Large-gradient small-section underground cavity excavating construction method

A technology for underground caverns and construction methods, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as high maintenance and operation requirements, worsening operating environment, and smoke exhausting of fuel equipment, so as to reduce construction interference and slag removal efficiency. High and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

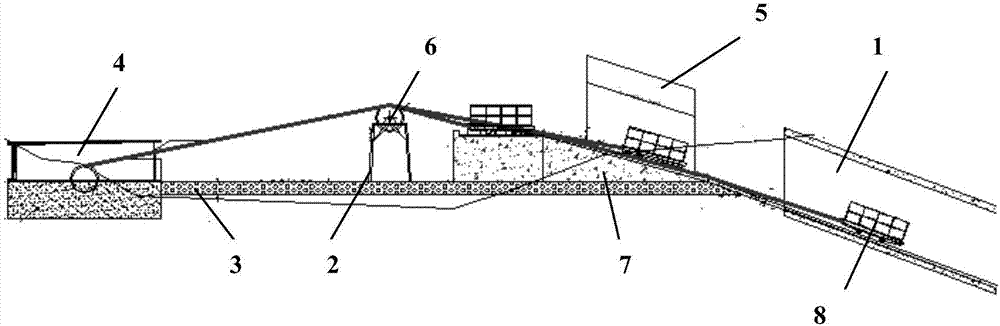

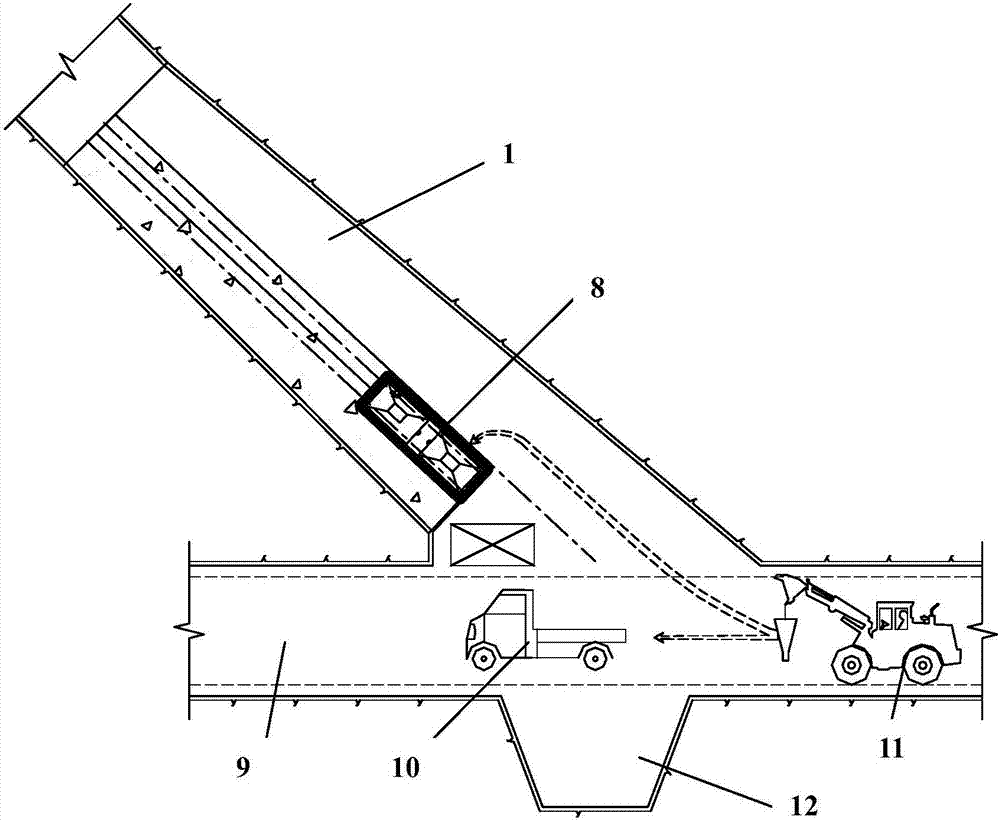

[0021] The construction method for excavating underground caverns with large slopes and small sections provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The length of the inclined shaft in the underground cavern in the second phase of a water supply project is 708.983m, and the comprehensive slope is 36.875%. The rock category is mainly extremely soft rock, which belongs to underground caverns with large slopes and small sections. The construction is difficult and the safety risk is high. How to reasonably select and arrange the transportation system and how to scientifically organize the close construction of each process is the key to ensure the smooth construction of the project.

[0023] According to the requirements of construction conditions, engineering quantity and construction period, after the demonstration and optimization of the construction technical plan, it was dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com