Monitoring method for relative magnitude of extrusion stress being surrounding rock pressure between tunnel preliminary bracing and surrounding rock

A technology of initial support and extrusion stress, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of inability to use on a large scale, inconvenient installation, high requirements, easy to grasp by construction technicians, low cost, construction interference small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

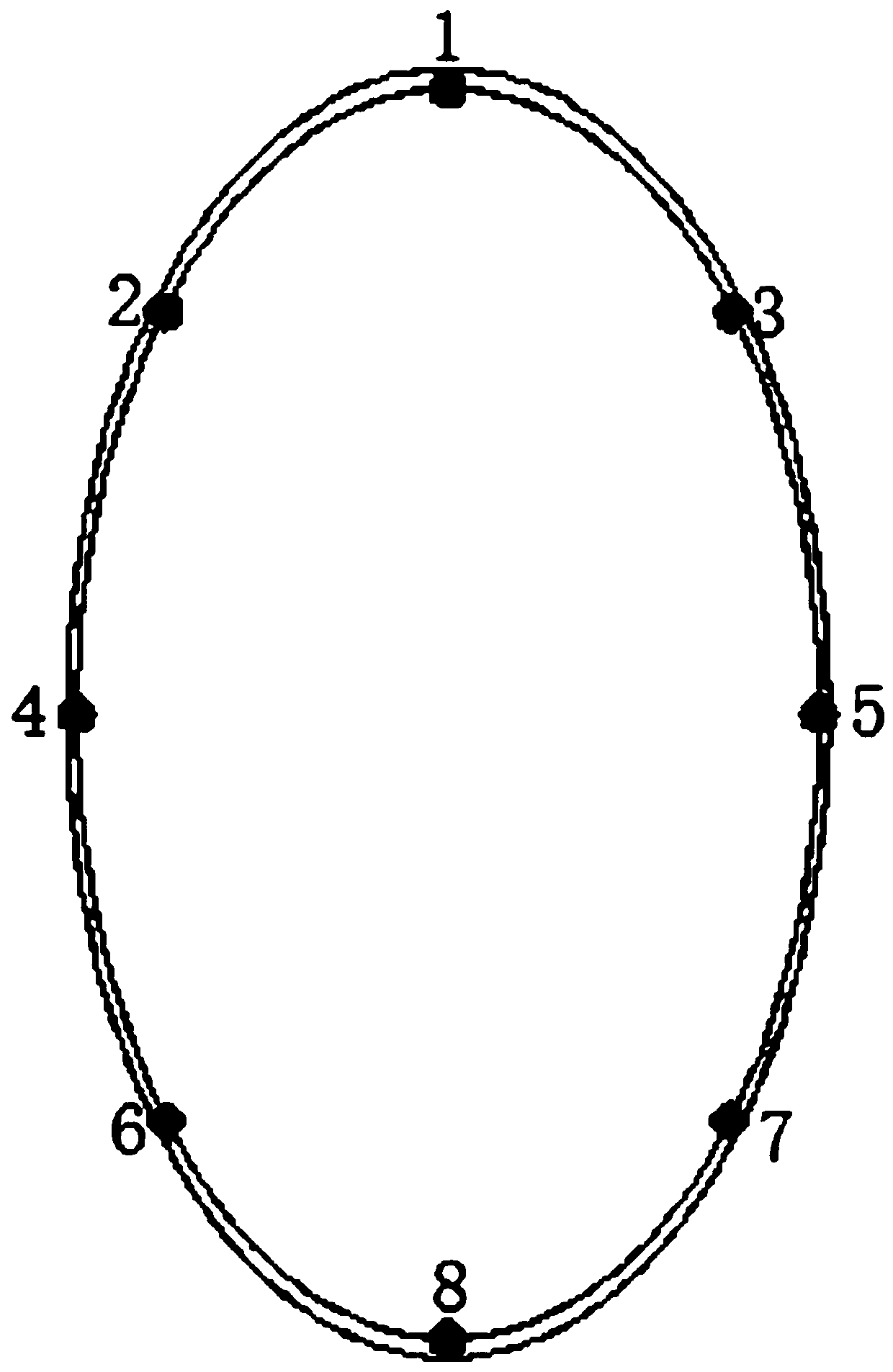

[0022] During the construction process, for the sections that need to know the relative size and distribution of the compressive stress (surrounding rock pressure) between the initial support and the surrounding rock (including the section where the initial support has not formed a ring and the section where the initial support has formed a ring), use Electromagnetic radiation monitoring sections are set at regular intervals, and the interval between electromagnetic radiation monitoring sections is generally set at 5m. Electromagnetic radiation monitoring points are arranged at representative positions on each section, such as image 3 and Figure 4 As shown, before the inverted arch is backfilled, the electromagnetic radiation monitoring points are generally arranged at the vault 1, the left arch waist 2, the right arch waist 3, the left wall 4, the right wall 5, the left arch foot 6, the right foot 7 and the middle of the inverted arch 8. After the inverted arch is backfille...

