Patents

Literature

253results about How to "Improve blasting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital mine safety monitoring and inspecting system

InactiveCN102999873AReduce outputSafe and efficient productionData processing applicationsInformation processingRelational system

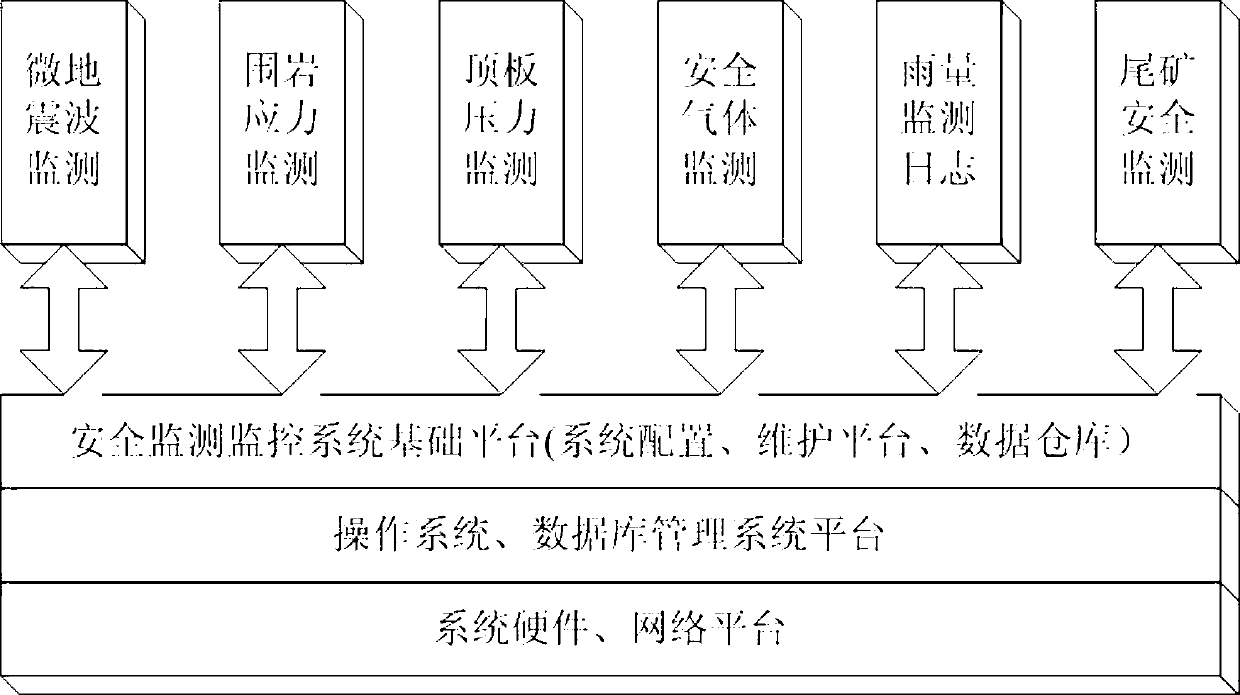

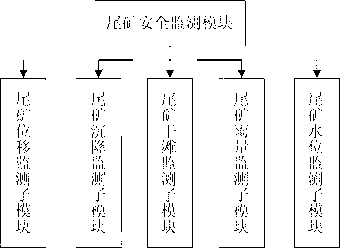

The invention provides a digital mine safety monitoring and inspecting system which sequentially comprises four layers, namely a system hardware and network platform, an operation system and database management system platform, a safety monitoring and inspecting system base platform and a safety monitoring and inspecting system software platform, wherein in the four layers, the lower layer provides service for the upper layer and provides interactive connectors. The digital mine safety monitoring and inspecting system is integrally constructed on the hardware platform and network platform, and interaction between the digital mine safety monitoring and inspecting system and a bottom layer hardware facility and a monitoring and inspecting system is achieved through an operation system and a database management system, the interactive information is processed and stored in the safety monitoring and inspecting system base platform in distributing mode, and the safety monitoring and inspecting system software platform at the highest layer achieves scanning and processing on the interactive information through different functional subsystems and issues control information to the operation system and database management system platform through the safety monitoring and inspecting system base platform. The digital mine safety monitoring and inspecting system has the advantages of being capable of achieving safety monitoring, safety alarm and safety control on mines.

Owner:SHANDONG GOLD GROUP

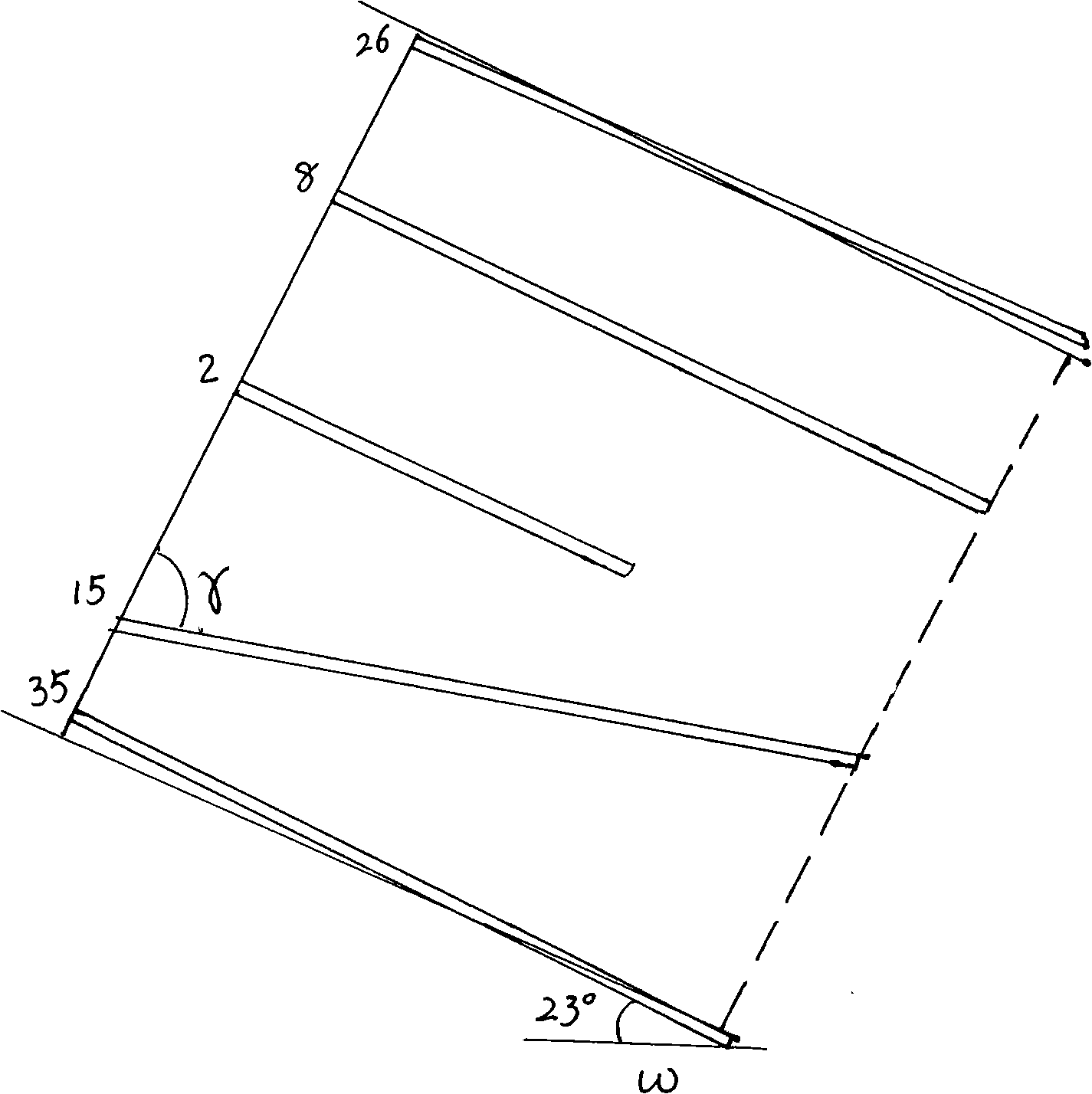

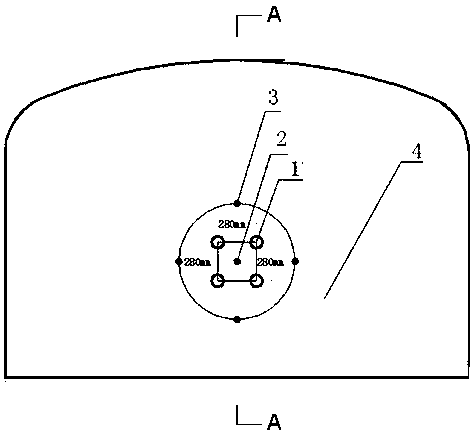

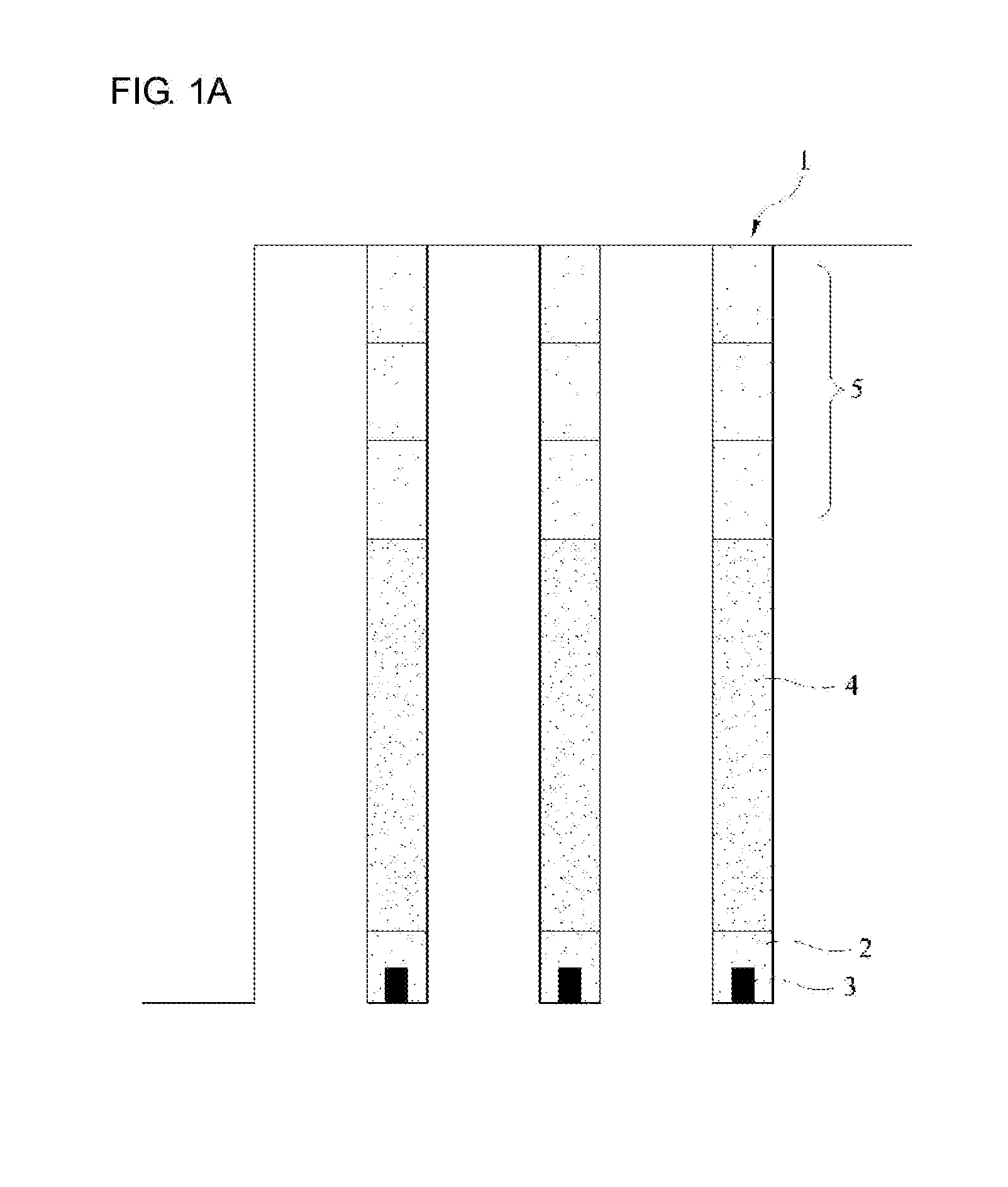

Dip laneway digging hole layout mode

The invention discloses a mine downhill roadway tunnelling shot hole arrangement way, which comprises cut holes, auxiliary holes, a peripheral hole and a bottom hole, wherein the cut holes are in a wedge arrangement way, and are arranged on the middle upper portion of a roadway cross section, wherein the pitch of two rows of wedge cut holes is larger 30% than the pitch of current wedge cut holes, a row of auxiliary straight holes are arranged between two rows of wedge cut holes, and the width of the auxiliary straight hole is 0.5 time than that of the cut holes, and a row of auxiliary throwing holes are further arranged under the two rows of the cut holes, and the drilling direction of the auxiliary throwing holes is drilled to the oblique upper portion in smaller than 90 degrees with the roadway cross section, and the auxiliary throwing holes are finally detonated with the bottom hole in the same section. The invention fully utilizes the least resistance line principle, reasonably distributes the wedge cut holes, and increases the blasting efficiency and tunnelling velocity.

Owner:山东科技大学科技产业总公司

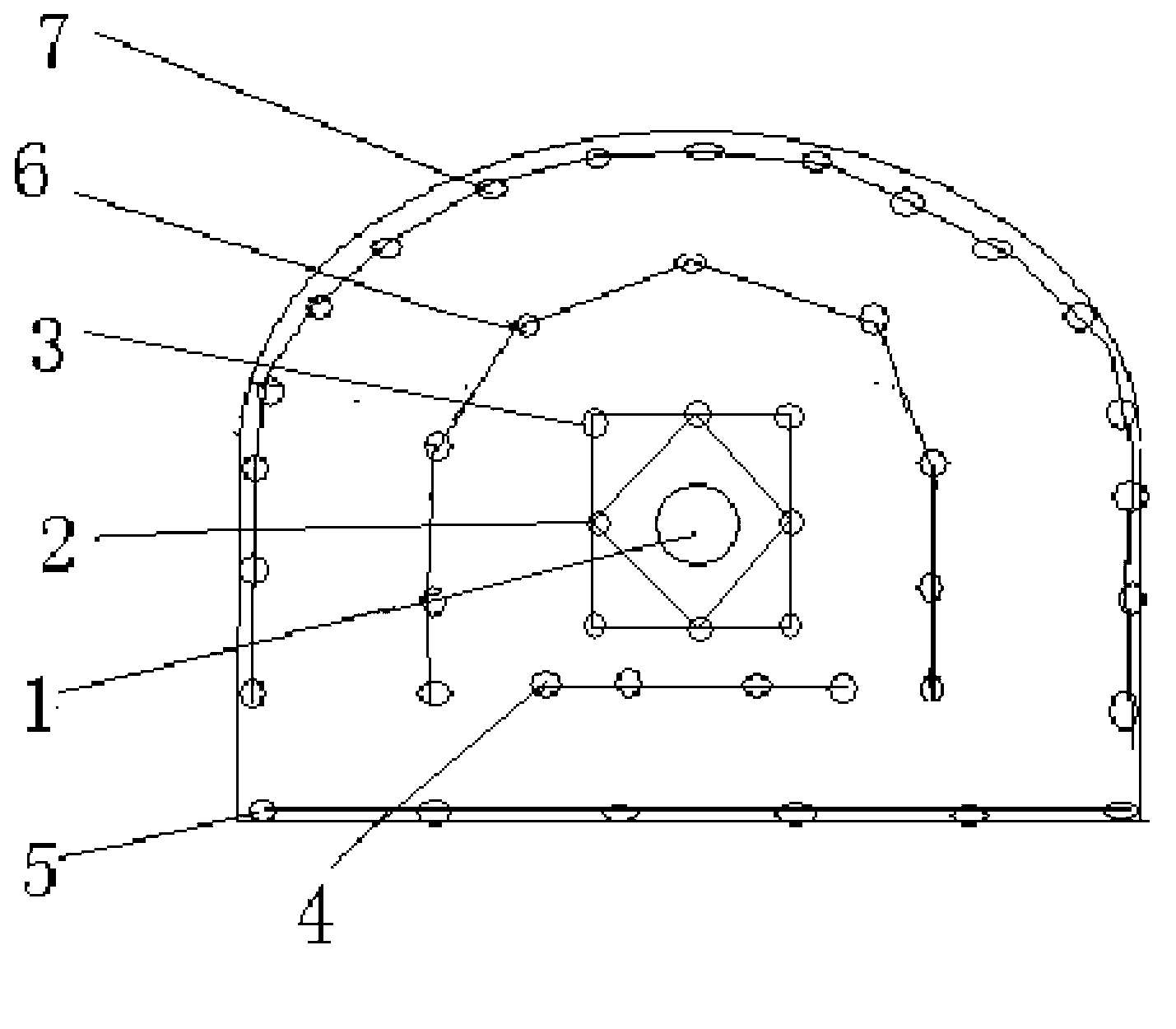

Channeling method in rapid roadway explosion

The invention discloses a channeling method in rapid roadway explosion. The arrangement structure of channeling holes is as follows: a large-diameter central hole of which the diameter is phi 100-120mm and the depth is more than 4m is drilled in the central position of a channeling area at a roadway cross section; 4-6 smashing swelling holes are formed around the central hole; a row of smashing holes are formed among the smashing swelling holes; a row of auxiliary throwing holes at intervals of 0.5m are further formed below the smashing swelling holes at the lowermost part; the drilling direction of the auxiliary throwing holes inclines towards to a position above a roadway, so as to form an inclined angle which is less than 85 degrees with the roadway cross section; and subsequently explosive is filled for exploding to form channel cavities. The channeling method utilizes the minimum resistance line theory, and the central hole enlarges the smashing free surface and the smashing swelling space of a drilled channel, deeper channel cavities are formed, and the depths of the ordinary auxiliary holes and the ordinary around holes are further deepened to 4m, so that the explosion efficiency is improved, and the once explosion depth is increased.

Owner:SHANDONG UNIV OF SCI & TECH

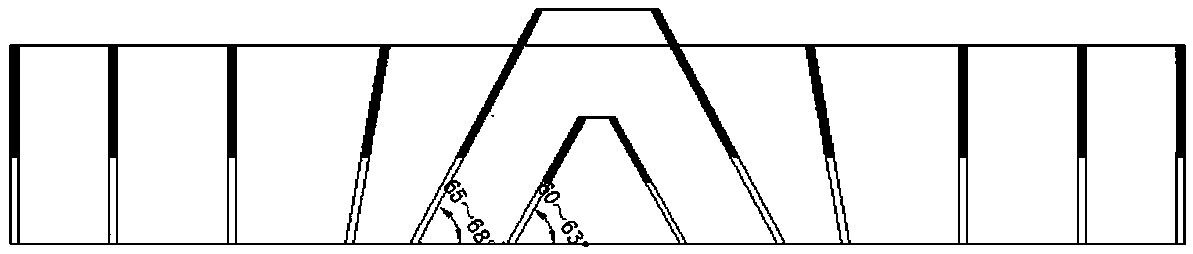

Tunnel millisecond blasting method

ActiveCN107764144AReduce the blast velocityReduced blasting noise and vibrationBlastingEngineeringStructural engineering

The invention discloses a tunnel millisecond blasting method. The method comprises the following steps of 1, distributing of blast holes, the number of the blast holes and the blasting parameters of the blast holes are designed, wherein the blasting parameters of the blast holes comprise hole diameters, hole distances, resistance lines and depth of a periphery hole, an reliever hole and a cut hole; 2, the blast holes are drilled in a tunnel boring face to be blasted; 3, explosive loading is carried out on the blast holes drilled in the tunnel boring face; 4, blocking and compacting is carriedout on the blast holes filled with explosive; 5, time delay setting is carried out on digital electronic detonators in all the blast holes; and 6, after the time delay setting is finished, wire connecting is carried out, and sequential detonation is conducted after determining that no errors exist. Compared with an existing millisecond blasting technology which is complex in blasting mechanism anddoes not have explicit theory and practice supports, the tunnel millisecond blasting method has the advantages that the different cut blasting methods are adopted for different surrounding rocks andfield conditions, so that the purposes of improving blasting efficiency, reducing the vibration speed and saving financial resources are achieved.

