Patents

Literature

75results about How to "Reduce chunk rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

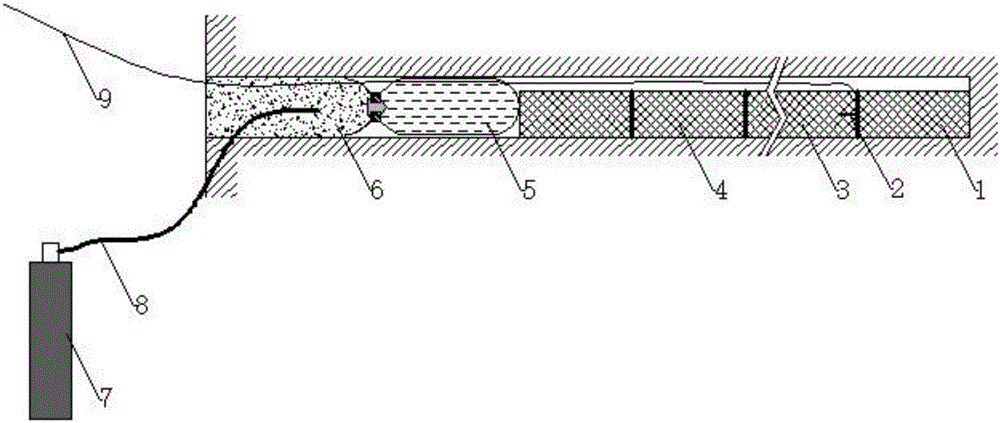

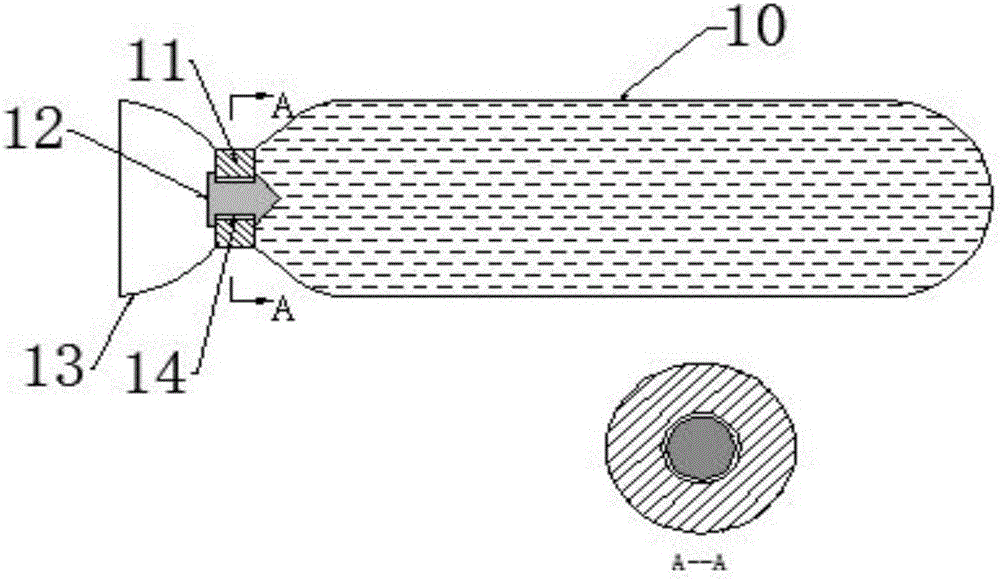

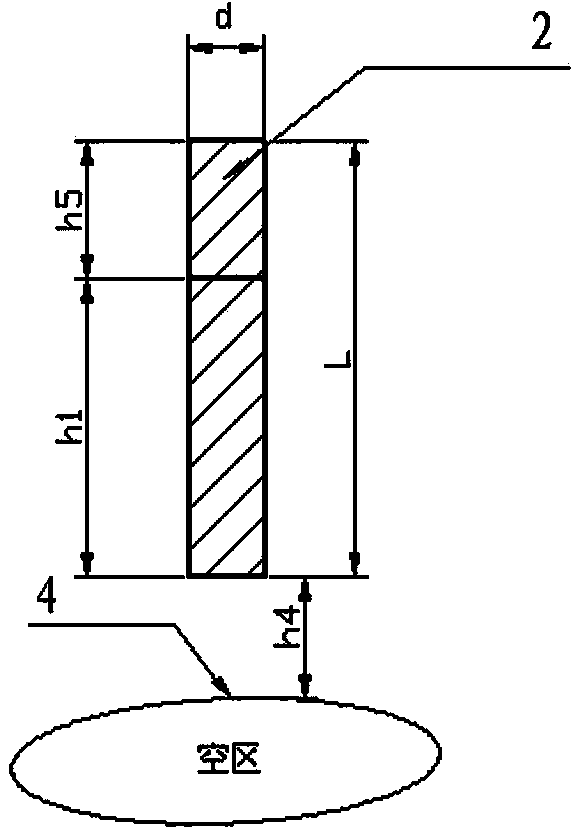

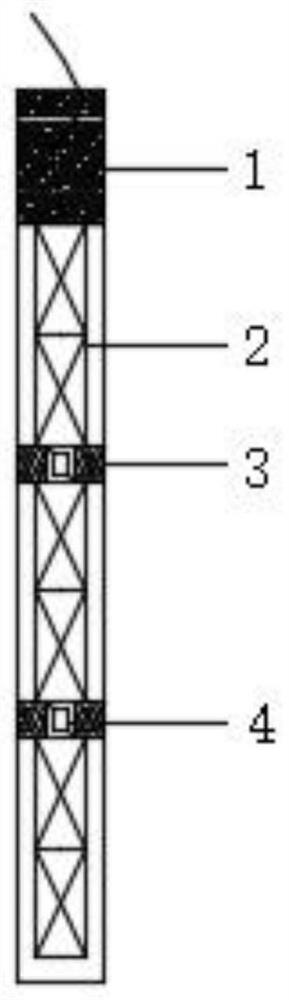

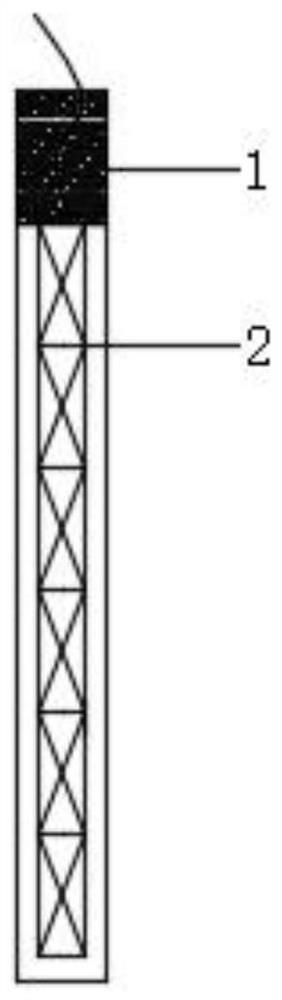

Mine water stemming bag and application of mine water stemming bag in borehole blockage

ActiveCN105066804AConvenient and fast blocking effectEfficient and reliable blocking effectBlastingCombined useSelf locking

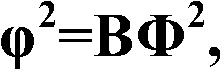

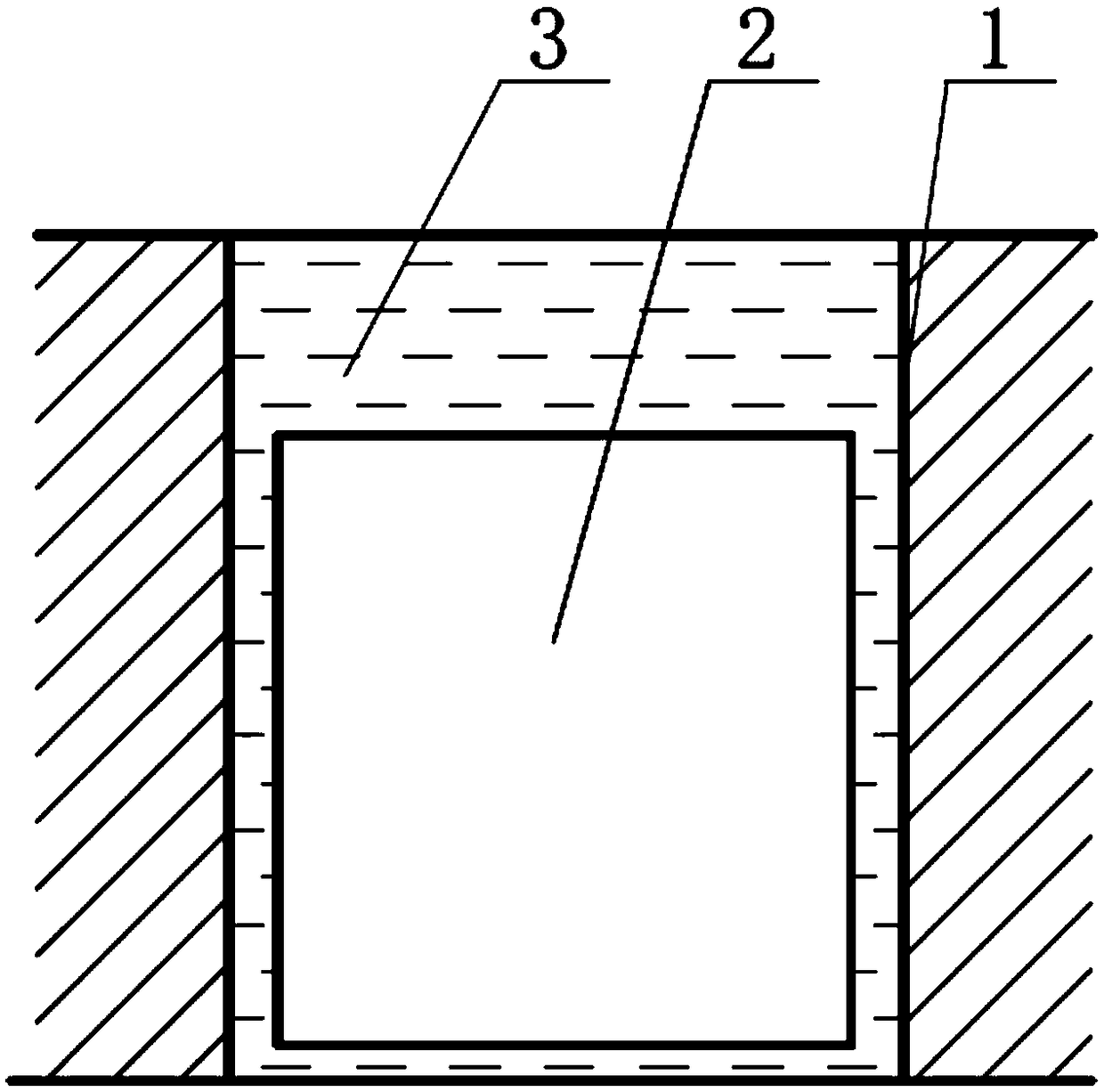

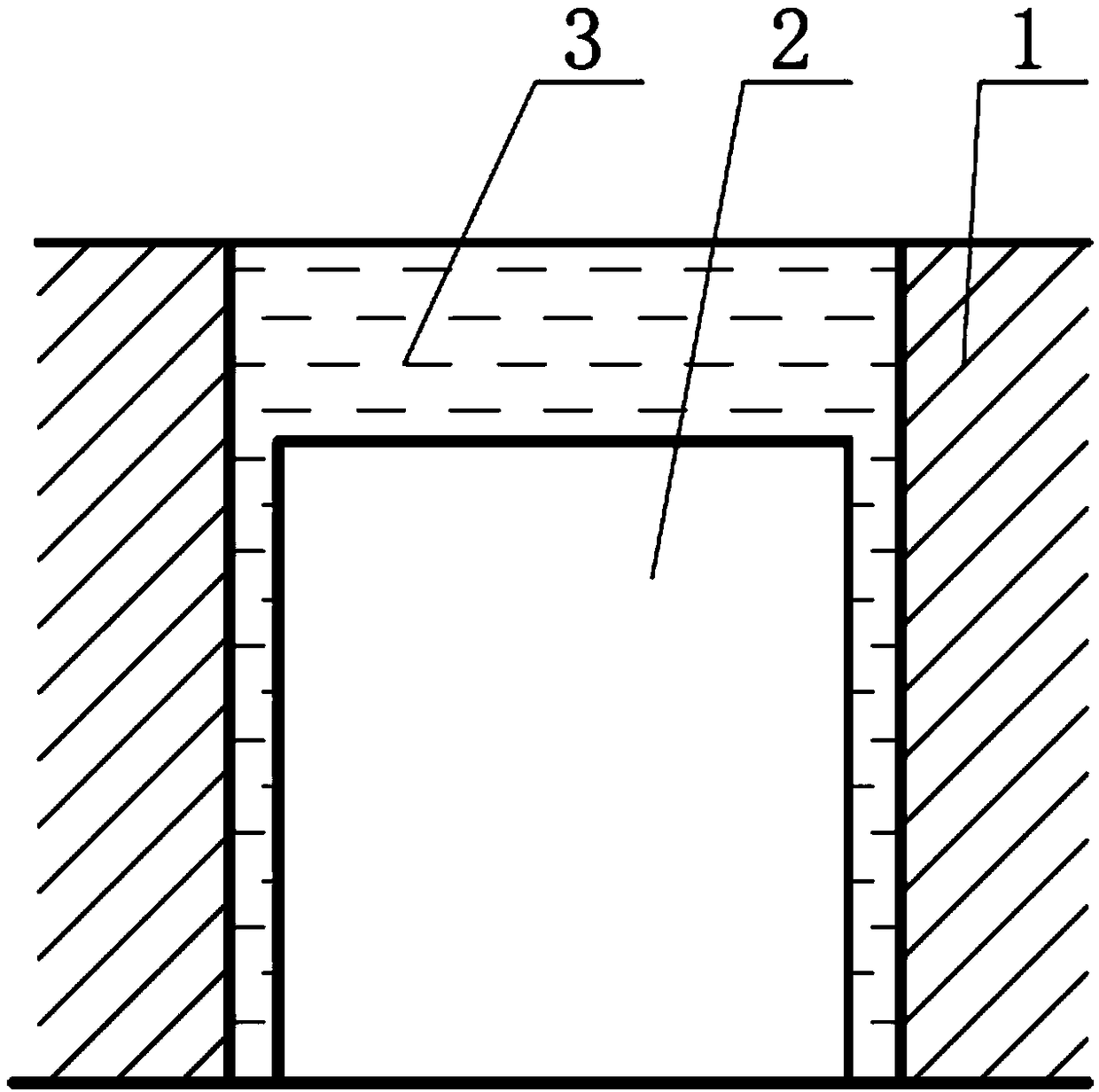

The invention provides a mine water stemming bag and an application of the mine water stemming bag in borehole blockage. By means of the mine water stemming bag, local self-locking can be achieved, and leakage of a bag opening can be prevented reliably. By applying the mine water stemming bag to borehole blockage and combining with polyurethane expansion foam composites, a convenient, quick, efficient and reliable borehole blockage effect can be achieved, labor intensity of manual borehole blocking is relieved, construction time is shortened, work efficiency is improved, and the forced mining and forced excavation technical requirements of underground metal mines are met on the premise that the blasting effect is guaranteed.

