Patents

Literature

649 results about "TEX-explosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

4,10-Dinitro-2,6,8,12-tetraoxa-4,10-diazatetracyclo[5.5.0.0⁵˒⁹.0³˒¹¹]-dodecane - which is most commonly and conveniently abbreviated TEX - is a dense (ρ = 1.985 g cm⁻³)nitramine high explosive, that derives from the very powerful and sensitive high explosive CL-20. Though related to CL-20 in that is shares the same cage structure TEX is more easily synthesized in good yield from cheap starting materials. Much unlike CL-20 TEX is friction insensitive, bears a low impact sensitivity and possesses a very low shock sensitivity and large critical diameter making it an interesting explosive filler for insensitive munitions. Its systematic name, 4,10-Dinitro-2,6,8,12-tetraoxa-4,10-diazatetracyclo[5.5.0.0⁵˒⁹.0³˒¹¹]-dodecane derives from its tetracyclic structure which is depicted below.

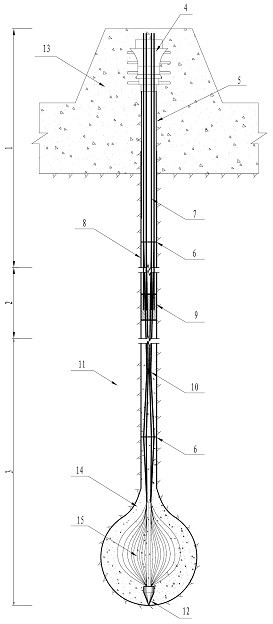

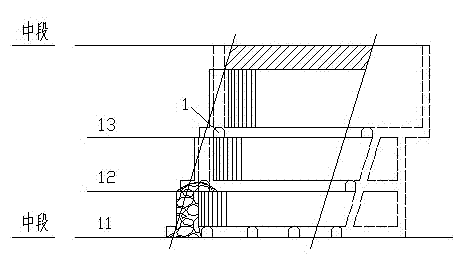

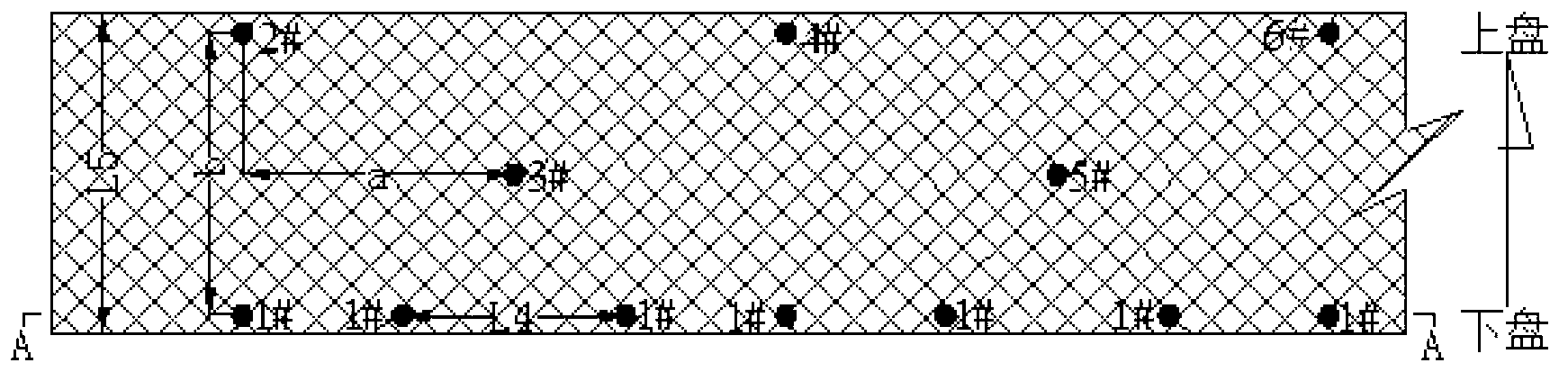

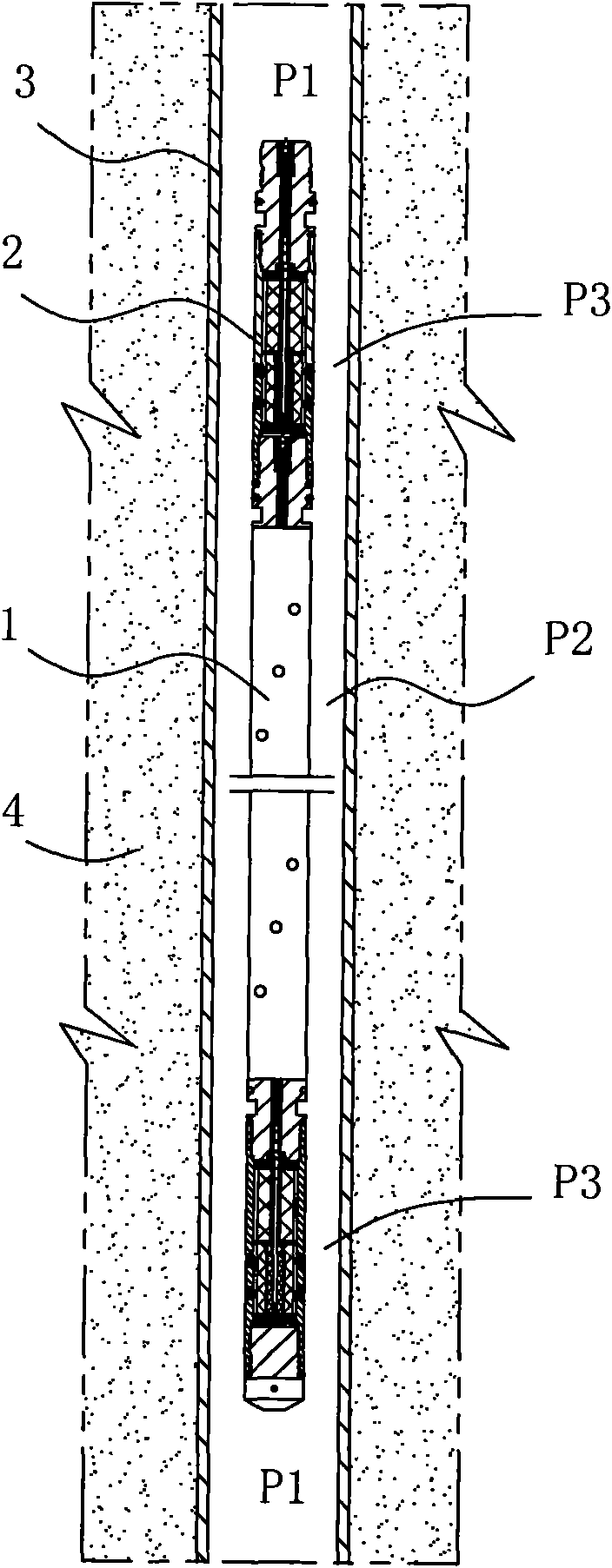

Explosion expanded internal anchor head prestressed anchor cable for strengthening weak rock and anchoring method thereof

InactiveCN102002947AExpand the force rangeIncrease safety reserveBulkheads/pilesAnchoring boltsTEX-explosivePre stress

The invention discloses an explosion expanded internal anchor prestressed anchor cable for strengthening a weak rock and an anchoring method thereof. The anchor cable comprises a bit expanded anchor cable hole and an anchor cable body with an explosion expanded internal anchor head, wherein the explosion expanded internal anchor head consists of a lantern-shaped steel frame and a grouting body; and the lantern-shaped steel frame comprises lanced steel tubes, wire meshes and detached steel strands which are hierarchically distributed from the interior to the exterior. The anchoring method comprises the following steps of: drilling an anchor cable hole by using a driller, putting explosive at the bottom of the hole for explosion after holing, cleaning the hole and making a spherical cavity formed at the bottom of the drilled hole; simultaneously making an initial sample of the explosion expanded internal anchor head anchor cable by using the steel strands, the steel tubes, the wire meshes, the explosive and the like, inserting the anchor cable, igniting the explosive in the initial sample of the anchor cable, and forming the lantern-shaped internal anchor head steel frame; and finally grouting, and stretching and locking the anchor cable. The invention can obviously improve the bearing capacity of the internal anchor head grouting body and the prestress of the anchor cable, effectively solves the problem of poor anchored force of the anchor cable in the process of strengthening the weak rock, and can shorten the length of the internal anchoring section and widen an effective range of anchoring the rock.

Owner:WUHAN UNIV

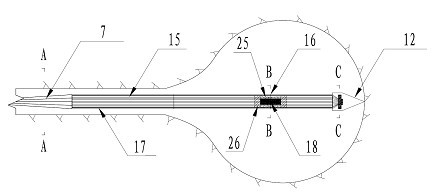

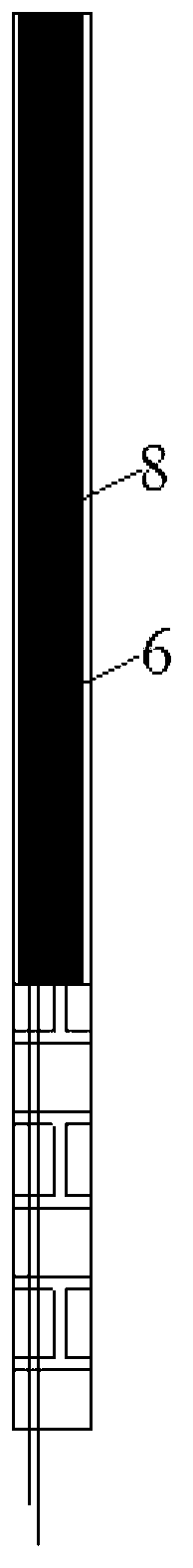

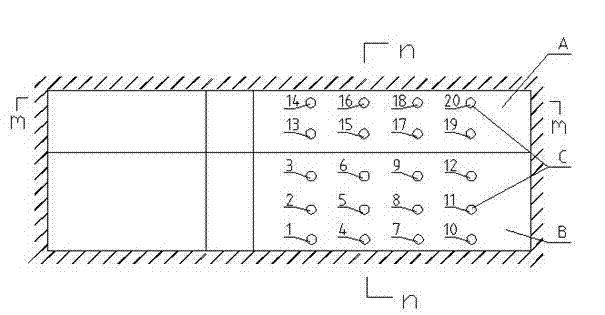

Overhand shrinkage spaced-loading split-blasting slot cutting method

ActiveCN103696769AQuality improvementControl chunk rateUnderground miningSurface miningTEX-explosiveMining engineering

The invention discloses an overhand shrinkage spaced-loading split-blasting slot cutting method, which aims at solving the problems that the ore discharging efficiency is low, the consumption of explosive is large, the rate of large ore blocks is high, the construction organization is complicated, a suspended roof is likely to form and the operation safety is poor in a traditional slot cutting process. The method comprises the following steps of step 1, determining geometric parameters of a cutting level; step 2, determining a position of a cutting open yard, to be specific, determining the parameter and height of a cross section, and selecting the position; step 3, determining rock drilling parameters in the slot cutting process, to be specific, determining the parameter of a resisting line, determining the hole-bottom distance parameter and determining side, hole and corner; step 4, forming a cutting slot; and step 5, discharging from the ore in a concentrating manner, wherein after the rearmost rows of blast holes in the uppermost layer of the cutting slot are exploded in an elementary error manner, ores falling into the cutting slot are concentratedly discharged through a first layer. By adopting the method for preserving the ores and finally discharging the ores concentratedly, the slot cutting can be safely and rapidly carried out for a chamber at the high quality.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

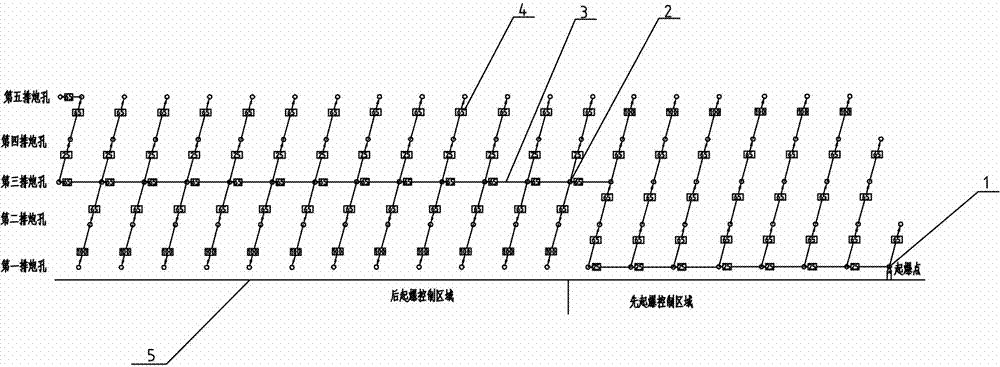

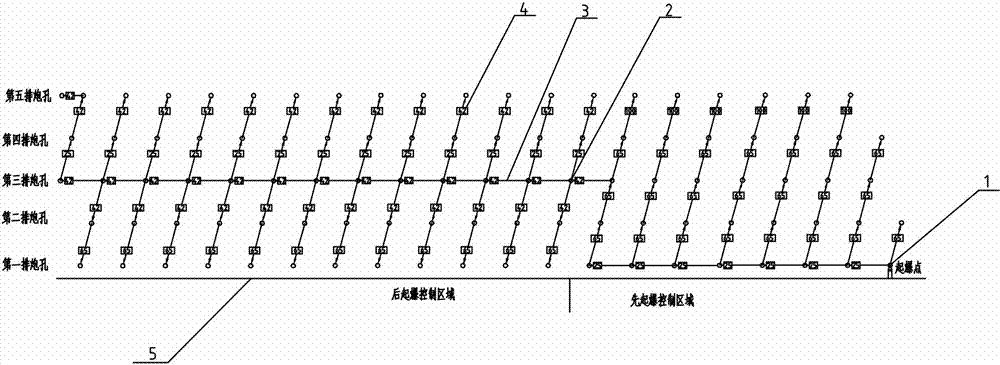

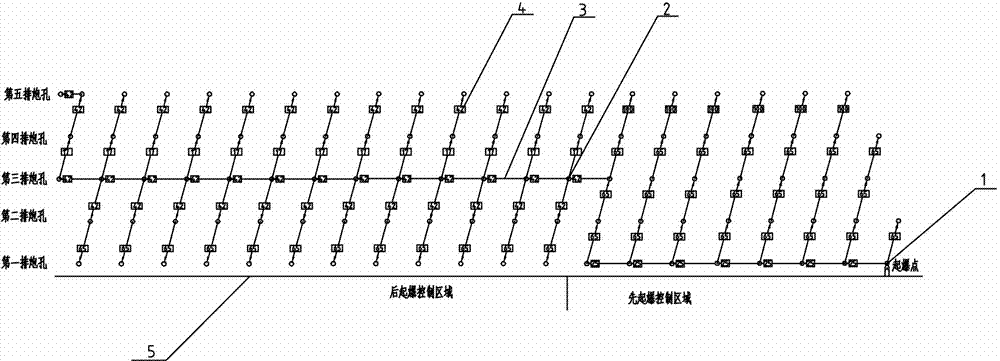

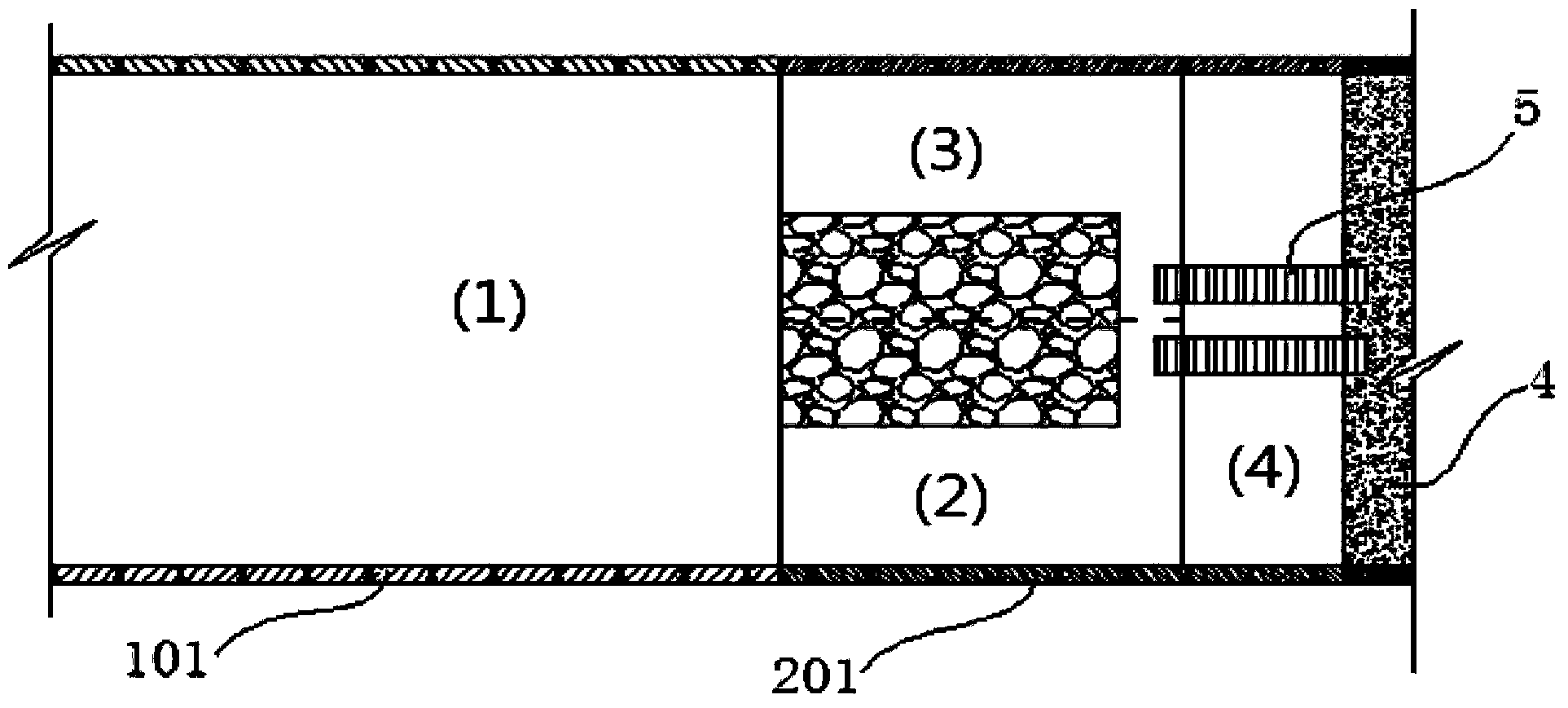

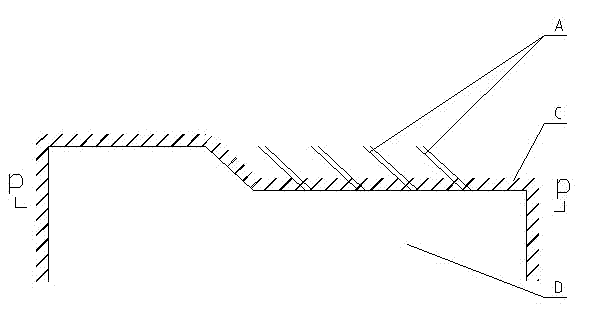

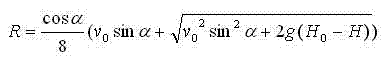

Open-bench blasting method capable of controlling forward stroke of blasting muck pile

An open-bench blasting method capable of controlling a forward stroke of a blasting muck pile comprises the steps of conducting deep hole arrangement, conducting drilling construction, arranging initiation bombs and detonators in deep holes, mounting explosives in the deep holes, conducting detonator delayed initiation design on an earth surface network in the same blasting area, connecting the detonators in the blast holes with detonators of the earth surface network, and initiating the detonators. The method is characterized in that the detonator delayed initiation design of the earth surface network in the same blasting area is that the blasting area is divided into an earlier initiation control area and a later initiation control area which are initiated in sequence, and blasting occurs in the two initiation areas at one time. According to the method, as the blasting area is divided into the two initiation areas, the earlier initiation control area is initiated to provide the later initiation control area with a moving space for containing goods supply and create a free face space condition for the blasting of the later initiation control area. The forward stroke of the blasting muck pile can be controlled precisely and effectively. The safety of the mining operation is ensured, the assistant workload of an electric shovel is reduced, the production efficiency is improved, and the damage and loss caused by the blasting can be reduced.

Owner:ANSTEEL GRP MINING CO LTD

Loading method suitable for field mixed loading of explosive and tool used for method

The invention relates to a loading method suitable for field mixed loading of explosive and a tool used for the method. The loading method suitable for the field mixed loading of the explosive comprises the following steps: 1) putting constituted detonated explosive into an explosive forming bag, introducing a detonating fuse connected with the detonated explosive out of the explosive forming bag, and binding a load bearing rope with a load bearing belt of the explosive forming bag; 2) enabling an explosive conveying hose to extend into the bottom of the explosive forming bag from an explosive conveying hole of the explosive forming bag, and fixing the rope and a detonating fuse on the hole of a blasthole by a load bearing rod after the explosive forming bag is taken into place; and 3) starting a mixed loading truck for the explosive, injecting the explosive into the explosive forming bag, removing an antistatic locating rod out of the blasthole when the length of an injected explosive section reaches the requirement of a user, and taking out the explosive conveying hose after the explosive loading amount reaches a designed volume to finish the explosive loading operation of the position. The loading method suitable for the field mixed loading of the explosive can be widely used for loading a fracture rock blasthole and an air interval outline blasthole under various conditions that explosive mixed loading is adopted for ground drilling and blasting, such as mines, traffic, hydroelectric power and the like.

Owner:GUANGDONG HONGDA BLASTING +1

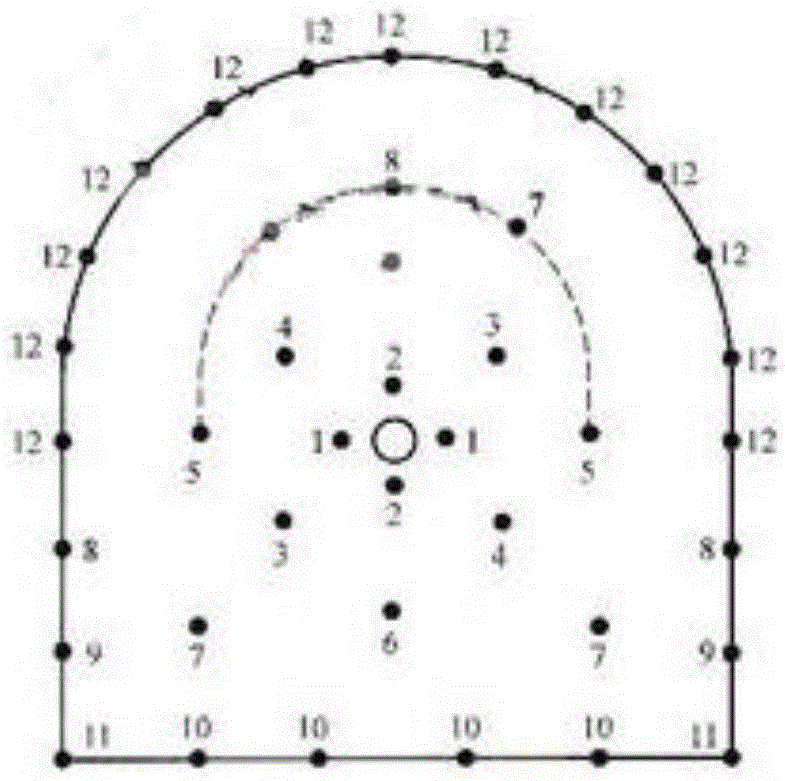

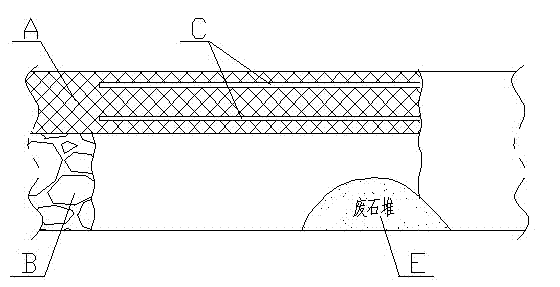

Hard roof directional pressurized explosion control method

InactiveCN103206903AImprove the utilization rate of explosion energyGood effect of dust suppressionBlastingDrill holeCoal

Disclosed is a hard roof directional pressurized explosion control method. Special drilling arrangement, loading structures and hole sealing manners are selected according to self-conditions of a roof, pressurized explosion transferring media is used to fully expel air in cracks, the characteristics of low compressing performance and high dynamite utilization rate of the pressurized explosion transferring media is utilized to perform directional or non-directional control explosion to slotted drilling holes or complete drilling holes, and expansion and pulse of the pressurized explosion transferring media are utilized for secondary loosening and weakening of surround rock of the drilling holes to accelerate development and penetrating of the roof cracks and strengthen presplitting weakening of the hard roof. The method mainly includes parallelly drilling holes and alternately loading dynamites at intervals; cutting grooves of the drilling holes; and explosion safety protection. The method is convenient to implement, simple to operate, low in cost and wide in application range, and can be popularized in loosening and weakening of common roofs or top coal and coal layers.

