Patents

Literature

52results about How to "Beautiful incision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

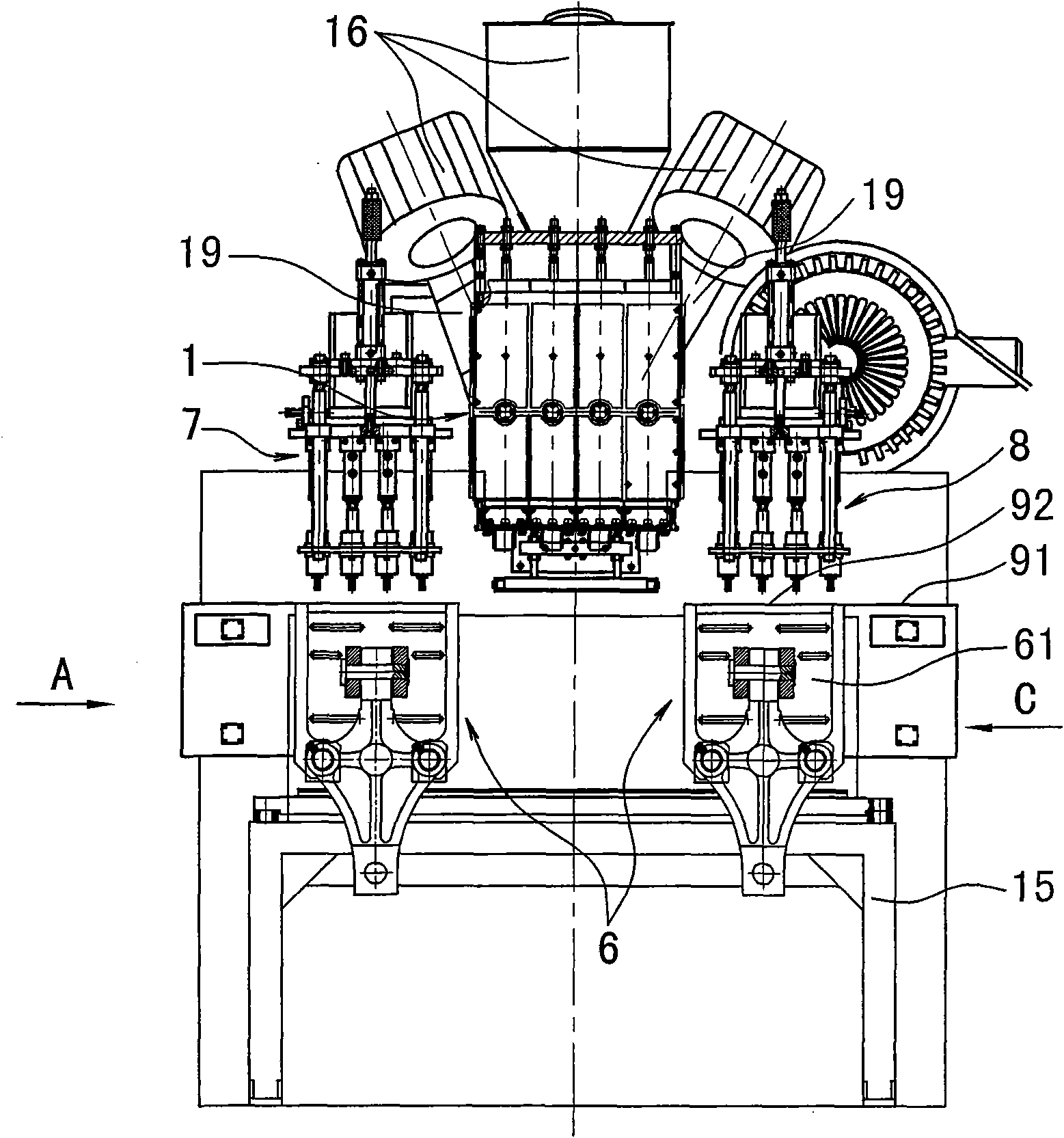

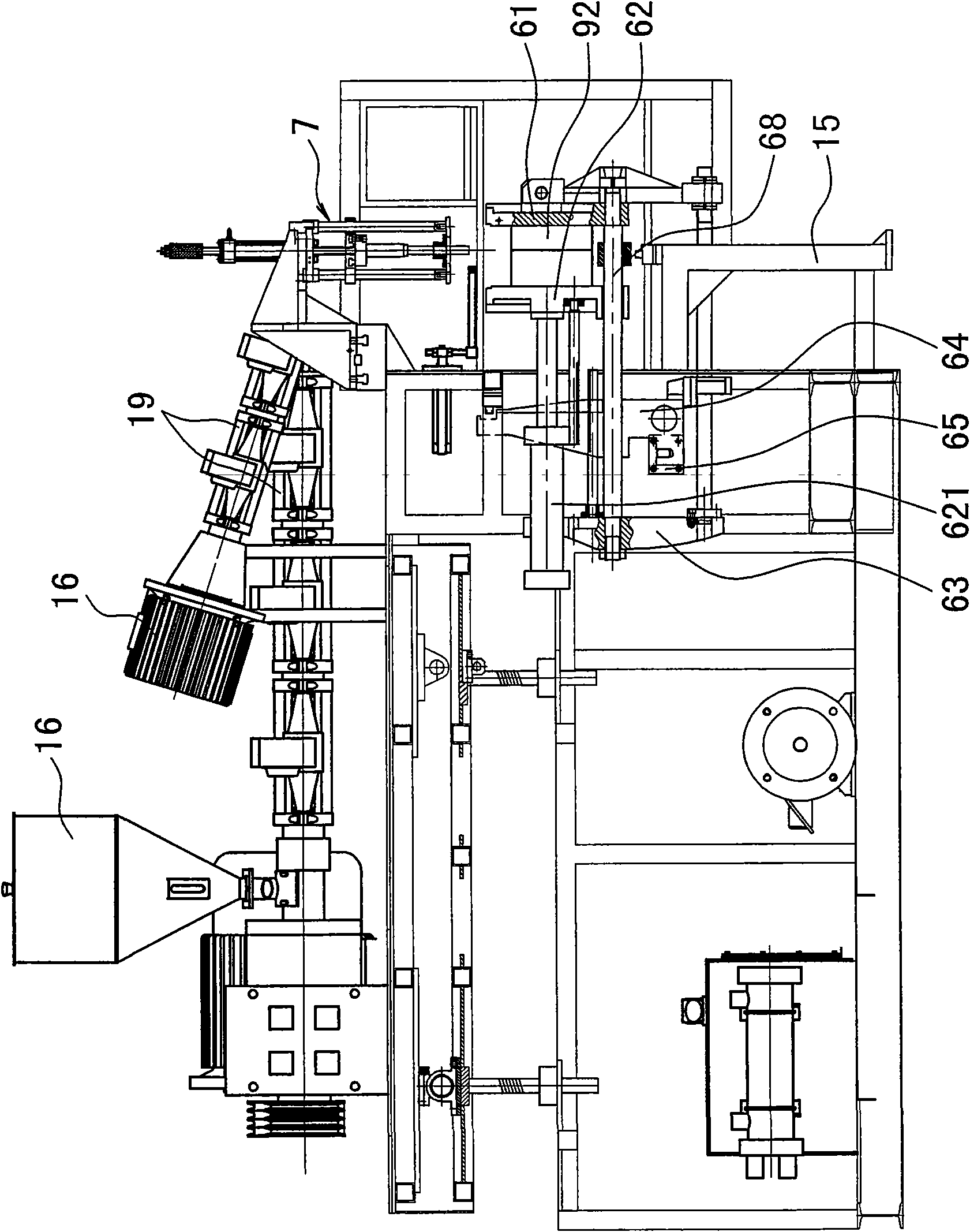

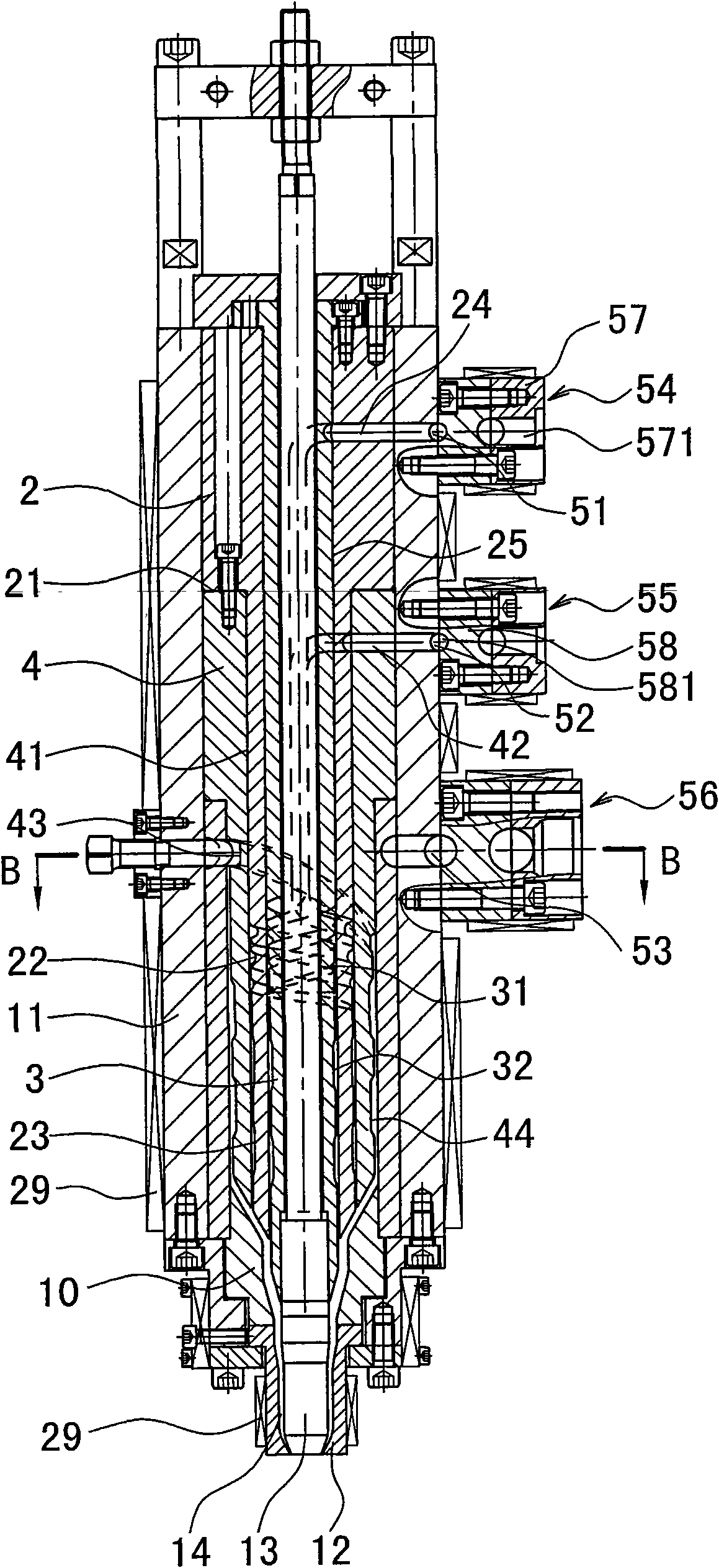

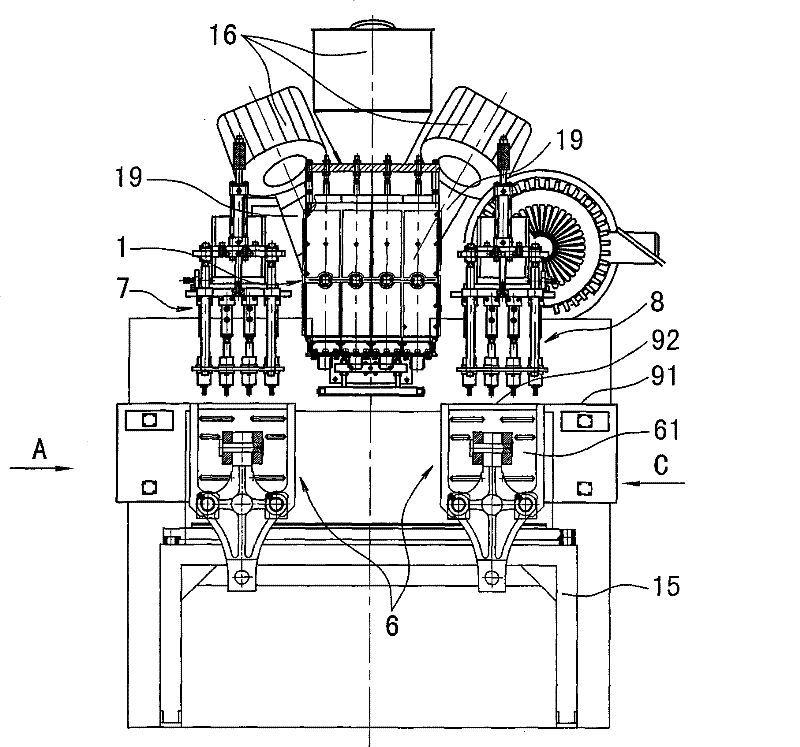

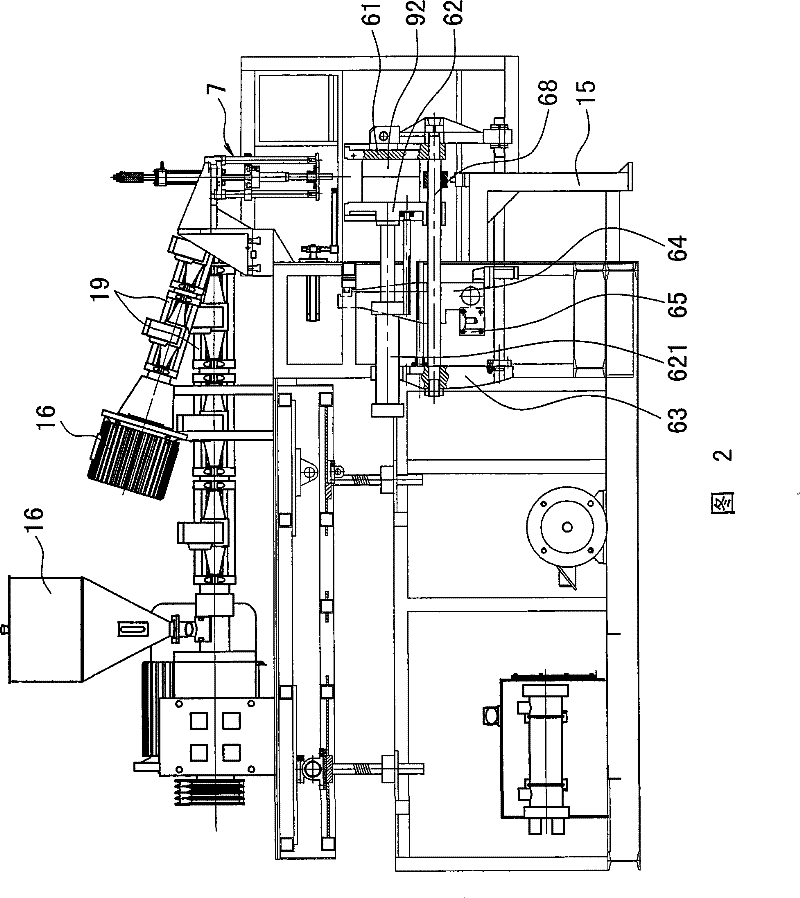

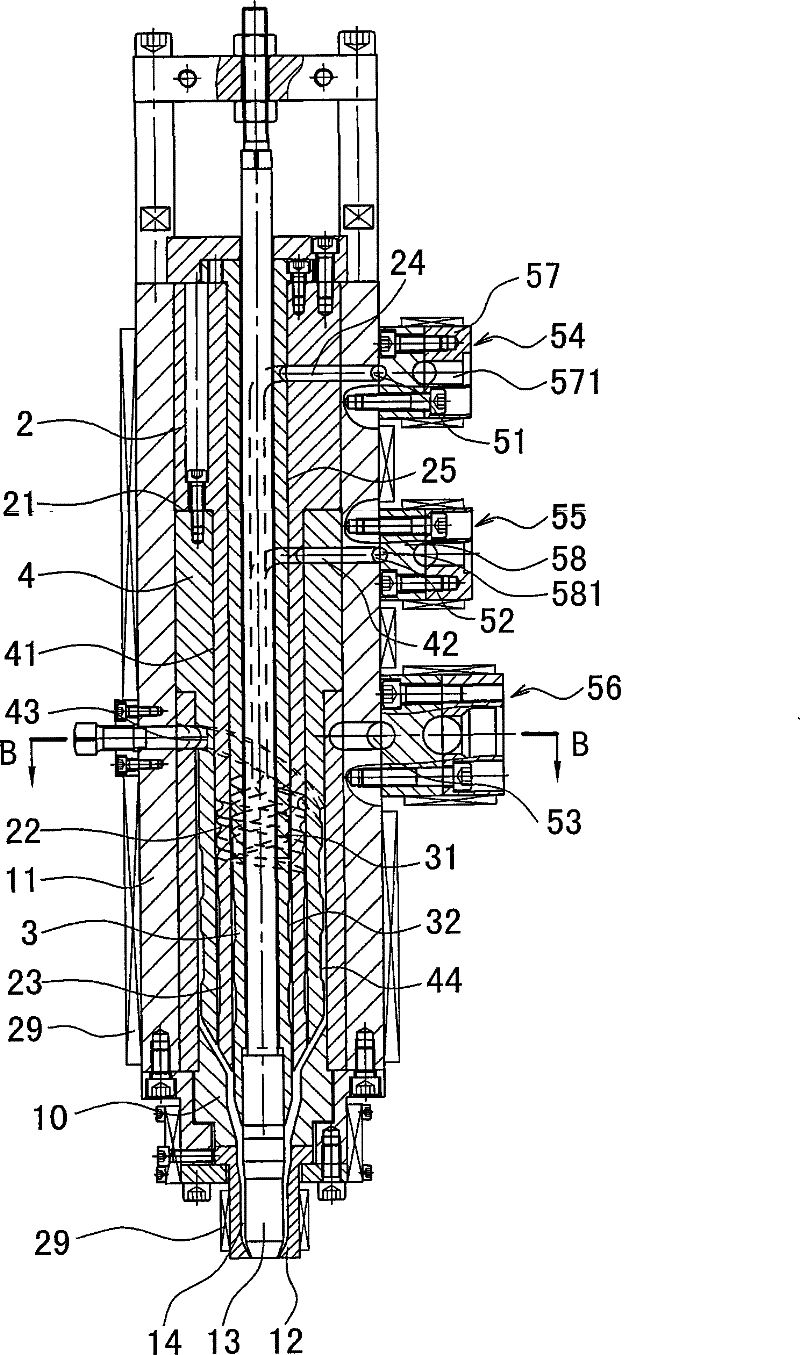

Multi-blank multi-layer co-extruding blow moulding machine

A multi-blank multi-layer co-extruding blow moulding machine comprises a plasticizing system, a mold head extruding system and a blow moulding system. The mold head extruding system comprises more than one mold head, each mold head is provided with a feeding port connected with a screw rod; the mold head comprises a mold head main body connected with a mouth mold which is provided with a core mold; the core mold and mouth mold form an extruding port, wherein a guide body A and a guide body C are mounted in the mouth mold main body; the guide body A is provided with a step; a small head under the step is sleeved in a middle hole C of the guide body C; the small head is provided with a guide groove A and a vertical flow passage A; a big head is provided with a transverse flow passage A; a guide body B is arranged in the guide body A; the guide body B is provided with a guide flow passage B and a vertical flow passage B; the guide flow groove B is communicated with the feeding port; the guide body C is provided with the transverse flow passage C; the transverse flow passage C is connected with the guide flow groove A and the feeding port B; the guide body C is provided with a guide flow groove C and a vertical flow passage C, the guide flow groove C is communicated with the feeding port C; the vertical flow passage A, the vertical flow passage B and the vertical flow passage C are jointed at the external wall of core mold and communicated with the extruding port.

Owner:浙江东方州强塑模实业有限公司

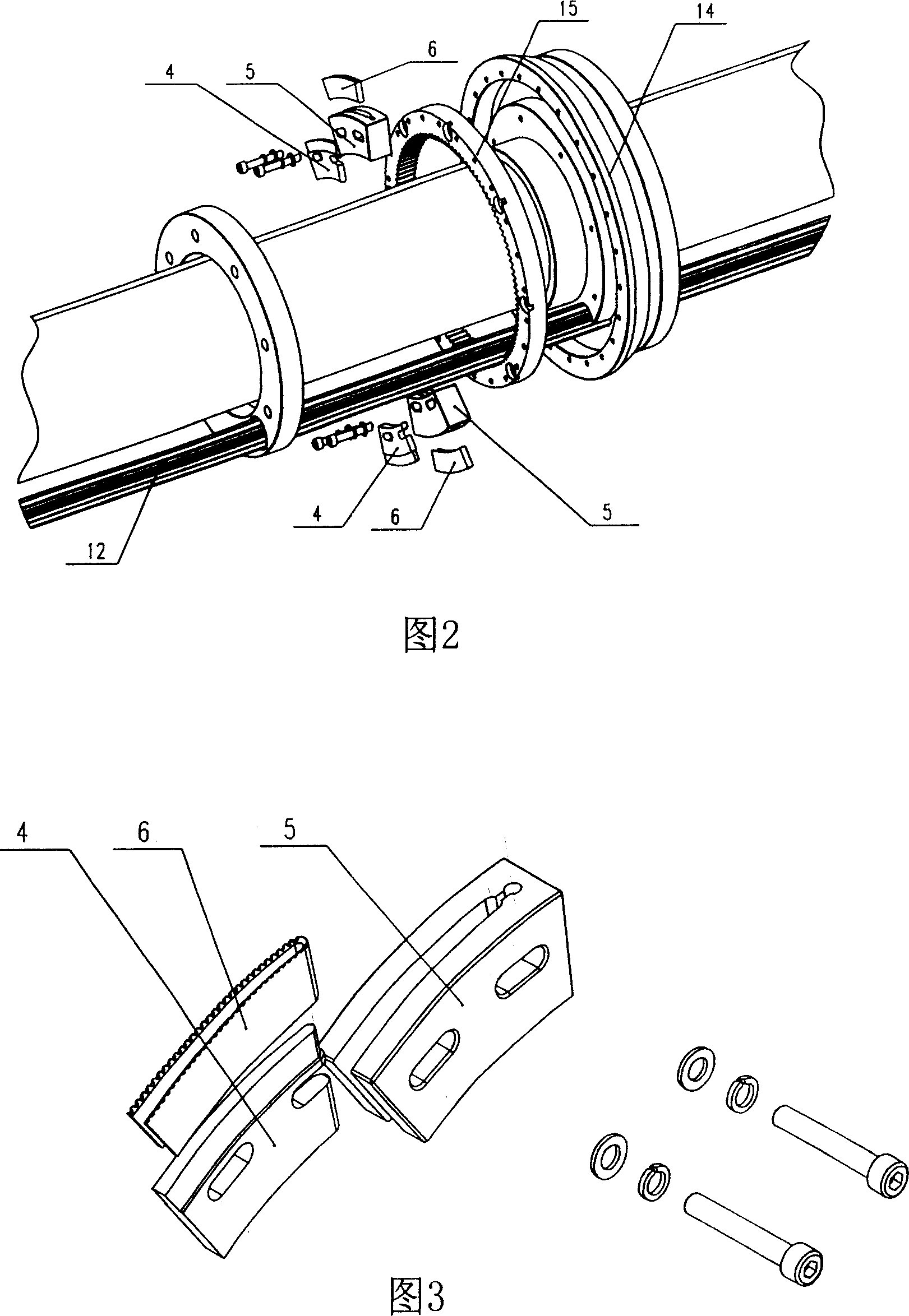

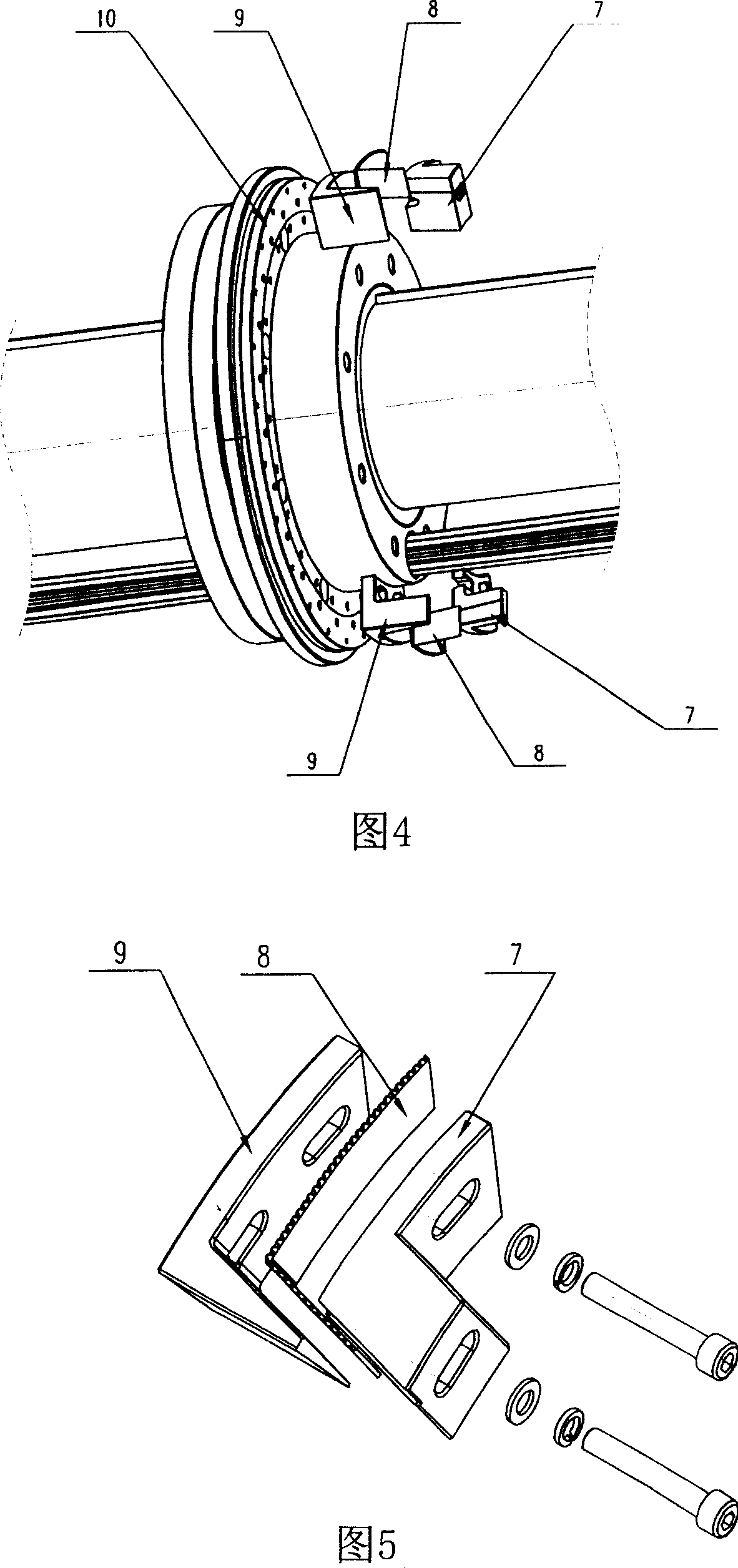

Automatic or electric adjusting thin blade type cutting groove mechanism of print fluting machine for paper carton