Owner:HUNAN CHENZHOU MINING CO LTD +1

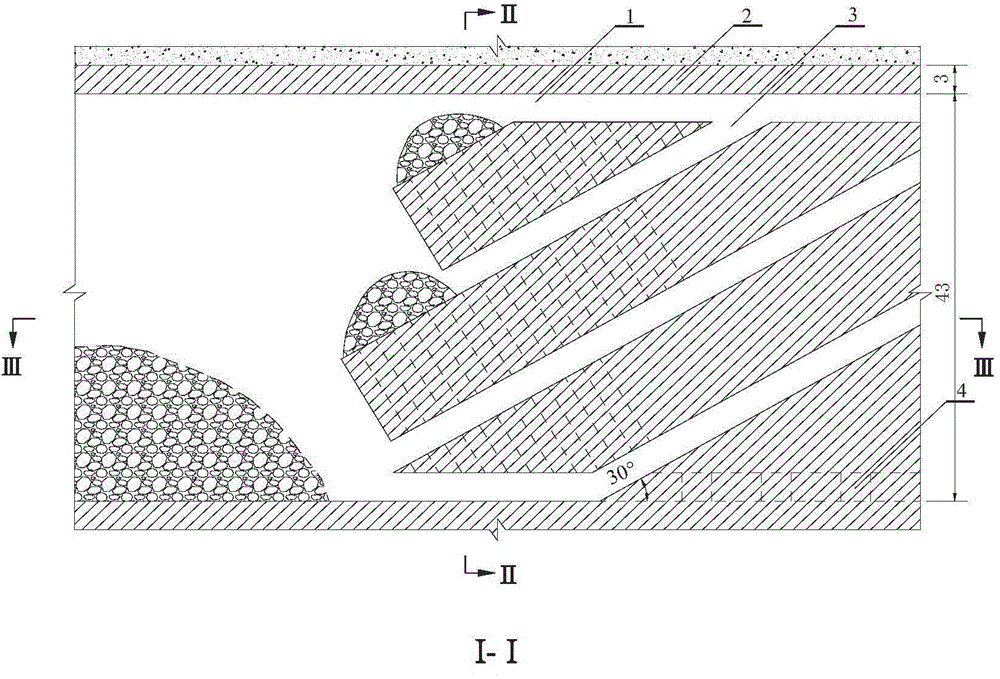

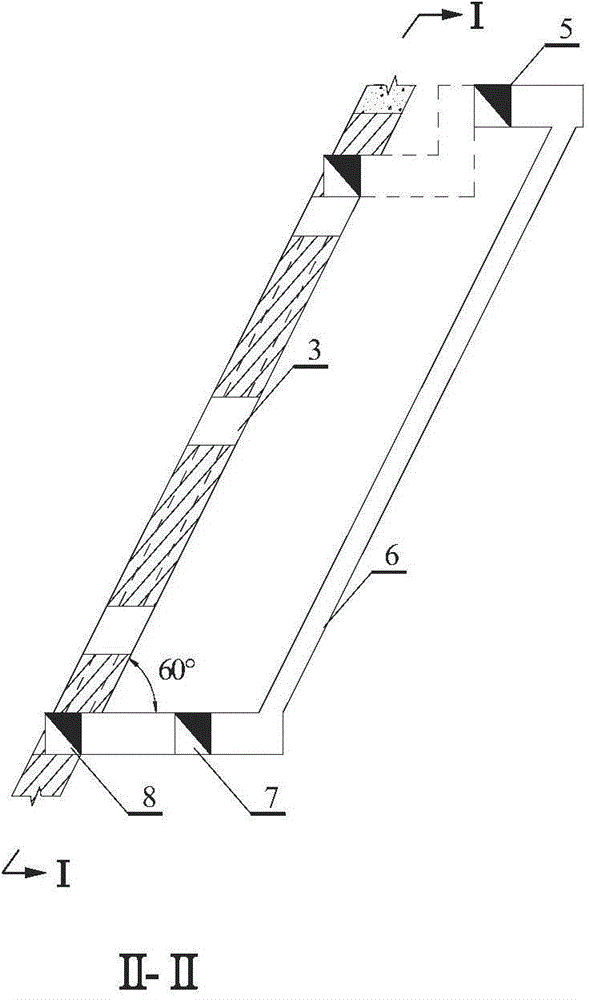

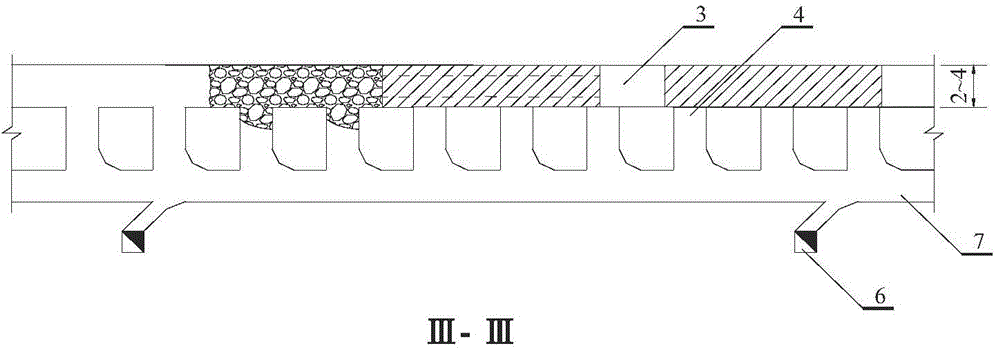

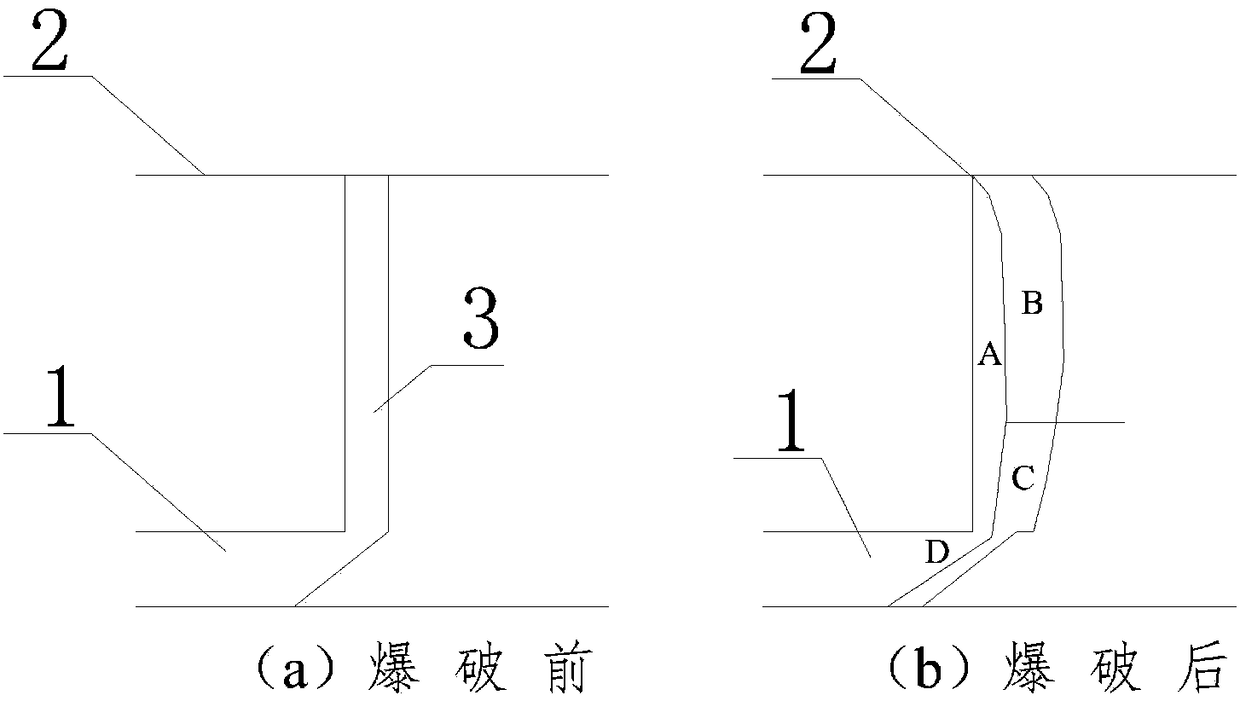

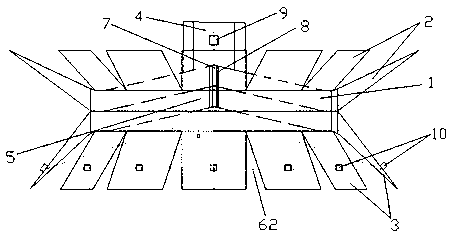

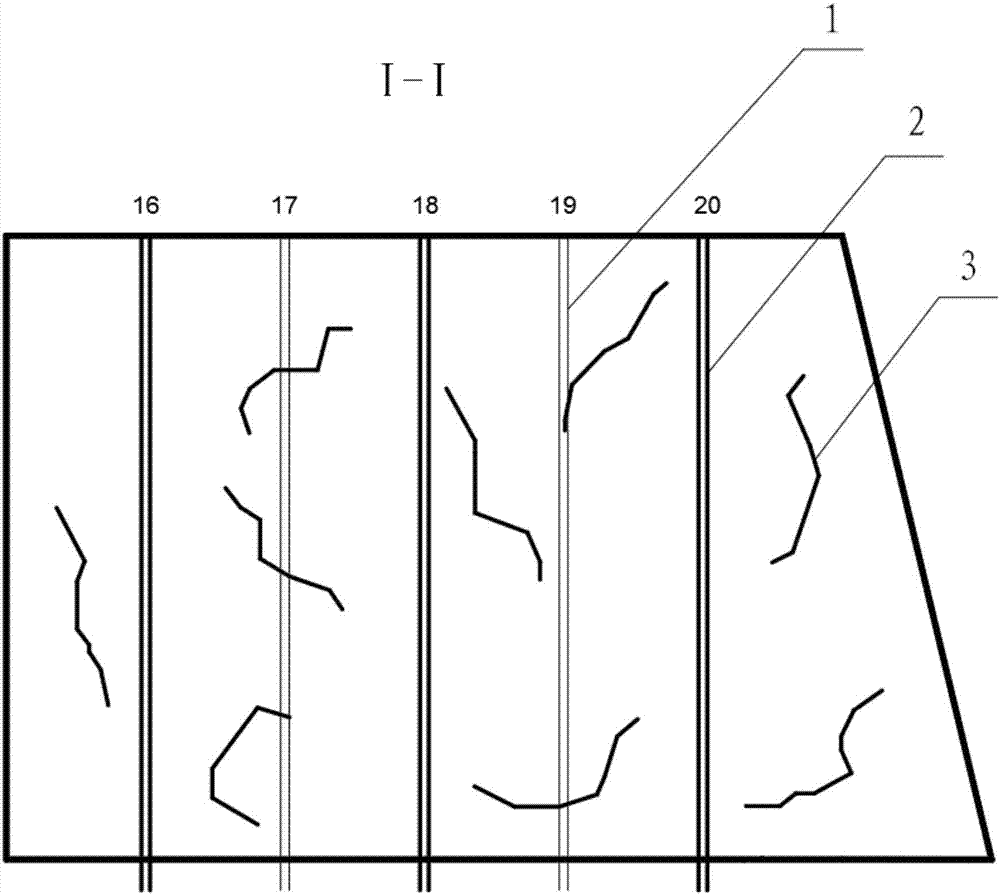

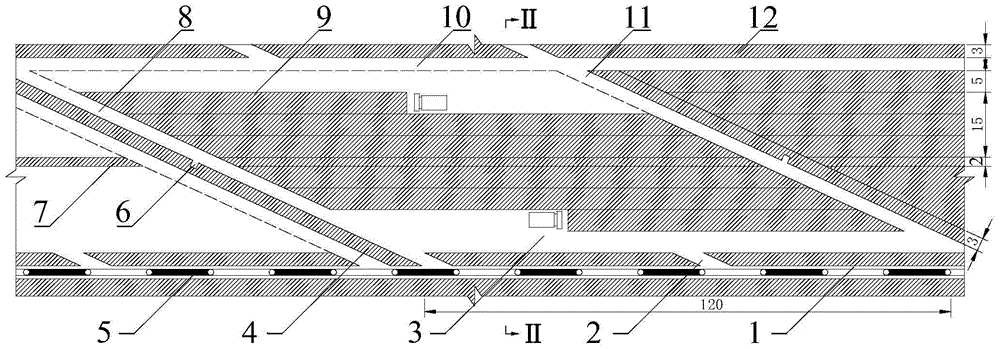

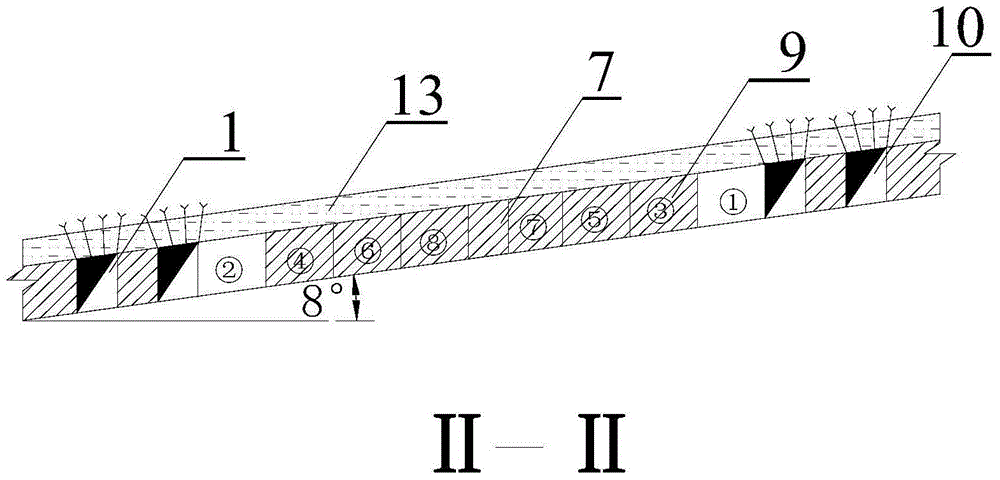

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

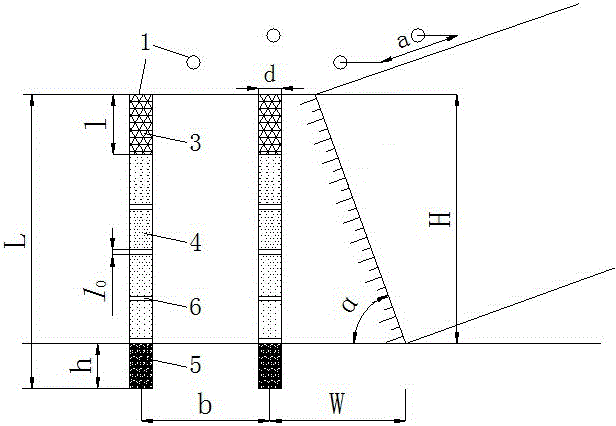

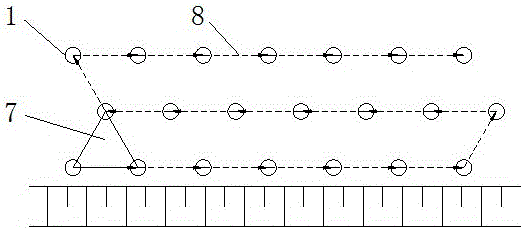

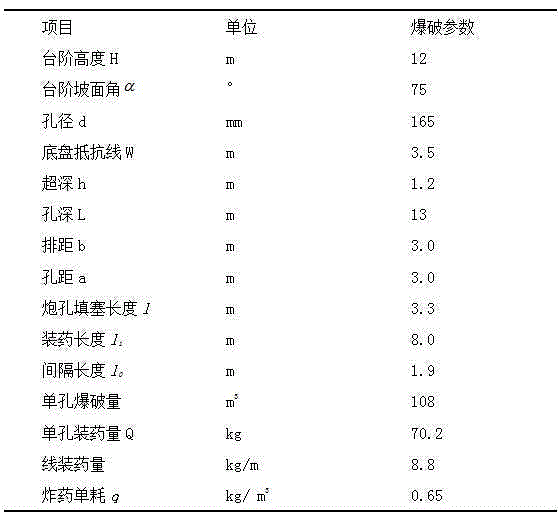

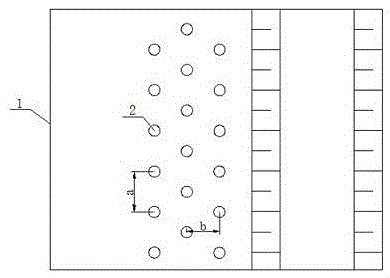

Method for improving bench blasting quality of deep-hole of super-hard rocks

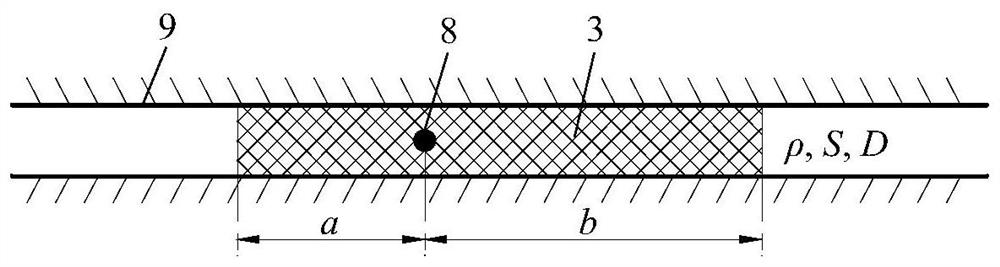

The invention discloses a method for improving the bench blasting quality of a deep-hole of super-hard rocks. The method includes the following steps that blast holes are formed in a step of a blast area, hole mesh parameters are determined, and perpendicular drilling is conducted; explosive loading structures are determined, and the explosive loading structures for segmented explosive loading and mixed explosive loading are adopted in the blast holes at the same time; explosives are determined, wherein the explosives are selected according to according to matching coefficients of explosive wave impedance and rock wave impedance; blasting parameters are determined and include the length W of a resistance line of a base plate, the hole pitch a, the row distance b, the super depth h and the blast hole filling length l; and blasting is conducted, wherein the explosives are loaded, the blast holes are filled with stemming on the tops of the blast holes, reverse blasting is conducted from the bottoms of the blast holes, and blasting is conducted in an inter-hole elementary error sequence. According to the method for improving the bench blasting quality of the deep-hole of super-hard rocks, due to the fact that the hole mesh parameters, the explosive loading structures, the explosives, the blasting parameters, the blasting position and the blasting sequence are reasonably selected, multi-way comprehensive functions are achieved, the performance of the explosives is fully achieved, the sufficient reaction of the explosives is ensured, the utilization rate of the blast holes is increased, and the boulder frequency and bedrocks of rock blasting are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

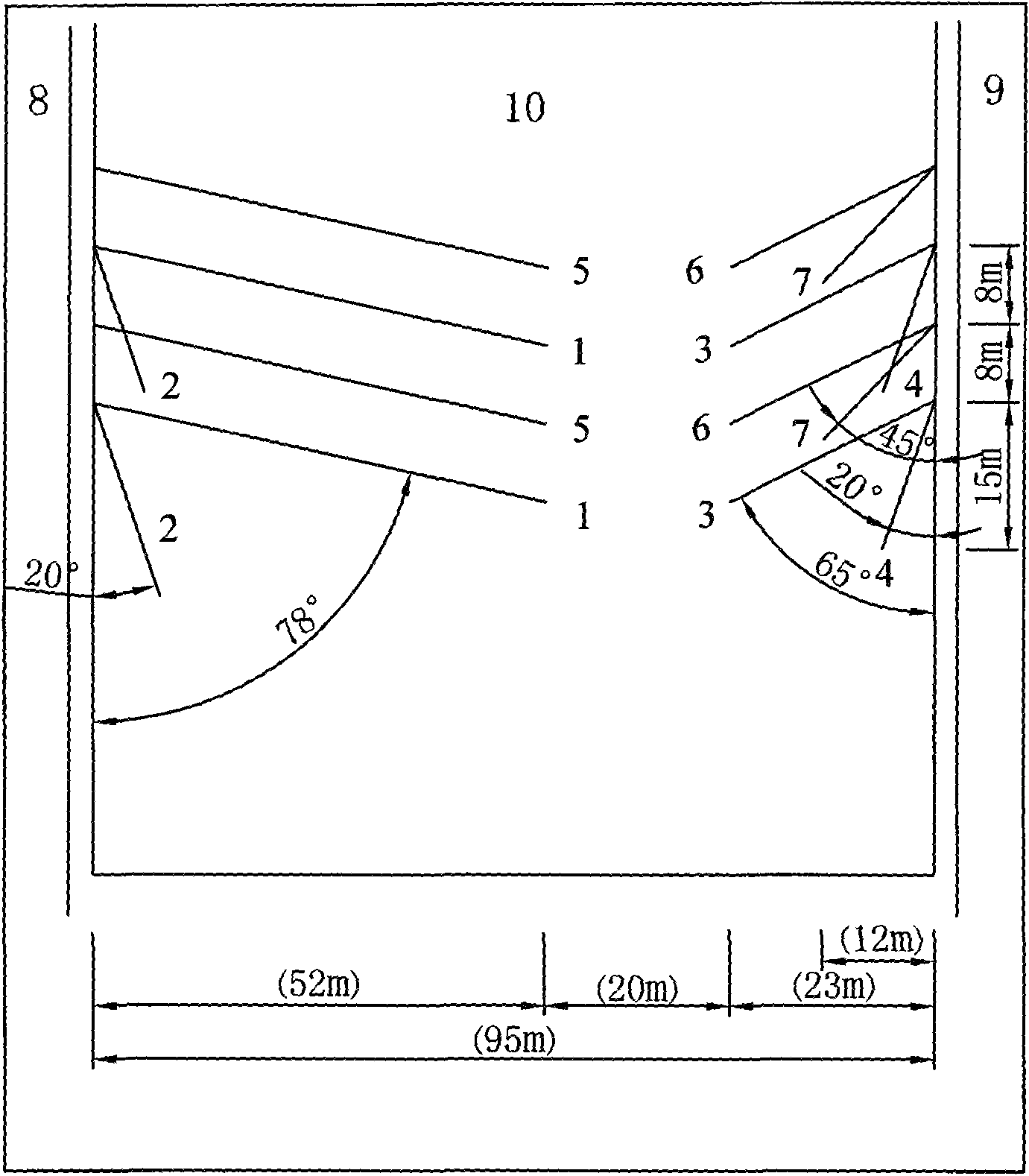

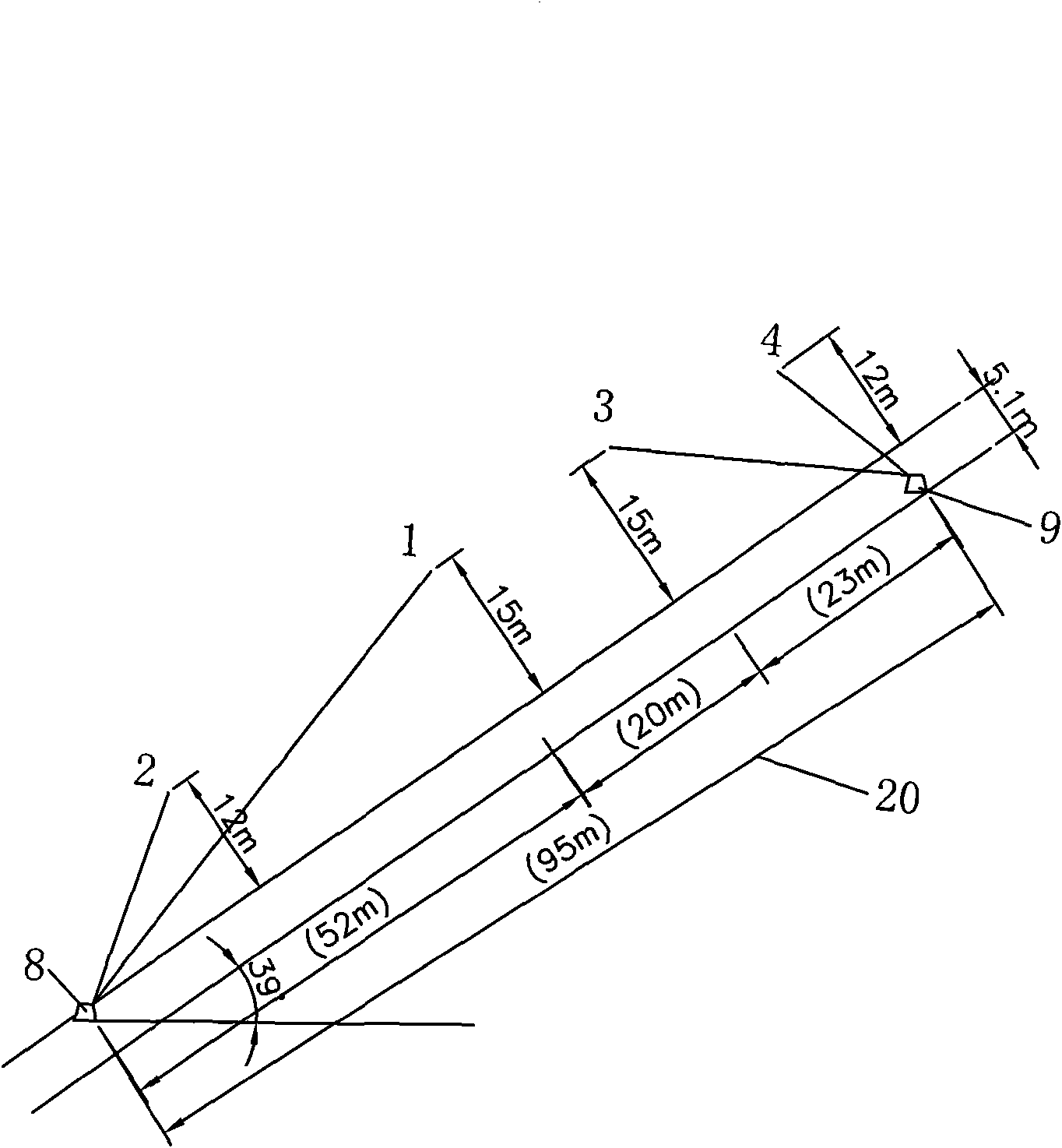

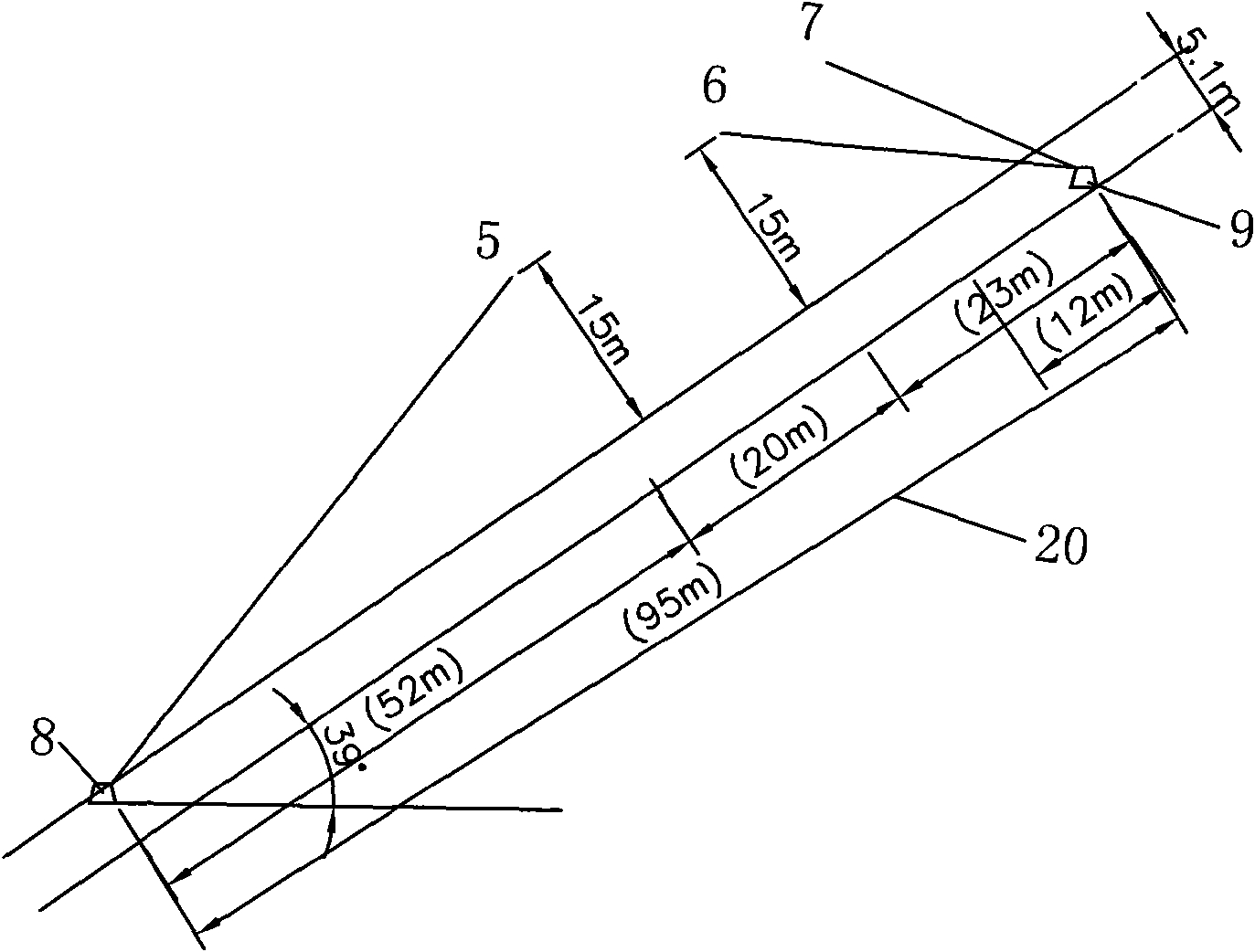

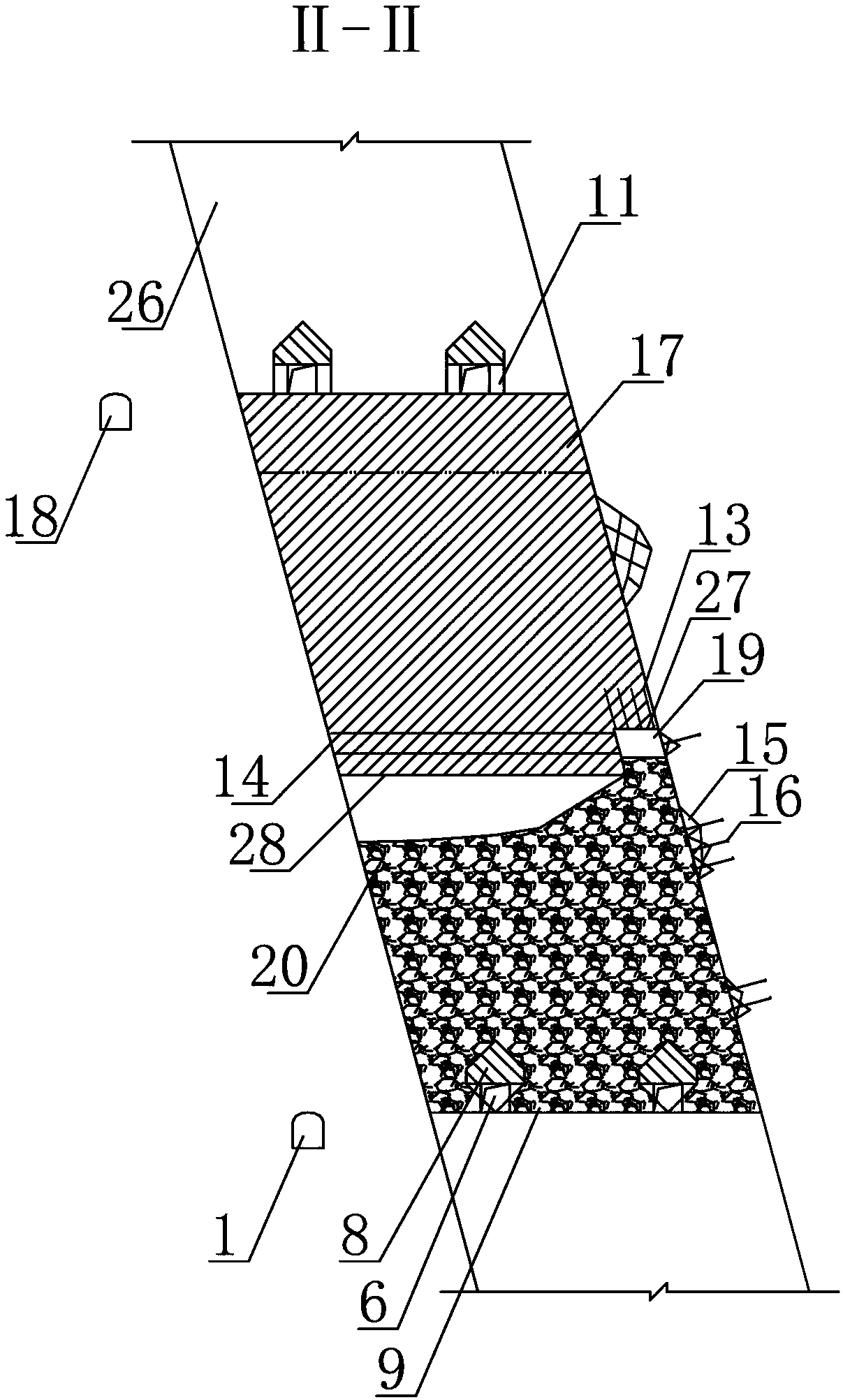

Overhand shrinkage spaced-loading split-blasting slot cutting method

ActiveCN103696769AQuality improvementControl chunk rateUnderground miningSurface miningTEX-explosiveMining engineering