Owner:CHINA UNIV OF MINING & TECH

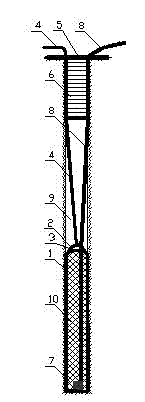

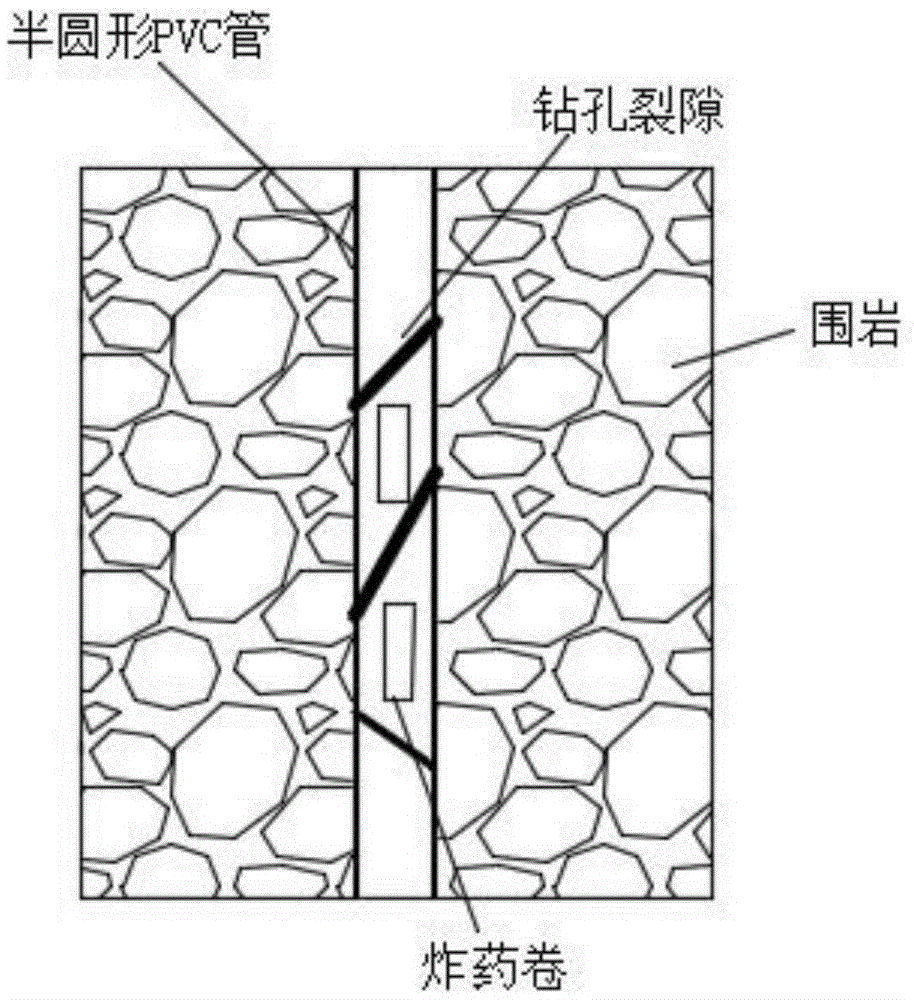

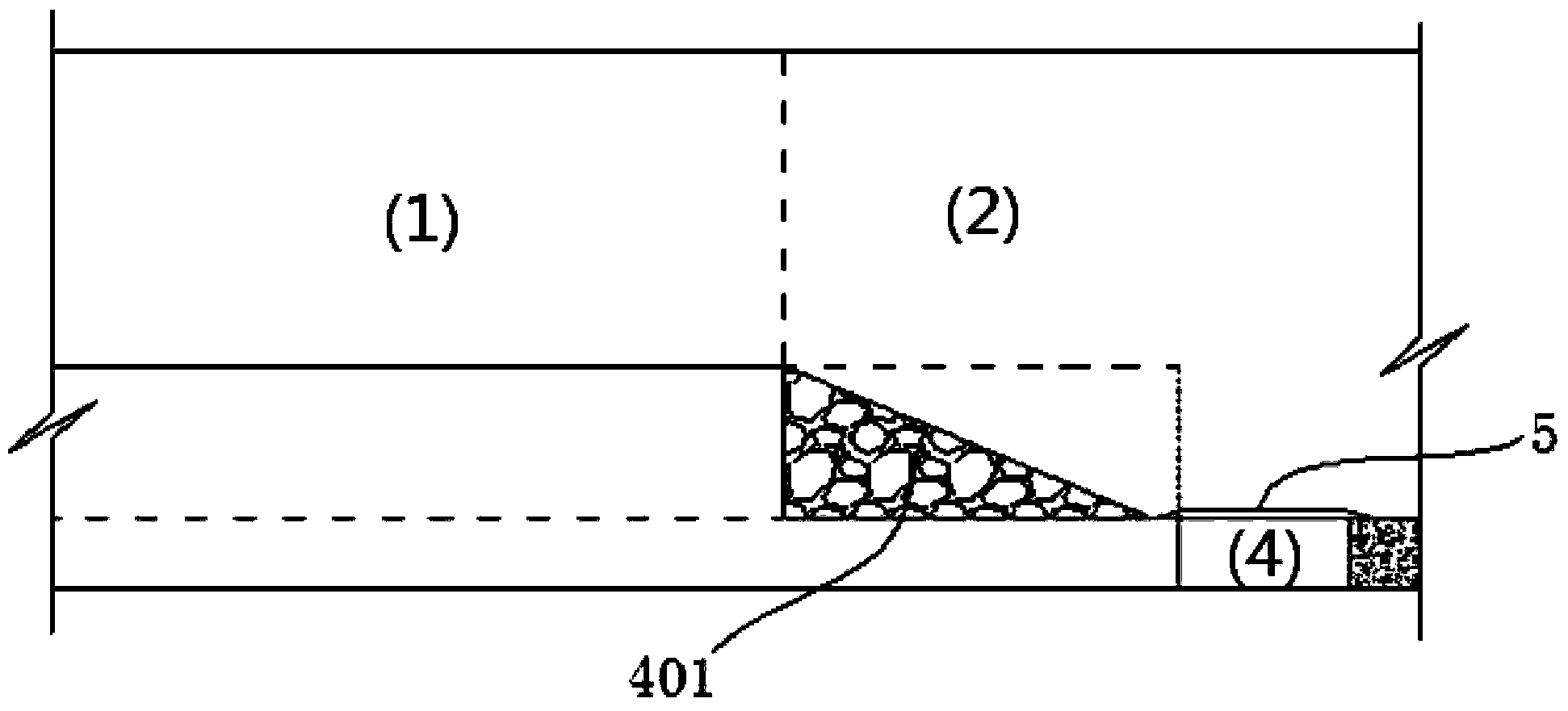

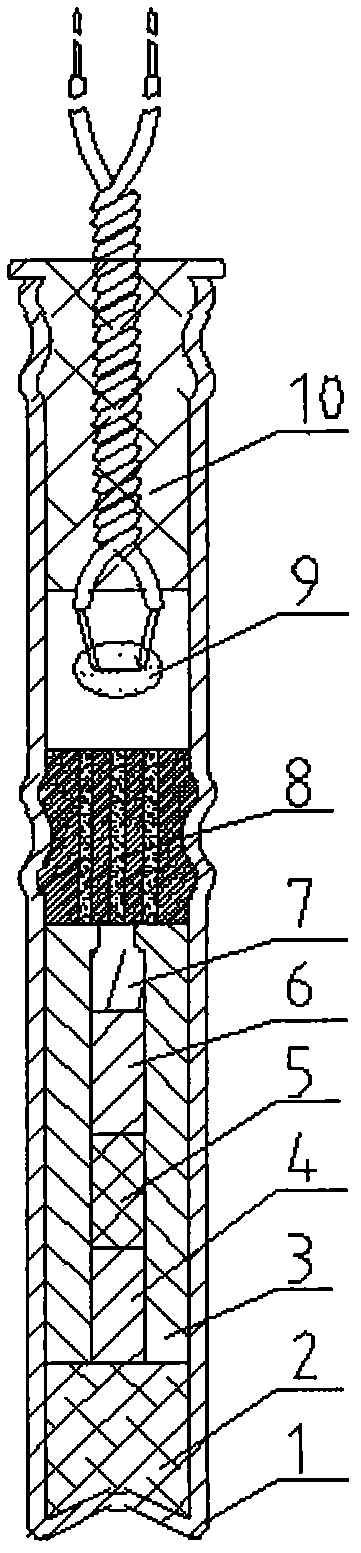

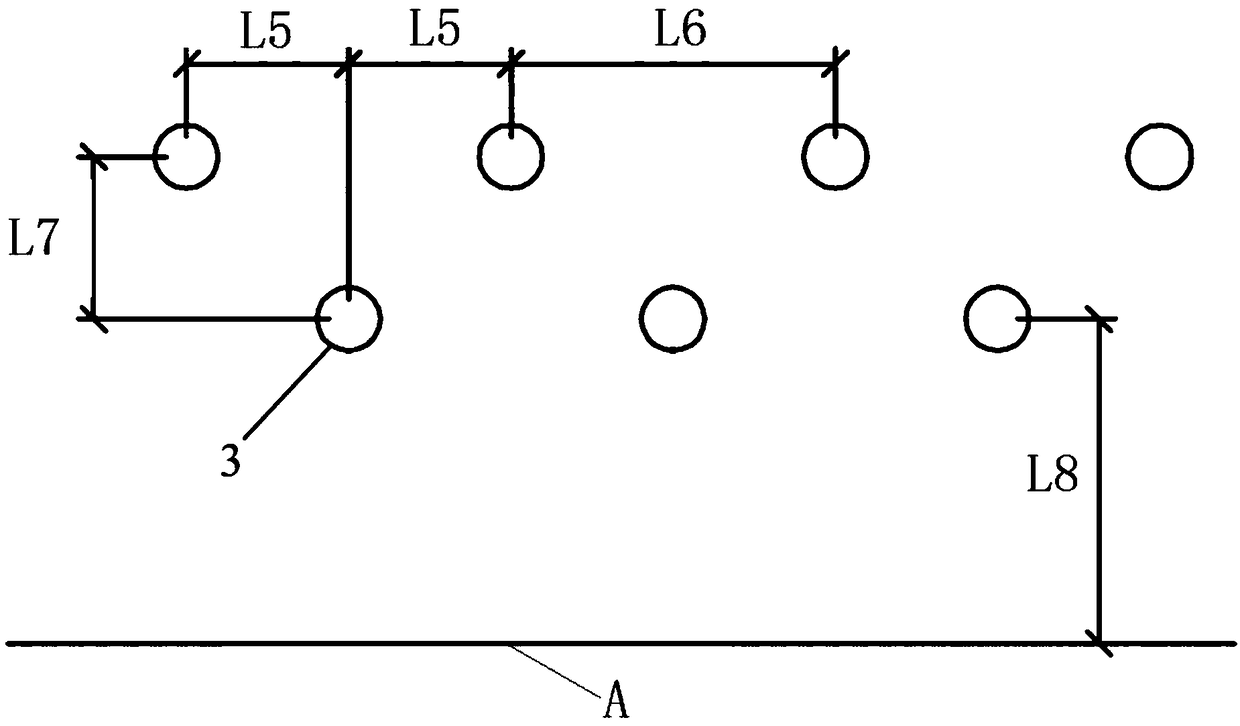

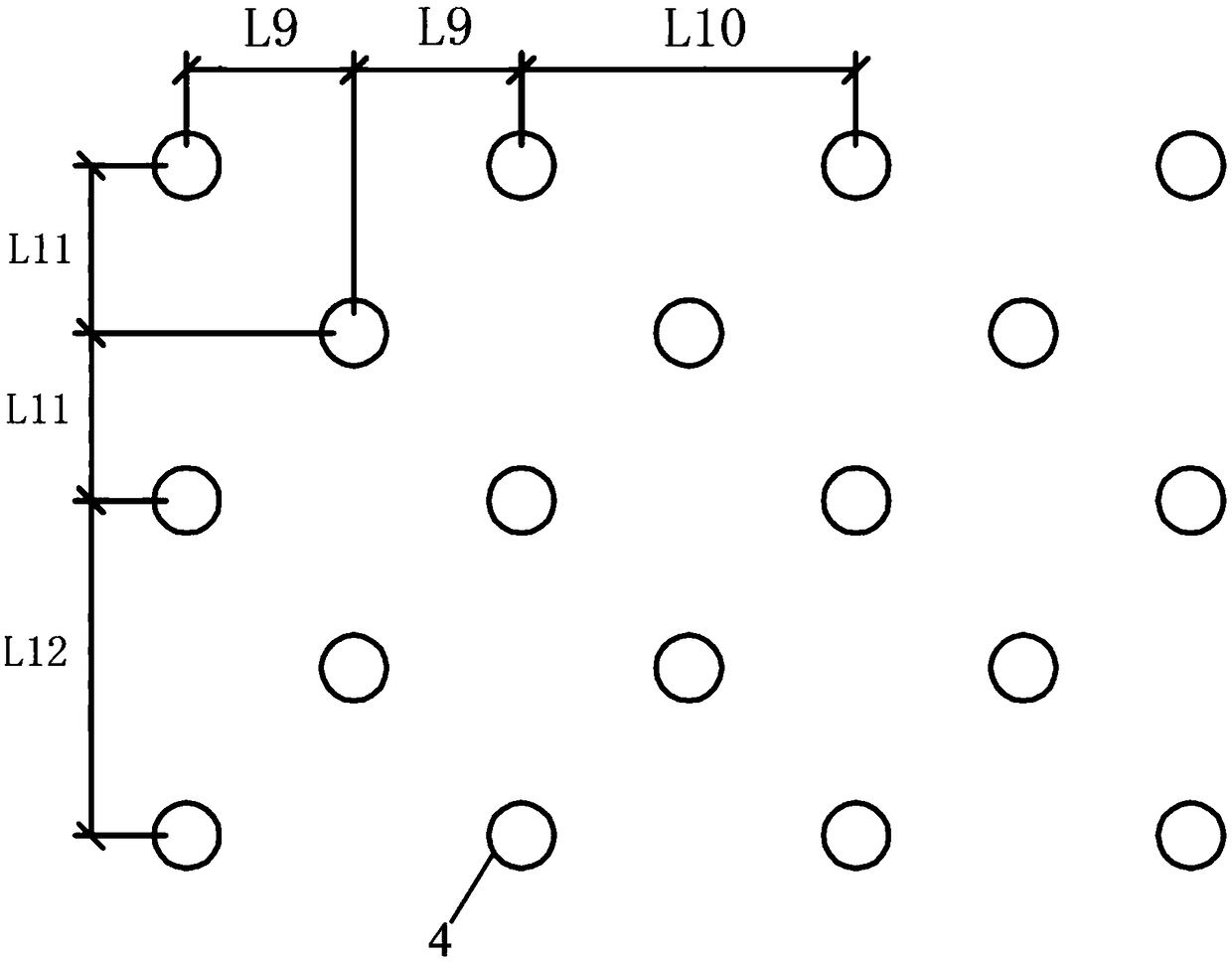

Blasting method for reducing depletion in steeply inclined thin ore body recovery

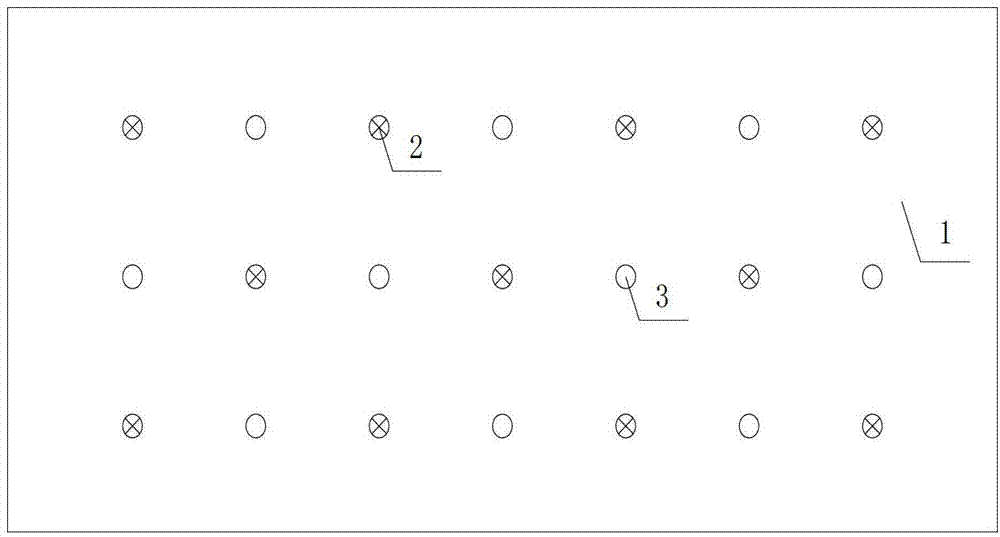

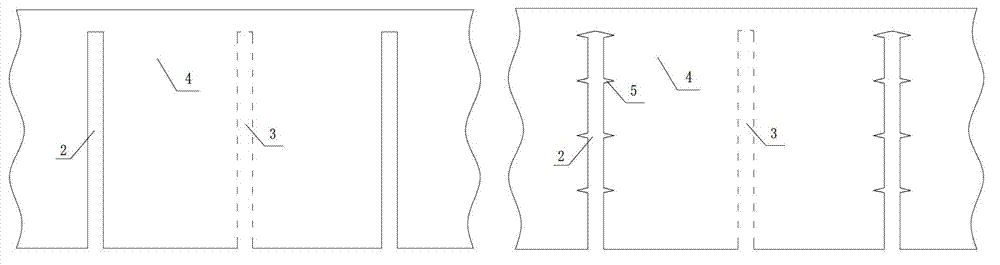

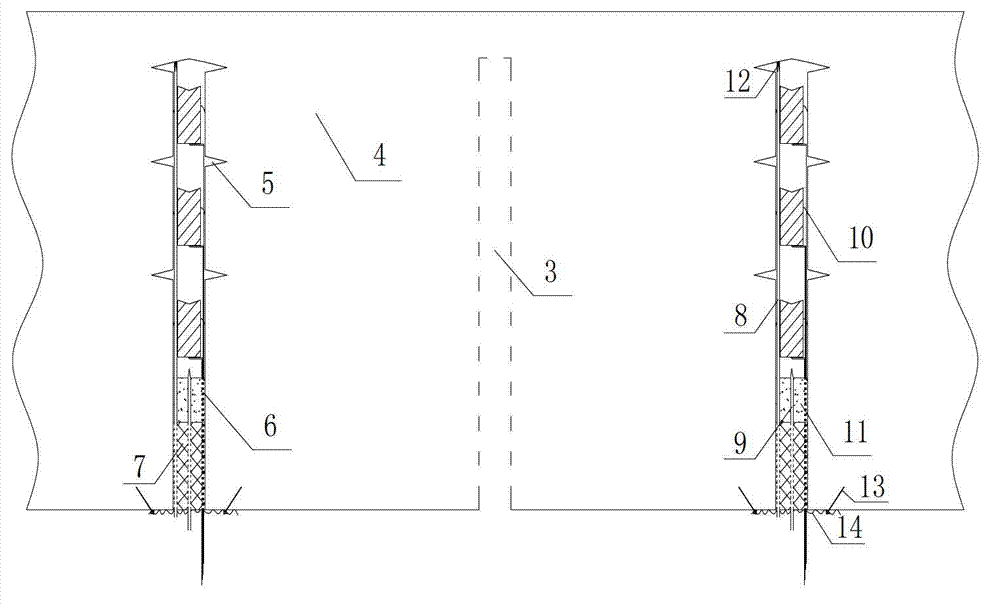

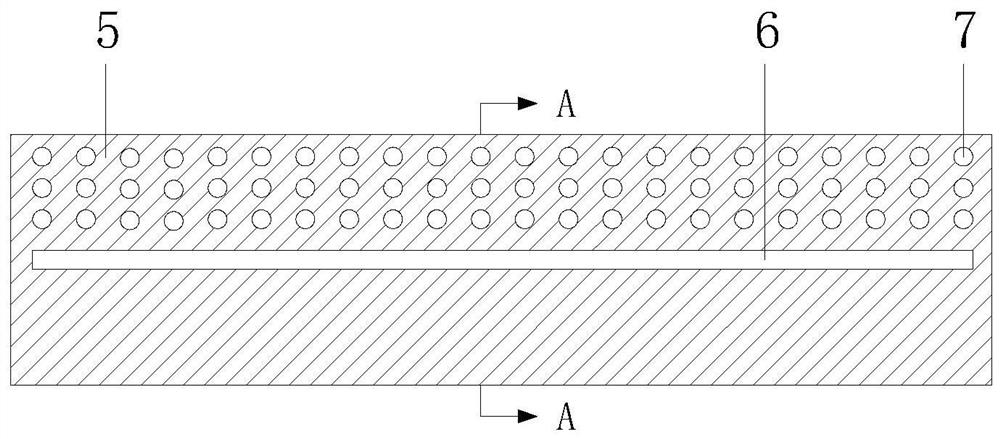

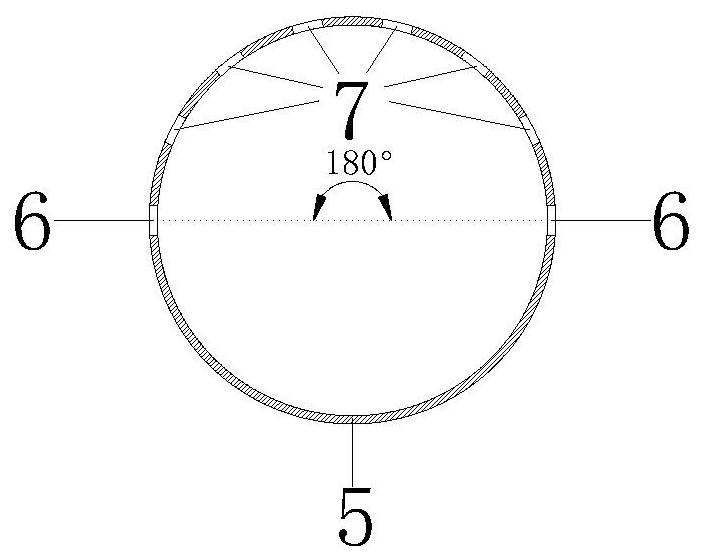

The invention provides a blasting method for reducing depletion in steeply inclined thin ore body recovery and belongs to the field of blasting engineering. The design process comprises the following steps: (1) actually detecting and locating a hole arrangement point in a lower subsection ore drift roadway (2) by using a total station; (2) drilling a recovery explosive-filled hole (3) and a presplitting hole (4) by using a middle-deep hole drill jumbo K41X and checking whether blast holes are in a good condition; (3) respectively filling the recovery explosive-filled hole (3) and the presplitting hole (4) by using a big cartridge rock water-gel explosive (6) and a small cartridge rock emulsion explosive (7) and stuffing the big cartridge rock water-gel explosive (6) and the small cartridge rock emulsion explosive (7) by using a nonmetal stuffing (5); and (4) after line connection is finished, detonating blast holes in a footwall, gradually carrying out microsecond detonating on the rest holes in a zigzag shape, detonating the blast holes by using a detonating tube (8) and igniting the blast holes by using an electric detonator. The blasting method for reducing the depletion in the steeply inclined thin ore body recovery, provided by the invention, has the advantages as follows: surrounding rock spallation of the footwall can be reduced, ore depletion is reduced, damages caused by the blasting impact to the surrounding rocks of the footwall can be reduced to a maximum extent, and the safety of follow-up ore removal is enhanced.

