Patents

Literature

78results about How to "Easy to change size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

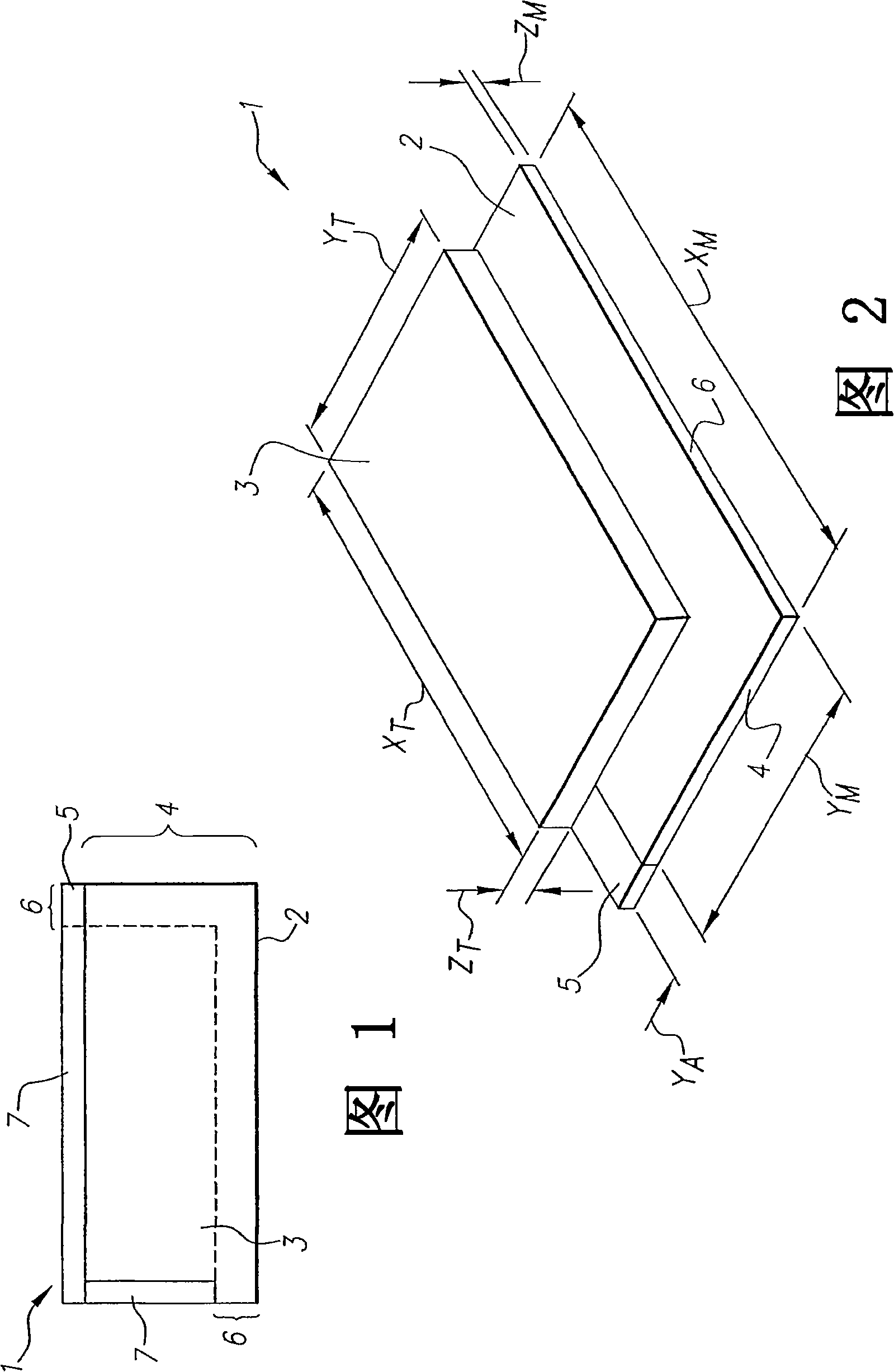

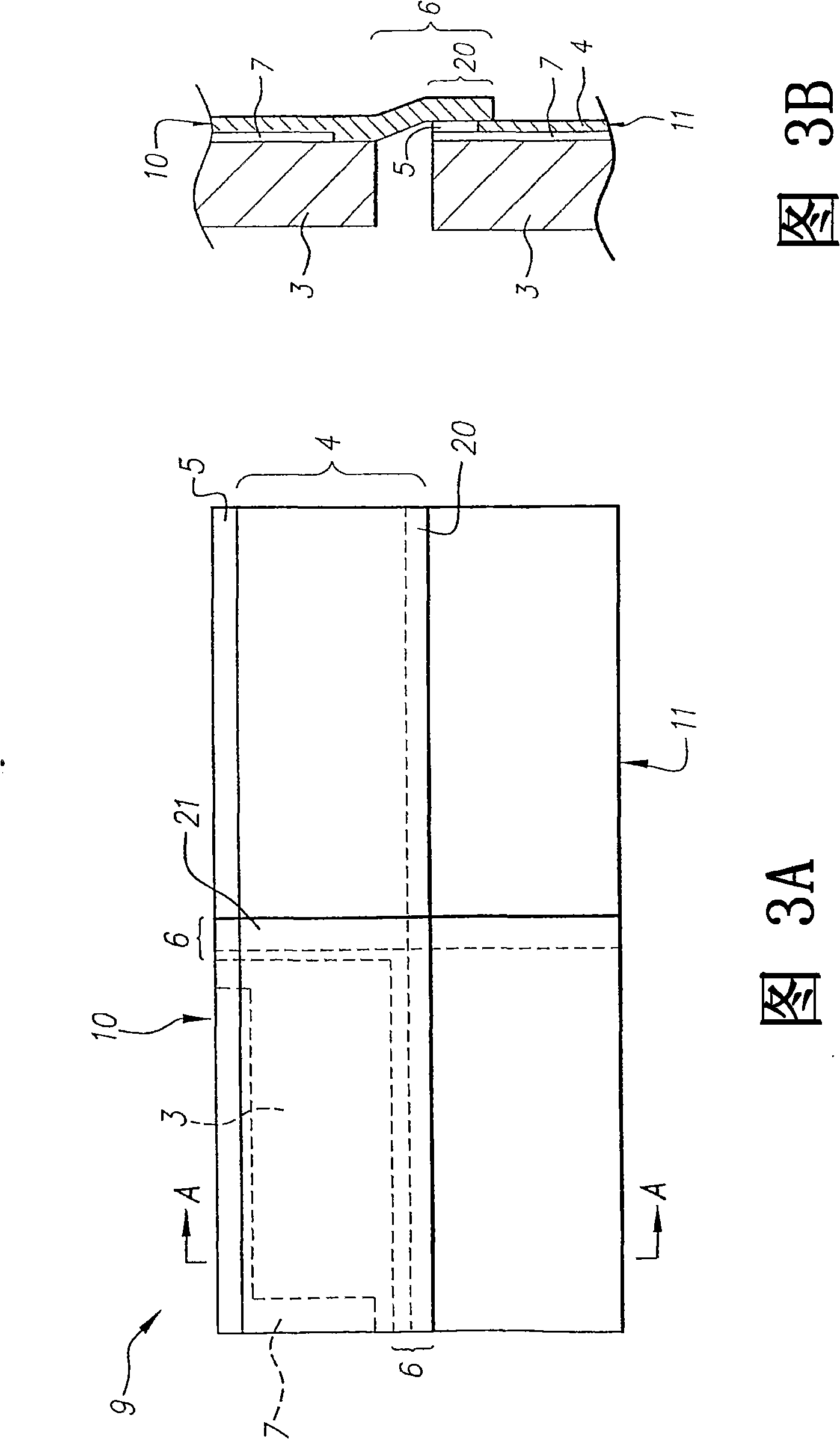

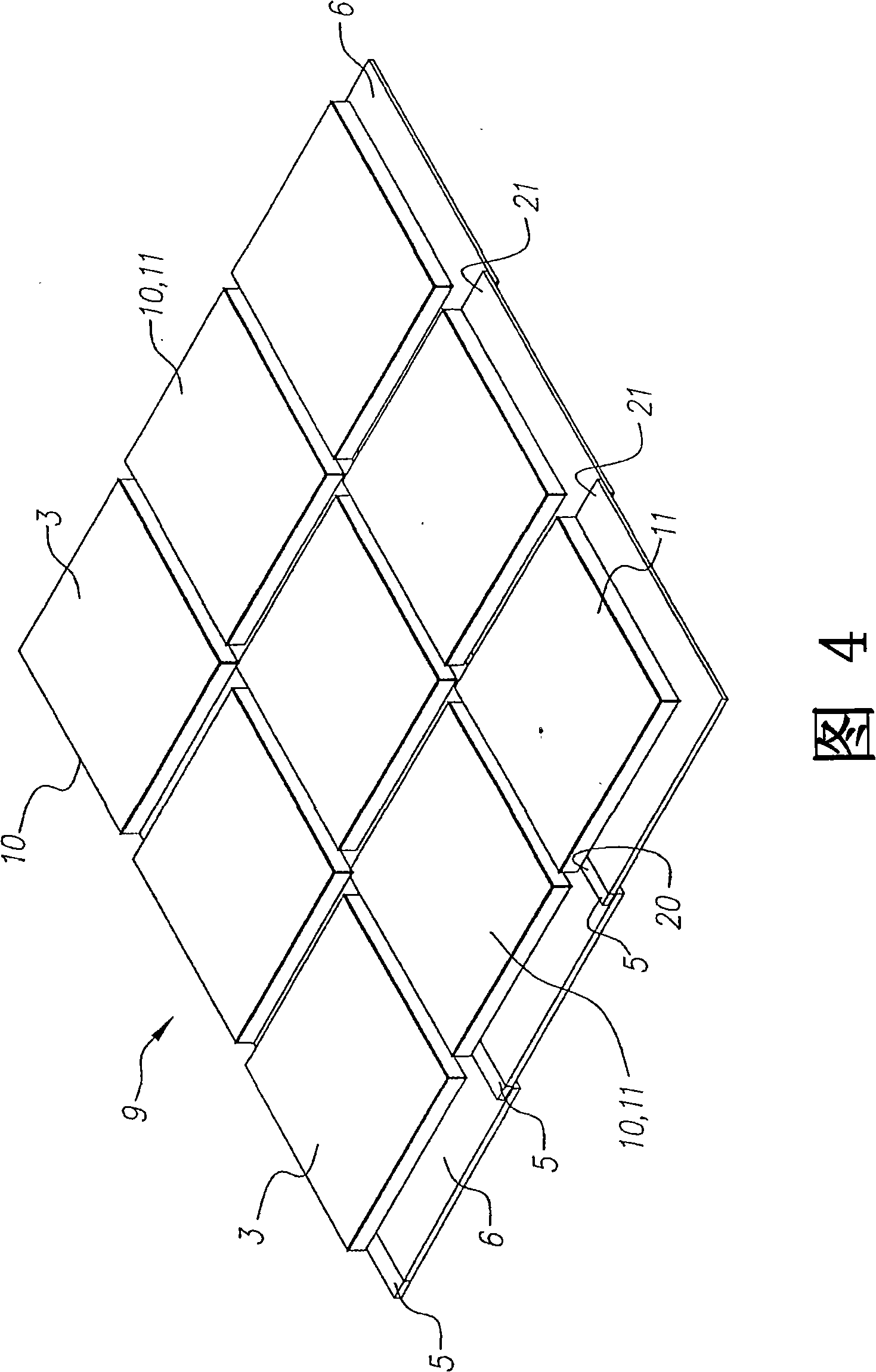

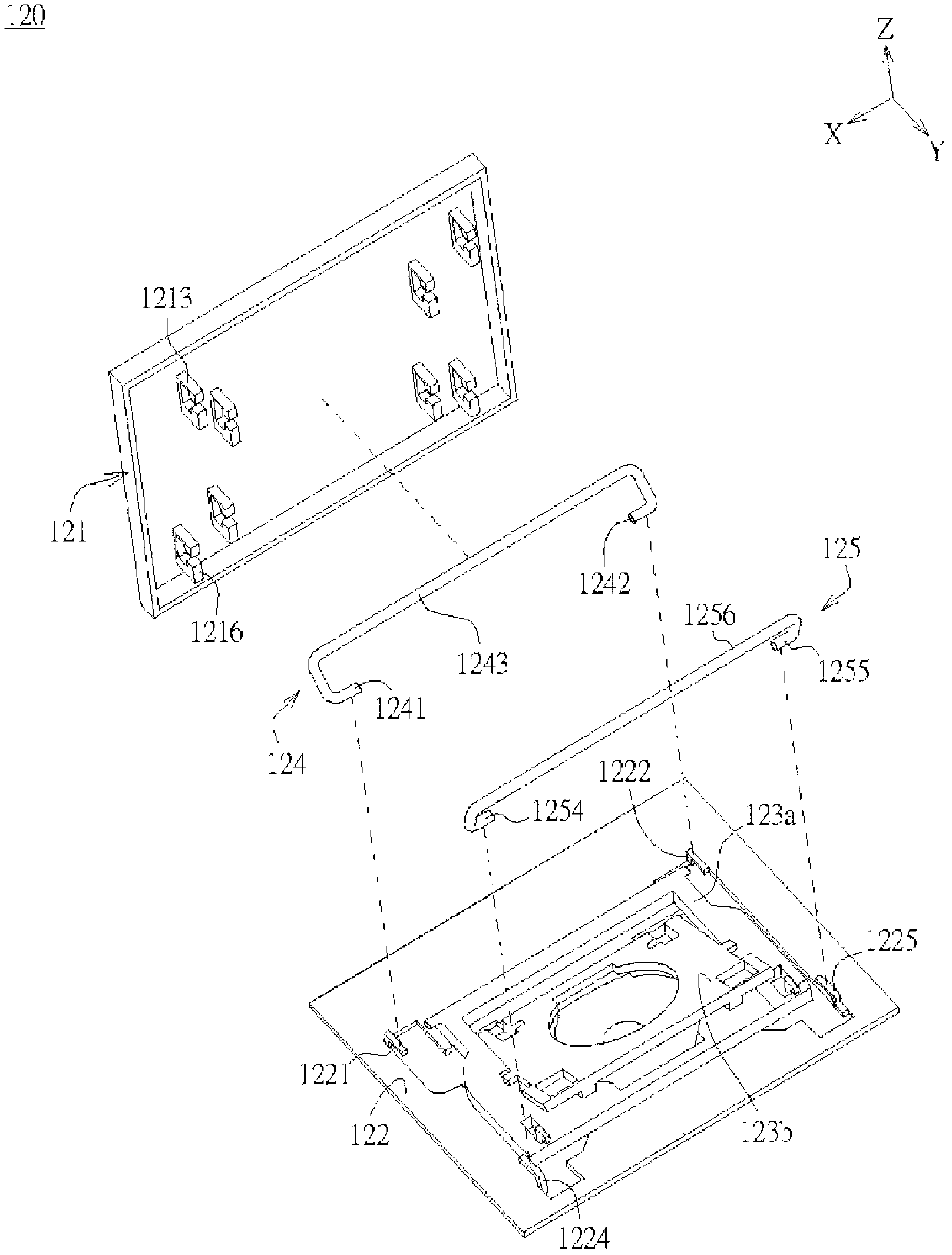

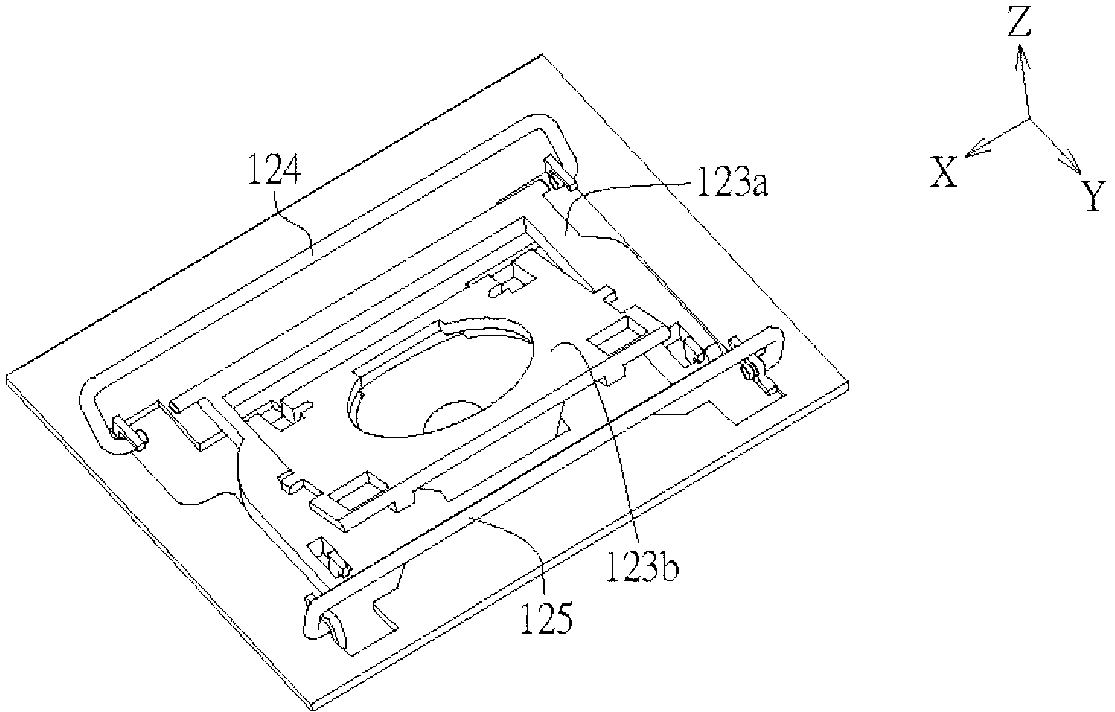

Tiled display for electronic signage

InactiveCN101283307AEasy to change sizeEasy to change shapeCathode-ray tube indicatorsNon-linear opticsDisplay deviceMultimedia

Owner:IND TECH RES INST

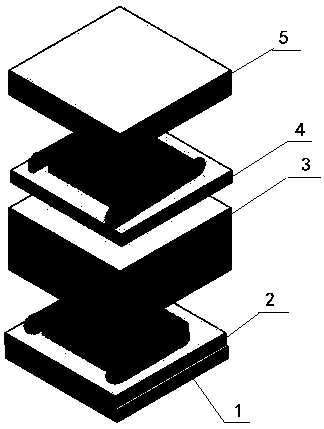

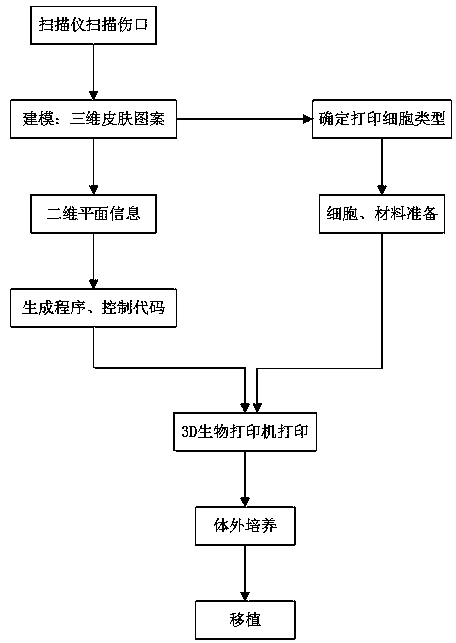

Tissue engineering skin and preparation method thereof

ActiveCN106421916AImprove survival rateHas the effect of resisting mechanical extrusionMicrocapsulesProsthesisBiocompatibility TestingSweat gland

The invention relates to tissue engineering skin and a preparation method thereof. The tissue engineering skin comprises a dermis layer and an epidermis layer, and is prepared from seed cells, cell growth factors and a biological scaffold material according to a biological 3D printing technology. The tissue engineering skin is similar to natural skin, comprises the dermis layer and the epidermis layer, can be produced in batches, can be closely attached to a wound, and has high biocompatibility, the dermis layer contains blood vessels, sweat glands and hair follicles, the shape, size and thickness of the tissue engineering skin can be easily changed, the elasticity and flexibility of the skin after sound healing can be enhanced, and the tissue engineering transplantation success rate can be increased.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

