Patents

Literature

97results about How to "Little construction disturbance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

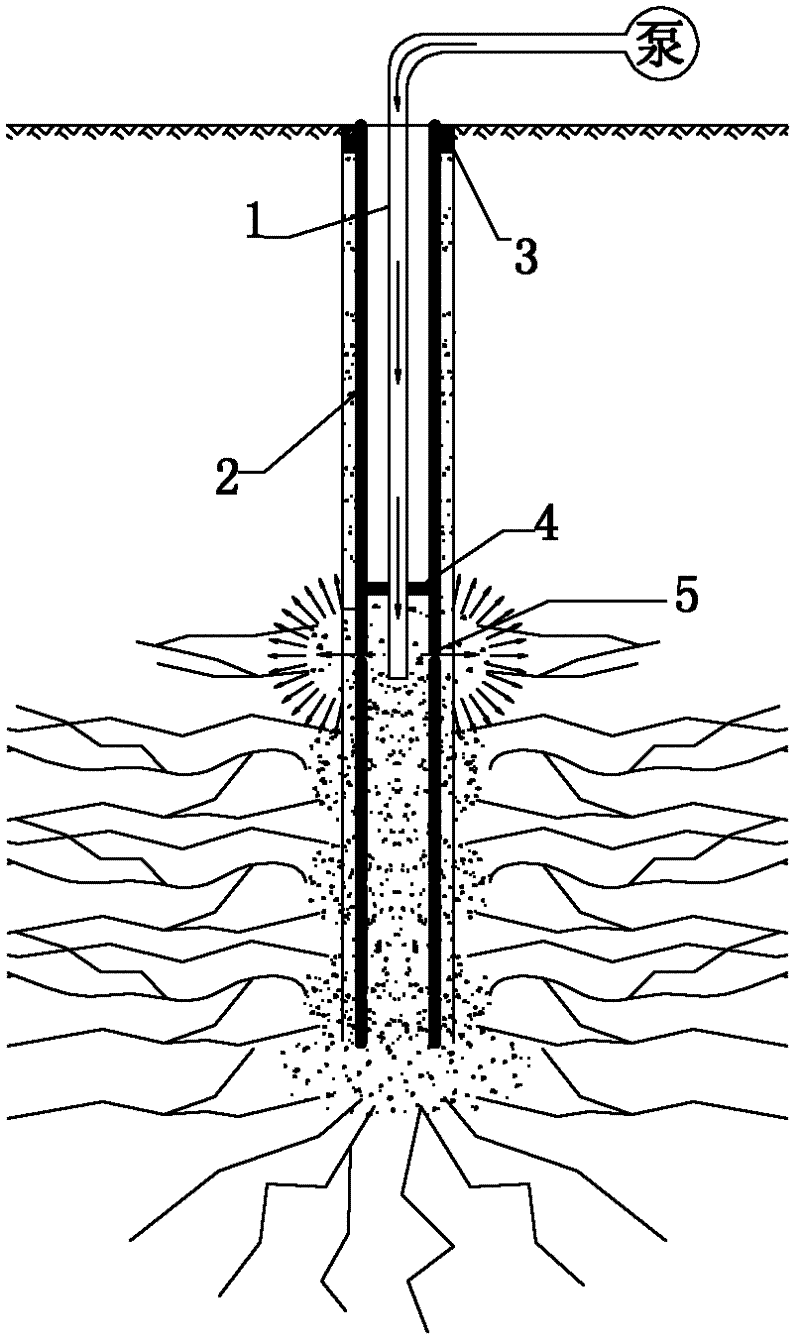

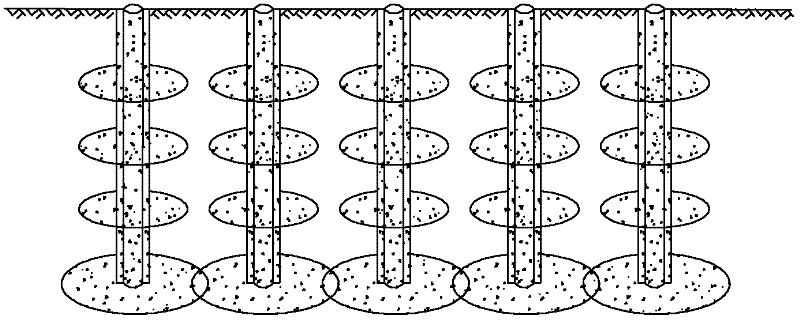

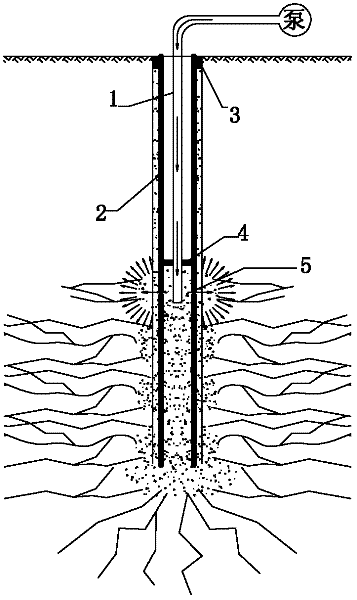

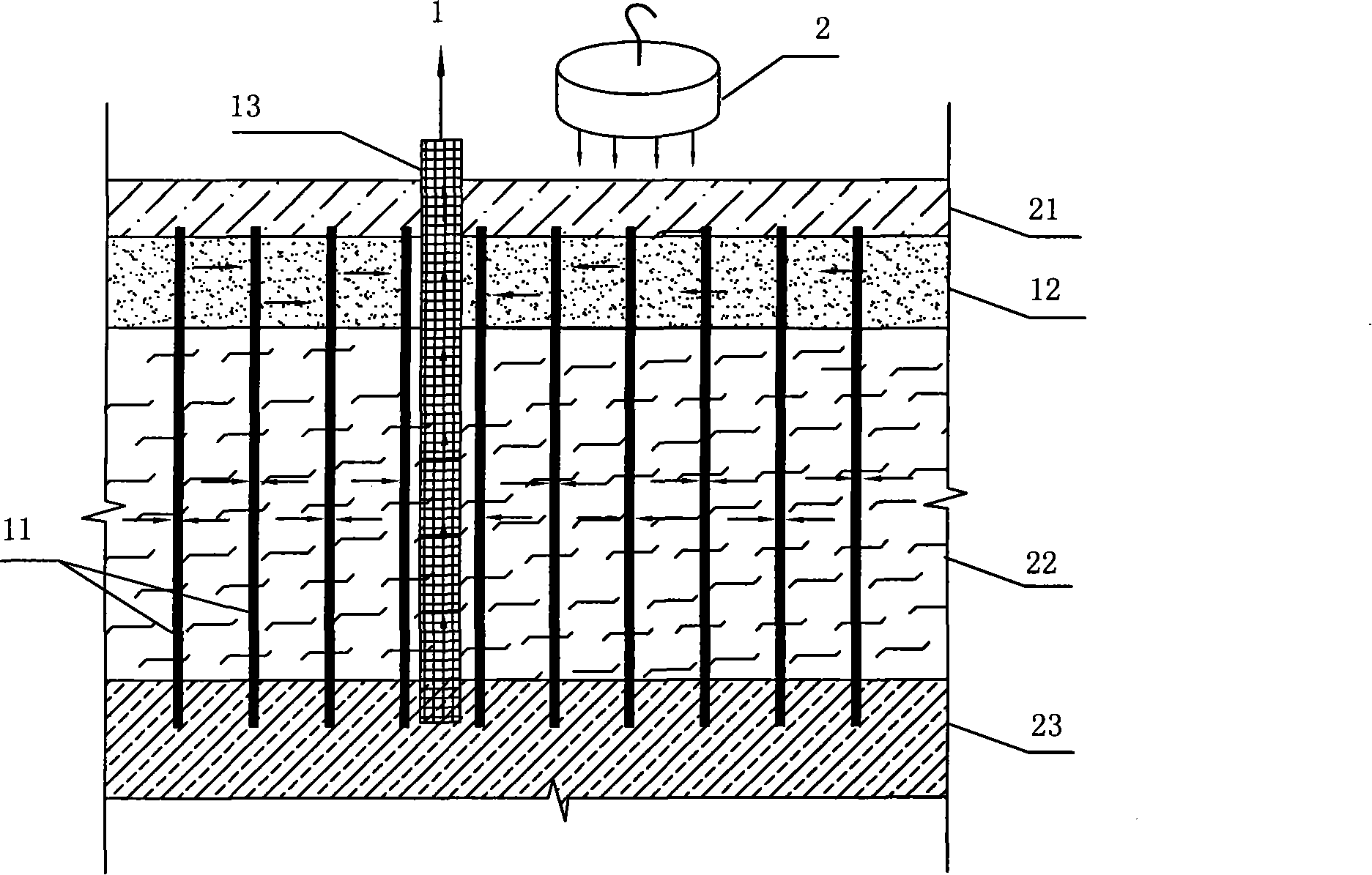

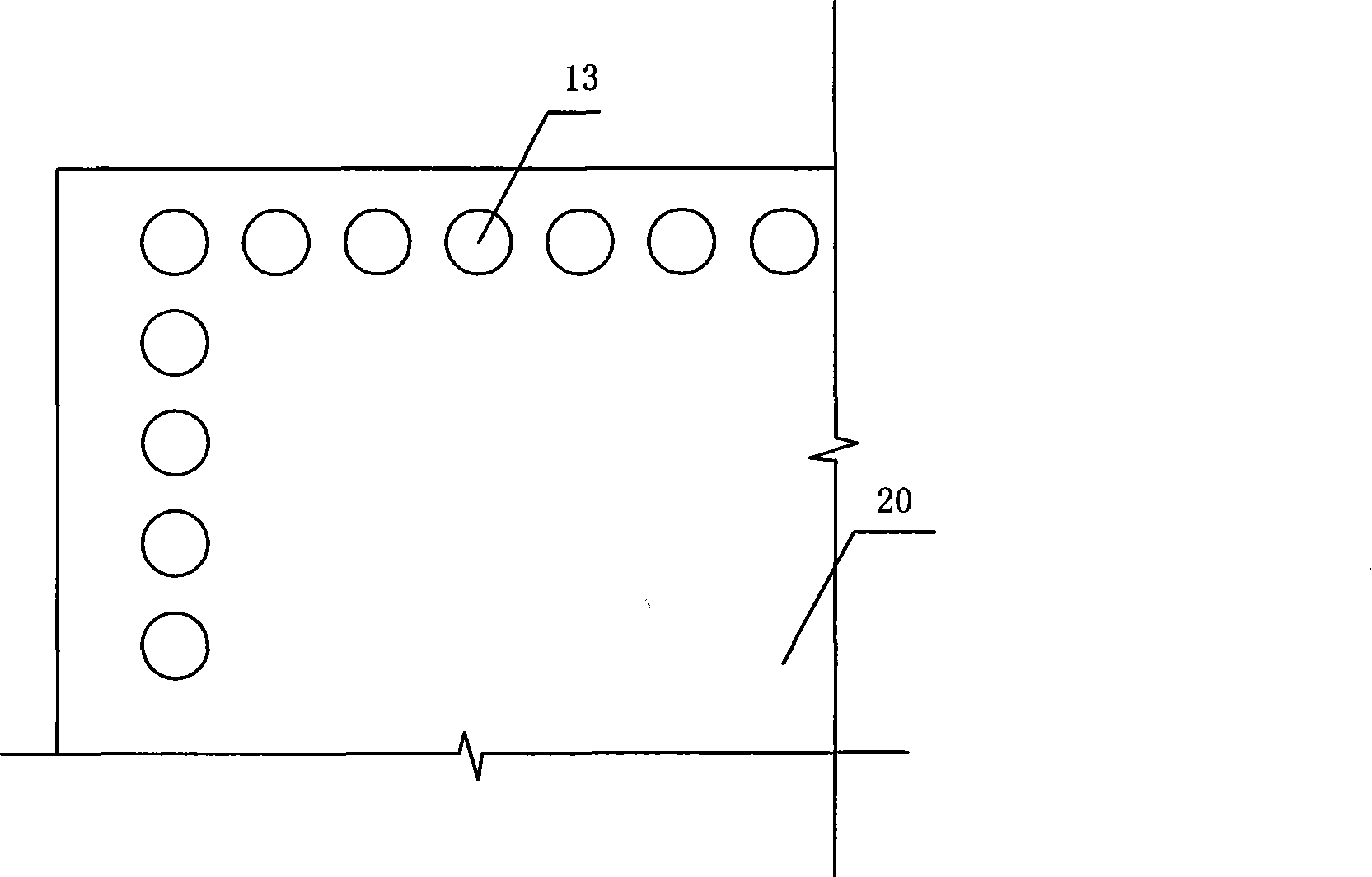

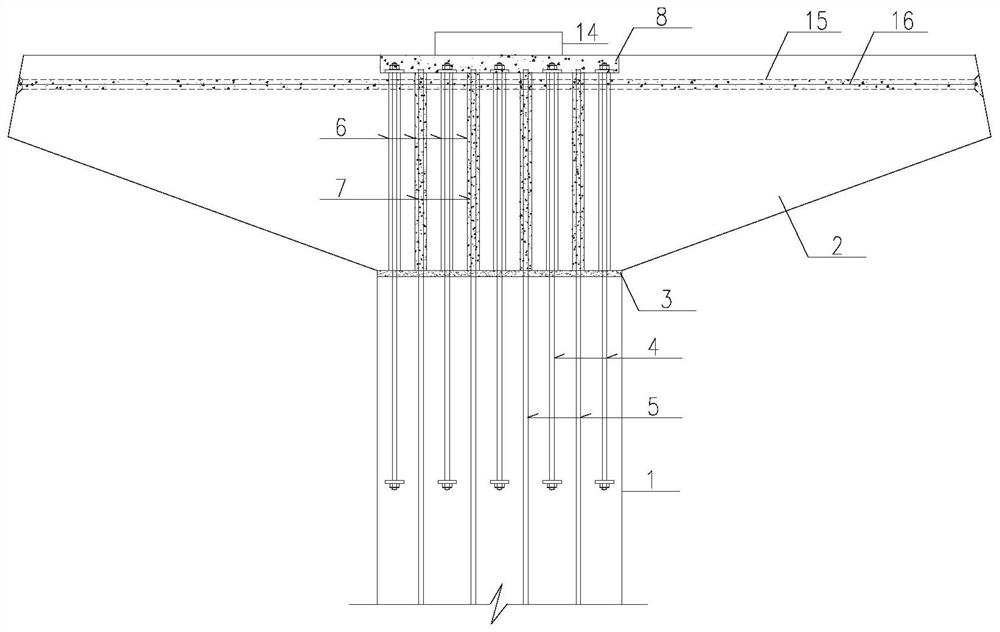

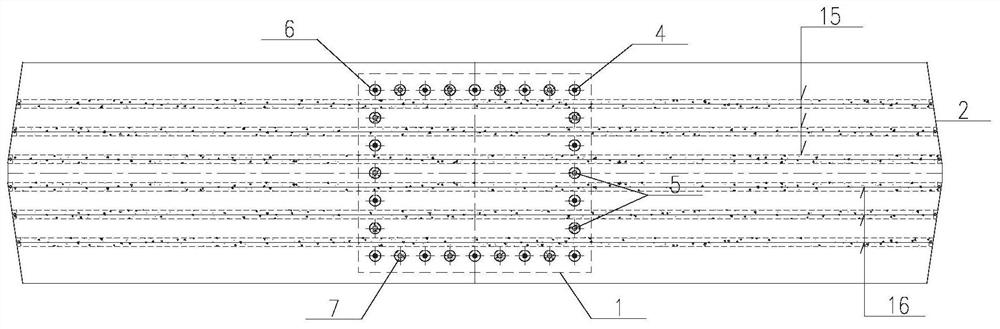

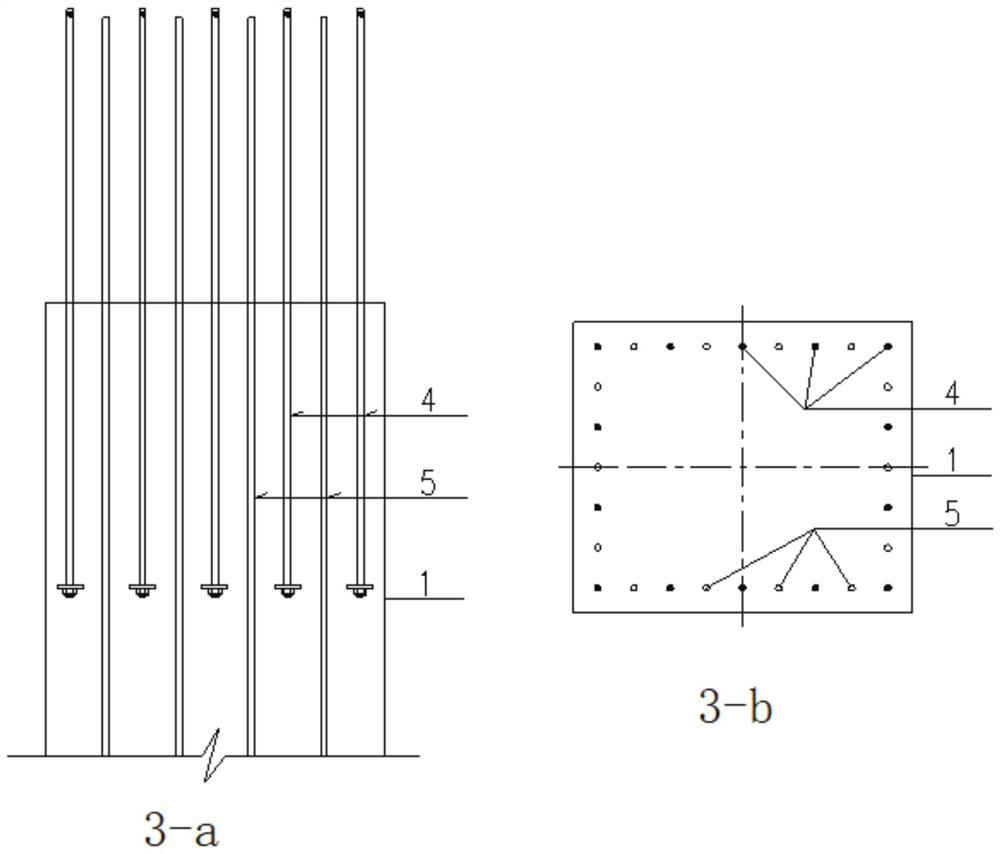

Grouting-type micro steel pipe pile and grouting reinforcement method

InactiveCN102493437AIncrease stressIncreased shear strengthExcavationsBulkheads/pilesSlurryPollution

The invention relates to a grouting-type micro steel pipe pile, comprising a steel pipe, wherein a plurality of spaced slurry outlet groups are formed in the side wall of the steel pipe along an axial direction, and a closed rubber loop is sleeved outside each slurry outlet group. Each slurry outlet group is composed of a plurality of slurry outlets uniformly distributed on a same horizontal plane. The invention further discloses a grouting reinforcement method of the steel pipe pile. According to the invention, a reinforcement effect is obvious, the vertical bearing capacity and the slope stability of a body to be reinforced can be increased from multiple aspects, nonuniform sedimentation can be effectively reduced, and the characteristics of small construction interferences, no pollution, simple construction process, low manufacture cost and the like are achieved at the same time.

Owner:SHANDONG UNIV

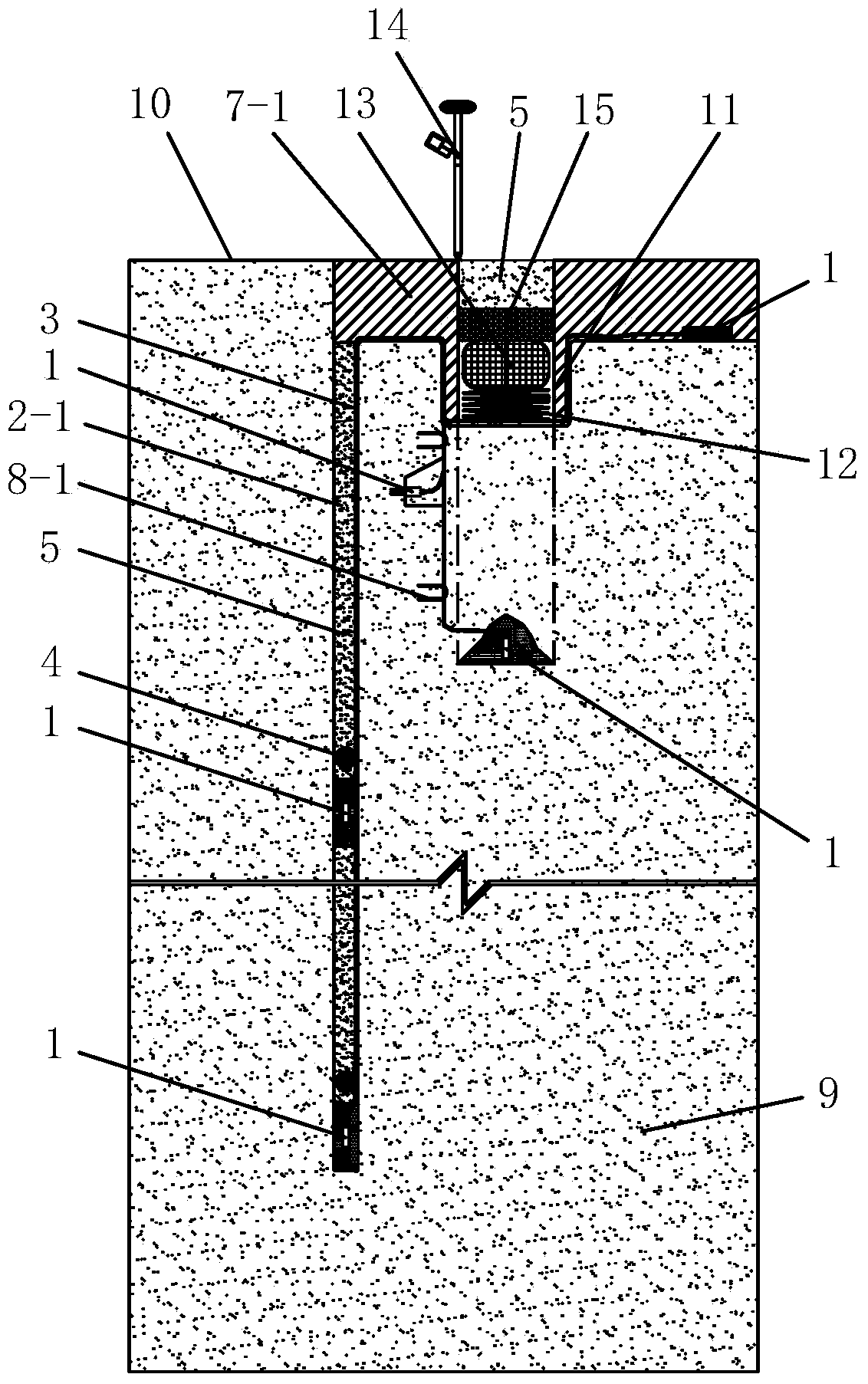

Packaged technology for underwater in situ automatically monitoring

ActiveCN101037864ASmooth and convenient in-situ monitoringShorten the timeArtificial islandsFoundation testingPore water pressureEarth surface

An in-situ automatic monitoring complete technology method for an underwater groundwork comprises a section surface subsidence monitoring method by multiple fixed inclinometers; a multipoint hydraulic difference surface subsidence monitoring method; a layered soil mass subsidence monitoring method; a pore water pressure monitoring method; and a horizontal and vertical displacement monitoring method; an automatic monitoring technology with a monitoring and control system disposed in the deep water sea bottom for long period. The invention can successfully and conveniently perform the in-situ monitoring of the underwater groundwork without disposing waterborne bases, arranging maritime platforms and passing through buildings; can perform full-course monitoring on the engineering, perform underwater automatic monitoring and real-time monitoring data transmission, in particular monitor continuously in the typhoon period; the automatic monitoring can save monitoring workers and cruise time; the automatic monitoring instruments are all disposed underwater, thereby having little influence on construction and decreasing instrument damage rate; the automatic monitoring can perform on-time on-point test to eliminate man-made reading error, and make the reading accurate, quick and precise.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +1