Owner:QINGHAI SHANJIN MINING

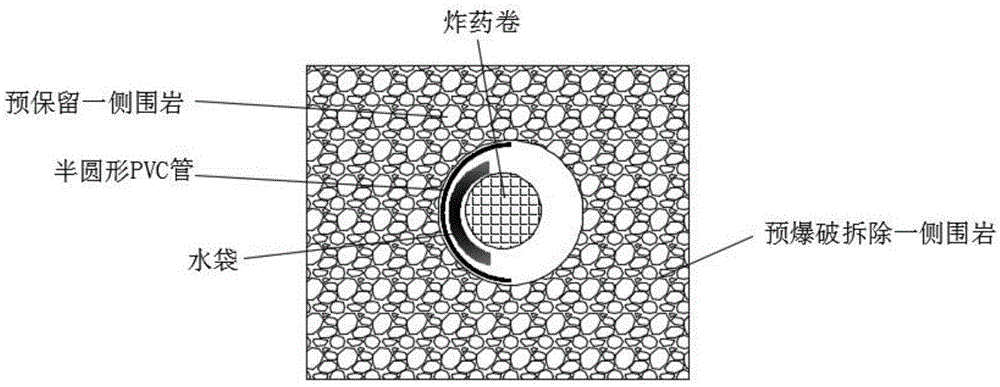

Precise control method for smooth surface blasting of fractured rock mass of highway tunnel

The invention relates to a precise control method for smooth surface blasting of fractured rock mass of a highway tunnel. The method comprises the following steps: step S1, acquiring the parameters required by precise control on smooth surface blasting; step S2, performing precise control on smooth surface blasting, namely arranging explosives according to a rule that no explosive cartridges are arranged at fractured positions inside a drilling hole; calculating the single-hole explosive load; determining the amount of water in a water bag; respectively controlling according to the drilling holes which are different in completeness; step S3, after blasting is ended, regulating the single-hole explosive load and water amount according to the overbreak and underbreak amount and the value of the half-hole ratio; step S4, drilling again and blasting again according to the updated single-hole explosive load and water amount, sequentially circulating until the tunnel is accomplished. According to the method, dynamic regulation is continuously performed and the explosion effect is precisely controlled as far as possible, so that the aim of controlling the overbeak and underbreak of blasting is realized, the utilization of the explosives is increased, loss of the explosives is reduced, and the engineering cost is lowered.

Owner:CHONGQING UNIV

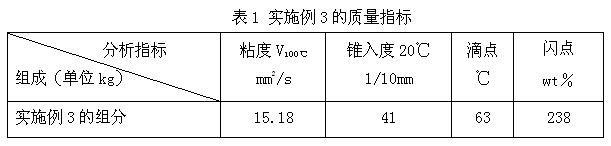

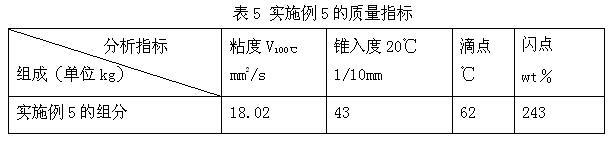

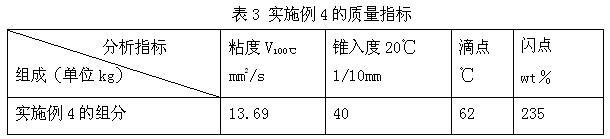

Integrated oil phase for emulsion explosive and preparation method thereof

InactiveCN102079681AGuaranteed emulsifying effectGuaranteed emulsification stabilityNon-explosive/non-thermic compositionsParaffin waxMicrocrystalline wax

The invention discloses an integrated oil phase for emulsion explosive and a preparation method thereof. The integrated oil phase for the emulsion explosive comprises the following components in part by mass: 10 to 18 parts of paraffin, 1 to 6 parts of microcrystalline wax, 45 to 65 parts of cerate and 25 to 35 parts of complex additive. The preparation method for the integrated oil phase for the emulsion explosive comprises the following steps of: preparing the components; adding the paraffin and the microcrystalline wax into an adjustable dehydrator, and heating for melting; adding the cerate, and fully stirring until the components are mixed and dissolved; raising the temperature for dehydration, and reducing the temperature; adding the complex additive, and stirring at a high speed until the components are mixed and dissolved; and filtering, discharging, cooling, forming and packaging. The integrated oil phase for the emulsion explosive integrates various components, has generality, and easily operates and controls the quality of the emulsion explosive, and can ensure the emulsifying property and emulsion stability in the production process of the emulsion explosive; the raw materials are easily obtained, low in cost and convenient to use; and the preparation method provides favorable guarantee for popularization and promotion in the industry.

Owner:GUANGDONG SUNION CHEM & PLASTIC

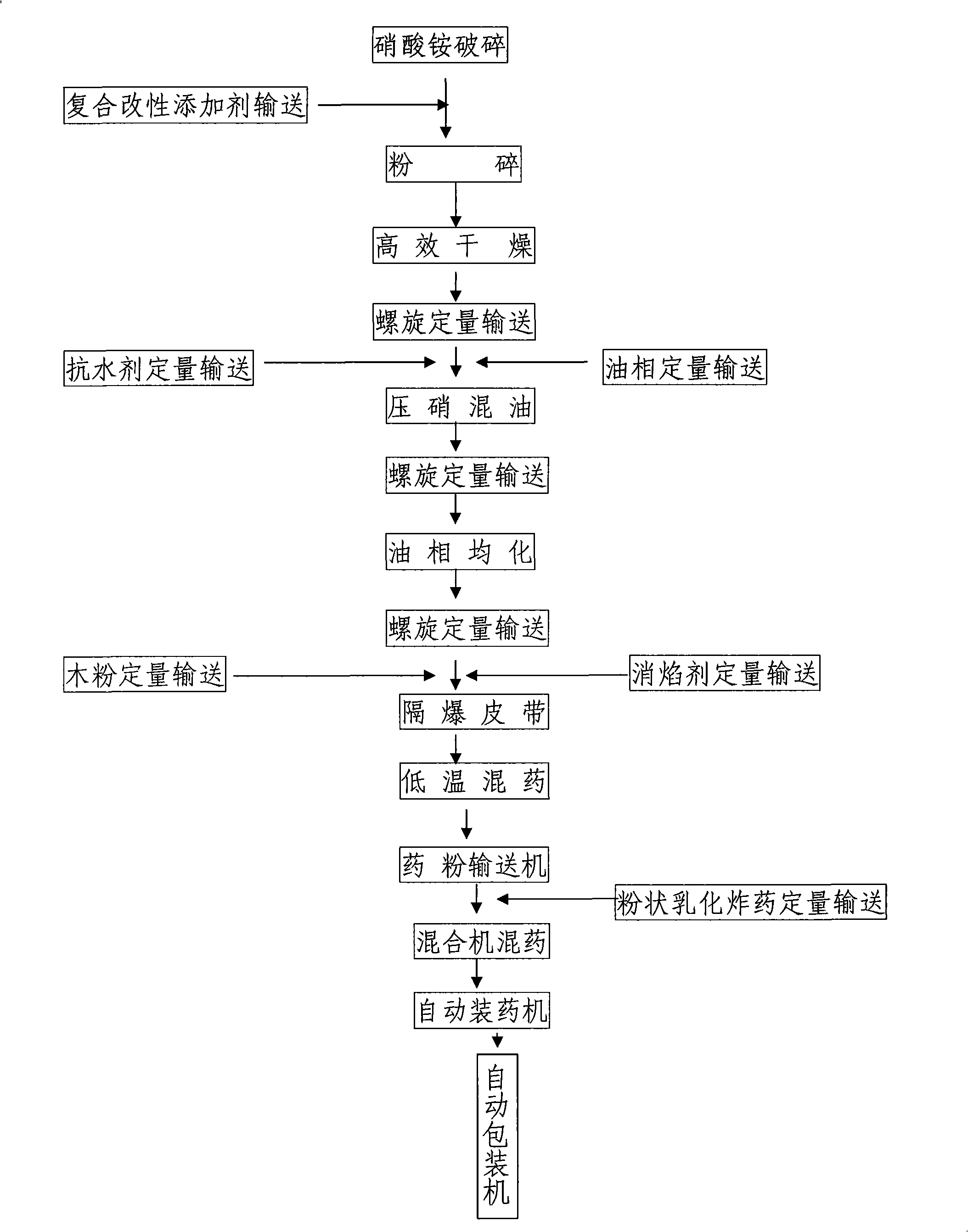

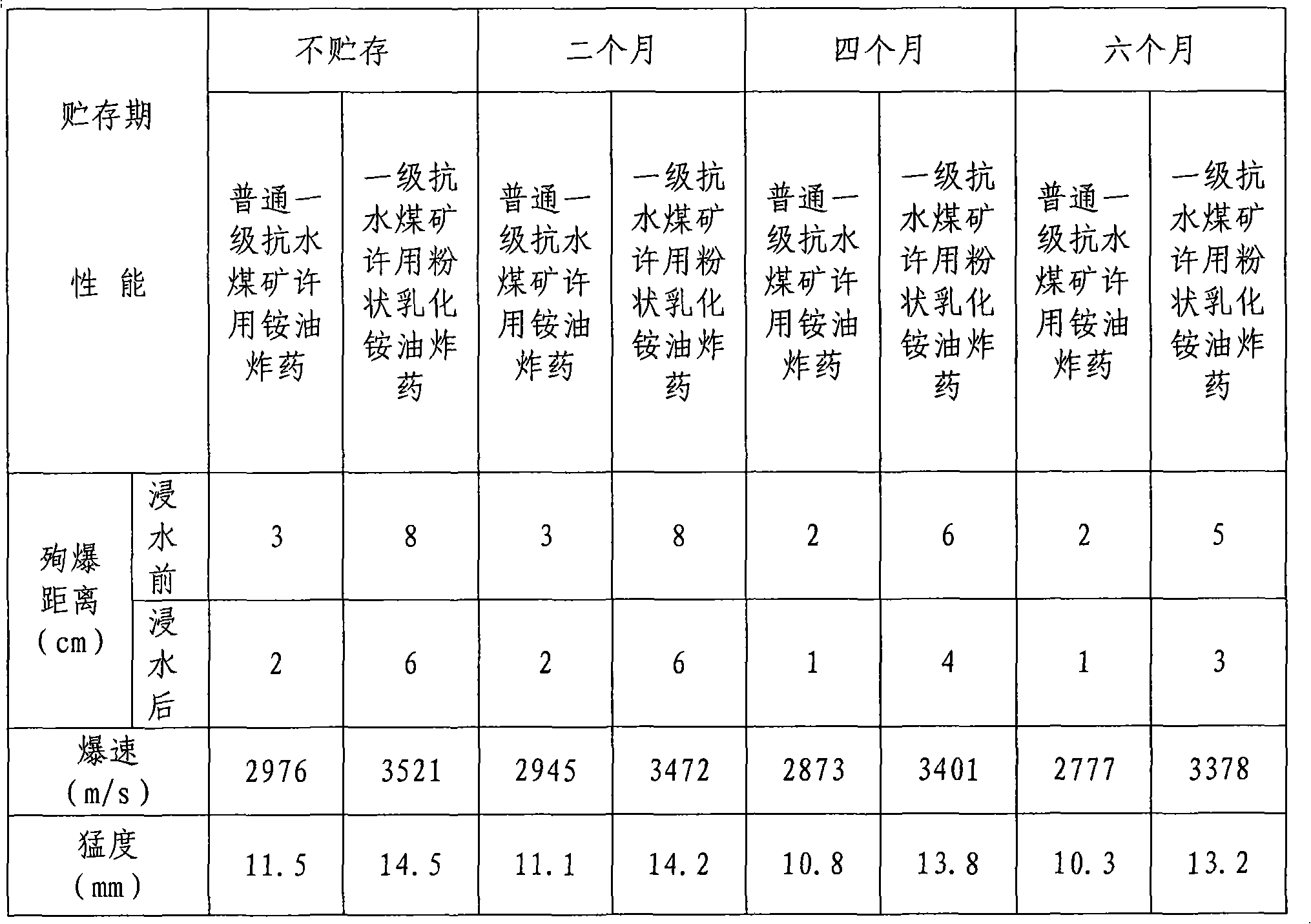

Coal mine admissible powdery emulsifying ammonium nitrate fuel explosive and preparing process thereof

ActiveCN101323552AGood explosive performanceGood storage stabilityExplosive working-up apparatusEmulsion explosiveFuel oil

The invention discloses a powdery emulsion ammonium nitrate fuel oil explosive allowed to be used in coal mines and a preparation technology thereof, which is compounded and prepared by using rock powdery emulsion explosive which has good characteristics of high sensitivity to initiation, high detonation velocity and high explosive grading, to mix with ammonium nitrate fuel oil explosive containing a certain amount of flame inhibitor, wherein, the rock powdery emulsion explosive accounts for 28 percent to 32 percent of the total weight of the explosive and the fire-resistant ammonium nitrate fuel oil explosive accounts for 68 percent to 72 percent of the total weight of the explosive. The rock powdery emulsion explosive is an industrial explosive like powder formed from water-in-oil type latex base material which is sprayed and dried. The rock powdery emulsion explosive can be mixed into ordinary ammonium nitrate fuel oil explosive to replace trinitrotoluene and plays a sensitization role in the explosive to increase the explosive performance of compound explosive. The grade I and the grade II explosive prescriptions of the invention are respectively applicable to the excavating working faces of low-methane rock or low-methane coal beds and mines and the preparation technology thereof is applicable to the discontinuous or continuous automatic production of the powdery emulsion ammonium nitrate fuel oil explosive used in the coal mines.

Owner:LIAONING HONGSHAN CHEM

Construction method for excavating weak surrounding rock tunnel by hydraulic breaking hammer

ActiveCN103643958AEasy to adjustGood crushing speedUnderground chambersTunnel liningTEX-explosiveDynamic monitoring

The invention discloses a construction method for excavating a weak surrounding rock tunnel by a hydraulic breaking hammer. The construction method comprises upper pilot tunnel excavation, deslagging, primary supporting, lower left pilot tunnel excavation, deslagging, primary supporting, lower right pilot tunnel excavation, shortcut backfilling, primary supporting, inverted arch and cavern excavation, deslagging, and construction of inverted arches, filling, small sidewalls, secondary lining and the like. The construction method adopts dynamic monitoring, performs scientific construction organization, avoids blasting explosive use, generates small amount of dust, has superhigh adaptability and good control performance for overexcavation and under-excavation, is small in surrounding rock disturbance, and is high in lining and building quality, stability, reliability and security degree; and mechanical characteristics of the surrounding rock are closer to a design condition.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

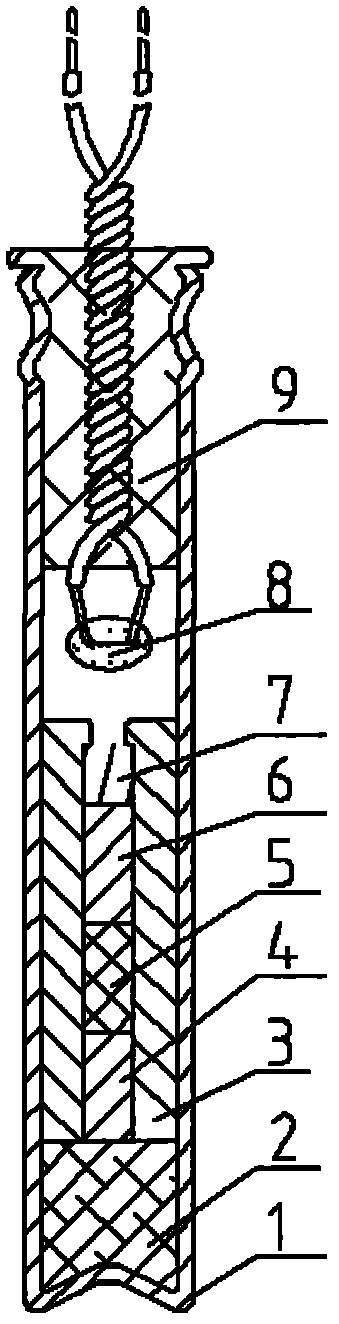

A non-priming charge detonator

The invention relates to the structure, charge and production process of a non-priming charge detonator. The invented non-priming charge detonator includes two types of instant detonators, electric igniter tip and non-electric plastic nonel, and a millisecond delay detonator with a lead core delay body. It stimulates the combustion of gunpowder in the steel pipe to generate high-pressure gas, which acts on the high explosive to make it burn in the steel pipe and develop into a high-speed detonation at the bottom of the steel pipe, thereby making a non-priming detonator. The design is optimized for reliable operation and simple fabrication.

Owner:ANHUI UNIV OF SCI & TECH

Temperature-controlled explosion method for gasified deep part coal body of coal mine underground coal bed

InactiveCN101463721AExtended service lifeBurn fullyConstructionsCoal gasificationTemperature controlCoal fired

The invention discloses a gasification method of underground coal seam which mainly comprises that a coal seam is duly and fully burnt during the underground coal seam gasification. The deep coal can not be burnt thoroughly or continuously as burnt wastes existing in the process of deep coal burning prevents the ventilation. The implementing method includes that firstly, holes are drilled in the coal seam at intervals along the coal seam strike, and then the bottom of the borehole is equipped with a temperature-controlled explosive. The concrete method is as follows: holes are drilled in the coal seam at intervals along the coal seam strike; then the bottom of the borehole is equipped with a temperature-controlled explosive; the production method of the temperature-controlled explosive is that the produced explosive can only be exploded at a temperature that is higher than a certain temperature, or the explosive is wrapped up with a shell externally, the shell can only be exploded at the temperature that is higher a certain temperature; during the burning of the coal seam, the heat released by burning increases the temperature of the coal seam near the borehole; the explosive explodes when the temperature of the coal seam near the borehole reaches to an explosive temperature; a loosening surface is excavated in the coal seam, so that the air can ventilate in loosening coal body, the burning is sufficient, thus ensuring the gasification effect, avoiding the insufficient burning of the coal seam, and ensuring the gasification stability.

Owner:庞继禄

Testing device for testing deflagration to detonation transition performance of propellant powder

The invention discloses a testing device for testing the deflagration to detonation transition performance of propellant powder. The testing device comprises an electric igniter, an end cover, ignition powder, a pressure sensor, a deflagration to detonation transition pipe and charged propellant powder, and further comprises a sleeve, a simulated bullet and a simulated launching pipe. The end cover is a cylinder with a center step through hole in the axial direction, and is connected with the sleeve through threads, the igniter and the ignition powder are arranged in the center through hole of the end cover, the sleeve is a cylinder with an observation slot along a generatrix of the cylinder, the deflagration to detonation transition pipe is arranged in the sleeve, and is compactly filled with the charged propellant powder, and the charged propellant powder is in close contact with the ignition powder. The simulated launching pipe is a cylinder with external threads at one end, and is connected with the sleeve through the threads, and the simulated bullet is arranged in the simulated launching pipe. The error of testing the wave surface-time relation of explosive and powder deflagration and detonation can be reduced, and the simulated launching pipe is closer to a real launching pipe, and can be equivalent to the actual launching environment.

Owner:XIAN MODERN CHEM RES INST

Integrated scattering type oriented explosion cylinder

The invention relates to the field of ammunition manufacturing and engineering blasting. An integrated scattering type oriented explosion cylinder is composed of a cylinder body, an end cover and an ignition device, wherein a cavity of the cylinder body is filled with explosives, and the ignition device is led out of a hole in the end cover. Conical or semicircular pits which are formed in rows and in lines and distributed in a regular or irregular mode are formed in the outer circumferential face of the tubular cylinder body, wherein the central axes of the pits are perpendicular to the longitudinal axis of the tubular cylinder body, the distance, along the longitudinal axis of the cylinder body, between the central axes of every two adjacent pits ranges from 1 cm to 50 cm, and protrusions in the corresponding shapes are formed in the inner wall face of the cylinder body through the pits. The cone vertex angle of the conical pits ranges from 30 degrees to 160 degrees, the length of the generatrix of the conical pits ranges from 0.5 cm to 20 cm, and the diameter of the bottom face of the conical pits is 2 to 50 times of the thickness of the wall of the cylinder body. The radius of the semicircular pits is 2 to 50 times of the thickness of the wall of the cylinder body. After the explosives are blasted, high-temperature and high-pressure detonation waves act on the pits, and high-speed jet flow is formed through extrusion drive. The integrated scattering type oriented explosion cylinder is simple in manufacturing process, low in cost and capable of being applied to the tunnel cutting blasting occasion, the presplitting blasting occasion and other occasions.

