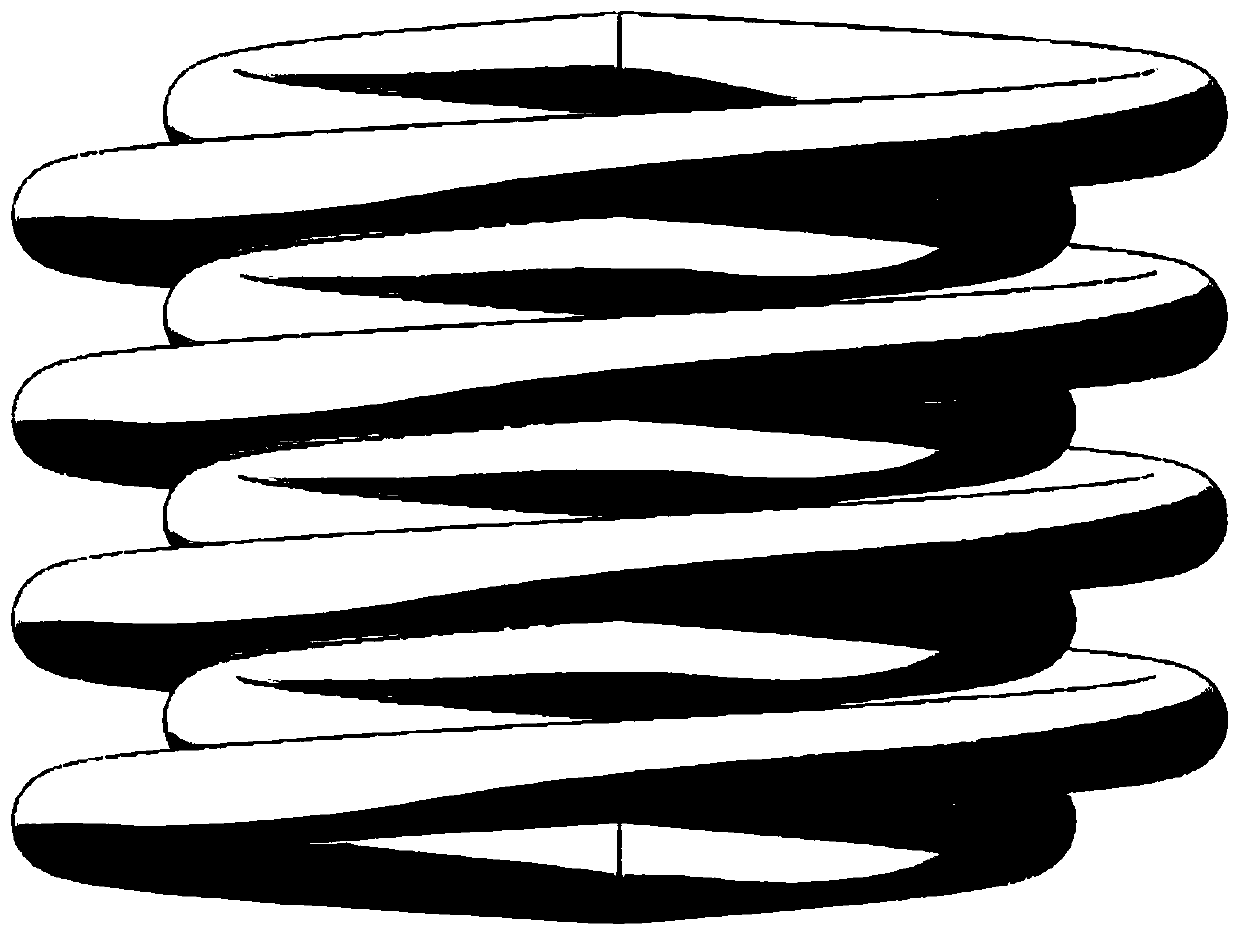

DNA double-spiral ejection and explosion integrated medium-length hole blasting device

A deep-hole blasting and double-helix technology, which is applied in blasting and other directions, can solve the problems of underutilized explosive energy and target medium damage, and achieve the effect of enhanced rock breaking effect, easy size, and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