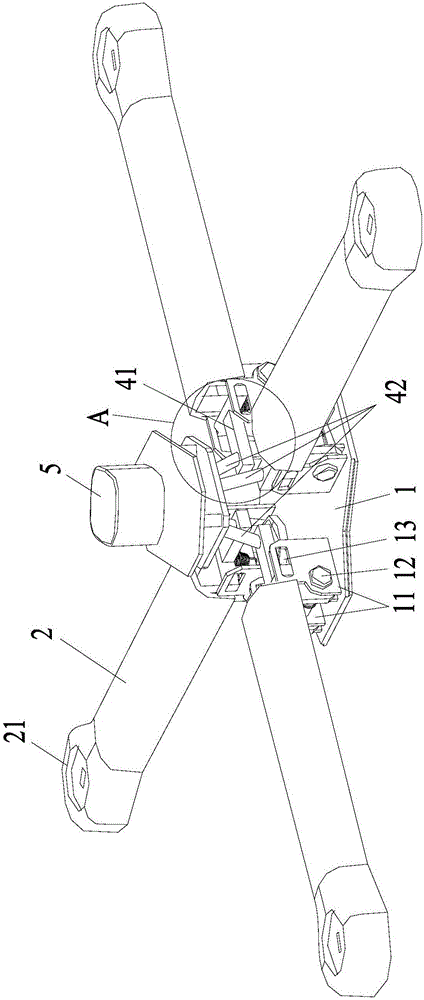

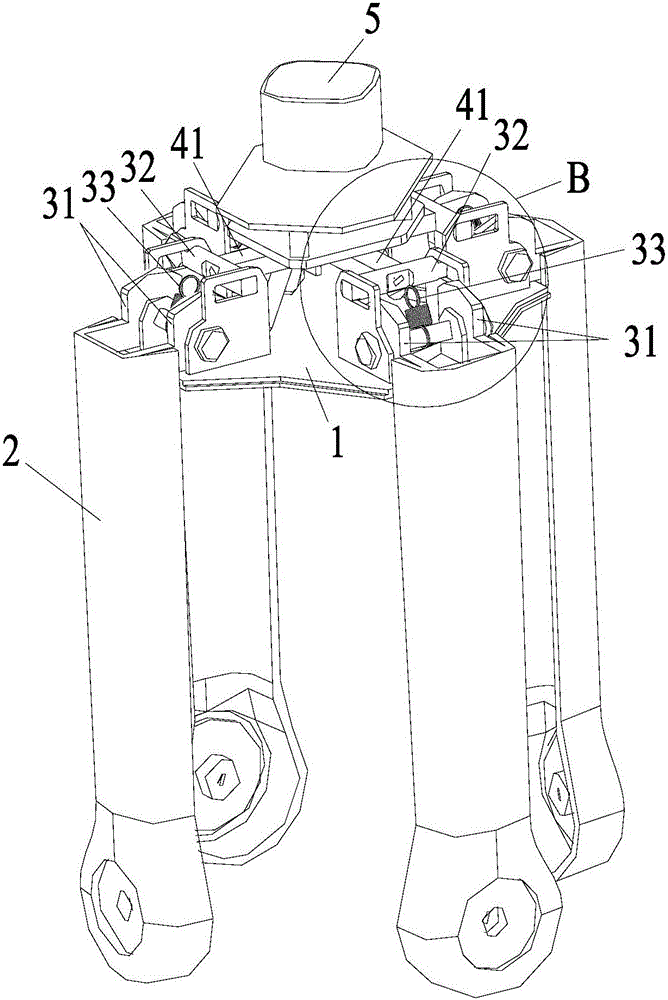

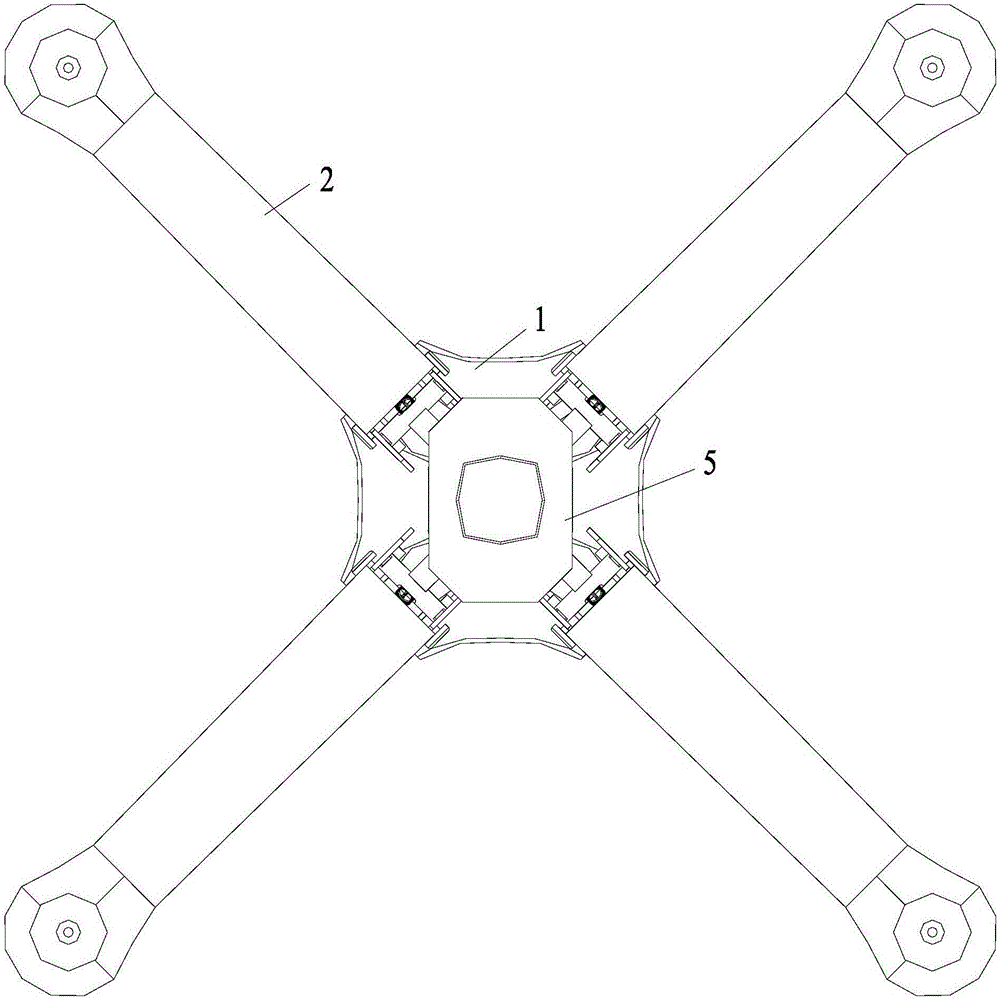

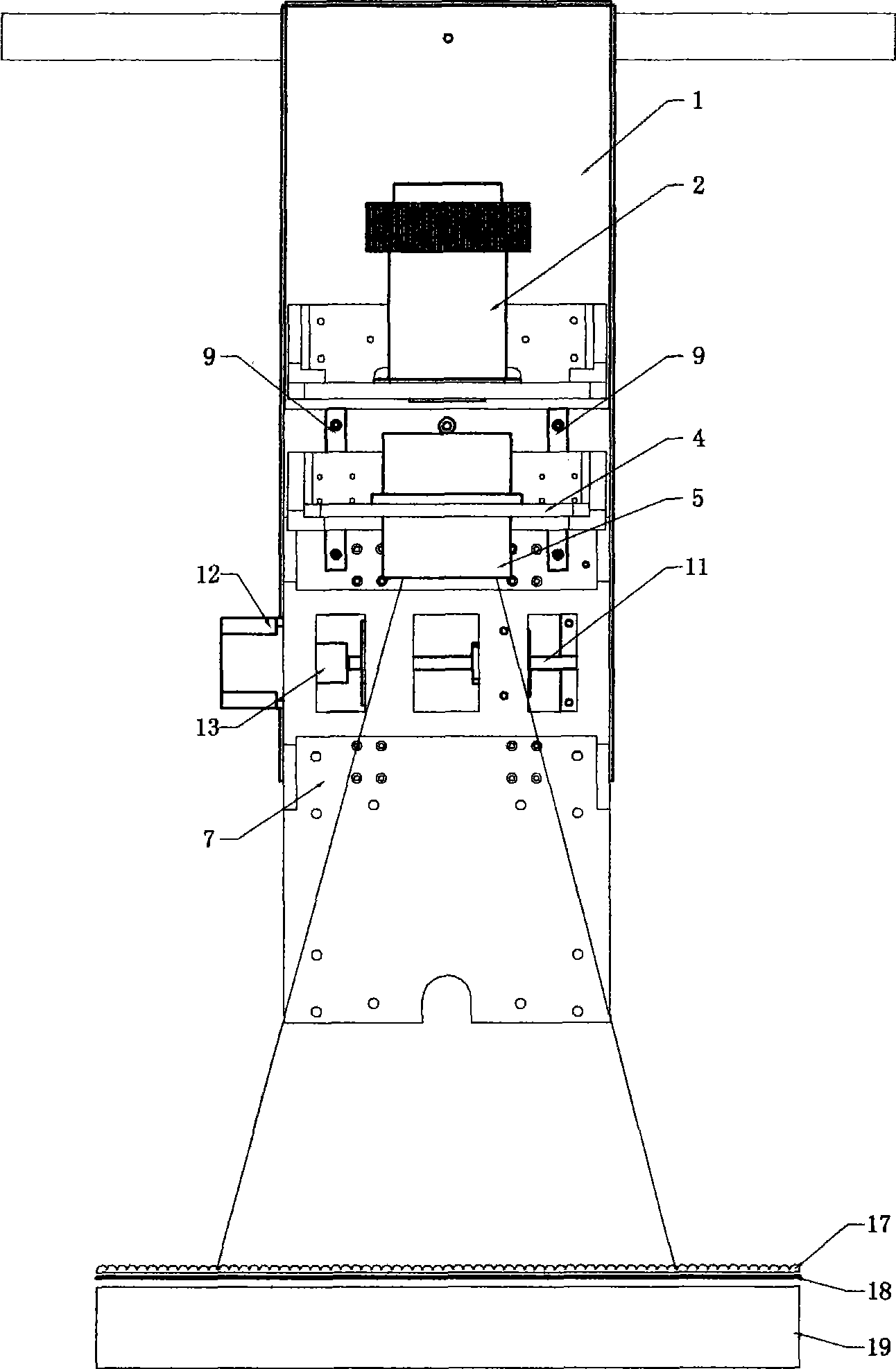

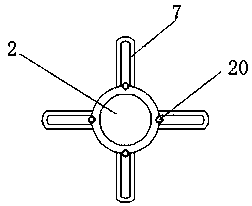

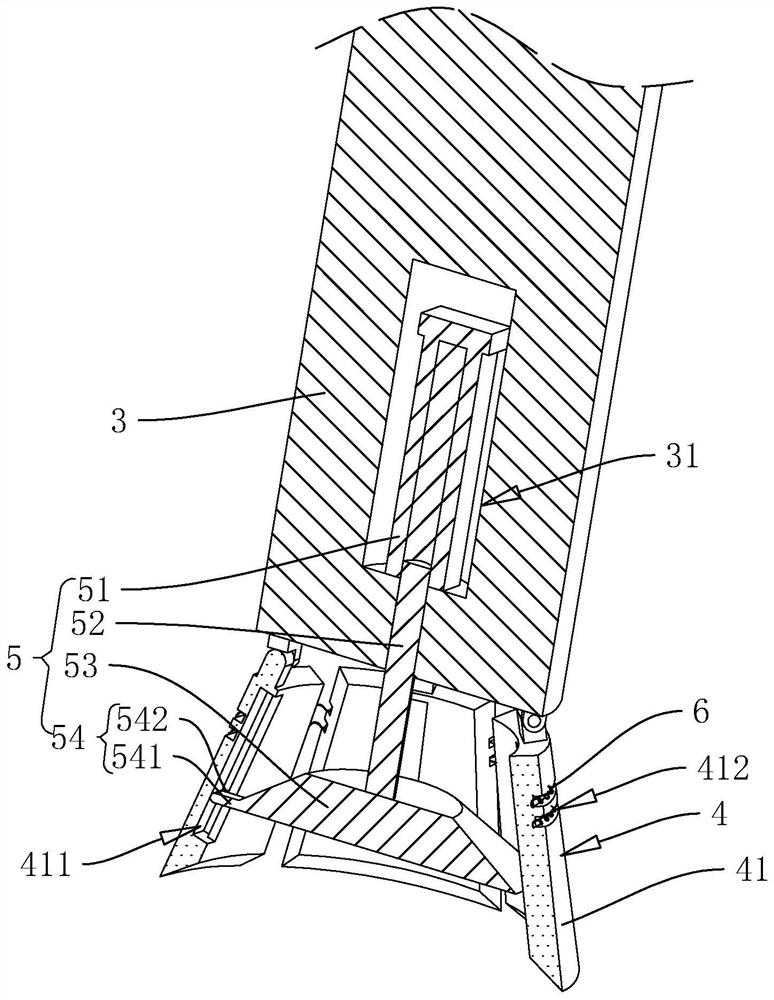

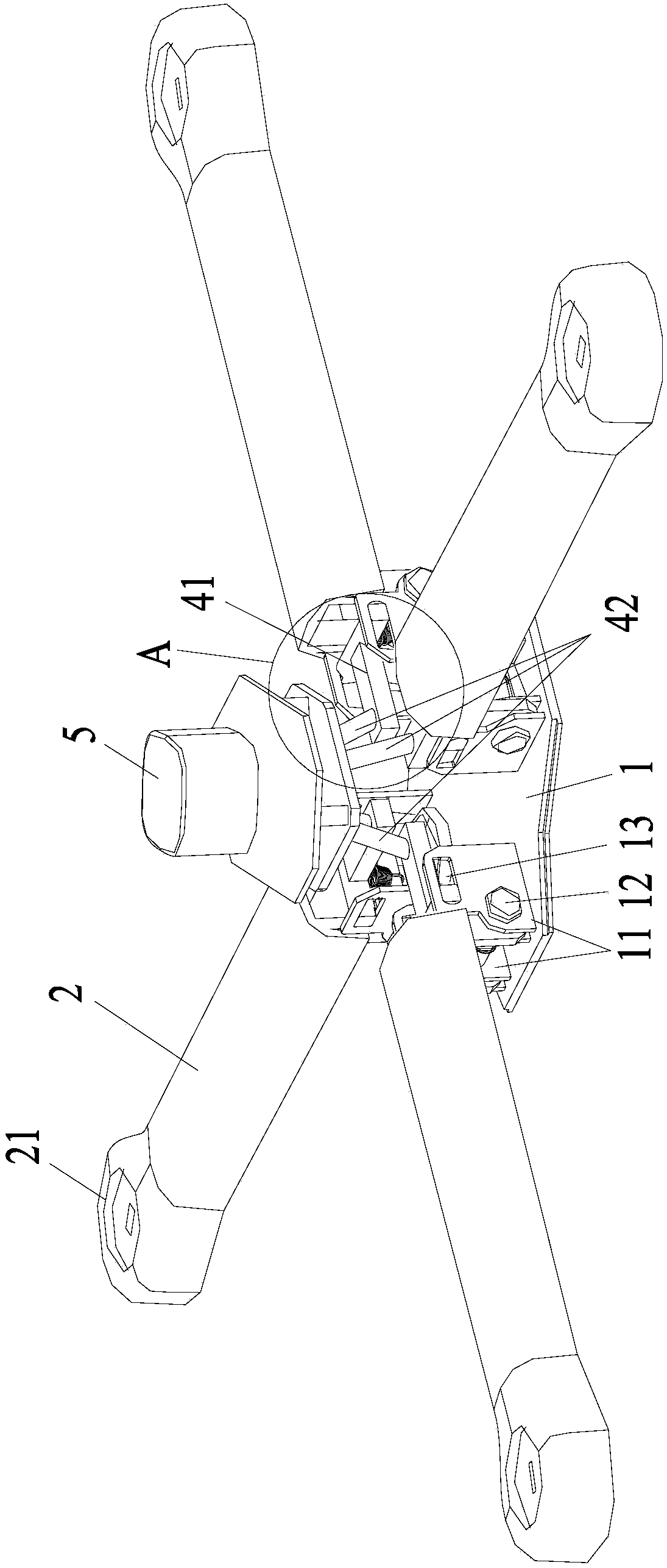

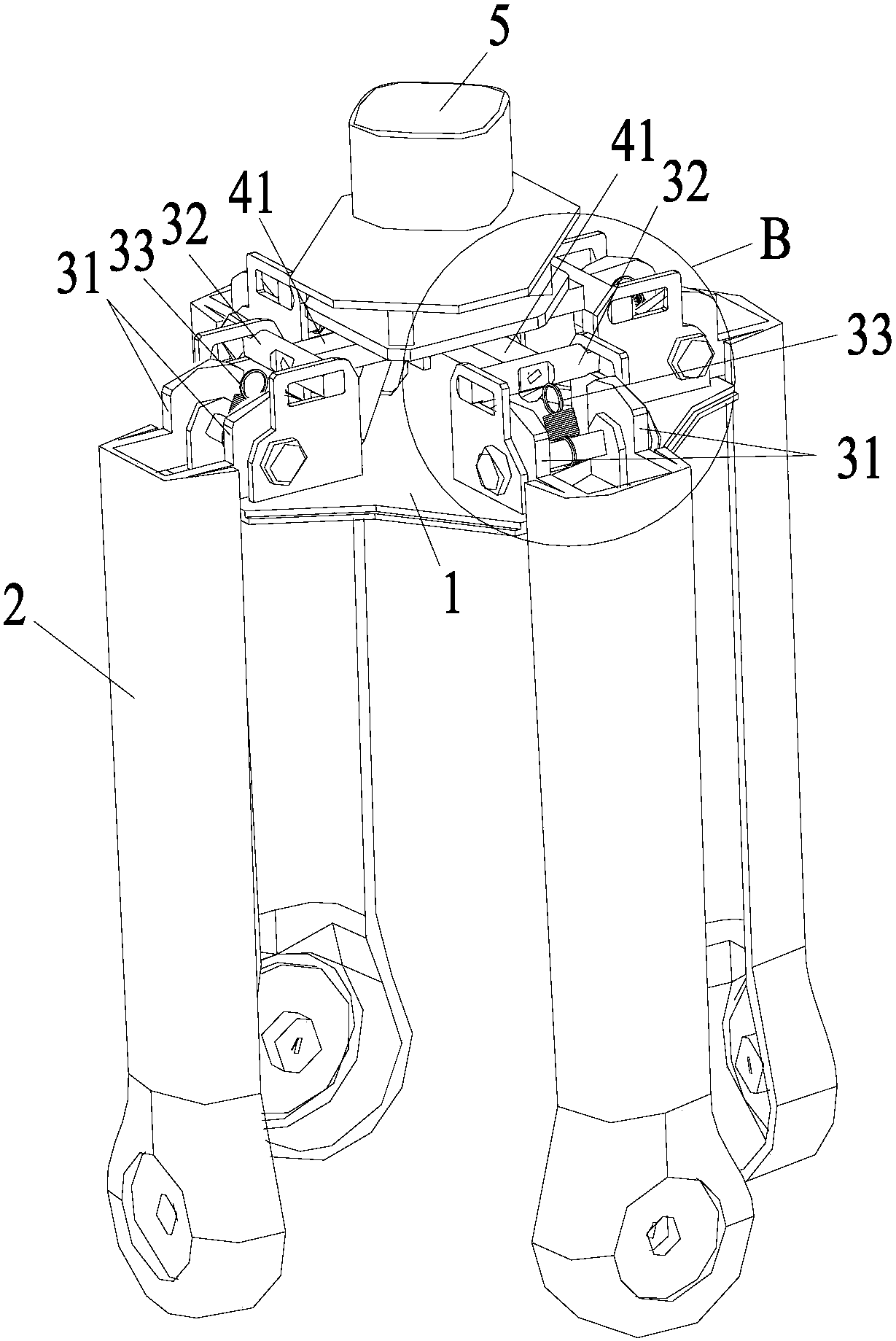

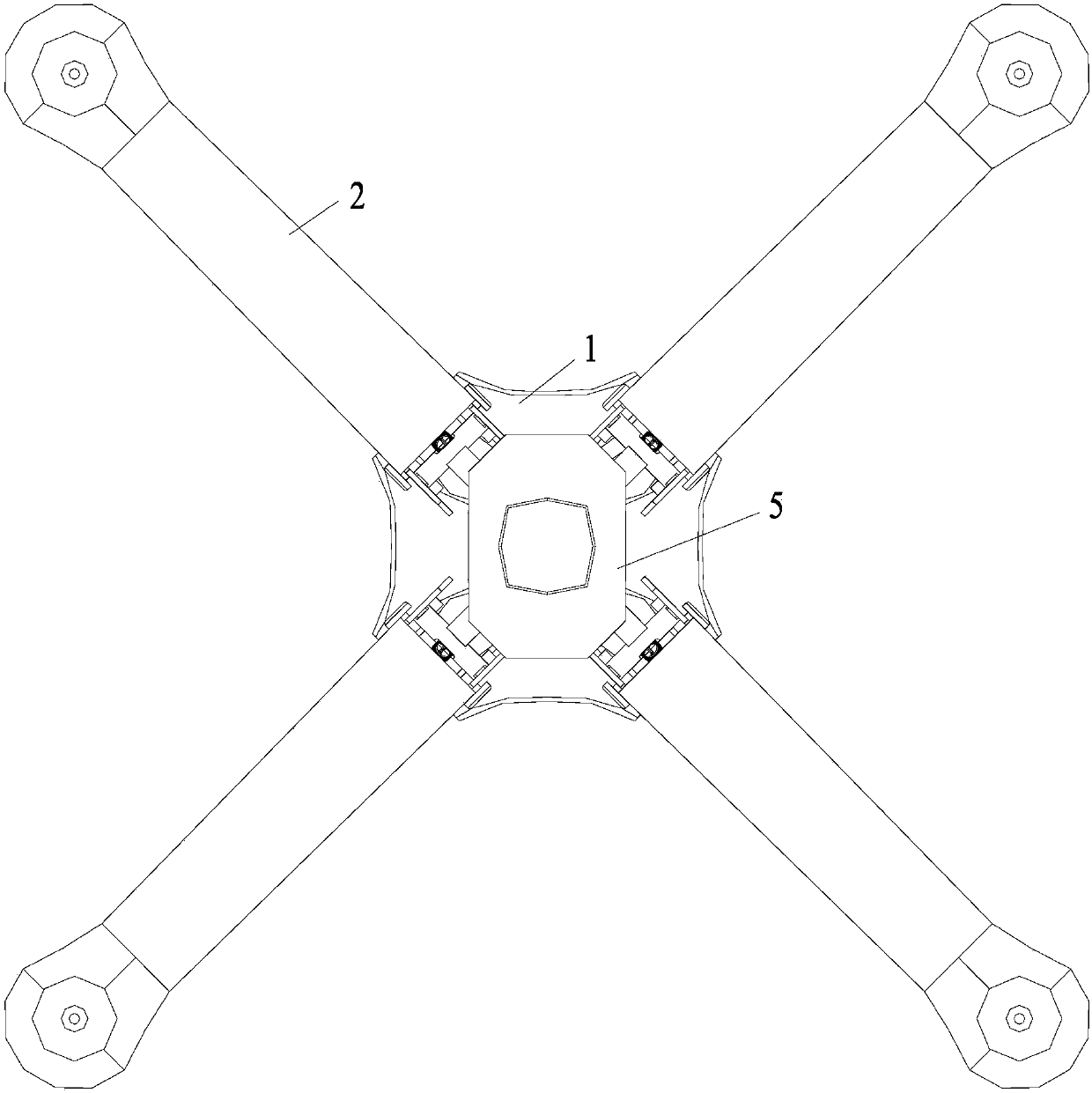

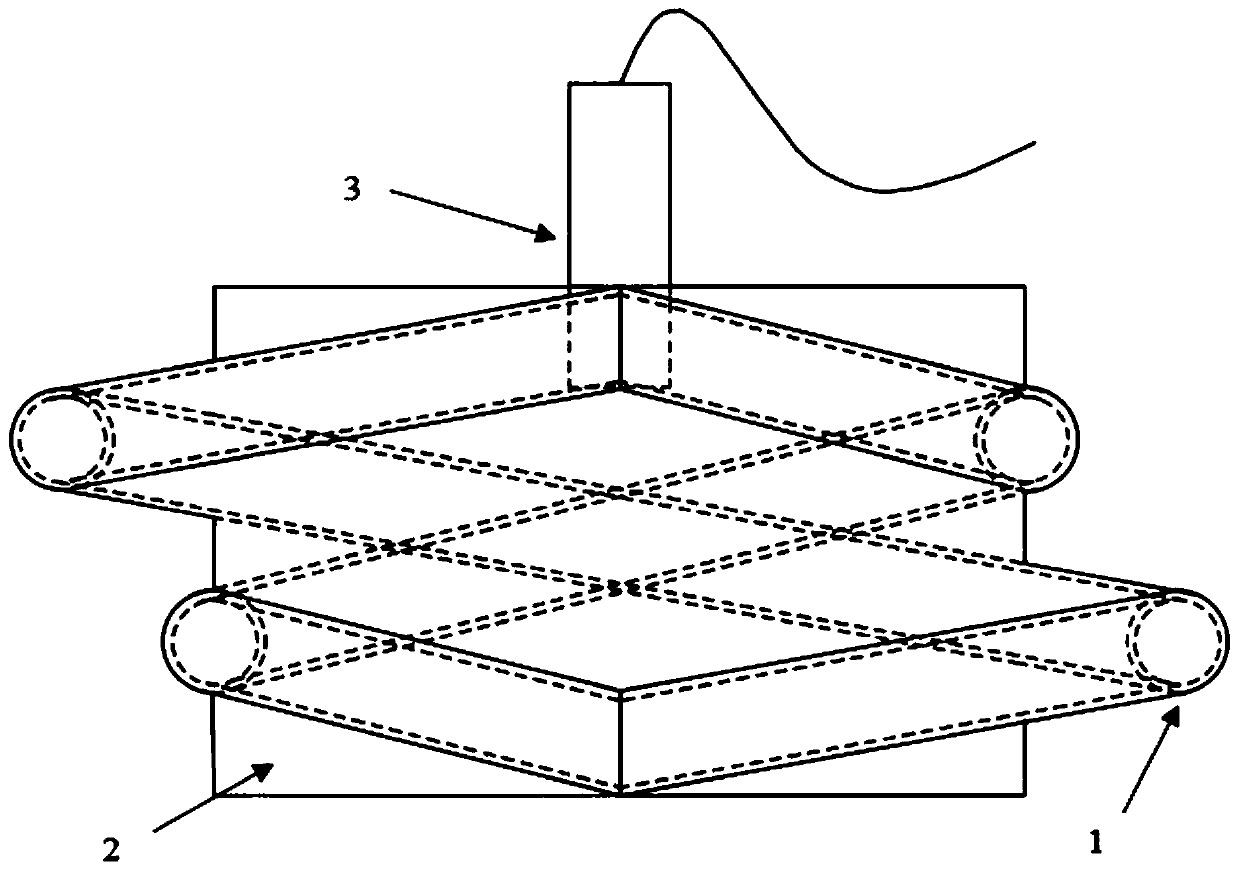

Unmanned aerial vehicle with multi-vehicle-arm synchronous folding mechanism

The invention relates to the field of unmanned aerial vehicles, in particular to an unmanned aerial vehicle with a multi-vehicle-arm synchronous folding mechanism. The unmanned aerial vehicle comprises a base, multiple vehicle arms, clamping assemblies and folding assemblies, wherein the base is in a flat board shape and is provided with multiple rotary shafts extending parallel to the base; the multiple vehicle arms are connected with the rotary shafts in the manner that the vehicle arms can rotate around the corresponding rotary shafts, and the vehicle arms can be in the unfolded state to be parallel to the base and the folded state to be perpendicular to the base; the clamping assemblies are used for keeping the multiple vehicle arms in the unfolded state; and the folding assemblies are used for synchronously releasing the clamping state of the clamping assemblies, so that the multiple vehicle arms are converted into the folded state synchronously from the unfolded state. The multi-vehicle-arm synchronous folding mechanism is composed of the clamping assemblies and the folding assemblies. By the adoption of the above technical scheme, the unmanned aerial vehicle capable of achieving synchronous folding of the multiple vehicle arms is provided, so that the size of the unmanned aerial vehicle is easy to change, and in the vehicle arm folding process, operation is easy, and use is convenient.

Owner:BEIJING BORUI AIFEI TECH DEV CO LTD

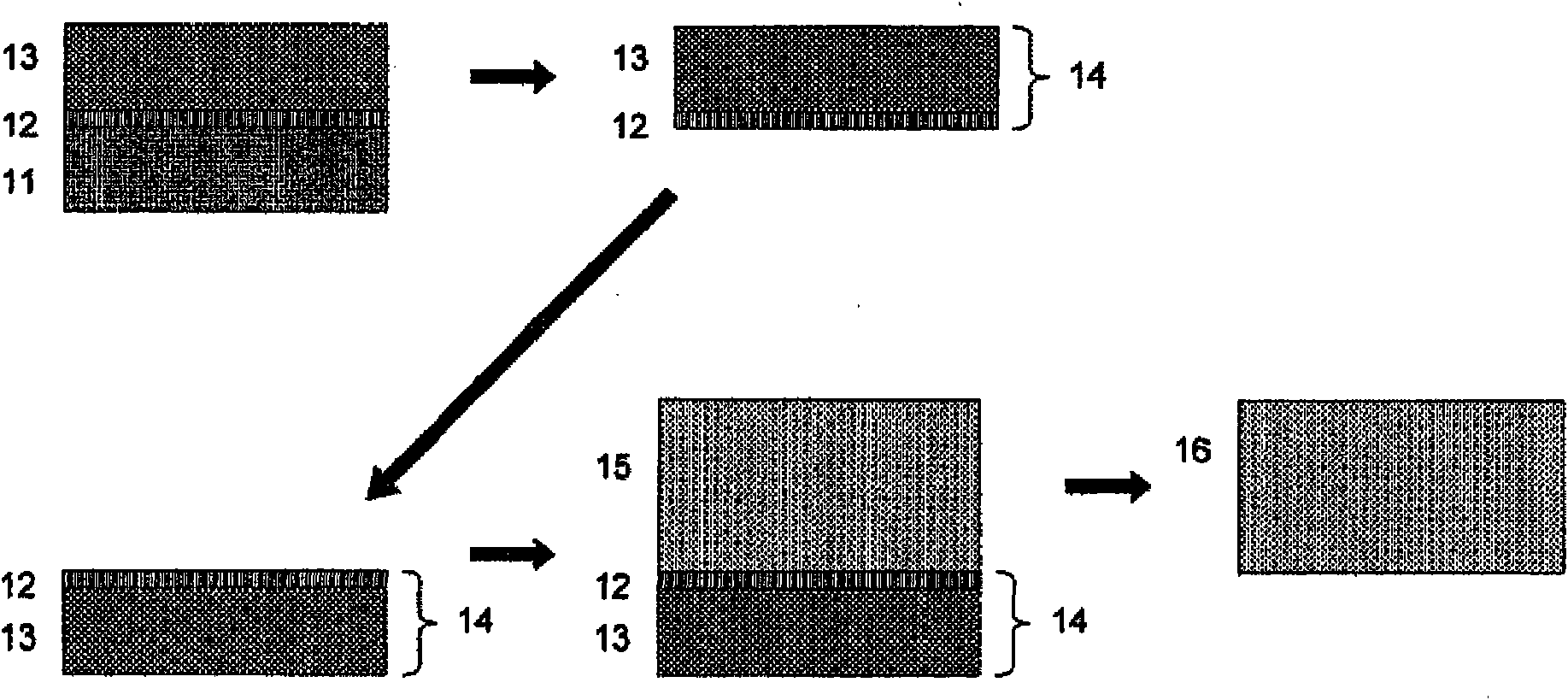

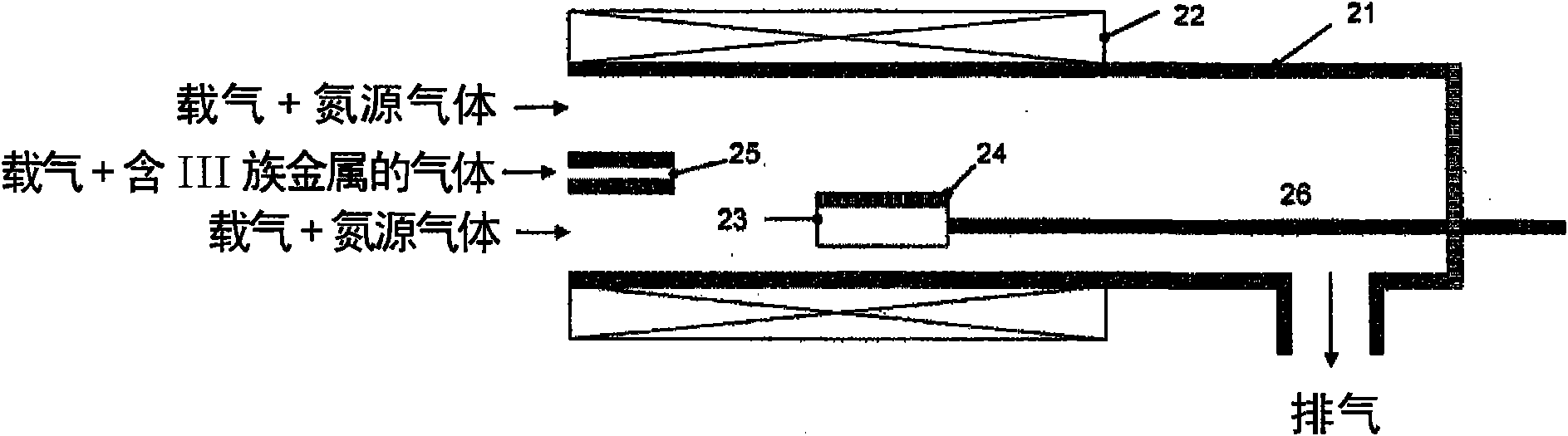

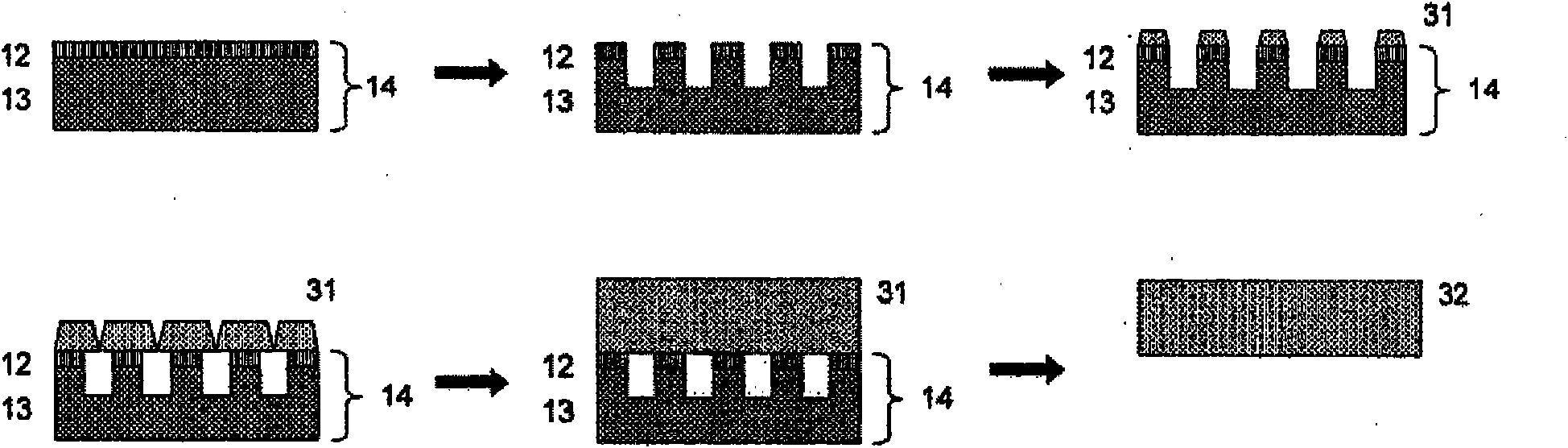

Process for producing laminate comprising Al-based group III nitride single crystal layer, laminate produced by the process, process for producing Al-based group III nitride single crystal substrate using the laminate, and aluminum nitride single cry

