Patents

Literature

316 results about "Underground cavern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

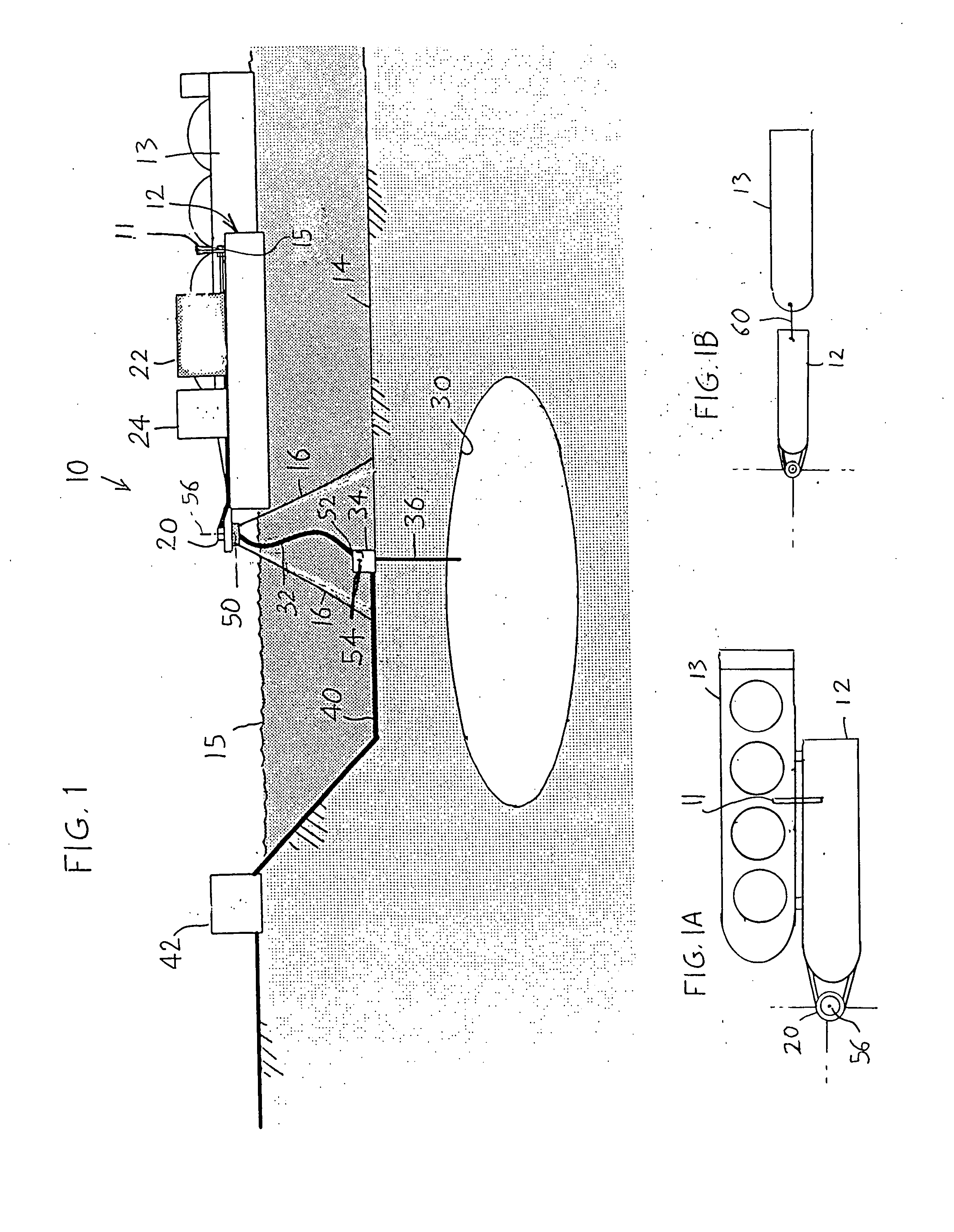

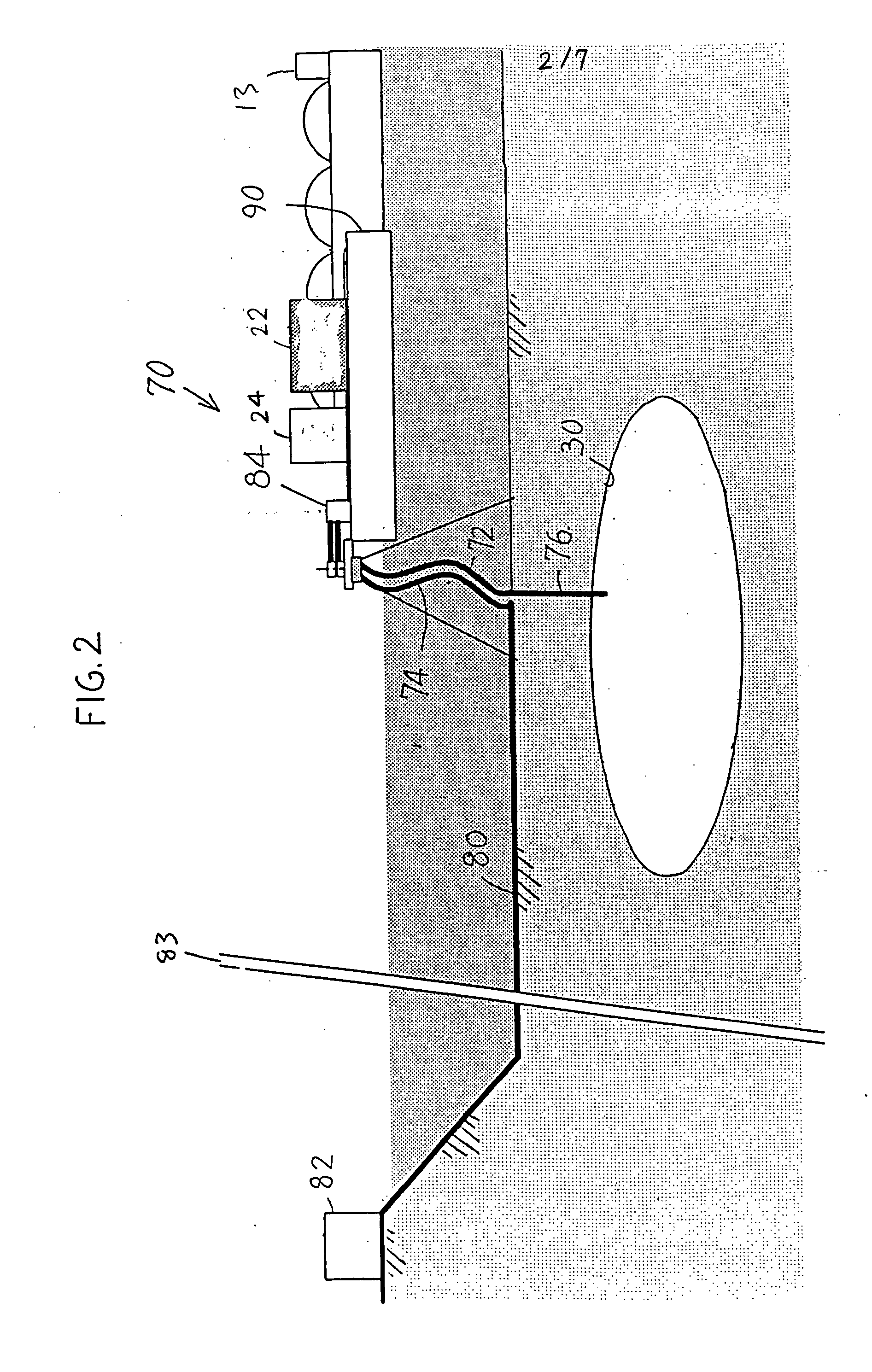

Gas offloading system

ActiveUS6973948B2Easy to passGas handling applicationsGas handling/storage effectsElectricityOcean bottom

