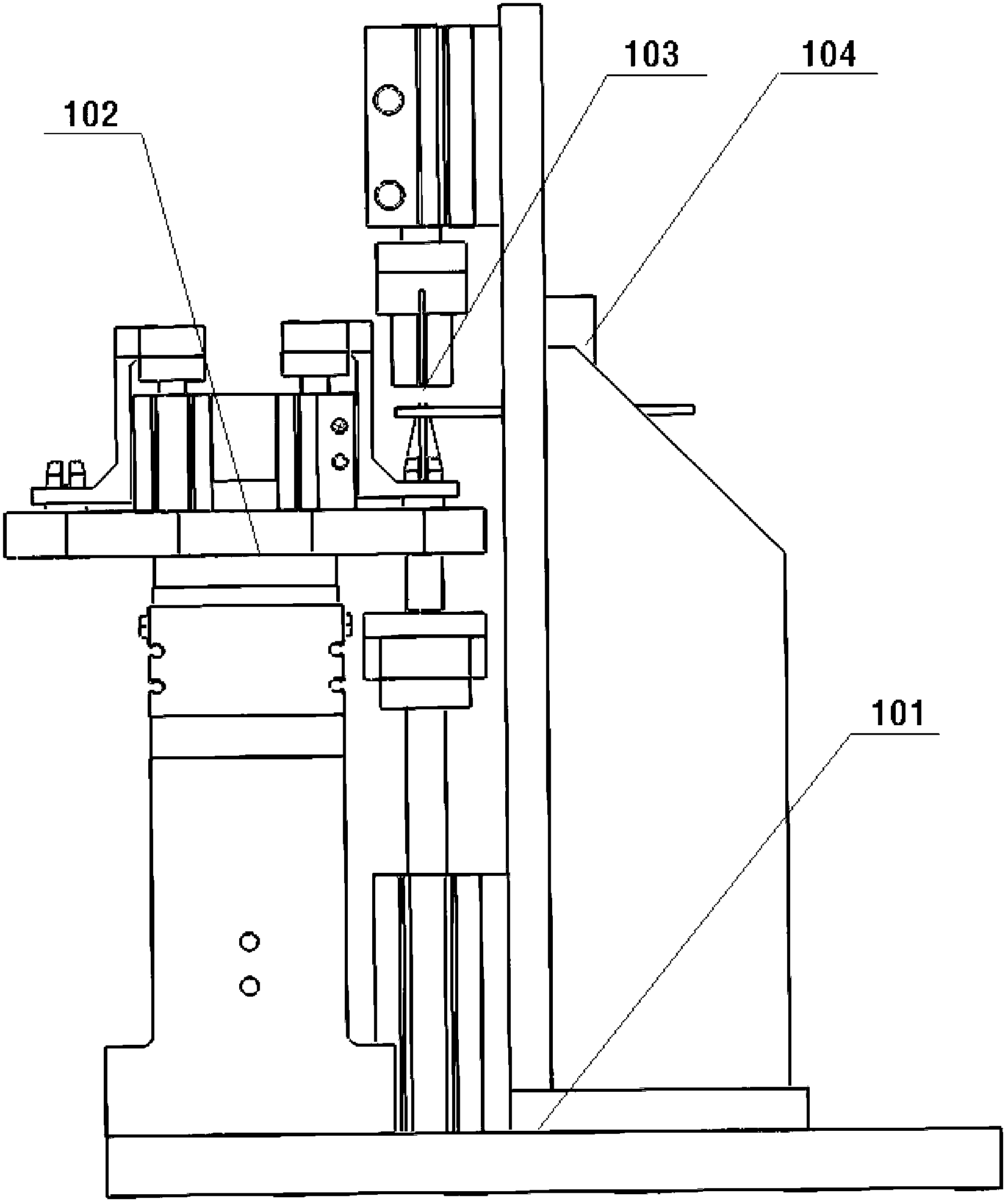

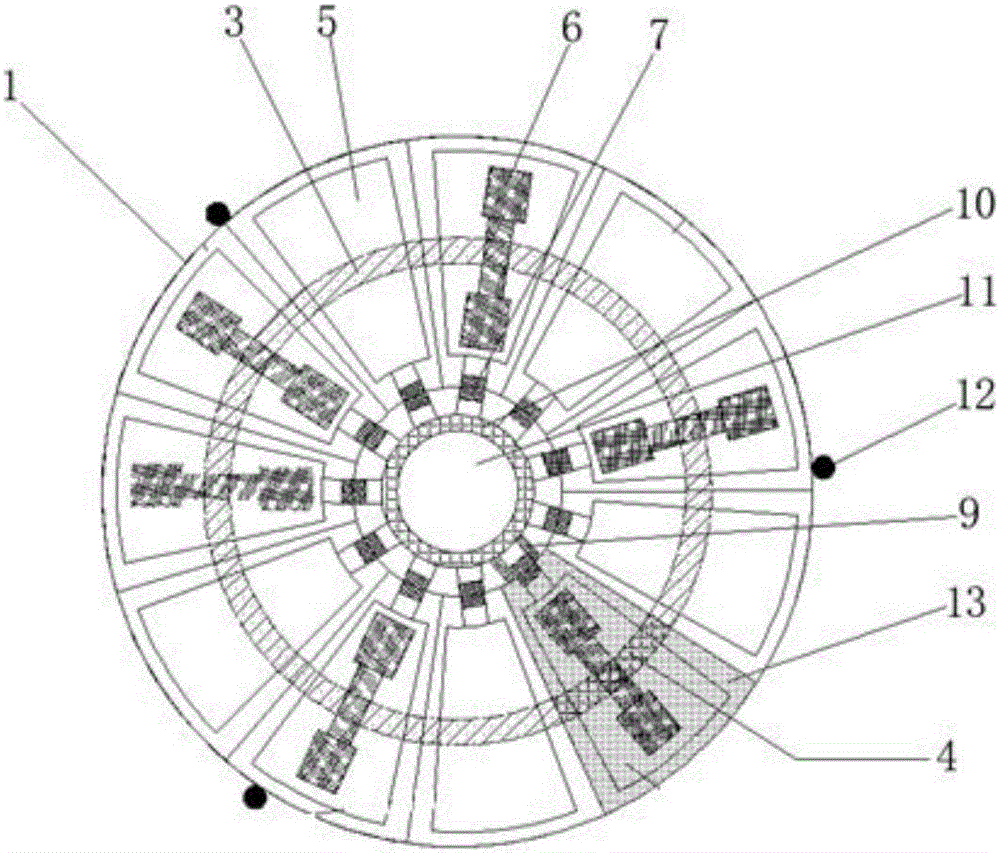

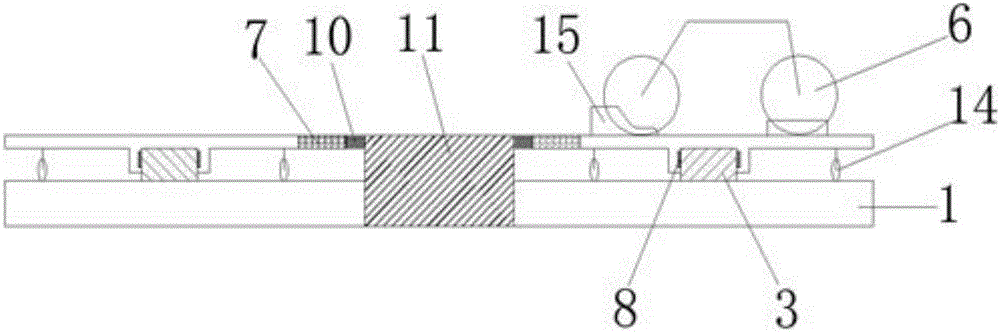

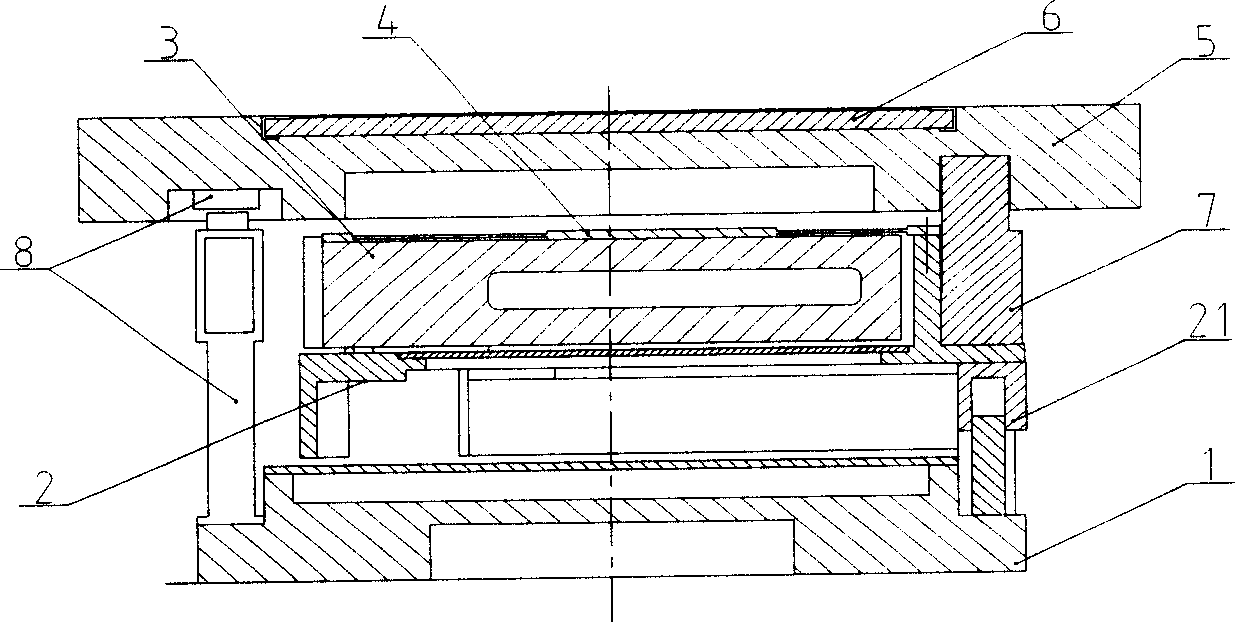

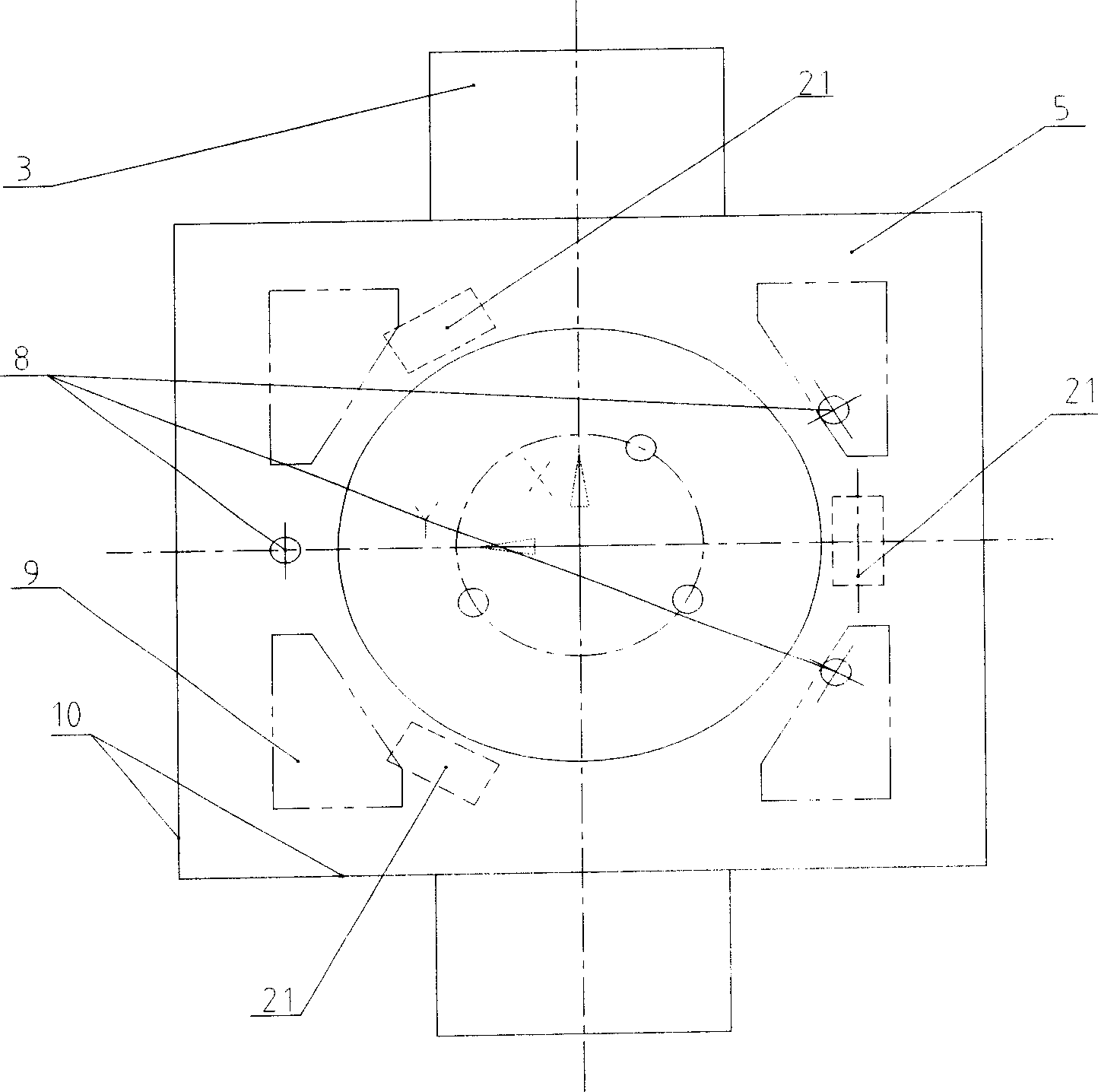

Stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform

ActiveCN104320016ASports reliableReliable drivePiezoelectric/electrostriction/magnetostriction machinesLinear motionElectricity

The invention relates to a stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform and the linear motion along the x and y direction and the rotating motion around the z axis direction can be implemented. The stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform comprises a lower layer of x axis linear driver assembly, a middle layer of y axis linear driver assembly and an upper layer of z axis rotating driver assembly which are connected in turn and sawtooth waves are input towards piezoelectric stacks based on the stick-slip inertia principle to implement the stepping type continuous feeding of an output terminal. The symmetry and the frequency of the sawtooth waves are changed to change the feeding direction and speed. The positioning motion of the rapid feeding positioning and the precise feed positioning can be implemented through different modes of control on the piezoelectric stacks and accordingly the rapid and high precision positioning can be obtained simultaneously. The stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform has the advantages of being small and compact in structure, large in output stroke, adjustable in speed, large in bearing capacity, stable and reliable in work, good in repeatability and suitable for large stroke of precision motion control occasions with strict space size constraints.

Owner:JILIN UNIV

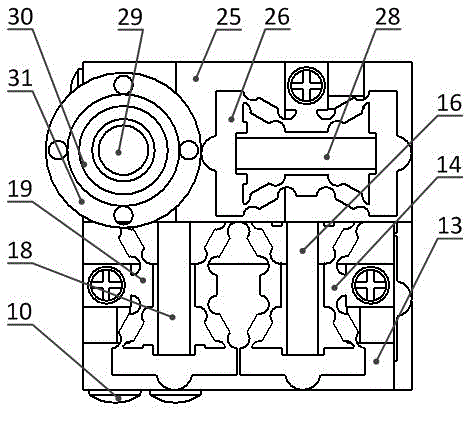

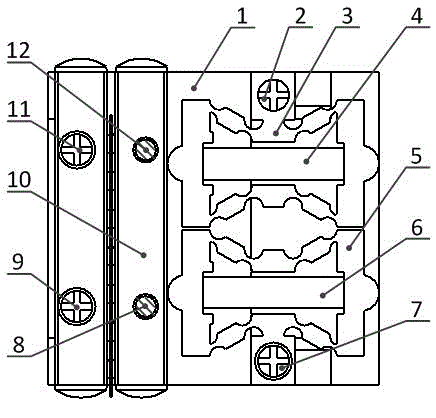

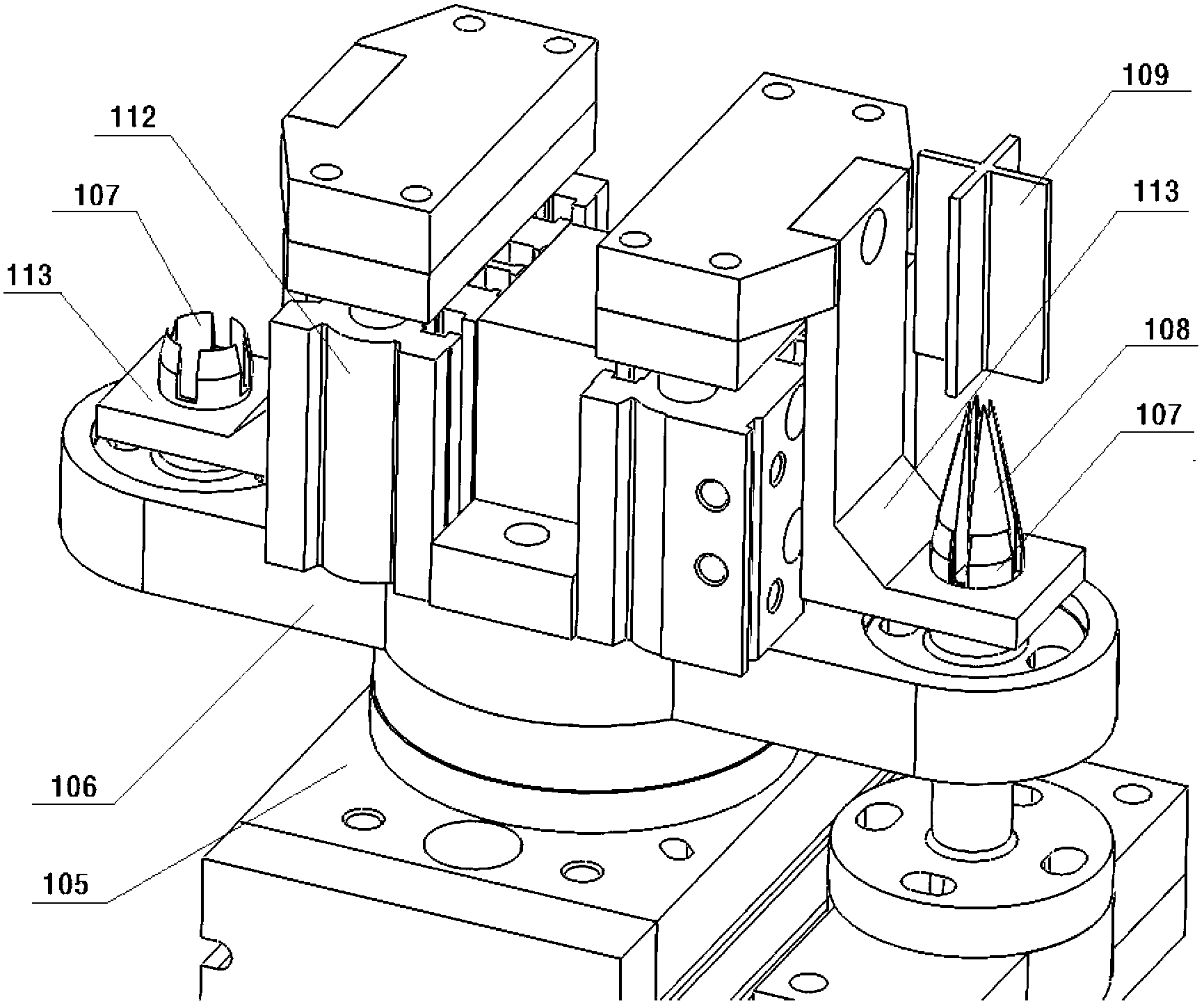

Micro-seal ring ferrule module

InactiveCN102699669AIngenious structureSports reliableMetal working apparatusMechanical engineeringThin walled

A micro-seal ring ferrule module comprises an assemble type bracket, a placing plate structure, a micro-seal ring ferrule structure and a micro-seal ring feed structure, wherein a placing plate cylinder is fixed on the placing plate cylinder bracket of the assemble type bracket; a placing plate is mounted on the placing plate cylinder; ring supporting sleeves are symmetrically fixed at two ends of the placing plate, and are thin-walled sleeve pipes; a cross recess is formed in the upper end of the ring supporting sleeve; two ring stripping cylinders are symmetrically fixed on the placing plate; the push rods of the ring stripping cylinders are used for fixing a ring stripping plate; the ring stripping plate is sleeved on each ring supporting sleeve; a cross recess is formed in a ring supporting tapered point rod; the ring supporting tapered point rod is connected with a tapered point rod cylinder used for driving the ring supporting tapered point rod to be inserted into the inner wall of the ring supporting sleeve from the bottom up; and a cross pressure head is arranged above the ring supporting tapered point rod, and is connected with a pressure head cylinder used for pressing the cross pressure head to the cross recess of the ring supporting tapered point rod and the cross recess of the ring supporting sleeve from the top down. The micro-seal ring ferrule module has the advantages that the structure is smart; the operation is reliable; and fatigue rupture on the micro-seal ring can be avoided.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

Secondary roller mechanism for full computer flat knitting machine

A auxiliary roller mechanism of all-computer flat knitting machine, comprising a power driving device, couple panel for a first left and right accordion pipe, couple panel for a second left and right accordion pipe, couple transition bar for a first and second leather cup, couple a first and second accordion pipe; couple strutting piece for a first and second transition bar, couple a first and second leather cup, characterized in that couple transition bar for a first and second leather cup is set rotationally on panels for a first and second left-and-right accordion pipes and on each ends there are a first and second transition bar gears connecting with power driving device, is belong to technology area for accessorial establishment of all-computer flat knitting machine. The merit of the mechanism is that there is no influence for efficiency of flat knitting machine because of replacing leather cup continually, working capacity of maintenance worker is lessen and only one electromotor is need for power driving mechanism so that there is less manufacturing cost.