InactiveCN101918624AEfficient manufacturingChange shapePolycrystalline material growthSolid-state devicesSingle crystal substrateSingle crystal

Disclosed is a process for producing a laminate, comprising (1) the step of providing a base substrate having a surface formed of a single crystal of a material different from a material for constituting an Al-based group III nitride single crystal layer to be formed, (2) the step of forming an Al-based group III nitride single crystal layer having a thickness of 10 nm to 1.5 mum on the single crystal plane of the provided base substrate, (3) the step of forming a non-single crystal layer having a thickness of not less than 100 times the thickness of the Al-based group III nitride single crystal layer on the Al-based group III nitride single crystal layer without breaking the Al-based group III nitride single crystal layer, and (4) the step of removing the base substrate. The production process can provide a substrate that is suitable for use as a base substrate for the production of a self-supporting substrate of an Al-based group III nitride single crystal, has a surface formed of a single crystal of an Al-based group III nitride, and is free from cracking and warpage.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH +1

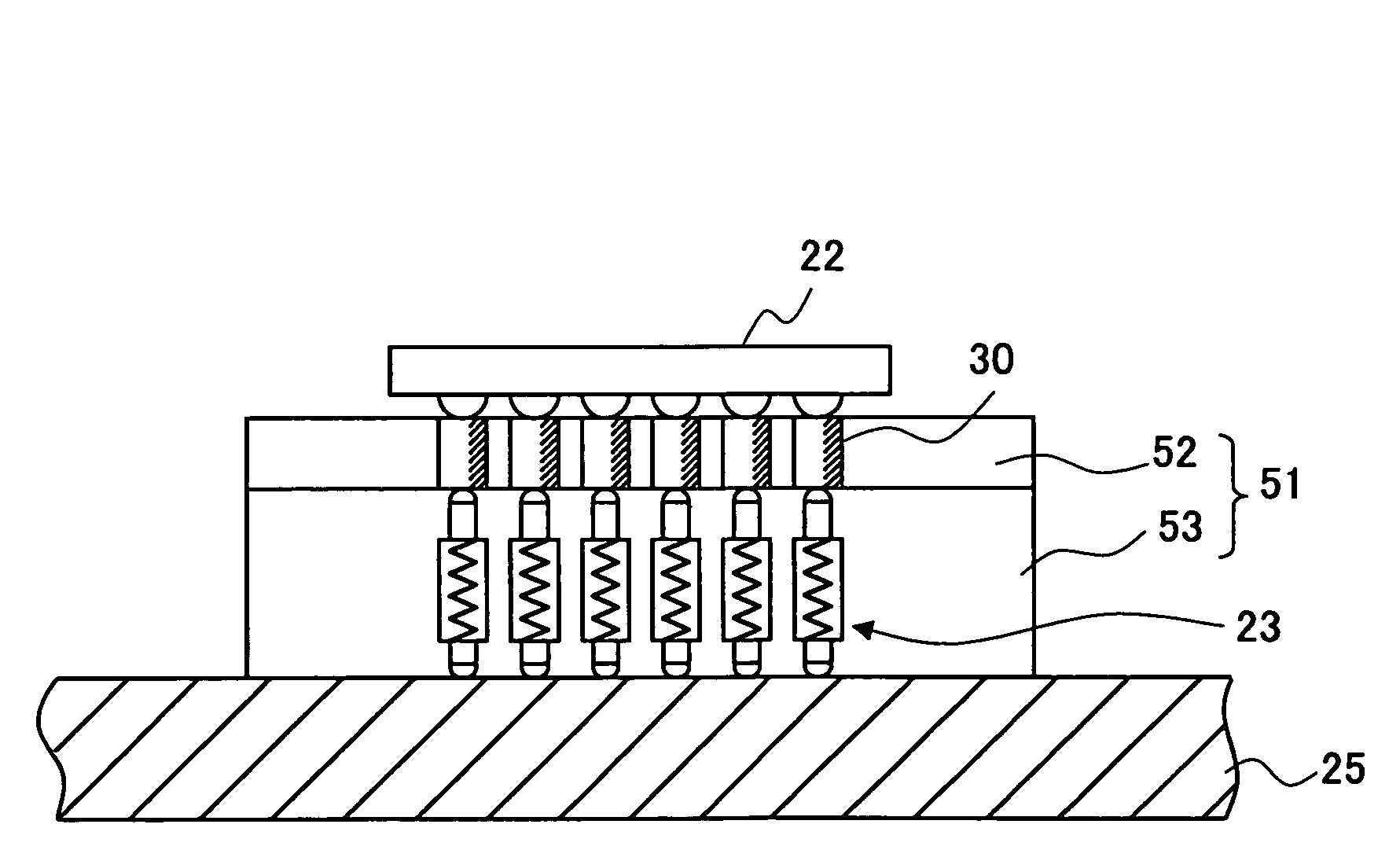

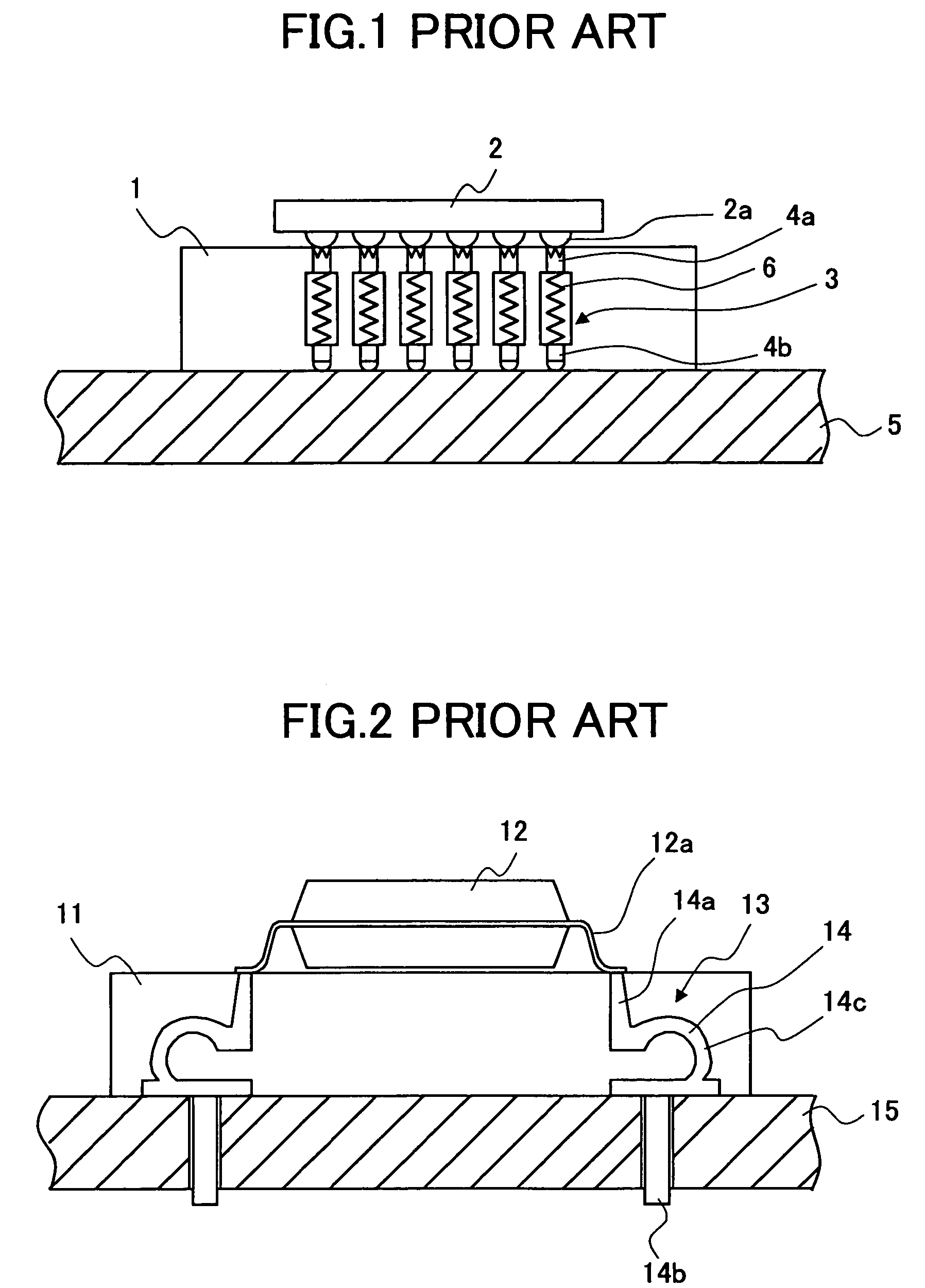

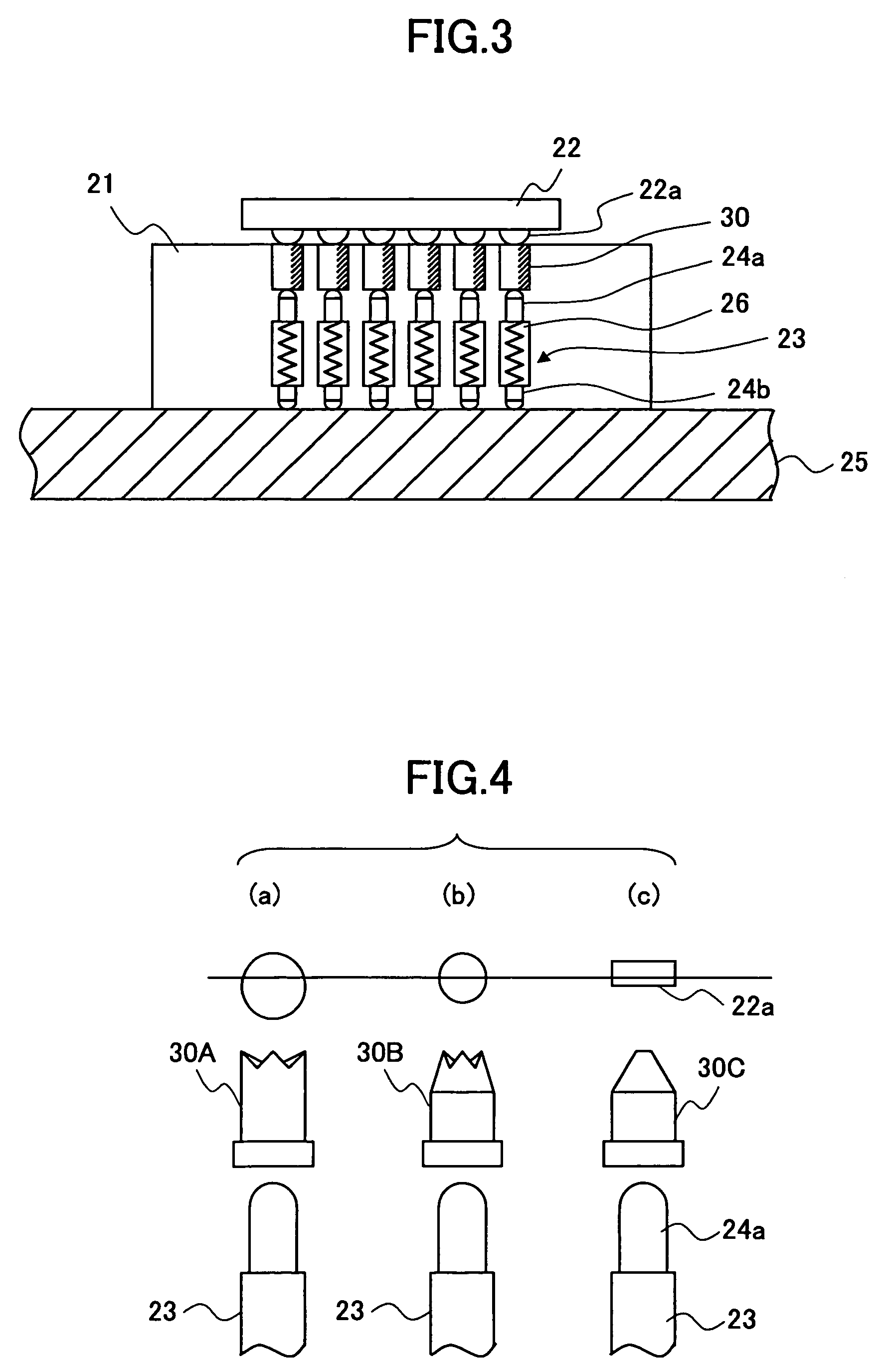

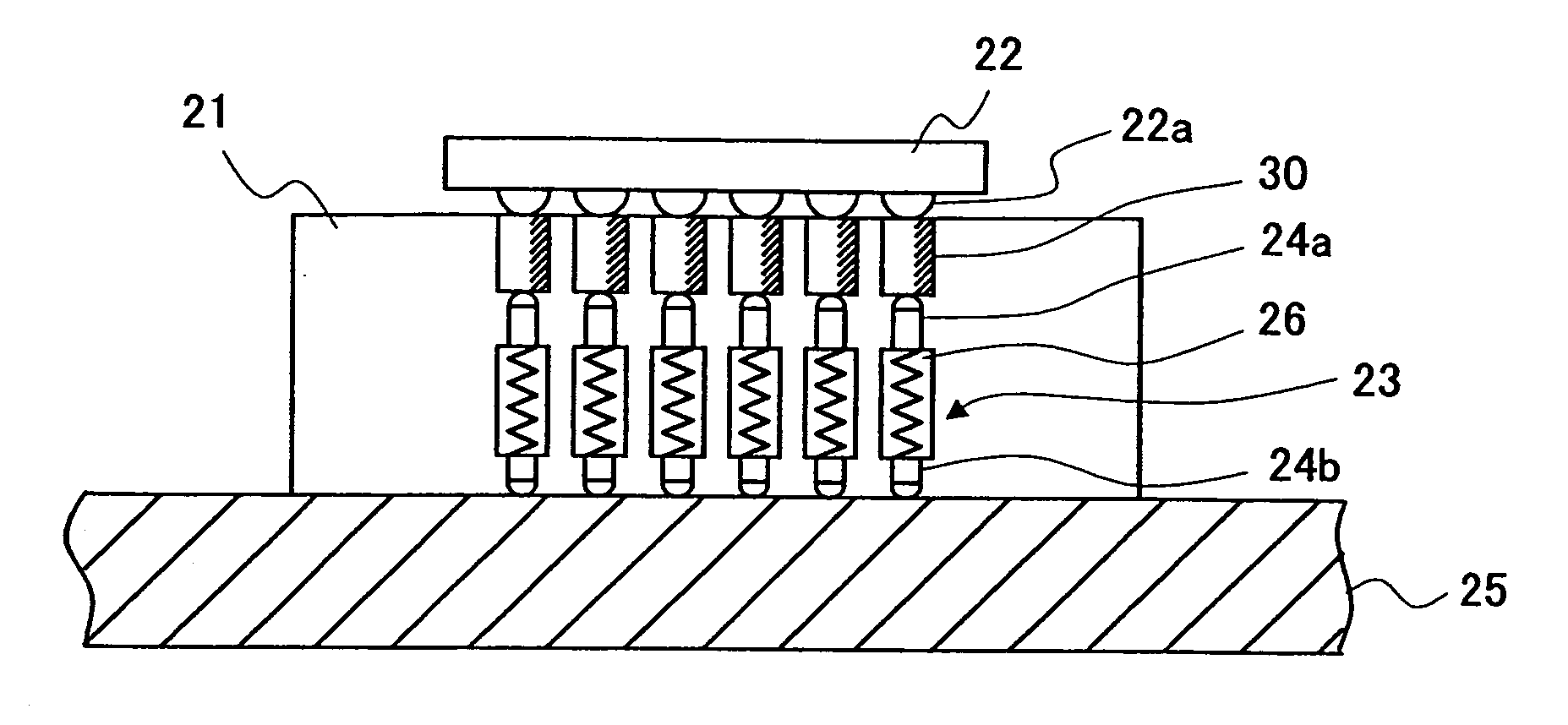

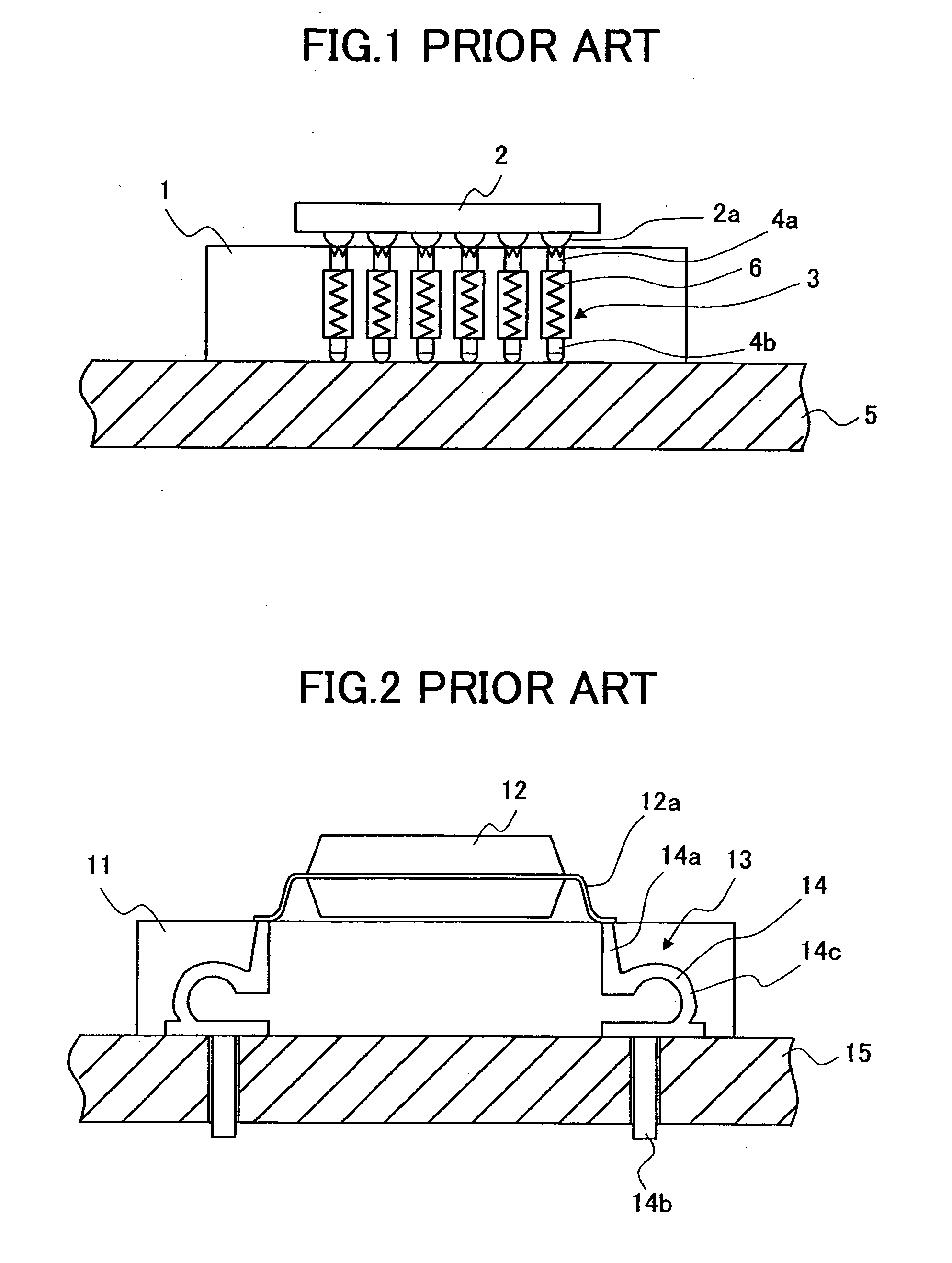

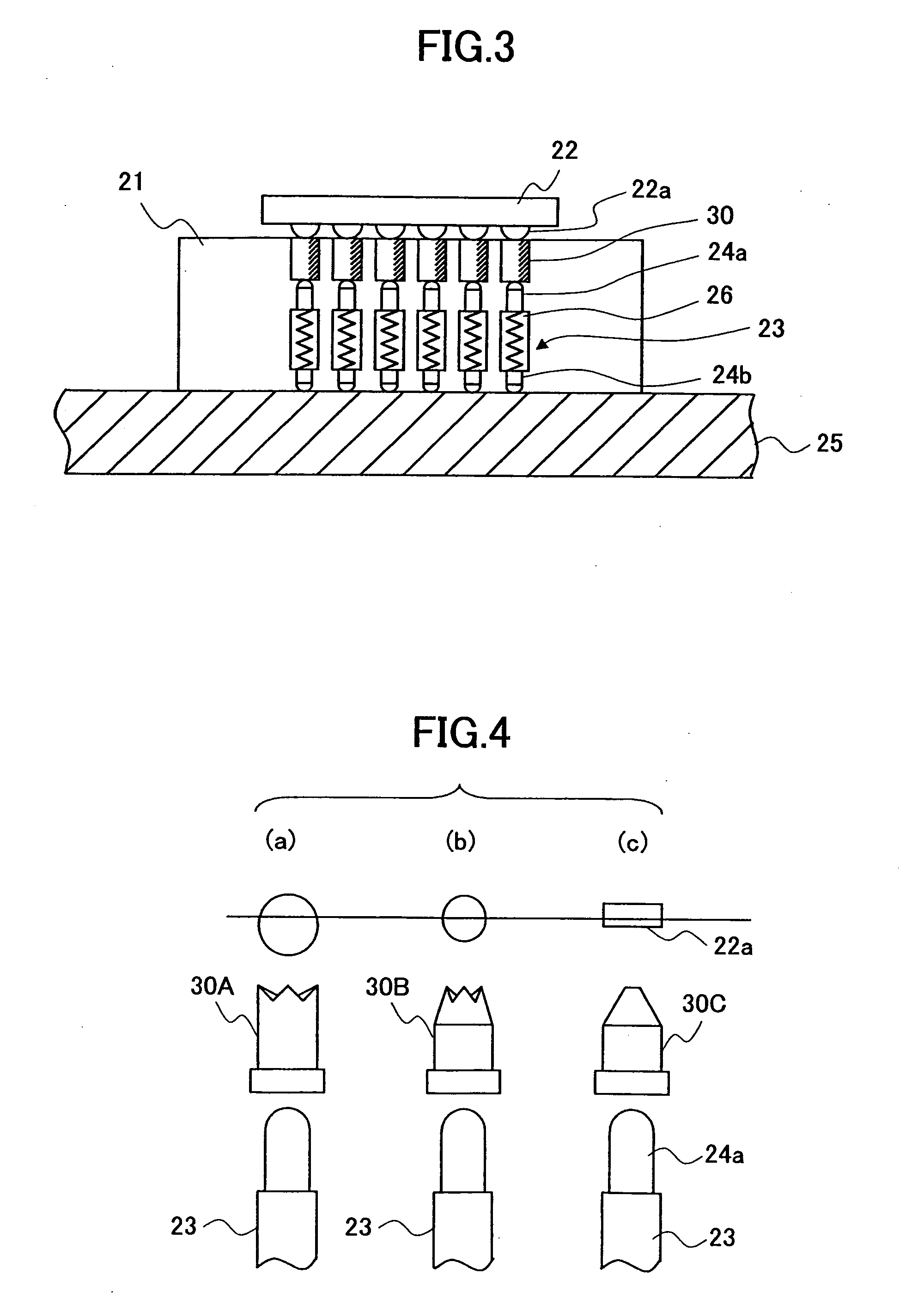

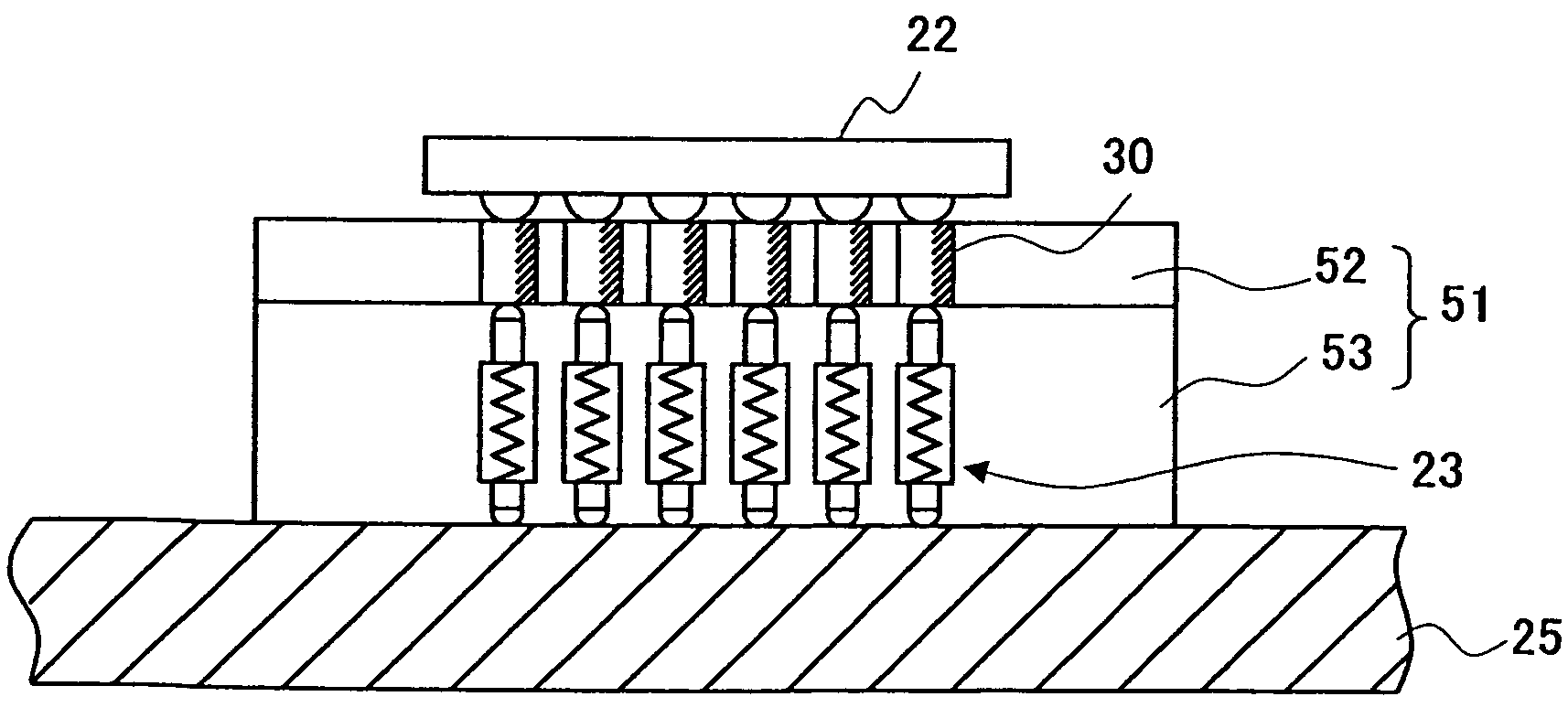

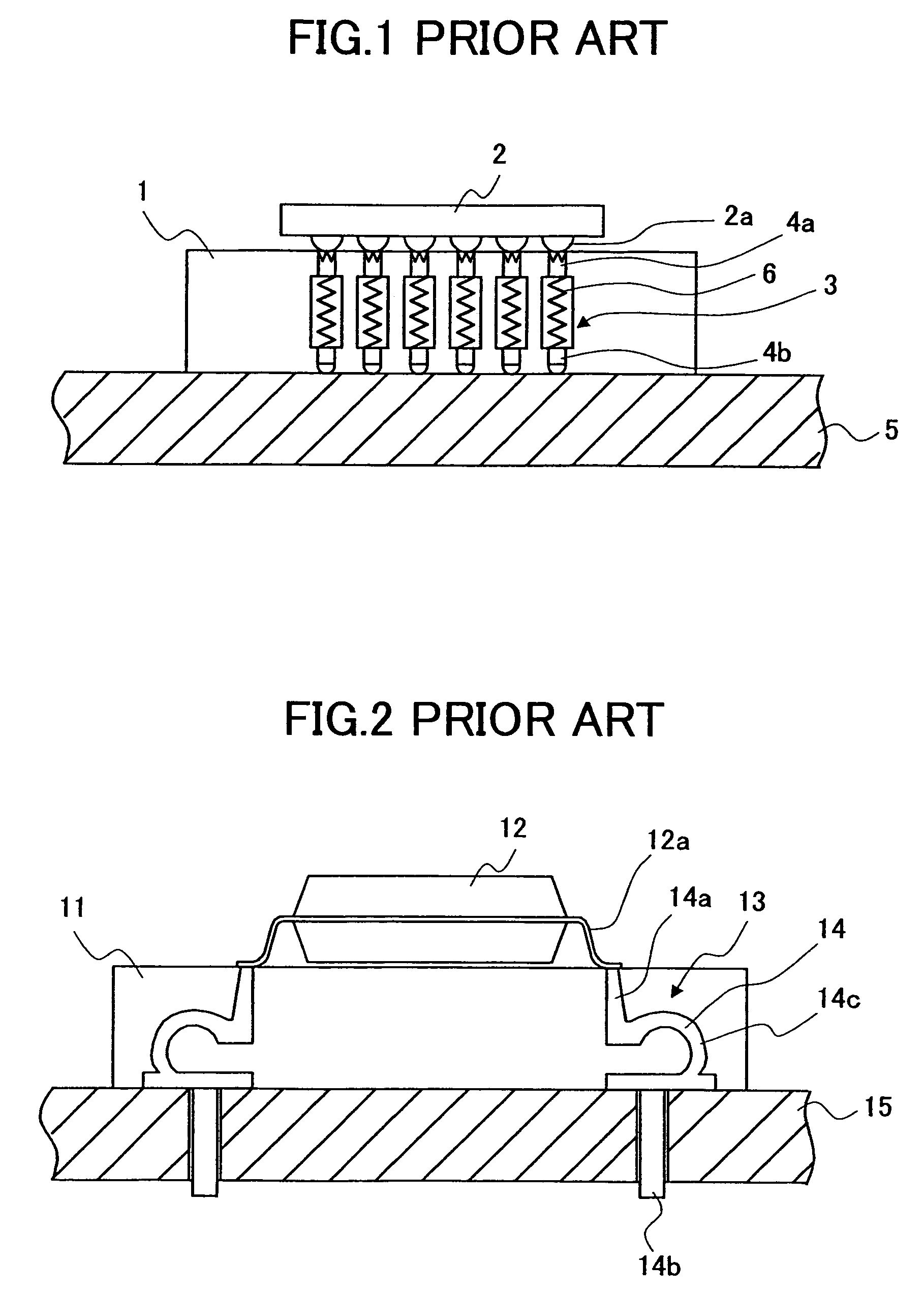

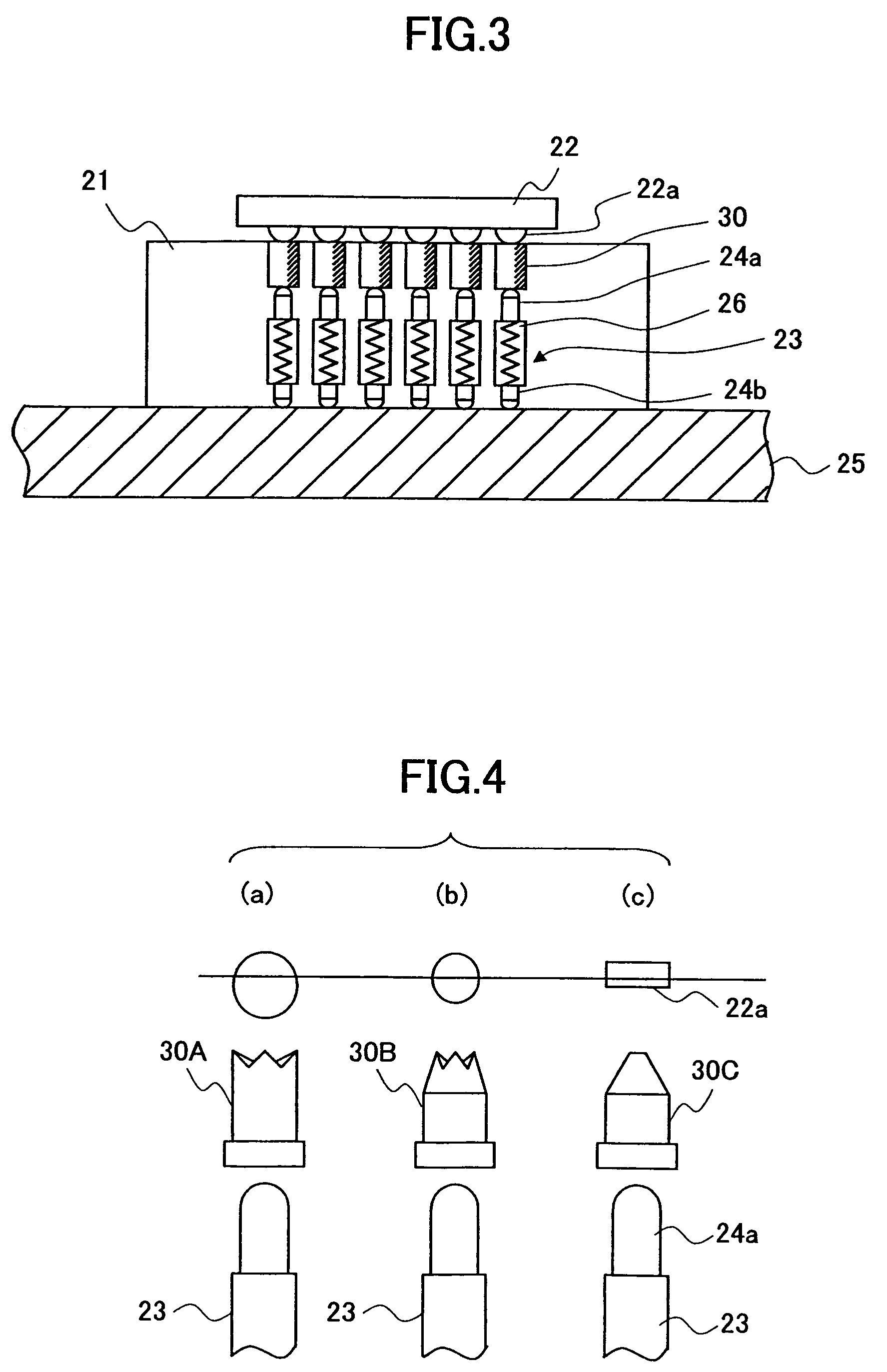

Contactor for electronic components and test method using the same

InactiveUS7309996B2Easy to shapeSmall sizeCoupling device connectionsElectric discharge tubesElectricityEngineering

A contactor configured to be electrically connected to the terminals of an electronic component is disclosed. The connector includes multiple contact electrodes contacting the terminals of the electronic component and multiple elastic electrodes each composed of an electrically conductive elastic body. The elastic electrodes generate a pressing force for pressing the contact electrodes against the terminals of the electronic component. The contact electrodes are separable from the elastic electrodes.

Owner:SOCIONEXT INC

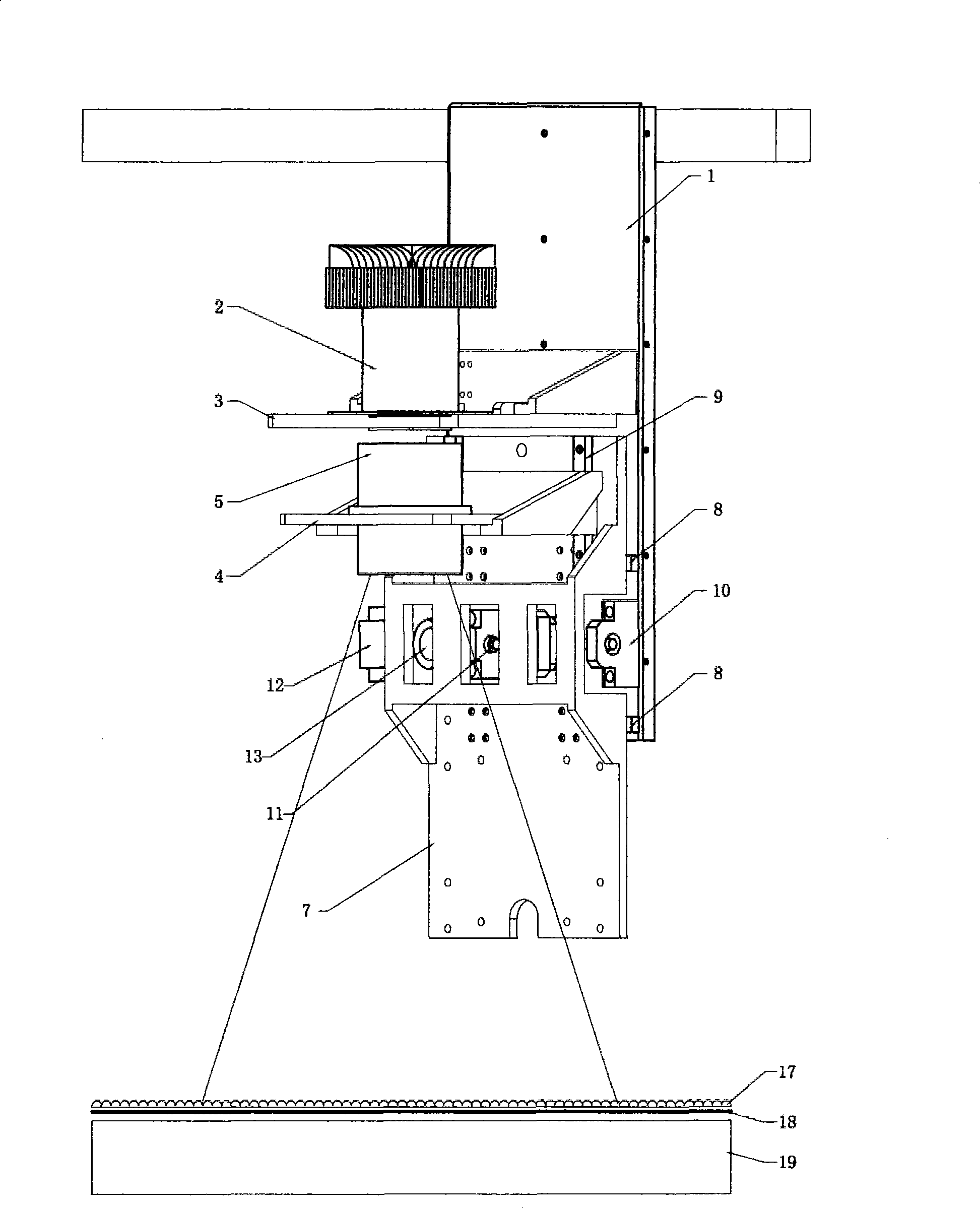

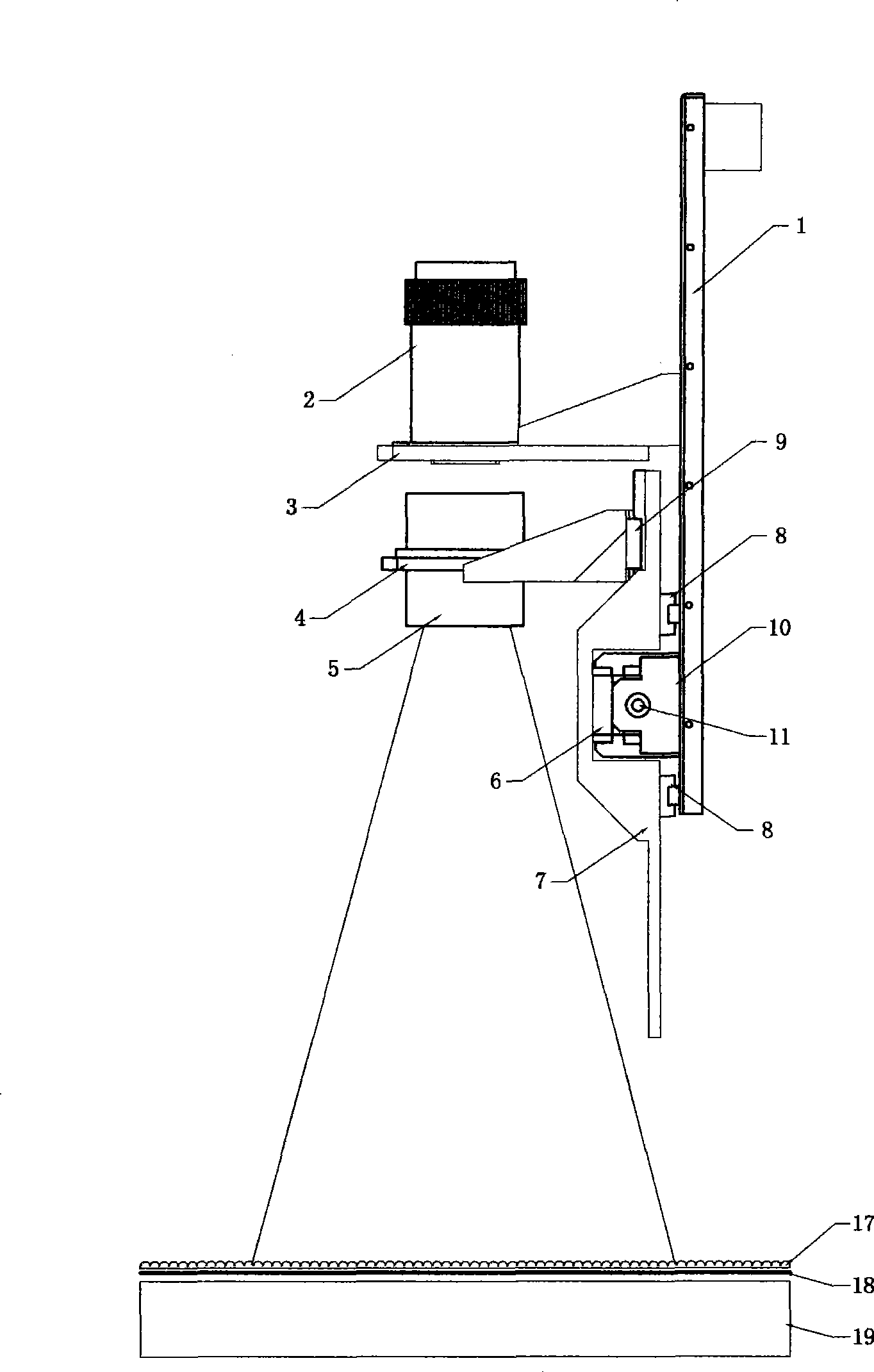

Stereo digital jigsaw imaging lens moving apparatus and method thereof

InactiveCN101464621ASimple structureEasy to operateViewersStereoscopic photographyCamera lensDisplay device

The invention discloses a stereo digital mosaic imaging lens shifter and a method thereof. The shifter comprises light source equipment, an LCD fixing plate, a lens, a lens fixing plate, a motor, a slipping device and a base plate; the LCD fixing plate and the slipping device are installed on the base plate; an LCD display seat and an LCD image display are installed on the LCD fixing plate; the light source equipment is installed on the LCD display seat; the lens is installed on the lens fixing plate; and the lens fixing plate is installed on a slide plate through the slipping device. The invention further provides the lens shifting method which comprises the following steps: by using the motor to drive the lens to continuously move and drive images on the LCD image display to continuously change, stereo photographic materials on a paper feeding platform are projected and photosensitized for a plurality of times; and through manually adjusting the lens fixing plate to move up and down, the focal length of the lens is focused. The shifter with the advantages of simple structure, convenient operation and high movement precision can conduct stereo multiple projection sensitization.

Owner:SHANGHAI YIYING DIGITAL TECH

Tissue engineering skin with layered structure and preparation method of tissue engineering skin

InactiveCN108452381AIncreased delivery distribution rateImprove survivabilityAdditive manufacturing apparatusProsthesisFiberHuman body

The invention discloses tissue engineering skin with a layered structure and a preparation method of the tissue engineering skin, and relates to the technical field of tissue engineering skin. The tissue engineering skin with the layered structure comprises a collagen layer, a collagen layer embedded in human skin fibroblast, a first multilayer collagen layer, a collagen layer embedded in keratinocyte and a second multilayer collagen layer. According to the tissue engineering skin disclosed by the invention, a manner that channels are innovatively generated in tissues by a temporary material such as gelatin is adopted, and human umbilical vein endothelial cells are adhered to the inner parts of the channels, so that the formed blood vessels are better fit with human body blood vessels; thetransporting and distributing rate of the formed blood vessels is increased; cells have higher viability and high multiplication rate; the printed skin with the layered structure is adopted, so thatthe interaction between cells of the formed skin structure and the interaction of the skin tissues and epimatrix are more stable, and regeneration of the skin tissue is facilitated.

