Construction method for additionally forming periphery auxiliary holes in periphery of vertical shaft periphery hole

A construction method and auxiliary eye technology, applied in blasting and other directions, can solve problems such as the small support range of umbrella drills, and achieve the effects of reducing construction costs, ensuring flatness, and achieving good technical and economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

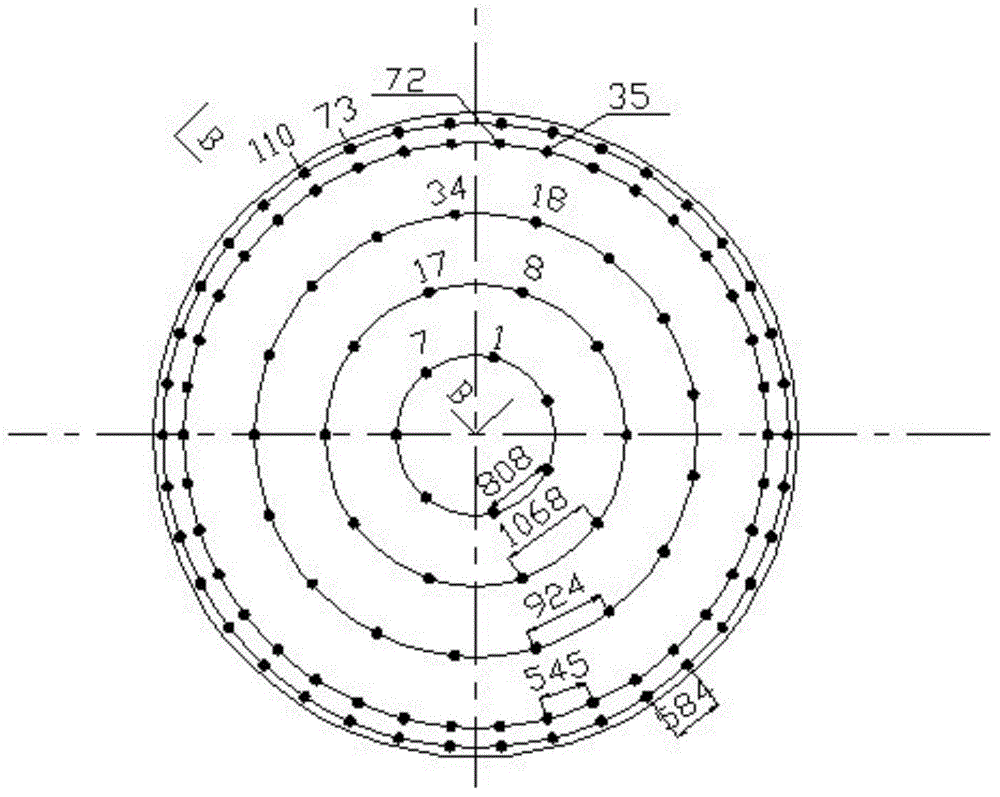

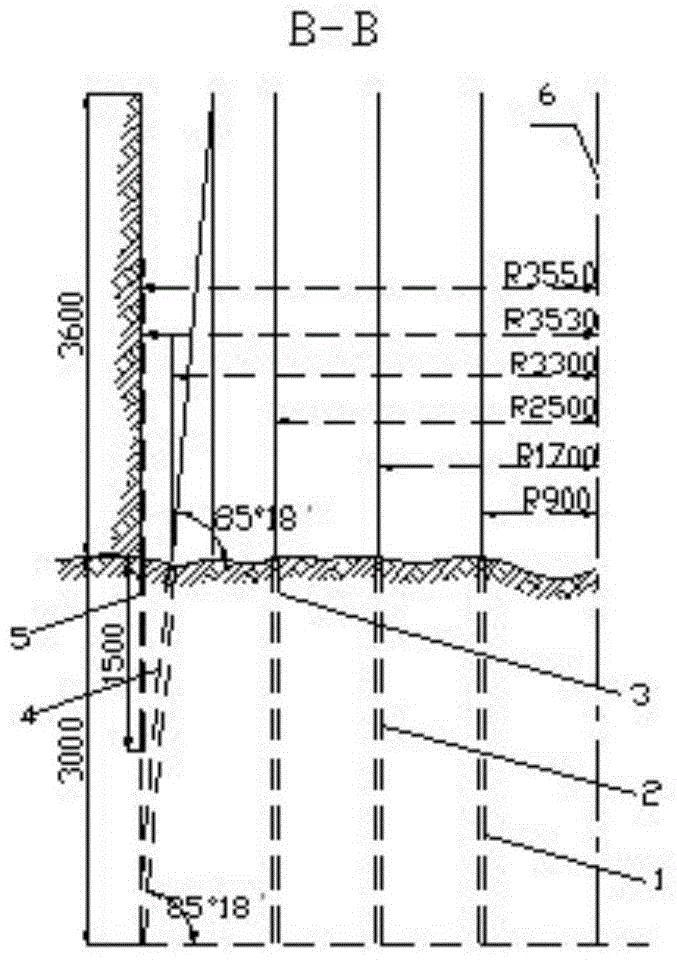

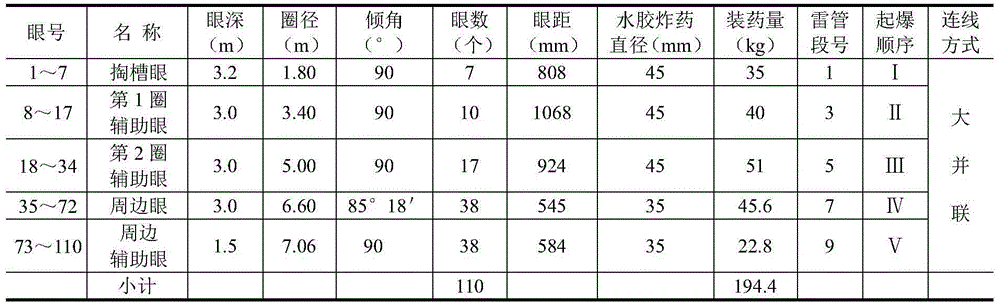

[0019] Such as Figure 1-2 As shown, a construction method for adding peripheral auxiliary holes outside the peripheral holes of the shaft, the specific implementation process is as follows: ①Use 6 hand-held YT-28 pneumatic drills to drill peripheral auxiliary holes after drilling the peripheral holes, the hole depth is 1500mm, It is required that the positioning radius is accurate, the eye positions are staggered from each other, the distance between the eyes is uniform, the inclination angle of the peripheral eyes is basically the same, and the peripheral auxiliary eyes should be vertical. ② The peripheral eye and peripheral auxiliary eye are charged at the same time according to the drilling and blasting design parameters. and trimming.

[0020] Table 1 Drilling and blasting parameter design of the bedrock section of the auxiliary shaft in Lengquan Mine

[0021]

[0022] Table 2 Drilling and blasting original conditions and blasting effects of the bedrock section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com