Owner:北京住总集团有限责任公司 +1

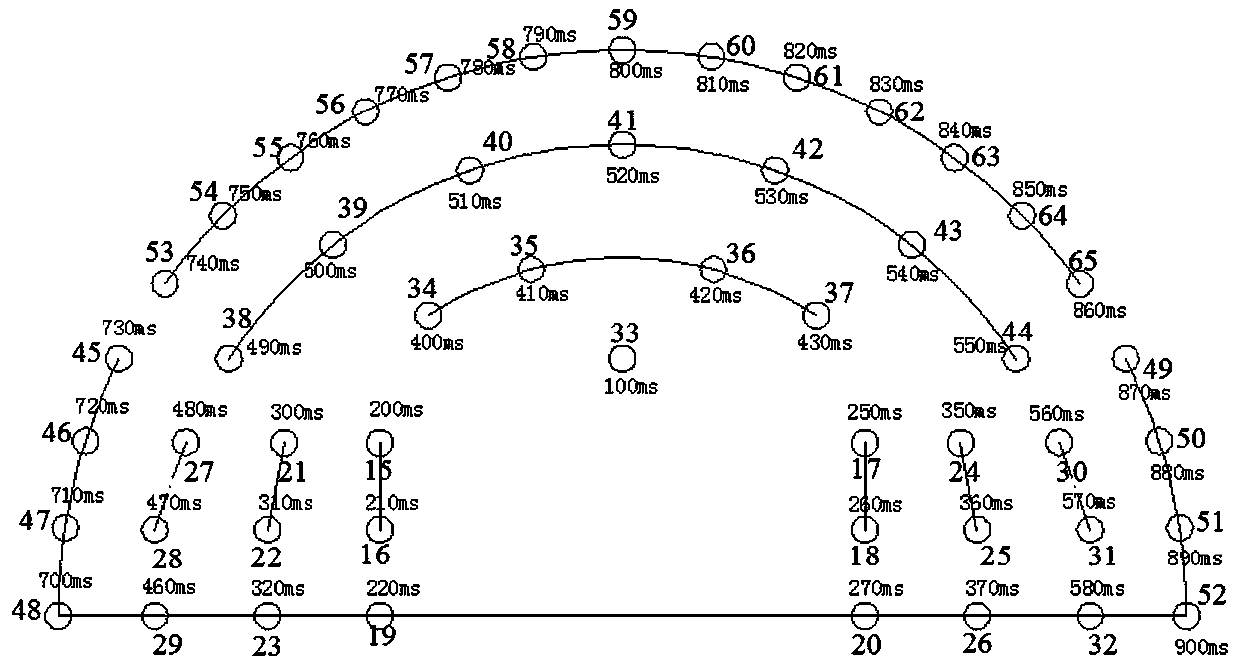

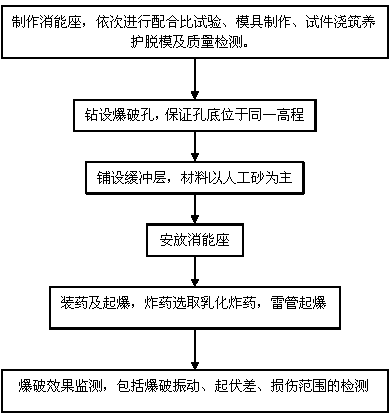

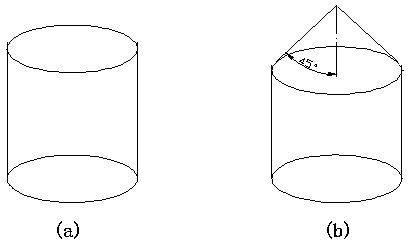

Method for blasting and excavating dam foundation and rock foundation

The invention discloses a method for blasting and excavating a dam foundation and a rock foundation. The method comprises the steps of step 1, drilling blast holes, and paving buffer layers at the bottom parts of the blast holes; step 2, vertically installing energy dissipation seats on the buffer layers, and filling explosive, wherein the energy dissipation seats are prepared by adopting concrete, the concrete is formed by cement, water, iron sand, superplasticizer and gel, the water-cement ratio is 0.24-0.28, the mass ratio of the iron sand and the cement is (1.6-3.0):1, and the mass of the superplasticizer is 1.0%-2.0% of that of the cement; step 3, blasting through a detonator. The method disclosed by the invention has the advantages that the operation is quick and convenient, the construction cost is low, the blast shock waves are reflected for multiple times through the energy dissipation seats, the energy of the blast shock waves is induced to gather in the horizontal direction, the full crushing of rock bodies between adjacent blast holes can be realized, the blasting efficiency can be further increased, meanwhile, the damage to the bottom parts of the blast holes can be further reduced, and the flatness of an excavation surface is increased.

Owner:WUHAN UNIV

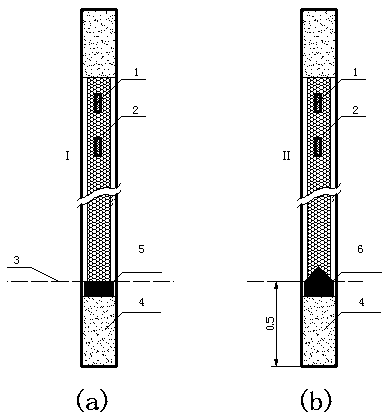

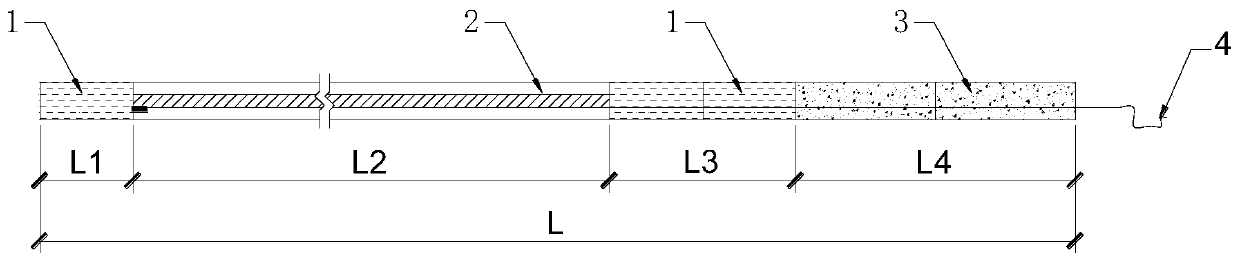

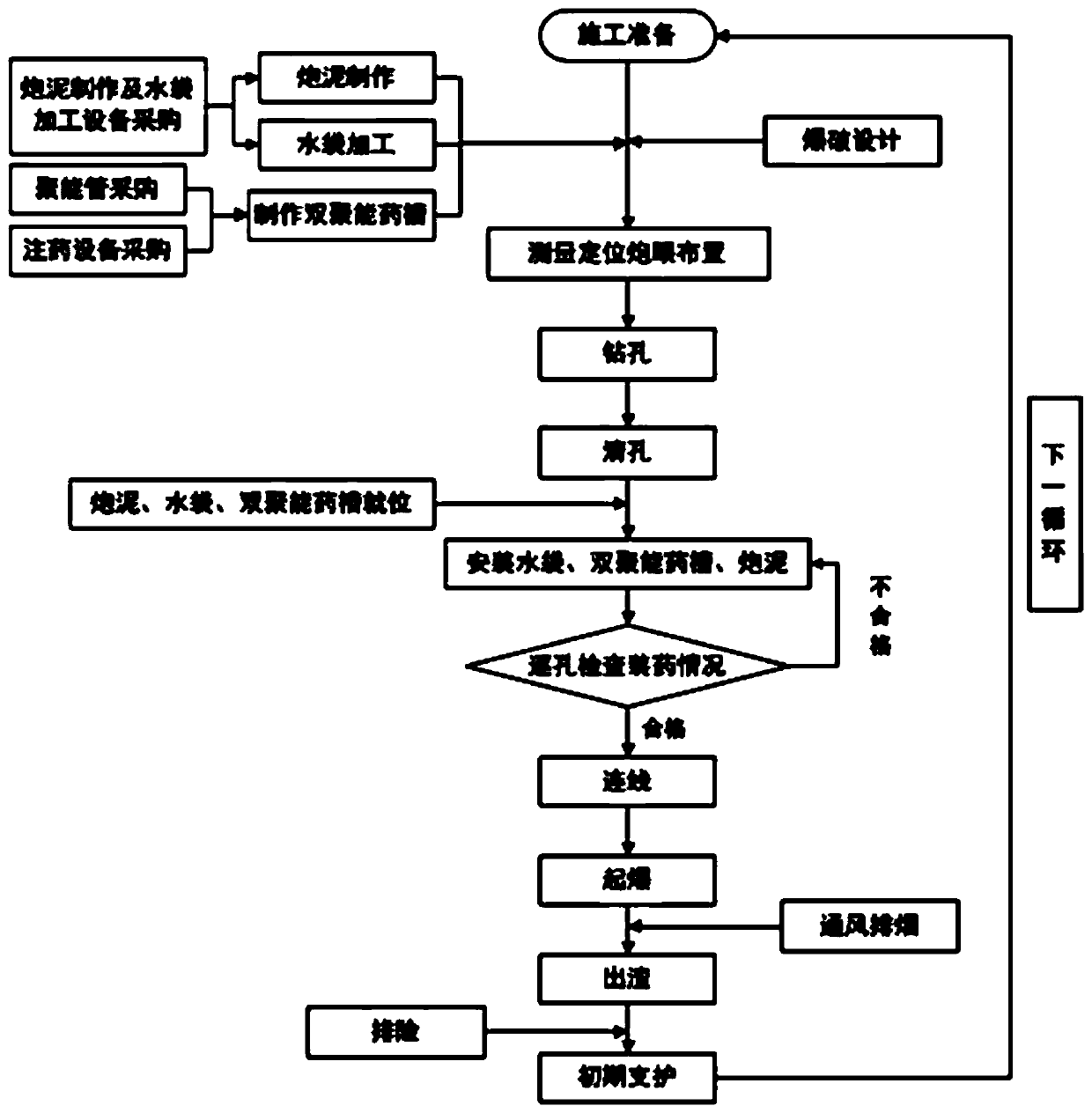

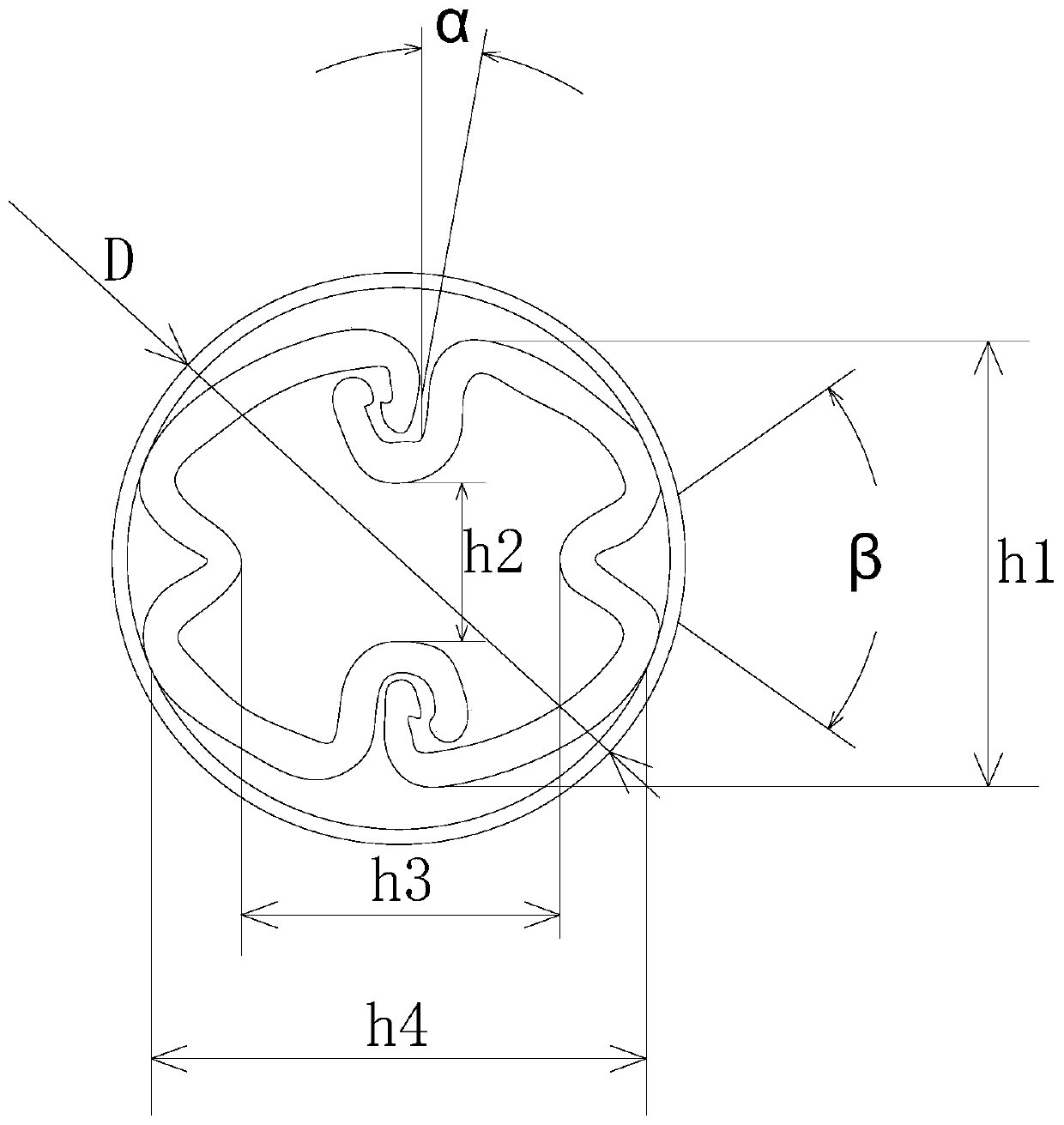

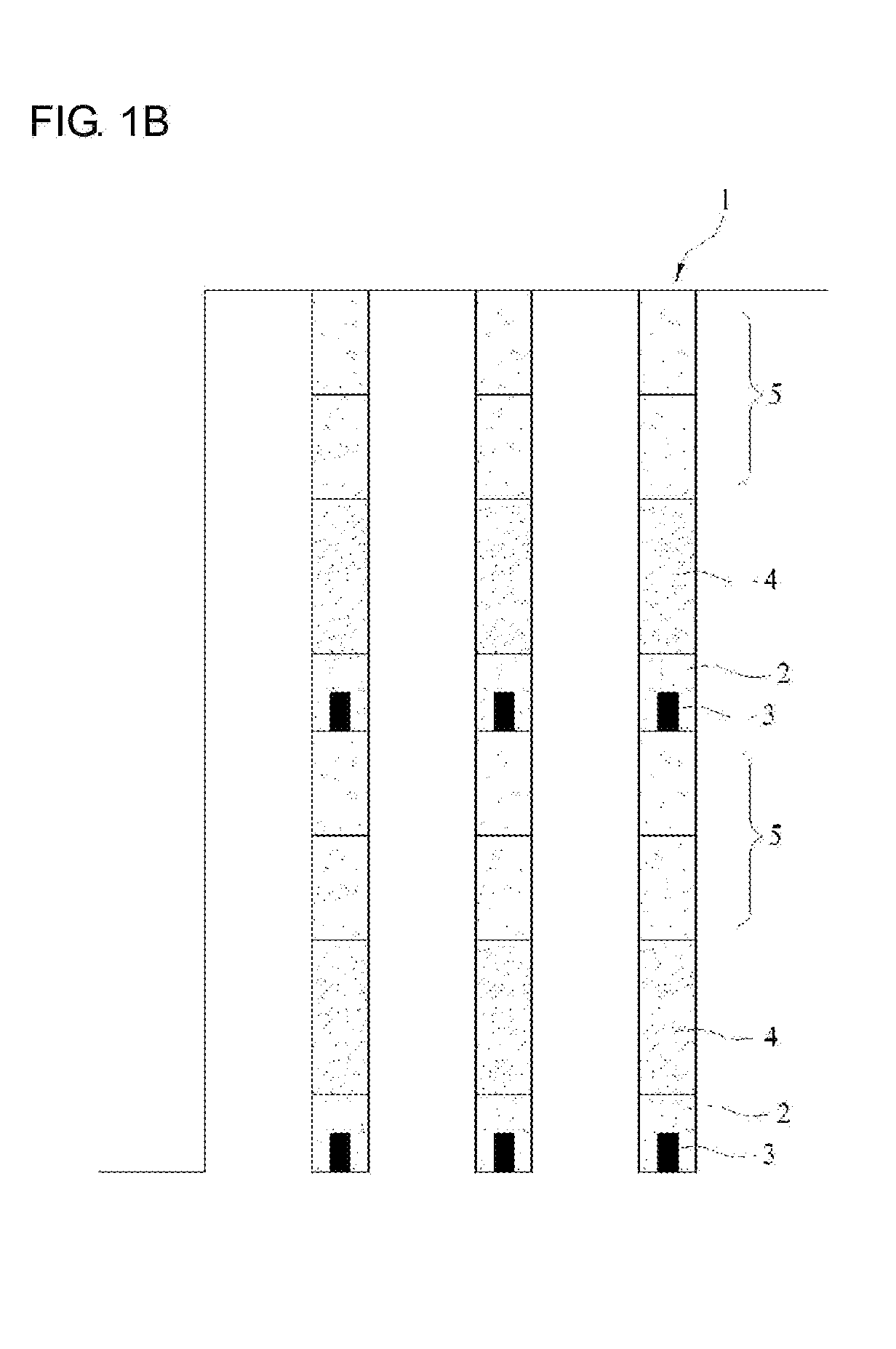

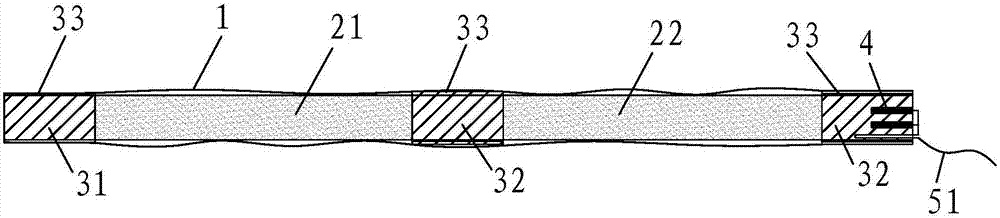

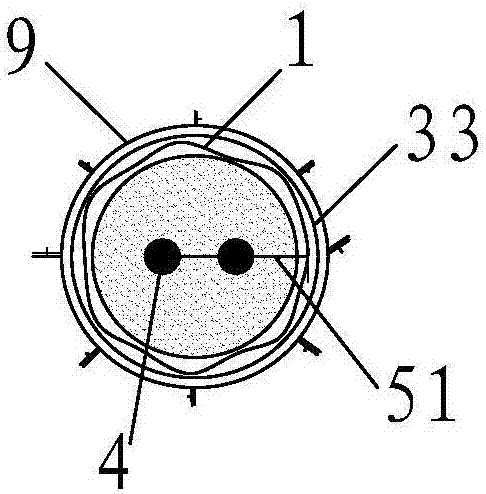

Periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting, and construction method thereof

PendingCN110332860AThe initial crack extension increasesEnhance static effectBlastingWorking environmentEngineering

The invention discloses a periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting, and a construction method thereof, and belongs to the technical field of tunnel construction. The periphery hole charging structure for energy-gathered hydraulic pressure smooth blasting is formed by a shot hole, water bags, an energy-gathered pipe powder charge and a stemming, wherein the water bags, the energy-gathered pipe powder charge and the stemming are arranged in the shot hole; the bottom of the shot hole is a section of water bag; the middle part of the shot hole is twosections of water bags; the energy-gathered pipe powder charge is arranged between the water bag on the bottom of the shot hole and the water bags in the middle of the shot hole; the stemming is blocked in the shot hole; a high-temperature high-pressure gas produced by explosion produces a 'water wedge' effect through a jet flow formed in an energy-gathered groove and the water bags in the smoothblasting shot hole under a blasting action, so that a rock initial crack is promoted to extend, expand and enlarge; meanwhile, due to a composite blocking function of the water bags and the stemming,the formed crack is favorably extended, expanded and enlarged; and the water bags are placed in the smooth blasting shot hole, and a water spray formed in the blasting process further plays a role infalling dust, so that the ventilation time is reduced, the working environment is improved, and the body health of constructing personnel is protected.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

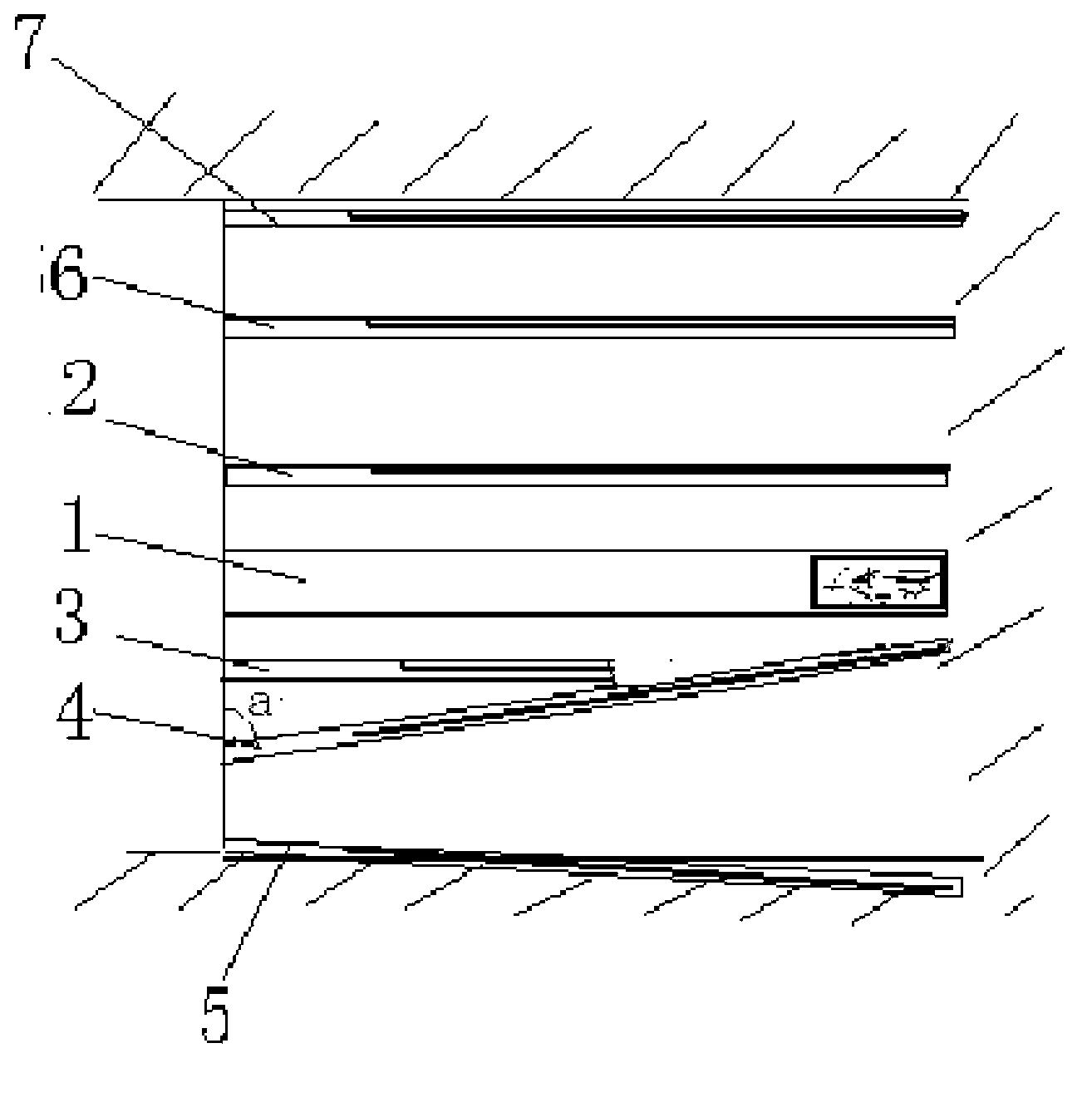

Method for enhancing slotting blasting efficiency of roadway (tunnel) tunneling

InactiveCN107843156APrevent rush outOptimal Blast Compensation CoefficientBlastingTunnelsDetonatorEngineering

The invention relates to a method for enhancing the slotting blasting efficiency of roadway (tunnel) tunneling. The method comprises the steps that four empty holes perpendicular to a working face andwith the diameters being 78 mm are dilled in the lower middle part of a roadway (tunnel) tunneling working face, a first explosive charging hole with the diameter being 50 mm is formed in the centerof a connecting line of the empty holes and serves as a first section hole for detonating, and four evenly-distributed second explosive charging holes with the diameters being 50 mm are drilled in a circumference with the radius being 40 cm by taking the center of the connecting line of the empty holes as a circle center and serve as a second section for detonating. According to the technical scheme, an inverse detonating mode is adopted, the first explosive charging hole in the middle and the surrounding second explosive charging holes adopt the mode of hole-bottom detonating, detonating primers are all arranged at the bottom of blast holes, and energy gathering cavities of both detonators and explosive cartridges face towards the outside of the holes, so that the propagation direction ofexplosive detonating waves and the direction of throwing rock are consistent; and on the one hand, complete crushing of the rock can be ensured, on the other hand, it can be ensured that the more crushed rock can be thrown out of the hole through explosive blasting energy, so that the slotting blasting efficiency is effectively improved.