Owner:TAIYUAN UNIV OF TECH

Contactor for electronic components and test method using the same

InactiveUS20080136433A1Eliminate disadvantagesEasy to change sizeCoupling device connectionsElectric discharge tubesElectricityElectronic component

A contactor configured to be electrically connected to the terminals of an electronic component is disclosed. The connector includes multiple contact electrodes contacting the terminals of the electronic component and multiple elastic electrodes each composed of an electrically conductive elastic body. The elastic electrodes generate a pressing force for pressing the contact electrodes against the terminals of the electronic component. The contact electrodes are separable from the elastic electrodes.

Owner:SOCIONEXT INC

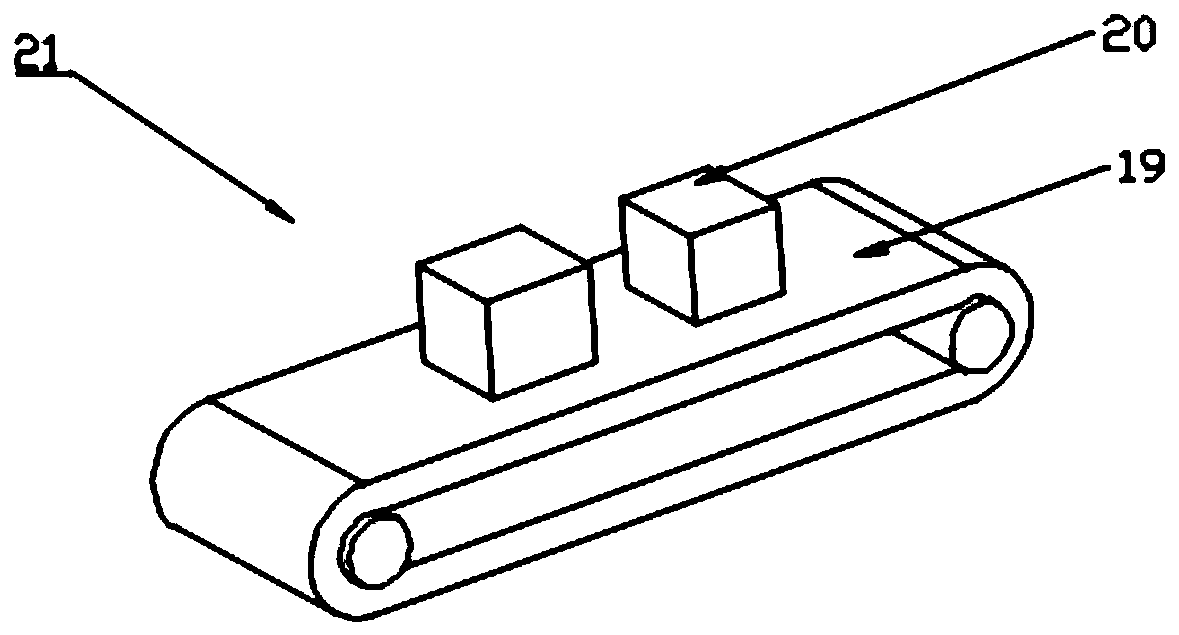

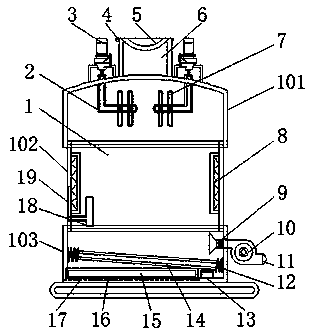

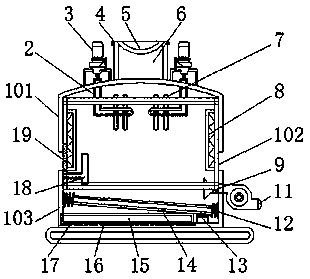

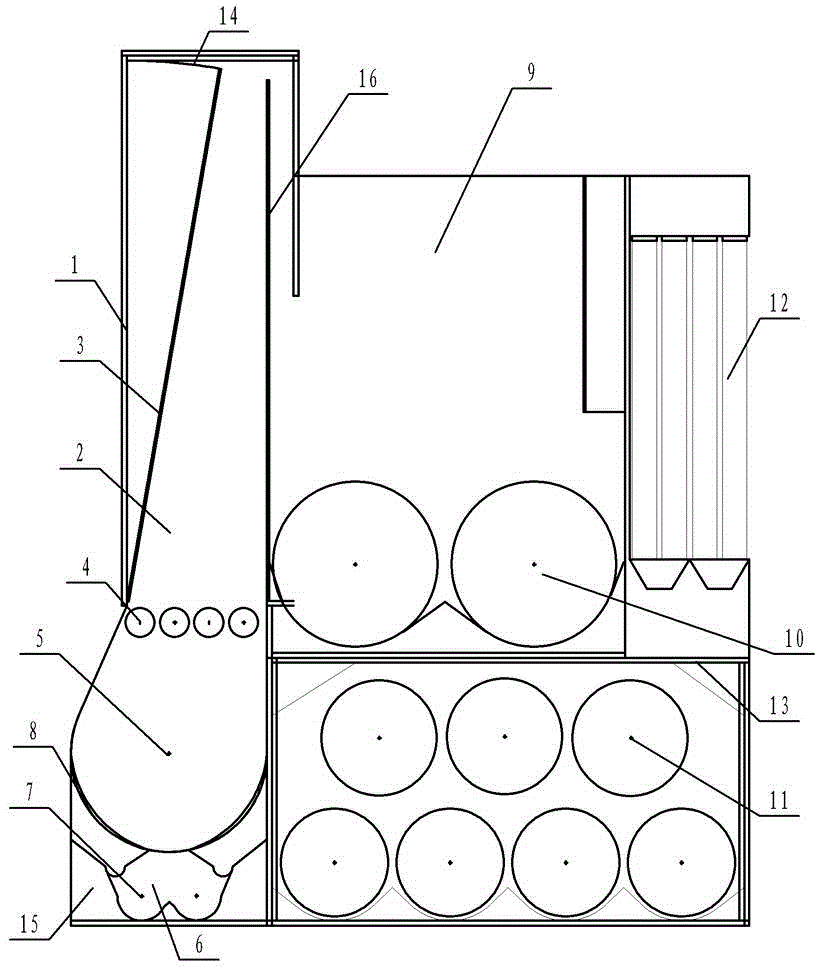

Fruit and vegetable screening machine

InactiveCN111589718ARelieve cloggingImprove flowNon-rotating vibration suppressionGradingEngineeringStructural engineering

The invention discloses a fruit and vegetable screening machine. The fruit and vegetable screening machine comprises a supporting frame, wherein a guide plate is arranged above the supporting frame; the top of the guide plate is provided with a feeding box; front and rear ends of the guide plate upwards extend to form baffle plates; a plurality of guide baffle plates are arranged between the baffle plates; a guide channel is formed between every two guide baffle plates; ends, away from the feeding box, of the guide baffle plates are provided with screening devices; each screening device comprises a screening board, a screening box, and a plurality of screening slots which are formed in the screening plate, wherein screening holes of different sizes are formed in the screening slots, the screening holes are sequentially arranged to the bottom ends of the screening slots from big to small in a longitudinal direction of the screening slots, the bottom ends of the screening slots are provided with screening baffle plates, a plurality of transfer slots are formed in the screening box, each transfer slot corresponds to multiple screening holes of the same dimension, transfer tubes are arranged between the screening holes and the transfer slots, notches are formed in side walls of joints of the transfer tubes and the screening holes, and distance adjustable devices are inserted into the notches. The fruit and vegetable screening machine disclosed by the invention is convenient for relieving a blockage phenomenon while quantity of fruits and vegetables is great.

Owner:安徽富牧通生物科技有限公司

Vacuum automatic film pasting all-in-one machine and film pasting method using same

PendingCN111497210AIncrease the scope of applicationEasy to inflateMechanical engineeringMobile phone

The invention discloses a vacuum automatic film pasting all-in-one machine and a film pasting method using the same. The film pasting all-in-one machine is simple in structure and can adapt to mobiledevices (such as mobile phones and tablet computers) with different sizes, so that the application range of the film pasting all-in-one machine is widened; the film pasting method is simple and reliable, and part of manpower is replaced with a machine, so that the film pasting efficiency and the film pasting quality are improved; in the film pasting process, a film pasting mechanism is inflated while a clamping space is vacuumized, so that the air pressure in the film pasting mechanism is larger than the air pressure in the clamping space, inflation is easier, the film pasting mechanism can more easily and more accurately paste a film onto mobile equipment, and the film pasting quality is guaranteed; and besides, in the film pasting all-in-one machine and the film pasting method using thesame, by arranging fixing piece positioning columns used for hanging a film fixing piece and the film fixing piece used for fixing the film, it can be guaranteed that the film does not make contact with the mobile equipment to be pasted with the film firstly before film pasting, and therefore the film pasting quality is guaranteed.