Embodiment 2

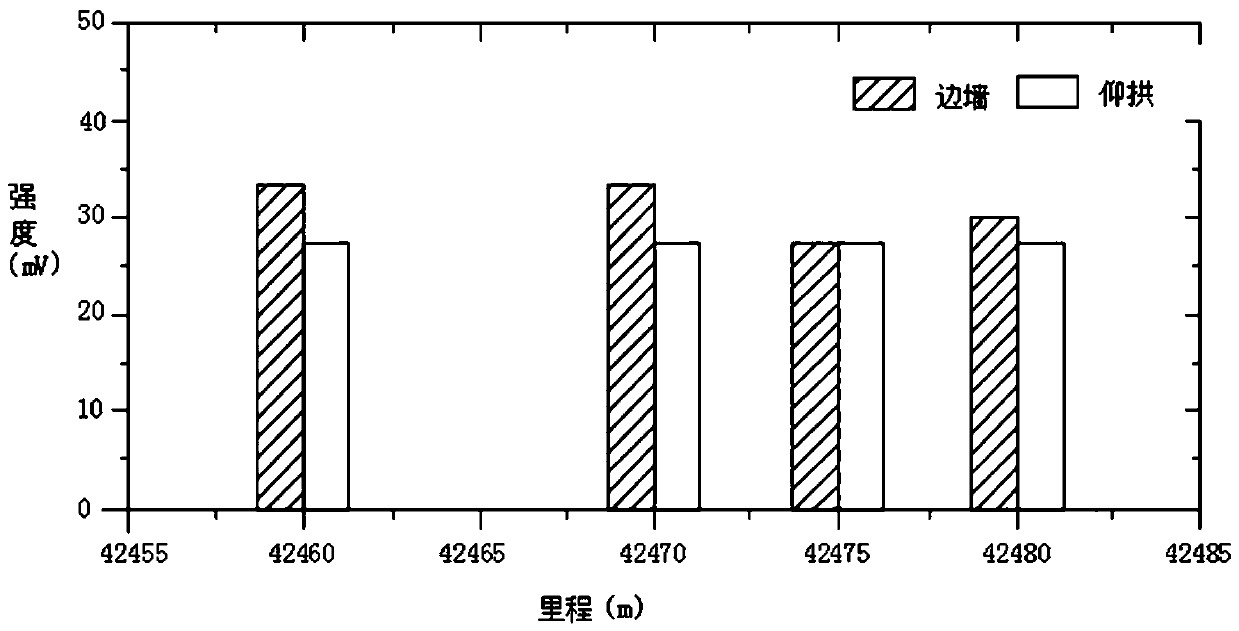

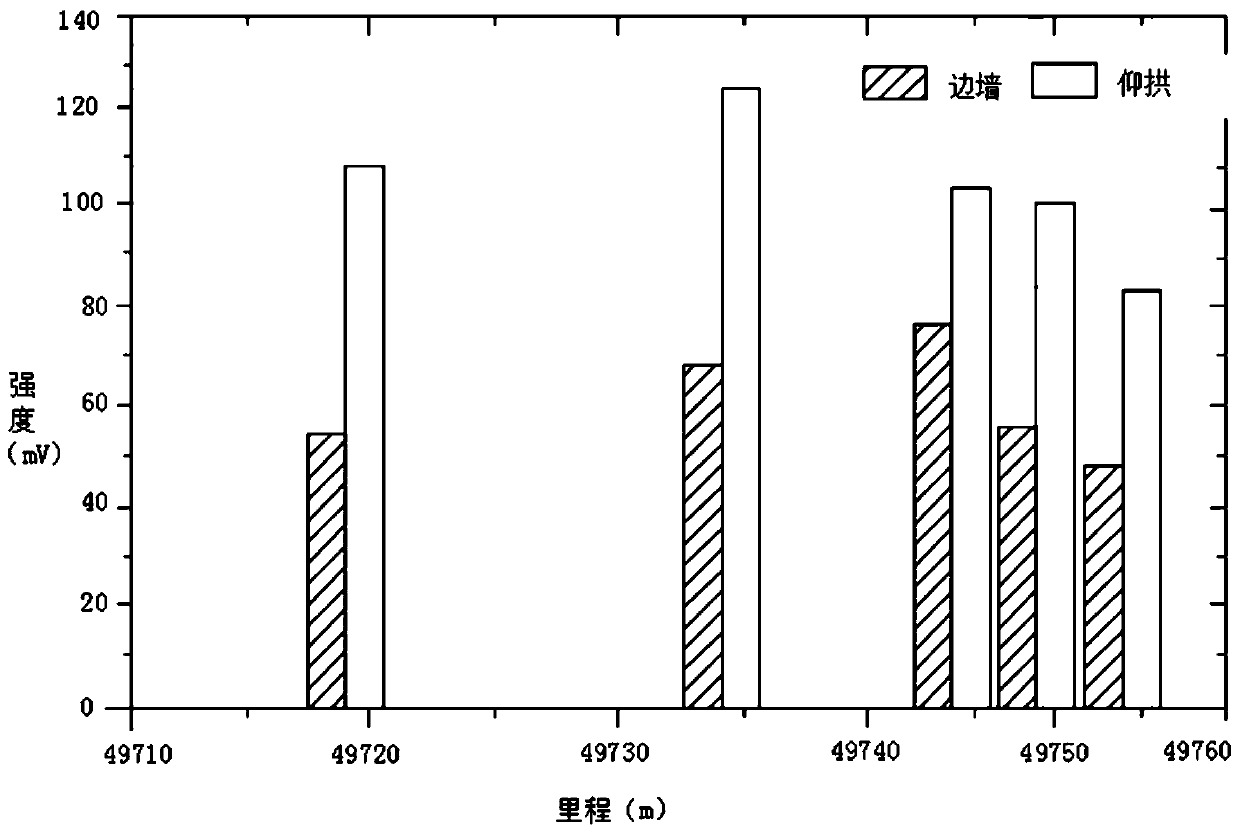

[0026] A railway tunnel is 14755m long and has a maximum buried depth of 1240m. The surrounding rock is mainly schistosed basalt, which is strongly compressed by large-scale geological structures. The residual structural stress in the tunnel site area is large, and the surrounding rock is broken and metamorphic. Cleavage development, poor stability. Serious large deformations occurred during the tunnel construction, with the maximum unilateral convergent deformation amounting to 87cm, and the deformation of the surrounding rock basically took about 70 days to reach stability. Severe large deformation caused primary support invasion, and secondary arch replacement was carried out in some sections. Due to the high in-situ stress in the tunnel site area and the complex and changeable geological conditions, the distribution of the compressive stress (surrounding rock pressure) between the primary support and the surrounding rock is also complex and changeable, which brings great d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com