Patents

Literature

36results about How to "Increase free surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

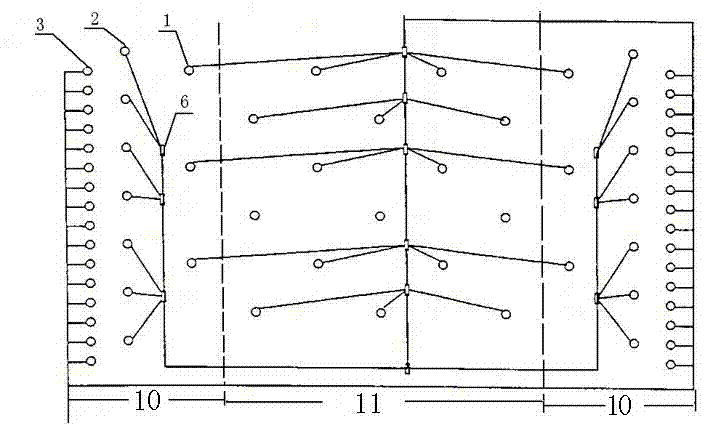

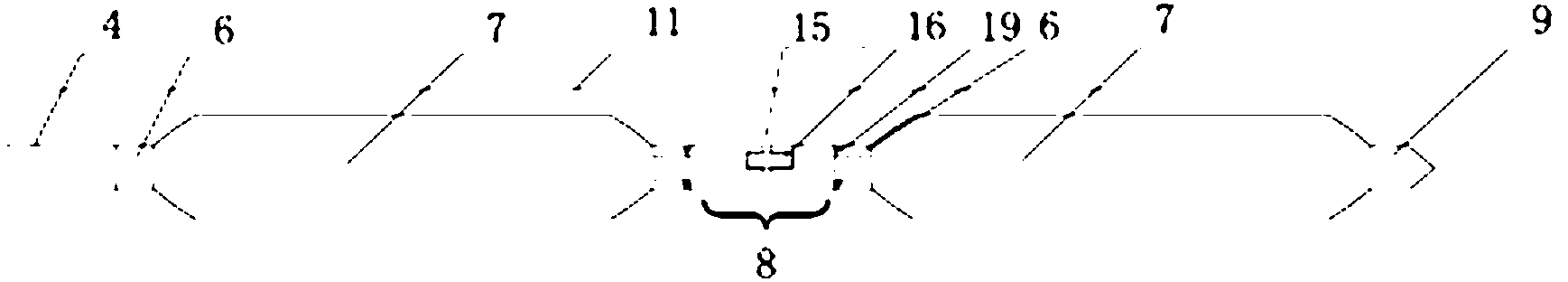

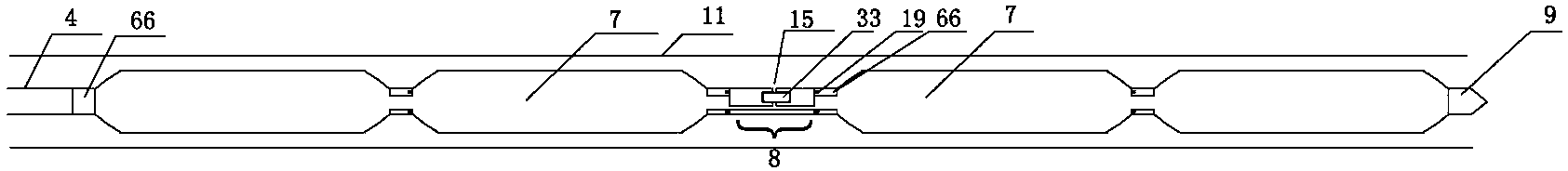

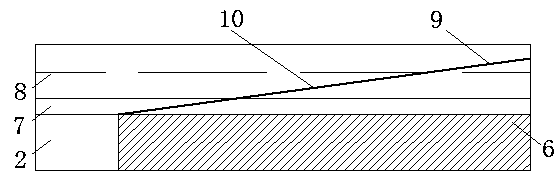

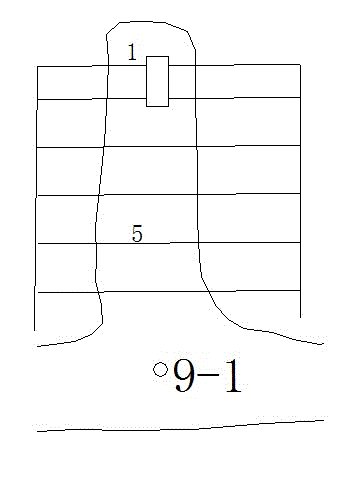

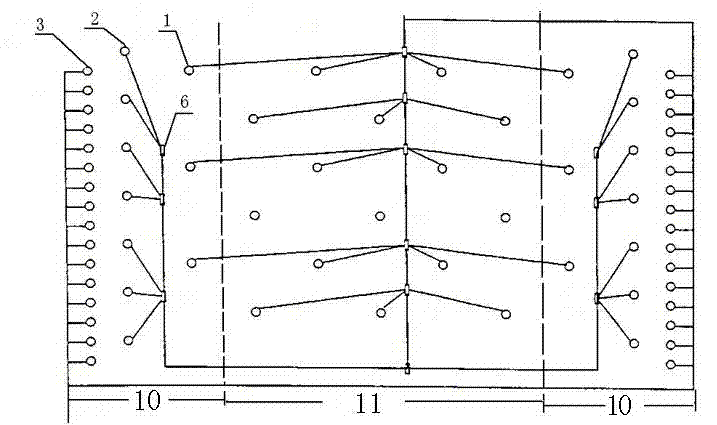

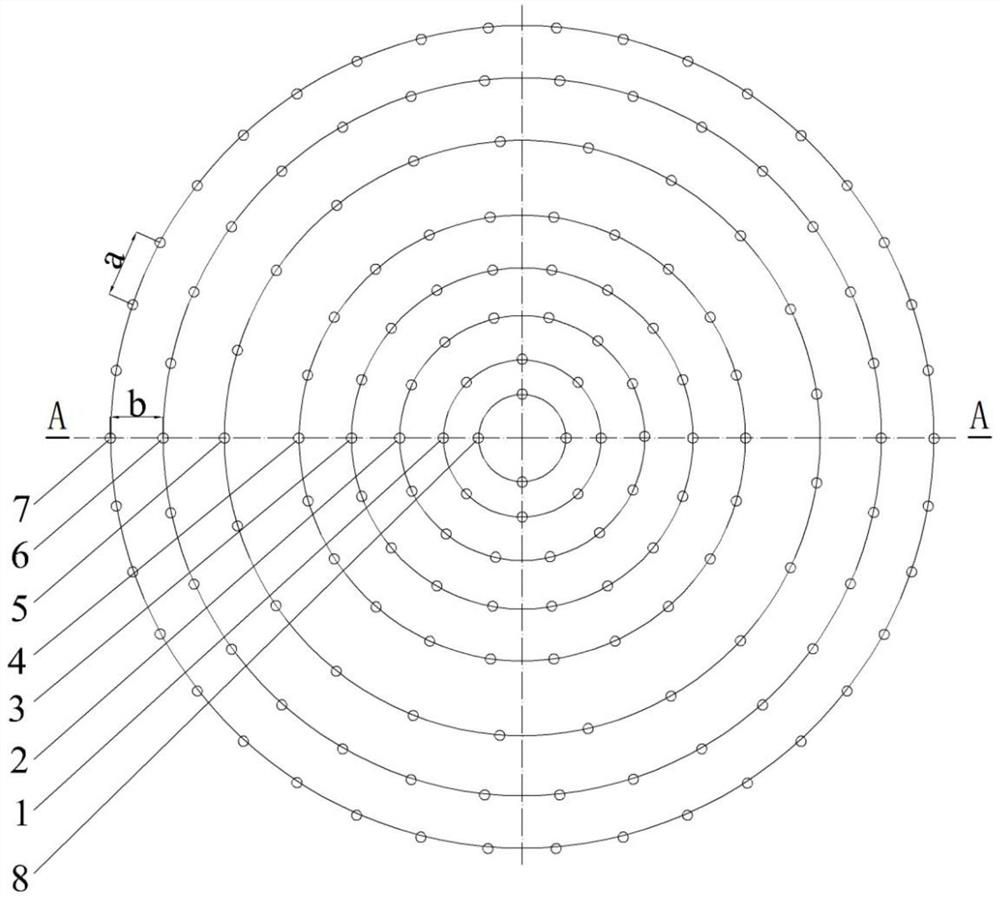

Multi-row micro-differential roadbed deep hole blasting construction method

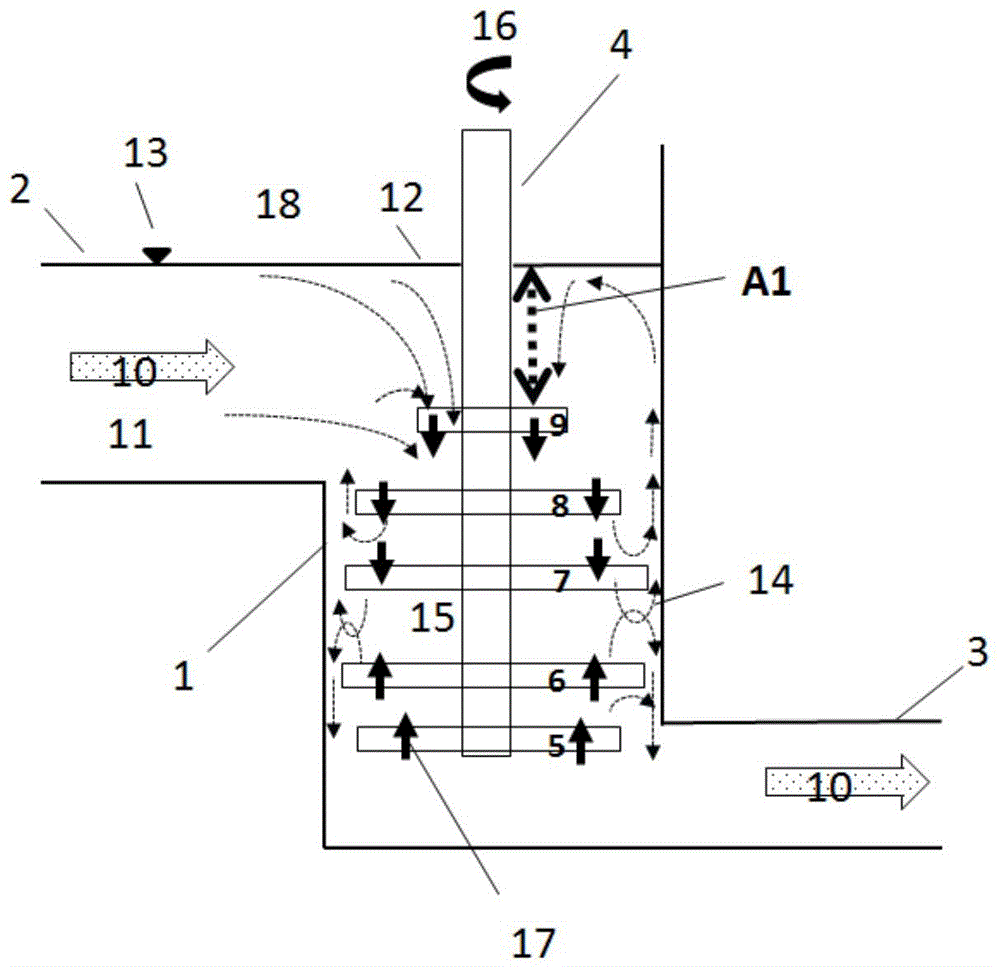

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

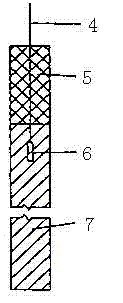

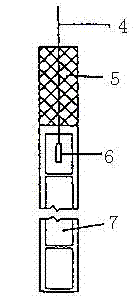

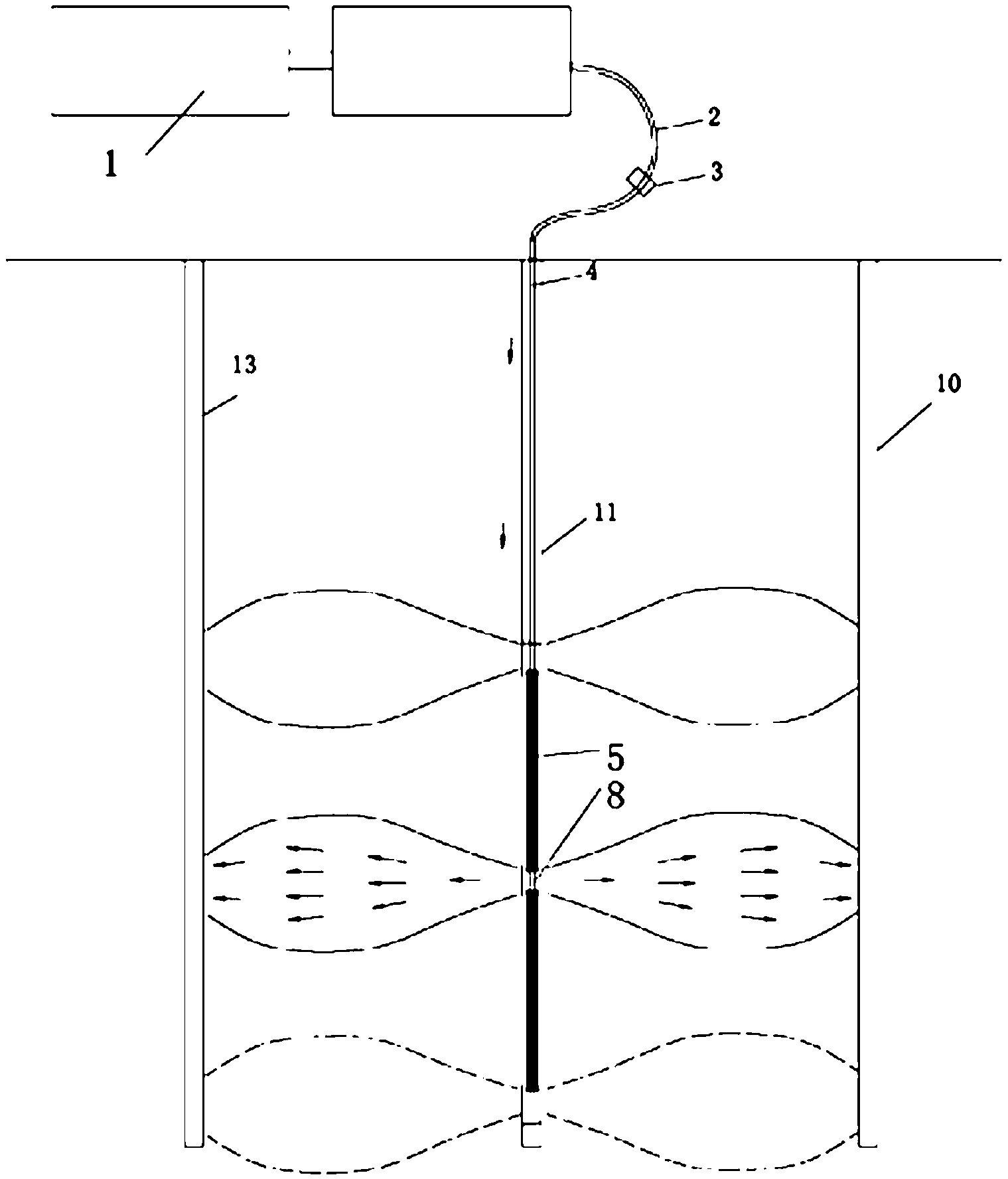

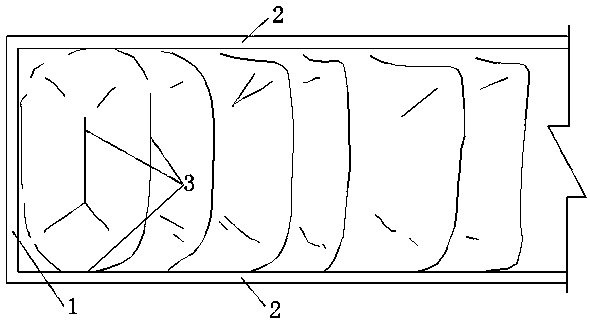

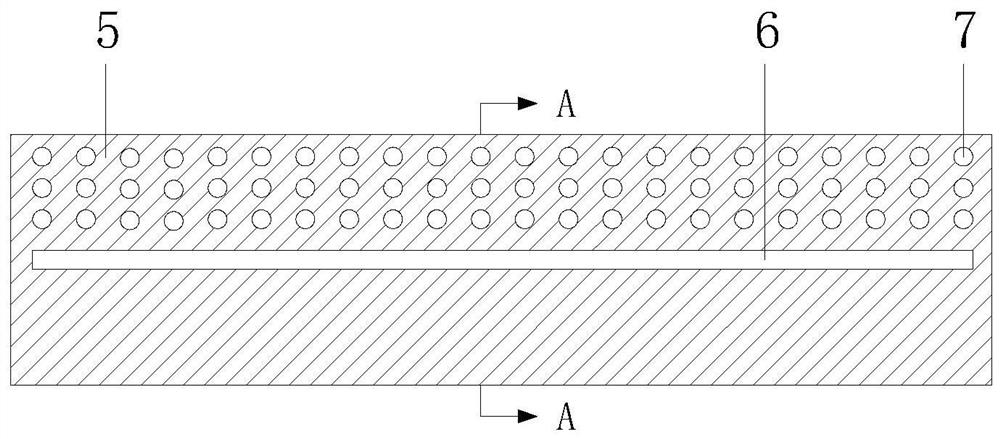

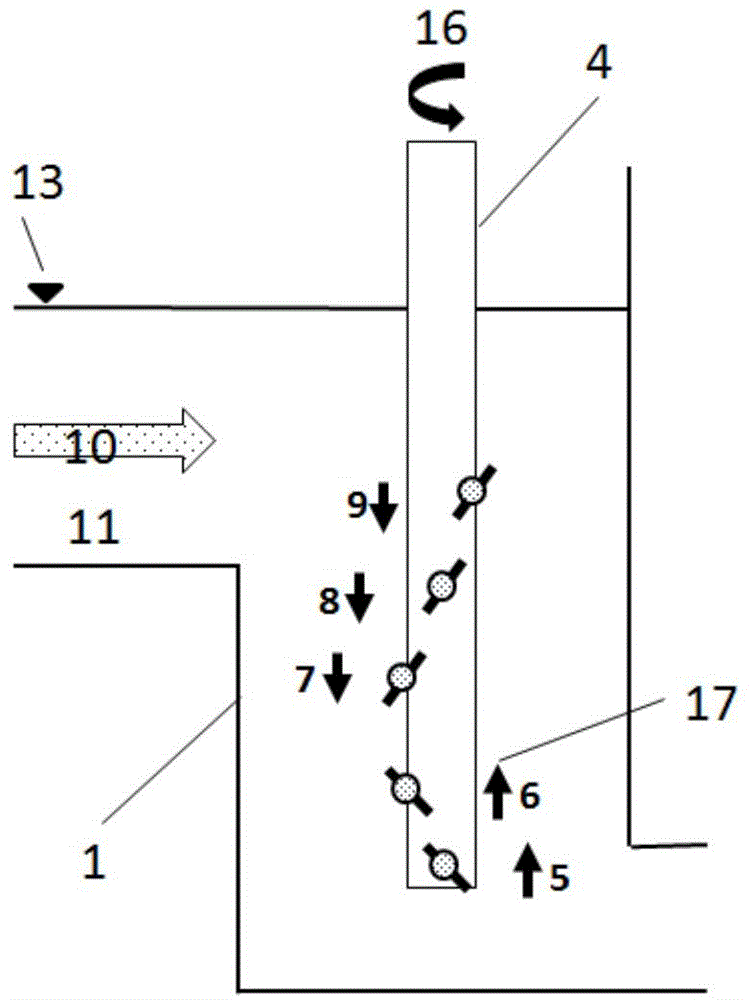

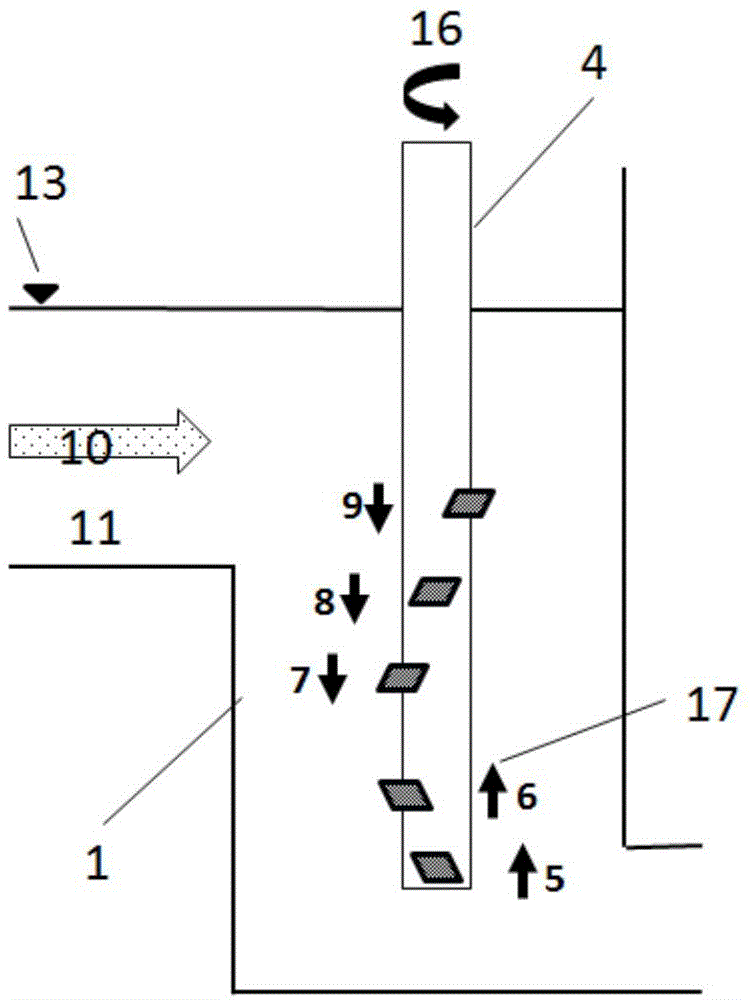

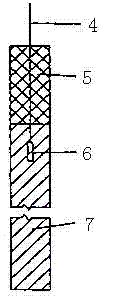

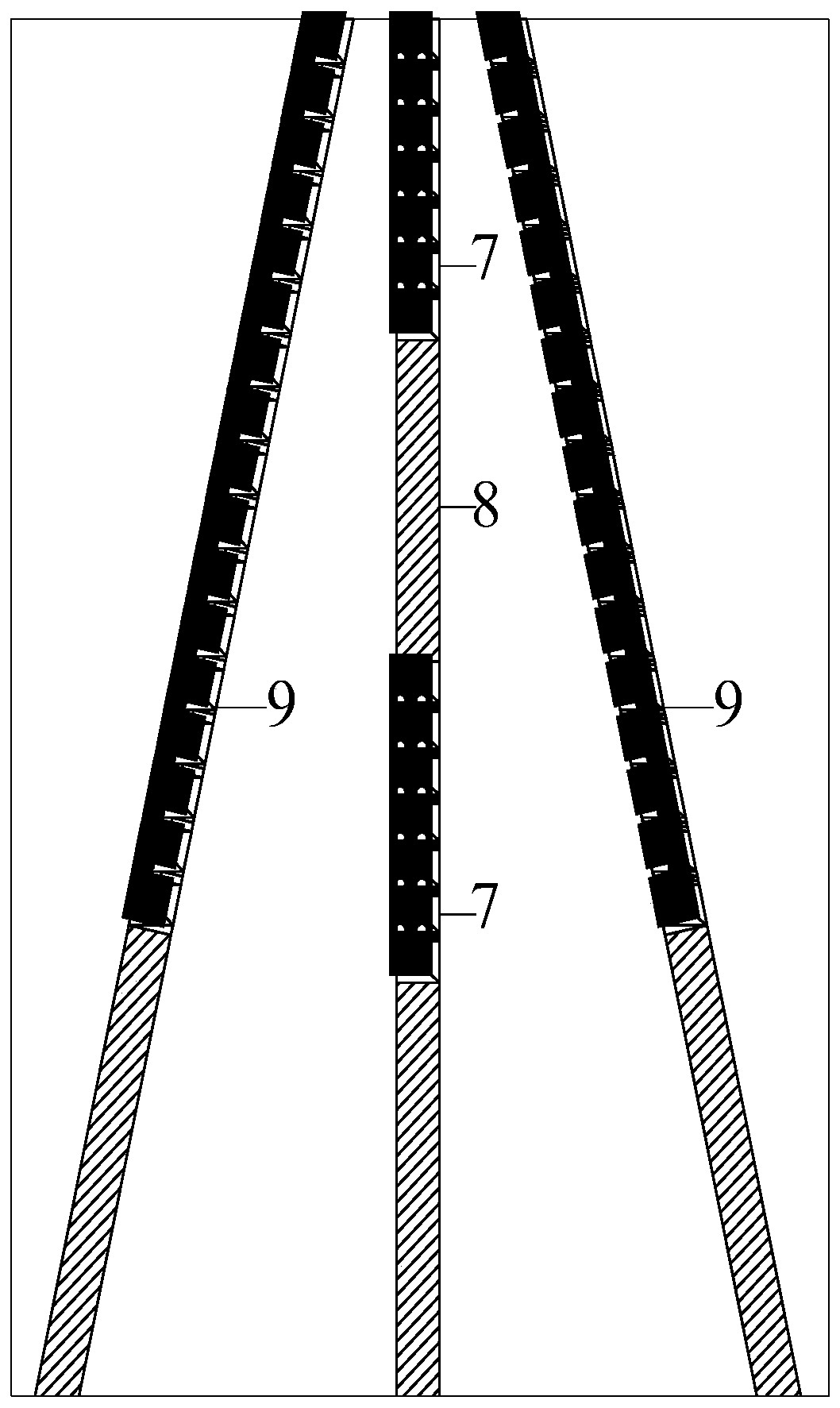

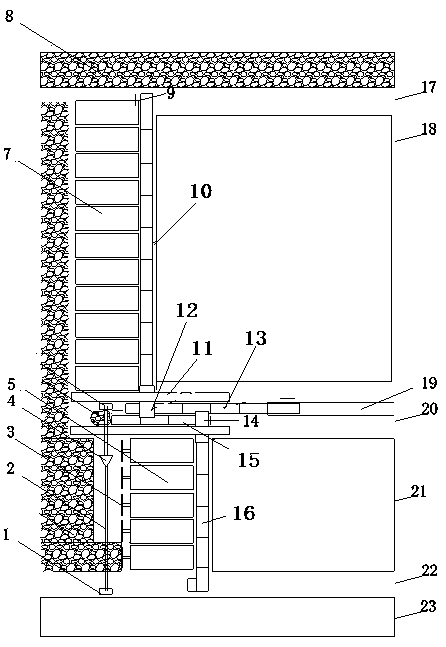

Segmental hydraulic fracturing coal seam pressure releasing device and method

InactiveCN102704905AFull pressure reliefLarge range of pressure reliefFluid removalGas removalCoal dustHydraulic pump

The invention relates to a segmental hydraulic fracturing coal seam pressure releasing device. A high pressure hydraulic pump station is connected to a segmental hydraulic fracturing hole packer through a high pressure hose and a steel push rod; and after the hole packer is fed into a fracturing hole by the push rod, water flows from the high pressure hydraulic pump station to the segmental hydraulic fracturing hole packer through the high pressure hose, flows through a pressure reducing mechanism and is injected into coal for hydraulic fracturing. Water flow also makes hole packing capsules on two sides of a water outlet swell to achieve a sealing effect, and a fracturing range is controlled between the two capsules. Due to the action of the pressure reducing mechanism, the pressure of the hole packing capsules is always greater than that of the water outlet to realize self sealing. During field implementation, a seam hole can be divided into a plurality of segments and is subjected to fracturing segment by