An automatically or electrically regulated blade-type slotting mechanism for the printing and slot-cutting machine of carton has the blade-type slot cutting knife with arc front end, V-shaped cross-section and two fixing plates, the blade-type corner cutting knife with L-letter shaped and two fixing plates, the blade-type edge cutting knife consisting of two semi-circular knives, and the slot cutting rubber pad surrounding a roller.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

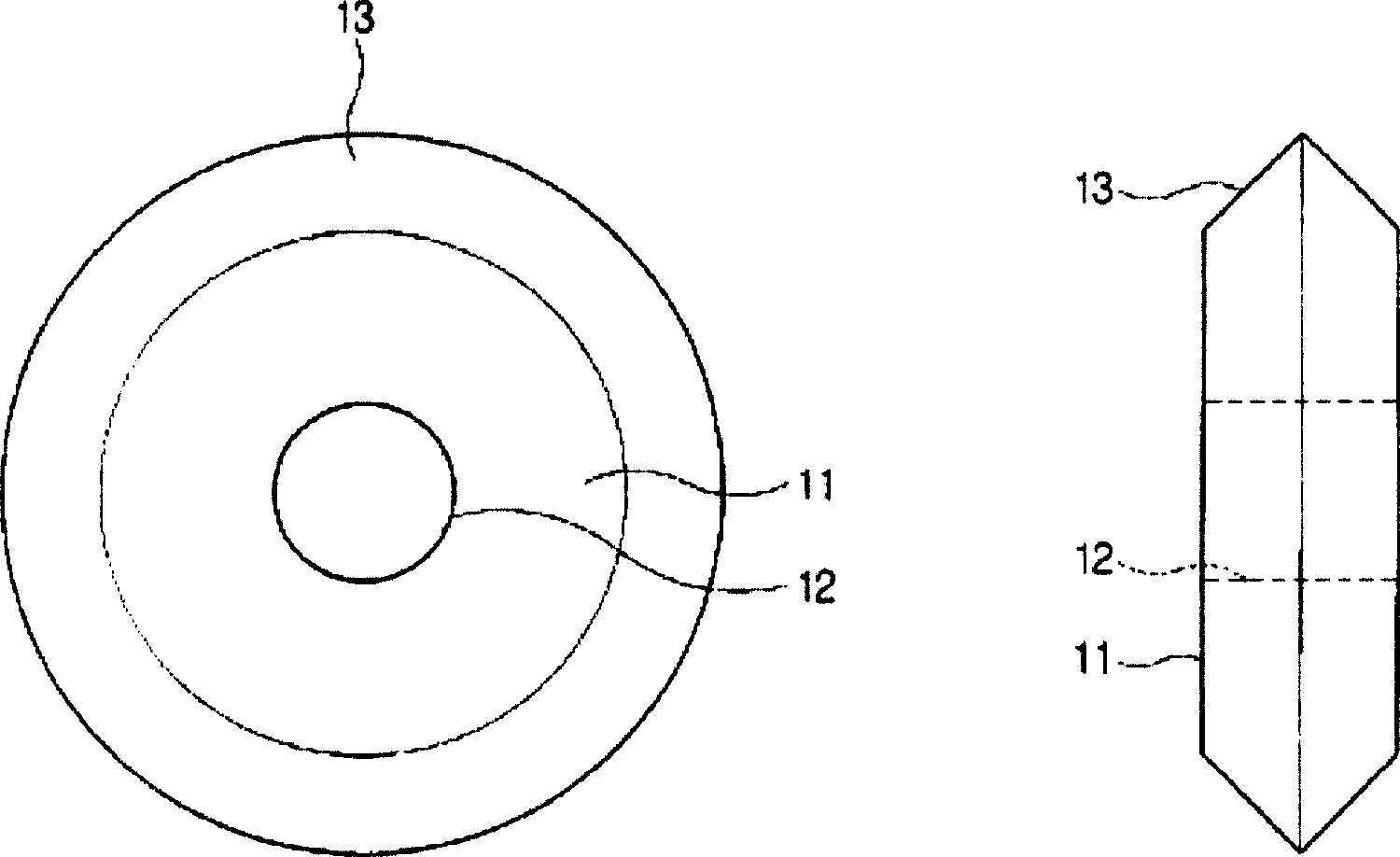

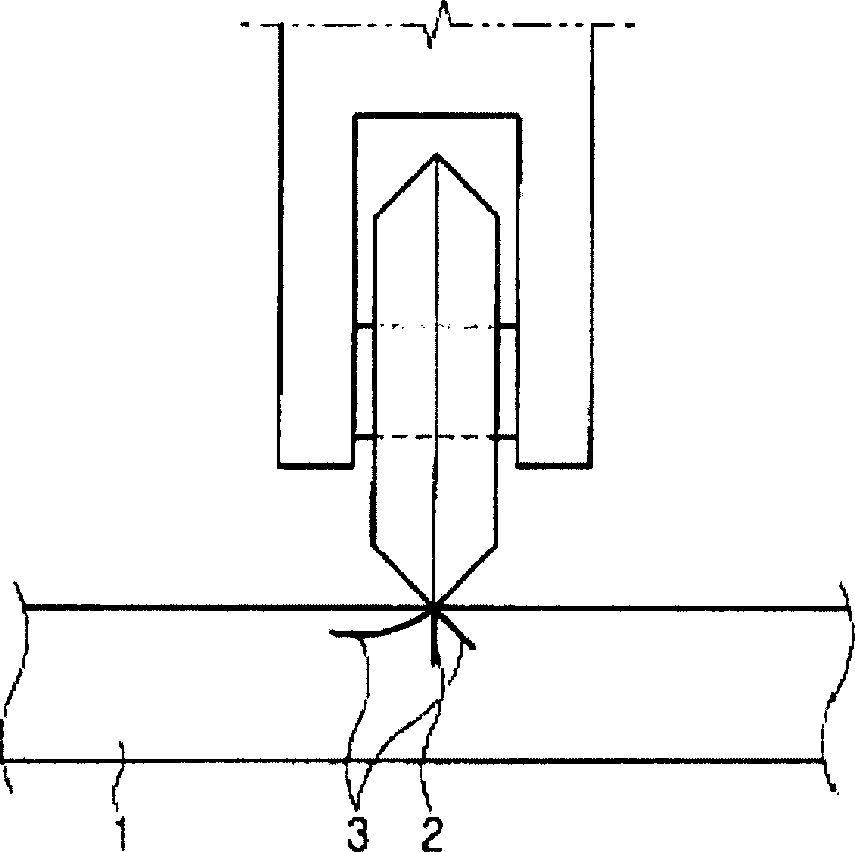

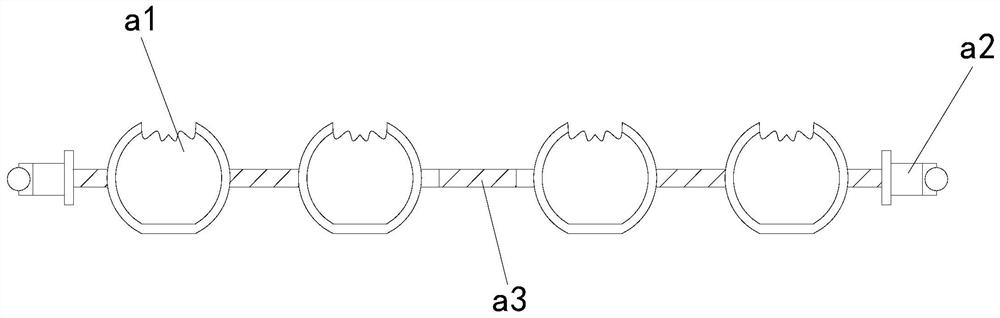

Roller scraping cutter

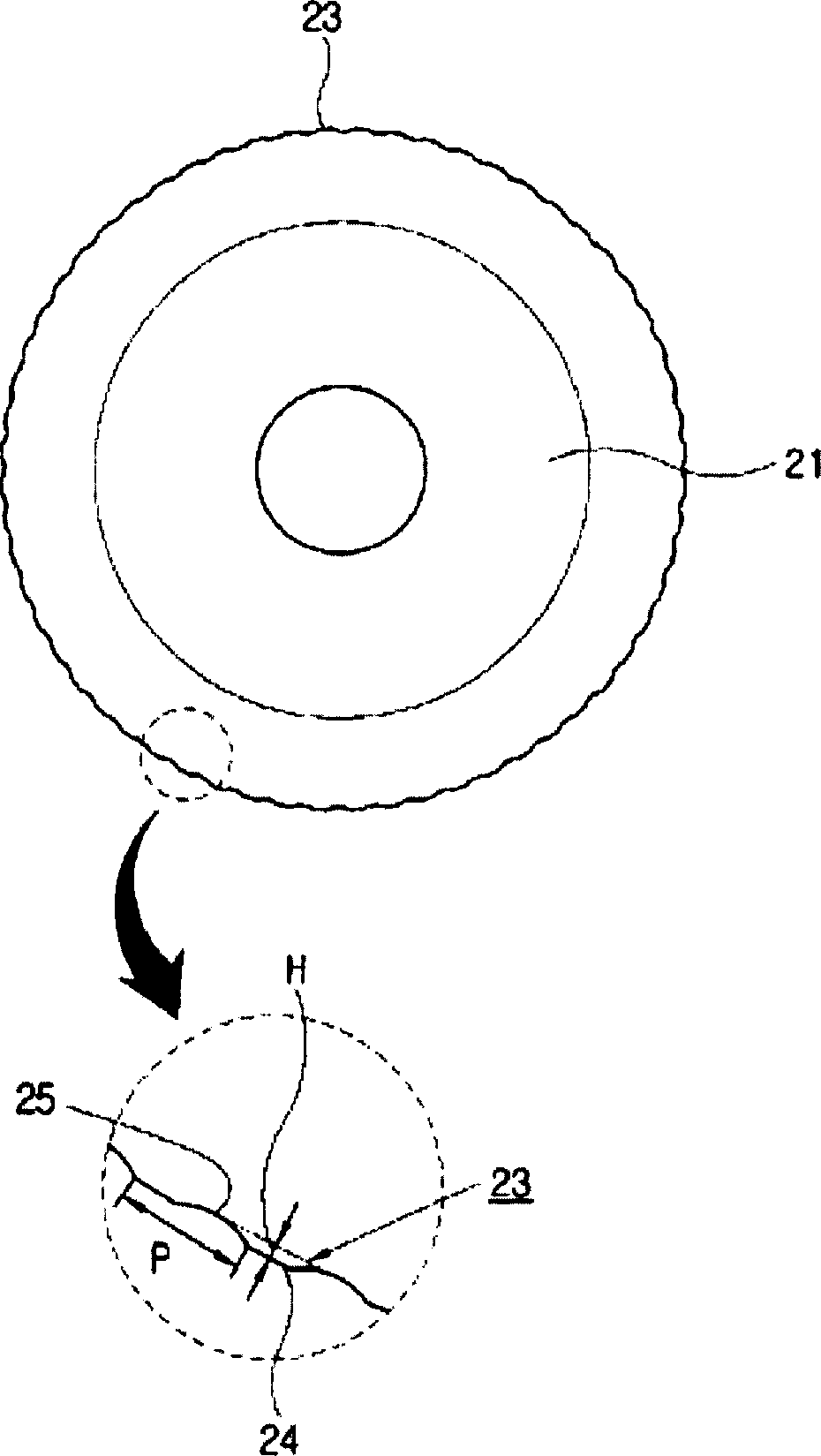

The invention relates to a scribing wheel cutter used for scribing a brittle material such as a glass plate or the like. The scribing wheel cutter consists of a main body part in which an axis hole is formed in a central part and a cutting part with a cross section of V form formed on an outer peripheral edge of the main body part. The cutter involves many numbers of a peripheral edge notch formed at a regular angle interval along the peripheral edge of the cutting part and many numbers of an inner circumference groove formed along an inner peripheral edge of the axis hole and being parallel to the axis line less numbers than those of the outer peripheral edge notches. A smooth cutting face after a cutting is obtained by reducing a shear force required for cutting of a product and minimizing the generation of horizontal cracks because perpendicular cracks can be deeply formed on the surface of glass being an object of the scribing in the method.

Owner:MJ TECH

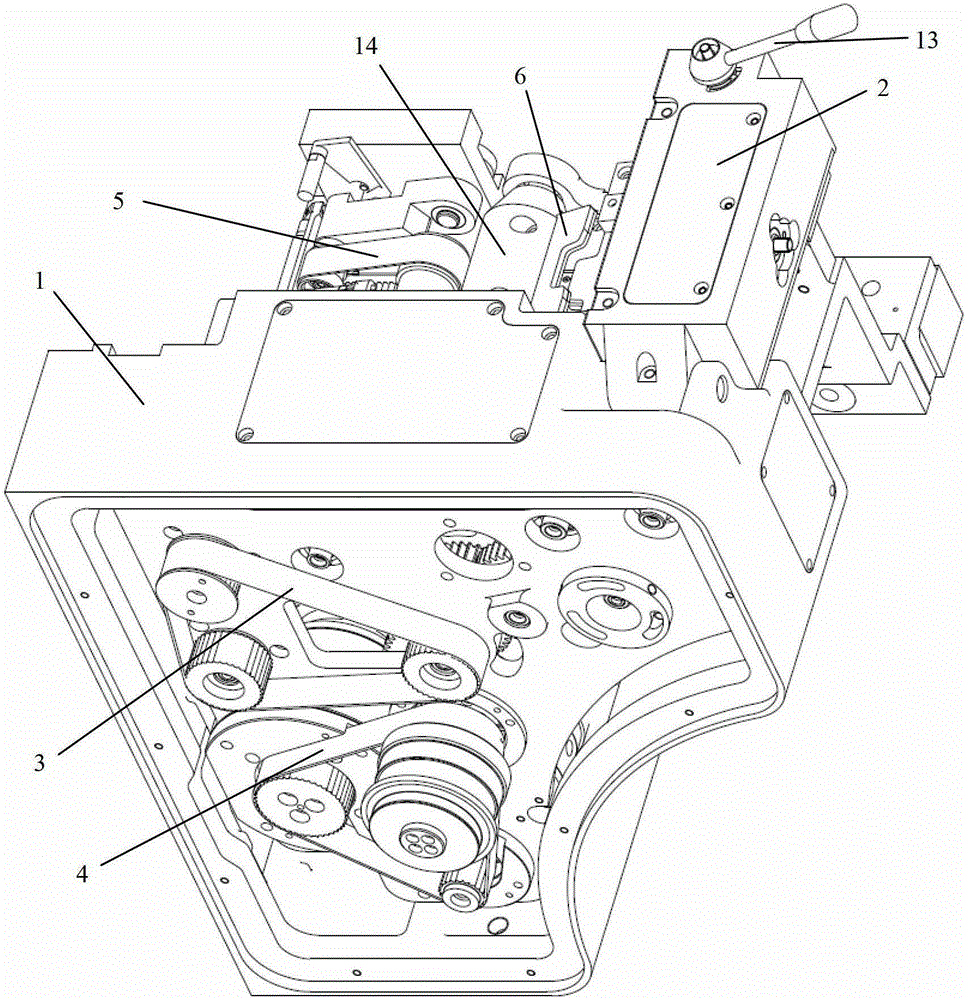

Food slicing device

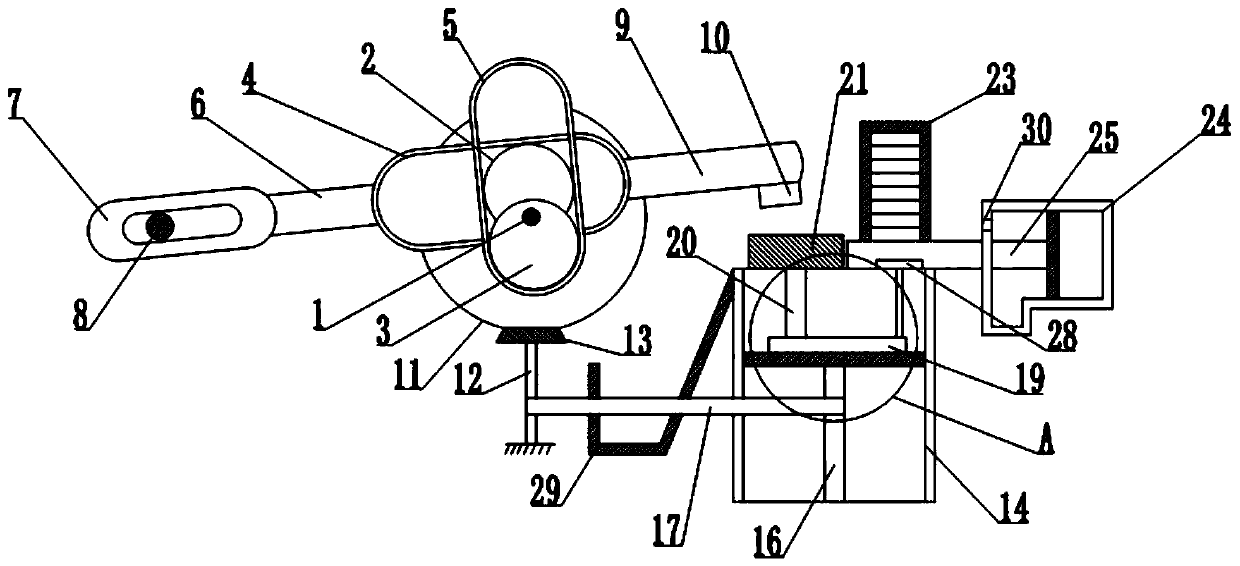

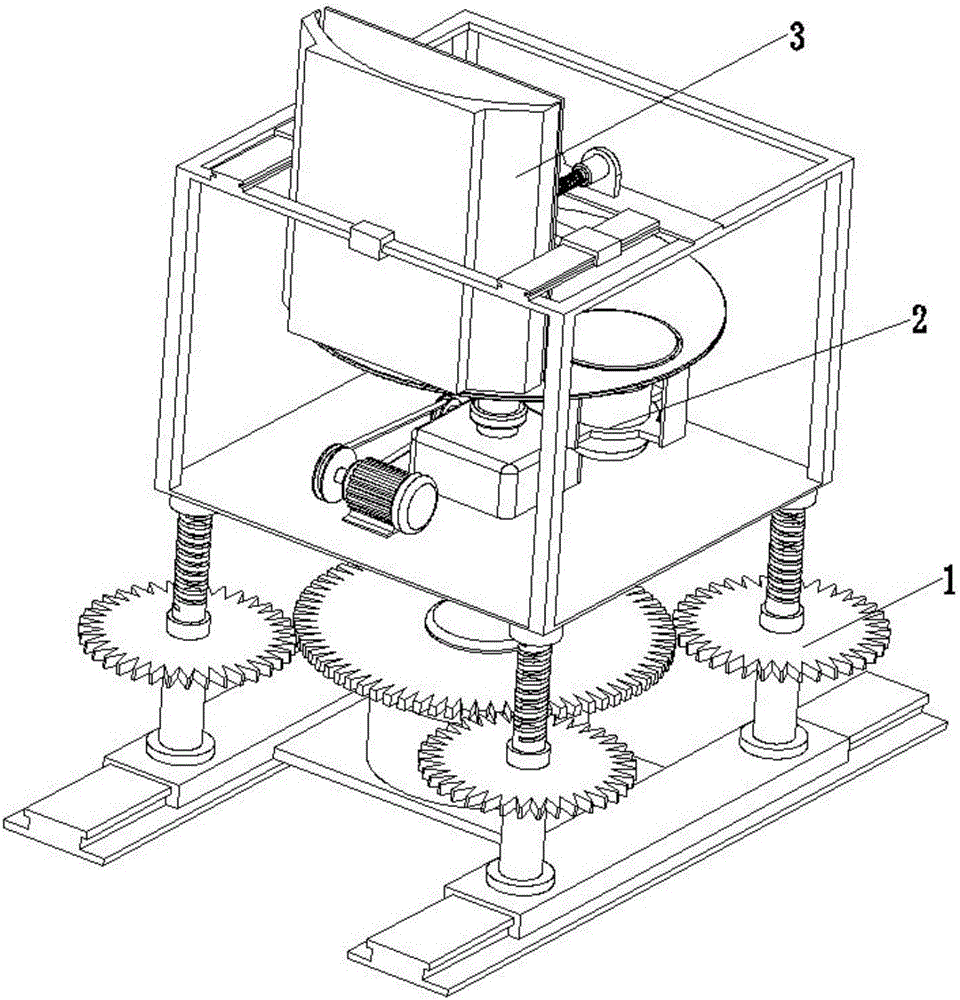

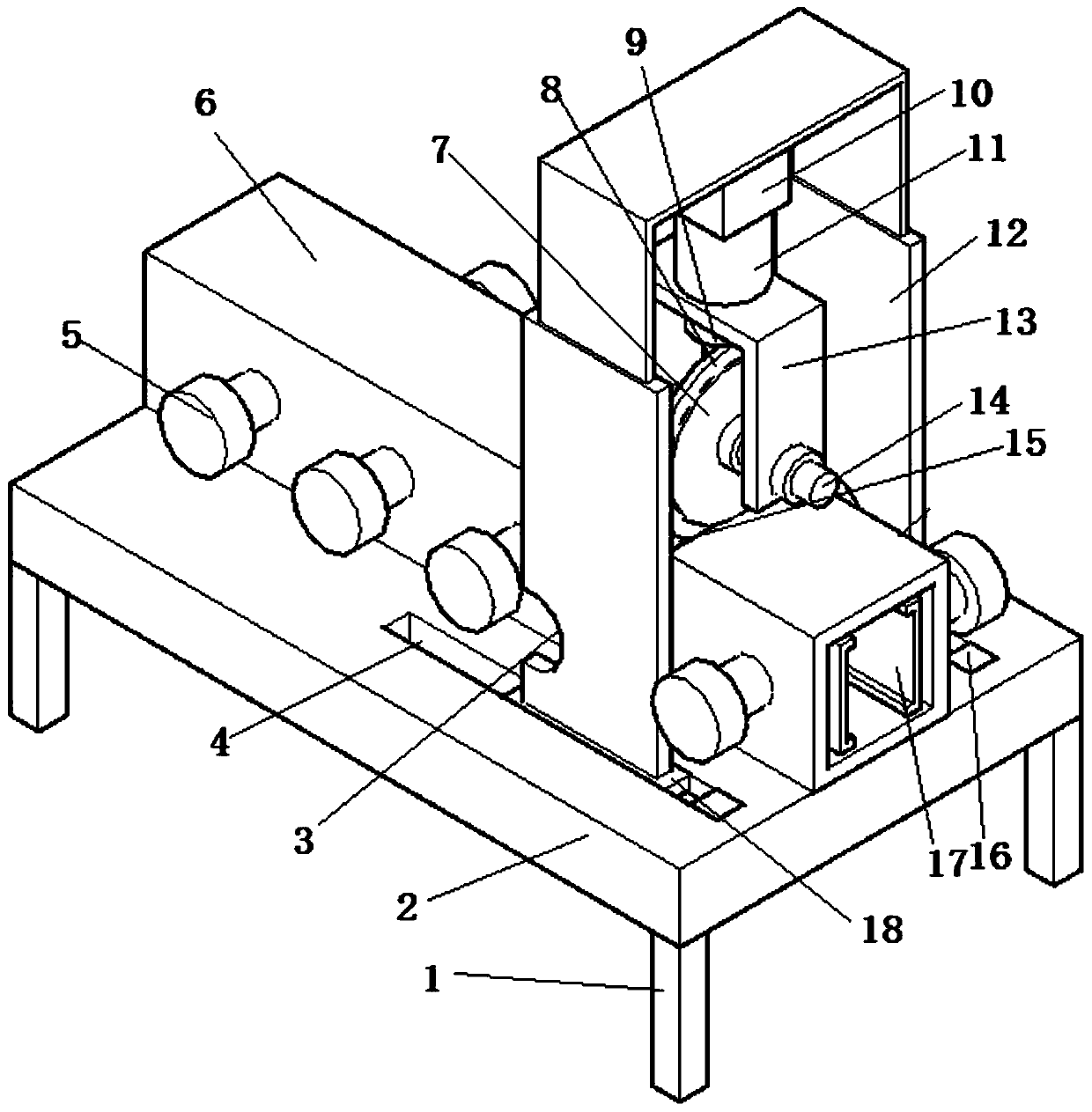

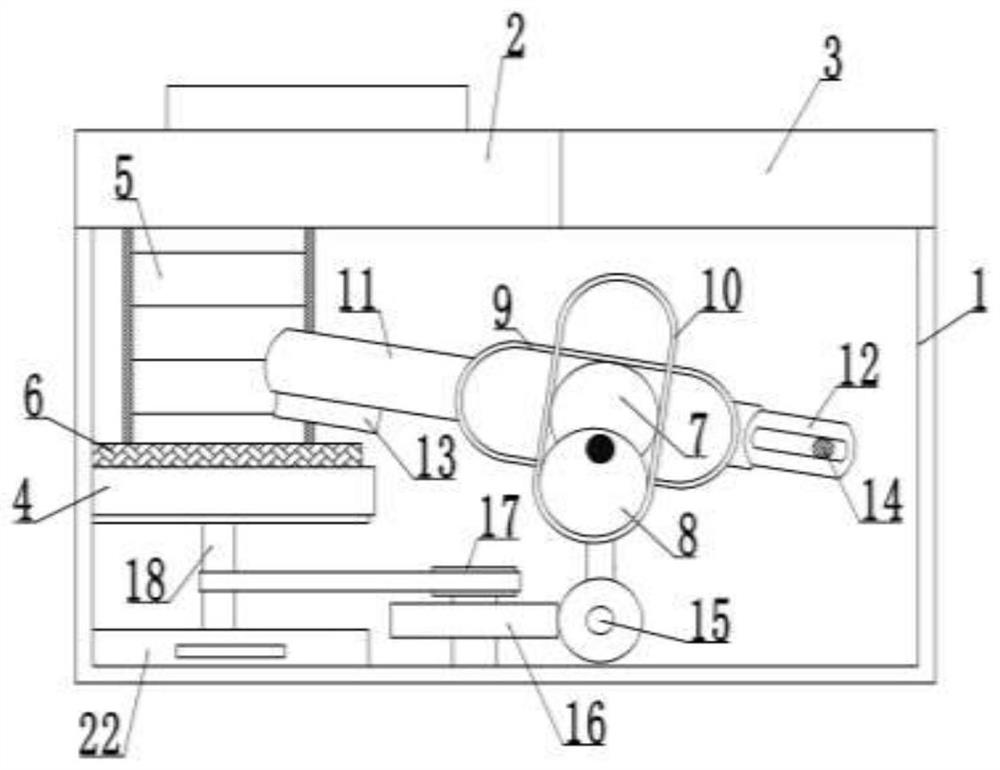

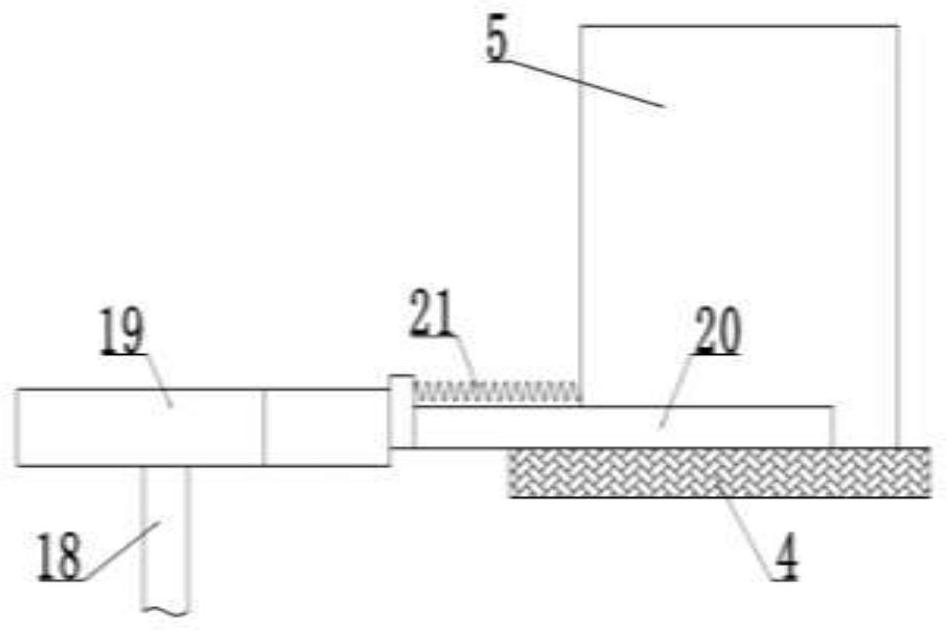

ActiveCN109702795AUniformity of influenceBeautiful incisionMetal working apparatusGear wheelEngineering

The invention discloses a food slicing device, and belongs to the technical field of devices for driving a cutting element to achieve cutting. The food slicing device comprises a rack; a motor is fixedly installed on the rack; an output shaft of the motor is fixedly connected with a first eccentric wheel and a second eccentric wheel; the first eccentric wheel is in sliding connection with a firstannular component; the second eccentric wheel is in sliding connection with a second annular component; the two sides of the first annular structure are connected with a first connection rod and a second connection rod; the end portion of the first connection rod is fixedly connected with a transverse frame; the second connection rod is detachably connected with a cutter; a cutting table is fixedly arranged on the rack and provided with a groove; an upper cavity and a lower cavity are arranged inside the cutting table; the interior of the upper cavity is rotationally connected with an incomplete gear engaged with a first rack; the first rack is connected with a slide rod; and the slide rod is fixedly connected with a vertical rod. By means of the technical scheme, the problem that synchronous conveying and batch slicing can not be achieved in the prior art is solved, the overall structure is simple, and practicability is high.