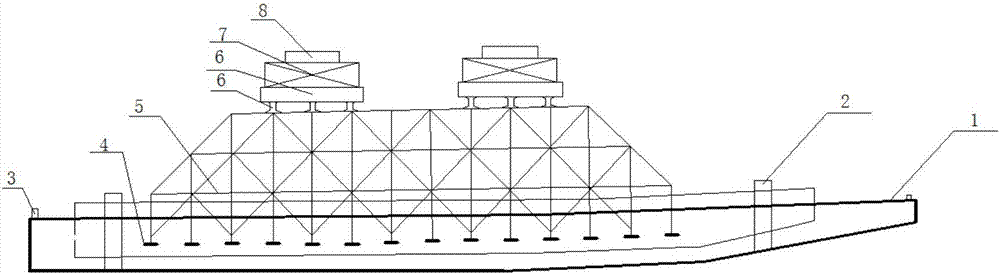

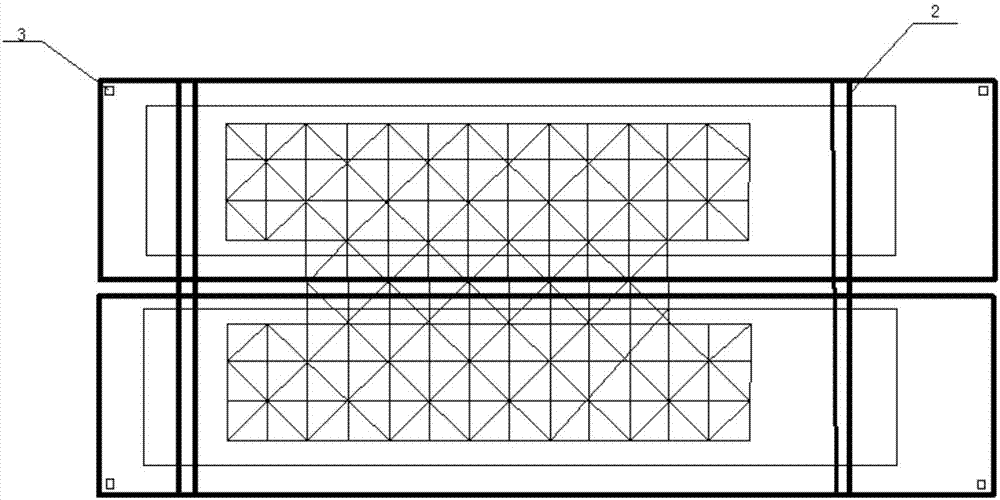

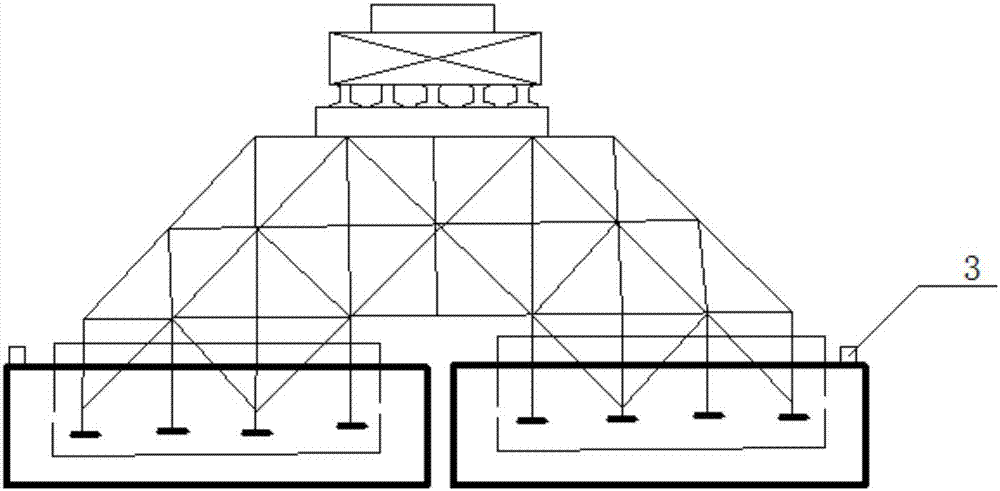

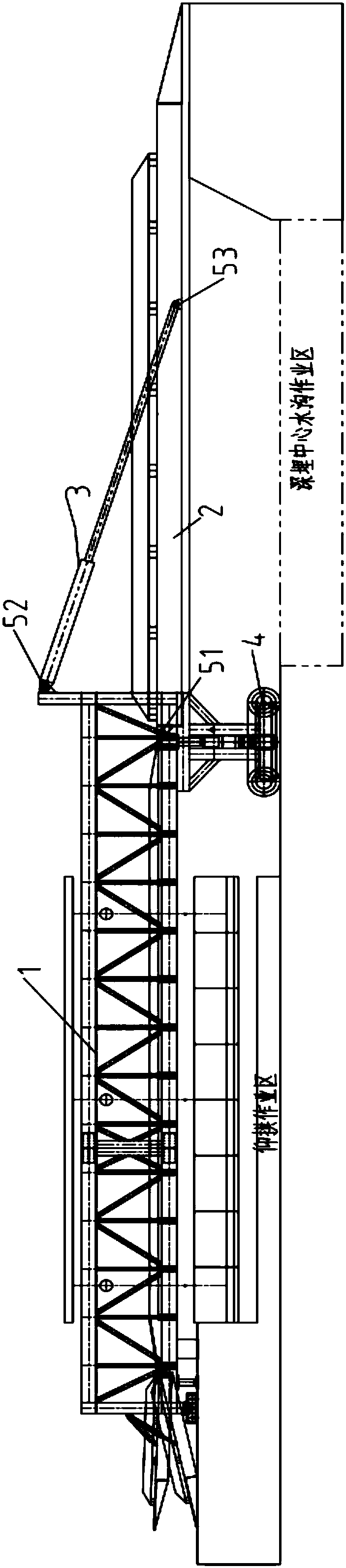

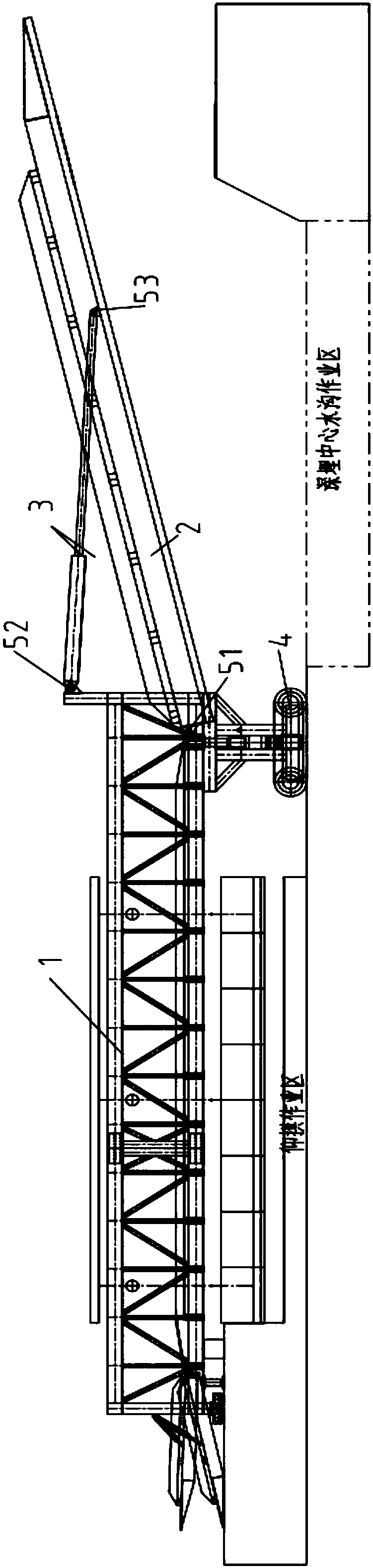

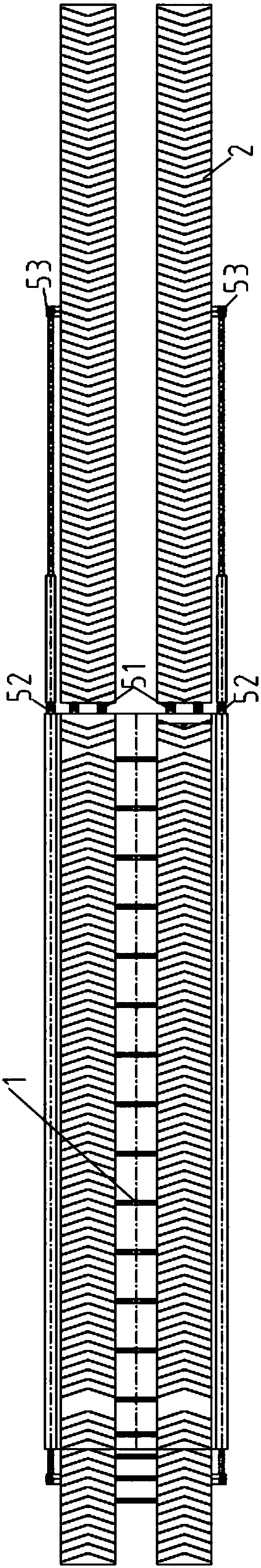

Floating tugboat used for steel beam installation, and system and method for bridge erection

InactiveCN107244388ASmall amount of reinforcementNo need to weighBridge erection/assemblyBarges/lightersTime segmentEngineering structures

The invention relates to the technical field of water bridge erection equipment, in particular to a floating tugboat for installing steel beams and a bridge erection system and method. The barge group of the floating tugboat drives the steel beam to move on the water by moving, and provides the support buoyancy for the steel beam to move on the water; the guiding mechanism is used to limit and guide the moving direction of the barge group in the water; the bridge erection system and method utilize The assembly platform assembles the steel beams in sections, and each section of the steel beam is pushed to the floating tugboat by the jacking mechanism and the sliding rail mechanism, and the floating tugboat is used to drive the section of the steel beam to the target position on the water, thereby forming a sectioned assembly. The efficient construction process of section-by-section hauling can not only reduce the amount of construction work in the water, but also ensure that the construction interference during the sea closure period of the water construction is small, and has the advantages of parallel construction, small reinforcement of steel beams, and no need for guide beam weight. .

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

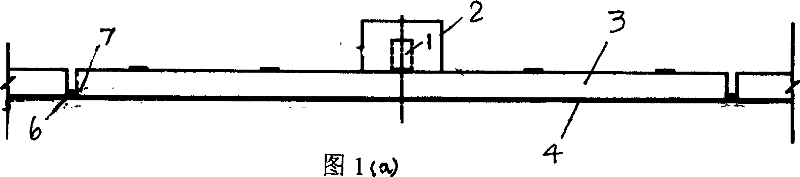

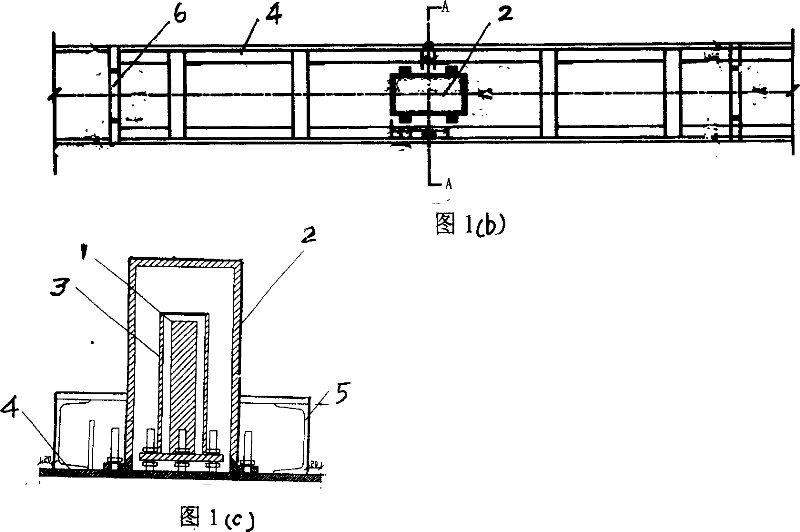

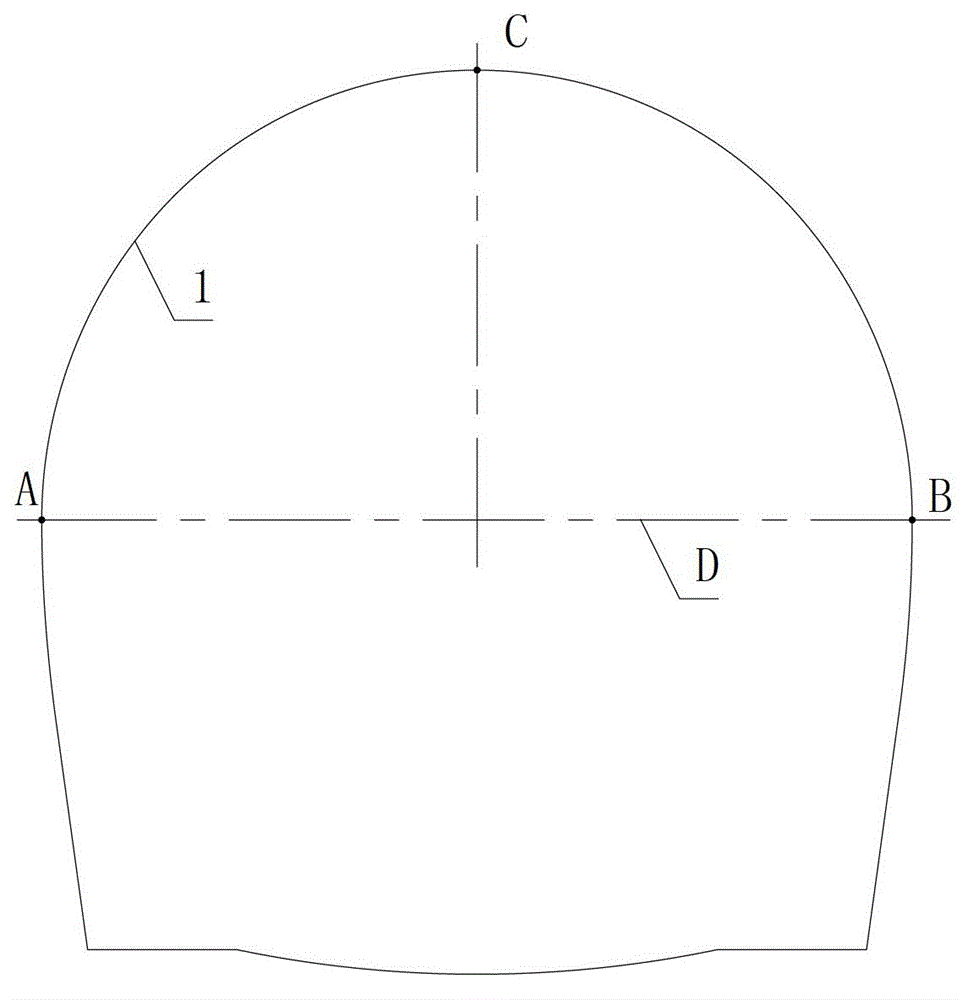

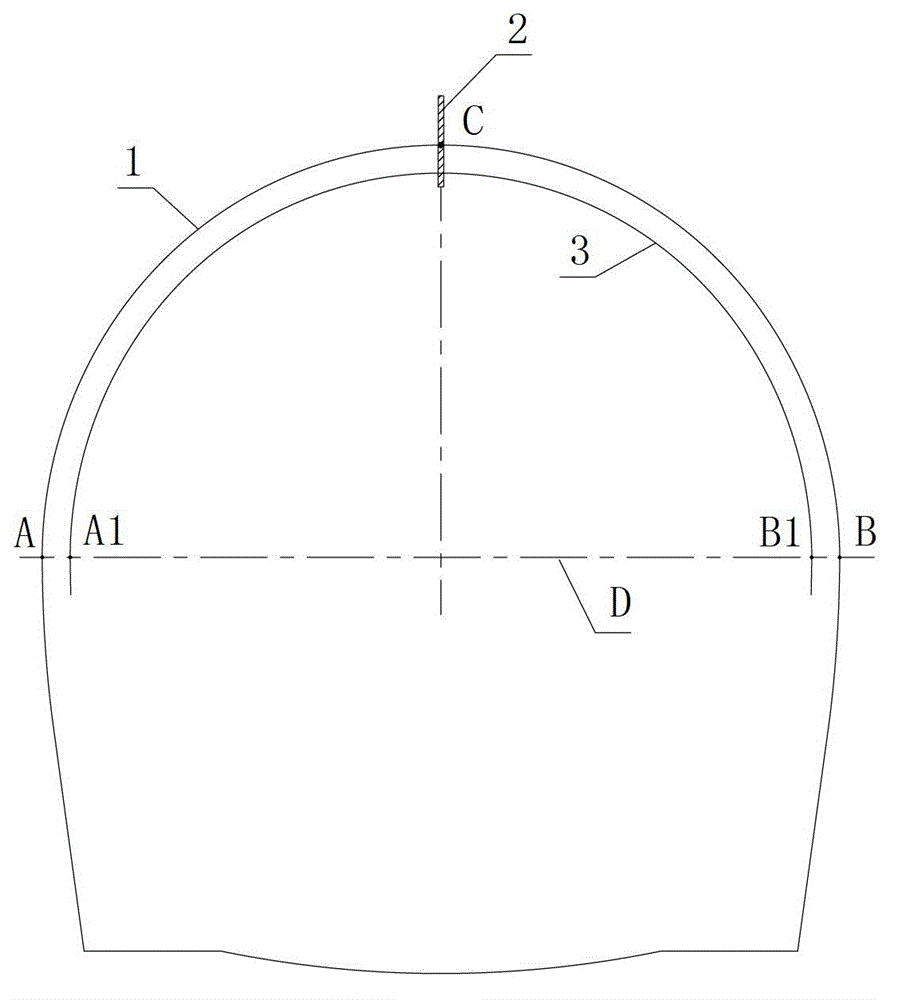

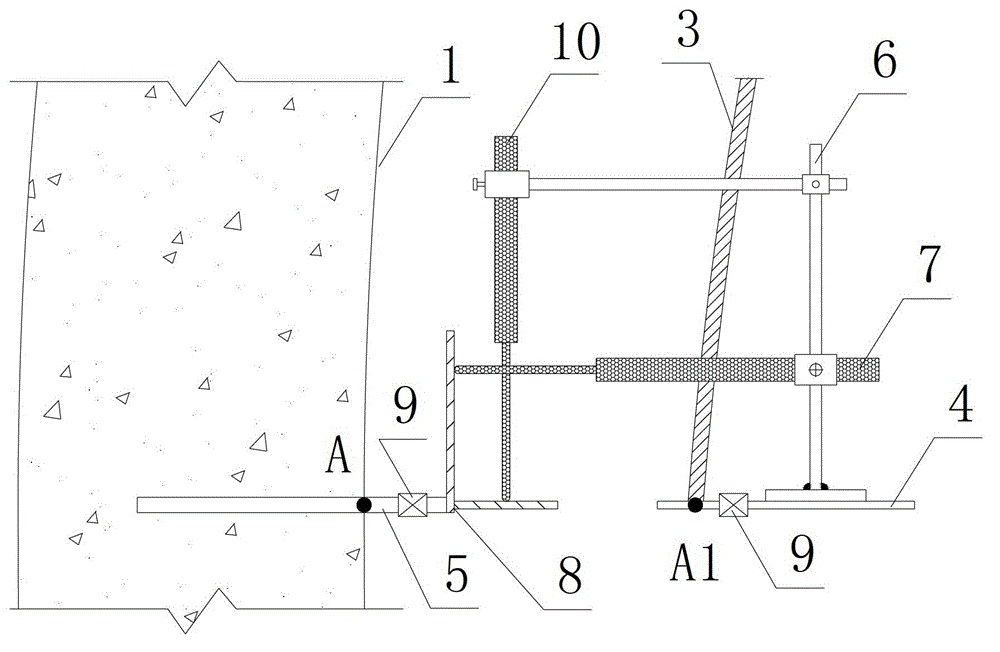

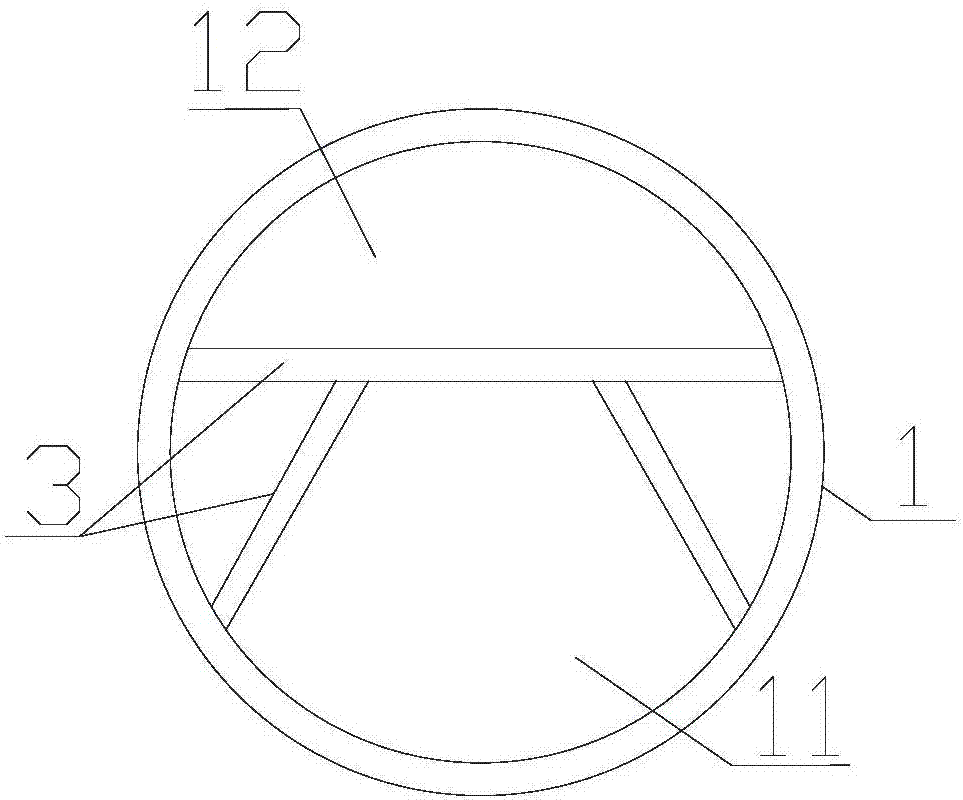

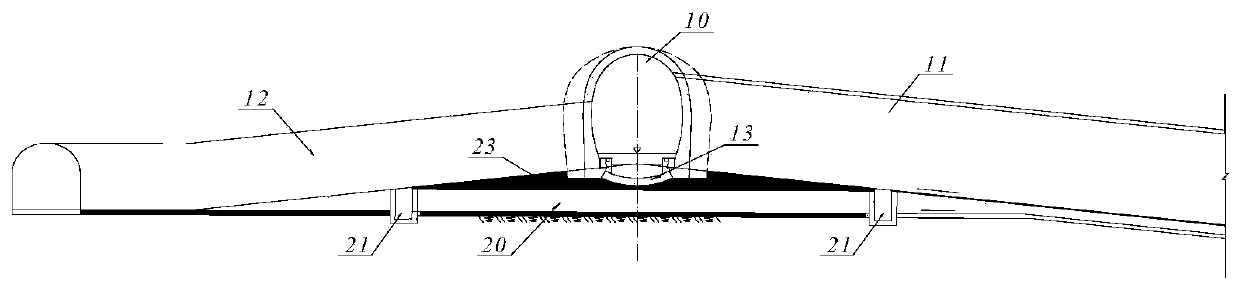

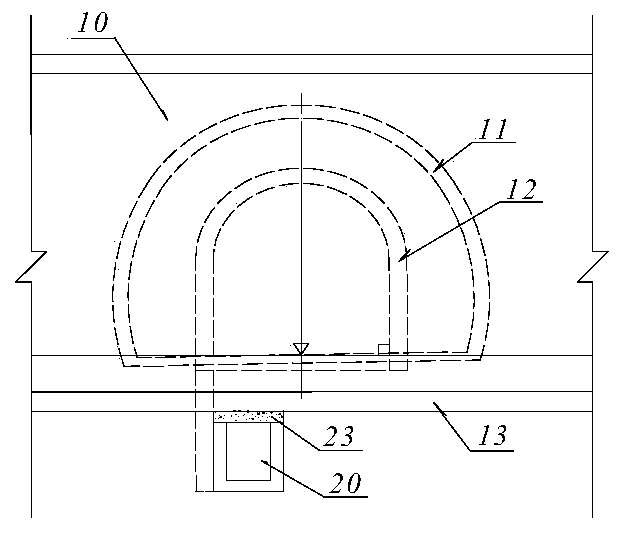

Monitoring and measuring method using displacement sensor to measure tunnel deformation

ActiveCN102914282ASimple measuring deviceQuick testMeasurement devicesMeasurement pointSensor holder