segment; meanwhile, a control hole parallel to the fracturing hole is constructed to increase a free face and can drain, bring out coal dust and achieve a hydraulic loosening effect, and the coal between the hydraulic fracturing hole and the control hole is penetrated through pressure finally, so that the coal seam releases pressure fully, the pre-extraction time of the coal seam is shortened and the extraction rate is improved.

Owner:CCTEG SHENYANG RES INST

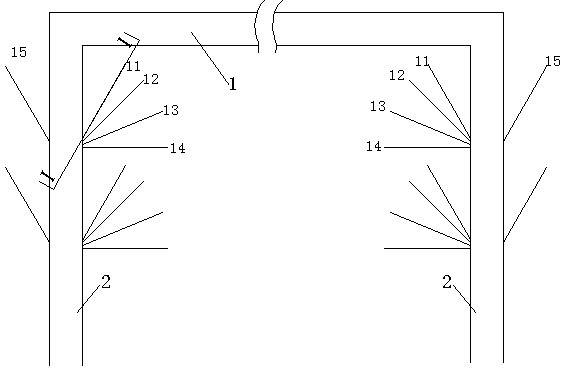

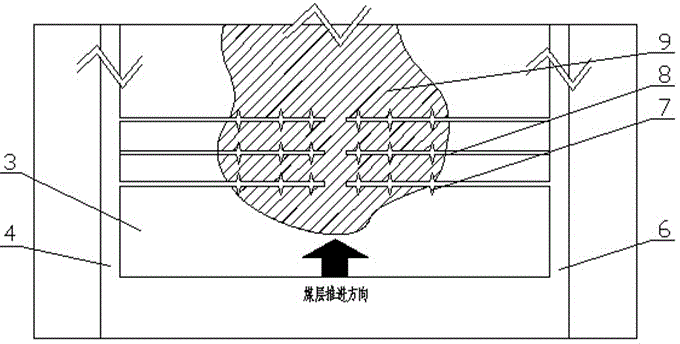

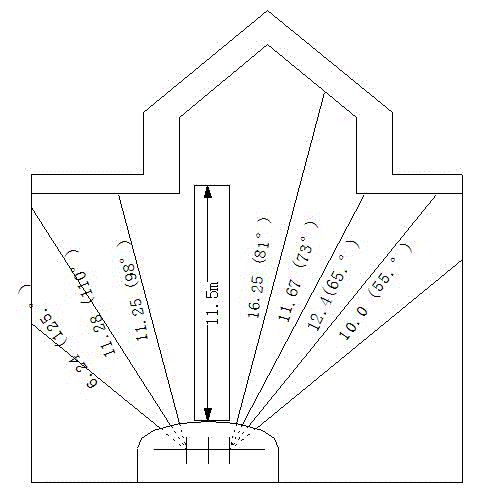

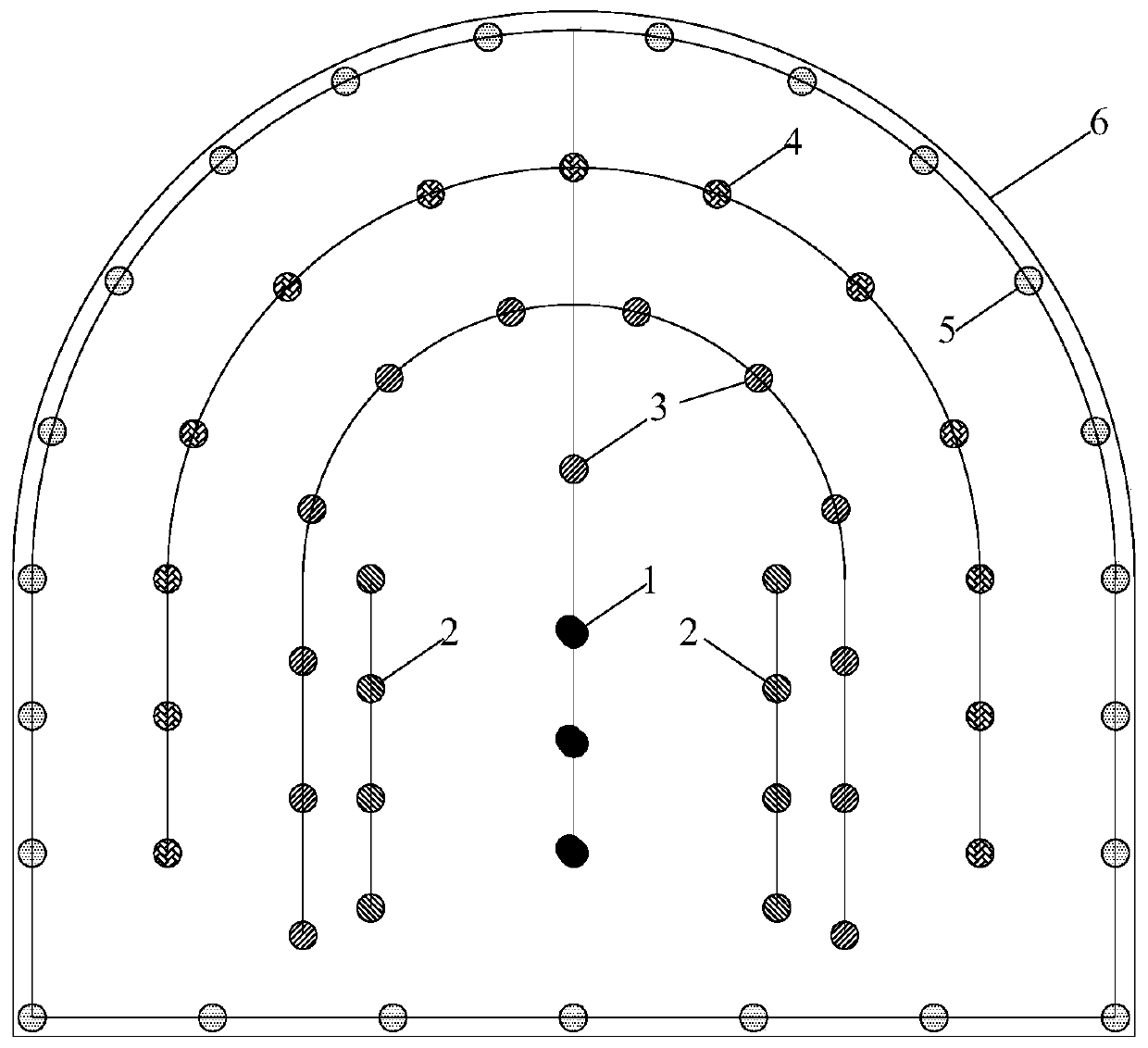

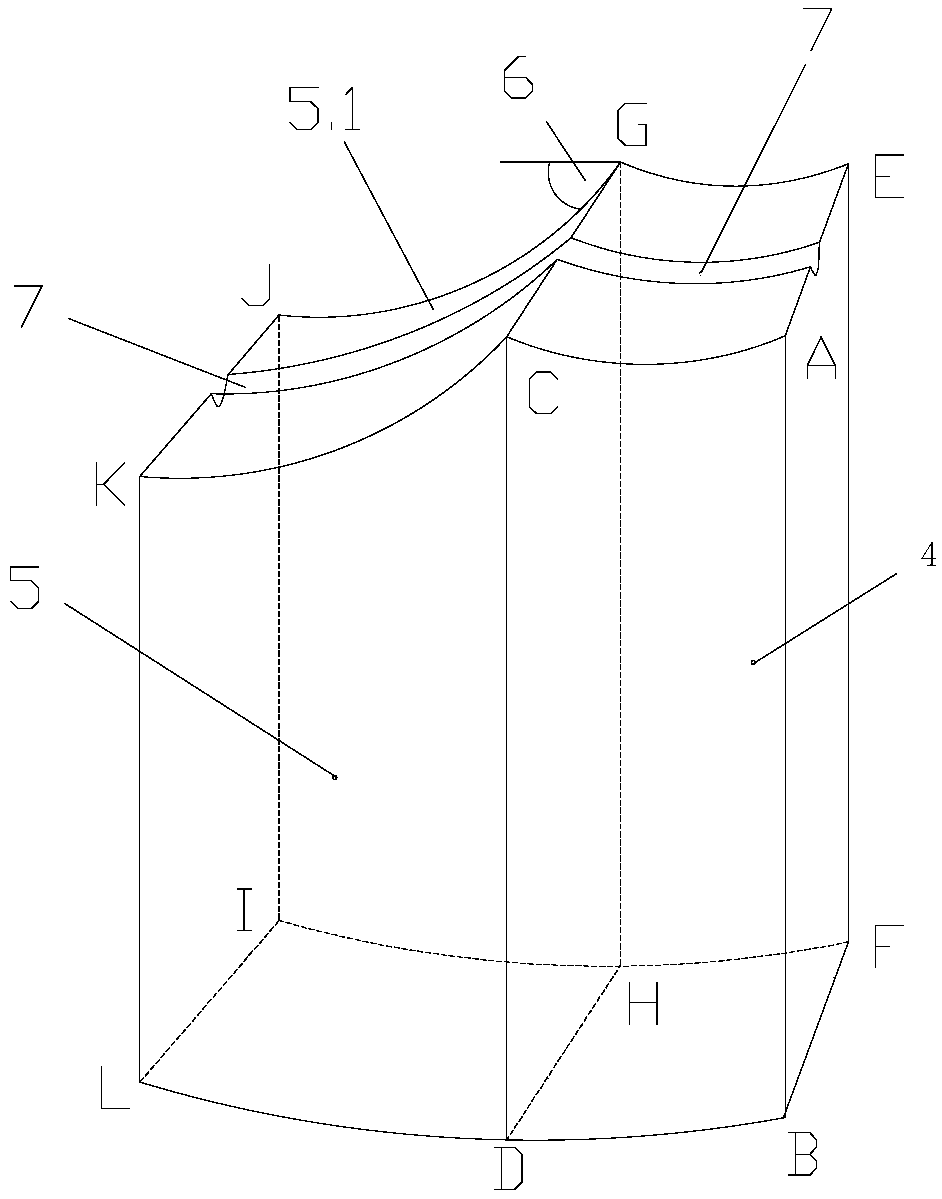

Method for hard roof advanced precracking control caving in coal mine stope

InactiveCN108643910AScientific controlEasy to operateUnderground miningSurface miningCoal miningGeomorphology

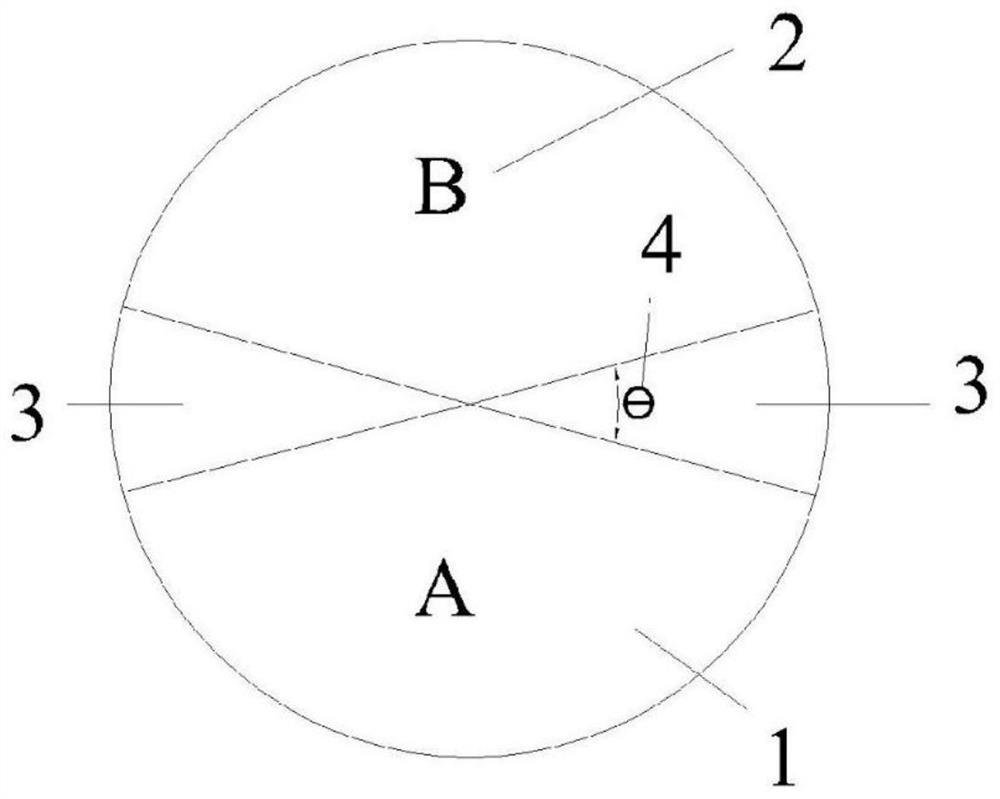

The invention discloses a method for hard roof advanced precracking control caving in a coal mine stope, and belongs to the technical field of coal mining, and particularly relates to a hard roof advanced precracking control caving method for determining parameters of borehole layout, such as, the pore opening positions, the depth of drilling holes, the angle of the drilling holes and numbers of the drilling holes of hard roof advanced precracking drilling in the coal mine stope and calculating the explosive payload of the drilling holes. According to the characteristics of hard roof fracture,five blast holes in a fan shape are formed to form a fixed angle; the middle portion and the end of the a working face which are most difficult to break of the hard roof can be effectively pre-cracked, so that the roof can collapse as required; based on the characteristics of blasting, the blasting sequence of the blast holes from the middle portion of a cutting hole to both ends can maximize thefree surface of the blasting and reduce the explosive payload, and the operation is convenient; and a calculation formula of the explosive payload of the hard roof of preceding loosening blasting indeep hole is given quantitatively to enable the control of hard roof to be more scientific, quantitative, accurate and simple.

