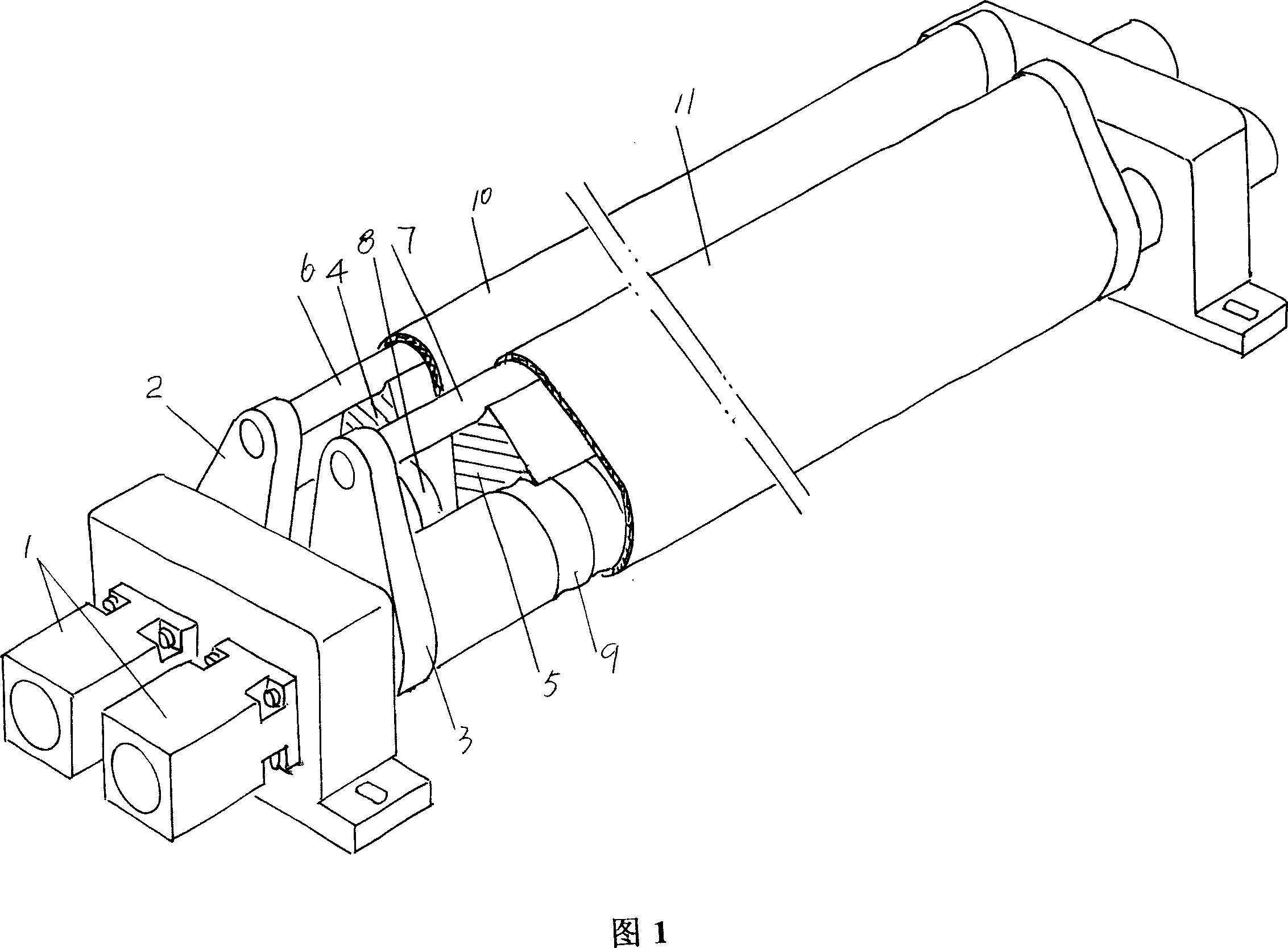

Secondary roller mechanism for full computer flat knitting machine

A technology for flat knitting machines and auxiliary rollers, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of high manufacturing cost, frequent adjustments, and easy slipping, etc., and achieves cost-saving manufacturing, simple overall structure, and easy to use. The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Through the applicant's description of the embodiments, it will be more helpful to understand the present invention, and make the positive effects of the present invention more manifest, but the embodiments should not be regarded as limiting the solution of the present invention.