The invention discloses an overhand shrinkage spaced-loading split-blasting slot cutting method, which aims at solving the problems that the ore discharging efficiency is low, the consumption of explosive is large, the rate of large ore blocks is high, the construction organization is complicated, a suspended roof is likely to form and the operation safety is poor in a traditional slot cutting process. The method comprises the following steps of step 1, determining geometric parameters of a cutting level; step 2, determining a position of a cutting open yard, to be specific, determining the parameter and height of a cross section, and selecting the position; step 3, determining rock drilling parameters in the slot cutting process, to be specific, determining the parameter of a resisting line, determining the hole-bottom distance parameter and determining side, hole and corner; step 4, forming a cutting slot; and step 5, discharging from the ore in a concentrating manner, wherein after the rearmost rows of blast holes in the uppermost layer of the cutting slot are exploded in an elementary error manner, ores falling into the cutting slot are concentratedly discharged through a first layer. By adopting the method for preserving the ores and finally discharging the ores concentratedly, the slot cutting can be safely and rapidly carried out for a chamber at the high quality.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

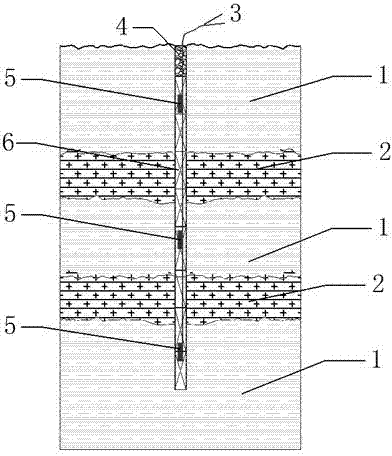

Segment pre-blasting technology for steeply dipping hard coal seam roof

InactiveCN101876520ADecrease the caving stepReduce cavingBlastingMine roof capsEngineeringMechanical engineering

The invention discloses a segment pre-blasting technology for a steeply dipping hard coal seam roof. Blast holes with different angles and length are distributed in gate roads of air return and transportation roadways in front of a working surface towards a roof rock in front of the working surface; and the blast holes are charged in an uneven way with large charge mass, which has controlled fracturing action on the hard roof.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

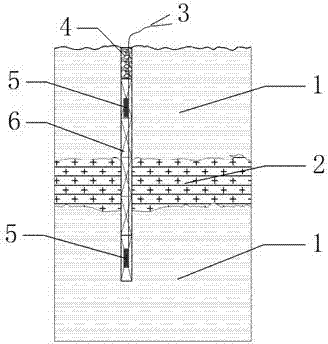

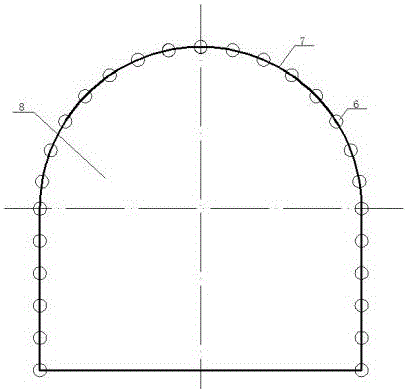

Periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting, and construction method thereof

PendingCN110332860AThe initial crack extension increasesEnhance static effectBlastingWorking environmentEngineering

The invention discloses a periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting, and a construction method thereof, and belongs to the technical field of tunnel construction. The periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting is formed by a shot hole, water bags, an energy-gathered pipe powder charge and a stemming, wherein the water bags, the energy-gathered pipe powder charge and the stemming are arranged in the shot hole; the bottom of the shot hole is a section of water bag; the middle part of the shot hole is twosections of water bags; the energy-gathered pipe powder charge is arranged between the water bag on the bottom of the shot hole and the water bags in the middle of the shot hole; the stemming is blocked in the shot hole; a high-temperature high-pressure gas produced by explosion produces a 'water wedge' effect through a jet flow formed in an energy-gathered groove and the water bags in the smoothblasting shot hole under a blasting action, so that a rock initial crack is promoted to extend, expand and enlarge; meanwhile, due to a composite blocking function of the water bags and the stemming,the formed crack is favorably extended, expanded and enlarged; and the water bags are placed in the smooth blasting shot hole, and a water spray formed in the blasting process further plays a role infalling dust, so that the ventilation time is reduced, the working environment is improved, and the body health of constructing personnel is protected.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

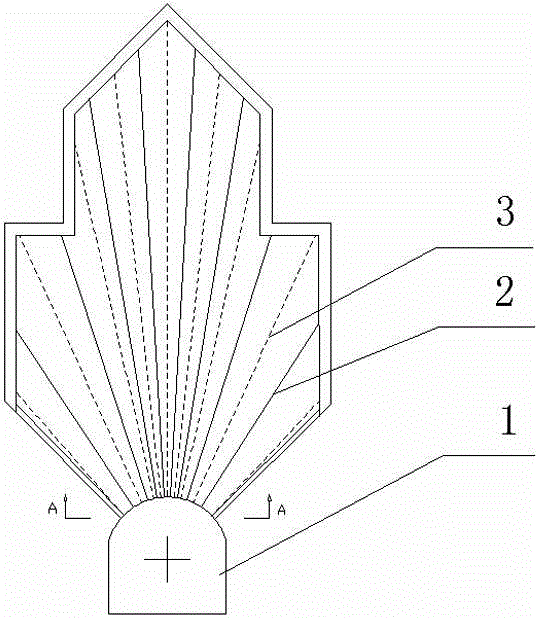

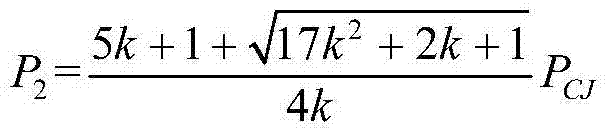

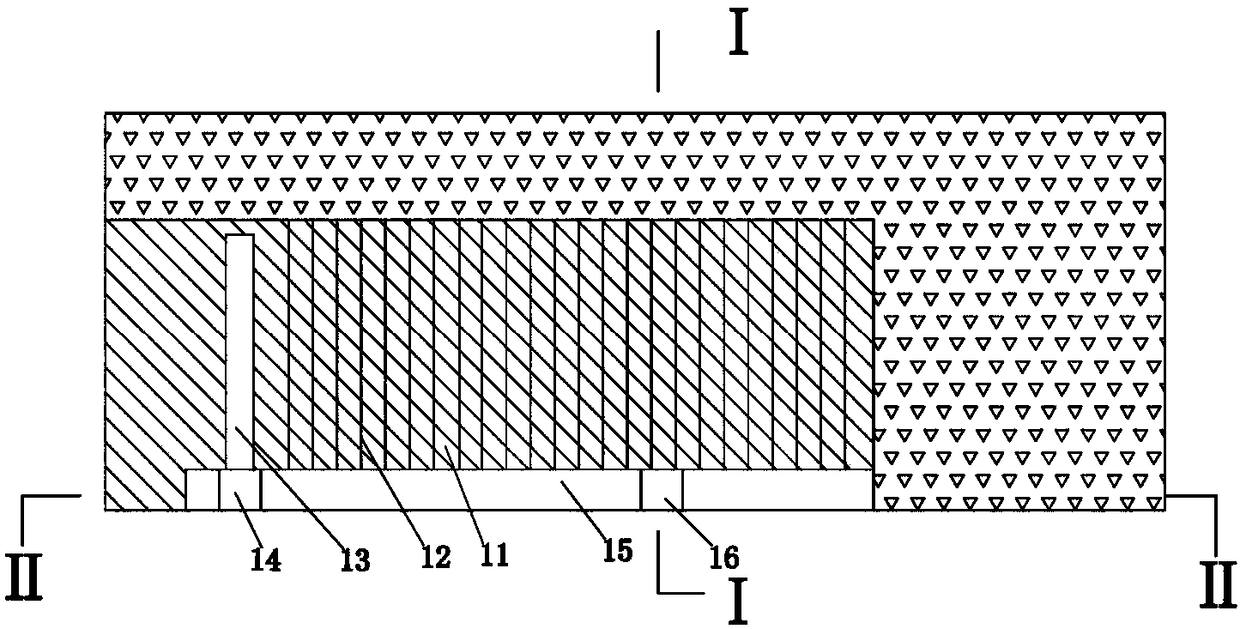

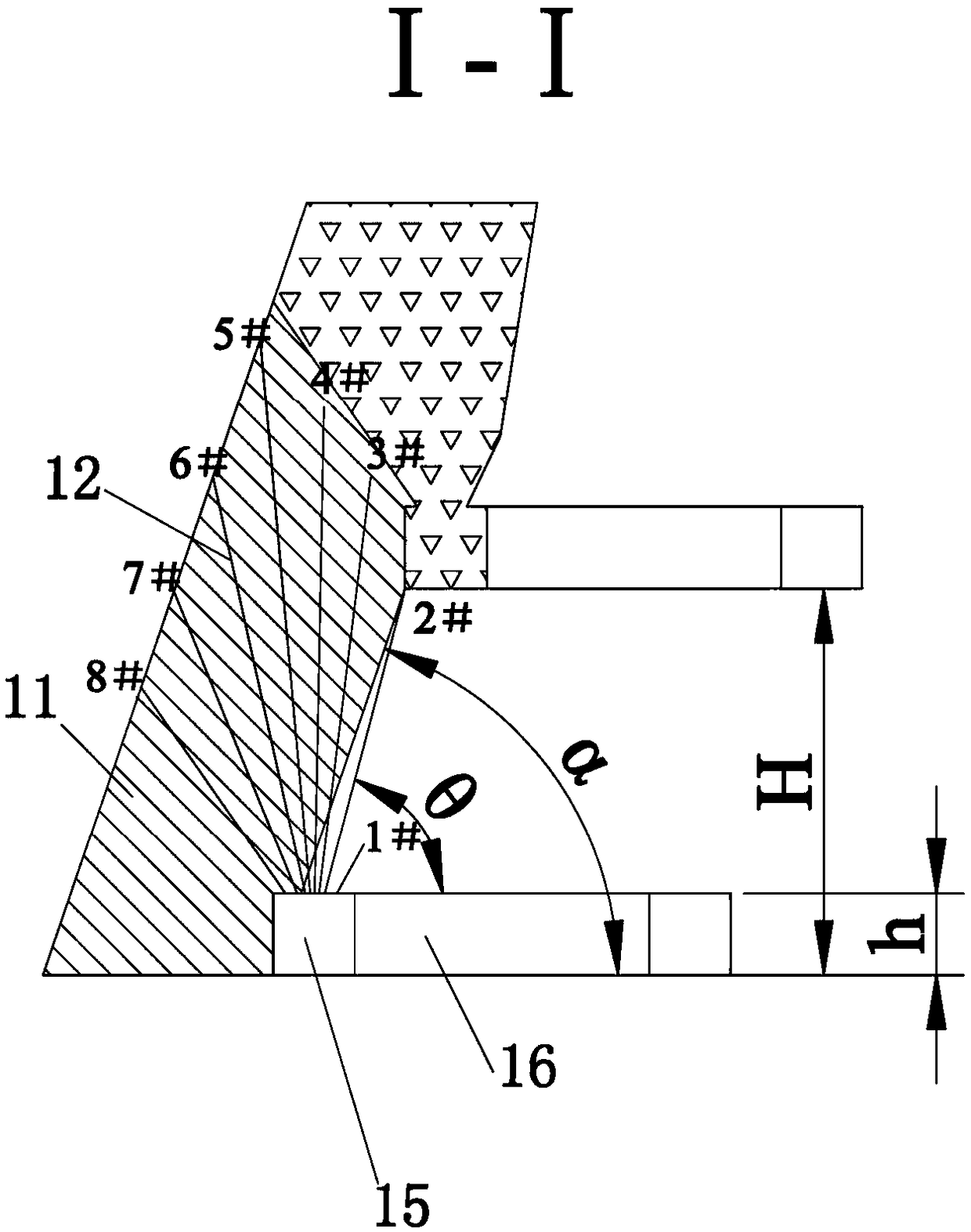

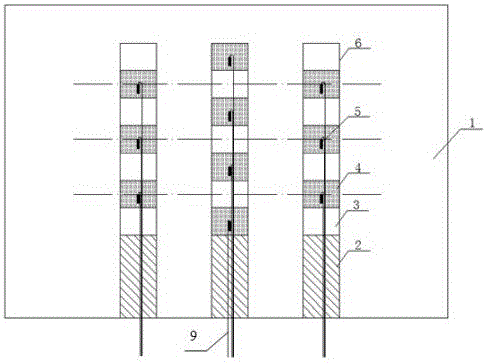

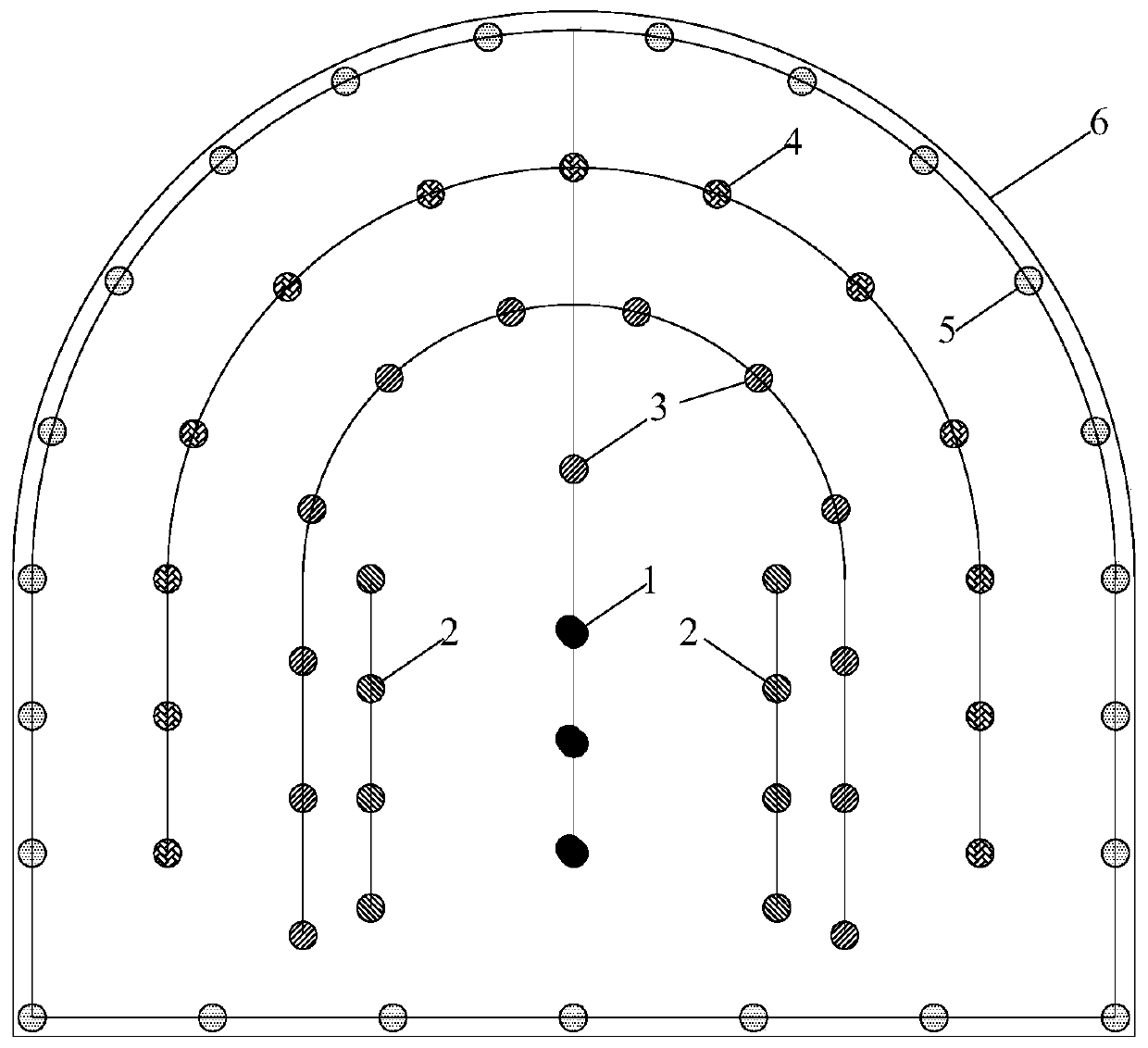

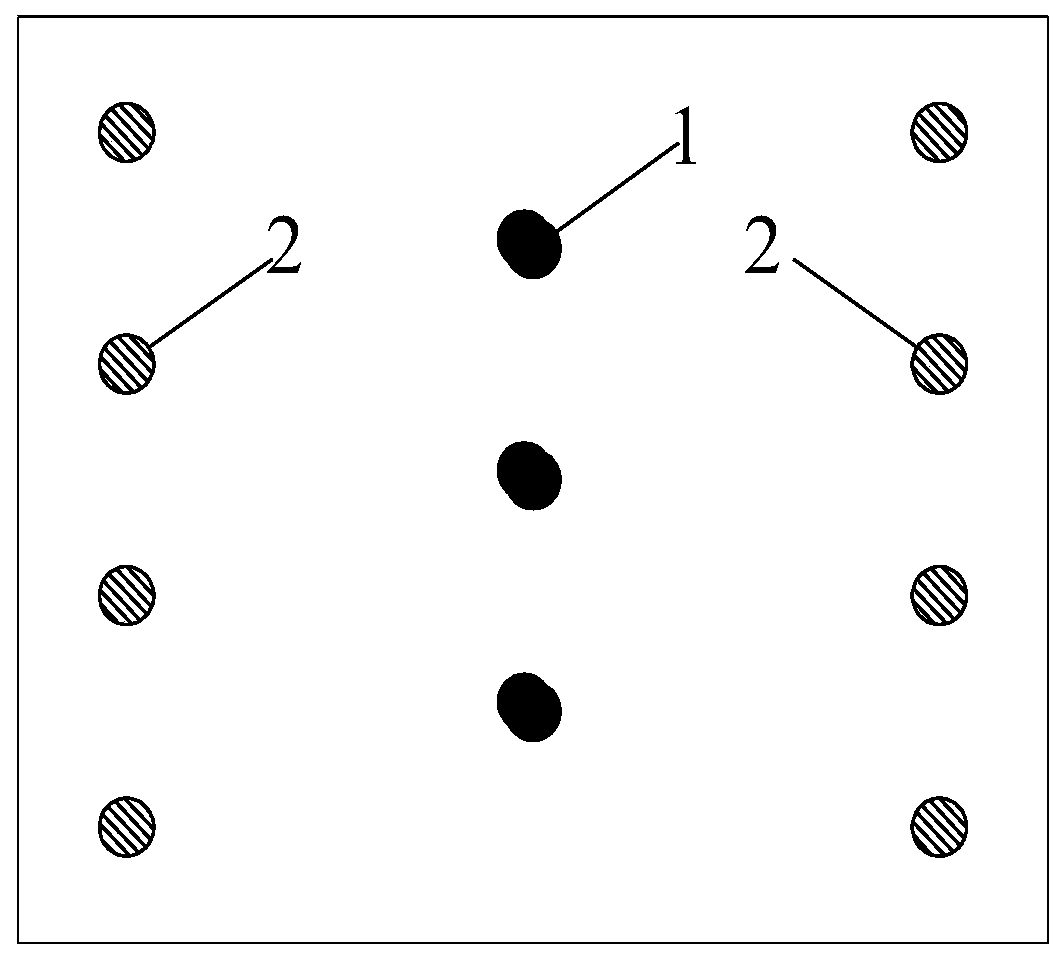

Medium-length hole blasting method used for underground mining

The invention belongs to the technical field of mining, and particularly relates to a medium-length hole blasting method used for underground mining. According to the method, blast holes are distributed in a fan shape, detonators are simultaneously buried in the middles and at the bottoms of the blast holes, the mode that delayed blasting is carried out from the middle to two sides simultaneously and every two rows of blast holes are taken as one group and are sequentially blasted is adopted in the blasting method, the blasting effect is obviously improved, the block rate is substantially reduced, and the ore removal efficiency is obviously improved. Compared with a traditional blasting method, the blasting method reduces the block rate from 27.6% to 6%, the ore removal efficiency of an ore removal equipment scraper is raised from 58 tons per machine team to 122 tons per machine team, the ore removal cost is reduced from 13.63 RMB per ton to 11.53 RMB per ton, recrushing times are substantially reduced and operation safety is guaranteed.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

