A Blasting Construction Method for Large-diameter Vertical Shaft in Deep Alluvial Layer in Frozen Soil

A construction method and technology for alluvial layers are applied in the field of permafrost blasting construction of large-diameter shafts in deep alluvial layers, and can solve the problems of long construction period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

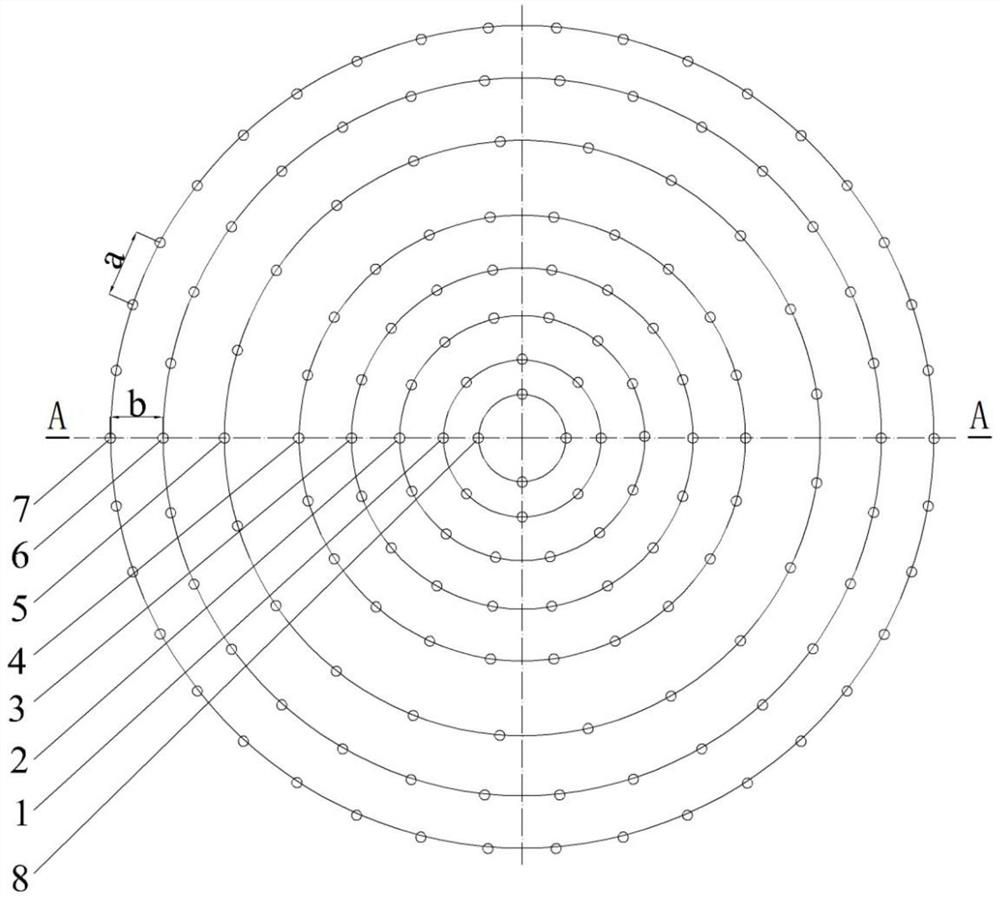

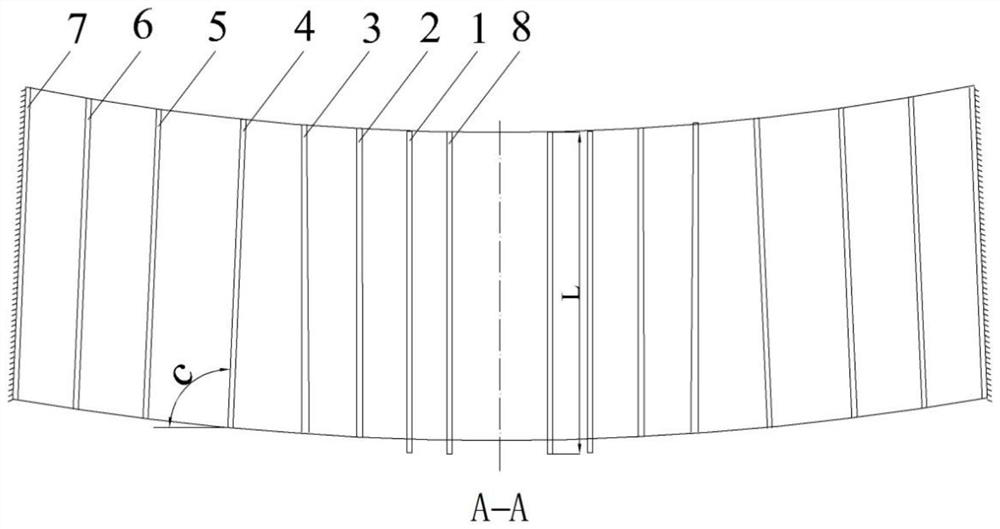

[0041] According to specific embodiments of the present invention, such as Figure 1-2 Shown, the present invention provides a kind of deep and thick alluvial layer large-diameter vertical shaft permafrost blasting construction method, the thickness of deep and thick alluvial layer in the present invention is not less than 400m, and the excavation waste path scope of shaft is 8-10m (excavation waste path can be 8m, 8.4m, 8.5m, 9m, 9.4m, 9.5m, 9.9m, 10m, etc.), the vertical shaft blasting effect has a great influence on the construction period, post-blasting forming, formwork support and other construction techniques. Based on the basic principle of smooth surface blasting, the best blasting effect can be achieved by optimizing the layout of blastholes, charge parameters, and initiation methods; the vibration of the shaft wall should be within a reasonable range to reduce damage to the shaft wall; blasting The size of the rear block is appropriate, which is convenient for shove...