The invention provides a monitoring and measuring method using a displacement sensor to measure tunnel deformation. The monitoring and measuring method comprises the steps of setting a measurement point on a section of an arc tunnel, and connecting a line; arranging a connection rod at an arc measurement point; fixing a displacement transfer rod on the connection rod and fixing a first base on the connection rod; arranging a horizontal measuring rod at the position of the measuring point, and arranging a second base on the horizontal measuring rod; respectively setting the crosspoints of the displacement transfer rod and a horizontal measuring line as a first measurement point and a second measurement point; fixing a displacement sensor bracket on the first base or the second base, and arranging a horizontal direction displacement sensor and a vertical direction displacement sensor on the displacement sensor bracket; measuring horizontal clearance variation and vertical clearance variation, judging the deformation situation of the tunnel accordingly, calculating the horizontal clearance variation between a left measurement point and a right measurement point, and calculating a mean value of the vertical clearance variation between the arc measurement point and the horizontal measurement line. The monitoring and measuring method provided by the invention has the advantages of rapidness in test, high testing precision, less interference on construction and low cost, can be used for monitoring in real time, and can be used for determining whether the tunnel is biased or not according to the testing result of the clearance variation of the channel.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

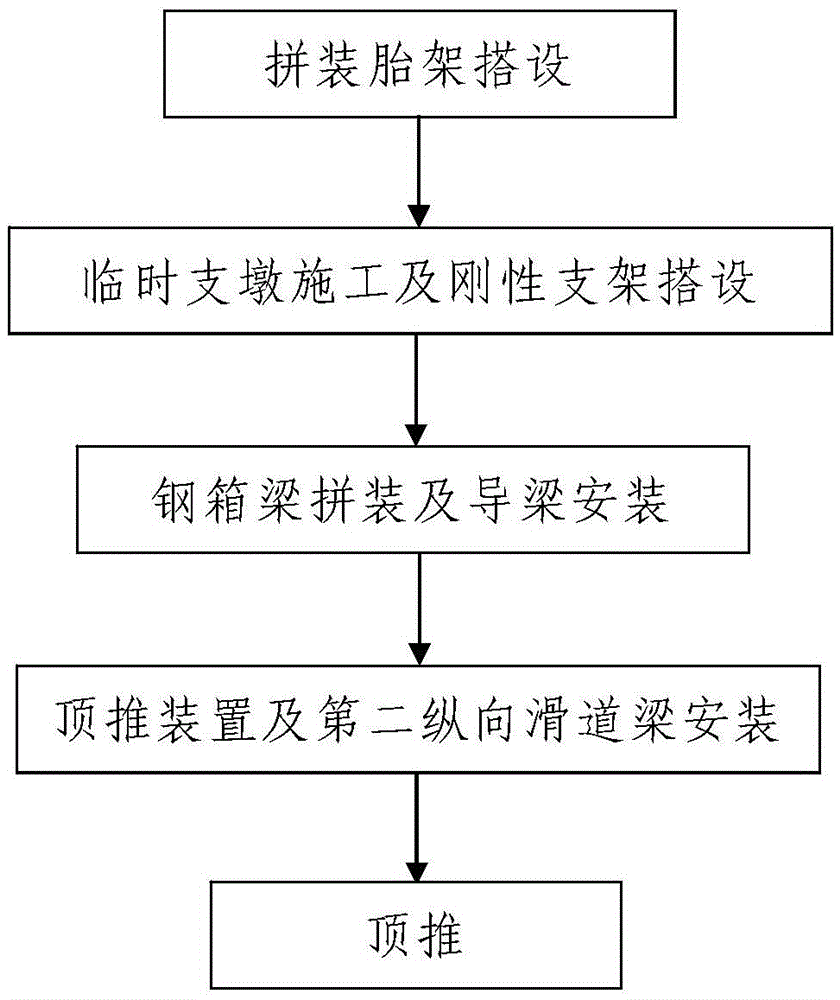

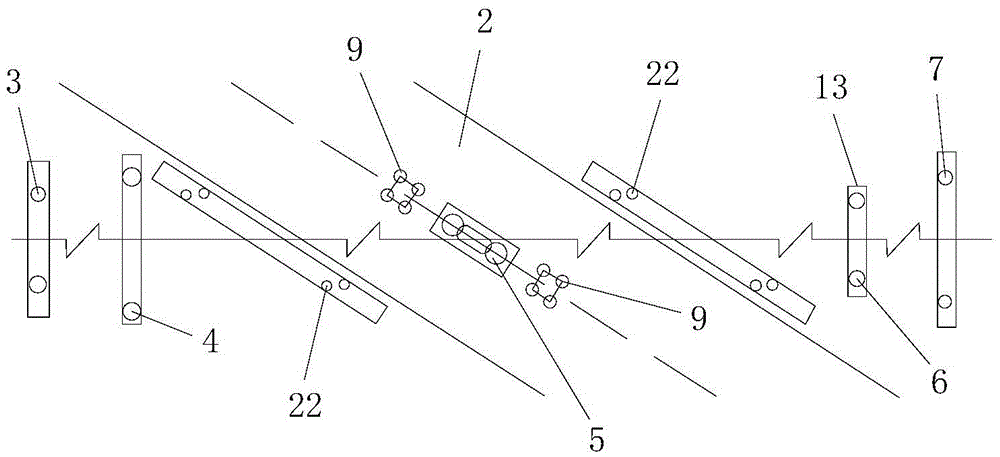

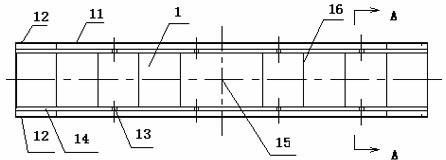

Incremental launching construction method for large-span steel box girder spanning constructed road

ActiveCN105568866AThe method steps are simpleSimple and fast operationBridge erection/assemblyButtressSteel box girder

The invention discloses an incremental launching construction method for a large-span steel box girder spanning a constructed road. An incremental launching steel box girder spans the constructed road, is supported by five permanent buttresses, and is formed by a plurality of steel box girder segments which are spliced back to front; the five permanent buttresses are all uncovered girder double-cylinder pillars; the uncovered girder double-cylinder pillars respectively consist of two cylindrical buttresses which are supported below the left side and the right side of the steel box girder; the incremental launching construction method for the incremental launching steel box girder comprises the following steps: I, splicing jig frames; II, constructing temporary buttresses and rigid brackets; III, splicing the steel box girder and mounting guide beams; IV, mounting an incremental launching device and a second longitudinal slideway beam; V, performing incremental launching. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient to construct and good in use effect, and by constructing the rigid brackets on the outer sides of the buttresses and mounting a longitudinal slideway and a transverse deviation correcting device, the incremental launching construction of the large-span steel box girder can be easily, conveniently and rapidly completed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

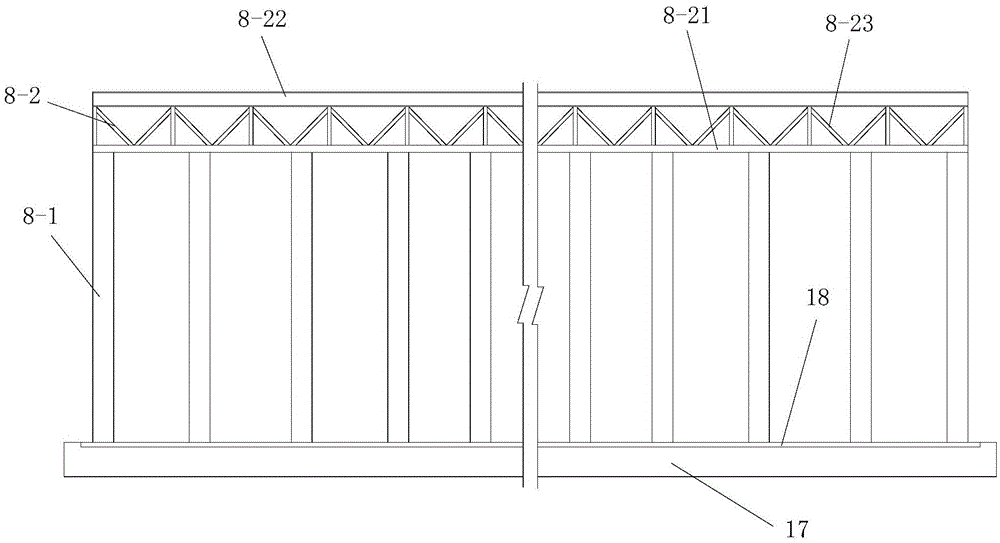

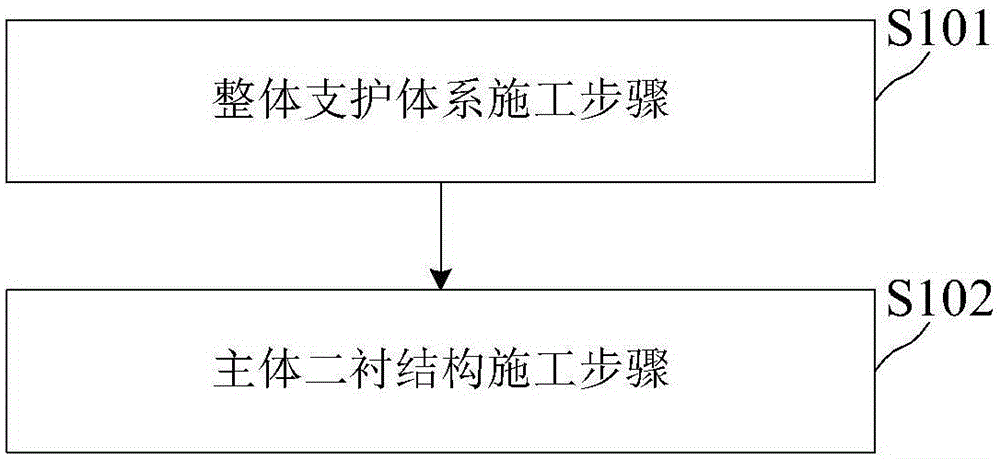

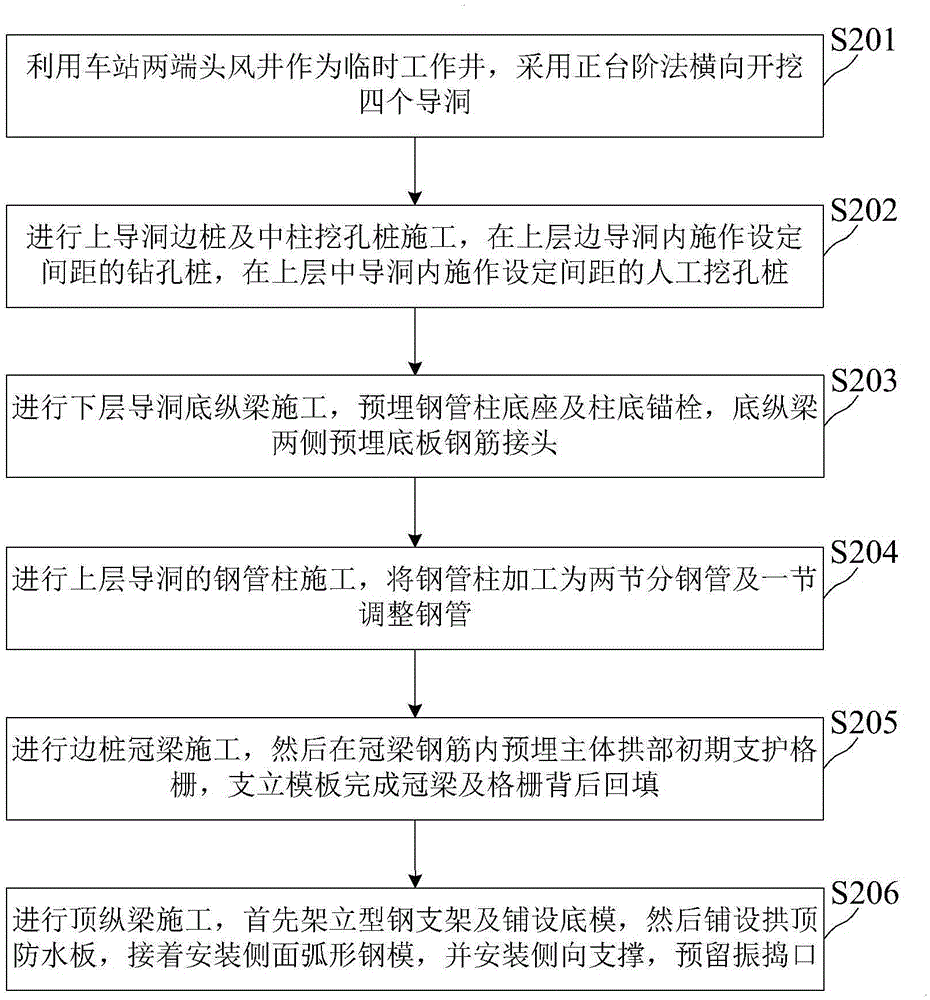

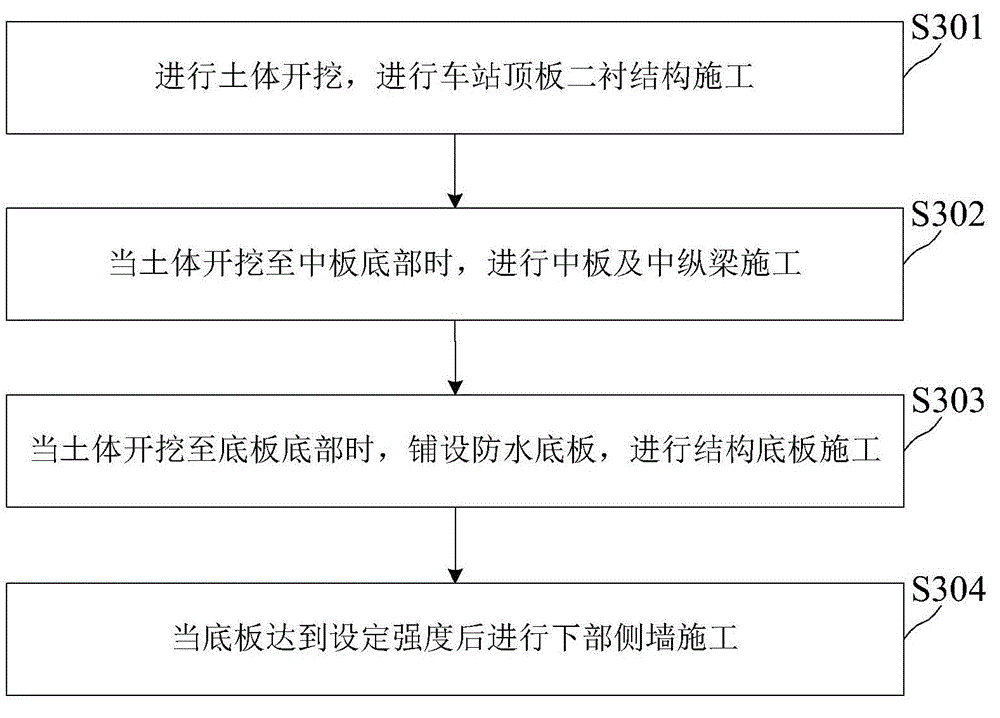

Mined metro station hole pile construction method

ActiveCN106703814AReduce the impact of settlementSave masonryUnderground chambersTunnel liningSupporting systemMetro station

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

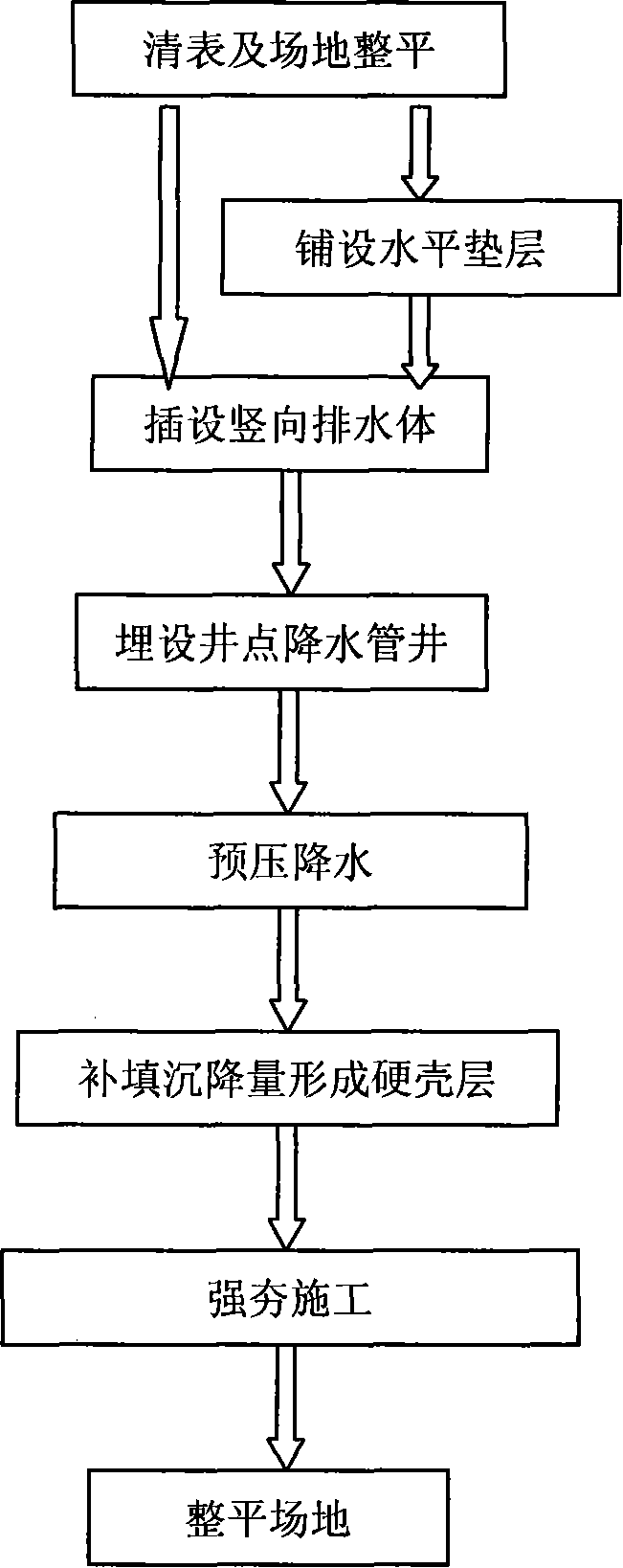

Precipitation prepressing association motivation induration deep densification method

ActiveCN101250868AIncrease the permeability coefficientAdd additional pressureSoil preservationSoil sciencePermeability coefficient

The invention discloses a deep strengthening method of dewatering reinforcement combined dynamic consolidation, which comprises the following steps: V1ing: a vertical drainage body is arranged in a strengthened foundation. V2ing, soft soil foundation is done with the dewatering reinforcement. V3ing, after a deep soil body below 8 meter of the ground surface of the strengthened foundation is acted by the dewatering reinforcement, the consolidation degree is above to 75 percent, and then the consolidation construction is done. The invention combines a dewatering reinforcement method and a dynamic consolidation method to be applied to strengthen the deep soil body of the soft soil foundation, particularly the permeability coefficient is not less than 10-6cm / s, and the water content of the soil body before the dynamic consolidation is not higher than a strengthened soft soil foundation which is 20 percent of the best water content. The foundation reinforcement effect is obvious, the construction period is capable of being reduced 1 / 3-2 / 3 as a whole, the construction cost is greatly reduced, the cost is saved (compared with a vacuum preloading method, the treatment cost in each square meter is reduced by 30-50 percent ), because the operating intensity is small, the demand for equipment is not high, and the deep strengthening method is suitable for popularization and application.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

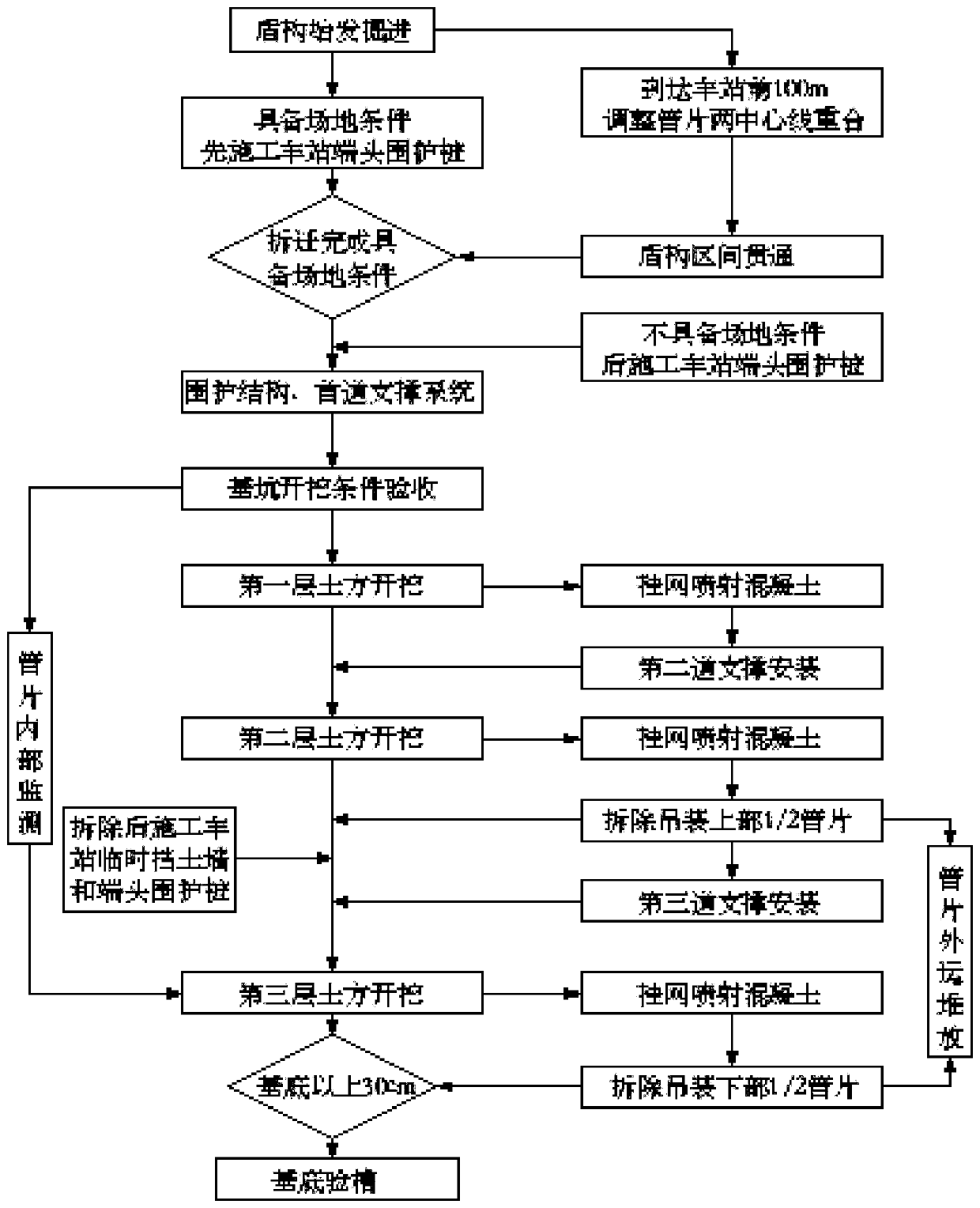

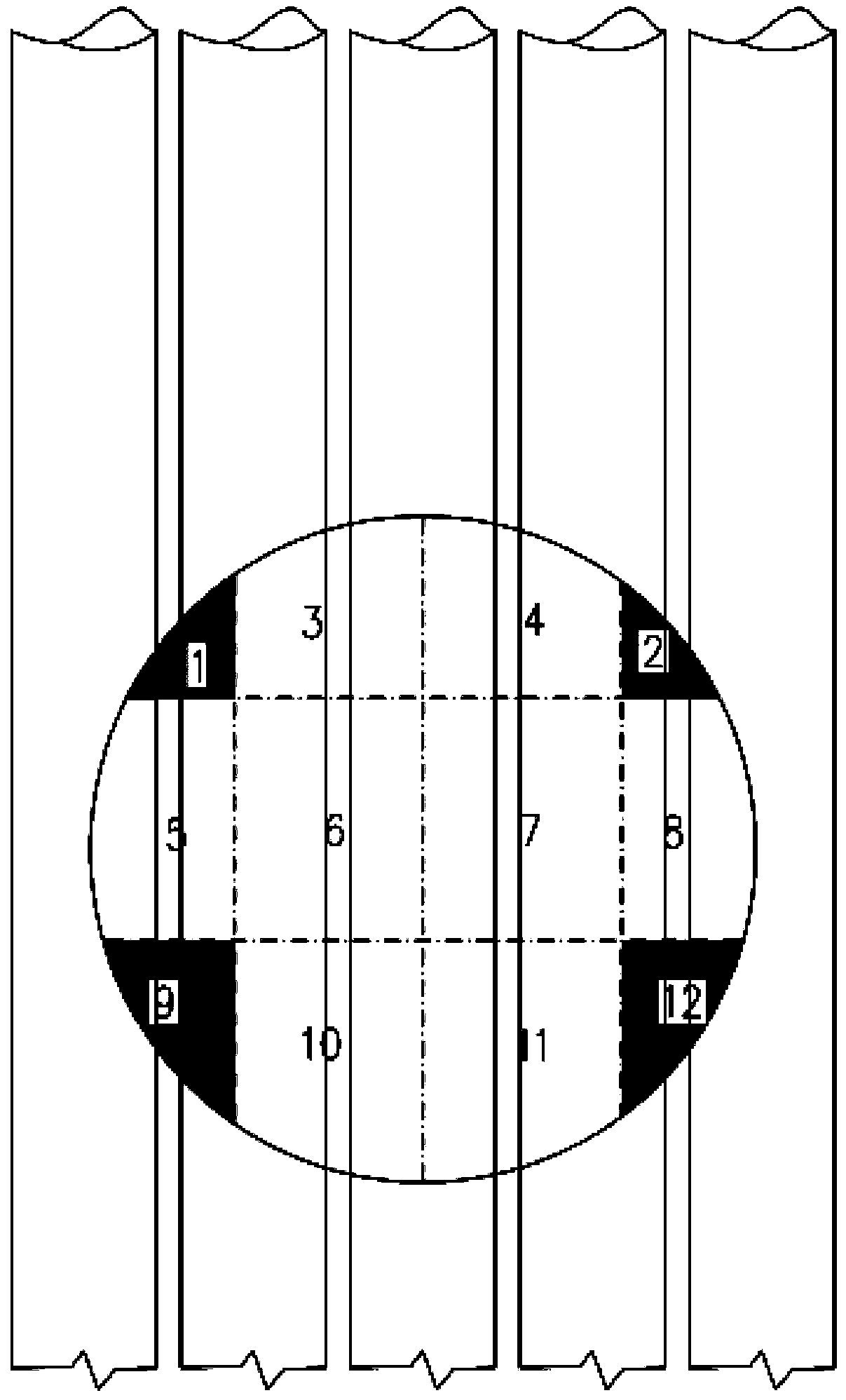

Tunnel-before-station open-cut station construction method

ActiveCN110424969ANot affected by land acquisition and demolitionControllable start timeArtificial islandsUnderground chambersArchitectural engineeringShield tunneling

The invention provides a tunnel-before-station open-cut station construction method. A shield tunneling machine carries out tunneling in advance to pass through the station range, and the problems that a station is influenced by land requisition and demolishing and does not have construction conditions, and starting and receiving conditions cannot be provided for the shield tunneling machine are solved; and the aim that the sections can be cut through firstly, and then the station is constructed is achieved.