Owner:江苏雪亮电器机械有限公司

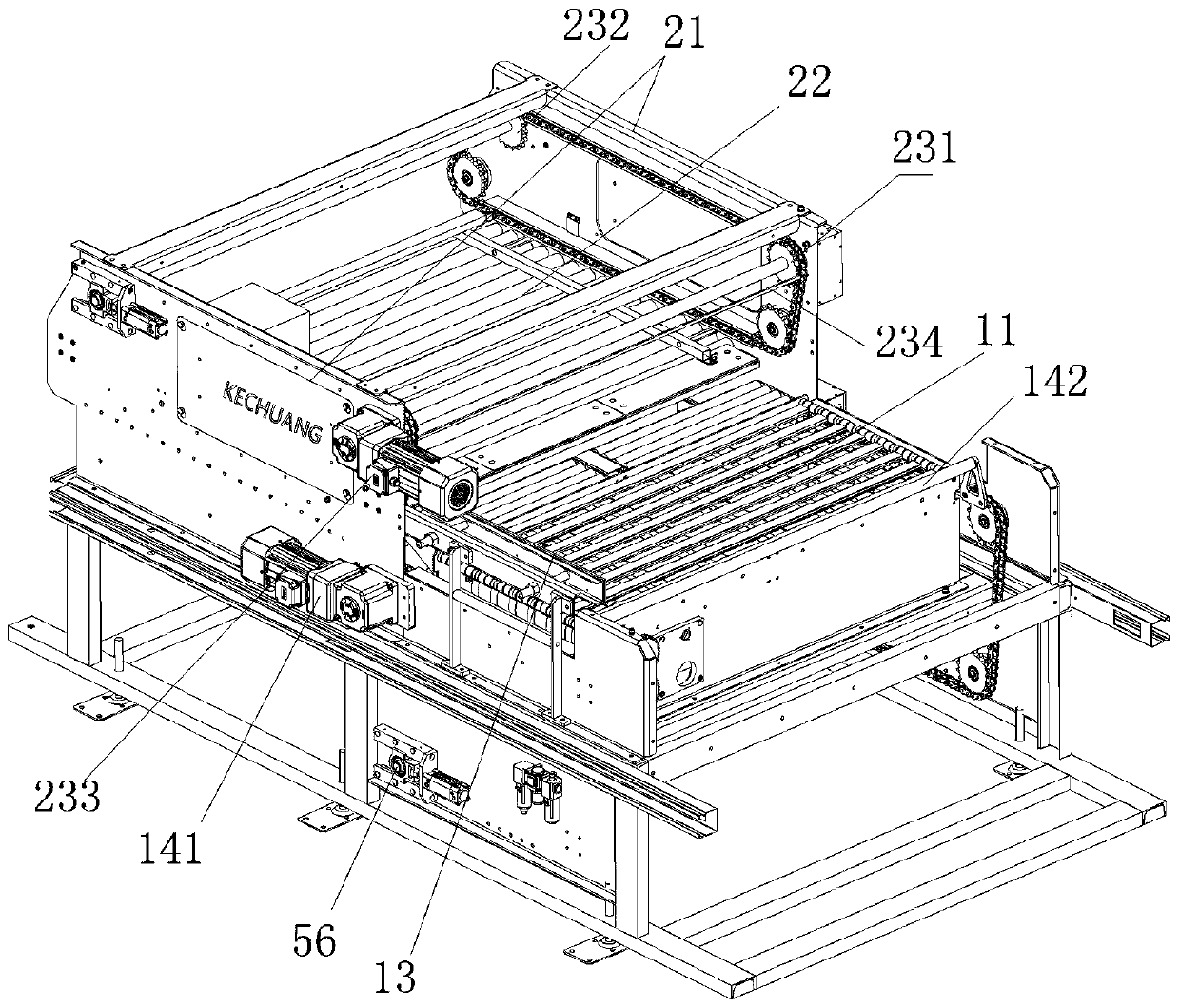

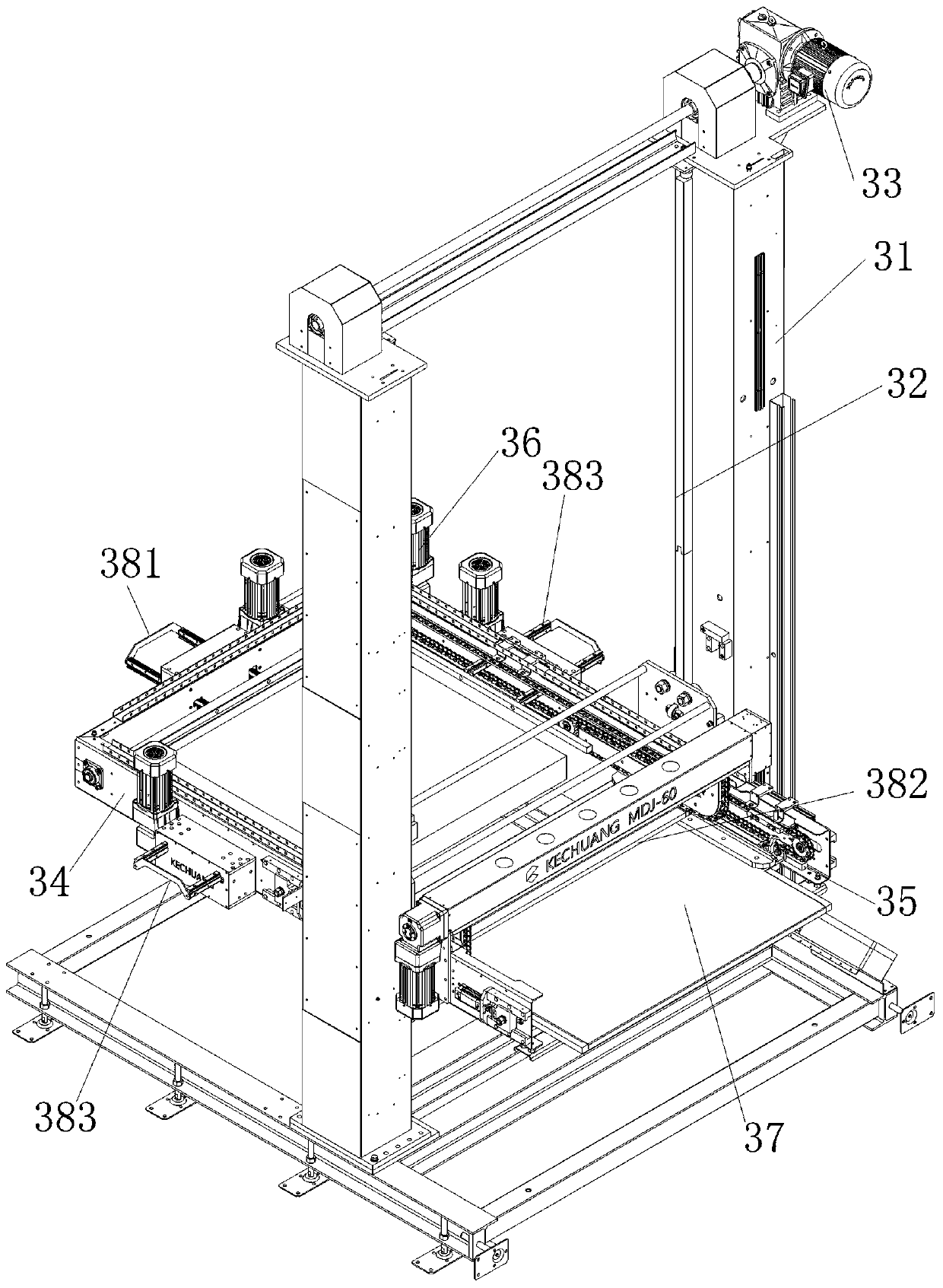

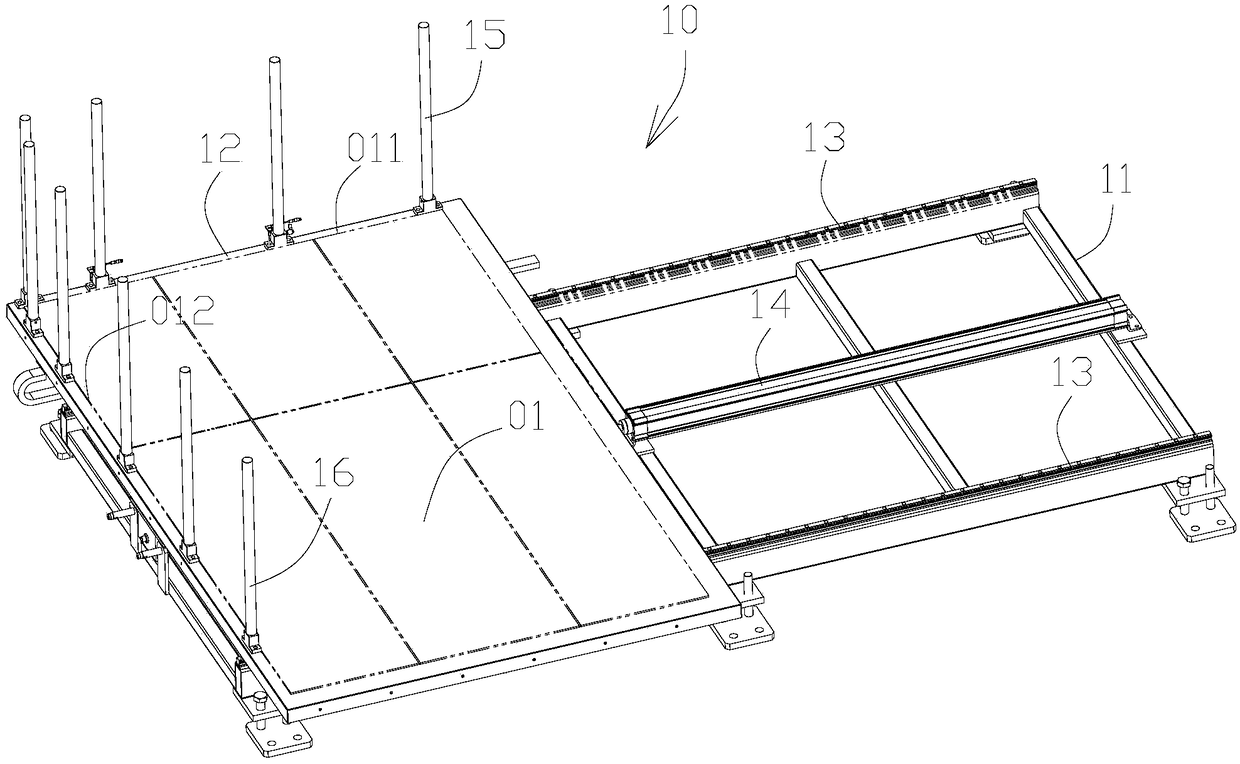

Automatic packaging box stacking machine capable of achieving selective stacking

PendingCN107697646AFacilitated releaseImprove reliabilityStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention discloses an automatic packaging box stacking machine capable of achieving selective stacking, and belongs to the technical field of stacking. The machine comprises an arranging and steering mechanism, a grouping pushing mechanism, a door type stacking mechanism and a matched tray storage supply mechanism which are sequentially arranged on a rack in the packaging box conveying direction. The arranging and steering mechanism comprises a feeding conveying device and a steering device arranged on one side of the feeding conveying device; the machine is characterized in that the steering device comprises a pre-steering baffle and a strengthening check block which are arranged at an interval in the feeding conveying direction, the pre-steering baffle is hinged to a pre-steering air cylinder on the rack through a bending rod and is hinged to the rack to form a swing stretching-out blocking and reset releasing structure, the strengthening check block is connected with a strengthening air cylinder on the rack, and forms a strengthening and resetting releasing structure by means of guidance of a sliding rail and sliding block pair perpendicular to the feeding conveying direction, a packaging box, required to be subject to steering, in the conveying process is subject to rotating and pre-steering operation around the blocked angle by means of blocking of the pre-steering baffle, and pressing strengthening of the blockage angle can be achieved by means of the strengthening check block.