Owner:NANJING MEISHAN METALLURGY DEV +1

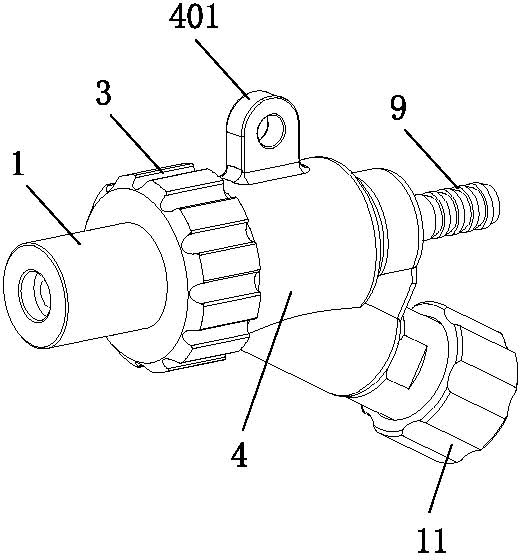

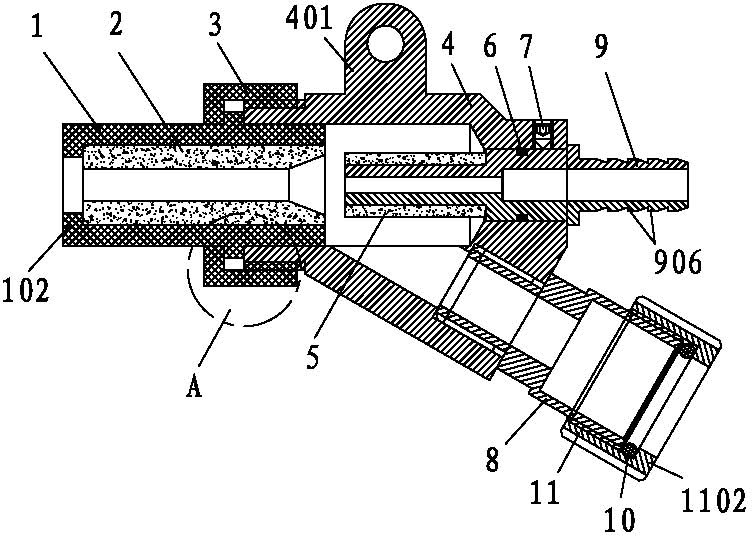

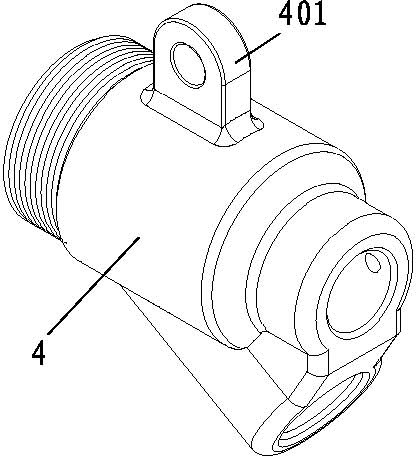

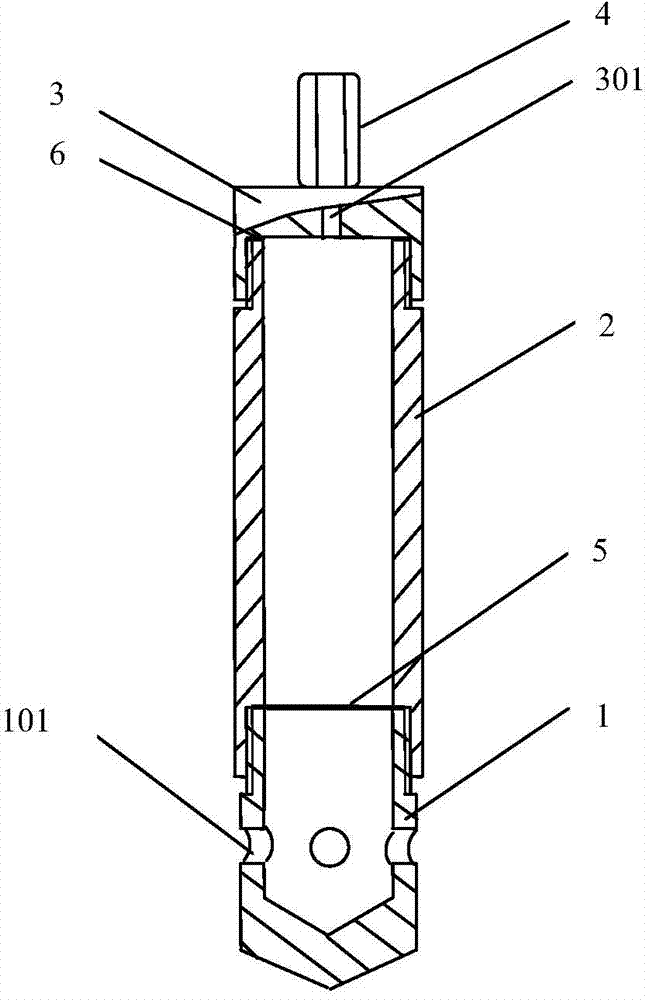

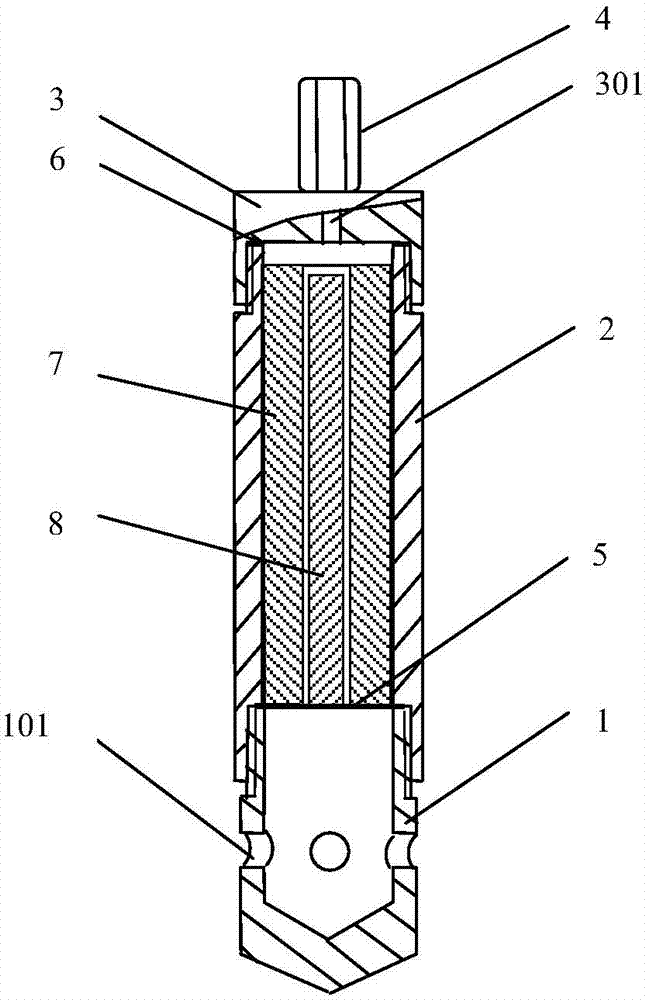

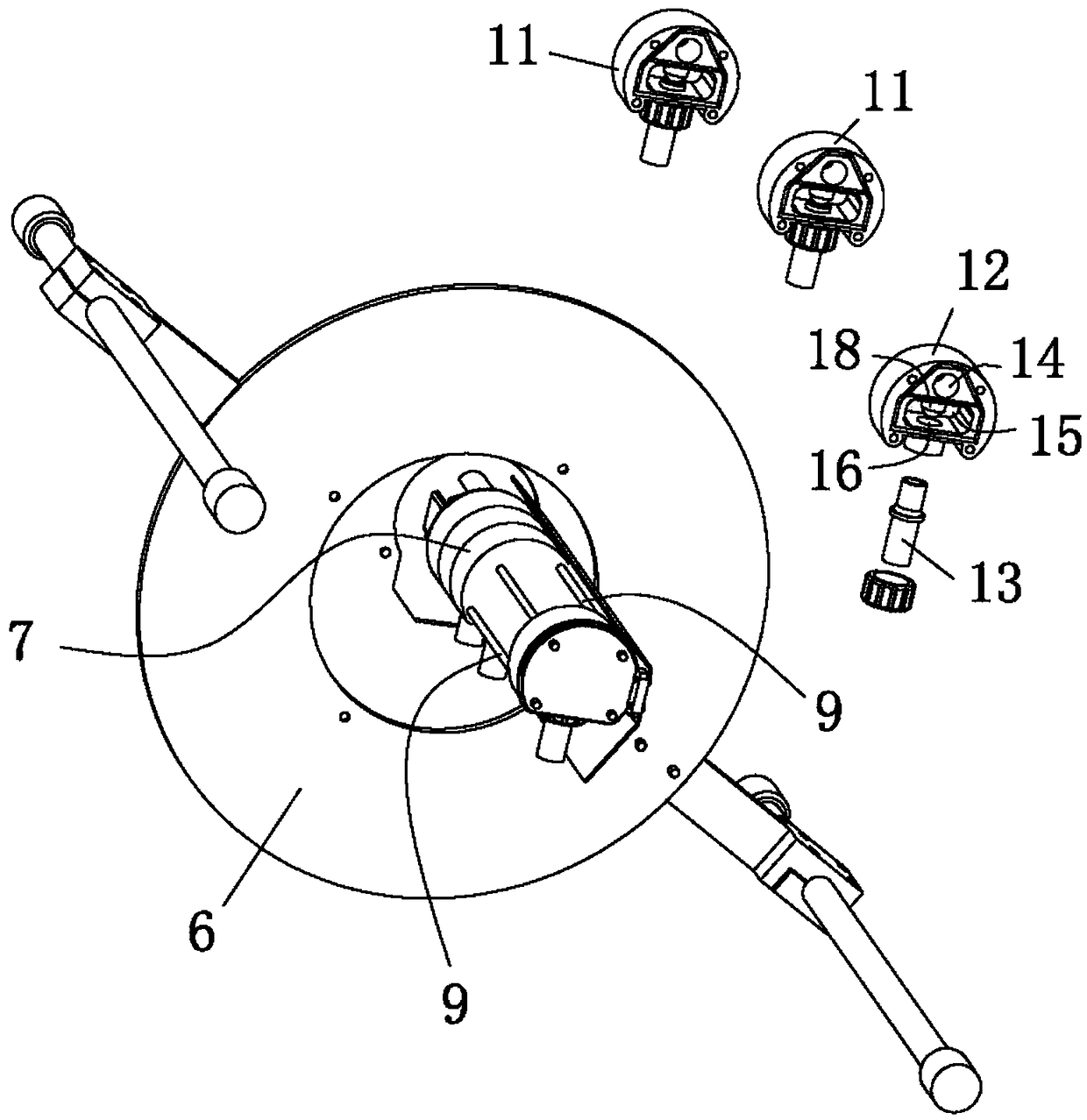

Sand-blasting gun

InactiveCN102642178AImprove blasting efficiencyImprove cleaning efficiencyBlast gunsSand blastingSpray nozzle

The invention relates to the technical field of surface treatment, in particular to a sand-blasting gun, which comprises a nozzle mechanism, a spray gun main body, an air supply mechanism and a sand supply mechanism. The nozzle mechanism comprises a nozzle, a nozzle sleeve and a locking nut, the nozzle is arranged in a cavity of the nozzle sleeve which is connected with a front end portion of the spray gun main body through the locking nut. The air supply mechanism comprises an air nozzle and a protective jacket which is sleeved on the outer wall on the front end portion of the air nozzle, the middle portion of the air nozzle is fixed on the back end portion of the spray gun main body, and the protective jacket and the front end portion of the air nozzle are located at the cavity of the spray gun main body. The sand supply mechanism comprises a sand nozzle and a sand nozzle sleeve, and two ends of the sand nozzle are respectively sleeved on the sand nozzle sleeve and the lower end portion of the spray gun main body. The nozzle sleeve and the locking nut both guarantee that the nozzle and the spray gun main body have a same axle wire, so that sand blasting efficiency of the sand-blasting gun can be improved, and cleaning and processing efficiency are improved accordingly. The protective jacket has good protective effects on the air nozzle, damage to the air nozzle caused by the sand flow is avoided, service life of the air nozzle is prolonged, and service life of the sand-blasting gun is prolonged accordingly.

Owner:东莞吉川机械科技股份有限公司

Preparation method of special-shaped boron carbide ceramic sandblast nozzle

The invention discloses a preparation method of a special-shaped boron carbide ceramic sandblast nozzle. The preparation method comprises the following steps: (1) proportioning all the raw materials in percentage by weight as follows: 50-70wt% of boron carbide powder, 20-40wt% of a sintering aid, 1-8wt% of a carbon source, 0.5-6wt% of an adhesive and 0.6-6wt% of a dispersing agent; (2) carrying out a spray drying granulation process on the obtained slurry into granules; (3) putting the granules into a manufactured soft mould sleeve and moulding by using a dry bag type granules method, thus obtaining a sandblast nozzle biscuit; (4) putting the sandblast nozzle biscuit into a debonding furnace, vacuumizing, heating for removing water and organics, then processing in a vacuum sintering furnace to obtain a finished boron carbide ceramic sandblast nozzle product. The method is suitable for volume production and the prepared boron carbide sandblast nozzle has the advantages of high hardness, good toughness, good wear resistance, long service life, low cost, and high performance cost ratio. The method can be used for preparing sandblast nozzle products with complicated hole structures.

Owner:NINGBO VULCAN TECH CO LTD

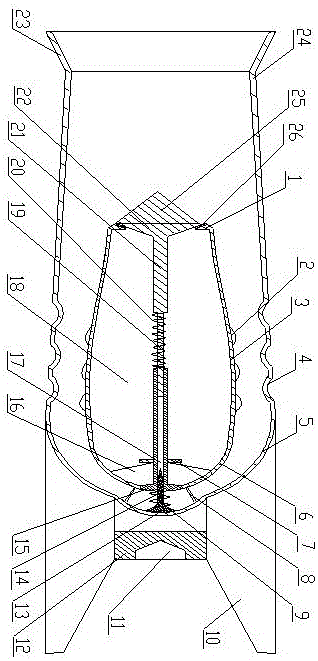

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

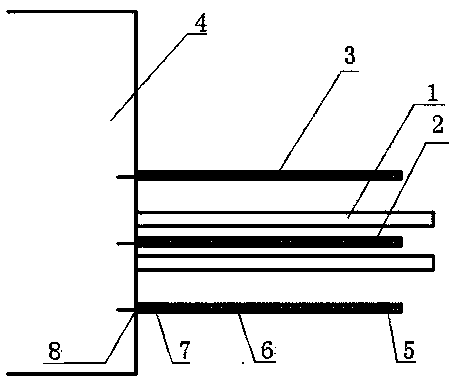

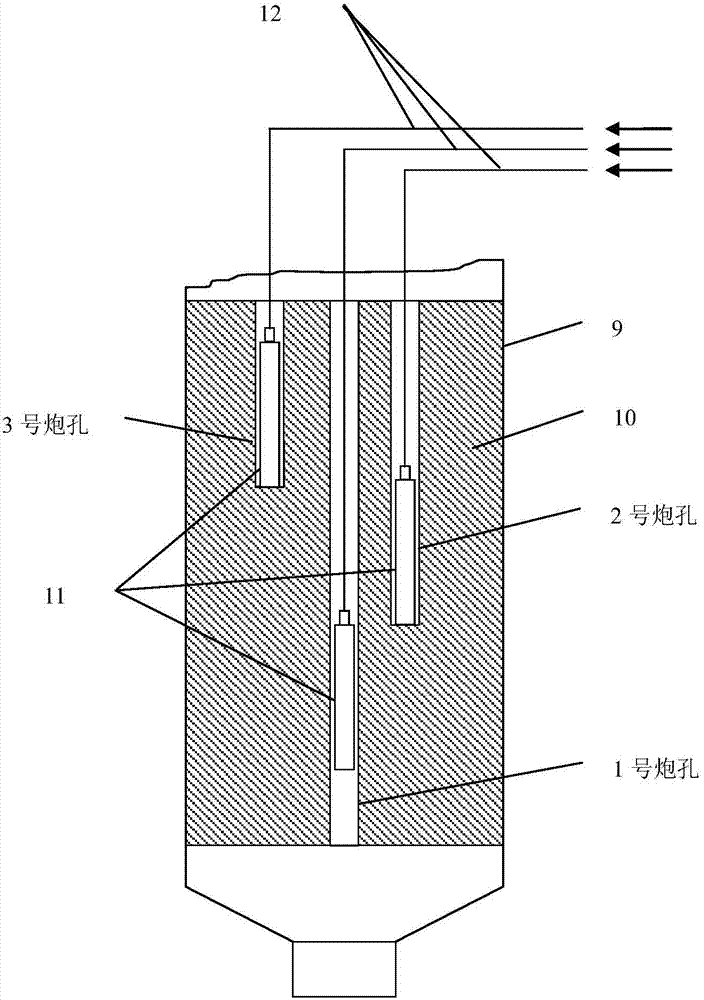

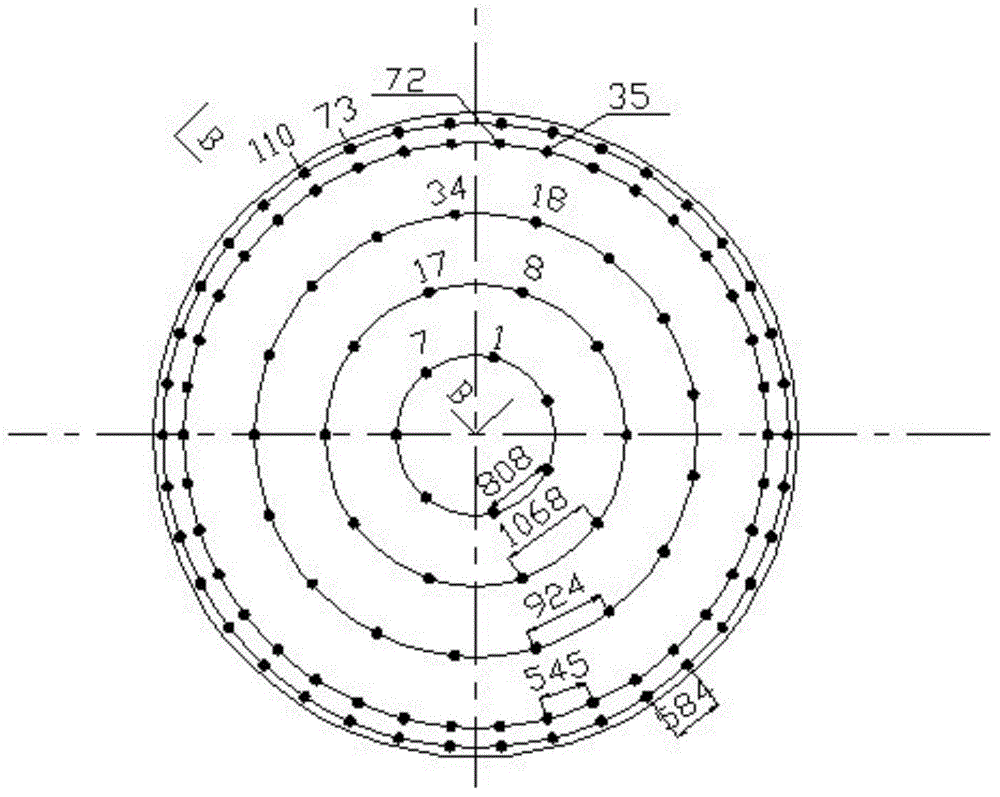

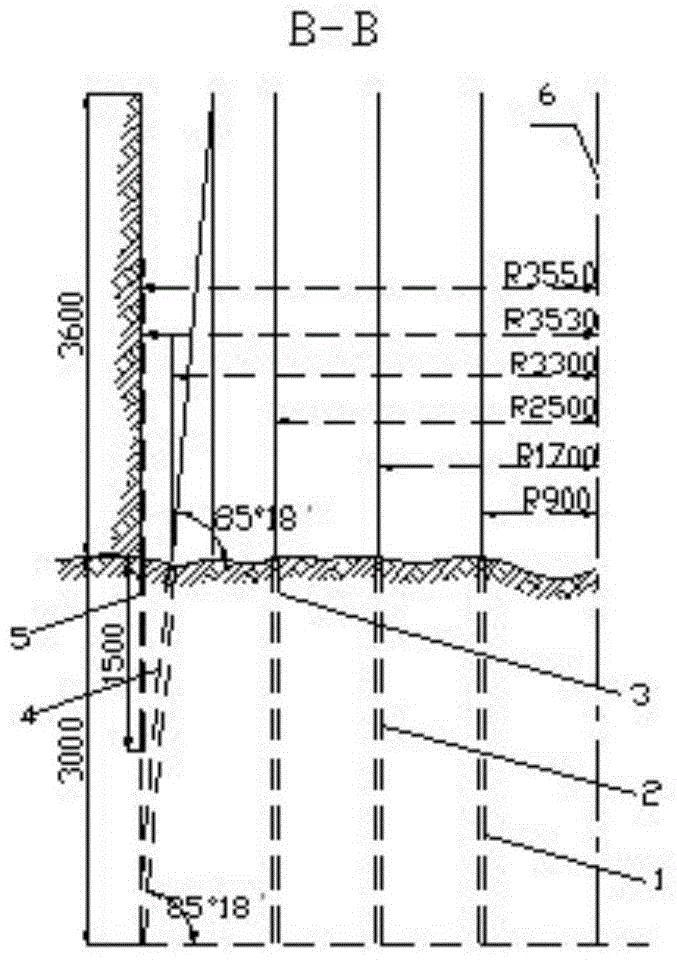

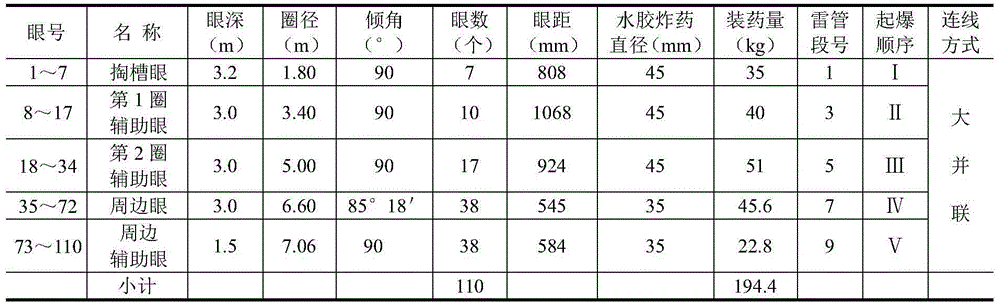

Construction method for additionally forming periphery auxiliary holes in periphery of vertical shaft periphery hole