Owner:中铁一局集团厦门建设工程有限公司 +1

Reverse osmosis water processing method and reverse osmosis drainage system in construction period of concrete faced rockfill dam

ActiveCN103132488AEasy constructionSmall nerf rangeBarrages/weirsEarth-fill damsReverse osmosisEngineering

The invention discloses a reverse osmosis water processing method and a reverse osmosis drainage system in a construction period of a concrete faced rockfill dam. A drainage blind material is arranged in a horizontal interface between a transition area and an upstream rockfill area, a sleeving is connected with one side, arranged on the upper stream, of the drainage blind material, the other side of the sleeving is connected with a horizontal drain pipe with a one-way water stop valve, connection threads are respectively arranged outside two ends of the horizontal drain pipe, the other side of the horizontal drain pipe is connected with a drainage hose, the other end of the drainage hose is placed in a water-collecting well, and a vertical drain pipe is further arranged. The reverse osmosis water processing method and the reverse osmosis drainage system in the construction period of the concrete faced rockfill dam are particularly applicable for reverse drainage in the construction period of the concrete faced rockfill dam, wherein the concrete faced rockfill dam is deep in foundation excavation of riverbed section toe boards, and long in upstream bedding filling construction period, and a dam body needs flood crossing and water retaining.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

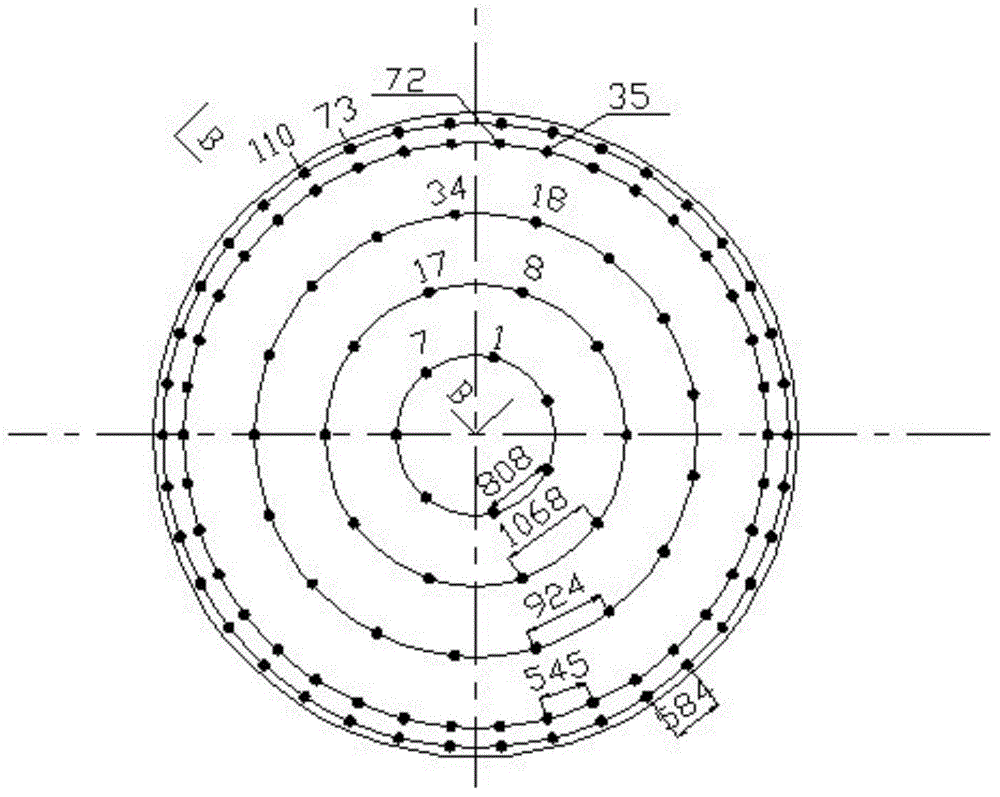

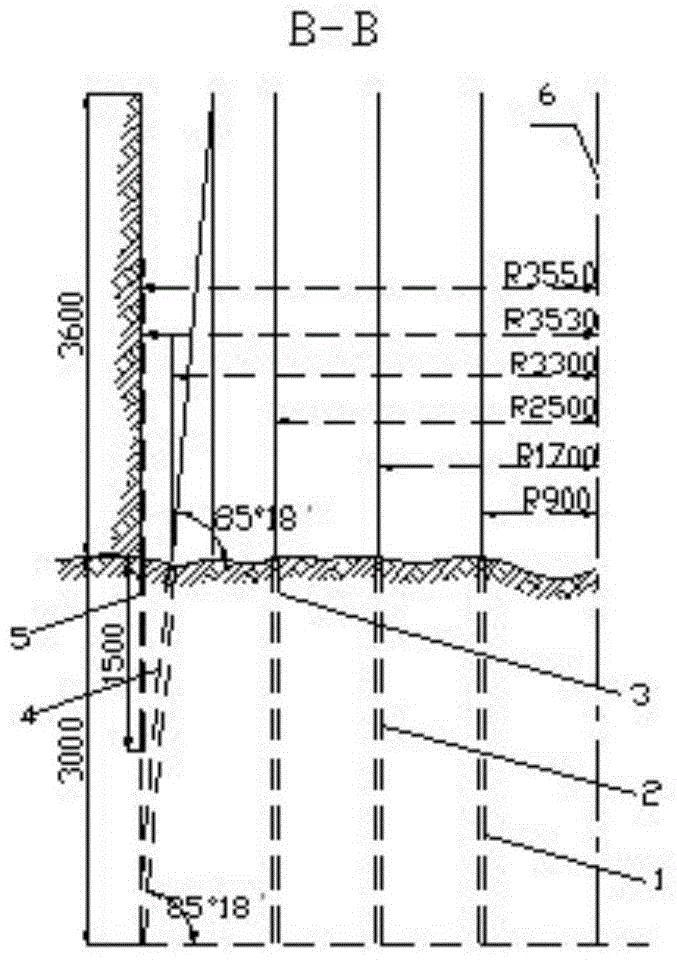

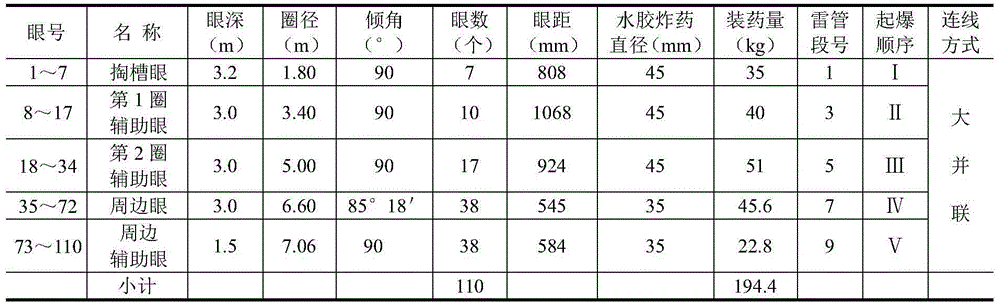

Construction method for additionally forming periphery auxiliary holes in periphery of vertical shaft periphery hole

The invention discloses a construction method for additionally forming periphery auxiliary holes in the periphery of a vertical shaft periphery hole. The construction method includes the following steps that (1), after the periphery hole is drilled through an umbrella drill, the periphery auxiliary holes are drilled, and the hole depth is 1500 mm; (2), explosives are loaded into the periphery auxiliary holes and the periphery hole at the same time, and the number of blasting cap sections of the periphery hole is seven, and the number of blasting cap sections of the periphery auxiliary holes is nine; (3), the periphery auxiliary holes are detonated after the periphery hole is detonated. The construction method has the advantages that six YT-28 type air drills are used for drilling the periphery auxiliary holes after the periphery hole is drilled through the umbrella drill, and therefore drilling time is not prolonged; shaft wall over-excavation and under-excavation are effectively avoided, cap retaining is avoided after the periphery hole is detonated, and therefore waste rock removing, net hanging and anchoring and shotcreting time is shortened; the costs for wind, water, electricity, manpower, sprayed concrete and other materials are lowered, supporting quality at the initial stage is improved, and large-section-height construction safety is guaranteed; detonation efficiency is improved, construction progress is accelerated, and good economical and technical effects are achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

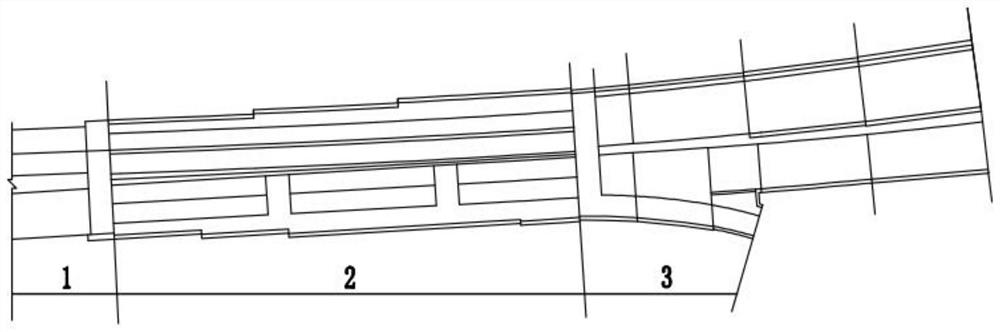

Advancing construction method of long tube shed

InactiveCN101737059ASave lap workLittle construction disturbanceUnderground chambersTunnel liningSubway stationSteel tube

The invention discloses an advancing construction method of a long tube shed, comprising the following steps of: horizontally drilling in a guiding way to form a guide hole from one end of an arch part of an undermining subway station by adopting a non-excavation horizontal guiding drilling technology; then back pulling a steel tube from the other end of the undermining subway station; then grouting; forming an advancing supporting and protecting system on the arch part of the undermining subway station; and validating after the excavation of the undermining subway station. The invention has the advantages that a more perfect construction technology is formed for constructing the single long tube shed with the length of 146m by horizontally drilling in a guiding way from one end of the undermining subway station, the problem that the length of a single tube shed positioned on the arch part of the traditional subway station is shorter is effectively solved, and a longer tube shed can be constructed in one step, the longitudinal effect of the tube shed positioned on the arch part of the undermining subway station is strengthened, the overlapping work amount needed by the subsection implementation of the tube shed is saved, the construction interference on the excavation of the undermining subway station is reduced, and the construction hazard of the undermining subway station is greatly reduced.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

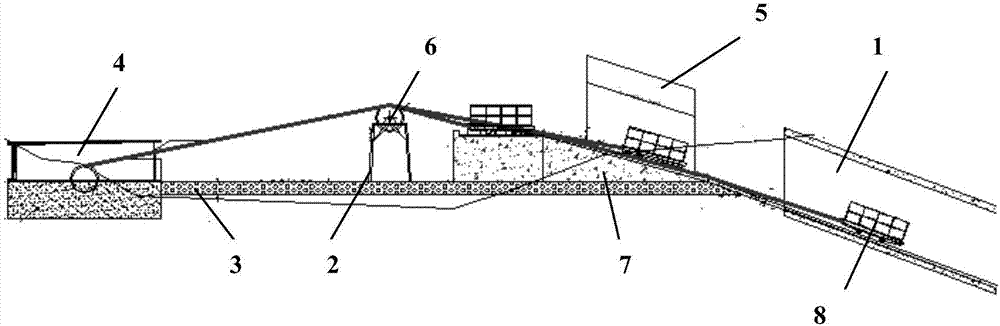

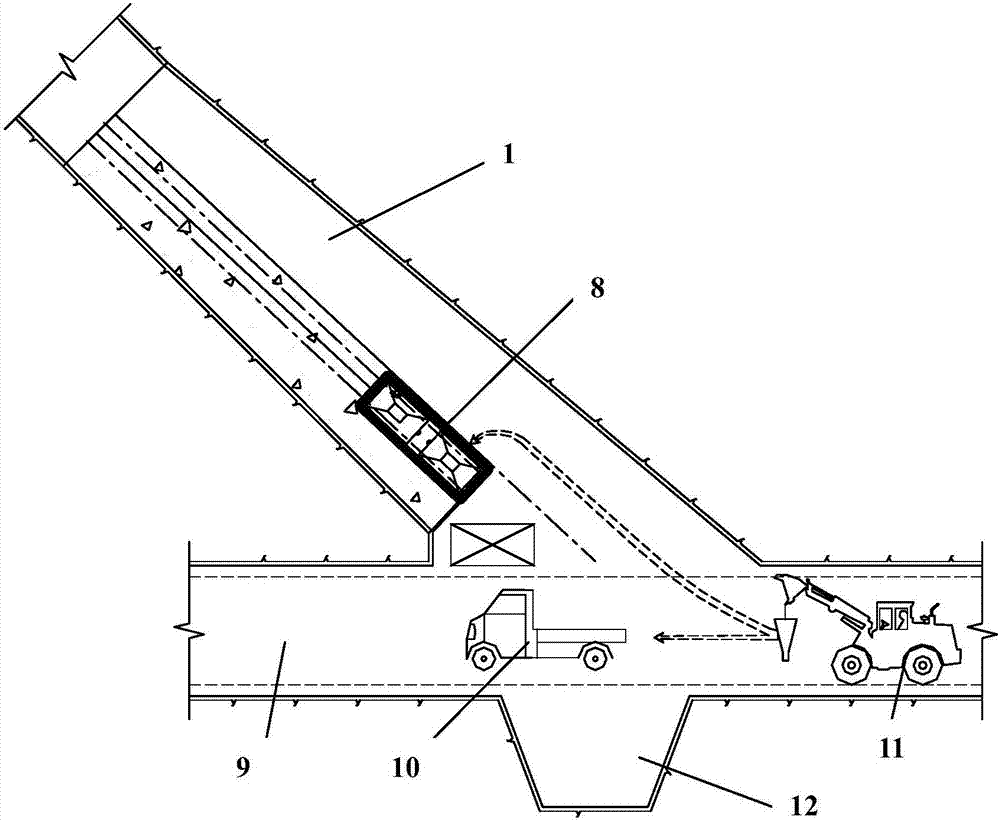

Large-gradient small-section underground cavity excavating construction method

InactiveCN107387094ALittle construction disturbanceReduce construction costsTunnelsDischarge efficiencySlag

The invention discloses a large-gradient small-section underground cavity excavating construction method. By combination of inclined shaft track transport and main tunnel trackless transport, people-oriented safety construction is realized, construction safety is guaranteed, construction interferences are reduced, construction cost is saved, and safety accidents in a construction process are avoided. In construction, the construction progress requirement is met, slag discharging efficiency is improved, and inclined shaft transport is no longer an engineering construction progress restriction factor. According to engineering construction practice, the construction method is effective and has advantages of technical reliability, high mechanization degree, convenience in operation, safety, reliability, high slag discharging efficiency, low operating cost and high economic benefits, thereby having a certain reference significance and popularization value in similar engineering construction.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

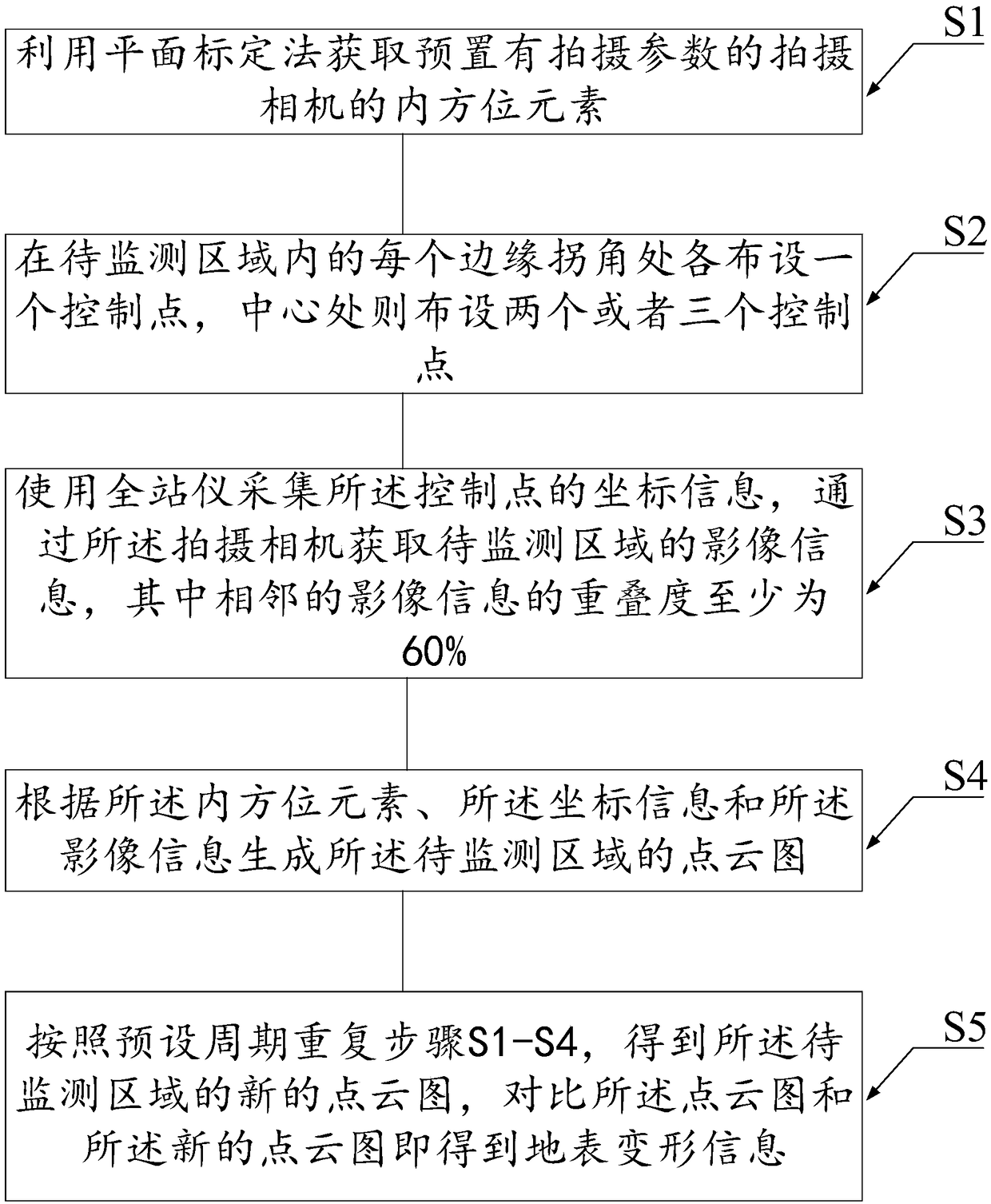

Shield subway construction ground surface deformation monitoring method based on close-range photogrammetry

The invention discloses a shield subway construction ground surface deformation monitoring method based on close-range photogrammetry, and aims to look for a more effective implementation scheme for shield subway construction monitoring. The method comprises the following steps: obtaining elements of interior orientation of a photographing camera; arranging one control point in each edge corner inan area to be monitored, and two or three control points at the center; using a total station to collect coordinate information of the control points, and obtaining image information of the area to be monitored through the photographing camera with photographing parameters preset; generating a point cloud map of the area to be monitored according to the elements of interior orientation, coordinate information and image information; and obtaining a new point cloud map of the area to be monitored, and obtaining ground surface deformation information by comparing the point cloud map with the newpoint cloud map. The shield subway construction ground surface deformation monitoring method based on close-range photogrammetry realizes multi-point monitoring through a close-range photogrammetry technology, solves the problem that the deformation condition of a monitoring point-free area is difficult to discover in existing single-point monitoring, and saves manpower.

