Method for improving fatigue reliability of axle box positioning node and axle box positioning node

A technology for positioning nodes and reliability, applied in axlebox installation, transportation and packaging, railway car body parts, etc., can solve the problem that the free surface of rubber layer is small, the internal stress of rubber cannot be released in time, and the unfavorable fatigue and reliability of axlebox positioning nodes Sex and other issues to achieve the effect of prolonging the service life and ensuring the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

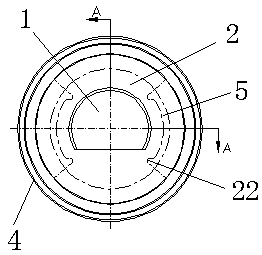

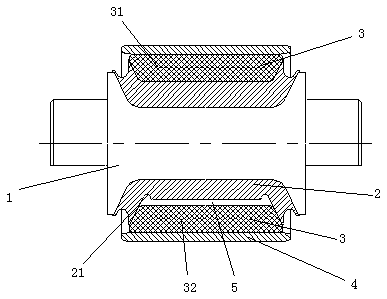

[0028] An axle box positioning node, including a mandrel 1, a rubber layer 2, a split casing 3, and an overall casing 4, the rubber layer 2 is vulcanized and bonded to the outside of the mandrel 1, and a part of the split casing 3 is vulcanized and bonded to the rubber layer 2 The outer side and the other part are assembled on the outer side of the rubber layer 2, the fixed surface is between the rubber layer 2 and the mandrel 1, and the vulcanized part of the split casing 3, and there is a free surface between the rubber layer 2 and the assembled part of the split casing 3 ; The integral body formed by mandrel 1, rubber layer 2 and split casing 3 is pressed into the overall casing 4. The fixed surface between the rubber layer 2 and the vulcanized part of the mandrel 1 and the split casing 3 ensures the overall performance of the axle box positioning node, and the free surface between the rubber layer 2 and the assembled part of the split casing 3 makes the axle box positioning...

Embodiment 2

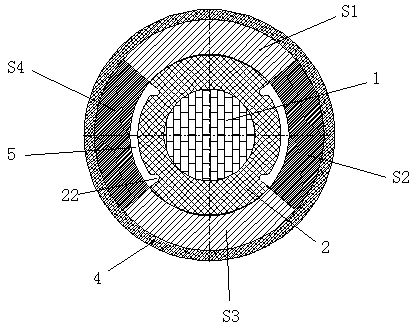

[0034] This embodiment is basically the same as Embodiment 1, the difference is that the outer surface of the split casing 3 of this embodiment is cylindrical as a whole, and is divided into four pieces S1-S4 in the radial direction, and S1 and S3 have the same specifications and are vulcanization components 31 and S2. The same specification as S4, it is an assembled component 32, and S1 and S3 are symmetrically vulcanized on the outside of rubber layer 2, and S2 and S4 are symmetrically assembled on the outside of rubber layer 2, that is, S1-S4 are symmetrically arranged on the outside of rubber layer 2 to ensure the positioning nodes of the axle box stability and overall performance.

[0035] The overall casing 4 is a hollow cylinder. First, vulcanize the rubber layer 2 between S1, S3 and the mandrel 1, then assemble S2 and S4 to the outside of the rubber layer 2, and finally press the assembled whole into the overall casing 4 to form a Complete axlebox positioning node.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com