Town rock medium-length hole accurate controlled blasting method

A precise control and stonework technology, applied in the field of blasting, can solve the problems of low reliability of large networks, large segment errors, and insufficient delay time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Based on various deficiencies in the prior art, we have done the following simulated blasting test, the specific implementation plan is as follows:

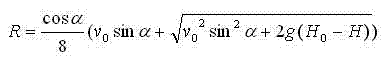

[0020] 1. Design and calculation of blasting parameters

[0021] In order to achieve good blasting effect in the step-controlled blasting of medium and deep holes, it must be based on the blasting area and surrounding environment of the construction site, the actual situation of the site and the drilling equipment invested. Reasonably determine parameters such as hole network parameters, hole layout method, drilling depth, charge structure, plugging length, detonation network, differential time, detonation sequence and unit consumption of explosives.

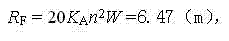

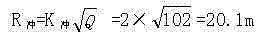

[0022] Blasting parameter design with an aperture of 80 mm

[0023] 1.1, hole diameter, hole depth

[0024] Aperture: 80mm

[0025] Hole depth: L 2 =H+h. (step height H=5m~15m; extra depth h=1m)

[0026] 1.2. Step height H and extra depth h

[0027] (1) Step height: H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com