Owner:SHANGHAI JIAO TONG UNIV

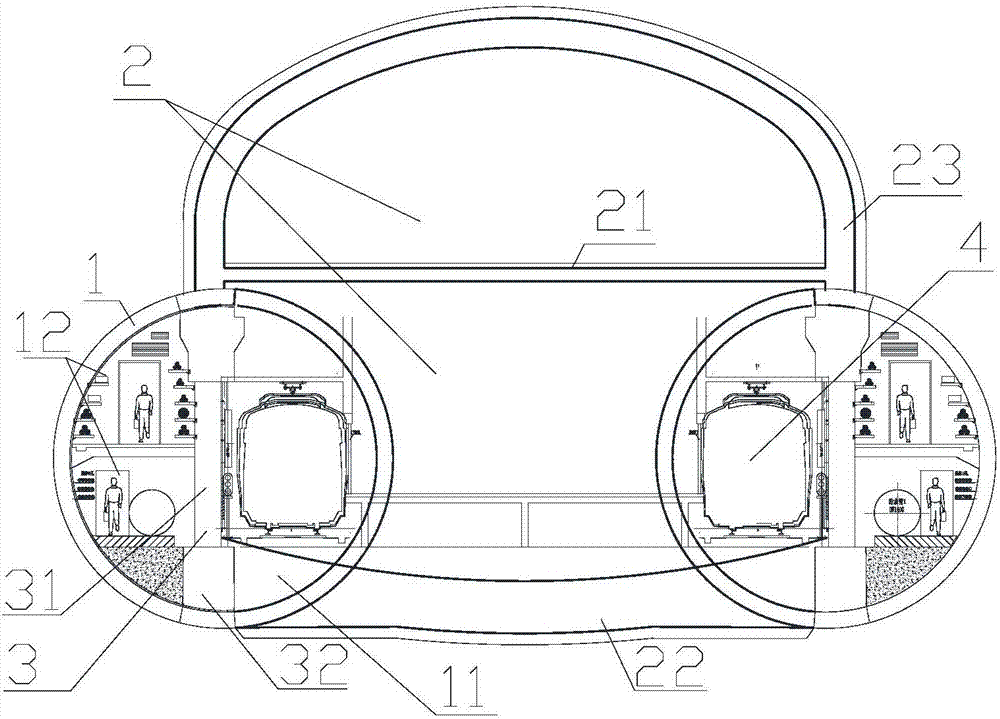

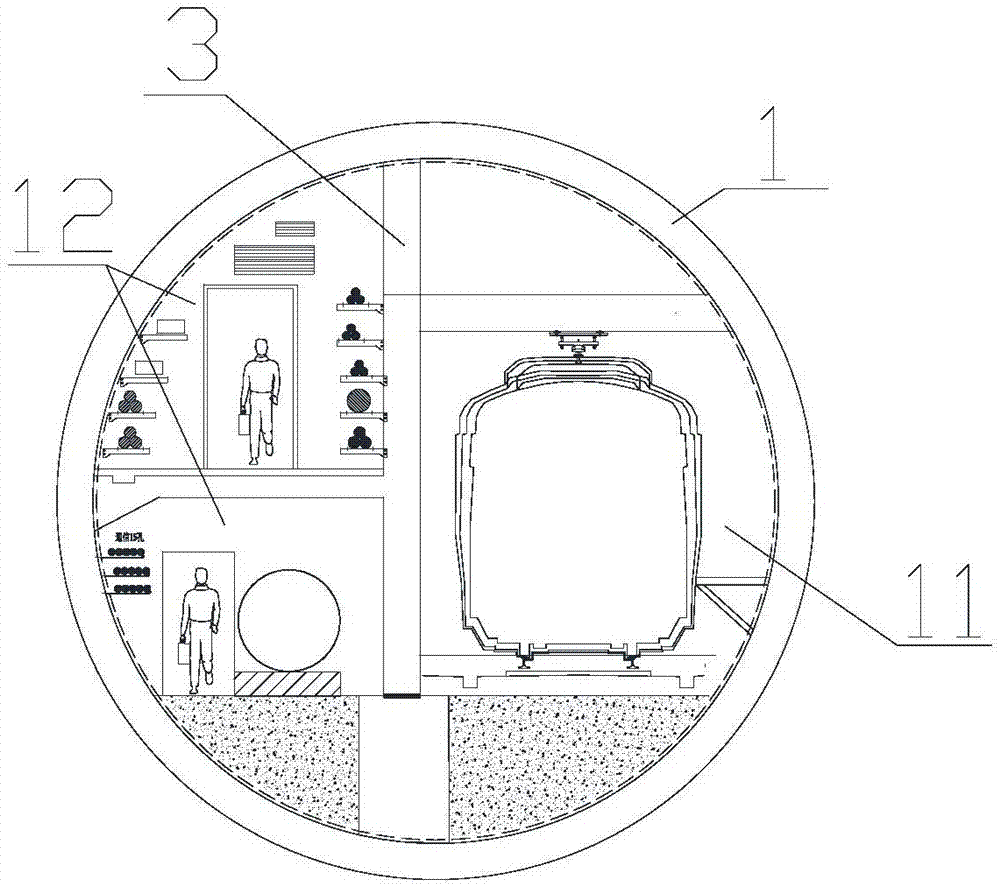

Construction method and building structure of co-construction of subways and city underground comprehensive pipe galleries

PendingCN106948834AReduce crowdingHigh space utilizationArtificial islandsUnderwater structuresUtility tunnelUrban area

The invention provides a building structure of co-construction of subways and city underground comprehensive pipe galleries. The building structure comprises section shield tunnels. An intermediate partitioning member used for dividing space in each section shield tunnel into two areas in the axial direction, wherein one of the areas serves as a subway travelling cabin, and the other area serves as pipe gallery cabins arranged continuously or at intervals in the axial direction. The invention further provides a building method of co-construction of the subways and the city underground comprehensive pipe galleries. By means of the structure and the method, the problem of building of common path sections of the large city center urban area comprehensive pipe galleries and the subways is solved, underground space is saved, construction disturbance is reduced, and the construction risk is lowered.

Owner:GUANGZHOU METRO DESIGN & RES INST

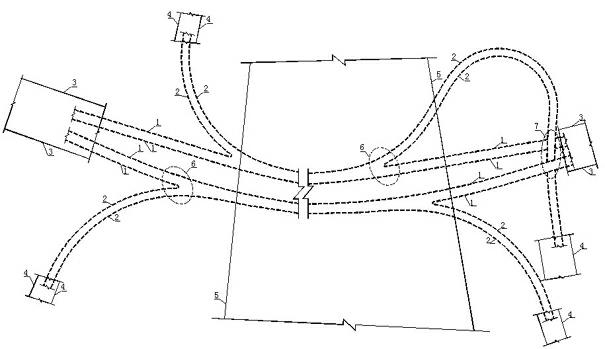

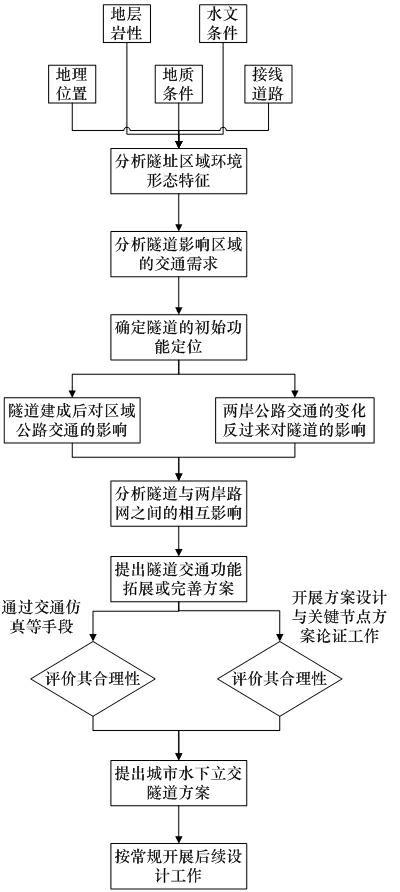

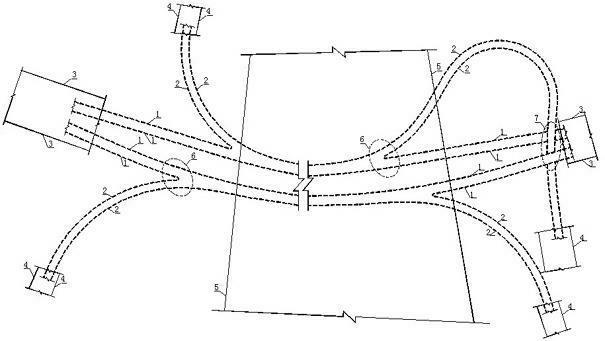

Urban underwater overpass tunnel system

InactiveCN102587417AIncrease profitFull play of traffic functionsArtificial islandsRoadwaysEngineeringUtilization rate

The invention discloses an urban underwater overpass tunnel system, which comprises a mainline tunnel and ramp tunnels. The mainline tunnel downwards penetrates into a water system, two ends of the mainline tunnel are connected with ground connection roads, one end of each ramp tunnel is connected with the mainline tunnel while the other end of the ramp tunnel is connected with another surface road, and an underground flyover crossing relation is formed between the mainline tunnel and the ramp tunnels or among the ramp tunnels. The urban underwater overpass tunnel system is structurally characterized in that under the premise that new underwater corridors are not added and the position of the mainline tunnel is not changed, the ramp tunnels are added, one end of each ramp tunnel is connected with the mainline tunnel while the other end of the ramp tunnel is connected with the other surface road, so that an underground overpass is formed, the utilization rate of underwater corridors is increased to the greatest extent, and traffic functions of the tunnels are sufficiently realized.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

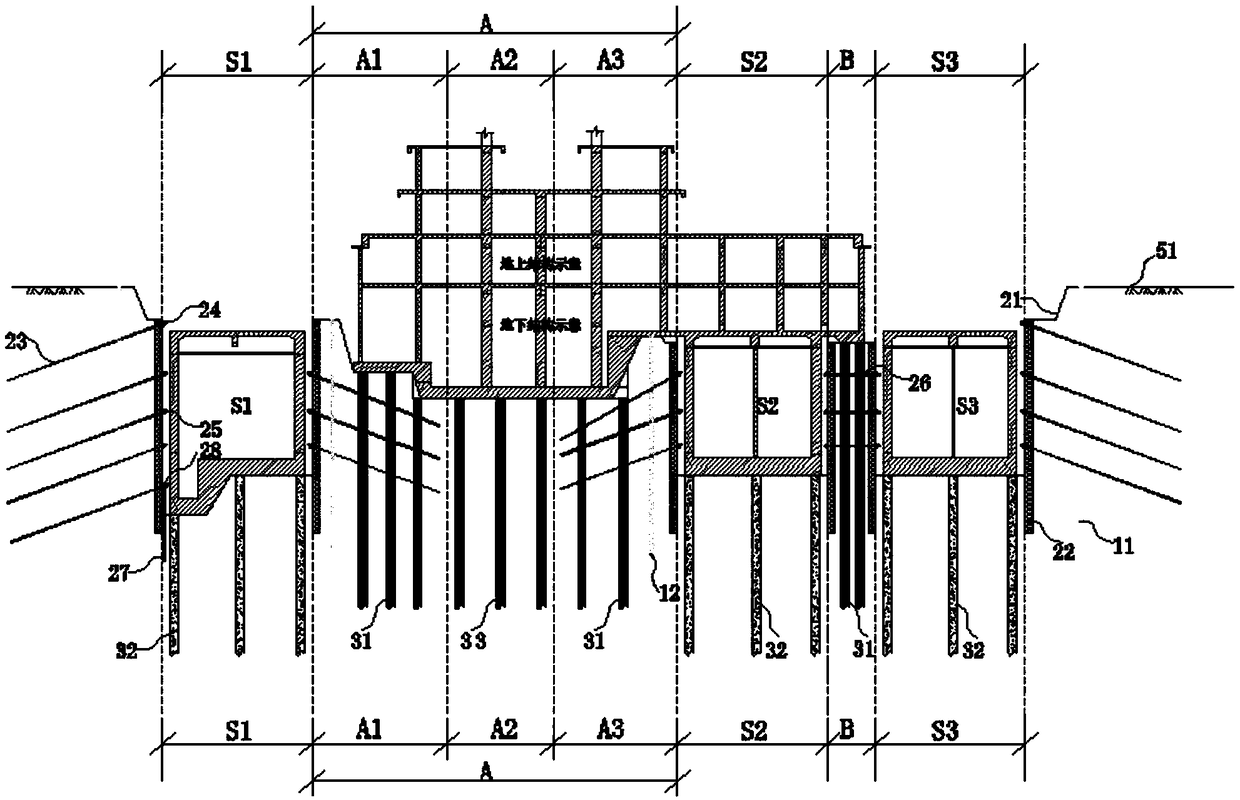

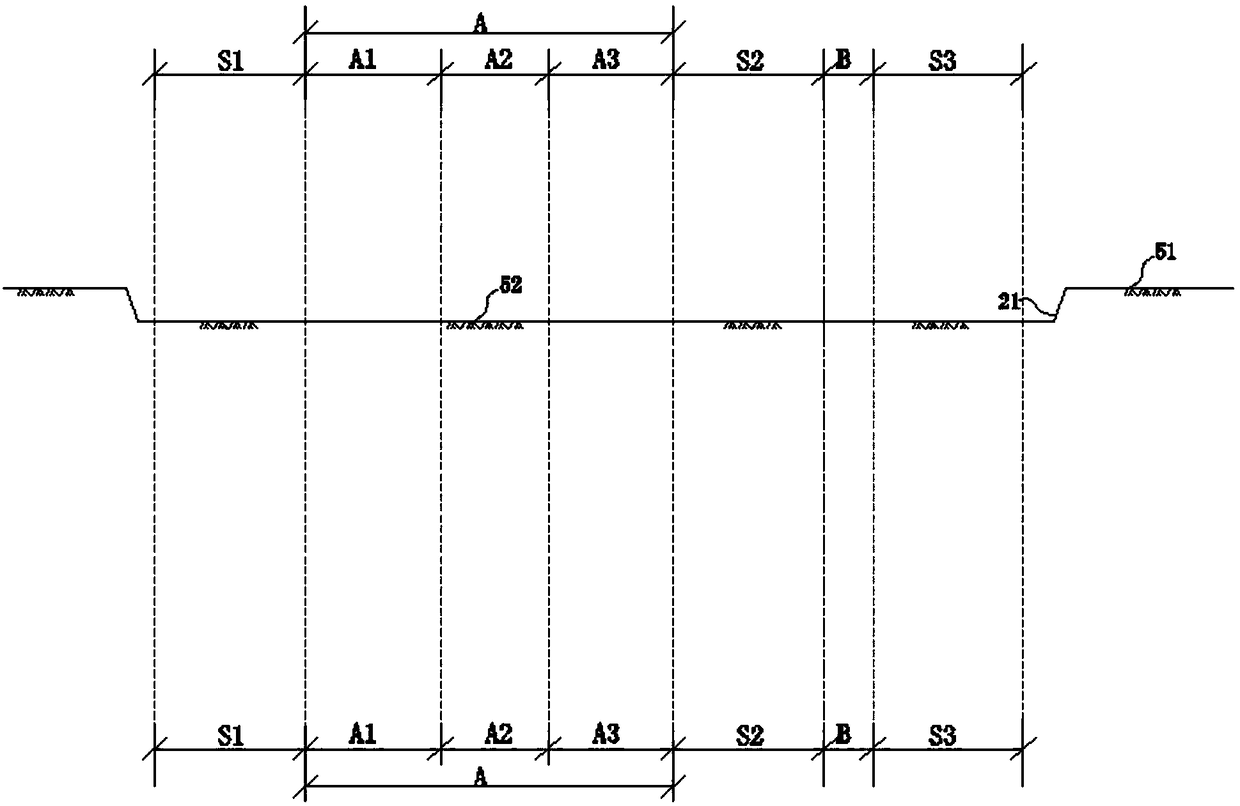

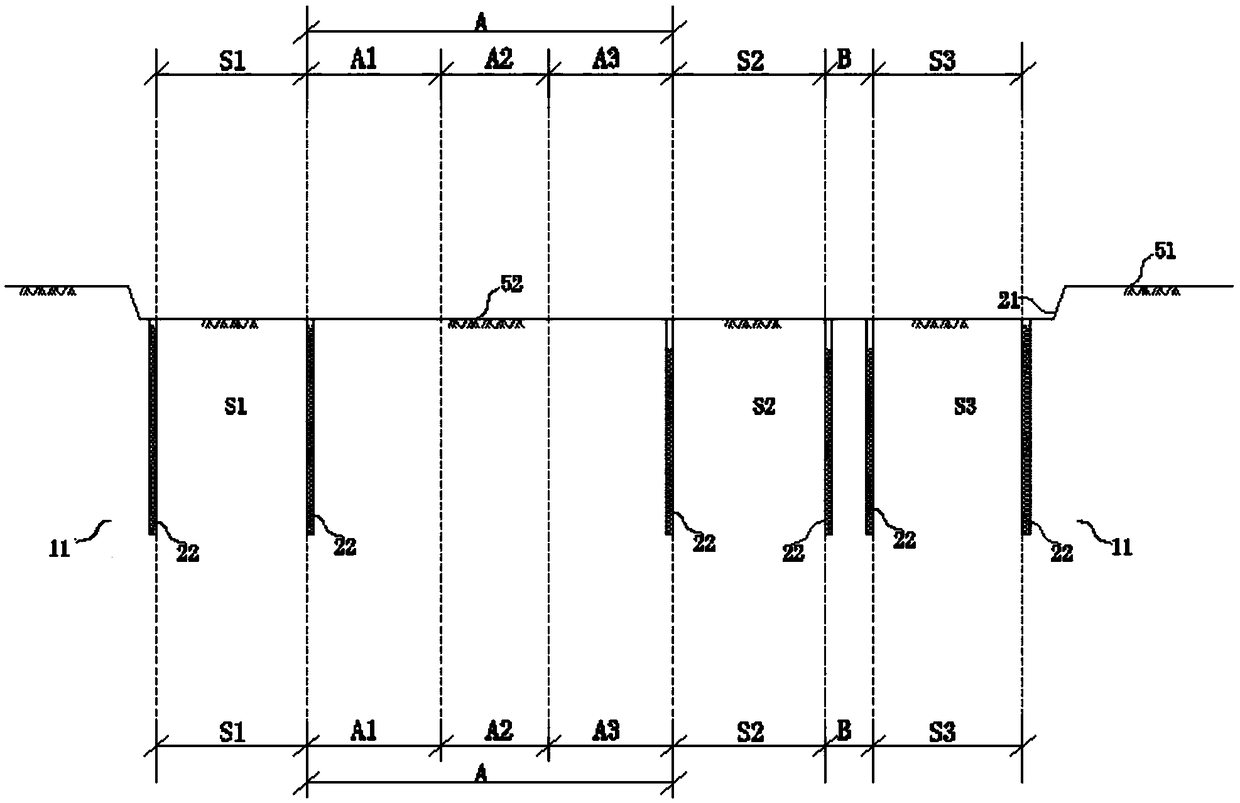

Construction method of foundation pit group and foundation pile group

ActiveCN108978676AClear construction processImprove protectionExcavationsHeight differenceMulti segment

The invention discloses a construction method of a foundation pit group and a foundation pile group. The foundation pit group comprises three or more parallel deep and narrow staggered foundation pitswith the height difference exceeding 13 m; and the foundation pile group is distributed in the deep and narrow foundation pits of the foundation pit group, and performs crossed operation with the deep and narrow foundation pits of the foundation pit group. The construction method includes the following steps that a BIM structure model of the foundation pit group and the foundation pile group is built; according to the BIM model, colliding detection is performed; the foundation pit group is divided into a narrow area and a deep area, and then the narrow area is divided into an influence area and a non-influence area; earthwork excavation is performed to an operation face; supporting pile construction of the deep area is performed; foundation pile construction of the influence area of the narrow area is performed; foundation pile construction of the deep area is performed; earthwork excavation and anchor rope construction of the deep area are performed, and foundation pile constructionof the non-influence area of the narrow area is performed at the same time; and local deep pit micro pile, micro pile anchor rope and micro pile top crown beam construction of the deep area is performed. The construction method is a fast, efficient, economical and reasonable continuous multi-segment large-height-difference long and narrow deep foundation pit group and foundation pile group construction method.

Owner:北京市机械施工集团有限公司 +1

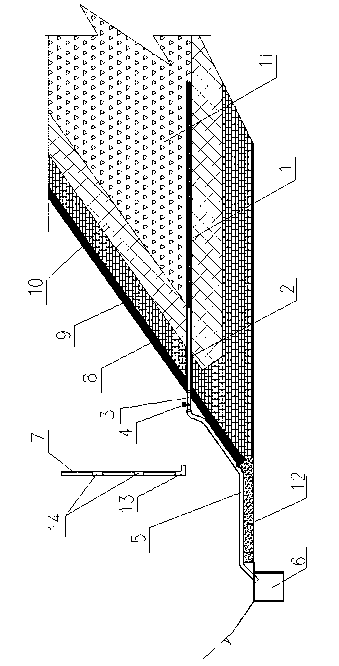

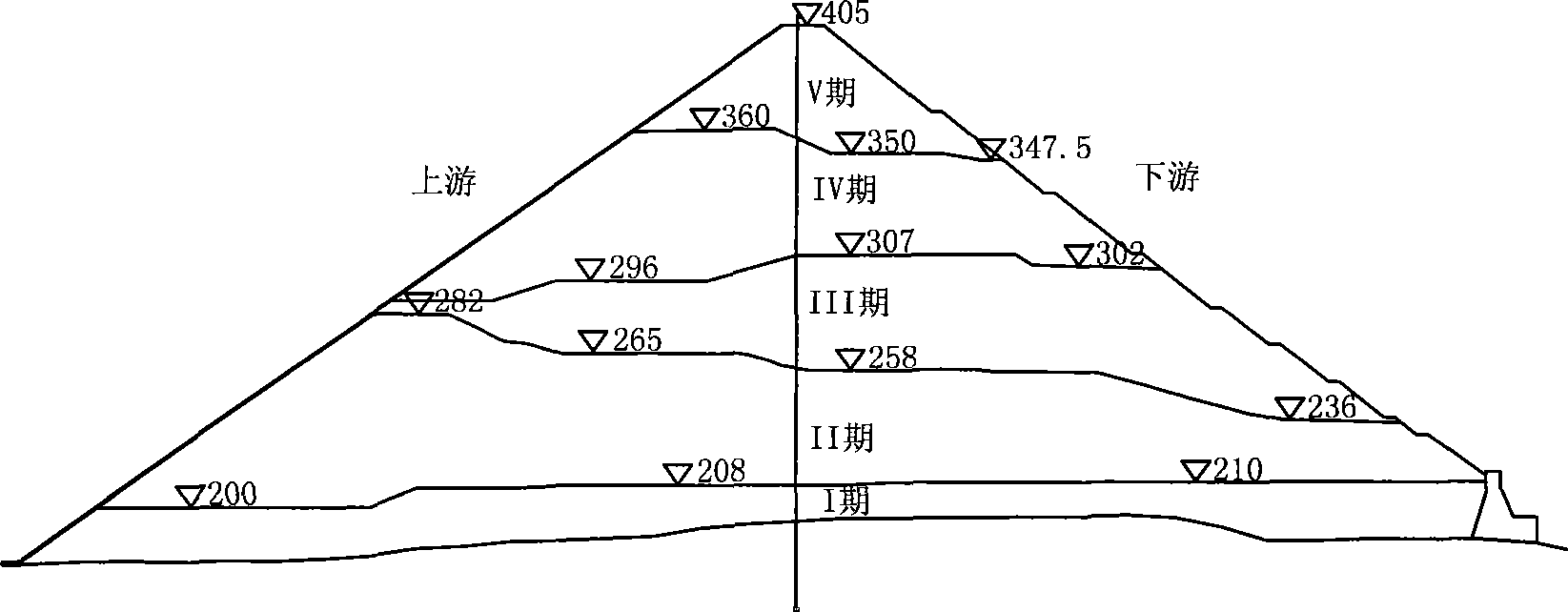

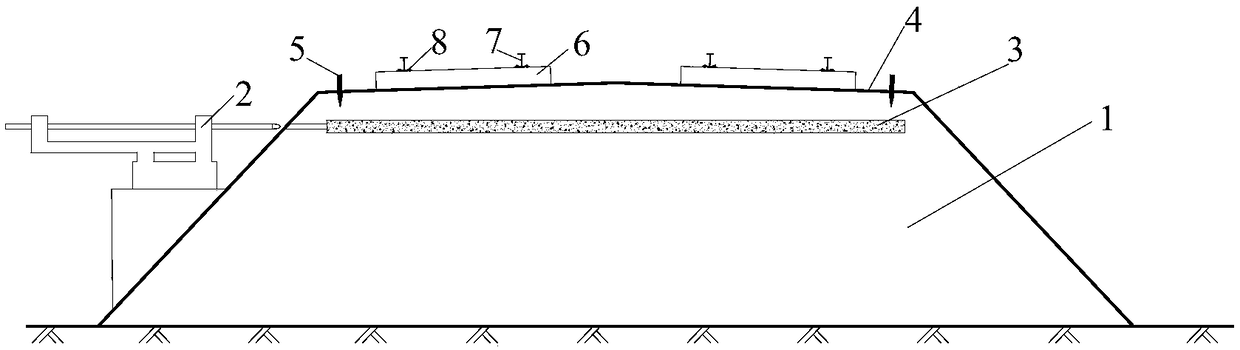

Dam body prepressing inverted filling construction method for ultra-high concrete panel rock-fill dam

InactiveCN101476309AImprove operational safetyLittle construction disturbanceEarth-fill damsRock-fill damsEngineeringBedding Material

The invention relates to a superhigh concrete faceplate rock-fill dam body precompressed reverse reclamation construction method, which comprises: performing the first stage reclamation of the dam body bedding, base and enrockment; performing the second stage reclamation to the dam body according to the normal step shape in upstream-high and downstream-low to form a flood protection economic section; performing the third stage reclamation by using enrockment materials after the flood season to cause the downstream of the section higher than the upstream and cause the embankment on the downstream part of the dam body to settle in the construction period; performing the other stages of reclamation of the enrockment dam until the height of the dam body reaches the designed value. The invention changes the previous reclamation arrangement which gives priority to the front part with complex construction processes, improves the dam body water storage period displacement distribution greatly, causes the maximum horizontal displacement of the upstream dam slope to reduce from 100cm to 50cm (upstream slope middle part ) and to distribute uniformly along the dam slop level, and such displacement distribution reduces the different deformation generated in the enrockment material and bedding material and plays an important role in improving the faceplate supporting condition.

