Reverse osmosis water processing method and reverse osmosis drainage system in construction period of concrete faced rockfill dam

A face rockfill dam and a treatment method technology, applied in the field of face rockfill dams, can solve the problems of high cost and complex process of reverse drainage system, etc., and achieve the effects of small weakening range, convenient and flexible transportation and installation, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

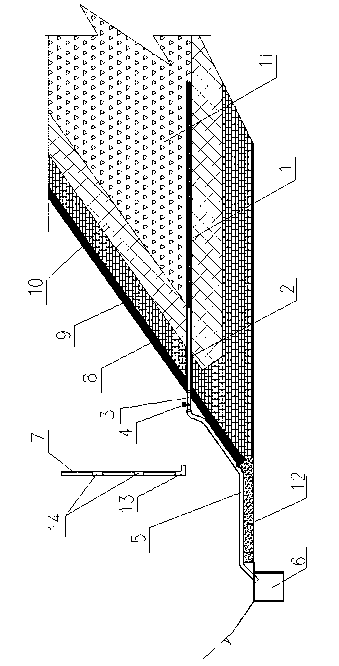

[0015] The reverse seepage drainage system during the construction period of the face rockfill dam is as follows: figure 1 As shown, the blind drainage material 1 is laid in the horizontal interface between the transition zone 10 and the upstream rockfill area 1. The upstream side of the blind drainage material 1 is connected to the sleeve 2, and the other side of the sleeve 2 is connected to a one-way water stop valve. 4, the horizontal drainage pipe 3, the two ends of the horizontal drainage steel pipe 3 are provided with joint threads, the other side is connected to the drainage hose 5, and the other end of the drainage hose 5 is placed in the water collection well 6, and a vertical drainage pipe is also provided 7, vertical drain pipe 7 is established in addition, vertical drain pipe 7 lower ends are connected with horizontal drain pipe 3 by bending 13, and vertical drain pipe 7 upper ends are connected with another section steel pipe by direct 14 to lengthen vertical drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com