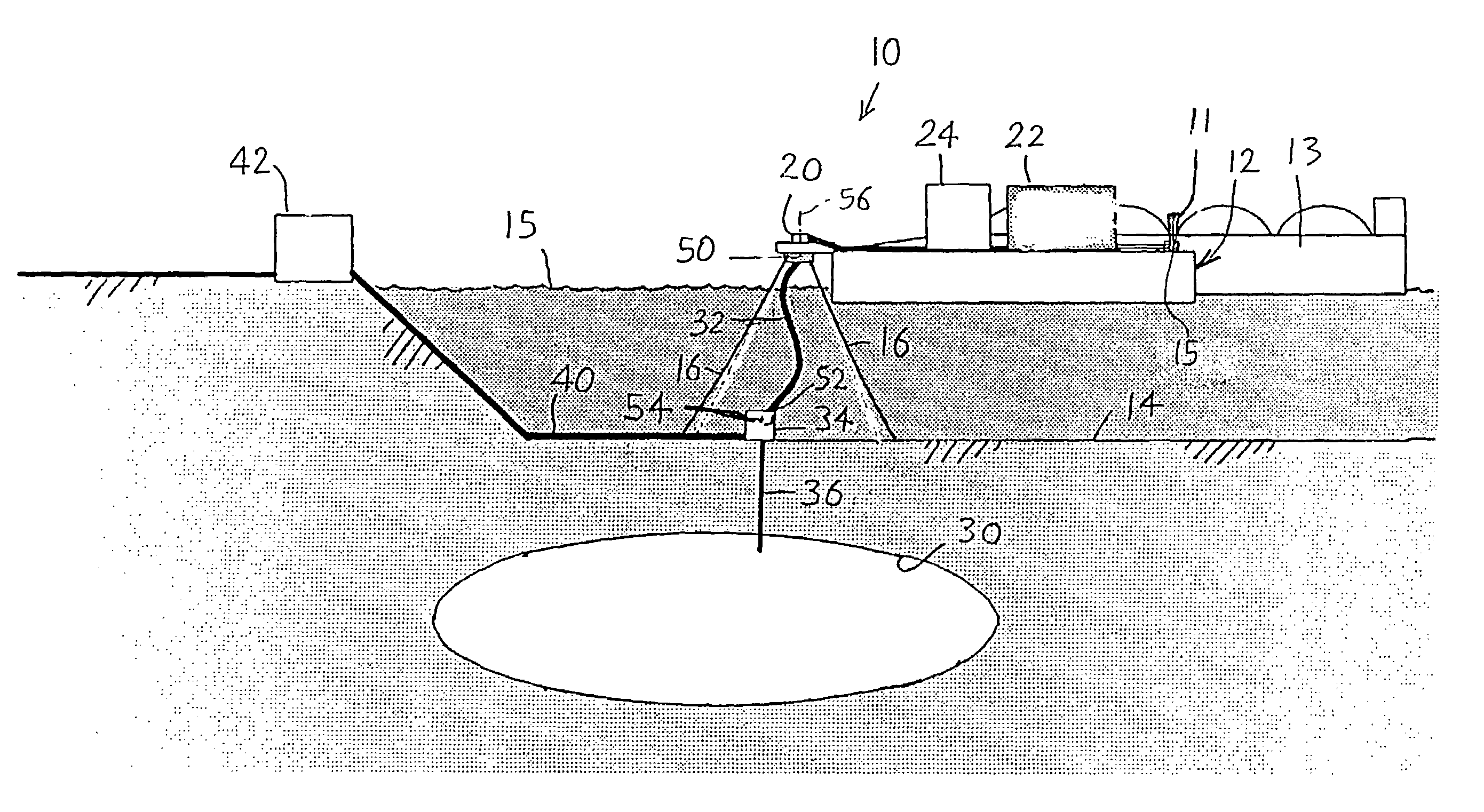

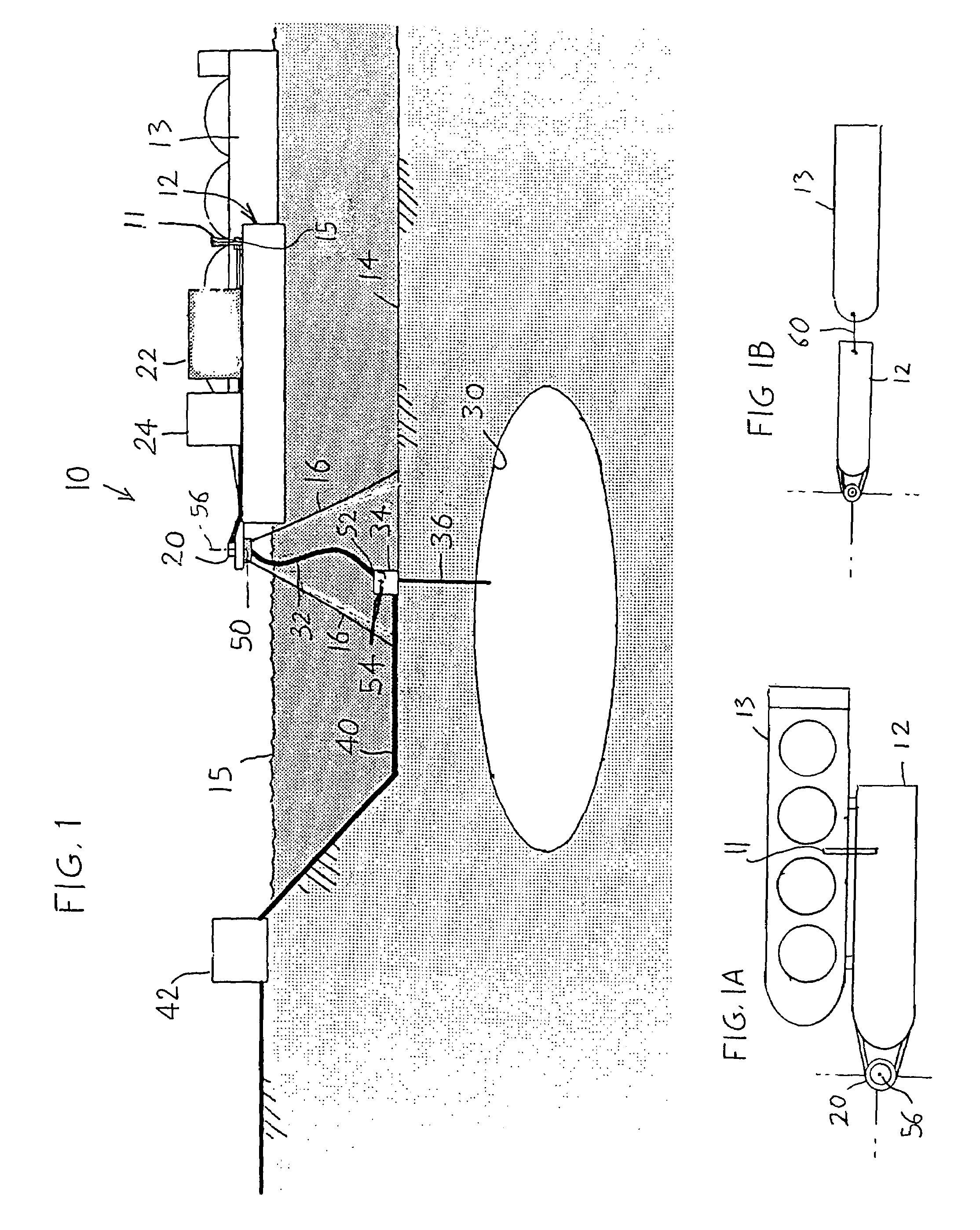

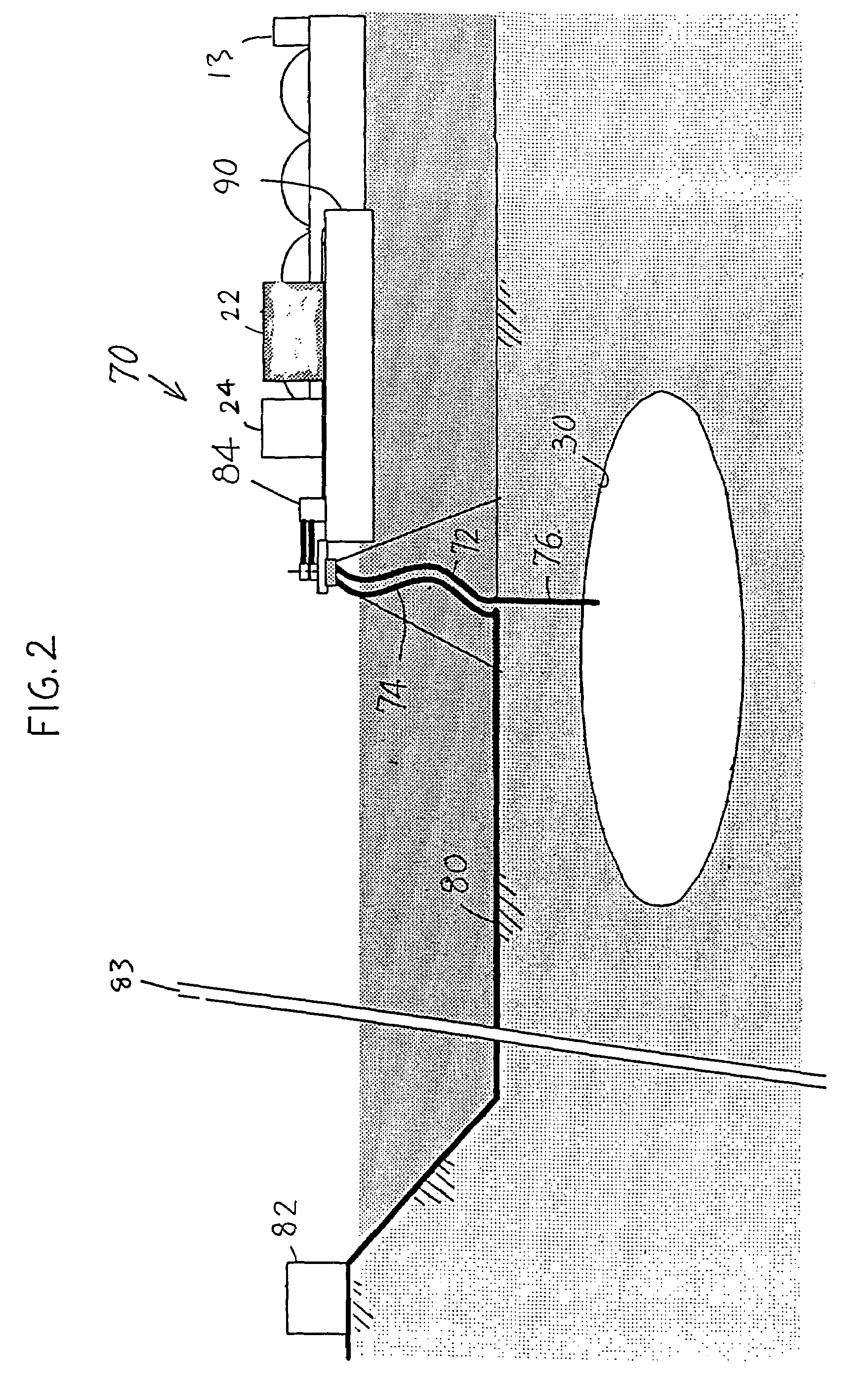

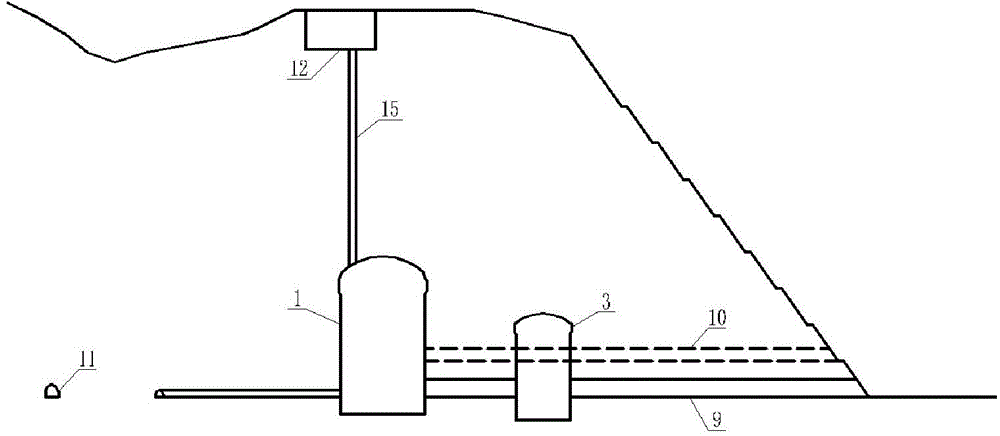

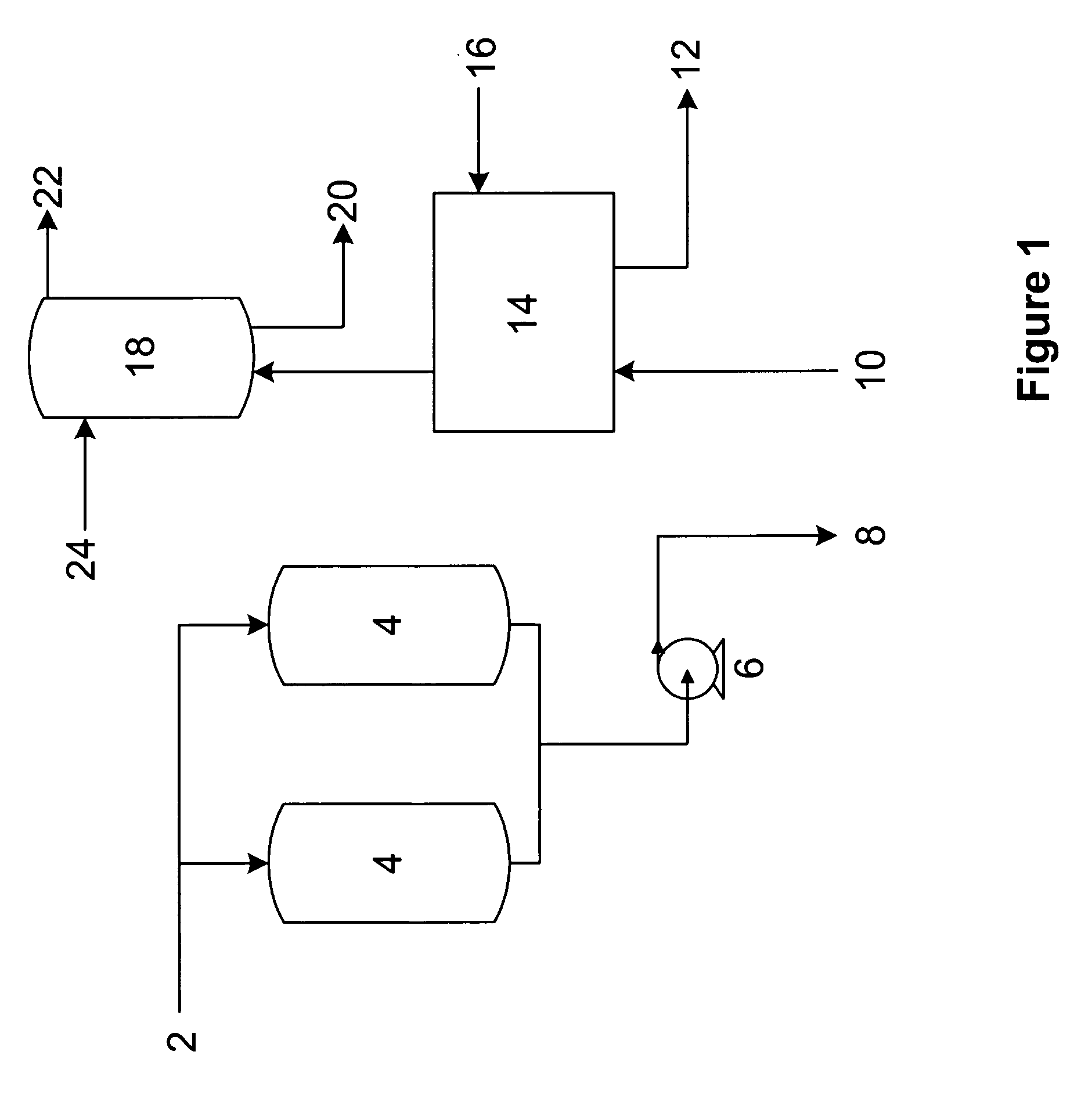

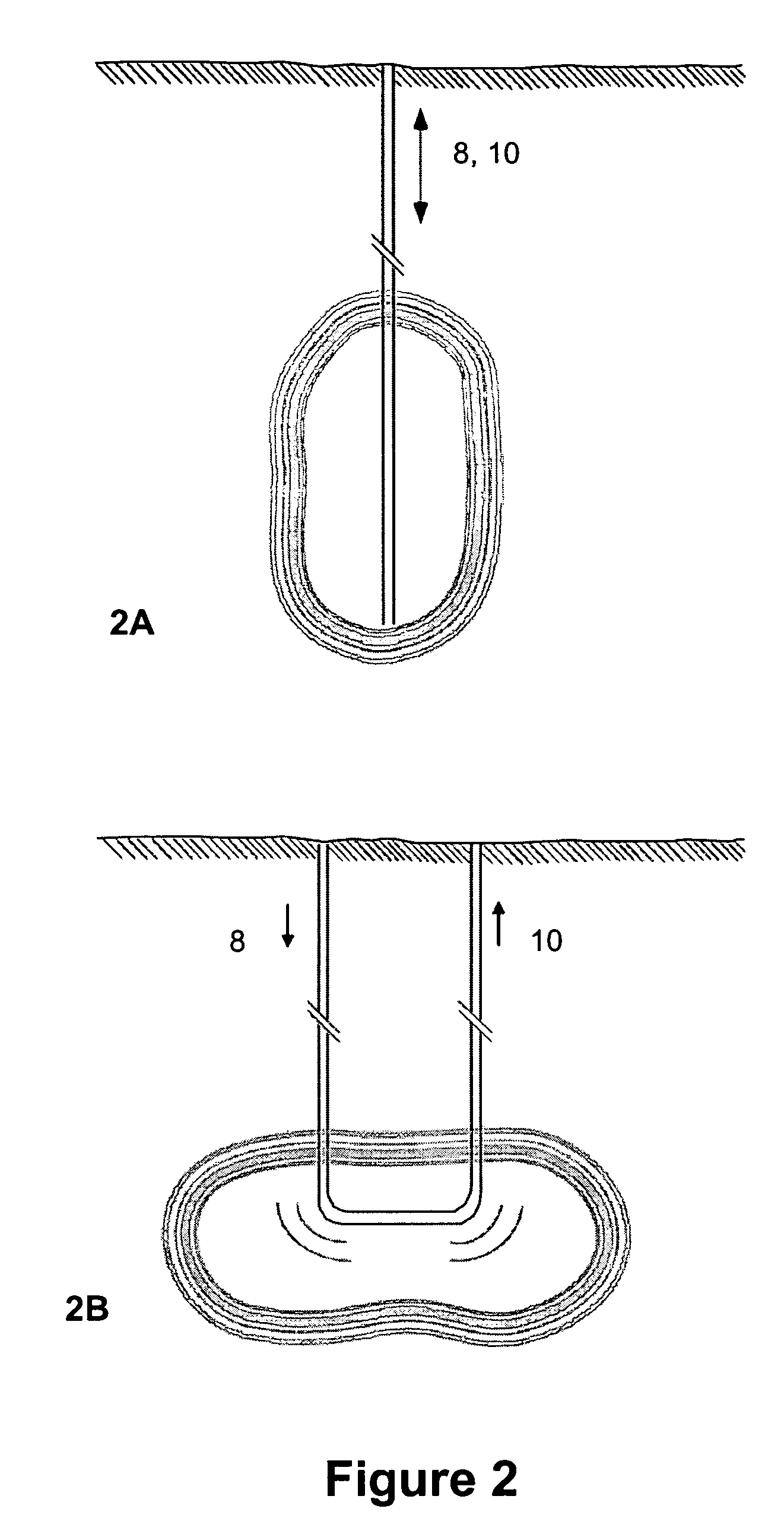

A system is described for offloading LNG (liquified natural gas) from a tanker for eventual delivery to an onshore gas distribution station. The system includes a floating structure that floats at the sea surface and that is connected to the tanker so they weathervane together. The floating structure carries a regas unit that heats the LNG to produce gas, and delivers the gas through a riser to an underground cavern that stores the gas. Gas from the cavern is delivered through a seafloor pipeline to an onshore gas distribution station. The regas unit includes water pumps and other equipment that is powered by electricity. The electricity can be obtained from an electric generator on the floating structure, with surplus electricity delivered through a sea floor electric power line that extends along the sea floor to an onshore electricity distribution facility. The electricity can instead be obtained by delivery from an onshore facility though a sea floor electric power line that extends up to the floating structure and to the regas unit.