Owner:WEIXIAN KECHUANG LIGHT IND EQUIP

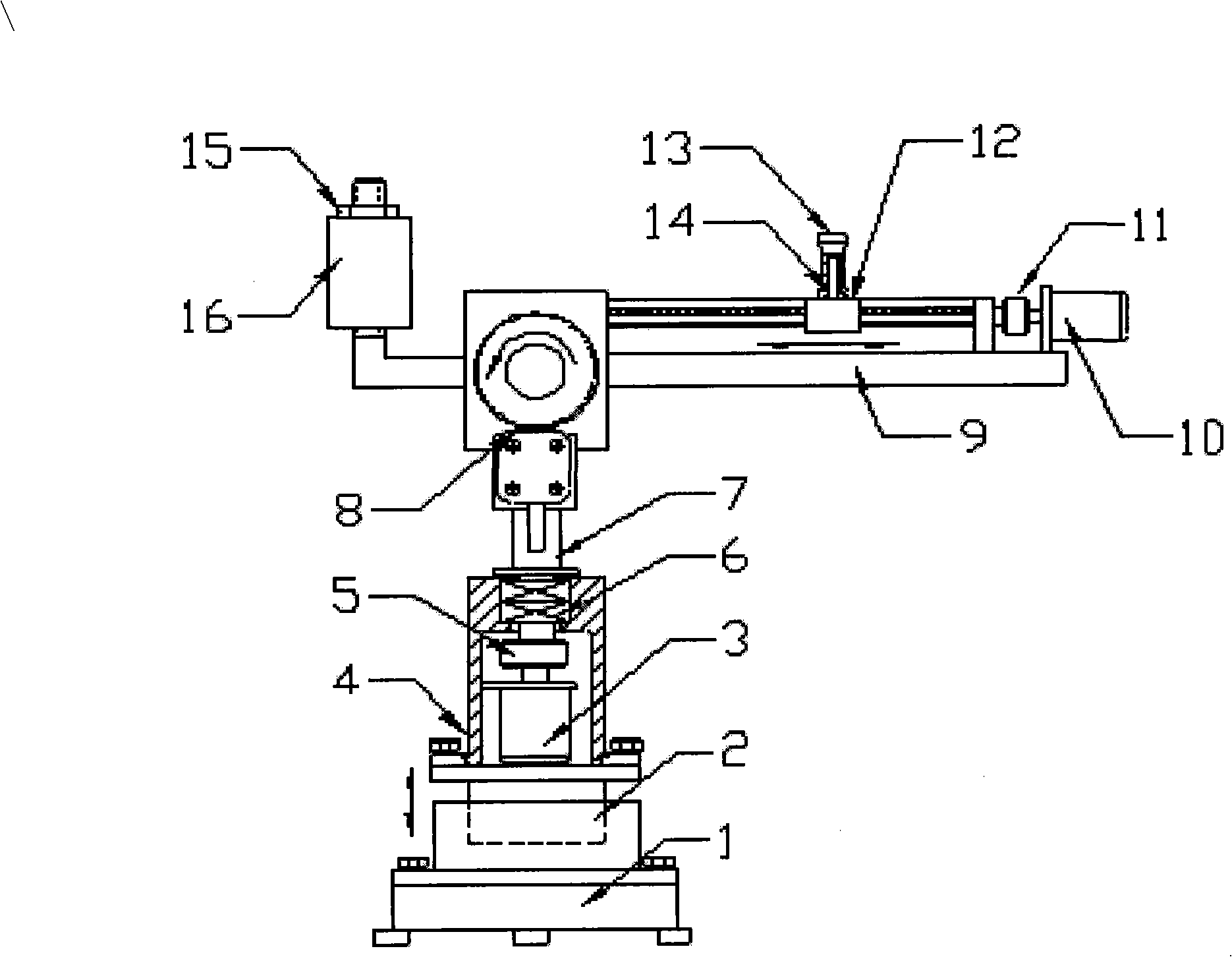

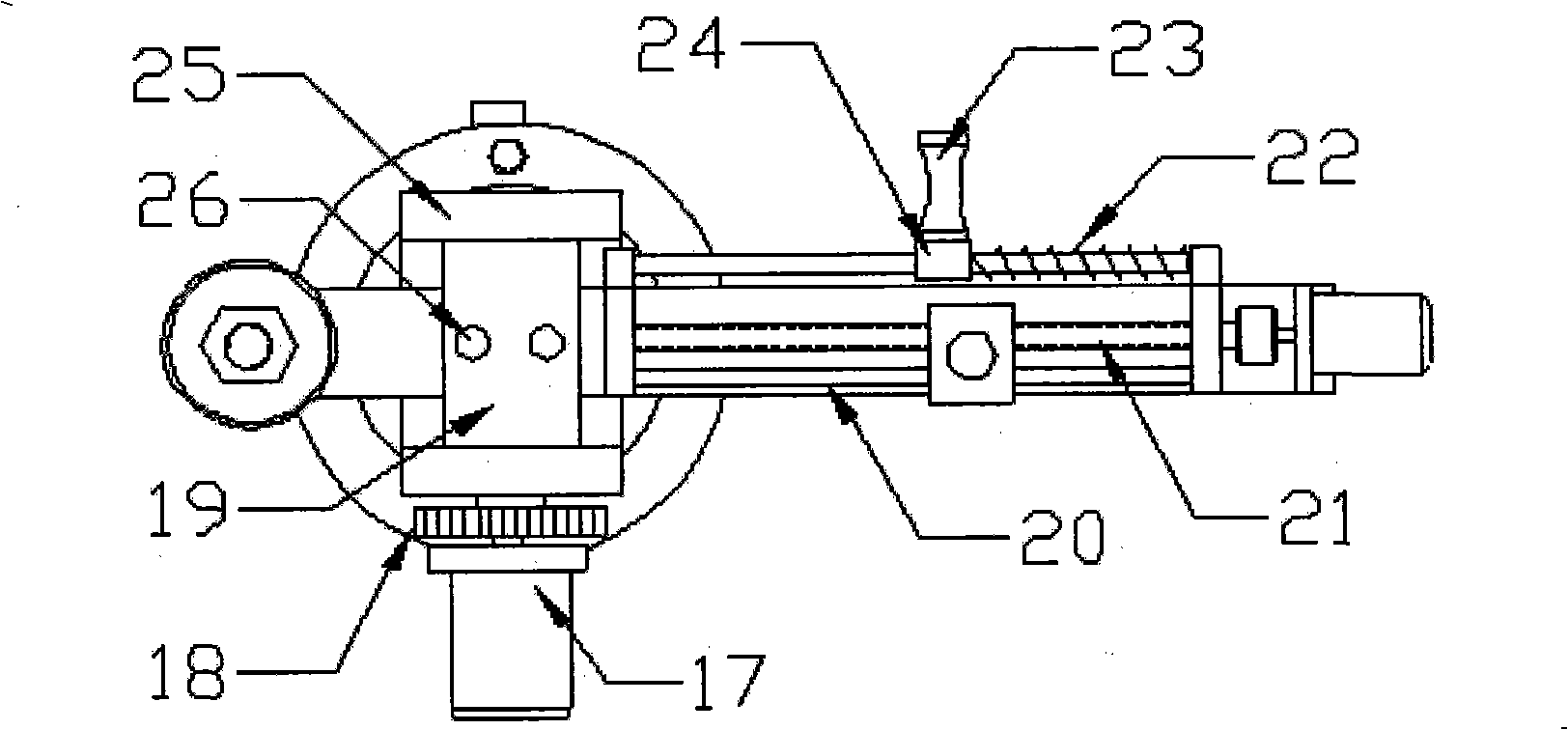

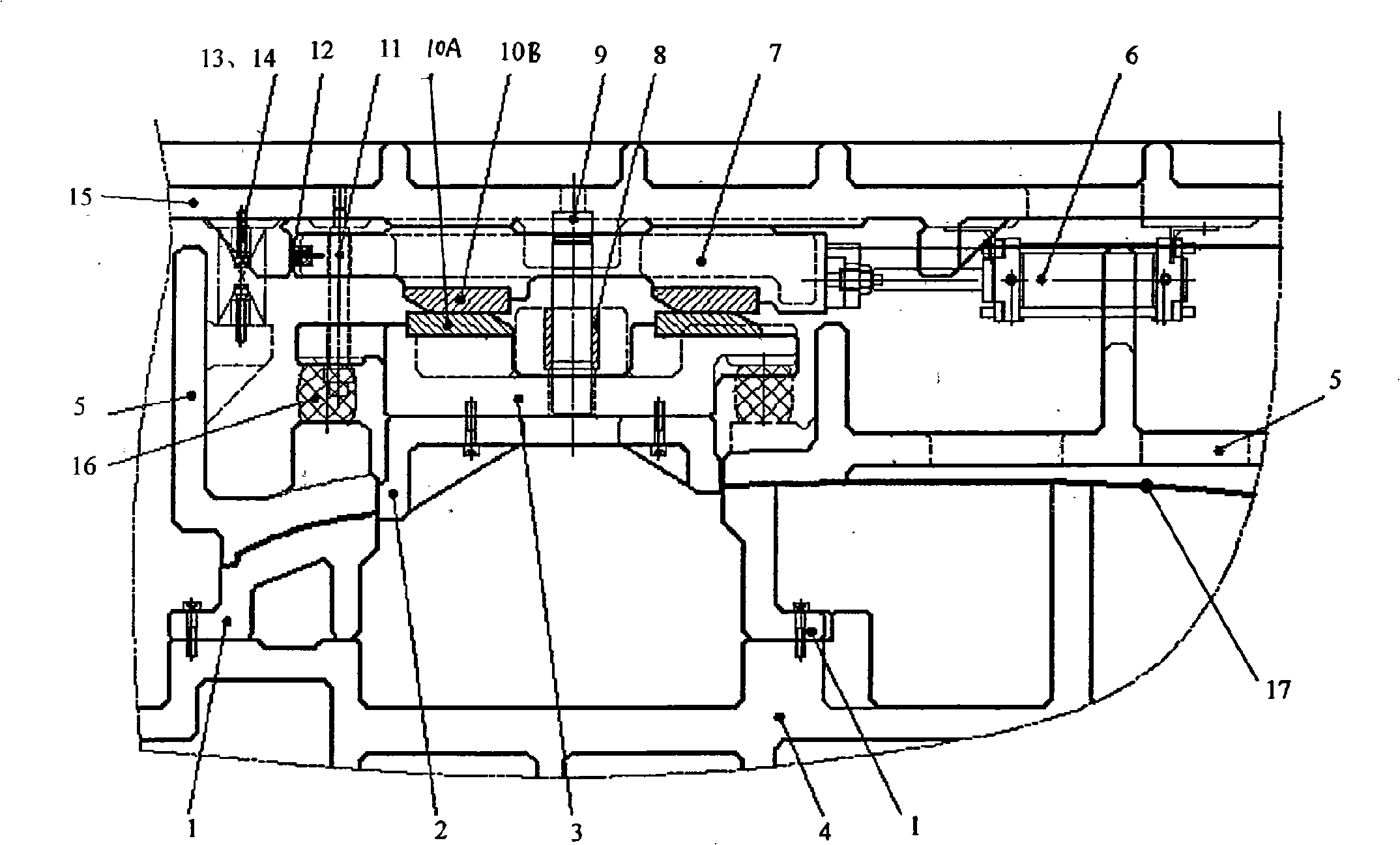

Three freedom shoulder, elbow joint force feedback type healing robot

InactiveCN101288620AMovement precisionSports reliableChiropractic devicesManipulatorThree degrees of freedomBall screw

The invention provides a force feedback rehabilitation robot of shoulder joint and elbow joint with three degrees of freedom. The rehabilitation robot comprises a base, a straight motor arranged on the base, a rotary motor support base arranged on the straight motor, a rotary motor arranged in the rotary motor support base, a V-range motor support base connected with the rotary motor and a V-range motor arranged on the V-range motor support base; the V-range motor is connected with a cantilever rotating shaft by a small gear and a big gear; cantilevers are arranged on the cantilever rotating shaft; a linear guide track, a rolling ball screw rod, a cantilever motor, a screw rod nut and a handle are arranged on the cantilever arranged at one side of the cantilever rotating shaft, and a balance weight is arranged on the cantilever arranged at the other side of the cantilever rotating shaft. The rehabilitation robot is mainly characterized in that the rehabilitation robot can respectively carry out the single-joint motion training of the shoulder joint and the elbow joint and can also carry out the dual-joint complex motion training; the motion training space of the shoulder joint is increased, the number of the training freedom degree is increased, the control algorithm is simple, the force feedback leads the motion to be more accurate and reliable, and the rehabilitation robot can simultaneously provide the detection for the end mechanical information.

Owner:HARBIN ENG UNIV

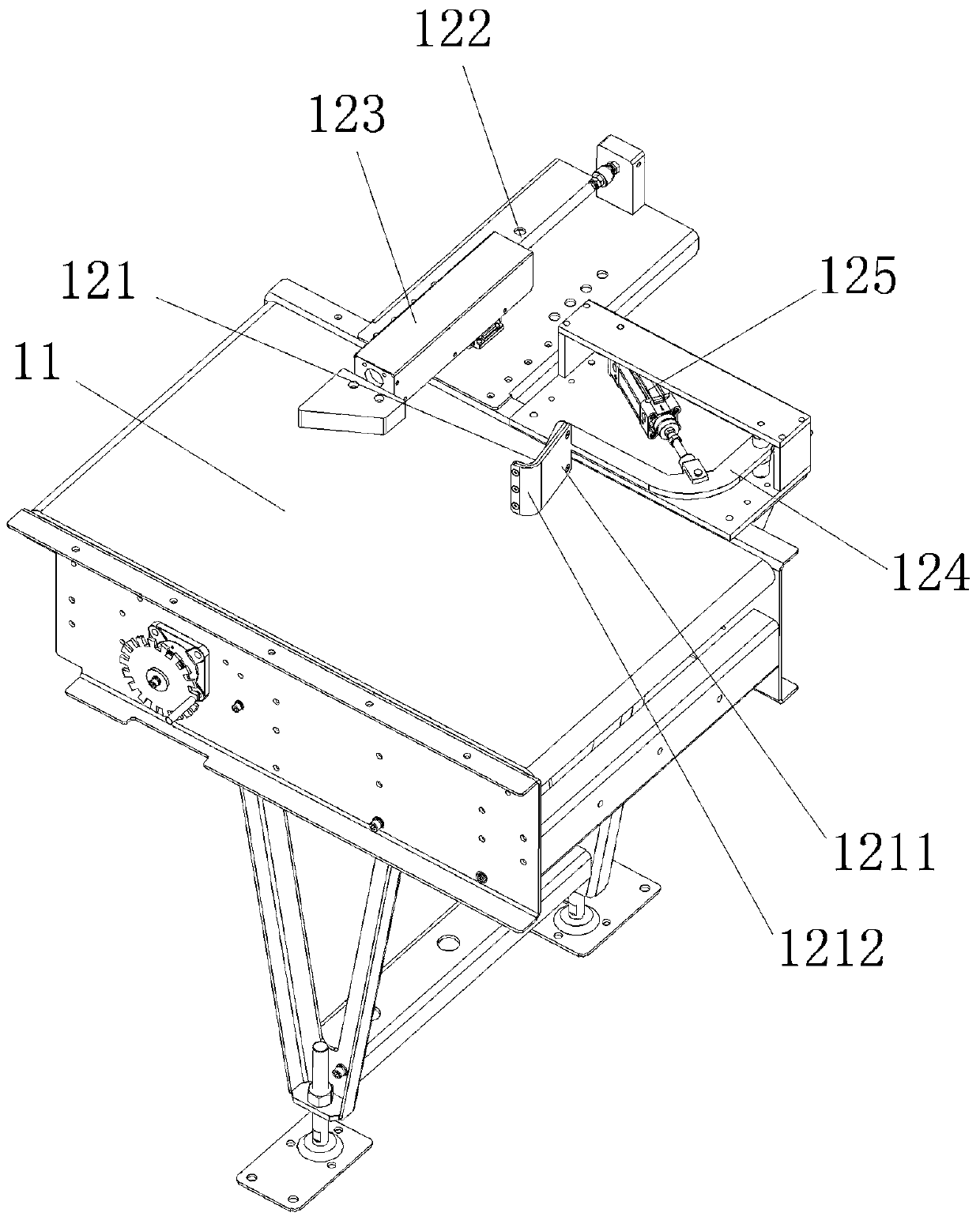

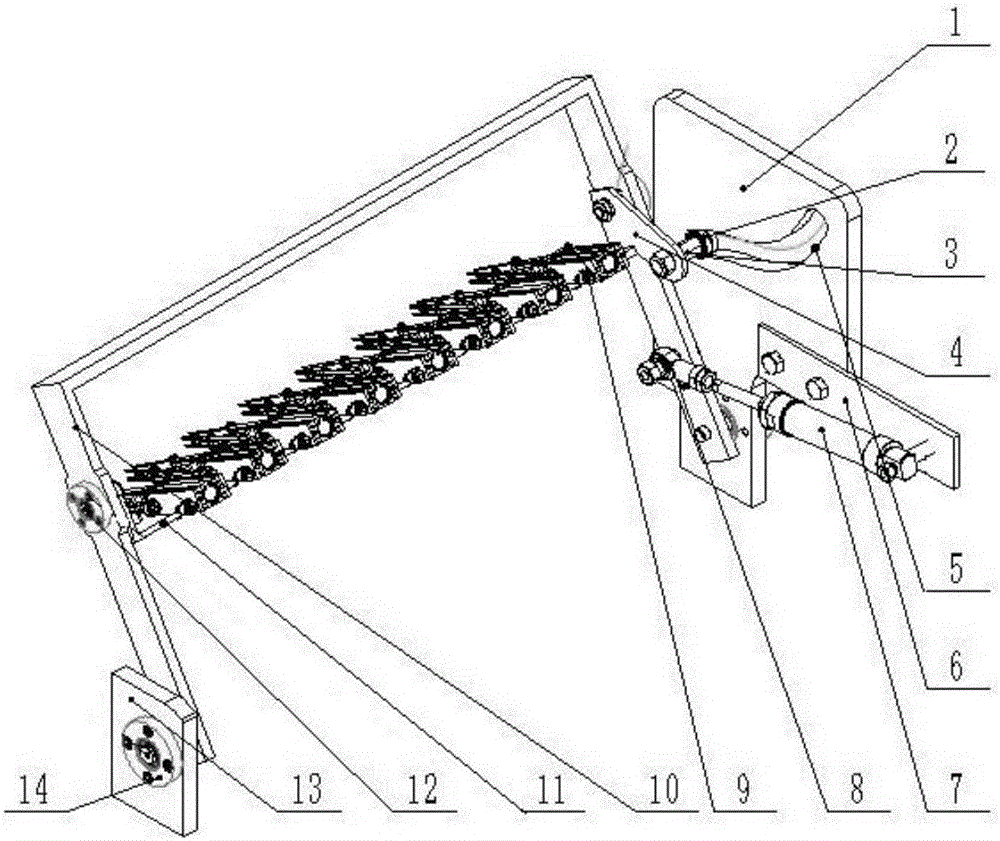

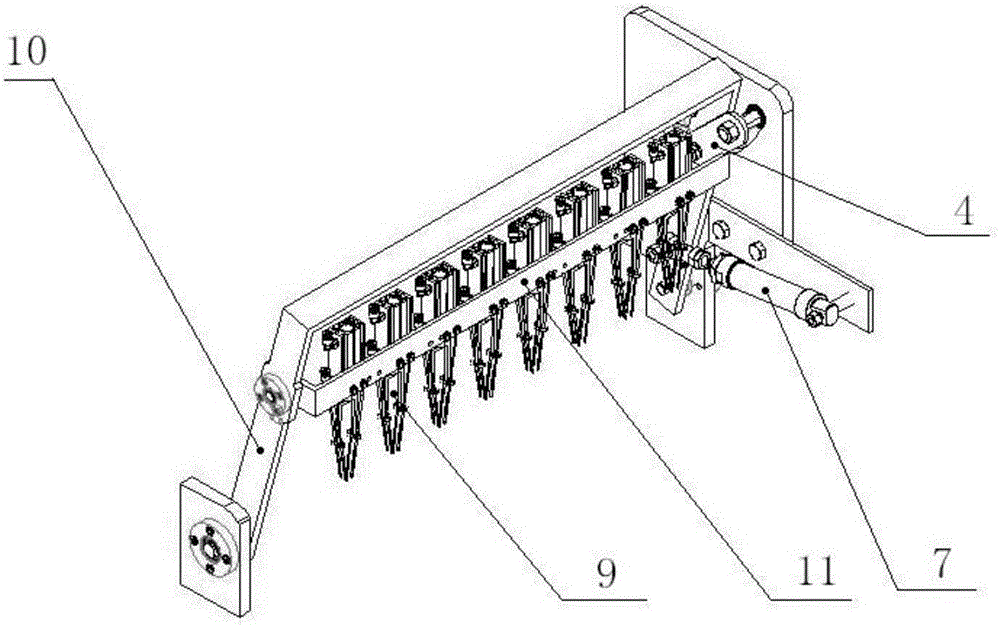

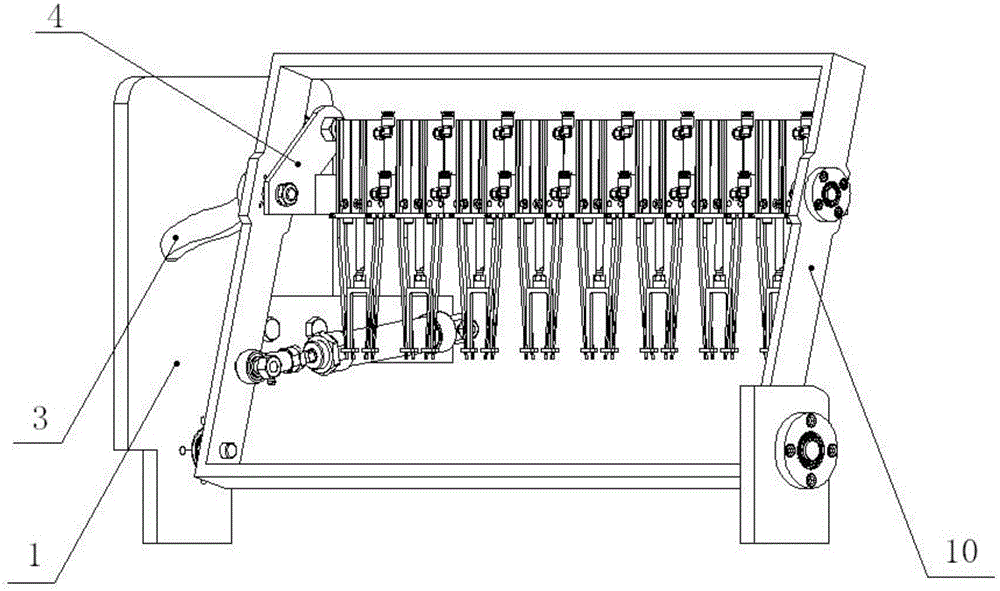

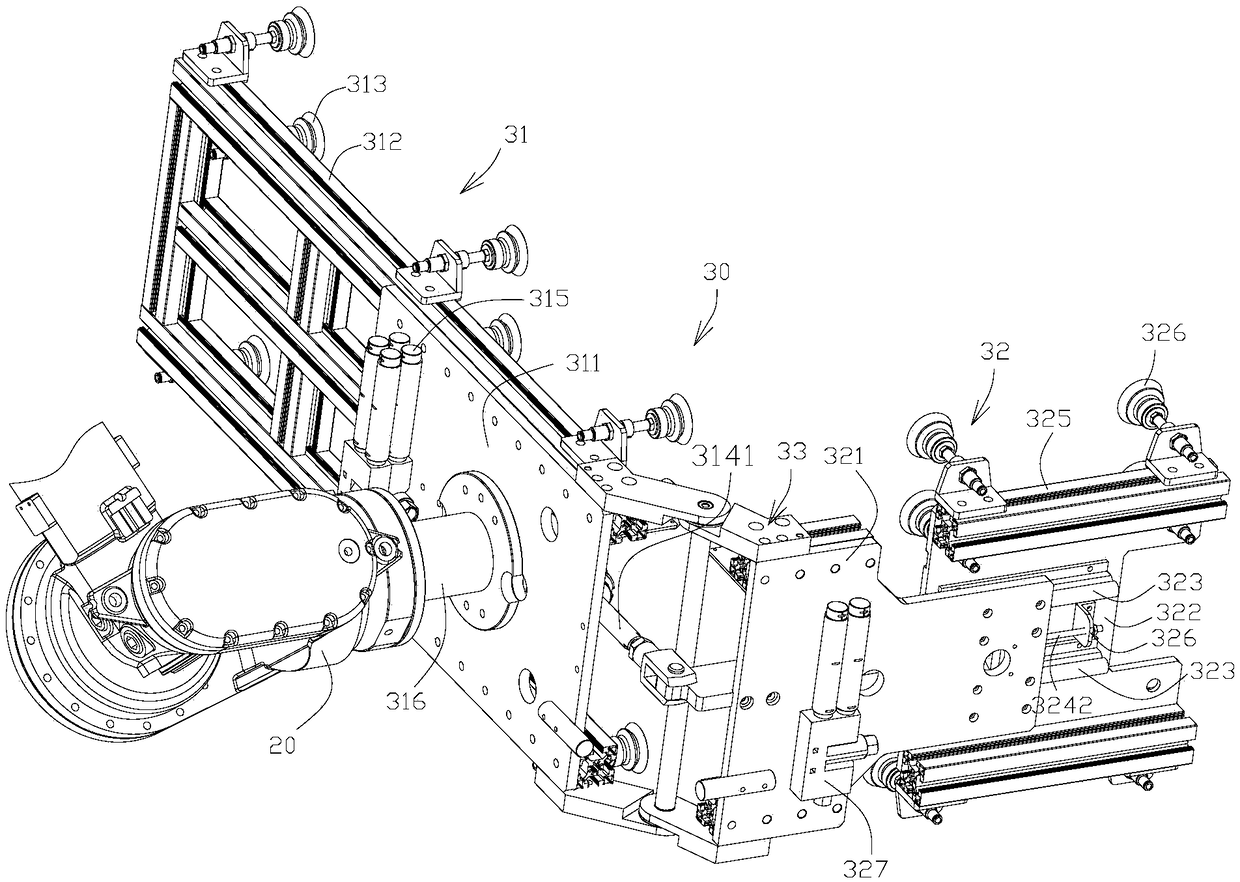

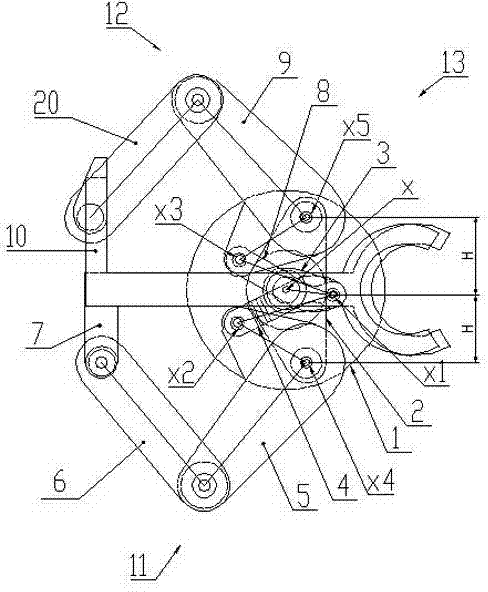

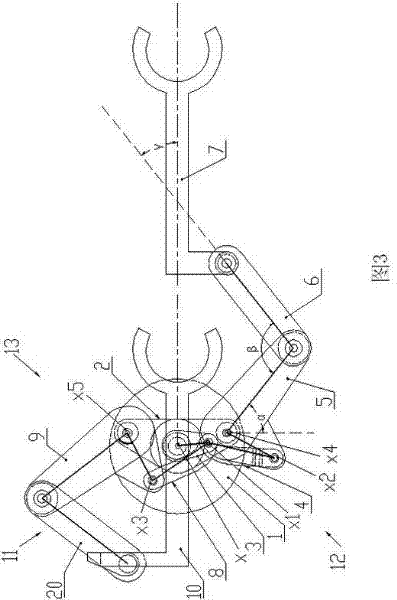

Pneumatic row-by-row seedling picking device of pot seedling transplanter

The invention provides a pneumatic row-by-row seedling picking device of a pot seedling transplanter. The device can realize the action of picking seedlings row by row; seedling picking and seedling throwing opportunities of a picking and throwing device are controlled by an air cylinder; and a needed seedling taking track is formed by the swinging of a large portal frame and the movement of one end of a small portal frame along a groove, and seedling picking and seedling throwing actions are realized by combining the control of the picking and throwing device.