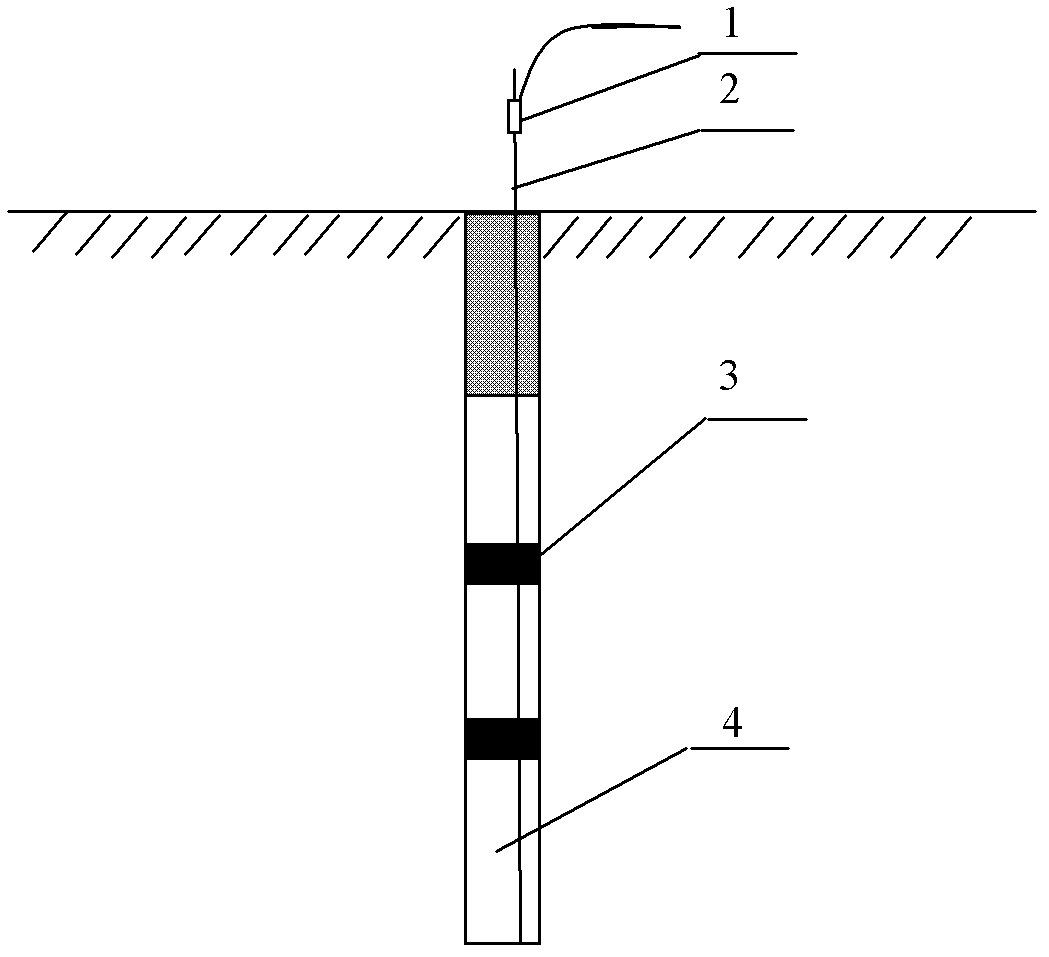

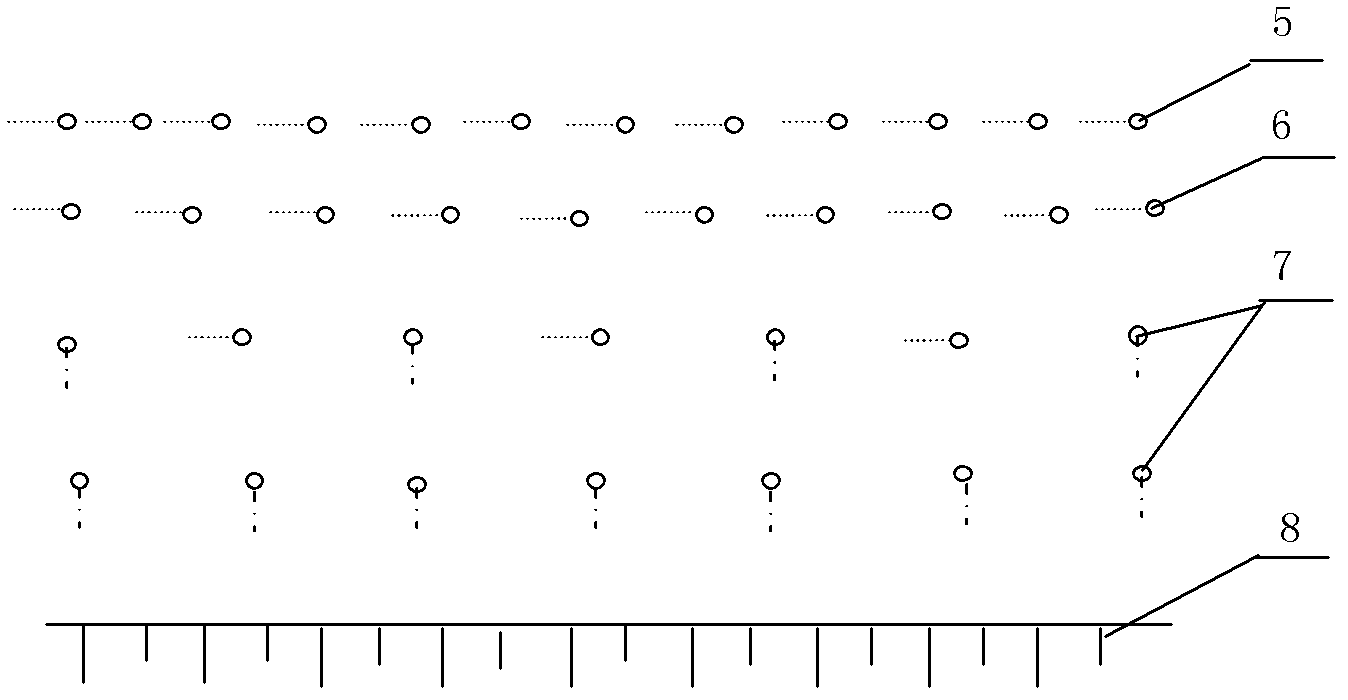

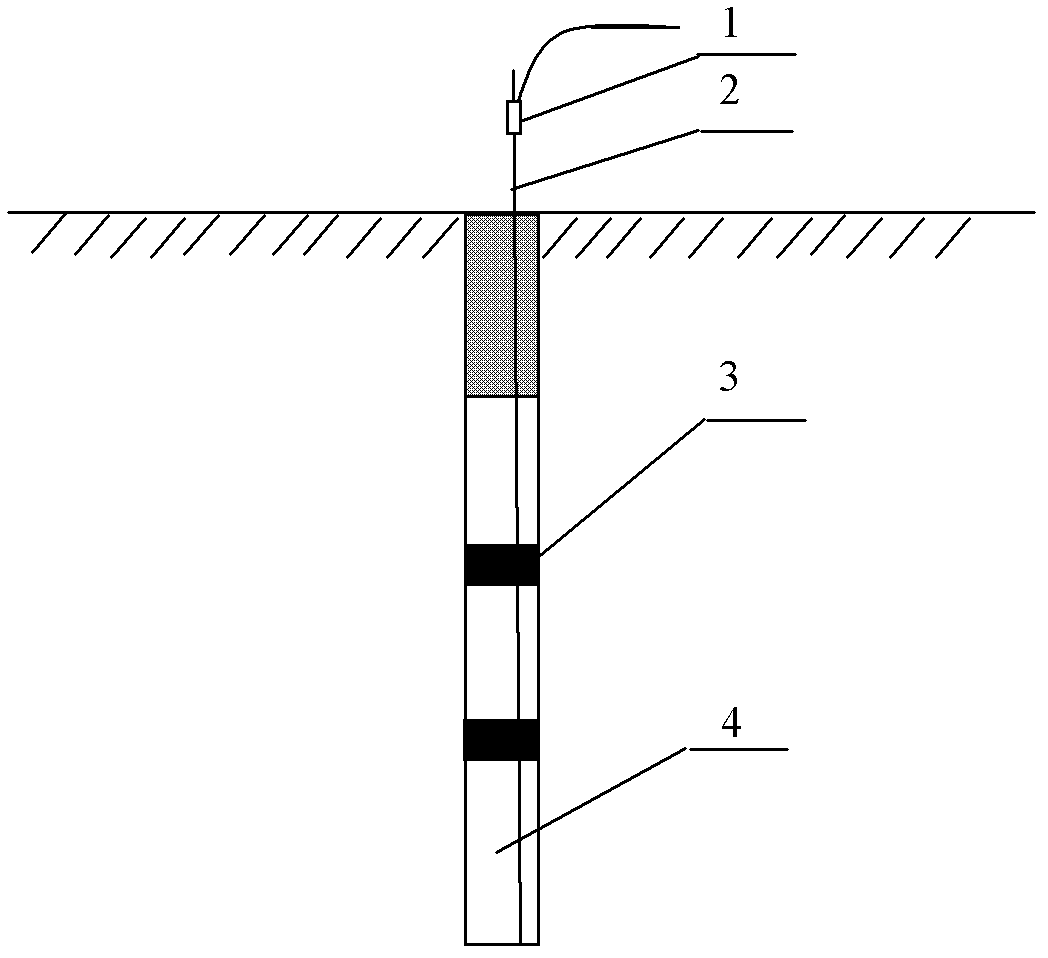

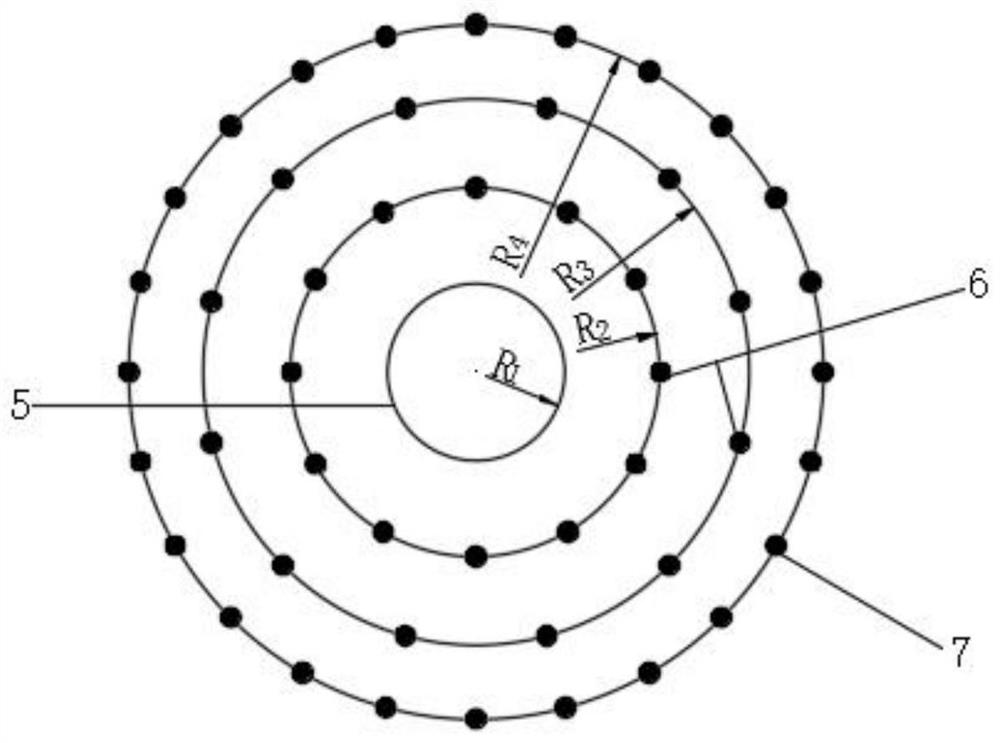

Presplitting blasting method for water holes close to high and steep slopes

The invention particularly relates to a presplitting blasting method for water holes close to high and steep slopes, which adopts a reversing hole distribution mode to distribute holes according to a profile map of a slope face. The technical parameters are that coefficient of not coupling of water hole presplitting hole (5) is 1.5-4.5, pitch of the water hole presplitting hole (5) is 1.5-3mm, space between rows of the water hole presplitting hole (5) and cushion hole (6) is 2.5-3m, thread stitching density of the water hole presplitting hole (5) is 1.5-3.5 kg / m, and the hole net parameter ofa main armament hole (7) is 4x4-6x5m2. Explosive charges (4) are filled in the bottoms of the water hole presplitting hole (5), and then a detonating cord (2) is filled in the water hole presplittinghole (5). Each of the 1-8 times of explosive charges is carried out according to the sequence of repeatedly enabling a spacer (3) to be filled in and enabling the explosive charges (4) to be filled in until completion of filling. After the water hole presplitting hole (5) is plugged, the detonating cord (2) and a non-conductivity booster detonator (1) are connected outside the water hole presplitting hole (5) to make preparation for detonation, and advance detonation time of the water hole presplitting hole (5) is 80-100ms. The presplitting blasting method has the advantages of reducing basalrate, reducing large blocks and being high in efficiency and low in consumption.

Owner:福建省新华都工程有限责任公司

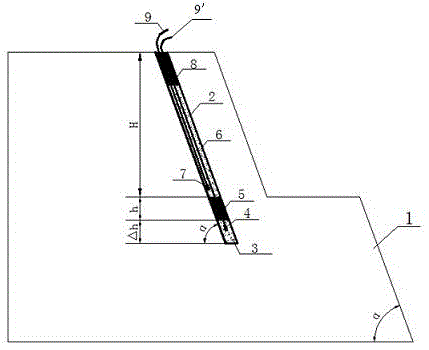

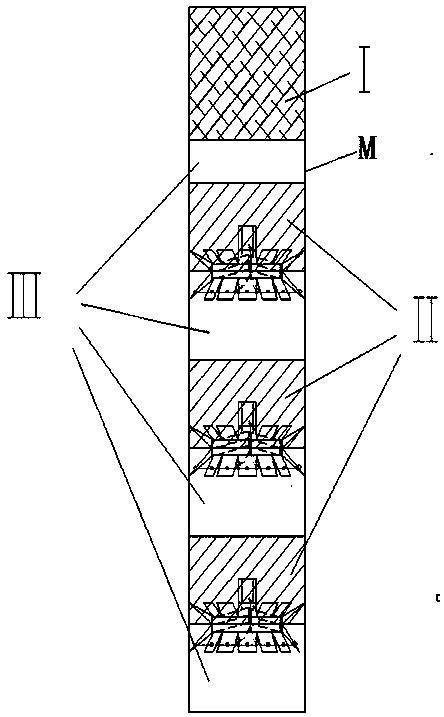

Charge system for advance rock breaking of surface mine

The invention discloses a charge system for advance rock breaking of a surface mine. The designed blast hole depth L=H / sin alpha'+ h / sin alpha'+ delta h / sin alpha', wherein H is the height of open-air stages, alpha' is the dip angle of blast holes, h is the extra depth, and delta h is the increased depth. An advance primer cartridge (3) and an advance primer detonator (4) are arranged at the blast hole deepened position at the bottom of each blast hole, and the lower portion of each advance primer detonator (4) is located at the position 1 / 4 of the upper portion of the corresponding advance primer cartridge (3). An isolation section (5) is arranged at the blast hole deepened position of each blast hole (2). A main primer detonator (7) is located at the position 1 / 4 of the lower portion of each main charge (6). The in-hole micro-delay detonation technology that the advance primer cartridges (3) and the main charges (6) on the upper portions carry out detonation in sequence is adopted so that advance pre-damage of rock on the upper portions of the stages can be achieved, and the situation that the perforating and blasting work of the lower stages is influenced by excessive breaking of the rock can be effectively avoided.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Ming method for stoping high-dipping thick orebody with medium and above stability in ore mass

ActiveCN107939402AAvoid collapsing intoReduce mix rateUnderground miningSurface miningMineralogyDeep hole

The invention discloses a mining method for stoping a high-dipping thick orebody with the medium and above stability in an ore mass. The method comprises the steps that an inverted-stepped mining faceis arranged in the thickness direction of the orebody in an ore room, mining is advanced from bottom to top, the mining face part close to a hanging wall is ahead of the mining face part close to a lying wall by a certain height, the advanced mining height of the mining face part close to the hanging wall is utilized to provide an operation space, a shallow hole is drilled upwards in the operation space, and a horizontally parallel medium-length hole is drilled in the direction of the lying wall to blast and break ores; and an anchor rod is used for anchoring partial unstable rocks on the hanging wall in the operation space, a part of the mined ores is temporarily left in the ore room to serve as a protective bottom column and a buffer layer of the hanging wall and provide a standing platform for upward operation and temporarily bearing hanging wall rocks, and a large quantity of ores are removed after ore room exploration is completed. The mining method is beneficial for reducing mixing of waste rocks in the mining process of the high-dipping thick orebody and improving the recycling ratio of resources, the blackness of the ores is even, the stope preparation work amount is less,and rock drilling and blast working are easy to organize.

Owner:KUNMING METALLURGY COLLEGE

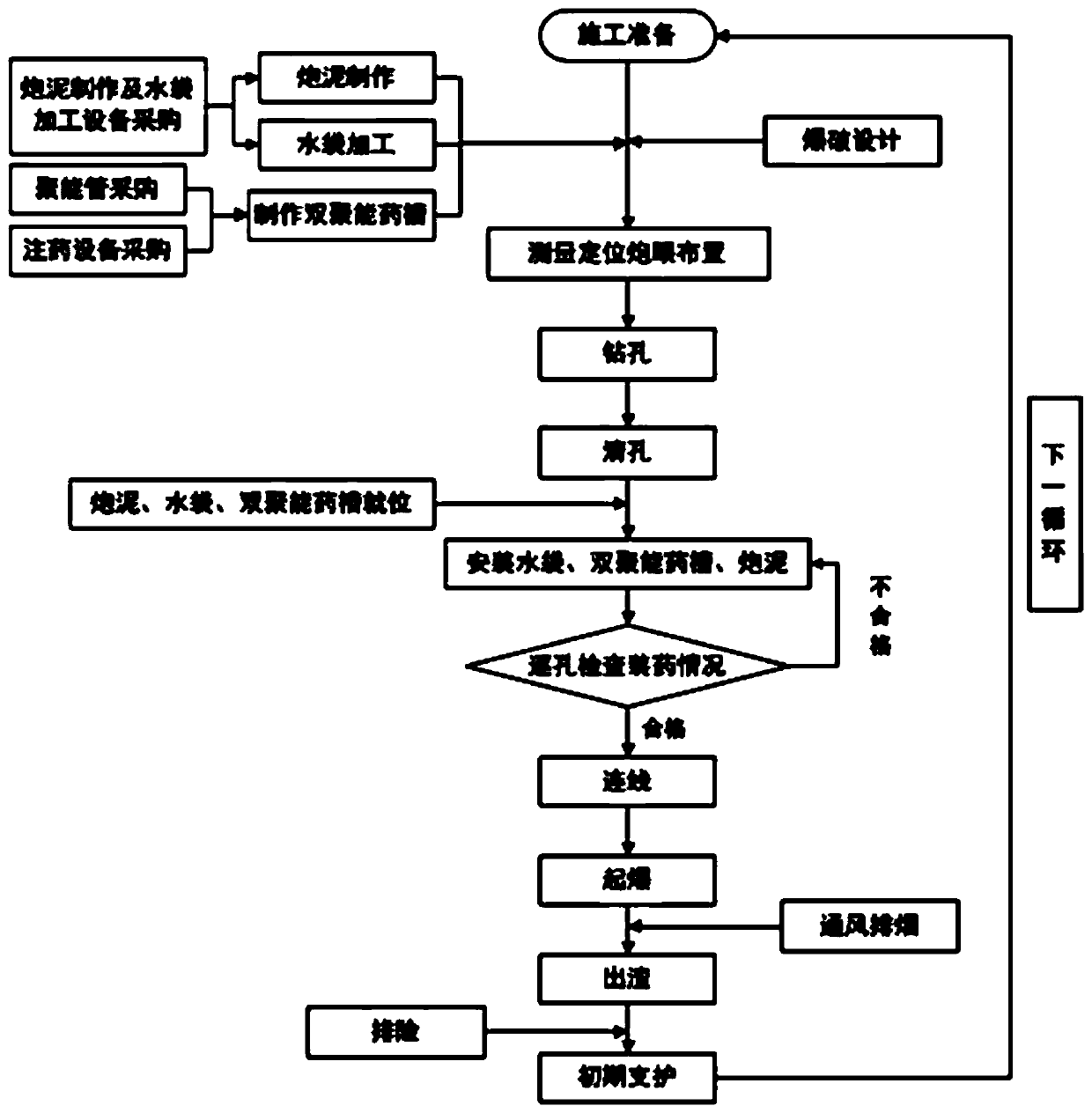

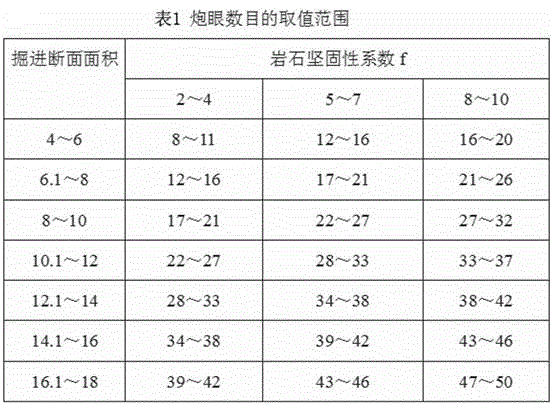

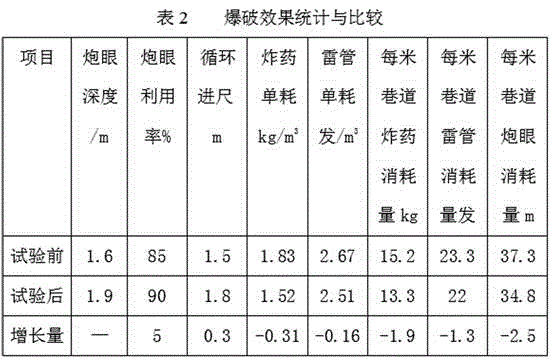

Medium-length hole blasting technology used in semi-coal-rock roadway

The invention relates to the field of underground blasting construction, in particular to a medium-length hole blasting technology used in a semi-coal-rock roadway. The technical problems that in existing semi-coal-rock roadway blasting, the blasting progress is slow, the shot hole utilization rate is low, the explosive amount is large, and the blasting cap combustion is high are solved. During application experimental investigation, 31 times of tunneling circulation are completed, and the tunneling roadway forming project amount of 55.8 m is completed. At the experimental stage, the actual shot hole depth is 1.8-2.0 m, the average shot hole depth is 1.9 m, the shot hole utilization rate is 90% or above and can reach 91.3% at most, and the average cyclic footage is 1.8 m. On the aspect of blasting material consumption, the average explosive unit consumption at the experimental stage is 1.52 kg / m<3>, and the blasting cap unit consumption at the experimental stage is 2.51 blasting caps per cubic meter. Working face rock is fully smashed, blasting lumpiness is uniform, the boulder yield is very low, blasting muck piles are concentrated, the throw distance of a large amount of rock is controlled at 6-15 m, the workloads of manual waste rock removal and roadway cleaning are reduced, waste rock pouring and rock loading of a rock loading machine are facilitated, and the work hour utilization rate and the rock loading productivity of the rock loading machine are increased.

Owner:DATONG COAL MINE GRP

Different-hardness-degree rock stratum blasting control method used in deep-hole bench blasting

The invention discloses a different-hardness-degree rock stratum blasting control method used in deep-hole bench blasting. The positions and number of detonation points are finely designed, two-point or multiple-point simultaneous detonation is adopted in the drilling blasting design, and detonation wave frontal collision is utilized to improve pressure of wave front, so that energy is centralized to break locally-hard and difficultly-blasted rock stratums, the different-hardness-degree rock stratum blasting problem in the deep-hole bench blasting is solved, the boulder yield in the hard rock stratum blasting is reduced, the safety of a detonating network is improved, and the different-hardness-degree rock stratum blasting control method is efficient, convenient and fast and facilitates quick construction.

