Medium-length hole blasting technology used in semi-coal-rock roadway

A technology for deep hole blasting and semi-coal rock, which is applied to the technical field of deep hole blasting in semi-coal rock roadways, and can solve the problems of low utilization rate of blast holes, large consumption of explosives and detonators, and slow blasting progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

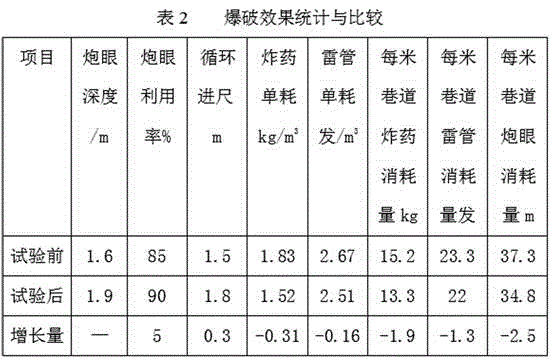

[0025] The specific implementation of the present invention is as follows.

[0026] 1. Project overview

[0027] Lane 5705 is a horizontal straight lane with a total length of 1360m. The section shape of the roadway is rectangular. 18×2.0m high-strength bolt, net width 3.2m, net height 2.35m, net sectional area 8.575m 2 , the excavation width is 3.5m, the excavation height is 2.5m, and the excavation area is 8.75m 2 . During the application test of deep hole blasting in roadway excavation, the rock is mainly coarse sandstone, which has good integrity and few cracks. The measured rock's Platts coefficient is f=10, which is relatively hard and difficult to blast. There is no water spraying during the excavation of this roadway.

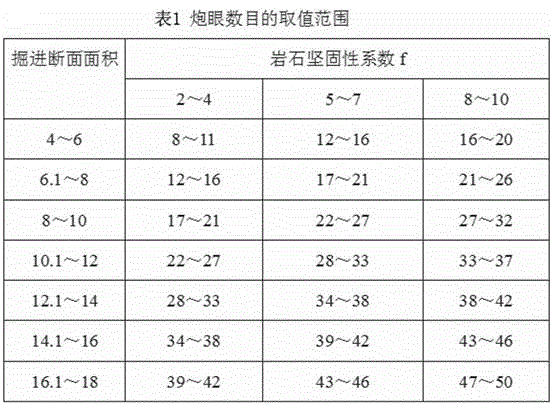

[0028] 2. Blasting parameter design

[0029] According to the site conditions, it is determined through research and demonstration that the existing construction equipment and blasting equipment will still be used. That is, the 7655-type air-leg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com