Owner:TAIYUAN UNIV OF TECH

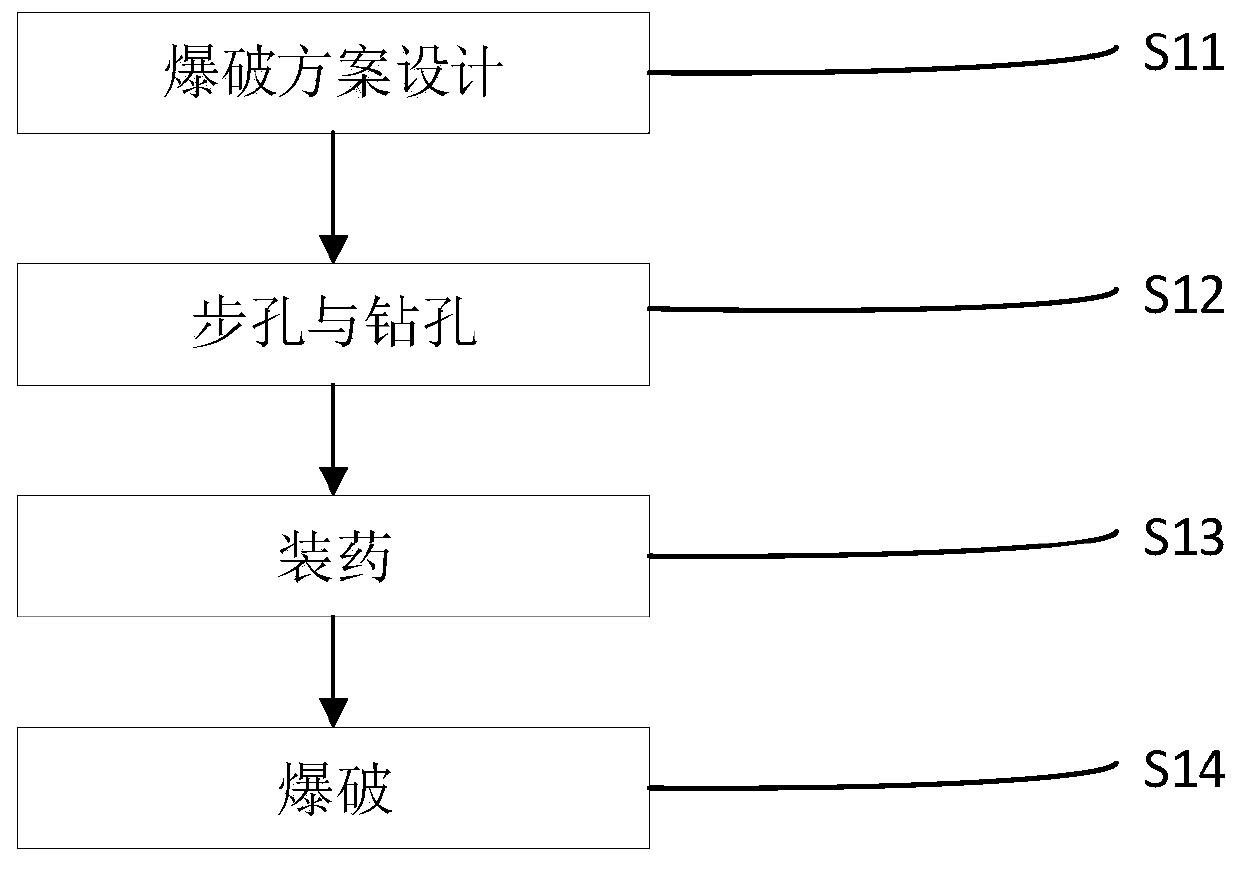

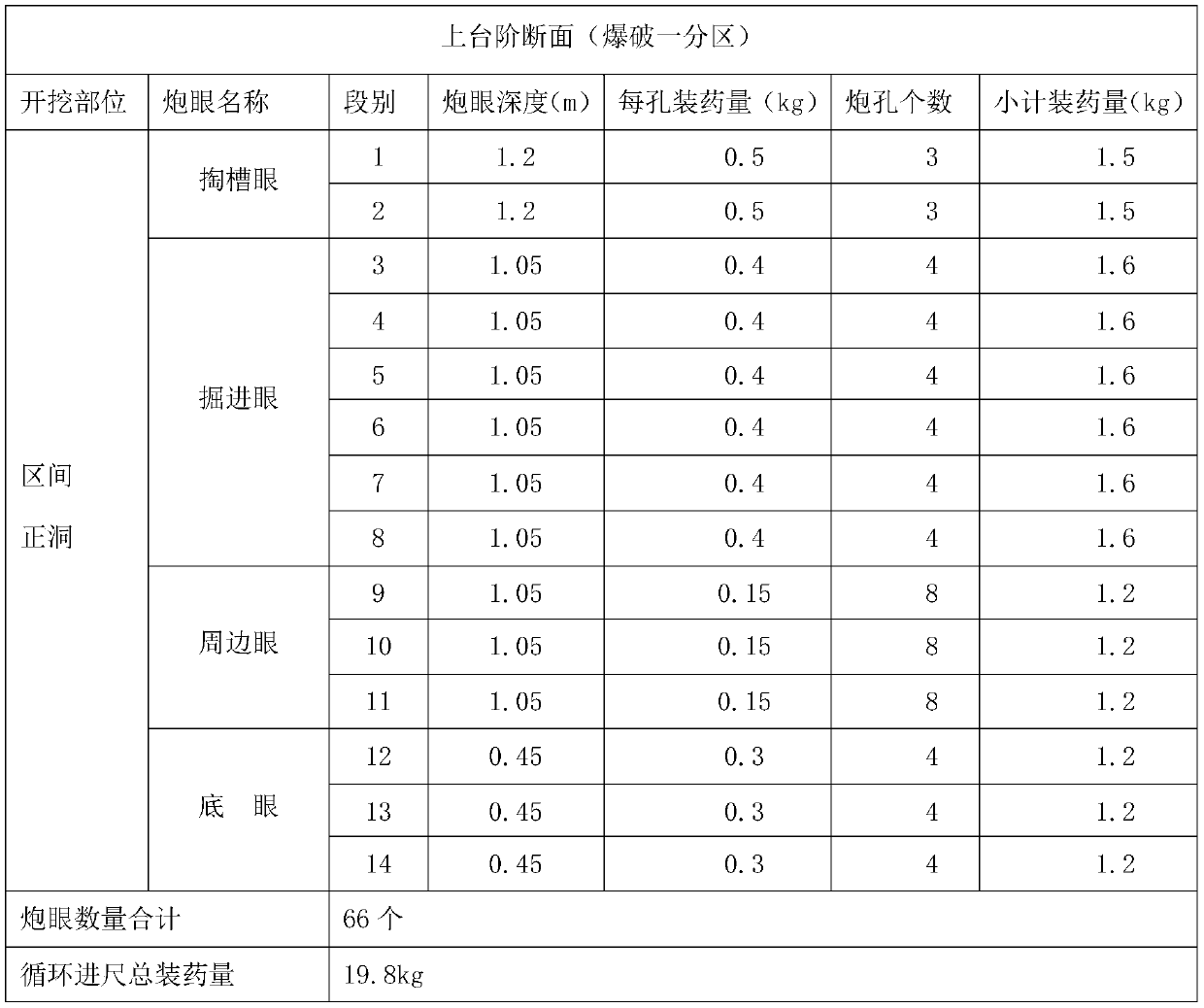

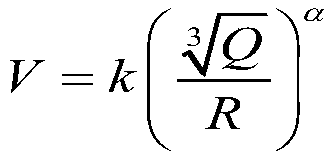

Millisecond blasting vibration and flying rock control method

The invention discloses a millisecond blasting vibration and flying rock control method. The millisecond blasting vibration and flying rock control method includes the following steps of 1), design ofa blasting scheme; 2), hole stepping and drilling; 3), powder charging; and 4), blasting, wherein detonator blasting is delayed through milliseconds, partition blasting is adopted in a blasting sequence, a first region close to an external building is blasted firstly, then a second region away from the external building is blasted, according to the blasting sequence of each region, cutholes are blasted, tunneling holes are blasted, then periphery holes are blasted, finally, bottom holes are blasted, the delay time of the cutholes is controlled to be set at 60 milliseconds-100 milliseconds, the delay time of the tunneling holes is set at 600 milliseconds-750 milliseconds, and the delay time of the periphery holes is set at 950 milliseconds-1,150 milliseconds. The control method is good inblasting effect, high in precision and good in safety.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

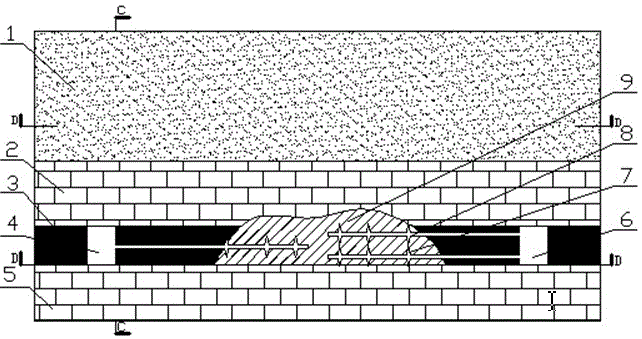

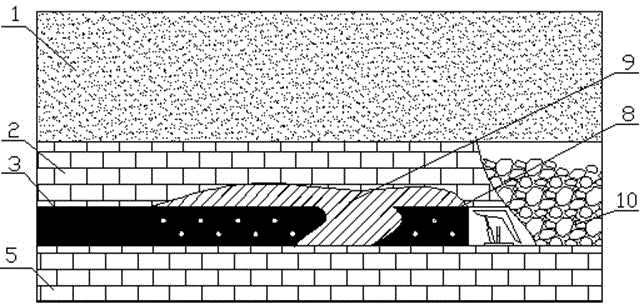

Horizontal segment blast cracking and chemical weakening method for igneous rock in thick coal seam

InactiveCN105909246AReduced mechanical strength propertiesContinuous progressDisloding machinesDust removalInjection volumeChemical solution

The invention provides a horizontal segment blast cracking and chemical weakening method for igneous rock in a thick coal seam. The method comprises the following steps: forming water injection drilling holes and a plurality of V-shaped grooves on one sides, close to working surfaces, of a tail entry and a haulage entry; carrying out a sampling test on the igneous rock, configuring a corresponding chemical solution, and determining the concentration, solution injection volume and solution injection time of the chemical solution; and then carrying out charging, stemming and sealing, and connecting a detonating cord for blasting. According to the invention, a physical method and a chemical method are combined, so that the general problem of difficult pushing of the igneous rock in the coal seam of the existing coal mine is solved; and the process is simple, the cost is low, the benefit is good, and the safety production of the coal mine is realized to the maximum extent.

Owner:TAIYUAN UNIV OF TECH

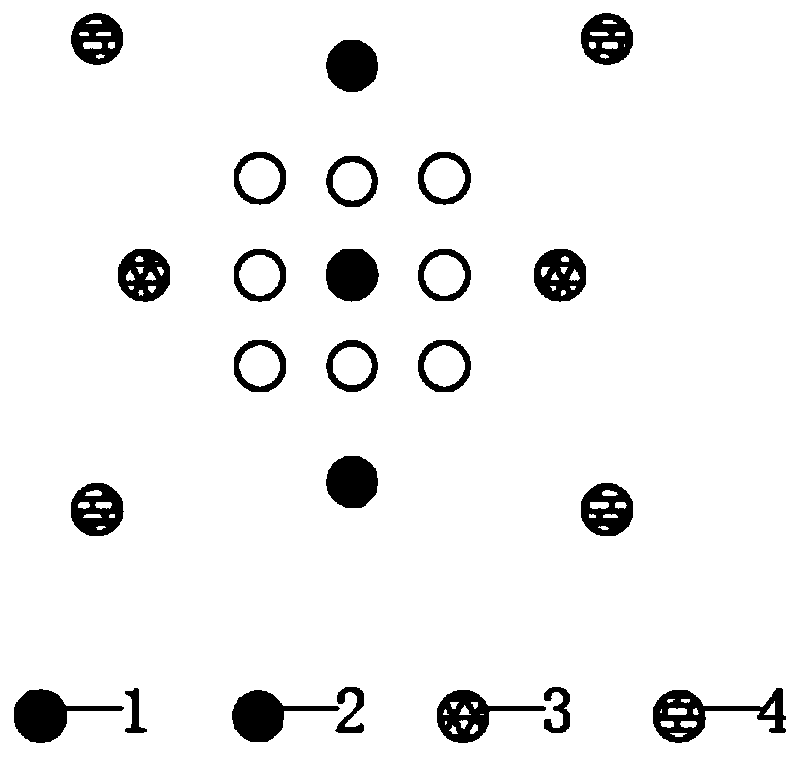

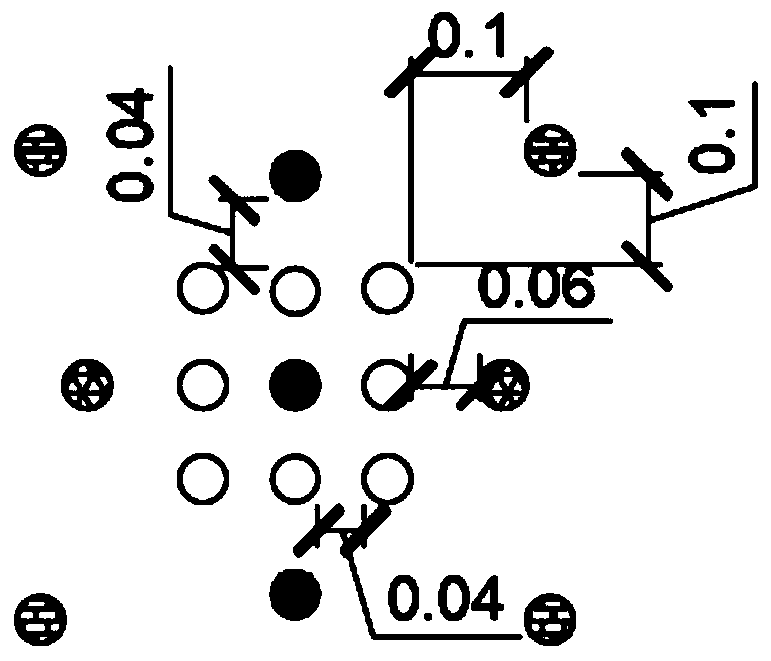

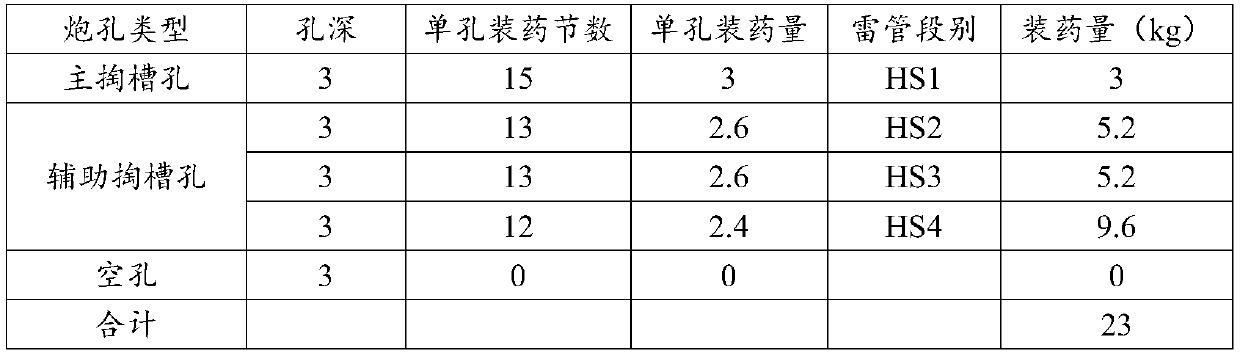

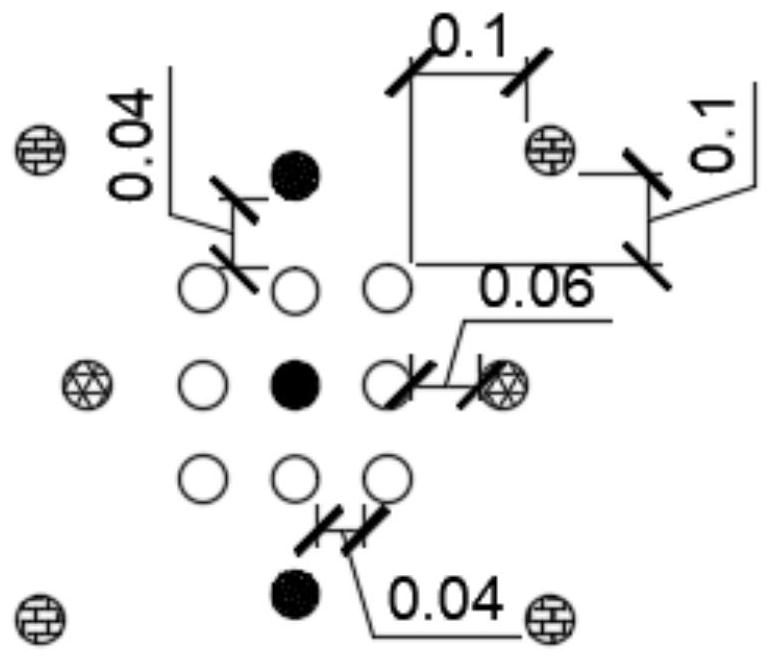

Cutting method combining deep hole cutting and small well cutting

InactiveCN102943673ASimple cutting processReduce cutting costsUnderground miningBlastingStructural engineeringEngineering physics

The present invention provides a cutting method combining deep hole cutting and small well cutting, and belongs to the technical field of ore belt mining. The invention adopts a cutting process combining deep hole cutting and small well cutting, not only cancels the roadway cutting, simplifies the cutting process, and reduces cutting cost significantly, but also provides an experimental basis to realize cutting of deep hole cutting blasting, and has strong promotion and application value. Medium-length holes on both sides of the small well are cut by dual radiation center construction. Taking the small well as a free surface, delay blasting is performed from small well center to the two sides to realize medium-length hole blasting pull trough without roadway cutting, and blasting initial free surfaces are created for follow-up blasting of medium-length hole breaking ground. The long axis direction of a cutting well is perpendicular to the row surface of the cutting deep hole, and the length direction is greater than the row spacing of the cutting deep hole, therefore the deep hole blasting gets the maximum free surface, greatly enhancing the blasting success rate which can reach 100%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

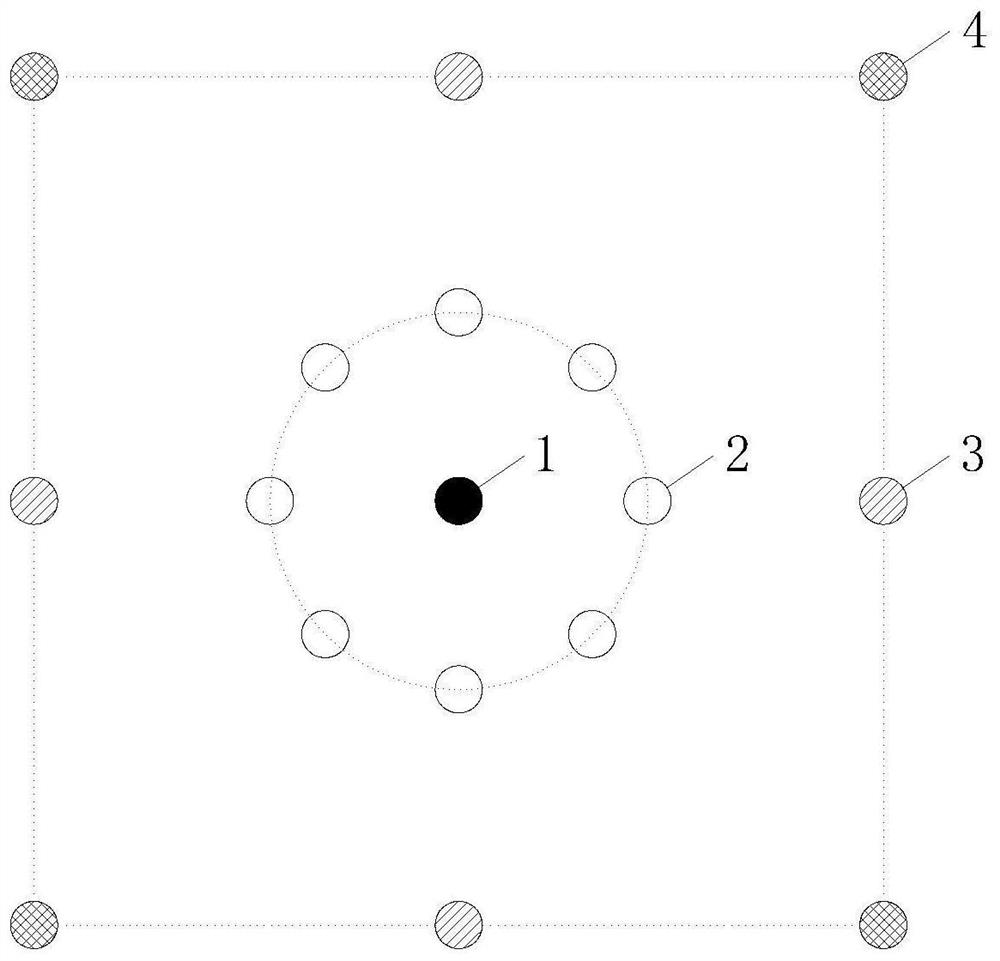

Cutting blasting method based on pre-blasting

The invention relates to a cutting blasting method based on pre-blasting. The cutting blasting method comprises the following steps: (1) a center charge hole is drilled in the center of a cut area, acircle of empty holes are drilled in the periphery of the center charge hole, main cutting holes and compensation cutting holes are drilled in the peripheries of the empty holes, and auxiliary holes,breaking holes and peripheral holes are sequentially drilled in the outer sides of the cutting holes; (2) the center charge hole is continuously filled with an explosive, the main cutting holes and the compensation cutting holes are continuously filled with 1 / 2 cumulative charge and 1 / 4 cumulative charge correspondingly, the auxiliary holes, the breaking holes and the peripheral holes are continuously filled with explosives, and blast holes are blocked by stemming; (3) the center charge hole is separately initiated to form a pre-blasted area; and (4) the remaining blast holes adopt micro-delayinitiation to achieve full-face one-time blasting. A large free face and rock breaking expansion space can be provided for cutting blasting, the surrounding rock clamping effect is overcome, the cutting effect is improved, and the overall blast hole utilization rate is increased.