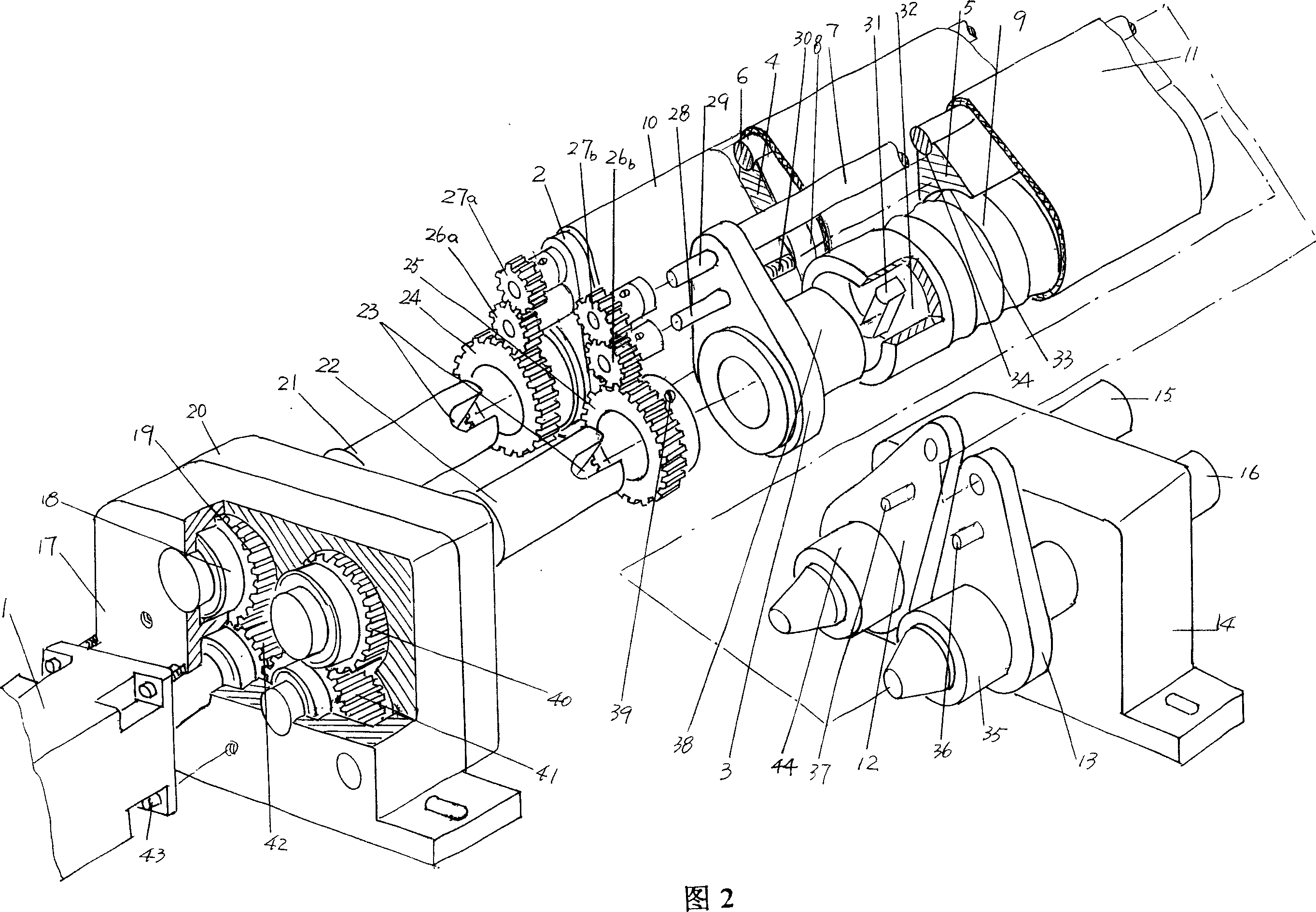

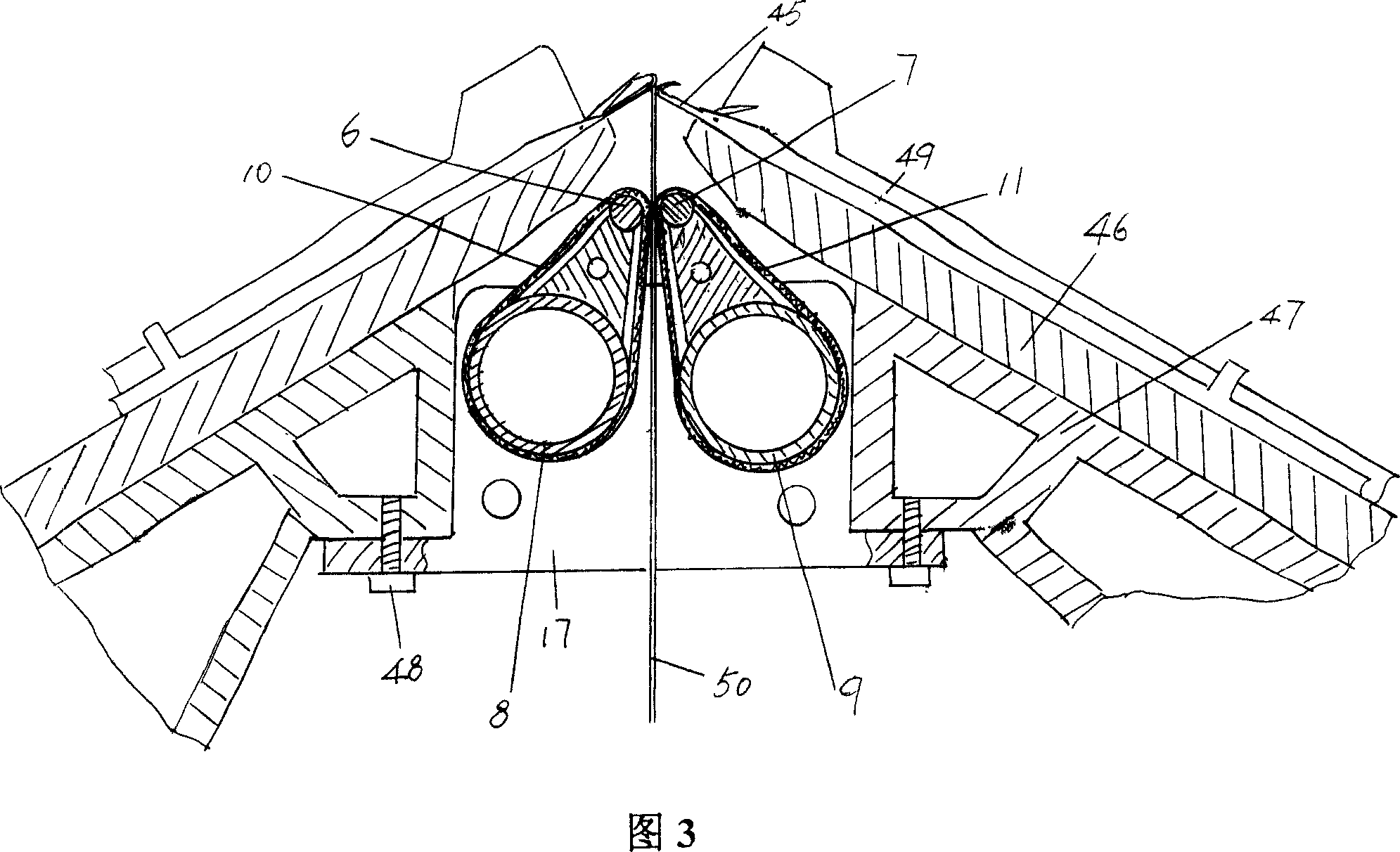

[0021]In Fig. 2, the gearbox 17 gear cover 20 as the power transmission device recommended by the present invention is fixed to the needle bed support 47 of the fully computerized flat knitting machine by fixing screws 48 (shown in Fig. 3) in the state of use. Yes, the motor 1 with forward and reverse functions is fixed with the gear box 17 by screws 43 . The power output shaft of the motor 1 extends into the cavity of the gear box 17 , and the driving gear 42 is fixed on the shaft end of the power output shaft of the motor 1 in the cavity of the gear box 17 . The first and second gear shafts 21 and 22 are respectively pivoted on the gear box 17 through bearings 18. Taking the position shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com