Owner:东莞市博亦德科技实业有限公司

Down feather storage device with size being changed conveniently

InactiveCN108146782AEasy to change sizeEasy to storeAnimal fibre deburring machinesShock-sensitive articlesSoftware engineeringDown feather

The invention discloses a down feather storage device with the size being changed conveniently. The down feather storage device comprises a storage chamber main body, rotating vanes, a push plate andfixing screws. The upper portion of the storage chamber main body is provided with rotating rods. The upper portions of the rotating rods are fixedly provided with motors. The right sides of the motors are provided with a feeding opening, the upper portion of the feeding opening is provided with a rotating shaft, the upper portion of the rotating shaft is fixedly provided with a fixing cover. Thelower portions of the rotating vanes are provided with the rotating rods, heating wires are arranged below the rotating vanes, a sucking pipe is fixed below the heating wires, and the right side of the sucking pipe is provided with a draught fan. The right side of the draught fan is fixedly provided with a discharging opening, the left side of the discharging opening is provided with a fixing spring, the left side of the fixing spring is provided with a transverse plate, and a vibrator is arranged below the transverse plate. The down feather storage device with the size being changed conveniently is provided with a first storage chamber, a second storage chamber and a third storage chamber, and therefore the height and size of the whole device can be changed through the first storage chamber, the second storage chamber and the third storage chamber.

Owner:ZHANJIANG ZIJIN DOWN PROD

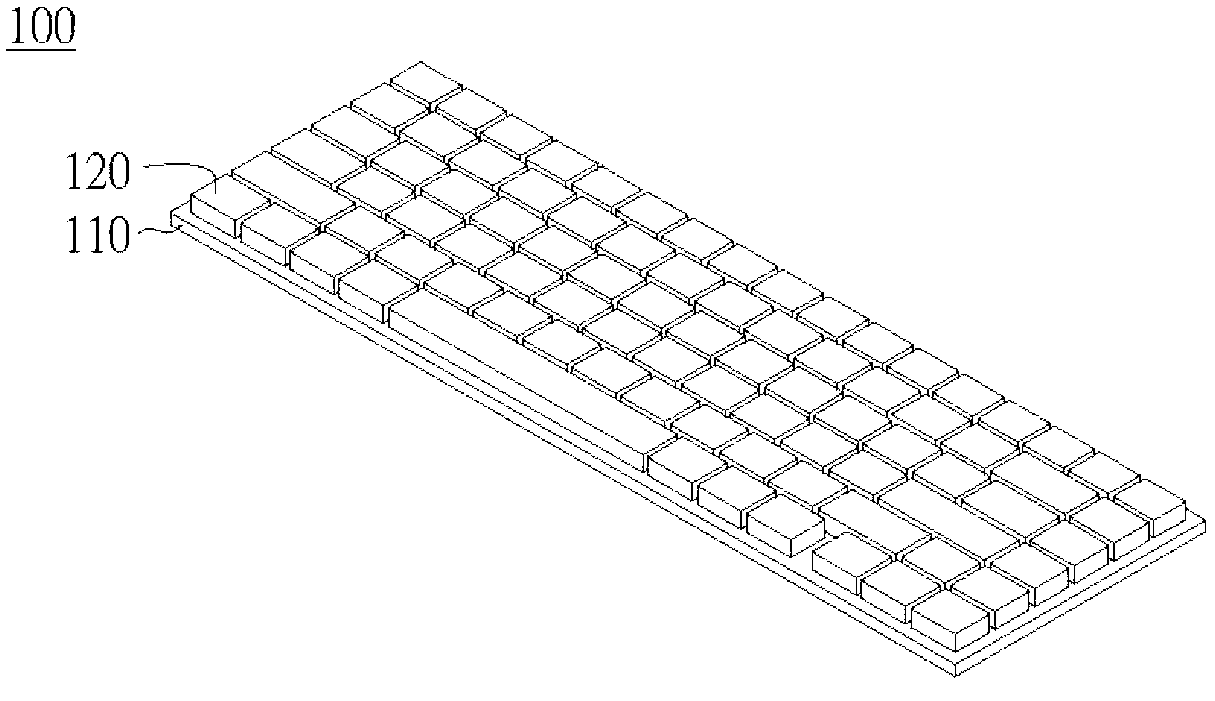

Key and keyboard with same

ActiveCN103219184AReduce slopeSimple structureElectric switchesEngineeringElectrical and Electronics engineering

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

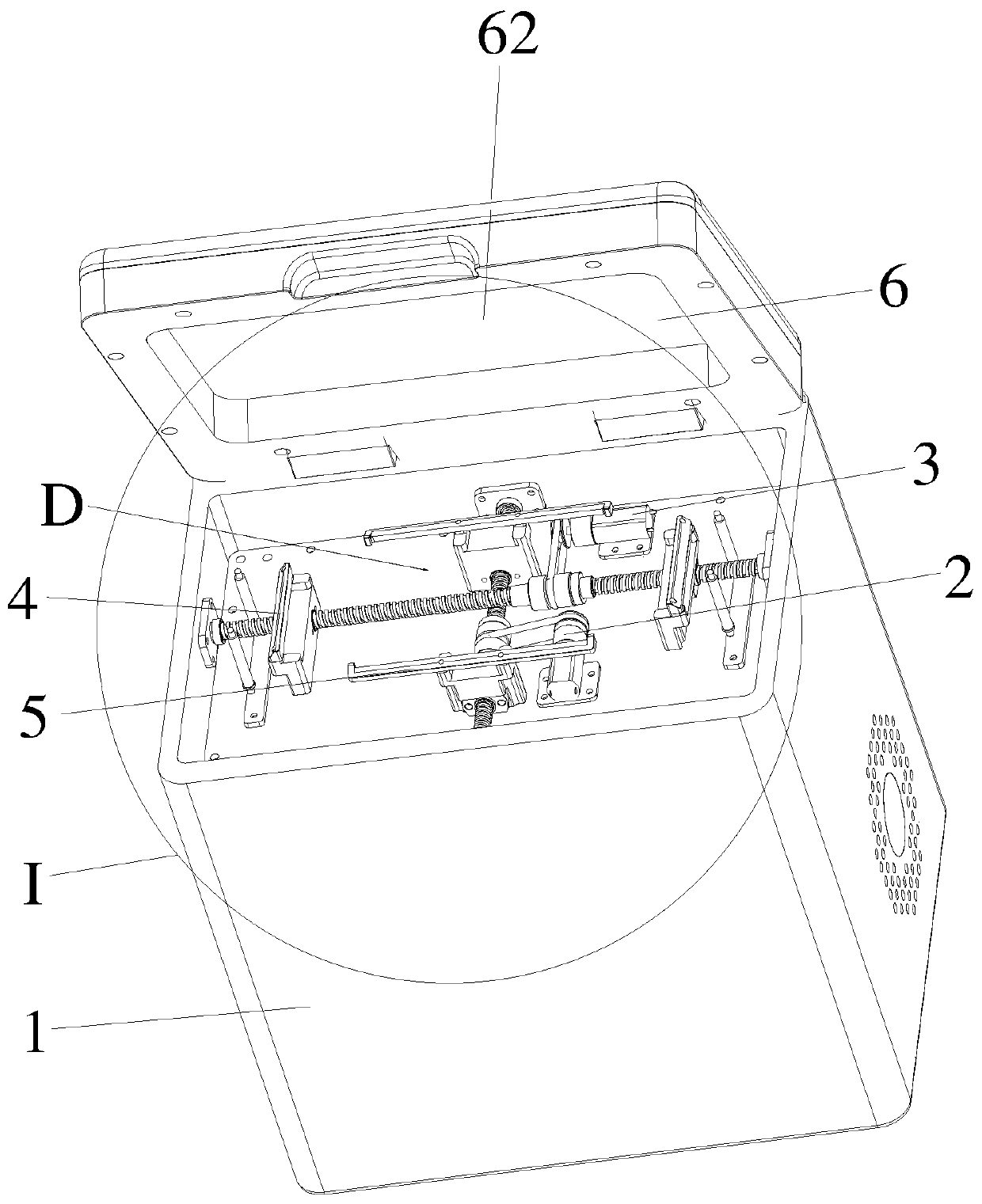

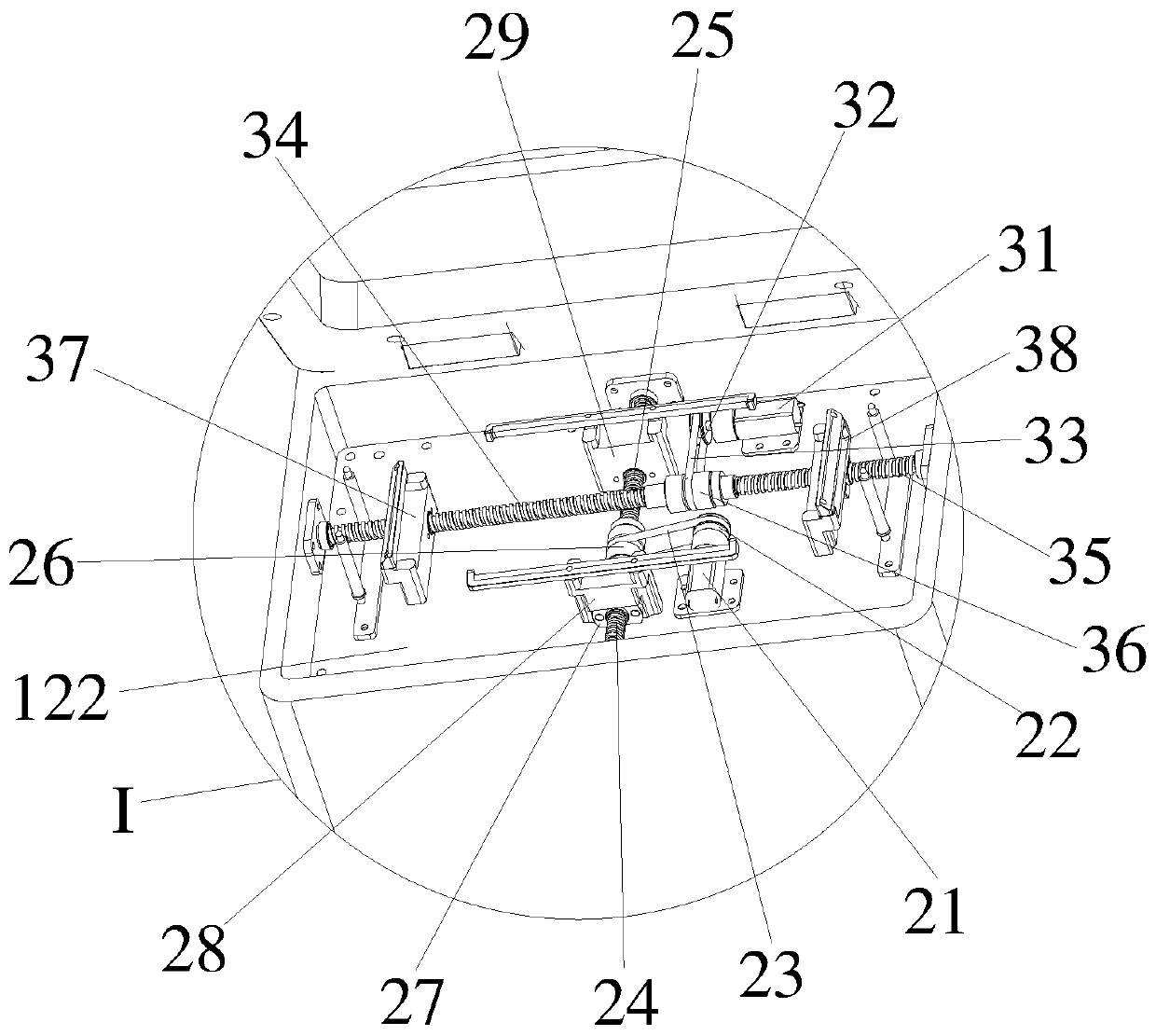

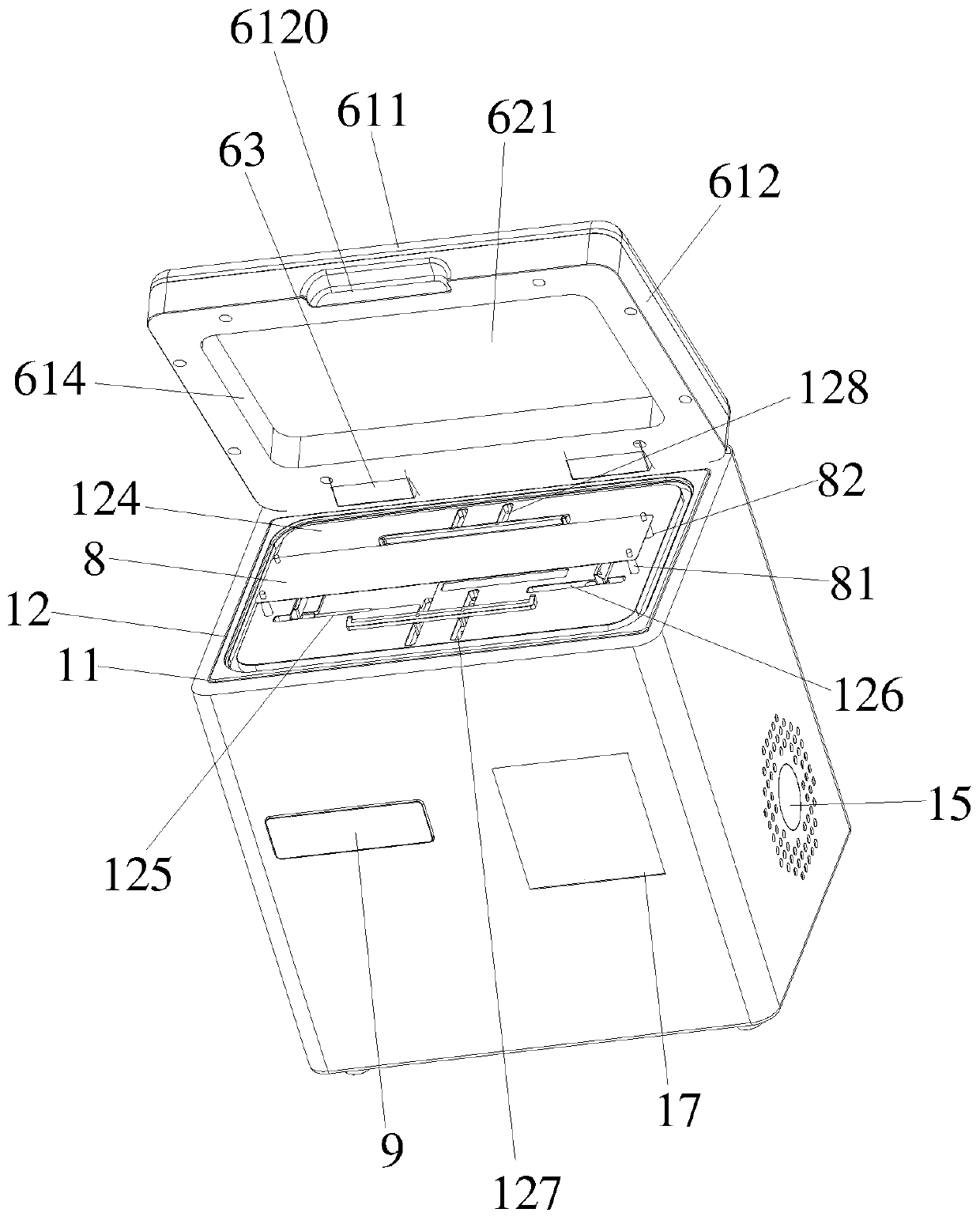

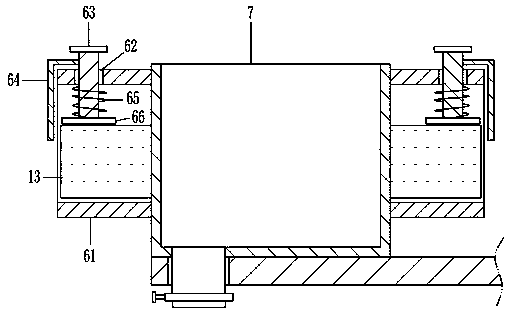

Multi-functional network box protection device

ActiveCN110087431AEasy to fixFixed and easy to changeClamping/extracting meansCooling/ventilation/heating modificationsEngineeringFunctional network

The invention relates to a multi-functional network box, and more specifically relates to a multi-functional network box protection device. The multi-functional network box protection device can fix and seal the multi-functional network box through a fixation and protection device, can fix multi-functional network boxes with different specifications through the fixation and protection device, cancarry out cooling on the fixation and protection device through an external cooling device so as to cool the multi-functional network box in the fixation and protection device and prevent the multi-functional network box from overheating, and can isolate vibration for the multi-functional network box through a lower buffer device. The multi-functional network box protection device comprises the fixation and protection device, the external cooling device and the lower buffer device. An inner pusher pushing rod is reversely pushed under the action of an elastic force of an inner pusher pushing spring so as to enable the inner pusher pushing rod to be extruded with the multi-functional network box and complete the fixation of the multi-functional network box; and a lower hinged sliding columnslides along a lower sliding waist groove to adjust the distance between multiple inner-end sliding pusher assemblies, thereby enabling the inner pusher pushing rods on the inner-end sliding pusher assemblies to be changed in spatial position.

Owner:滨州高新区国有资本投资运营有限公司

Adjustable combined dining table

InactiveCN107510248AWith bufferReduce lossesNon-rotating vibration suppressionExtensible tablesEngineering

Owner:HUIZHOU OUYE SCI & TECH

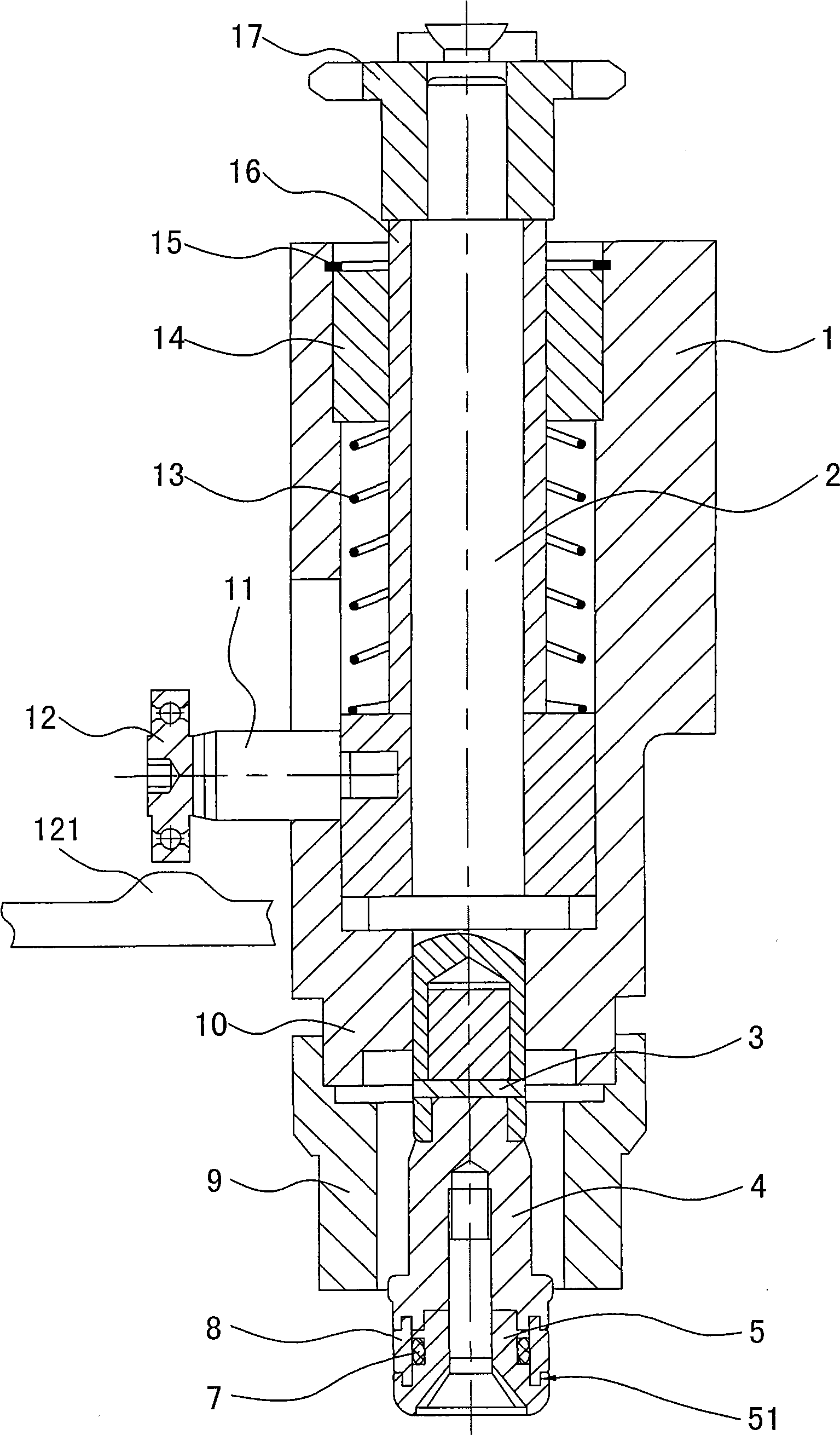

Heating plug for loading and unloading plastic bottle blank by rotary lifting

The invention relates to a heating plug for loading and unloading plastic bottle blank by rotary lifting, which comprises a machine body connected on a heater running mechanism. A core shaft is arranged in the machine body, the end of the core shaft is connected with the head of the plug, the outer wall of the head is provided with a mobile groove which is internally provided with an expanding sleeve, one end of the expanding sleeve is fixed by a limit block, and the inner side of the expanding sleeve is provided with an elastic ring. The heating plug is characterized in that the core shaft is provided with an upper check ring, a spring and a sliding sleeve, the sliding sleeve is connected with a shaft pin which is provided with a roller, a material pushing convex rail contacts with the roller, and the lower part of the machine body is connected with a blank unloading sleeve. The plug of the technical proposal automatically completes the loading and unloading of the bottle blank by the lifting of the core shaft, the whole part is arranged in the machine body, the structure is simple, and the mechanical running has accurate positioning and reliable effect.

Owner:汪祥建

LED lamp printing and dyeing device

InactiveCN108656720APrevent slidingMobile status is stableRotary pressesOther printing apparatusLED lampThreaded rod

The invention discloses an LED lamp printing and dyeing device. The device comprises a base, the base is of a hollow structure, two symmetric first supporting rods are arranged on the base, a thread rod which is horizontally arranged is arranged in the base, one end of the thread rod is rotatably connected with the inner wall of the base, the other end of the thread rod penetrates the side wall ofthe base, the thread rod is sleeved with two symmetric first sliding blocks, the first sliding blocks are in threaded connection with the thread rod, the upper side wall of each first sliding block is connected with a second supporting rod which is vertically arranged, a strip opening matched with each second supporting rod is formed in the upper side wall of the base, the second supporting rodspenetrate the strip openings, clamping blocks are connected to the positions, above the base, of the side walls of the opposite sides of the two second supporting rods, and clamping grooves are formedin the clamping blocks. The fixing effect on a lamp is good, and a printing and dyeing head is convenient to disassemble and replace.

Owner:HAINING XINSHIDA PHOTOELECTRIC

Contactor for electronic components and test method using the same

InactiveUS7518388B2Eliminate disadvantagesEasy to change sizeCoupling device connectionsElectronic circuit testingElectricityEngineering

A contactor configured to be electrically connected to the terminals of an electronic component is disclosed. The connector includes multiple contact electrodes contacting the terminals of the electronic component and multiple elastic electrodes each composed of an electrically conductive elastic body. The elastic electrodes generate a pressing force for pressing the contact electrodes against the terminals of the electronic component. The contact electrodes are separable from the elastic electrodes.

Owner:SOCIONEXT INC

Boiler waste heat utilization device

PendingCN113757710AAvoid wastingHeating evenlyHeat recovery systemsRecuperative heat exchangersWater storageProcess engineering

The invention discloses a boiler waste heat utilization device which specifically comprises a base, a water storage barrel and a top cove, a heating space is formed in the base, and a smoke outlet is formed in the top of the heating space; the water storage barrel is arranged at the top of the base, a heat exchange device is arranged in the water storage barrel, and the bottom of the heat exchange device is communicated with a matched cornice at the top of the heating space; the top cover is arranged at the top of the water storage barrel, an adjusting device is arranged in the top cover, and the bottom of the adjusting device communicates with the top of the heat exchange device; the heat exchange device comprises a flow dividing disc, the side face of the flow dividing disc communicates with spiral heat exchange pipes through rotating devices, and the multiple sets of rotating devices and the multiple sets of spiral heat exchange pipes are arranged. The invention relates to the technical field of waste heat utilization. According to the boiler waste heat utilization device, heat in smoke can be used for conducting auxiliary heating on water, heat waste is avoided, boiler heating can be more uniform, and the heat exchange efficiency can be improved conveniently.

