Rotatable flaking device for cable conductor insulating layer

A cable conductor and insulation layer technology, which is applied in the direction of cable installation devices, cable installation, dismantling/armored cable equipment, etc., can solve the problems of flat and beautiful cuts, inability to limit the position of cables, and inability to control the length of devices, etc., to achieve The effect of preventing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

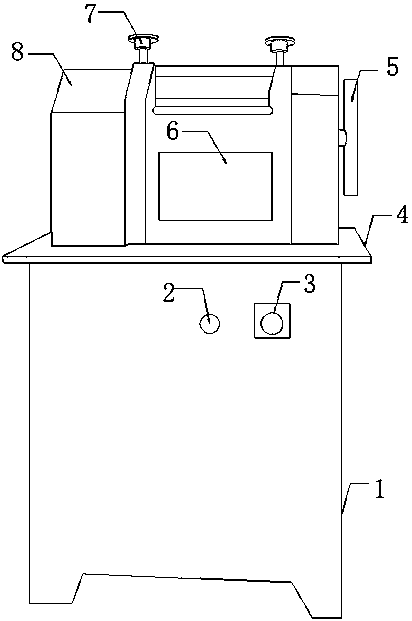

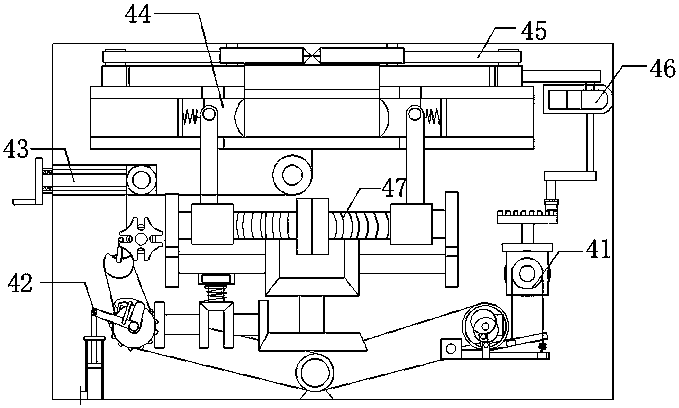

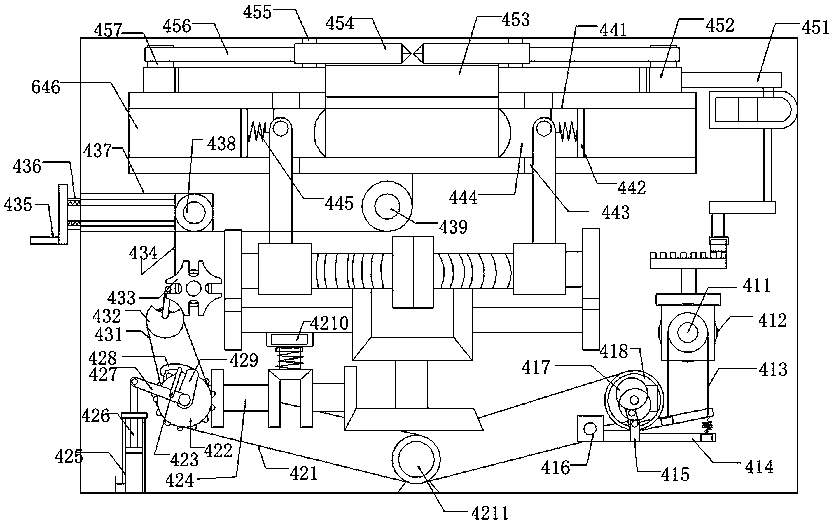

[0028] see Figure 1-Figure 5 , the present invention provides a cable conductor insulation layer rotary shaving device, the structure of which includes: a fixed base 1, an indicator light 2, a start key 3, an intelligent adjustment ring cutting shaving device 4, a movable frame 5, a workbench 6, a threader 7, The device housing 8, the workbench 6 is perpendicular to the upper surface of the fixed base 1 and the two form an integrated structure by welding, the indicator light 2 is parallel to the start key 3 and embedded in the front surface of the fixed base 1 at the same time And it is electrically connected with it, and the described refrigeration adjustment circular cutting and flaking device 4 is perpendicular to the center of the upper surface of the workbench 6, and the two are connected together by clearance fit, and the movable frame 5 is vertically embedded in the intelligent adjustment circular cutting and flaking device 4. The right end faces are connected together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com