Owner:JIANGSU UNIV

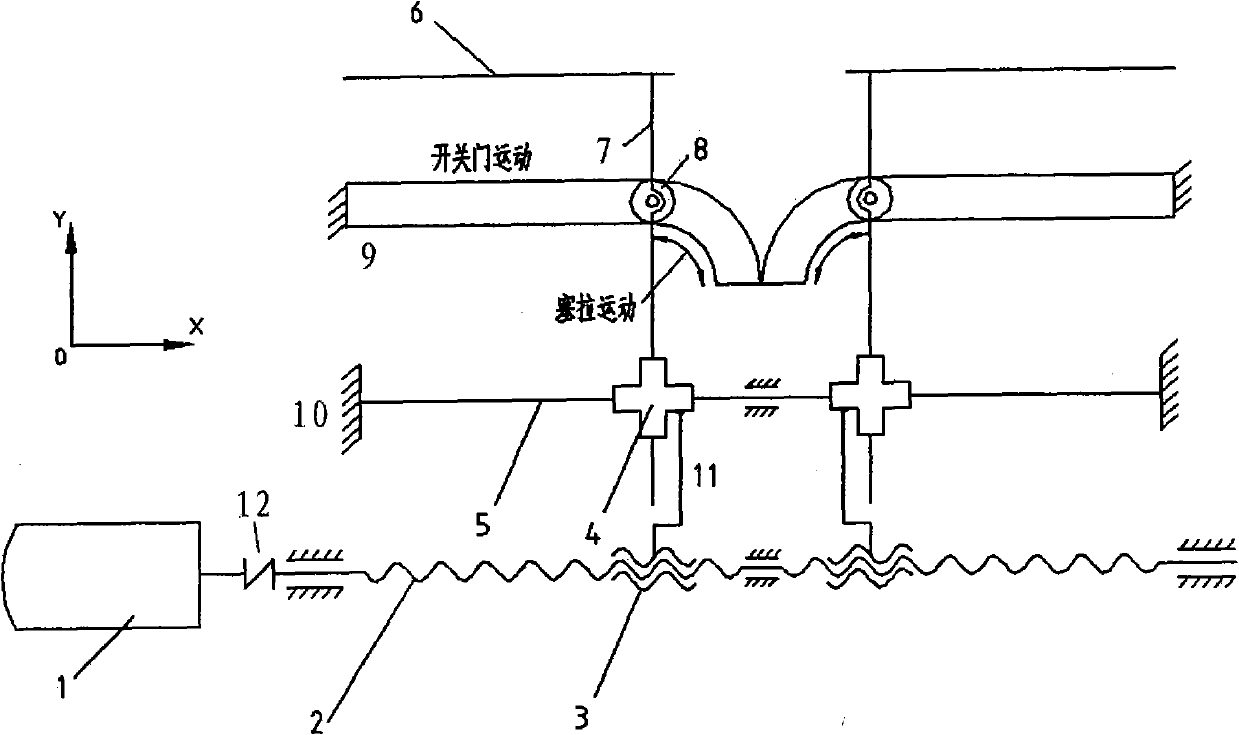

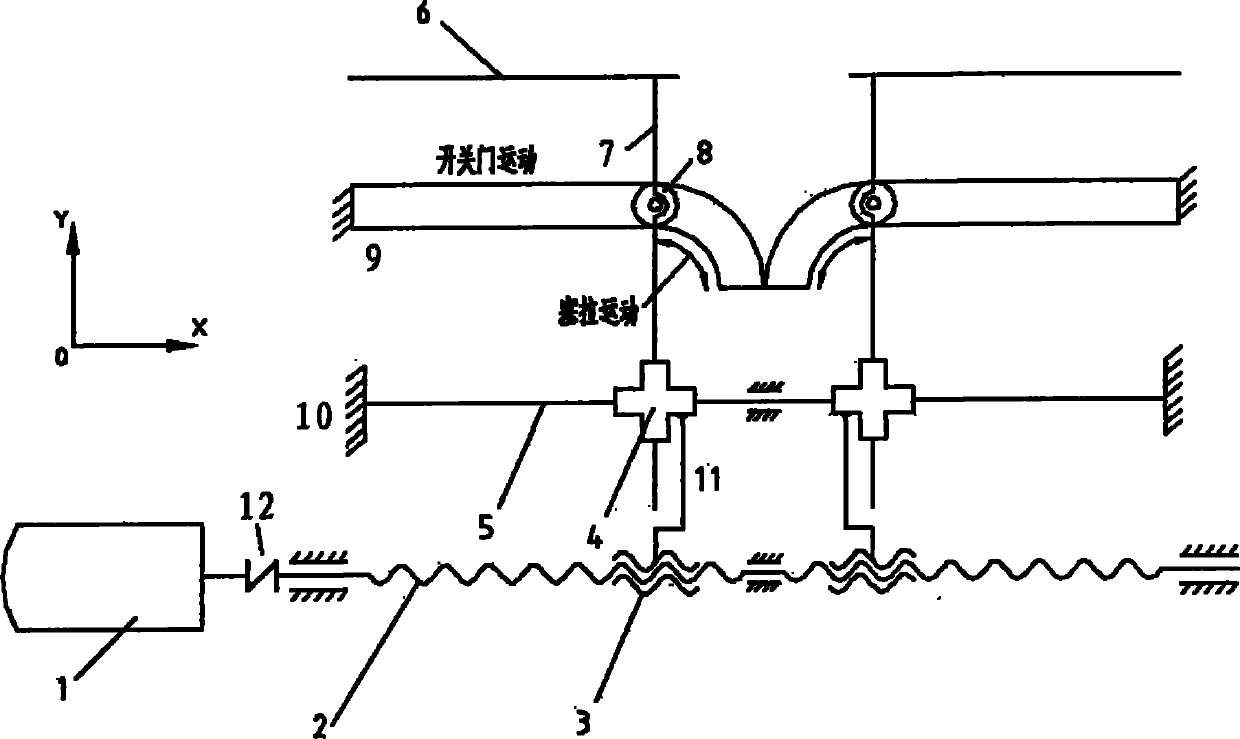

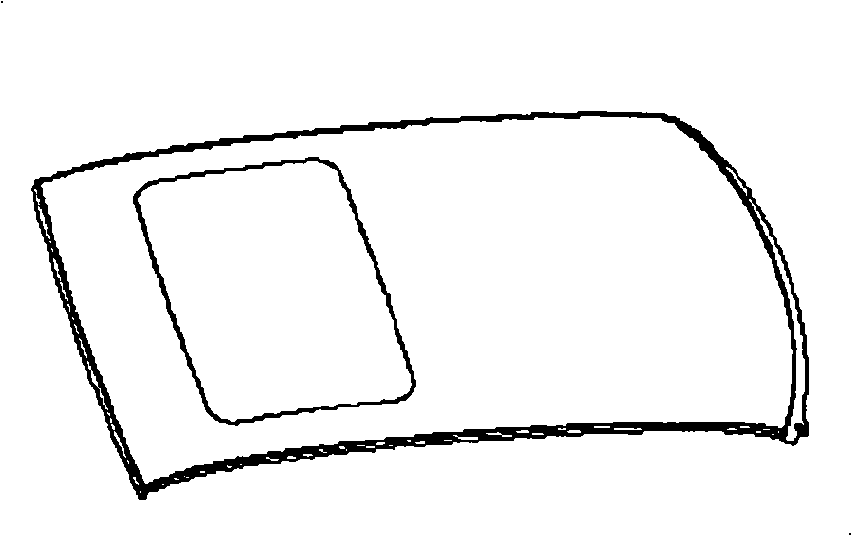

Cross slider type sliding plug door mechanism

The invention discloses a cross slider type sliding plug door mechanism, relates to an opening / closing and sealing mechanism of a sliding plug door for a high-speed train, and is particularly applied to opening / closing and sealing the door of a subway or the high-speed train. The cross slider type sliding plug door mechanism consists of a stepping motor, a screw rod, a screw rod nut, a support, a main shaft, a cross slider, a guide rod, a sliding plug door body, a guide wheel and a guide slot. The main shaft is fixed on the support. One hole in the cross slider matches the main shaft and can slide along the main shaft, and another hole of the cross slider perpendicular to the hole is matched with the guide rod. The sliding plug door body is fixedly coupled to the guide rod through a bolt. The guide wheel is arranged on the guide rod, and is limited in the guide slot to move. The guide slot is made into a shape of a line and a circular arc. When the guide wheel is driven by the cross slider to move along the guide slot, the guide wheel drives the sliding plug door to open and close and the sliding plug movement is realized. The movement of the cross slider is realized by driving the screw rod to rotate through the stepping motor, so the screw rod nut moves linearly, and the screw rod nut is fixedly coupled to the cross slider.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL +1

Hole-punching and switching mechanism of mould

The invention discloses a punching switching mechanism of a die, which consists of a piercing female die, a piercing male die, a male die installation seat, a lower die holder, an eccentric swage, an air cylinder, a drive, inclined wedge skateboards and an upper die holder, etc. The piercing female die is fixed on the lower die holder; the piercing male die is fixed on the male die installation seat; a lower inclined wedge skateboard is fixed at the upper part of the male die installation seat; the air cylinder is fixed on the upper die holder, wherein, the free end of the air cylinder is connected with the drive to pull the drive to move horizontally; an upper inclined wedge skateboard is fixed below the drive to work with the lower inclined wedge skateboard fixed at the upper part of the male die installation seat. The mechanism adopts the air cylinder as the power source to switch the horizontal movement to vertical movement via the inclined wedge skateboards, and to protrude the piercing male die out of the eccentric swage for punching or to withdraw the piercing male die into the eccentric swage to stop punching, thus achieving punching switching. The mechanism has the advantages of high accuracy, stable and reliable movement and easy manufacturing.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

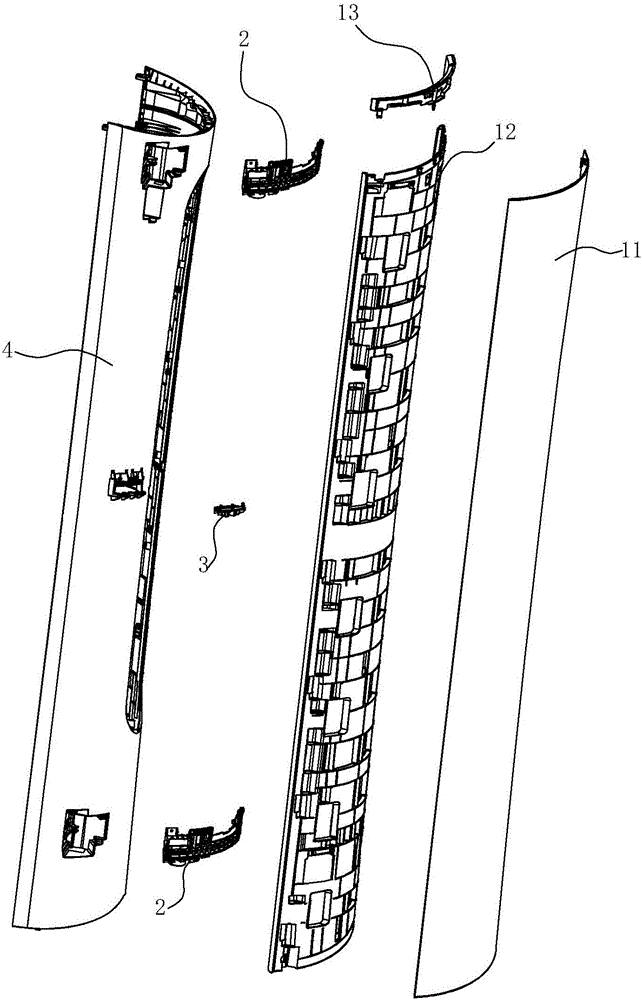

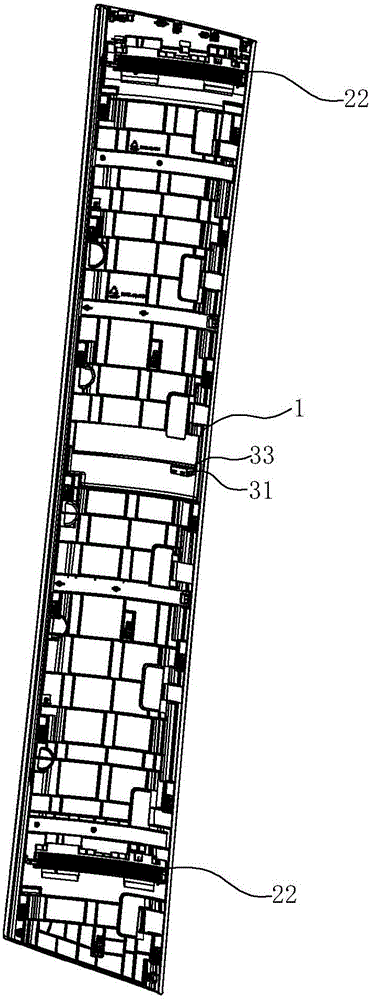

Sliding door structure for air conditioner

ActiveCN105972789AStrengthen supportReduce frictional resistanceAir-flow control membersEngineeringFront panel

The invention discloses a sliding door structure for an air conditioner. The sliding door structure comprises a sliding door component, a front panel and a movement mechanism arranged between the sliding door component and the front panel. The movement mechanism comprises an upper drive device and a lower drive device which are arranged in a spaced manner. Each drive device comprises a drive mechanism arranged on the outer side of the front panel and a rack, wherein each rack is arranged on the inner side of the sliding door component and is driven by the corresponding drive mechanism to transversely slide. The sliding door structure for the air conditioner is characterized in that the movement mechanism further comprises a sliding rail device used for limiting the movement locus of the sliding door component, and the sliding rail device is arranged between the two drive devices; and by additionally arranging the sliding rail device in the middle, the movement locus of the sliding door component is limited, and the supporting effect on the sliding door component can be enhanced, so that the sliding door component slides more stably and reliably.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

