Induction heating apparatus and induction heating method thereof

An induction heating device and a heating device technology, applied in induction heating and other directions, can solve the problems of inability to meet industrial needs, single temperature distribution, uncontrollable, etc., and achieve the effects of convenient operation and maintenance, good product quality, and small maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

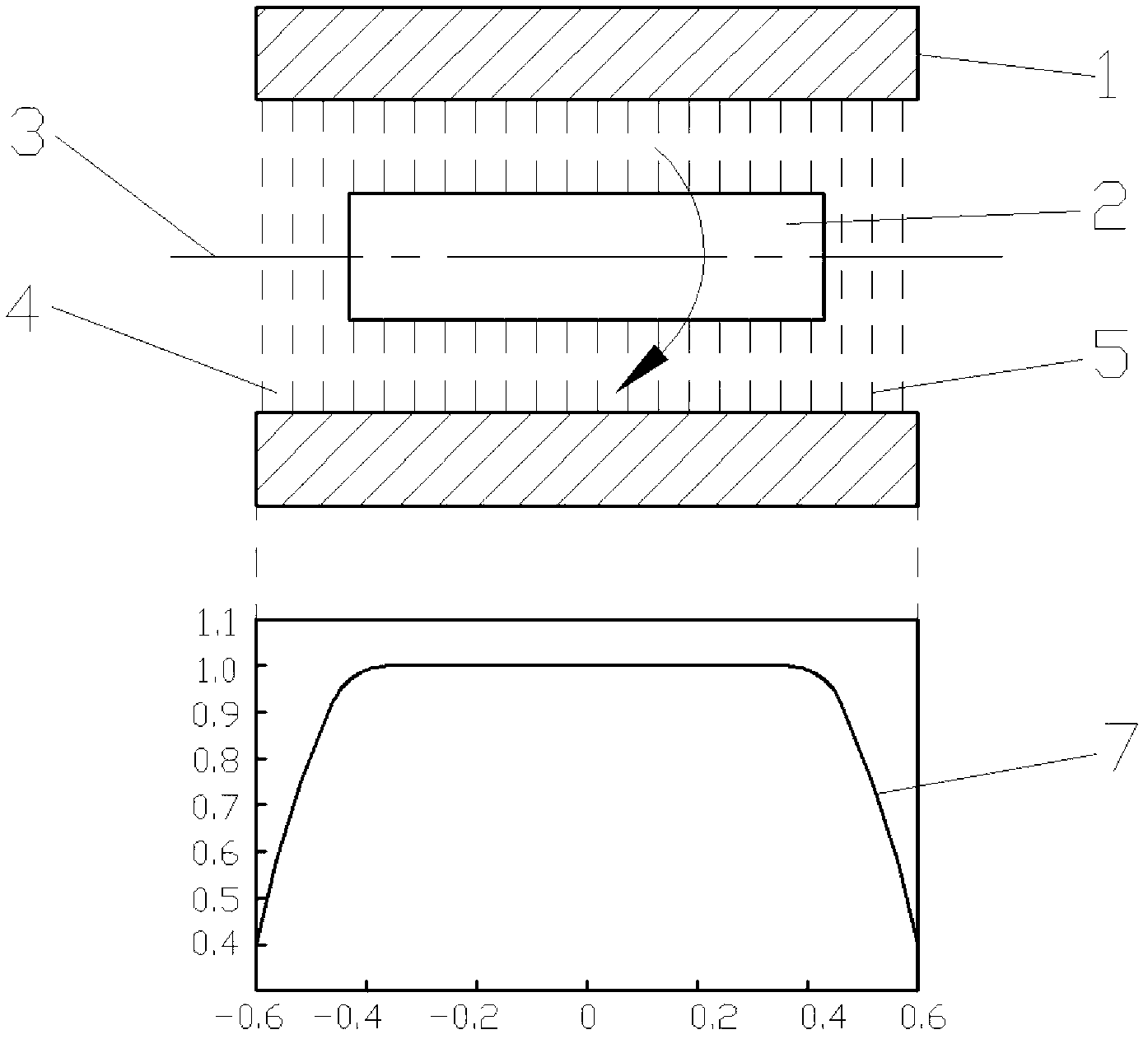

[0062] This embodiment provides an induction heating device, including a heating device and a rotary drive device, the spindle 2 is arranged in the heating device through the rotary drive device, and the rotary drive device drives the spindle 2 to rotate and cut the magnetic force lines 5 formed in the heating device, The heating device includes an iron core mechanism 1 with an air gap 4, and a superconducting coil that interacts with the iron core mechanism 1 to form a static magnetic field, and the spindle 2 is movably arranged in the air gap 4 through a rotary drive middle.

[0063] Further, the spindle 2 is rotated along the air gap axis 3 as a central axis by a rotary drive device.