Owner:王伟

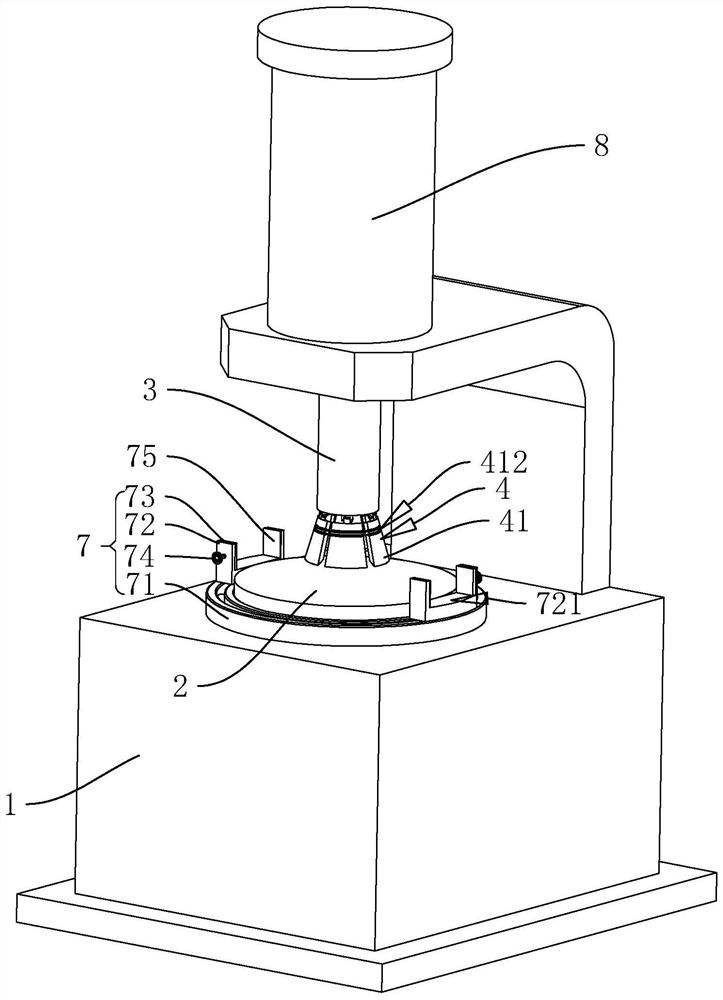

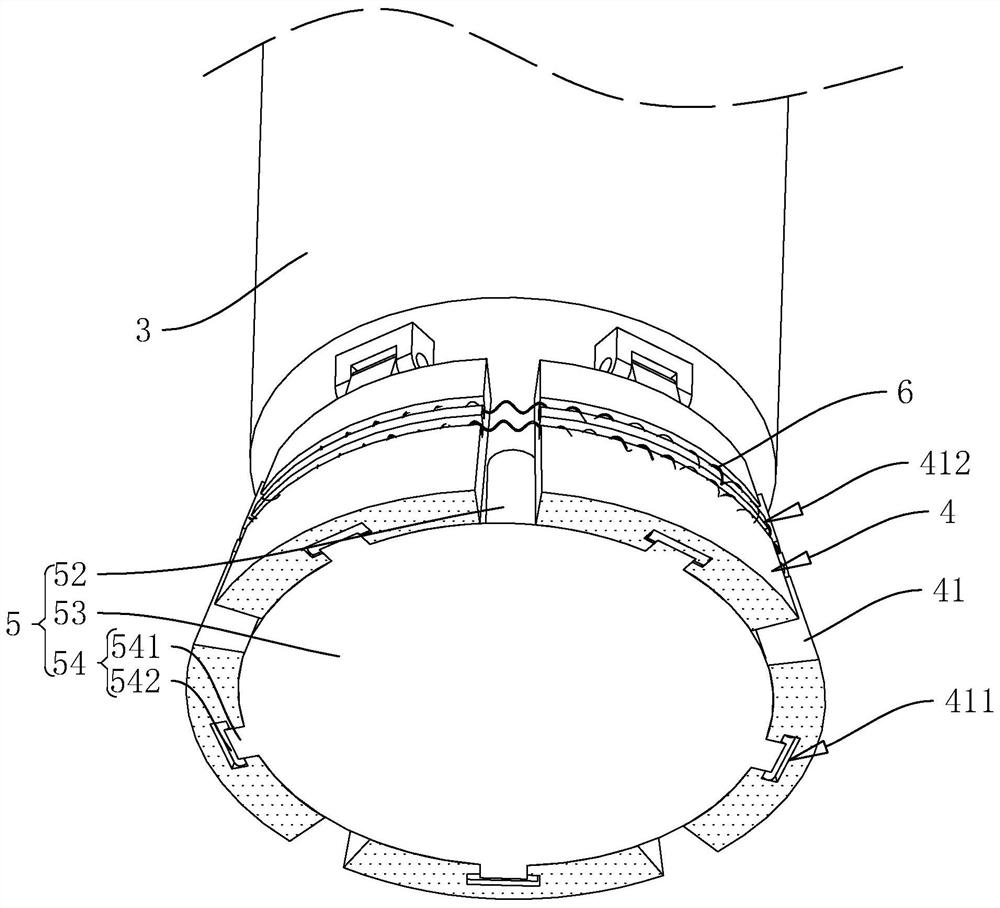

Guardrail punching machine

PendingCN113857336AImprove convenienceReduce pull strengthShaping toolsPerforating toolsPunchingStructural engineering

The invention discloses a guardrail punching machine, and relates to the field of punching equipment. The guardrail punching machine comprises a rack, a pressure-bearing table and a punching head, the pressure-bearing table is connected with the rack, the punching head is slidably connected with the rack, the punching head is located at the top of the pressure-bearing table, the guardrail punching machine further comprises a punching ring and a driving assembly, the punching ring is arranged at the end, close to the pressure-bearing table, of the punching head, the punching ring comprises a plurality of punching cutters, and the multiple punching cutters are all hinged to the punching head. The driving assembly comprises driving blocks and guiding pieces, the driving blocks are located on the inner walls of the punching cutters and can move towards the side close to the punching head, the guiding pieces are located at the sides, facing the punching cutters, of the driving blocks, driving grooves are formed in the punching cutters, the driving grooves are formed in the moving direction of the driving blocks, the guiding pieces can slide along the driving grooves and can drive the punching cutters to move towards the sides away from each other or close to each other. According to the machine, the convenience of punching through holes with different diameters in a guardrail can be improved.

Owner:陕西雄峰实业集团有限公司

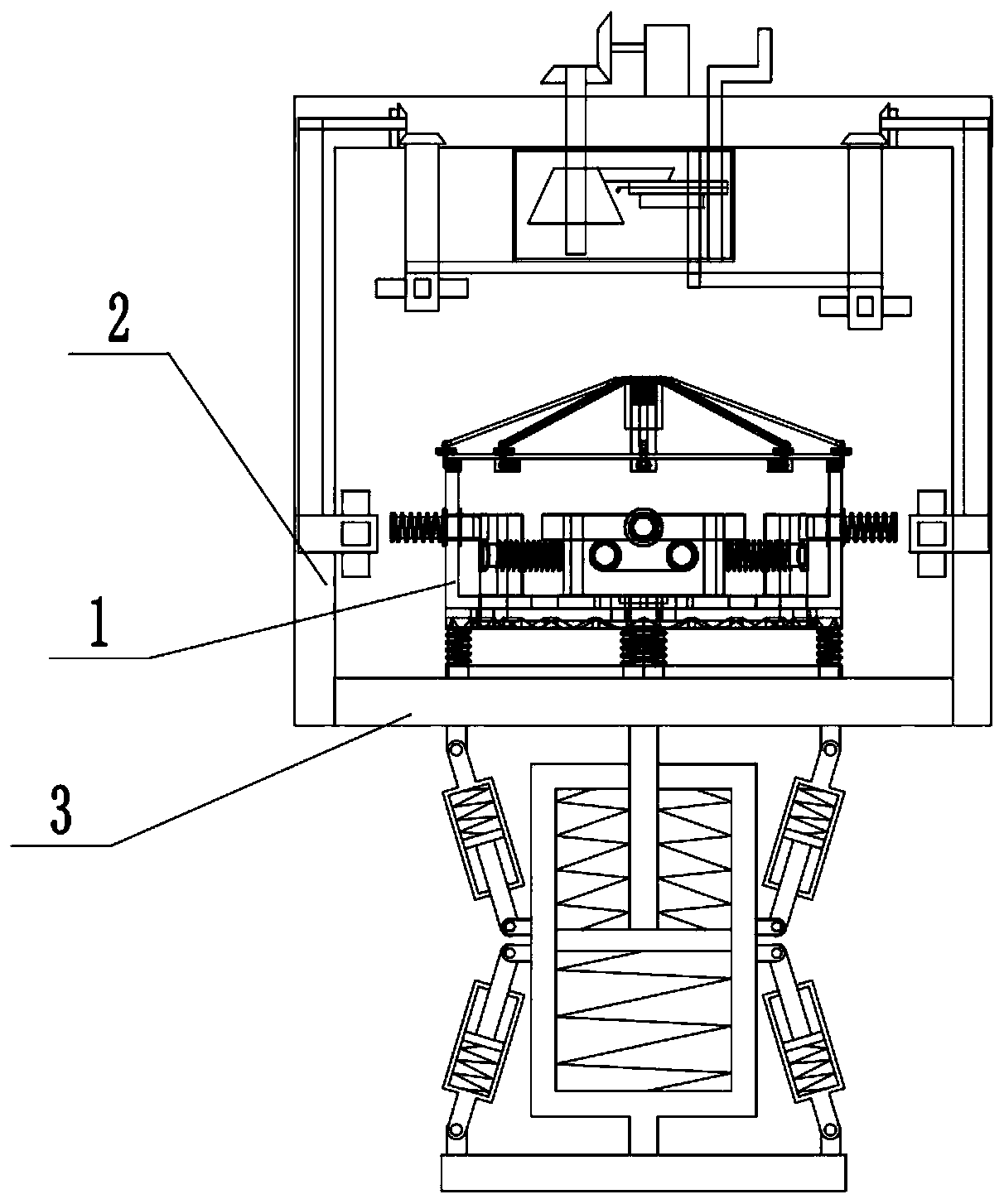

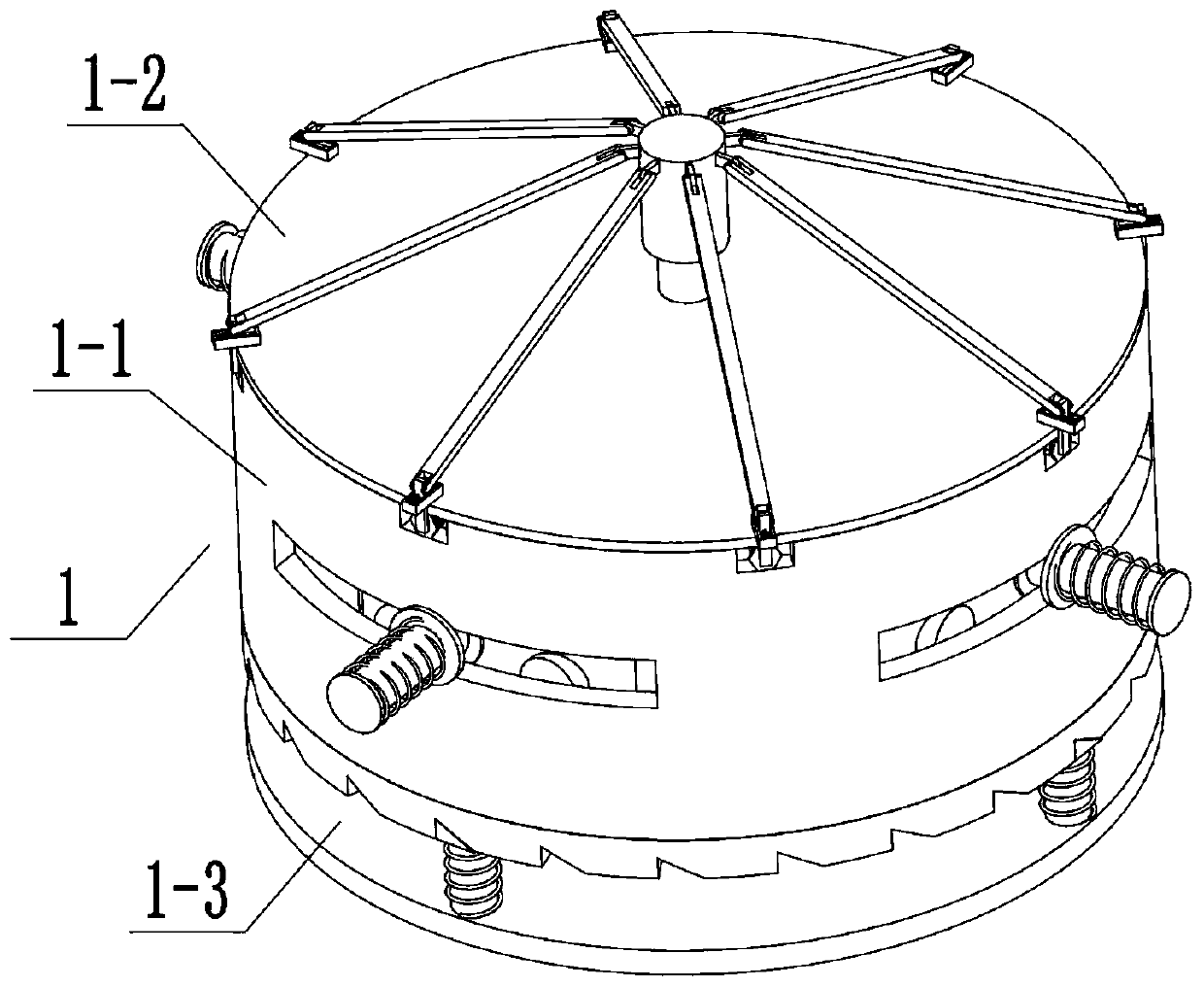

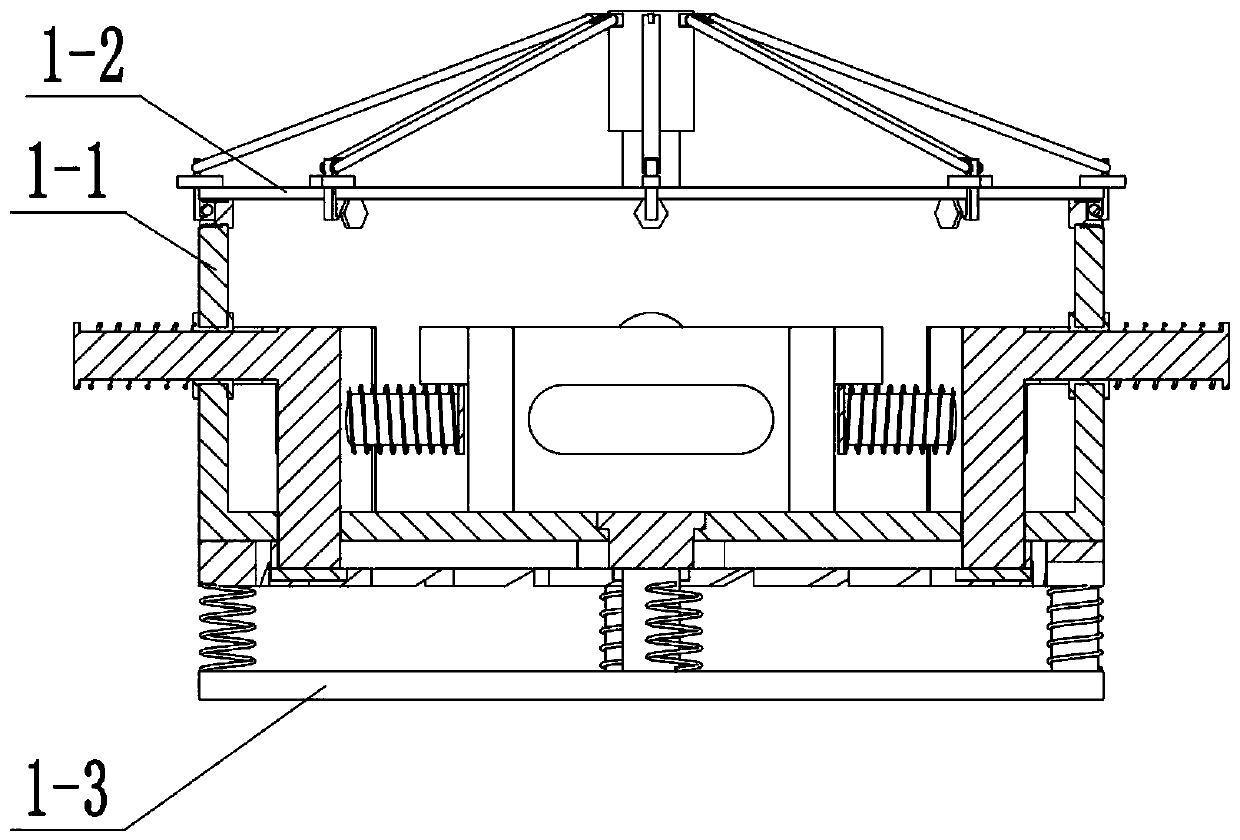

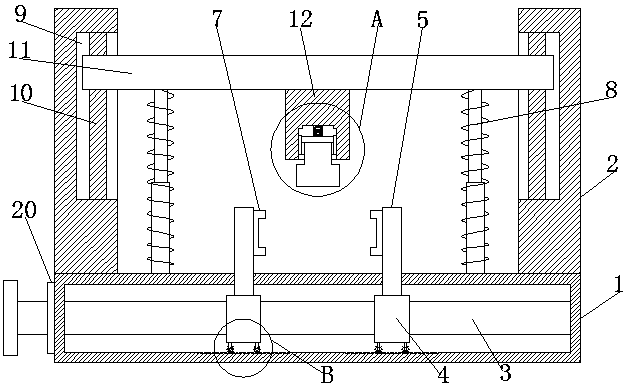

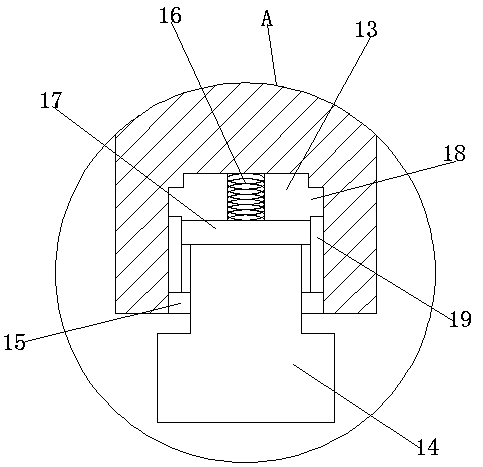

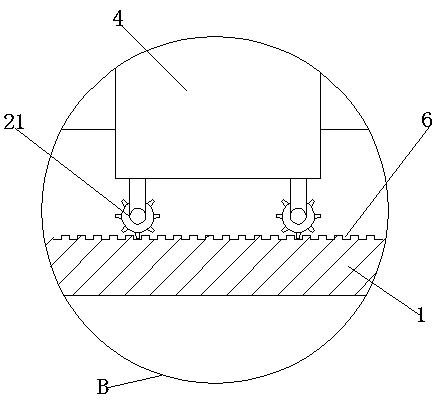

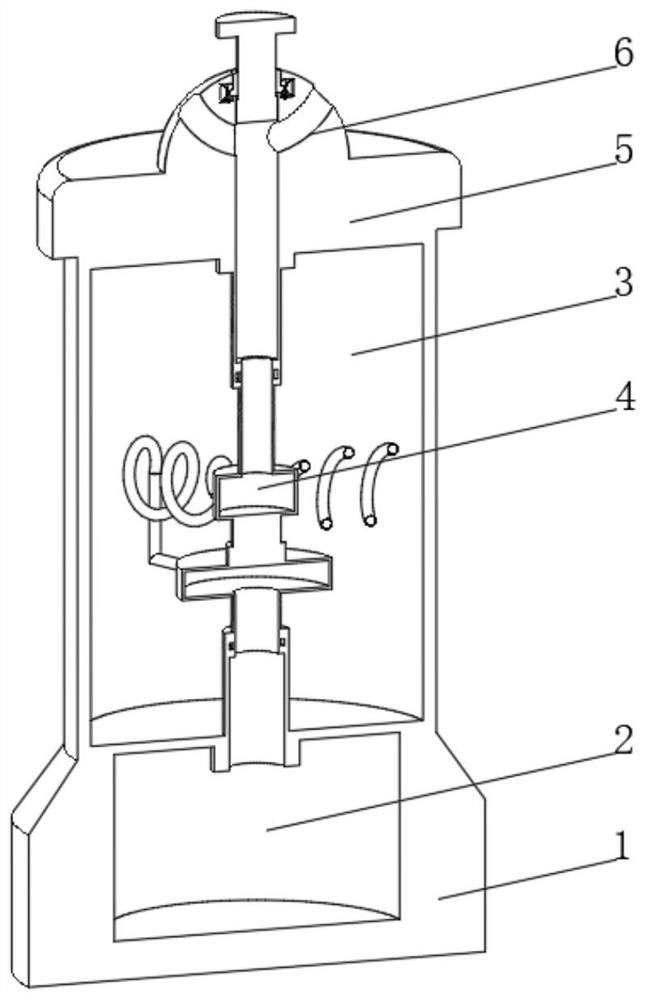

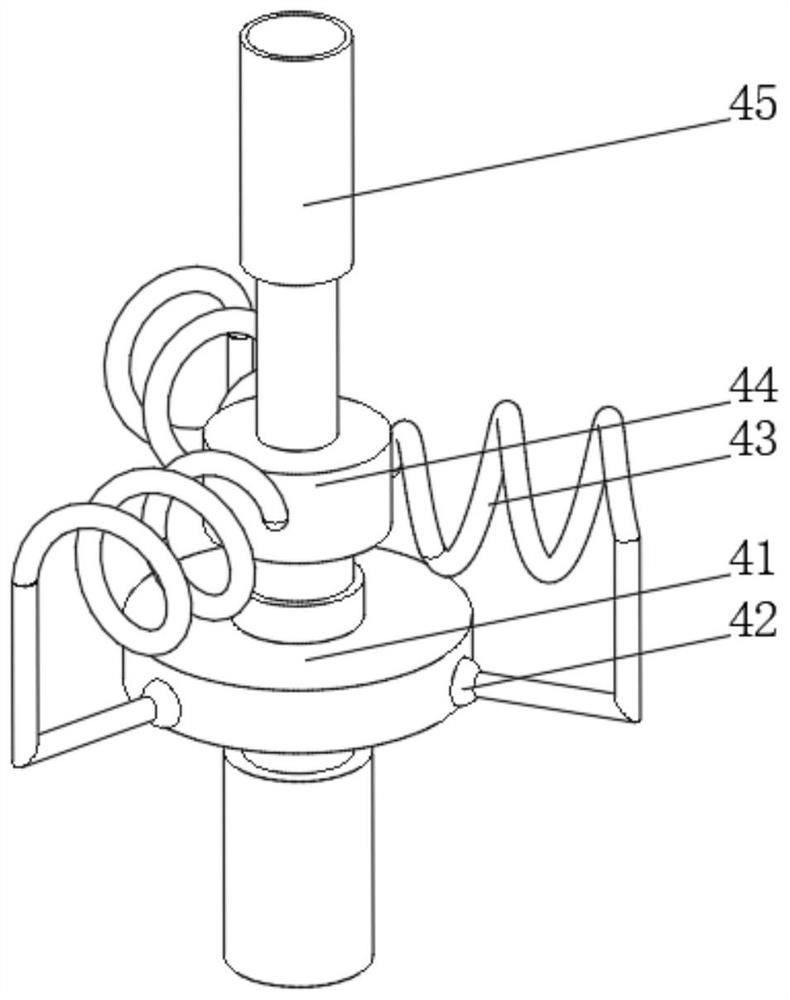

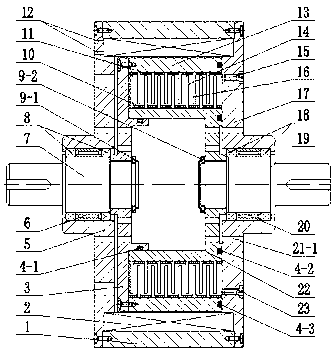

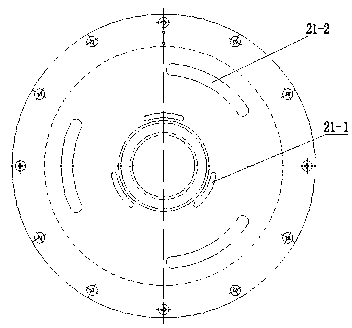

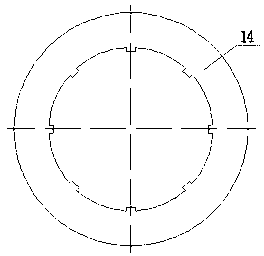

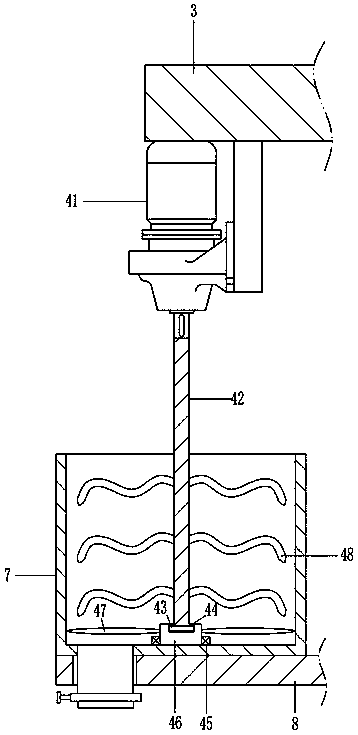

Multi-plate magnetorheological soft start device

ActiveCN102297213BEasy to change sizeSimple structureConveyorsFluid clutchesMagnetorheological fluidEngineering

The invention discloses a multi-plate magnetorheological soft start device, which is characterized in that: a right shaft is in threaded connection with a right sealing disk; the outer ring of the right sealing disk is provided with a key groove which is matched with internal teeth of internal friction plates; a left shaft is in threaded connection with a left sealing disk; the left sealing disk is connected with a sealing ring through a screw; the inner ring of the sealing ring is provided with a key groove which is matched with external teeth of external friction plates; the internal friction plate and the external friction plates are alternately arranged; a magnet exciting coil is arranged between a left end plate and a right end plate; and the upper part of the right end plate is provided with a fluid injecting bolt, and the lower part of the right end plate is provided with a fluid discharging bolt. Magnetorheological fluid is taken as a working medium, the in-plate magnetic induction density is regulated by controlling the current of the magnet exciting coil, and the transmission torque is changed, so that the controlled soft start of heavy mechanical equipment is realized. The multi-plate magnetorheological soft start device has a hollow symmetrical structure, has high heat dissipation and high reliability and is convenient to operate.

Owner:苏州方德锐精密机电科技有限公司

Photovoltaic component border device and border main body thereof

InactiveCN102496641AEasy to change sizeGuaranteed StrengthPhotovoltaic supportsPhotovoltaic energy generationMechanical equipmentElectrical and Electronics engineering

The invention discloses a photovoltaic component border main body. A mounting groove for placing a photovoltaic solar panel is reserved on the upper part of the photovoltaic component border main body, and a fixed groove is reserved on the lower part of the photovoltaic component border main body. The mounting groove is formed by a lower side plate and a curved plate, wherein the curved plate is upwards extended along one side of the lower side plate and towards the other side of the lower side plate. The curved plate provides a surplus material for a change in the shape or size of the mounting groove in which the photovoltaic solar panel is placed, and can be pressed down or tilted upwards on the premise of ensuring certain strength to easily change the size of the mounting groove, so that the photovoltaic component border main body can be randomly bent by utilizing mechanical equipment according to the size and shape of a photovoltaic component. Therefore, the application range of the photovoltaic component border main body is widened. The invention also discloses a photovoltaic component border device with the photovoltaic component border main body.