Owner:ANHUI UNIV OF SCI & TECH

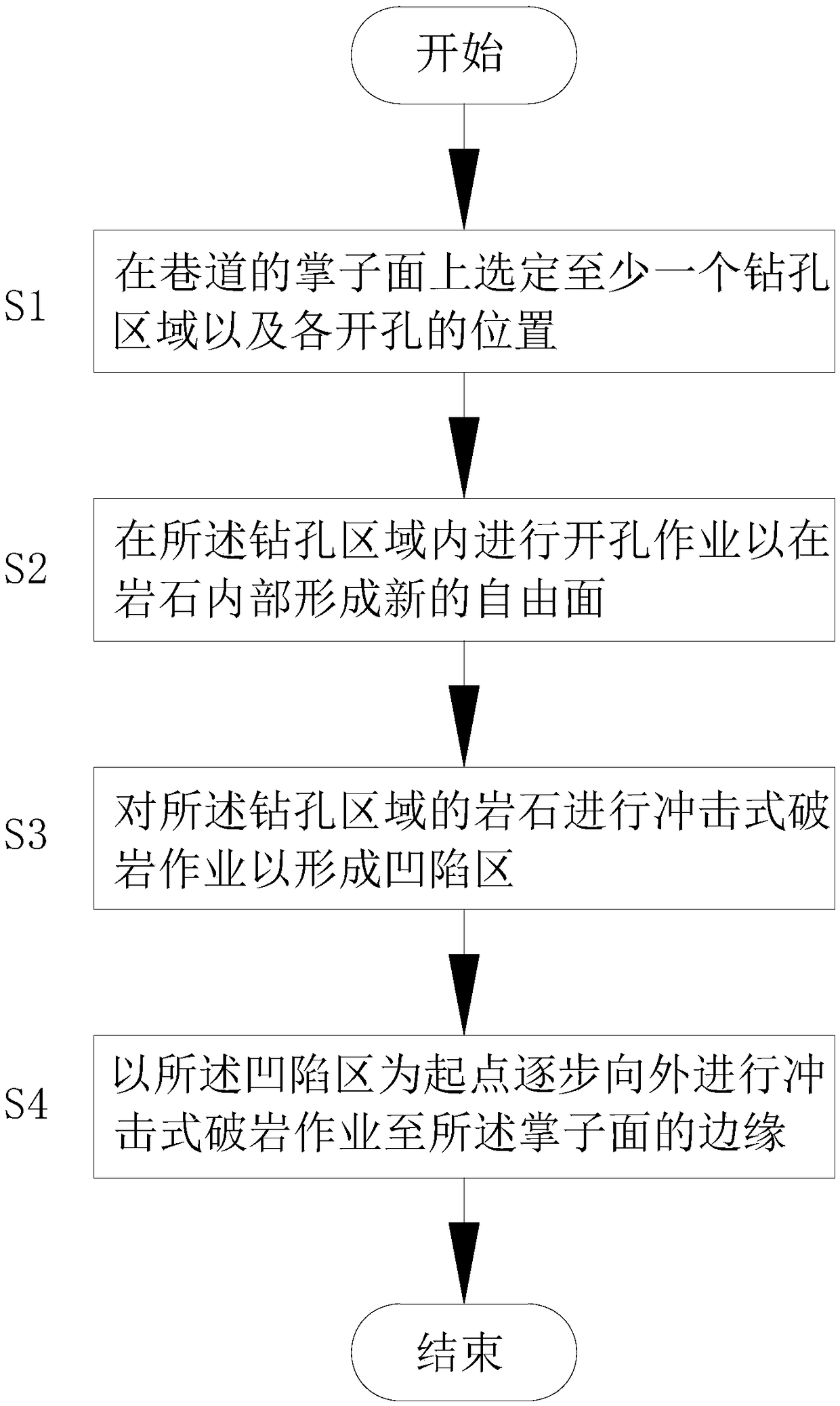

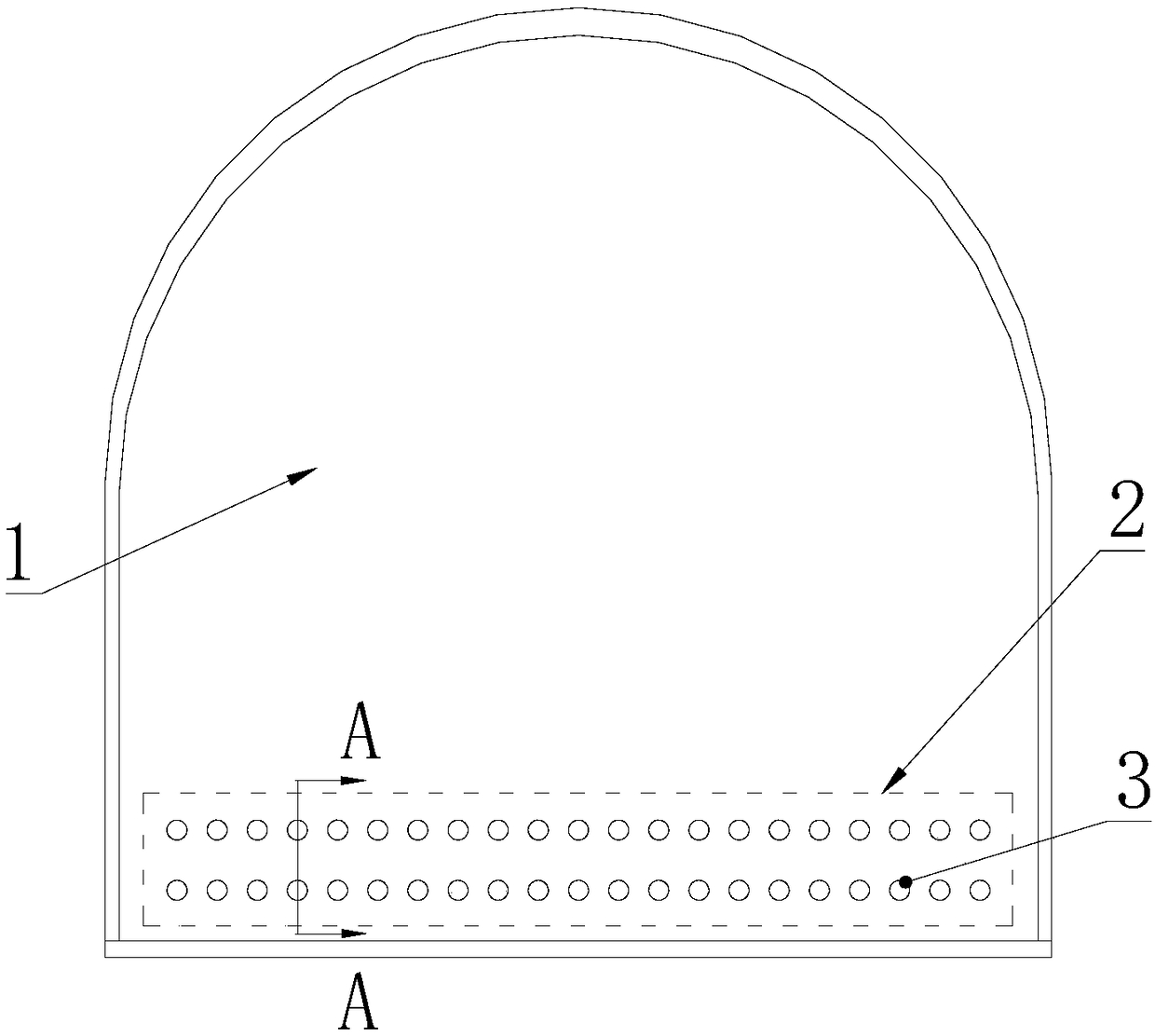

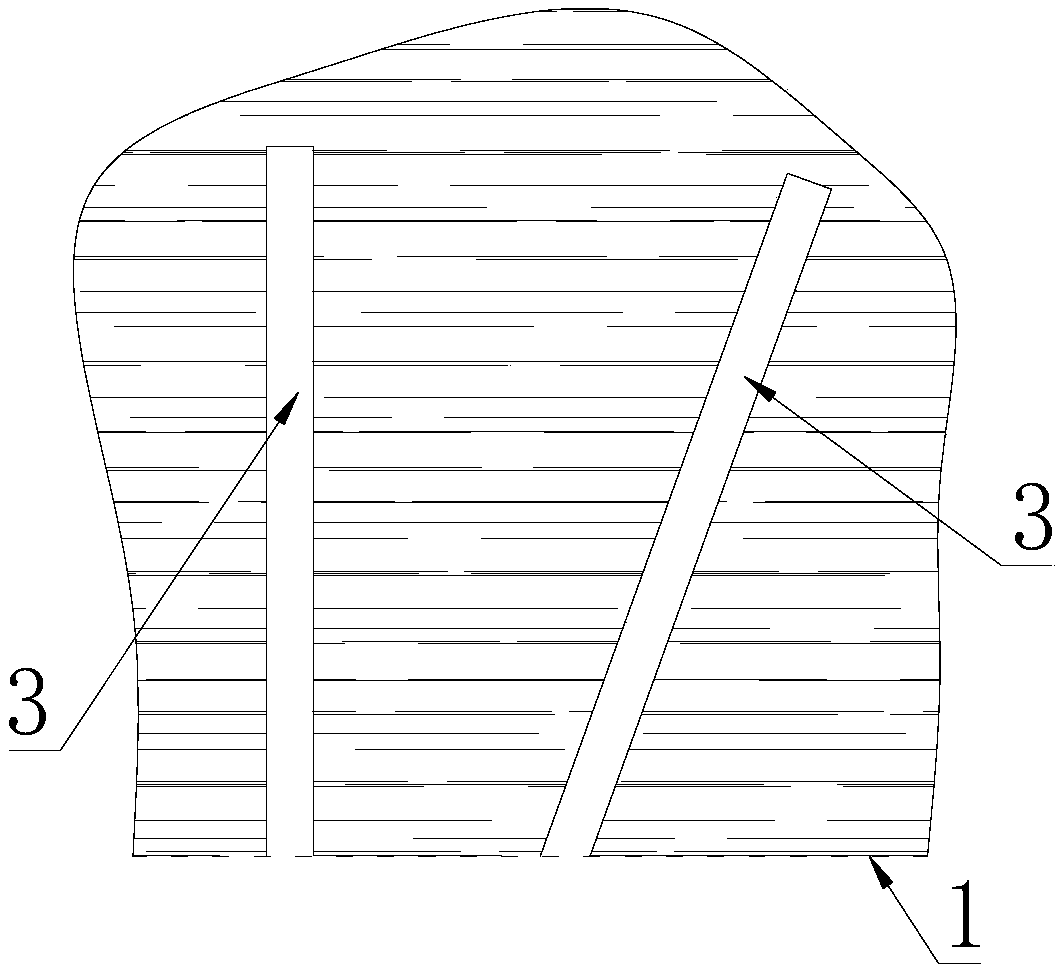

Mechanical rock breaking method for coal mine rock roadway

InactiveCN109026028AIncrease free surfaceBreach of integrityTunnelsMaterial resourcesMechanical equipment

The invention relates to the technical field of coal mine rock roadway excavation, in particular to a mechanical rock breaking method for a coal mine rock roadway. The method includes the following steps that S1, at least one drilling region and the location of each hole are selected on the excavating face of the roadway; S2, drilling operation is performed in the drilling region so as to form a new free face in rock; S3, impact type rock breaking operation is conducted on rock in the drilling region so as to form a sunken region; S4, by using the sunken region as a starting point, impact typerock breaking operation is conducted outward gradually to the edge of the excavating face. By means of pre-opening, the free face of rock mass is increased, the integrity of the rock mass is destroyed, the difficulty of impact type rock breaking is reduced, and the speed of roadway excavation is greatly increased; the drilling operation is completed by mechanical equipment, the operation speed ishigh, the work efficiency is improved, and labor and material resources are effectively saved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

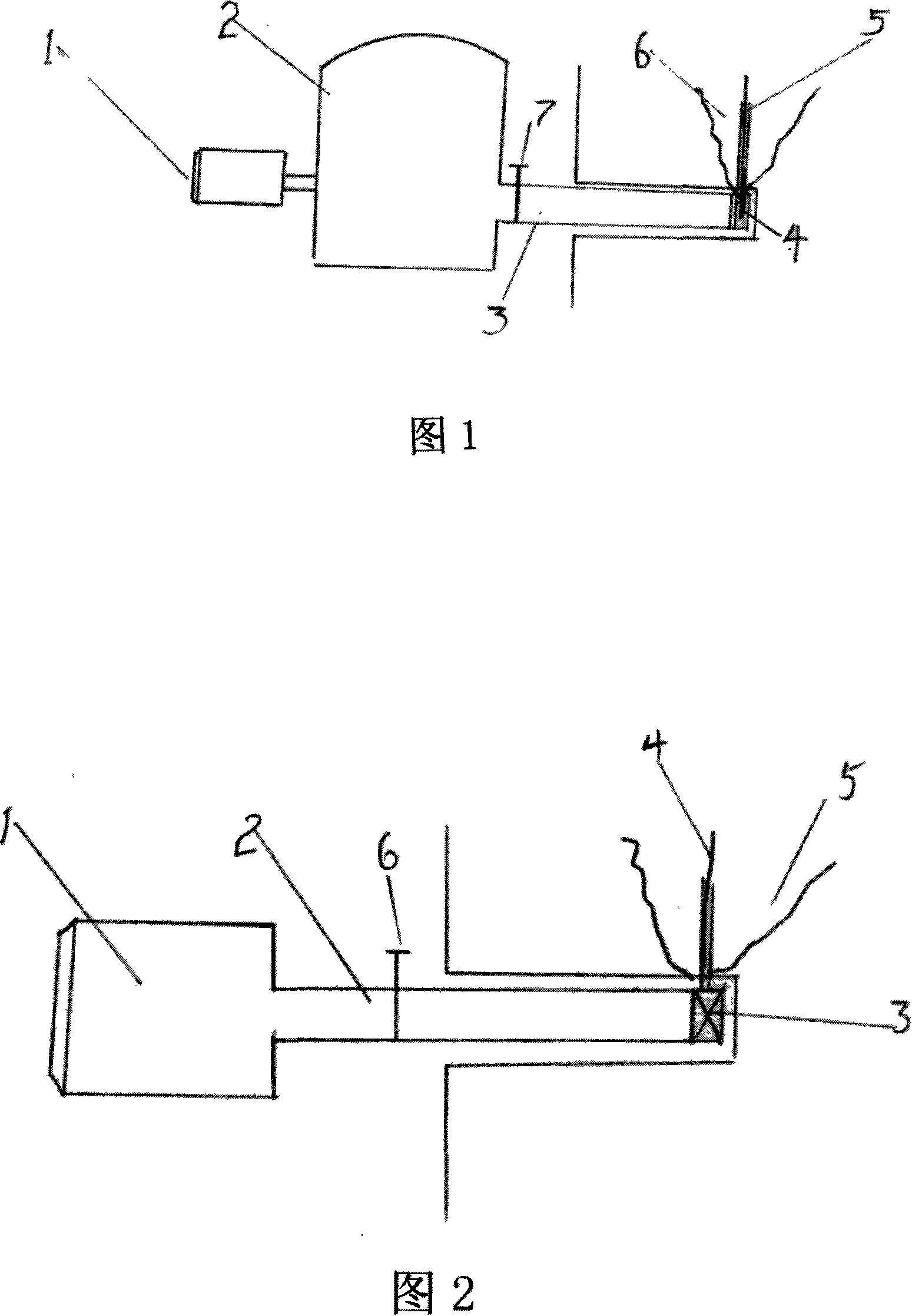

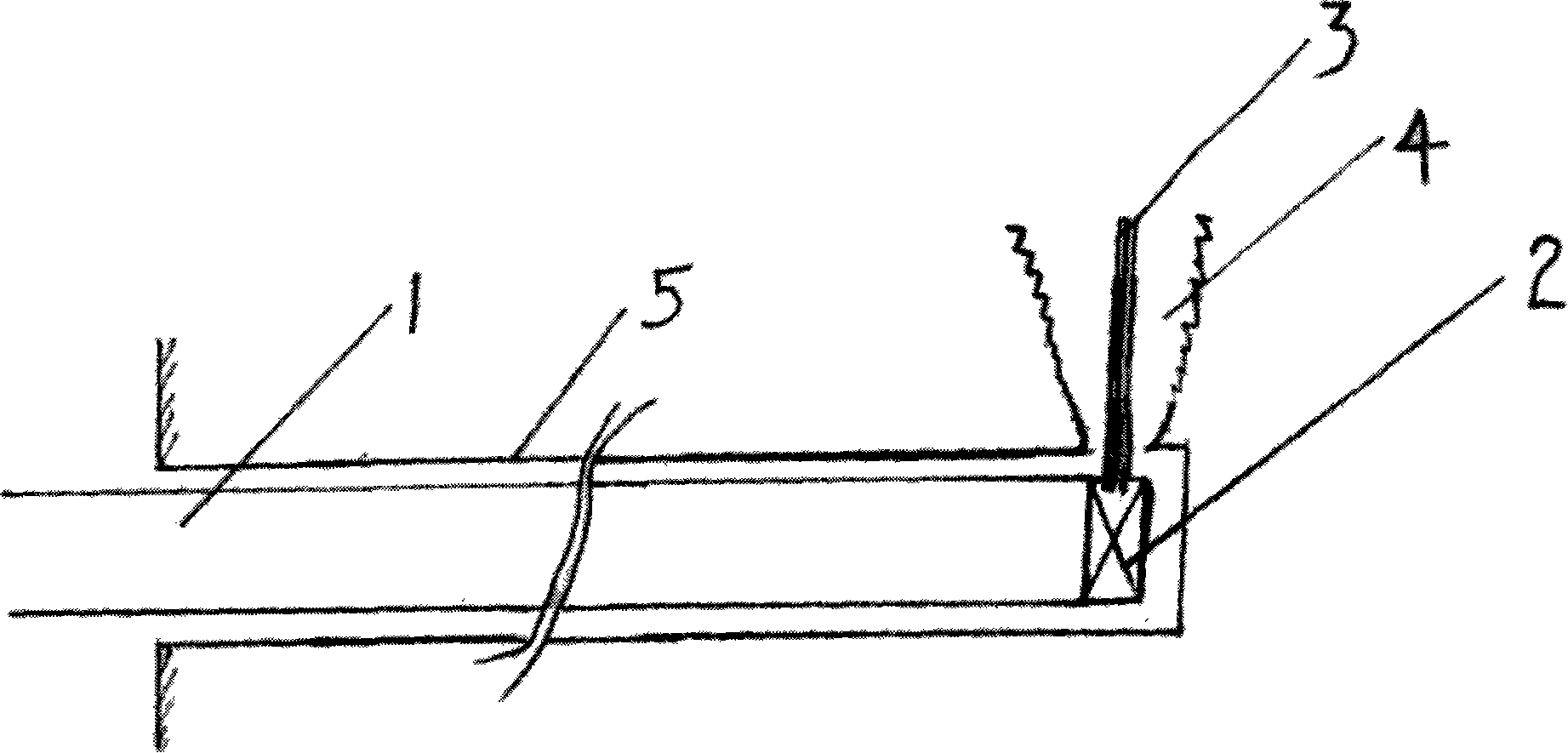

Coalbed drilling hole inside directional dissevering method

A directional separation method inside a drill hole of a coal seam is characterized in that a high-pressure pump is connected with an energy storage tank; after a switch of a high-pressure pipe of the drill hole is turned on, the liquid inside the energy storage tank will impact a coal (rock) wall of the drill hole via the high-pressure pipe and an end cutting hole, and cracks will be made by the impact; when the pressure pipe rotates and moves, and drives the end cutting hole to rotate and move together, so as to realize the directional cutting inside the drill hole of the coal seam.

Owner:杜志刚

Large-diameter drilled pile construction method

The invention discloses a large-diameter drilled pile construction method. The large-diameter drilled pile construction method comprises the following steps: (1) a drilling platform is built; (2) a steel protection cylinder is constructed; the top surface of the steel protection cylinder is higher than the top surface of the drilling platform by 50 cm; (3) a down-hole drill is used for construction; 28-30 small holes are drilled in the pile foundation plane range; gaps between the small holes are controlled within 35-40 cm; and the drilling depth is above the pile bottom elevation by 30 cm; (4) finished holes are constructed; (5) the holes are cleaned through reverse circulation, so that the residue thicknesses at the bottoms of the finished holes are lower than 5 cm, the mud weights in the holes are 1.03-1.1, and the sand contents are not higher than 2%; (6) a reinforcement cage is placed; and (7) concrete is poured. The large-diameter drilled pile construction method can overcome theconstruction difficulties of high-strength rock layers, improves the quality of drilled piles, and guarantees the stability of a bridge main tower.