Owner:象山锦绣升平食品有限公司

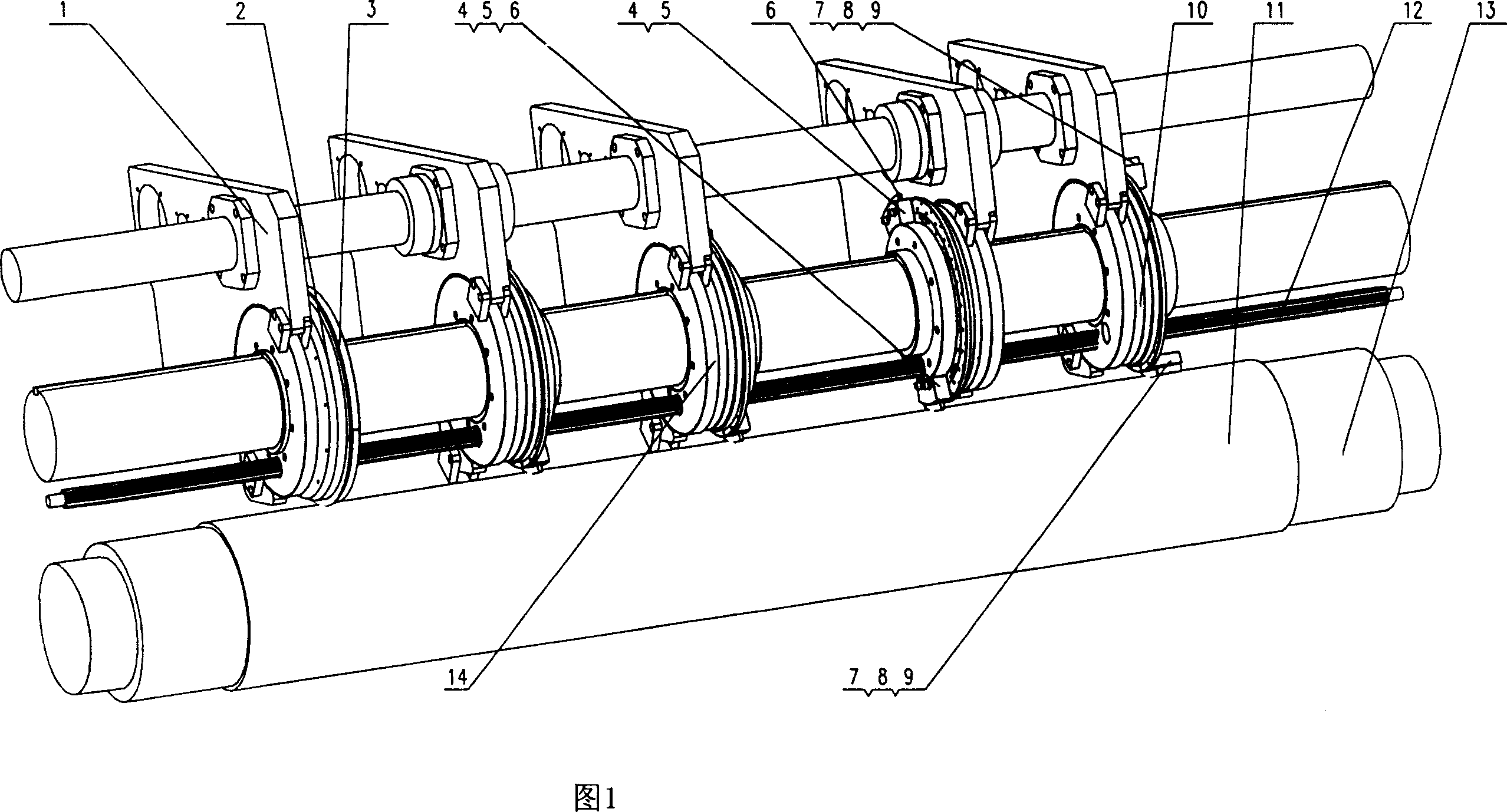

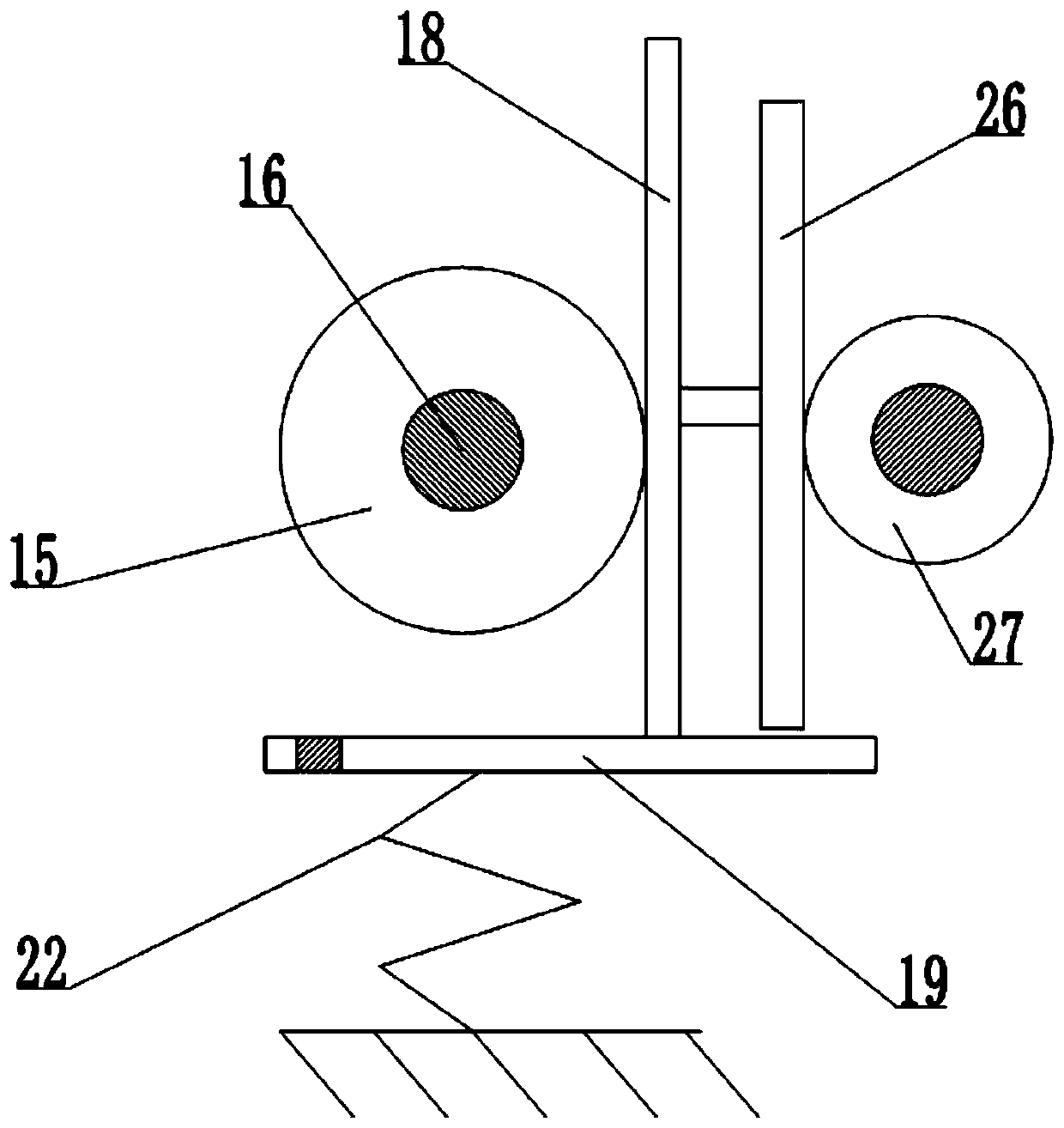

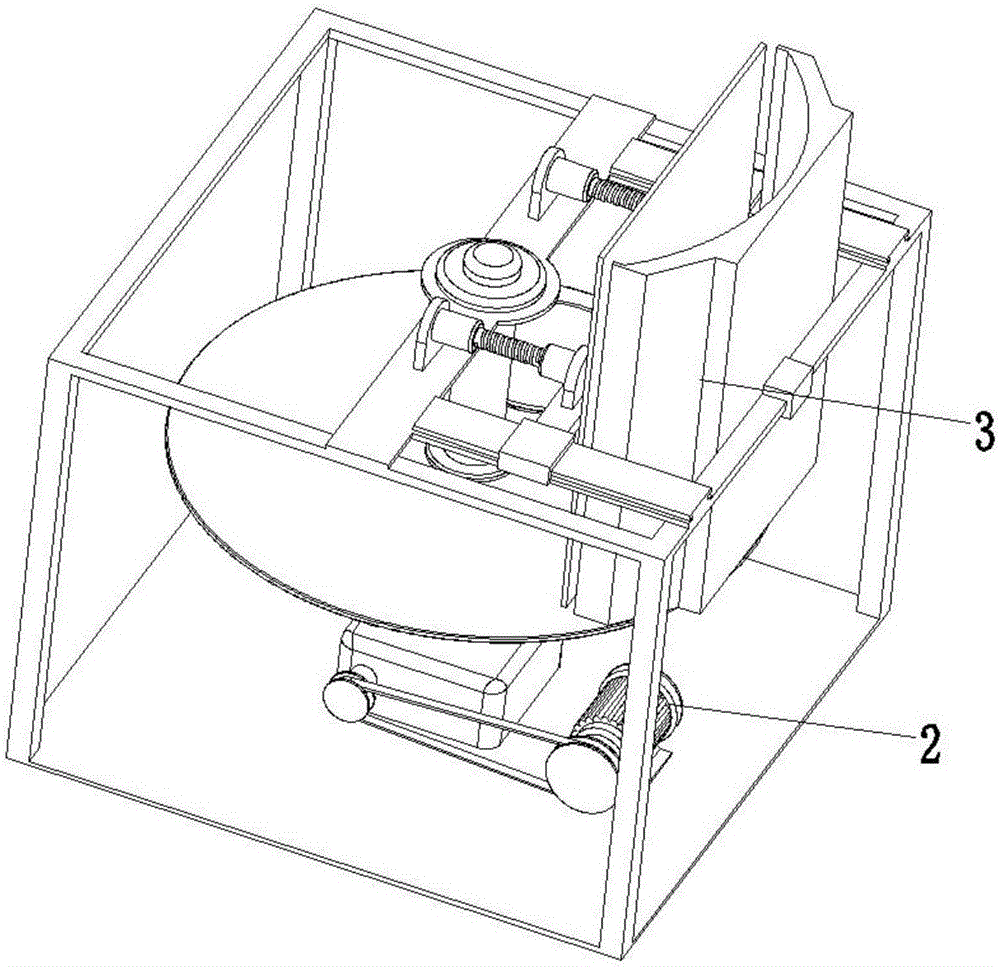

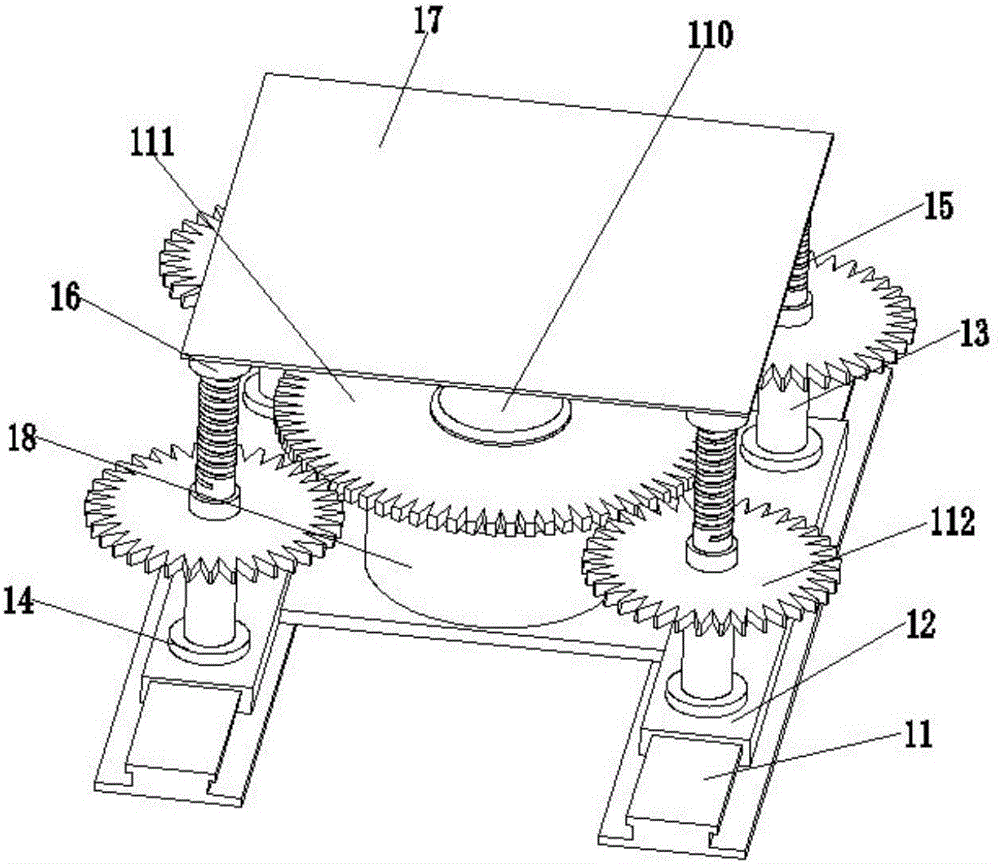

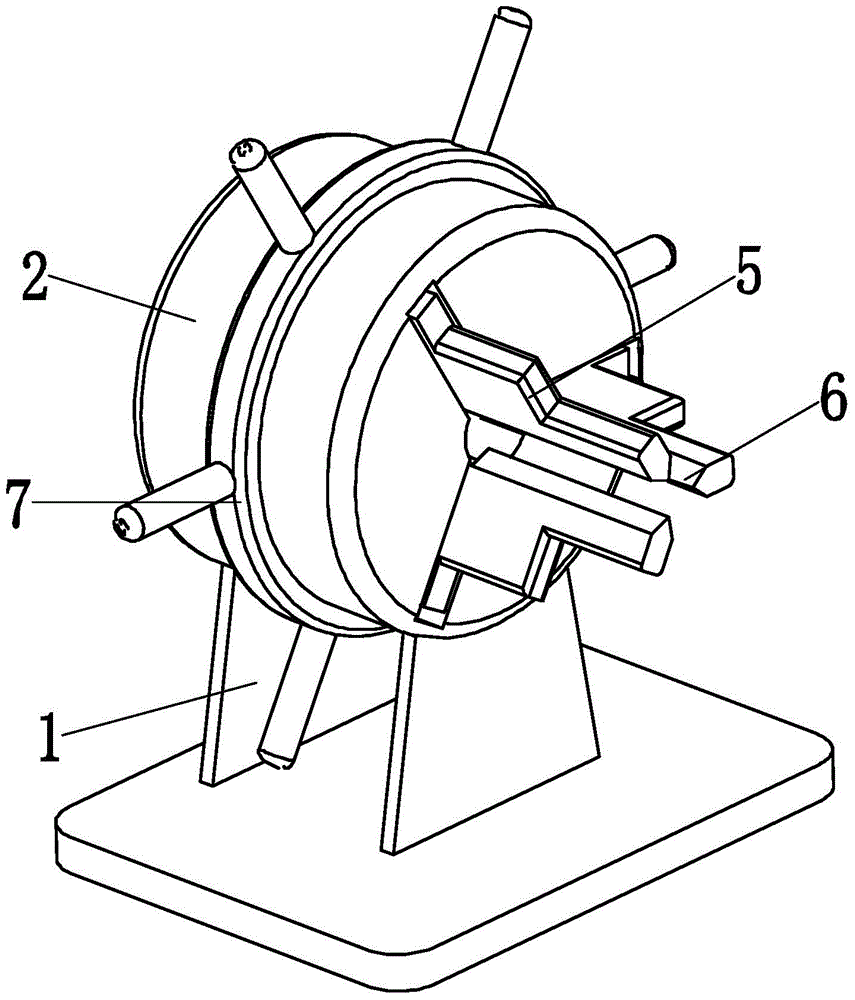

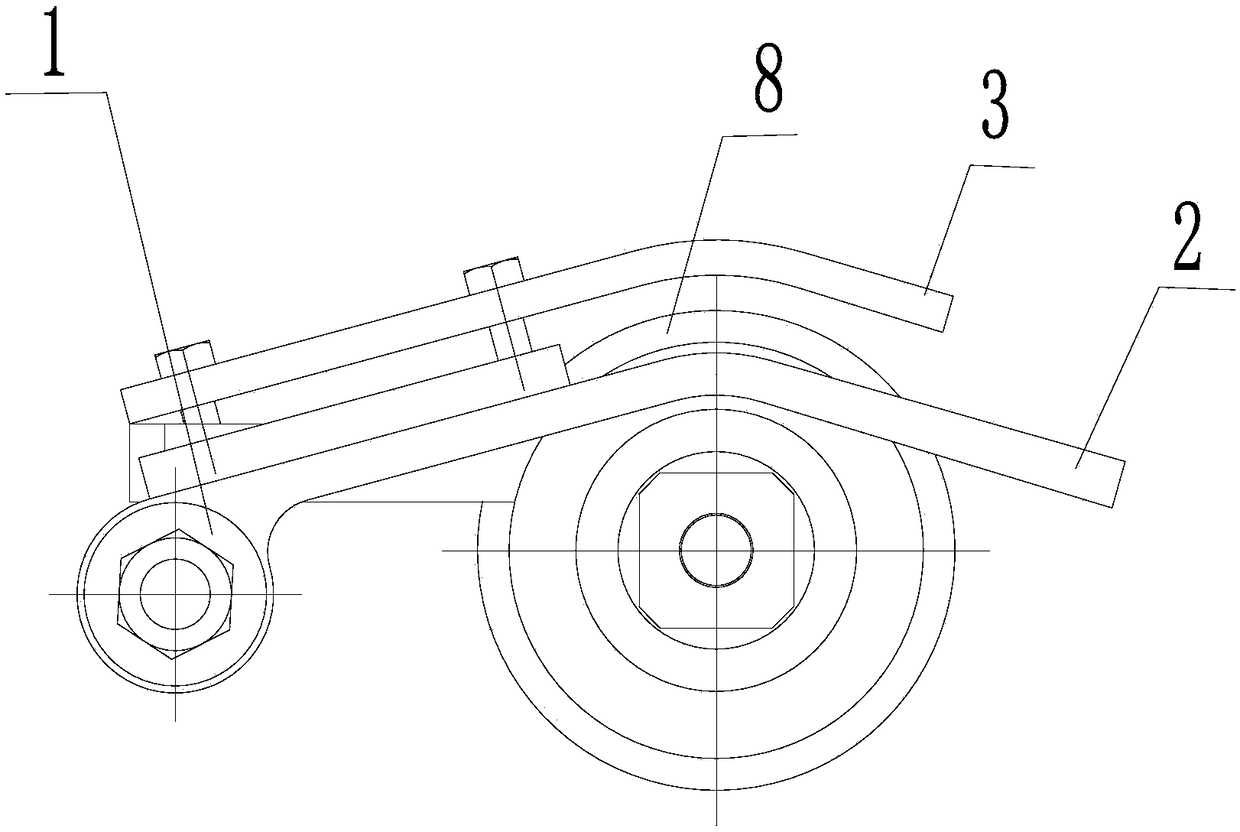

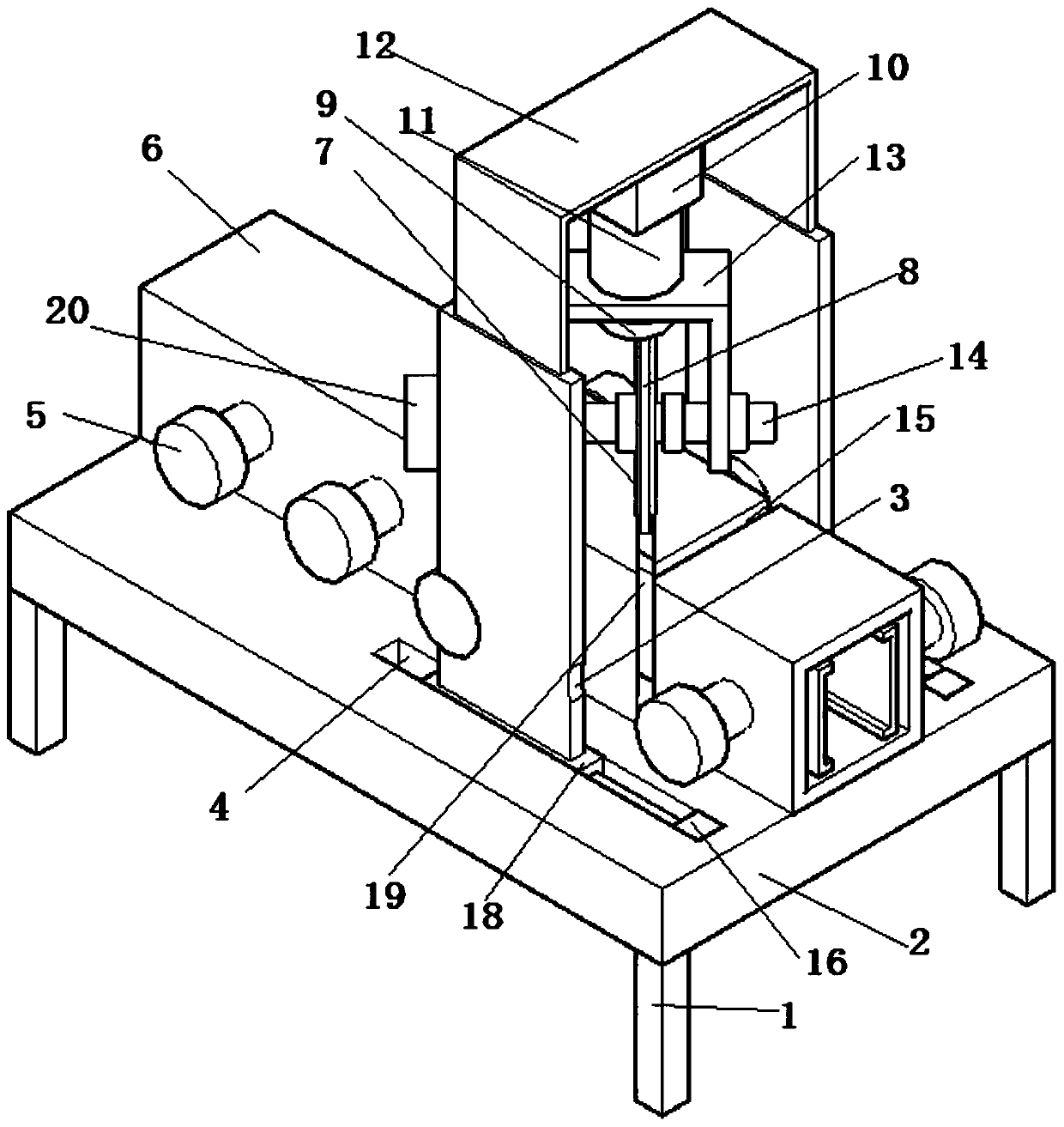

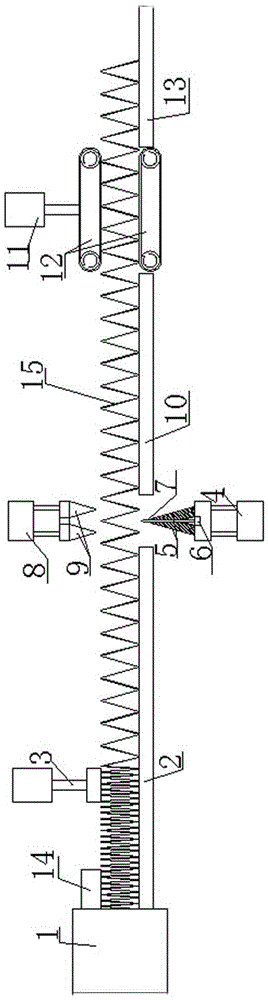

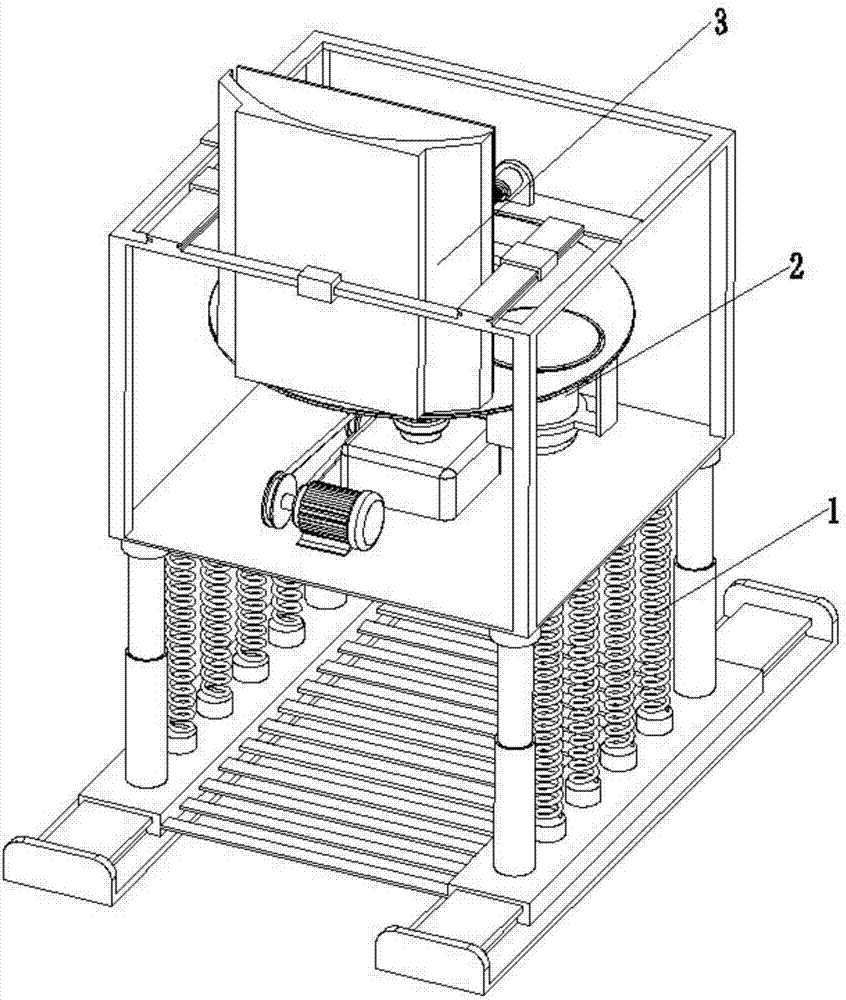

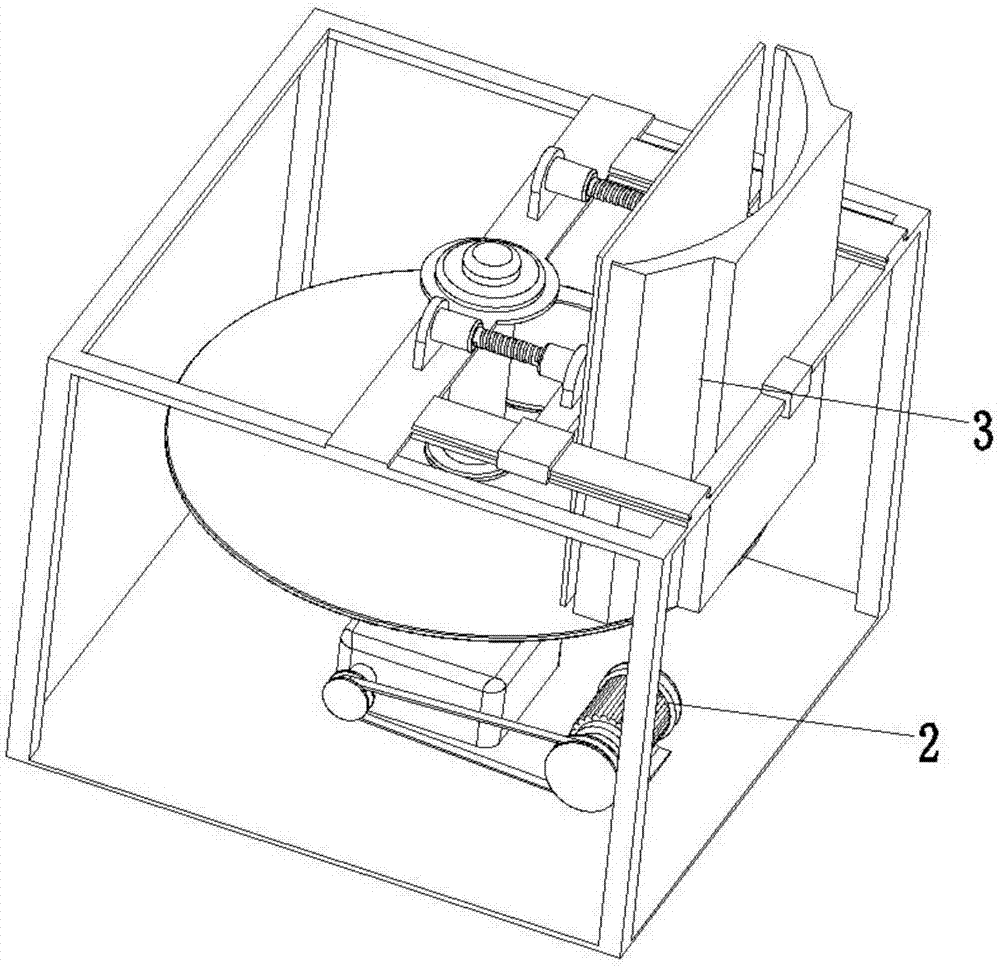

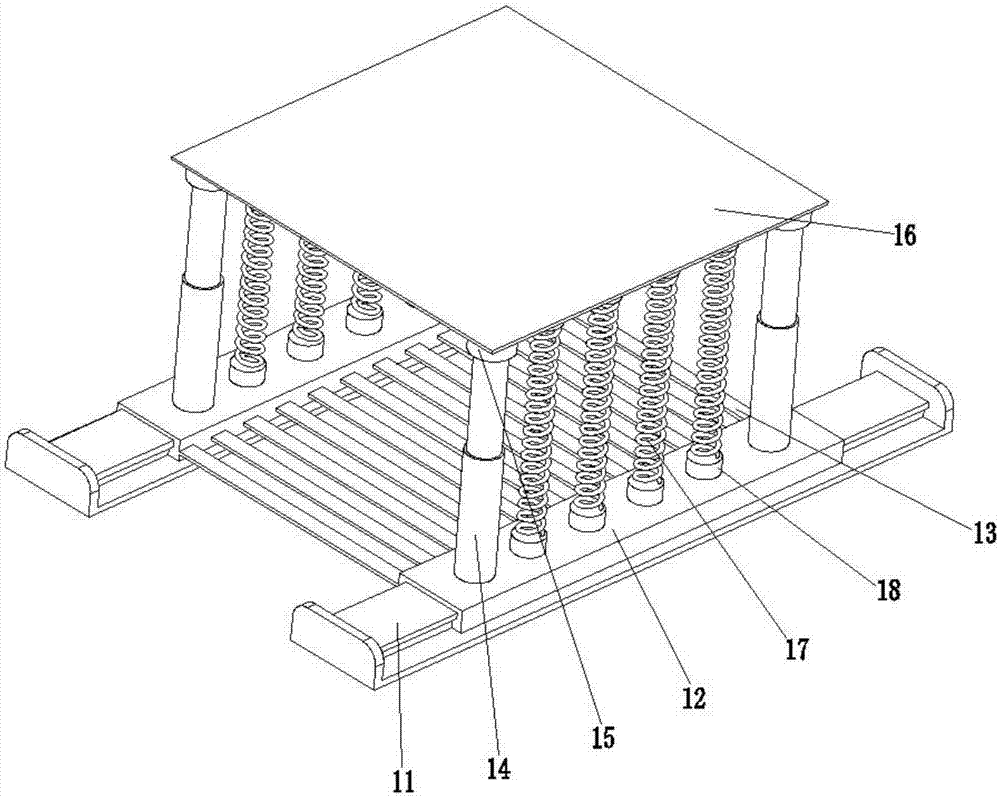

Pueraria lobata slicer

ActiveCN106426339AImprove slicing efficiencyHigh degree of automationStands/trestlesMetal working apparatusLobataEngineering

The invention relates to a pueraria lobata slicer. The slicer comprises a moving base, a rotary cutting device and a clamping device, wherein the rotary cutting device is located on the moving base and is fixedly connected to the moving base, and the clamping device is located in front of the rotary cutting device and is fixedly connected to the rotary cutting device. The slicer can automatically slice pueraria lobata of different sizes and shapes, the slicing efficiency is high, the slicing attractiveness is high, breakage hardly occurs in the slicing process, and the automation degree is high.

Owner:南通江海港建设工程有限公司

Optical fiber stripping device

The invention discloses an optical fiber stripping device, which comprises two stripping blades which are arranged side by side, wherein the stripping blades are respectively arranged on a fixed cutter rack and a movable cutter rack which are arranged oppositely on the left and the right; the fixed cutter rack is connected to a height block; the height block is arranged on a base; and the movable cutter rack is arranged on the top of a sliding table. When an optical fiber is stripped, the position of the movable cutter rack is adjusted such that a distance between the two blades is equal to a diameter of a bushing, then the optical fiber slides from top to bottom along a gap between the two blades, and the optical fiber is slightly rotated. The hardness of a rubber skin is much smaller than that of a Kelvar wire doped in the bushing, so that the rubber skin is cut off by the blades in the process that the optical fiber slides down, while the bushing and the Kelvar wire cannot be damaged. In the whole process, time and labor are saved, the stripping quality can be guaranteed, a phenomenon that a worker is injured due to careless operation can be avoided, and a cut of the rubber skin is flat and looks beautiful.

Owner:无锡爱沃富光电科技有限公司

Cutting device for machining building materials

InactiveCN111151805AEasy to operateImprove accuracyTube shearing machinesShearing machine accessoriesMachine buildingConstruction engineering

The invention discloses a cutting device for machining building materials. The cutting device comprises a base plate and a support plate; a chute is fixed on the base plate; two slide blocks are symmetrically mounted in the chute; clamping blocks for fixing pipes are mounted on the side walls of the slide blocks; a moving mechanism is mounted in the chute; a fixed disc is mounted on the upper endsurface of a top plate; a damping rotary drum is rotationally sleeved in the fixed disc; a dial is peripherally arranged on the upper end surface of the fixed disc; a pointer for indicating scales isarranged on the damping rotary drum; and a cutting device is mounted in the damping rotary drum. The cutting device for machining the building materials is provided with the damping rotary drum capable of being rotatably adjusted above a cutting blade, realizes precise adjustment of the cutting angle of the cutting blade through fit use of the pointer and the dial, and is convenient and fast in operation, high in precision and stable and reliable in cutting angle.

Owner:赣州全冠建材有限公司

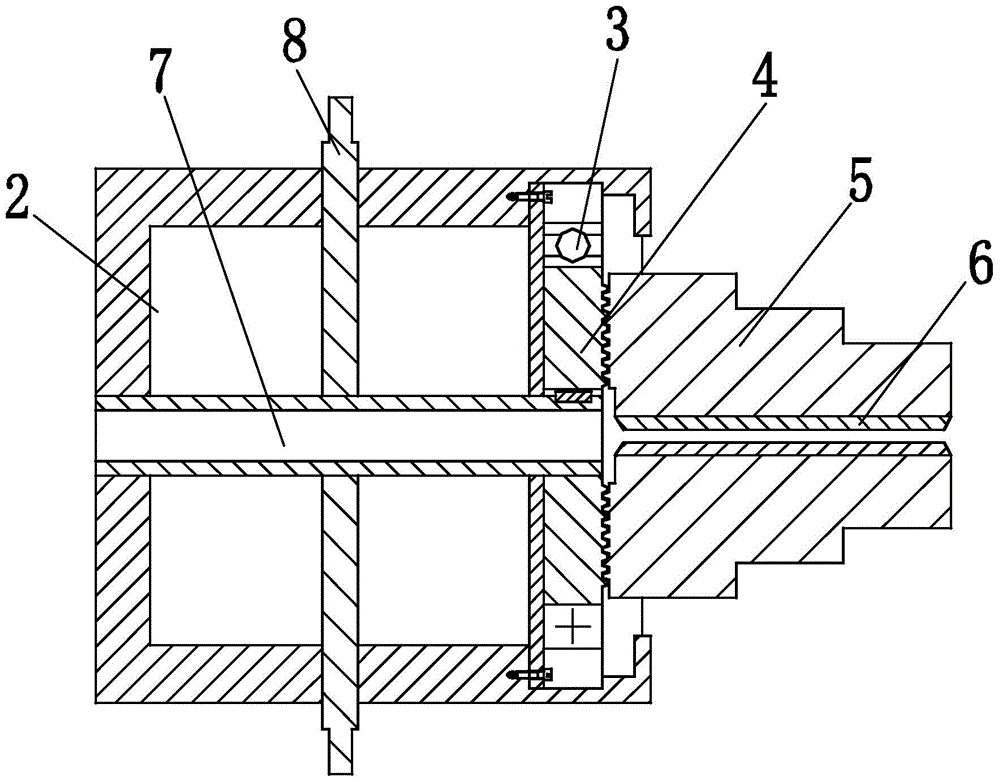

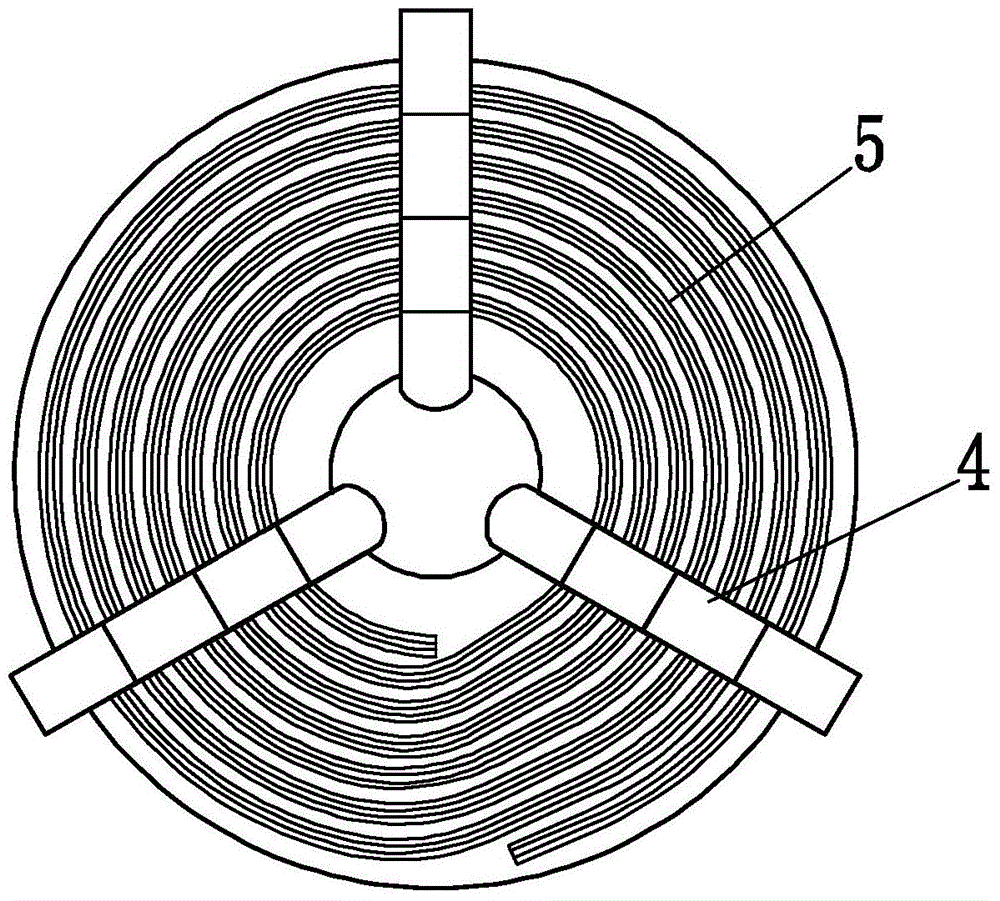

Rapid cut-off device for steel wire ropes

InactiveCN104874707ARealize the function of cutting to lengthCompact structureEngineeringMechanical engineering

