Roller scraping cutter

A scraper and roller technology, used in glass manufacturing equipment, glass cutting devices, glass production, etc., can solve the problems of roller scraper slippage, weakening the effect of vibration impact, unable to obtain vibration impact, etc., achieving beautiful incisions and minimal formation of horizontal cracks the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

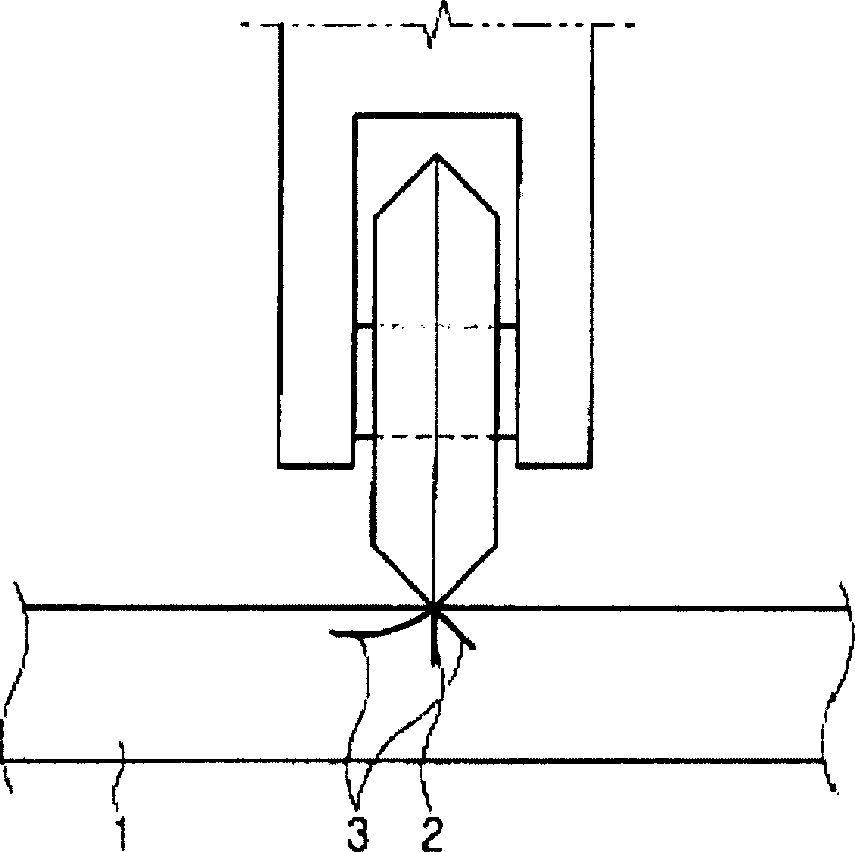

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

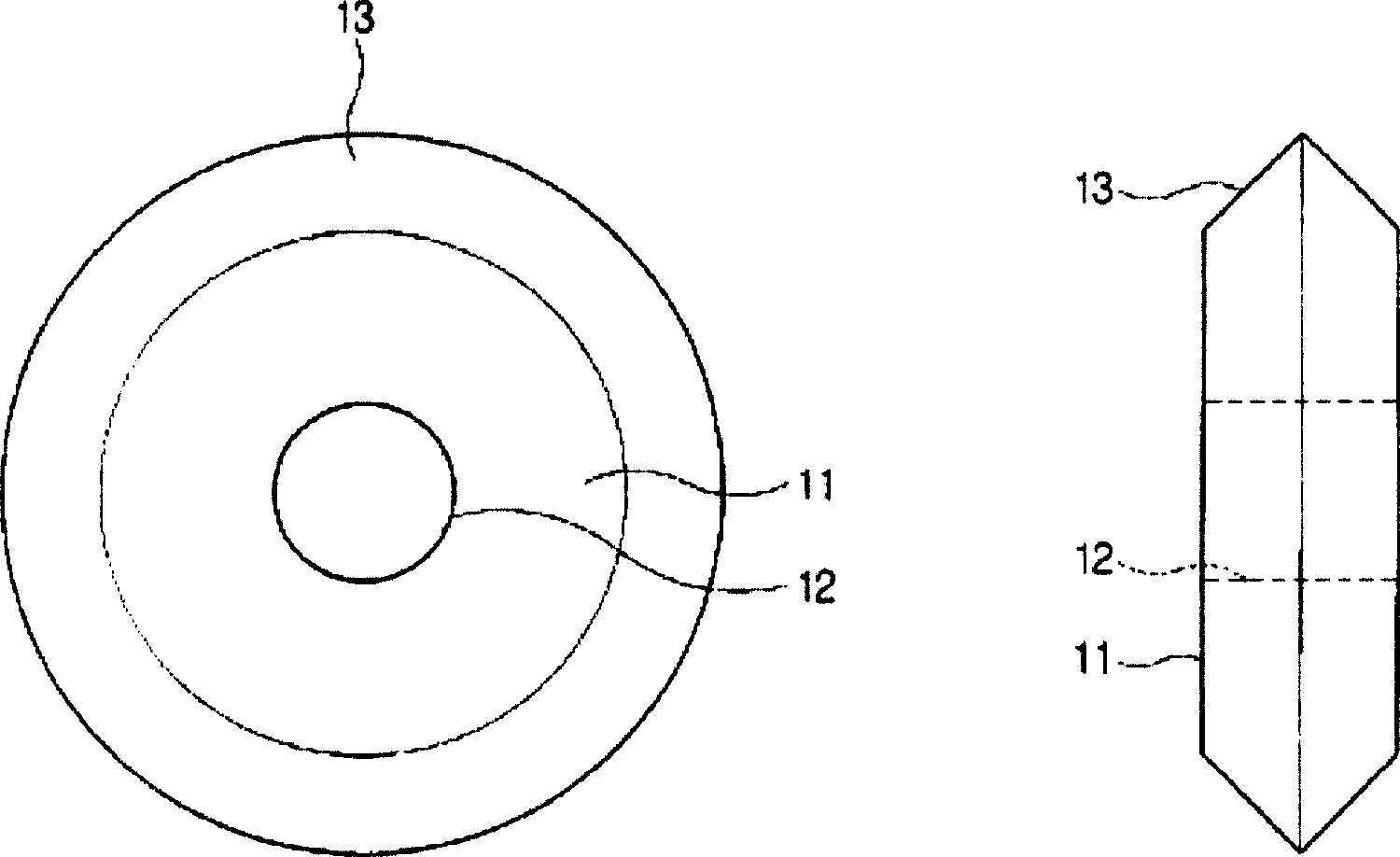

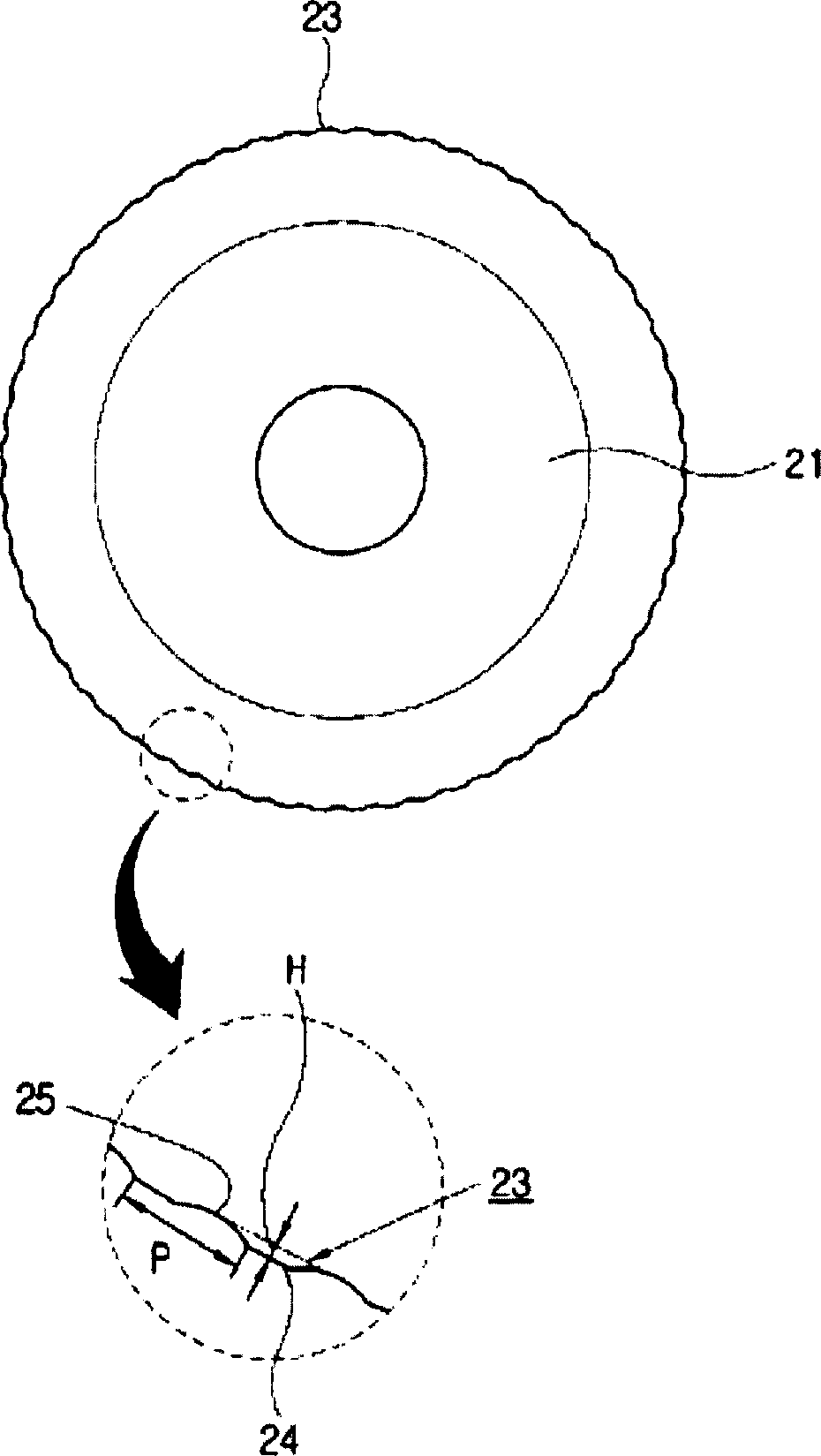

[0029] Such as Figure 5a and Figure 5b As shown, one embodiment of the roller scraper of the present invention is composed of a main body 111 having a shaft hole 112 at the center, and a cutting portion 113 having a V-shaped section at the outer periphery of the main body 111 .

[0030] The shaft hole 112 has a larger diameter than the aforementioned shaft so that a shaft (not shown) is inserted into the shaft hole 112 and fitted.

[0031] The cutting portion 113 has 18 outer peripheral notches 114 formed at equal angular intervals along the outer periphery. Here, the outer peripheral notch 114 is formed in a radial direction perpendicular to the circumferential direction on the outer periphery. This is for easy processing of the outer peripheral notch 114 .

[0032] In the shaft hole 112 part of the main body 111, six inner peripheral grooves 115 parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com