Owner:SHANGHAI CIVIL ENG GRP FIFTH

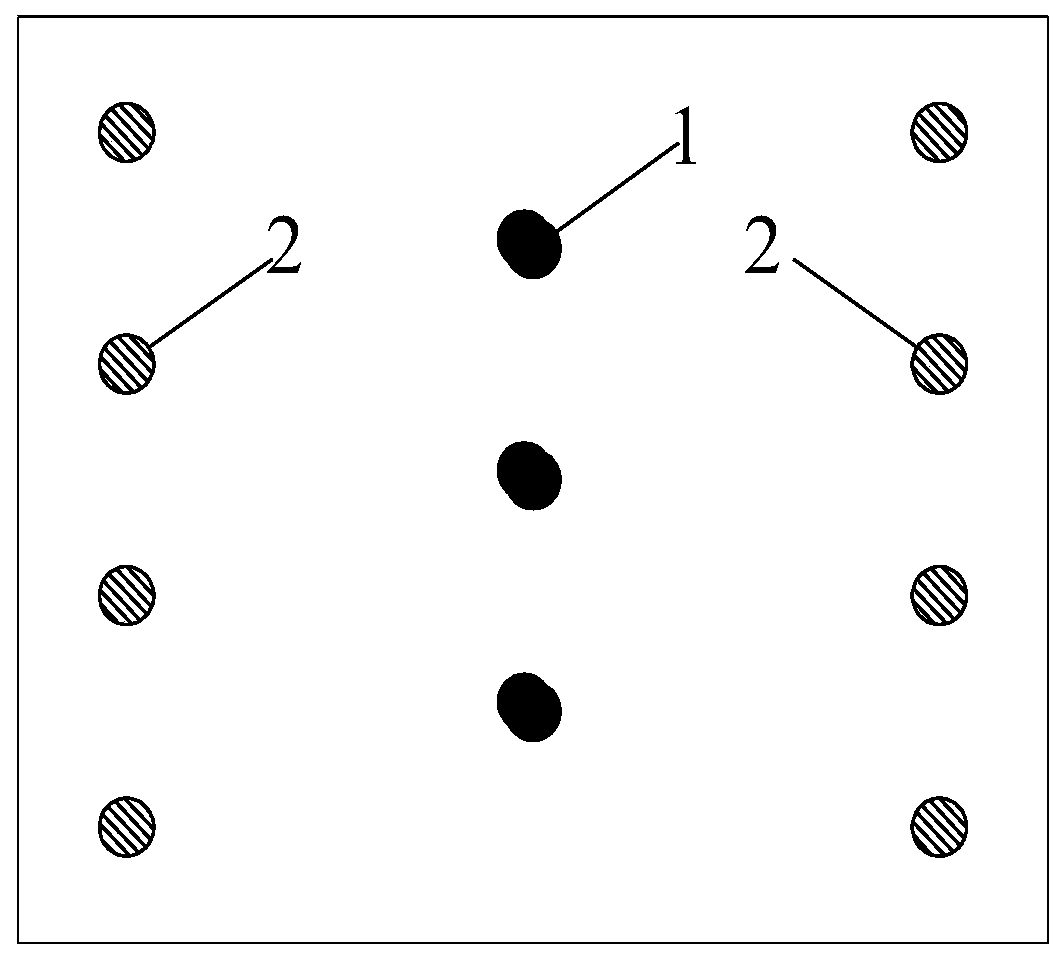

Cutting blasting method suitable for excavation of high-plastic low-strength rock tunnel

The invention discloses a cutting blasting method suitable for excavation of a high-plastic low-strength rock tunnel. The cutting blasting methodis improved from reducing the distance between cuttingholes and changing charging structures of the cutting holes, the distance between the cutting holes is reduced to ensure that the explosion stress wave energy generated by explosives is much higher than the energy required for plastic deformation of plastic rock mass during the explosion, and in addition, the design of auxiliary cutting holes provides support for effectively expanding cutting cavities; and the cutting method is to arrange nine main cutting holes, the center hole is charged, the remaining eight holes are empty holes, the auxiliary cutting holes are distributed in the upper direction, the lower direction, the left direction and the right direction of the nine holeslocated in the center andfour corners of a peripheral square, a small number of charged holes and a large numberof empty holes are combined forcutting blasting, the blasting efficiency is improved, the unit consumption of the explosives is reduced, and the blasting effect of the cutting holes is improved.

Owner:SICHUAN UNIV

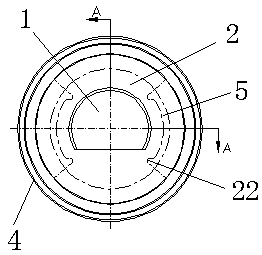

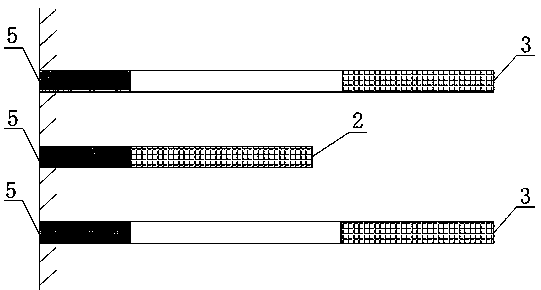

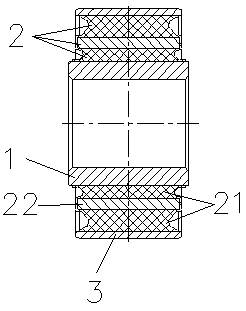

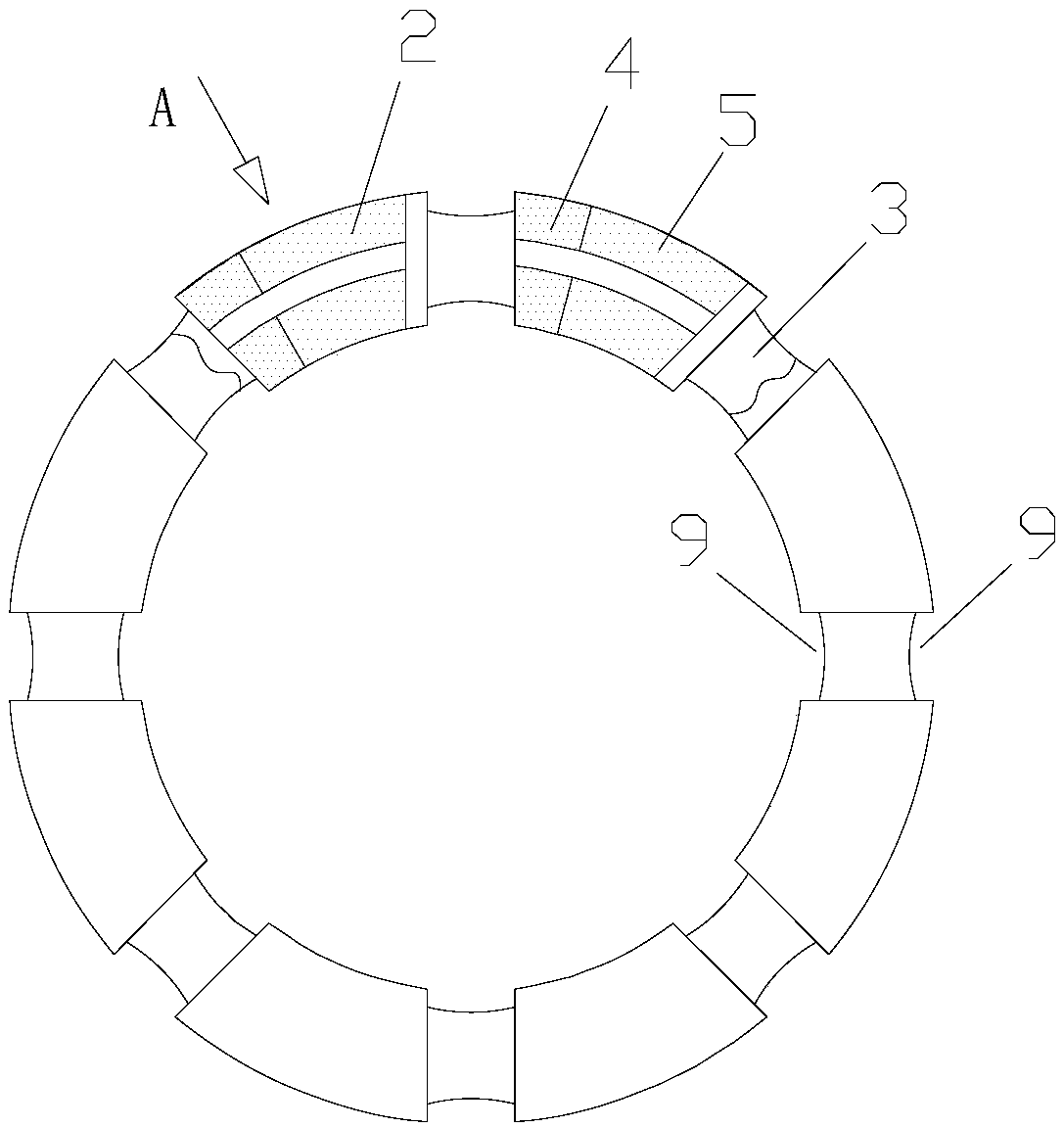

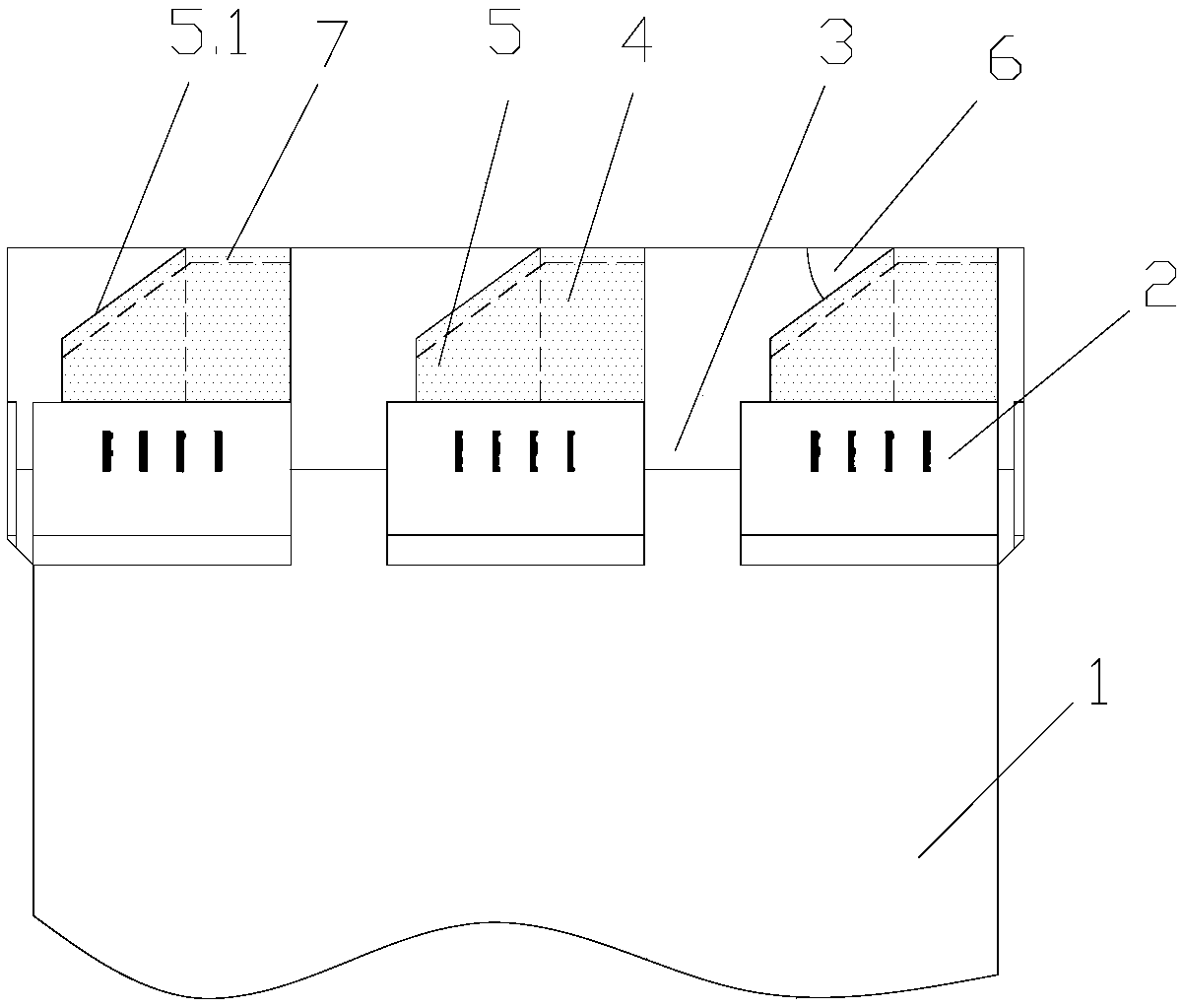

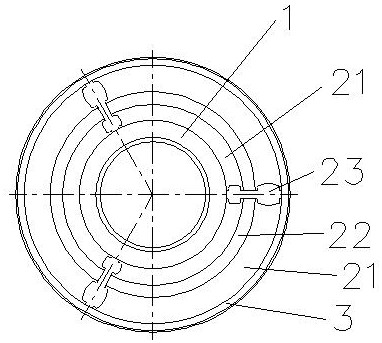

Method for improving fatigue reliability of axle box positioning node and axle box positioning node

PendingCN107804336AAvoid crackingGuaranteed performanceBogiesAxle-boxes mountingStress concentrationEngineering

The invention provides a method for improving the fatigue reliability of an axle box positioning node and the axle box positioning node. The axle box positioning node is designed to comprise a mandrel, a rubber layer, a sectioning cover and an integral cover; by means of vulcanized adhesion between the rubber layer and the mandrel, partial vulcanized adhesion between the rubber layer and the sectioning cover and pressing of the positioning node in the integrated cover after partial assembly, the free surface of the rubber layer is increased on the basis that the adhesive strength between the rubber layer and the mandrel and between the rubber layer and the sectioning cover, so that the internal stress of the rubber layer is conveniently and greatly released in time when the axle box positioning node is loaded, the situation that cracks occur due to rubber stress concentration is avoided, and the service life of the product is prolonged.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

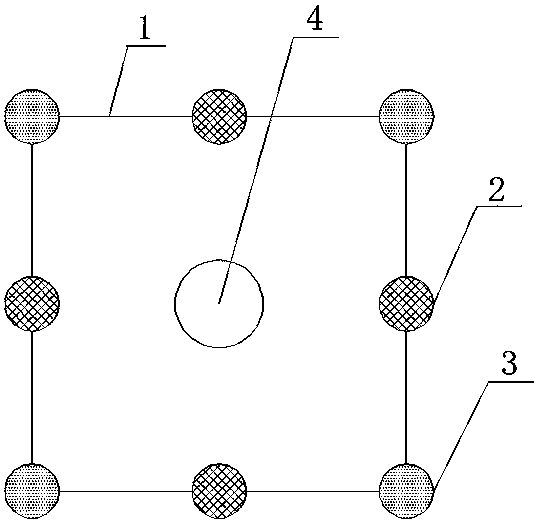

Sectional type slotting method

The invention relates to methods for tunneling, in particular to a sectional type slotting method. The sectional type slotting method includes the following steps that a square slotting region is arranged on the slotting surface of a tunnel, a first set of blast holes are formed in the midpoints of four edges of the square slotting region, a second set of blast holes are formed in four corners ofthe square slotting region, and a compensation hole is formed in the center of the square slotting region; explosives are placed at the bottoms of the first set of blast holes and the second set of blast holes, and orifices of the blast holes are blocked; and the first set of blast holes are detonated at first, and detonation of the second set of blast holes is delayed. Due to the fact that the depths of the slotting holes are different in the tunneling direction in a sectional type slotting mode, free surfaces are created for the second set of blast holes after the first set of blast holes are detonated, the slotting effect is improved, detonation clamping performance of the detonation bottoms is reduced, and the detonation effect of the detonation bottoms is greatly improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method and device for producing glass article from glass melt

InactiveCN105314819AAvoid the riskLow wavinessTransportation and packagingGlass furnace apparatusSurface layerMetallurgy

A method for producing a glass article from a glass melt is provided that includes continuously introducing the glass melt into a stirrer vessel, stirring the glass melt in the stirrer vessel by at least one blade stirrer, continuously discharging the glass melt from the stirrer vessel, and shaping the glass melt to obtain the glass article. The blade stirrer comprises at least one stirrer blade fixed and basically vertical to a stirrer shaft of the stirrer vessel. The method is characterized in that: the stirring is sufficient to draw the glass melt located at a surface of the stirrer vessel into the stirrer vessel so that a formation of a surface layer of the glass melt with a different composition from the composition of the glass melt introduced is prevented or at least minimized; and the stirring is sufficient so that the glass melt which is located at a surface in the stirrer vessel is not drawn into the stirrer vessel or is drawn in only insubstantially.

Owner:SCHOTT AG

Multi-row micro-differential roadbed deep hole blasting construction method

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

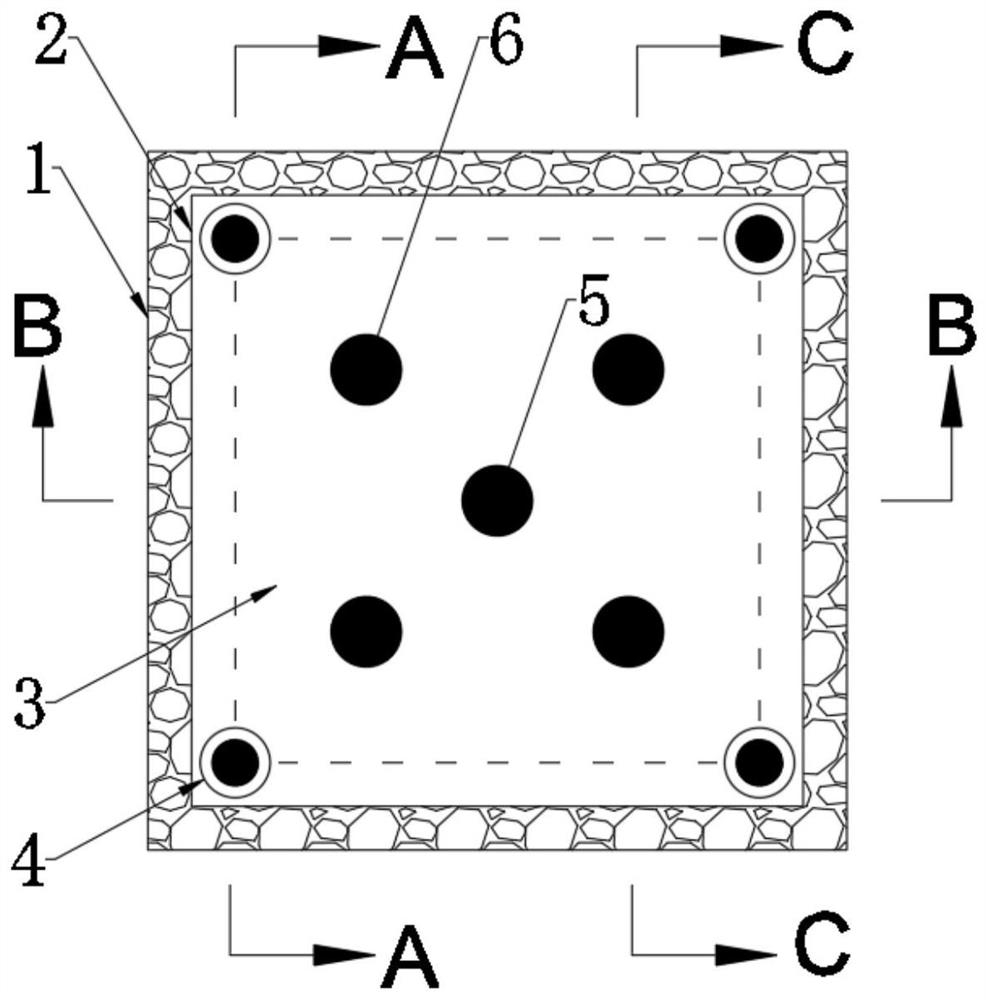

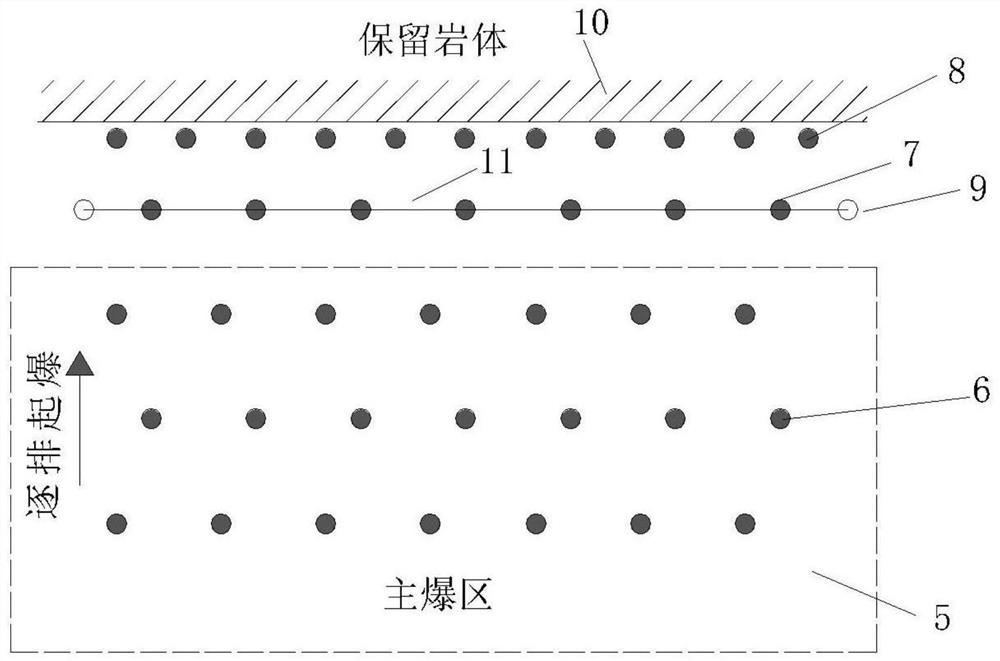

Controlled blasting construction method of beam nest on vertical shaft wall

ActiveCN112432570ASafe and efficient control of blastingIncrease free surfaceBlastingShaft sinkingTEX-explosiveArchitectural engineering

The invention relates to a controlled blasting construction method of a beam nest on a vertical shaft wall. The method comprises the following steps that the beam nest outline boundary is determined on the vertical shaft wall; a set of corner blasthole is arranged and constructed in each corner of the beam nest according to the beam nest outline boundary, a central blasthole is arranged and constructed in the center of the beam nest, and at least one set of auxiliary blasthole is arranged and constructed between each corner blasthole and the central blasthole; 90-degree kerf explosive tubes are arranged in all the corner blastholes, and a first-section explosive and second-section explosives are arranged in the central blasthole and the auxiliary blastholes; and detonating is carried out according to the detonating sequence of corner blasthole explosives, central blasthole top explosives, auxiliary blasthole top explosives, central blasthole bottom explosives and auxiliary blasthole bottom explosives to finish controlled blasting construction of the beam nest. According to the method, 90-degree kerf explosive bags are arranged in the corner blastholes of peripheral holes of the beam nest to form vibration isolation pre-cracks, and a staged and sectioned blasting manner is adopted in a main blasting area, so that safe and efficient controlled blasting of the beam nest on the vertical shaft wall is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