Owner:SINGLE BUOY MOORINGS INC

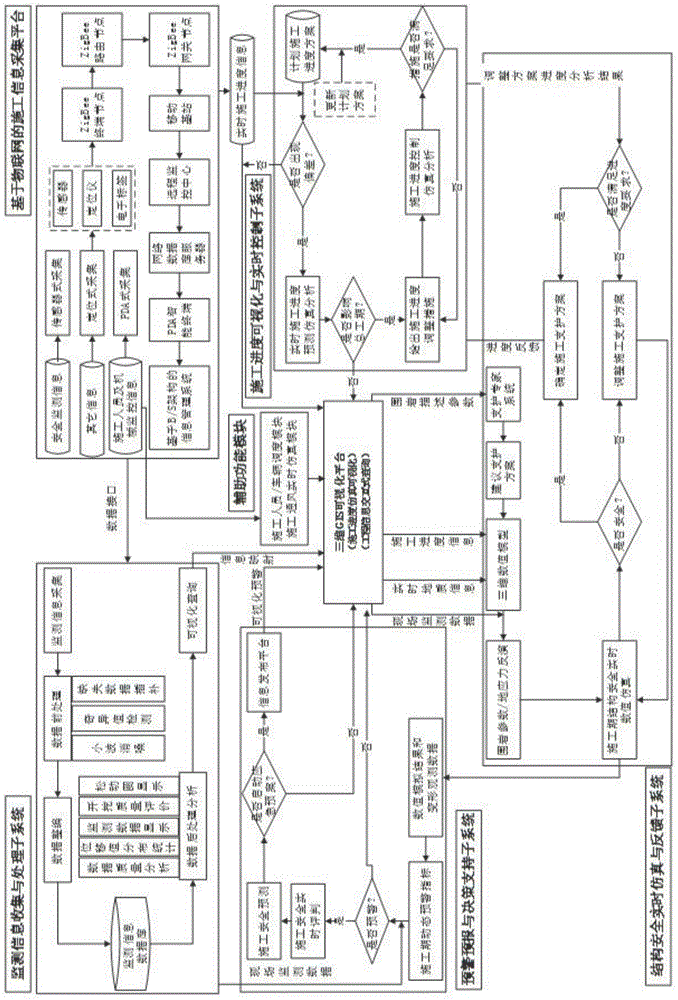

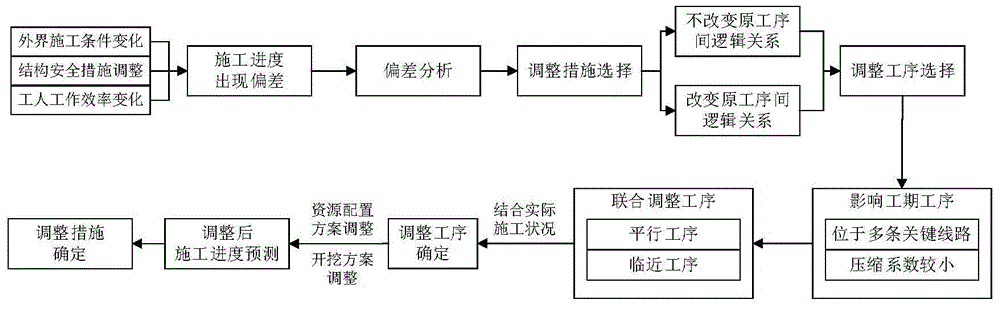

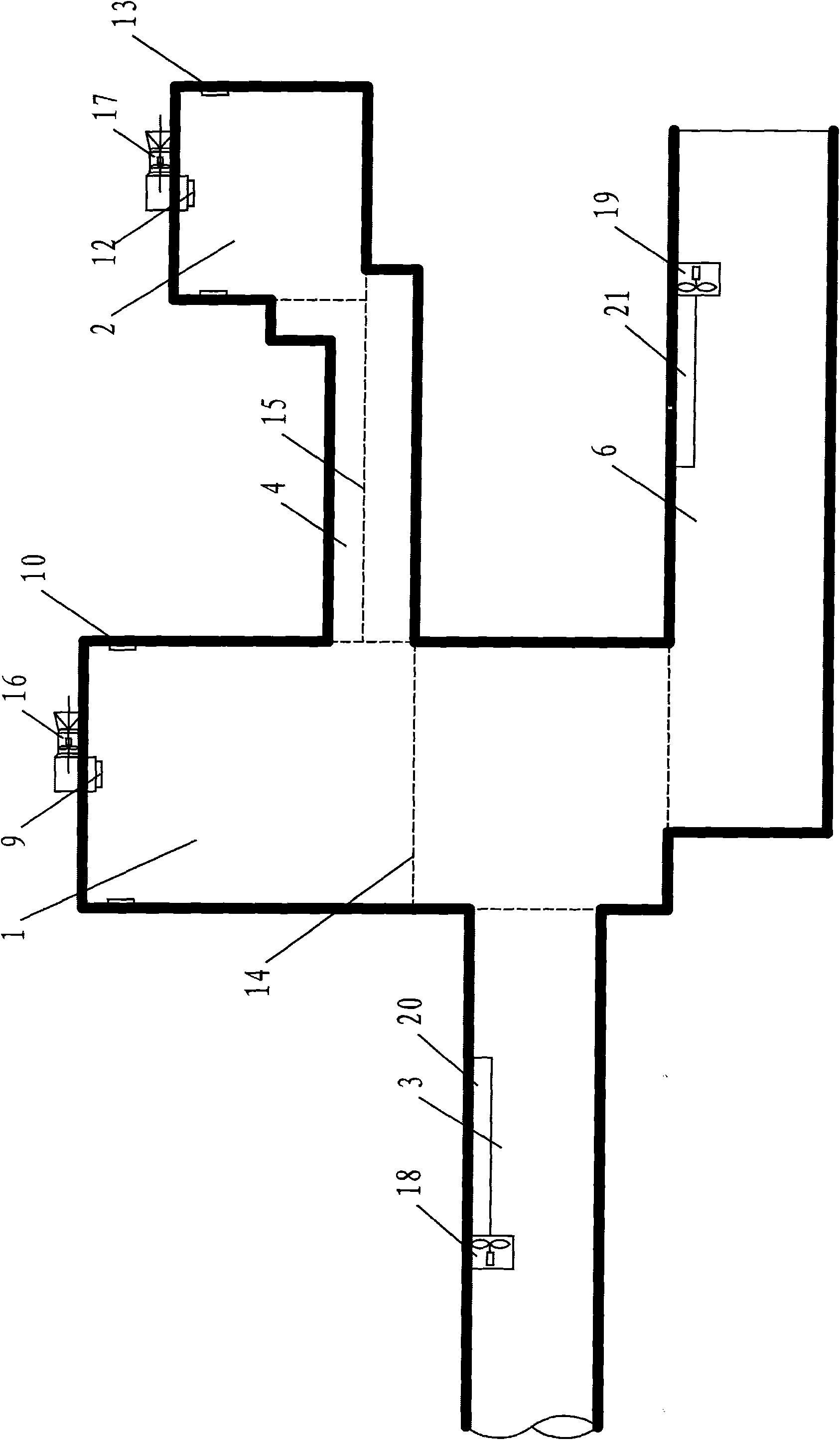

Construction expert information system applicable to extra-large underground cavern group

InactiveCN104463717ARealize acquisitionReal-timeData processing applicationsData informationThe Internet

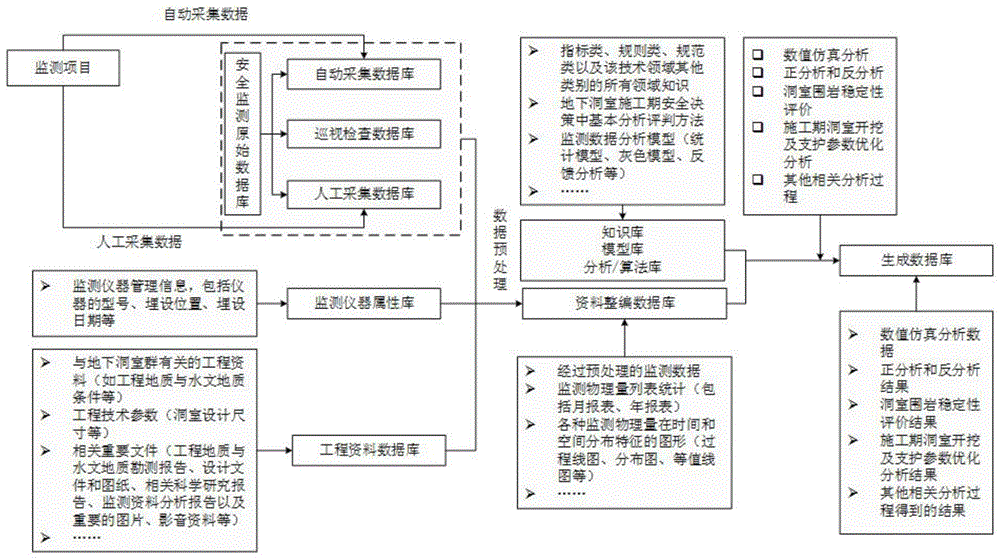

The invention relates to a construction expert information system applicable to an extra-large underground cavern group. The system comprises a data information acquisition and wireless transmission platform and five main subsystems, wherein the data information acquisition and wireless transmission platform is a construction information acquisition and wireless transmission platform based on the Internet of Things, the five systems include the information collecting and processing subsystem, the construction progress visualization and real-time control subsystem, the construction real-time simulation and feedback subsystem, the early warning, forecasting and decision supporting subsystem and the extra-large underground cavern group construction site information management system based on B / S architecture. The construction expert information system has the functions in the aspects of construction information collection, construction progress organization and management, construction monitoring, construction safety control, construction early warning and emergency decisions for construction safety of the extra-large underground cavern group, and the complex, changeable and uncertain construction environmental conditions of underground engineering can be met; construction progress and construction safety of underground caverns can be dynamically analyzed, predicted and displayed, and powerful analysis tools and technical supports can be provided for progress control and construction safety management decisions of the underground cavern group.