The invention relates to a rapid cut-off device for steel wire ropes. The device comprises a cut-off support, a casing, a cut-off plummer block, a rotating disk, three pawls, three cutters, a hollow rotating shaft and a handle, wherein the cut-off support is located below the casing, three limiting holes are symmetrically formed in the right side of the casing and along the center axis of the casing respectively, a through hole is formed in the center position of the rotating disk, three pawls are symmetrically mounted in three limiting holes in the right side of the casing and along the center axis of the rotating disk respectively, spirally-circling trapezoid teeth are formed on the right end surface of the rotating disk, trapezoid teeth are formed on bottom end surfaces of the three pawls respectively, the rotating disk is meshed with the three pawls through the trapezoid teeth, the cutters are fixed at the bottoms of the pawls, one end of the hollow rotating shaft is connected with the rotating disk through keys, the other end of the hollow rotating shaft is connected with the casing, and the handle is located in the middle of the hollow rotating shaft. The device can cut off the steel wire ropes in fixed length, the cut is attractive, the equipment layout is compact, the occupation space is small, and the mechanical automation is high.

Owner:ANQING HUAXIN HEAVY IND

Cutting method of rabdosia rubescens decoction pieces

InactiveCN108743659AAvoid softening unevenlyImprove appearancePlant ingredientsEngineeringMechanical engineering

The invention discloses a cutting method of rabdosia rubescens decoction pieces. The cutting method of the rabdosia rubescens decoction pieces comprises the steps of infiltrating, softening, cutting,drying and packaging. The cutting method of the rabdosia rubescens decoction piece particularly comprises the following steps: intermittently spraying rabdosia rubescens with water, putting into a container, softening by utilizing steam, pressing, cutting into small blocks by using a medicine cutting knife, drying, throwing into a packaging bag, introducing inert gas, sealing and packaging. The cutting method provided by the invention has the advantages of simple and efficient operation, excellent quality, color and luster of medicine materials, high qualification rate and the like, and has wide popularization and application prospects.

Owner:安徽益草堂中药饮片有限公司

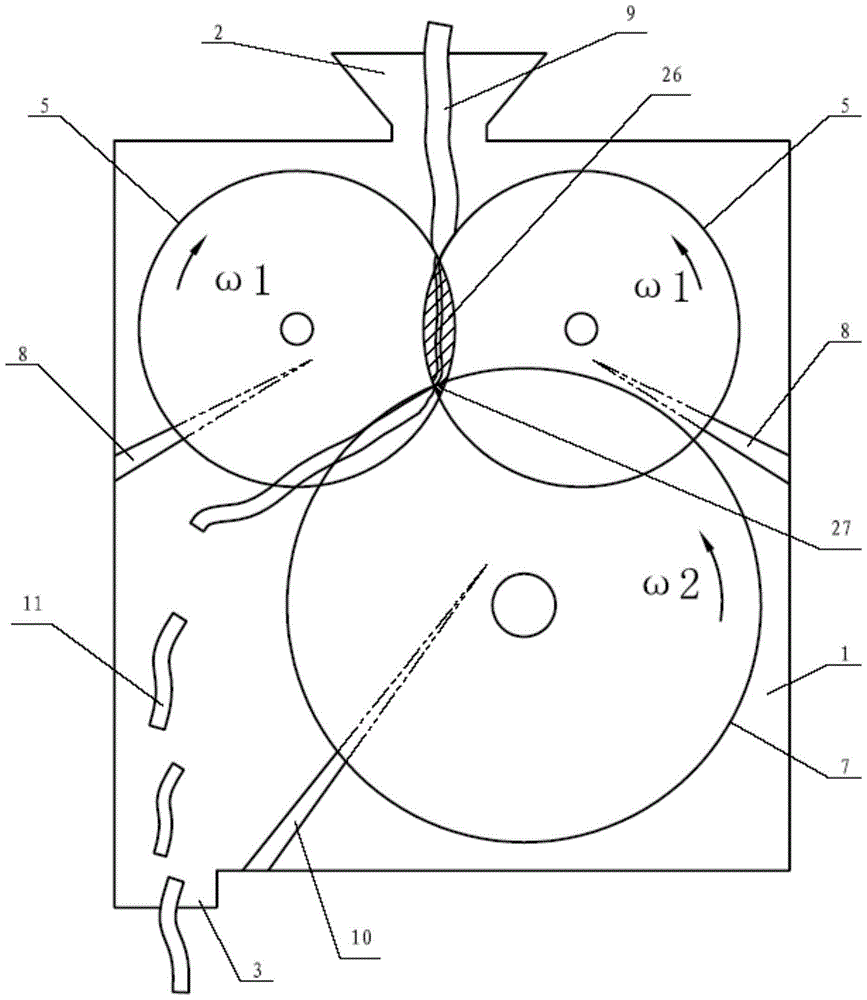

Crusher

The invention discloses a crusher. The crusher comprises a shell (1), and a primary crushing mechanism and a secondary crushing mechanism which are arranged in the shell (1), wherein the primary crushing mechanism is arranged above the secondary crushing mechanism; the primary crushing mechanism is used for driving materials to be crushed to move downwards for primary crushing; the secondary crushing mechanism is used for performing secondary crushing on the materials subjected to the primary crushing. The crusher has the advantage of the conventional crusher, can be applied widely, and has high adaptability to rubber products of different types and different properties. Products are uniform in shapes, and notches are tidy and attractive. The crusher is suitable for rubber products with very high toughness and viscoelasticity, integrates a plurality of cutting ways, and has high product treatment adaptability and high crushing efficiency.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Novel tipping paper cutting device

InactiveCN108772867AGuaranteed uptimeReduce the number of occurrences of axial misalignmentMetal working apparatusEngineeringPaper cut

The invention provides a novel tipping paper cutting device which comprises a cutting board, a protective cover, cutting round knives, a belt wheel and a round knife shaft. The cutting board is a platy part, and two cutting knife seams are formed in the surface of the cutting board in a spaced mode; the top end parts of the two cutting round knives are exposed out of the cutting knife seams, and in the cutting process, the cutting board limits and supports tipping paper; the protective cover is arranged above the cutting board in a covering mode; the two cutting round knives are mounted on theround knife shaft; and the round knife shaft is driven by the belt wheel so as to drive the cutting round knives to rotate to make the cutting action. When the novel tipping paper cutting device is used, the tipping paper penetrates through the surface of the cutting board, and the round knives extend out of the cutting board seams to cut the tipping paper; the novel tipping paper cutting deviceis provided with the protective cover for shielding an equipment hazard source; and the novel tipping paper cutting device is stable in cutting, smooth and attractive in incision, the tipping paper istensioned firstly and then cut, thus tensioning force of the tipping paper is uniform in distribution, the tipping paper is stable in operation, and the frequency of breaking and axial position offset of the tipping paper can be decreased.