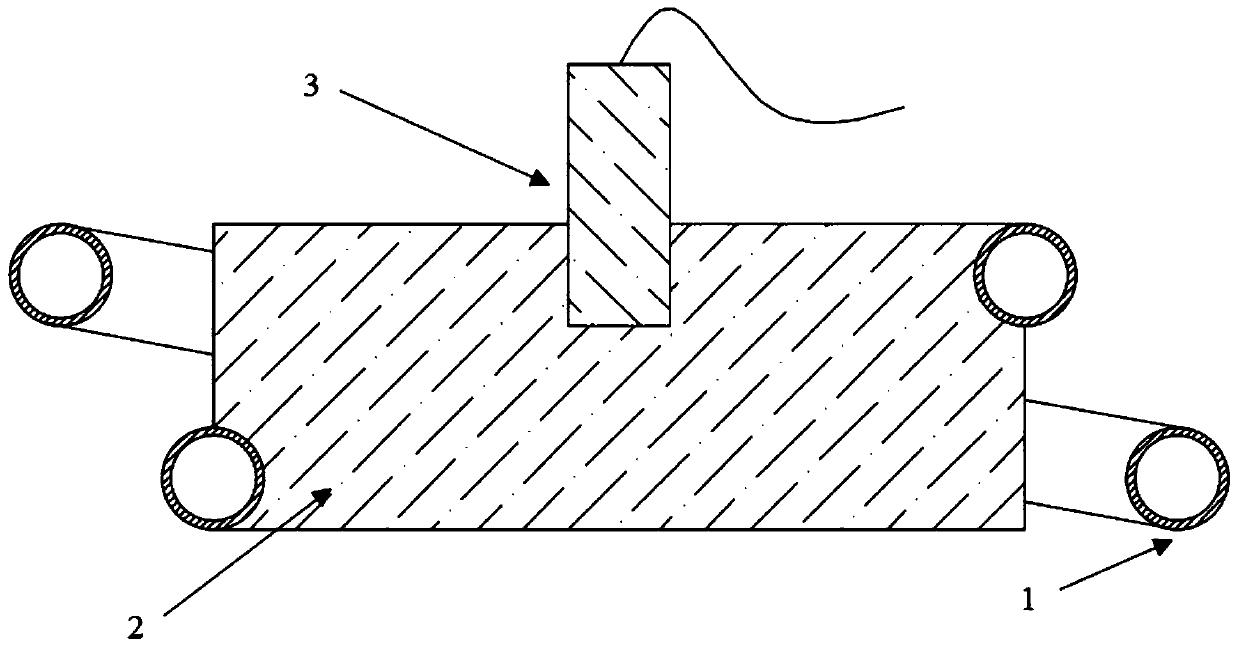

Embodiment 1

[0034] refer to Figure 4 , DNA double-helix tubular medicine-shaped cover with an inner diameter of 21.00mm and a height of 50mm, an inner diameter of the outer cover of 28mm and a height of 50mm, and the tube material is iron; the tube diameter is 5mm. The explosive is an emulsion explosive sensitized with 4% glass microspheres. After mixing evenly, fill the explosive into a cylindrical plastic bag and compact it. The density is guaranteed to be 1.1g / cm 3 to 1.3g / cm 3 , and then pack the packaged explosive into the cavity surrounded by the spiral tube. The experiment uses a non-priming detonator 3 to detonate, and the detonator 3 is placed in the center of the surface at one end of the shaped charge.

[0035] A steel pipe 4 penetration test was carried out on the shaped charge of this embodiment. The steel pipe 4 has a wall thickness of 5 mm, a diameter of 35 mm, a penetration depth of 2 to 3 mm, a penetration gap width of 4 to 5 mm, and a depression of 1 to 2 mm in the st...

Embodiment 2

[0037] refer to Figure 4 , DNA double-helix tubular medicine-shaped cover with an inner diameter of 30mm and a height of 50mm, an outer cover with an inner diameter of 42mm and a height of 50mm, and the tube material is aluminum; the tube diameter is 5mm. The explosive is an emulsion explosive sensitized with 4% glass microspheres. After mixing evenly, fill the explosive into a cylindrical plastic bag and compact it. The density is guaranteed to be 1.1g / cm 3 to 1.3g / cm 3 , and then pack the packaged explosive into the cavity surrounded by the spiral tube. The experiment uses a non-priming detonator 3 to detonate, and the detonator 3 is placed in the center of the surface at one end of the shaped charge.

[0038] A steel pipe 4 penetration test was carried out on the shaped charge of this embodiment. The outer diameter of the steel pipe 4 is 50 mm, the wall thickness of the steel pipe 4 is 4 mm, and the pipe length is 300 mm. After the test, the steel pipe parallel to the cha...