Owner:SINOHYDRO BUREAU 14 CO LTD +8

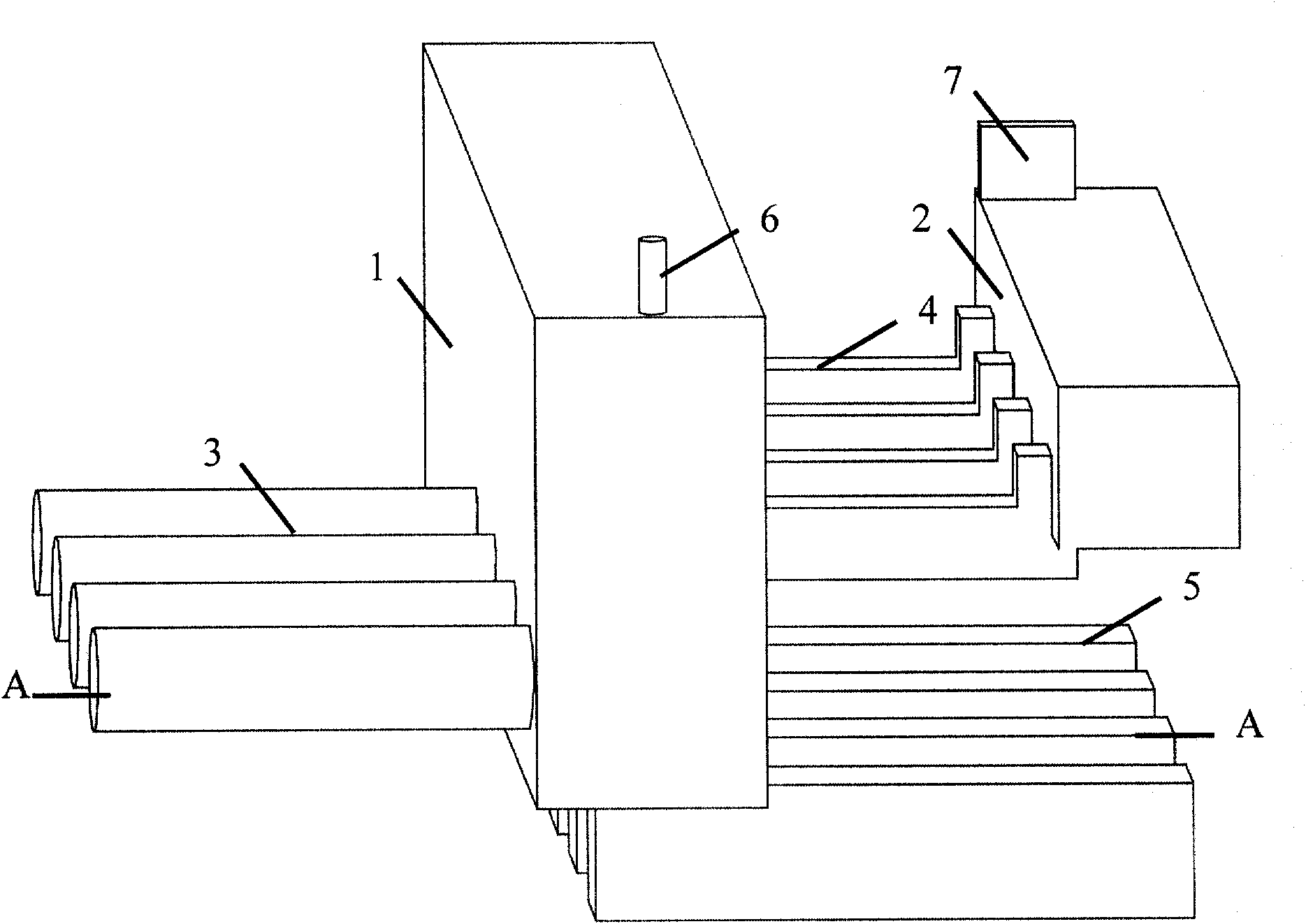

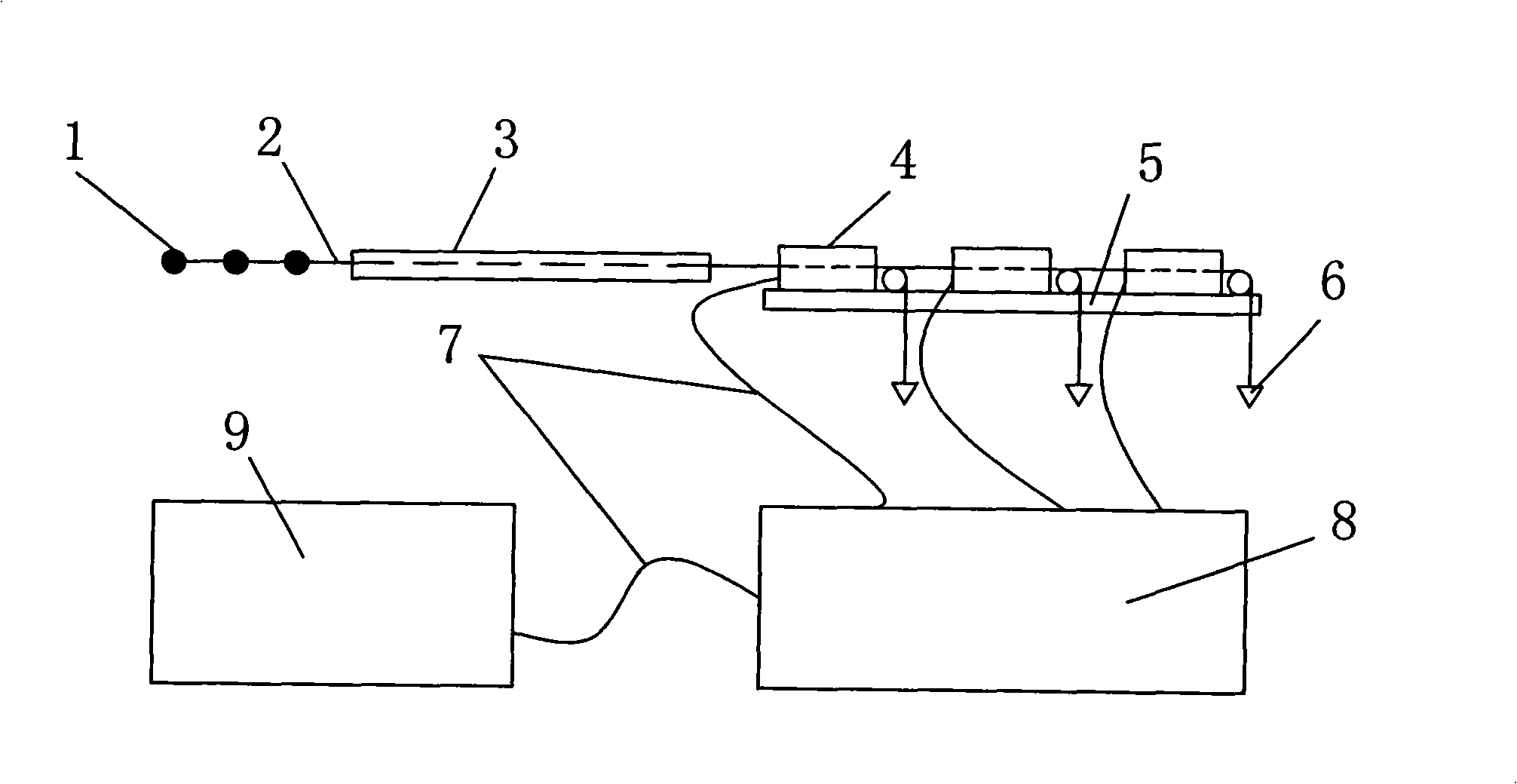

Fire simulation experiment equipment for caverns in hydraulic and hydro-power engineering and simulation experiment method

ActiveCN101914904AEasy to adjustGood experimental repeatabilityHydraulic engineering apparatusEducational modelsUnderground cavernControl engineering

The invention relates to fire simulation experiment equipment for caverns in hydraulic and hydro-power engineering. The equipment comprises a cavern simulation system, a fire source system, a ventilation and smoke discharge system, a detecting and warning system and a measurement, collection and data analysis system, wherein the cavern simulation system is used for simulating a three-dimensional restricted space of fire generation; the fire source system is used for simulating different fire scenes and can be arranged at any position in the constituent parts of the cavern simulation system; the ventilation and smoke discharge system is used for simulating ventilation and smoke discharge in the cavern; and the detecting and warning system is used for detecting, identifying and warning on the fire inside the cavern simulation system; and the measurement, collection and data analysis system is used for measuring, collecting and processing data, comparing and analyzing experimental data and forecasting and estimating an accident. The equipment and the method of the invention can be used for carrying out experimental study on generation and development mechanism, ventilation, smoke discharge, control and prevention of the cavern fire in the hydraulic and hydro-power engineering, and providing reasonable and correct scientific proofs for engineering design and operation of underground caverns construction and fire safety of construction.

Owner:CHINA ACAD OF SAFETY SCI & TECH

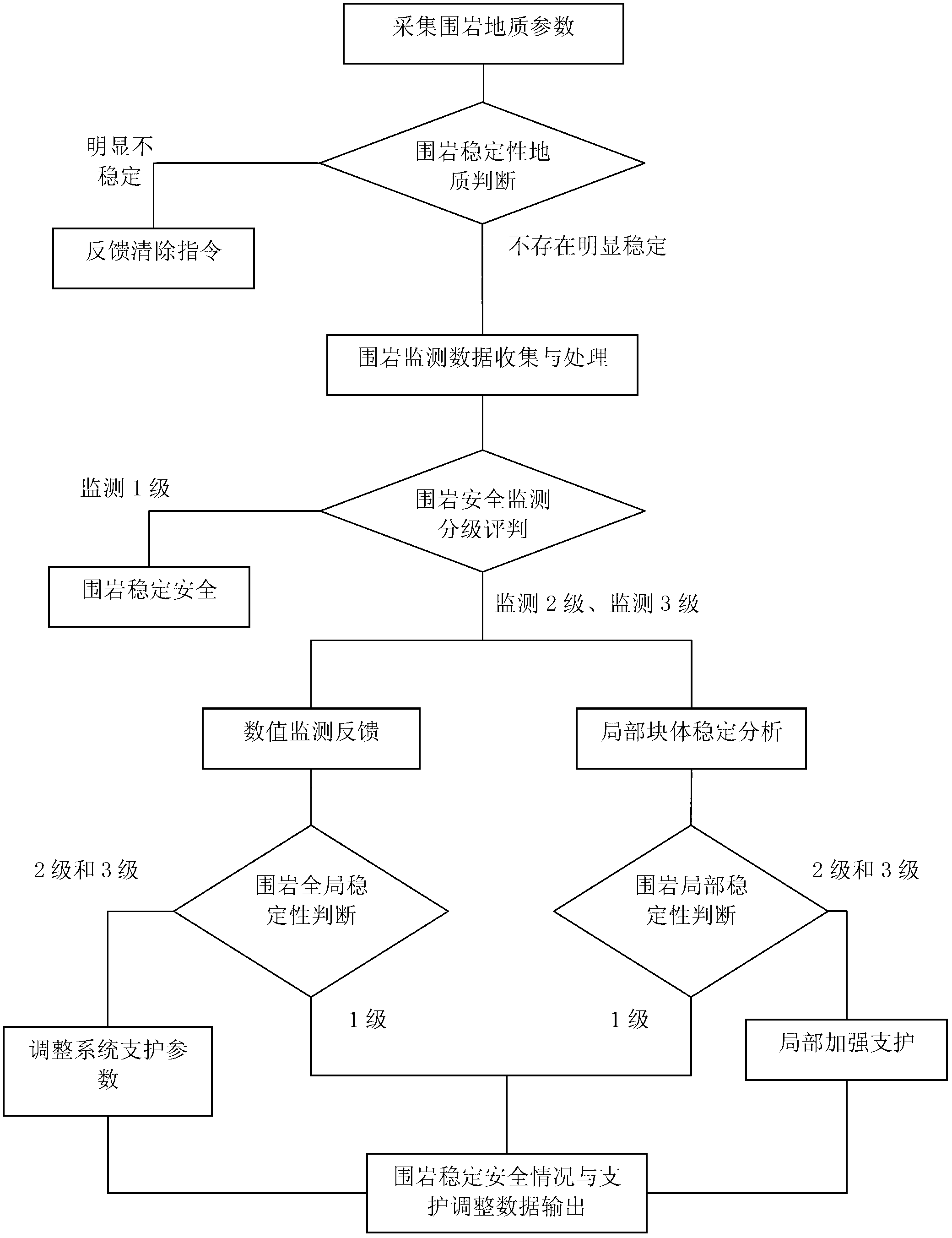

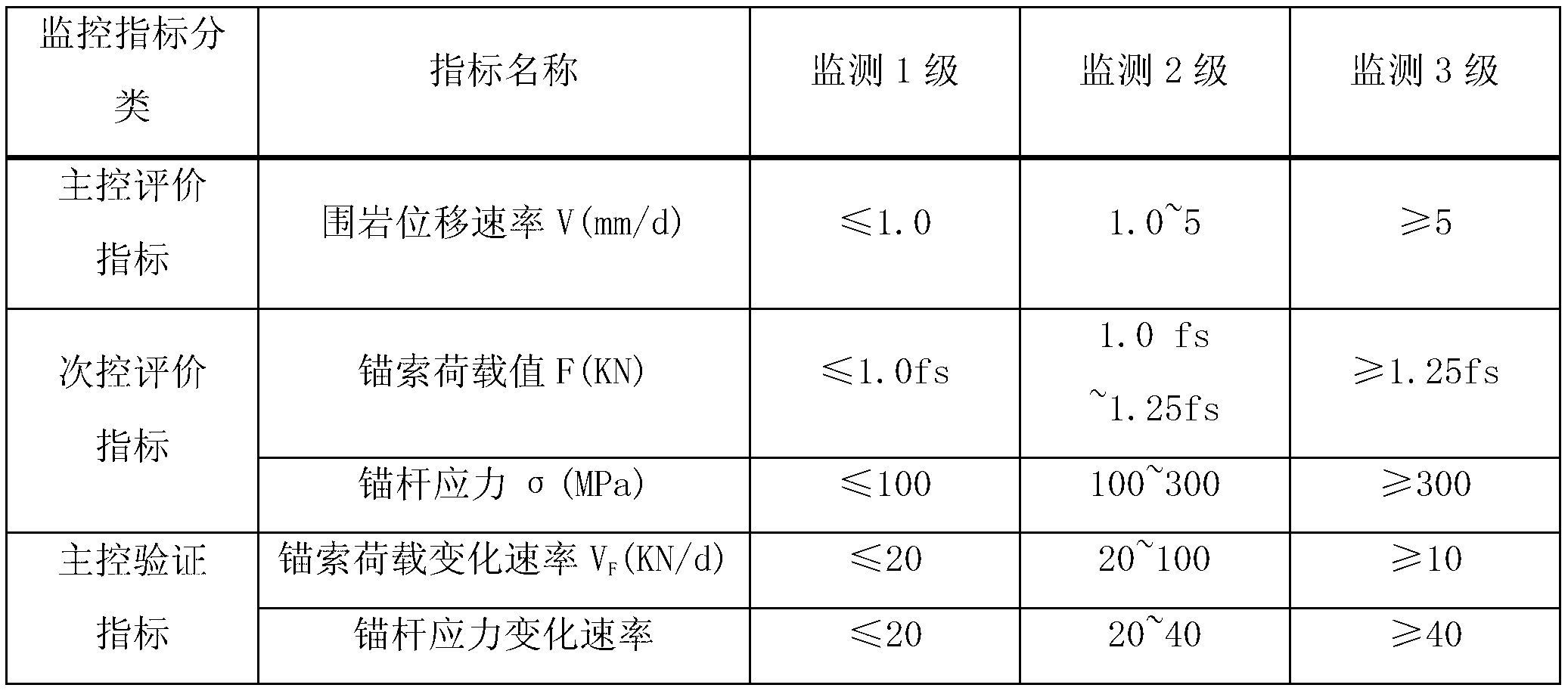

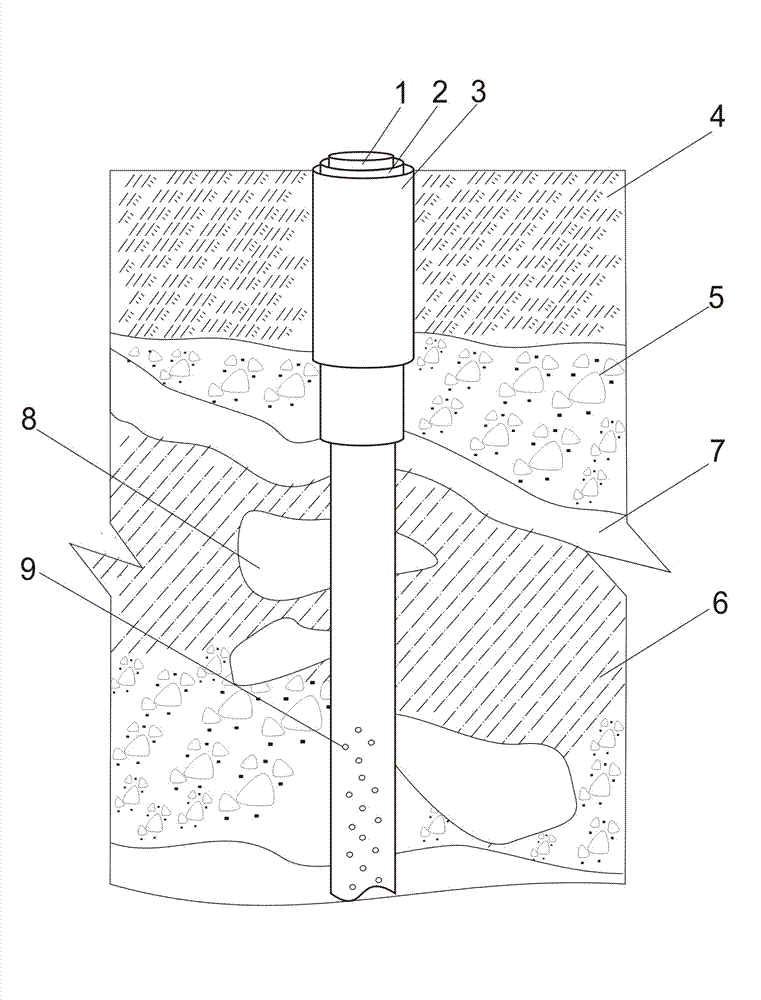

Method for quantitatively evaluating surrounding rock stability of ultra-large underground cavern group in construction period

