Vertical shaft type ring spinning automatic yarn falling device

An automatic doffing and ring spinning technology, applied in textiles and papermaking, etc., can solve the problems of complex spatial curves of drum cams, unstable movement, and reduced success rate of doffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

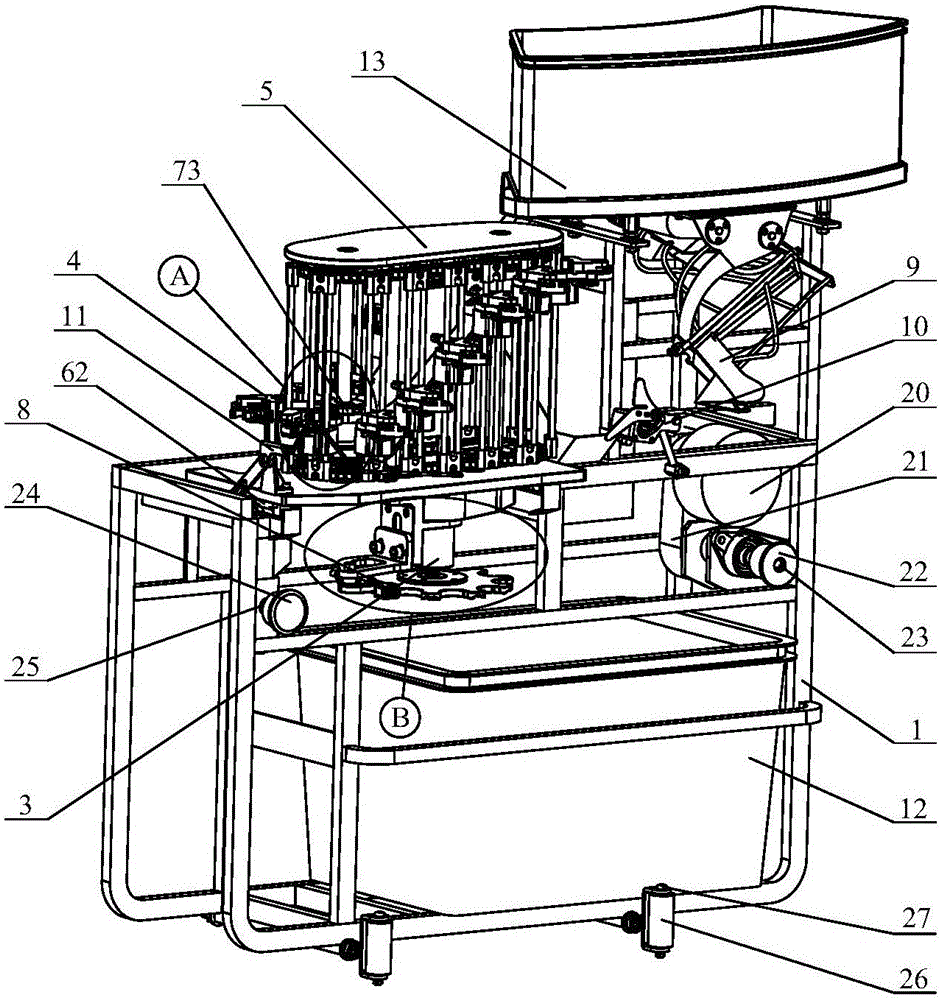

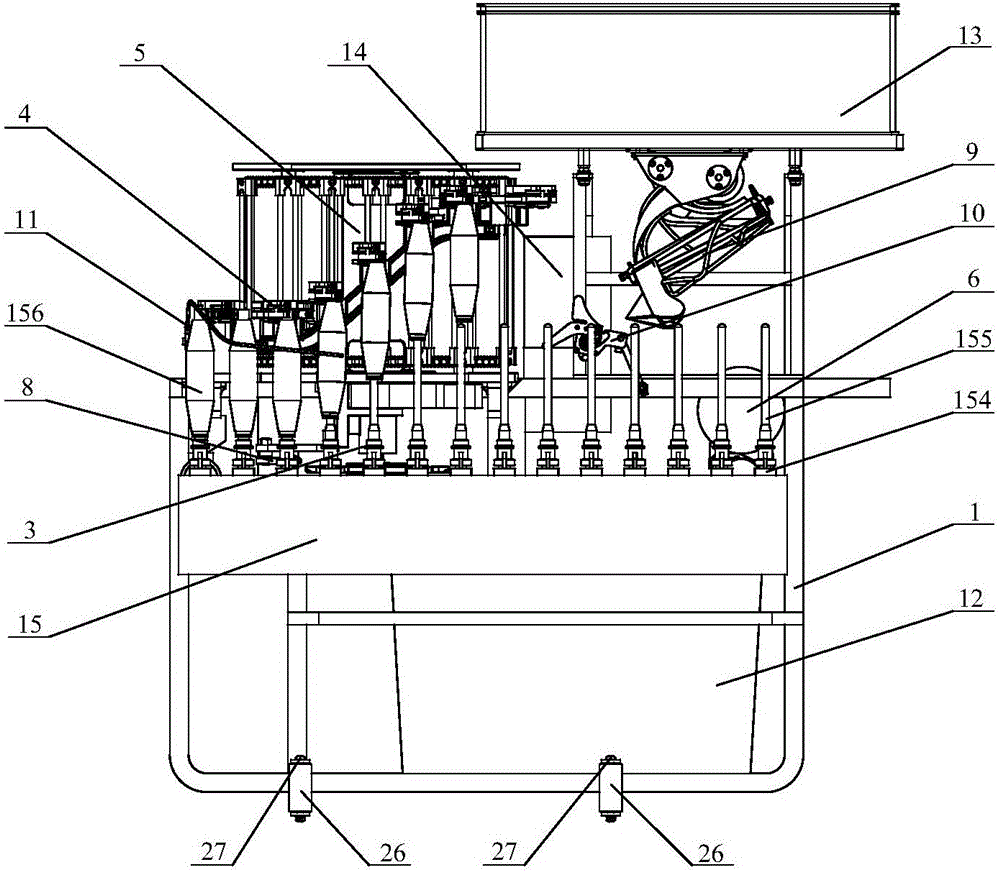

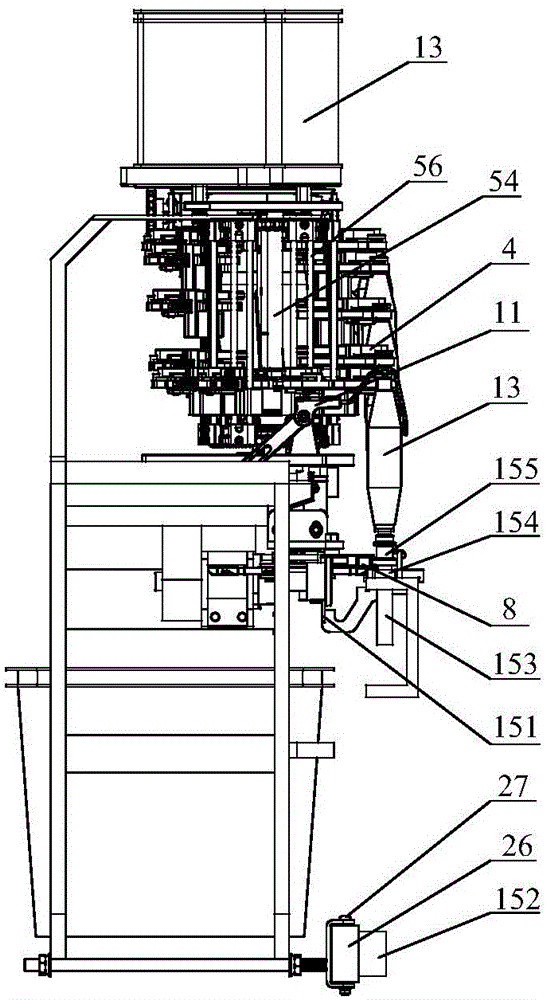

[0054] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

[0055] An embodiment of the vertical shaft ring spinning automatic doffing device designed by the present invention, such as Figure 1 to Figure 14 As shown, it includes a vehicle frame 1, a traveling mechanism 2, a positioning mechanism 3, a doffing transmission mechanism 5 and N manipulators 4; the doffing transmission mechanism includes a base 51, a space cam track 52, a first transmission shaft 53, a Two transmission shafts 54, the first transmission wheel 531, the second transmission wheel 532, the third transmission wheel 541, the fourth transmission wheel 542, the first flexible transmission member 551, the second flexible transmission member 552, N guide posts 56 and N a vertical slider 57; the first transmission shaft 53 and the second transmission shaft 54 are respectively sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com