Owner:WUHAN UNIV

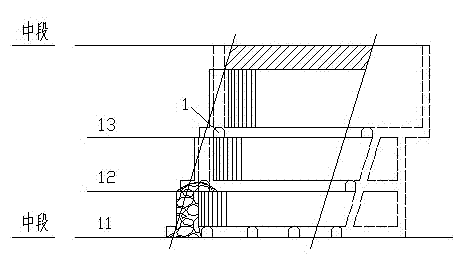

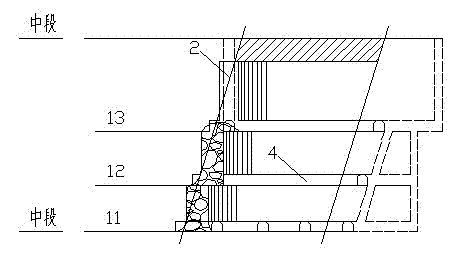

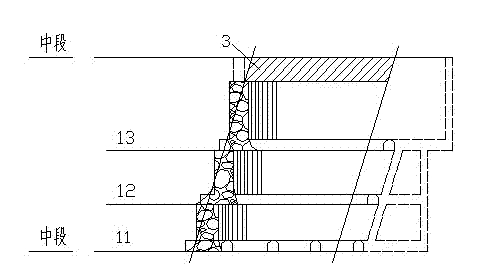

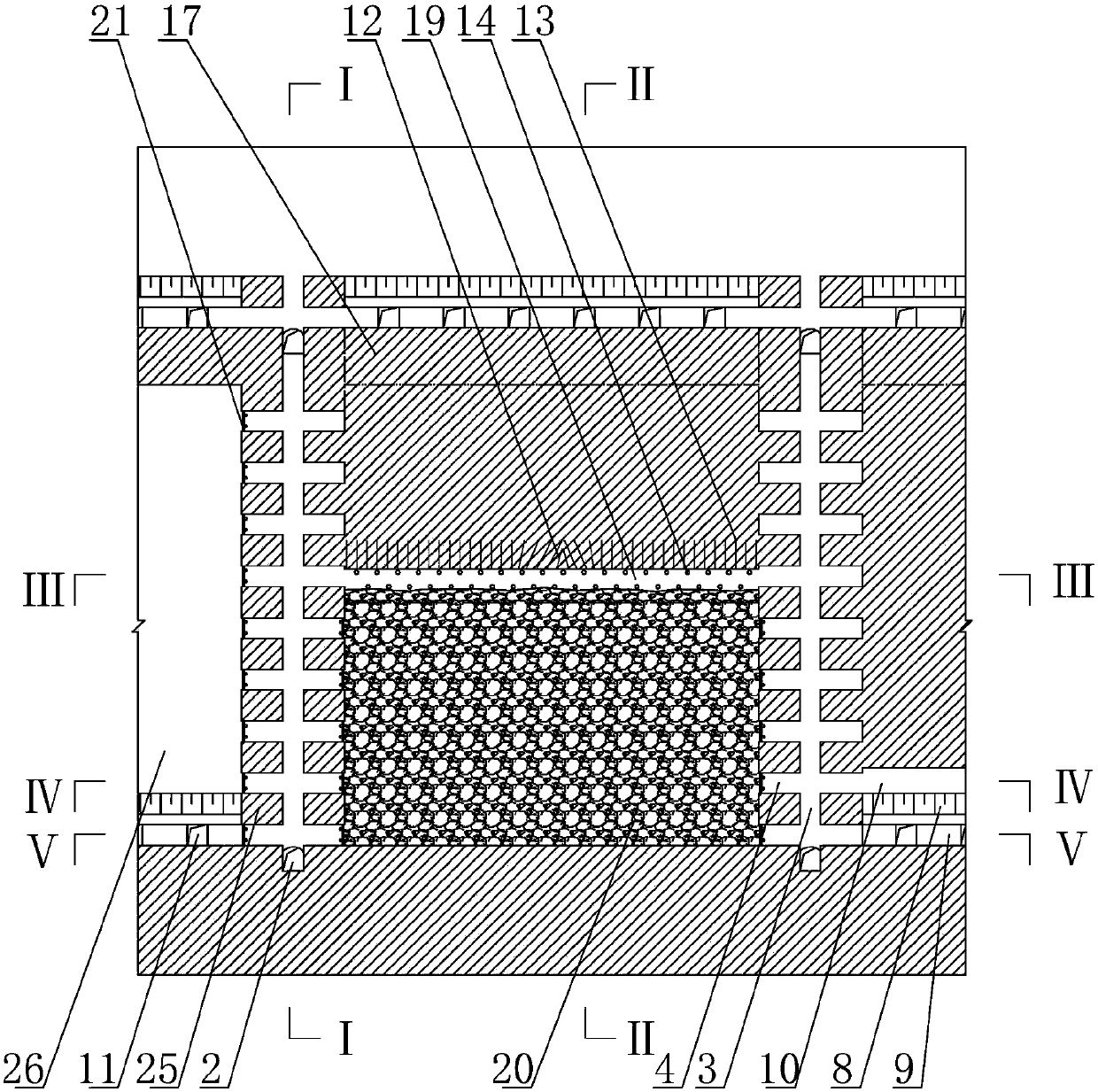

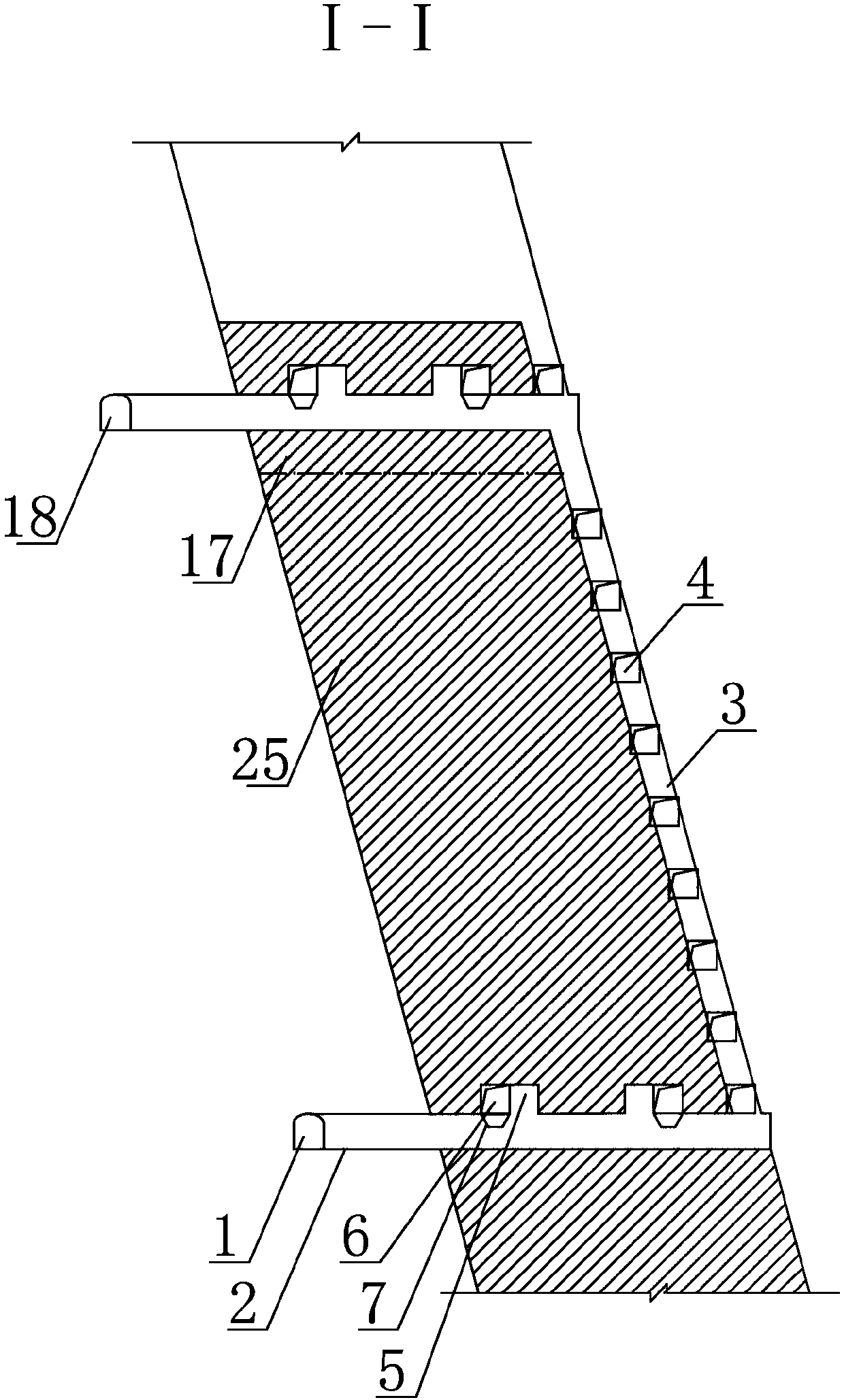

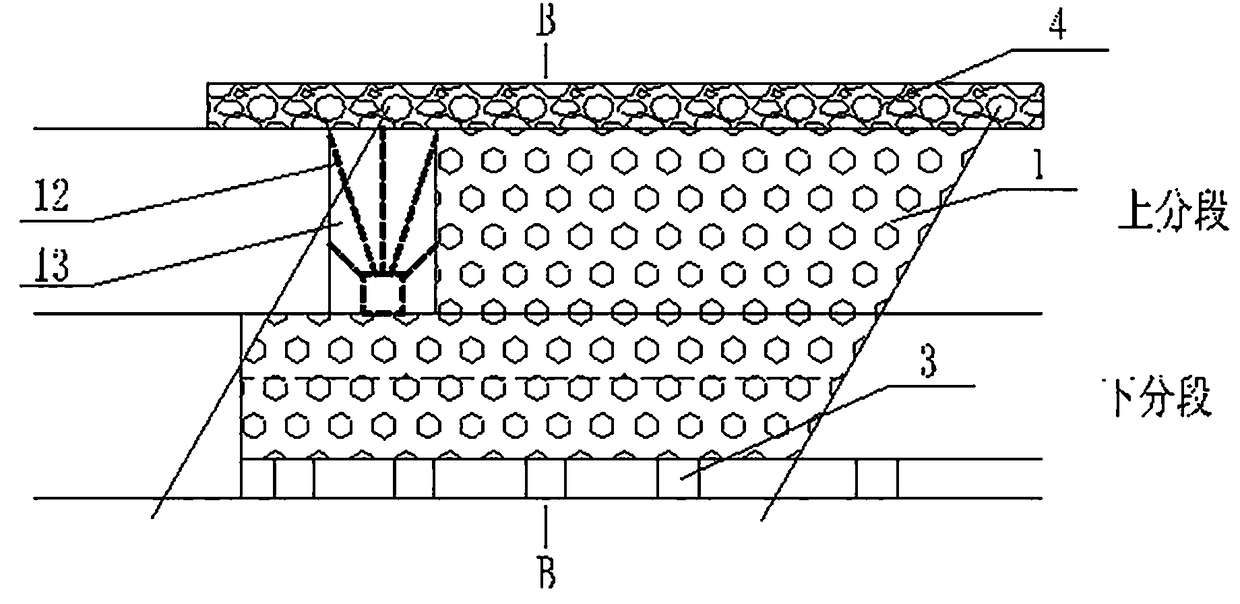

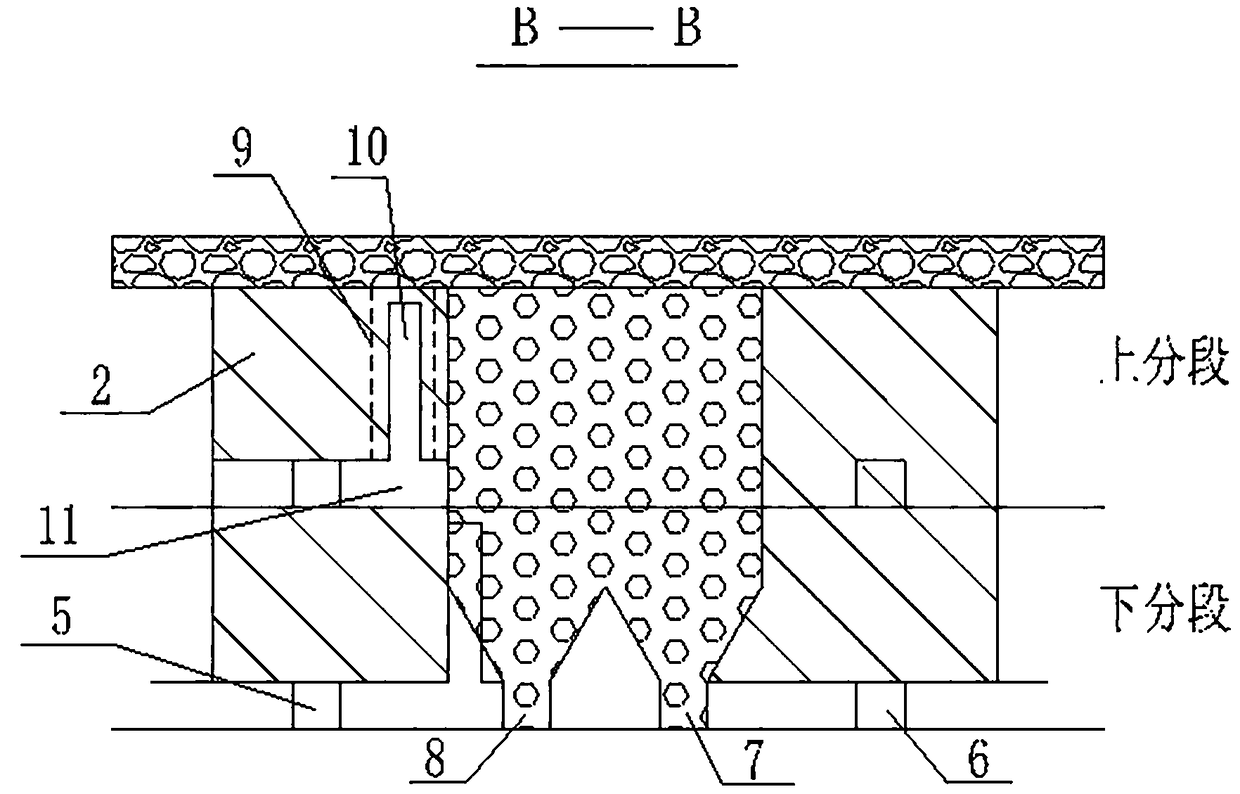

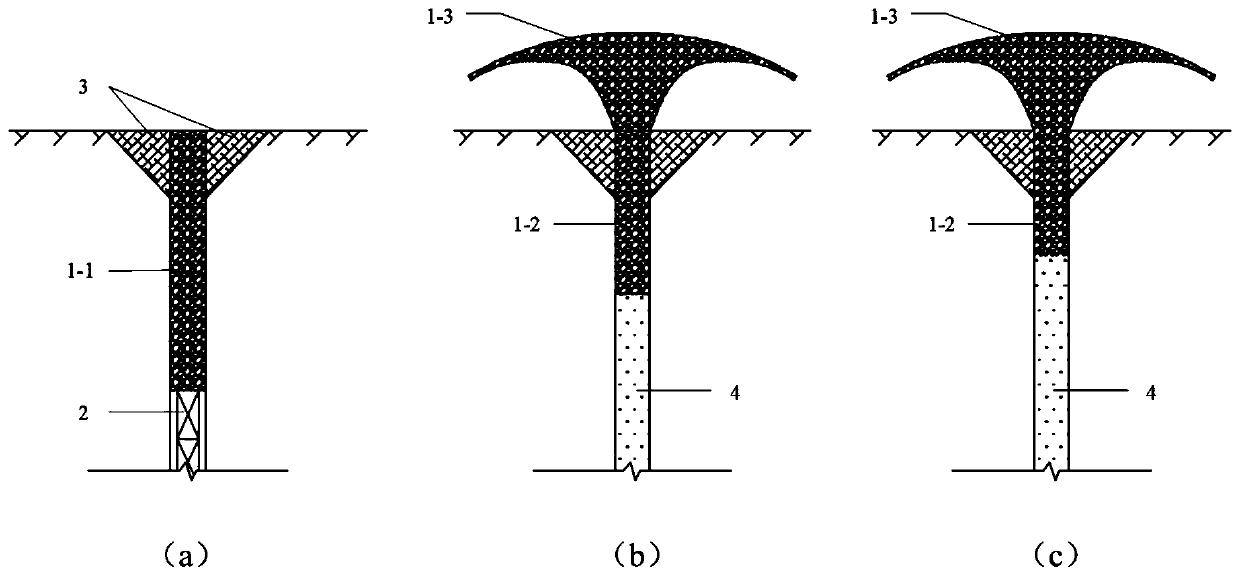

Method for mining thick ore body through segmental ore breaking and subsequent cemented filling

InactiveCN107130962AEnsure safety and stabilityPrevent weatheringUnderground chambersUnderground miningShotcreteMesh reinforcement

The invention discloses a method for mining a thick ore body through segmental ore breaking and subsequent cemented filling. The method comprises the following steps: 1) dividing the ore body into a plurality of segments along the vertical direction of the ore body; 2) dividing the ore body into a plurality of stopes in each segment along the trend of the ore body; 3) arranging rock drilling roadways along a direction perpendicular to the trend of the ore body in each stope, wherein the rock drilling roadways penetrate the ore body and extend to the hanging wall rock of the ore body; 4) supporting the rock drilling roadways formed in the step 3): a, spraying concrete onto the wall surfaces of the roadways; b, knocking anchor poles into the two sides and the tops of the roadways; c, fixedly laying steel mesh reinforcement onto the two sides of the roadways; and d, spraying a 100-mm-thick layer of concrete onto the surfaces of the steel mesh reinforcement; and 5) carrying out mining: a, mining the ore body from hanging segment to footwall segment successively; and b, mining every stope in each segment in such a manner that primary mining is carried out on odd or even stopes at first and then secondary mining is carried out on the rest stopes.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

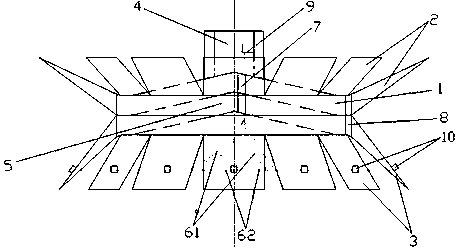

Low dilution sublevel caving mining method of steep inclined medium thick orebody

ActiveCN108252717AImprove recycling conditionsImprove recovery rateUnderground miningSurface miningMineralogy

The invention relates to a low dilution sublevel caving mining method of steep inclined medium thick orebody. The mining method comprises the stage of mining the orebody from top to bottom in sections, a lower side wall transportation road, a ore drawing chute and a vein crossing roadway. The method comprises the following steps of, determining the position of a vein mining approach; driving a cutting lane to an upper wall boundary of an orebody and a cutting well in a route along a vein; arranging upward parallel blast holes in the cutting lane, and blasting row by row to form a cutting groove; arranging an upward fan-shaped hole in the route along the vein, wherein a short blast hole of 2 - 4m is arranged in the lower side wall. The sequence of initiation of fan-shaped holes is that, blasting the lower side wall side hole first and then blasting the upper side wall side hole to reduce accumulation of blasting gas and the size of blasting cavity; pouring the ore after blasting into the ore drawing chute through the vein connection tunnel and transporting it out through the stage transportation system. The method has the advantages of improving the ore recovery rate and reducing the ore dilution rate.

Owner:ANSTEEL GRP MINING CO LTD

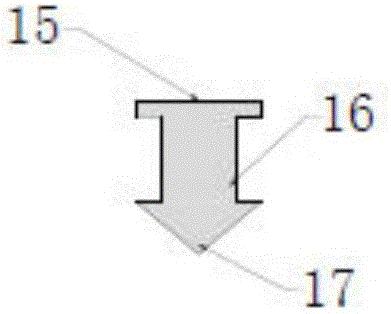

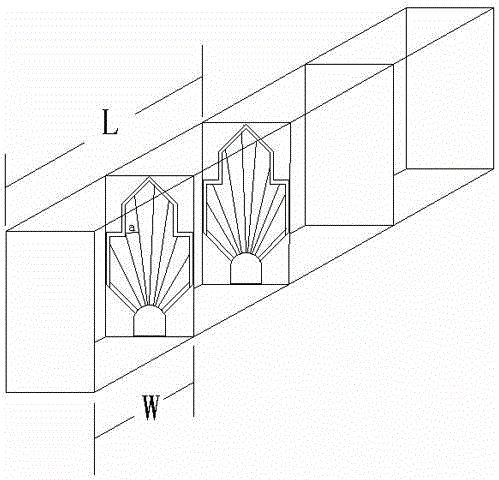

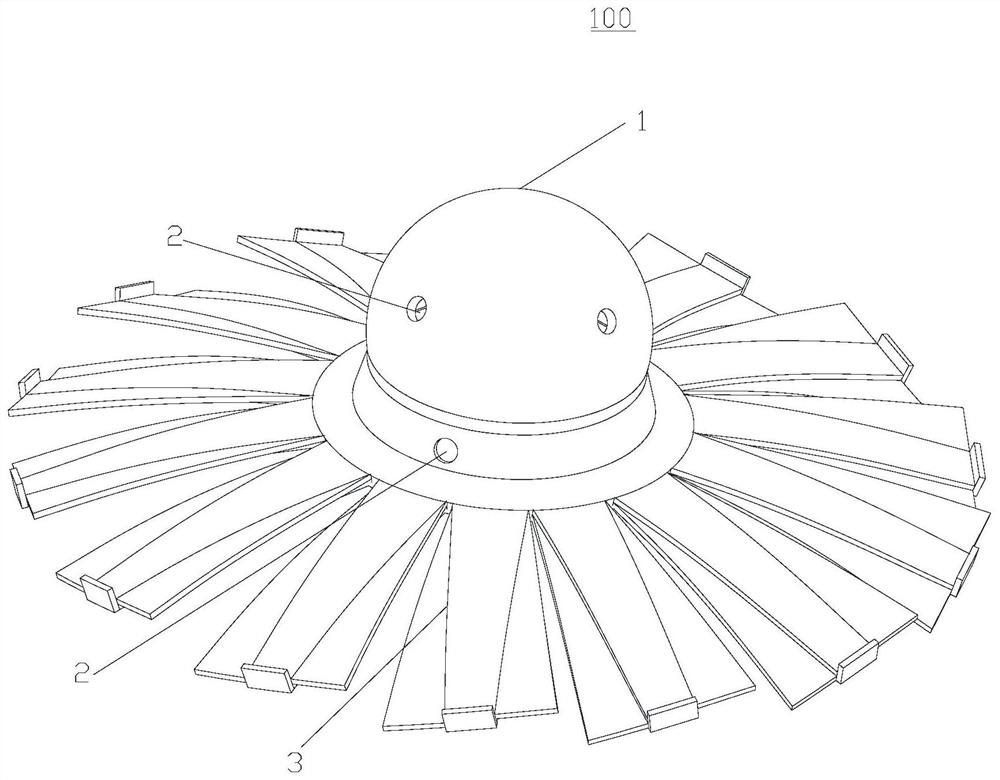

Blast hole uncoupling energy gathering spacing device suitable for non-coal mine mountain and using method thereof

The invention relates to a blast hole uncoupling energy gathering spacing device suitable for a non-coal mine mountain and a using method thereof. The blast hole uncoupling energy gathering spacing device suitable for the non-coal mine mountain comprises a tray body, upper barbs and lower barbs, the upper barbs and the lower barbs are arranged on the periphery of the tray body and used for clamping the hole wall, the tray body comprises an inverted conical disk body and an internal thread column arranged on the upper surface of the inverted conical disk body and provided with internal threads,and the inner wall of the internal thread column is provided with a suspension rubber band buckle; and rubber band holes where rubber bands penetrate are formed in the positions, located below the internal thread column, on the inverted conical disk body, the upper surfaces of the lower barbs are provided with buckles for inward binding rubber bands, the buckles on the surfaces of the lower barbsare provided with the inward binding rubber bands in a penetrating manner, the inward binding ends of the inward binding rubber bands penetrate the rubber band holes to be connected to suspension rubber band buckles, and the tray body is further provided with a detonating cord hole where a detonating cord penetrates. By means of the blast hole uncoupling energy gathering spacing device, through tray installation between plugging and charging, generation of rockets is prevented, flying stone is reduced, and the safety factor of explosion is improved.