Owner:BAODING TIANWEI YINGLI NEW ENERGY RESOURCES

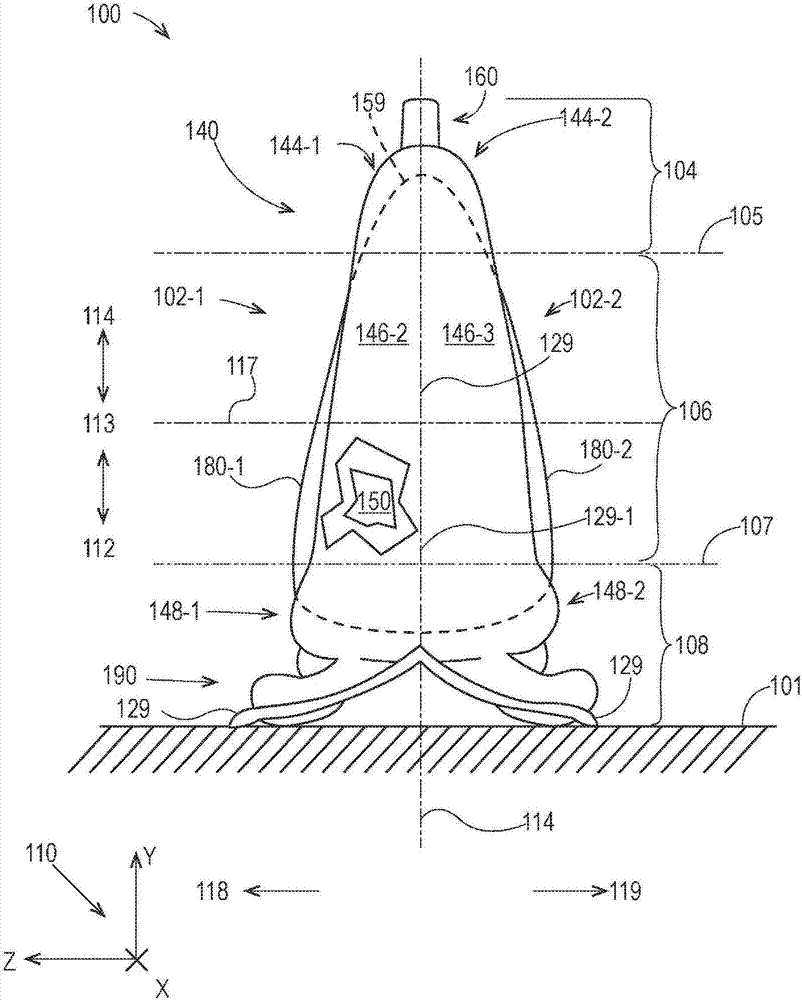

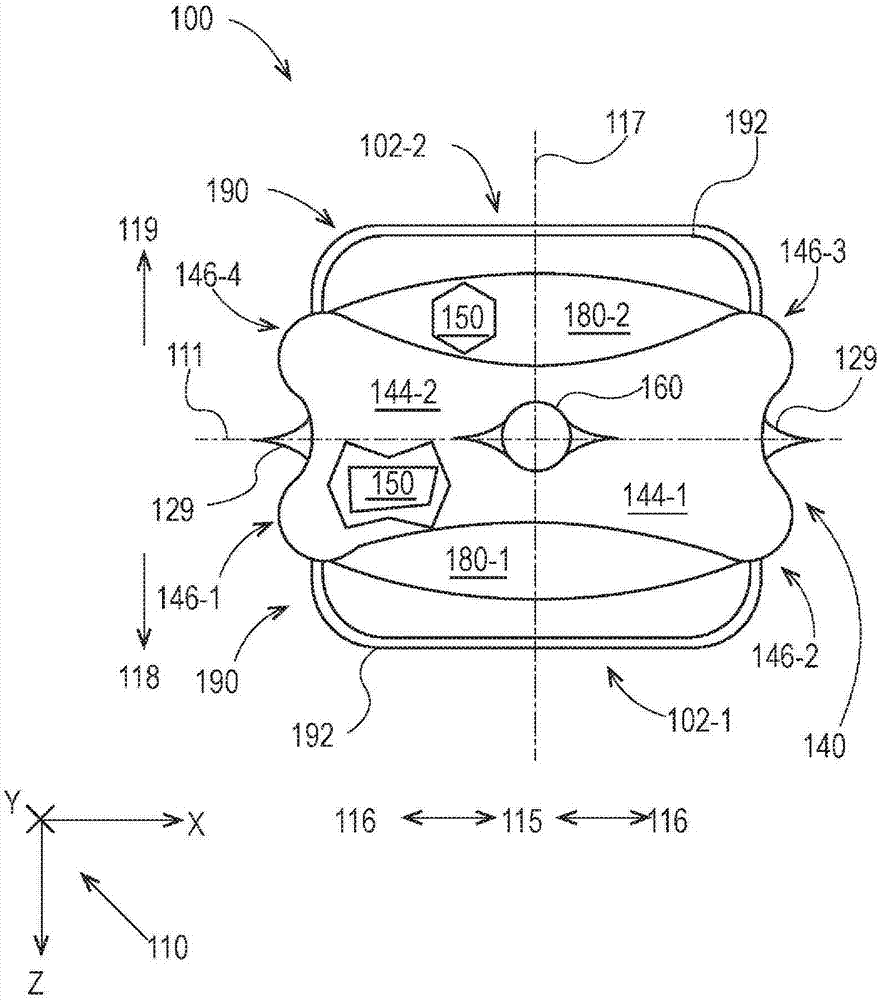

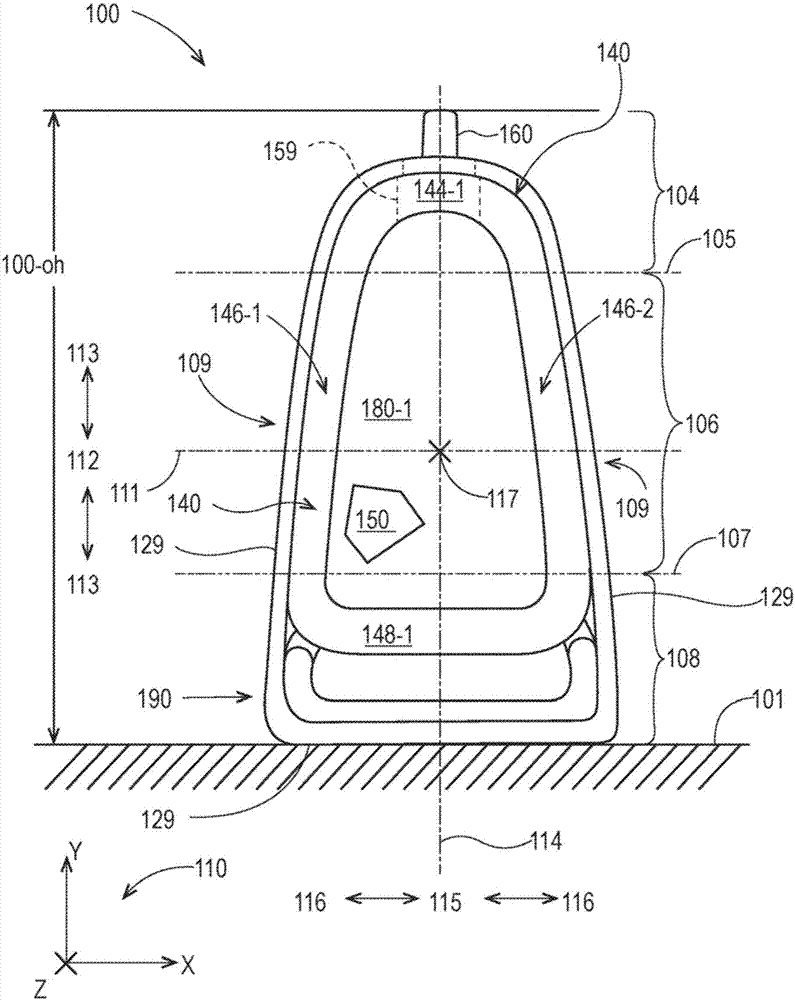

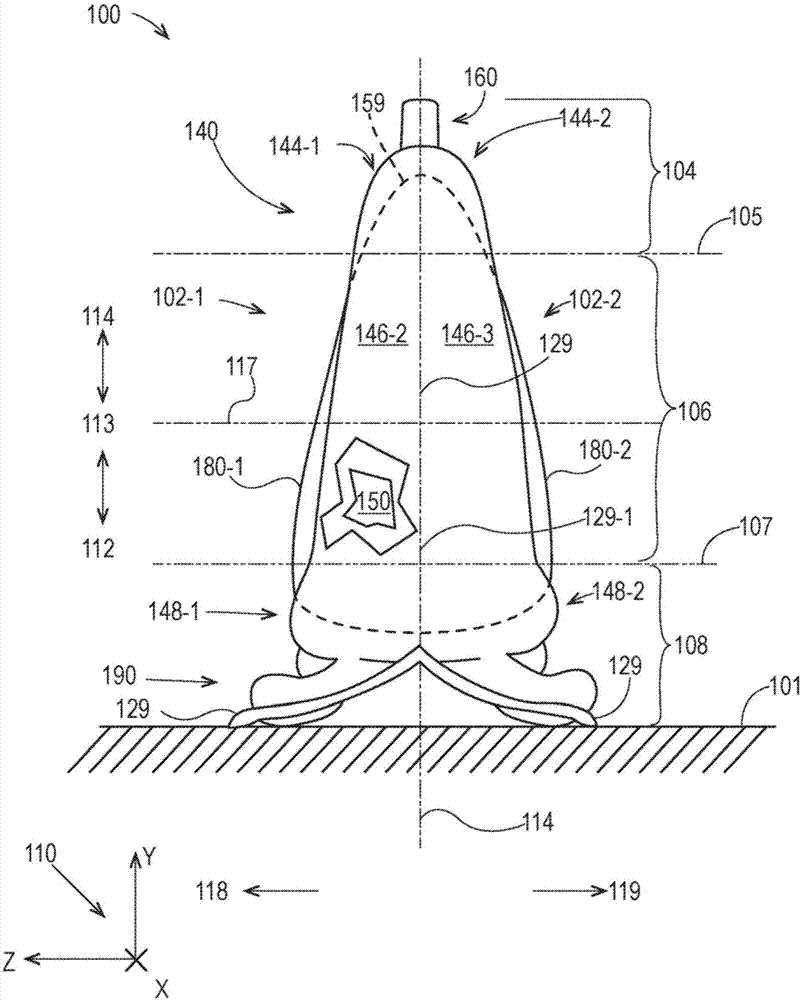

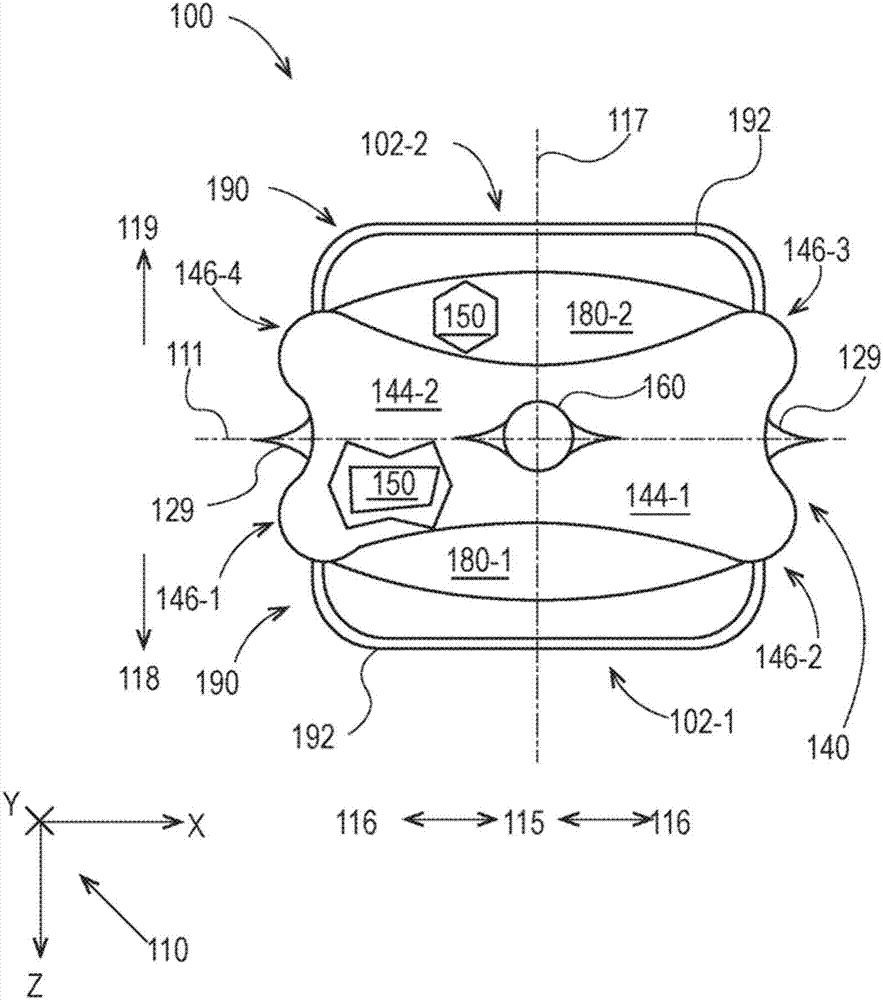

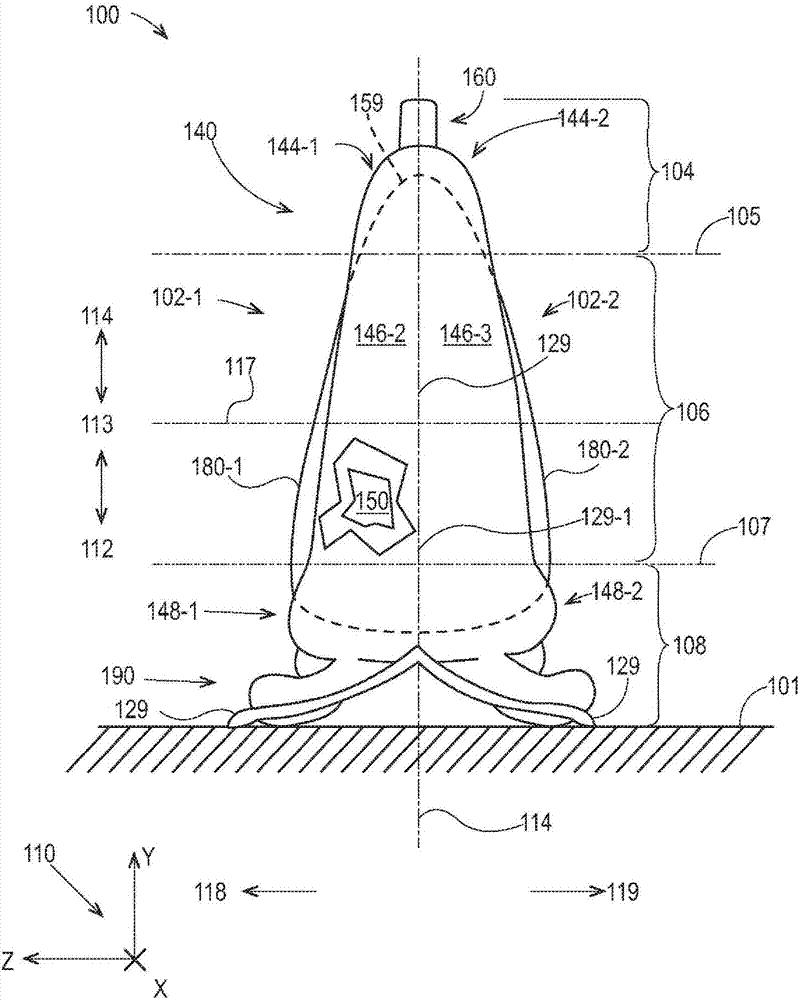

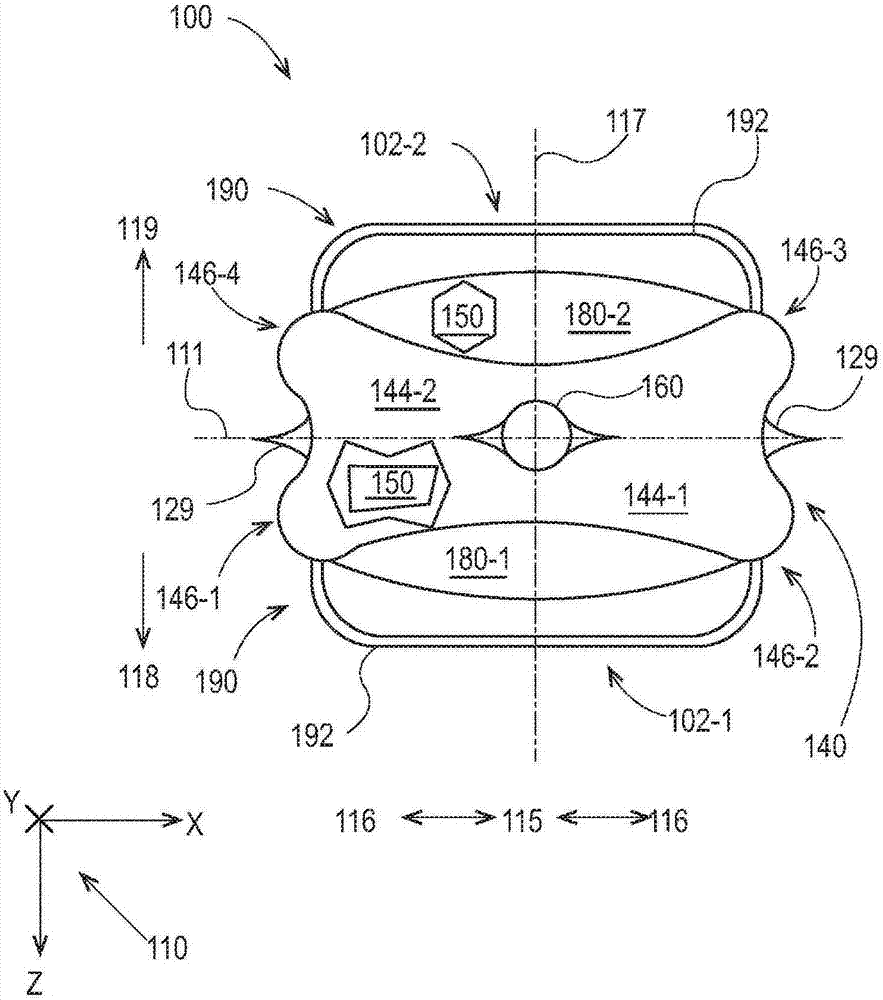

Flexible containers with product dispensing visibility

ActiveCN107428437ACheap manufacturingReduce complexitySingle-unit apparatusFlexible containersVisibilityEngineering

Flexible containers with a flow channel in a sealed leg of a gusset and having product dispensing visibility.