The invention discloses a construction method for additionally forming periphery auxiliary holes in the periphery of a vertical shaft periphery hole. The construction method includes the following steps that (1), after the periphery hole is drilled through an umbrella drill, the periphery auxiliary holes are drilled, and the hole depth is 1500 mm; (2), explosives are loaded into the periphery auxiliary holes and the periphery hole at the same time, and the number of blasting cap sections of the periphery hole is seven, and the number of blasting cap sections of the periphery auxiliary holes is nine; (3), the periphery auxiliary holes are detonated after the periphery hole is detonated. The construction method has the advantages that six YT-28 type air drills are used for drilling the periphery auxiliary holes after the periphery hole is drilled through the umbrella drill, and therefore drilling time is not prolonged; shaft wall over-excavation and under-excavation are effectively avoided, cap retaining is avoided after the periphery hole is detonated, and therefore waste rock removing, net hanging and anchoring and shotcreting time is shortened; the costs for wind, water, electricity, manpower, sprayed concrete and other materials are lowered, supporting quality at the initial stage is improved, and large-section-height construction safety is guaranteed; detonation efficiency is improved, construction progress is accelerated, and good economical and technical effects are achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

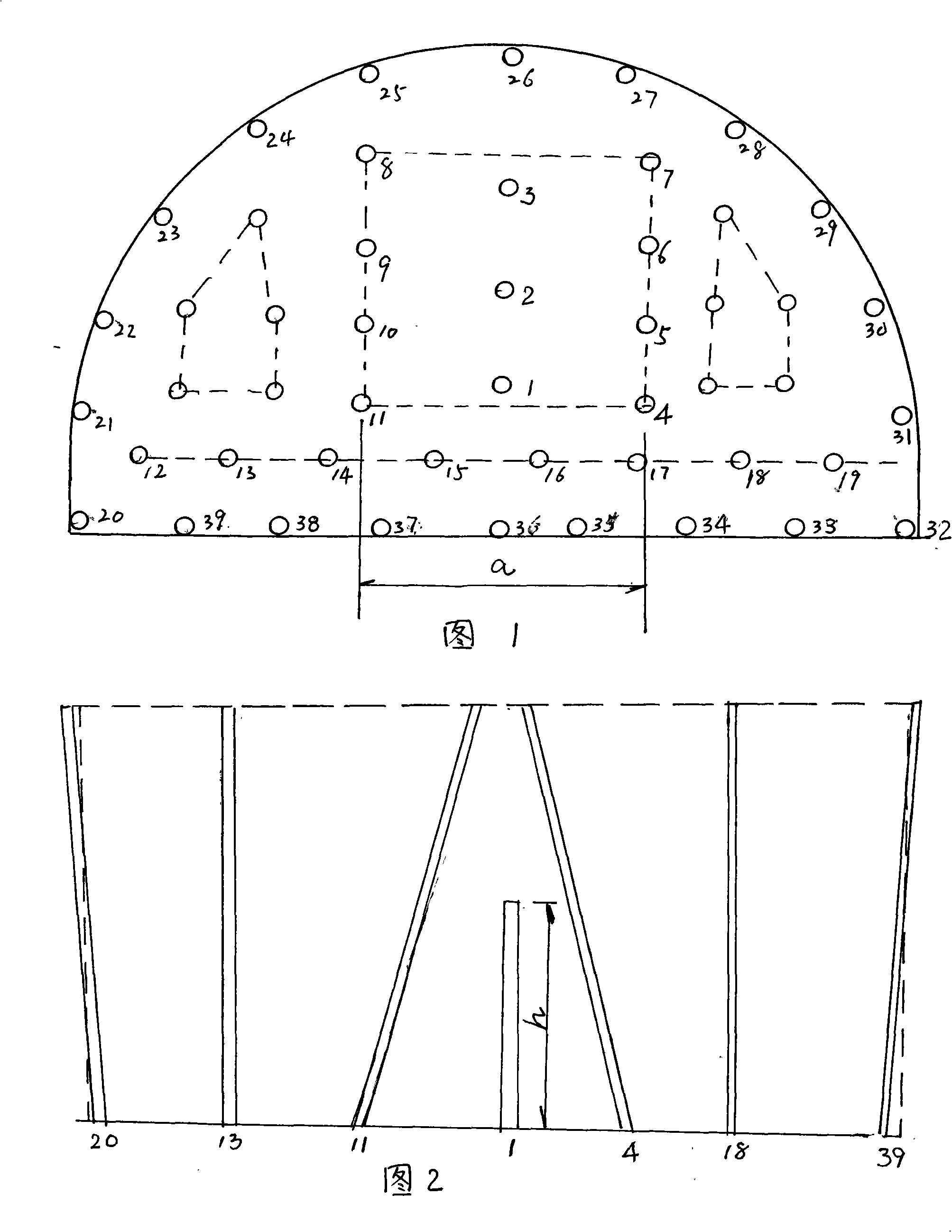

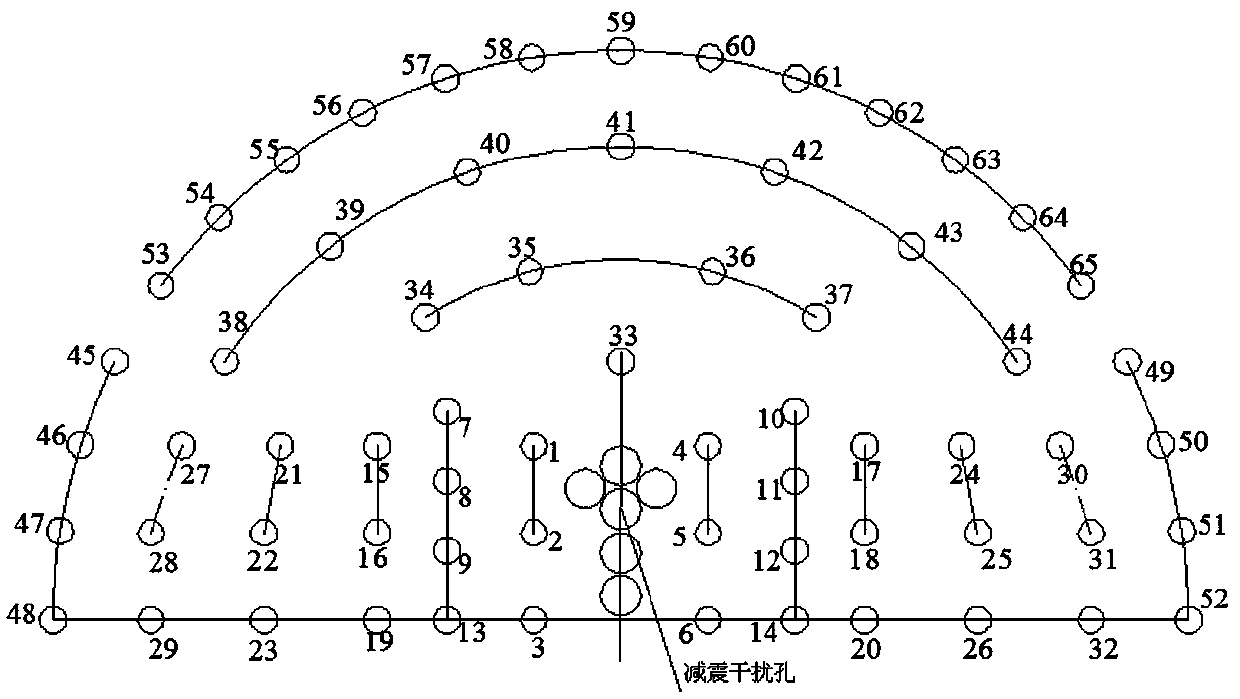

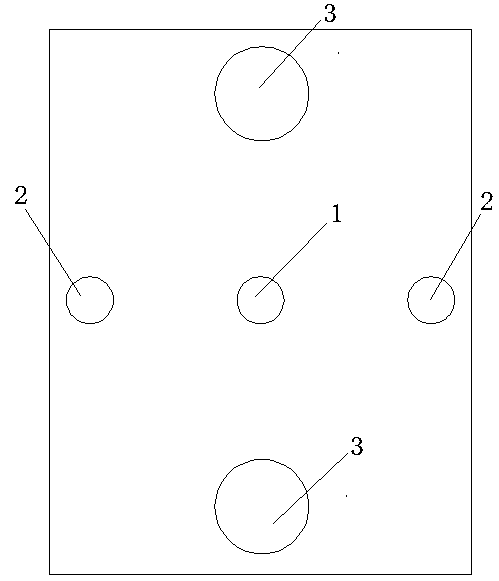

Precontrol roof sublevel ore breaking once shaft forming method

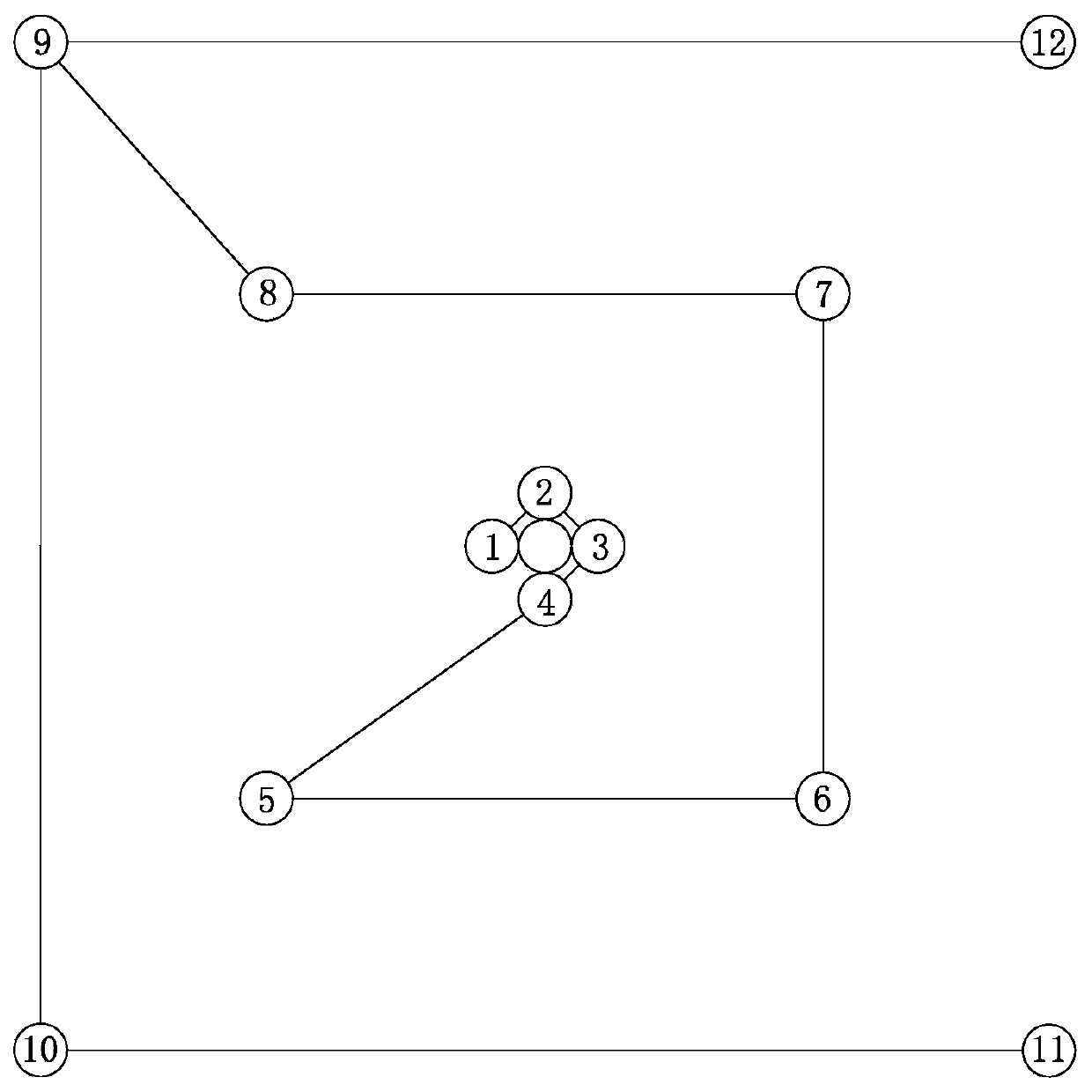

The invention discloses a precontrol roof sublevel ore breaking once shaft forming method. A blasting scheme using parallel deep holes as free surfaces is adopted; the parallel deep holes comprise an empty hole and charging holes; the charging holes comprise grooving holes (1)-(4), auxiliary holes (5)-(8) and peripheral holes (9)-(12); the grooving holes (1)-(4) are evenly distributed at the periphery of the empty hole in sequence; the gaps between each of the grooving holes and the empty hole are 300 mm; the peripheral holes (9)-(12) are also evenly distributed at the periphery of the empty hole in sequence; the distances of adjacent two peripheral holes are 2 m; the auxiliary holes (5)-(8) are respectively positioned in the middle positions of connecting lines of the grooving hole (4) and the peripheral hole (10), the grooving hole (3) and the peripheral hole (11), the grooving hole (2) and the peripheral hole (12) and the grooving hole (1) and the peripheral hole (9); the grooving holes (1)-(4), the auxiliary holes (5)-(8) and the peripheral holes (9)-(11) are connected through explosion guide pipes of 25 ms in sequence; the peripheral hole (12) is connected with the peripheral hole (9) through an explosion guide pipe of 65 ms; the charging holes and the empty hole are parallel to each other along full height of a courtyard; the empty hole serves as an explosion compensation space to detonate a detonator; and the grooving holes (1)-(4), the auxiliary holes (5)-(8) and the peripheral holes (9)-(12) are detonated gradually to achieve the section design requirements. The precontrol roof sublevel ore breaking once shaft forming method solves the problems of insufficiency of free surfaces and compensation space in a traditional precontrol roof sublevel ore breaking blasting operation, is high in mining efficiency, and guarantees the construction safety.

Owner:SHANDONG HUALIAN MINING

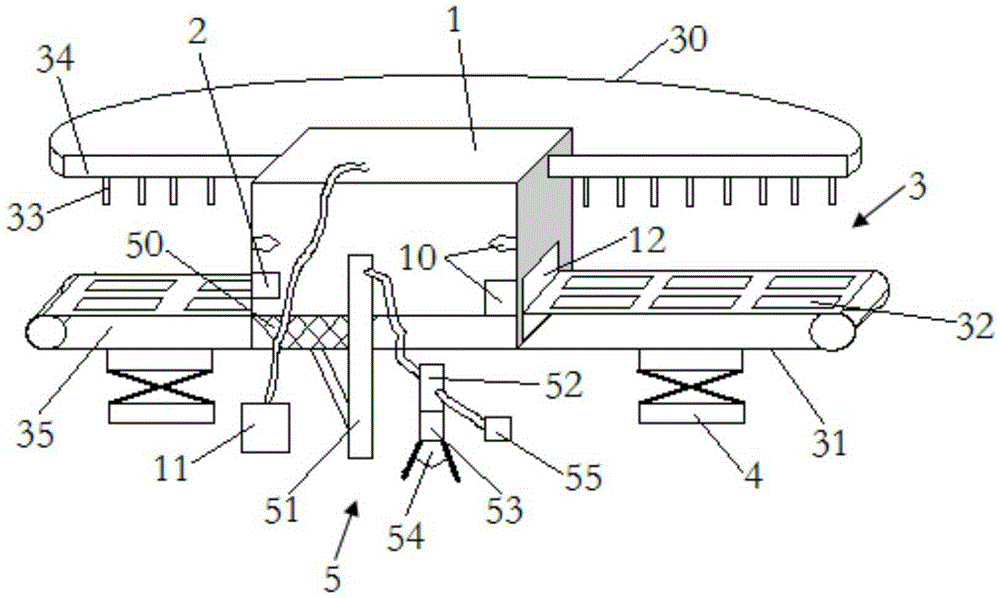

Sand blasting machine

ActiveCN106078533AAdjustable angleAccurate in and outBlast gunsAbrasive feedersSand blastingSpray nozzle

The invention discloses a sand blasting machine, which comprises a sand blasting chamber. The sand blasting chamber comprises a feeding hole for feeding and discharging workpieces, and spray nozzles arranged in the sand blasting chamber; the spray nozzles are fixed on a spray nozzle drive mechanism; a feeding mechanism capable of driving the workpieces to feed and discharge is matched on the feeding hole; the spray nozzle drive mechanism comprises at least one swinging mechanism arranged in the sand blasting chamber; each swinging mechanism is provided with one spray nozzle and is driven by a first drive part to swing to the left and right; the feeding mechanism comprises a placement platform used for placing workpieces and a second drive part; and the placement platform comprises at least one positioning table used for placing the workpieces, and a sealing plate arranged behind the positioning table and matched with the feeding hole of the sand blasting chamber. A plurality of swinging mechanisms are arranged in the sand blasting chamber, and a plurality of spray nozzles can swing to blast sand on the workpieces when being used for blasting sand, so that a uniform and efficient sand blasting effect is realized; and in addition, the workpieces can be quickly fed and discharged in the sand blasting chamber through the feeding mechanism, so that the sand blasting efficiency of the workpieces is further improved.

Owner:宁波精益微型轴有限公司

Improved sand-blasting machine

PendingCN108673349AReduce outflowReduce contentAbrasive feedersAbrasive machine appurtenancesSand blastingCam

The invention discloses an improved sand-blasting machine, and belongs to the technical field of machinery. The improved sand-blasting machine comprises a machine frame, a motor, a first rotating shaft, a first guide sleeve, a clamping plate, a driving air cylinder, a rotating rod, and a second guide sleeve. The first rotating shaft is in key connection with a first bevel gear; the first bevel gear meshes with a second bevel gear; the number of teeth of the second bevel gear is twice that of the first bevel gear; a second rotating shaft is in key connection with the upper portion of the secondbevel gear; the second rotating shaft is in connection with a cam; the cam is in contact with a rolling wheel in a matched mode; a plurality of sand-blasting devices are in fixed connection with theother end of the rolling wheel; a spring is in connection with the other end of the sand-blasting devices; the spring is fixedly arranged on the lateral wall of the machine frame; the sand-blasting devices are connected with a feed opening by material sending pipelines; and the feed opening is connected with a sand-storage tank. Automatic sand-blasting is achieved, and omnidirectional sand-blasting is achieved to a workpiece during sand-blasting process, and sand-blasting efficiency is high.

Owner:湖北省麻城市和丰精密机械有限公司

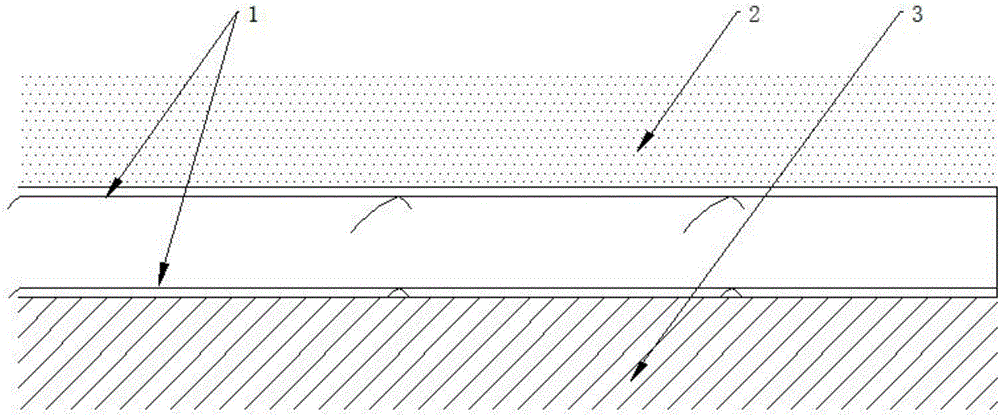

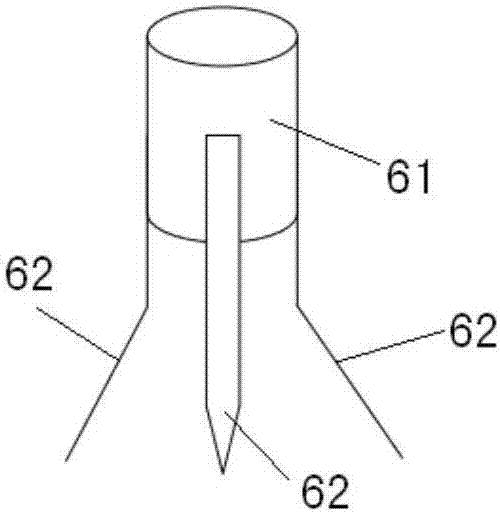

Explosive tube having air gap and method of blasting bedrock using same

ActiveUS20160377392A1Improve blasting effectReduce usageBlasting cartridgesBlastingBedrockEngineering

An explosive tube having an air gap and a method of blasting bedrock using the same, comprising: a filling tube having a filling space which is to be filled with explosives; and an air tube, the upper part of which is connected with another tube to form an air gap space therein, and which has an insertion hole formed on the bottom of the air tube to introduce the explosives into the filling space, the air tube being integrally formed on the filling tube. A plurality of tubes filled with explosives are connected with each other and inserted into blasting holes formed through bedrock to break the bedrock by blasting the explosives. By forming an air gap in the upper part of the tube.