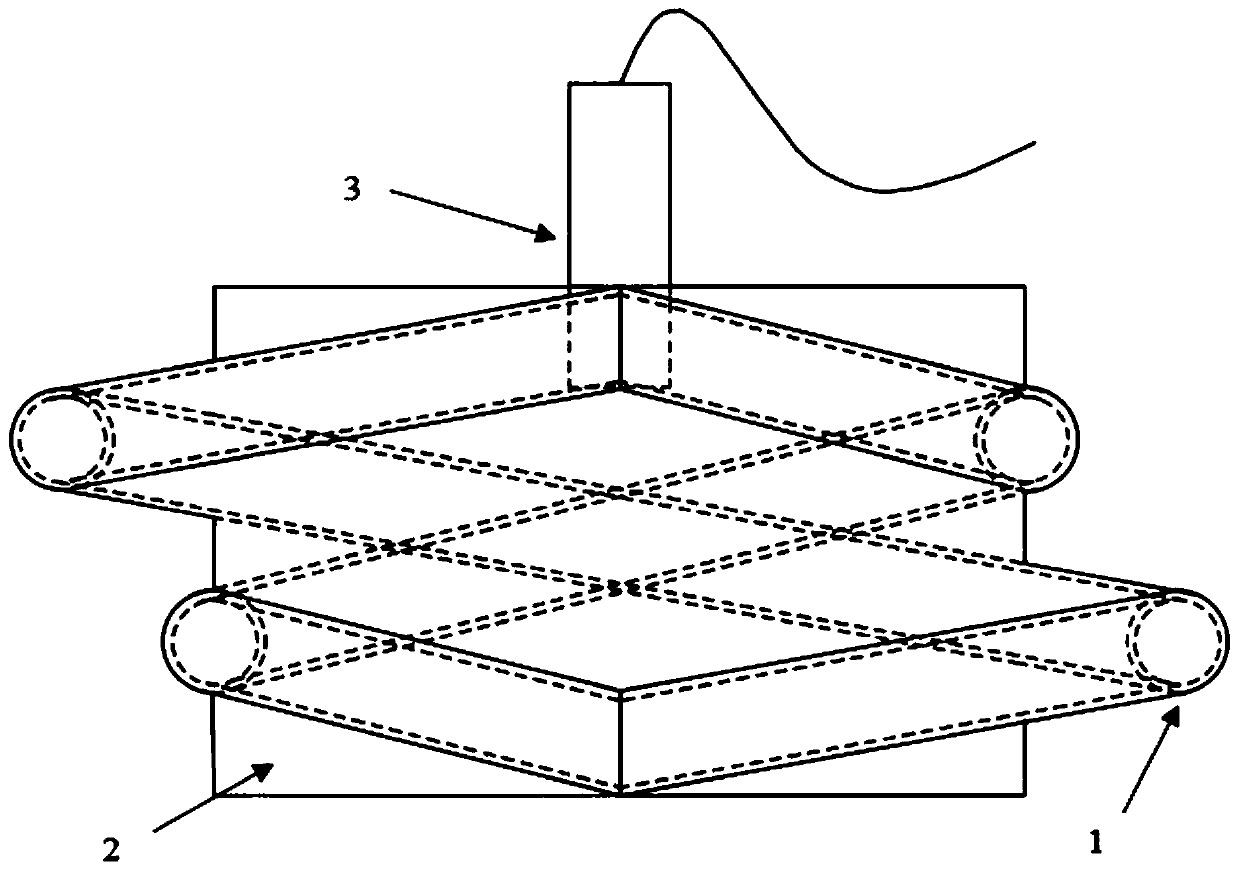

Embodiment 3

[0040] refer to Figure 5 , DNA double-helix tubular drug-shaped cover with an inner diameter of 35mm and a height of 30mm, an outer cover with an inner diameter of 42mm and a height of 30mm, and the tube material is plastic; the cross-sectional diameter of the tube is 5mm, and the explosive is an emulsion explosive sensitized by 4% glass microspheres. After mixing evenly, fill the explosives into a cylindrical plastic bag, compact and package, and the density is guaranteed to be 1.1g / cm 3 to 1.3g / cm 3 , and then pack the packaged explosive into the cavity surrounded by the spiral tube. The experiment uses a non-priming detonator 3 to detonate, and the detonator 3 is placed in the center of the surface at one end of the shaped charge.

[0041] The steel plate 5 penetration test was carried out on the shaped charge of this embodiment. The length, width, and thickness of the steel plate 5 were 300 mm, 100 mm, and 15 mm, the penetration depth was 1 to 2 mm, and the penetration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com