ActiveCN103233741AGuarantee smooth constructionIntuitive and accurate stability judgment dataTunnelsUnderground cavernCollection methods

The invention relates to a method for monitoring the surrounding rock stability of an ultra-large underground cavern group in a construction period, in particular to a method for monitoring the surrounding rock stability of an ultra-large underground cavern group and used in a hydropower station construction period. The method includes the following steps: collecting geological parameters of surrounding rock through various geological collection methods, judging whether the geology of the surrounding rock is instable remarkably according to the collected geological parameters, processing the collected geological parameter information on yes judgment and grading the processed data with each grade of data corresponding to the preset stability degree judging value. The method for effectively and quantitatively evaluating the surrounding rock stability of the ultra-large underground cavern group in the construction period has the advantages of being capable of acquiring directly-perceived accurate stability judgment data and favorable for stabilizing the surrounding rock, ensuring construction safety and guaranteeing smooth engineering construction and long-term safe stable operation. The method is especially suitable for monitoring the surrounding rock stability of the ultra-large underground cavern group in the construction period.

Owner:POWERCHINA CHENGDU ENG

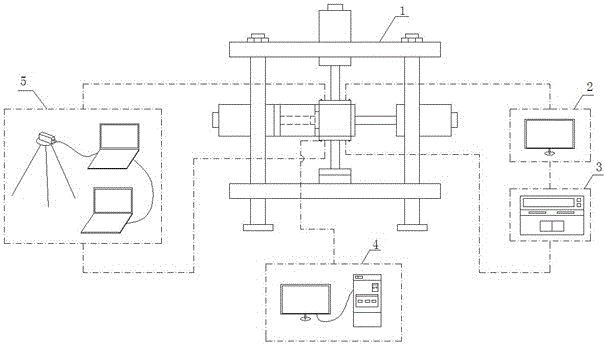

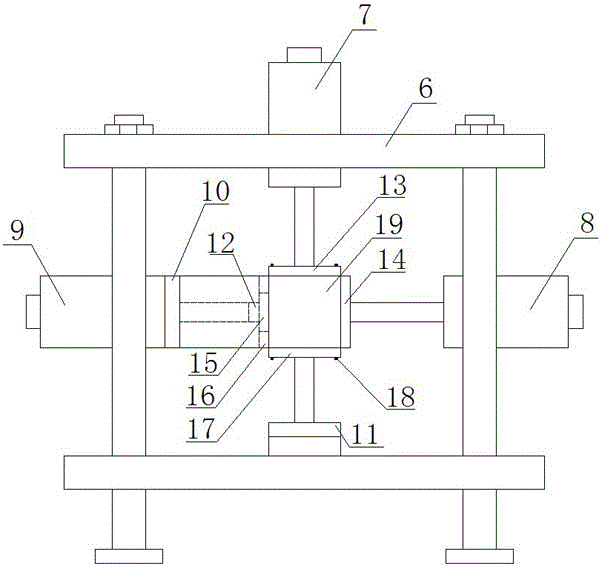

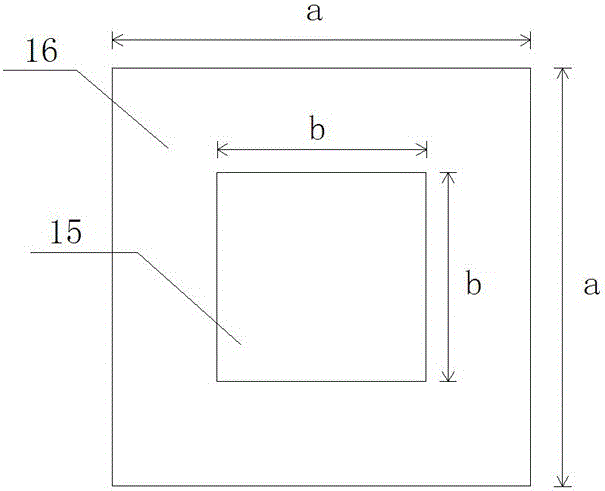

Unilateral unloading test device for brittle rock in biaxial stress state and test method of unilateral unloading test device

ActiveCN106053238AMaterial strength using tensile/compressive forcesAutomatic controlData acquisition

The invention discloses a unilateral unloading test device for brittle rock in a biaxial stress state and a test method of the unilateral unloading test device. The device comprises a two-axis servo control real-time loading and unloading system, a stress-strain monitoring system, an automatic control and data acquisition system, an acoustic emission monitoring system and a portable image acquisition and analysis system, wherein a confining pressure state in a stratum under certain conditions as well as a unilateral excavation unloading operating condition of an underground cavern in a construction process can be simulated; the overall stress-strain level of a rock sample is recorded by the stress-strain monitoring system; a local unilateral unloading rate is controlled and fed back by the automatic control and data acquisition system; the acoustic emission monitoring system and the portable image acquisition and analysis system monitor crack initiation, expansion, opening and closing features of cracks in a unilateral unloading region and an influence domain of the unilateral unloading region in the whole process and observe and analyze a formation and expansion mechanism of the cracks, and theoretical basis and experimental basis are provided for research of cavern side wall splitting failure caused by excavation unloading.