Owner:LEE JIN SUNG

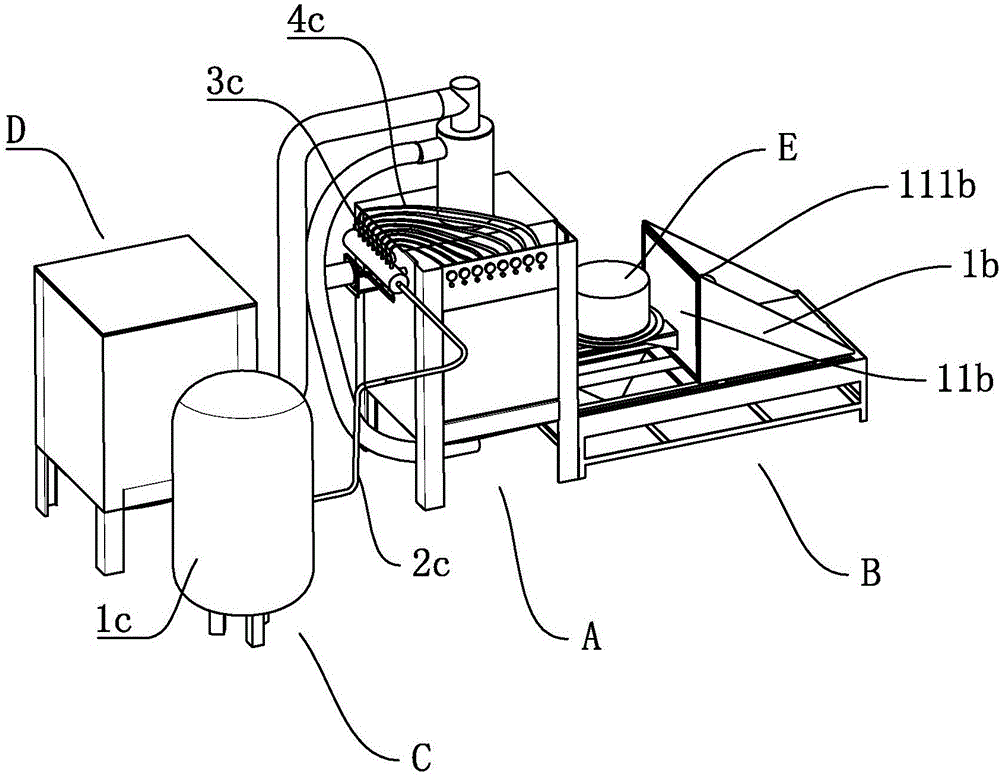

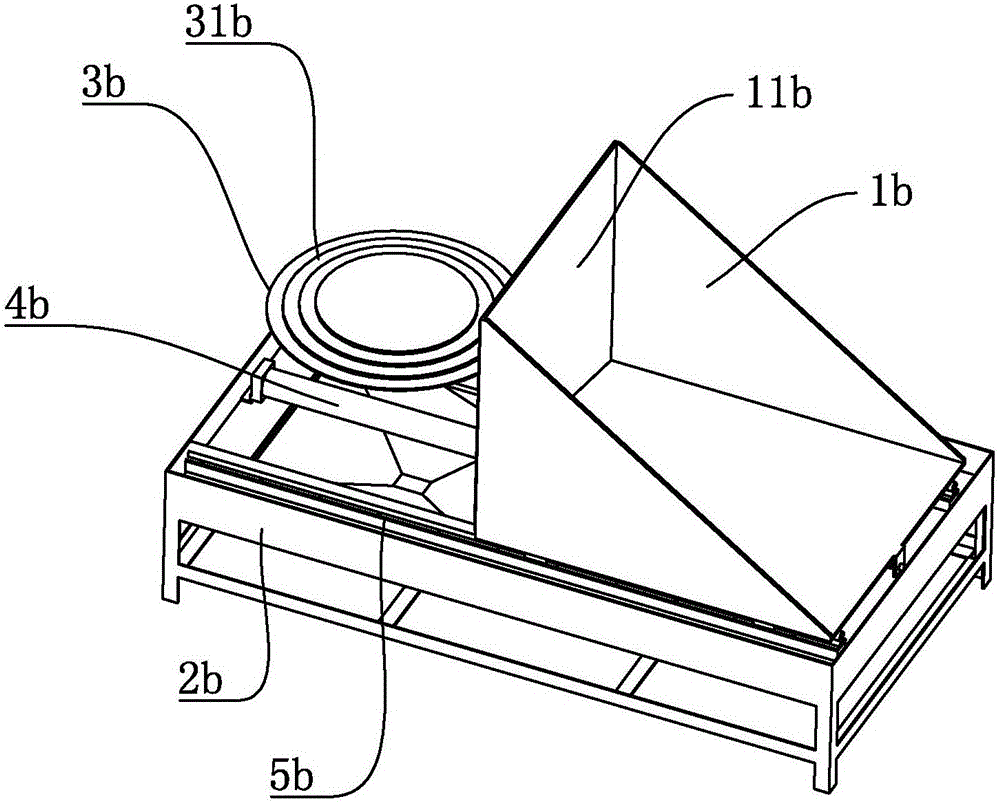

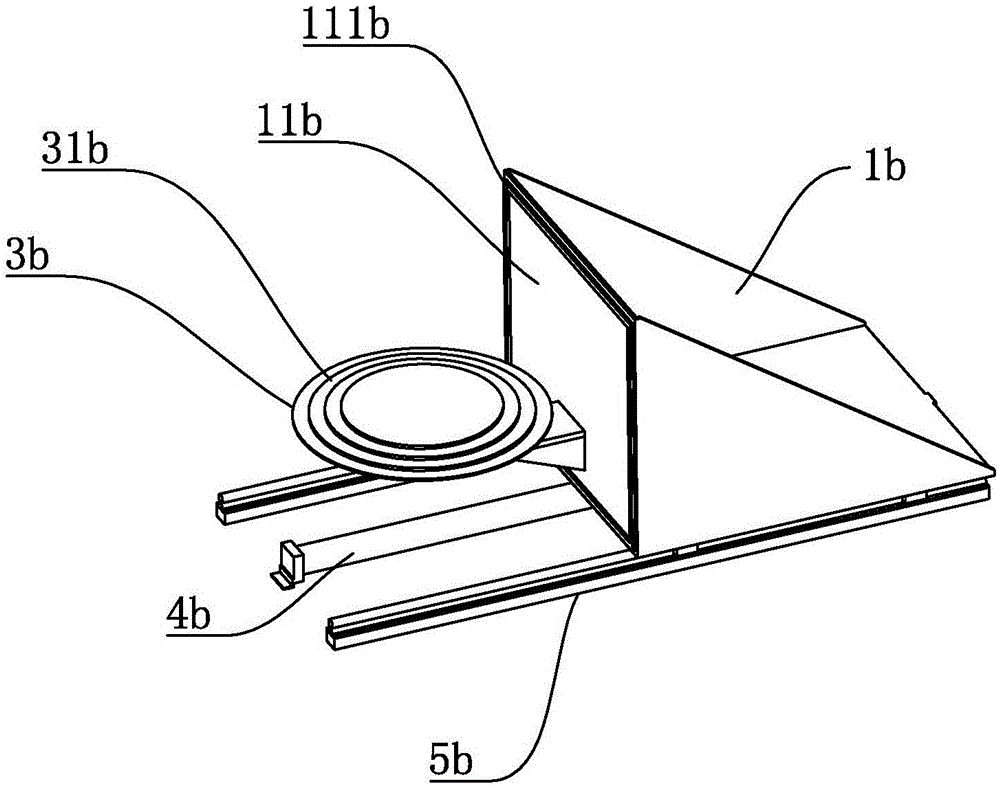

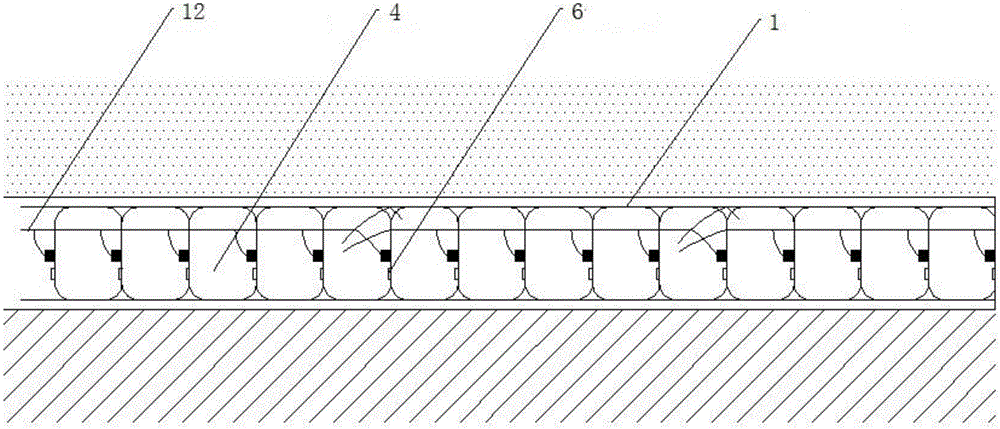

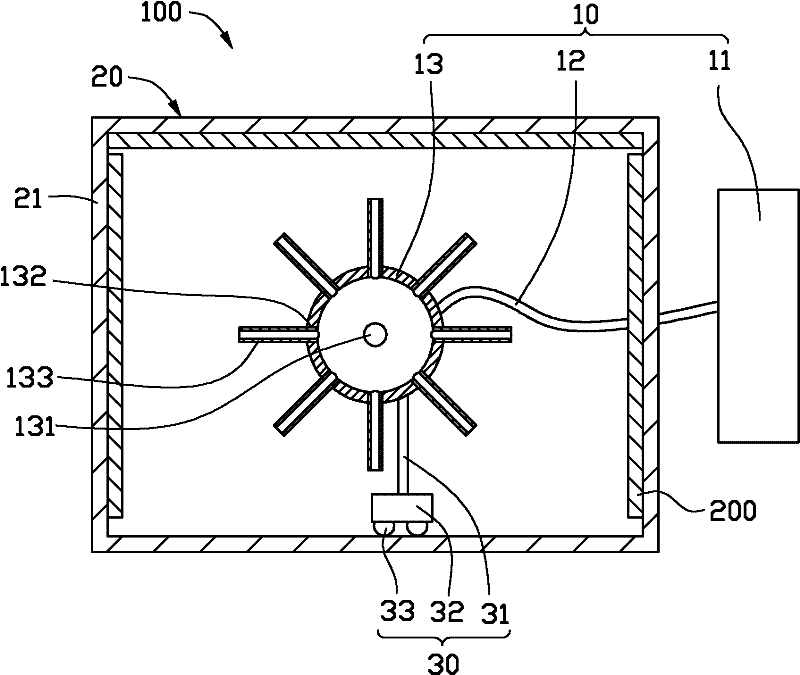

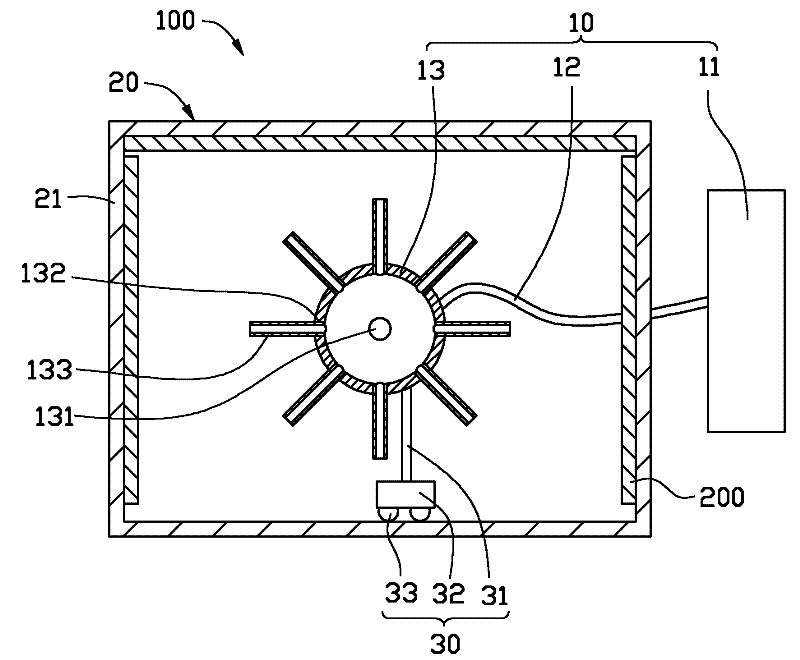

Air cushion type space-reserved drift and fill type mining device and method

InactiveCN106014415AExtension of timeIncreased overall time, increased throughputUnderground miningSurface miningEngineeringCut and fill

The invention provides an air cushion type space-reserved drift and fill type mining device and method and belongs to the technical field of mine cut and fill mining. The device comprises an air cushion, a fixing mechanism and auxiliary equipment. The air cushion comprises air bags, inflating and deflating valves, safety valves and the like. The air cushion is fixed to ore body drift and fill road sides by the fixing mechanism through fixing ropes, and the air cushion is inflated through the auxiliary equipment. In the using process of the device, the air cushion is erected on the side close to an ore about every 10 m before filling of a drift and fill path is carried out, multiple air cushions are consecutively erected along the total length part in the axial direction of the drift and fill path, and then the drift and fill path is filled. When the device and the method are used for mining adjacent mining drift and fill paths, the air cushions can be recycled first, the space reserved for the air cushions serves as a blasting free surface, and mining blasting is carried out in a row-by-row lateral blasting mode; the blasting efficiency and mining efficiency can be greatly improved, consumption of explosives can be greatly reduced, holes can be reduced, the total time of total mining circulation can be prolonged, the capacity of total mining circulation can be improved, and the safety of recovery work is promoted.