Embodiment 2

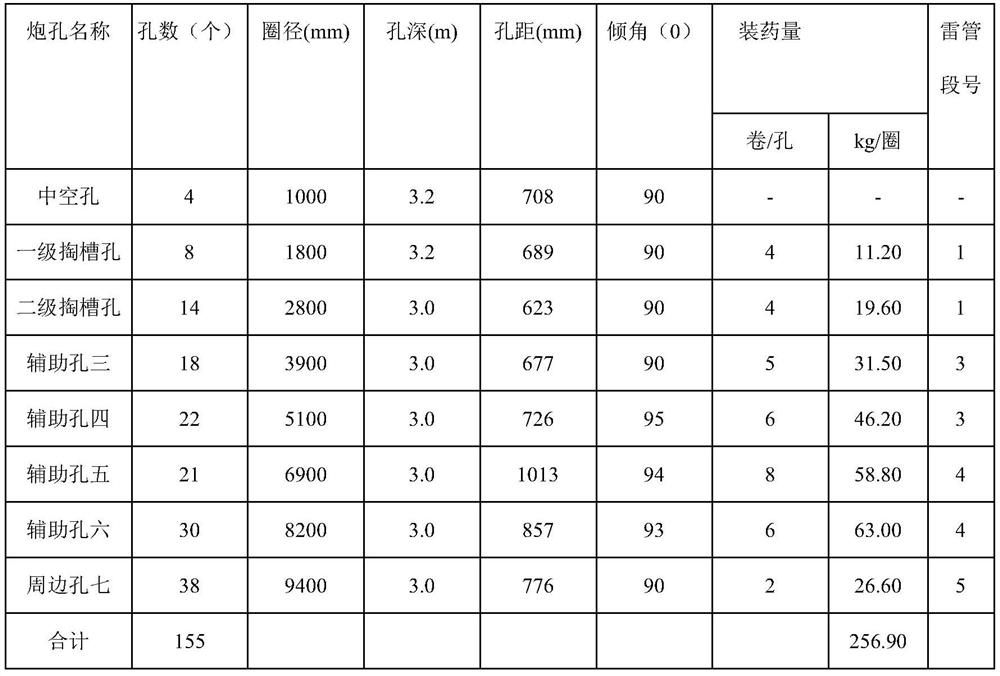

[0060] The blasting parameters in the frozen soil blasting construction method in the above-mentioned embodiment 1 are a rough range, which can be selected according to the actual situation in the construction. In Example 2, taking the excavation of a shaft with a barren diameter of 9.4m and maintaining the temperature of the permafrost at -10°C as an example, a set of blasting parameters with better blasting effects is designed. The optimized blasting parameters can achieve better blasting effects and ensure cycle footage, to achieve rapid blasting of shafts. The amount of explosives loaded in a single hole of the first-level cut hole 1 and the second-level cut hole 2 is 1.4kg; the amount of explosives loaded in a single hole of the auxiliary hole three 3 is 1.75kg; The amount of explosives is 2.1kg; the amount of explosives installed in a single hole of the auxiliary hole five 5 is 2.8kg; the amount of explosives installed in a single hole in the peripheral hole seven 7 is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com