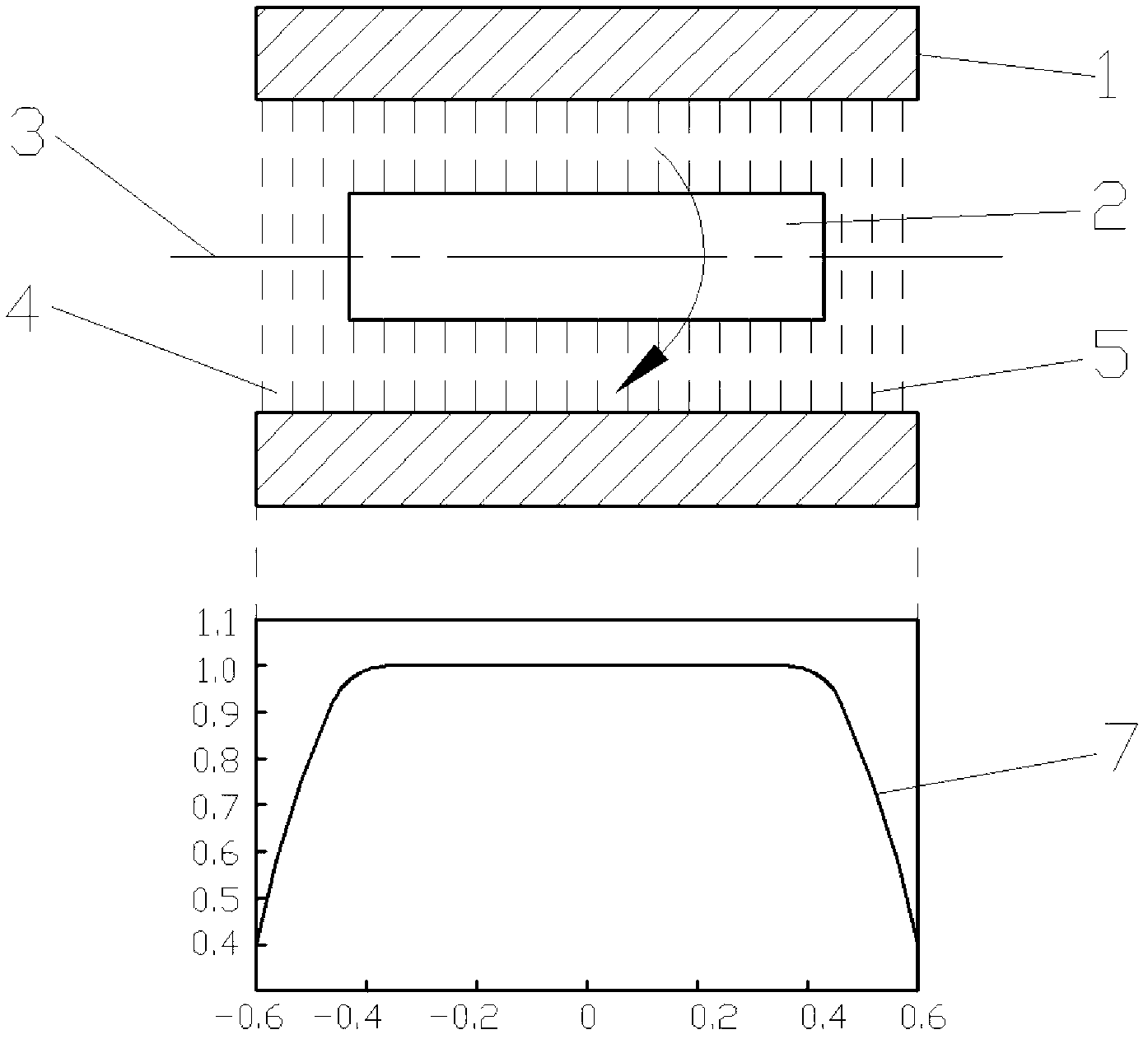

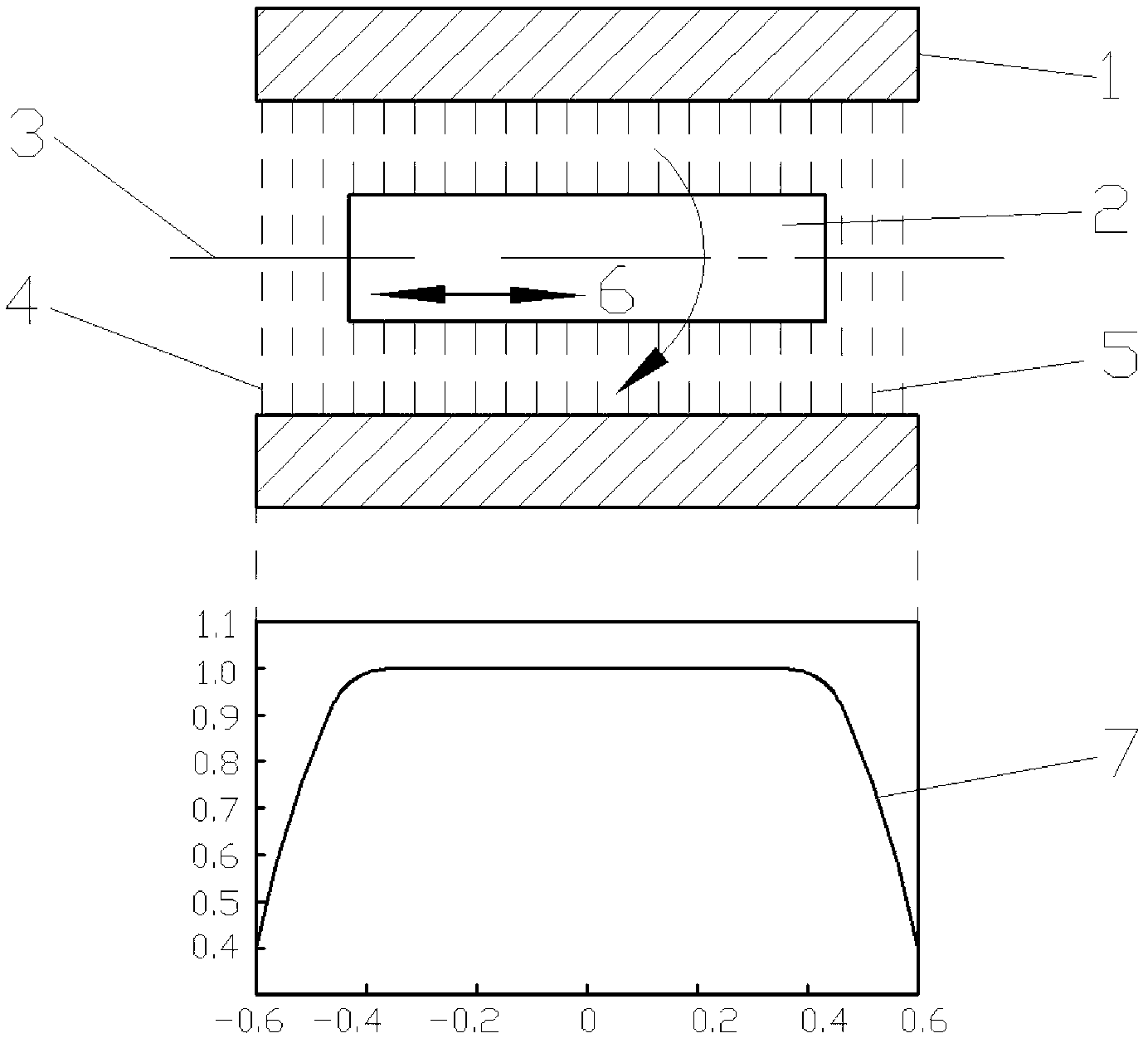

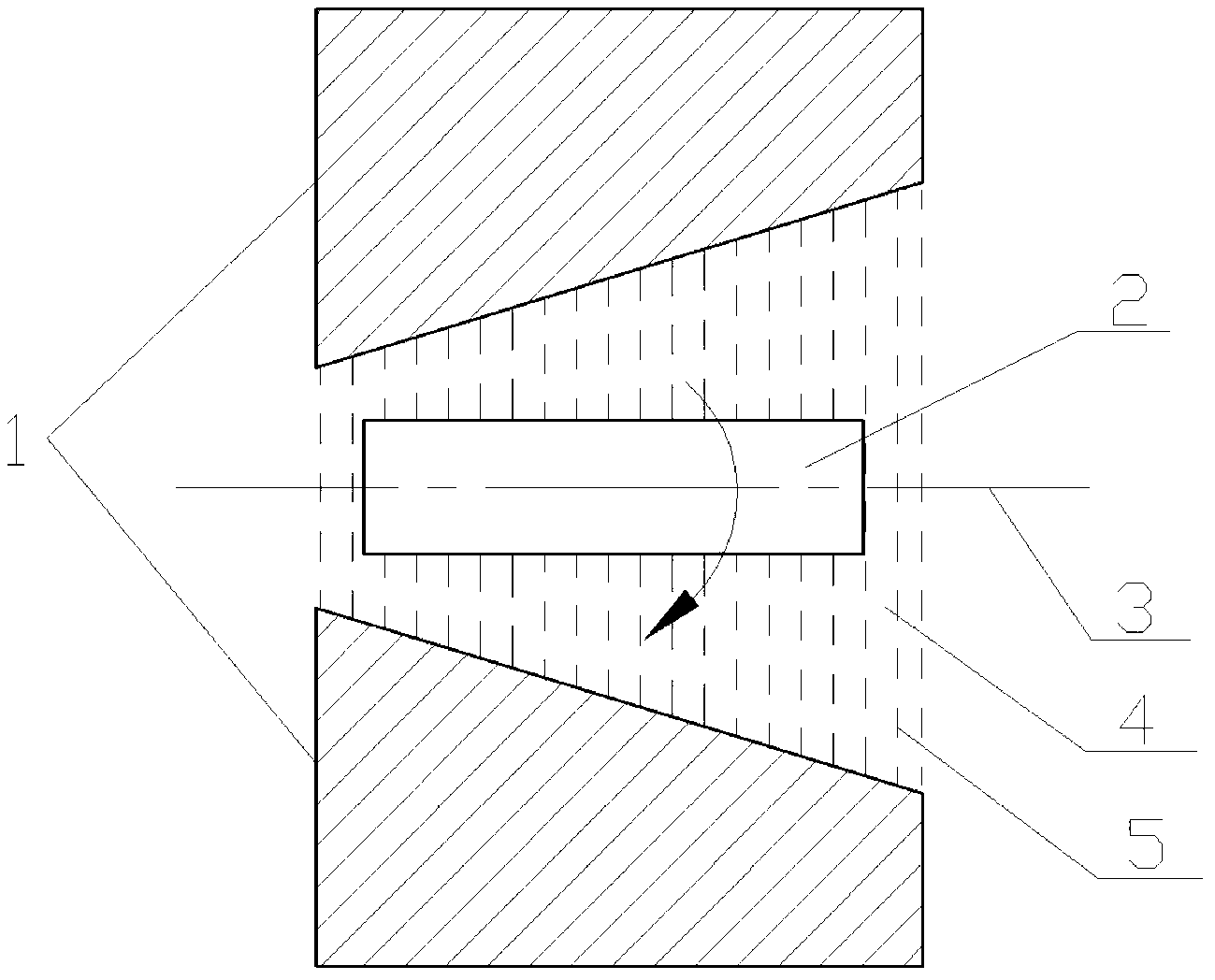

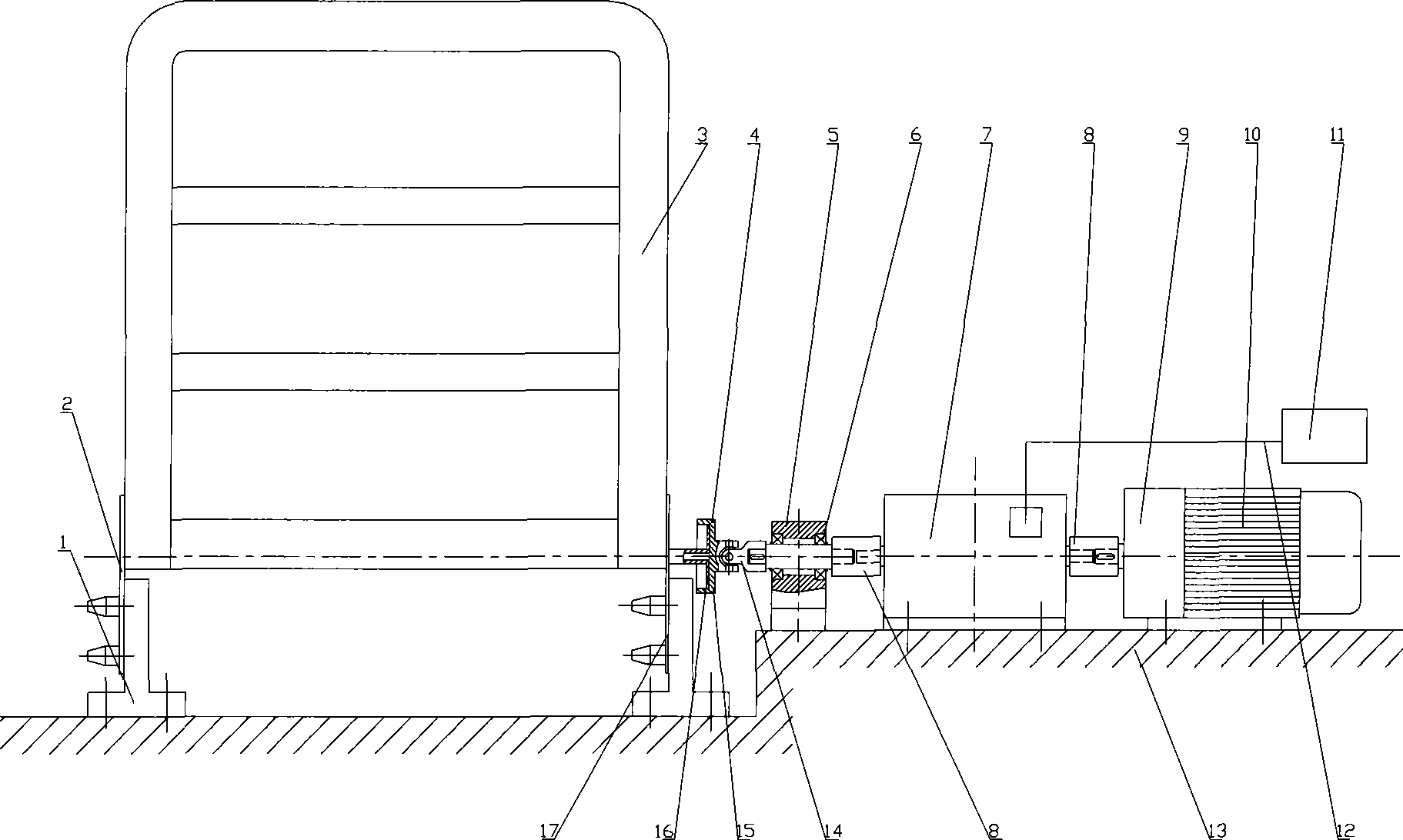

Induction heating apparatus and induction heating method thereof

ActiveCN103313449AImprove efficiencyImprove heating efficiencyInduction heatingTemperature gradientMagnetic line

The invention discloses an induction heating apparatus, comprising a heating device and a rotary driving device. A spindle is arranged in the heating device through the rotary driving device and is driven by the rotary driving device to rotate, so as to cut magnetic lines of force formed in the heating device; the heating device comprises an iron core mechanism provided with an air gap and a superconductive coil interacted with the iron core mechanism to form a static magnetic field, and the spindle is movably arranged in the air gap through the rotary driving device; and the invention also discloses an induction heating method thereof. According to the induction heating apparatus and induction heating method thereof, various control methods are adopted to realize the condition that the temperature of a heated workpiece can be regulated and controlled in the two dimensions of radial and axial directions, so that a heated tool can realize various temperature gradients to adapt to different application requirements.

Owner:JIANGXI LIANOVATION SUPERCONDUCTOR APPL CO LTD

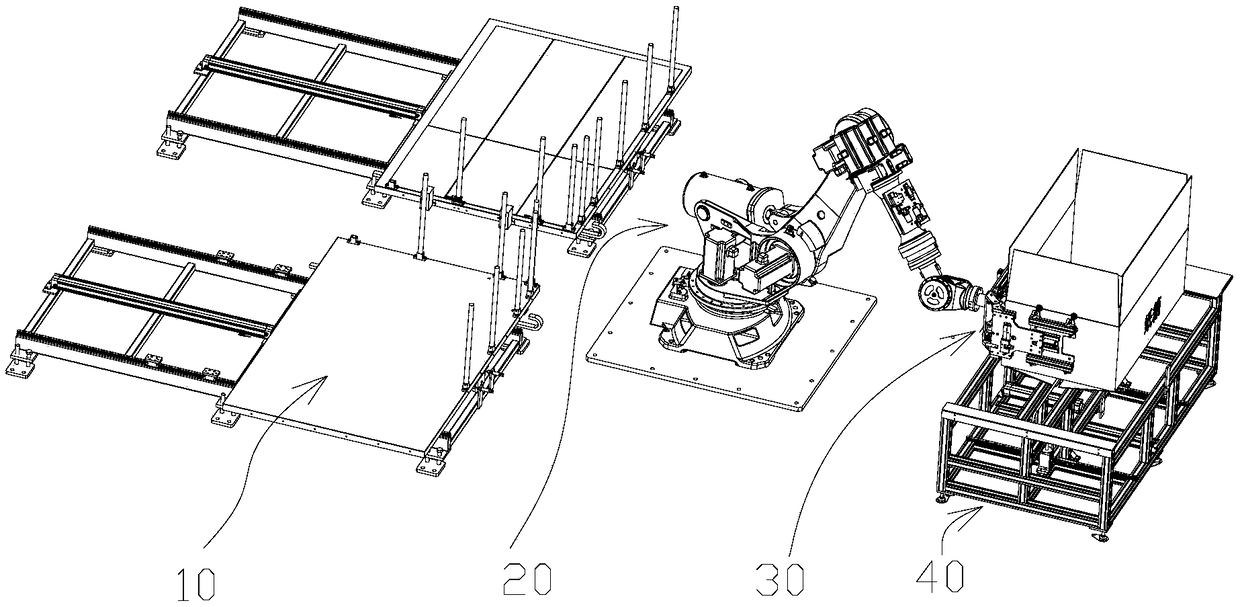

Unpacking equipment of robot and unpacking method

The invention discloses unpacking equipment of a robot. The unpacking equipment comprises a feed platform, the robot, an unpacking manipulator and a folding machine, wherein the feed platform is usedfor feeding and supplying materials; the robot is connected with the unpacking manipulator so as to drive the unpacking manipulator to take the materials and open cartons above the folding machine under the overturning action of a vacuum chuck; and the folding machine is matched with the robot so as to press and fold large and small hinges of the cartons. The invention further discloses an unpacking method. The unpacking method comprises the steps that the unpacking manipulator is driven to grab the cartons by the robot, the manipulator is driven to put the cartons above the folding machine and open the cartons by the robot, and the robot is matched with the folding machine so as to press and fold the large and small hinges at the bottoms of the cartons. Compared with the prior art, the feed process is simple and convenient, continuous material taking and supplying can be realized, and the unpacking efficiency is greatly improved. The unpacking equipment of the robot has the characteristic of flexibility in production and is suitable for unpacking various cartons of different specifications.

Owner:南京埃斯顿智能系统工程有限公司

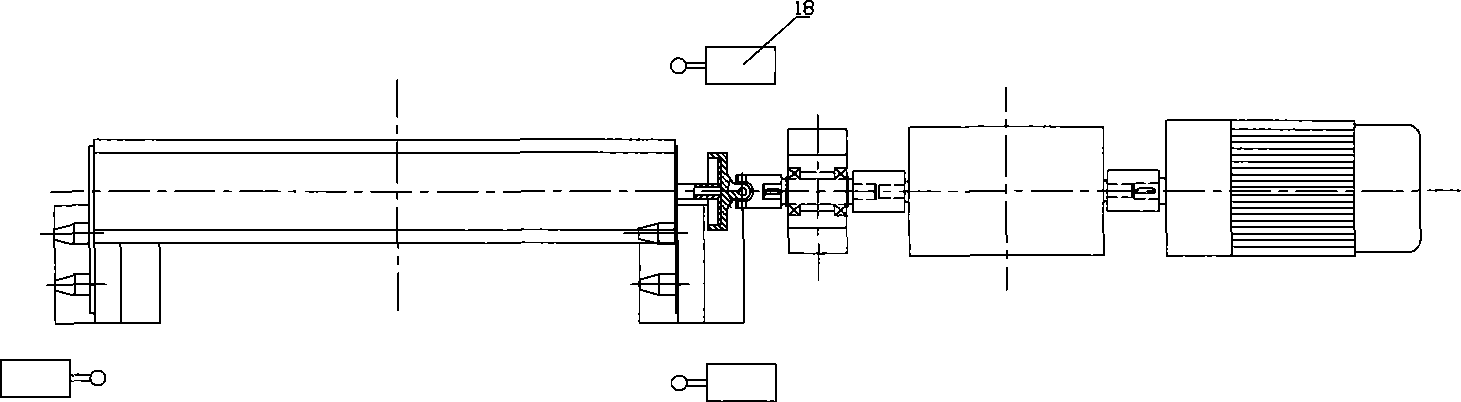

Torquemoment detection device for angle regulator for seat of vehicle

InactiveCN101393059AEliminate eccentric momentHigh degree of automationVehicle testingWork measurementCouplingReduction drive

The invention relates to a torque detection device for an angle adjuster of an automobile seat, which comprises a torque sensor, a flexible coupling, a reducer, a driving motor and a torque measurement instrument. The device is characterized in that the device also comprises a fixed end of a cross fork shaft, a free end of the cross fork shaft, a petal basket of the angle adjuster, and a fixture, wherein four pin shafts of the fixture are inserted into four fixing holes at the lower end of a frame of the automobile seat and are fixed, a forkhead of the pedal basket of the angle adjuster is connected with the free end of the cross fork shaft for eliminating eccentric distance produced during the rotation, the fixed end of the cross fork shaft is arranged on a bearing support, an output shaft of the cross fork shaft is connected with an output shaft at one end of the torque sensor through the flexible coupling, an output shaft at the other end of the torque sensor is connected with the reducer and the driving motor through the flexible coupling, and the torque sensor is connected with the torque measurement instrument through a signal wire. The device has the advantages of high automation degree, convenient operation, reliable movement, simple structure, and convenient maintenance.

Owner:SHANGHAI INST OF TECH

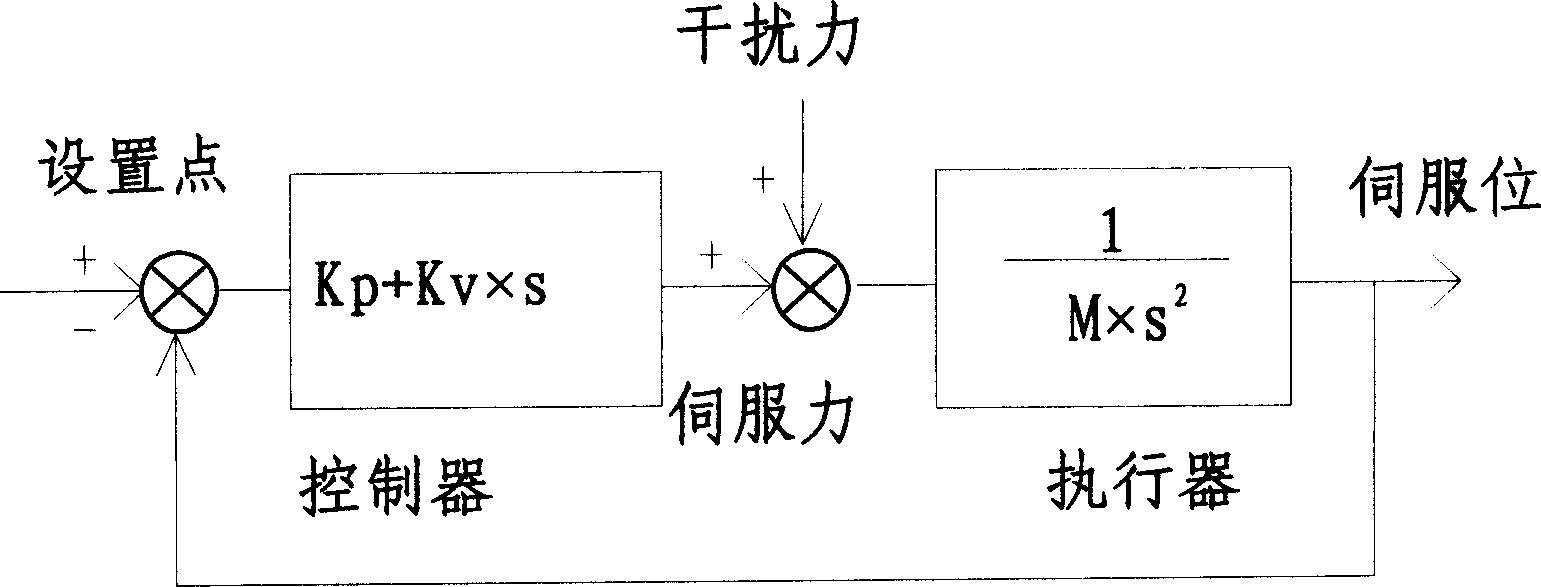

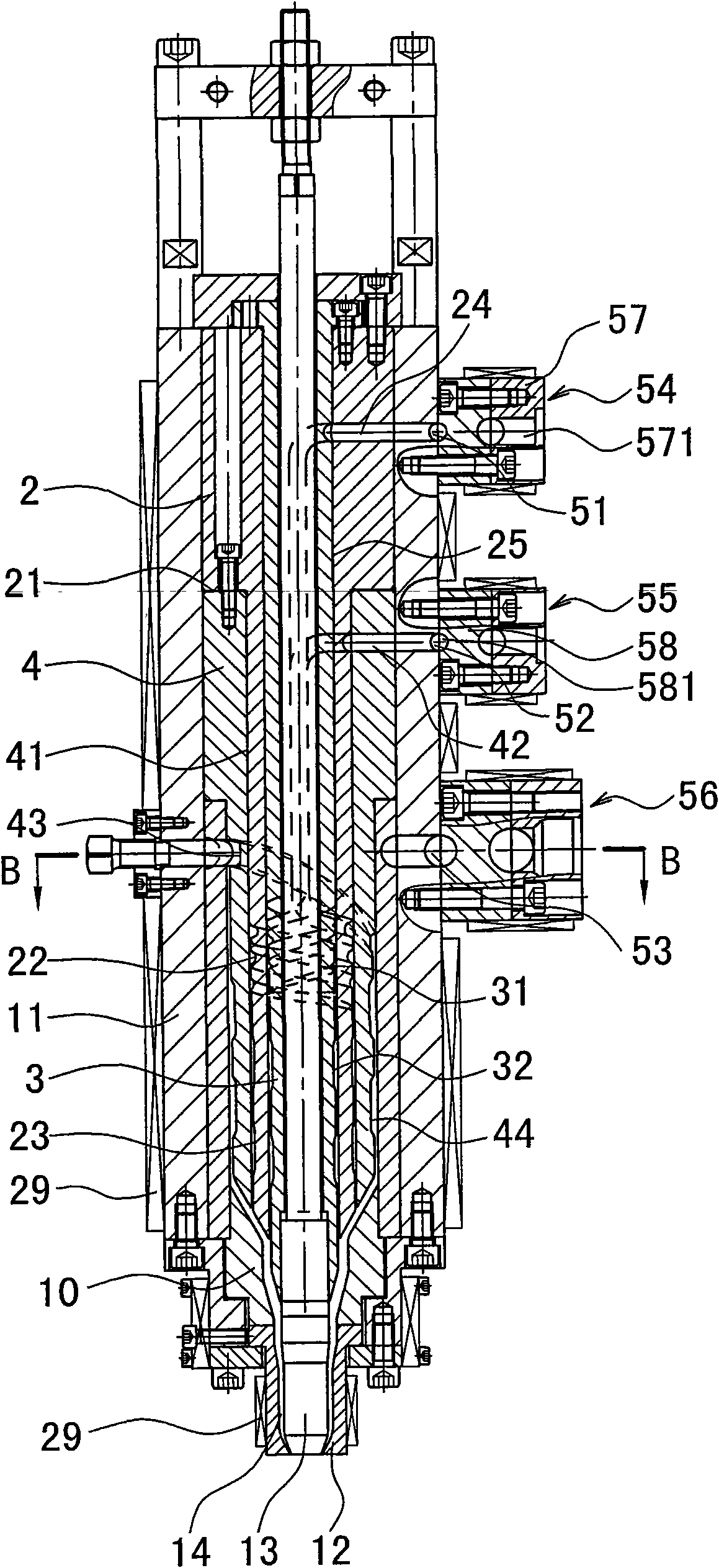

Close-range seed implantation robot and bed connection-type automatic control operating table

The invention discloses a close-range seed implantation robot and bed connection-type automatic control operating table. The end parts of the two sides of an operating bed are respectively fixedly provided with an operating table mounting rack; a horizontal guide rod is fixedly connected between the inner sides of the two operating table mounting racks; the outer side of one operating table mounting rack is connected with a horizontally moving servo motor through a lead screw drive seat; an output shaft of the horizontally moving servo motor is connected with one end of a first ball screw through the operating table mounting rack; the other end of the first ball screw can be rotatably connected onto the inner side of the other operating table mounting rack; the horizontal guide rod is arranged parallel to the first ball screw; the horizontal guide rod is in sliding connection with one end of the bottom of a support slider; the first ball screw is in threaded connection with the other end of the bottom of the support slider; the support slider is provided with an operating table vertical moving frame; and an operating table feed moving mechanism is arranged on the operating table vertical moving frame. The close-range seed implantation robot and bed connection-type automatic control operating table can be combined with the existing operating bed, and is easy to automatically control; and with the adoption of the bed-type automatic control operating table, the operating precision can be greatly improved, and the operating effect can be ensured.