Owner:HOHAI UNIV

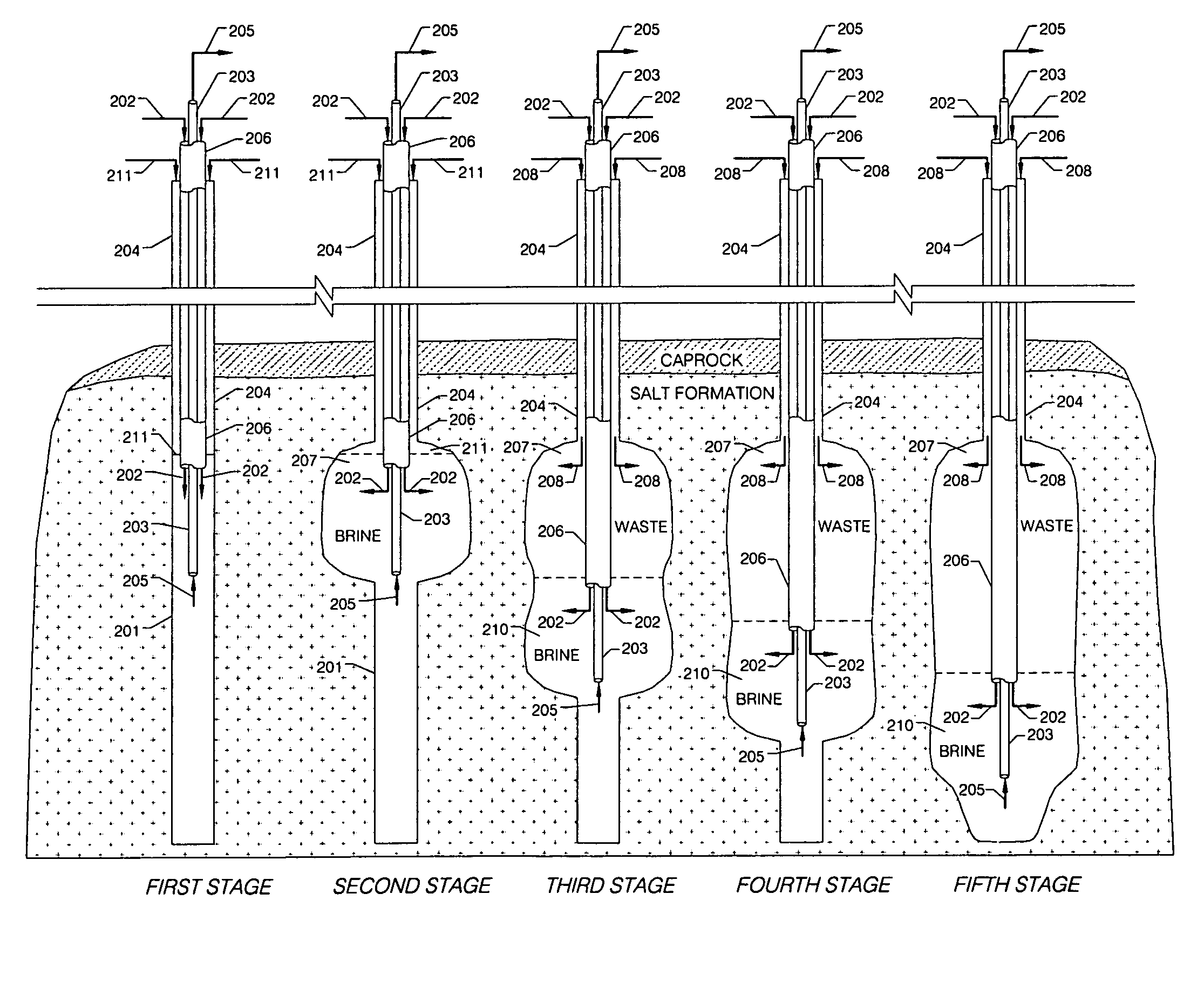

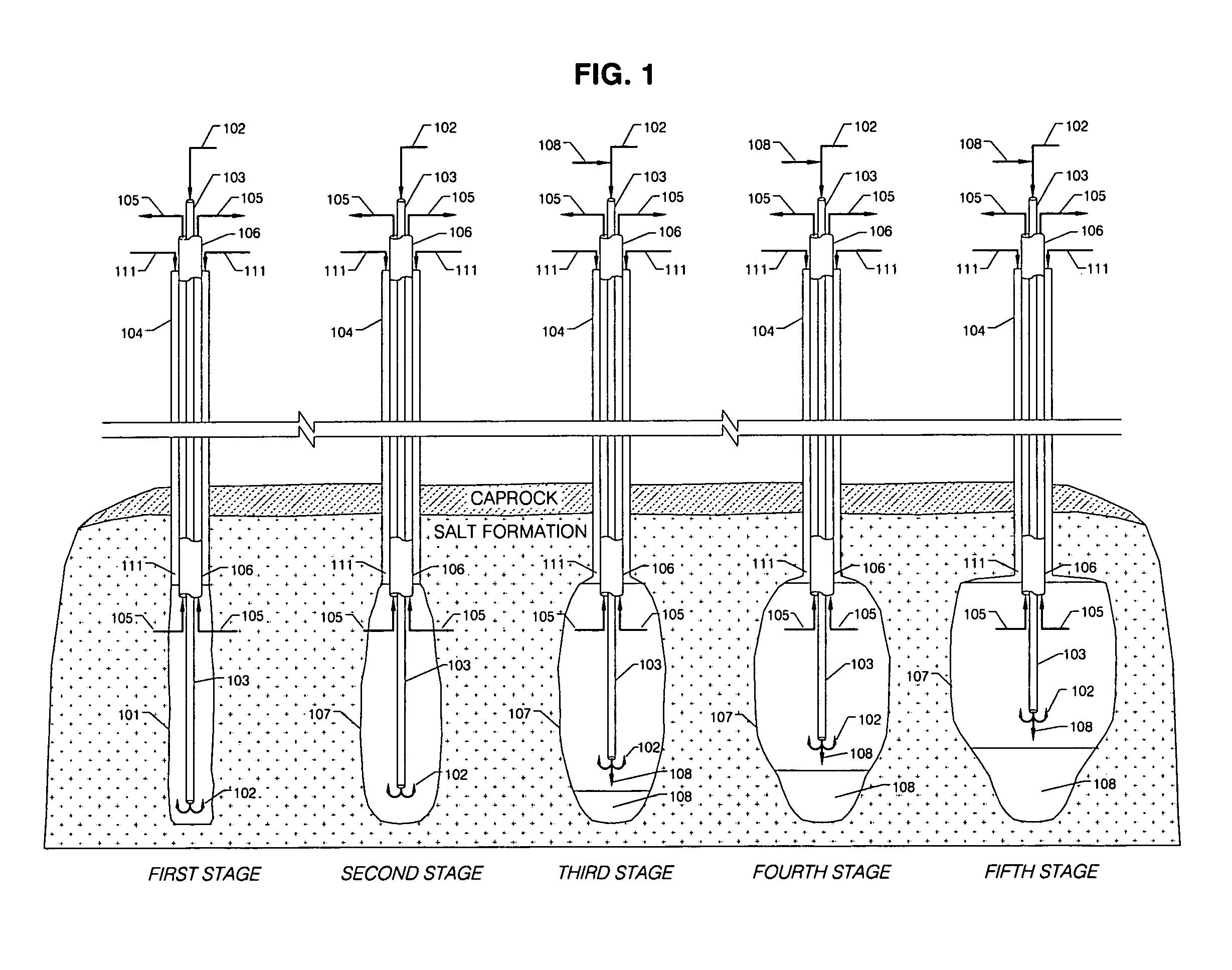

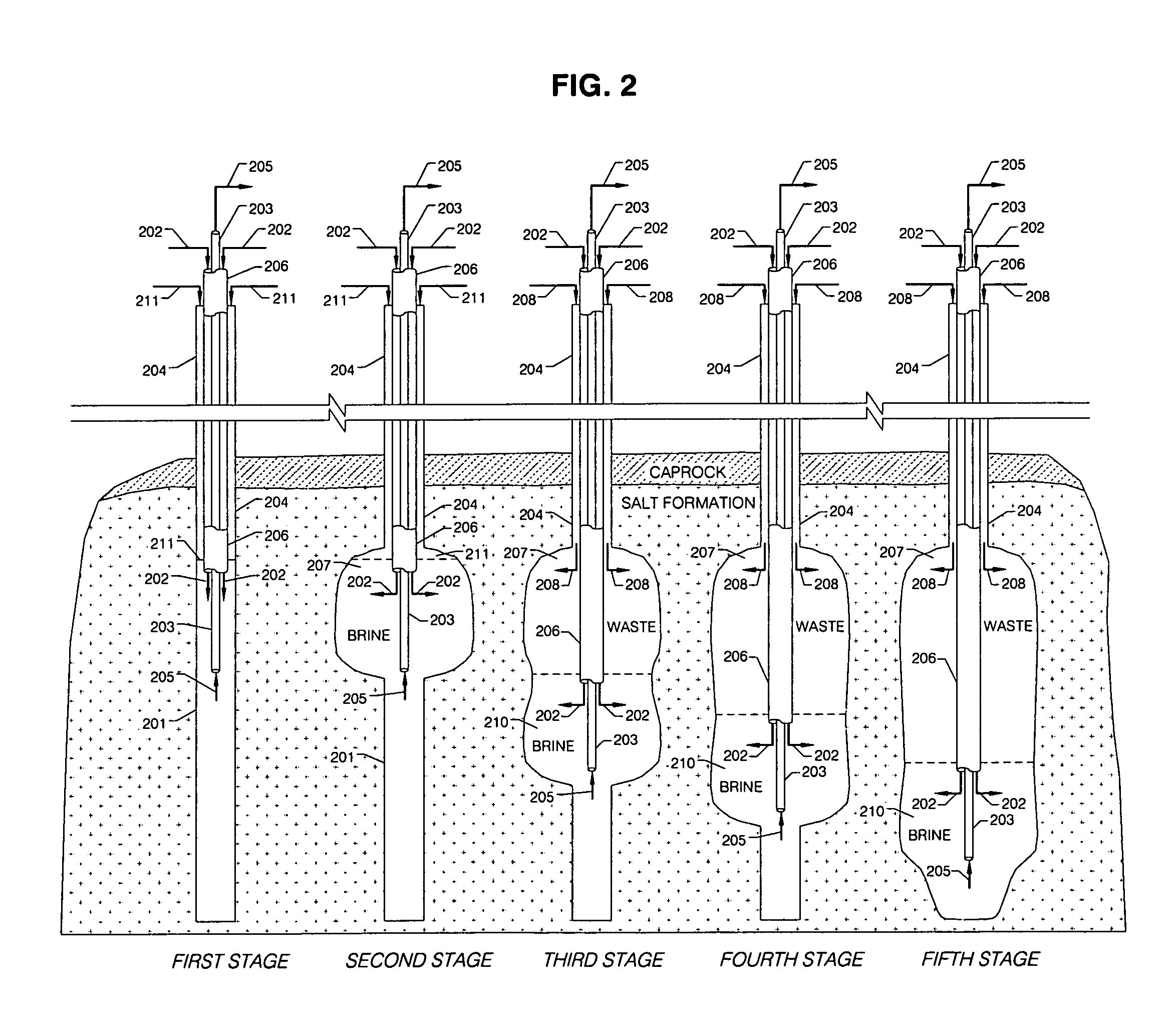

Simultaneous development of underground caverns and deposition of materials

A method is provided for simultaneously developing caverns while depositing wastes or other materials in them. A well is first drilled into a salt formation and the development of a salt cavern by means of solution mining is initiated. When the development of the cavern has been carried out to an extent sufficient to accommodate the injection of a prescribed amount of wastes or other materials, injection of the wastes or other materials through the well is started while continuing to develop the cavern by solution mining. The injection of the wastes or other materials may be carried out continuously or intermittently. The proportion and rates of wastes or other materials and mining water injected into the well are monitored and regulated so that cavern development continues at a rate that allows the cavern to reach an intended prescribed size while the wastes or other materials are injected and deposited into the cavern.

Owner:MPEH LLC

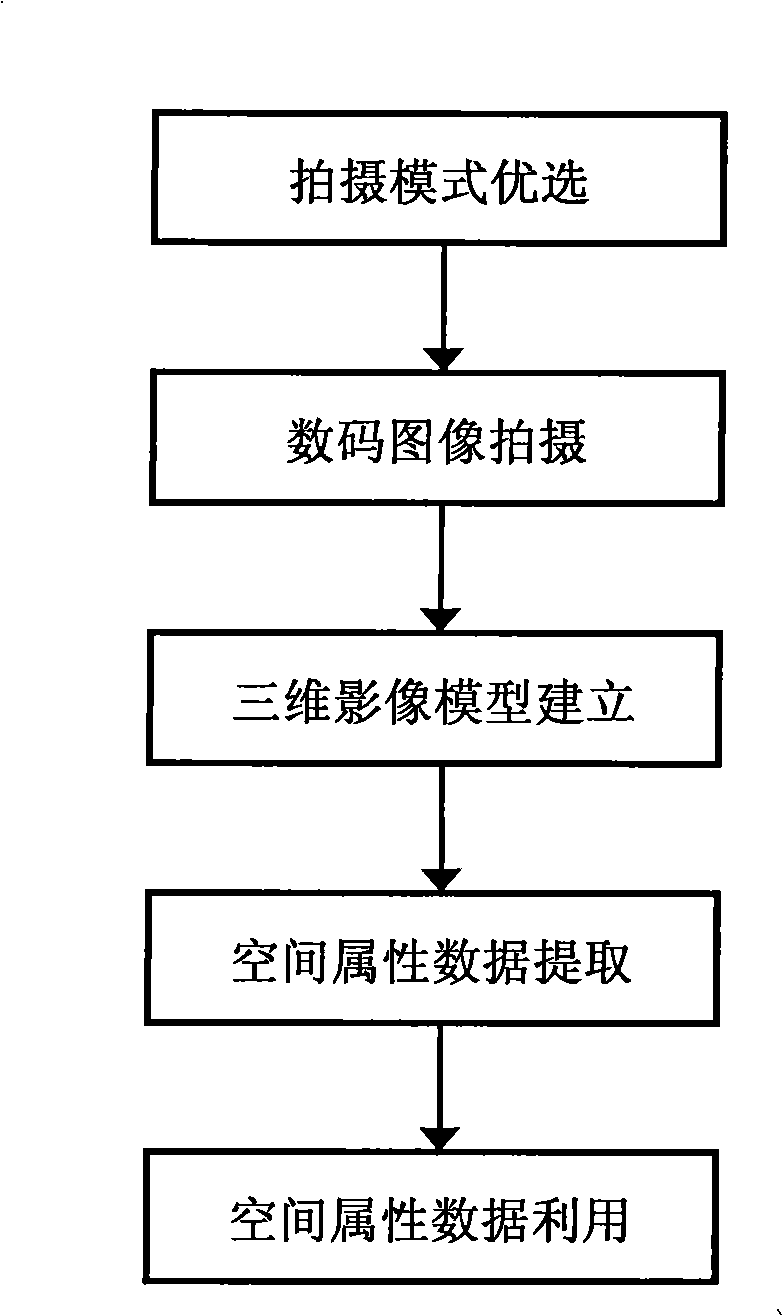

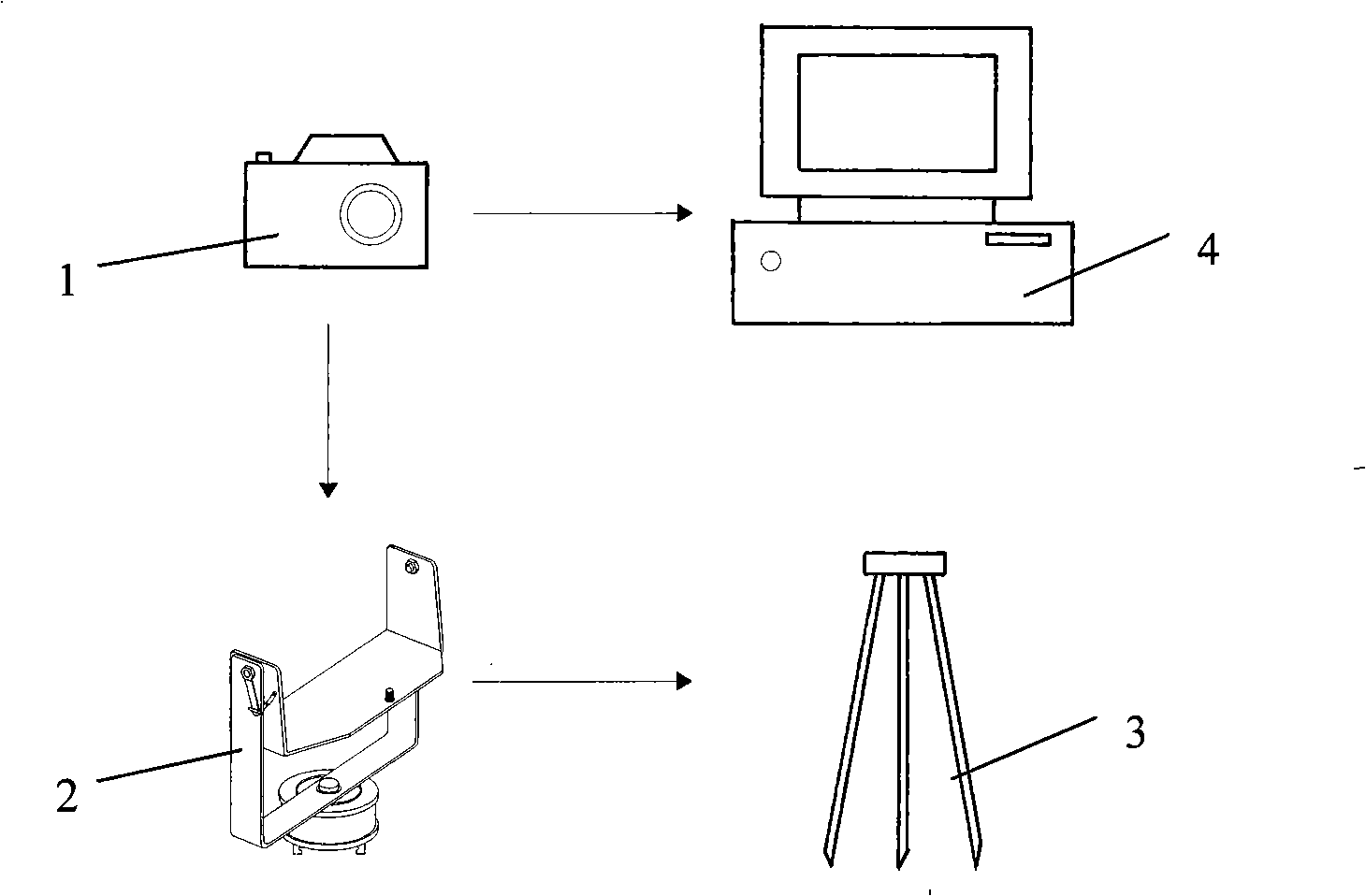

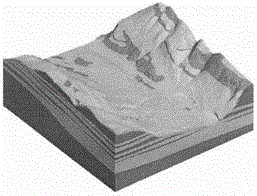

Digital remote sense geological mapping process and device

ActiveCN101334278AEasy to operateApplicable resultsPicture interpretationUnderground cavernSteep slope

The invention relates to a method and a device for digital remote sensing geology mapping, the technical problem to be solved by the invention is to provide a method for digital remote sensing geology mapping based on the techniques, such as digital photogrammetry, digital image processing, and static three-dimensional image establishment and engineering geology analysis, etc. The technical proposal to solve the problem is: A) the preference of shooting modes, one corresponding mode of three shooting modes which are a basic mode, an extended mode and a strip-map mode, is selected according to three site conditions which are a high and steep slope, foundation pit excavation and an underground cavern; B) the shooting of digital images; C) the establishment of a three-dimensional image model; D) the extraction of spatial attribute data; and E) the utilization of the spatial attribute data. The method and the device of the invention can be applied to the geology mapping (logging) of the high and steep (rock) slope, the foundation pit excavation and the underground cavern in various constructions, such as water conservancy, hydroelectric power, transportation and mines, etc.