Owner:HUBEI CHINA TOBACCO IND

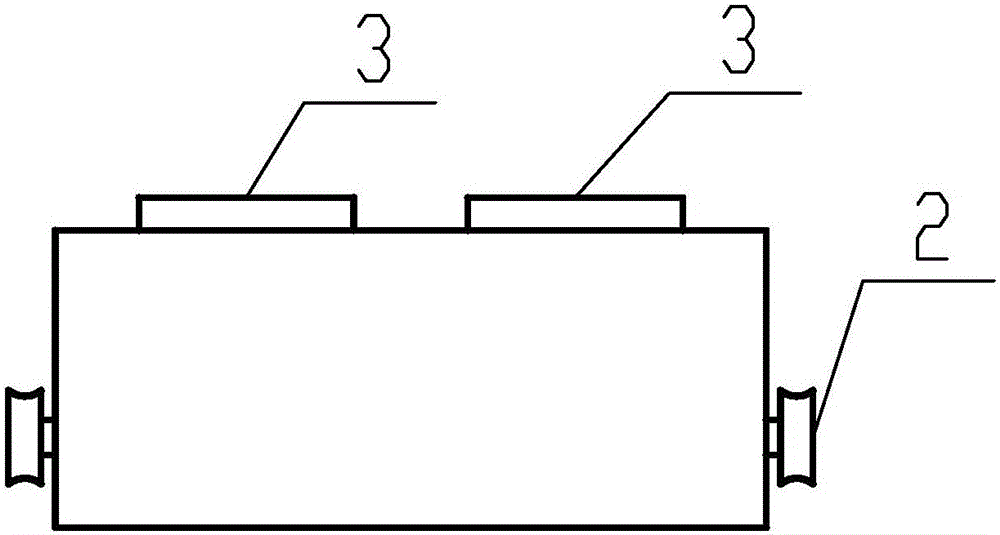

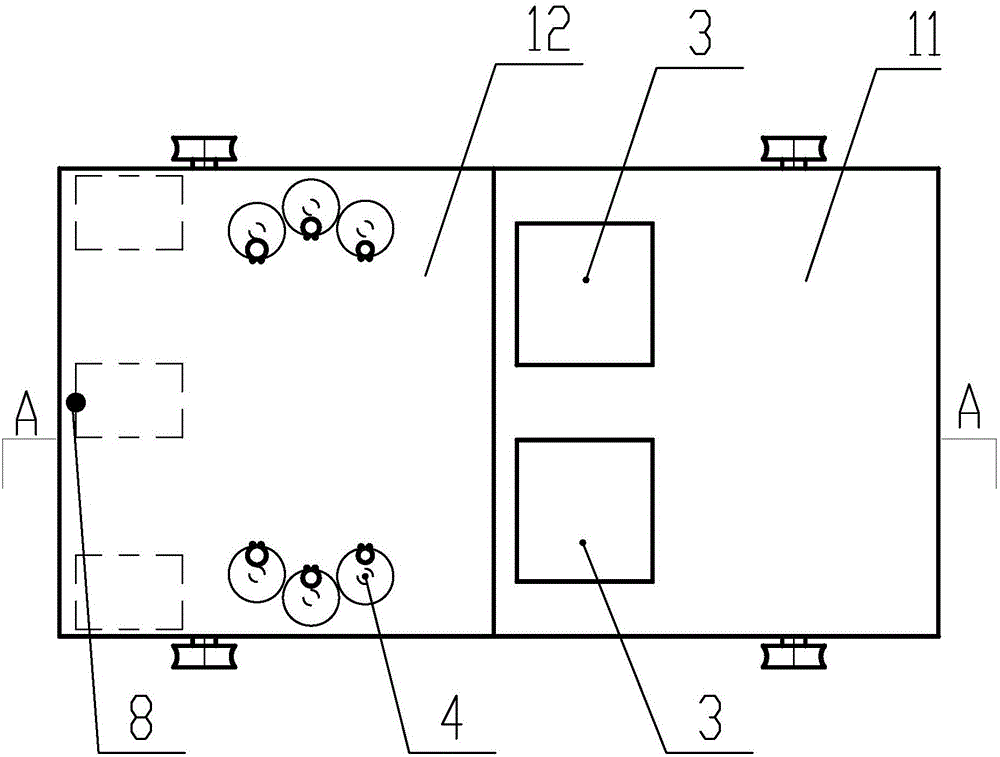

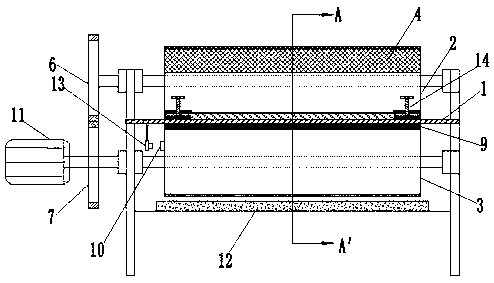

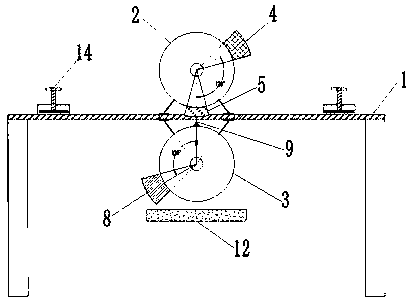

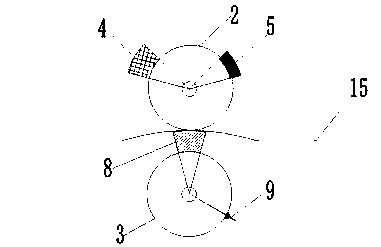

Multi-blank multi-layer co-extruding blow moulding machine

A multi-blank multi-layer co-extruding blow moulding machine comprises a plasticizing system, a mold head extruding system and a blow moulding system. The mold head extruding system comprises more than one mold head, each mold head is provided with a feeding port connected with a screw rod; the mold head comprises a mold head main body connected with a mouth mold which is provided with a core mold; the core mold and mouth mold form an extruding port, wherein a guide body A and a guide body C are mounted in the mouth mold main body; the guide body A is provided with a step; a small head under the step is sleeved in a middle hole C of the guide body C; the small head is provided with a guide groove A and a vertical flow passage A; a big head is provided with a transverse flow passage A; a guide body B is arranged in the guide body A; the guide body B is provided with a guide flow passage B and a vertical flow passage B; the guide flow groove B is communicated with the feeding port; the guide body C is provided with the transverse flow passage C; the transverse flow passage C is connected with the guide flow groove A and the feeding port B; the guide body C is provided with a guide flow groove C and a vertical flow passage C, the guide flow groove C is communicated with the feeding port C; the vertical flow passage A, the vertical flow passage B and the vertical flow passage C arejointed at the external wall of core mold and communicated with the extruding port.

Owner:浙江东方州强塑模实业有限公司

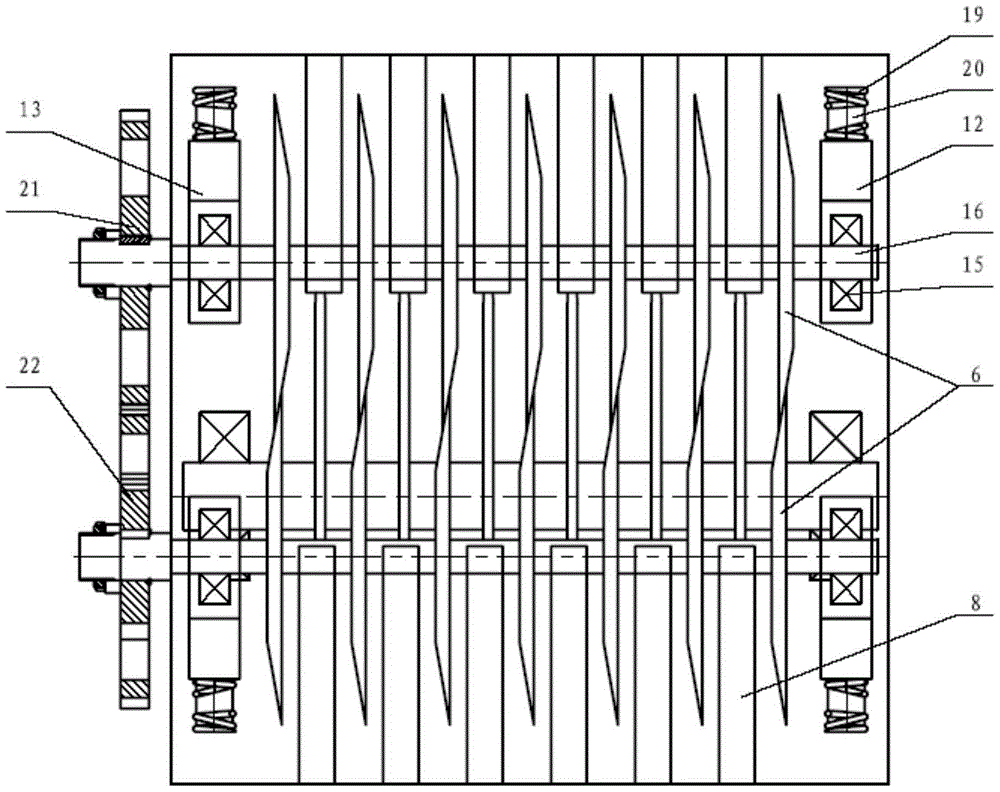

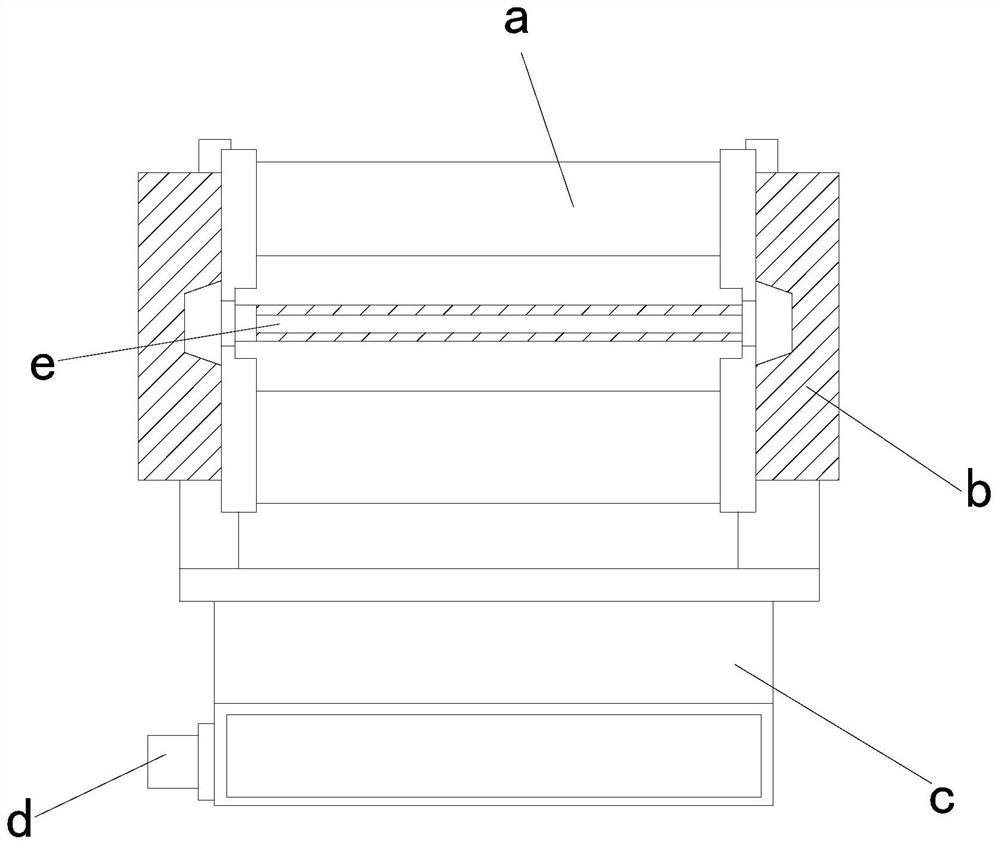

Cutting device suitable for pressing gauze element and used for gauze element production and processing

InactiveCN113601574AOptimize the way it worksAdd Tensioning ComponentsMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of gauze element production and processing, in particular to a cutting device suitable for pressing a gauze element and used for gauze element production and processing. The cutting device comprises a mounting plate, wherein two groups of chutes A are formed in the upper surface of the mounting plate; mounting plates A are fixedly installed on the two side surfaces of the mounting plate; limiting grooves A are symmetrically formed in the opposite faces of the two mounting plates A; limiting grooves B are symmetrically formed in the opposite faces of the two mounting plates A; and cavities are formed in the two mounting plates A. According to the device, by adding a pressing component, the gauze element can be pressed when the gauze element is wound and needs to be cut, the purpose of facilitating cutting is achieved, the operation mode of a cutter is optimized through a refitting box, the cutter can synchronously move along with the pressing component, the purposes of saving time and improving efficiency are achieved, and a tensioning component is added to the device, so that the gauze element can be tightened during cutting, and the purposes of convenient cutting and attractive cut are achieved.

Owner:LIXIN FUYA GAUZE CO LTD

Cutting device used for environment-friendly type PVC wire duct

The invention discloses a cutting device used for an environment-friendly type PVC wire duct. The cutting device comprises a work table with supporting legs. A wire duct clamping assembly is arrangedon the work table. A telescopic installation frame connected to the work table in a sliding manner is arranged above the wire duct clamping assembly. A drive base body is arranged on the portion, located above the wire duct clamping assembly, of the bottom of the telescopic installation frame. A cutting knife holder is arranged at the bottom of the drive base body. A disc-shaped cutting knife driven by a motor is transversely arranged on the cutting knife holder. The cutting device can conduct horizontal cutting and can also conduct 45-degree inclined cutting, notches are flat and attractive,and cutting is convenient.

Owner:六安中财管道科技有限公司

Fungus root cutting machine

The invention belongs to the technical field of artificially planting and picking funguses and cutting fungus roots, and mainly provides a fungus root cutting machine. The fungus root cutting machine comprises a machine frame, wherein wheels are mounted on two sides of the machine frame; electronic scales and automatic cutting heads are separately and fixedly arranged on an upper panel of the machine frame, and microsensors are arranged on the automatic cutting heads; a power supply and a controller are arranged in the machine frame; the controller is connected with the automatic cutting heads and the microsensors; the power supply is used for providing the power supply for the automatic cutting heads, the controller and the microsensors. According to the fungus root cutting machine disclosed by the invention, the conventional fungus root cutting mode is broken; compared with the conventional fungus root cutting technique, the fungus root cutting machine has the advantages that under the premise that the fungus root cutting requirements are met, the working efficiency is improved, the labor intensity is reduced, the fungus root cutting uniformity is guaranteed to be consistent, the product quality of fungus production is sufficiently guaranteed, and the production cost of cutting of fungus roots is reduced.

Owner:LUOYANG QIAOJIANGBEI BIOLOGICAL TECH CO LTD

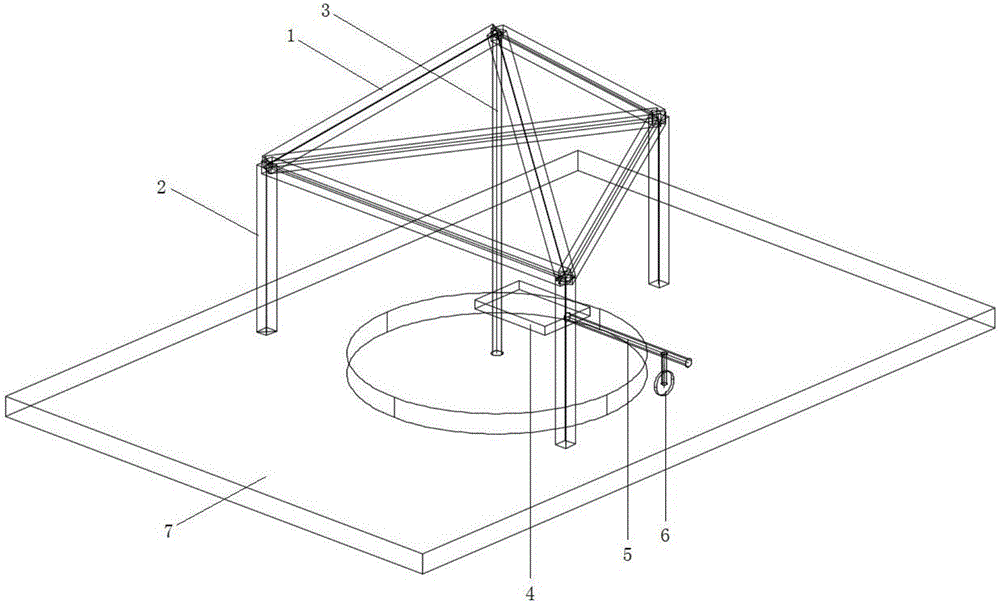

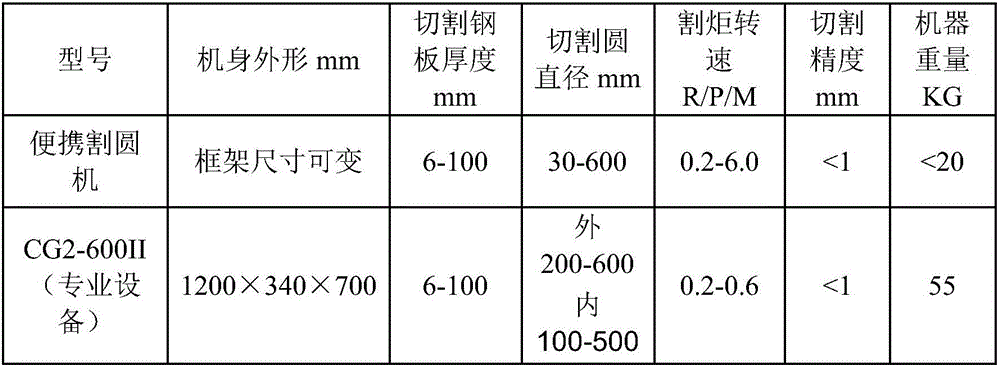

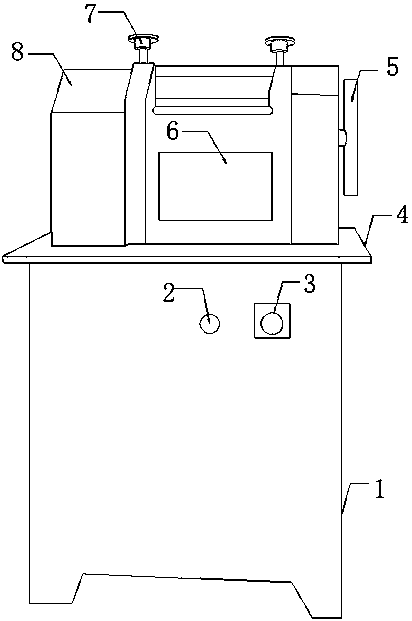

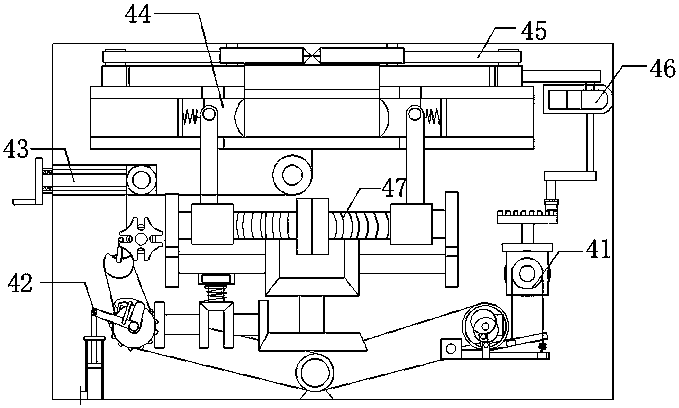

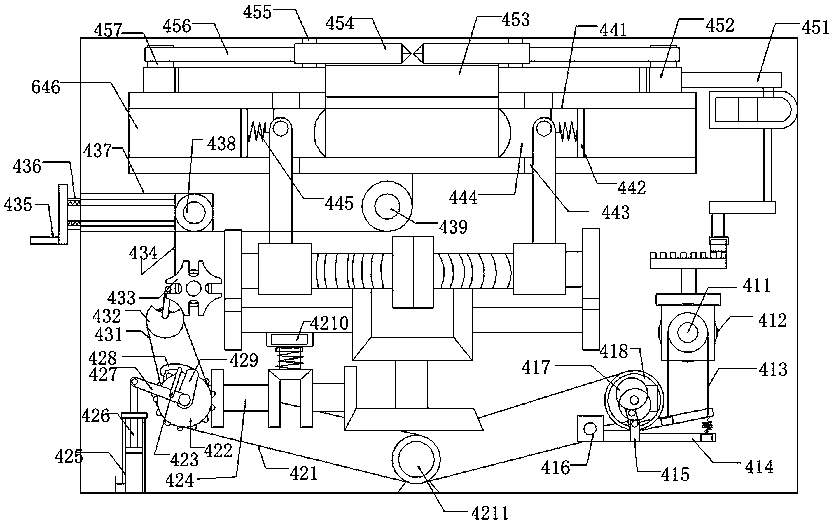

Portable circle cutting machine suitable for circular thick plate cutting and cutting method thereof

InactiveCN106583879AReduce purchasing costsLow costGas flame welding apparatusSheet steelThick plate

The invention provides a portable circle cutting machine suitable for circular thick plate cutting and a cutting method of the portable circle cutting machine. The portable circle cutting machine comprises a cutting machine and a triangular-pyramid-shaped frame. Supporting legs which are used for fixing the frame to a steel plate to be cut are arranged on the three vertexes of the bottom surface of the frame. A stand column which is used for aligning to the circle center of the steel plate to be cut is fixedly arranged below the vertex of the frame. A rotating platform where the cutting machine is placed is arranged on the lower portion of the stand column, a guide rod is transversely arranged on the outer side of the rotating platform, and a guide wheel is arranged at the lower end of the outer side of the guide rod. The portable circle cutting machine can process workpieces with the specifications beyond the working range of the circle cutting machine, can also omit the purchase expense of a circle cutting machine, saves the cost, is high in efficiency, smooth in notch and attractive, has the effect close to the effect of plasma cutting of a machine tool, can be arranged on the horizontal plane or the inclined plane in an attracted mode to conduct 0-45-degree groove cutting, and can be widely applied to petroleum, chemical engineering, shipbuilding and machining enterprises.

Owner:CNOOC ENERGY TECH & SERVICES +1

Rotatable flaking device for cable conductor insulating layer

ActiveCN108418143AAvoid entanglementShorten the lengthApparatus for removing/armouring cablesElectrical conductorWelding

The invention discloses a rotatable flaking device for a cable conductor insulating layer. The device comprises a fixed base, an indicating lamp, a starting button, an intelligent adjusting circular cutting flanking device, a movable rack, a worktable, a threaded device and a device housing. The worktable is vertical to the upper surface of the fixed base and forms an integrated structure througha welding manner. The indicating lamp and the starting button are embedded into the front surface of the fixed base in a manner of parallel in a left-and-right direction and are electrically connectedwith same. A refrigerating adjusting circular cutting flaking device is vertical to the central part of the upper surface of the worktable and furthermore is connected with same in a clearance fitting manner. The movable rack is vertically embedded into the right end surface of the intelligent adjusting circular cutting flanking device and is connected with same in a clearance fitting manner. A cable flanking device can realize automatic and accurate length controlling, and furthermore the device can utilize circular cutting for realizing smooth and attractive incision, thereby realizing a purpose of higher intelligence of the device.

Owner:嘉兴翼波电子有限公司

Cloth cutting device

ActiveCN110093773AReduce manual labor intensityQuality assuranceLiquid surface applicatorsTextile selvedgesEmulsionCushion

The invention discloses a cloth cutting device, and relates to the field of cutting devices. The cloth cutting device comprises a first cylinder above a workbench and a second cylinder below the workbench, wherein the first cylinder is provided with a heating device and a cushion block, the second cylinder is provided with a brush and a cutter, the first cylinder is connected with a first gear, the first gear is connected with a second gear, one side of the second gear is connected with the second cylinder, the other side of the second gear is connected with a stepping motor, a proximity switch is arranged below the workbench, and the two ends and two sides of the workbench are provided with clamping devices. The cloth cutting device has the advantages that the stepping motor and the gearsdrive the devices on the first cylinder and second cylinder to apply a white emulsion on a cutting line to bond a yarn, the white emulsion is heated and dried, then a knife is used for cutting to complete cutting, the occurrence of raw edges is avoided, the later processing and use are facilitated, the generation of fluffs, dust and the like is also prevented from polluting the working environment, a healthy working environment is created for workers, no dust removal device needs to be additionally arranged, the cutting process is integrated and automatic, the labor is saved, and the cuttingquality is ensured.

Owner:佛山市顺德区新飞腾纺织服装有限公司

Bread slicing machine

InactiveCN112776021ASimple structureIngenious designMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a bread slicing machine, and relates to the technical field of food processing equipment. The bread slicing machine comprises a case, wherein a placing table and a motor are fixedly mounted in the case, a material containing box is fixedly mounted on the placing table, a through hole is formed in the rear side wall of the material containing box, a feeding mechanism is connected in the through hole, a notch is formed in the placing table, and a baffle plate is connected to the placing table; an output shaft of the motor is connected to a first eccentric wheel and a second eccentric wheel, the first eccentric wheel is slidably connected to a first annular component, the second eccentric wheel is slidably connected to a second annular component, the left side and the right side of the first annular component are fixedly connected to a first connecting rod and a second connecting rod respectively, and the bottom of the first connecting rod is detachably connected to a cutter; a long-strip-shaped opening is formed in the second connecting rod, a supporting rod is fixedly mounted in the machine box, and the supporting rod is arranged in the long-strip-shaped opening. The bread slicing device solves the problems that in the prior art, a bread slicing device cannot slice bread in batches, and the thickness of the sliced bread cannot be accurately mastered, so that operation is easy and convenient, and practicability is high.