Owner:TIANJIN UNIV +1

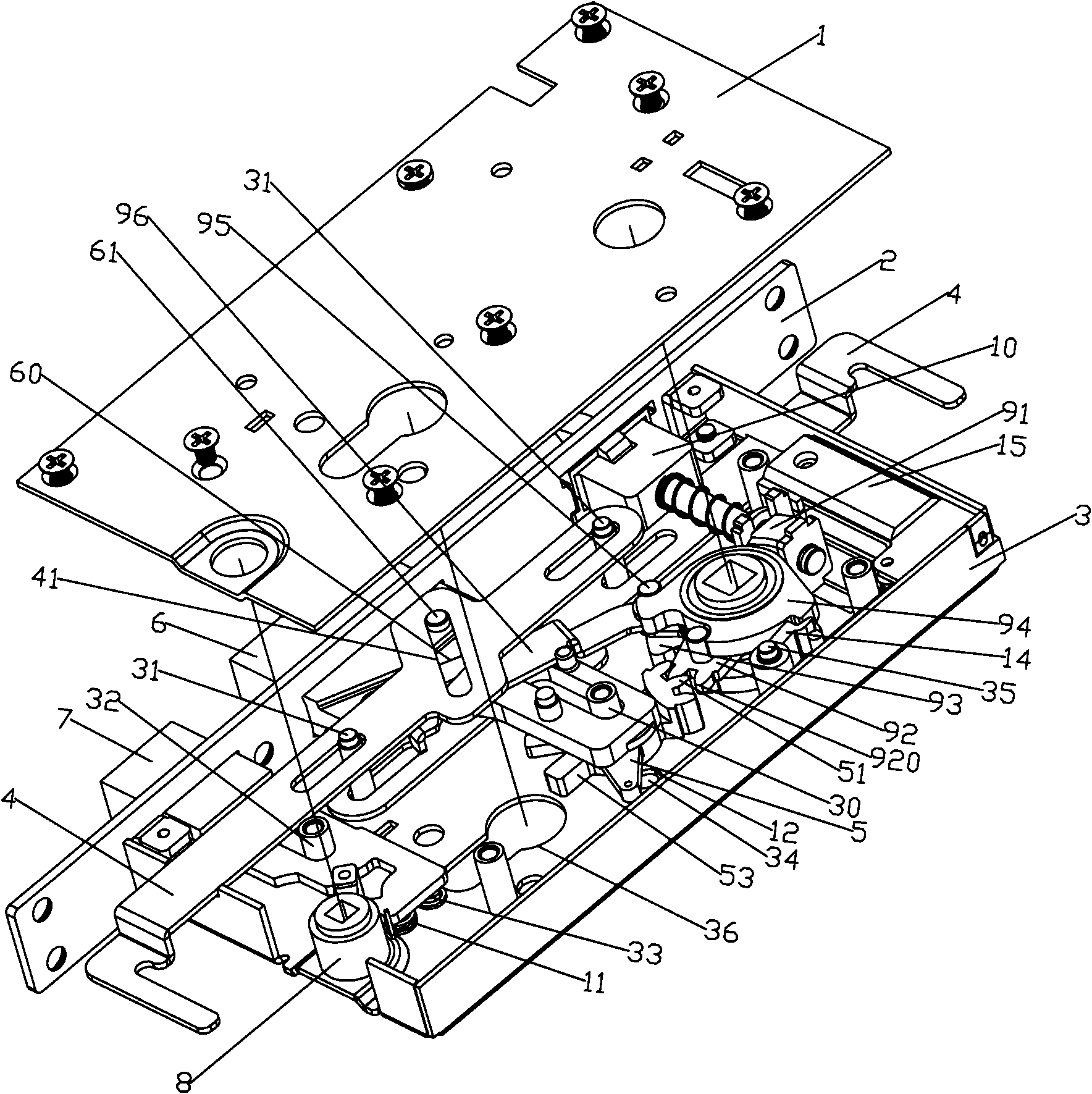

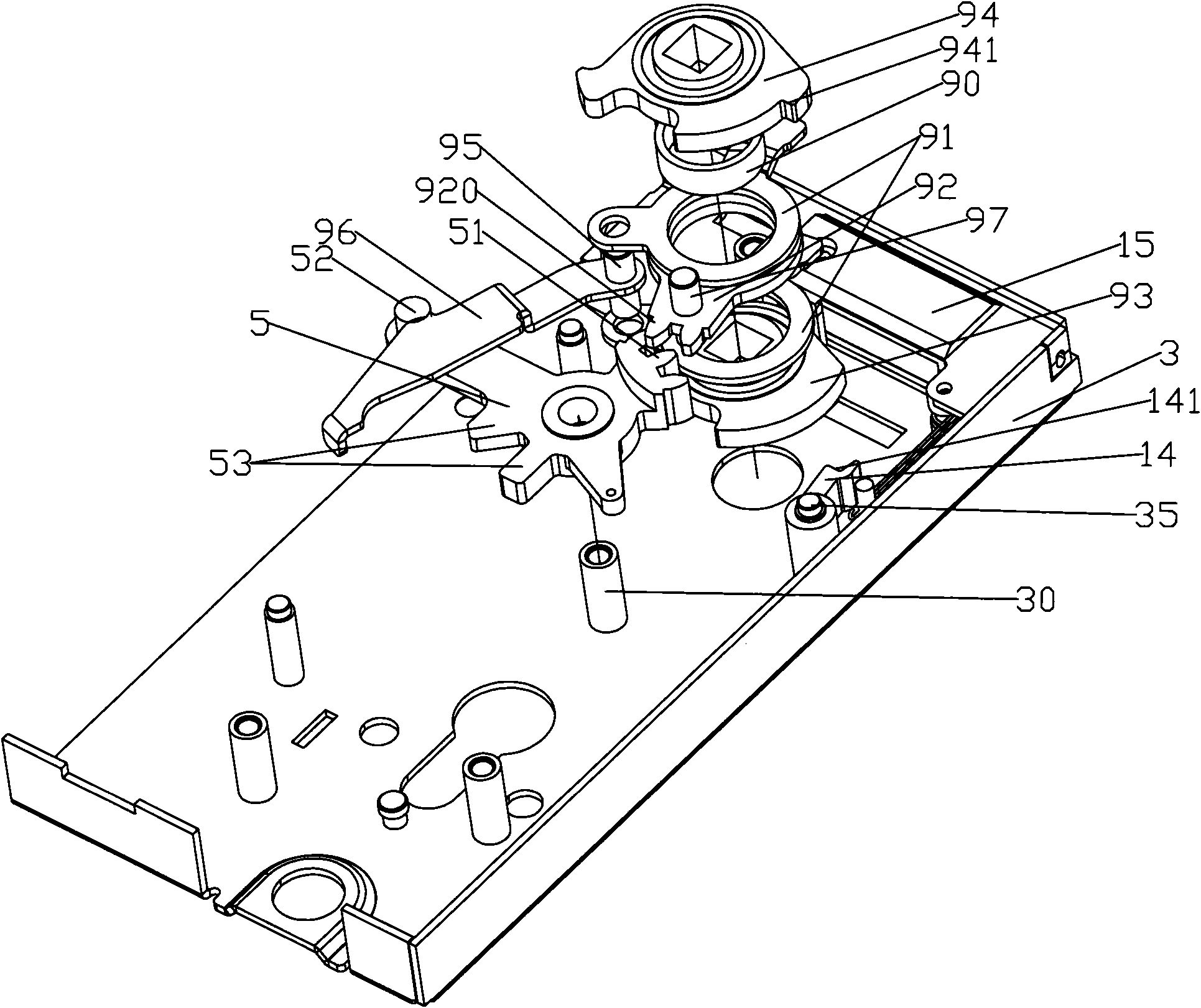

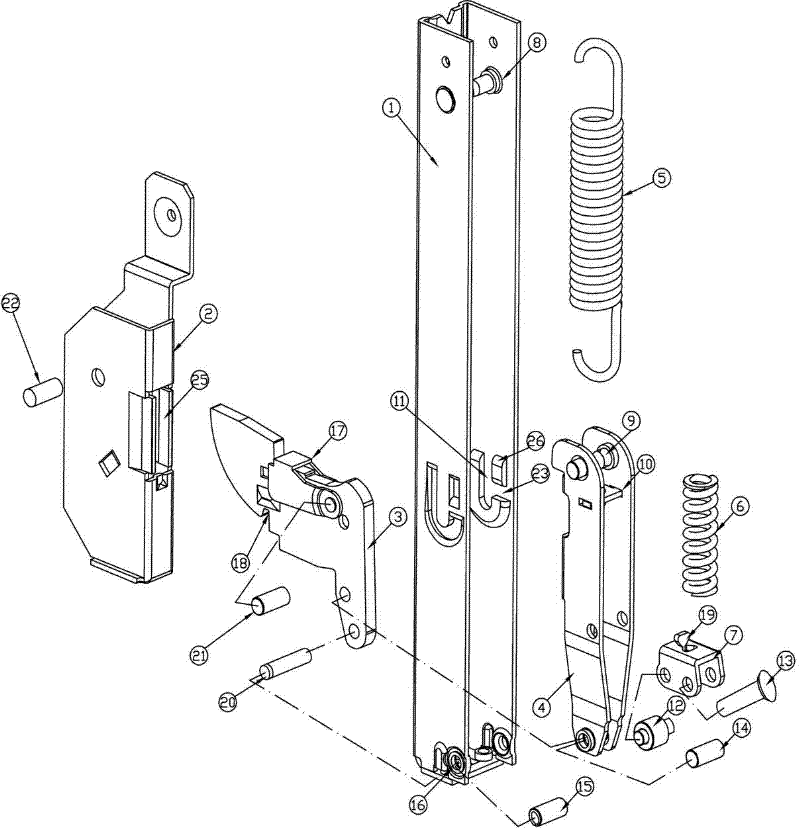

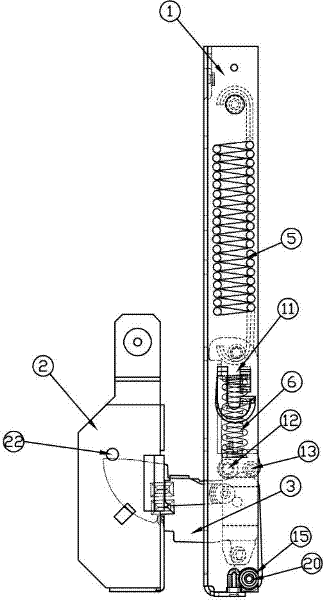

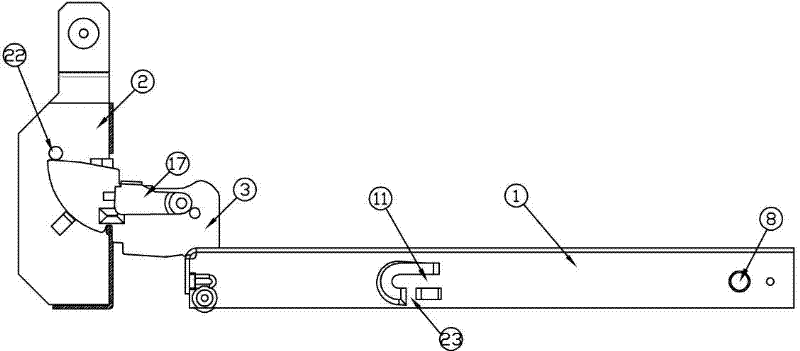

Lock core for electronic safe-guard door lock

InactiveCN101614088ASports reliableSimple structureNon-mechanical controlsHigh volume manufacturingEngineering

The invention relates to a lock core for an electronic safe-guard door lock, which comprises a lock cover, a lock shell, a shifting fork component arranged on the lock shell, a large square tongue component, a latch bolt component comprising a latch bolt and a mechanical locking head, wherein the large square tongue component comprises a large square tongue and a toothed crank arm, the large square tongue is arranged on the lock shell in a sliding mode and is provided with a guiding chute, the toothed crank arm is provided with an upright post, a first gear and a shifting block shifted by the mechanical locking head, and the upright post is positioned in the guiding chute; the shifting fork component comprises a switch board, an inner shifting fork, an outer shifting fork, a gear plate and a shifting plate, the gear plate is provided with a second gear meshed with the first gear, one end of the switch board is an end head driven by the mechanical locking head, while the other end is connected with the shifting plate rotatablely, and the shifting plate is provided with a driving part for driving the latch bolt to perform telescopic actions; and a motor component comprises a motor and a clutch mechanism driven by the motor to control the outer shifting fork to rotate. The lock core has the advantages of reliable movement, simple and compact structure, good manufacturability, suitability for mass production, and high safety and reliability.