[0064] Further, the iron core mechanism 1 includes two iron cores, and the air gap 4 is formed by placing the two iron cores at equal distances from each other.

[0065] Further, the distance between the two iron cores can be adjusted.

[0066] In this embodiment, the rotational speed of th...

Embodiment 2

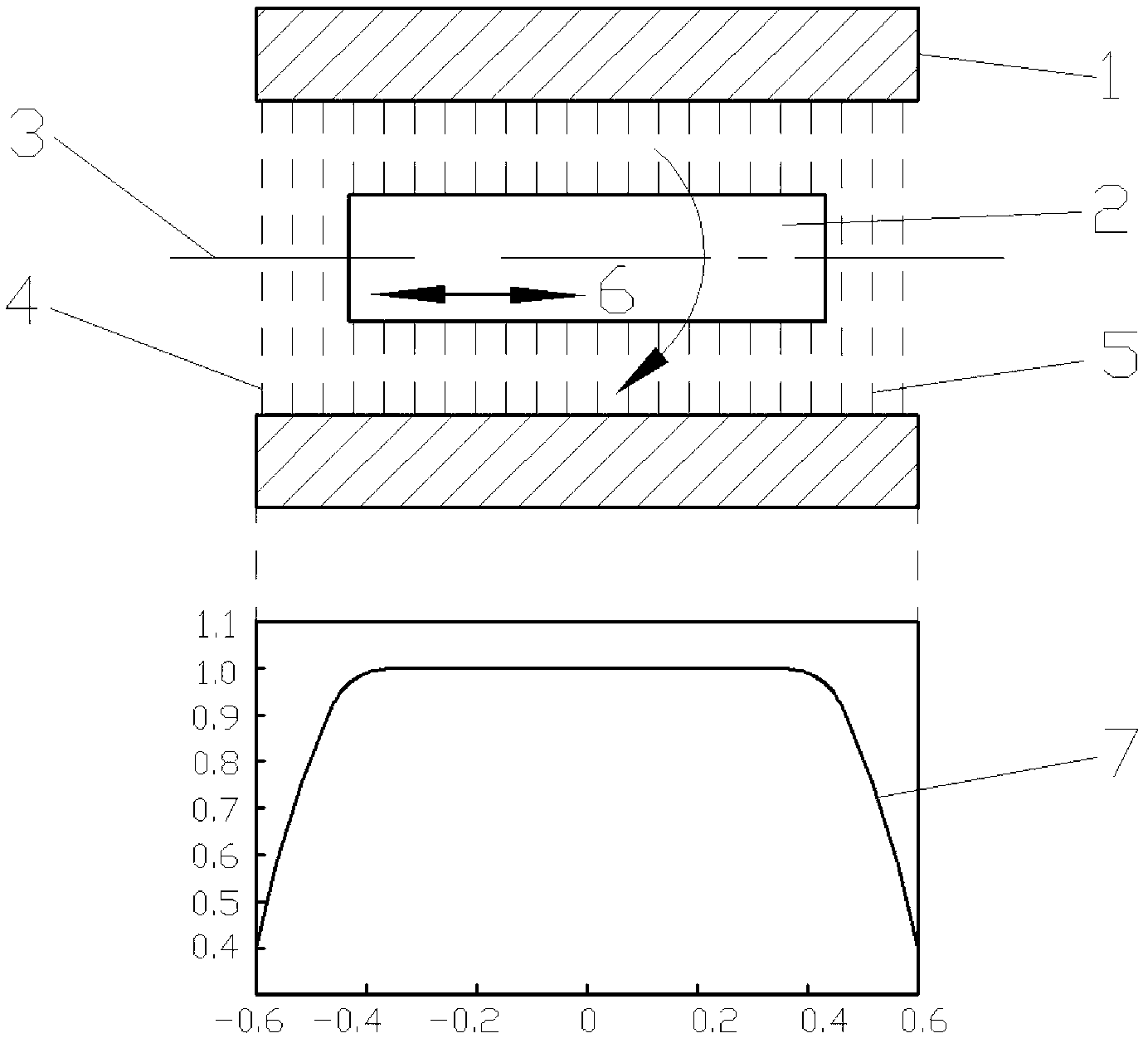

[0074] Embodiment 2 is the second induction heating method of the induction heating device provided in Embodiment 1.

[0075] The induction heating method that the present embodiment provides, comprises the following steps:

[0076] Step 1, firstly, a static magnetic field 5 distributed according to a pre-designed law is formed in the air gap through the iron core mechanism 1 and the superconducting coil;

[0077] Step 2, put a spindle 2 of a certain specification in the static magnetic field, and the spindle is driven to rotate by the rotating drive device, thereby heating the spindle;

[0078] Step 3, while the spindle 2 is rotating, the heated spindle is moved 6 along the axis of the air gap, so as to adjust the distribution of the heating power density in the axial direction of the spindle, and complete the induction heating of the spindle satisfying the requirement of the axial temperature gradient.