Owner:合肥市福客多快餐食品有限公司

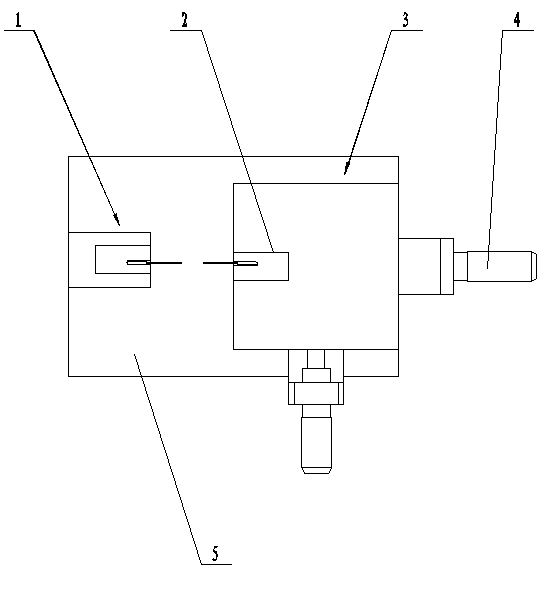

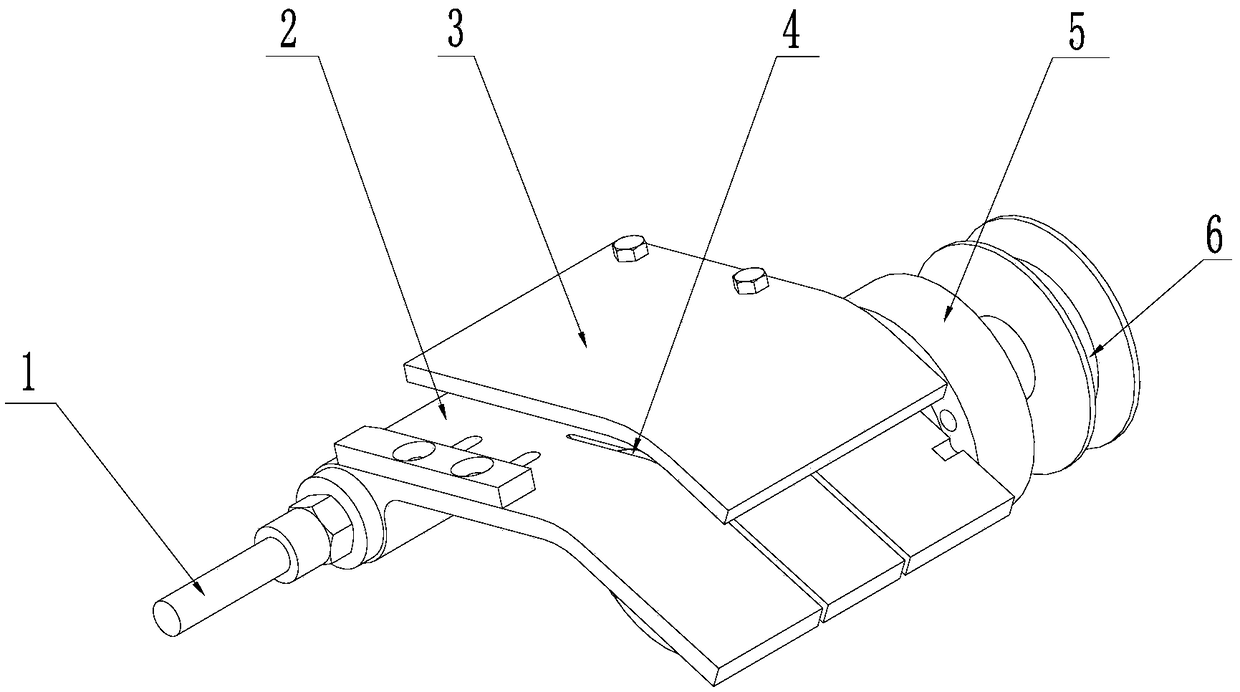

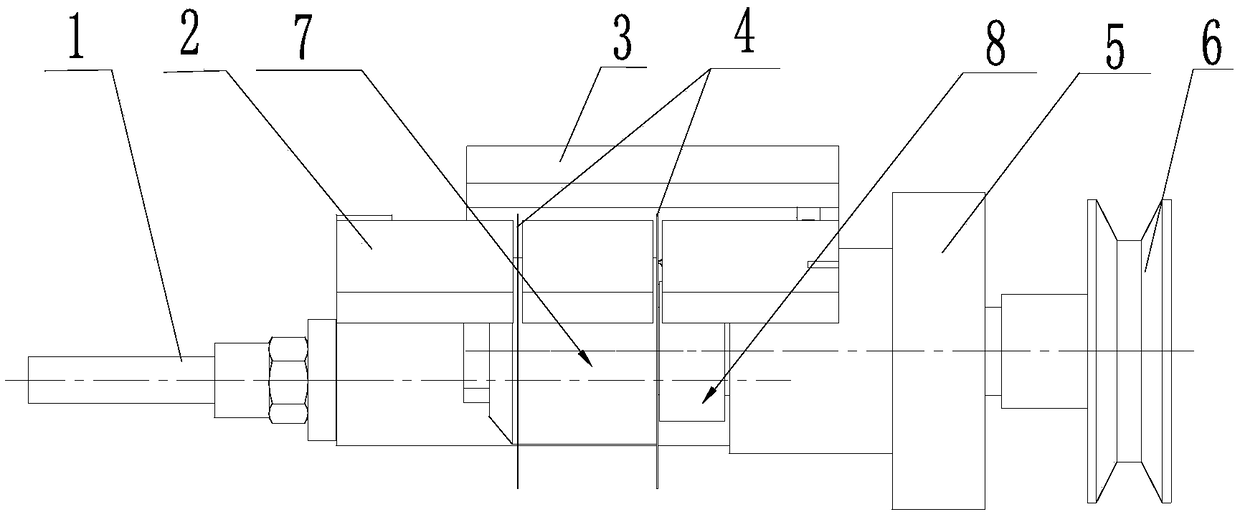

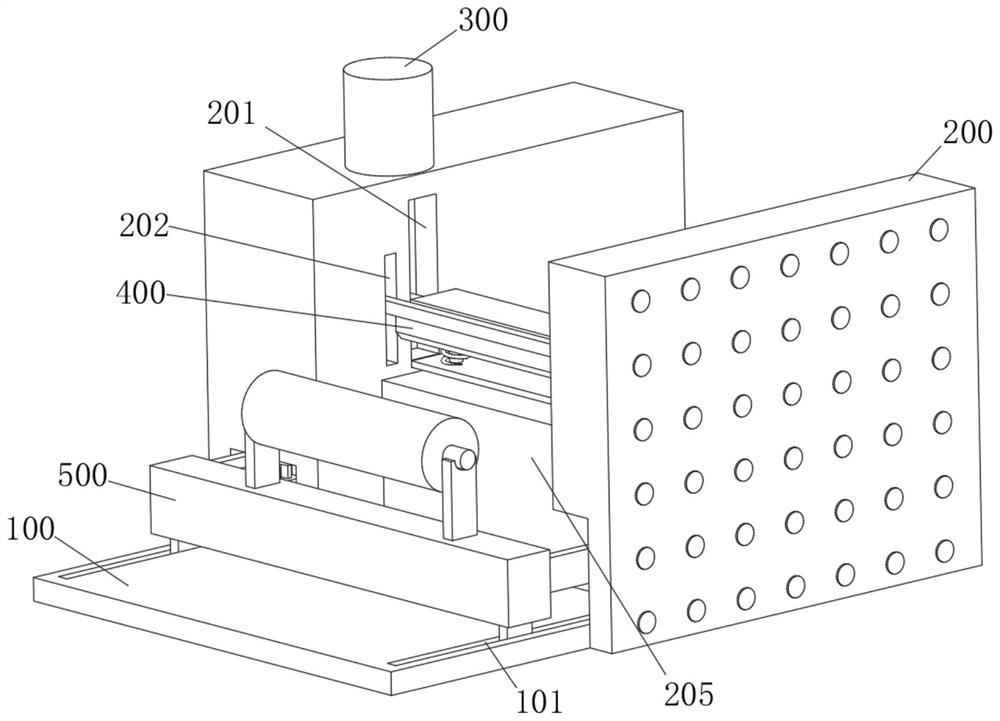

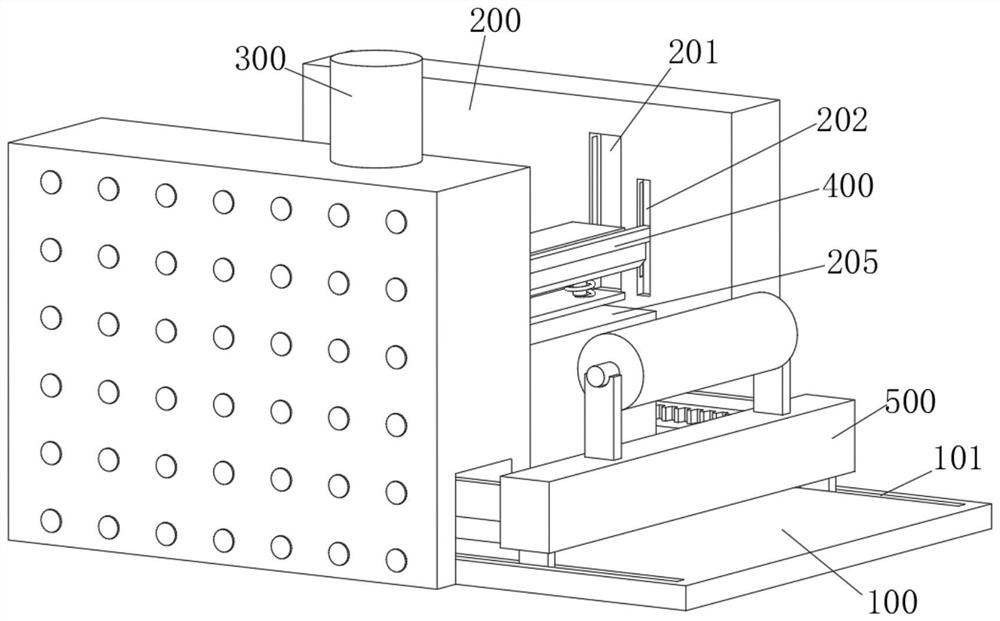

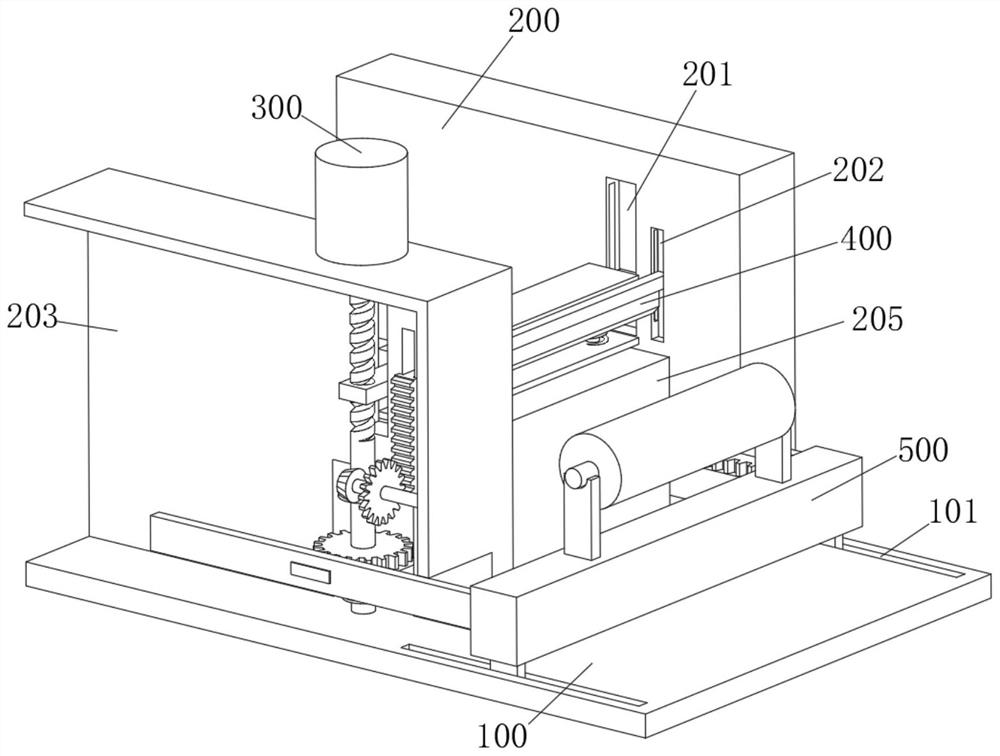

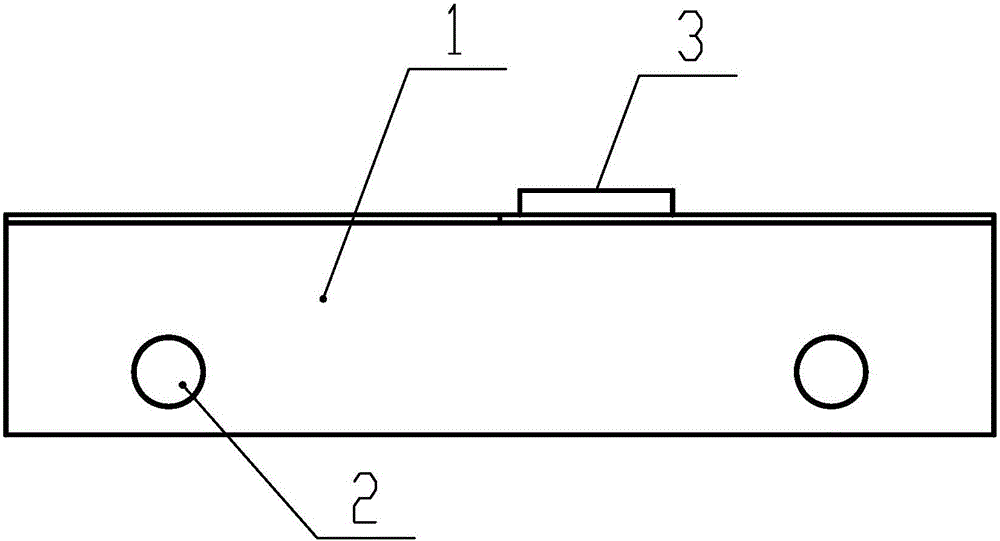

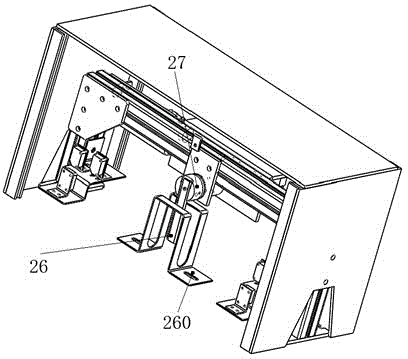

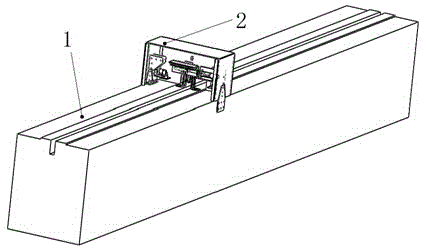

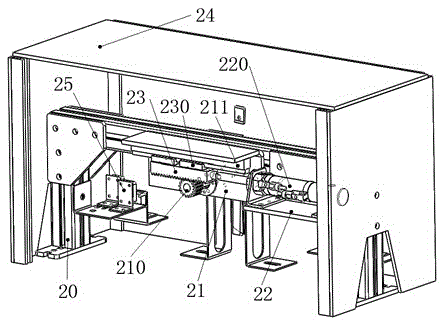

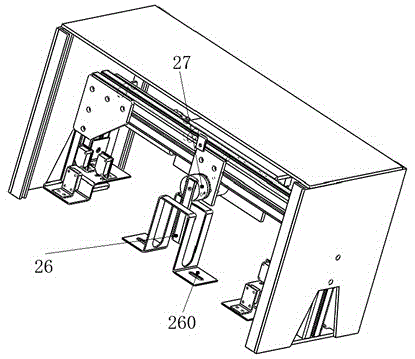

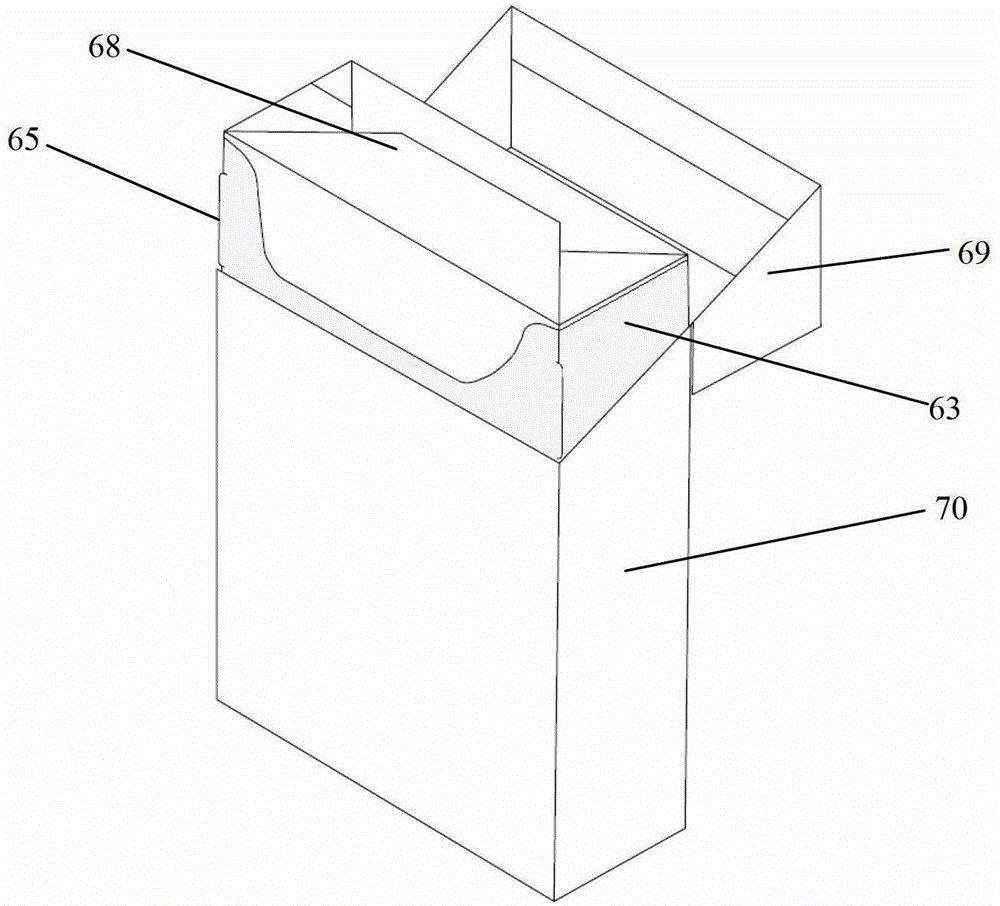

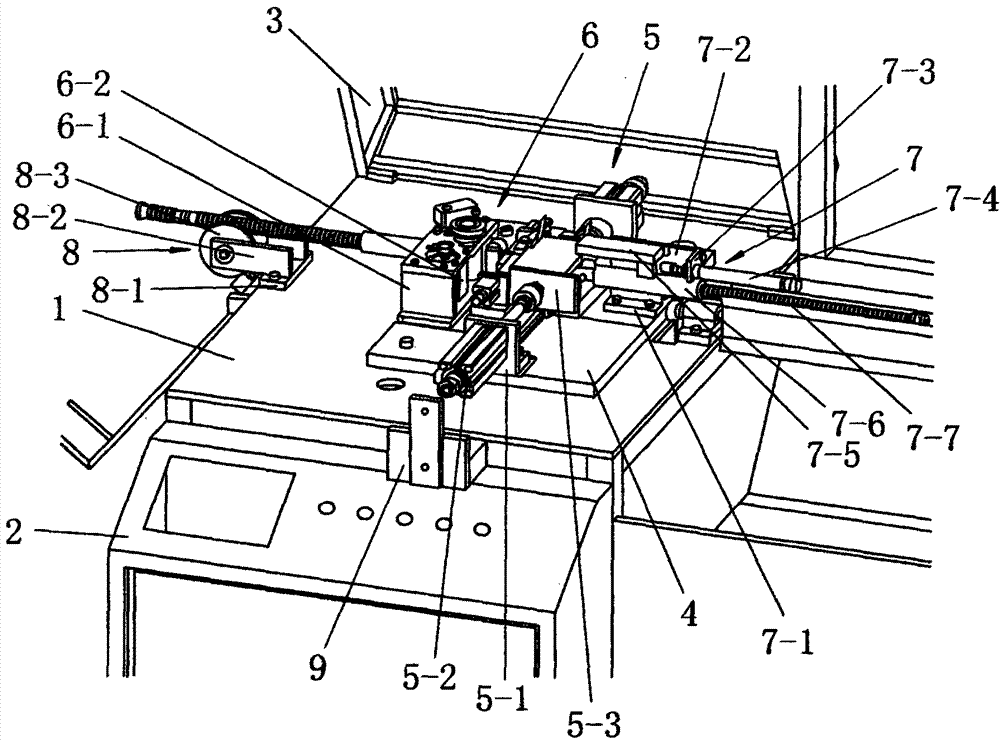

Door pocket film automatic cutting device

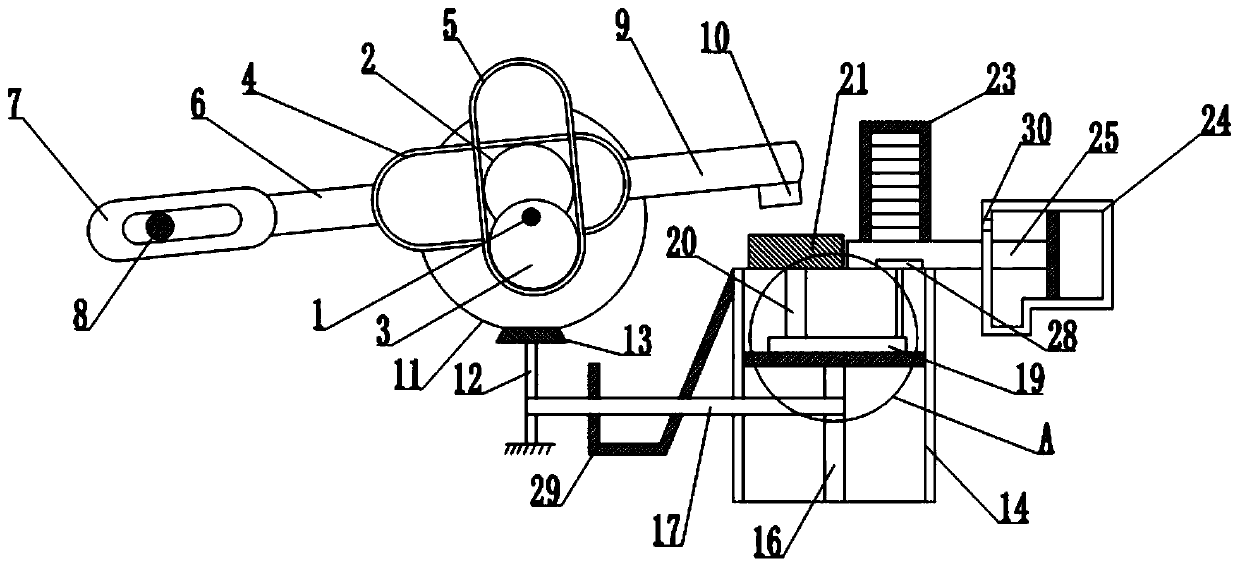

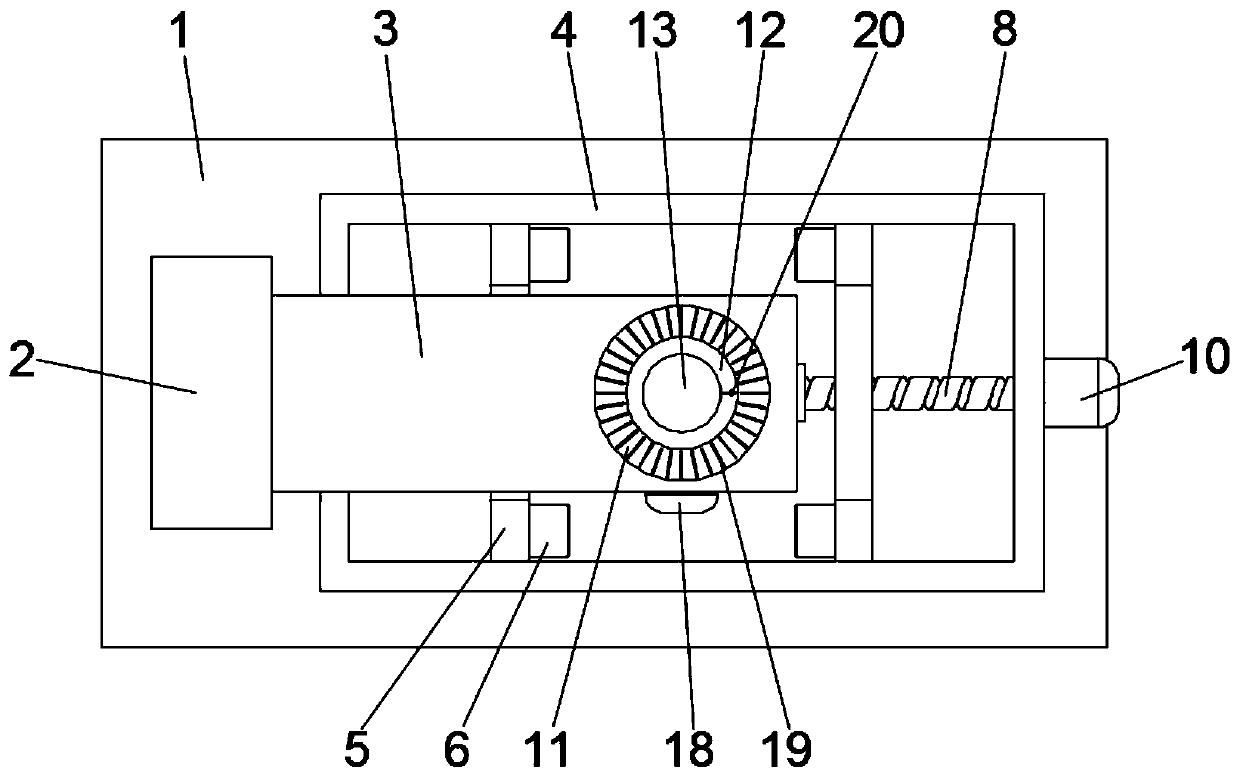

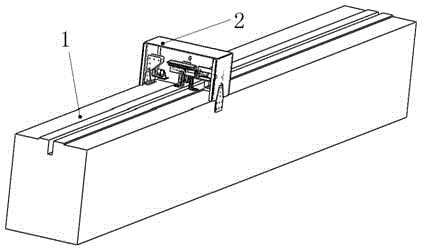

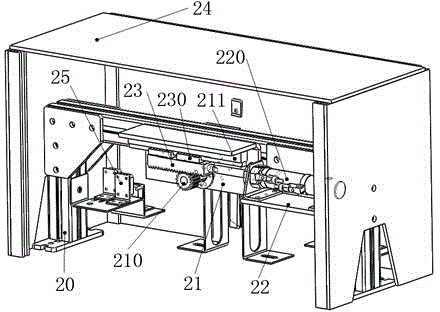

ActiveCN104552413ABeautiful incisionImprove film cutting efficiencyMetal working apparatusLinear motionEngineering

The invention discloses a door pocket film automatic cutting device and relates to film cutting devices. According to the technical scheme, the door pocket film automatic cutting device comprises a base (1) and a film cutting mechanism (2) arranged on the base (1), the film cutting mechanism (2) comprises a door-shaped bracket (20), a cylinder (220), a gear shaft (210), a rack (23) and a cutter (26), the cylinder (220) is fixed to the door-shaped bracket (20) through a cylinder support plate (22), the gear shaft (210) is fixed to the door-shaped bracket (20) through a gear shaft support plate (21), the cutter (26) is fixed to the other end of the gear shaft (210), the working end of the cylinder (220) is connected to the rack (23), the gear shaft (210) is matched with the rack (23) during film cutting, and a chute (230) is arranged at the upper end of the rack (23) and matched with a sliding block (211) arranged on the gear shaft support plate (21). The door pocket film automatic cutting device uses the cylinder as a power source, achieves film cutting by converting the reciprocating linear motion of the cylinder into the rotary motion of the gear shaft, completes the whole film cutting process automatically and is neat and attractive in appearance of cut and high in film cutting efficiency.