Owner:FUZHOU UNIV

Explosion method for open-cast mining underground goaf position

Owner:ANSTEEL GRP MINING CO LTD

High sublevel double-hexagon caving mining method

InactiveCN109356581AHigh recovery rateReduce depletionDisloding machinesUnderground miningMineralogy

The invention belongs to the technical field of mining, and particularly relates to a high sublevel double-hexagon caving mining method. The method comprises the following steps of 1, preliminary mining cutting; 2, rock drilling; 3, exploding and ore breaking; and 4, ore removing. The method integrates the advantages of the sublevel caving without sill pillar method, the block stoping method, thehigh-end wall drawing method and other methods, and therefore the recovery rate of pure ore is improved, and the problem of excessive loss and dilution is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

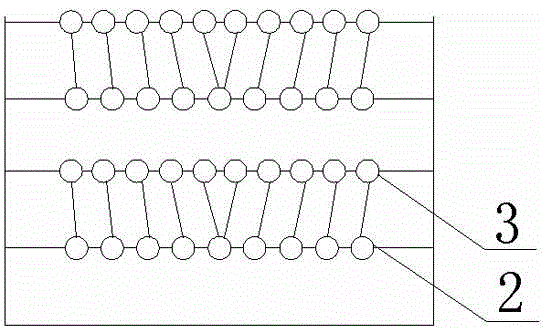

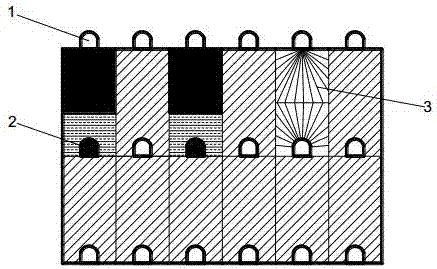

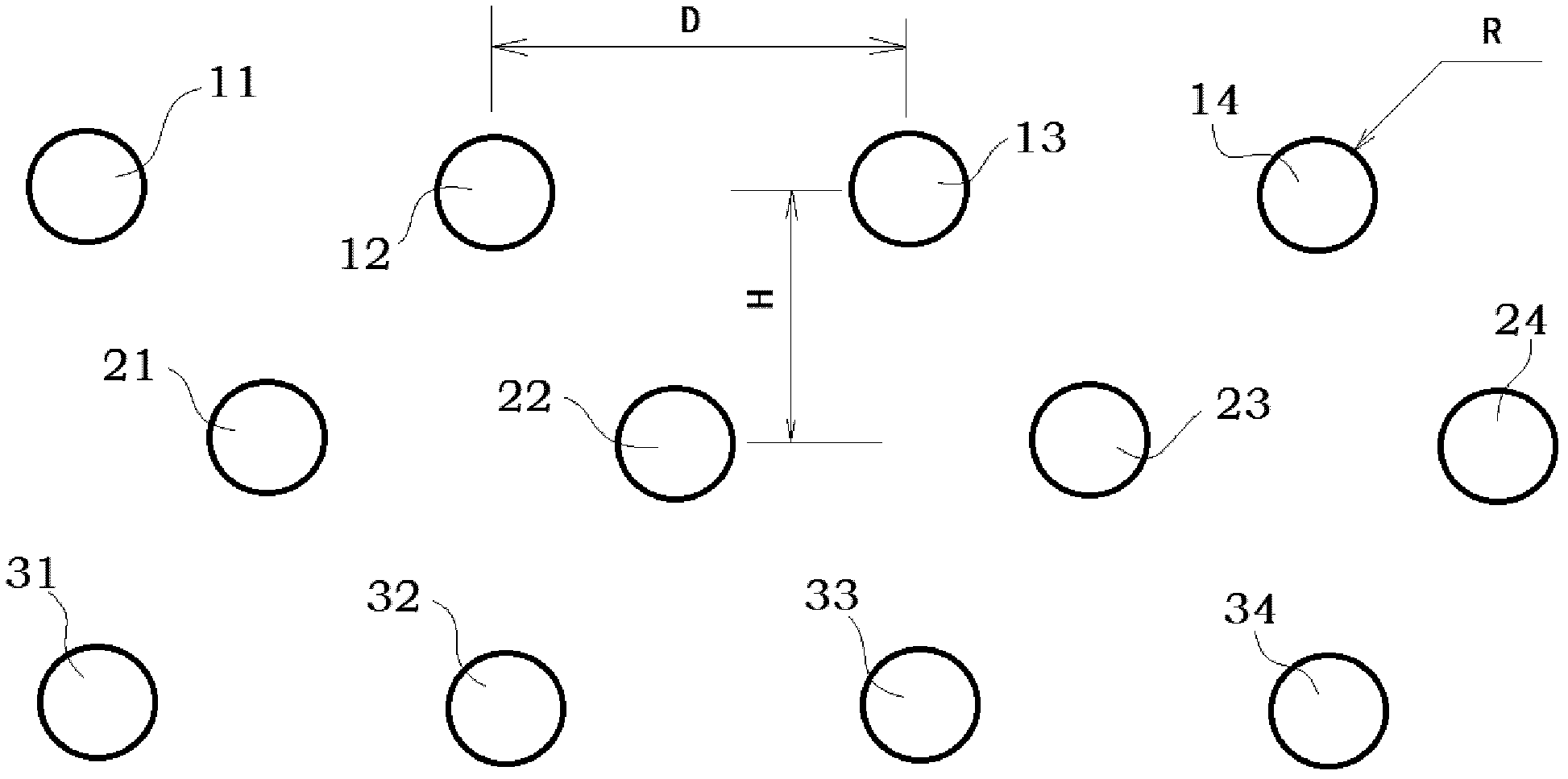

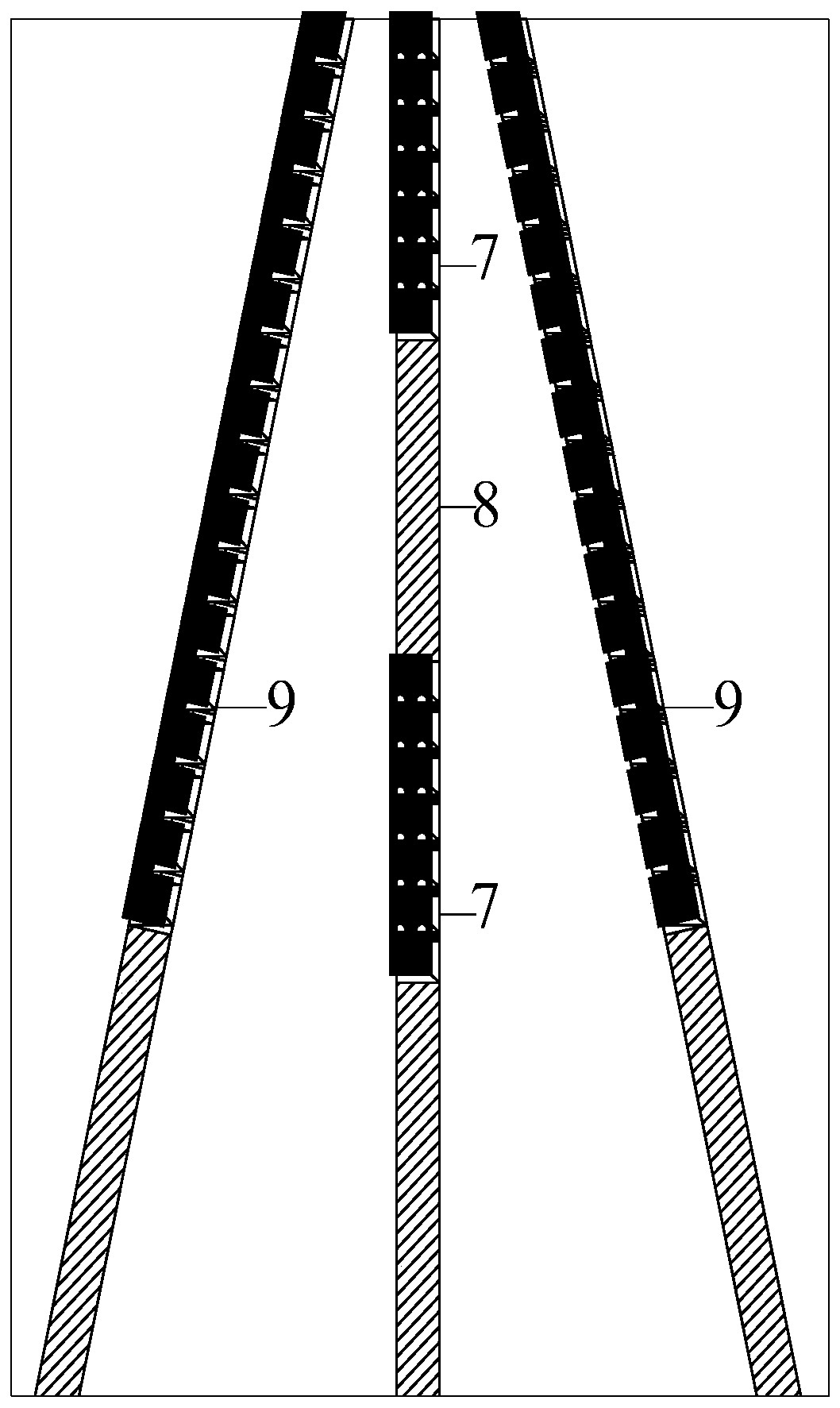

Drivage peripheral hole homoenergetic blasting method

The invention discloses a drivage peripheral hole homoenergetic blasting method. Peripheral holes (6) are dug on a roadway contour line of a surrounding rock (1) at the end part of a roadway; explosives (4) and cushioning materials (3) are alternatively arranged in each peripheral hole (6) from inside to outside; the explosives (4) in the adjacent peripheral holes (6) are distributed in a shape of a Chinese character pin; detonators (5) are arranged in sections along the explosives (4); nonel tubes (9) of the detonators (5) are led out of the holes along the hole walls of the peripheral holes (6); hole orifices of the peripheral holes (6) are plugged by stemming (2); then detonation is carried out according to a designed detonation network connecting line. According to the method disclosed by the invention, the explosives (4) and the cushioning materials (3) are distributed symmetrically, so that energy is more uniformly distributed, an energy utilization rate of the explosives is improved, a contour of a roadway section is well controlled, the back break phenomenon is avoided, and roadway supporting cost is reduced; meanwhile, the uniformly distributed explosive energy can enable a fragment size for blasting to be uniform, obviously improve a blasting effect and improve shovel-loading efficiency after blasting.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

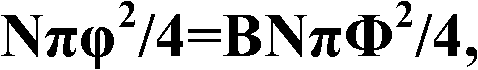

Process and system for striping and mining solid ore rock masses of surface mine

InactiveCN102562070AImproved drilling processLarge block rate and gun root residual rate decreasedOpen-pit miningPetrologyDrill hole

The invention relates to a process for striping and mining solid ore rock masses of a surface mine, which comprises a step of drilling a blast hole array, wherein the blasthole array comprises a plurality of rows of blast holes; adjacent rows of blast holes are mutually staggered along the directions of the rows; each blast hole corresponds to a non-blast hole of the adjacent row of blast holes; on each row, the distance between each two adjacent blast holes serves as a hole pitch; and the distance between each two adjacent blast hole rows serves as a row pitch. The process is characterized in that a small-aperture drill bit and a small hole network spacing are selected to drill the holes; the rock drilling speed is improved for more A times than before; the construction operation is carried out according to the small hole network spacing; the number of the drilled holes is increased to B times that of the original drilled holes; the area of each drilled hole is equivalent to one Bth of the area of the original drilled hole; and both A and B are natural numbers greater than 1. According to the invention, the boulder frequency and the blast root residual ratio can be greatly reduced, the striping and mining operations are continuously carried out, the process is convenient to operate, other investment is not required, the explosive load is unchanged, the drilling time is shortened, and the secondary blast quantity is greatly reduced.

Owner:江西分宜珠江矿业有限公司

Blasting method and application of using shear thickening liquid as blockage of blasting blast holes

The invention discloses a blasting method and application of using shear thickening liquid as blockage of blasting blast holes. The method comprises the steps of filling the blasting blast holes withthe shear thickening liquid, and using the shear thickening liquid to completely cover or partially cover gas blasters in the blasting blast holes; using the shear thickening liquid to completely cover the blasting blast holes to completely fill the gas blasters in the blasting blast holes; detonating the gas blasters. The blasting method applies the shear thickening liquid as a blast hole blockage material for blocking the blast holes, the blockage effect of the blast holes is good, flying stones and splashing are hardly generated during the blasting process, the blasting degree is deep, theblasting efficiency is high, the method is not limited to the arrangement of the blasting blast holes, the freedom of arrangement of the blasting blast holes is more flexible, the blasting process ismore moderate, strong air shock waves are nor generated, damage to the surrounding environment and workers is not caused, blasting noise is small, and the blasting process is safe.

Owner:远军热能动力科技有限公司

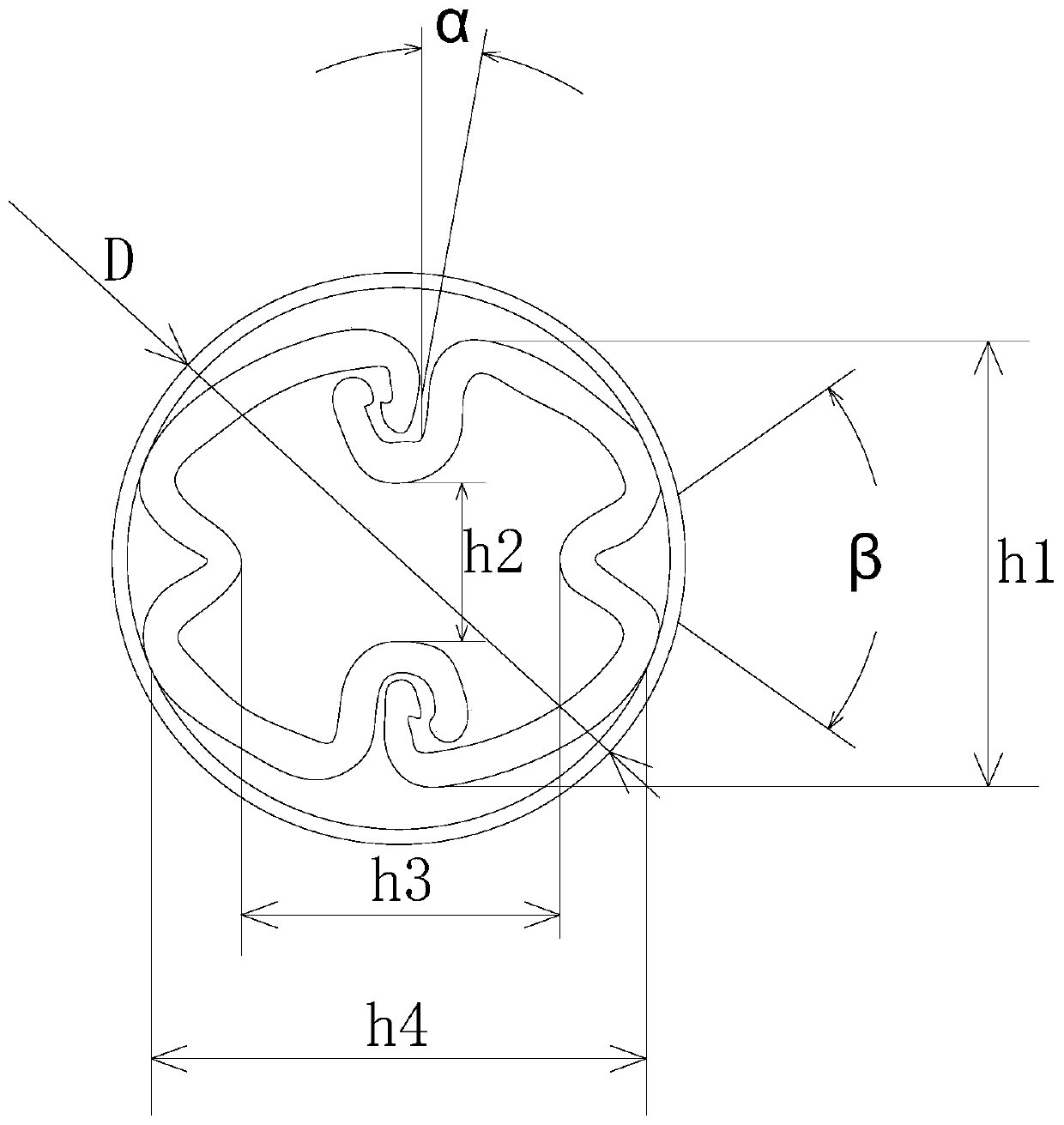

Heading shaped crack blasting method suitable for high-stress ore bodies

ActiveCN111473701AIncrease the amount of blasting in linear metersSolve the high unit consumptionBlastingTunnelsDetonationTEX-explosive

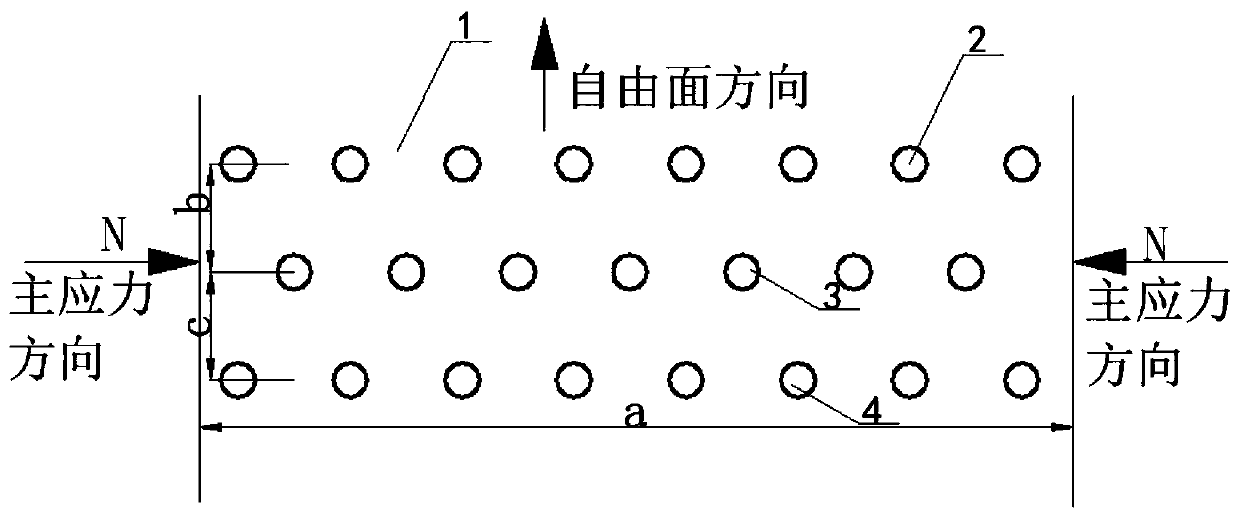

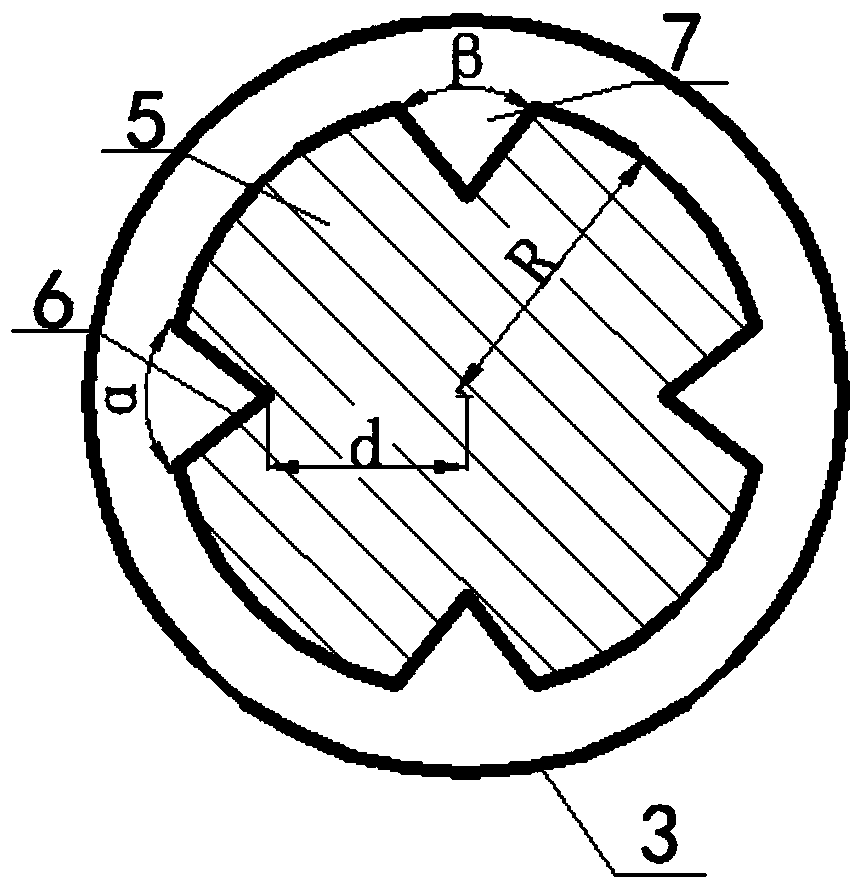

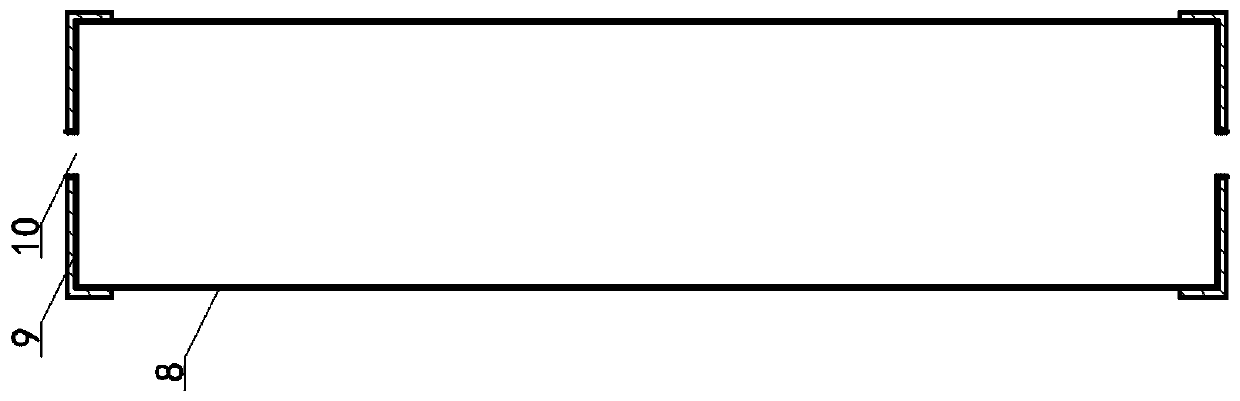

The invention discloses a heading shaped crack blasting method suitable for high-stress ore bodies. The row interval between front-row main blasting gun holes (2) and rear-row main blasting gun holes(4) is 2.5-3.0 times that of a conventional retreating type sectional blasting manner, and a row of heading cracking holes (3) is formed between the front-row main blasting gun holes (2) and the rear-row main blasting gun holes (4). Bidirectional shaped charging devices are mounted in the heading cracking holes (3). The bidirectional shaped charging devices comprise charging pipes, and cross-shaped energy gathering grooves are formed in the charging pipes. The heading cracking holes (3) carry out detonation 15-17 ms earlier than the front-row main blasting gun holes (2), and the rear-row mainblasting gun holes (4) carry out detonation 17-25 ms later than the front-row main blasting gun holes (2). According to the method, unit consumption is reduced by 15% to 20%, the gun hole blasting output per meter hole is increased by 18.5% to 20.5%, and the blasting effect is greatly improved; and the boulder yield is reduced by 35.7%, and the problems that in the high-stress mine ore body extraction process, the unit consumption of explosives is high, and the energy utilization rate is low are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