Owner:CHENGDU PUTAISHENG TECH

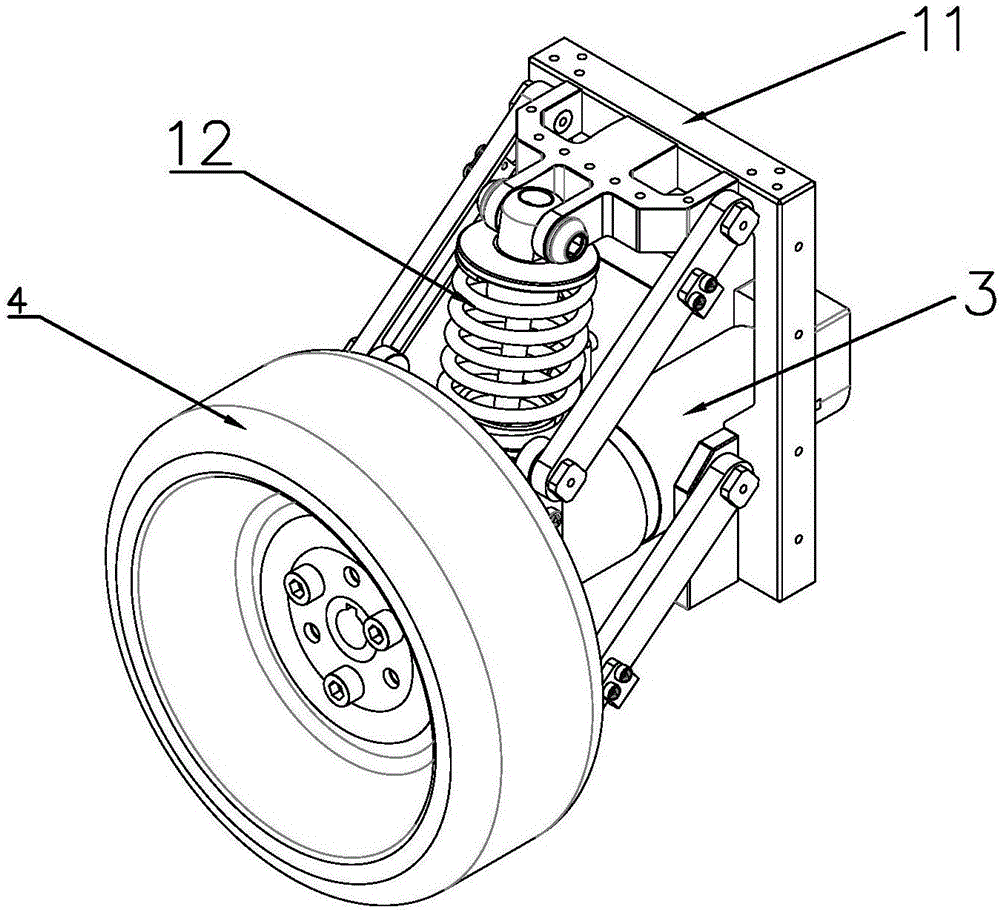

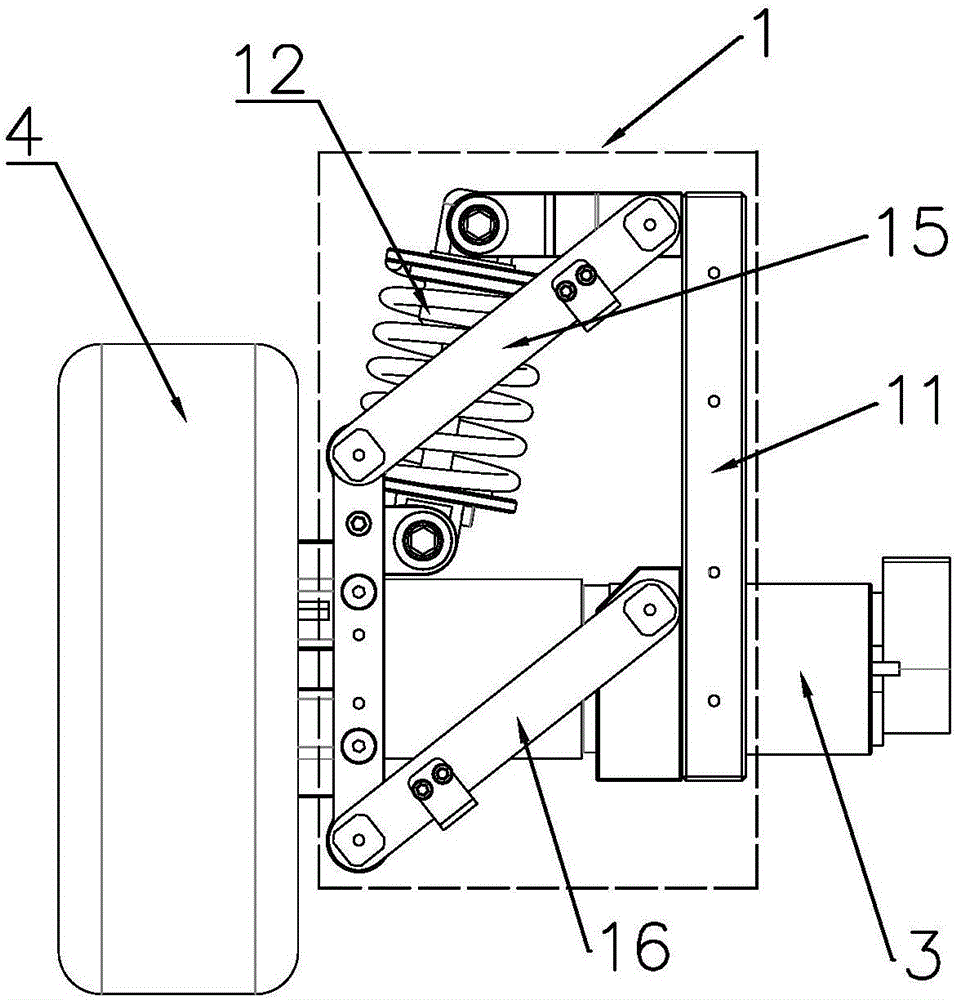

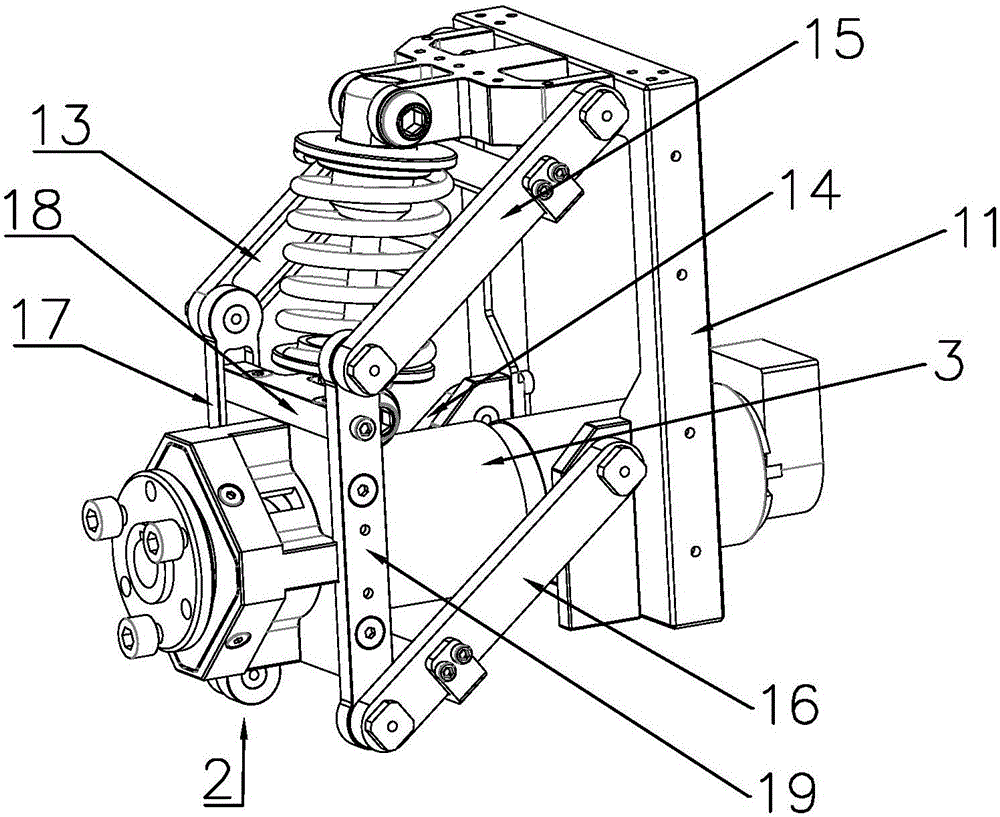

Robot vehicle body suspension system

InactiveCN106427446AImprove fitImprove environmental adaptabilityMotor depositionResilient suspensionsEngineeringShock absorber

The invention discloses a robot vehicle body suspension system, comprising a suspension mechanism, a coupling mechanism, a motor, a driver and a wheel. The suspension mechanism comprises a support frame, a connecting rod assembly, a transverse arm assembly and a shock absorber; the support frame, the transverse arm assembly and the connecting rod assembly form two parallelogram mechanisms; the shock absorber is positioned between the two parallelogram mechanisms and in a vertical direction; the support frame and the connecting rod assembly are respectively connected with the two ends of the shock absorber. The motor is arranged on the lower part of the suspension mechanism and is fixedly connected to the connecting rod assembly. The coupling mechanism is used for connecting a motor output shaft with the wheel. The driver is embedded on the motor. The robot vehicle body suspension system has a strong environmental adaptability which ensures the robot wheels to touch the ground all through the movements in different environments. The robot vehicle body suspension system also has the advantages of stable motion, simple structure and reliable performance, and is worth popularizing in the industry.

Owner:成都普诺思博科技有限公司

Push device driven by sheave

The invention discloses a push device driven by a sheave. The push device comprises a drive driving plate, a motor, a driven sheave, a drive driving lever, a cam, a roller, a first connecting rod, a second connecting rod, a support, a sleeve, a third connecting rod and a push plate. The bottom of the drive driving plate is connected with a motor shaft, and the motor is arranged on a rack. A sheave mechanism is composed of the drive driving plate and the driven sheave. The drive driving plate is fixedly connected with the drive driving lever, the drive driving plate is provided with an inward concave position, and the drive driving lever is located at the inward concave position of the drive driving plate. The geometrical center axis of the driven sheave is connected with the cam, the cam and the roller move in a matched manner, and the cam and the roller are constantly kept in an engagement state. The first connecting rod and the second connecting rod are hinged, and the second connecting rod and the third connecting rod are hinged. The sheave mechanism and a three-link mechanism are matched, the effect of intermittent pushing is achieved, the requirement for the pushing stroke and the speed can be met, rotation of the connecting rods is avoided, and running is stable and reliable.

Owner:潘玲玉

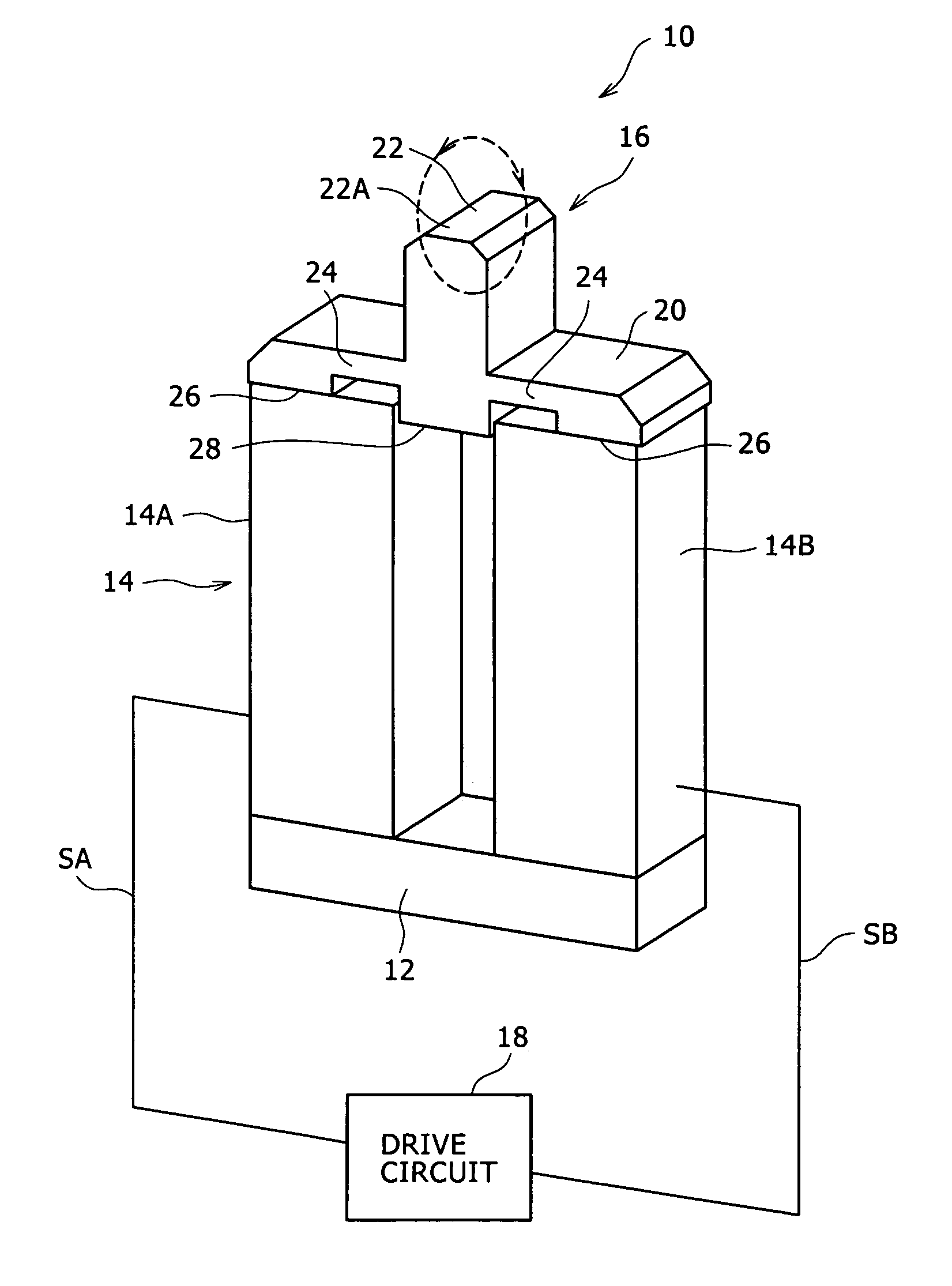

Exciting method for elastic vibration member and vibratory driving device

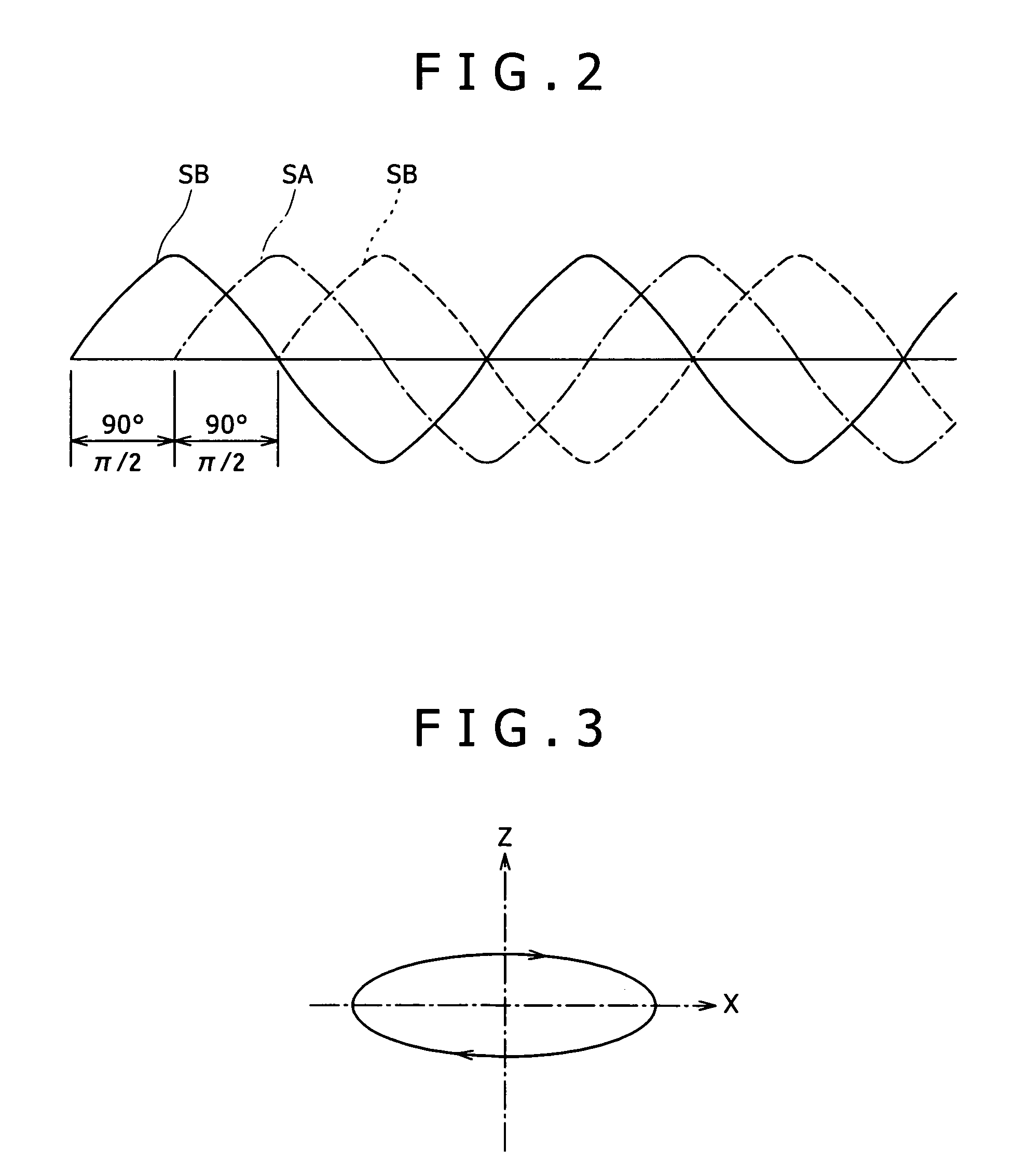

InactiveUS7521839B2Low costDesigned easily and flexiblyAcupuncturePiezoelectric/electrostriction/magnetostriction machinesPhase differenceElastic vibration

Disclosed herein is an exciting method for an elastic vibration member which may include arranging two support members each formed from an electro-mechanical energy transducer; supporting the elastic vibration member to the two support members at their front ends; and supplying drive signals having the same frequency and a phase difference to the two support members, circularly or elliptically vibrating the elastic vibration member.

Owner:SONY CORP

Round disk type electric car parking garage and method for parking and picking up car

The invention discloses a round disk type electric car parking garage and a method for parking and picking up the car; the round disk type electric car parking garage comprises a cylinder, round disks, a power device, a tray, a fan-shaped chassis and a lifting mechanism; the cylinder is perpendicular to the ground, and several round disks are fixedly arranged on the cylinder at equal space; the circle center of every round disk is overlapped with the axis of the cylinder and in parallel to the ground; the upper part of the joint between every round disk and the cylinder is provided with the power device, and the power device is in the shape of ring and sleeved on the cylinder; the power device can rotate on the cylinder; a fan opening is arranged at the same position of several round disks; the fan opening is provided with the fan-shaped chassis, and the fan-shaped chassis is connected with the cylinder through the lifting mechanism, and the lifting mechanism can axially move on the cylinder; several trays are arranged at the upper surface of every round disk around the cylinder at equal space. The round disk type electric car parking garage and the method for parking and picking up the car can well solve the problems that electric cars are disorderly placed to obstruct other passage, and the electric car is easy to loss.

Owner:CHANGAN UNIV

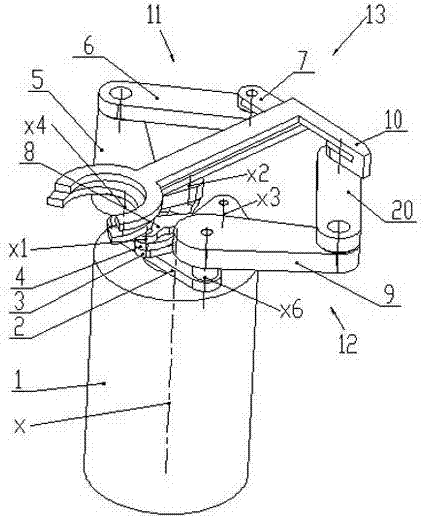

Hinge

ActiveCN102400623ASufficient expansion spaceAvoid scalding accidentsCooking vesselsPin hingesNatural stateTorsion spring

The invention relates to a hinge, in particular to a hinge used between a furnace door and a furnace body of an electric steaming furnace. The hinge comprises a hinge rotating component, a hinge fixing seat (2) and a hinge positioning sheet (3), wherein the hinge rotating component comprises a shell (1), a positioning sheet connecting component (4) and a tension spring (5); the lower end of the positioning sheet connecting component (4) is connected with the hinge positioning sheet (3); the upper end of the positioning sheet connecting component (4) is connected with one end of the tension spring (5) through a tension spring lower end fixing rod (9); the side wall of the positioning sheet connecting component (4) is in sliding fit with a limit groove (11) on the shell (1) through a bulge; and the other end of the tension spring (5) is connected with a tension spring upper end fixing rod (8) on the shell (1). The hinge is characterized in that: a distance between the tension spring upper end fixing rod (8) and the tension spring lower end fixing rod (9) is greater than the length of the tension spring (5) in a natural state. The hinge for the electric steaming furnace has a reasonable structure and is higher in sealing property.

Owner:宁波欧燕电器有限公司

Planar articulated robot arm mechanism

ActiveCN102476383ASimple structureSimple transmission structureArmsRotational axisControl engineering

A planar articulated robot arm mechanism belongs to the technical field of an industrial robot. The planar articulated robot arm mechanism comprises a drive unit, a base platform and a double-telescopic arm assembly, wherein the drive unit is provided with at least one rotating shaft, i.e. a rotating shaft inner shaft, the base platform in which the rotating shaft inner shaft is arranged is connected with a lifting mechanism of the drive unit, the double-telescopic arm assembly is respectively and symmetrically arranged on the base platform through rotary joints relative to the rotary axis of the drive unit, the rotating shaft inner shaft is fixedly connected with a public drive connecting rod of the double-telescopic arm assembly, and a lifting shaft of the lifting mechanism and the rotating shaft inner shaft are respectively connected with a controller of the drive unit through a motor. According to the planar articulated robot arm mechanism, since a seven-parallel-rod mechanism is adopted, the rotating action of a double SCARA (selective compliance assembly robot arm) double-arm assembly can be realized, and the telescopic action can also be realized; and with the lifting mechanism in the drive unit, the lifting motion of the double SCARA double-arm assembly can be realized. The planar articulated robot arm mechanism is simple and compact in structure, is high in structural rigidity, is flexible and reliable in motion, is high in position precision and is high in reliability.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

High precision silicon slice bench and uses thereof

ActiveCN1866494APrecise positioningSports reliableSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention discloses a high-precision silicon chip table and utility, which comprises the following parts: air-float support, leveling organization, plane motor and reed, wherein the square lens is set on the reed, which is supported by at least three square lens supports with bottom on the upper surface of leveling organization; the sucker is set on the upper surface of square lens to place silicon chip; the electric vortex sensor is set between air-float support and square lens; the leveling organization is composed of at least three leveling executers along circumferential direction, which correspond to square lens supports; the mirror plane is set on the square lens, which aligns mark board and reflects laser beam. The invention can assemble high-precise silicon chip within 50 nm vertical precision and 10 nm leveling precision, which improves manufacturing precision of semiconductor equipment greatly.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

Multi-blank multi-layer co-extruding blow moulding machine

A multi-blank multi-layer co-extruding blow moulding machine comprises a plasticizing system, a mold head extruding system and a blow moulding system. The mold head extruding system comprises more than one mold head, each mold head is provided with a feeding port connected with a screw rod; the mold head comprises a mold head main body connected with a mouth mold which is provided with a core mold; the core mold and mouth mold form an extruding port, wherein a guide body A and a guide body C are mounted in the mouth mold main body; the guide body A is provided with a step; a small head under the step is sleeved in a middle hole C of the guide body C; the small head is provided with a guide groove A and a vertical flow passage A; a big head is provided with a transverse flow passage A; a guide body B is arranged in the guide body A; the guide body B is provided with a guide flow passage B and a vertical flow passage B; the guide flow groove B is communicated with the feeding port; the guide body C is provided with the transverse flow passage C; the transverse flow passage C is connected with the guide flow groove A and the feeding port B; the guide body C is provided with a guide flow groove C and a vertical flow passage C, the guide flow groove C is communicated with the feeding port C; the vertical flow passage A, the vertical flow passage B and the vertical flow passage C are jointed at the external wall of core mold and communicated with the extruding port.

