Precise control method for smooth surface blasting of fractured rock mass of highway tunnel

A refined control and smooth blasting technology, which is applied in blasting and other directions, can solve the problems of affecting the construction environment, large fragmentation of broken rocks, waste of explosives, etc., to reduce engineering costs, improve the degree of crushing, and reduce large rocks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below.

[0037] In the present invention, S1 represents step 1, S101 represents step 01 in S1, S102 represents step 02 in S1, and so on.

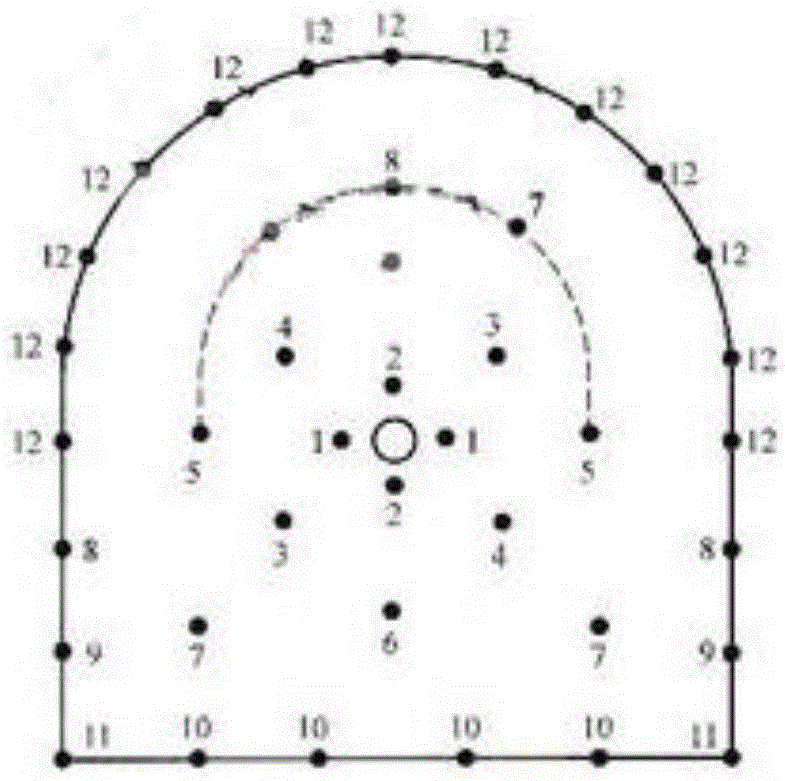

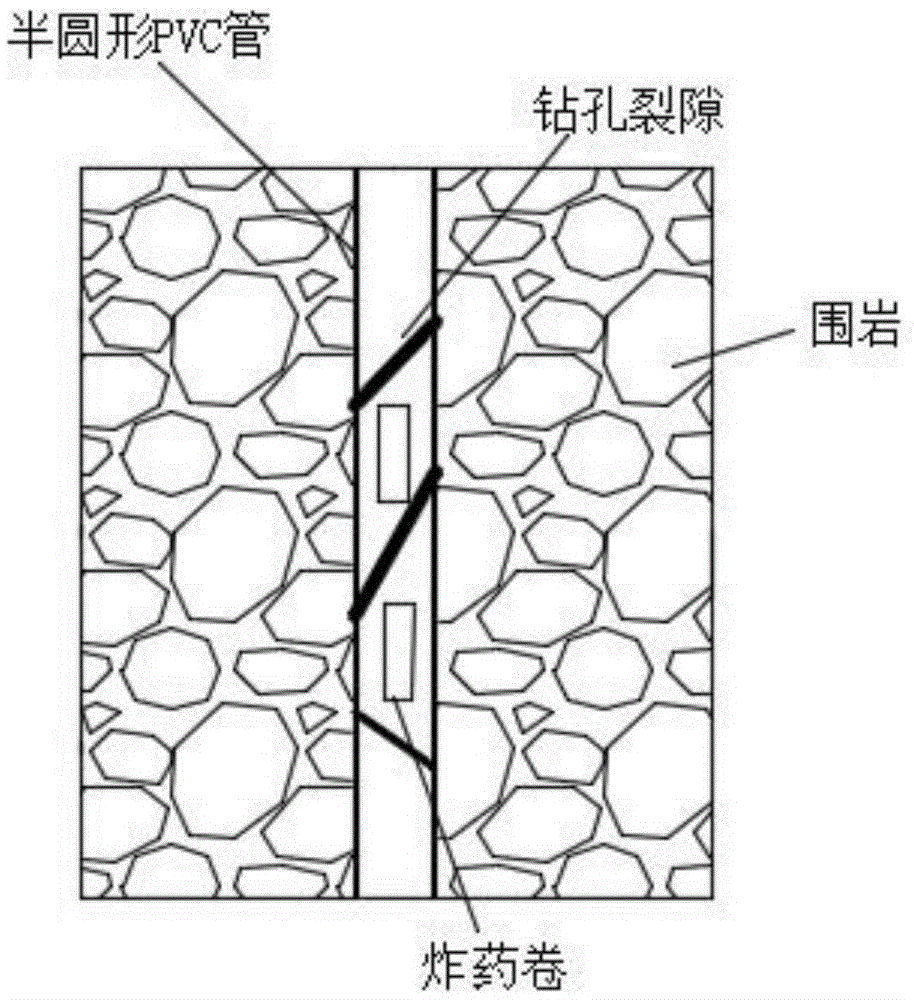

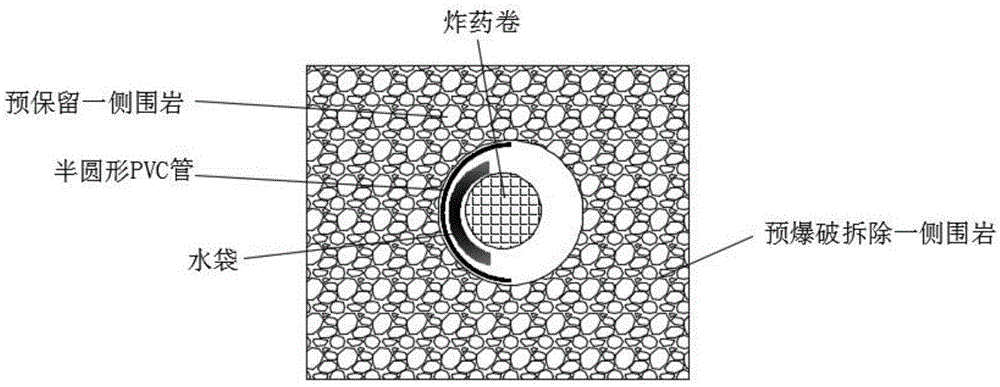

[0038] see Figure 2-Figure 5 , a refined control method for cracked rock mass smooth blasting in a highway tunnel, comprising the following steps:

[0039] S1: Parameters required to obtain fine control of smooth blasting:

[0040] S101: Drill holes at the drill holes arranged in the existing highway tunnel smooth blasting design. Use the existing technology to drill holes. All current drill holes are composed of all current peripheral holes and all current auxiliary holes; blasting In the process of blasting, the blasting is carried out in sections, and in each blasting process, the auxiliary eyes will all explode.

[0041] S102: The number of all current peripheral eyes on the rock mass section of the tunnel design outline before blasting is recorded as N 2 , use the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com