Owner:HITACHI ELEVATOR CHENGDU

A kind of preparation method of antibacterial and anti-inflammatory toothpaste containing pure natural plant extract

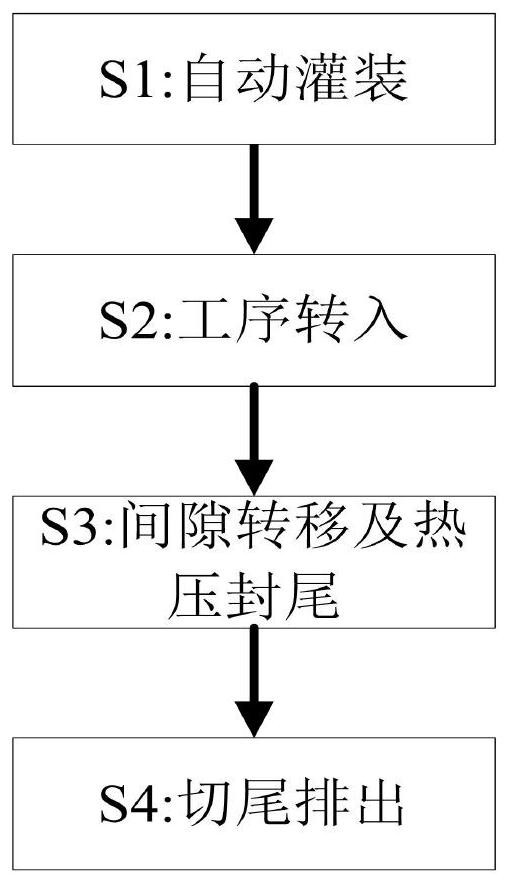

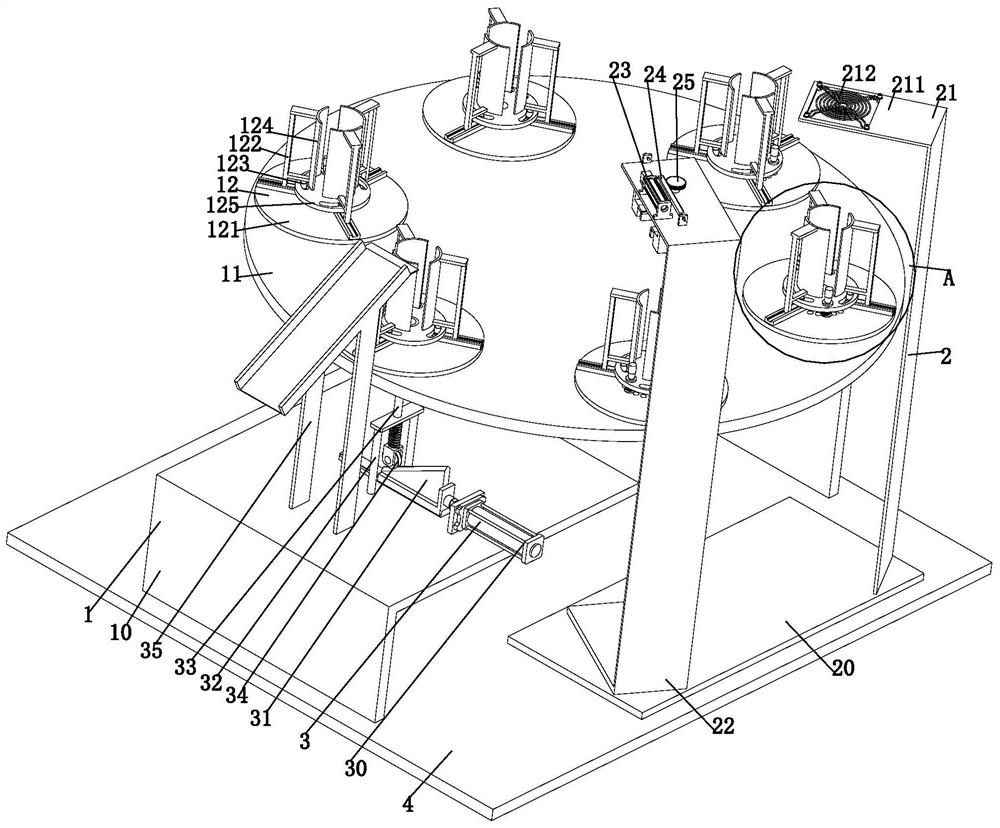

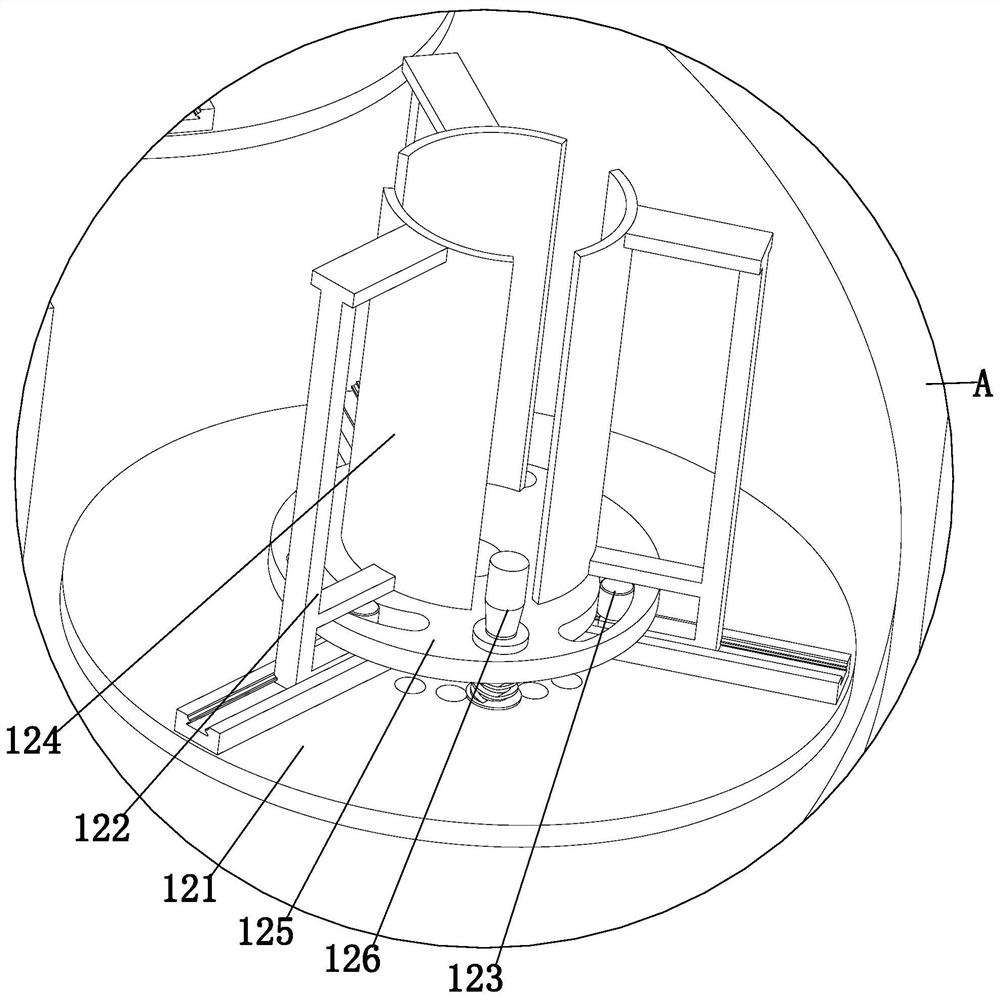

ActiveCN113120352BPrevent tippingAvoid deformationWrapper twisting/gatheringPackaging machinesToothpaste ProductAnti bacterial

The invention provides a method for preparing an antibacterial and anti-inflammatory toothpaste containing pure natural plant extracts, which includes a surrounding mechanism, a hot-pressing mechanism, a top-down mechanism and a bottom plate; the invention solves the problems existing in the sealing process of empty toothpaste tubes today: Toothpaste empty tubes can only be guided and fixed for one type and size of toothpaste empty tubes when sealing, which limits the sealing range of toothpaste empty tubes and cannot meet market demand, and cannot stabilize the transmission process of sealing, reducing toothpaste empty tubes. The quality of the tube sealing; the empty toothpaste tube after sealing needs to be clamped to the tail cutting machine for tail cutting. This method cannot stabilize the tail cutting process, resulting in uneven cuts at the end of the toothpaste empty tube, which reduces the quality of the toothpaste finished product The packaging quality of toothpaste is manually transferred during the sealing process, which increases the labor intensity of the workers. A series of steps such as preheating, hot-press sealing, tail cutting, and top-contact discharge cannot be realized in the sealing process. , Reduced production efficiency and other issues.

Owner:广东日和堂医药科技有限公司

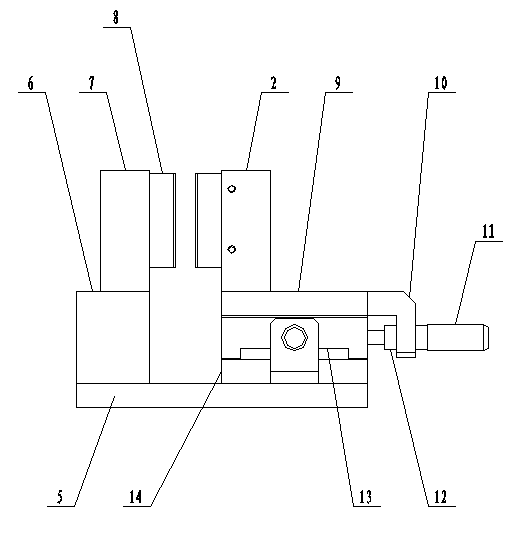

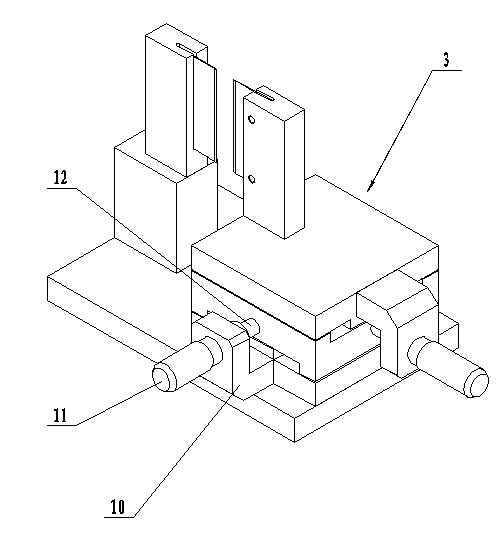

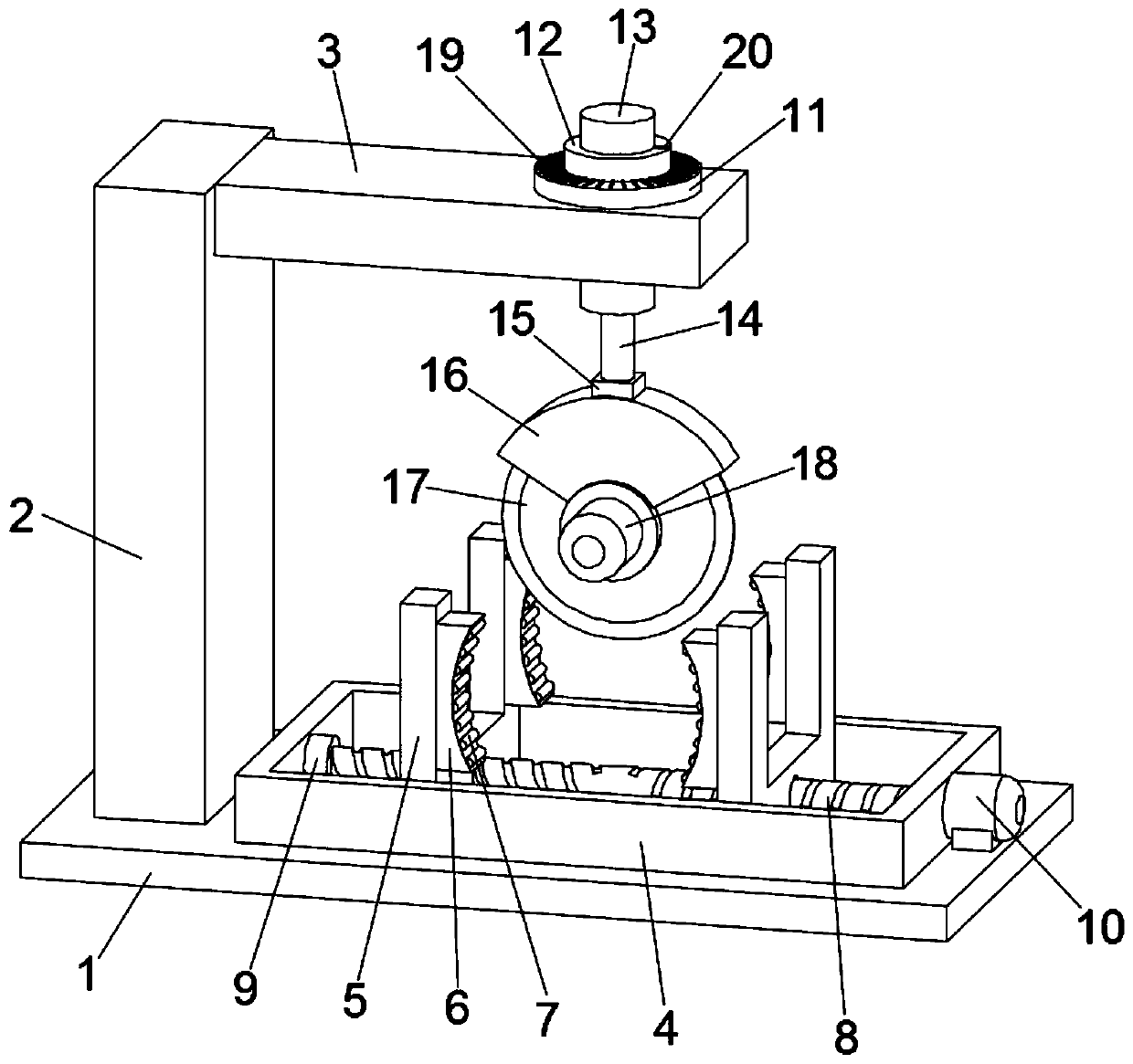

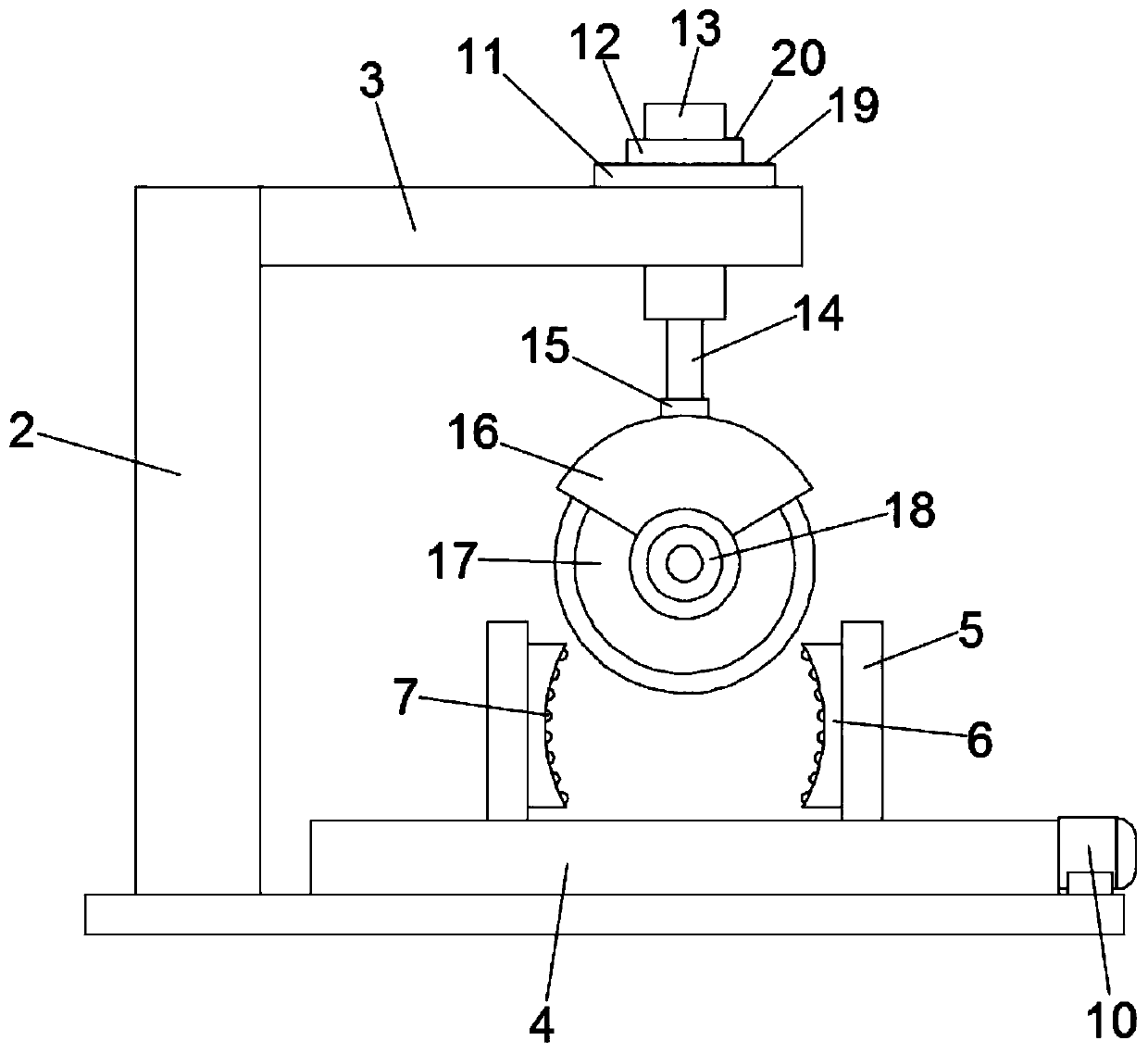

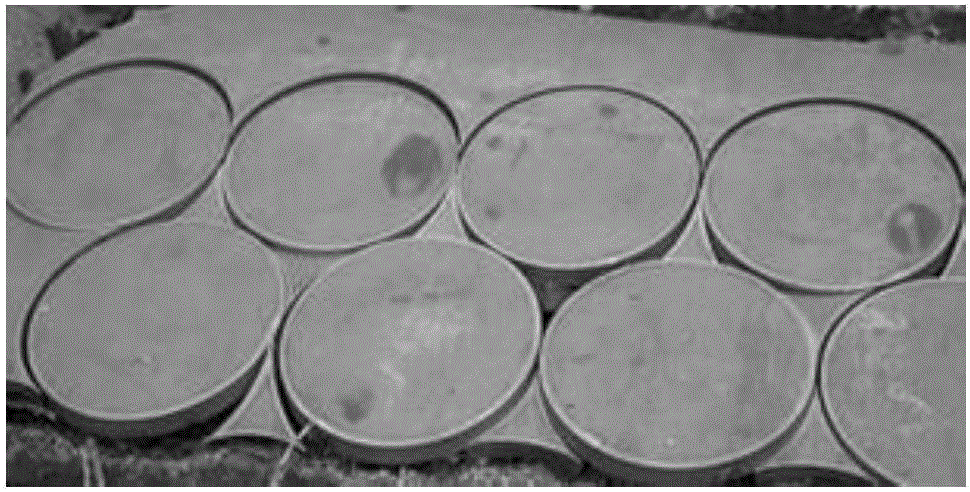

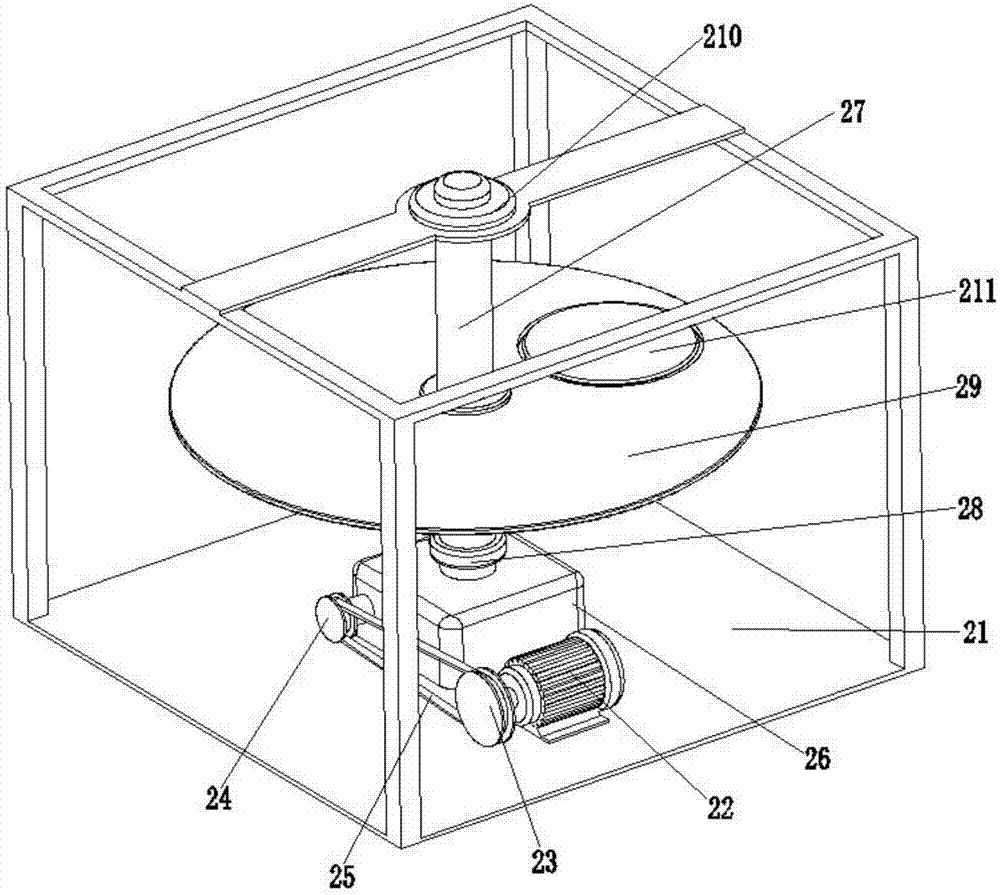

Rotary cutting device of kudzu root slicer

The invention relates to a rotary-cutting device of a kudzuvine root slicing machine. The rotary-cutting device comprises a rotary-cutting support, an electric motor, a driving pulley, a driven pulley, a driving belt, a speed reducer, a rotary-cutting rotating shaft, a coupling, a rotary-cutting rotating disk, a rotary-cutting bearing, a rotary-cutting knife, a rotating motor and a support frame, wherein the electric motor is located on a connecting platform at the lower end of the rotary-cutting support, the driving pulley and the driven pulley are connected through the driving belt, the upper end of the rotary-cutting rotating shaft is fixed in the middle of a cross bar at the upper end of the rotary-cutting support through the rotary-cutting bearing, the rotary-cutting rotating disk is located in the middle of the rotary-cutting rotating shaft, a rotary-cutting through hole is formed in the rotary-cutting rotating disk, the rotary-cutting knife is located in the rotary-cutting through hole and is made of stainless steel, and the rotating motor is located right below the rotary-cutting knife and fixed below the rotary-cutting rotating disk through the support frame. The rotary-cutting rotating disk and the rotary-cutting knife can rotate concentrically at the same speed, kudzuvine roots are sliced, slices are uniform in thickness, cuts are attractive in appearance, and the overall efficiency of slicing of the kudzuvine roots is improved.

Owner:南通江海港建设工程有限公司

A door cover automatic film cutting device

ActiveCN104552413BBeautiful incisionImprove film cutting efficiencyMetal working apparatusLinear motionEngineering

Owner:HITACHI ELEVATOR CHENGDU

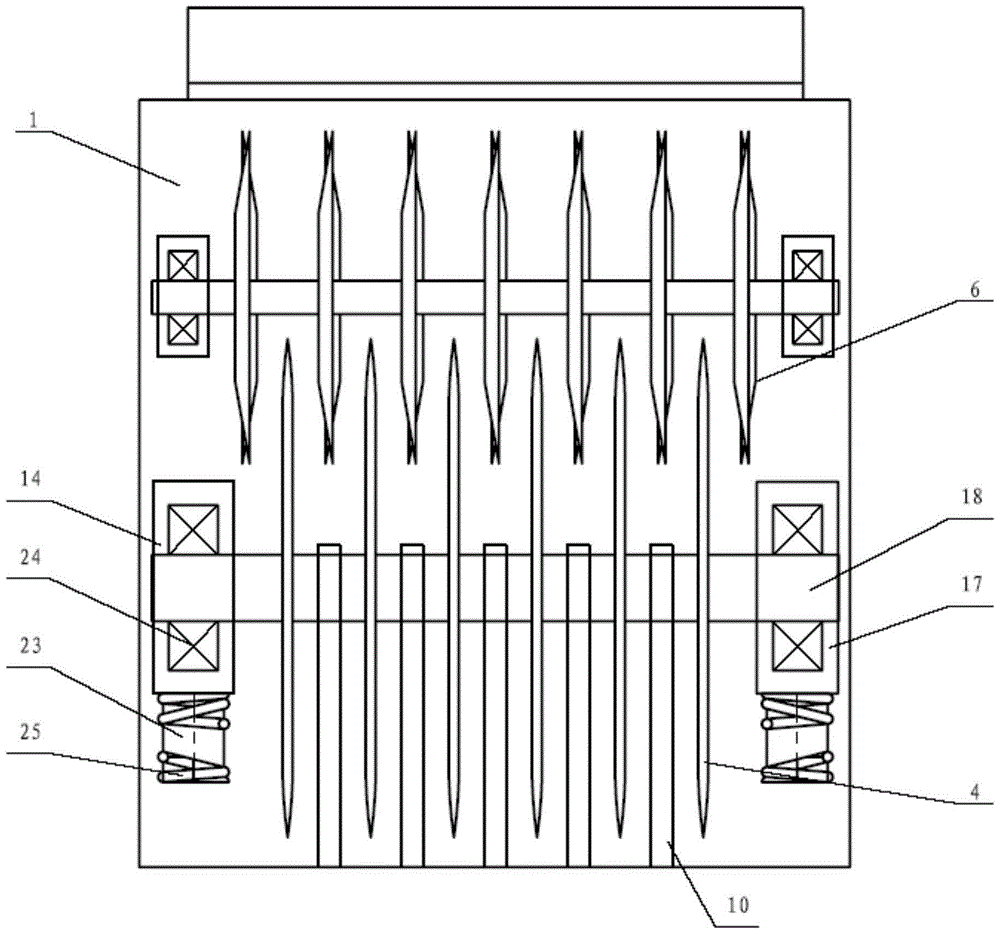

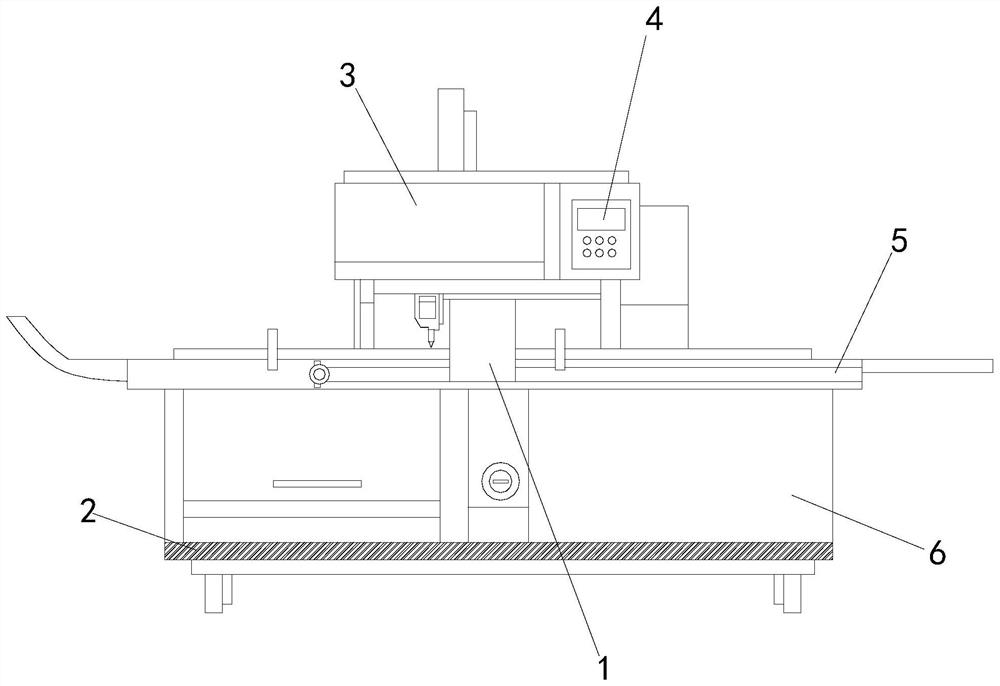

Automatic paper cutting machine for air conditioner filter element

InactiveCN107175704AIncrease the filter paper gapSave man hoursMetal working apparatusPulp and paper industryFilter paper

The invention provides an automatic paper cutter for an air filter element. A first workbench is provided at the exit of the paper folding machine, and a second workbench and a third workbench are successively arranged behind the first workbench. The first workbench There is a first cylinder on the top; a third cylinder is set on the lower part between the first workbench and the second workbench, and a fourth cylinder is set on the upper part. The filter paper clamping mold is also installed on the third cylinder, and the filter paper clamping mold is installed on the third cylinder. A paper cutter is provided upwards through the sliding cylinder in the middle, and a filter paper pressing mold is provided downwards in the fourth cylinder, and the filter paper pressing mold and the filter paper pressing mold correspond to the folding edge of the filter element; between the second workbench and the third workbench There is a conveyor belt, and the conveyor belt works by pressing through the second cylinder. The invention greatly saves man-hours, the number of folds of paper cutting can be controlled more accurately, and the incision is smooth and beautiful, and it only takes less than 10 seconds to complete a process.