Owner:UNIV OF SCI & TECH OF CHINA

Spherical atomized aluminum-zinc amorphous alloy powder with high physical activity and preparation method thereof

ActiveCN108213406AHigh purityAchieve amorphous alloyingTransportation and packagingMetal-working apparatusCombustionBoiling point

The invention discloses spherical atomized aluminum-zinc amorphous alloy powder and a preparation method thereof. An aluminum particle undergoing thermal self-explosion and becoming a particle with ananoscale during combustion is designed and prepared, the combustion rate of the aluminum particle is increased, and thus the energy release rates of aluminiferous explosives, pyrotechnic compositionsand other objects are greatly increased. The melting points and the boiling points of two types of metal differ greatly, the metal separates in the melting processes of the metal under the high-temperature impact, the metal with low melting points is melted and gasified first, under the effect of thermal expansion, alloy particles expand and burst, and finer particles are formed. Even the metal with low boiling points is gasified when reaching the boiling point temperature, more violent burst is realized under the action of gas expansion, and finer particles are formed. Zinc and aluminum aresubjected to amorphous alloying, an amorphous alloy particle realizes thermal self-explosion in the ignition process by using the melting and boiling points of zinc and melting and gasification characteristics, the gasification rate of the amorphous alloy particle is increased, and thus the combustion efficiency of the amorphous alloy particle is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

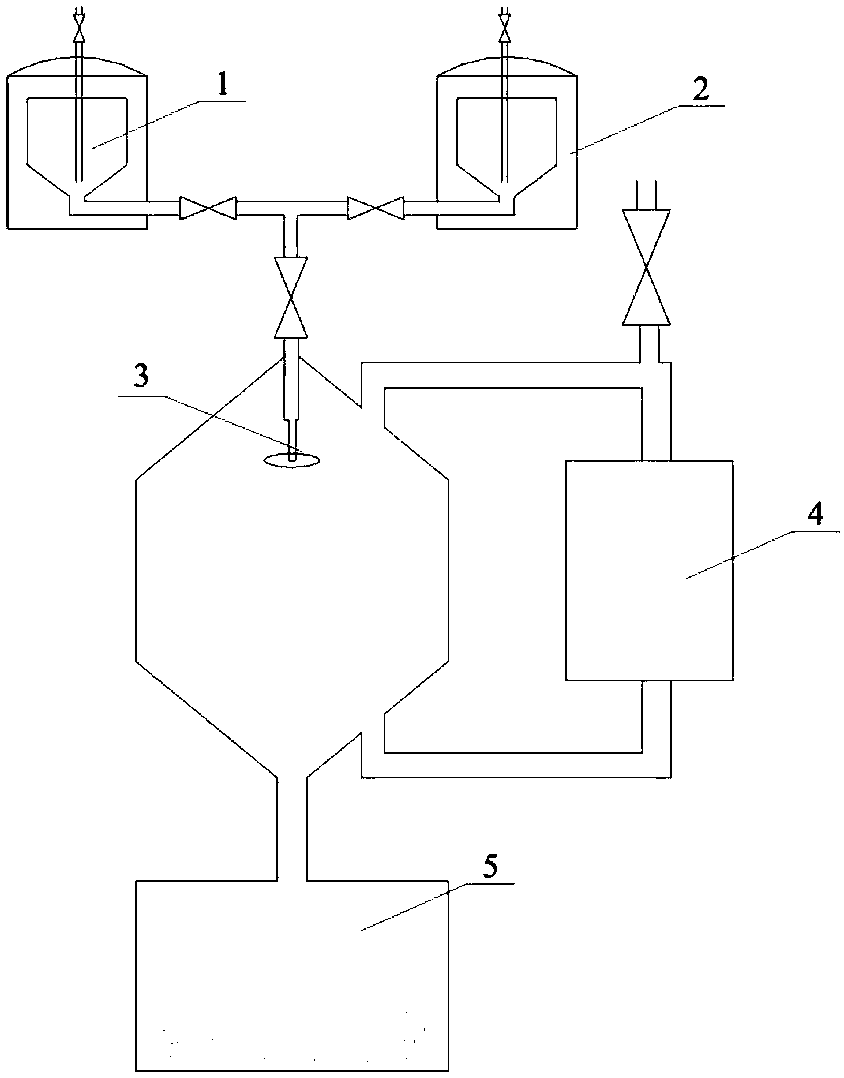

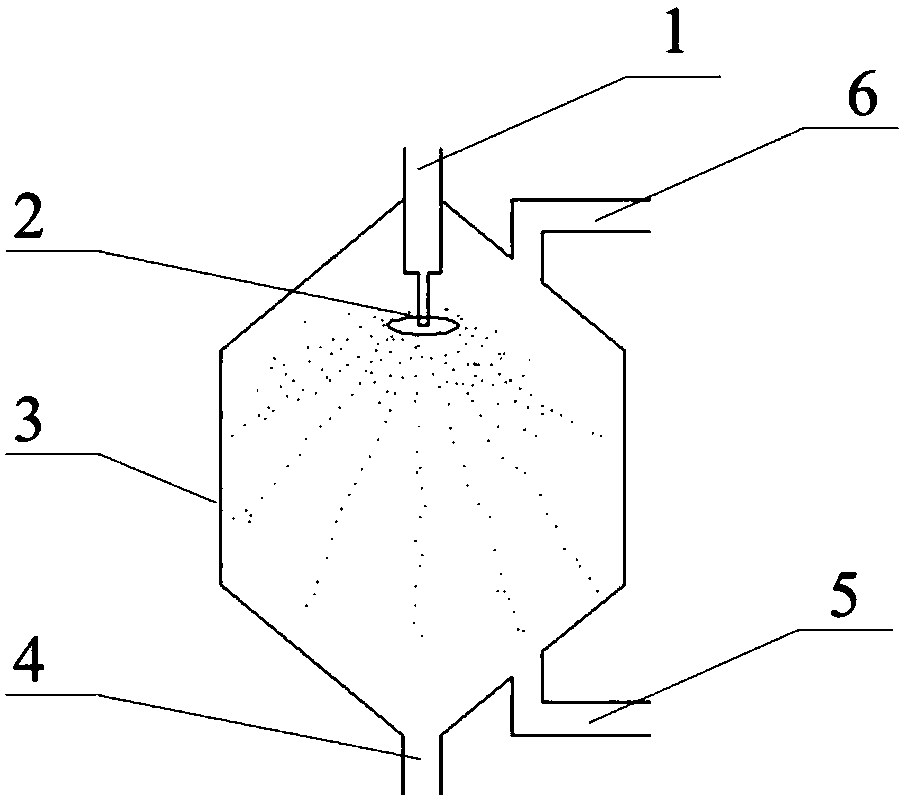

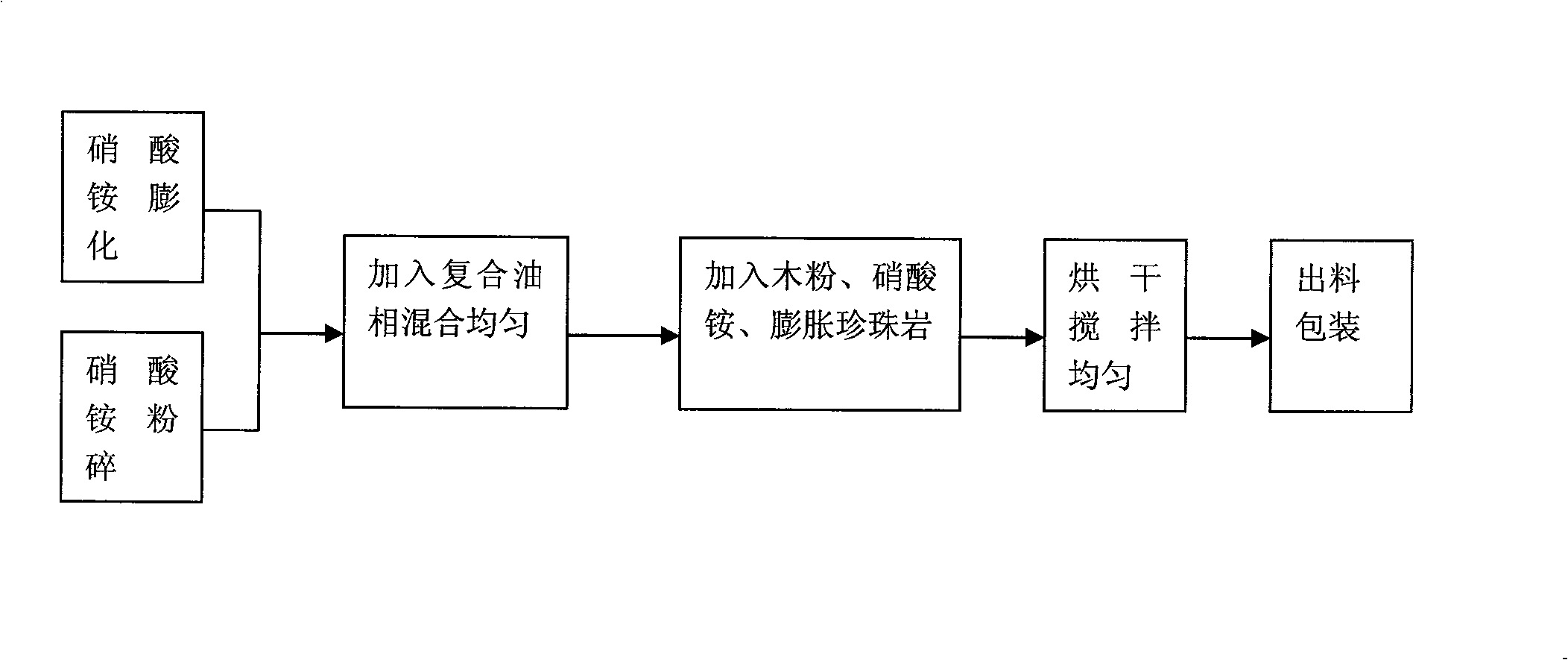

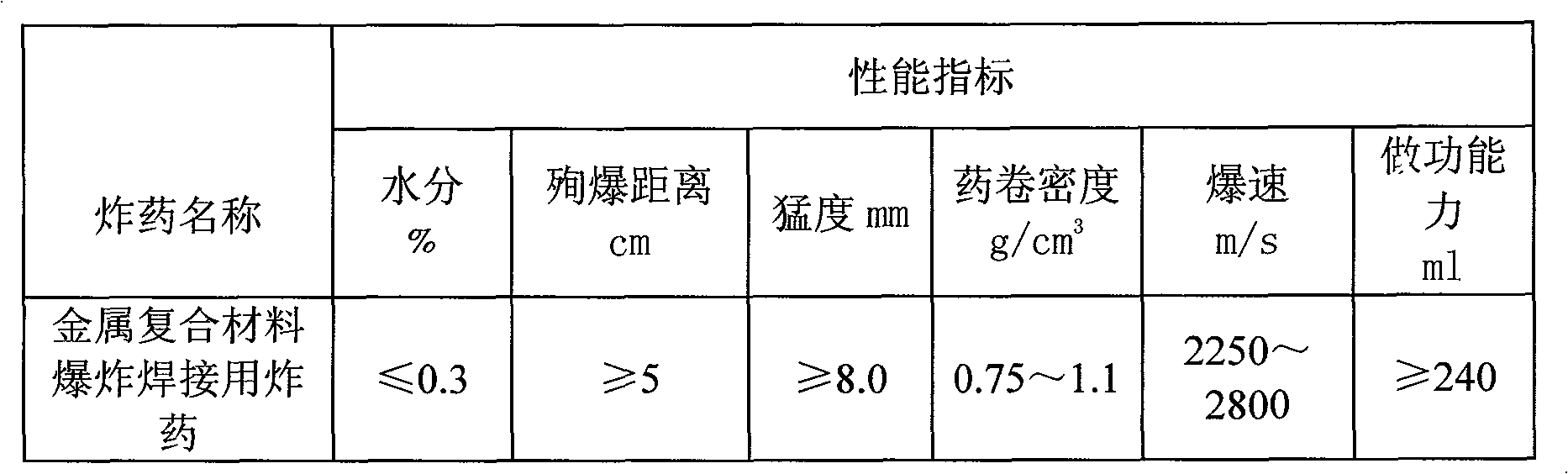

Blasting explosive for explosion welding of metallic composite and manufacturing method therefor

The invention relates to a blasting explosive for explosive welding of metal composite materials and a method for manufacturing the same. The mass compositions of the blasting explosive comprise 43 to 75 percent of expanded ammonium nitrate, 15 to 50 percent of crushed ammonium nitrates, 1.5 to 3.5 percent of compound oil phase, 1.5 to 3.5 percent of wood powder, and 2 to 6.0 percent of expanded perlite. The method comprises the following steps: firstly, performing expansion treatment on part of the ammonium nitrate to obtain the expanded ammonium nitrate, and then crushing other ammonium nitrates, and filtering other ammonium nitrates through a sieve of 40 meshes; secondly, mixing the expanded ammonium nitrate and the crushed ammonium nitrates with the compound oil phase, the wood powder and the expanded perlite in a wheel mill; and finally, taking out the materials from the wheel mill at a temperature 40 DEG C below and packaging the materials. The blasting explosive does not contain TNT which is toxic to human bodies, and has the advantages of stable explosive performance, low cost, simple manufacturing method, and applicability to industrial production; besides, the bonding rate and the bonding strength of interfaces of large-area metal composite materials between stainless steel and steel, nickel and steel and the like which are welded through explosive welding by using the blasting explosive.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

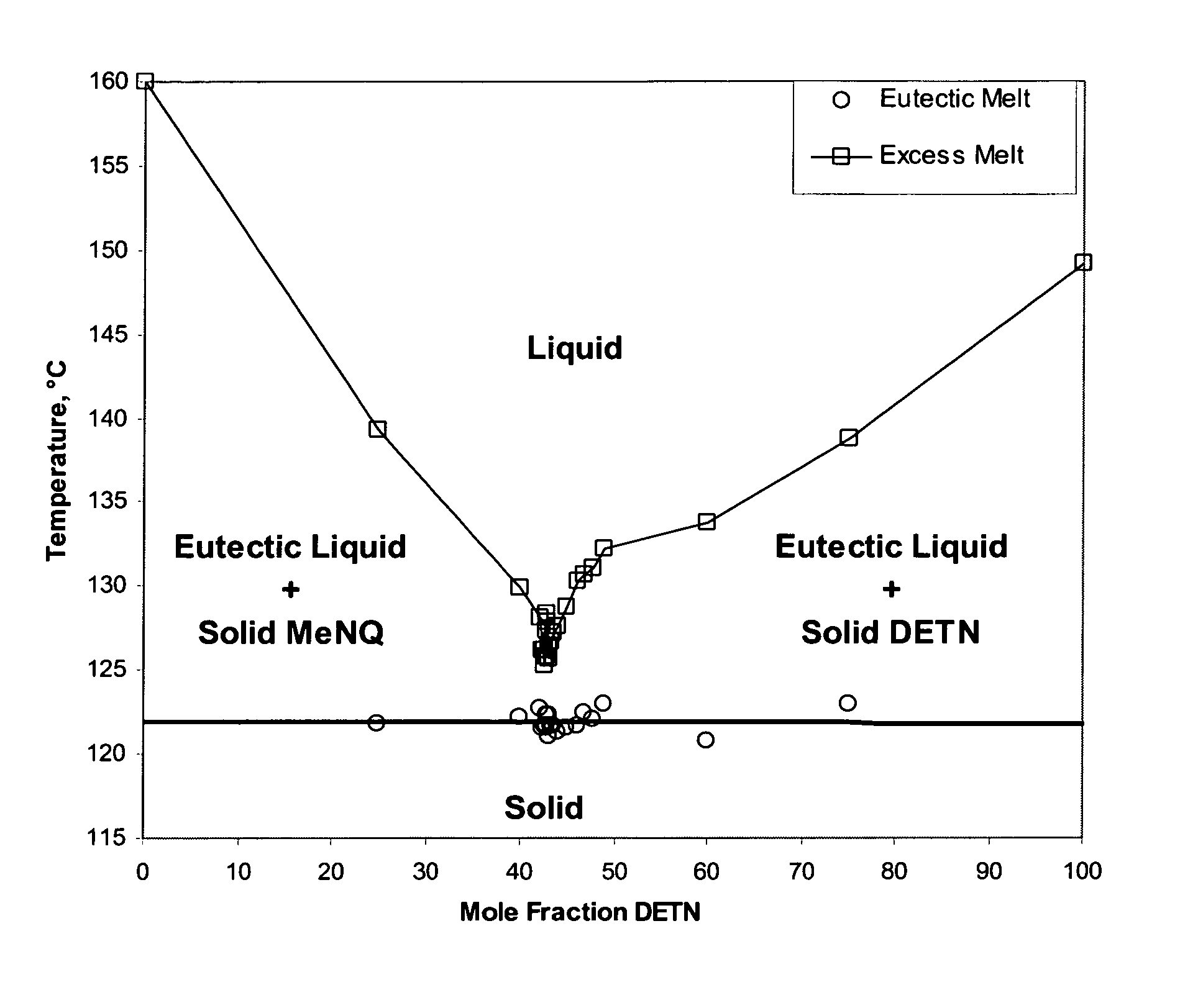

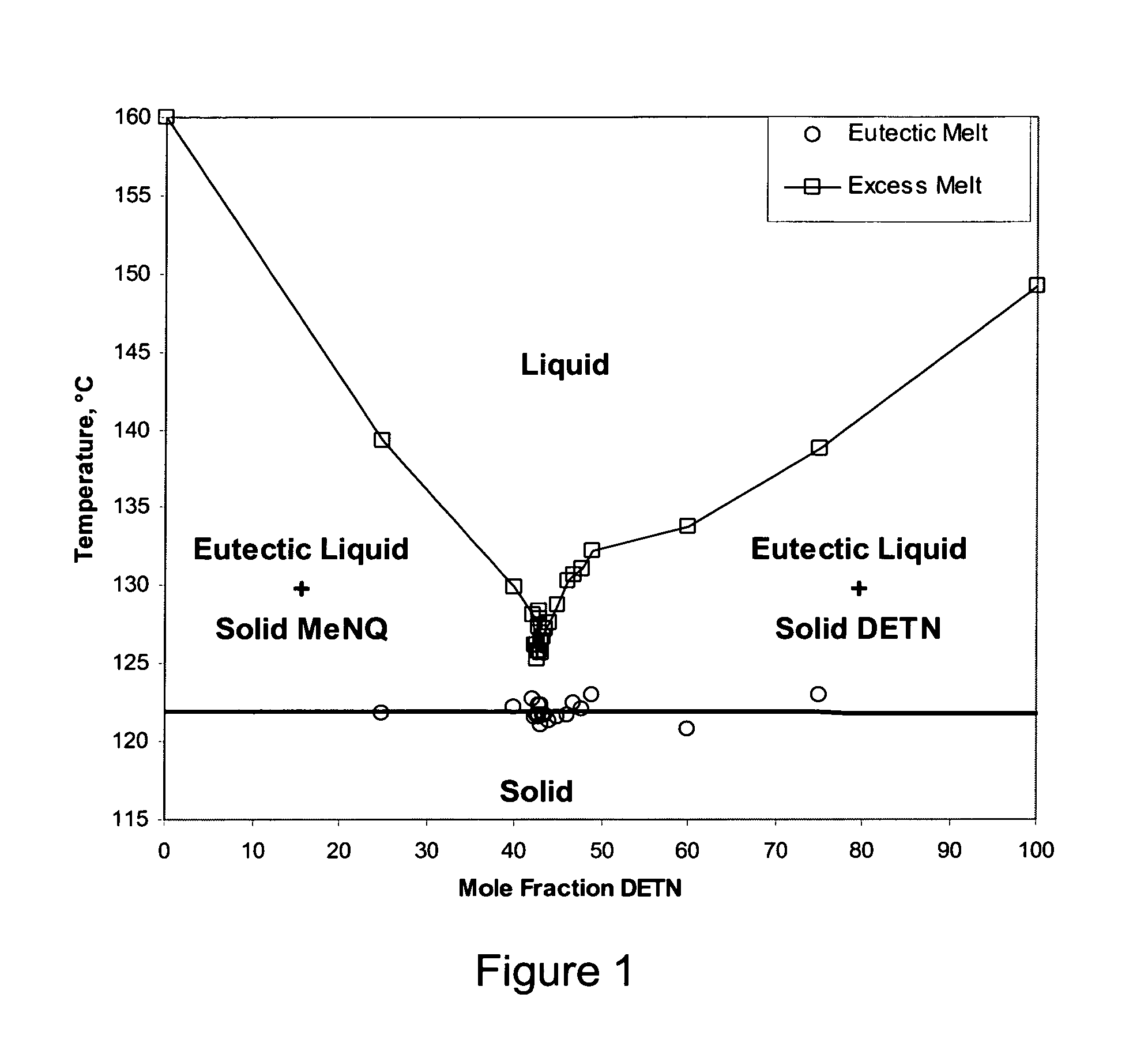

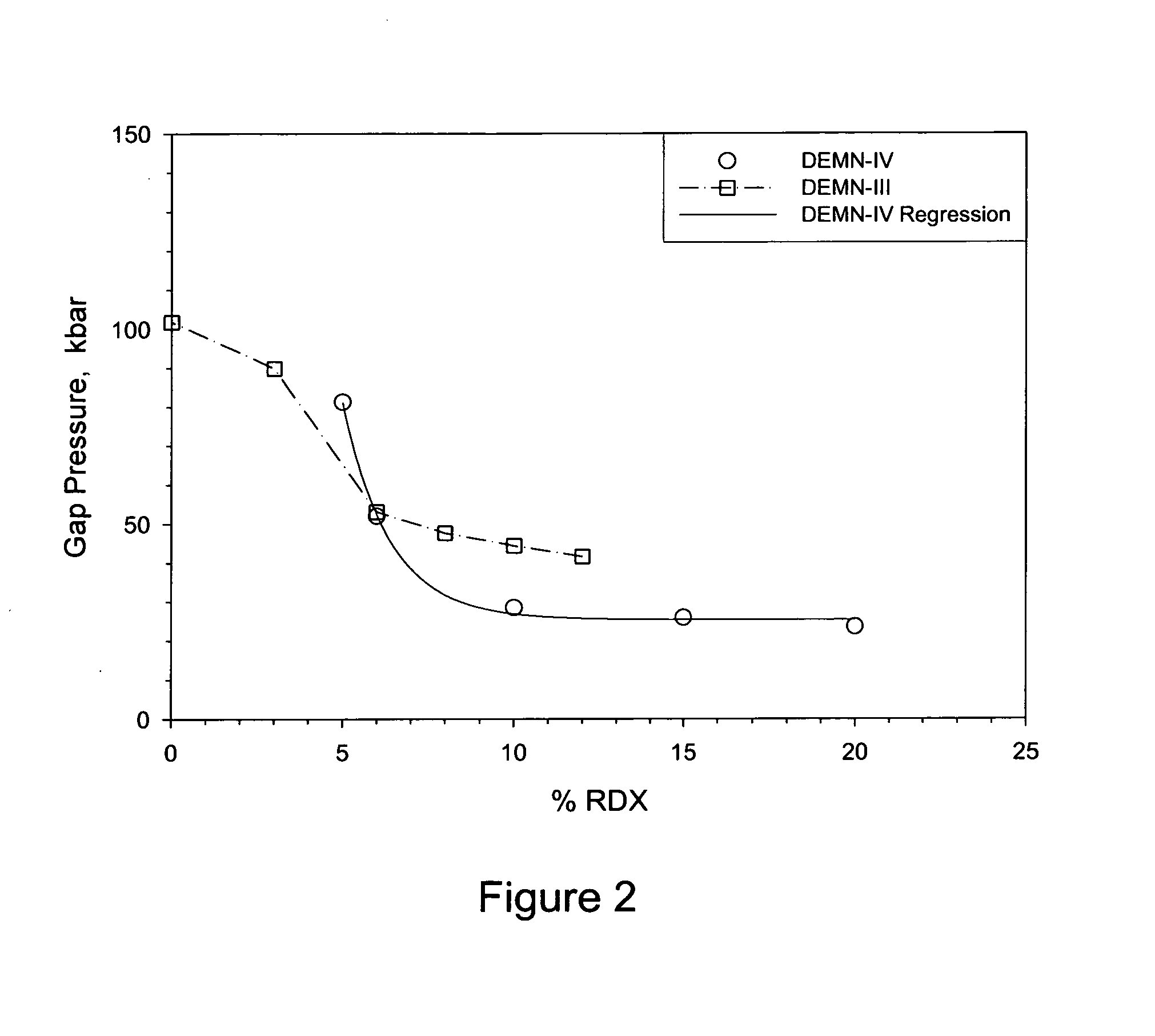

Melt cast insensitive eutectic explosive

InactiveUS8663406B1Nitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive mixture shapingDiethylenetriamineMelting temperature

A insensitive explosive comprises:34.9 wt % diethylenetriamine trinitrate (DETN),33.4 wt % ethylenediamine dinitrate (EDD),25.4 wt % methyl-guanidine (MeNQ), and6.3 wt % guanidine (NQ).This quaternary eutectic is used in combination with a sensitive explosive. A low melting temperature facilitates melt casting to fill 155 mm artillery shells.