Owner:UNIV OF SCI & TECH BEIJING +1

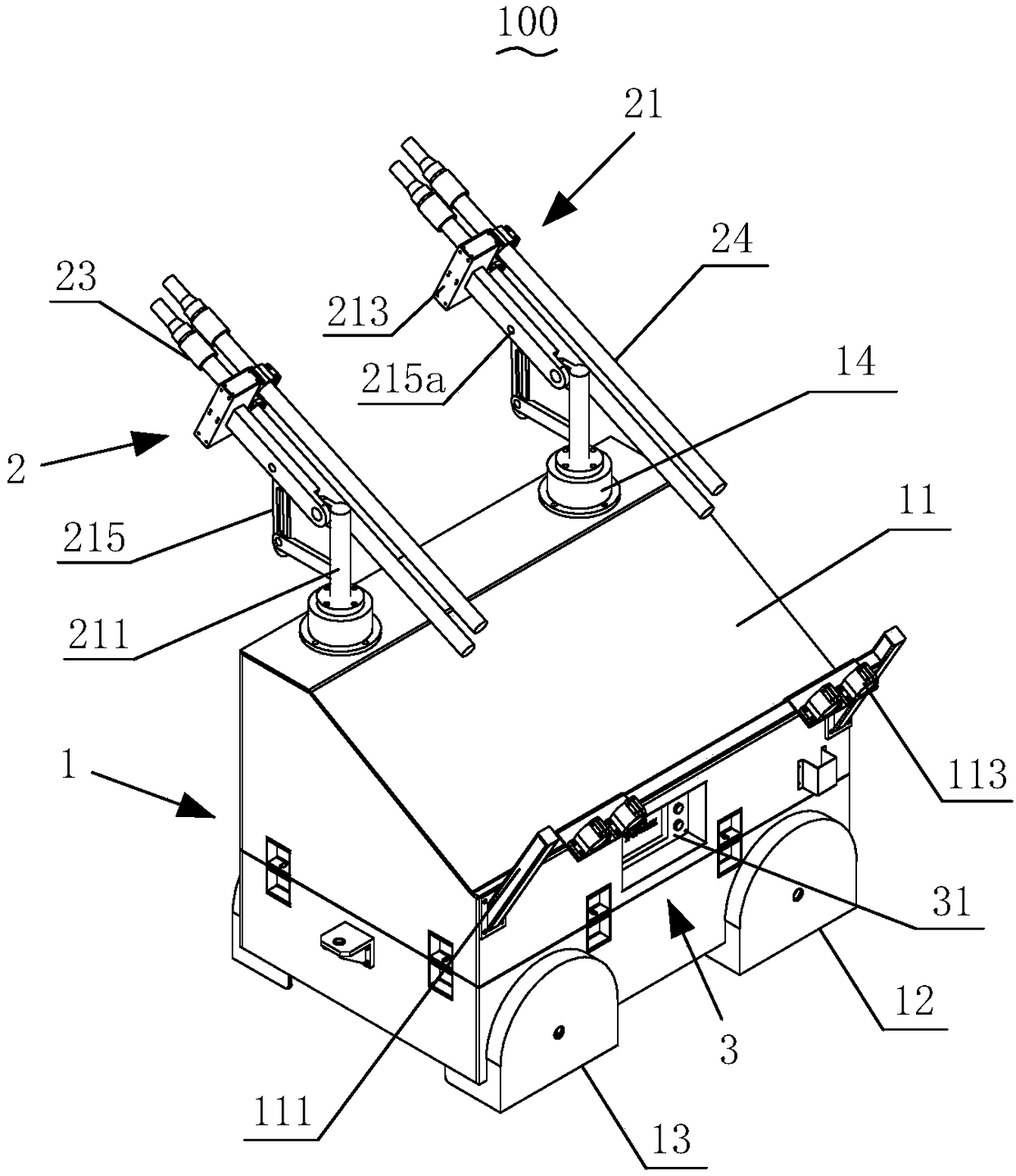

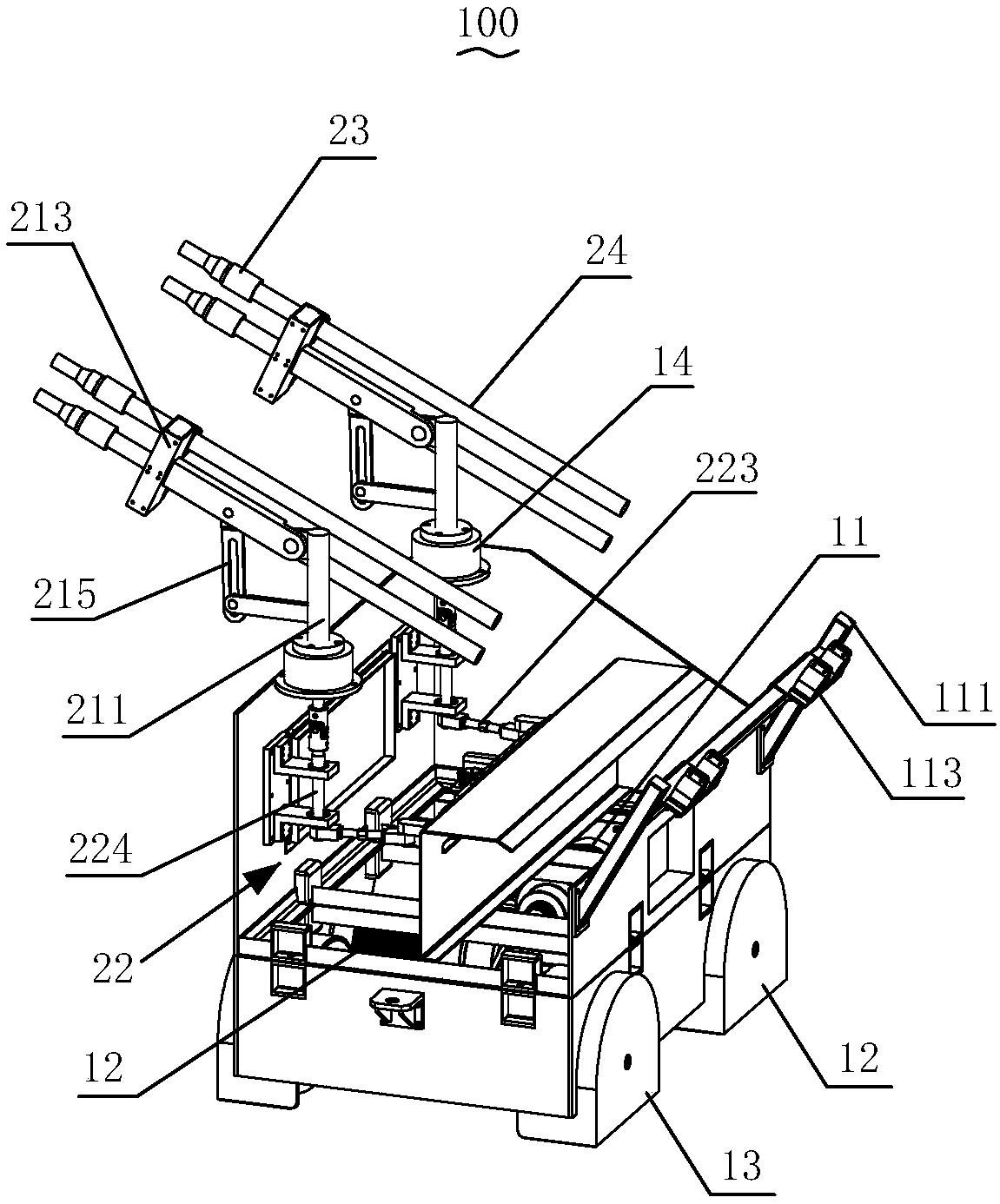

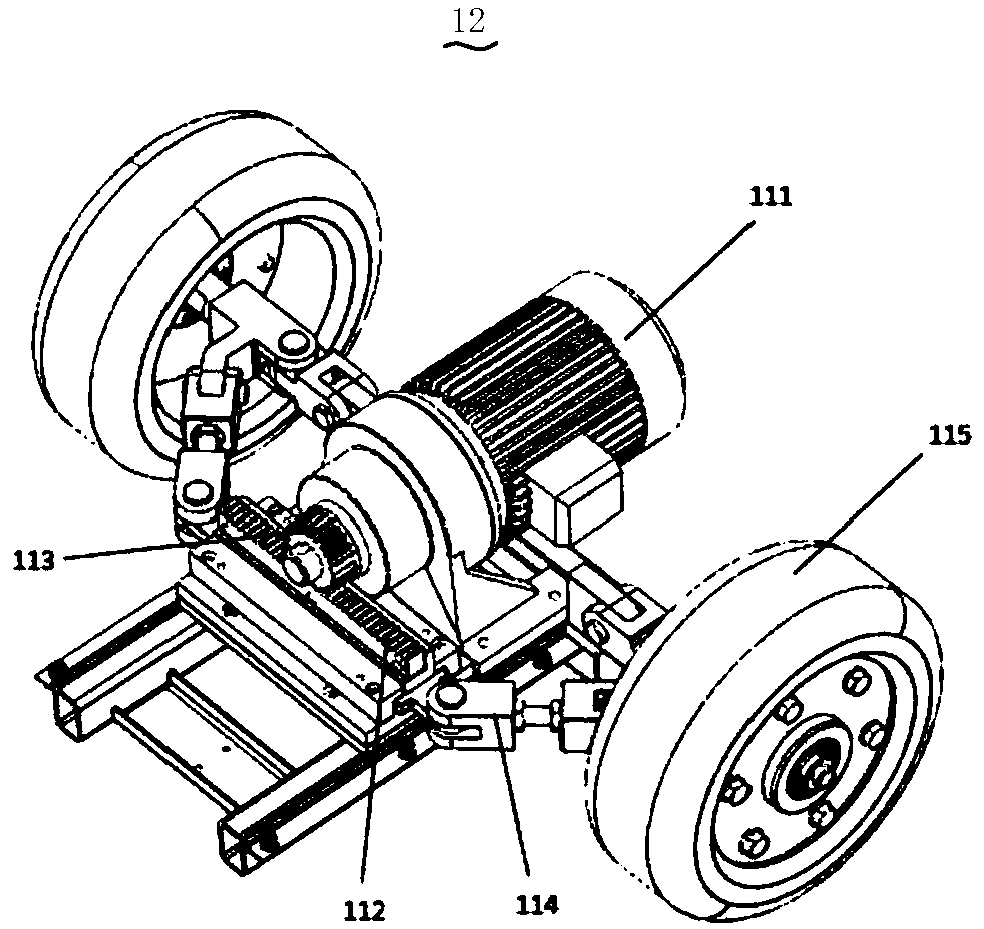

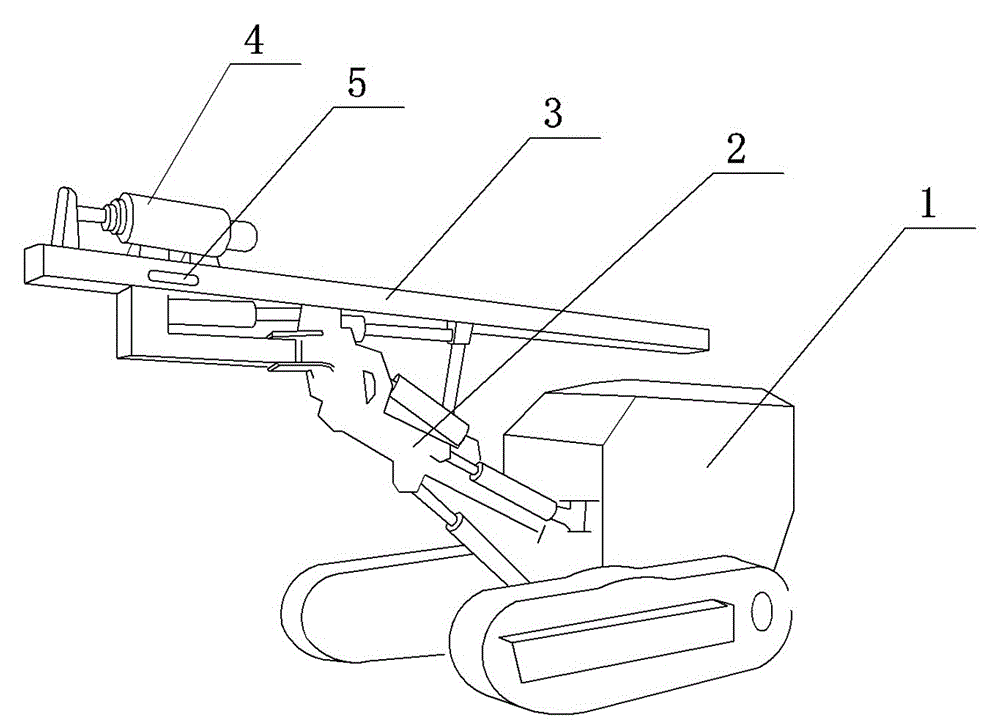

Sand blasting equipment, sand blasting system and sand blasting method

PendingCN109176321AIncrease freedomIncrease flexibilityBlast gunsAbrasive machine appurtenancesSand blastingEngineering

The invention provides sand blasting equipment, a sand blasting system and a sand blasting method. The sand blasting equipment is used for carrying out sand blasting on a tower drum, and comprises a spraying vehicle, a sand blasting device and a controller, wherein the spraying vehicle comprises a protective shell, a front wheel mechanism and a rear wheel mechanism are arranged at the bottom of the protective shell, the sand blasting device comprises a sand gun, a clamping mechanism used for fixing the sand gun and a swing mechanism for enabling the sand gun to rotate, the sand blasting deviceis arranged on the protective shell of the spraying vehicle, the swing mechanism is connected with the clamping mechanism, the controller is arranged on the spraying vehicle, and is correspondingly connected with and used for driving the front wheel mechanism and the rear wheel mechanism of the spraying vehicle and the swing mechanism of the sand blasting device. The sand blasting system comprises the above sand blasting equipment, a roller frame and the tower drum. The invention further provides the sand blasting method. According to the equipment, the system and the method, automatic sand blasting can be realized, artificial and manual swing for sand blasting operation can be replaced, uninterrupted continuous operation is carried out, and the sand blasting quality and the sand blastingefficiency are improved.

Owner:SUZHOU TITAN NEW ENERGY TECH CO LTD

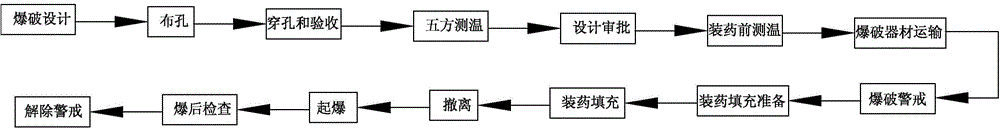

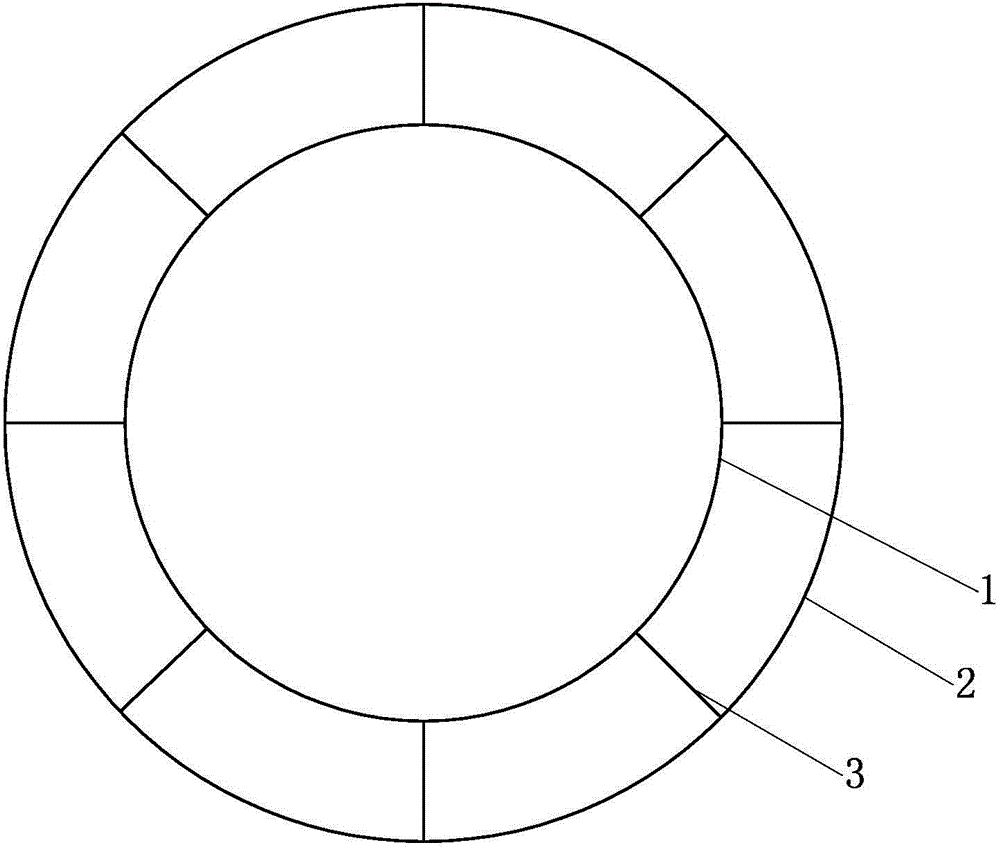

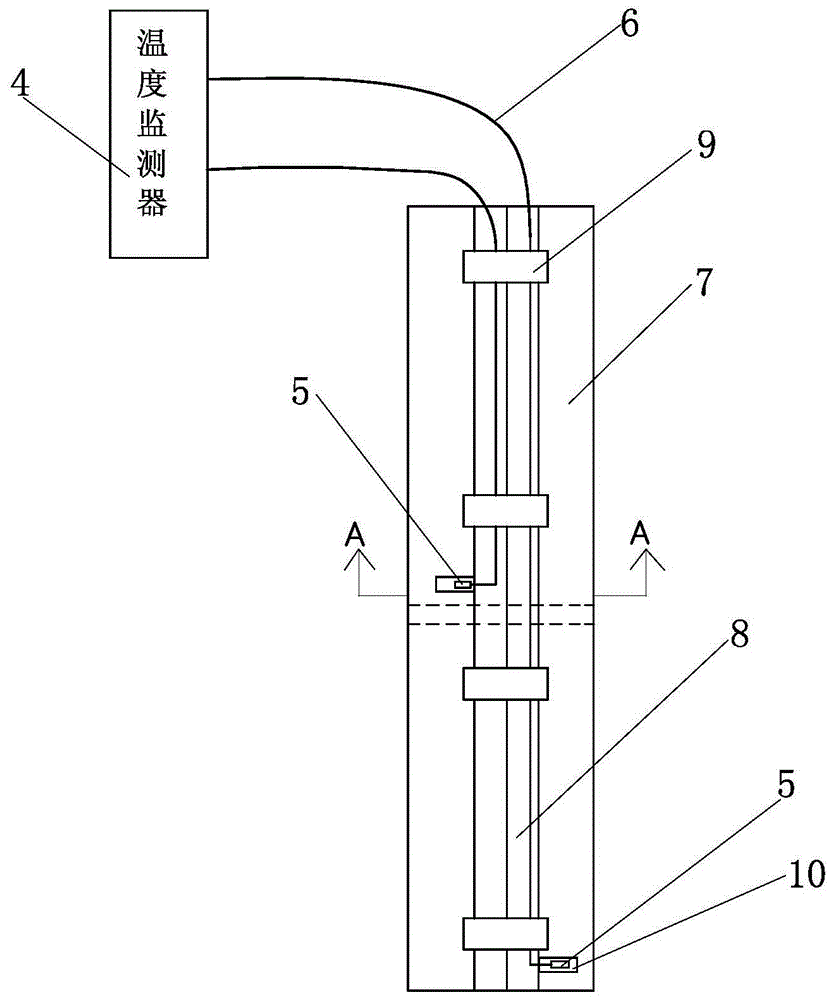

Blasting method for high-temperature sealed fire areas

The invention discloses a blasting method for high-temperature sealed fire areas. The blasting method comprises the following steps that a, blasting design is carried out; b, holes are distributed; c, holes are drilled, checked and accepted; d, five-position temperature measurement is carried out, wherein temperature measurement is carried out twice, according to the temperature measurement of the second time, thermal insulation pieces are placed in blast holes firstly, then the gaps between inner cylinders and outer cylinders of the thermal insulation pieces are filled with water, and the temperatures of all points between the inner cylinders and the outer cylinders are measured ten minutes later; e, design approval is carried out; f, temperature is measured before explosive filling; g, blasting supplies are transported; h, blasting warning is carried out; j, explosive filling preparation is carried out, wherein adhesive plasters are used for fixing explosive columns and filling sections on the same bamboo bar; k, explosive filling is carried out; l, evacuation is carried out; m, initiation is achieved; n, inspection after blasting is carried out; o, warning is withdrawn. According to the method, the thermal insulation pieces are used for separating the temperatures of the blast holes and the explosive and the initiation supplies, the method is simple and reliable, good in safety, low in cost, long in rebound time, and capable of reliably and safely guaranteeing explosive filling and further safely and efficiently achieving blasting.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

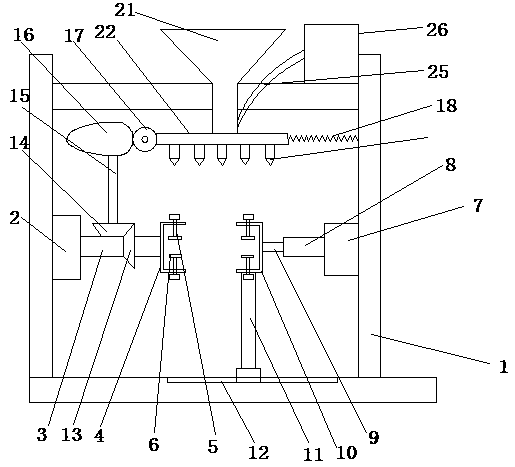

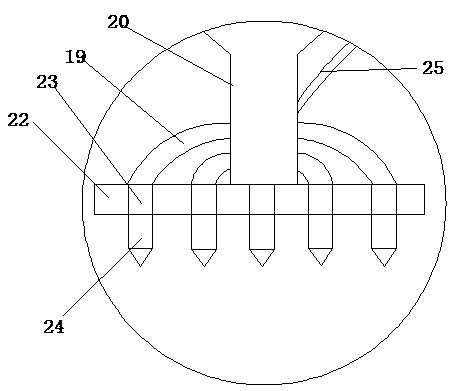

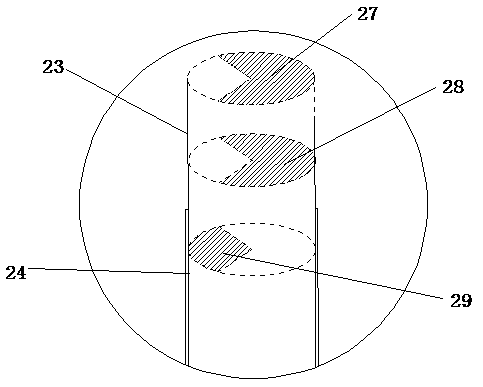

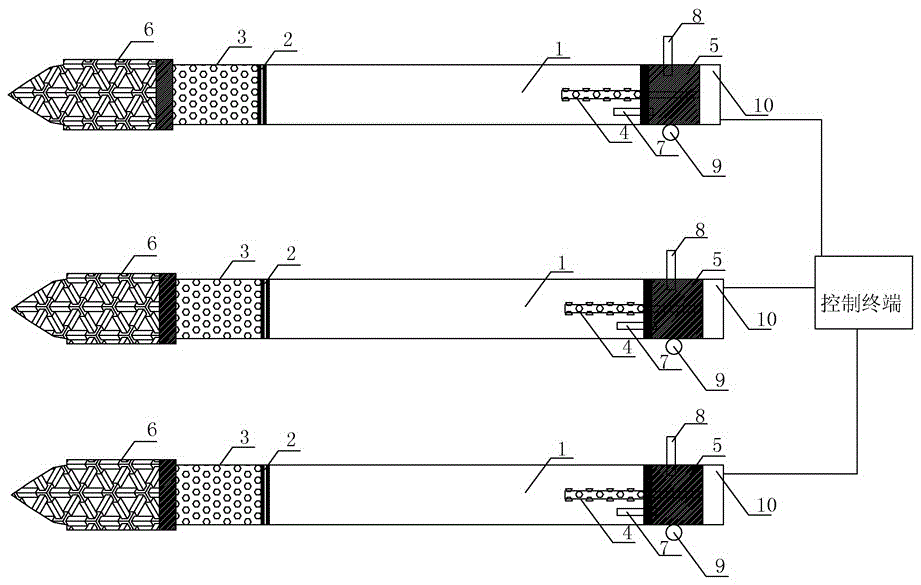

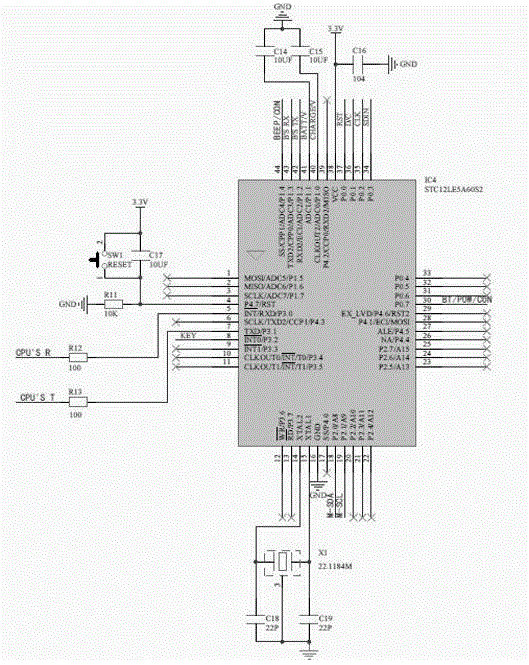

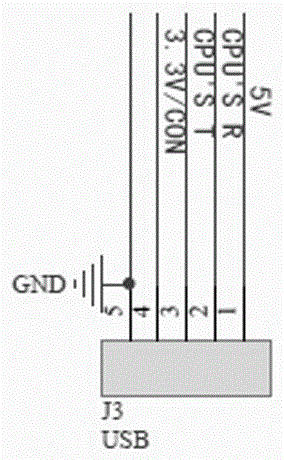

High-energy physics fracturing device

InactiveCN106197168AReal-time monitoring of working statusEnsure mining qualityDisloding machinesBlasting cartridgesHigh energyComputer terminal

The invention relates to a high-energy physics fracturing device. The high-energy physics fracturing device comprises a control terminal and a plurality of medium phase change fracturing device bodies connected with the control terminal. The control terminal detects and controls the working state of the medium phase change fracturing device bodies connected with the control terminal. Each medium phase change fracturing device body comprises a storage pipe, a constant pressure energy discharging device, an energy guide device, a trigger device, a controller, a fixing device, a pressure sensor, a gas concentration detection sensor and a battery. The control terminal controls the working state of the medium phase change fracturing device bodies through the controllers. The controllers transmit received pressure value signals and received gas concentration signals in the storage pipes to the control terminal. The control terminal comprises an LCD touch screen. Each controller comprises a 51 single chip microcomputer and provided with an LED which is connected with the 51 single chip microcomputer. The high-energy physics fracturing device adopting the structure has the advantages of being capable of improving the blasting quality and efficiency and decreasing safety accidents, convenient and flexible in using and low in invested cost.