Owner:ZHEJIANG HUADONG ENG DIGITAL TECH CO LTD

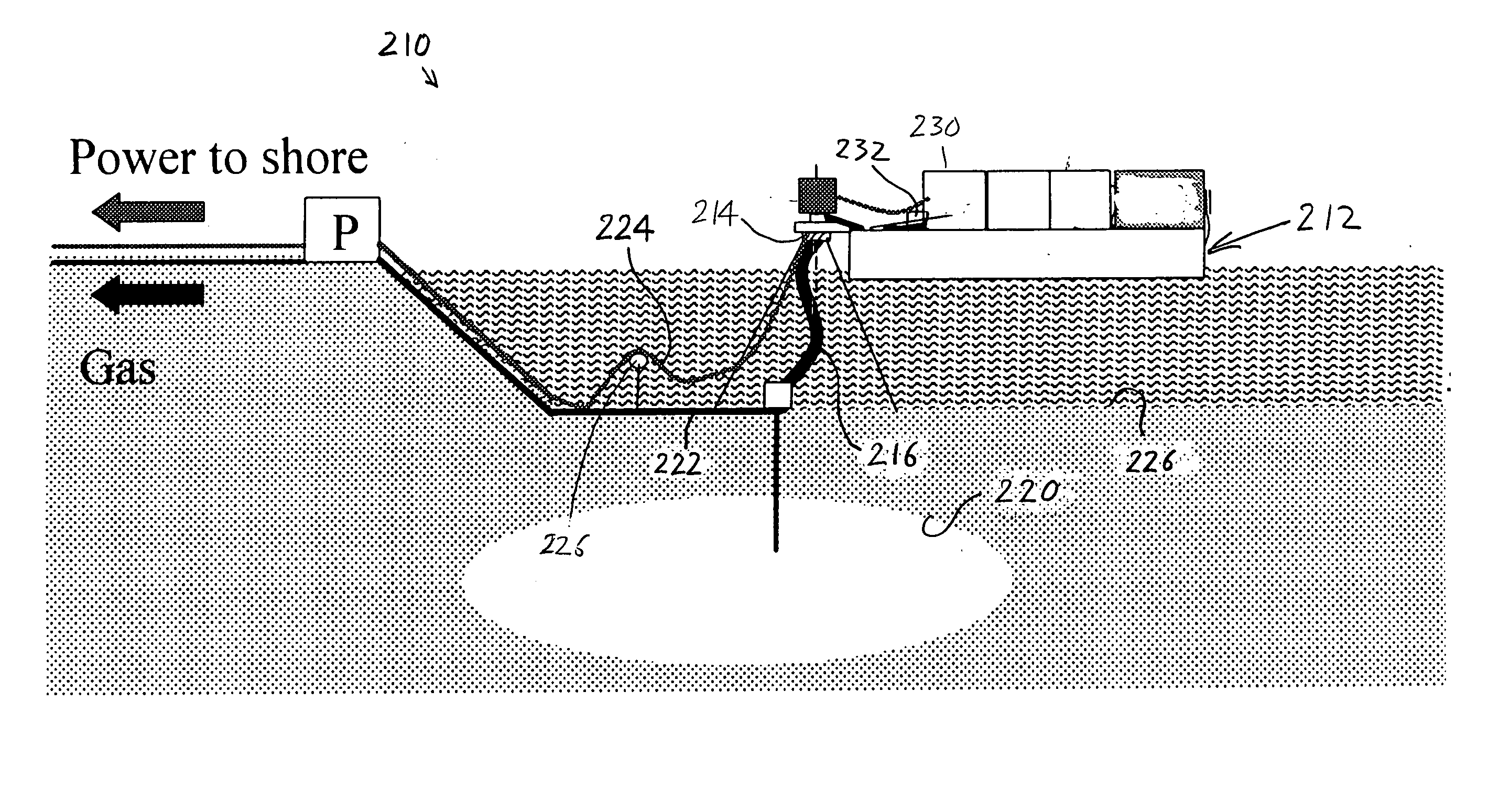

Gas offloading system

ActiveUS20050061395A1Easy to passGas handling applicationsGas handling/storage effectsElectricityOcean bottom

A system is described for offloading LNG (liquified natural gas) from a tanker for eventual delivery to an onshore gas distribution station. The system includes a floating structure that floats at the sea surface and that is connected to the tanker so they weathervane together. The floating structure carries a regas unit that heats the LNG to produce gas, and delivers the gas through a riser to an underground cavern that stores the gas. Gas from the cavern is delivered through a seafloor pipeline to an onshore gas distribution station. The regas unit includes water pumps and other equipment that is powered by electricity. The electricity can be obtained from an electric generator on the floating structure, with surplus electricity delivered through a sea floor electric power line that extends along the sea floor to an onshore electricity distribution facility. The electricity can instead be obtained by delivery from an onshore facility though a sea floor electric power line that extends up to the floating structure and to the regas unit.

Owner:SINGLE BUOY MOORINGS INC

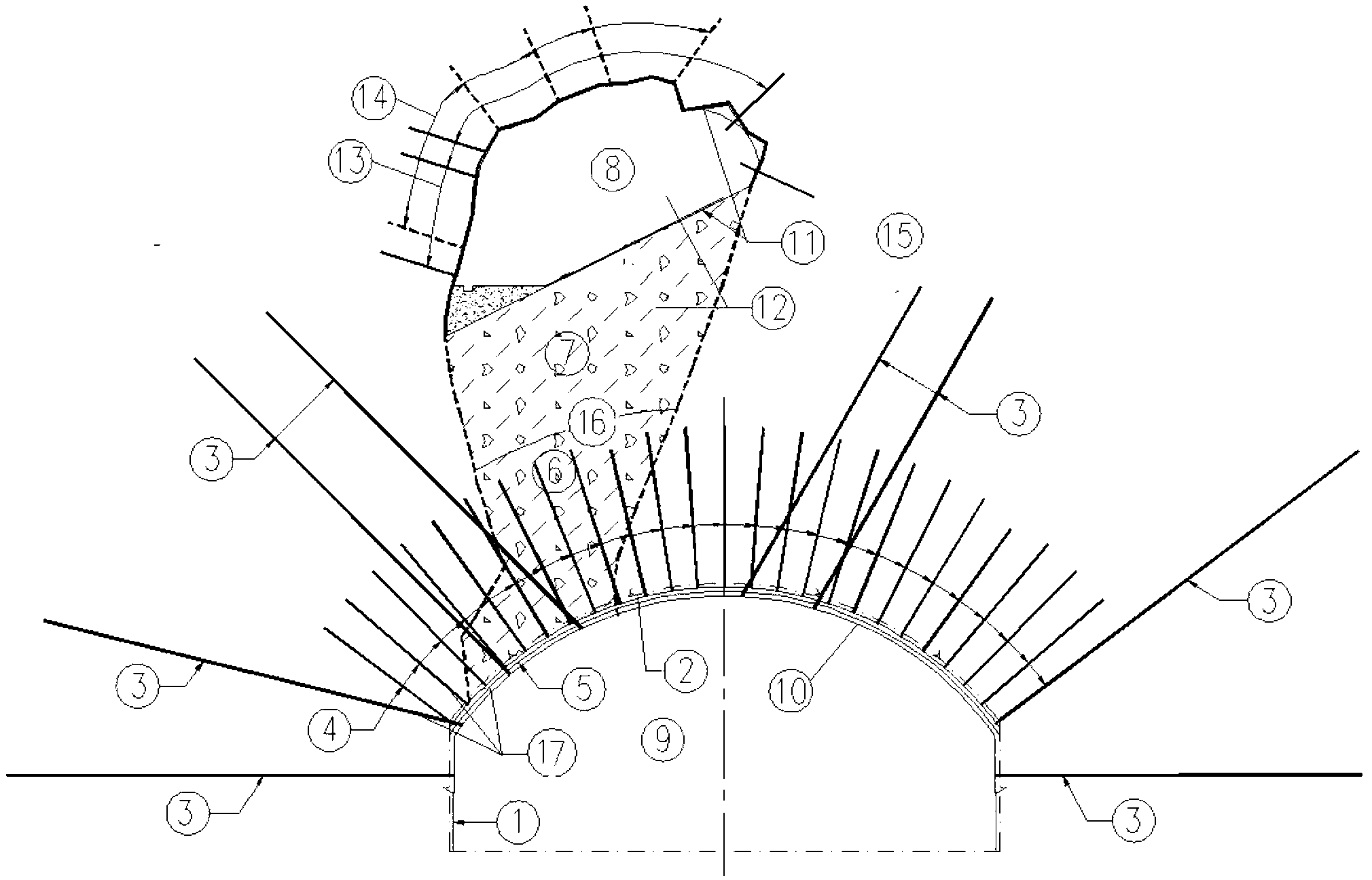

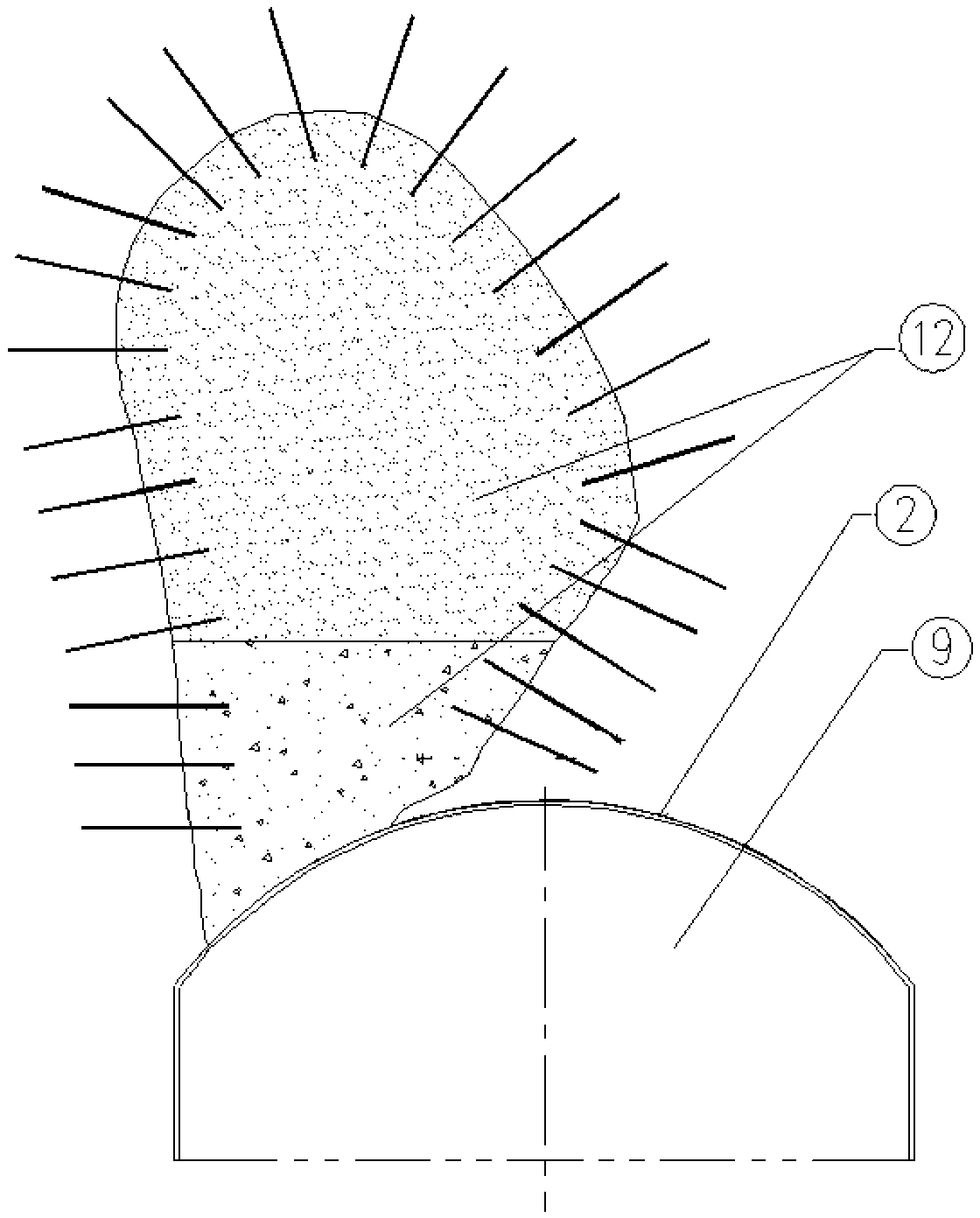

Method of treating lining after collapse of underground cavern crown

ActiveCN103321653ASave engineering investmentShorten the construction periodUnderground chambersTunnel liningUnderground cavernBeam matching

The invention discloses a method of treating a lining after collapse of an underground cavern crown, relates to the field of underground cavern construction, and provides a method of treating the lining after collapse of the underground cavern crown, with low workload, low cost and effective collapse prevention. The method includes the steps of a, clearing collapse waste in the cavern; b, inserting at least one reinforcing anchor bar into the residual collapse waste and surrounding rock on two sides of the residual collapse waste, and allowing one end of each reinforcing anchor bar, close to the cavern, to be located in the same cross section; c, connecting an arch beam matching with the cross section of the cavern crown in shape to all reinforcing anchor bars, and attaching the arch beam to the cavern crown; d, subjecting the residual collapse waste to systematic consolidation grouting; and e, repeating the steps from a to d until the collapse waste in the cavern is fully cleared. The method is applicable to repairing collapsed underground caverns.

