Multi-blank multi-layer co-extruding blow moulding machine

A co-extrusion and blow molding machine technology, applied in the field of plastic machinery, can solve problems affecting blowing quality, work performance, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

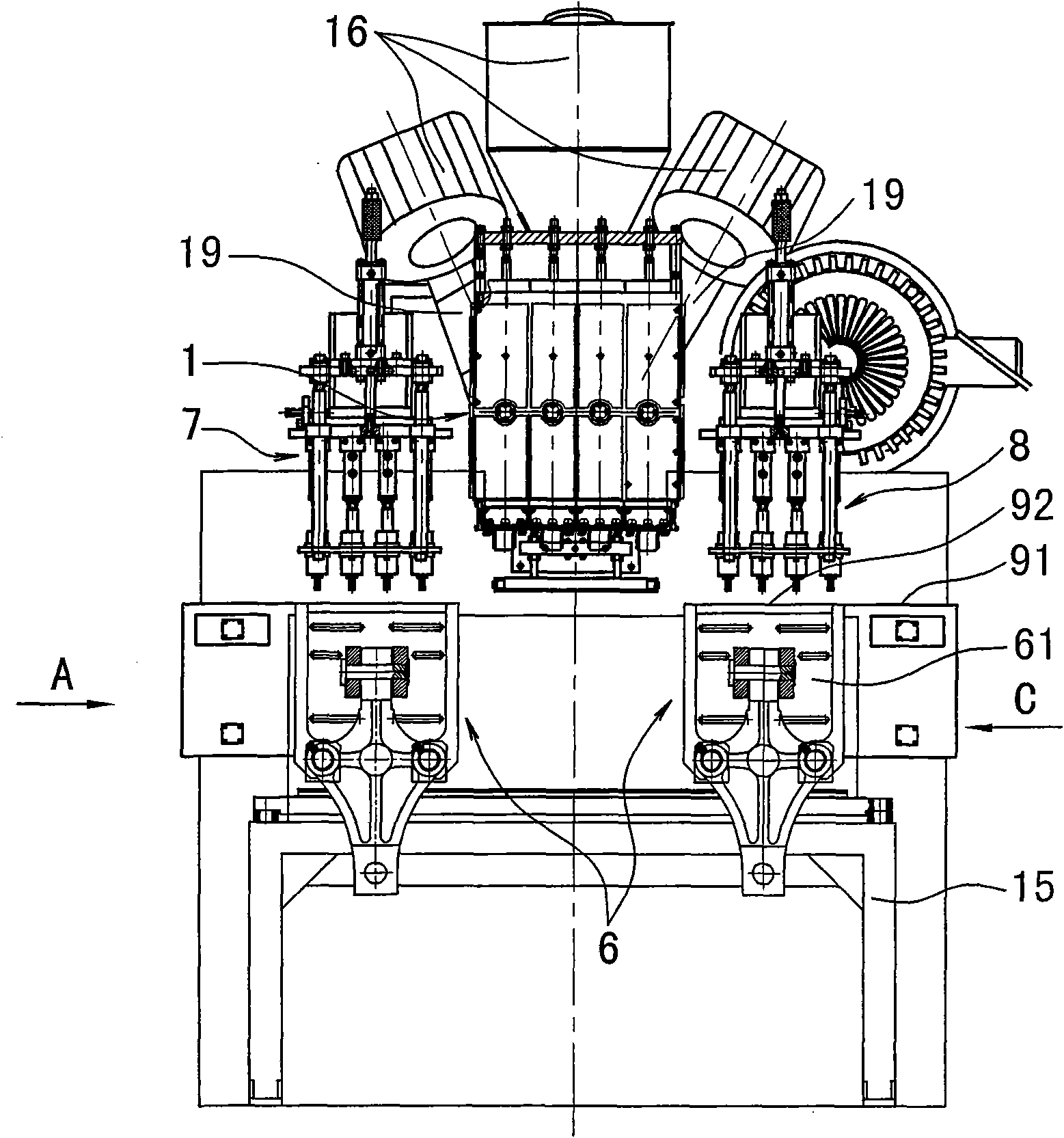

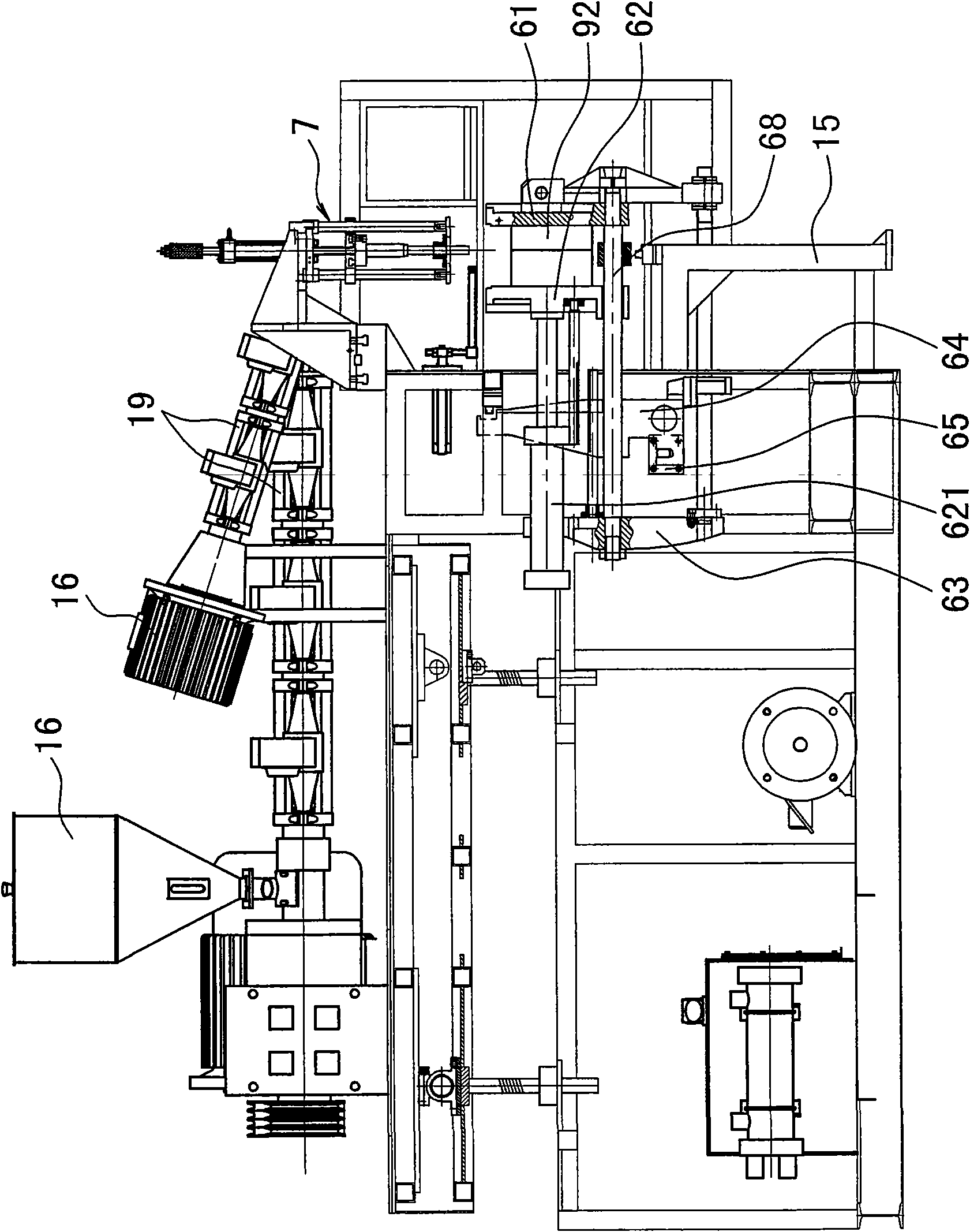

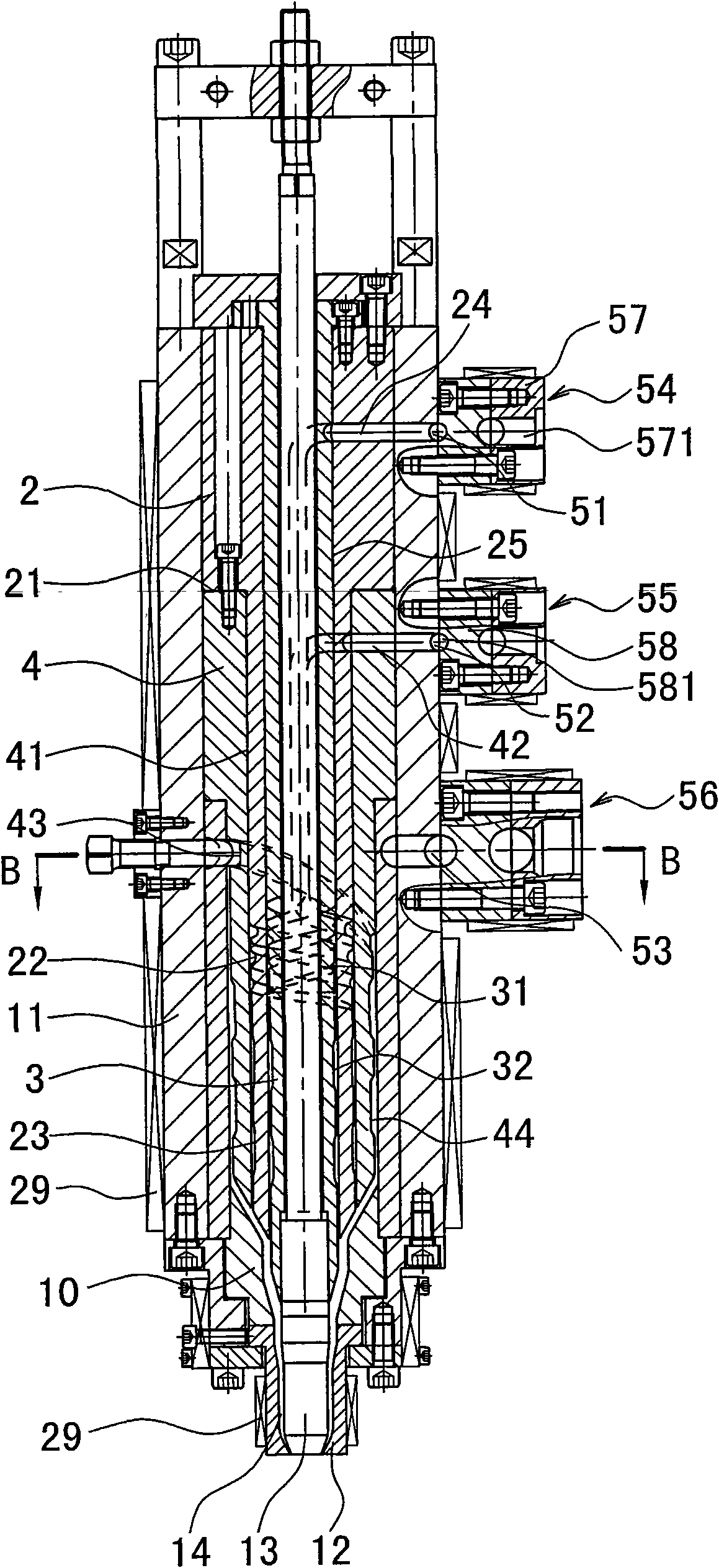

[0019] The invention discloses a multi-preform multilayer co-extrusion blow molding machine, such as figure 1 , figure 2 As shown, it includes a plasticizing system, a die extrusion system, and a blow molding system. The plasticizing system includes a hopper 16, a barrel 19, a screw in the barrel, and an electric heating device on the barrel; the mold The head extrusion system includes more than one die head, each die head is made with a feed port connected to a screw, the die head includes a die head body 11, the lower end of the die head body 11 is connected to a die 12, and the center of the die 12 is provided with a core die 13 The gap between the core mold 13 and the die 12 forms an annular extrusion port 14; there are two blow molding systems, each of which includes a blowing mechanism and a mold opening and closing mechanism. The mold opening and closing mechanism includes a guide rod 68. The front template 61, the middle template 62 and the rear template 63 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com