Owner:THE PROCTER & GAMBNE CO

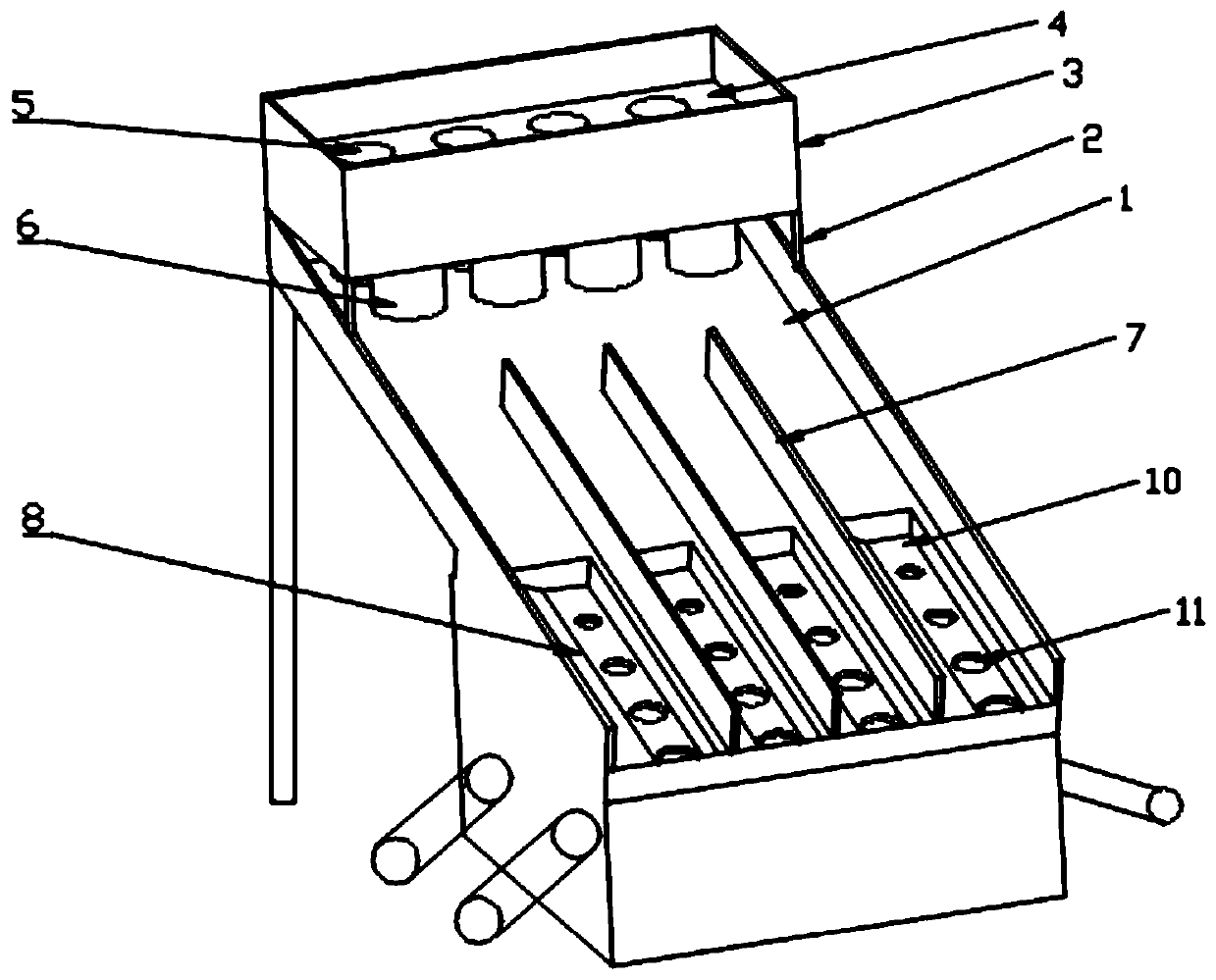

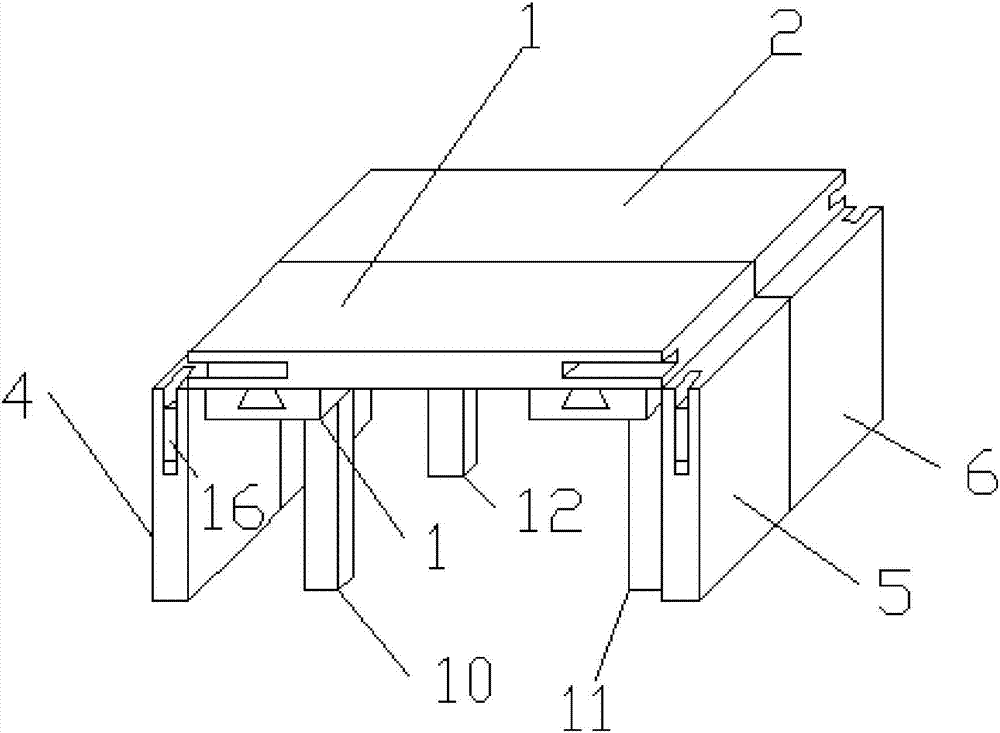

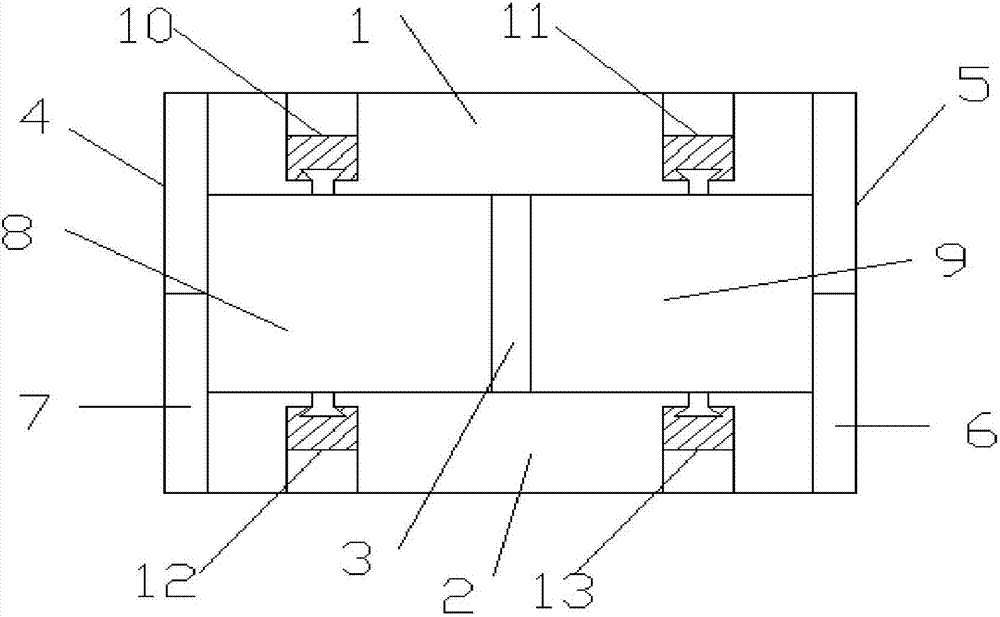

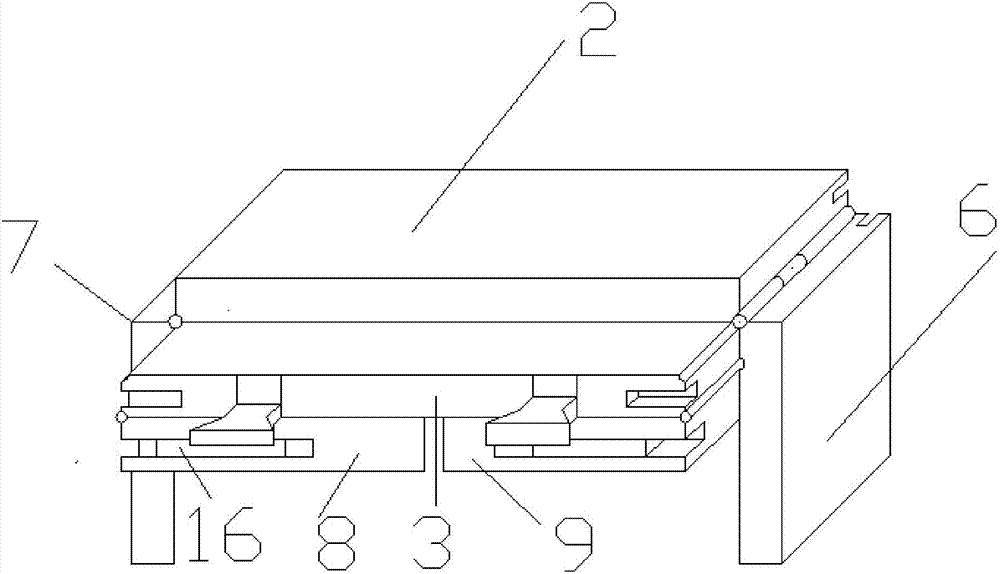

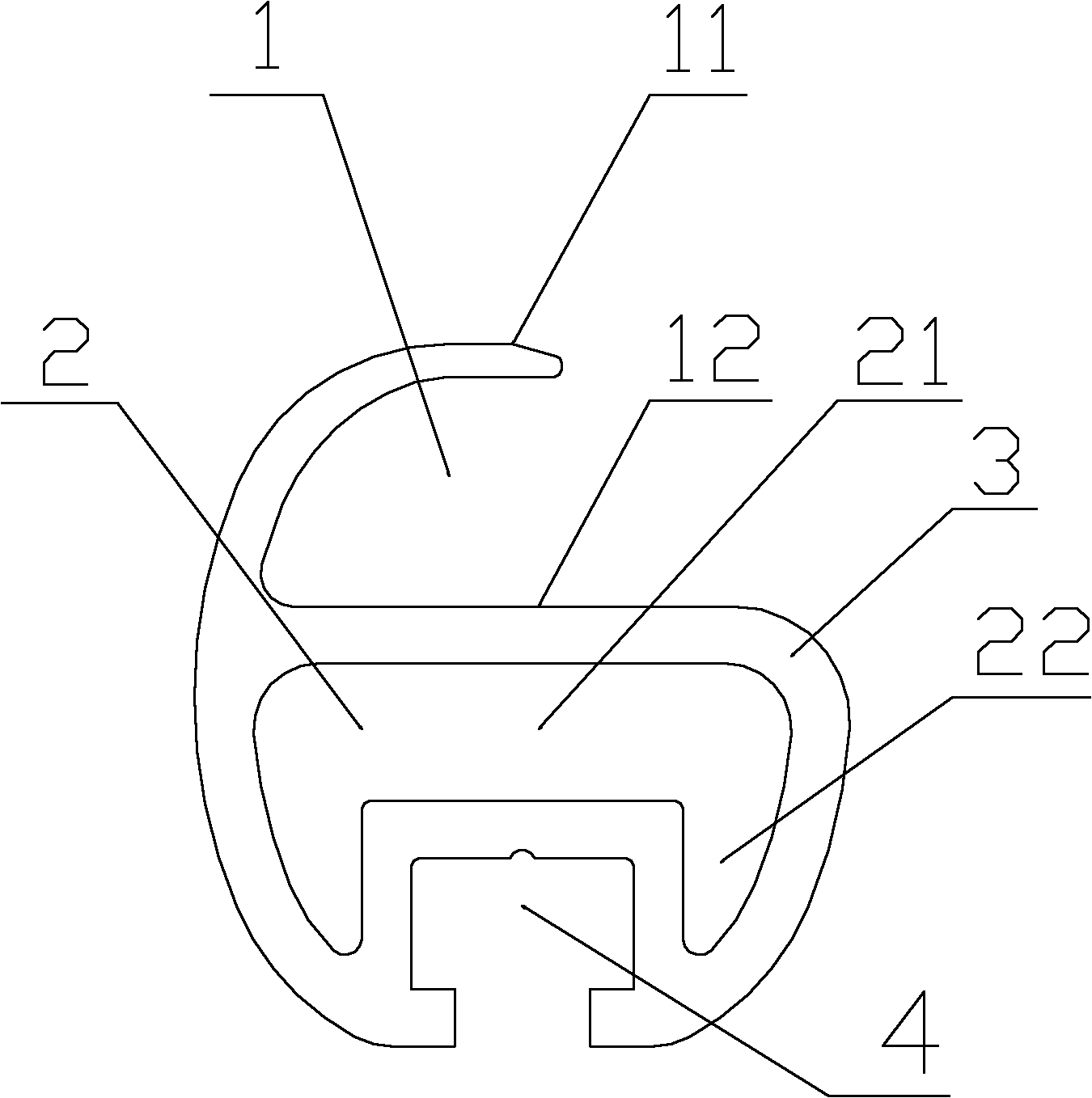

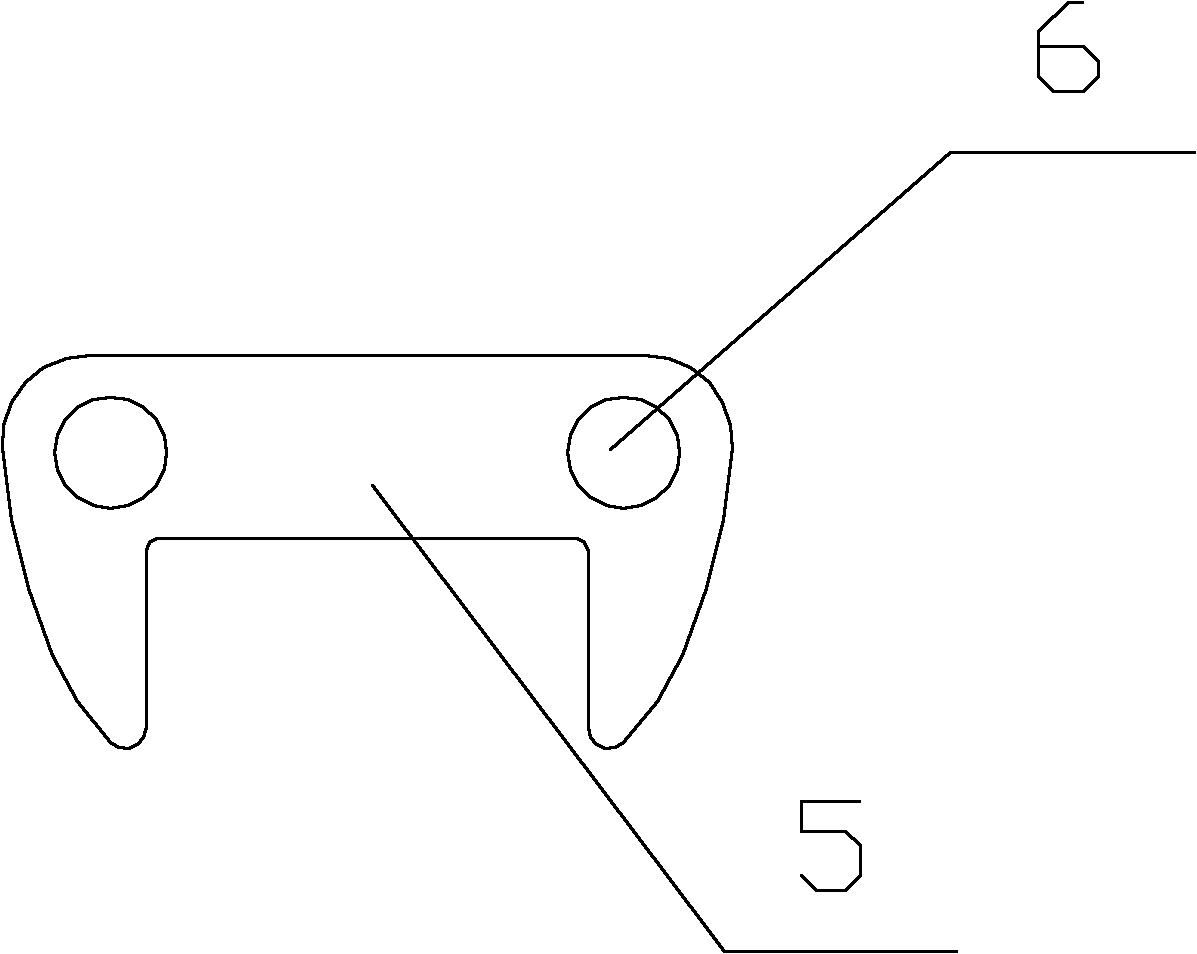

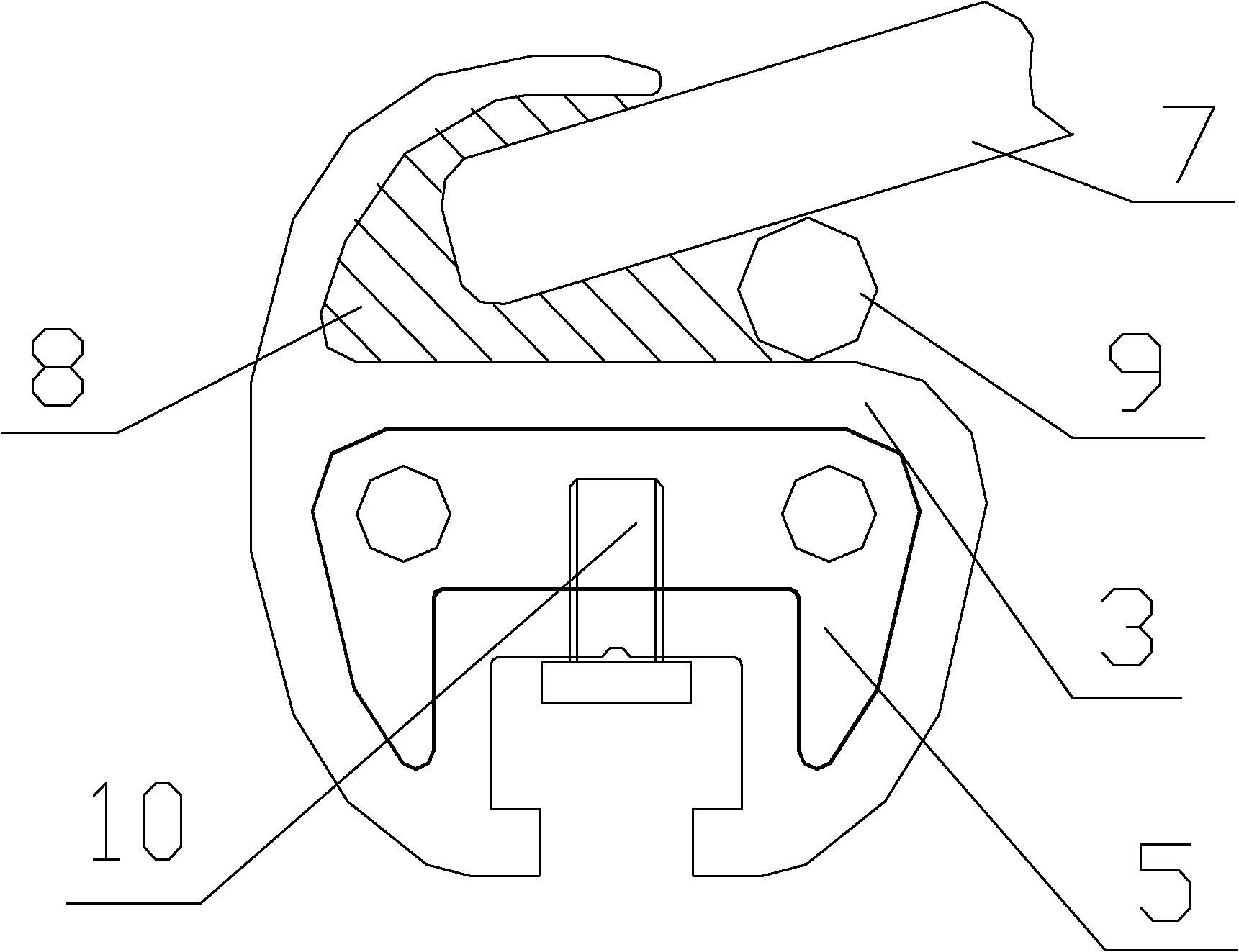

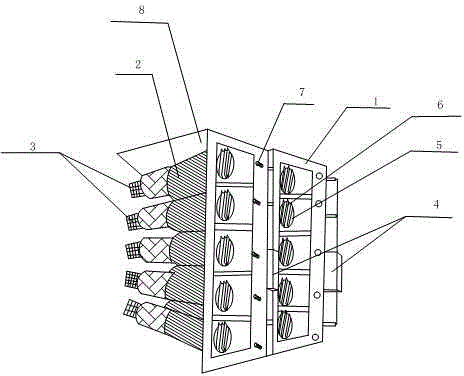

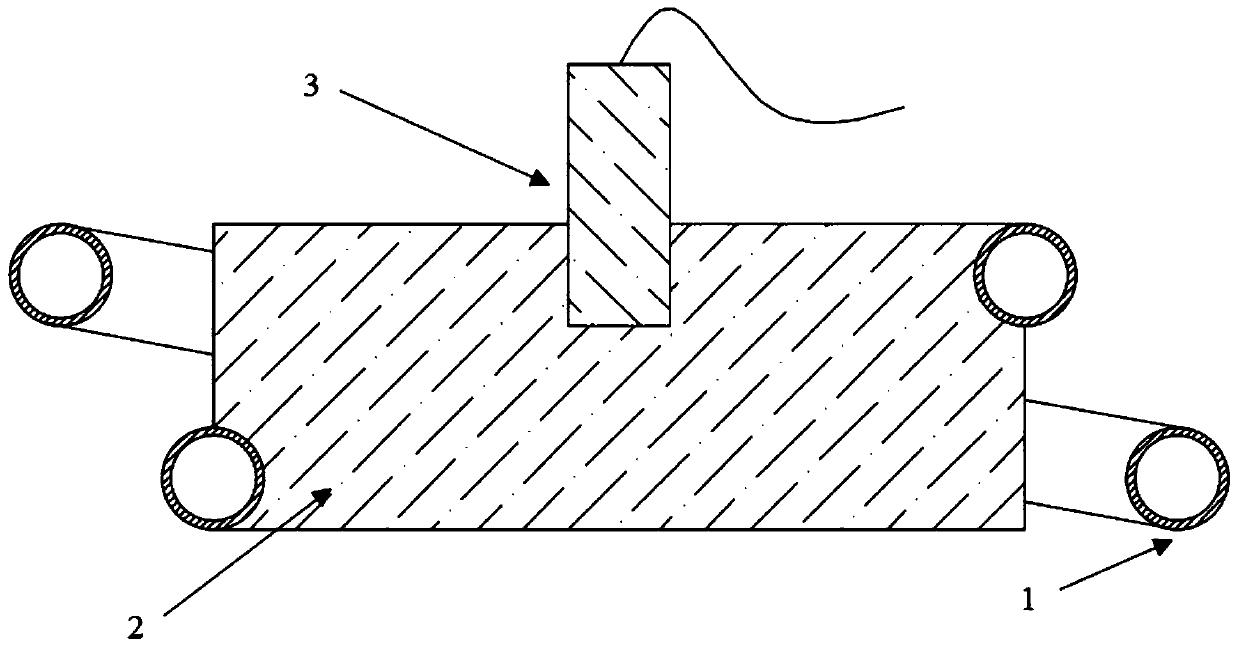

Plate frame filtering device for ventilating system

InactiveCN104436889AEasy to change sizeIncrease the number of filtersDispersed particle filtrationAir volumeFan blade

The invention discloses a plate frame filtering device for a ventilating system. The plate frame filtering device comprises a plurality of mounting plates (1), a plurality of filtering elements (2), adsorption layers (3), air outlets and a plurality of pulse dust collectors (4), wherein every two adjacent mounting plates (1) are fixed to each other through a plurality of fastening bolts (7); the plurality of filtering elements (2) are vertically connected with each mounting plate (1); an adsorption layer (3) is arranged at the air inlet end of each filtering element (2); a plurality of air outlets (5) are uniformly formed in each mounting plate (1); each air outlet (5) is correspondingly connected with a filtering element (2); a plurality of fan blades (6) are further arranged on each air outlet (5); a pulse dust collector (4) is mounted on each mounting plate (1). The plate frame filtering device can perform large air volume air flow exchange through the structure, can conveniently change the size according to the practical requirement, and is very suitable for the industrial filed.

Owner:SICHUAN APOCO TECH

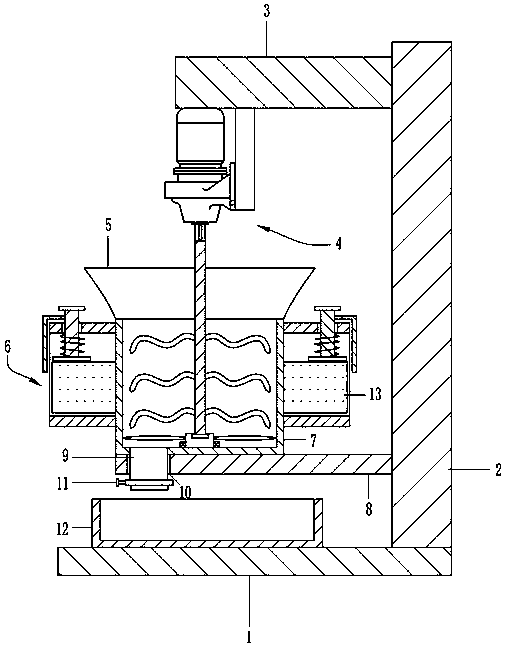

Magnetic field generating device for preparation of magnetic graphene

InactiveCN110813130AFast preparationEasy to change sizeRotary stirring mixersTransportation and packagingGraphiteGraphene

The invention relates to a magnetic field generating device, in particular to a magnetic field generating device for preparation of magnetic graphene. The technical scheme aims to provide a magnetic graphene preparation magnetic field generating device which is applied to quick preparation of magnetic graphene and has convenient change of the magnitude of a magnetic field. The magnetic field generating device for preparation of the magnetic graphene includes a mounting plate, a mounting bracket, a bearing bracket, a stirring member, a material discharge hopper, fixed members, a stirring box, asupport plate, a material discharge pipe, a valve, a collecting box and magnets, wherein the mounting bracket is fixedly connected to the top surface of the mounting plate, the collecting box is placed on the top surface of the mounting plate, and the bearing bracket and the support plate are connected to the side part of the mounting bracket sequentially and fixedly; and the stirring box is fixedly connected to the top surface of the support plate, and a guide hole is formed in the support plate. The effects of quick preparation of graphene and convenient change of the magnitude of the magnetic field are achieved through the magnetic field generating device.

Owner:张美容

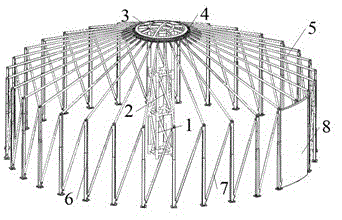

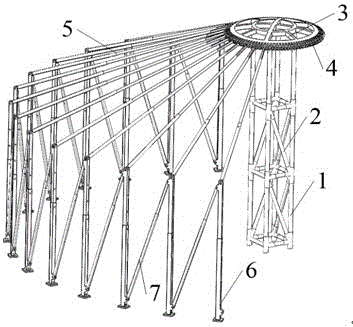

Internal load-bearing integrated ger

The invention discloses an internal load-bearing integrated ger. The ger comprises arrangement and connection manners of components of a bearing structure and a surrounding structure of the ger, and a ger load bearing manner; a load-bearing tower frame in the ger is a main load bearing component; and the heights of the load bearing structure and a maintenance structure can be adjusted, thereby achieving purposes of changing the height and the size of the ger. According to the internal load-bearing integrated ger, component connection parts are improved, thereby facilitating the integrated dismounting of the ger.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

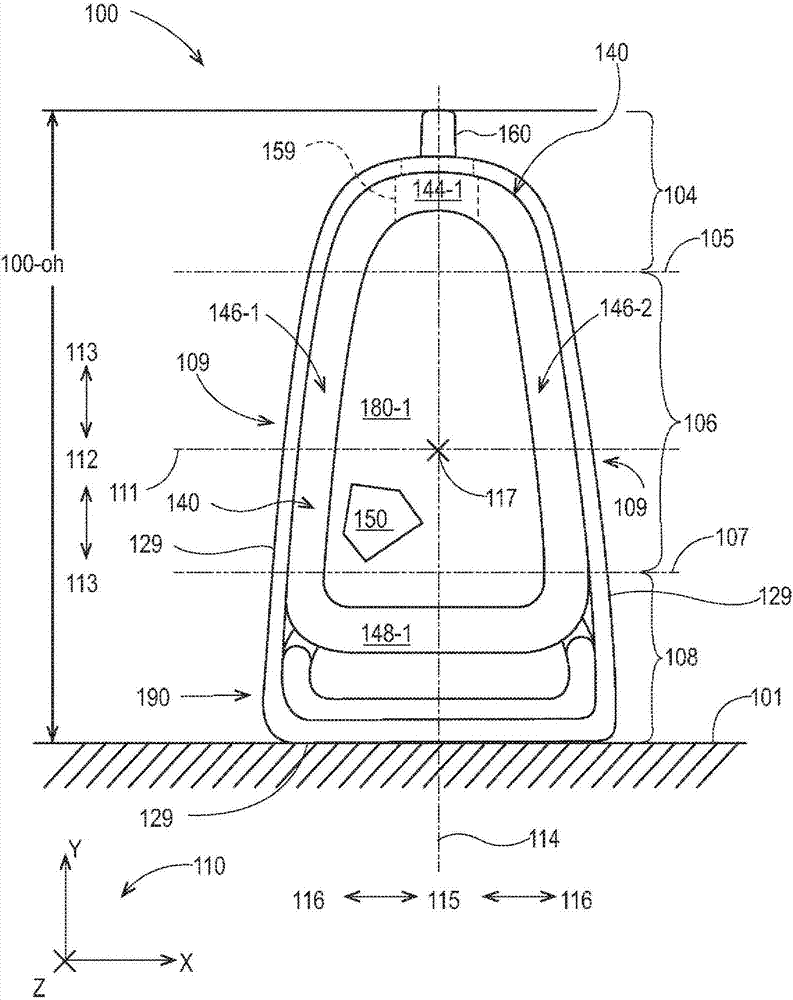

Flexible containers with integral dispensing spout

ActiveCN107406184ACheap manufacturingEasy to printFlexible containersPliable tubular containersMechanical engineeringMultiple dosing

A flexible container (2000) comprises: a multiple dose product volume for a fluent product; a structural support frame including a folded leg of a gusset on a top of the container, wherein the structural support frame supports the product volume in a stand-up orientation; a dispenser (2060) for dispensing fluent product (2051), formed by a tear-open opening in a sealed leg of the gusset in the top of the container; and a flow channel in fluid communication with the product volume and the dispenser. Externally compressing the container allows to dispense the fluent product through the flow channel the dispenser, and the dispenser, in stand-up position of the container, is situated higher than an uppermost portion of the structural support frame.

Owner:THE PROCTER & GAMBLE COMPANY

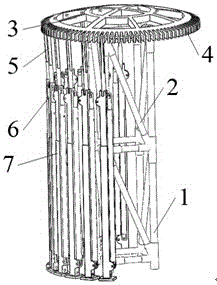

Compound down feather separator

ActiveCN104399666AChange trafficChange flow rateGas current separationFibre separationStructural engineeringProcess engineering

The invention relates to down feather processing equipment, in particular to a compound down feather separator. The compound down feather separator comprises a compartment, wherein an inner space of the compartment is divided into a raw material compartment and a finished product compartment by a baffle plate; a movable spacing plate is arranged in the raw material compartment; the lower end of the movable spacing plate is hinged to the raw material compartment, and the upper end of the movable spacing plate is connected with a pull rope; two layers of screens are arranged at the bottom of the raw material compartment; a discharging bin is arranged in the middle of of the space below a sieve plate; impurity compartments are arranged at the two edges of the discharging bin; a raw material stirring shaft is arranged above the sieve plate; a bottom spacing plate is arranged in the middle of the finished product compartment; a stirrer is arranged below the bottom spacing plate; and discharge stirring shafts are arranged above the bottom spacing plate. The compound down feather separator enables the size of the inner space of the compartment to be changed and the flow and the flow velocity of wind to be changed to obtain needed down feathers, so that the down feather processing procedures are reduced, and the product quality is improved; and the two-layer screen structure enables the size of sieve holes to be changed easily so as to treat down feather raw materials with different qualities.

Owner:HENAN PENGDA DOWN PROD

UAV with multi-arm synchronous folding mechanism

ActiveCN105857571BEasy to change sizeEasy to operateWing adjustmentsFuselagesEngineeringMechanical engineering

The present invention relates to the field of unmanned aerial vehicles; more specifically, the present invention relates to an unmanned aerial vehicle having a multi-arm synchronous folding mechanism. The UAV includes: a base, which has a flat plate shape and is provided with a plurality of rotation axes extending parallel to the base; and a plurality of arms, which are capable of rotating around the rotation axes respectively. The shaft is connected and can be in an unfolded state parallel to the base and a folded state perpendicular to the base; a snap-on component used to keep the plurality of machine arms in a deployed state; and a folding component used to synchronously release the snap-on component The snap-on state allows multiple arms to synchronously transition from the unfolded state to the folded state. The snap-on component and the folding component constitute a multi-arm synchronous folding mechanism. By adopting the above technical solution, the present invention provides a UAV that can achieve synchronous folding of multiple arms, which makes it easy to change the size of the UAV and is simple to operate and easy to use during the process of folding the arms.

Owner:BEIJING BORUI AIFEI TECH DEV CO LTD

DNA double-spiral ejection and explosion integrated medium-length hole blasting device

The invention discloses a DNA double-spiral ejection and explosion integrated medium-length hole blasting device. The device comprises a DNA double-spiral tubular explosive cover, explosives and an igniter. The explosive cover is formed by spiral staggered winding of two hollow round pipes according to a certain pitches; the explosives are general explosives positioned in a spiral cavity; and theigniter is a general priming device. The device changes explosive loading and acting modes of traditional explosives; each single-chain spiral pipe forms spiral jet flows sprayed to the periphery after priming of the explosives to invade rock masses; the jet flows are overlapped in staggered areas of two round pipe space to strengthen a local invasion effect; and meanwhile, impact waves and explosion gas are generated in positions without the spiral pipes for directly acting on rocks. The device integrates ejection and explosion to obtain excellent blasting sections during reduction of the uselevel of the explosives. The introduced DNA double-spiral explosive cover is simple in form, various in shape, easy to machine and convenient to use, improves the efficiency, and reduces the cost.

Owner:UNIV OF SCI & TECH OF CHINA +1

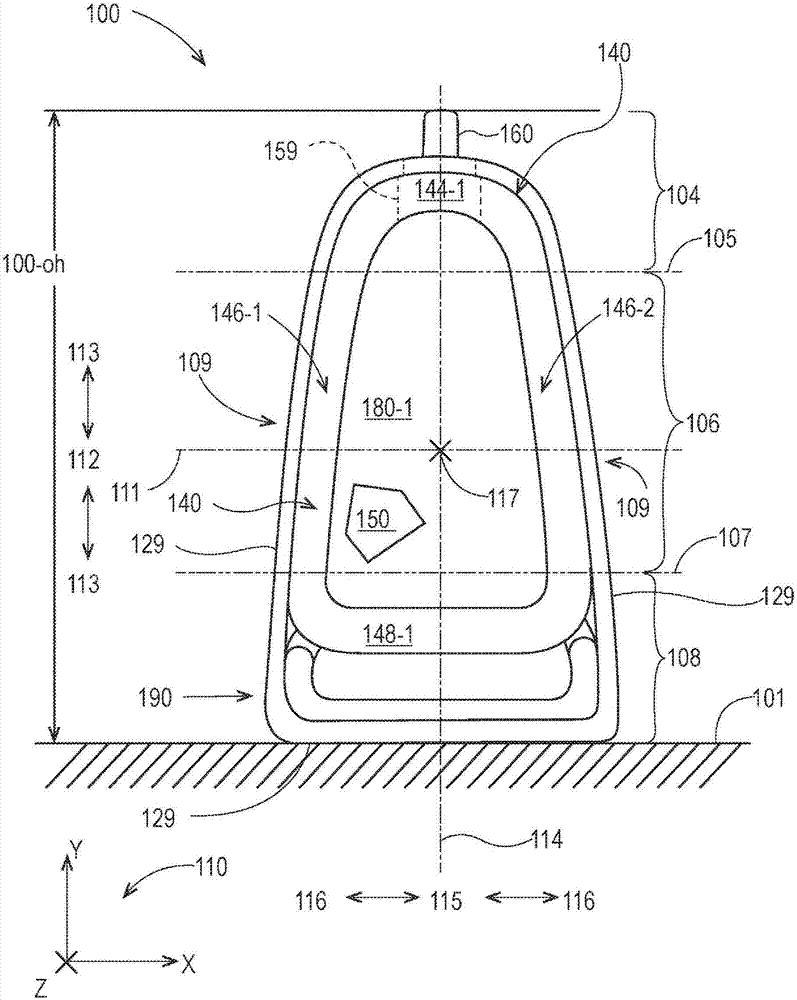

Flexible containers with easily variable sizing

ActiveCN107000912ACheap manufacturingEasy to printBag making operationsPaper-makingMechanical engineeringSizing

Non-durable self-supporting flexible containers with easily variable sizing. Line ups of flexible containers have similar sizes, shapes, and constructions, but hold differing amounts of fluent product at unexpected fill heights.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com