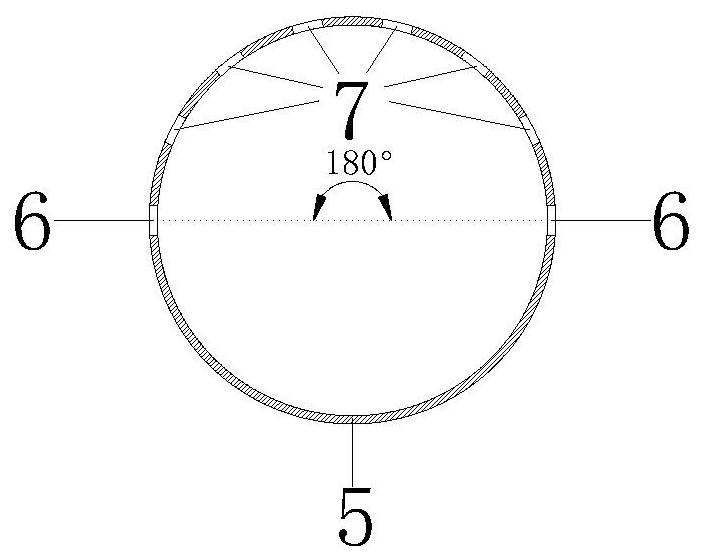

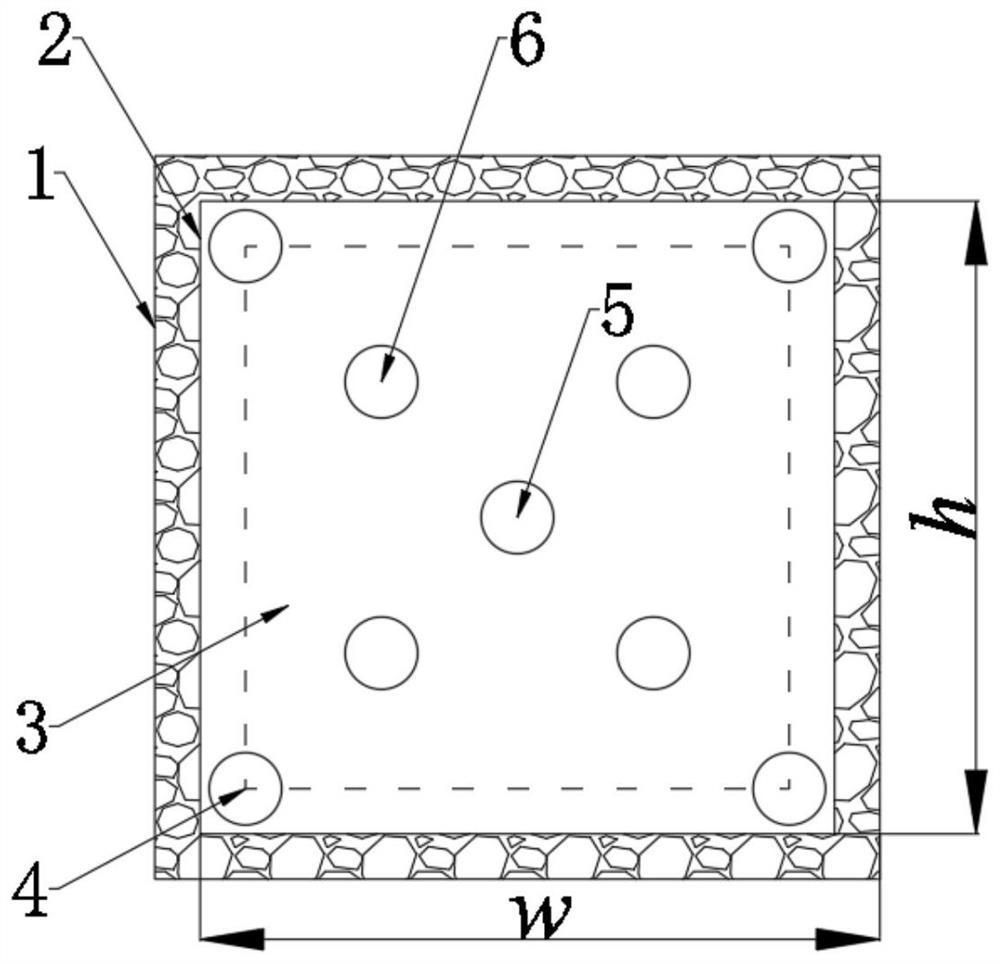

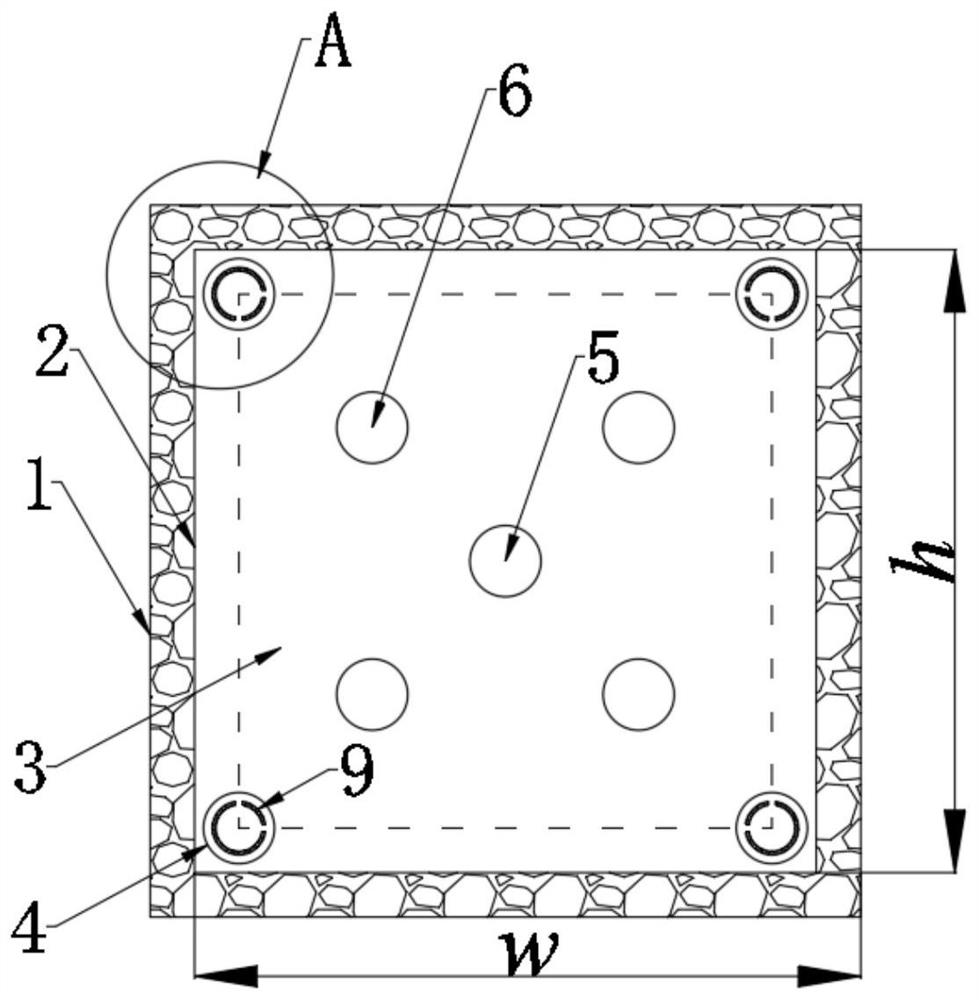

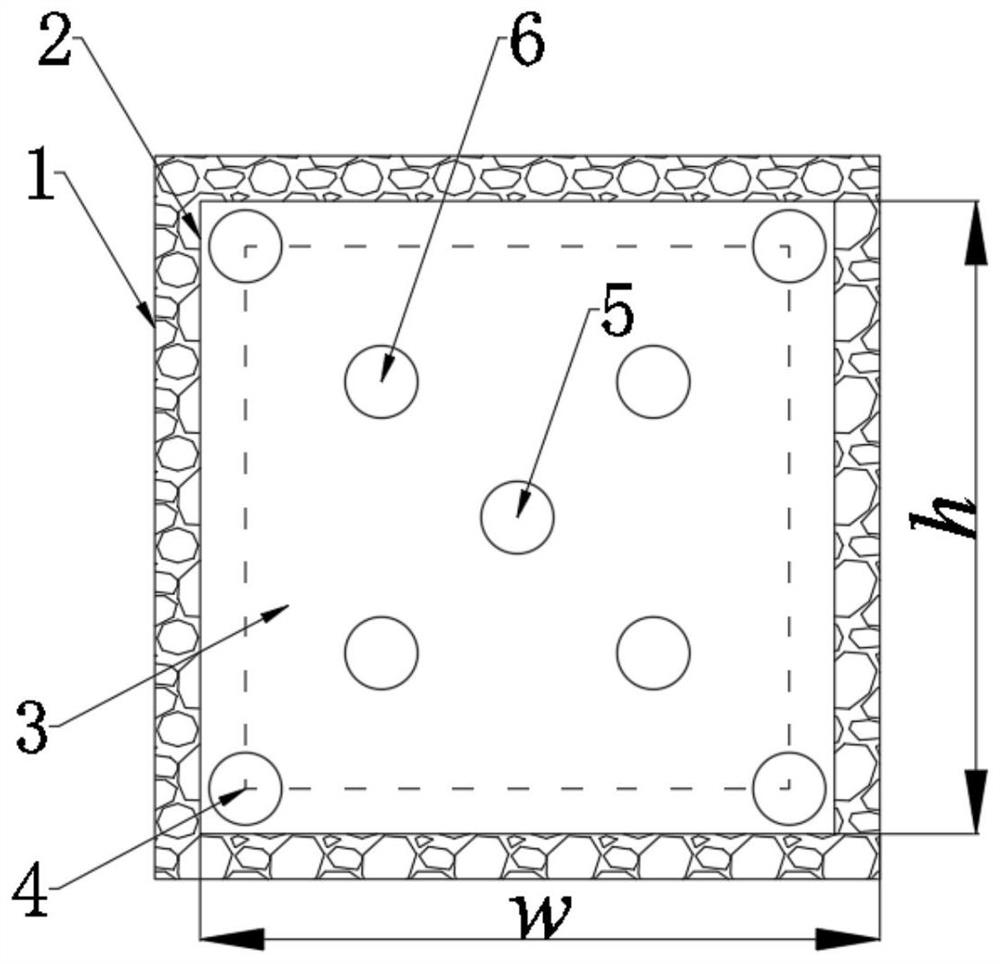

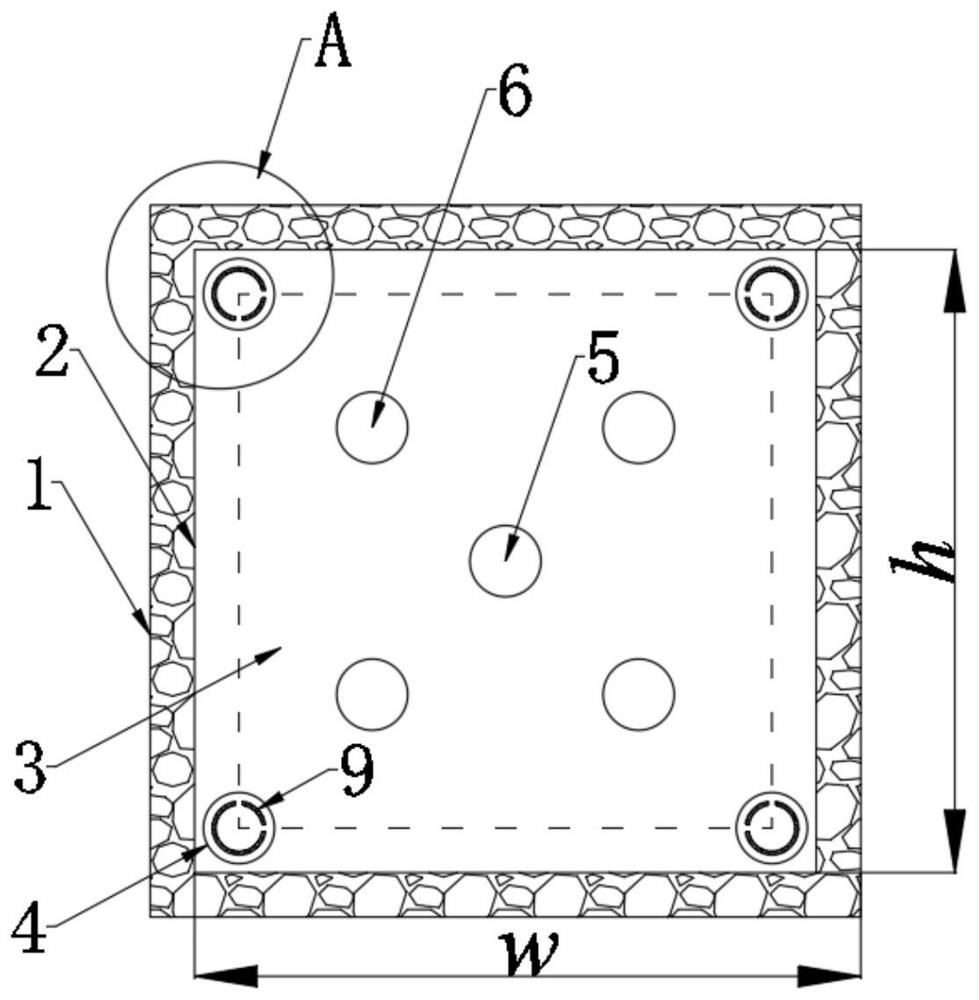

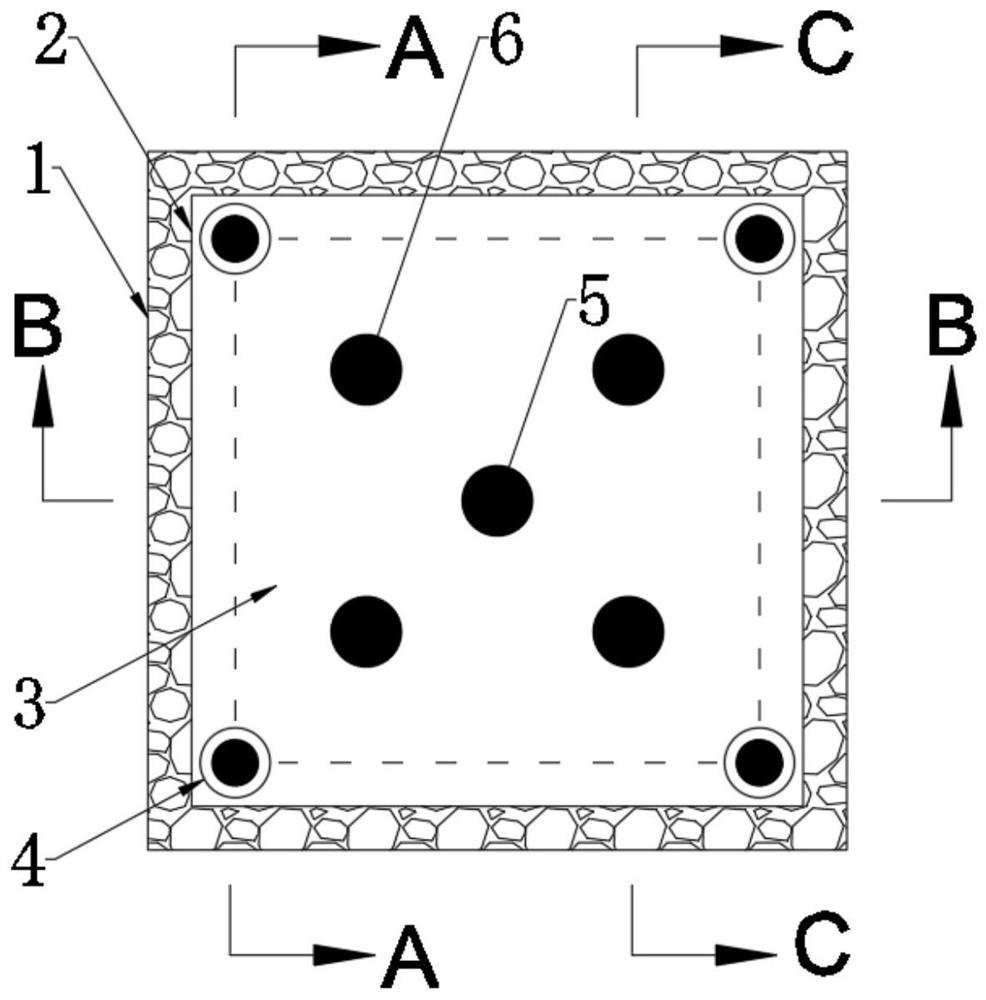

Small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method

InactiveCN111595214ABig room for expansionIncrease free surfaceBlasting cartridgesBlastingTEX-explosiveStructural engineering

The invention discloses a small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method, which comprises the following steps of: 1) drilling; 2) charging:enabling central cutting undermine holes to use a decked charge structure and the small-hole reinforced fracturing grain, filling a second-decked small-hole reinforced fracturing grain into the bottom of each central cutting undermine hole, then, immediately filling tap-hole clay of which the length is 400-500 mm, then, filling a first-decked small-hole reinforced fracturing grain, finally, blocking by the tap-hole clay, filling a second-stage single-surface hoop slit grain into wedge-shaped cutting undermine holes, blocking by the tap-hole clay, filling third-decked common explosive in auxiliary holes, blocking by the tap-hole clay, filling four-decked common explosive in caving holes, blocking by the tap-hole clay, filling five-decked common explosive in surrounding holes, and blockingby the tap-hole clay; and 3) blasting. According to the method disclosed by the invention, the volume of a cutting undermine cavity can be enlarged, a free surface is increased, a surrounding rock clamping function is lowered, and a blast hole use ratio and an explosive energy use ratio are improved.