Owner:SHIYAN FUERDUN TECH CO LTD

Fiber blanket slitter

The invention discloses a fiber blanket slitter. The fiber blanket slitter structurally comprises a thread reaming frame machine body, a base plate, a slitting box device, a controller, a machining table and a loading table. The base plate is installed below the loading table and connected with the loading table in a locked manner. According to the fiber blanket slitter, the problems that when a slitting process is conducted on a fiber blanket, due to the special material of the blanket, cuts tend to be irregular, so that filamentary materials inside the blanket tend to get out, a finished product of the blanket looks not quite attractive due to the filamentary materials in disarray distribution, and the next process cannot be carried out quickly and conveniently are solved; with the slitter, the oblique cuts and filamentary materials which are not cut in place are used in sufficient cooperation, so that the cuts look more attractive, and furthermore, the filamentary materials at the cuts can be collected more conveniently due to mutual cooperation between retrieving barrel devices, and the trouble of extra manual cleaning is avoided.

Owner:刘清杰

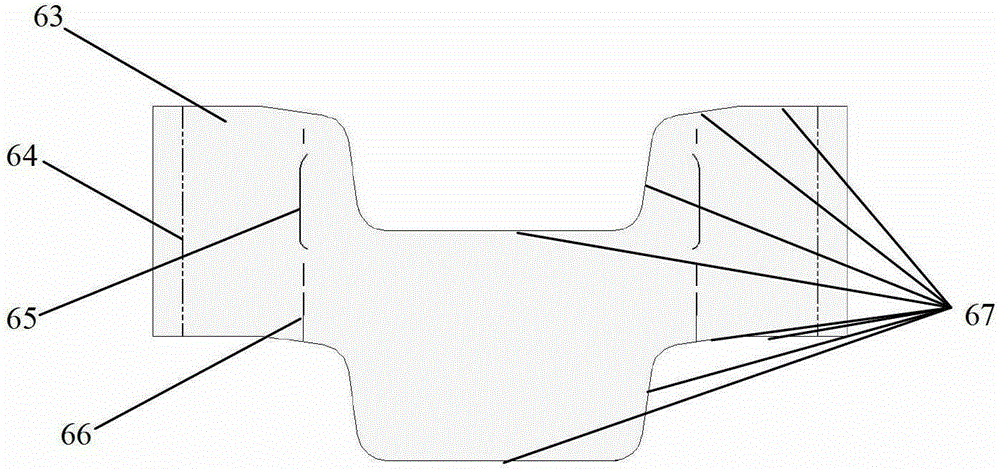

Cutting and conveying device and method for inner frame paper of reversible hard box cigarette pack

ActiveCN104044775BEasy to change sizeBeautiful incisionWrapping material feeding apparatusPackaging cigarettePulp and paper industryPaper cut

Owner:CHINA TOBACCO MACHINERY TECH CENT

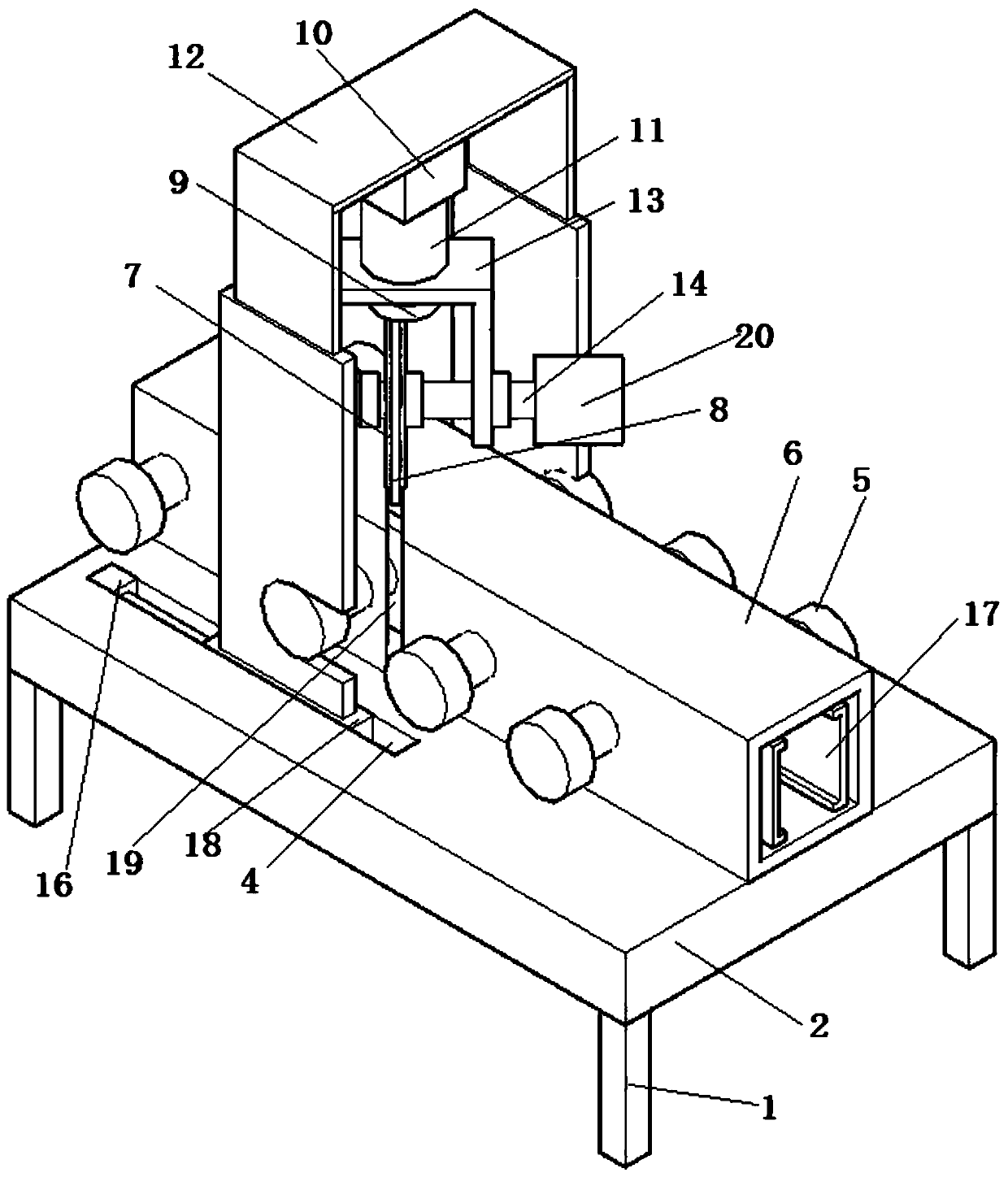

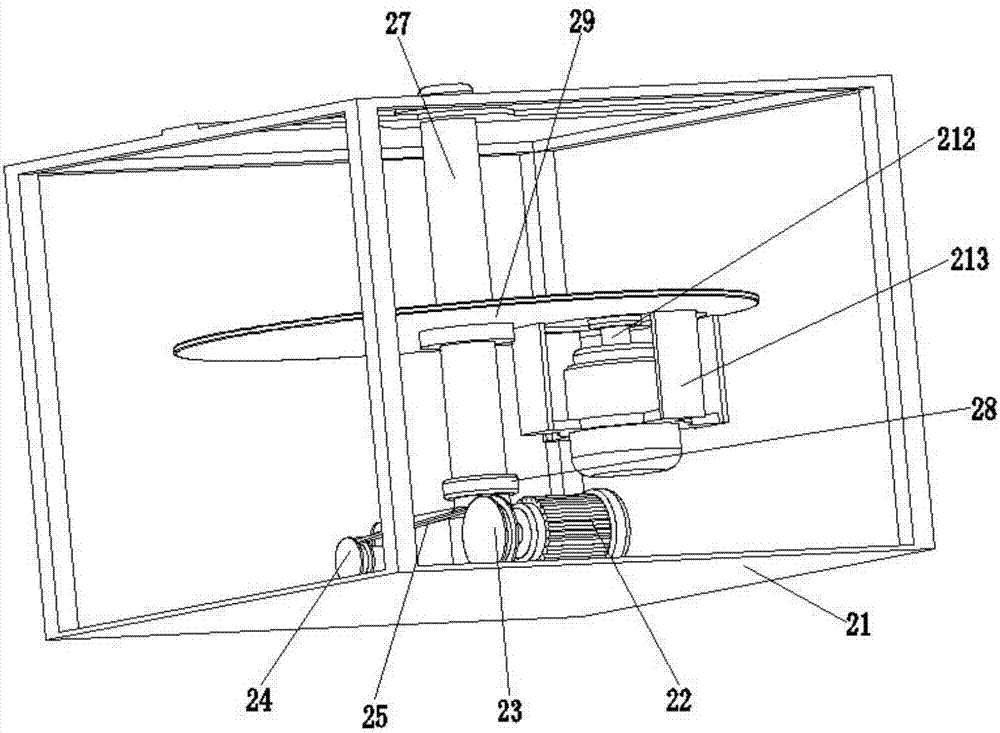

A liftable kudzu root slicer

ActiveCN106346529BImprove slicing efficiencyHigh degree of automationStands/trestlesMetal working apparatusEngineeringAutomation

The invention relates to a liftable kudzuvine root slicing machine. The slicing machine comprises a moving base, a rotary-cutting device and a clamping device, wherein the rotary-cutting device is located right above the moving base and fixedly connected with the moving base, and the clamping device is located in front of the rotary-cutting device and fixedly connected with the rotary-cutting device. The slicing machine can automatically slice kudzuvine roots in different sizes and shapes, the slicing efficiency is high, the attractiveness of slices is good, the breakage phenomenon in the slicing process is reduced, and the automation degree is high.

Owner:南通江海港建设工程有限公司

A fully automatic cutting machine

ActiveCN104816321BSave human effortIncrease production capacityMetal working apparatusOptical axisEngineering

The invention discloses a fully automatic cutting machine, which comprises a frame, a control box and a protective shell. The frame is provided with a bottom plate, and the bottom plate is provided with a cutting device, a driving device, a feeding device, a guiding device and an adjusting device; The cutting device includes a cylinder holder, a cutting cylinder and a knife holder, the cutting cylinder is installed on the cylinder holder, and the cutting cylinder is connected to the knife holder; the driving device includes a support, and a stepping motor is installed on the support; The feeding device includes a feeding base plate, a connecting plate is fixed on the feeding base plate, the connecting plate is connected to the cylinder fixing plate, the cylinder fixing plate is installed and fixed with a cylinder, the cylinder is connected to the guide rail, the bottom end of the guide rail is connected to the moving conduit, and the moving conduit is covered with an optical axis. The optical axis passes through the cutting device, the driving device, and is mounted on the guiding device. Compared with the prior art, the present invention has the advantages that: the structure of the present invention can realize the mechanical cutting of rubber hoses for air conditioners, save manpower, increase production capacity, and reduce product defective rate, and at the same time, the cuts are neat and beautiful.

Owner:JIANGMEN HONGMEIDA RUBBER PLASTICS PROD CO LTD

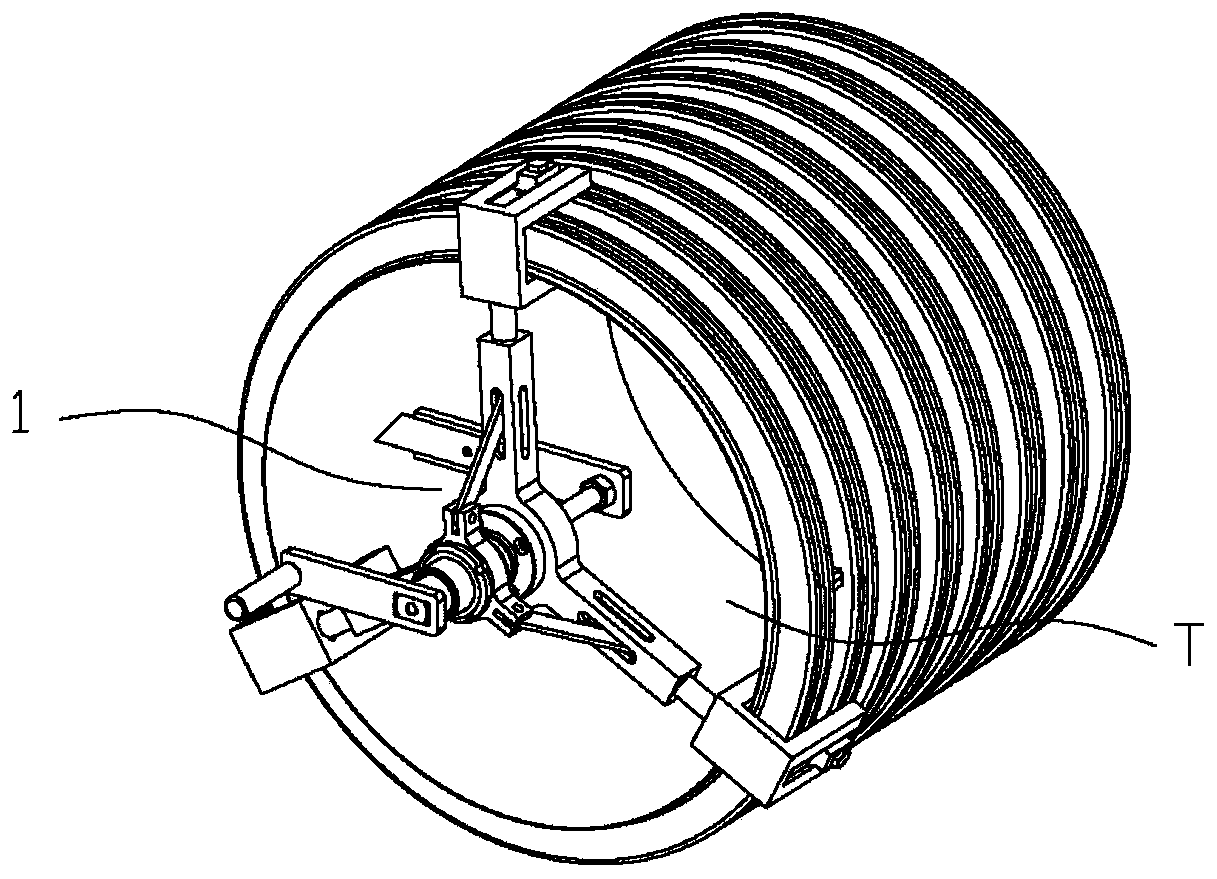

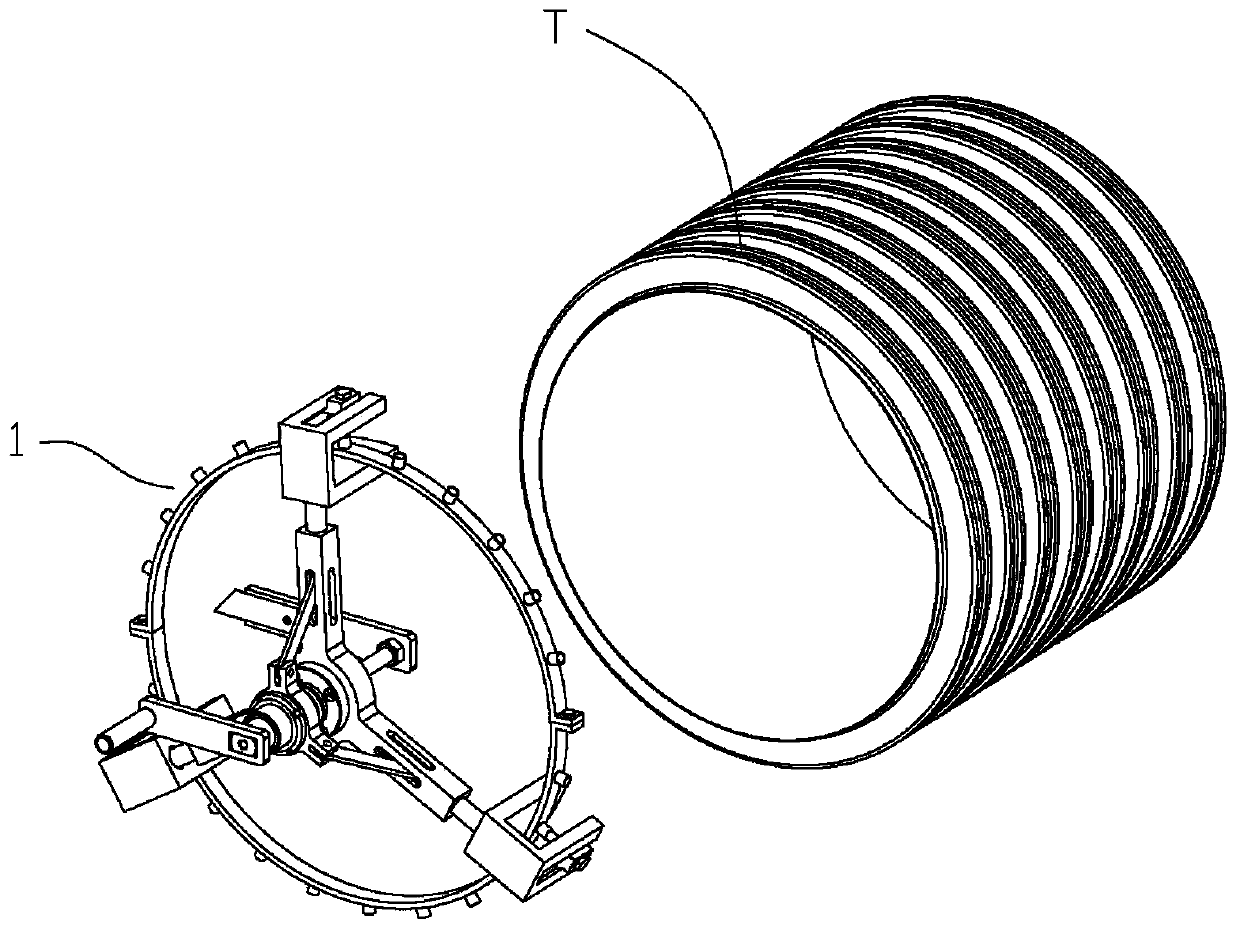

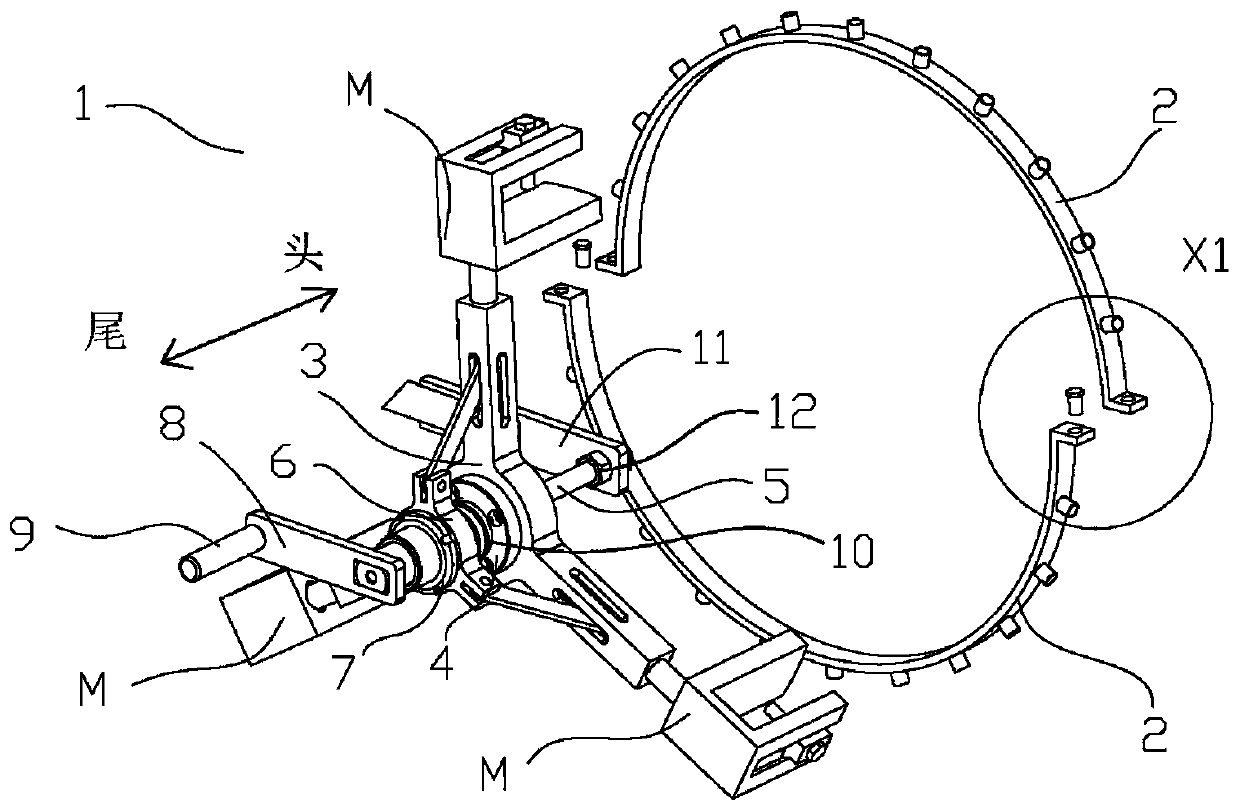

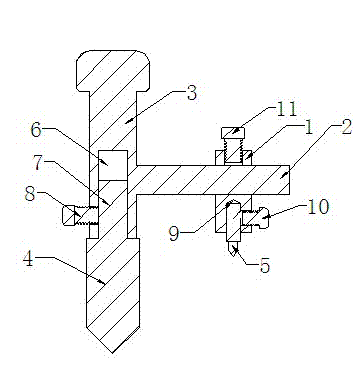

Double-wall corrugated pipe cutter

ActiveCN111318753AEfficient cuttingBeautiful incisionTube shearing machinesStructural engineeringLantern

The invention discloses a double-wall corrugated pipe cutter. The double-wall corrugated pipe cutter comprises a pair of positioning hoops, a main support, a main rotating shaft, a main cylinder seat,a reset spring, a connecting fork, an annular screw-in snap ring, a handle and three detachable stretching assemblies; the main support comprises an annular main lantern ring, three long-strip-shapedmain transverse strips are arranged on the side wall of the main lantern ring; the main rotating shaft penetrates through the main lantern ring; the main cylinder seat is arranged at the tail part ofthe main rotating shaft; the reset spring is arranged on the main cylinder seat; the connecting fork is arranged on the main cylinder seat and extrudes the reset spring; the annular screw-in snap ring is arranged on the main cylinder seat and extrudes the connecting fork; the handle is connected with the main rotating shaft; and the three detachable stretching assemblies are arranged between theconnecting fork and the main support, and each stretching assembly comprises a long-strip-shaped first connecting piece, a rod-shaped second connecting piece, a door-shaped clamping support and a clamping sliding block. According to the double-wall corrugated pipe cutter, due to the fact that the three stretching assemblies are adopted, effectively cutting the inner wall of a pipe by blades can becarried out, notches are neat and attractive, the operation is easy, and the cutting efficiency is high.

Owner:江苏恒昌波纹管有限公司

Tapping and positioning mould of heat-shrinkage casing pipe on surface of copper bar

InactiveCN102773874AStandard beautyPrecise positioningMetal working apparatusEngineeringKnife blades

The invention discloses a tapping and positioning mould of a heat-shrinkage casing pipe on the surface of a copper bar, and belongs to the technical field of high-voltage power transmission and distribution equipment. The tapping and positioning mould of the heat-shrinkage casing pipe on the surface of the copper bar comprises a cutter rest and a main shaft fixing frame with a cutter rest guide rail; the cutter rest is installed on the cutter rest guide rail and can move left and right along the cutter rest guide rail; the lower end of the main shaft fixing frame is provided with a detachable hole positioning shaft; and the lower end of the cutter rest is provided with a detachable cutter blade. After the structure is adopted, because of the arranged main shaft fixed frame and hole positioning shaft, positioning is carried out when tapping is required; then the tapping is carried out by the cutter blade on the cutter rest, the positioning is accurate, and a notch is beautiful; and meanwhile, because the hole positioning shaft and the cutter rest can be adjusted, holes with different sizes can be tapped, the tapping requirement of various diameters can be met; and with the device, the positioning is accurate, and the cutting speed is high, thus tapped holes are standard and beautiful, meanwhile, the working efficiency is also improved, and the production cost is lowered.

Owner:镇江大全智能电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com