Owner:GORVERNMENT OF THE UNITED STATES

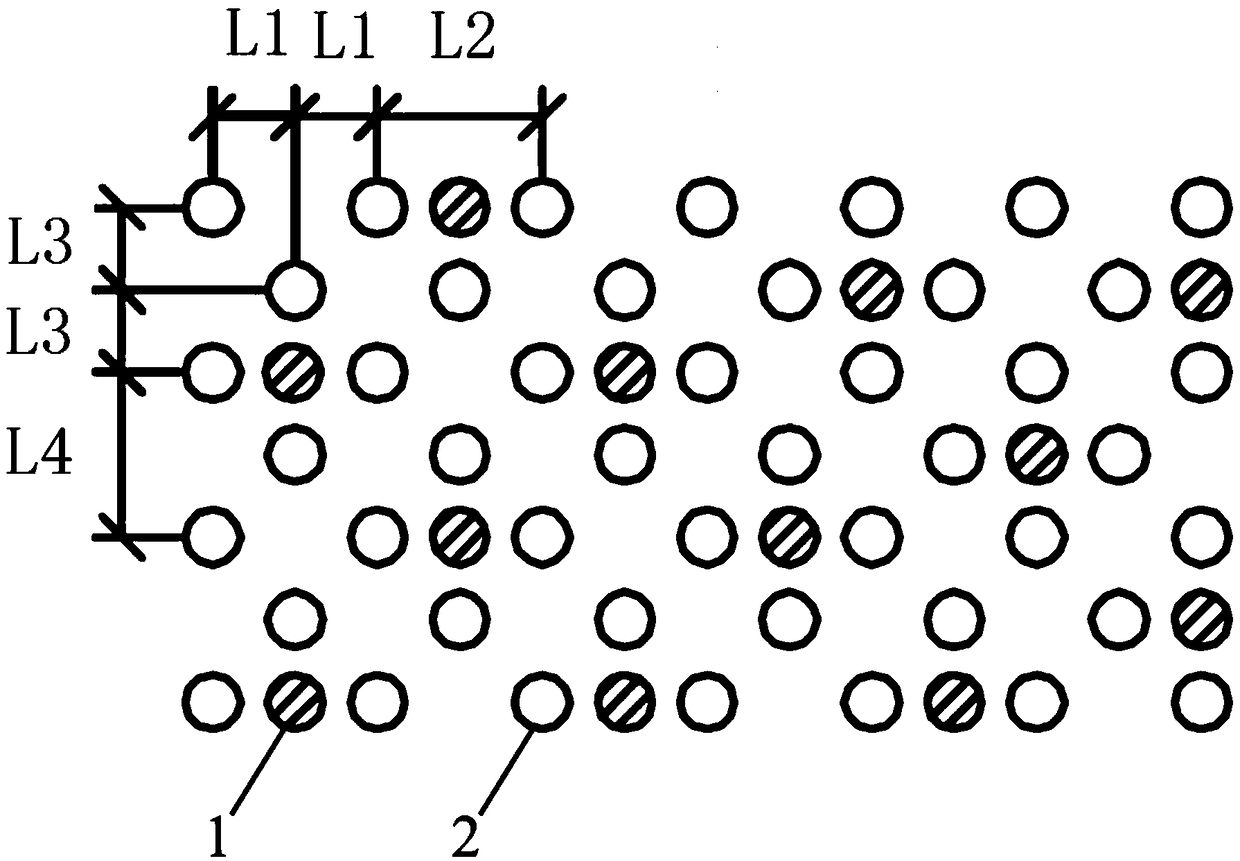

Pre-splitting blasting construction method for shield tunneling in upper soft and lower hard strata

ActiveCN109000525ASolve efficiency problemsSolve serious tool wearBlastingTunnelsStructure of the EarthSlurry

The invention discloses a pre-splitting blasting construction method for shield tunneling in upper soft and lower hard strata. The pre-splitting blasting construction method for shield tunneling in the upper soft and lower hard strata comprises the following steps that according to a determined blasting area, pre-splitting blasting hole arrangement is carried out, specifically, hole arrangement forms of blasting holes, auxiliary holes and shock absorption holes are included, and drilling construction is carried out after the hole arrangement is qualified through acceptance; after the drillingis completed, the explosive quantity calculation and charge processing are carried out, then a charge structure is determined and the initiation network is designed; anti-floating counterweight of explosive, charge emplacement and protection are carried out, then initiation is carried out, and the blasting effect is tested after completion of blasting; after the blasting construction is completed,the remaining holes are sealed and blocked to avoid slurry leakage when a shield passes through the blasting area, and after the hole sealing is completed, shield tunneling is carried out. The pre-splitting blasting construction method greatly saves the construction cost of the shield and can effectively solve the technical problem of processing boulders and hard rock sections encountered in shield tunneling by adopting the pre-splitting blasting technology for the sections.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