Owner:HENAN COAL SCI RES INST

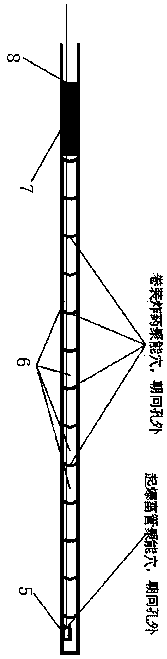

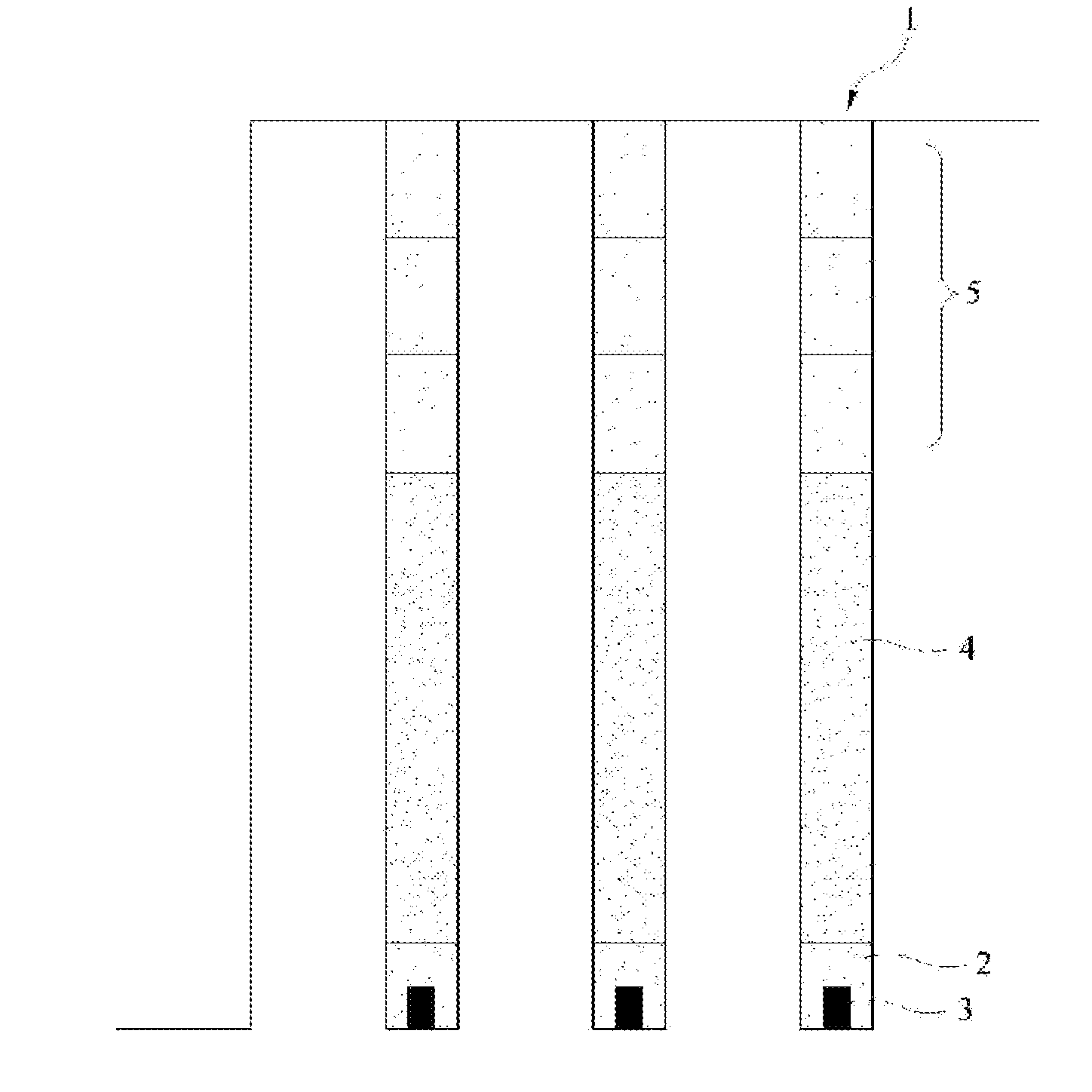

Charge hole-sealing method for deep-hole roof presplitting blasting in underground coal mine

The invention discloses a charge hole-sealing method for deep-hole roof presplitting blasting in an underground coal mine. The charge hole-sealing method comprises the following steps: step 1, prefabricating a plurality of explosive cartridges; step 2, assembling and connecting the plurality of explosive cartridges end to end to form an explosive cartridge group, embedding a detonator in explosiveat one end close to a reel at the rearmost end, of the reel, connecting the detonator with a detonation fuse and leading out the detonation fuse from one end of the reel, and assembling the pluralityof explosive cartridge groups in a flexible sleeve pipe; step 3, pushing the flexible sleeve pipe provided with the plurality of explosive cartridge groups to a part with a specified depth, of a blasting hole, by a push rod, and leading out and serially connecting detonation fuses of the plurality of explosive cartridge groups, and then connecting the detonation fuses with a blaster; step 4, pushing a backstop into the blasting hole by virtue of the push rod and locating the backstop at the outer sides of the explosive cartridge groups; and step 5, pushing the hole-sealing explosive cartridges into the blasting hole by virtue of the push rod and locating the hole-sealing explosive cartridges at the outer side of the backstop, and tamping and compacting the hole-sealing explosive cartridges by virtue of the push rod. The charge hole-sealing method disclosed by the invention has the following beneficial effects: rapid, fixed-point and accurate charge is realized for the blast hole in ahigh-position roof rock stratum in the underground coal mine, and rapid hole-sealing for the blast hole is realized.

Owner:CCTEG CHINA COAL RES INST

Drilling machine direction angle monitoring method and system

The invention discloses a drilling machine direction angle monitoring method and system which are used for determining the punching and hole drilling direction and monitoring in the hole drilling process. The system comprises a measuring controller and a handheld instrument, wherein the measuring controller is arranged on a drilling machine or a cross beam of a drilling machine; the handheld instrument is used for receiving and displaying the target direction, target obliquity, current direction, current obliquity, direction adjustment instruction, direction maximum permissible error and obliquity maximum permissible error, which are provided by the measuring controller. According to the invention, an electronic compass and a gyroscope are used for monitoring variation between the changed azimuth and the initial azimuth of the drilling machine, so that the purposes of improving positioning accuracy of the drilling machine and improving blasting efficiency are realized; in addition, the method and system can be used for real-time monitoring, so that adjustment can be carried out in time. Whether hole drilling is required to be carried out continuously or not is selected manually and the drilling machine does not stop in the process.

Owner:ZHENGZHOU SHUANGJIE TECH CO LTD

Sand blasting device

The invention discloses a sand blasting device, which comprises material blasting equipment and a sand blasting cabin, wherein grinding materials which are used for sand blasting are arranged in the material blasting equipment; the sand blasting cabin is used for providing a sand blasting environment; the sand blasting equipment comprises a hollow spray nozzle; the spray nozzle is arranged in the sand blasting cabin; and a plurality of spray holes which are communicated to the inside of the spray nozzle are formed on the surface of the spray nozzle, and are used for spraying the grinding materials to multiple directions. In the sand blasting device, the spray nozzle with the plurality of spraying holes are used for performing sand blasting on the surface of a workpiece, and sand blasting can be performed on the surfaces of a plurality of workpieces at different positions in the sand blasting cabin simultaneously, so that the sand blasting efficiency can be greatly improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

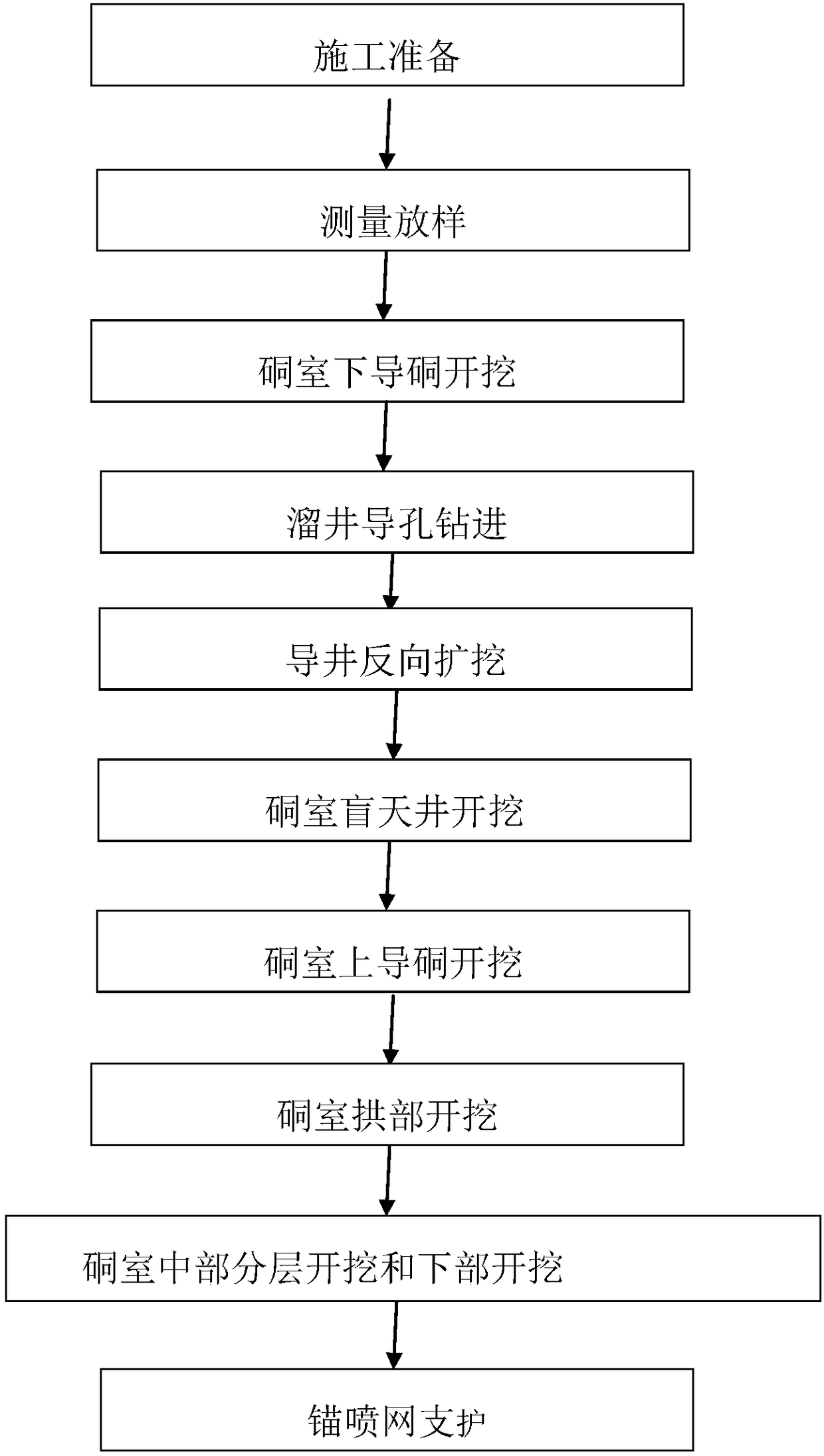

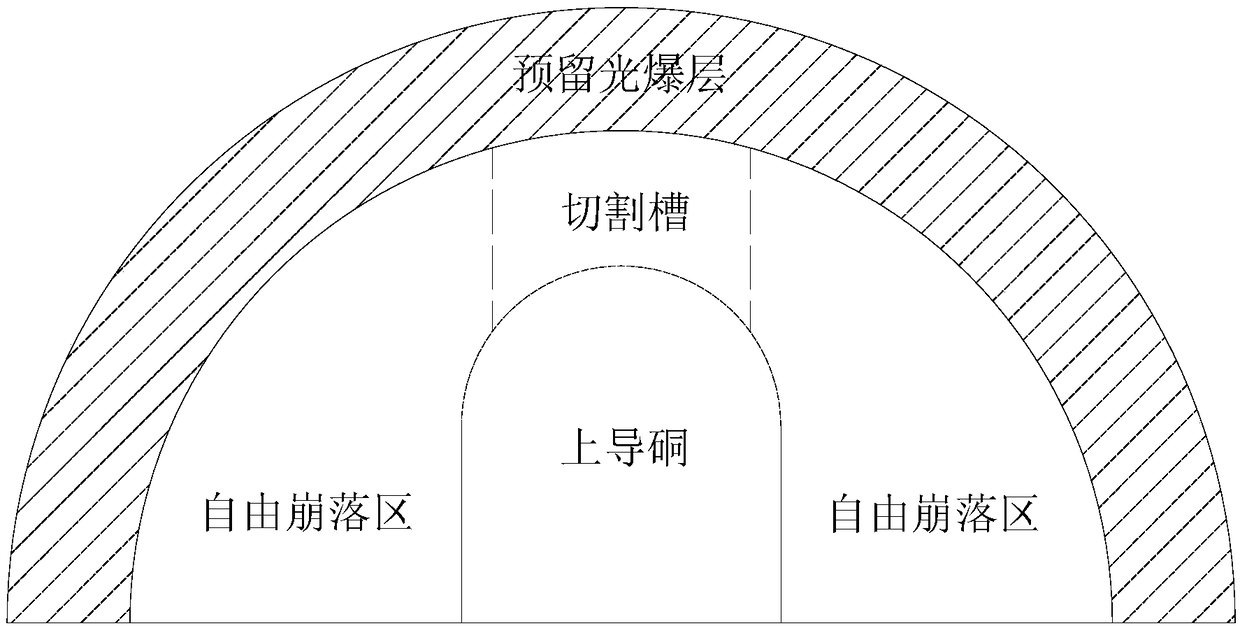

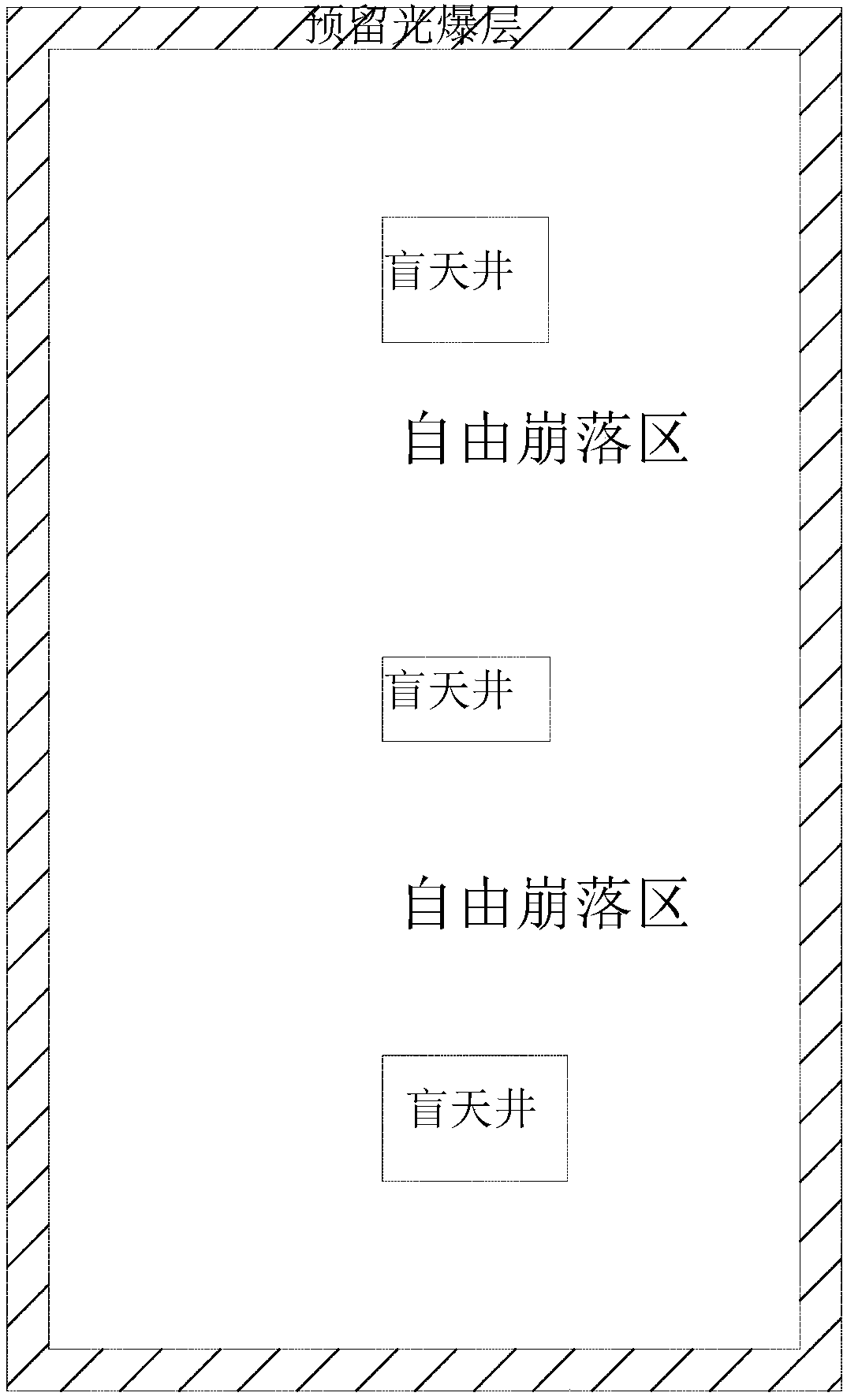

Double-channel underground chamber construction method

InactiveCN108343455AImprove blasting efficiencySpeed up work progressUnderground chambersSmooth surfaceBuilding construction

The invention relates to the field of engineering construction and discloses a double-channel underground chamber construction method. The double-channel underground chamber construction method comprises the following steps that (1) construction preparation is conducted; (2) measuring and setting out are conducted; (3) a chamber lower guiding chamber is excavated, specifically, the lower guiding chamber communicating with a chute is excavated along the center axis of the chamber from a chamber inlet-outlet gate way channel, and the excavation section of the guiding chamber is the same as the section of the chamber inlet-outlet channel in size; (4) chute guiding holes are drilled; (5) a guiding well is excavated for expansion in the reverse direction; (6) chamber blind raises are excavated;(7) a chamber upper guiding chamber is excavated, specifically, with a chamber arching line as a bottom plate, an upper guiding chamber communicating with the three blind raises are tunneled along the axis of a crushing chamber; and (8) a chamber arched part is excavated, specifically, through the upper guiding chamber, an arched part cutting groove is excavated above the blind raise in the middle of the chamber, the through the constructed arched part cutting groove, tunneling is conducted from the middle to the two ends of the chamber, and smooth surface blasting is conducted to form an arched part. The double-channel underground chamber construction method has the effects that the total excavation cost of the chamber is recued, and the construction period is shortened.