Owner:CHINA GEZHOUBA GROUP CO LTD

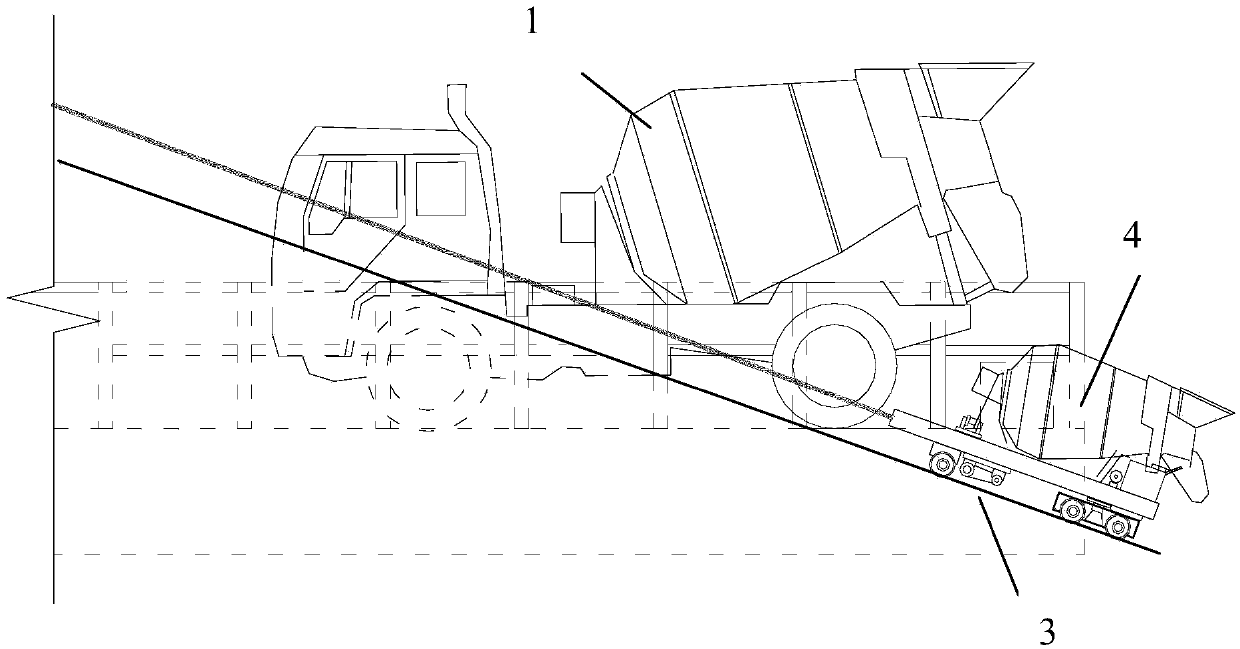

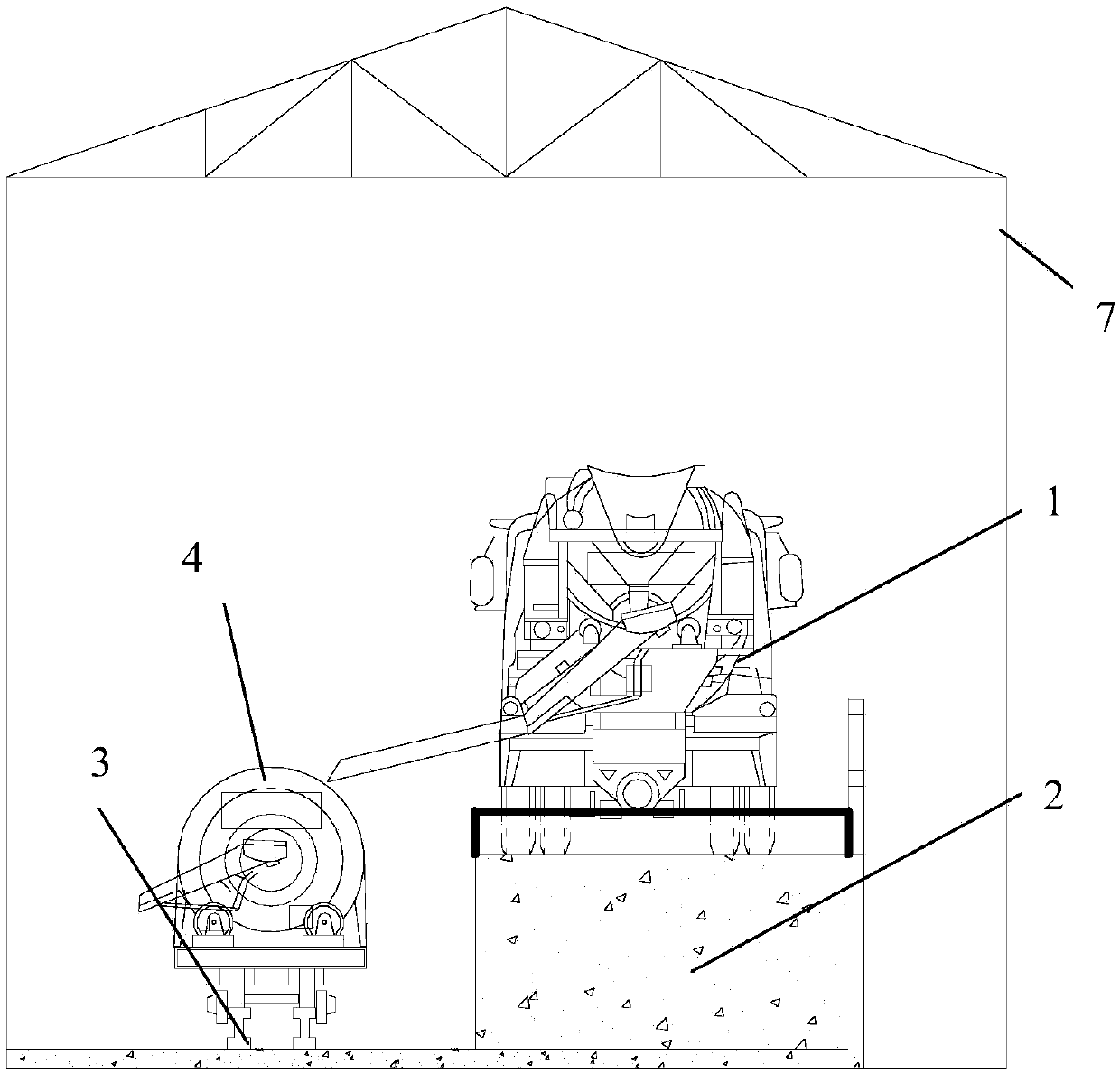

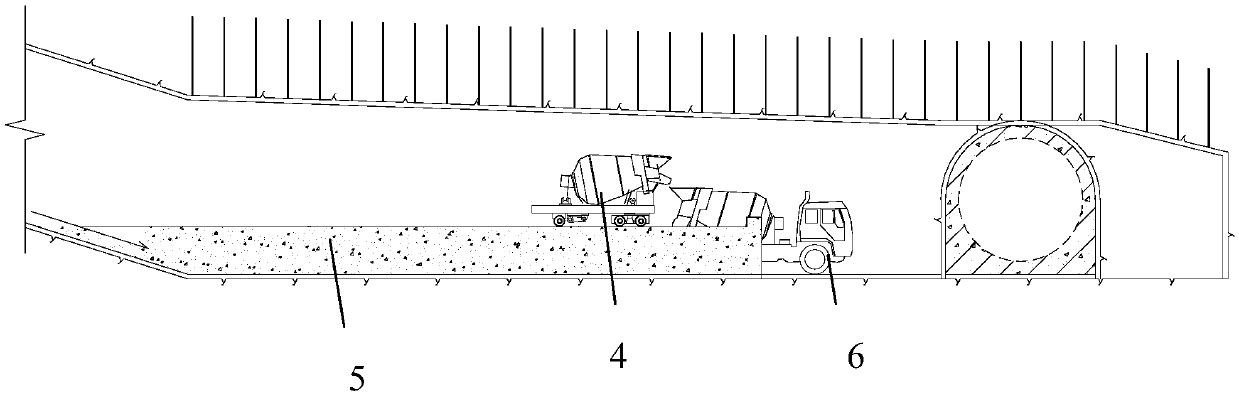

Large-slope inclined well concrete transportation method

ActiveCN109681266AGuaranteed normal transportationLittle construction disturbanceUnderground chambersTunnel liningEngineeringStructural engineering

The invention discloses a large-slope inclined well concrete transportation method which comprises the following steps of building a concrete mixing plant; equipping with a ground concrete stirring transportation tank car; pouring a hole concrete unloading platform; laying rails, putting a wheel-rail concrete stirring transportation tank car on the rails, and dragging the wheel-rail concrete stirring transportation tank car with a single-rope mine drum hoist arranged at an inclined well hole; pouring a hole bottom concrete unloading platform, and equipping with a hole bottom concrete stirringtransportation tank car; transporting concrete in the concrete mixing plant to the hole concrete unloading platform with the ground concrete stirring transportation tank car; transporting the concreteinto the wheel-rail concrete stirring transportation tank car; transporting the concrete in the wheel-rail concrete stirring transportation tank car into the hole bottom concrete stirring transportation tank car; transporting the concrete in the hole bottom concrete stirring transportation tank car to a pouring site in a main hole and the like. The large-slope inclined well concrete transportation method can realize the targets of rapidness in transportation and safety in construction of inclined well concrete, ensures main hole lining concrete construction, reduces construction interferenceand lowers the construction cost.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

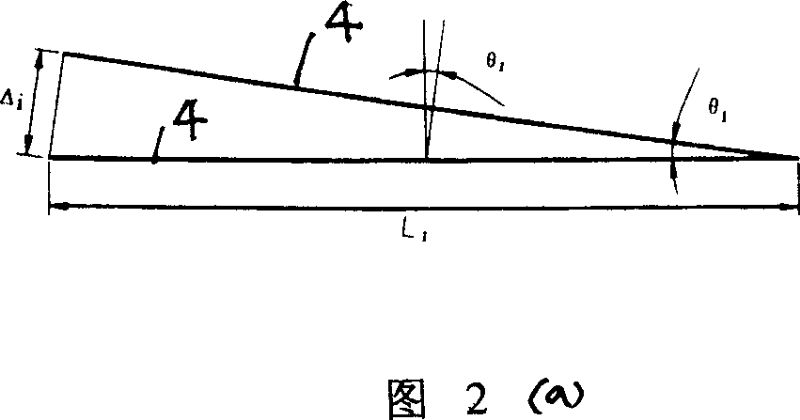

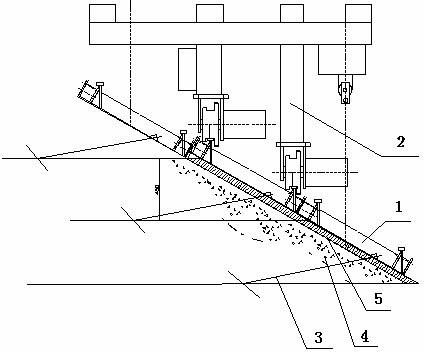

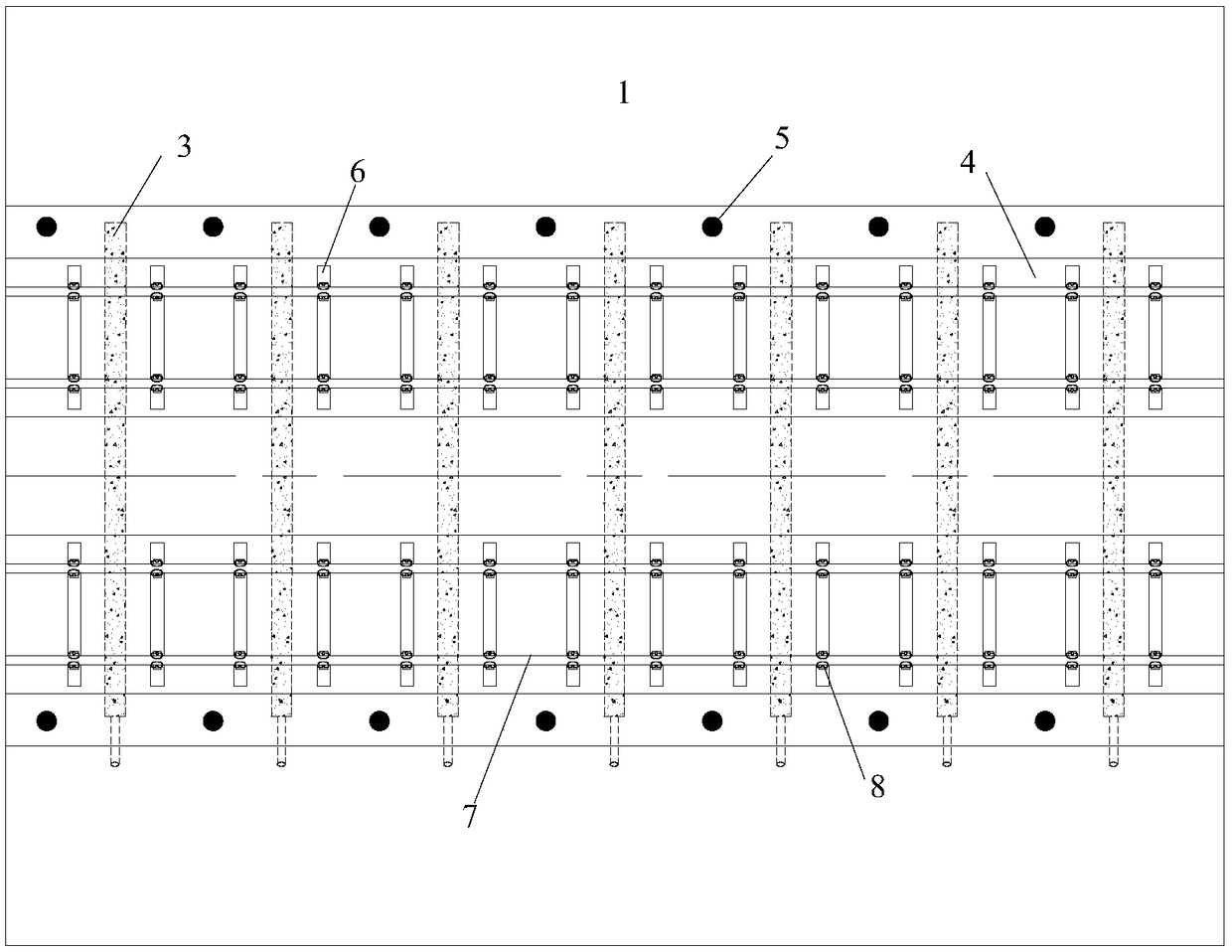

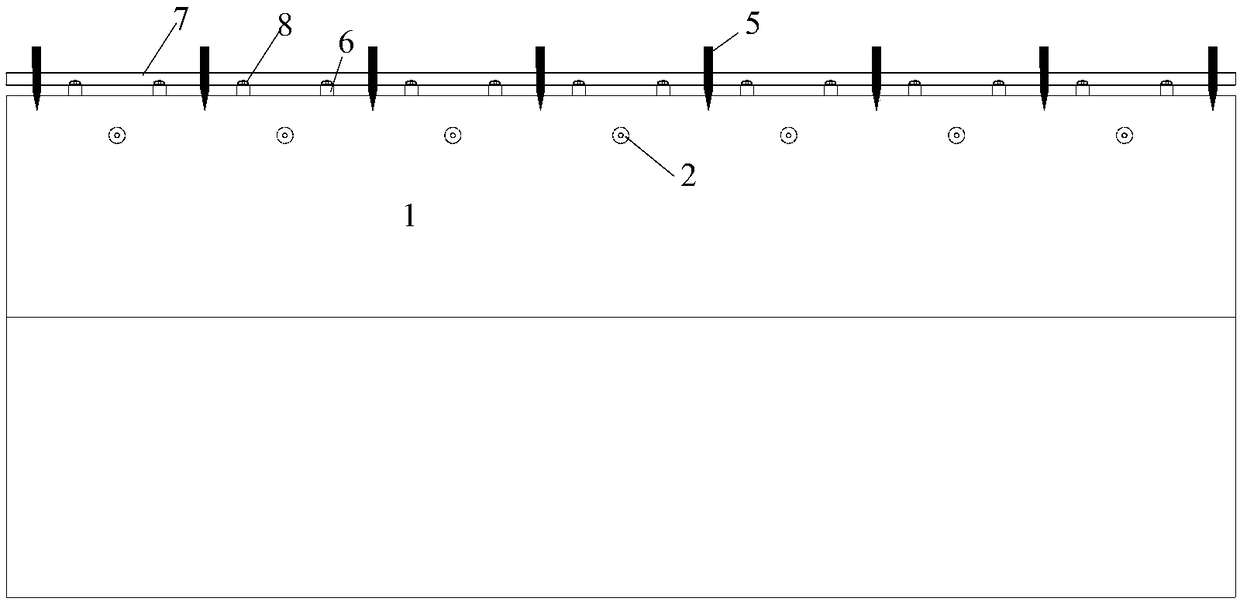

Face slab dam rolling and slope fixing device and face slab dam rolling and slope fixing construction method

InactiveCN102619197AUniform densityUniform thicknessEarth-fill damsRock-fill damsUltimate tensile strengthBedding Material

The invention discloses a face slab dam rolling and slope fixing device and a face slab dam rolling and slope fixing construction method, and relates to the field of building construction. The face slab dam rolling and slope fixing device comprises special formworks and a formwork transfer trolley, wherein each special formwork comprises an oblong bottom plate; and the bottom plate is provided with a positioning and connecting plate, a separation plate, a movable track and a rack track. The face slab dam rolling and slope fixing construction method comprises the following steps of: mounting a first layer of special formwork; primarily rolling a bedding material; mounting a second layer of special formwork by using the formwork transfer trolley after mortar strength is allowed; lifting the second layer of special formwork by using the formwork transfer trolley to perform mortar pouring; lifting the first layer of special formwork by using the formwork transfer trolley and then translating to a third layer for mounting; performing rolling construction; and circularly repeating to finish dam face slab rolling and slope fixing. According to the face slab dam rolling and slope fixing device and the face slab dam rolling and slope fixing construction method, a concrete face slab rock fill dam bedding layer and slope fixing mortar are formed at one time, the construction quality of an upstream slope face of the face slab dam bedding material is improved, the construction progress of a dam is quickened, safe construction is facilitated, and the construction cost is reduced.

Owner:CHENGDU NO 4 CONSTR ENG

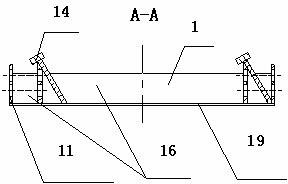

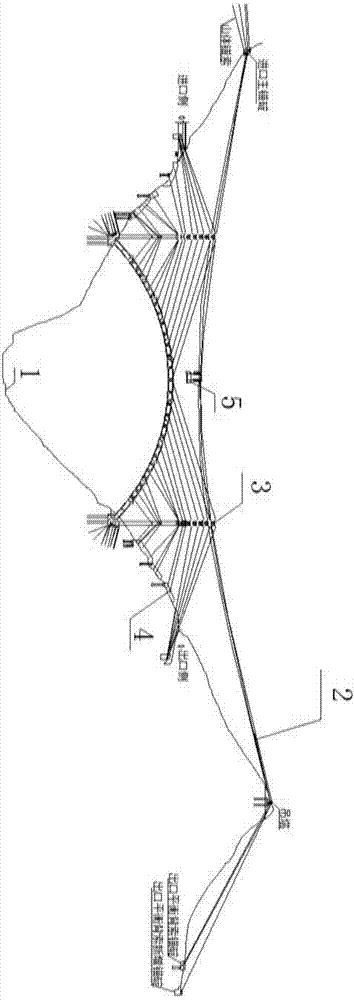

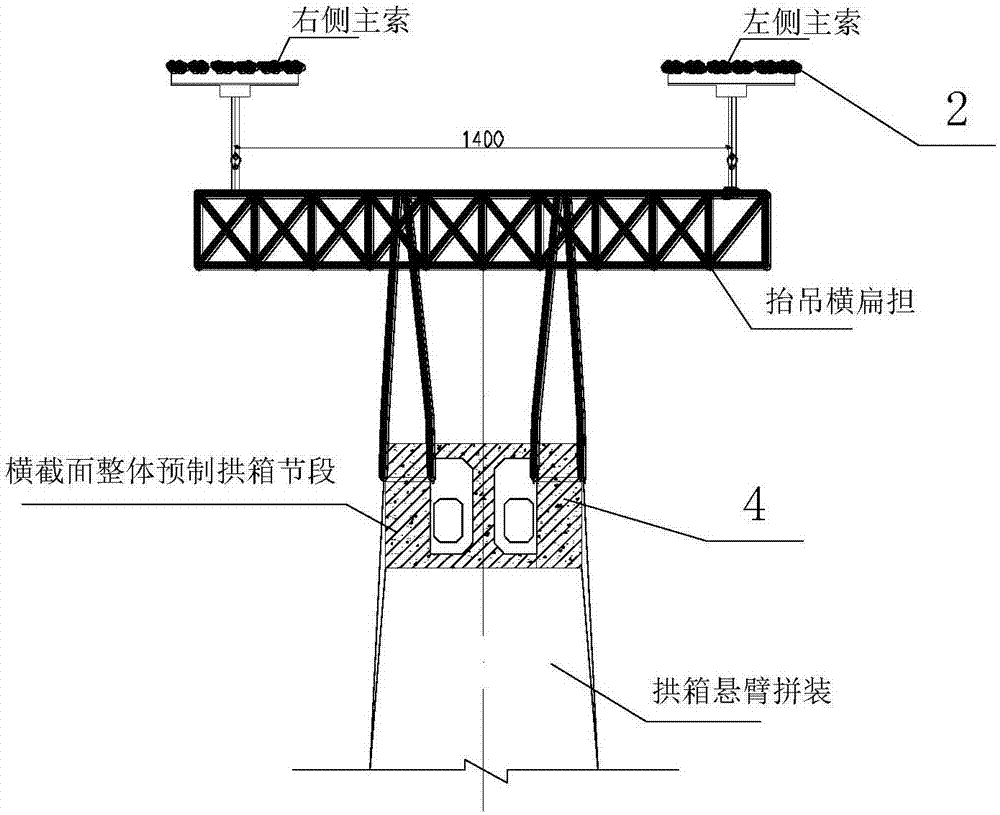

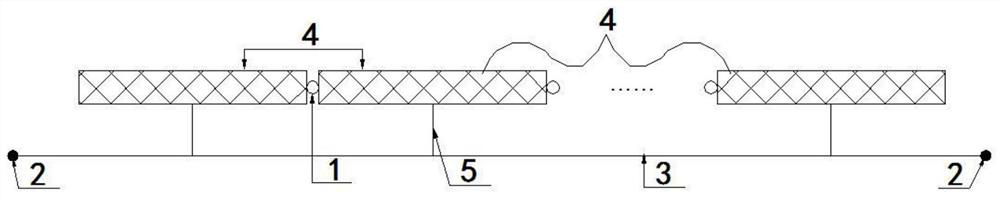

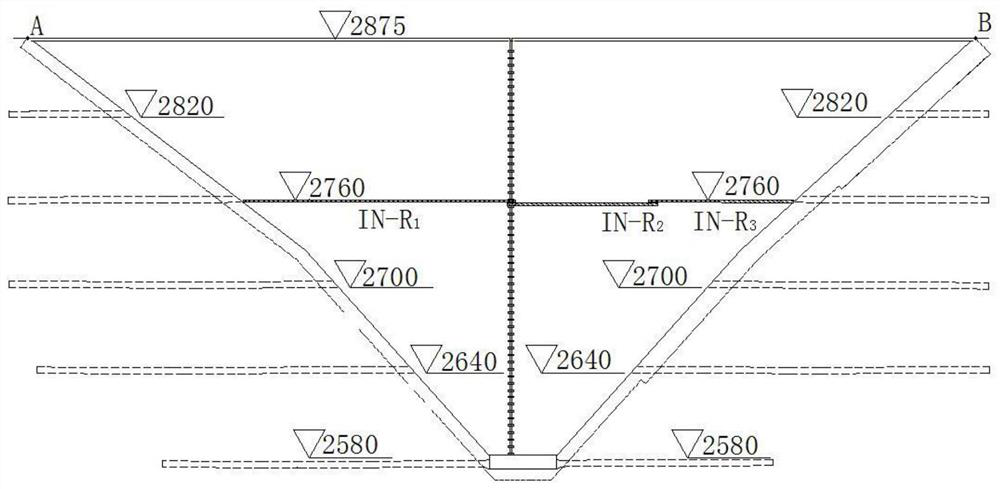

Construction method for deep canyon arch aqueduct arch ring hoisting single base rib closure

The invention discloses a construction method for deep canyon arch aqueduct arch ring hoisting single base rib closure. An arch box prefabricating yard is arranged along one side of a canyon bottom; double groups of fixed cable cranes are arranged on mountain bodies on two sides; juncture piers and pier tops are provided with steel structures to form combined buckling towers, suspension clasps areseparately arranged, and a bank slope back cable anchoring system is arranged; cross sections of arch boxes are wholly and longitudinally prefabricated in a multi-section way, a gantry crane transports arch box sections to the positions below main cables, double groups of cable cranes performs hoisting and installation after a rotation platform turns for about 900, and single base rib closure isachieved. By utilizing the double groups of fixed cable cranes arranged on the mountain bodies on two sides, the arch boxes rotate in the prefabricating yard in situ, the arch boxes are transversely and wholly not separated during prefabrication an are longitudinally prefabricated and hoisted in the multi-section way. Large-curve arch box rotating body fertility is not needed, and occupied area issaved. Transverse wind cables used in an arch box cantilever state are not needed, and construction interference is reduced. The boxes are not separated in the transverse direction, single base rib closure and aching are achieved, the working efficiency is greatly improved, and a construction period is shortened.