Owner:ANHUI UNIV OF SCI & TECH +1

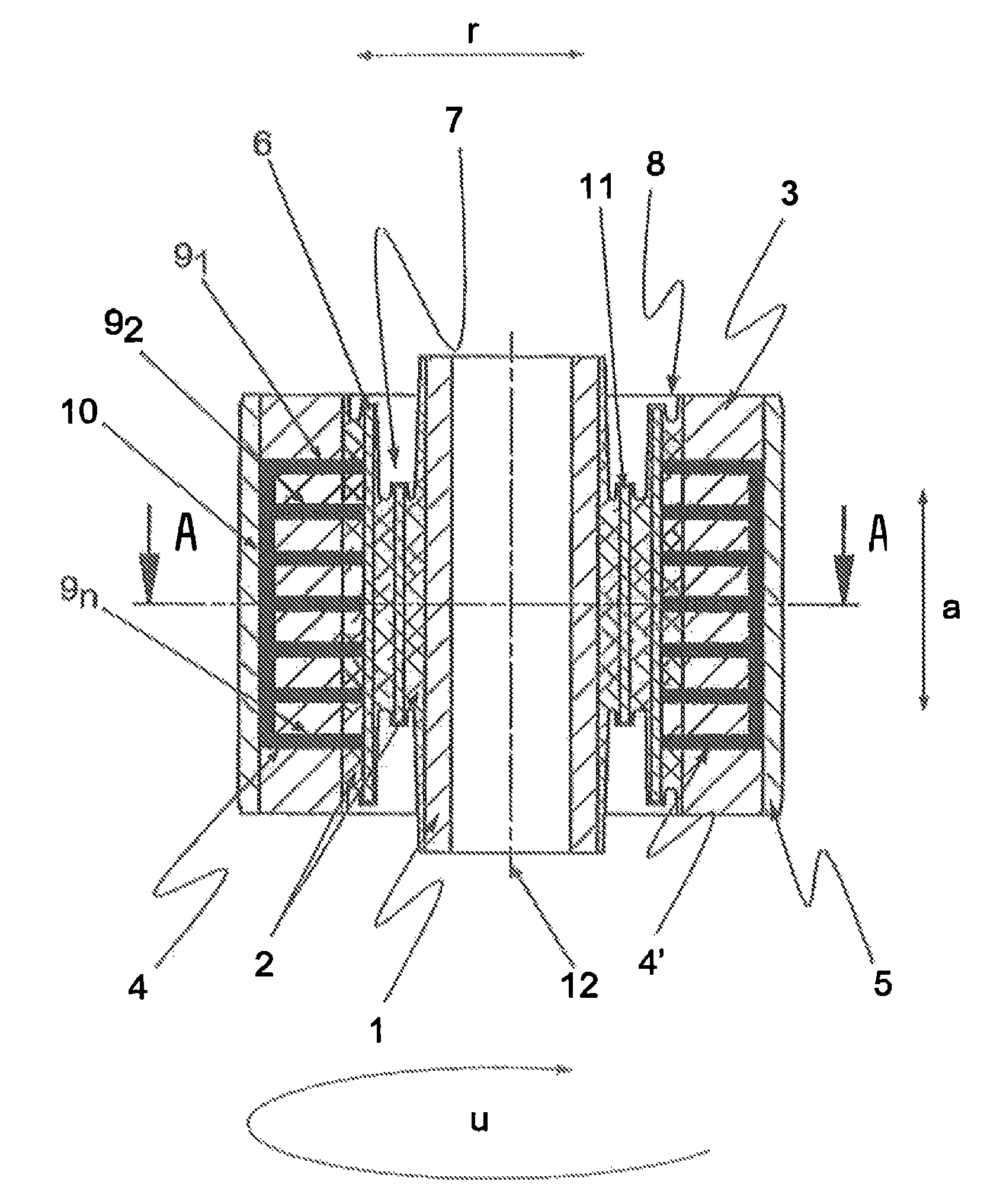

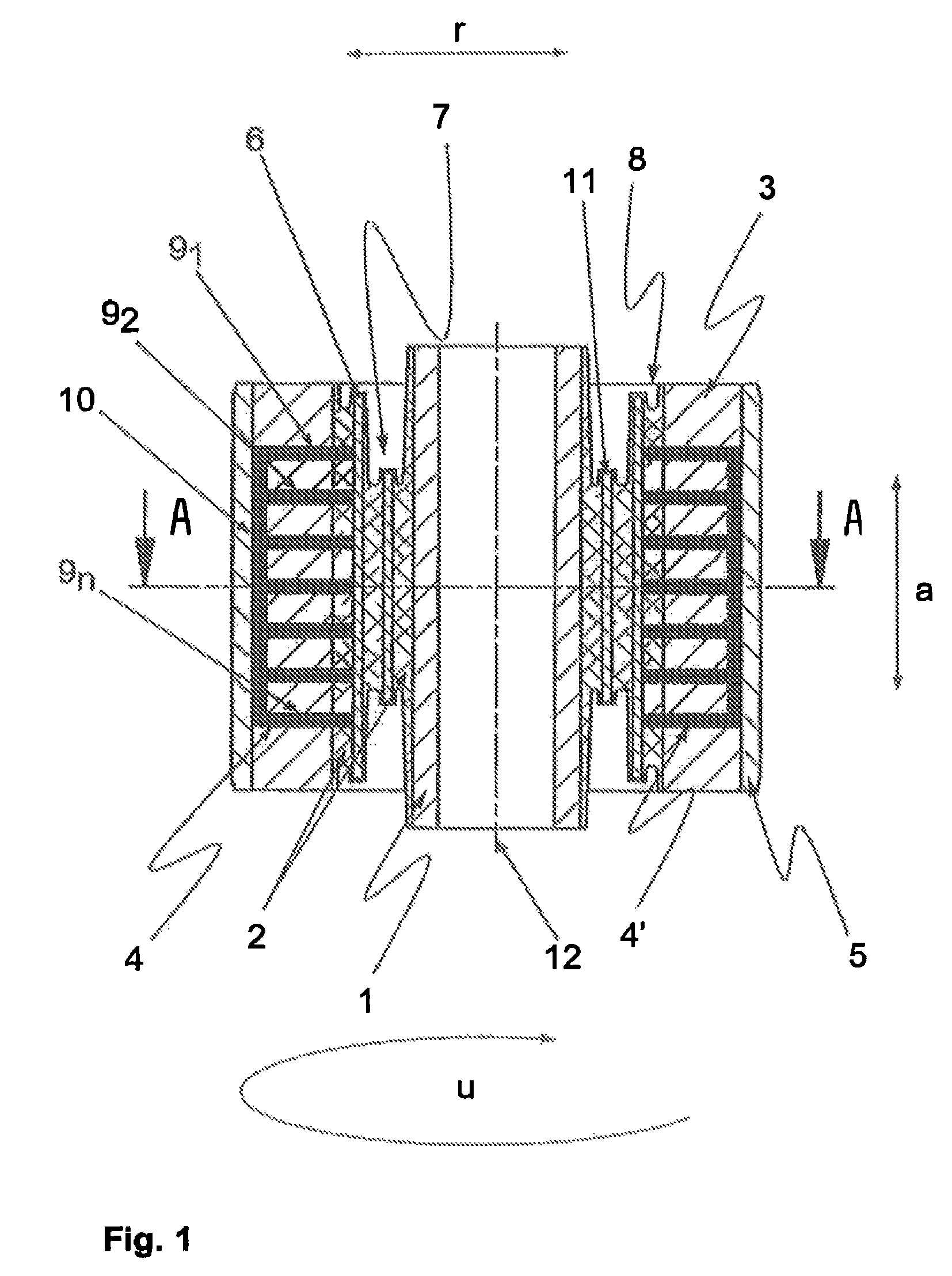

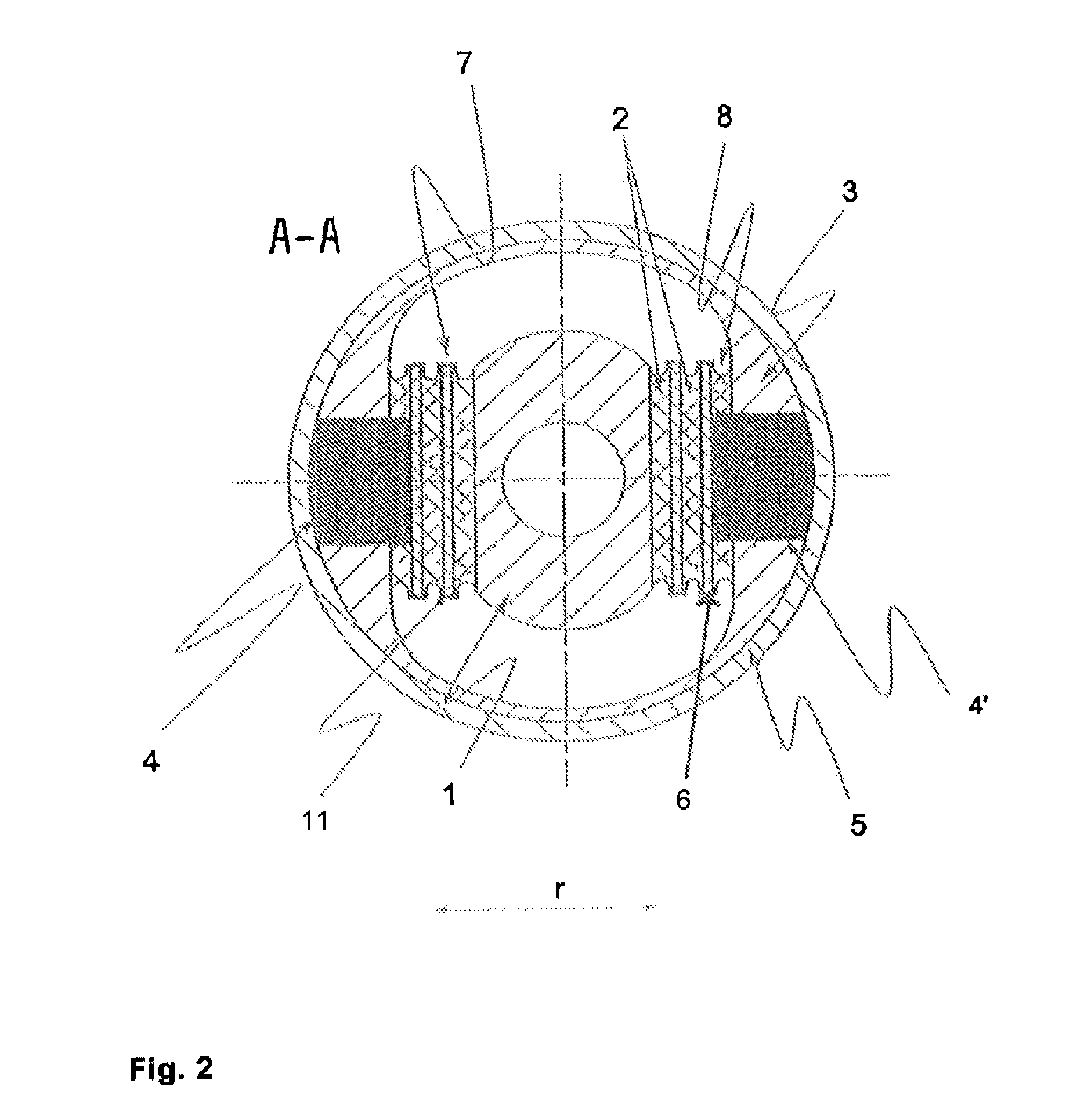

Elastomeric plain bearing having switchable rigidity

ActiveUS8807543B2Improving endurance and durabilityIncrease stiffnessMachine framesLiquid springsElastomerMechanical engineering

Owner:AUDI AG

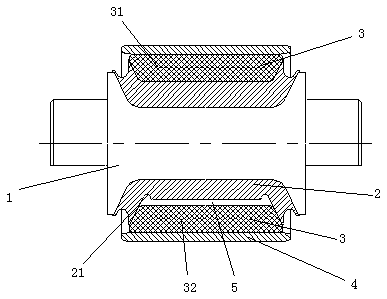

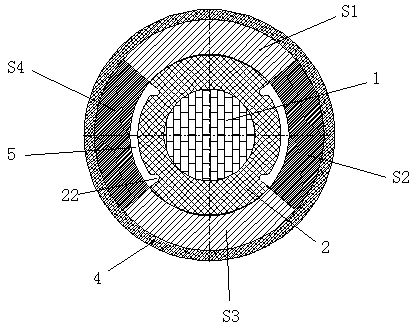

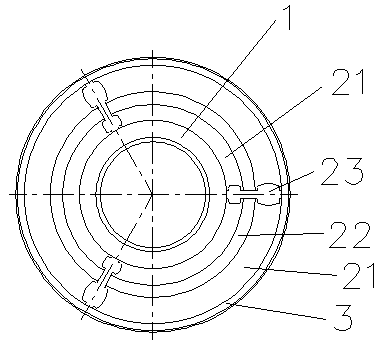

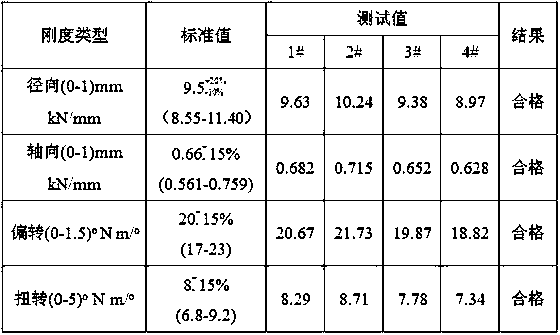

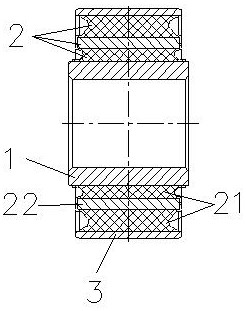

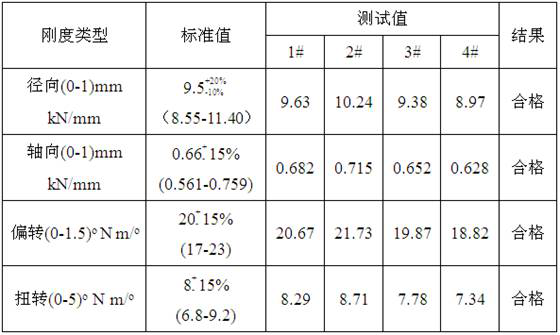

Shock absorbing method and structure of spherical hinge for wheelless axle bogie

ActiveCN109185331AAchieving radial precompressionImprove radial stiffnessNon-rotating vibration suppressionPivotal connectionsBogieMetal rubber

The invention relates to a shock absorbing method and structure of a spherical hinge for a wheelless axle bogie, which adopt the method of arranging a split composite layer structure between a metal inner sleeve and a metal outer sleeve to meet the performance requirements of the spherical hinge, wherein the composite layer structure is that a metal separator plate is arranged inside a rubber layer and is vulcanized to form a rubber-metal-rubber structure, and a parting surface is arranged at the splitting position of the composite layer structure to meet the radial, axial, deflection and torsional stiffness requirements, and reduce rubber stress. As the split composite lay structure is arranged between the metal inner sleeve and the metal outer sleeve, the invention can realize large radial pre-compression to rubber, improve radial rigidity of the spherical hinge and realize minimal torsional rigidity. The invention has the characteristics that the free surface of rubber is greatly increased by the parting surface arranged at the splitting position, which can greatly reduce the stress caused by the extrusion to rubber, improve the fatigue life of rubber and the service life of thespherical hinge.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Drilling hole inside directional dissevering method

InactiveCN101122238ACutting direction controllableControllable split rangeFluid removalGas removalEngineeringHigh pressure

A directional cutting method inside a drill hole is characterized in that a high-pressure pipe is arranged inside the drill hole; an end cutting-hole is arranged at the high-pressure pipe of the final drill hole position; when the high-pressure liquid ejects from the cutting-hole, cracks will be made by the liquid around the cutting hole to control the rotation and movement of the high-pressure pipe, and the cutting hole will rotate and move as well, so as to realize the directional cutting inside the drill hole.

Owner:杜志刚

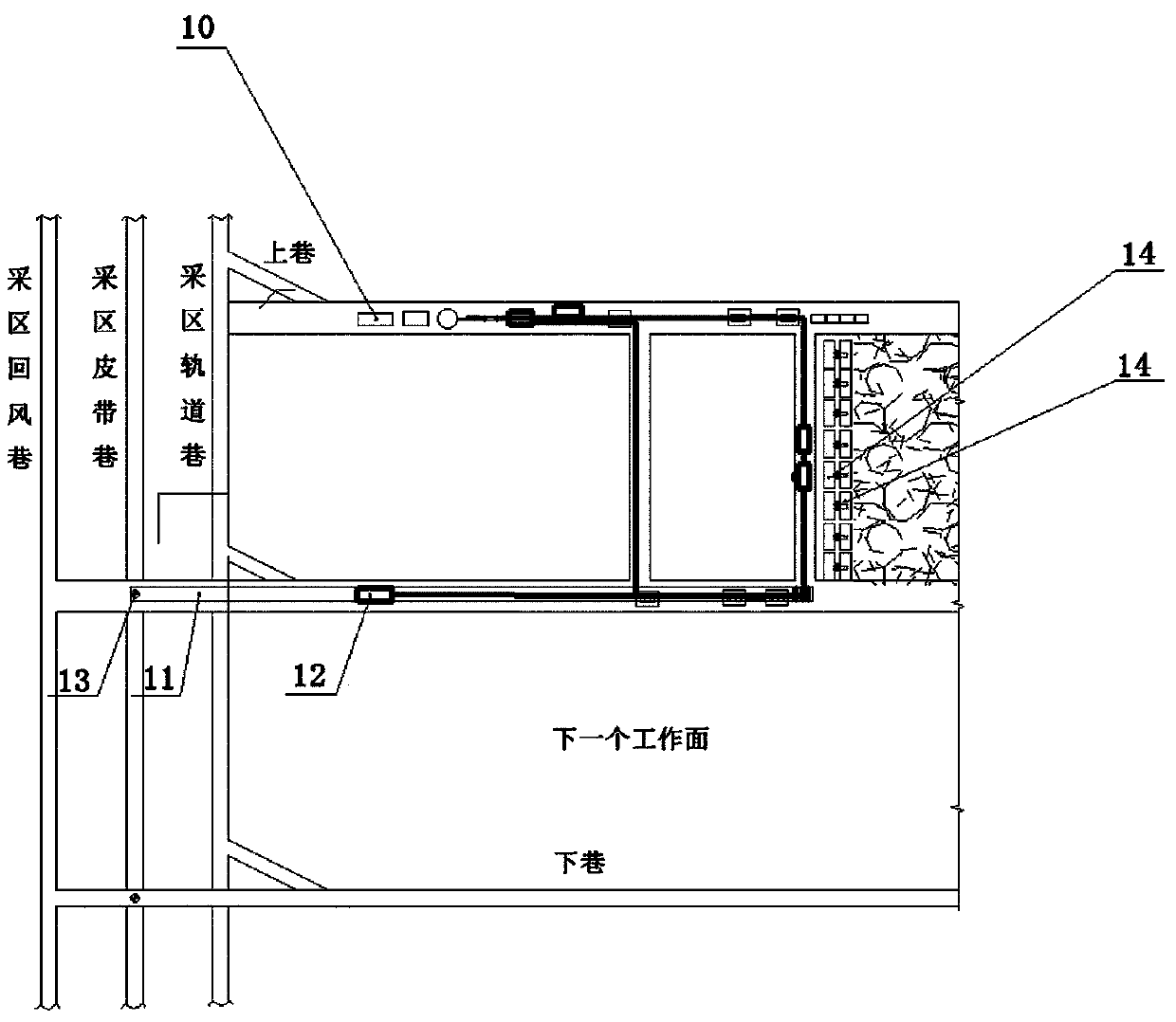

A Coal Mining Method for Separate Mining of Coal and Gangue in Thick Gangue Coal Seam

InactiveCN104653182BIncrease free surfaceReduce difficultyUnderground miningSurface miningShortest distanceMovable type

The invention discloses a coal mining method for separate mining of coal and gangue in a thick gangue-containing coal seam. It is characterized in that the upper, middle and lower troughs are respectively arranged on the upper, middle and lower parts of the longwall coal mining face, and the coal mining face is divided into upper and lower sections, and the upper part of the working face is equipped with a conventional working face self-moving hydraulic support, The roof is managed by the caving method, and a normal scraper conveyor is supplemented. The motor is placed on the upper end of the working face and transported downward. The mined coal and gangue are transported downward to the gangue in the Zhongshun trough by the scraper conveyor. Separation platform; the length of the lower section of the working face is just enough to fill the gangue extracted from the working face and the lower section in the goaf, and a self-moving hydraulic filling support with a goaf retaining board is installed, and the filling method is adopted Management of the roof, supplemented by a high-power short-distance scraper conveyor, the motor is placed at the lower end of the working face, and transported upwards, the mined coal and gangue are transported upwards to the Zhongshun trough for coal and gangue separation by a high-power short-distance scraper conveyor tower.

Owner:SHANDONG UNIV OF SCI & TECH +1

A Construction Method of Controlled Blasting for Shaft Wall Beam Cocks

ActiveCN112432570BSafe and efficient control of blastingIncrease free surfaceBlastingShaft sinkingDetonationTEX-explosive

The invention relates to a controlled blasting construction method for a beam nest on the shaft wall, comprising the following steps: determining the contour boundary of the beam nest on the shaft wall; arranging and constructing a group of corner points at each corner point of the beam nest according to the contour boundary of the beam nest Blast holes, arrange and construct a central blast hole in the center of the beam socket, arrange and construct at least one set of auxiliary blast holes between each corner point blast hole and the center blast hole; install 90° slits in each corner point blast hole Cartridge, install the first stage explosive and the second stage explosive in each center hole and auxiliary hole; The detonation sequence of the explosives at the bottom of the auxiliary blast hole is detonated, and the controlled blasting construction of the beam nest is completed. The present invention installs 90° slit charges in blastholes at the corners of holes around beam nests to form vibration-isolation pre-cracks, adopts staged and segmented blasting methods in the main blasting area, and realizes safe and efficient control of shaft wall beam nests blasting.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

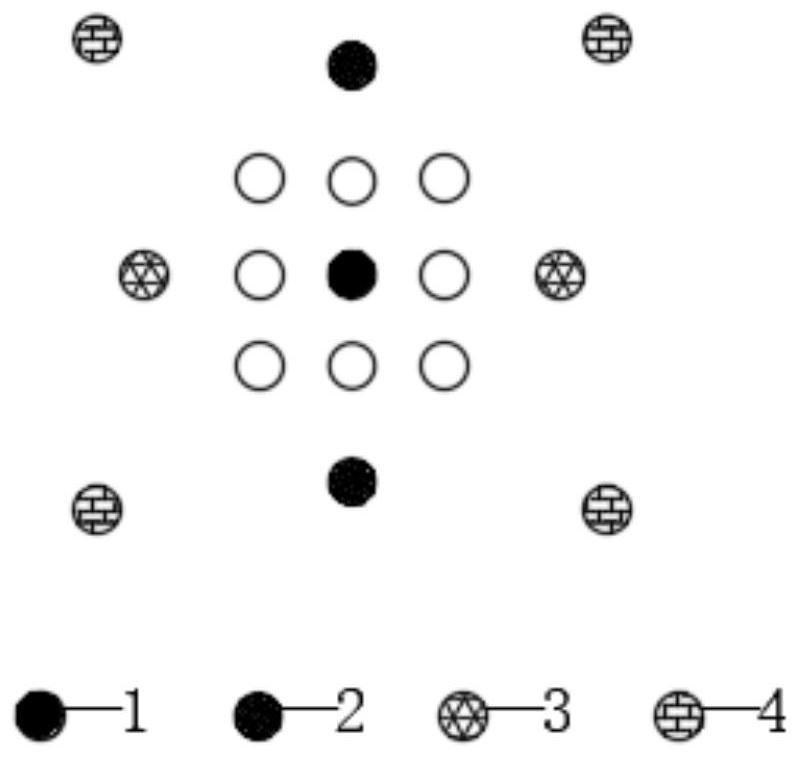

Cutting blasting method suitable for excavation of high-plasticity and low-strength rock tunnels

The invention discloses a cutting blasting method suitable for excavation of high-plastic and low-strength rock tunnels, which is improved from two aspects of reducing the distance between the cutting holes and changing the charge structure of the cutting holes, and reduces the distance between the cutting holes. distance to ensure that the explosion stress wave energy produced by the explosive is much higher than the energy required for the plastic deformation of the plastic rock mass during the explosion, and the design of the auxiliary cut hole provides support for effectively expanding the cut cavity; the cut of the present invention The method is to arrange the nine holes of the main cutting hole, the center hole is filled with medicine, and the remaining eight holes are all empty holes. The auxiliary cutting holes are arranged in the upper, lower, left and right directions of the central nine holes and the four corners of the peripheral square. Cutting blasting is carried out by combining a small number of charging holes and a large number of empty holes, which improves the blasting efficiency, reduces the unit consumption of explosives, and improves the blasting effect of cut holes.

Owner:SICHUAN UNIV

A mining method for thick and large ore bodies

ActiveCN105626074BAvoid consumptionReduce consumptionUnderground miningSurface miningDetonatorMaterial consumption

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV

A Blasting Method for Reducing Harmful Effects Based on Wave Catch-Energy Dissipation

ActiveCN111197950BImprove protectionPrevent extensionClimate change adaptationBlastingDetonationExplosive Agents

The invention discloses a blasting method for reducing harmful effects based on choke-energy dissipation, which belongs to the technical field of mining construction and comprises the following steps: sequentially arranging blastholes in the main blast zone, wave choke holes, energy dissipation holes, empty holes on the working face hole; prepare the energy-gathering-energy-dissipating blaster; put water, explosives, and rubber pads into the blaster; put ordinary explosives into the main gun hole, and put the blaster with energy-gathering effect into the choke hole, which has energy dissipation The blaster is loaded into the energy dissipation hole; the water gun mud is sealed; and the micro-differential detonation. In the present invention, multiple methods such as directional crack wave damming formed by detonation of the choke hole first, directional energy absorption of the blaster in the energy dissipation hole, air hole suppressing wing crack initiation, displacement of the space to guide the explosion energy propagation of the energy dissipation hole and other methods are superimposed and applied, greatly greatly Reduces blast hazard effects.