Owner:浙江省隧道工程集团有限公司

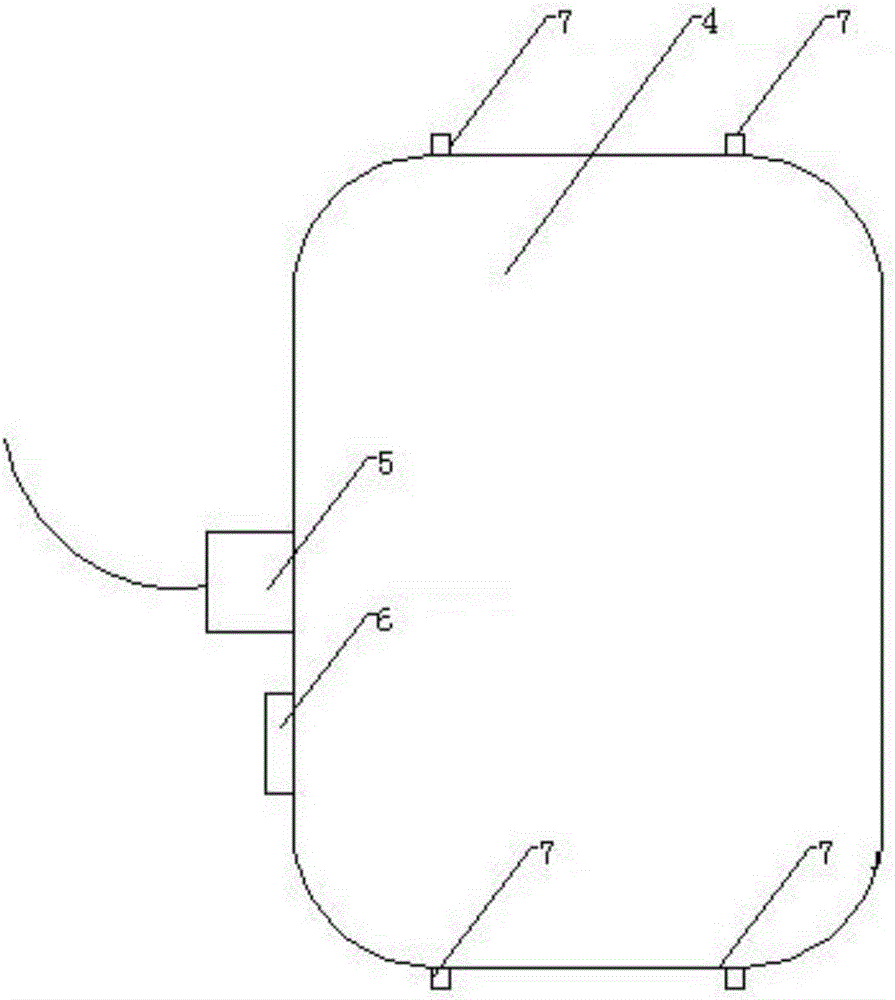

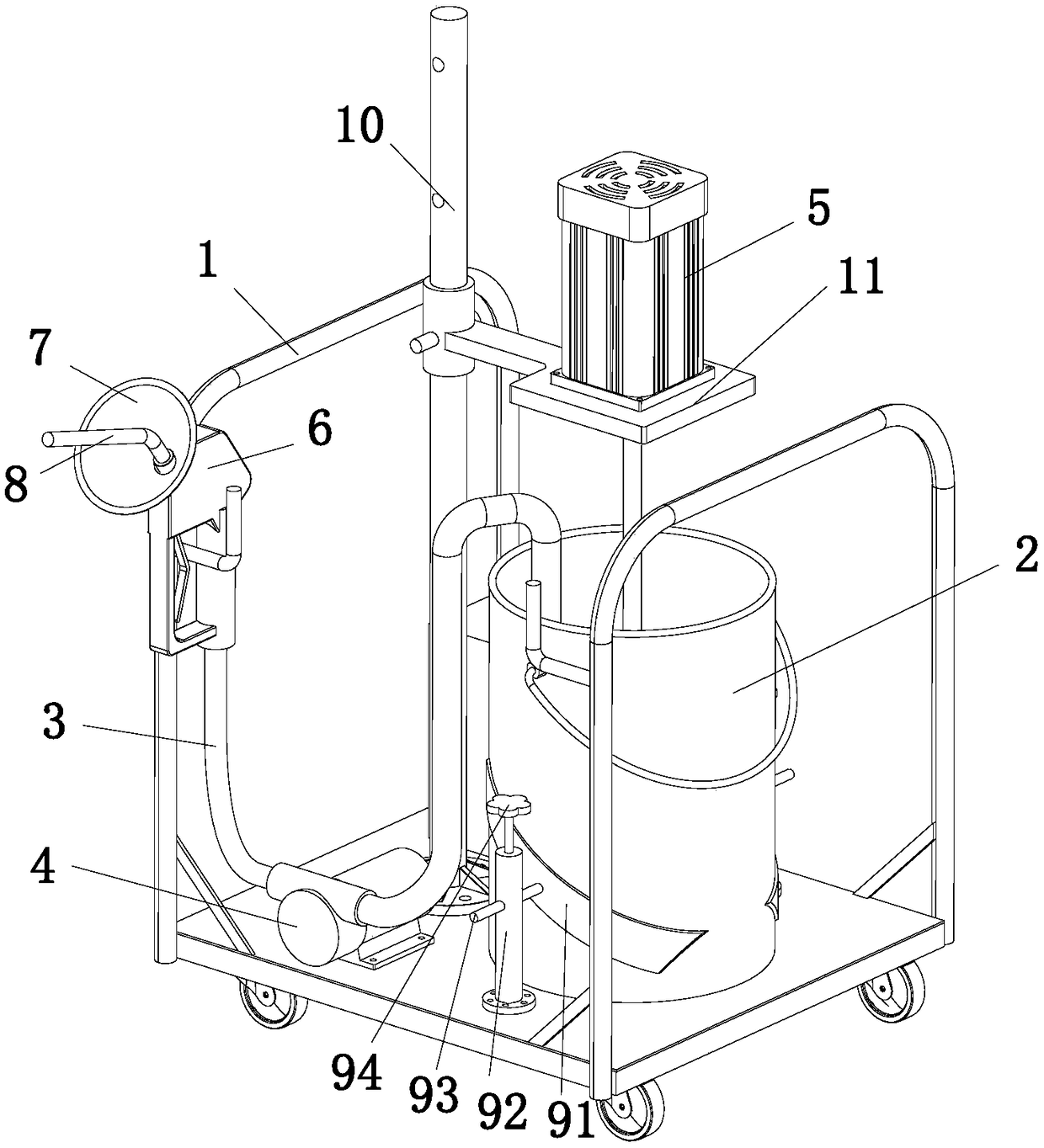

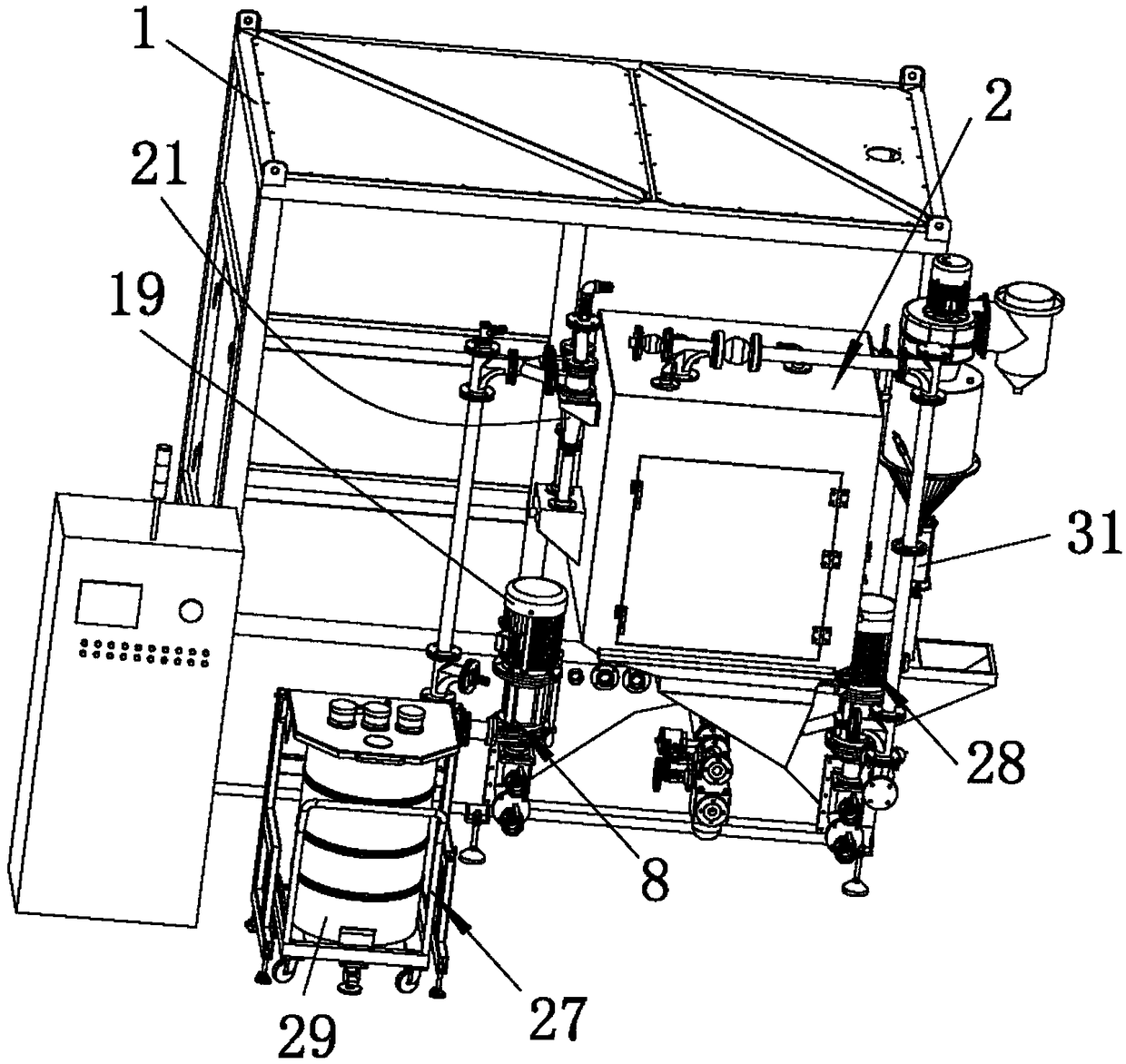

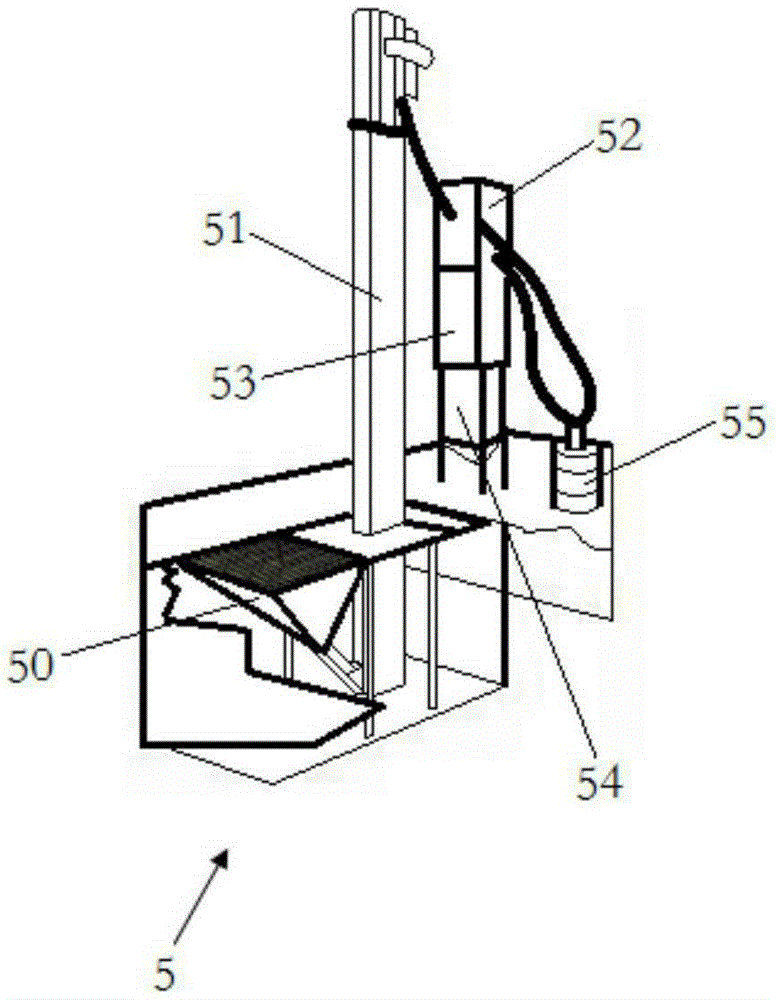

Static blasting expansion agent filling equipment and method

The invention discloses static blasting expansion agent filling equipment and method. The static blasting expansion agent filling equipment comprises a vehicle frame used for moving the equipment, a material barrel arranged on the vehicle frame and used for storing blasting expansion agents, a stirring device arranged on the vehicle frame and used for stirring the blasting expansion agents in thematerial barrel, a conveying pipeline used for conveying the blasting expansion agents in the material barrel into blastholes, and a driving device used for providing conveying power for the blastingexpansion agents in the conveying pipeline. According to the static blasting expansion agent filling equipment, the multiple blastholes are filled with the blasting expansion agents in the material barrel from the conveying pipeline through the driving device, the multiple blastholes are quickly filled with the blasting expansion agents, it is ensured that the maximum expansion pressure of the blasting expansion agents in the multiple blastholes are kept in the same period, and thus expansion blasting force of the expansion agents is exerted to the maximum extent.

Owner:CCFEB CIVIL ENG

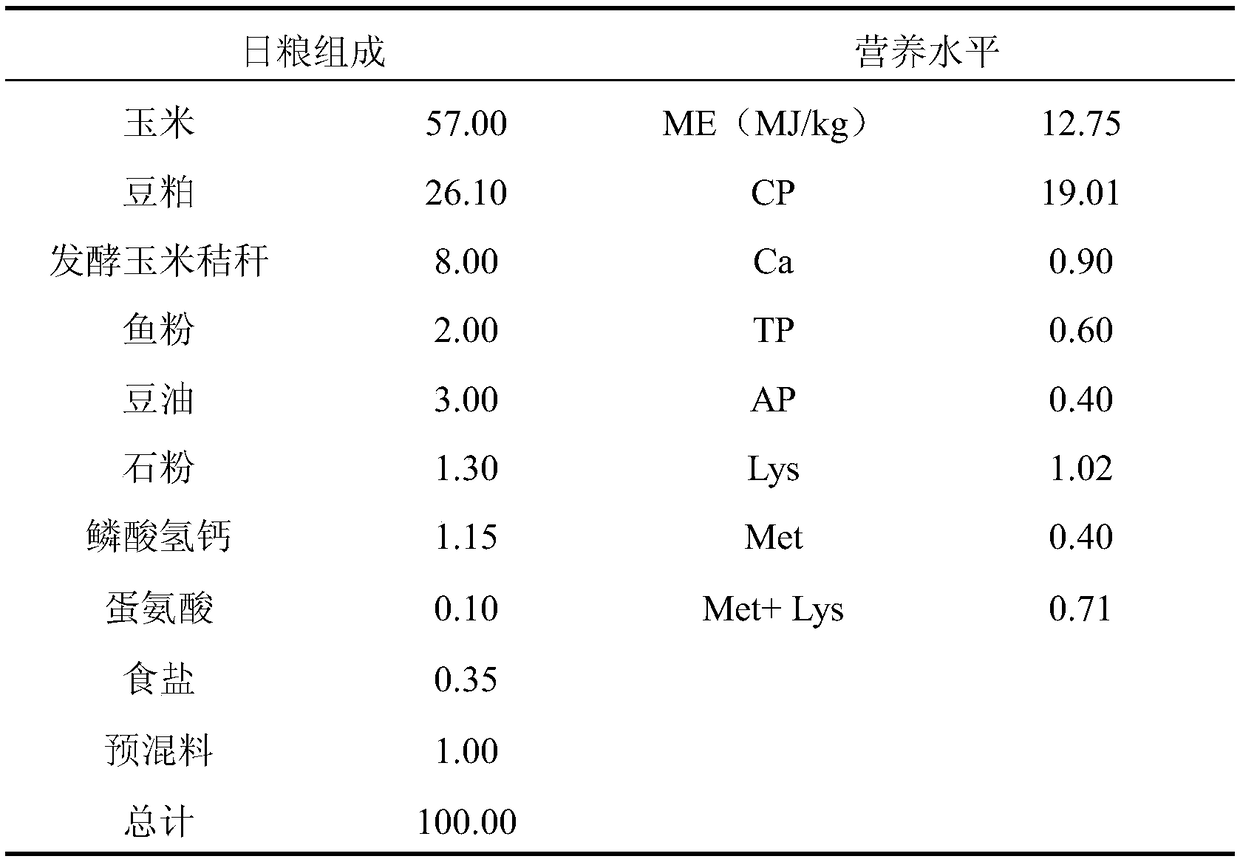

Fermentation method of corn straw, fermented corn straw prepared by method and applications of fermented corn straw

InactiveCN109287855AHigh in proteinImprove growth performanceFood processingLactobacillusCorn stoverLivestock

The invention discloses a fermentation method of corn straw, fermented corn straw prepared by the method and applications of the fermented corn straw, and belongs to the technical field of biologicalfermentation. The fermentation method of corn straw comprises the following processes: steam explosion, aerobic fermentation, and anaerobic fermentation. The method for fermenting corn straw of the invention can effectively degrade cellulose components in the corn straw, and increase the protein content of the corn straw. When feeding livestock and poultry, the fermented corn straw of the invention can significantly improve the growth performance of animals, maintain the intestinal environment stability and reduce the number of enteric pathogenic bacteria.

Owner:QINGDAO AGRI UNIV

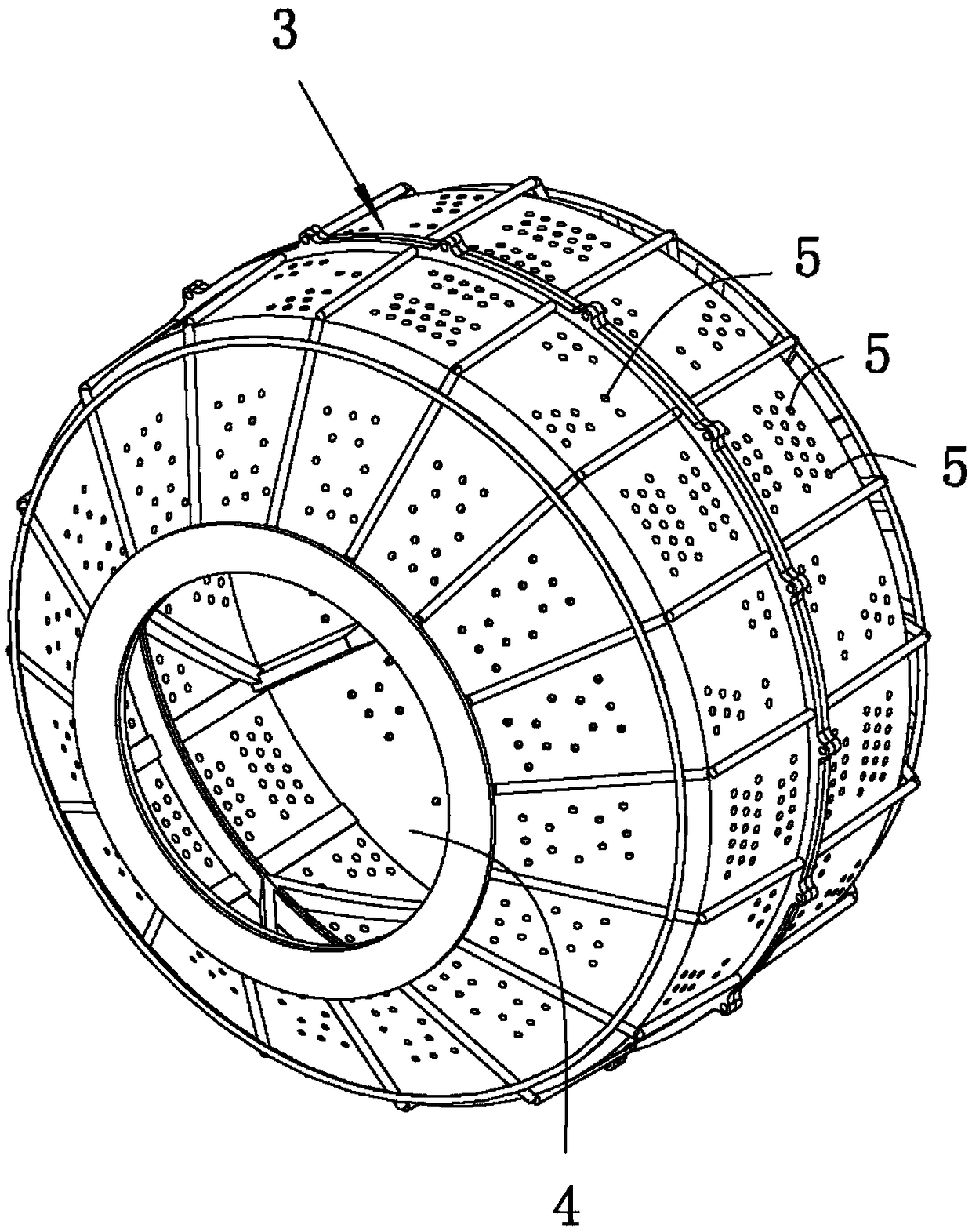

Automatic roller type sand blasting machine

ActiveCN109129208AImprove blasting efficiencySimple structure designAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention relates to the technical field of sand blasting of workpieces, and particularly discloses an automatic roller type sand blasting machine. The automatic roller type sand blasting machinecomprises a machine frame, a sand blasting chamber arranged on the machine frame, a roller rotatably arranged in the machine frame and located in the sand blasting chamber, a cover plate mounted on the machine frame or / and the sand blasting chamber and used for covering an opening of a material accommodating cavity, a spraying assembly arranged on the cover plate and located in the material accommodating cavity and a first sand pumping mechanism arranged on the machine frame, wherein the material accommodating cavity and a plurality of sand leaking holes which are communicated with the material accommodating cavity are arranged / formed in the roller; the first sand pumping mechanism is used for extracting sand water at the lower end of the sand blasting chamber and spraying the extractedsand water to workpieces in the material accommodating cavity through the spraying assembly; and during actual use, the workpieces need sand blasting are loaded in the material accommodating cavity ofthe roller, the spraying assembly is used for performing the operation of sand blasting on the workpieces in the roller, besides, the roller along with the workpieces in the roller continuously rotates, and remained sand sprayed by the spraying assembly flows out of the roller through the sand leaking holes; and the structural design of the sand blasting machine is simplified, and the sand blasting efficiency of the workpieces is improved.

Owner:东莞吉川机械科技股份有限公司

Workpiece circulation type automatic sand returning dry sand blasting room

InactiveCN105269466AAchieve loops and continuityImprove blasting efficiencyAbrasive machine appurtenancesAbrasive blasting machinesScrapEngineering

The invention discloses a workpiece circulation type automatic sand returning dry sand blasting room. The workpiece circulation type automatic sand returning dry sand blasting room comprises a sand blasting room body, circular workpiece supply systems, a control system, an automatic sand returning system, a sand blasting system and a sand removing system. The circular workpiece supply systems are divided into the upper circular workpiece supply system and the lower circular workpiece supply system. Lifting mechanisms are arranged below the lower circular workpiece supply system. A plurality of workpiece fixing bases are arranged on the lower circular workpiece supply system. A plurality of workpiece hooks are arranged on the upper circular workpiece supply system. Lifting doors are arranged on the two side faces of the sand blasting room body. The automatic sand returning system is composed of a sand falling groove, a lifting machine, a separating machine, a sand returning box, a pressure tank and a waste basket. According to the workpiece circulation type automatic sand returning dry sand blasting room, circular workpiece supply is achieved through the circular workpiece supply systems, and the sand blasting efficiency is improved. By means of the automatic sand returning system, sand materials are recycled, separated and repeatedly utilized, indoor accumulated sand is removed in time, sand material accumulation is prevented, and therefore the sand blasting effect cannot be affected.

Owner:重庆明治百通机械制造股份有限公司

Sand blasting process suitable for plasma spraying

InactiveCN109055882AIncrease roughnessHigh bonding strengthMolten spray coatingSand blastingSurface roughness

The invention discloses a sand blasting process suitable for plasma spraying. The process comprises the following steps of firstly, a workpiece base body is subjected to cleaning, impurity removal anddrying; secondly, the non-spraying face of the workpiece is subjected to coating and shielding treatment; and thirdly, the spraying face of the fixed workpiece base body is subjected to sand blasting, the sand blasting pressure ranges from 0.2 to 0.4 Mpa, and the sand blasting height ranges from 20 cm to 100 cm. Through the sand blasting process, the surface roughness of the workpiece base body is improved, a clean combination interface is provided, the subsequent coating quality is improved, the strength, hardness, corrosion resistance and wear resistance of the base body are improved, and the service life is prolonged.

Owner:芜湖通潮精密机械股份有限公司

Shot hole plugging device for coal mine underground excavation

The invention relates to a shot hole plugging device for coal mine underground excavation, and discloses a novel stemming plugging device. The device is capable of improving blasting efficiency of an explosive material, and is capable of conducting dust falling on dust generated during blasting. The shot hole plugging device for coal mine underground excavation is characterized in that one end of a gas collecting tube is placed on one end of an outer sleeve and is communicated with the outer sleeve, the diameter gradually increases from one end of the gas collecting tube to the other end of the gas collecting tube, three arc-shaped grooves are distributed at equal intervals on the outer wall of the other end of the outer sleeve, the arc-shaped grooves form arc-shaped protrusions in the inner wall of the outer sleeve, the diameter gradually increases from one end of the outer sleeve to the other end of the outer sleeve, an outer semisphere shell body is arranged on the other end of the outer sleeve and is communicated with the outer sleeve, the diameter of the outer semisphere shell body is equal to that of the other end of the gas collecting tube, multiple supporting plates are arranged on the outer wall of the outer semisphere shell, installation blocks are arranged among the multiple supporting plates, and screw mounting holes are formed in the installation blocks.

Owner:CHINA UNIV OF MINING & TECH

Arrangement method for double-empty-hole rhombic cutting holes in drift filling mining

InactiveCN109372509AIncrease profitImprove blasting effectDisloding machinesBlastingDrift miningStop time

The invention discloses an arrangement method for double-empty-hole rhombic cutting holes in drift filling mining, and belongs to the technical field of mineral mining. The double-empty-hole rhombic cutting hole arrangement method is adopted, therefore, the blasthole utilization rate is high, and the blasting effect is good; a small quantity of explosives are contained in the bottoms of empty holes and are detonated in the end, therefore, residues formed by blasting in the cutting holes are cast out of the holes, good blasting compensation spaces are provided for subsequent auxiliary hole blasting, and the cyclical footage is increased; and in addition, the blasting efficiency is improved, the cyclical footage is increased, on one hand, the rock drilling blasting cost is reduced, on the other hand, the primary mineral caving amount is increased, the drift stoping circulation operation frequency is decreased, therefore, the drift stoping time is shortened, the production capacity of a downward drift filling mining method is improved, and the drift mining safety and stability are facilitated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com