Owner:SINOHYDRO BUREAU 9

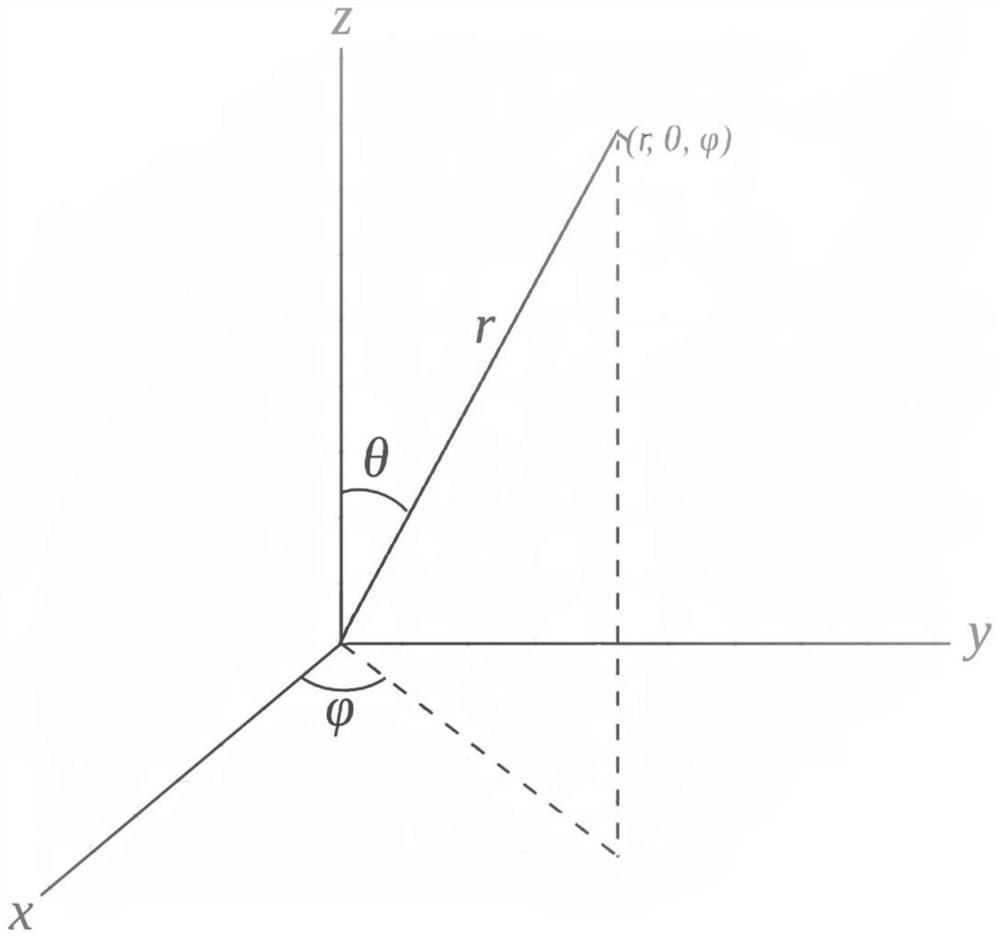

Core wall dam settlement monitoring method based on array displacement meters

InactiveCN112304274AEasy to install and buryAccurately obtain the initial value of settlementBarrages/weirsHeight/levelling measurementMeasurement pointClassical mechanics

The invention discloses a core wall dam settlement monitoring method based on array type displacement meters, which relates to the field of dam safety monitoring. The method comprises the following steps of S1, completing the installation of the array type displacement meters through employing a horizontal installation and burying method, S2, establishing a data processing three-dimensional coordinate system according to the burying orientation of the array type displacement meter, and recording and reading included angles phit and thetat between each standard measurement unit and an X axis and a Z axis due to dam body deformation after a period of time t, S3, rechecking the measured value of each measurement unit, and if finding that the ith standard measurement unit is invalid or the measured data of the included angles phit(i) and thetat(i) with the X axis and the Z axis are abnormal, taking the measured value of the (i-1)th measurement unit or the (i+1)th measurement unit or the average value of the two measurement units as the measured value of the ith measurement unit, S4, calculating the deformation monitored by each standard measurement unit of the array type displacement meter over time, and S5, accumulating the deformation of all standard measurement units from the base point to the measurement point of the array type displacement meter to obtain the total deformationcorresponding to each measurement point.

Owner:YALONG RIVER HYDROPOWER DEV COMPANY

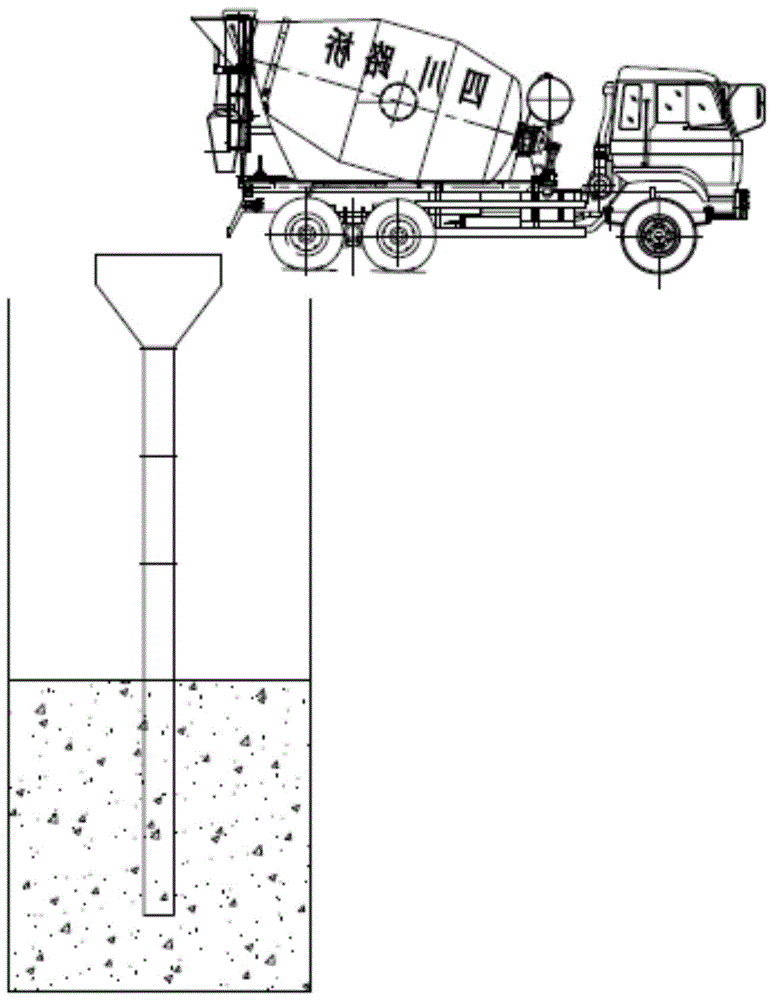

Method applicable to pouring of concrete for artificial excavating pile body

InactiveCN106013094AImprove construction efficiencyReduce process changeoverBulkheads/pilesVisibilityStructural engineering

The invention discloses a method applicable to pouring of concrete for an artificial excavating pile body. The method is characterized by comprising the following steps: (1) mixing of concrete; (2) start of pouring; (3) control on pouring buried depth; (4) conversion between no vibration and vibration, and (5) pile head pouring processing. Compared with conventional rinsing pile pouring method and dry pile pouring method, the pouring method disclosed by the invention has the following advantages: 1. compared with a conventional dry pile pouring method, according to the anhydrous underwater concrete pouring method, layered pouring and vibration are not needed, and therefore, the risk of artificial under-hole operation is reduced, and the pouring efficiency is improved; 2. according to the anhydrous underwater concrete pouring method, water injection into the hole is not needed, the influence of high and cold drift beds with relatively great permeability is reduced, and the safety is improved; 3. according to the anhydrous underwater concrete pouring method, the visibility is relatively good and the quality is easy to guarantee; and 4. when the phenomena of pipe plugging and conduit exhaust occur during pouring, the quality accident of pile breakage cannot be caused.

Owner:SICHUAN ROAD & BRIDGE GRP

Method for lifting railway roadbed with settlement diseases

ActiveCN108642975AAchieve lift repairLifting effect is controllableRailway tracksEngineeringDisease cause

The invention discloses a method for lifting a railway roadbed with settlement diseases. The method for lifting the railway roadbed with the settlement diseases comprises the steps of S1, drilling holes and positioning; S2, unlocking fasteners; S3, carrying out rotary jet grouting: starting horizontal rotary jet grouting equipment, horizontally drilling forwards along the drilling position, and stopping rotary jet grouting when a drill bit has a distance of 1-2 m from an opposite side slope surface; enabling the drill bit to gradually exit in a reverse direction and carrying out rotary jet grouting of a quick-setting material; stopping grouting when the rotary jet grouting drill bit moves back to a position with a distance of 1.5 m from the surface of a side slope; and continuing to reversely rotate the drill bit till the drill bit completely exits a roadbed body so as to finish the making of a horizontal rotary jet grouting pile; and S4, moving rotary jet grouting pile equipment to the next pile position; and repeating the process till all lifting works of a railway roadbed settlement superstandard section are finished. According to the method for lifting the railway roadbed withthe settlement diseases, a foundation bed structure and a track structure above the rotary jet grouting pile are integrally lifted under a condition of not affecting the normal operation of railway sothat the operation space utilization efficiency is enhanced and the online operation amount is reduced; and the lifting effect of the roadbed with superstandard settlement is controllable, efficient,energy-saving, environmentally friendly and cost-effective.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

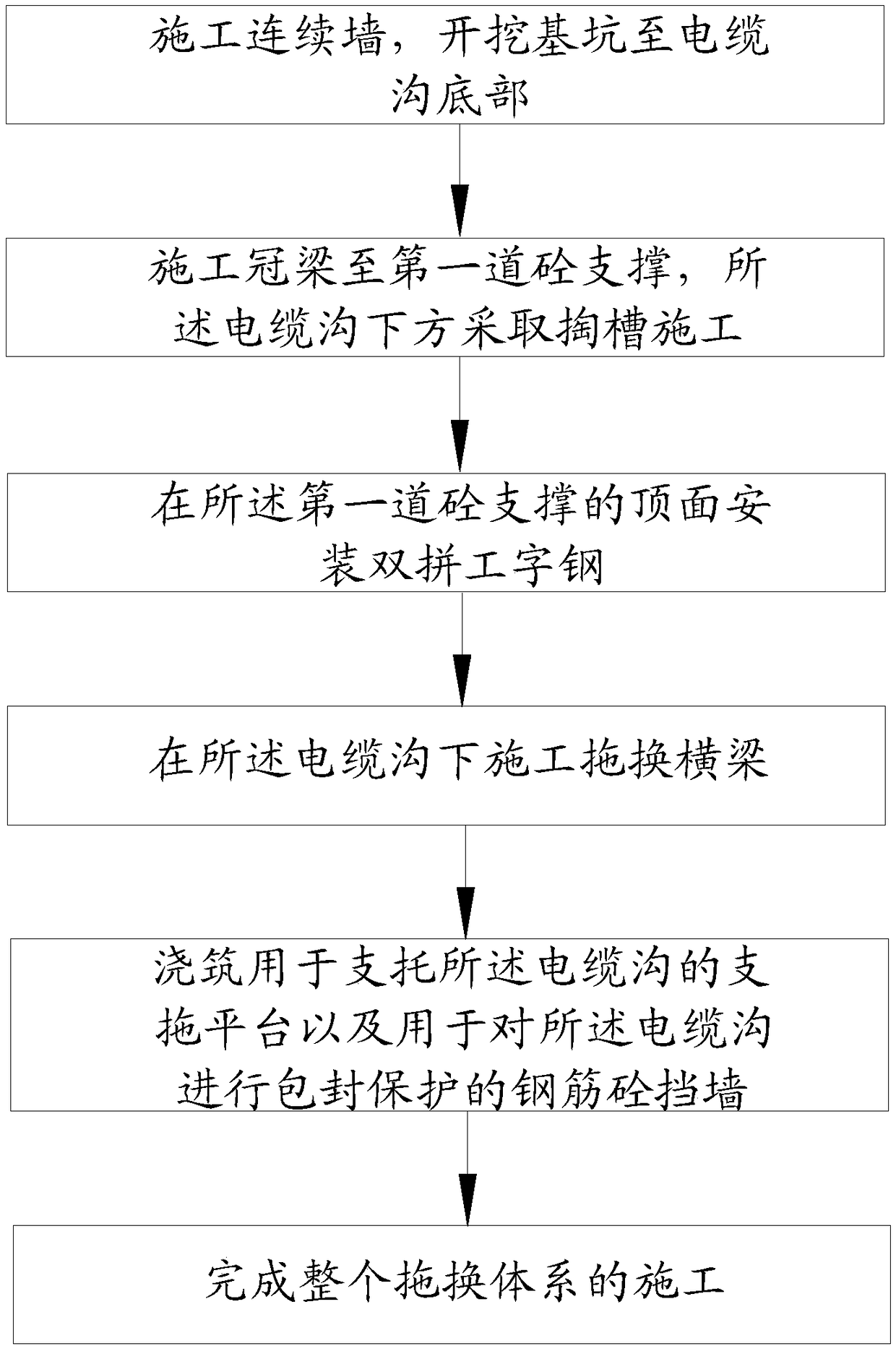

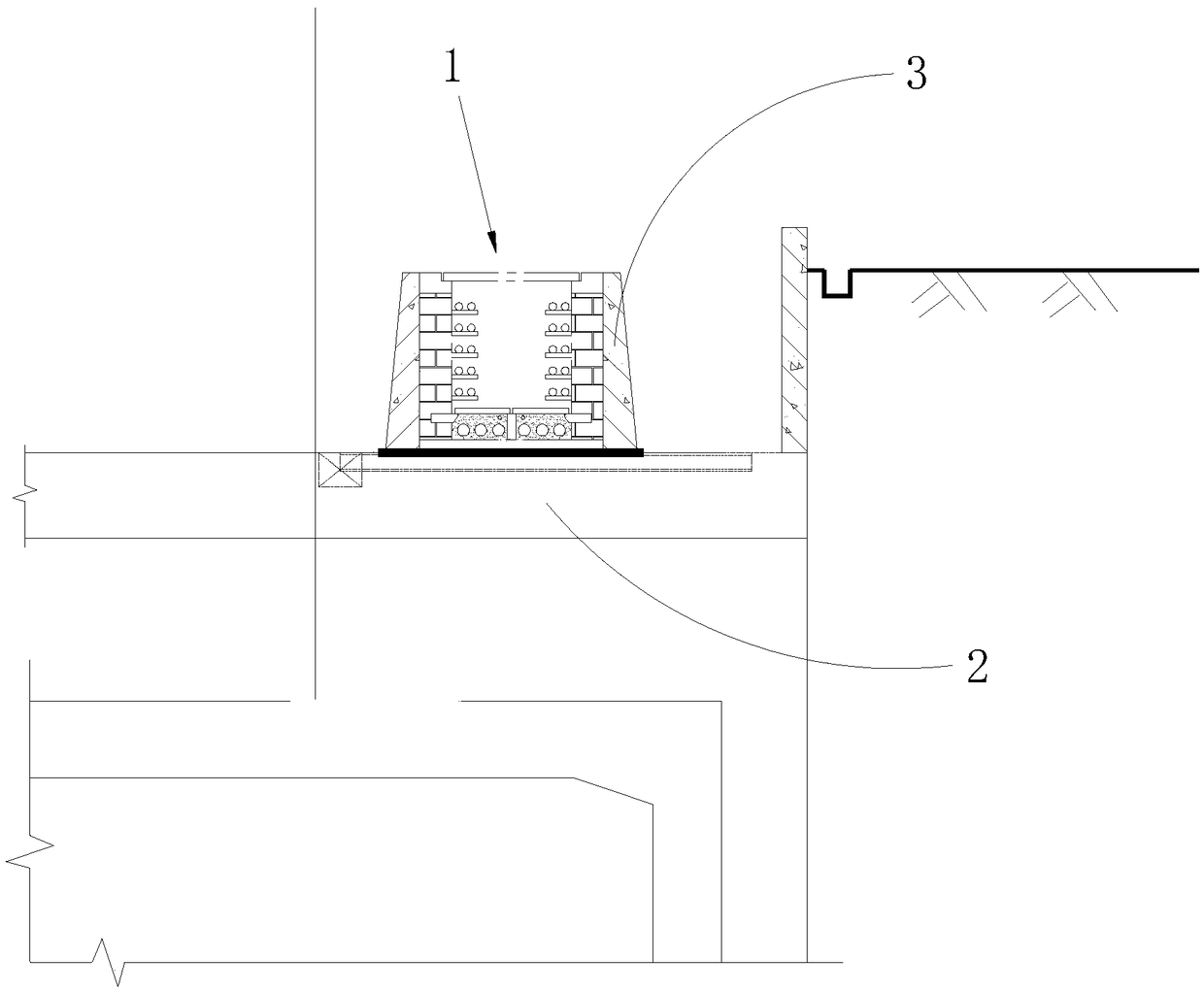

Cable trench in-situ support construction method

InactiveCN109372019AEnsure safetyShorten the construction periodCable installations on groundArtificial islandsReinforced concreteEngineering

The invention relates to the technical field of cable trench support and discloses a cable trench in-situ support construction method comprising the following steps: (1) constructing a continuous wall, excavating a foundation pit to the bottom of the cable trench; (2) constructing a crown beam to a first ballast support, and taking gutter groove under the cable trench; (3) mounting double-strandedsteel on the top surface of the first ballast support; (4) dragging and changing the beam under the cable trench; (5) pouring a supporting platform for supporting the cable trench and a reinforced concrete retaining wall for encapsulating and protecting the cable trench; and (6) completing the construction of the entire dragging system. The construction method has the beneficial effects of increasing construction efficiency, reducing construction interference, preserving energy and protecting the environment.

Owner:SHENZHEN MUNICIPAL ENG

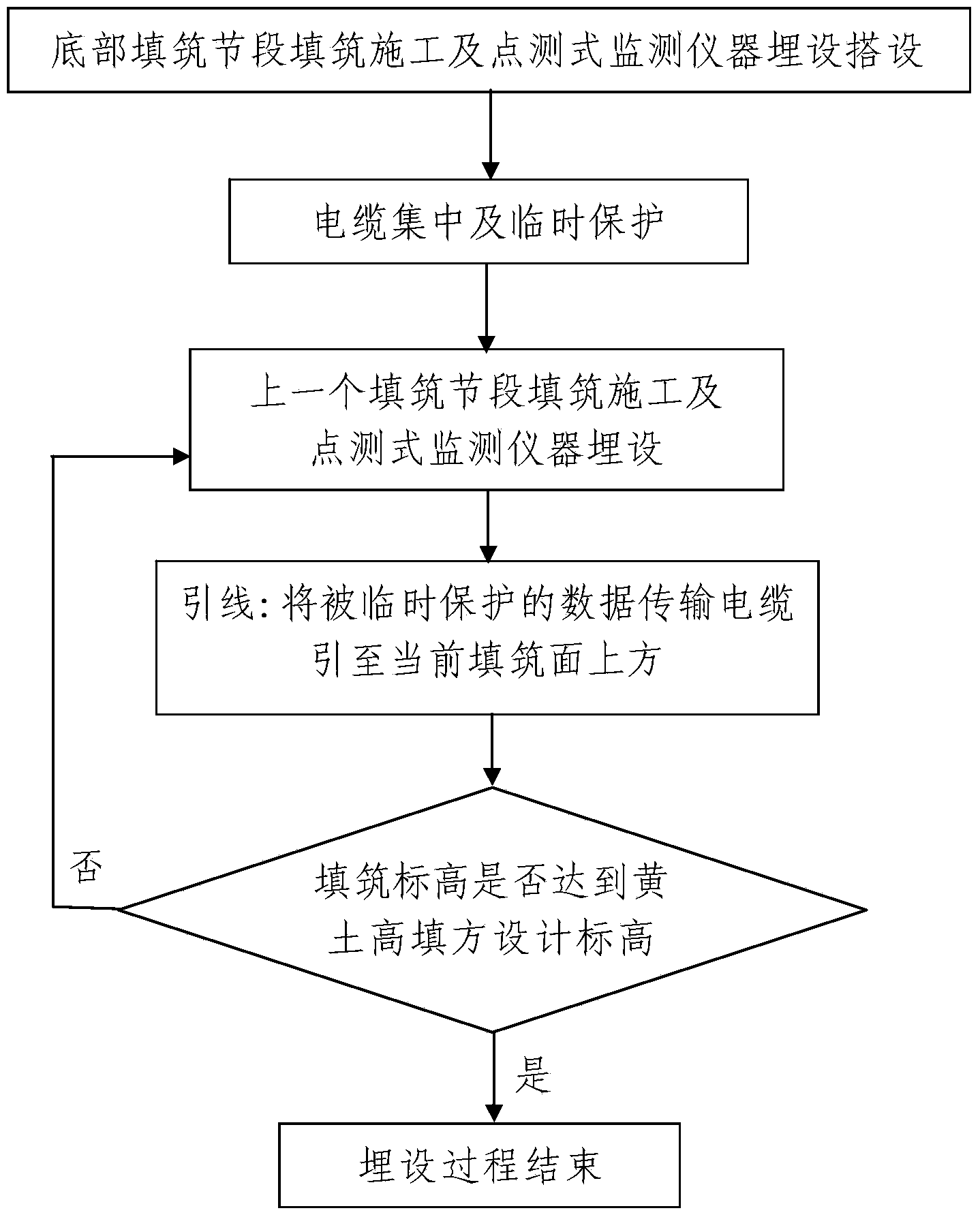

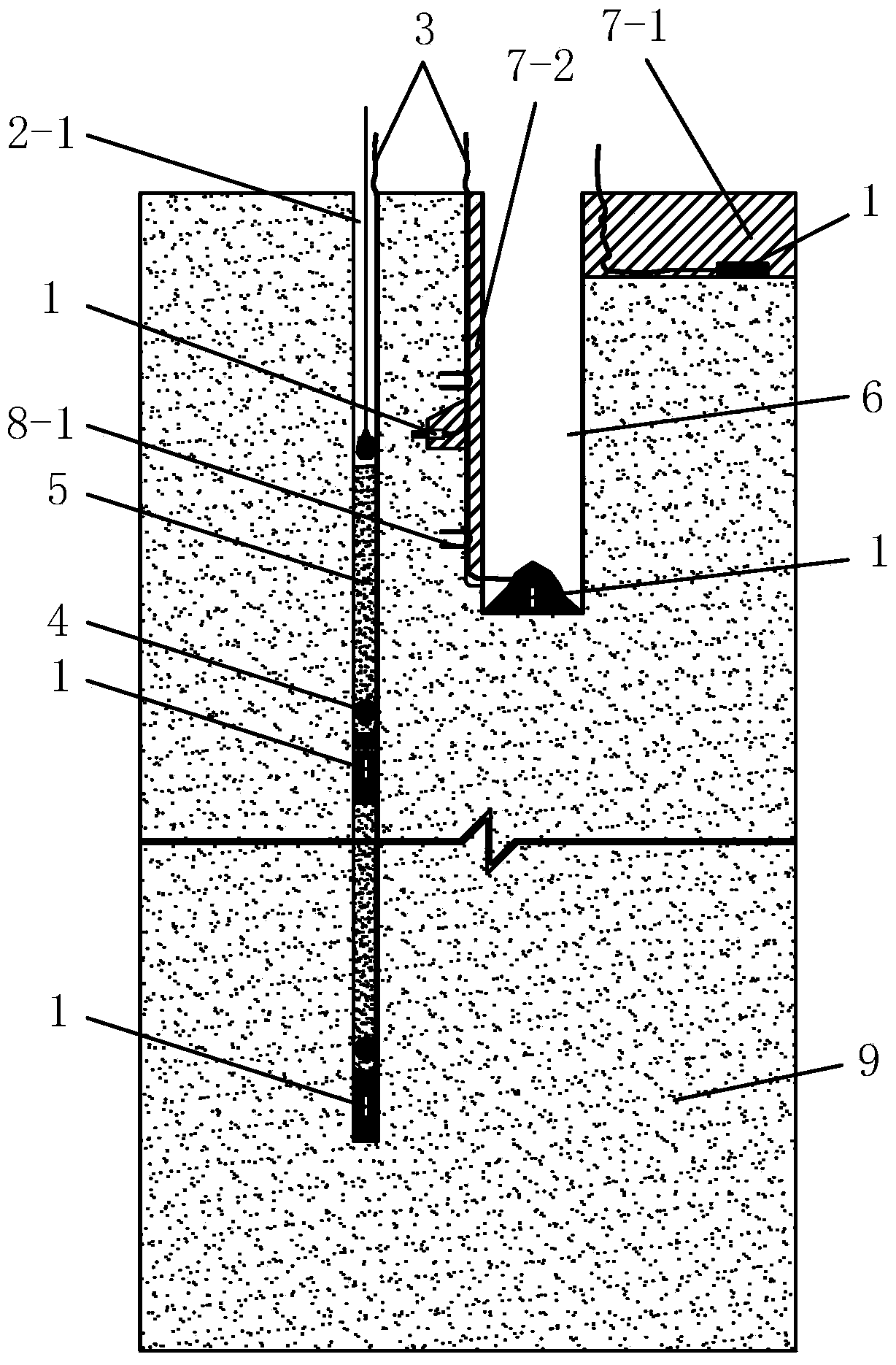

Burying-before-guiding type step-by-step burying method for monitoring instruments in synchronous construction with loess high fill

