Cabinet air-conditioner dust gauze self-cleaning device and operation method thereof

A cabinet-type air conditioner and filter screen technology, applied in the field of air conditioner filter screen cleaning devices, can solve the problems of unsatisfactory dust removal effect, poor suction effect, poor dust removal effect, etc., and achieve the effects of ingenious design, low cost, and comprehensive dust collection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

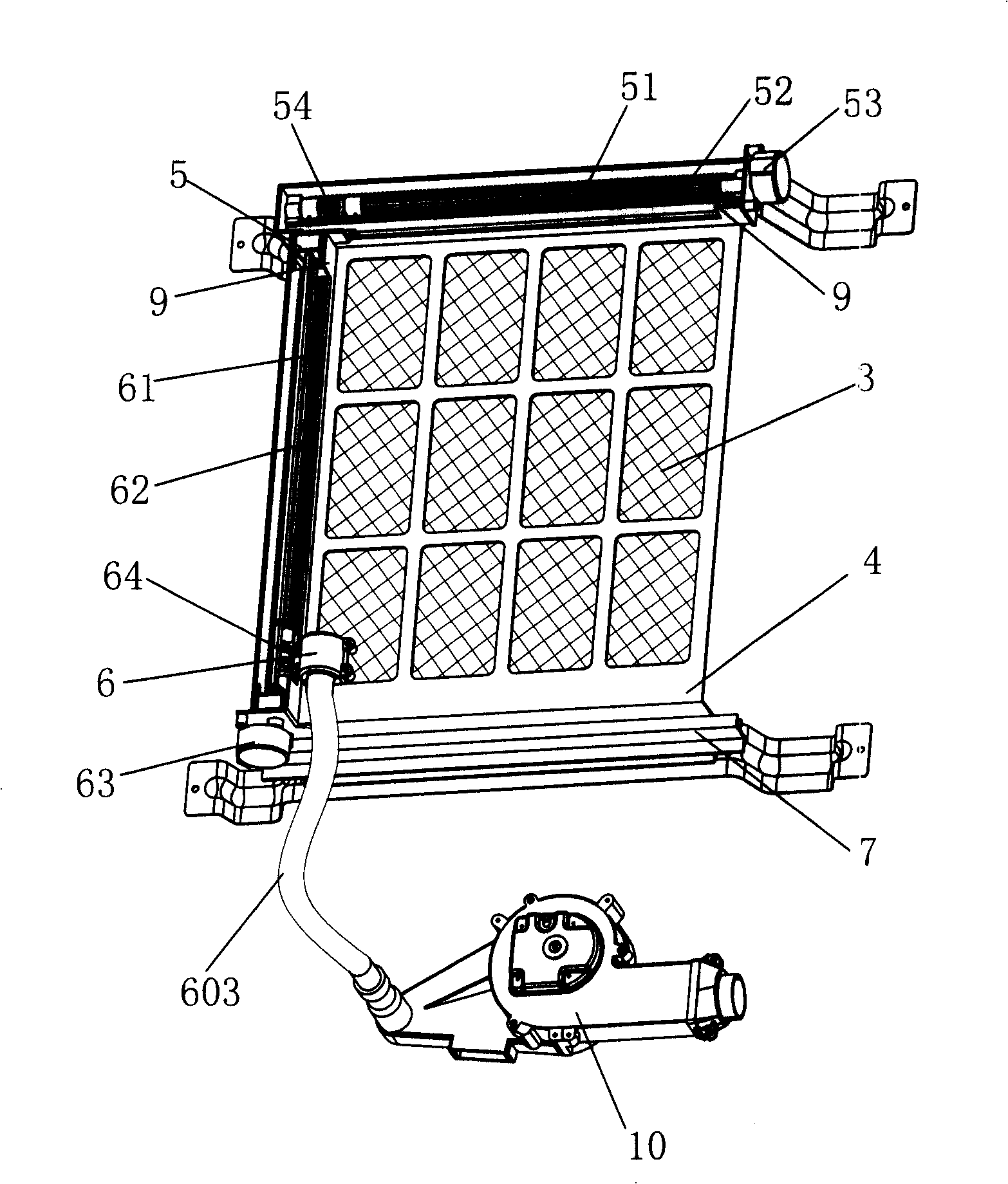

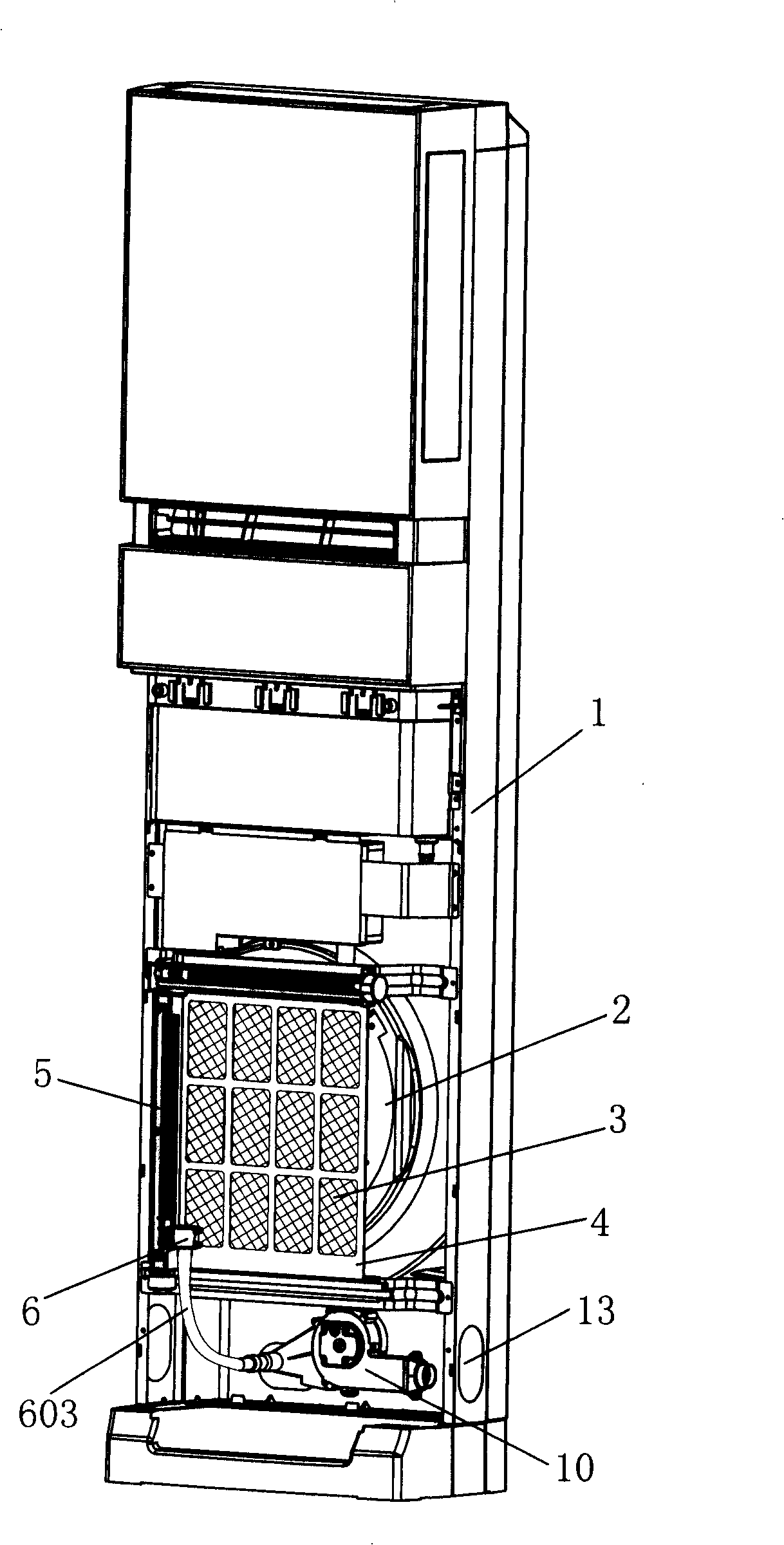