[0079] Further, in the step 3, the movement of the spindle along the a...

Embodiment 3

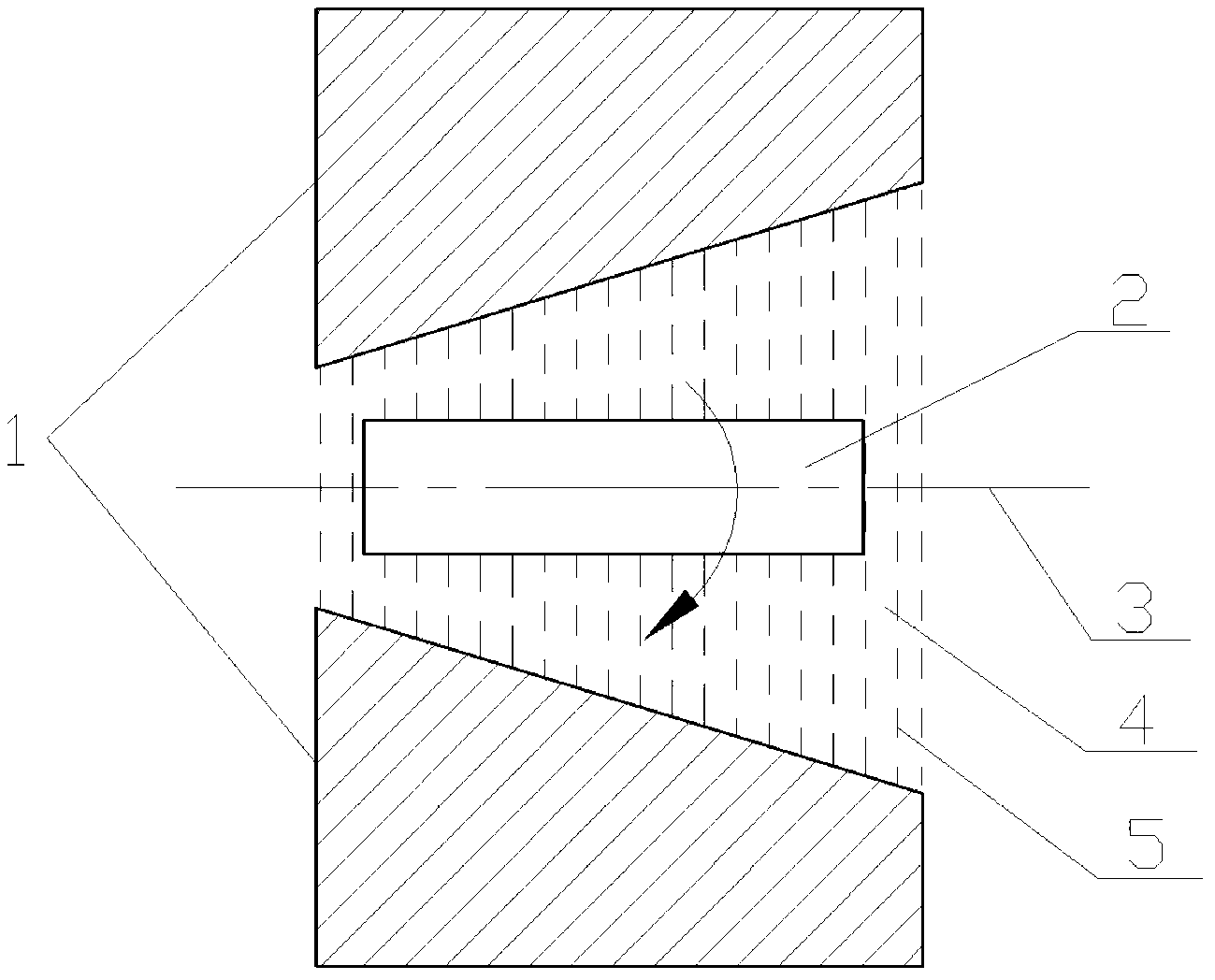

[0082] This embodiment is a modification example of Embodiment 1.

[0083] On the basis of embodiment 1, this embodiment provides another induction heating device. The difference between this embodiment and embodiment 1 is:

[0084] The iron core mechanism includes two iron cores, and the air gap is formed by placing the two iron cores at different positions corresponding to different distances;

[0085] Different positions corresponding to different distances between the two iron cores are realized by moving the relative positions of the two iron cores or by changing the thickness of the iron cores;

[0086] The distance between the two iron cores can be adjusted.

[0087] Further, the change of the thickness of the iron core is a linear change or a step change.

[0088] The induction heating method of the induction heating device provided by the present embodiment comprises the following steps:

[0089] Step 1, pre-adjust the width of the air gap;

[0090] Step 2, formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com