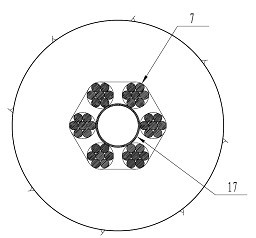

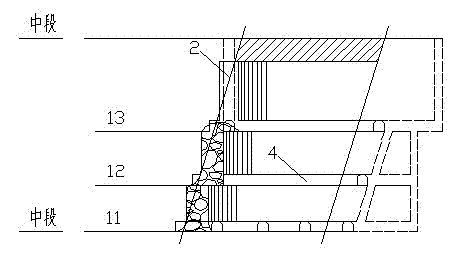

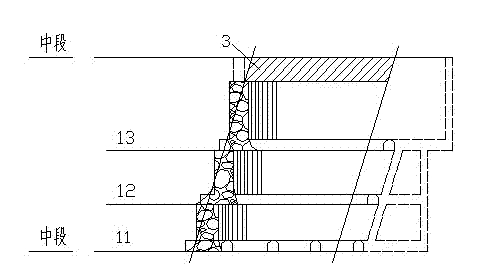

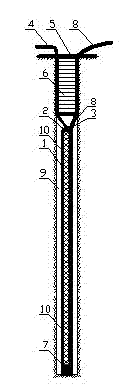

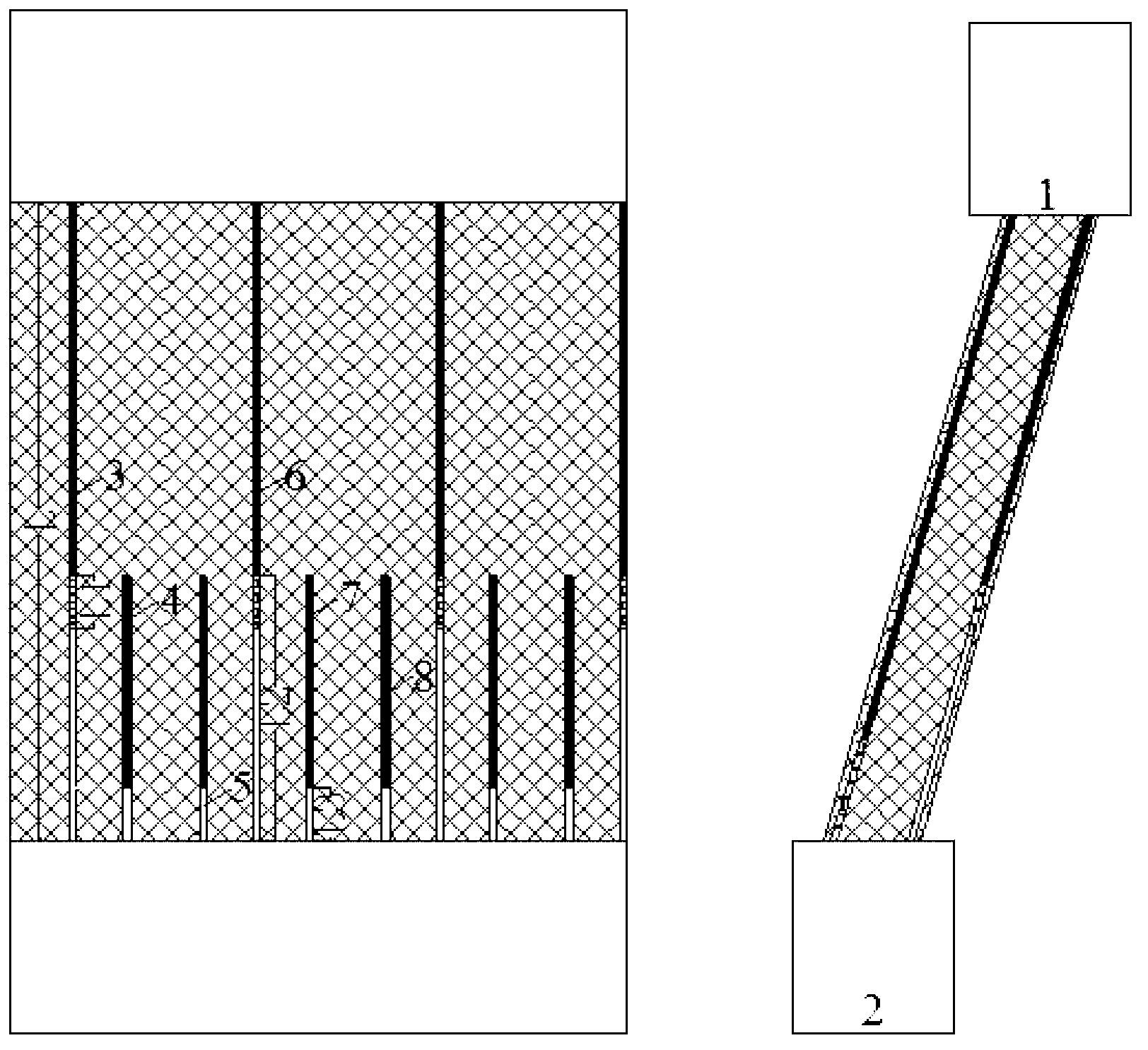

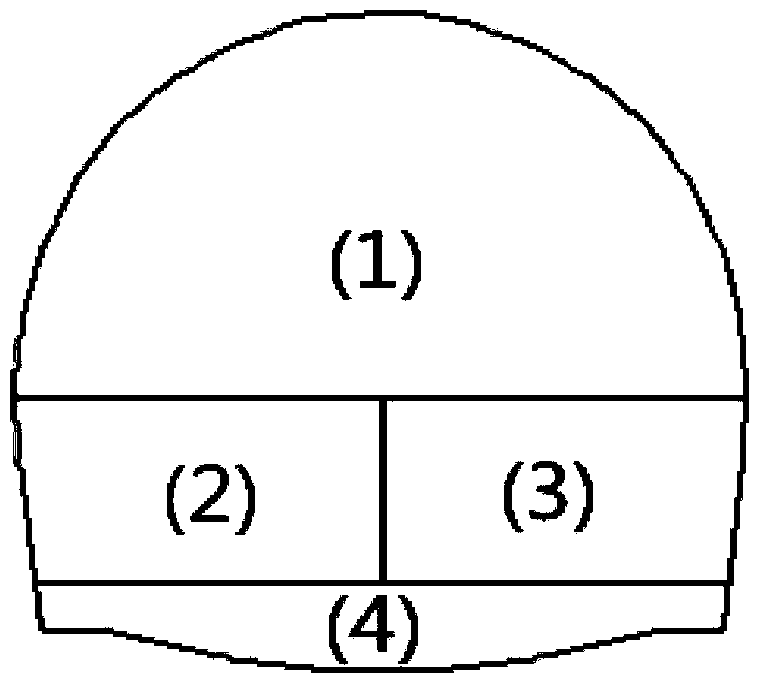

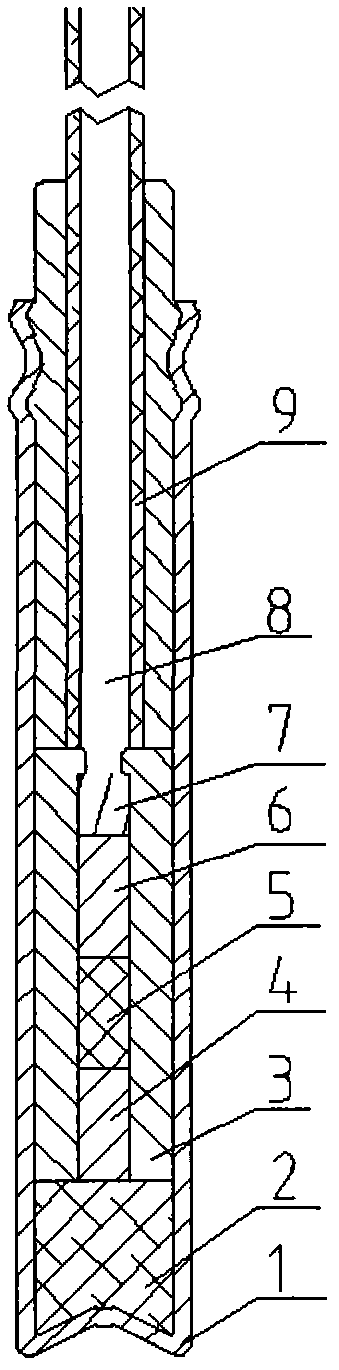

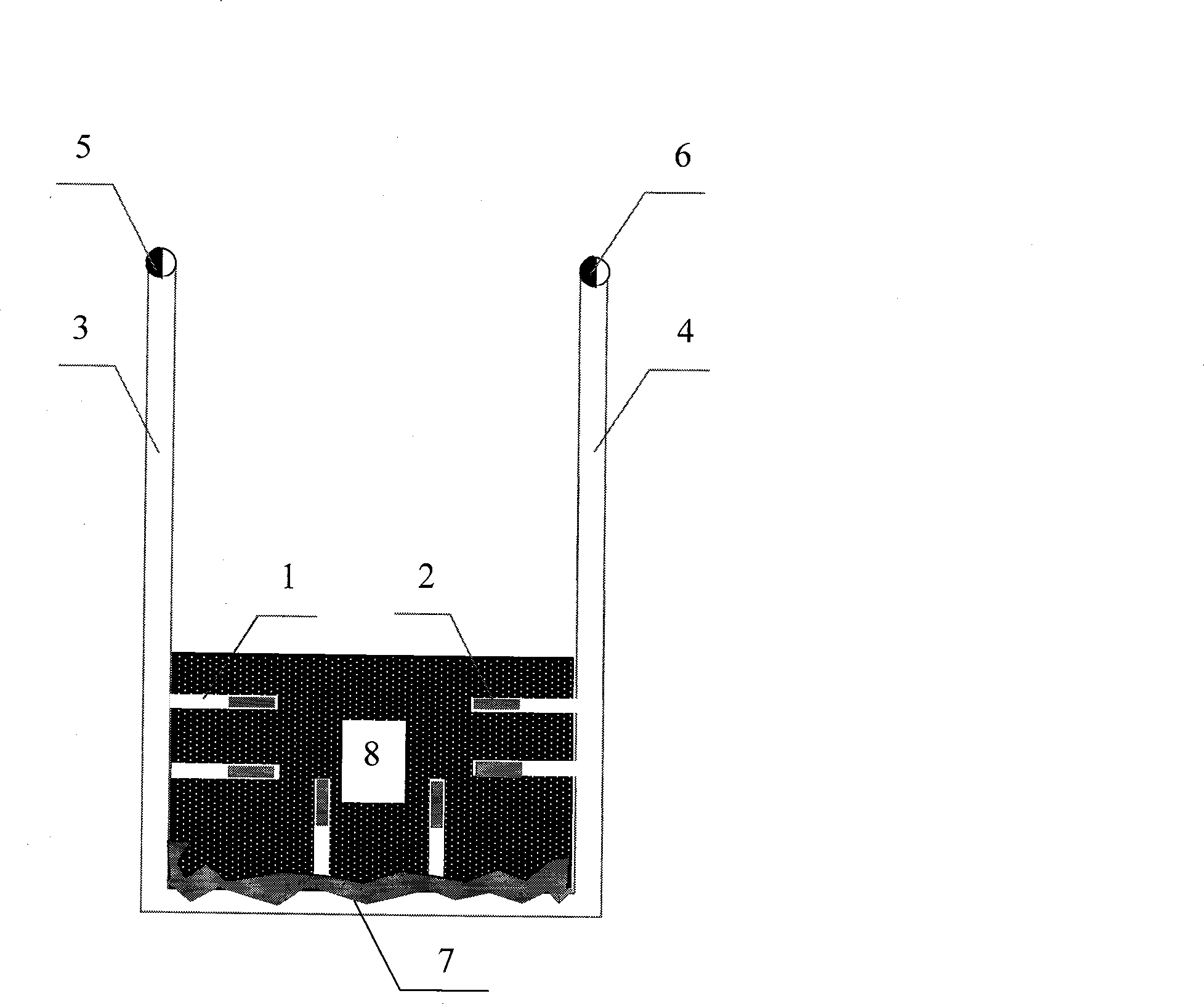

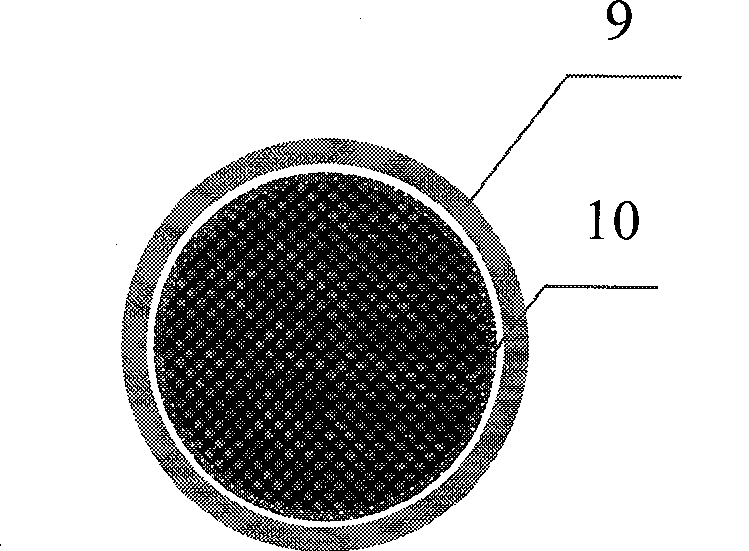

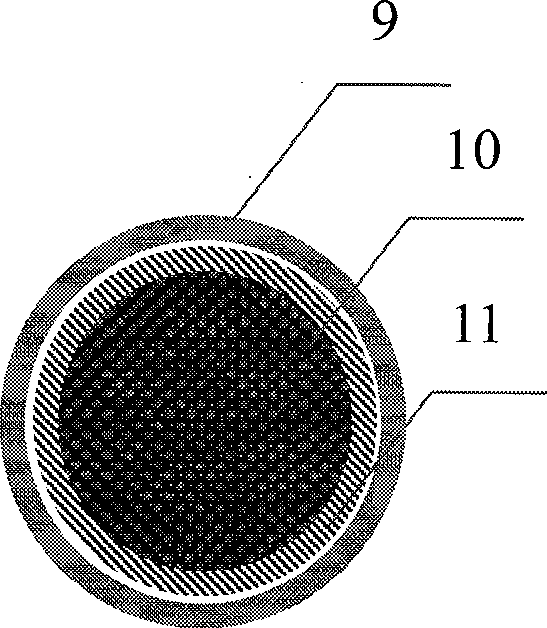

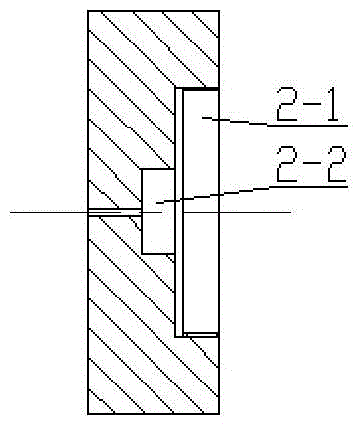

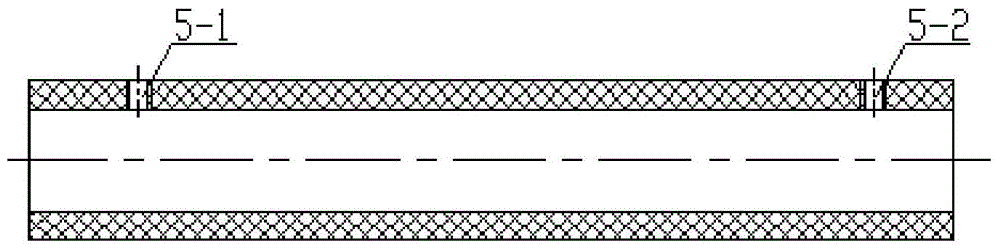

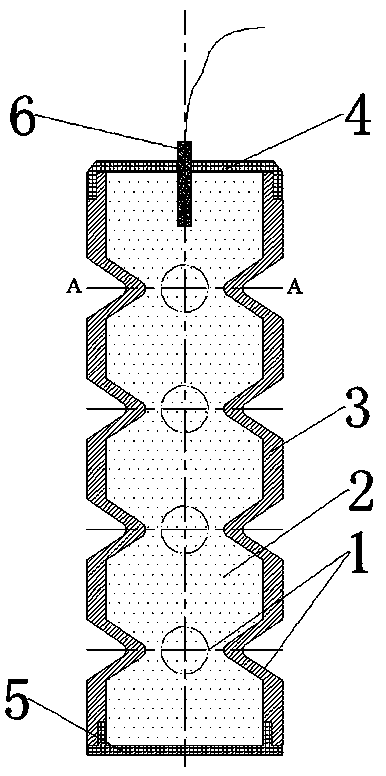

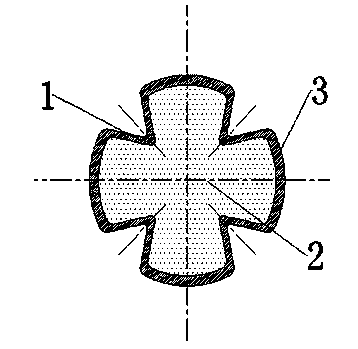

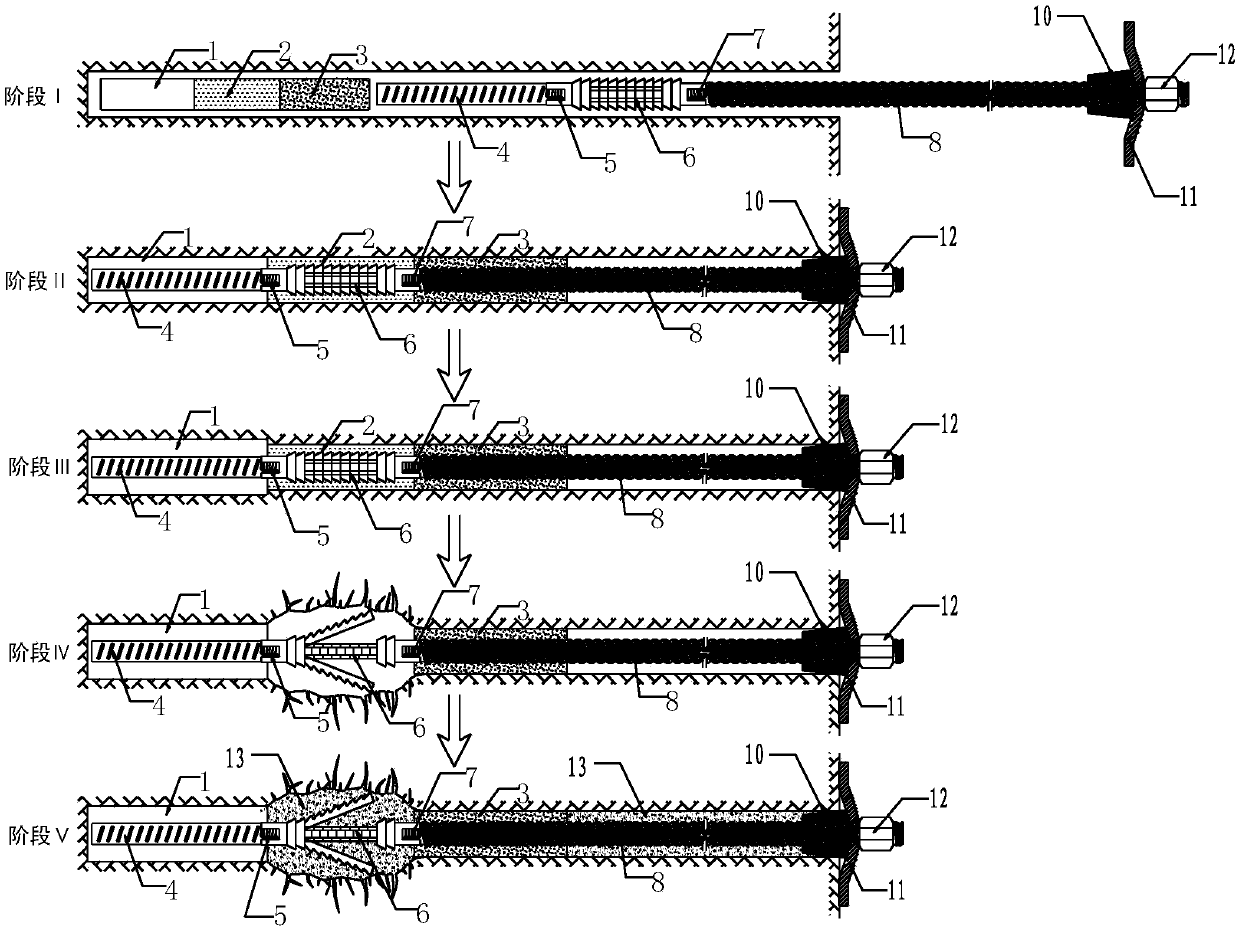

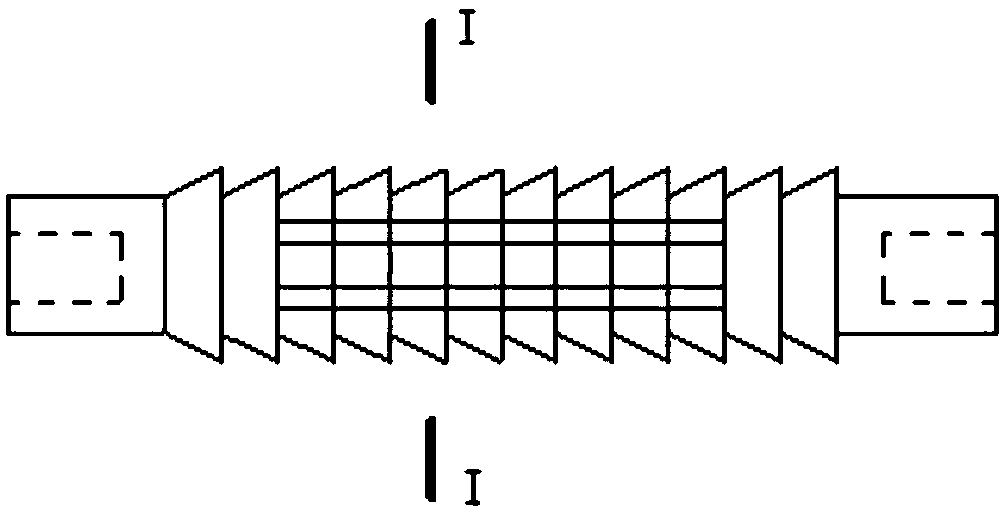

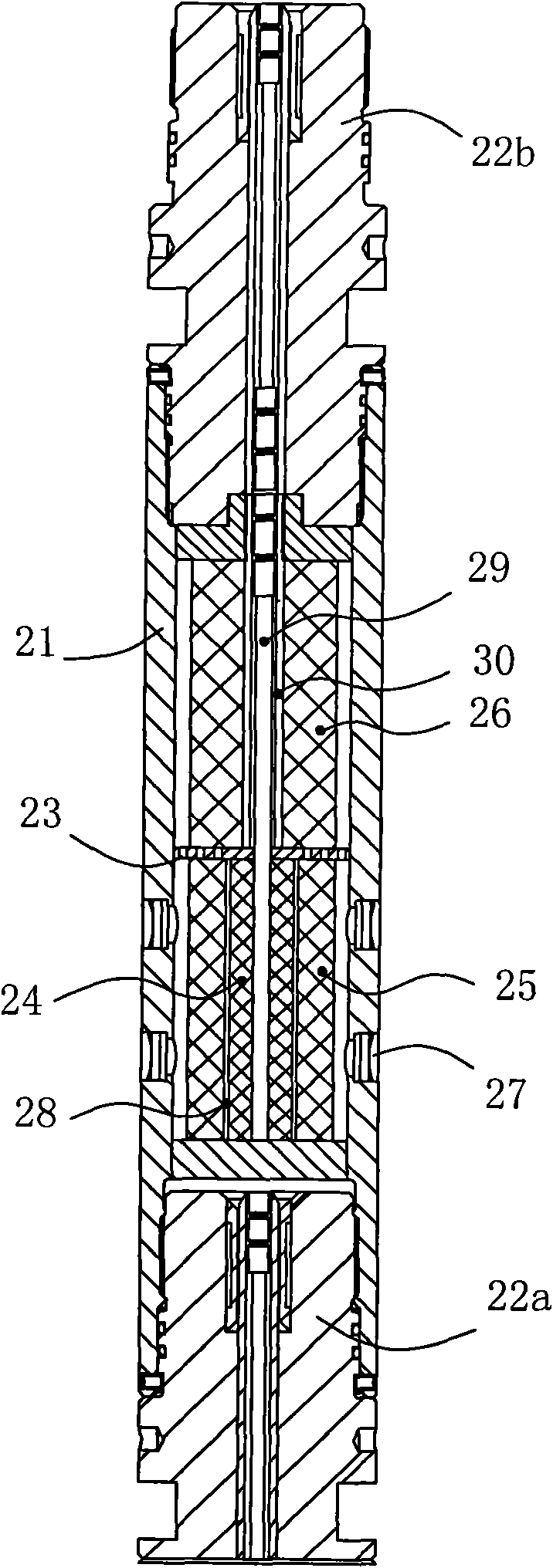

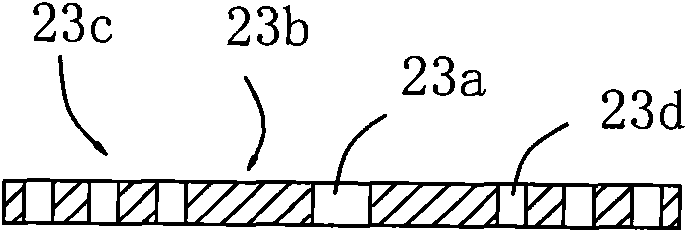

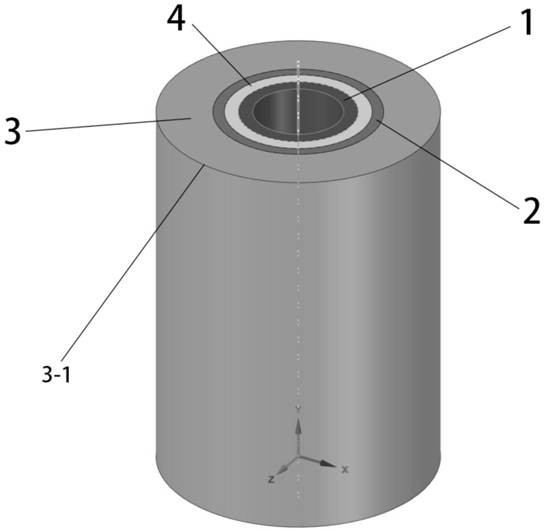

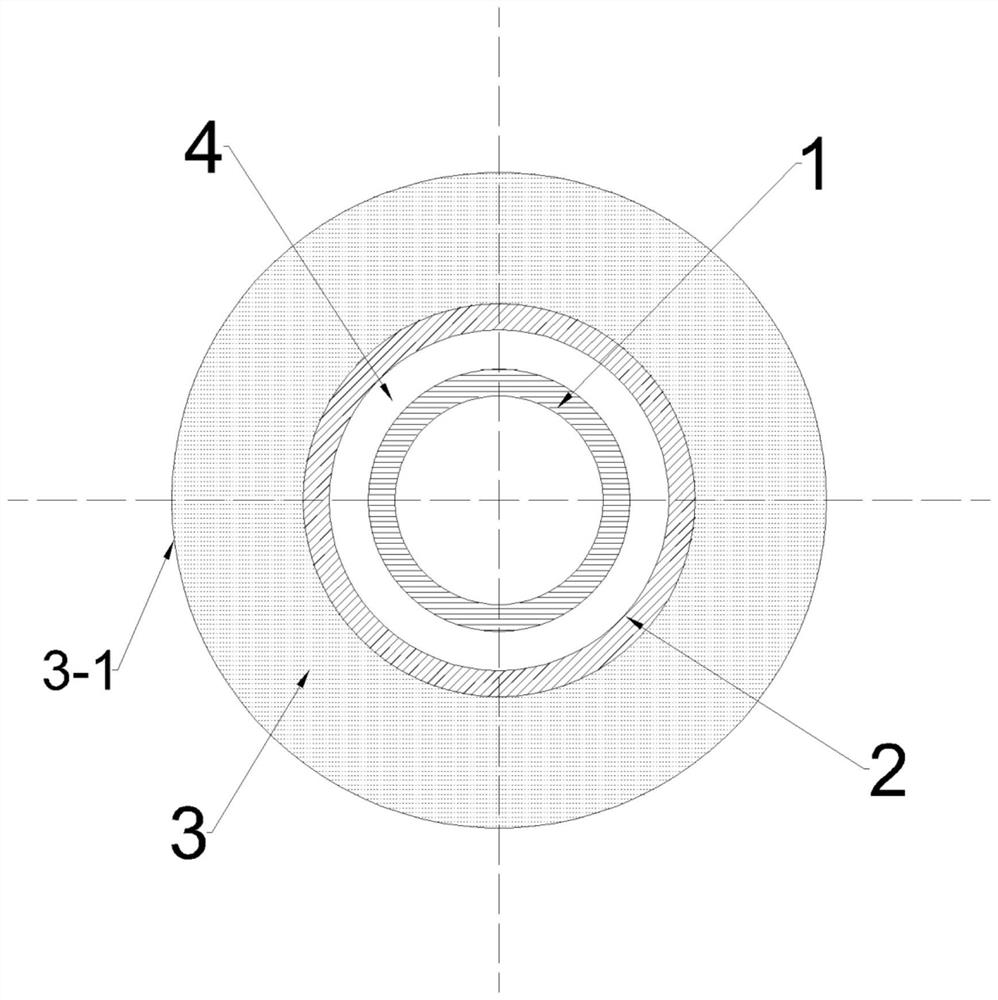

Full-length prestress anchor grouting supporting device and process capable of expanding internal anchor solids in combined mode

ActiveCN107740410AImprove ultimate anchoring forcePlay the role of secondary hole expansionClimate change adaptationBlastingDetonationTEX-explosive

The invention discloses a full-length prestress anchor grouting supporting device and process capable of expanding internal anchor solids in a combined mode. The full-length prestress anchor groutingsupporting device comprises an inner section anchor rod body and an outer section anchor rod body, wherein a detonation device is arranged between the two rod bodies, and the outer section anchor rodbody is a hollow rod body and comprises a slurry stopping plug, a tray and a nut on the outer peripheral part of the outer end. According to the full-length prestress anchor grouting supporting deviceand the process, an anchor rod is anchored and installed at the bottom part of a stratum drilling hole through a combined type anchoring cartridage, and the combined type anchoring cartridage sequentially comprise a first expanded cartridage, a second explosive cartridge and a third quick-coagulation cartridage in the length direction, and the first expanded cartridage can generate volume self-expansion holes on the wall of the drilling hole; the detonation device can detonate an explosive in the second explosive cartridge, so that a local explosion hole cavity is formed in the stratum, andthe detonation device can be automatically opened to form a reversed claw type structure; and after anchor rod prestress is applied, the local explosion hole cavity, free section drilling holes and rock-soil body fractures around the drilling holes can be sealed through grouting of the outer section hollow rod body so as to form a full-length prestress anchoring supporting effect.

Owner:SHANDONG JIANZHU UNIV

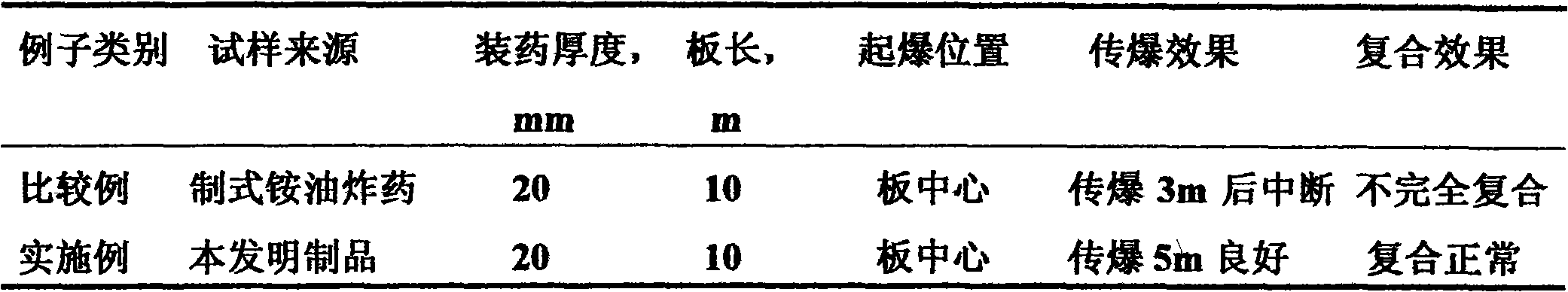

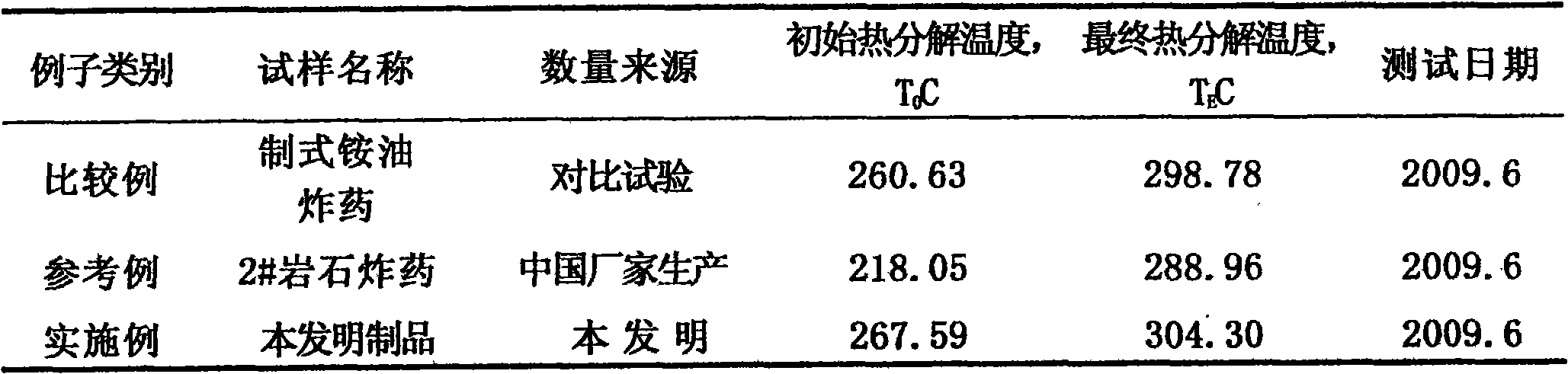

High-looseness high-sensitivity ammonium nitrate fuel oil explosive for explosion welding and preparation method thereof

InactiveCN101948363AChange the old concept that cannot be mixedGood crystal shapeExplosivesDetonationSorbent

The invention provides a high-looseness high-sensitivity ammonium nitrate fuel oil explosive for explosion welding and a preparation method thereof. The high-looseness high-sensitivity ammonium nitrate fuel oil explosive is characterized by comprising a powdery compound modifying agent and aiming at solving the unsolved problems of easily serious agglomeration under severe environments of rainy reason, foggy days and the like, low detonation sensitivity during winter charge, poor explosion propagation property when a large board explodes and compounds during the practical use of the traditional porous ammonium nitrate fuel oil explosive. The added powdery compound modifying agent comprises a crystal pattern transition agent, a dispersing agent, a lubricating agent, an absorbing agent and a centralite. The preparation method comprises the steps of: adding the compound modifying agent and the porous granulated ammonium nitrate together into an edge runner mill, raising the temperature to ensure that the porous ammonium nitrate is sensitized through crystal transition, and then adding fuel oil after the temperature is reduced, and evenly stirring and mixing at low temperature to obtain the modified porous ammonium oil explosive with good looseness, high detonation sensitivity and explosion propagation distance of exceeding 5m. The invention is especially suitable for the large-board compound explosive welding engineering.