Owner:浙江东方州强塑模实业有限公司

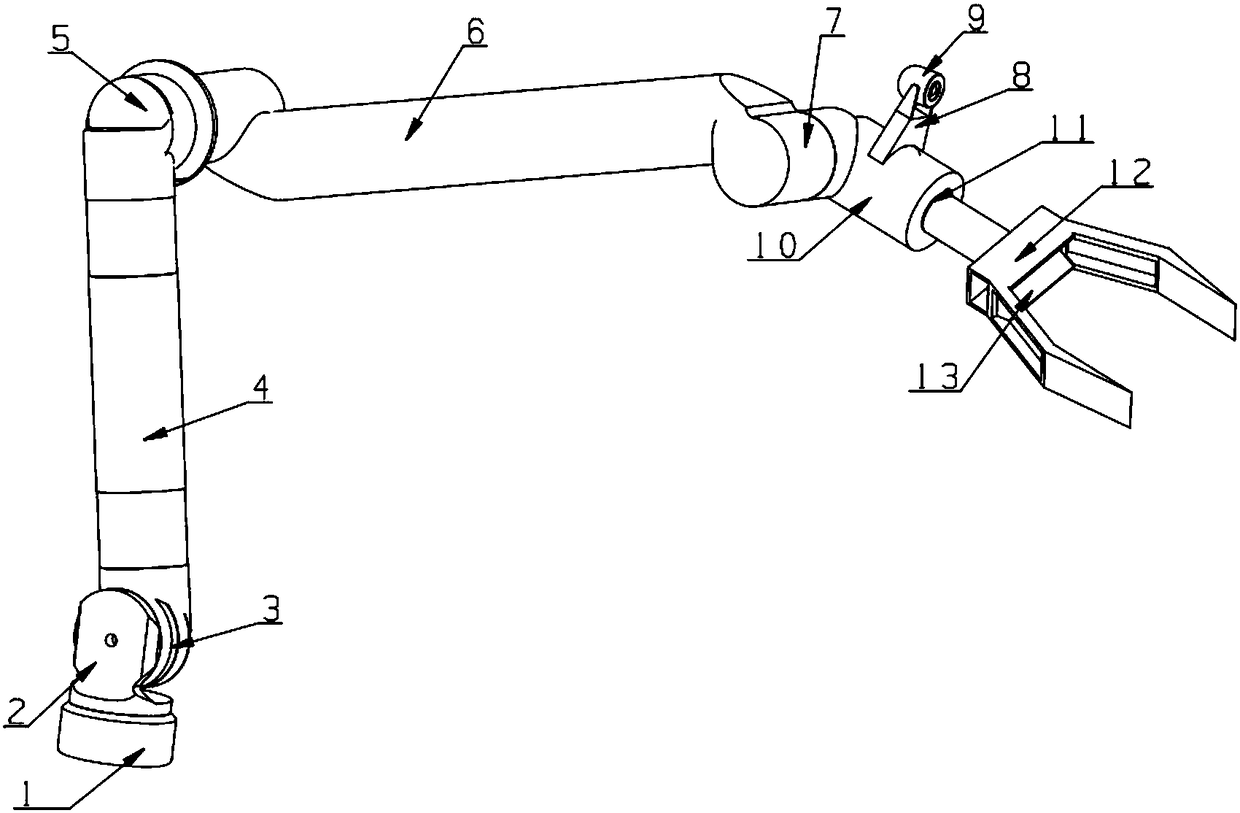

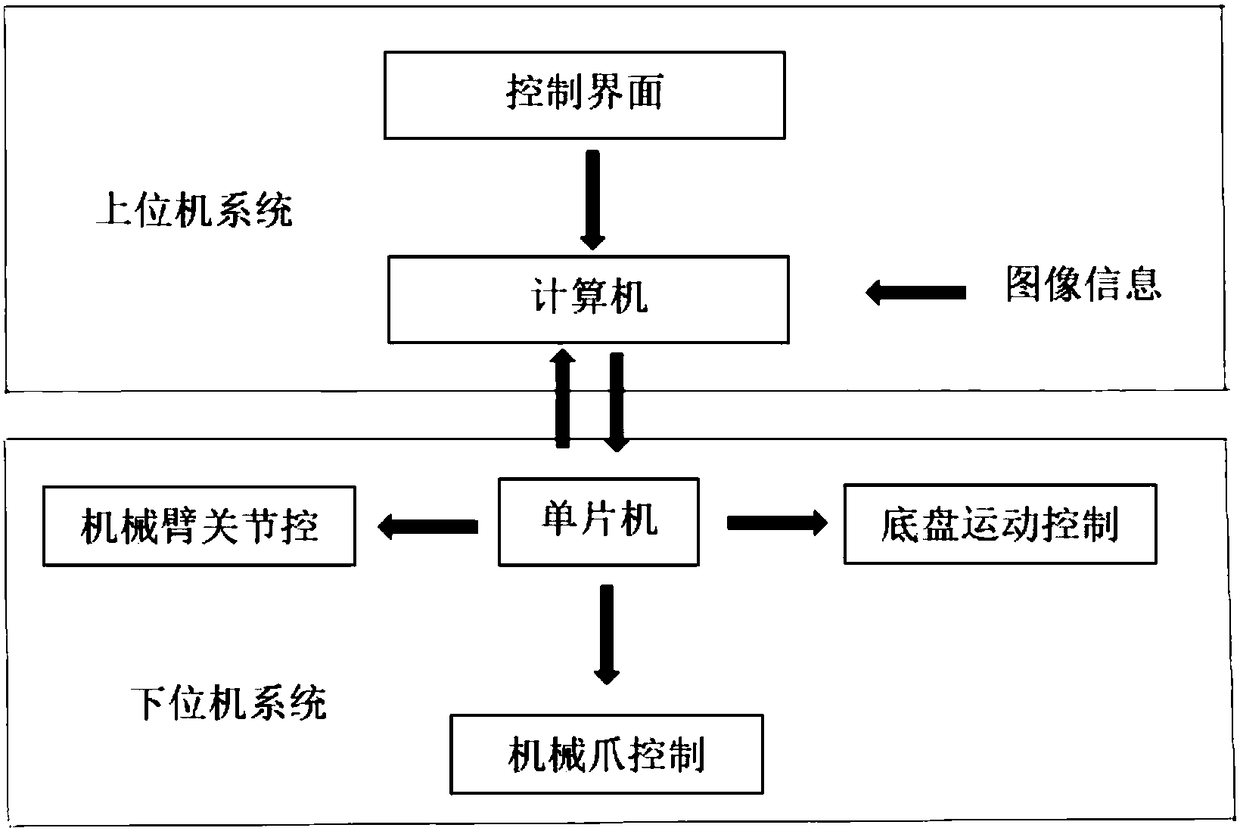

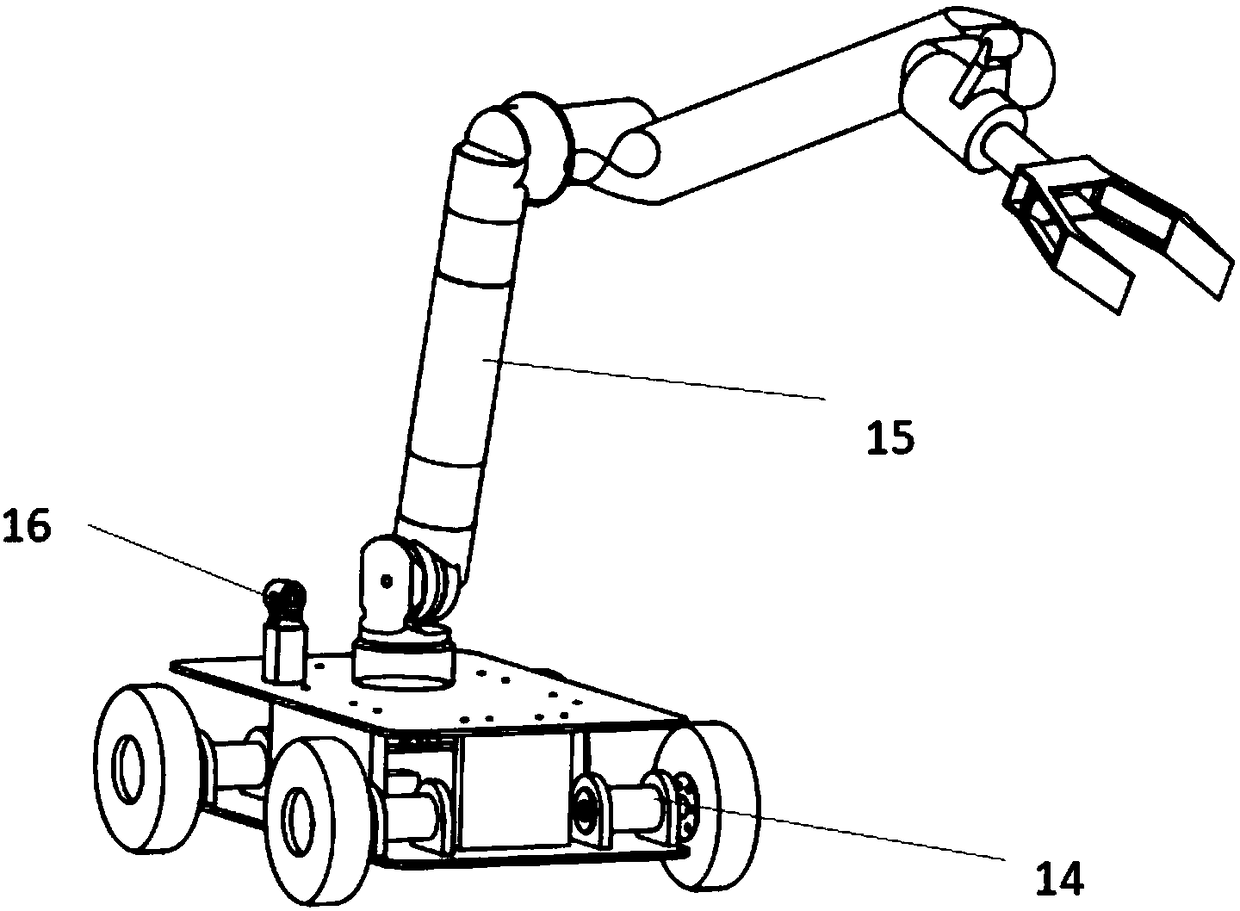

Mechanical arm mechanism of explosive-handling robot and control system and method of mechanical arm mechanism

InactiveCN108406784AEnsure safetyIncrease flexibilityProgramme-controlled manipulatorControl systemRobot

The invention provides a mechanical arm mechanism of an explosive-handling robot and a control system and method of the mechanical arm mechanism. The mechanical arm mechanism comprises a big mechanical arm. One end of the big mechanical arm is connected with a rotary holder through a mechanical arm support, and the other end of the big mechanical arm is connected with one end of a small mechanicalarm. The other end of the small mechanical arm is connected with a mechanical claw support. A camera is arranged at the end of the mechanical claw support. A mechanical claw is arranged at the upperend of the mechanical claw support. A mechanical claw opening and closing mechanism is mounted on the mechanical claw. A first steering engine, a second steering engine, a third steering engine and afourth steering engine used for providing steering power are separately arranged between the big mechanical arm and the mechanical arm support, between the big mechanical arm and the small mechanicalarm, between the small mechanical arm and the mechanical claw support as well as between the mechanical claw support and the mechanical claw. The camera transmits received information to a controller.The controller controls the rotary holder and the steering engines to operate. The mechanical arm mechanism has the characteristics of being high in flexibility and wide in coverage.

Owner:SHAANXI UNIV OF SCI & TECH

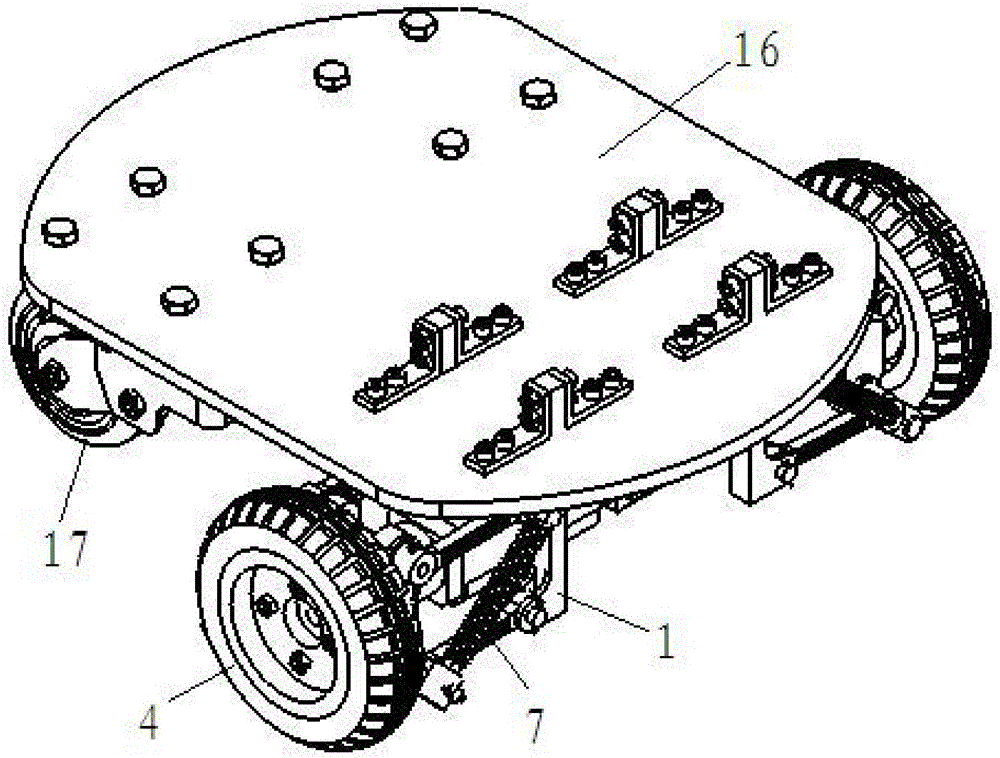

Multi-connecting-rod hang system for wheeled movable robot

The invention discloses a multi-link suspension system for a wheeled mobile robot, which comprises two driving wheels (4) located at the front end, and the inside of the two driving wheels (4) is provided with a vertical plate type reducer bracket (5), the center of the reducer bracket (5) is provided with a first through hole for passing through the output shaft of the reducer (3) and coaxial with the driving wheel (4), and the two reducer brackets ( 5) respectively connected with the parallelogram connecting rod swing mechanism. The invention provides a multi-link suspension system for a wheeled mobile robot, which can ensure that the driving wheels are always on the ground, improve the ground adaptability of the robot chassis, and prevent the driving wheels from being lifted off by the driven wheels, causing the driving wheels to spin or slip. , affect the motion performance of the robot, reduce the wear of the driving wheel, and improve its motion stability and reliability.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

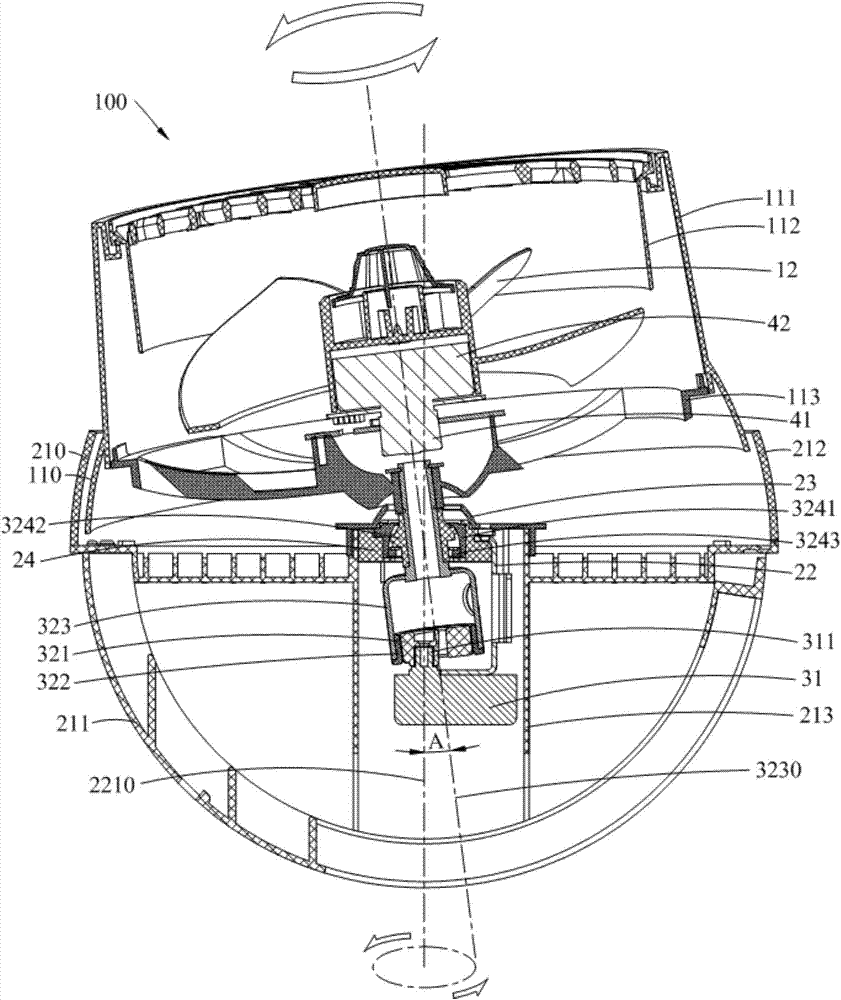

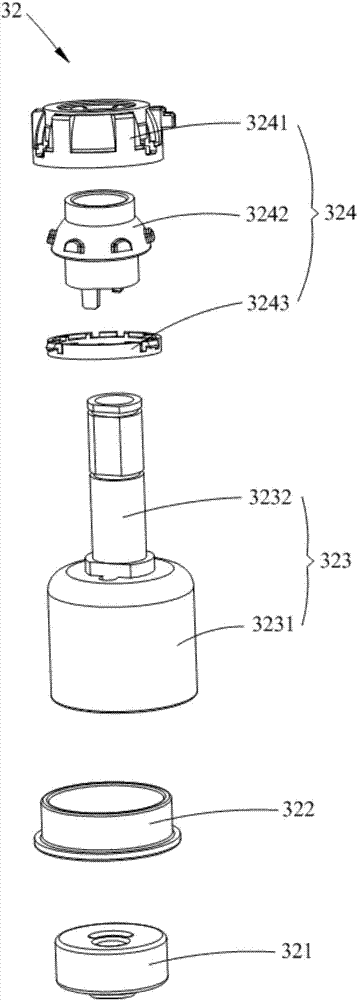

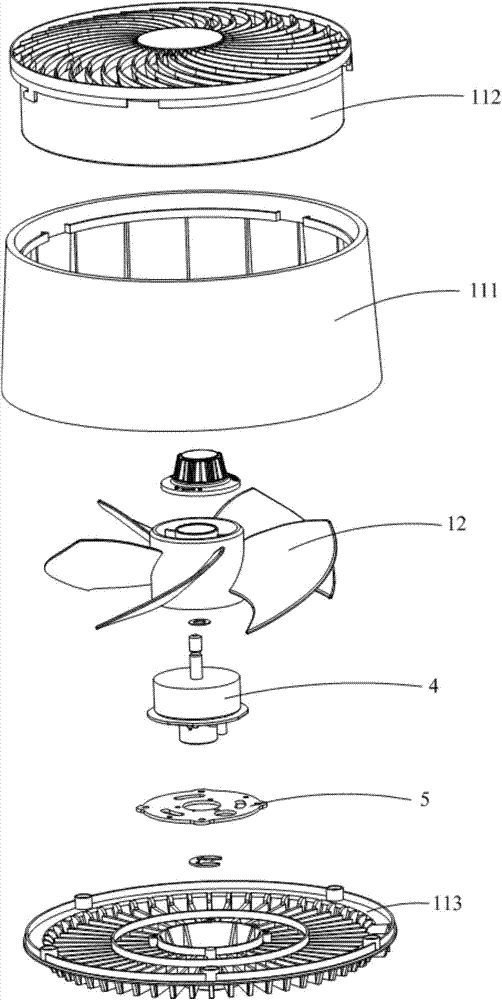

Fan head assembly and fan

ActiveCN107237772APromote homogenizationSolve the problem of no differentiated selling pointPump componentsEngine fuctionsDrive motorEngineering

The invention is suitable for the field of household appliances, and discloses a fan head assembly and a fan. The fan head assembly comprises a wind-out base, a wind-in base and a rotary oscillating mechanism, wherein the wind-in base is arranged on one side of the wind-out base, and the rotary oscillating mechanism is used for driving the wind-out base to conduct rotary oscillating motion relative to the wind-in base. The rotary oscillating mechanism comprises a rotary oscillating driving motor assembled on the wind-in base and a rotary oscillating transmission pair which is in transmission connection with the rotary oscillating driving motor and the wind-out base. According to the fan head assembly and the fan, the wind-out base can conduct the rotary oscillating motion relative to the wind-in base, and a conventional design thinking that a wind-out base and a wind-in base in an existing fan are relatively stationary is broken. Because the wind-out base conducts stereoscopic rotary oscillating motion relative to the wind-in base, products are very cool in the operating process, and the problems that an existing fan product is serious in homogenization and has no differentiated selling point are well solved; and meanwhile the wind-supplying area is effectively enlarged, rotary output of the wind direction is achieved, and the output wind is gentler and more natural.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com