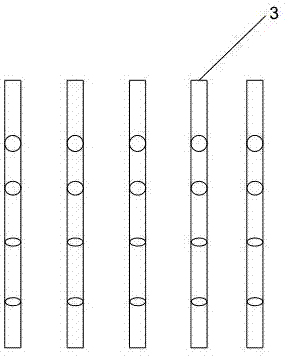

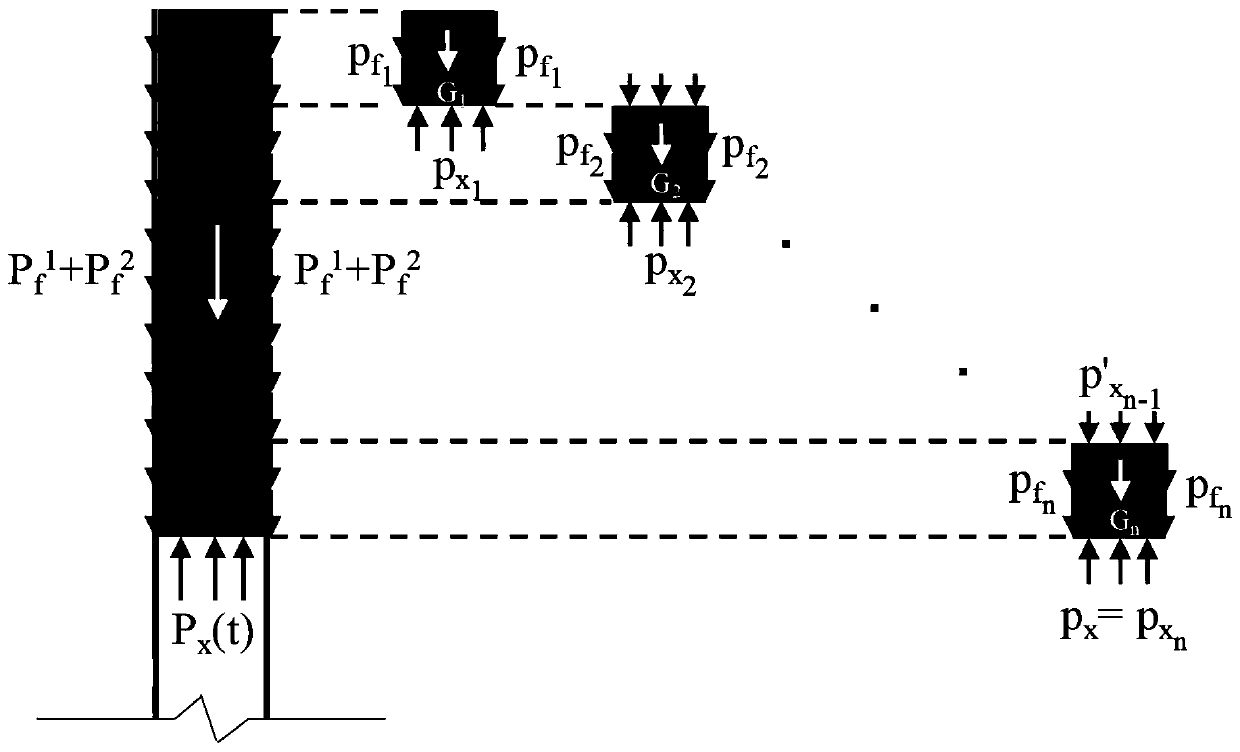

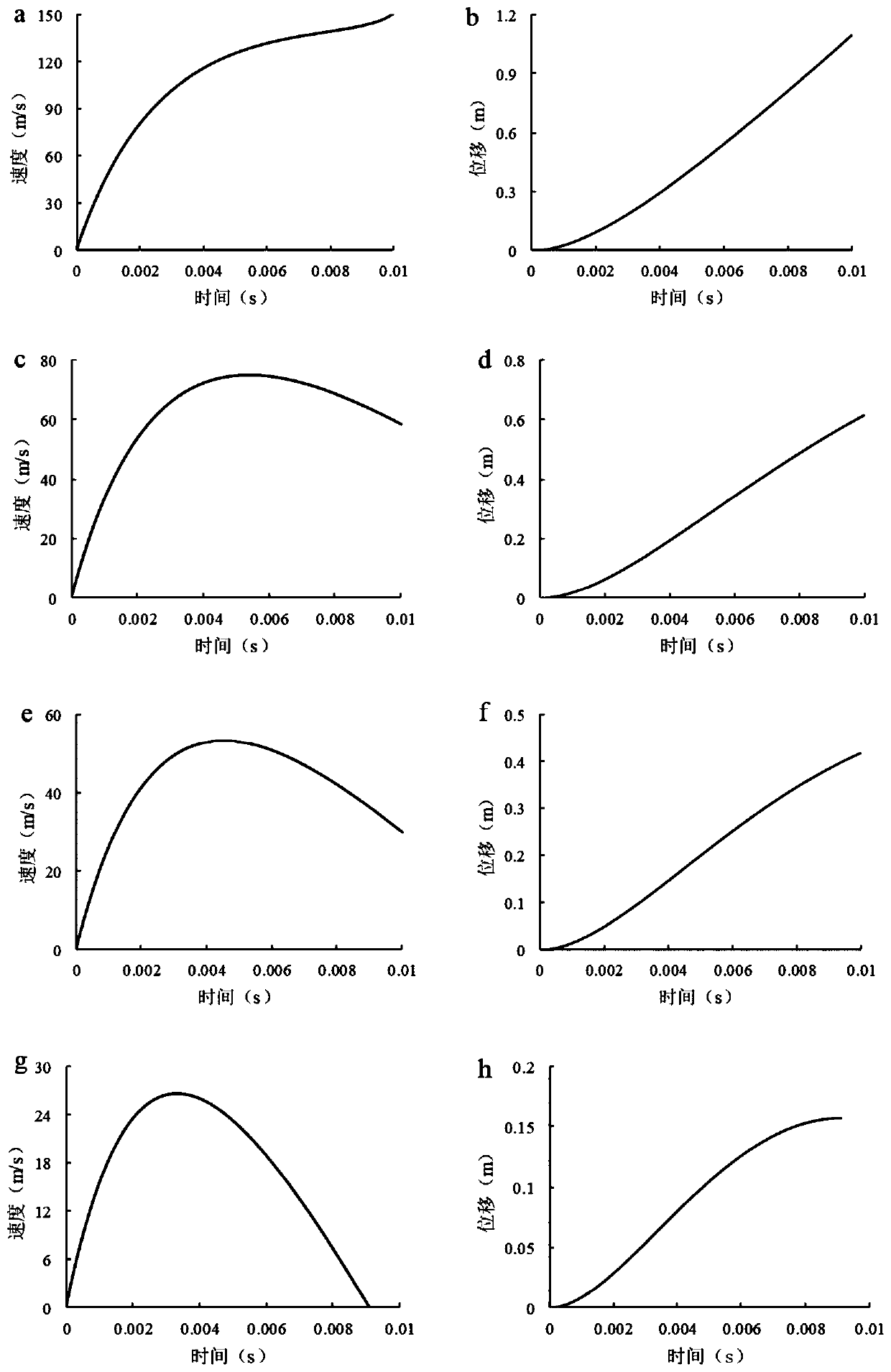

Transport type blast hole blocking structure design method

ActiveCN111207642AExpand the scope of actionAvoid premature disclosureBlastingDetonationExplosive Agents

The invention discloses a transport type blast hole blocking structure design method. The method comprises following steps of S1, based on blast design, determining a blast parameter; S2, carrying outstress analysis on a blast hole blocking structure, and calculating detonation gas expansion pressure, sliding friction force between a blast hole wall and the blocking structure, and blocking structure gravity; S3, determining a solving method of a blast hole blocking structure motion rule; S4, on the basis of a transport type design principle of the blast hole blocking structure, determining arange of a bottom motion distance of the blast hole blocking structure in the blast process; and S5, using a trial method to determine a range of an optical blocking length of the blast hole blockingstructure. The blast hole blocking structure optimized through the provided transport type design method is used, during blast, before the detonation gas pressure is relieved, the blast hole blockingstructure is allowed to move by a certain distance, but the structure does not rush out of a blast hole, thus the action range of detonation gas can be widened, a hole opening boulder yield is reduced, too early leakage of the detonation gas can be avoided, and the explosive energy use rate can be obviously improved.

Owner:WUHAN UNIV

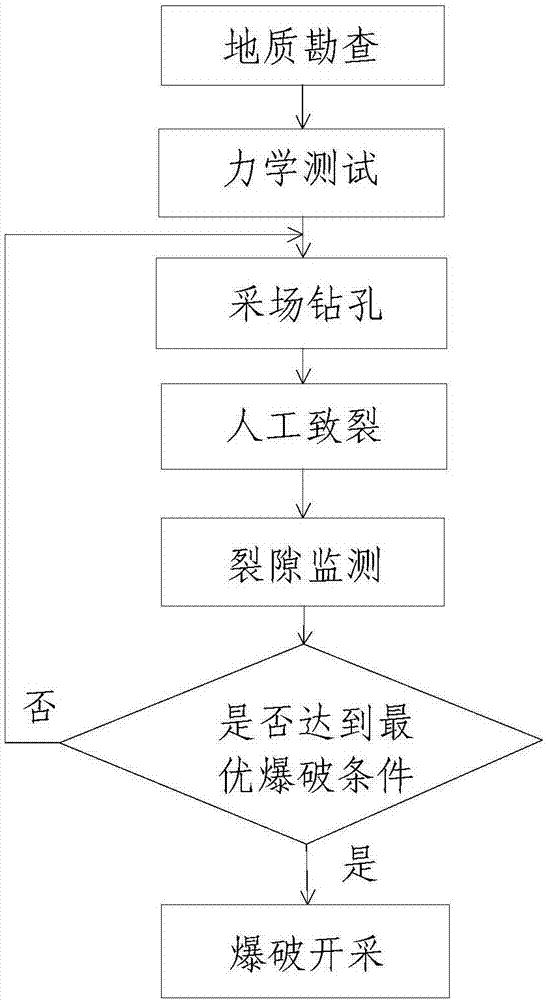

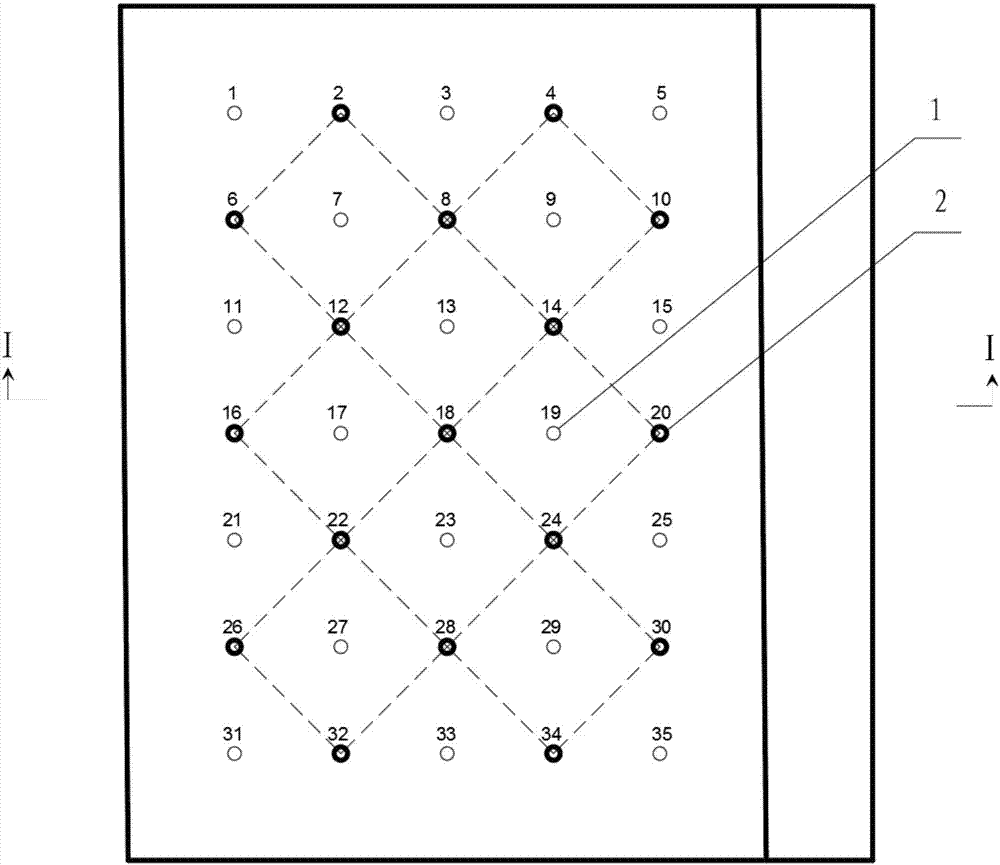

Surface mining method

InactiveCN107387086ADecrease the firmness factorReduce the rate of blasting large blocksUnderground miningSurface miningMechanical propertySurface mining

The present invention relates to the technical field of surface mining, and more particularly, to a surface mining method for the purpose of solving the problems of excessively high unit explosive consumption and excessively high boulder yield of hard rock or extra-hard rock mines in blasting mining. The surface mining method comprises the following steps: manual cracking, i.e., manually cracking a surface bench according to fundamental geological data, a fracture spacing law, and mechanical properties and a firmness coefficient of mine rock; fracture monitoring, i.e., monitoring the manually cracked area to obtain a distribution and extension range of fractures; and blasting mining, i.e., carrying out blasting mining according to the distribution and extension range of fractures. The surface mining method of the present invention can be applied to surface mining of any mine variety, and more particularly, to surface mining of hard rock or extra-hard rock mines.

Owner:NORTHEASTERN UNIV

Mechanized continuous mining method of gently inclined thin veins based on mining machine

ActiveCN105019904BIncrease production capacityImprove efficiencyUnderground miningSurface miningEngineeringEarth surface

The present invention discloses a mining- machine- based slowly inclined thin ore vein mechanized continuous mining method, a middle-section tape transport lane is arranged along an ore body, false inclination uphill is tunneled at intervals of a certain distance; a continuous rib pillar and a top pillar or a bottom pillar are arranged between adjacent back- mining units; accurate mining cutting is started from the lower middle section tape transport lane, a mining machine passes, from the back- mining unit edge position, through the top pillar or the bottom pillar for tunneling left and right false inclination uphill to the upper middle section tape transport lane; back- mining is started from the position of the tape transport lane uphill from the right side, the ore body is back mined by the mining machine to left side uphill, the mining machine is in no load, and descends along the left false inclination uphill to the bottom of the back- mining units, the ore body is back mined by the mining machine from left side uphill position to right side uphill, then the mining machine is in no load, and ascends from the right side uphill to the position near the tape transport lane, the mining is performed in the anti-clockwise direction circulation way, a central position reserved ore pillar is left; ores are loaded onto a belt by a carry-scraper for conveying to a ground surface main ore bin. The conveying is easy, work security is high, back- mining efficiency is high, and production capacity is large.

Owner:CENT SOUTH UNIV +1

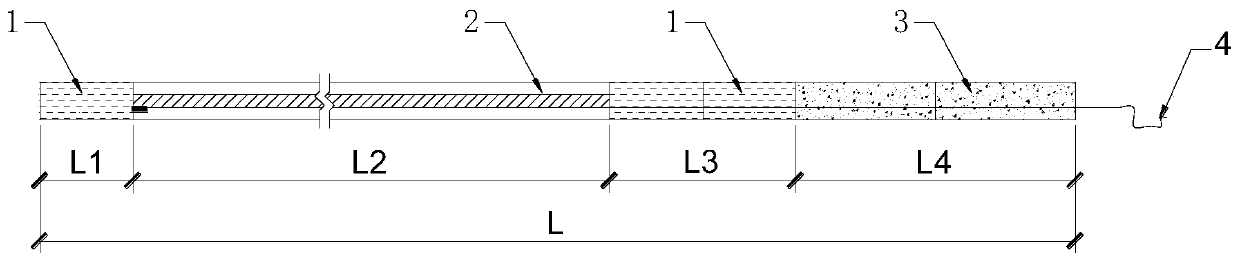

In-hole explosive charging structure for controlling blasting toe rock and construction method of in-hole explosive charging structure

The invention discloses an in-hole explosive charging structure for controlling blasting toe rock. An inertia partition layer is arranged in an explosive charging segment, and the explosive charging segment is partitioned into an upper explosive charging segment and a lower explosive charging segment. A first detonating primer is arranged on the middle and lower portion of the upper explosive charging segment, and a second detonating primer is close to the top end of the lower explosive charging segment. The first detonating primer and the second detonating primer are connected to a blasting network through leg wires correspondingly. According to the in-hole explosive charging structure, explosives filling a blast hole are divided into the upper explosive charging segment and the lower explosive charging segment through the inertia partition layer; the explosives located above the inertia partition layer are used for forming an ideal blasting crater so that the crushing and casting effects of a rock mass can be guaranteed; the explosives located below the inertia partition layer are used for enhancing crushing of a hole bottom rock mass so that the blasting toe rock can be decreased; the adjustment and control effect, on transmission of blasting energy, of the detonating primers is utilized fully, and optimized utilization of the explosive energy is achieved; and the dual purposes that the ideal blasting crater is formed to guarantee the crushing and casting effects, and the crushing of the hole bottom rock mass is enhanced to decrease the blasting toe rock can be achieved.