Owner:殷海权

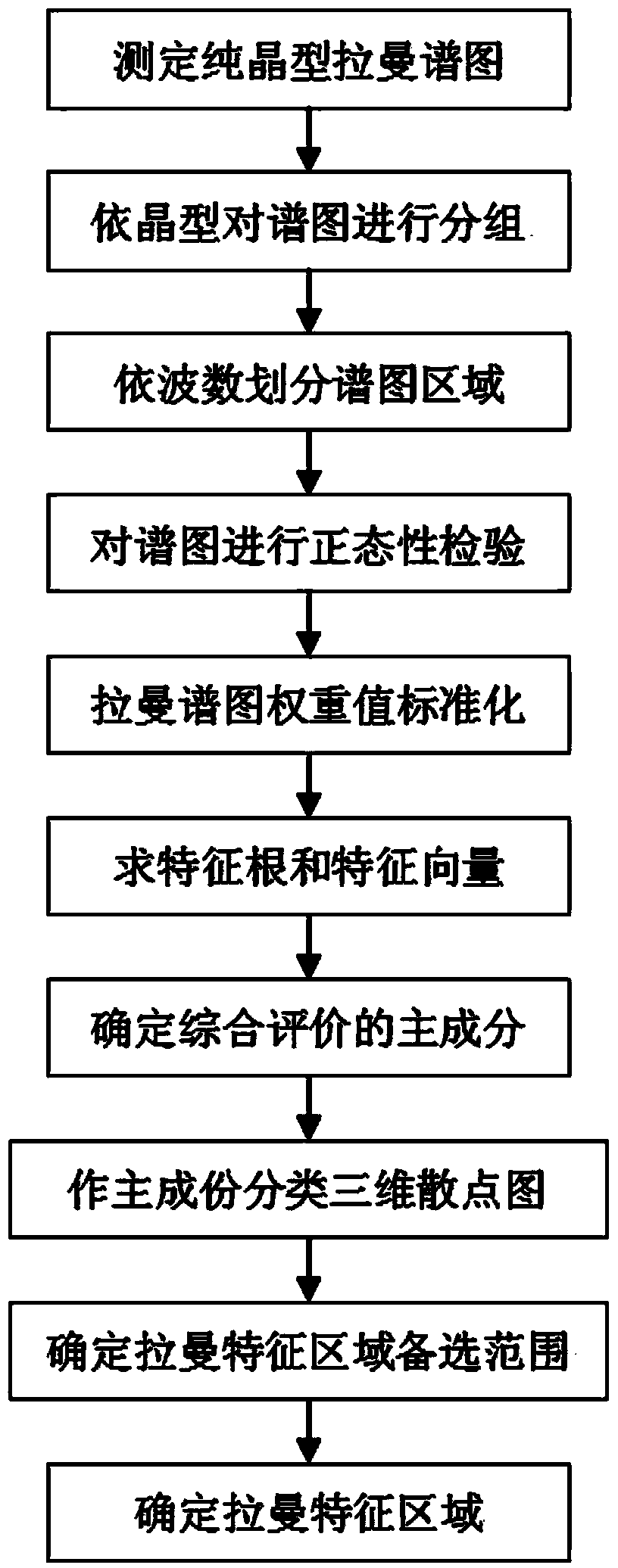

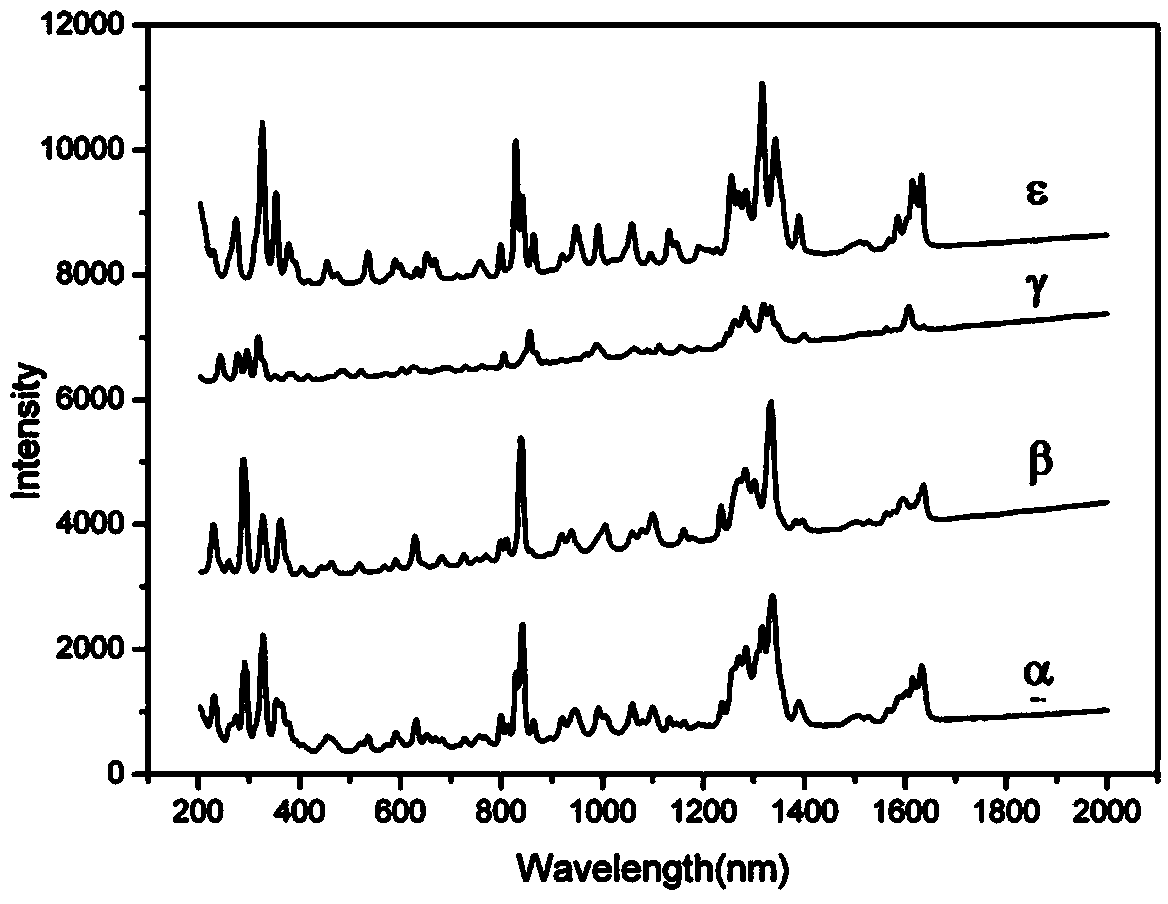

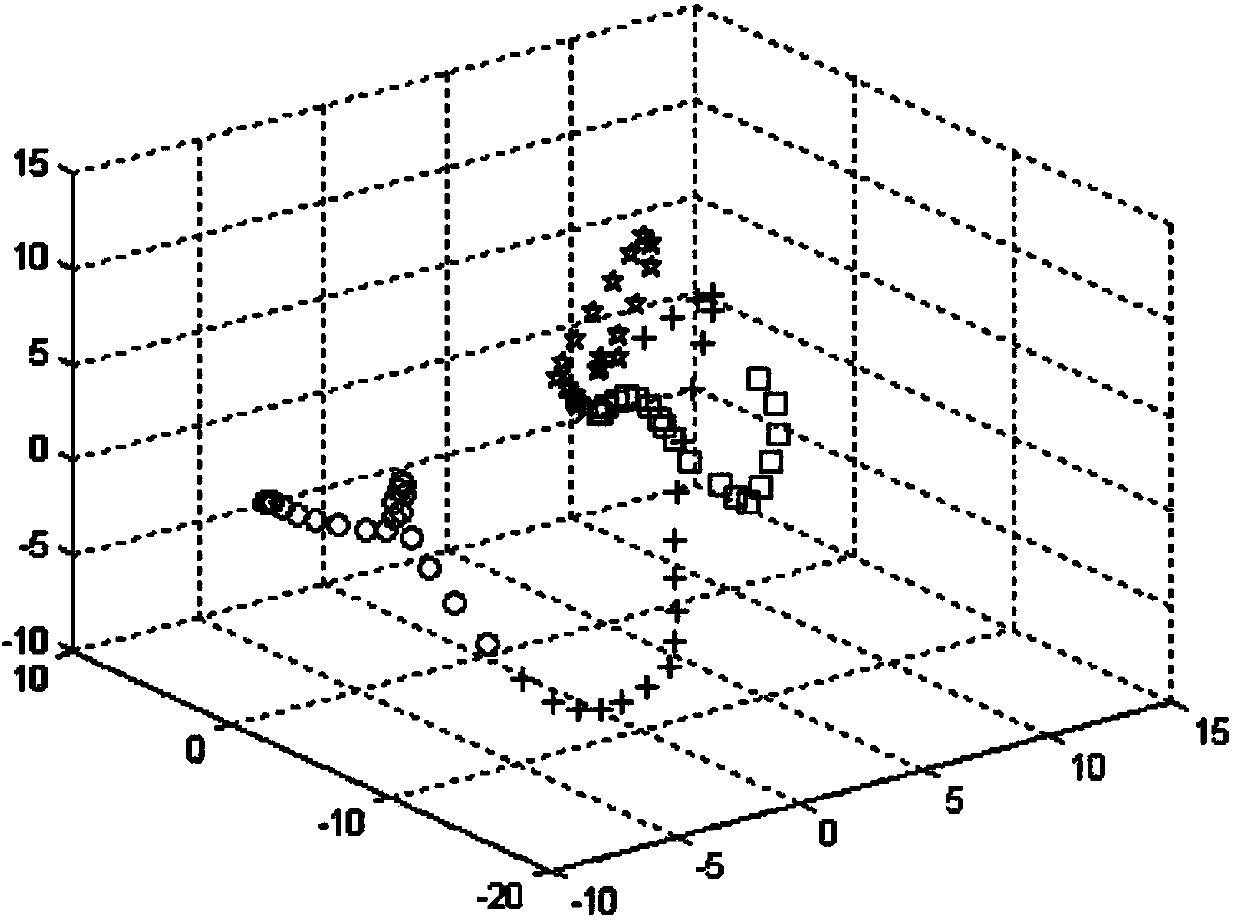

Explosive CL-20 crystal form quantitative analysis Raman feature region determination method

In order to solve the problems of weak Raman spectroscopy vibration frequency, complex Raman peak shape, peak position overlapping, difficult spectrogram analysis and the like of the Raman spectroscopy method for quantitative analysis of the explosive CL-20 crystal in the prior art, the present invention provides an explosive CL-20 crystal form quantitative analysis Raman feature region determination method, wherein Raman spectrograms of four crystal forms such as alpha-, beta-, gamma- and epsilon- of the explosive CL-20 pure product are subjected to region division according to the wave number range, a main component analysis method is adopted to treat the Raman spectrograms of various regions, and a main component classification three-dimensional scatter diagram is adopted to determine the quantitative analysis Raman feature region. With the explosive CL-20 crystal form quantitative analysis Raman feature region determination method, the Raman spectrogram with characteristics of representativeness and simple and clear peak shape can be obtained, application of the Raman spectroscopy method to carry out crystal form quantitative analysis on the explosive CL-20 is simple and feasible, and the determination result is accurate and reliable.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

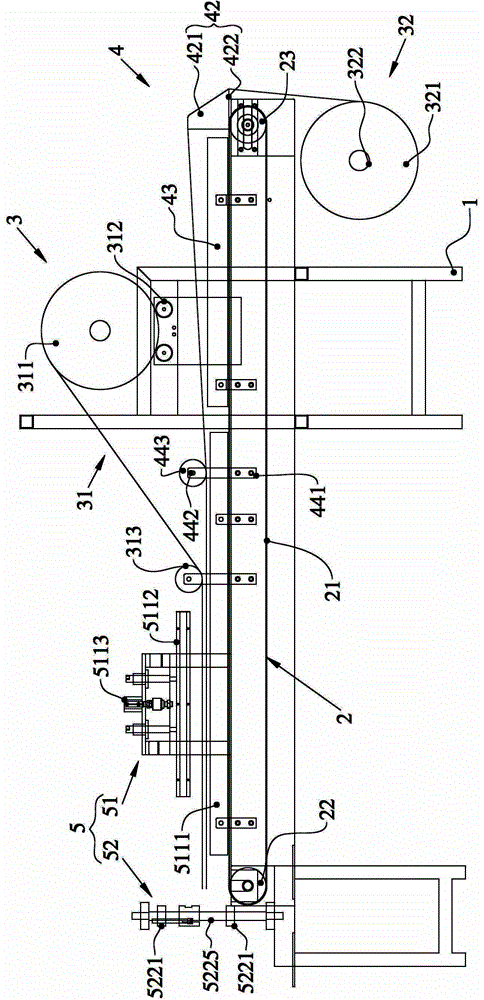

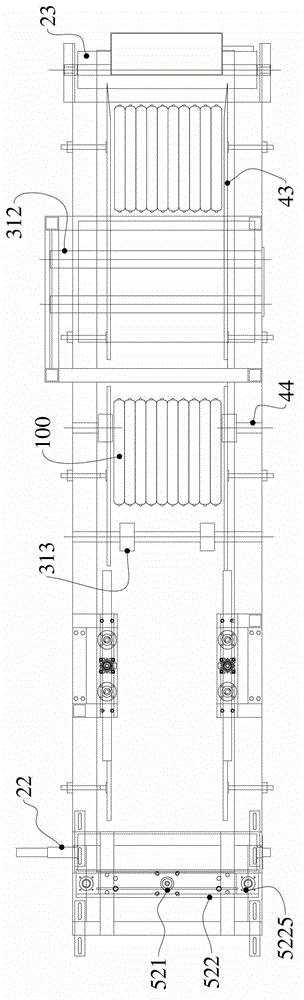

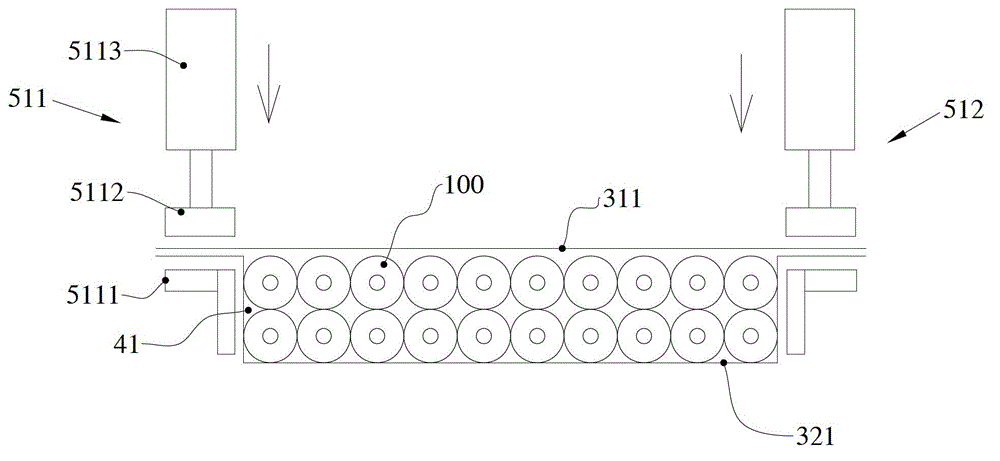

Belt medium package machine

ActiveCN104029842AReduce gapSolid appearanceWrapping material feeding apparatusWrapper twisting/gatheringVertical edgeEngineering

The invention belongs to the field of columnar explosive package and particularly relates to a belt medium package machine which comprises a machine frame, a conveying mechanism arranged on the machine frame and used for conveying columnar explosives, a film supply mechanism used for supplying an upper film and a lower film, a film bending mechanism arranged at the output end of the film supply mechanism and used for bending the lower film to form a containing groove for containing the columnar explosives and an edge sealing mechanism arranged above the conveying mechanism and used for sequentially sealing the corresponding transverse edges and the corresponding vertical edges of the upper film and the lower film to package the columnar explosives. The conveying mechanism is adopted to convey the columnar explosives between the upper film and the lower film, the bending mechanism is utilized to bend the lower film to form the containing groove to locate the columnar explosives, and the edge sealing mechanism is utilized to seal the corresponding transverse edges and the corresponding vertical edges of the upper film and the lower film sequentially to form a columnar explosive package. The package efficiency is high, gaps between the columnar explosives in each columnar explosive package is small, mutual movement cannot happen easily, the whole columnar explosive package is stable in appearance, and the package and shaping effects are good.

Owner:江苏天明化工有限公司

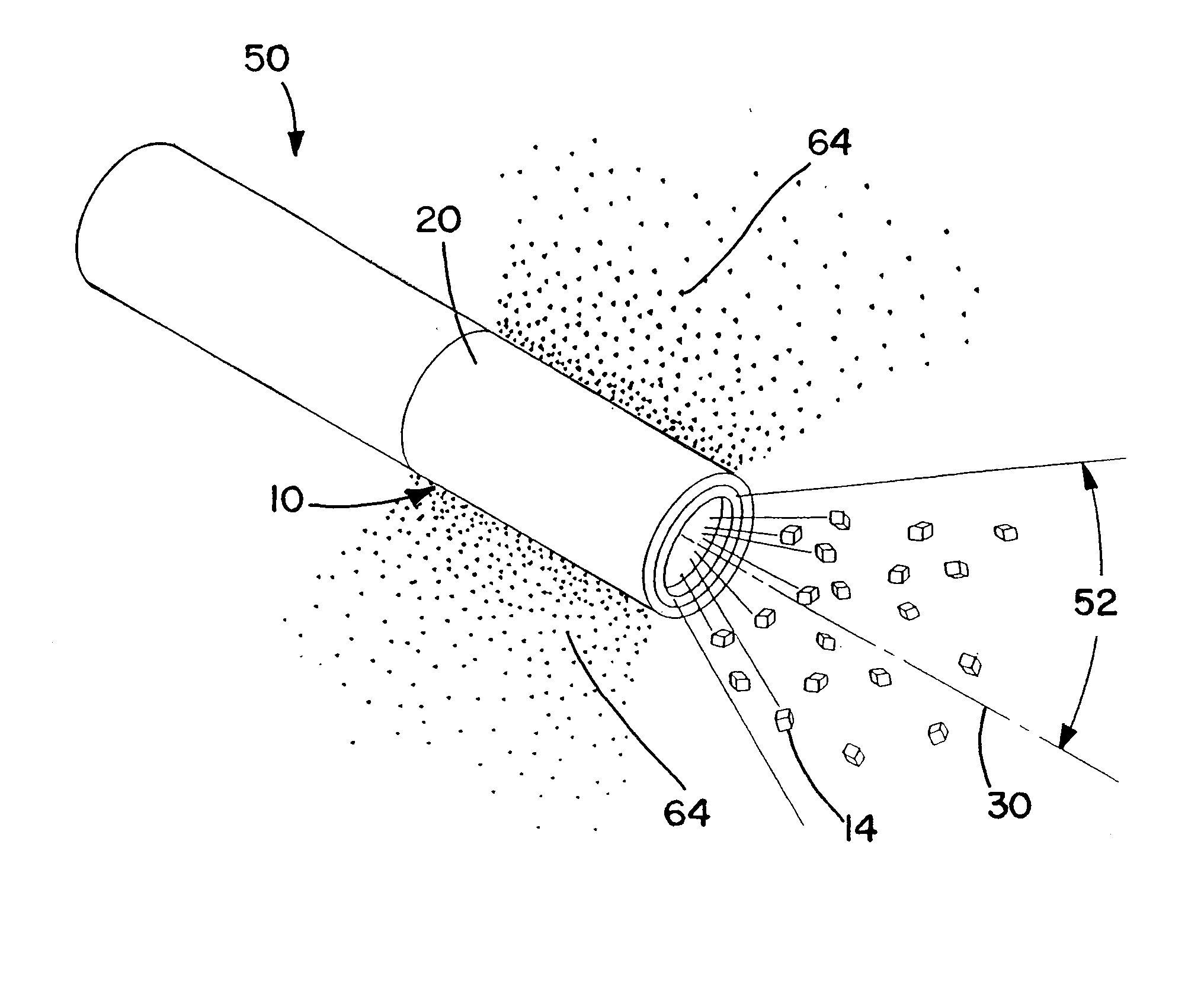

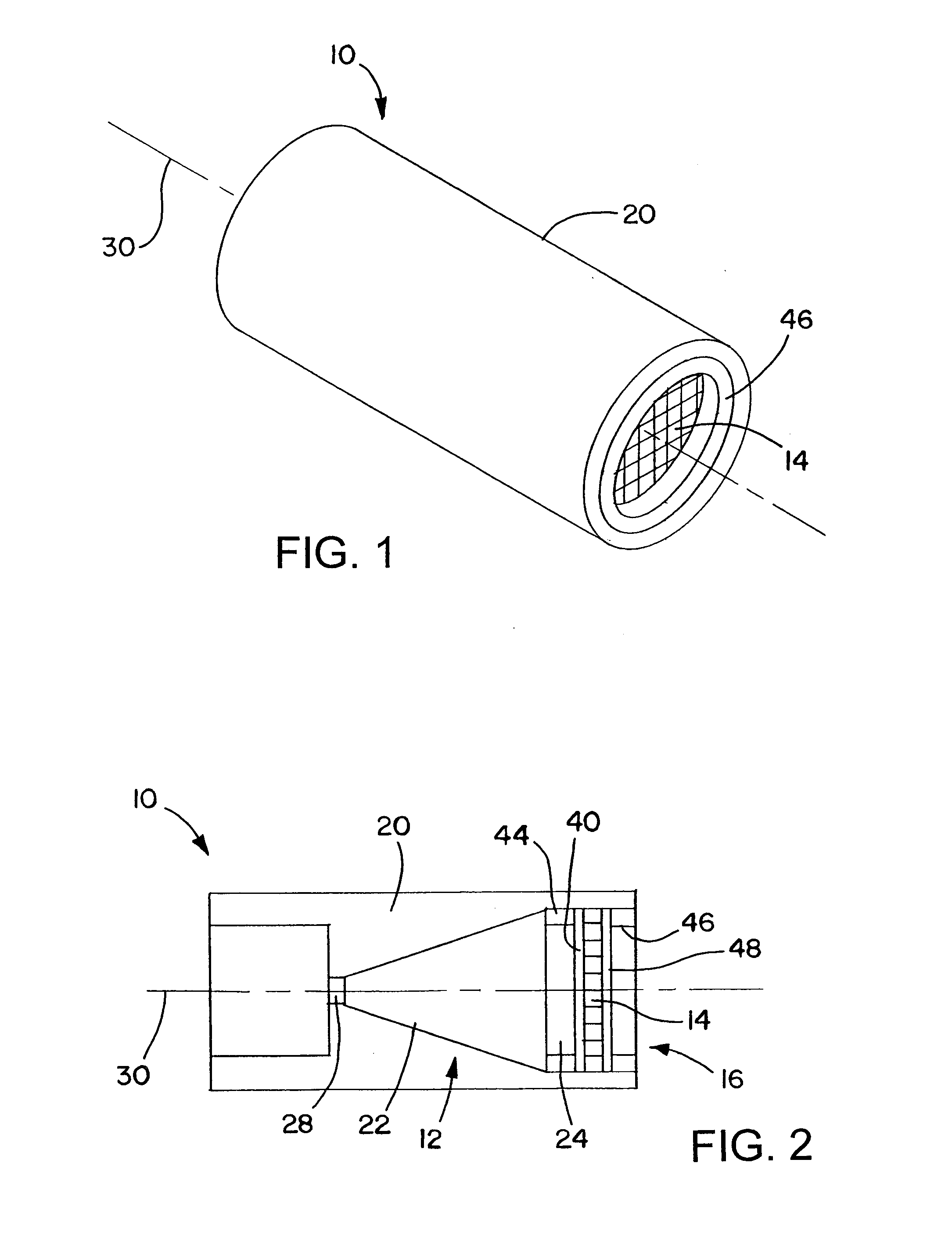

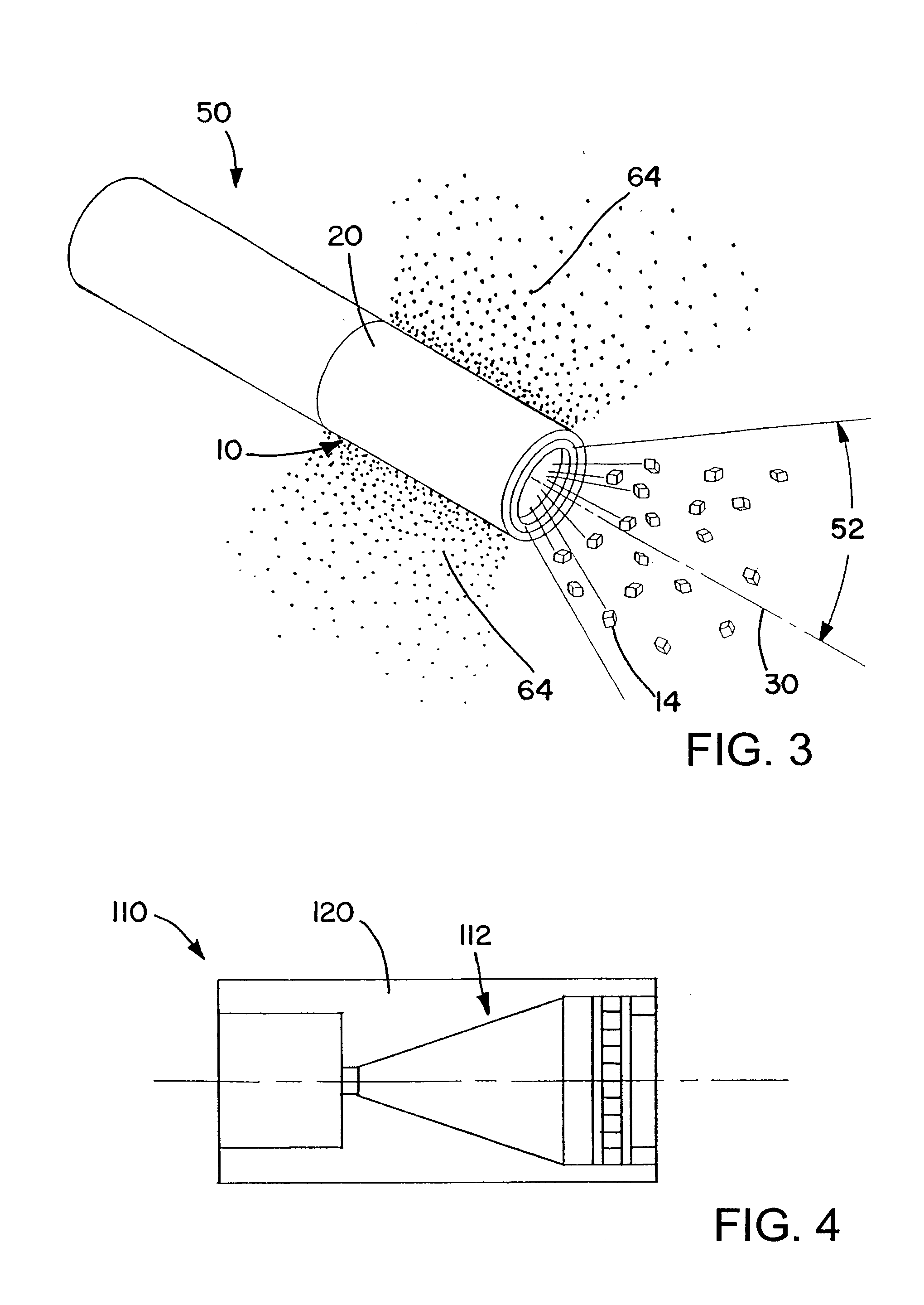

Low-collateral damage directed fragmentation munition

Owner:RAYTHEON CO

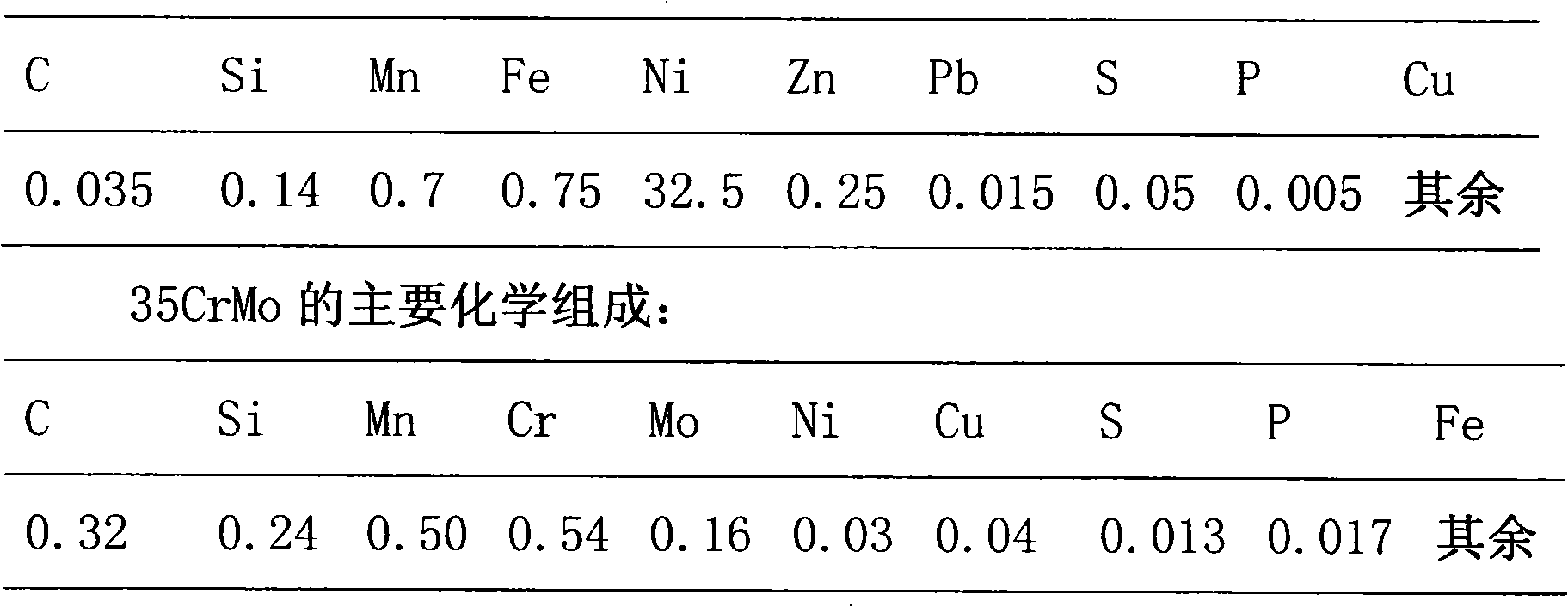

Big thickness BFe30-1-1/35CrMo explosive welding high intensity high corrosion resistance composite board