ActiveCN103410181AFast installationQuality improvementFoundation testingEngineeringData transmission

The invention discloses a burying-before-guiding type step-by-step burying method for monitoring instruments in synchronous construction with loess high fill. The loess high fill under construction comprises multiple filling segments from bottom to top. The multiple monitoring instruments to be buried are spot measurement type monitoring instruments. The burying-before-guiding type step-by-step burying method comprises the following steps: step one, the filling segment at the bottom is filled, and the spot measurement type monitoring instrument at the bottom is buried; step two, cables are centralized and protected temporarily; step three, the previous filling segment is filled and the previous spot measurement type monitoring instrument is buried; step four, the cables are guided, specifically, the data transmission cables which are protected temporarily are guided onto a current filling surface; step five, whether the burying process is finished is judged, namely, when the filling elevation reaches the designed elevation of the loess high fill, the burying process is finished; otherwise, the data transmission cables are all centralized at one position and protected temporarily, and then the step three is returned to. The burying-before-guiding type step-by-step burying method is simple in step, convenient to implement, and good in burying effect; the burying process does not interfere with the construction process of the loess high fill, and the construction process of the loess high fill and relevant parameters after the construction is completed can be monitored.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

Self-propelled lifting composite trestle for tunnel deep-buried ditch construction

PendingCN108343446AEasy to moveImprove construction efficiencyConstructionsUnderground chambersBuilding constructionCivil engineering

The invention relates to a self-propelled lifting composite trestle for tunnel deep-buried ditch construction. The self-propelled lifting composite trestle for the tunnel deep-buried ditch construction comprises a self-propelled trestle and a simple trestle. The self-propelled trestle is connected with the simple trestle through a trestle rotating shaft. A hydraulic oil cylinder is connected to the upper portion of a bracket which is at the front end of the self-propelled trestle through an oil cylinder pipe rotating shaft. The hydraulic oil cylinder is connected with the simple trestle through an oil cylinder rod rotating shaft. A crawler walking system is connected to the lower end of the self-propelled trestle. The self-propelled lifting composite trestle has complete functions and little disturbance in construction. The electric crawler-type walking of the combined trestle is achieved, and the simple trestle can be lifted electrically to facilitate the operation of machinery on thebottom; the self-propelled lifting composite trestle is especially for the deep-buried ditch construction, and the installation of materials and deep-buried pipes and the transportation of concrete can be carried out on the simple trestle; and at the same time, the installation of materials and deep-buried pipes and the transportation of concrete can be synchronized with the construction of various processes, and construction interference is reduced.

Owner:THE FIRST ENG OF CHINA RAILWAY 16TH CONSTR BUREAU GROUP

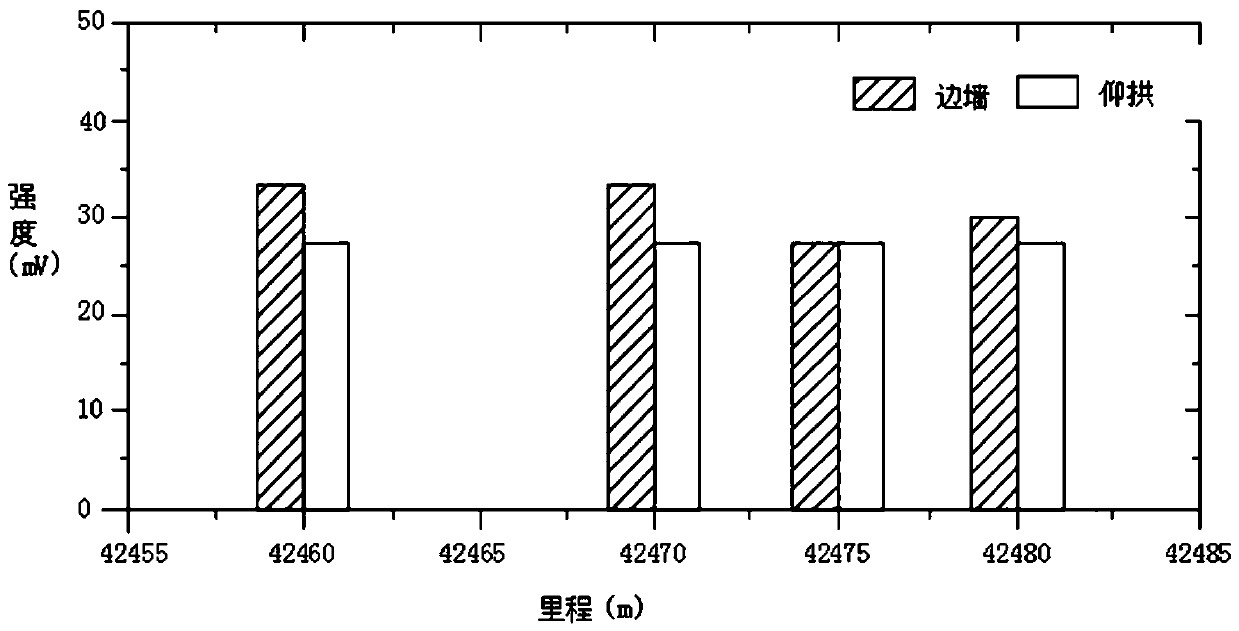

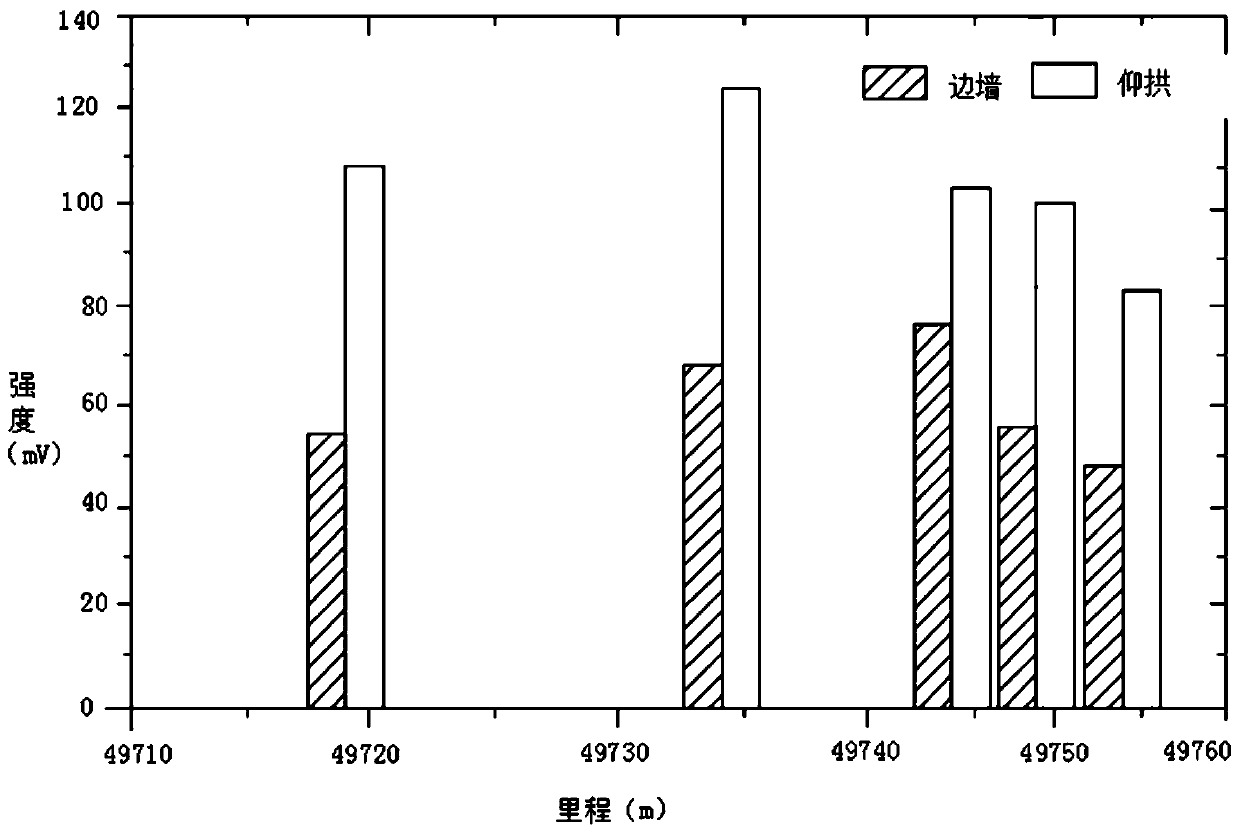

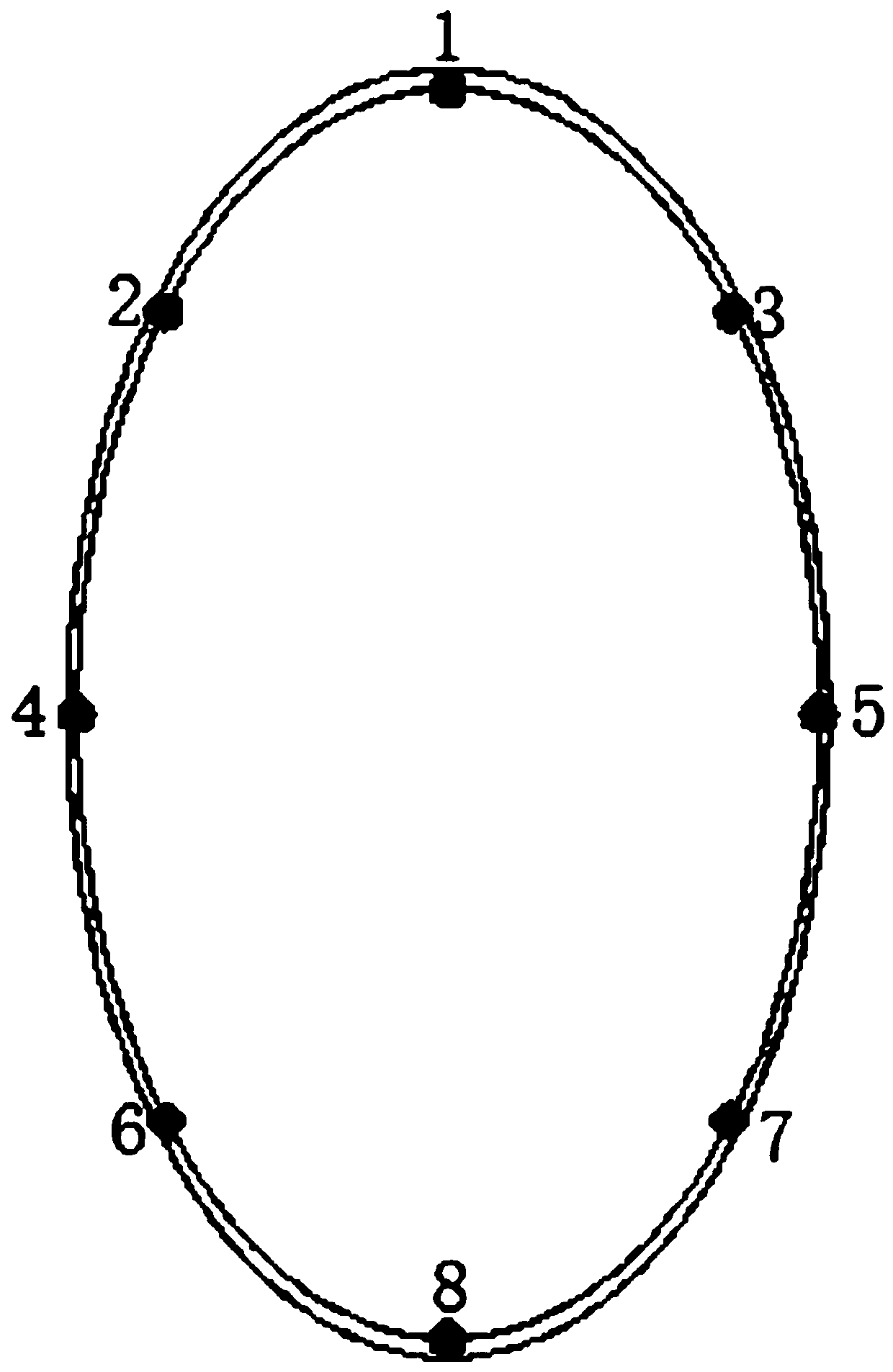

Monitoring method for relative magnitude of extrusion stress being surrounding rock pressure between tunnel preliminary bracing and surrounding rock

InactiveCN110261014AEasy to masterSimple monitoring methodForce measurementRelative magnitudeVariable Characteristic

The invention discloses a monitoring method for the relative magnitude of the extrusion stress being the surrounding rock pressure between a tunnel preliminary bracing and a surrounding rock. The method comprises: step one, during the construction process, arranging electromagnetic radiation monitoring sections at certain cycle intervals for a zone that includes a preliminary bracing non-cyclic section and a preliminary bracing cyclic section and has the relative magnitude of the extrusion stress being the surrounding rock pressure between the tunnel preliminary bracing and the surrounding rock and a distribution rule that need to be obtained, and arranging electromagnetic radiation monitoring points at representative positions on all sections; and step two, monitoring electromagnetic radiation intensities of different monitoring periods at the tunnel bracing structure surfaces of all monitoring points. The monitoring method is simple; since no device needs to be preburied, the disturbance to construction is low; the on-site construction technicians can obtain the information easily; the cost is low; and the method can be applied widely and can adapt to the variable characteristic of the surrounding rock and geological conditions under the complicated geological conditions.

Owner:FUZHOU UNIV

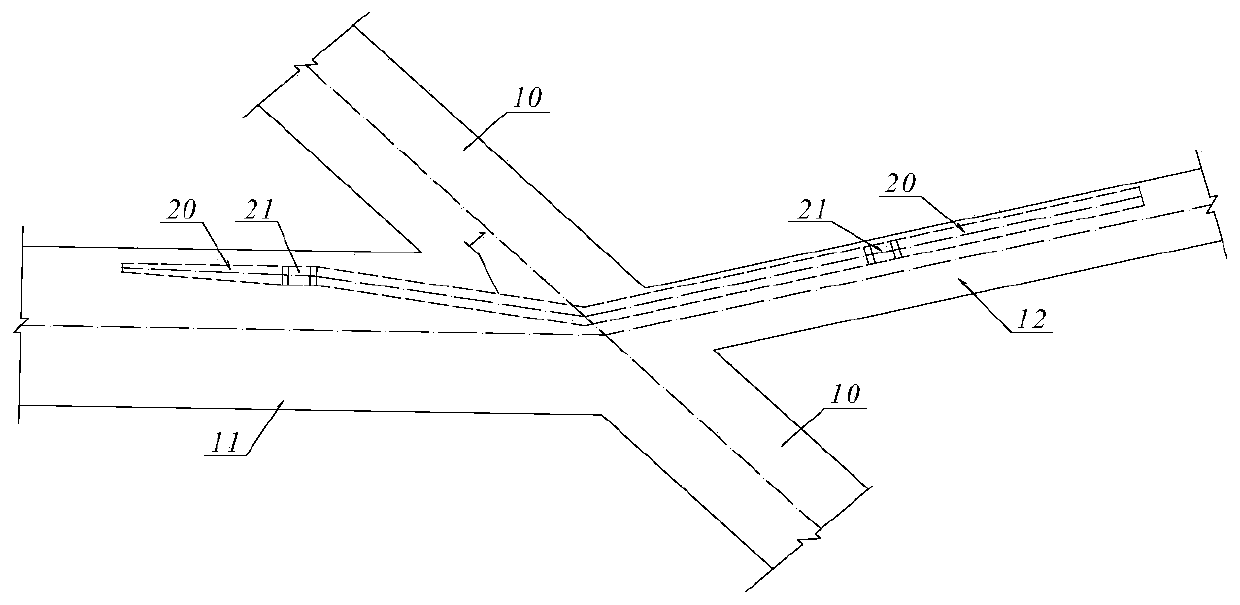

Connection structure between drainage tunnel and main line tunnel

PendingCN111322086ALittle construction disturbanceImprove construction periodDrainageTunnelsArchitectural engineeringWater well

The invention discloses a connection structure between a drainage tunnel and a main line tunnel so as to avoid large-scale downward excavation at the intersection of an existing transverse tunnel anda main tunnel, reduce the impact on the existing transverse tunnel and the main line tunnel, effectively reduce the construction safety risk of deep foundation pit support in the tunnel, reduce the interference to the main tunnel and transverse tunnel construction, shorten the construction period of a project, and save the project investment. The connection structure comprises the main line tunneland the existing transverse tunnel located on one side of the main line tunnel, the new-built drainage tunnel is arranged on the other side of the main line tunnel, and the new-built drainage tunneland the existing transverse tunnel form an intersection with the main line tunnel; and groove broaching, excavating and constructing of a drainage ditch are conducted under the inverted arch of a lining structure of the main line tunnel, the two ends of the drainage ditch extend into the new-built drainage tunnel and the existing transverse tunnel, a water collecting well is arranged, and a concrete filling layer is arranged from the upper part of the drainage ditch to the inverted arch of the lining structure.

Owner:中铁二院贵阳勘察设计研究院有限责任公司

Prefabricated assembly type pier column and top cap connecting structure and construction method thereof

InactiveCN113202017AFast assembly and constructionLittle construction disturbanceBridge structural detailsBridge erection/assemblyCrack resistanceReinforced concrete

The invention provides a prefabricated assembly type pier column and top cap connecting structure and a construction method thereof. The connecting structure comprises a prefabricated pier column and a prefabricated top cap, an anti-shearing tenon is arranged on the top of the prefabricated pier column, an anti-shearing groove is formed in the bottom of the prefabricated top cap, prestressed tendons and connecting steel bars are arranged in the prefabricated pier column, and a plurality of embedded corrugated pipes are arranged in the prefabricated top cap; and pore channels are reserved in the pre-buried corrugated pipes, the pore channels correspond to the prestressed tendons and the connecting steel bars one to one, and the prefabricated pier column and the prefabricated top cap are spliced through splicing seams. The prestressed tendons are arranged, so that the crack resistance of the splicing seams is improved, and the post-earthquake self-resetting capability and the connection reliability are enhanced; the splicing seams are made of ultra-high performance concrete or epoxy mortar, so that the splicing seams can bear certain tensile stress without cracking, and the durability of the splicing seams is improved; the reinforced concrete anti-shear tenons and the anti-shear grooves are arranged to form a mortise and tenon structure, and the joint anti-shear capacity is high; and the connecting structure is particularly suitable for splicing the prefabricated pier column and the top cap in a large cantilever top cap T-shaped pier or an overline frame type pier.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

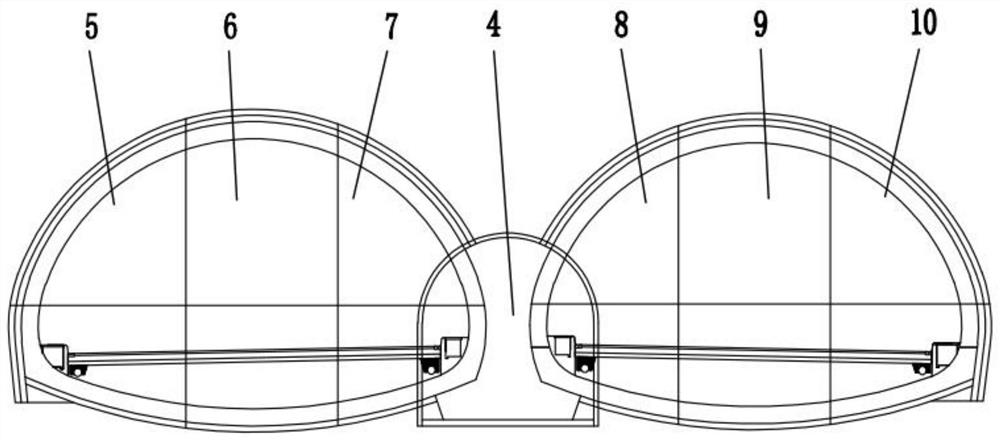

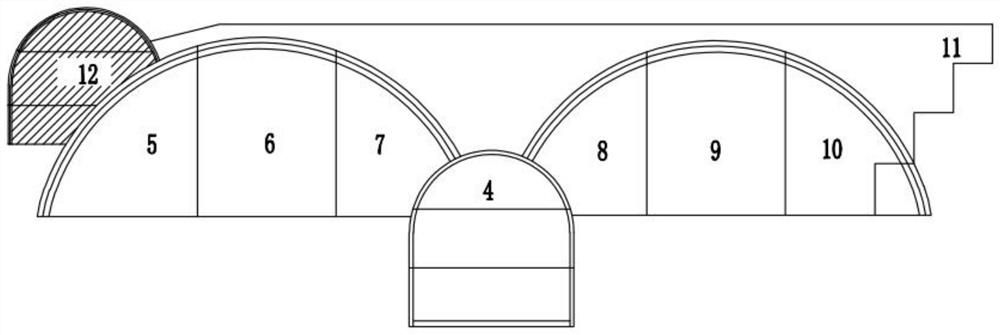

Method for synchronously constructing pilot tunnel excavation and mid-partition wall lining in double-arch tunnel

PendingCN112554889ARealize forward excavationSolve the problem of low elevation and difficult frontal bottom excavationTunnelsArchitectural engineeringStructural engineering

The invention discloses a method for synchronously constructing pilot tunnel excavation and mid-partition wall lining in a double-arch tunnel. The method includes the steps that step (1) double-arch tunnel underground excavation construction enters a C ramp from an inclined shaft to an open excavation section bifurcation part, downwards penetrates through a deep foundation pit open excavation section to the end part of a double-arch tunnel section through a 5# channel, and additionally opens a 2# transverse channel, and according to the principle from near to far and from top to bottom, 2# transverse channel excavation and double-arch underground excavation tunnel entering construction are sequentially conducted in a stepped and sub-pilot tunnel mode; step (2) the double-arch tunnel excavation is conducted in sequence according to the principle from near to far and from a high place to a low place; step (3) a double-arch 1# tunnel is used as a main transportation channel for advanced construction, a 3-1 transverse channel is excavated obliquely downwards into a double-arch 0# tunnel, a tunnel section mid-partition wall is constructed, and then a double-arch 3# tunnel is excavated;and step (4) the double-arch 1# tunnel continues to be excavated in advance, a 3-2 transverse channel is excavated, and the double-arch 0# tunnel is excavated. According to the method for synchronously constructing pilot tunnel excavation and mid-partition wall lining in the double-arch tunnel, synchronous construction of main tunnels and middle pilot tunnels in the two sides of the double-arch tunnel is achieved, and the construction period is greatly shortened.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com