Owner:ANHUI UNIV OF SCI & TECH

Diamond bit used for engineering investigation and its making method

The invention provides a diamond bit used for engineering investigation. The diamond bit includes a bit steel body and bit fan-shaped cutting teeth arranged at the front end of the bit steel body. A water port is arranged between every two adjacent fan-shaped cutting teeth, the fan-shaped cutting teeth are composed of fan-shaped cylindrical cutting teeth and fan-shaped trapezoidal cutting teeth, the cutting surfaces of the front ends of the fan-shaped trapezoidal cutting teeth are slope surfaces, and bit circular grooves are formed in the fan-shaped cutting teeth. The diamond bit has a scientific and reasonable structure, has wide adaptability to the stratum and is excellent in drilling effect. At the same time, the invention further provides a preparation method of the diamond bit, whichcombines a hot-pressing method with a cold-pressing method and exerts the dual advantages of the hot-pressing method and the cold-pressing method, the stable performance of the bit is ensured and theadaptability of the bit to the stratum is improved.

Owner:WUHAN WAN BANG LASER DIAMOND TOOLS

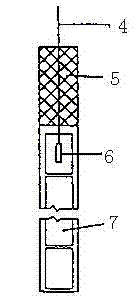

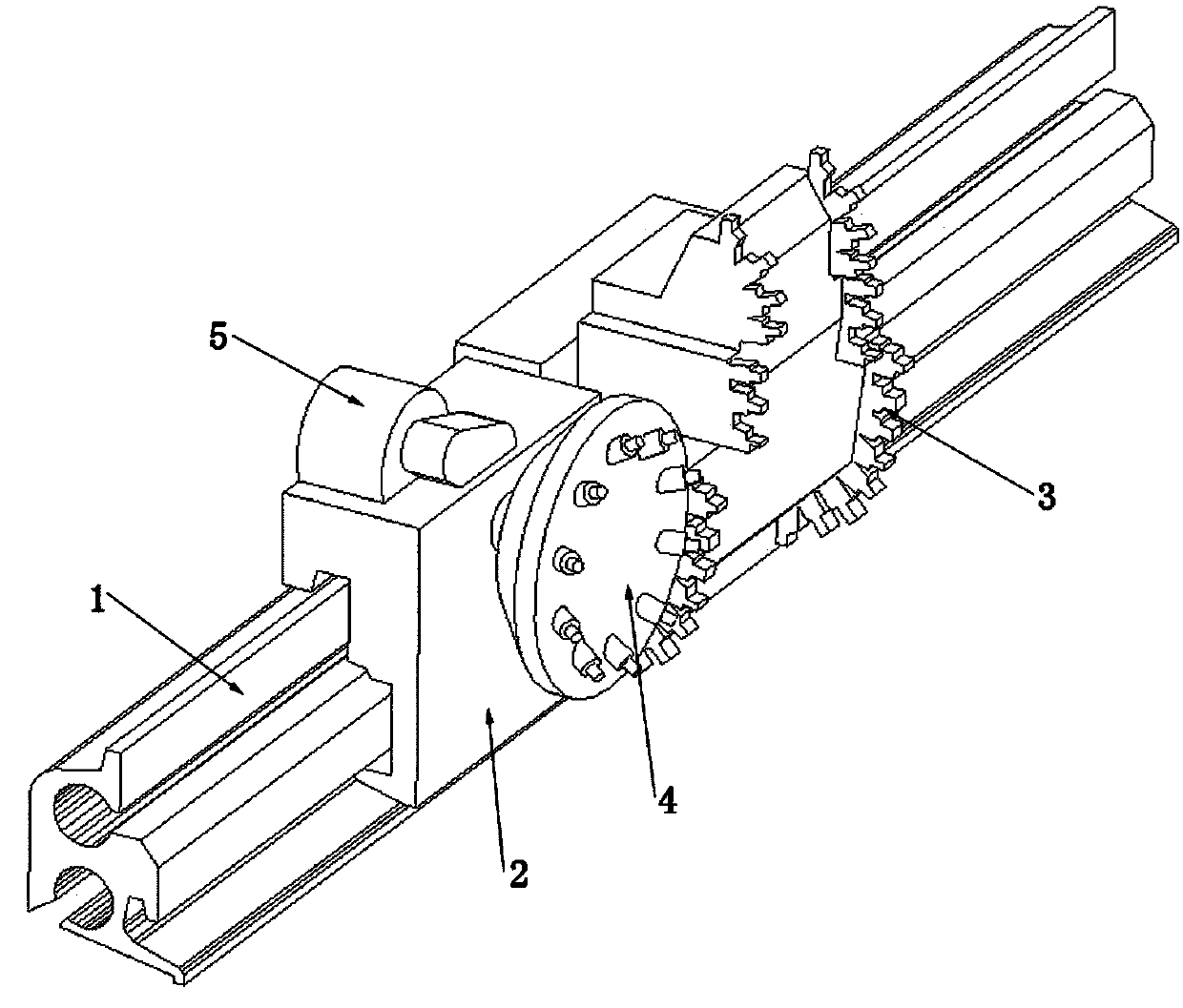

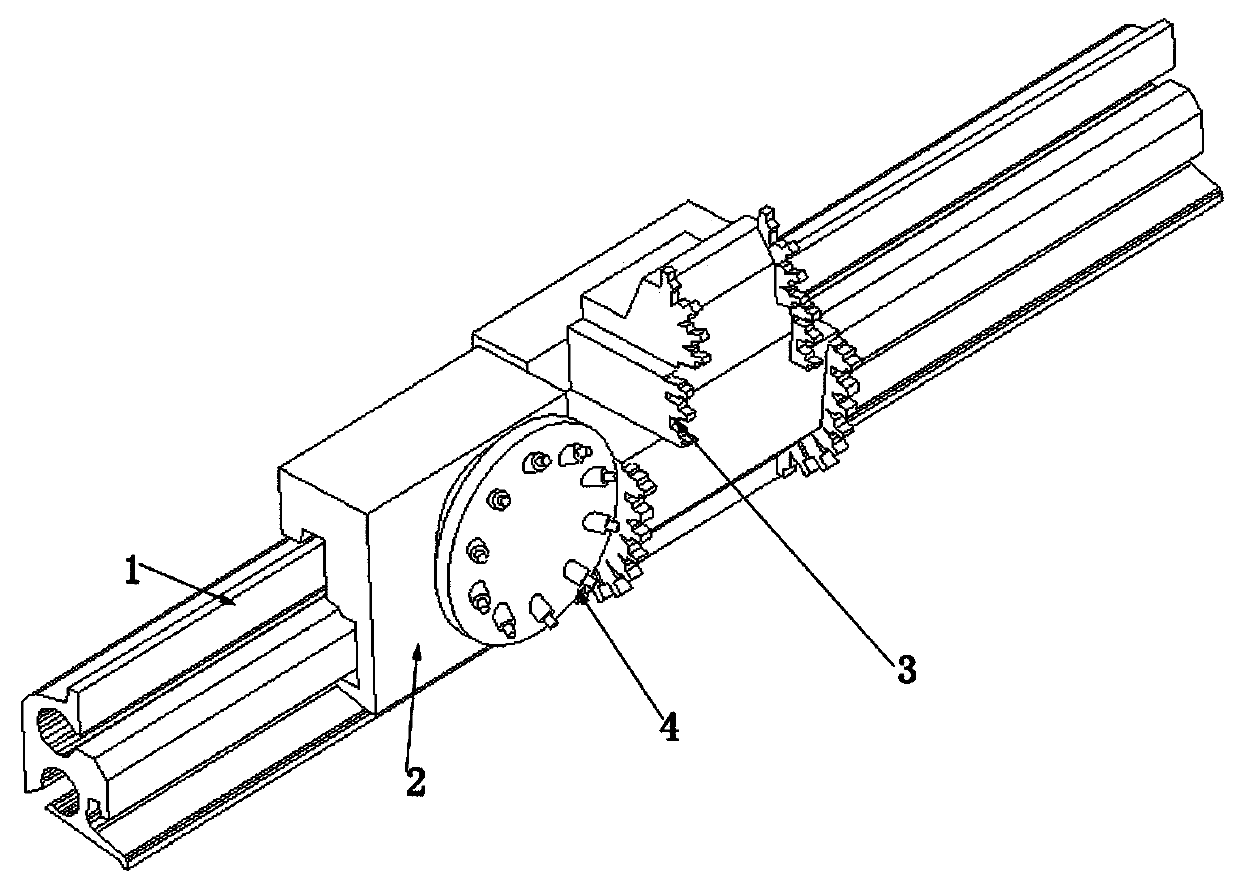

Thin and extremely thin coal seam mining method and device

InactiveCN110005414AIncrease free surfaceEasy to plan offUnderground miningSurface miningEquipment OperatorReciprocating motion

The invention belongs to the technical field of coal seam mining devices, and particularly relates to a thin and extremely thin coal seam mining method and device. An underground mine coal field is divided into a plurality of mining areas, air return roadways, belt conveyance roadways and track conveyance roadways in the mining areas are developed, and ventilation and conveyance systems of the mining areas are constituted; upper roadways and lower roadways and open-off cuts are driven along the coal seam direction, and independent return air systems are constituted; belt conveyors and scraperreversed loaders are installed in the lower roadways, coal conveyor systems are formed through milling coal holes in working faces and belt conveyors in the mining areas, and self-moving air bag supports are installed in the open-off cuts; and coal is ploughed through coal ploughs, and the ploughed coal is transported into the down trough scraper reversed loaders. Equipment operators all work in well-supported roadways without entering the working faces. The self-moving air bag supports are adopted to support roofs, and the coal ploughs move back and forth in the working faces to complete themining process of cutting, loading, transporting, supporting and treatment, thus 0.4-0.8 ultra-thin coal seam working face unmanned mining is realized.

Owner:江阴市康盛机械有限公司

Damping method and structure of ball joint for axleless bogie

ActiveCN109185331BAchieving radial precompressionImprove radial stiffnessNon-rotating vibration suppressionPivotal connectionsBogieVulcanization

The invention relates to a shock absorbing method and structure of a spherical hinge for a wheelless axle bogie, which adopt the method of arranging a split composite layer structure between a metal inner sleeve and a metal outer sleeve to meet the performance requirements of the spherical hinge, wherein the composite layer structure is that a metal separator plate is arranged inside a rubber layer and is vulcanized to form a rubber-metal-rubber structure, and a parting surface is arranged at the splitting position of the composite layer structure to meet the radial, axial, deflection and torsional stiffness requirements, and reduce rubber stress. As the split composite lay structure is arranged between the metal inner sleeve and the metal outer sleeve, the invention can realize large radial pre-compression to rubber, improve radial rigidity of the spherical hinge and realize minimal torsional rigidity. The invention has the characteristics that the free surface of rubber is greatly increased by the parting surface arranged at the splitting position, which can greatly reduce the stress caused by the extrusion to rubber, improve the fatigue life of rubber and the service life of thespherical hinge.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

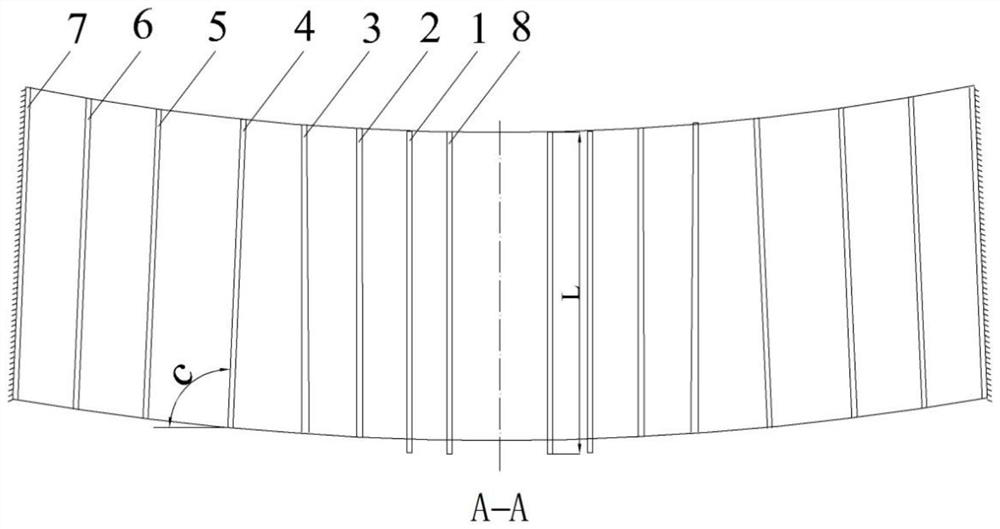

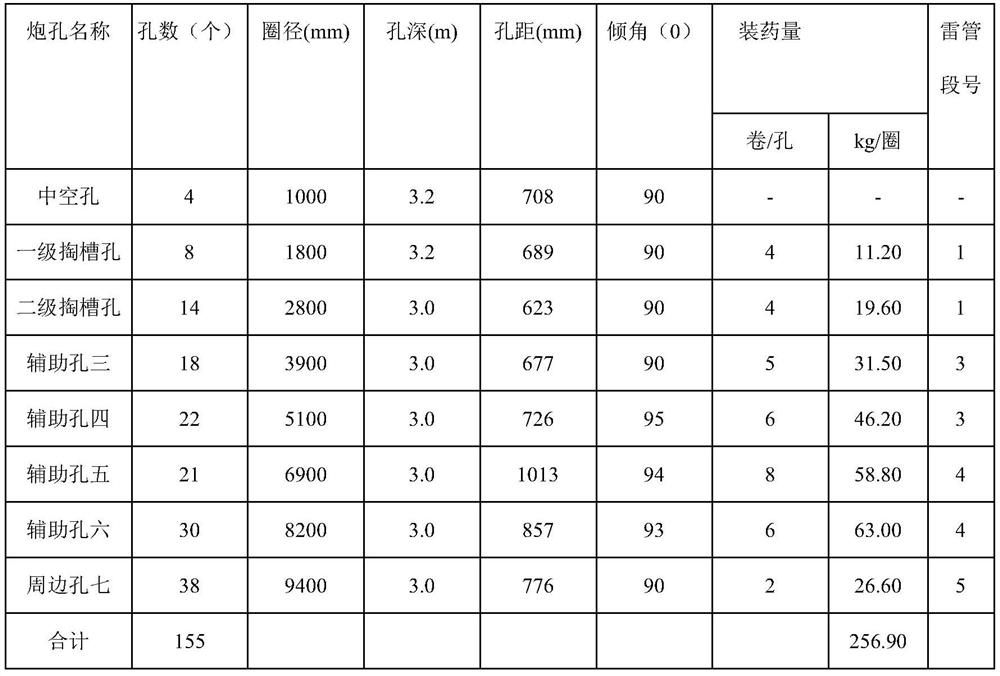

A Blasting Construction Method for Large-diameter Vertical Shaft in Deep Alluvial Layer in Frozen Soil

ActiveCN112197657BEnsure loop footageImprove the speed of tunneling constructionBlastingPipeMechanical engineering

The present invention provides a construction method for blasting frozen soil of large-diameter shafts in deep alluvial layers. The construction method includes the following steps: step S1, the shaft is constructed by freezing method; according to the design range of shaft excavation diameter, two circles of cutting holes are excavated from the inside to the outside , four circles of auxiliary holes and one circle of peripheral holes; the four circles of auxiliary holes are successively auxiliary holes three, auxiliary holes four, auxiliary holes five and auxiliary holes six from the inside to the outside, and one circle of peripheral holes is peripheral hole seven; step S2, drilling After the hole is formed, use a high-pressure air gun to clear the hole; step S3, fill the cutout hole, auxiliary hole and peripheral holes from the bottom of the hole to the hole opening and fill the energy-concentrating tube and loess blasting clay in sequence. The loess clay is filled with water clay, and the outer peripheral surface of the energy gathering tube is provided with a slit along the axial direction, the length of the slit is less than the axial length of the energy gathering tube, and the slit is far away from the axial ends of the energy gathering tube; Step S4 , detonate the cut hole, the auxiliary hole, and the peripheral hole sequentially from the inside to the outside.

Owner:河南隧通工程技术有限公司

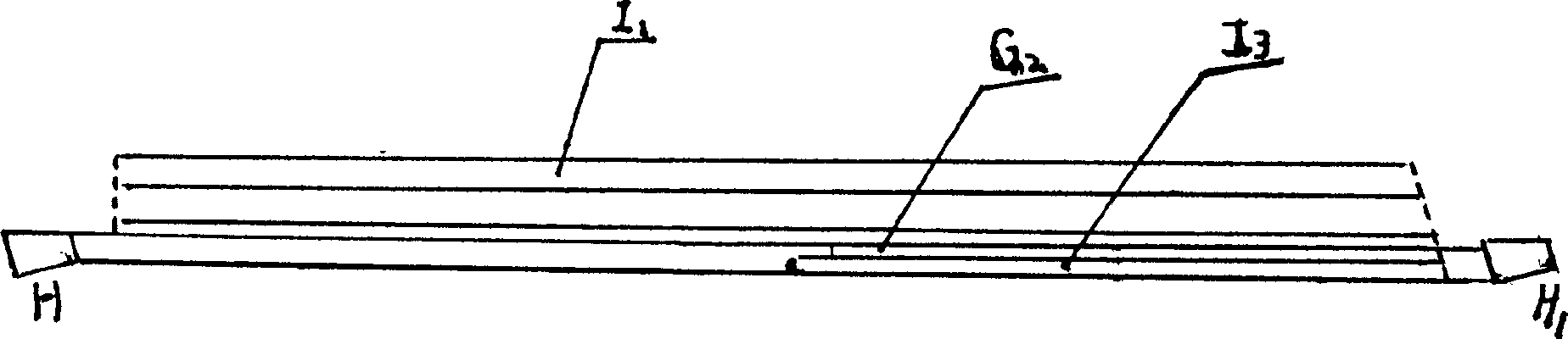

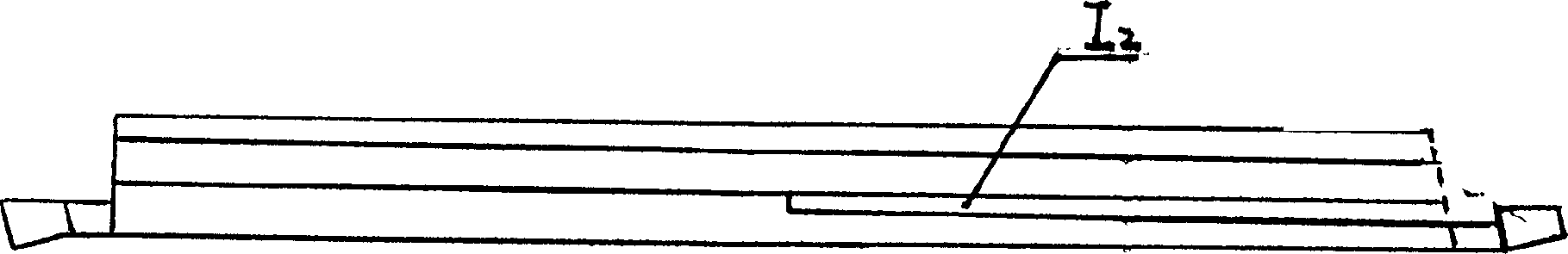

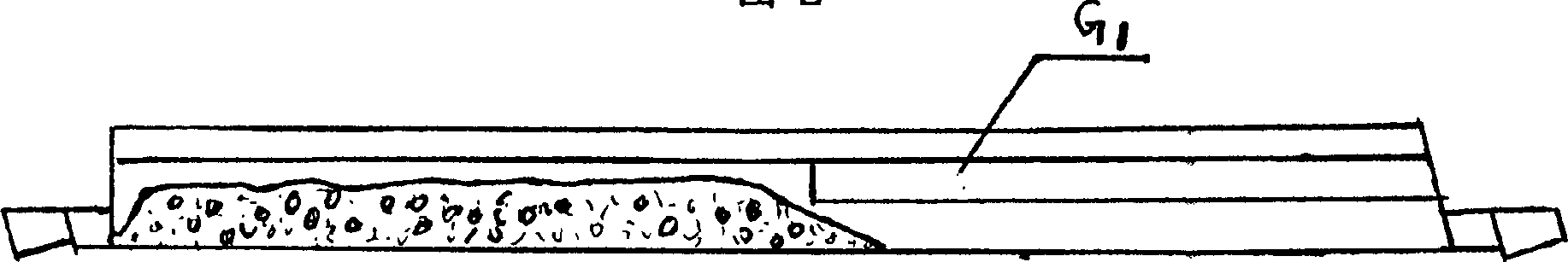

Mining method for once-mining overall height of gypsum ore deposit

InactiveCN1126860COptimize layoutReduce the rate of penetrationUnderground miningSurface miningGypsumMaterials science

The invention is a mining method for mining the whole height of the I gypsum group of the gypsum ore deposit at one time, which has the characteristics of low comprehensive cost and high labor productivity. The method of layer-by-layer mining from bottom to top is adopted in the mining of the mine, first in the gray shale G 2 Drill the shot in the middle, take out the G 2 Separately loaded and transported away, and then in plaster I 3 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 3 , after the mining room is wide enough, the gypsum I 2 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 2 , then in red shale G 1 Drilling holes in the middle and shooting down the red shale G 1 , but not transported away, piled in the mine, and finally in the gypsum I 1 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 1 . The invention has the advantages of simple process, easy realization and popularization.

Owner:LIAOYANG SHENGDA GYPSUM MINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com