Construction method for deep canyon arch aqueduct arch ring hoisting single base rib closure

A technology for aqueducts and canyons, which is applied in the construction field of super-large concrete arch aqueduct arch rings in deep canyons. It can solve the problems of difficult hoisting control, large construction interference, and large floor area, so as to reduce construction interference, shorten construction period, and lift off the ground. The effect of large height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

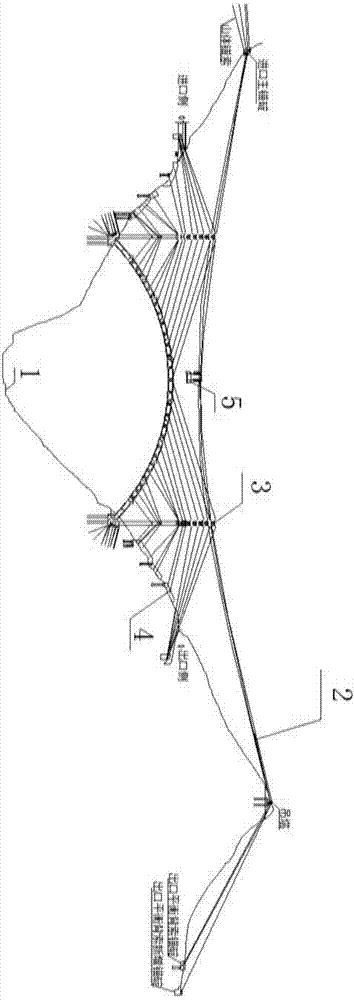

[0022] Such as Figure 1~3 As shown, the multi-segment hoisting and single-base rib closure construction method of the super-large reinforced concrete arch aqueduct arch ring in the deep canyon includes the following steps:

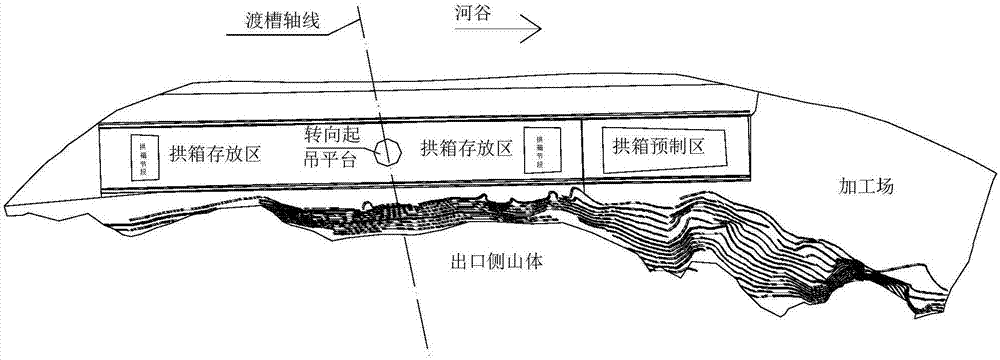

[0023] The first step is to set up the arch box prefabrication field 1 along the side of the valley bottom;

[0024] Step 2: Arrange two orbital gantry cranes in the prefabrication site for transporting the arch box segment, and arrange a rotating platform under the center line of the main cable as a lifting platform;

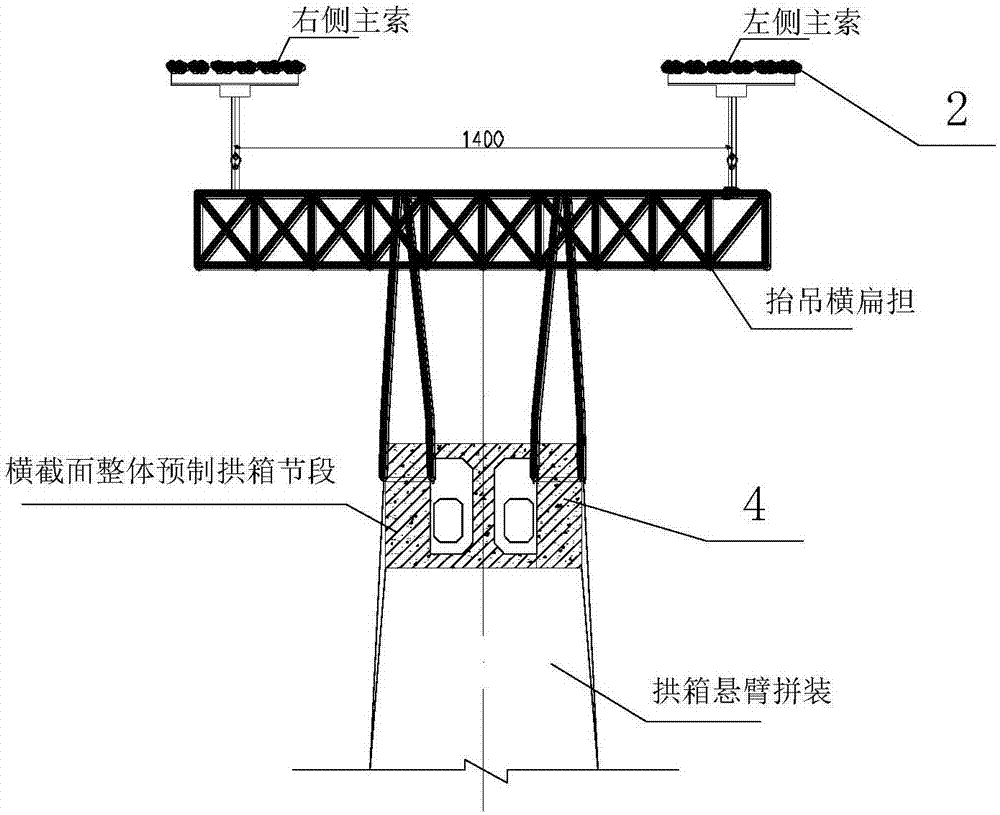

[0025] The third step is to use the mountains on both sides of the aqueduct to set ground anchors or low towers to anchor the main cable 2 and arrange cable cranes;

[0026] The fourth step is the layout of the anchorage structure of the back cable, including the arrangement of the buckle tower 3 and the anchorage structure 4 of the back cable;

[0027] In the fifth step, after the strength of the prefabricated arch box 5 meets the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com