Damping method and structure of ball joint for axleless bogie

A technology of bogies and ball joints, which is applied in the field of rail transit, can solve the problems of vehicles that cannot be applied to bogies without axles, and achieve the effects of reducing rubber stress, increasing free surfaces, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

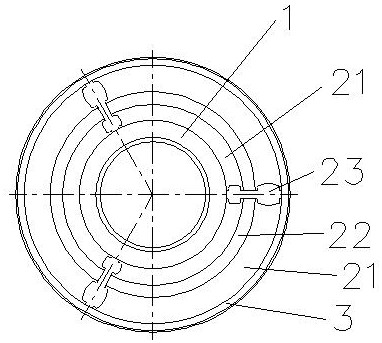

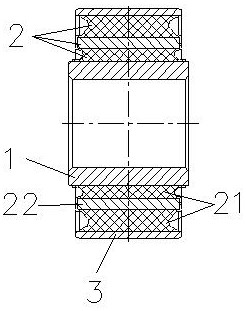

[0030] Such as figure 1 and figure 2 As shown, this embodiment is the best embodiment of the present invention, a structure of a ball joint for a wheelless bogie, which is an inner metal inner sleeve 1, a split-type composite layer structure 2 in the middle, and an outer metal inner sleeve. The jacket 3, wherein the composite layer structure 2 is a rubber-metal-rubber structure formed by setting a metal separator 22 inside the rubber layer 21 and vulcanizing the rubber layer 21, and the composite layer structure 2 is vulcanized and bonded to the metal inner sleeve 1 and the metal outer sleeve 3 between. The split composite layer structure 2 used can not only ensure that the precompression can be transferred from the outer rubber to the inner rubber when the ball joint is formed, but also reduce the deflection stiffness and torsional stiffness of the ball joint. Axial stiffness has very little effect. The parting surface at the parting position enables the rubber layer 21 t...

Embodiment 2

[0038] In this embodiment, the metal inner sleeve 1 and the composite layer structure 2 are vulcanized and bonded, and the composite layer structure 2 and the metal jacket 3 are assembled by interference. By setting the interference amount between the composite layer structure 2 and the metal jacket 3 Controls the amount of pre-compression of the rubber layer.

Embodiment 3

[0040] In this embodiment, the composite layer structure 2 can be divided into four lobes or more. When the composite layer structure 2 is divided into four lobes, the two lobes can be vulcanized symmetrically on the outside of the metal inner sleeve 1 first, and then pressed into the metal outer sheath 3 together with the other two lobes, so that a smaller diameter axis can be achieved Stiffness ratio; In addition, this method can also be used to realize that the assembled two petals are a hollow structure, and the vulcanized two petals are a solid structure, so that the radial space and solid functions can be realized.

[0041] At the same time, when there are more petals, the difficulty of design and processing will increase accordingly.

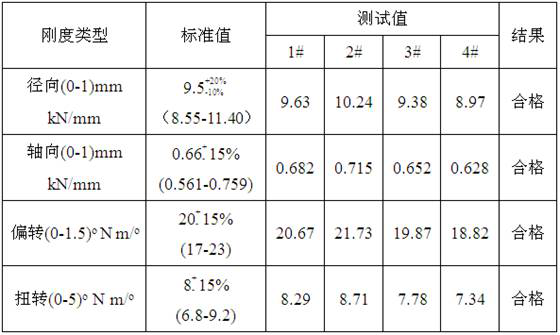

[0042] It can be seen from the above embodiments that the present invention also relates to a shock absorbing method for a ball joint used in a wheel-axle bogie, which adopts the method of setting a split composite layer structure 2 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com