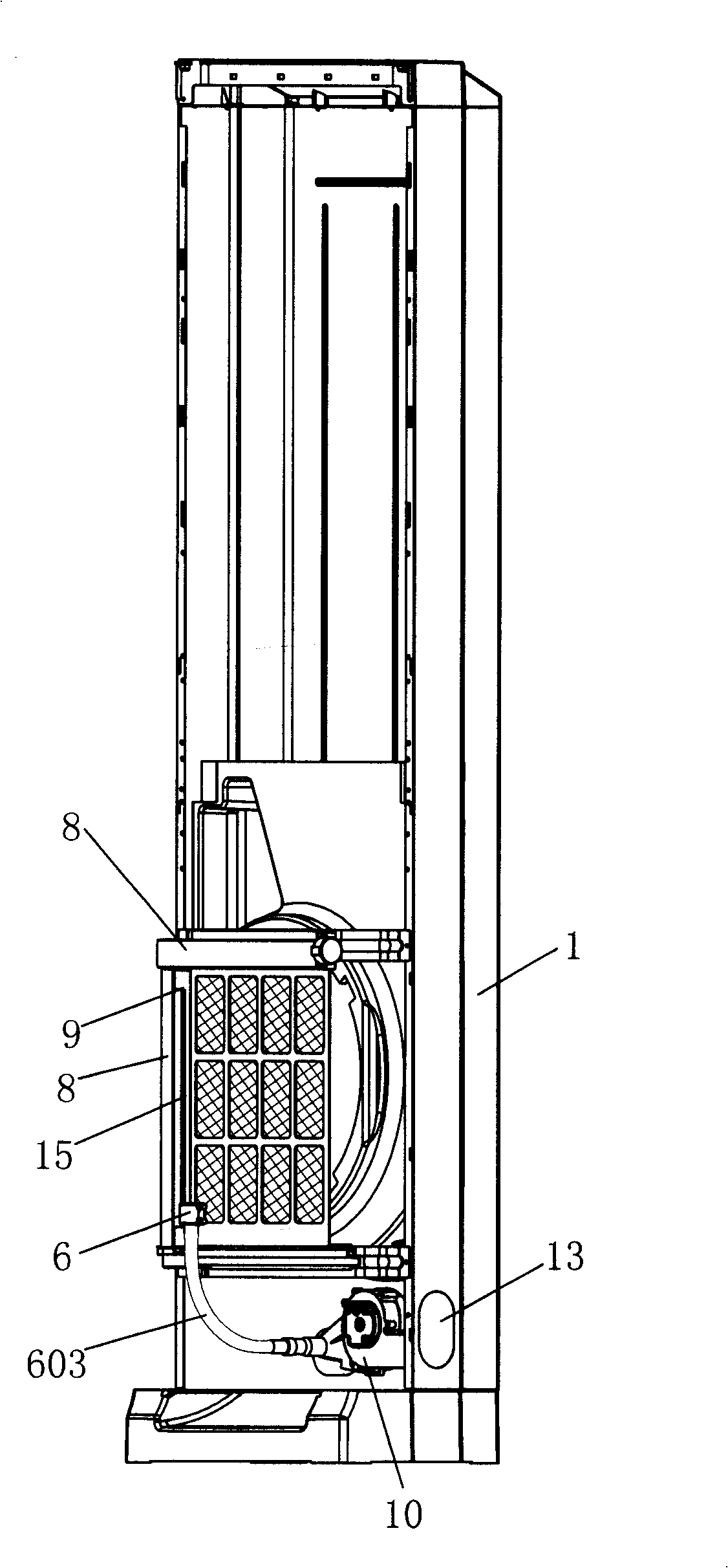

[0031] like Figure 1 to Figure 4As shown, the self-cleaning device for the filter screen of the cabinet type air conditioner of the present invention includes a suction nozzle mechanism and a filter screen mechanism. Frame 4; the suction nozzle mechanism is attached to the external side of the filter screen 3, including a base body 5 vertically placed on the filter screen 3 and a suction nozzle 6 arranged on the base body 5, and the base body 5 is formed by the main body The drive mechanism drives it to slide between the left and right sides of the filter screen along the track 7. The main drive mechanism is arranged on the upper or lower side of the filter screen frame 4; The screen 3 slides between the upper and lower sides to suck the dust attached to the filter screen, and the auxiliary driving mechanism is arranged on the base 5 . The external side of the suction nozzle mechanism can be provided with a dust cover 8 (see image 3 ), to prevent dust from sticking to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com