Owner:CHANGAN UNIV

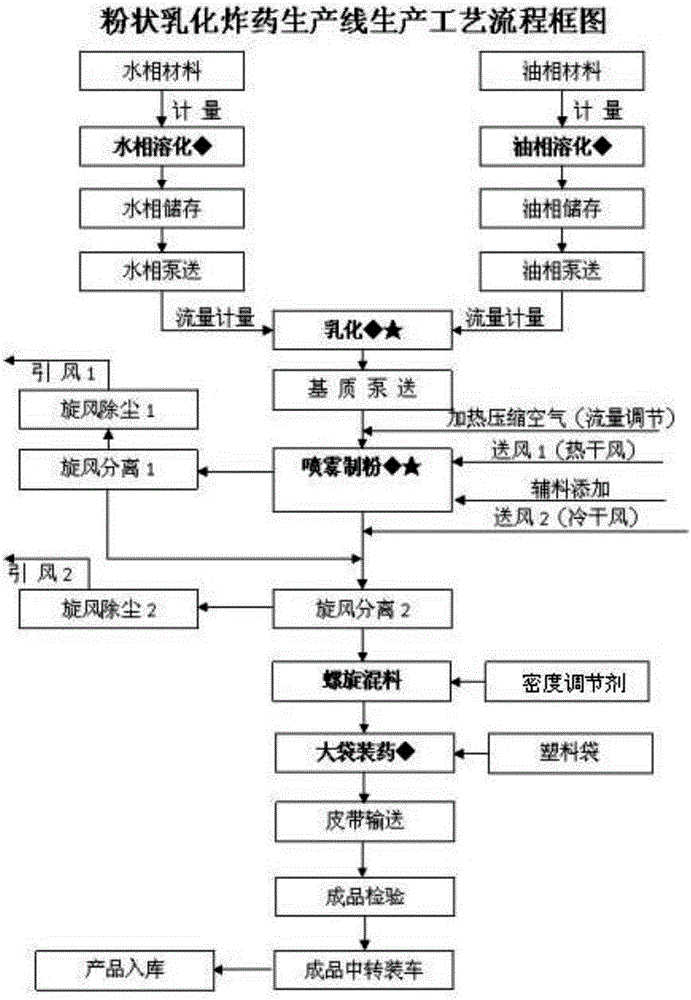

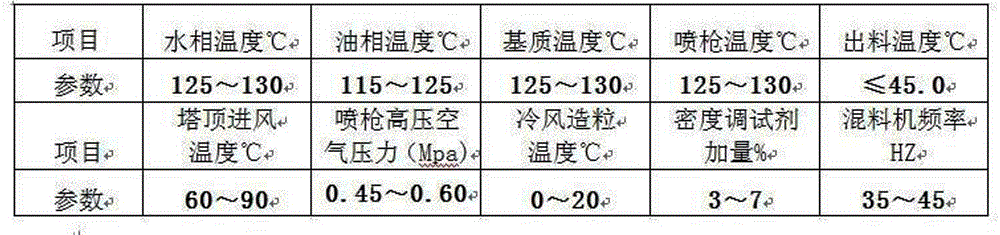

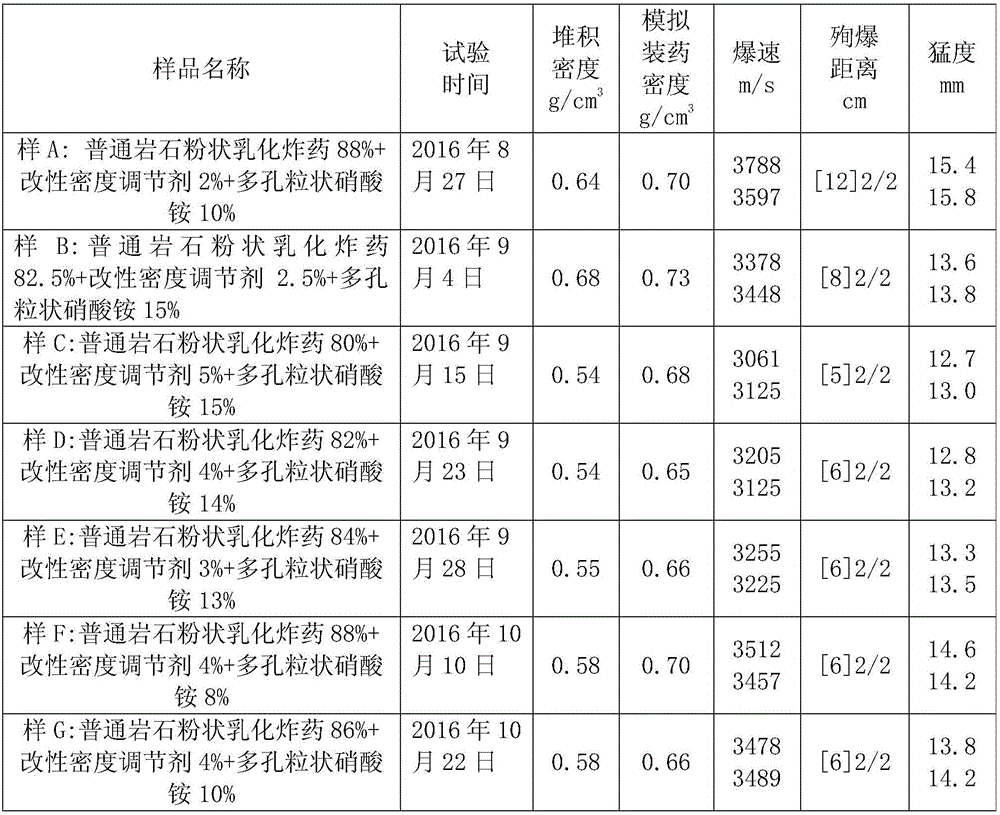

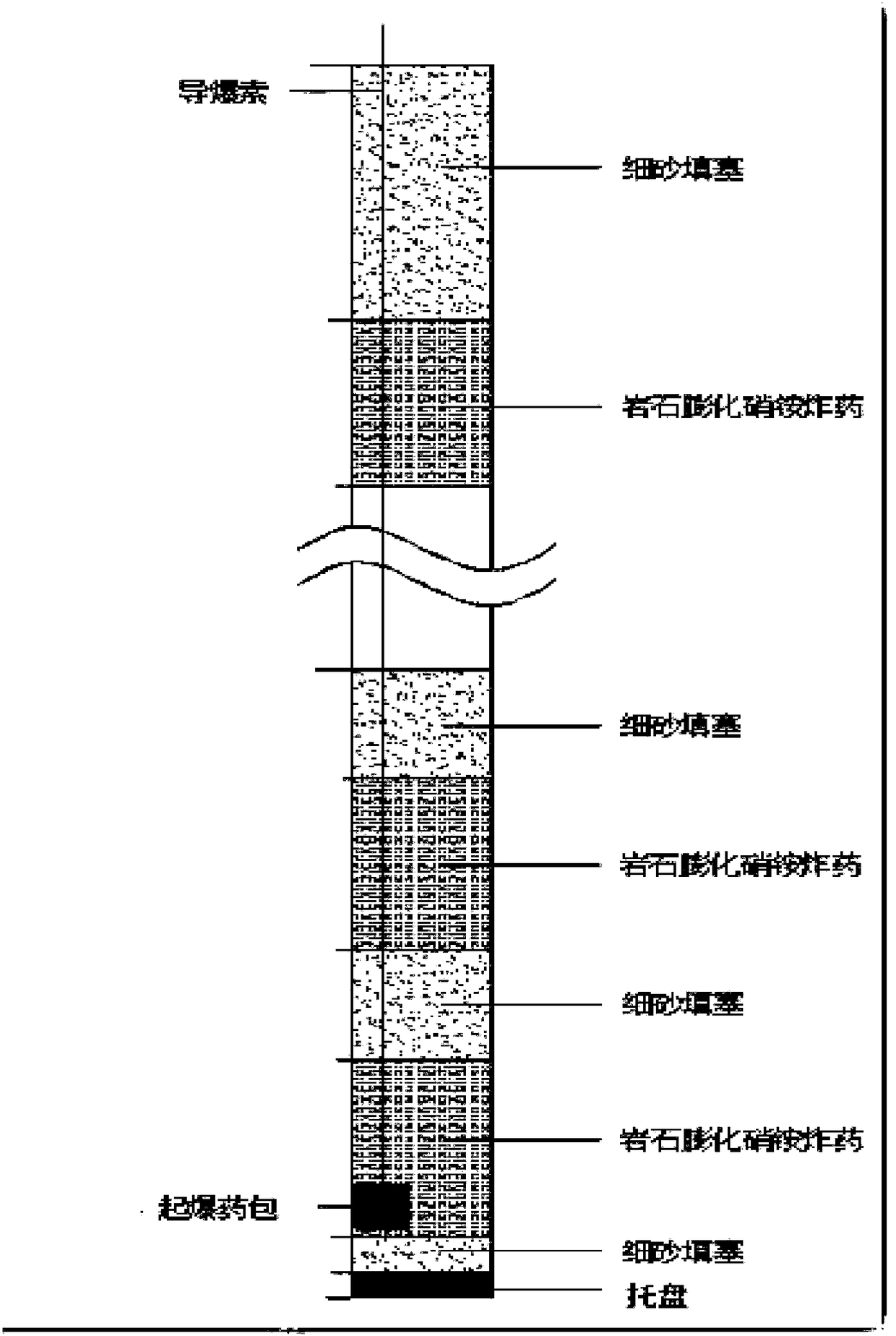

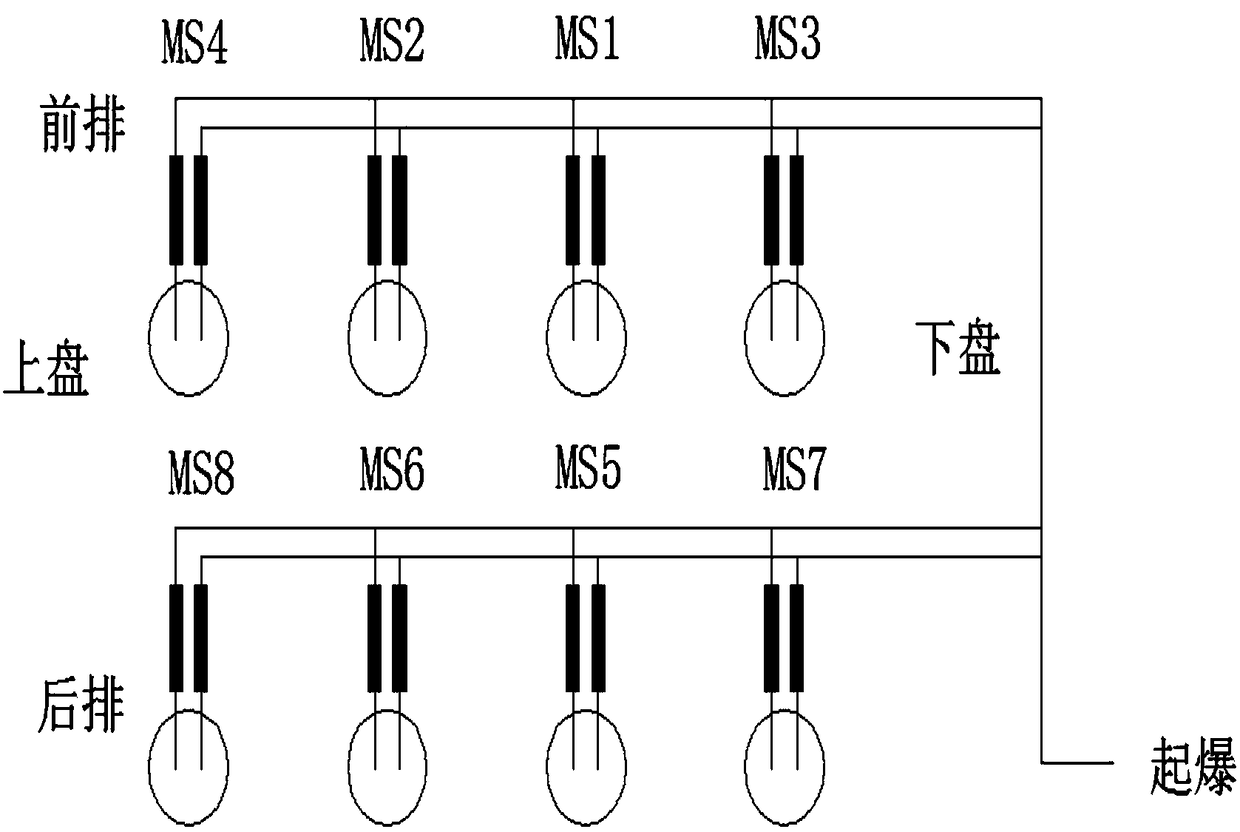

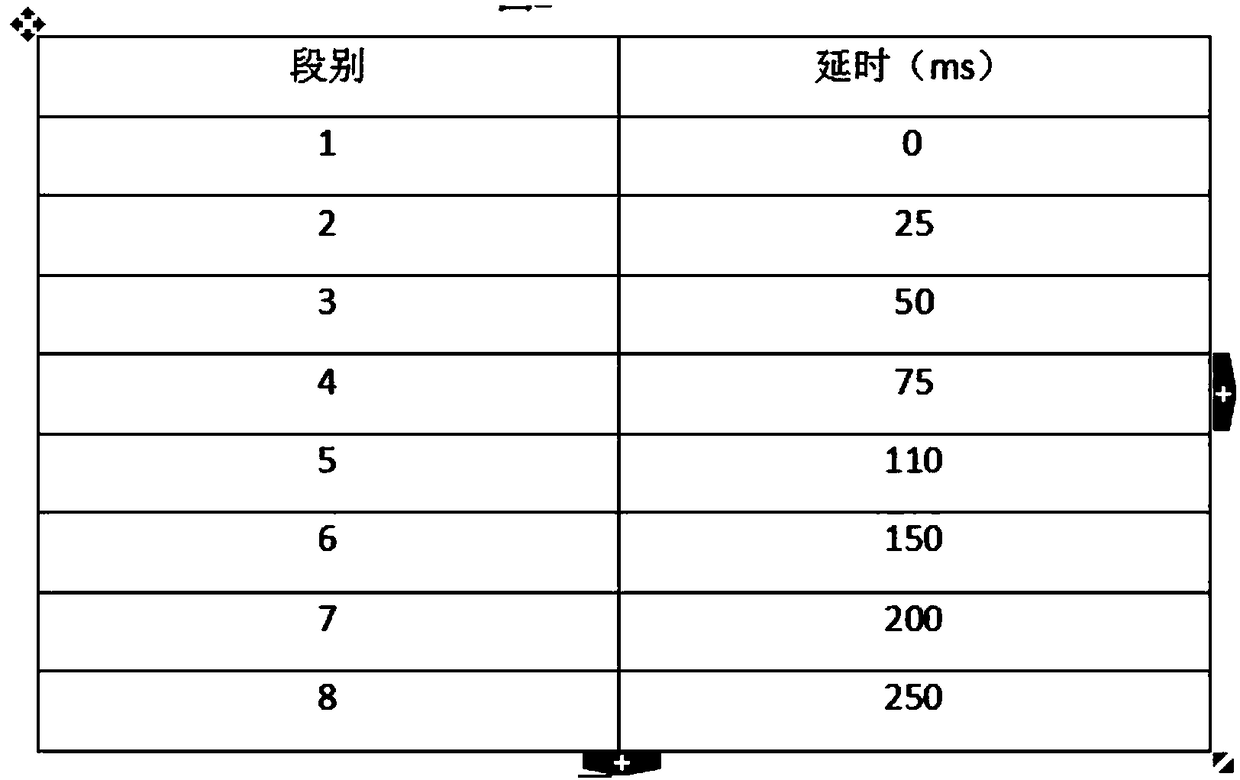

Low-density rock powder emulsion explosive and method thereof

ActiveCN106631641AReduce sensitivityReduce charge per meterExplosive working-up apparatusNon-explosive/non-thermic compositionsPrillGranularity

The invention discloses a low-density rock powder emulsion explosive and a method thereof, and belongs to the field of industrial mining. The explosive is prepared from 80%-90% of normal rock powder emulsion explosive, 3%-7% of modified density conditioning agent and 7%-15% of porous granulated ammonium nitrate; the normal rock powder emulsion explosive is prepared form 80%-92% of ammonium nitrate, 3%-5% of water and 5%-6% of composite fuel oil; the modified density conditioning agent is prepared from 80%-85% of fine perlite and15%-20% of diesel; the bulk density of the porous granulated ammonium nitrate is 0.73-0.86 g / cm<3>, as for the granularity, the content of grains of the diameter of 0.5-2.5 mm is at least larger than 90%. According to the low-density rock powder emulsion explosive and the method thereof, the problems of high boulder yield after the blasting using of the powder emulsion explosive, massive emission load of poisonous gases after the explosion, high product sensitivity, high security risk during production and usage and the like are solved, meanwhile the problem of half-explosion of water blasthole products of partial users when using powder explosive products of expanded ammonium nitrate explosive, modified ammonium nitrate fuel oil mixture and the like is thoroughly solved. The low-density rock powder emulsion explosive can thoroughly replace current powder explosive products of the normal powder emulsion explosive, expanded ammonium nitrate explosive, modified ammonium nitrate fuel oil mixture and the like at home.

Owner:HENAN HUATONG CHEMICAL CO LTD

Large-section-height multi-row micro-difference extrusion blasting method

The invention discloses a large-section-height multi-row micro-difference extrusion blasting method. A vertical deep hole is adopted as a blast hole, hole distribution is conducted according to the principle that explosive is evenly distributed in a to-be-blasted rock body, and the hole distribution manner is a rectangular hole distribution manner. Through determination on blasting parameters, anexplosive filling structure is designed, the multi-hole rowed hole distribution manner is selected on the vertical plane, a deflection center point is selected as a blasting point, and micro-difference sequential blasting is adopted between the adjacent holes and is adopted in holes between rows. The large-section-height multi-row micro-difference extrusion blasting method has the beneficial effects that a favorable free face is created for subsequent ore body rock blasting, and the rock clamping action is lowered; in the rock block motion process after rock body crushing, rock blocks are mutually in collision, mutual rubbing happens, impact pressure and shearing force are generated, the rock blocks are crushed again, a rock block diameter reducing blasting method is provided, the blastedrock body crushing degree can be improved, the blasting vibration effect is reduced, harm to ground buildings is lowered, and mine safety is maintained.

Owner:临沂会宝岭铁矿有限公司

Small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method

InactiveCN111595214ABig room for expansionIncrease free surfaceBlasting cartridgesBlastingTEX-explosiveStructural engineering

The invention discloses a small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method, which comprises the following steps of: 1) drilling; 2) charging:enabling central cutting undermine holes to use a decked charge structure and the small-hole reinforced fracturing grain, filling a second-decked small-hole reinforced fracturing grain into the bottom of each central cutting undermine hole, then, immediately filling tap-hole clay of which the length is 400-500 mm, then, filling a first-decked small-hole reinforced fracturing grain, finally, blocking by the tap-hole clay, filling a second-stage single-surface hoop slit grain into wedge-shaped cutting undermine holes, blocking by the tap-hole clay, filling third-decked common explosive in auxiliary holes, blocking by the tap-hole clay, filling four-decked common explosive in caving holes, blocking by the tap-hole clay, filling five-decked common explosive in surrounding holes, and blockingby the tap-hole clay; and 3) blasting. According to the method disclosed by the invention, the volume of a cutting undermine cavity can be enlarged, a free surface is increased, a surrounding rock clamping function is lowered, and a blast hole use ratio and an explosive energy use ratio are improved.

Owner:ANHUI UNIV OF SCI & TECH +1

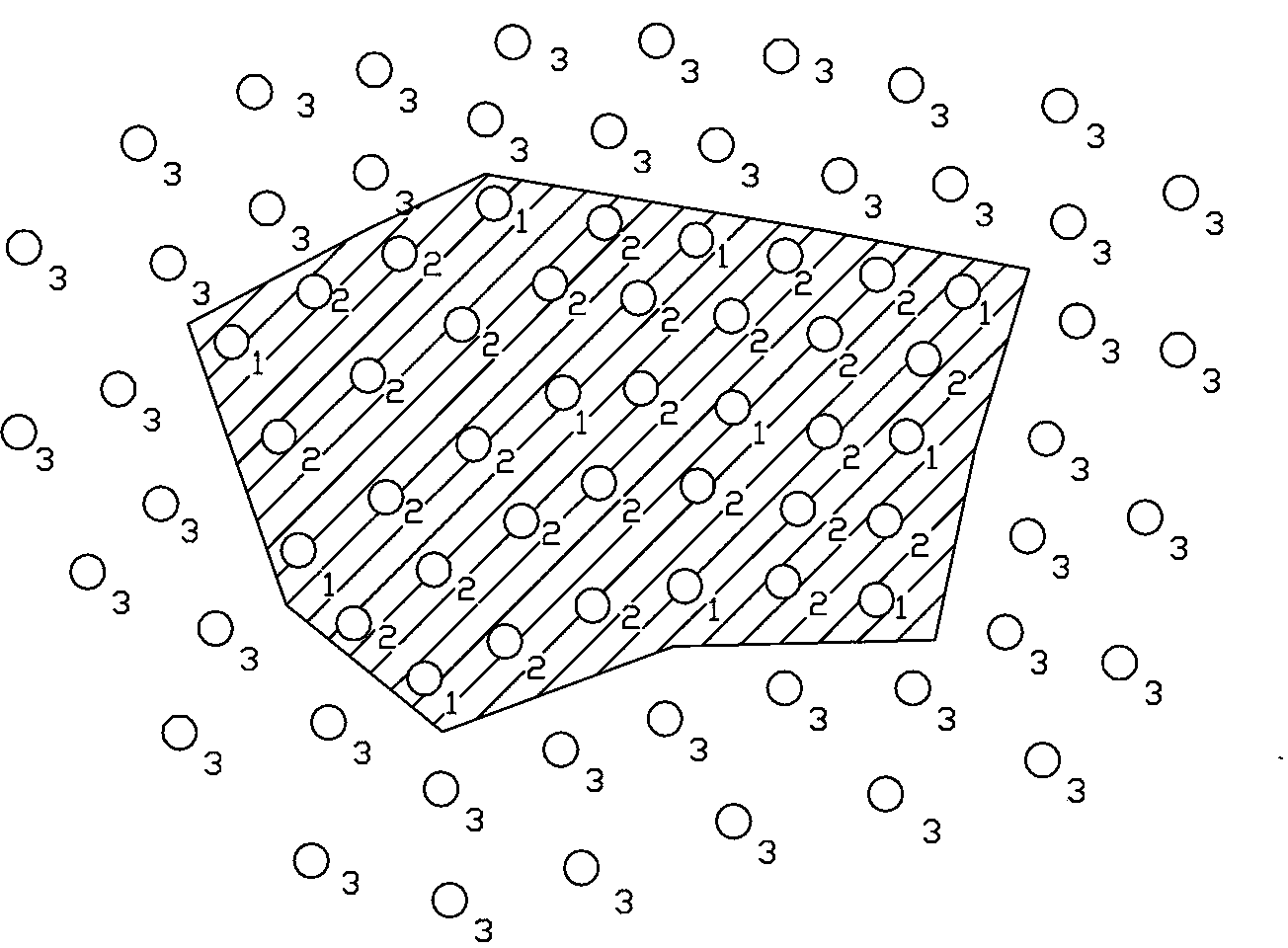

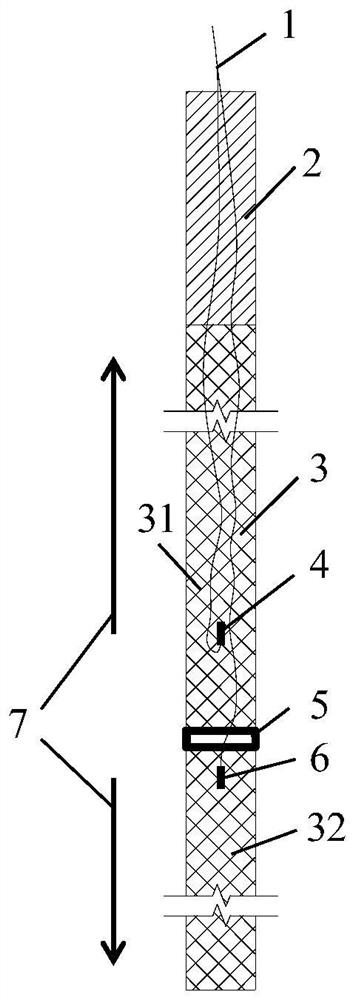

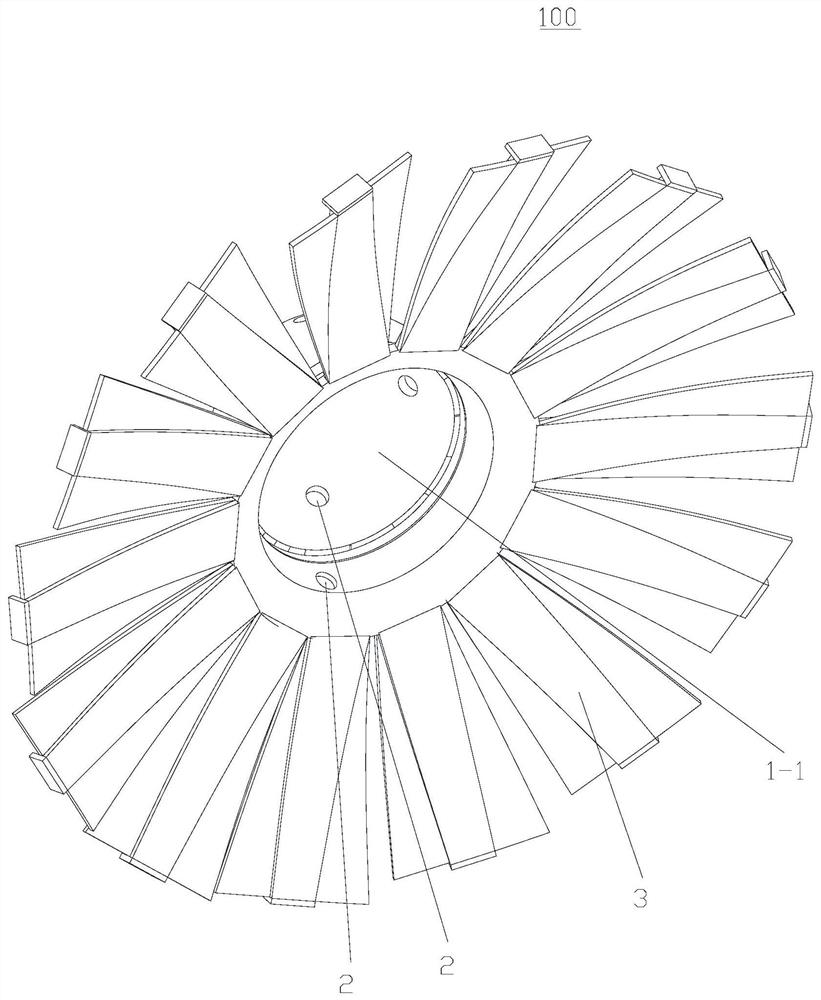

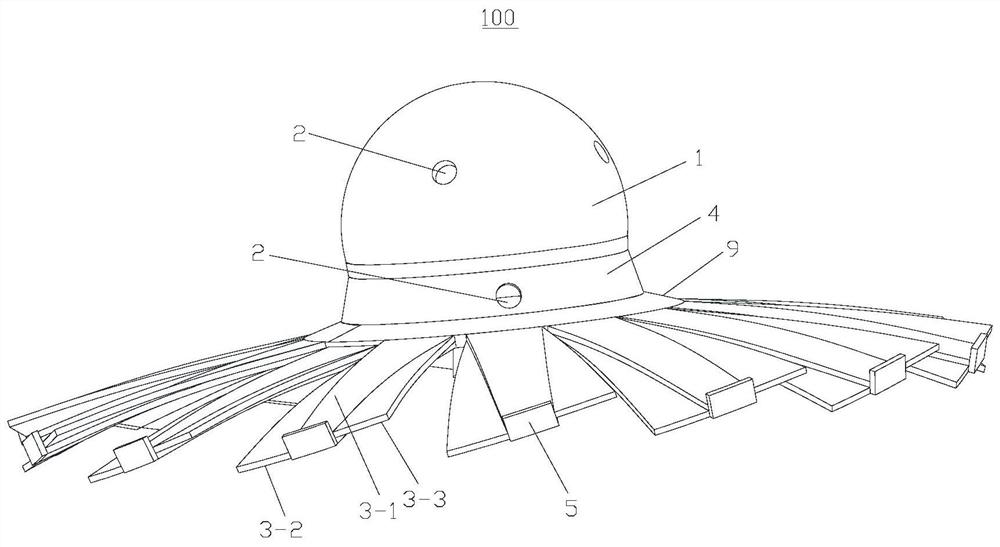

Downhole upward blast hole blanking plug and using method thereof

PendingCN113982529APrevent movementReduce wasteBlastingSealing/packingDetonationStructural engineering

The invention discloses a downhole upward blast hole blanking plug comprising a plugging head, a lead hole is formed in the plugging head, a plurality of elastic blades are arranged on the plugging head in the circumferential direction, and each elastic blade comprises a middle part, a first connecting part and a second connecting part; the first connecting part is thinner than the middle part and is arranged close to the bottom surface of the middle part, and the second connecting part is thinner than the middle part and is arranged close to the top surface of the middle part; the first connecting part of one adjacent elastic blade is opposite to the second connecting part of the other adjacent elastic blade; the end, away from the plug, of the elastic blade is inclined relative to the plug, and the side, connected with the middle part, of the second connecting part is lower than the other side; in every two adjacent elastic blades, the first connecting part of one elastic blade and the second connecting part of the other elastic blade can be overlapped through extrusion. The blanking plug can be effectively prevented from moving, and the reaction time of detonation gas can be effectively prolonged.

Owner:湖北三鑫金铜股份有限公司

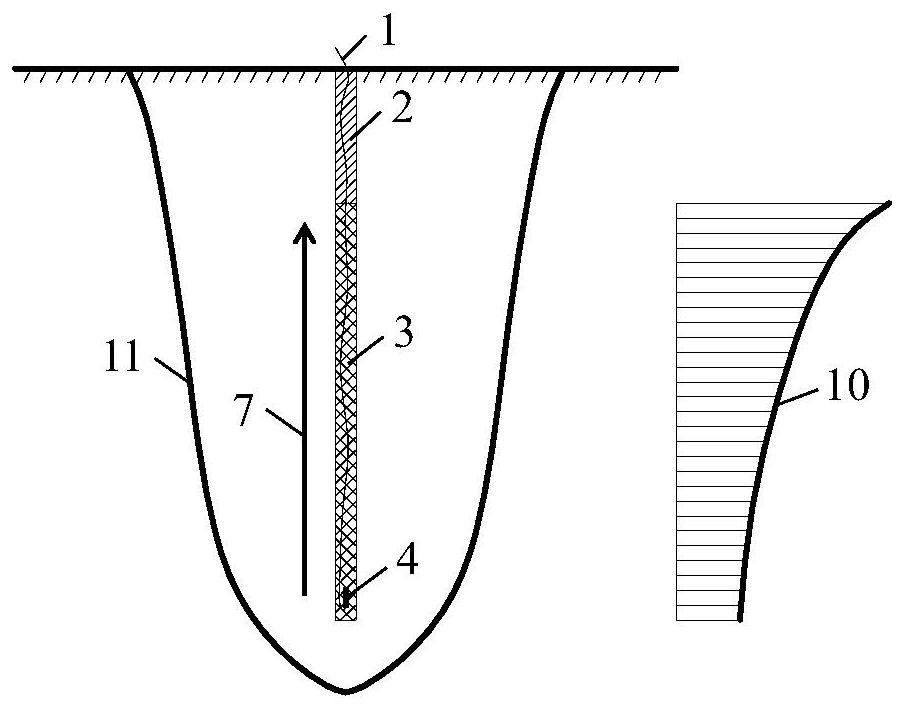

Large-diameter offshore wind power rock-socketed single pile excavating method

The invention discloses a large-diameter offshore wind power rock-socketed single pile excavating method. The large-diameter offshore wind power rock-socketed single pile excavating method comprises the following steps that immersion of a pilot shaft pile casing is carried out; a petroleum drilling machine is adopted for excavating a pilot shaft through the pilot shaft pile casing; a geological drill is adopted for drilling two to three rings of main blast holes and one ring of outline blast holes, and a casing off hole is lowered down; a dedicated CO2 phase change expansion crack pipe is mounted, the interiors of the main blast holes are mounted in a segmented manner, and the interiors of the outline blast holes are continuously mounted; a blast network is connected; a rock-socketed single pile steel pile casing is lowered down; mud and weathering sand between the pilot shaft pile casing and the rock-socketed single pile steel pile casing are sucked away; the pilot shaft pile casing and a drilling casing pile are pulled out; underwater slag cleaning is carried out; and concrete is poured to form a rock-socketed single pile foundation. Pilot shaft mechanical excavating and CO2 expansion rock breaking and expanded excavating are combined, the technical problem that a 2-4mm-diameter petroleum drilling machine and a common geological drill are used for finishing excavating of an offshore rock-socketed single pile foundation with the diameter being 8 to 10 m and above can be solved, the expansion pressure generated by a CO2 phase change is controllable, the explosion impact waves and the vibration speed are small, and the method is economic and environment-friendly.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com