The invention provides a heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate. Firstly, the explosion speed of dynamite is controlled within about 800-1000m / s by the optimal design of dynamite formula. Secondly, by a principle of selecting the lower limit of the charging main parameter, the charging auxiliary parameters such as clearance and charging size of basic composite plate are reasonably designed, sand soil foundation added by water is selected and configured and the water content and density thereof are controlled, thus ensuring the once recombination rate of the heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate to achieve 100 percent and the adhesion strength thereof to achieve or even exceed the national standard, and avoiding the crack generation of the heavy section composite plate and high-strength basic plate during the explosion welding process. Finally, the subsequent crack of the composite pate is ensured not to be generated in the subsequent processing by the formulation of heat disposal parameters. The composite plate has ultra-high anticorrosion performance and extremely high high-temperature strength and anti-impact toughness.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Dynamic seal pressing method and device for improving complex perforation pressing crack effect

The invention relates to dynamic seal pressing method and device for improving complex perforation pressing crack effect in petroleum development. High-energy gas generated by complex perforation can be sealed in a perforating section, effective pressure action time can be prolonged and capability for doing work on stratum pressing crack can be strengthen. In the dynamic seal pressing method, shafts at the upper end and the lower end of the perforating section of a composite perforating gun are sealed by gas generated by explosive explosion and gunpowder detonation when the composite perforating gun carries out pressing crack. The dynamic seal pressing device comprises a tubular body which is connected with the end part of the perforating gun, wherein a pressure relief hole with a plug piece is arranged on the tubular body; an inner cavity of the tubular body is provided with an explosive column, first-class explosive and second-class explosive; the first-class explosive is packaged outside the explosive column; the second-class explosive is isolated from the explosive column; and an explosion isolating plate with a sieve mesh is arranged between the second-class explosive and the first-class explosive. After the explosive column is exploded, the first-class explosive is ignited, and the first-class explosive ignites the second-class explosive. The periphery of the shaft near the dynamic seal pressing device is full of the generated high-pressure gas.

Owner:XIAN TONGYUAN PETROTECH

Millisecond blasting ore-waste separating method of gentle-inclined narrow ore body

The invention relates to a millisecond blasting ore-waste separating method of a gentle-inclined narrow ore body. The method comprises the steps of: respectively drilling ore blast-holes and barren rock blast-holes in an ore body and a barren rock once at a time, with the array pitches of the blast-holes being 0.6-0.8m, the distances of the blast-hole being 0.5-0.7m and the depths of the blast-holes being 1.2-2.0m; selecting explosive loading quantity of the ore blast-hole to be 0.75-0.9kg per hole, and selecting the explosive loading quantity of the barren rock blast-hole to be 1.0-1.15kg per hole; adopting non-electric detonator millisecond blasting, wherein the blasting time difference is 0.5-1 second, and blasting all barren rock blast-holes before the first ore blast-hole, wherein the blast-hole blasting order is from bottom to top and from outside to inside. By adopting the blasting parameters, non-electric detonator millisecond blasting and segment blasting, the ore and barren rock throwing distances can be controlled; the ore and barren rock are separated; the impoverishment rate in mining is reduced; the grade of mined raw ore is improved; discharge of the barren rock is reduced; and the grade of the raw ore, and the utilization rate and recovery rate of the resource are improved, and composite economic results of enterprises are increased.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

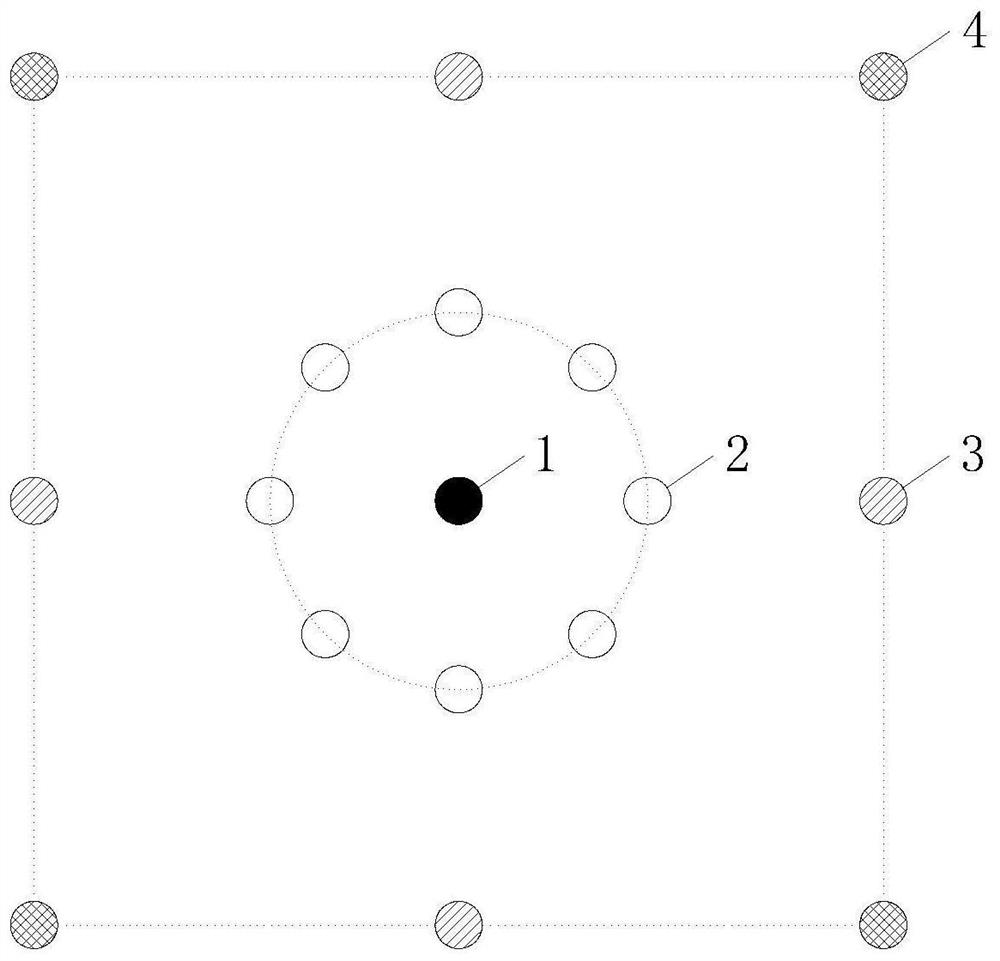

Cutting blasting method based on pre-blasting

The invention relates to a cutting blasting method based on pre-blasting. The cutting blasting method comprises the following steps: (1) a center charge hole is drilled in the center of a cut area, acircle of empty holes are drilled in the periphery of the center charge hole, main cutting holes and compensation cutting holes are drilled in the peripheries of the empty holes, and auxiliary holes,breaking holes and peripheral holes are sequentially drilled in the outer sides of the cutting holes; (2) the center charge hole is continuously filled with an explosive, the main cutting holes and the compensation cutting holes are continuously filled with 1 / 2 cumulative charge and 1 / 4 cumulative charge correspondingly, the auxiliary holes, the breaking holes and the peripheral holes are continuously filled with explosives, and blast holes are blocked by stemming; (3) the center charge hole is separately initiated to form a pre-blasted area; and (4) the remaining blast holes adopt micro-delayinitiation to achieve full-face one-time blasting. A large free face and rock breaking expansion space can be provided for cutting blasting, the surrounding rock clamping effect is overcome, the cutting effect is improved, and the overall blast hole utilization rate is increased.

Owner:ANHUI UNIV OF SCI & TECH

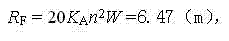

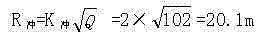

Town rock medium-length hole accurate controlled blasting method

ActiveCN102818486APrecisely control the amount of priming chargePrecise control of blasting vibrationBlastingDetonatorTEX-explosive

The invention discloses a town rock medium-length hole accurate controlled blasting method which comprises the following steps of: (1) designing and calculating blasting parameters and according to a blasted object, determining hole pattern parameters, a hole arrangement mode, a drilling depth, a charge structure, a length of stemming, a priming circuit, elementary error time, a firing order and explosive single consumption, carrying out checking calculation on a flying stone distance and calculating a safety distance of a blast wave; (2) carrying out arrangement before blasting, which comprises hole arrangement, hole drilling, formed hole inspection and acceptance, charging, stemming, networking and safety alert; and (3) blasting and checking a blasting effect. In the blasting method, initiating equipment is a digital electronic detonator; at least two layers of explosive bags are arranged in blast holes; the explosive bags on the same layer on the same row are on the same plane and the explosive bags on the adjacent rows are arranged in a staggered mode; and in the initiating process, the blasting is carried out from the hole bottom to the hole top from bottom to top by adopting a V-type sequence. According to the invention, by the characteristics of the digital electronic detonator, the specific charging structure and the specific initiating sequence, the accurate blasting on town rocks is implemented.

Owner:CHONGQING BLASTING CONSTR +1

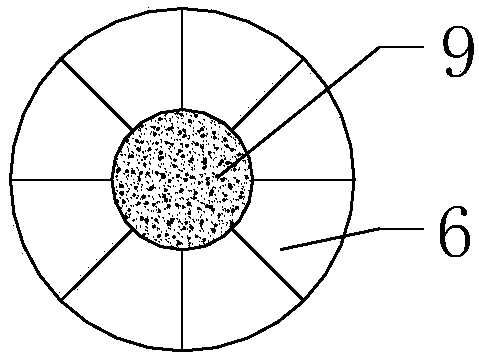

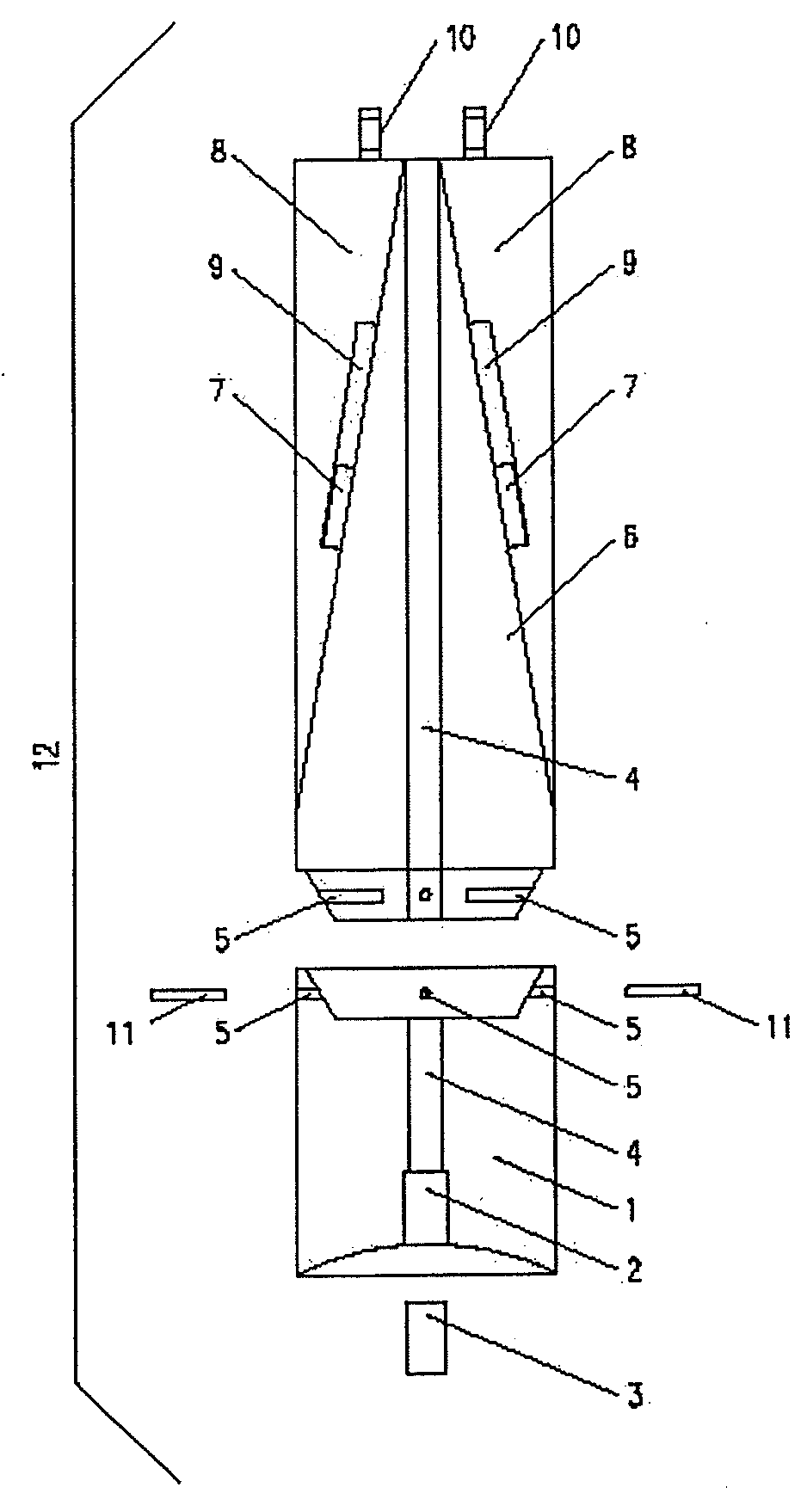

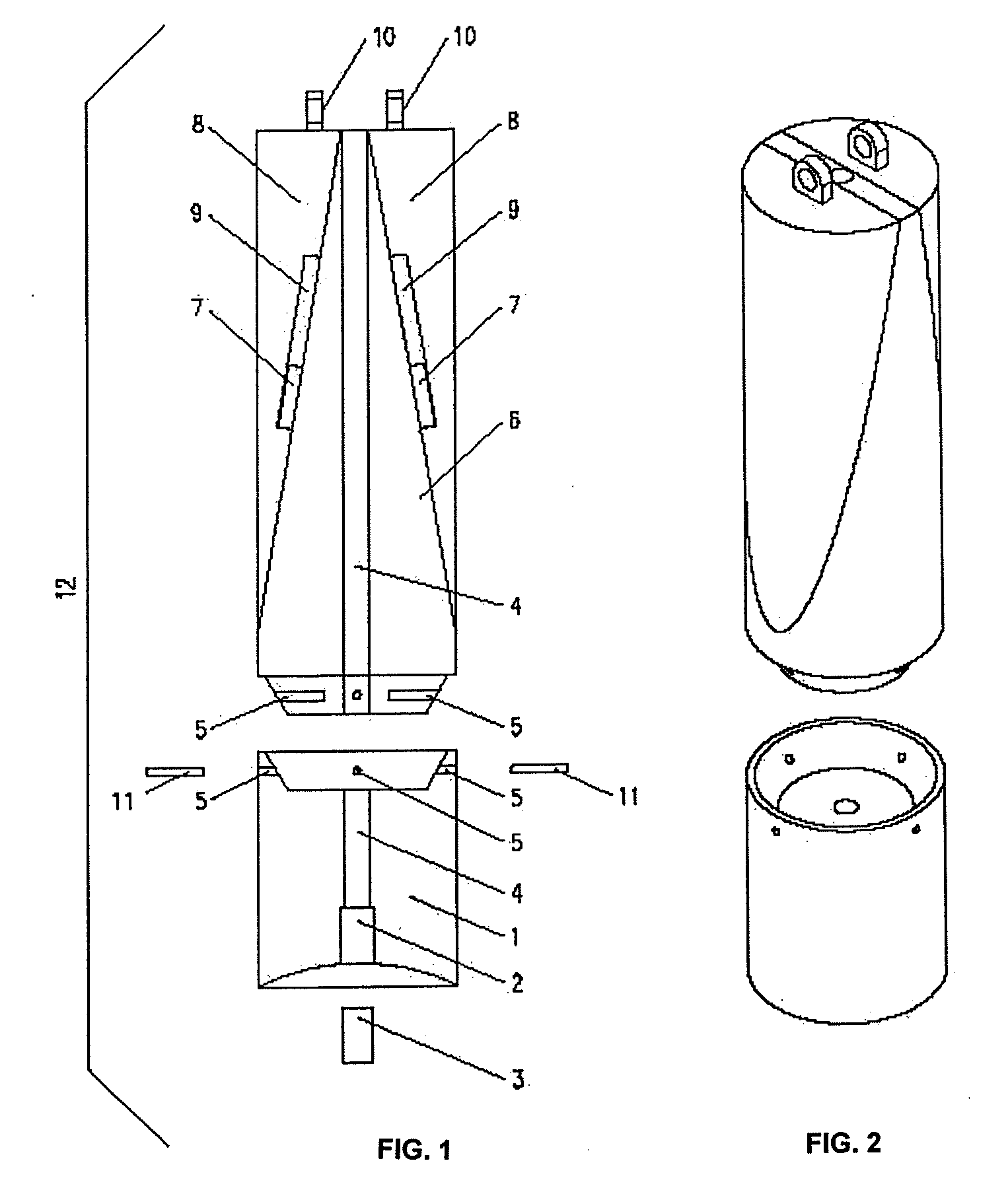

Mechanical Stemming Apparatus for Mining Blasting Operations

InactiveUS20080236434A1Reduce the possibilityBlasting cartridgesFluid removalTEX-explosiveStructural engineering

This invention discloses an apparatus to mechanically stem (plug) a borehole or blast hole to contain or confine the gases generated by explosives, thus preventing the energy generated by explosives to be released to the atmosphere. An assembly of the mechanical stemming apparatus for mining blasting operations according to the present invention comprises 2 pieces, placed one over the other: a base piece (1) and a central piece (6), and additionally includes two lateral wedge pieces (8) and four supporting pivots (11). The mechanical stemming apparatus according to the present invention and the entire apparatus set form a cylindrical body with a diameter lower than the borehole diameter and a length directly proportional to the diameter and depth of the boreholes or blast holes.

Owner:CAUCHOS INDS

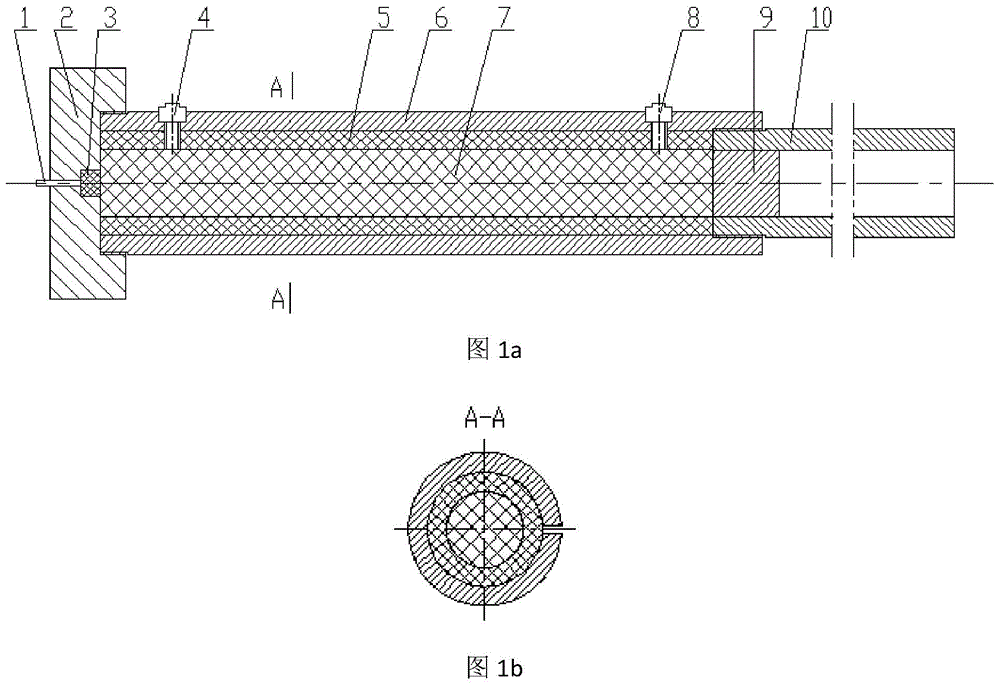

Method for preparing explosive composite pipe in local vacuum environment

PendingCN113231728AAvoid local defect problemsExplosive Freedom of ChoiceMetal working apparatusTubular articlesDetonatorTEX-explosive

The invention provides a method for preparing an explosive composite pipe in a local vacuum environment. The method comprises the following steps of: coaxially arranging a first to-be-composited pipe, a second to-be-composited pipe and a pvc pipe from inside to outside, and filling explosive and a detonator between the pvc pipe and the second to-be-composited pipe to form an explosive device of a to-be-welded pipe; sealing the two ends of a gap between the first to-be-composited pipe and the second to-be-composited pipe by using sealing strips, and vacuumizing to form a vacuum gap environment; and detonating the explosive device, and welding and combining the to-be-composited pipes by utilizing high pressure generated by explosion of the explosive to obtain the high-quality explosive composite pipe. According to the method for preparing the explosive composite pipe in the local vacuum environment, the phenomenon that in a traditional preparation method, large-area melting of a composite pipe bonding interface occurs due to the fact that gap air is not exhausted in time is effectively eradicated; the bonding strength of the explosive composite pipe is obviously improved; and compared with a traditional explosive welding method which needs to consider gap exhaust, the method has the advantage that the explosive velocity of the explosive can be selected more freely.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com