Owner:POWERCHINA CHENGDU ENG

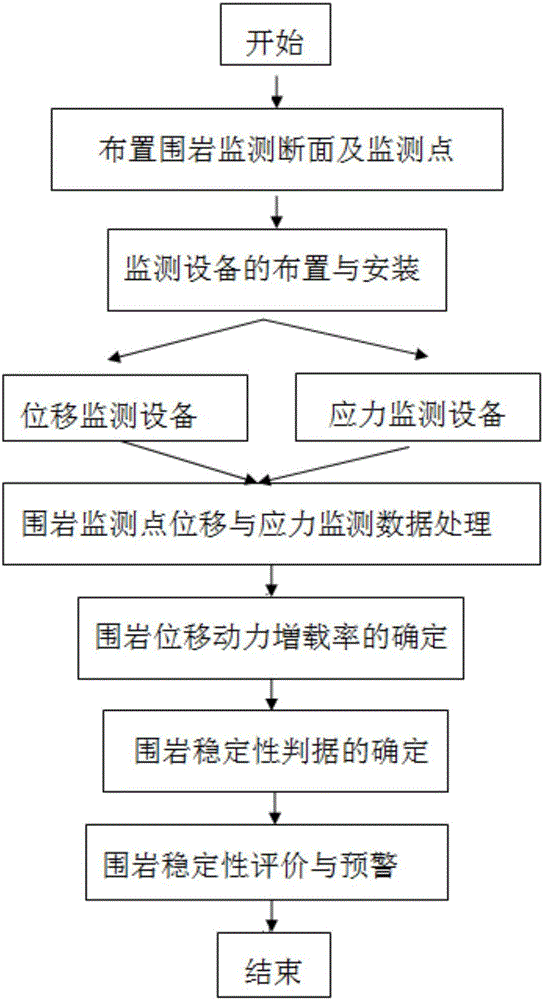

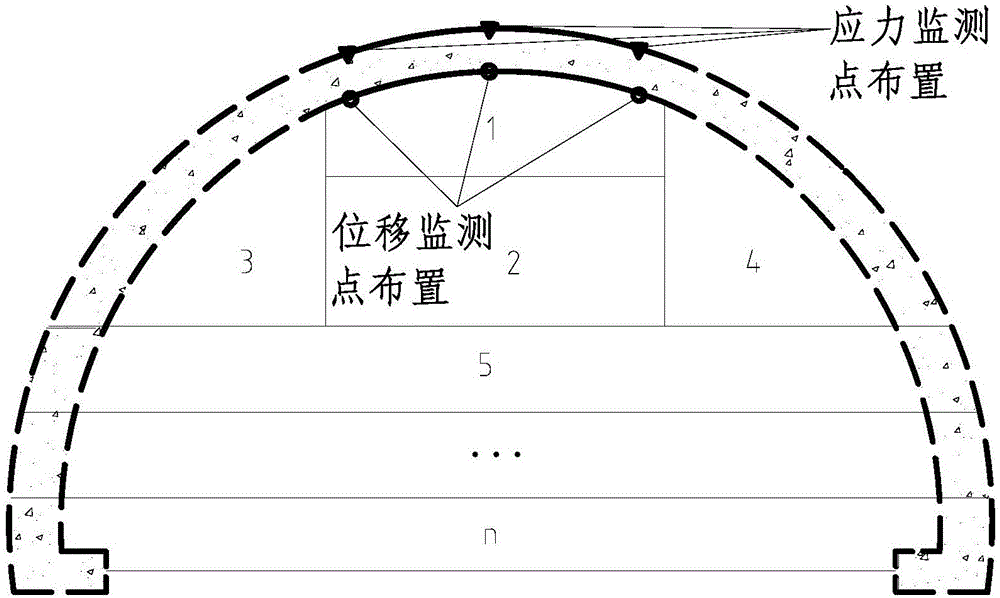

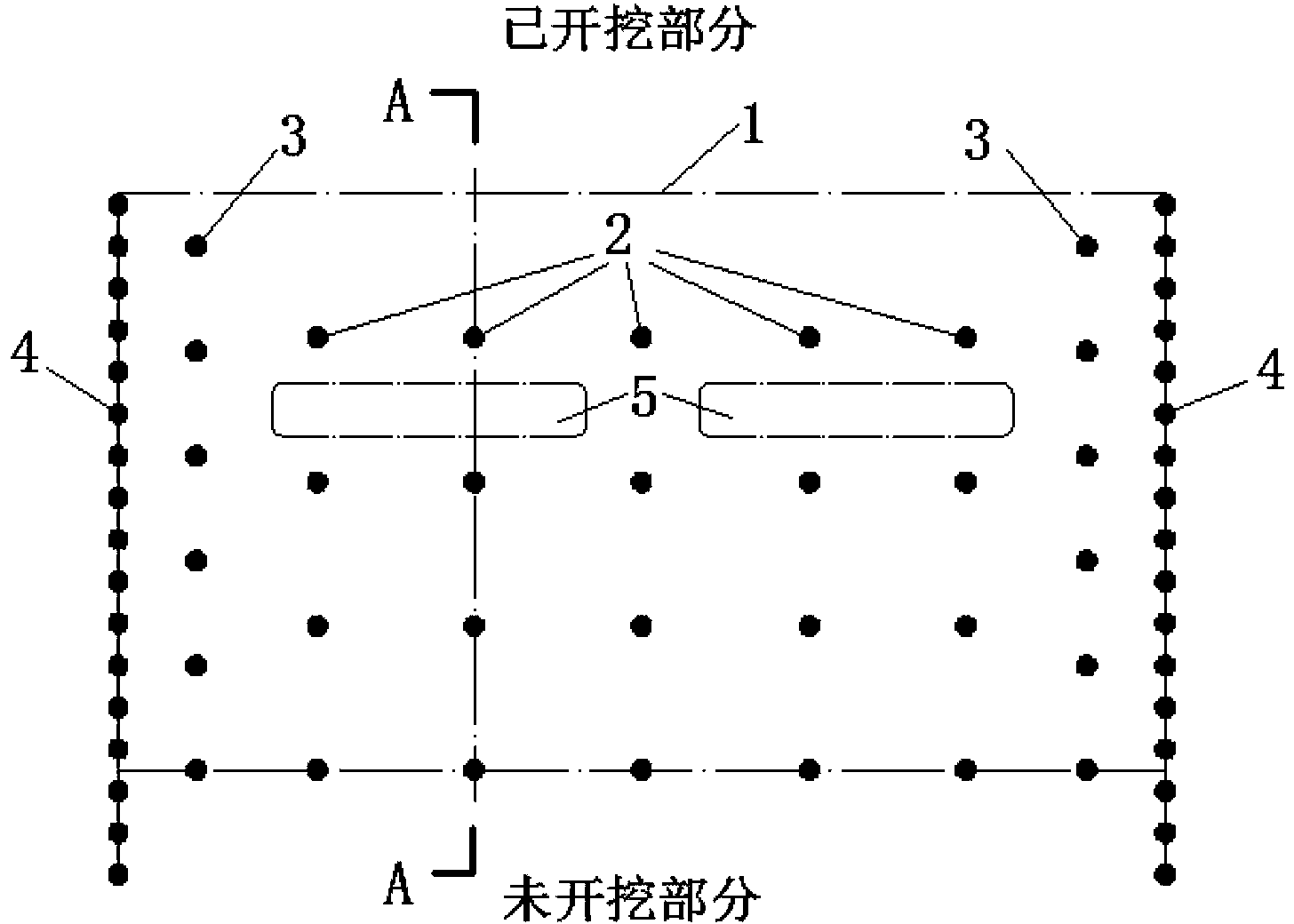

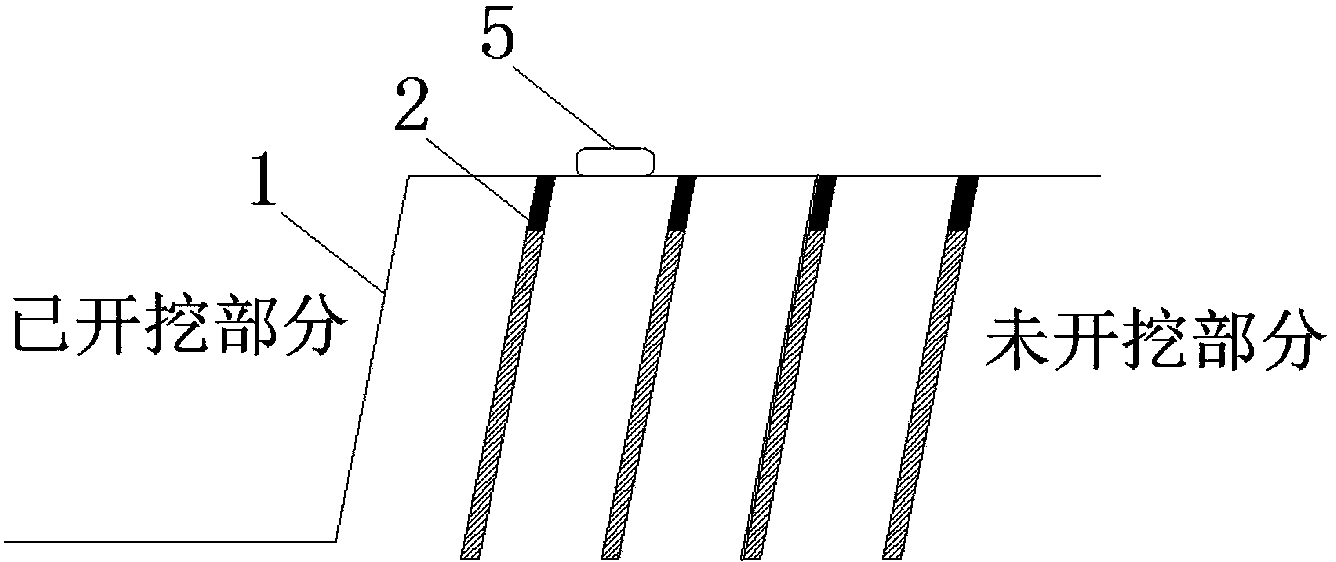

Large-span underground construction surrounding rock excavation stability monitoring and early warning method

ActiveCN104989456AReflect stressReflect displacement changesMining devicesUnderground cavernDeformation monitoring

The invention discloses a large-span underground construction surrounding rock excavation stability monitoring and early warning method. The method comprises the steps that a surrounding rock monitoring section is selected, and section monitoring points are arranged; a surrounding rock deformation monitoring device and a stress monitoring device are installed; the surrounding rock deformation monitoring device and the stress monitoring device are applied according to the stability conditions of the surrounding rock at different stability stages, and the stress and displacement of corresponding monitoring points of the different excavation stages are monitored; the surrounding rock excavation displacement power load increasing rate eta i is determined and serves as the surrounding rock excavation stability evaluation parameter, and evaluating and early warning are conducted on the surrounding rock stability. The large-span underground construction surrounding rock excavation stability monitoring and early warning method has the advantages that the underground cavern surrounding rock excavation monitoring area stress change parameter and the corresponding displacement response parameter are organically coupled, the parameters can reflect the dynamic change rule of the surrounding rock stability along with the excavation construction, and analysis and prediction can be carried out on the future surrounding rock excavation deformation development rule and the stability evolutionary trend.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Multi-casing structure capable of facilitating bridge-pile construction in cavern development areas and construction method thereof

InactiveCN103195058ASolve the problem of severe excessGuarantee quality and safetyBulkheads/pilesUnderground cavernStrength of materials

Disclosed are a multi-casing structure capable of facilitating the bridge-pile construction in cavern development areas and a construction method thereof. The multi-casing structure is characterized in that the thicknesses of steel plates of casings are computed through material mechanics formulas; the length of an internal casing is spliced into the designed depth of the pile foundation of a bridge-pile according to the thicknesses of required steel plates; the length of an external first casing is spliced into the distribution depth of an underground cavern though a plurality of groups of steel casings; and the diameters of the casings are designed into that the inner diameter of the internal casing is equal to the designed pile diameter of the bridge-pile and the diameter of the external first casing is 25-35 centimeters larger the designed pile diameter of the bridge-pile during a dual-casing construction. The construction method comprises transporting every groups of the casings to the position of a pile hole though a 25-ton crane; hoisting a first group of the casing to settle through a 60-ton main crane; penetrating a steel bar manually and placing a steel casing on a #-shaped frame; changing slings; hoisting a second group of the casing; subjecting the pile hole to welding; subjecting the steel casing to a second assembly; hoisting the steel casing up lightly; and disassembling the steel bar to enable the steel casing to settle. Therefore, the problem of severe over-quantity of concrete of the bridge-pile construction in the cavern overdevelopment areas is completely solved, and the construction cost can be effectively controlled under the premise of guaranteeing the construction quality and the construction security.

Owner:SICHUAN CHUANJIAO ROAD & BRIDGE

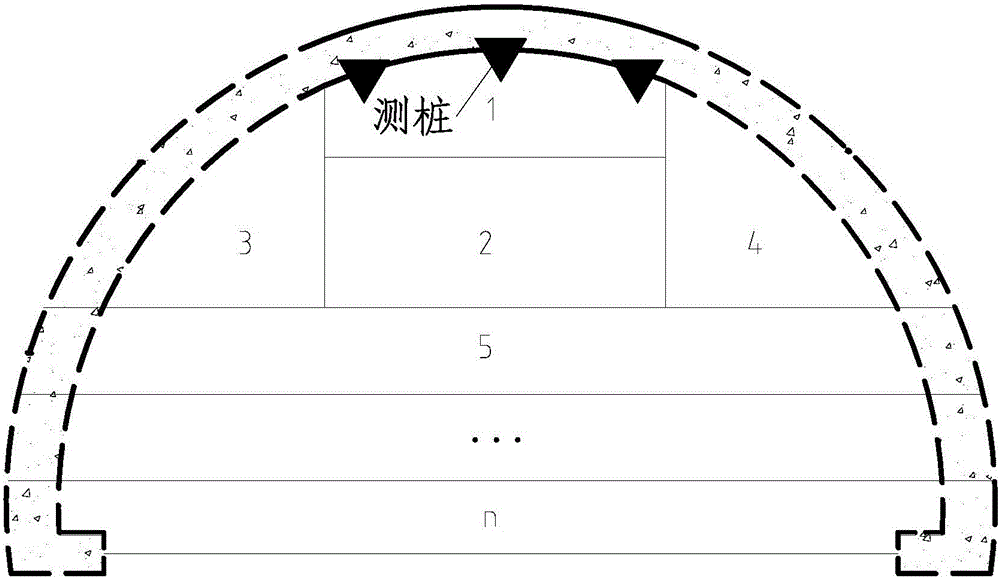

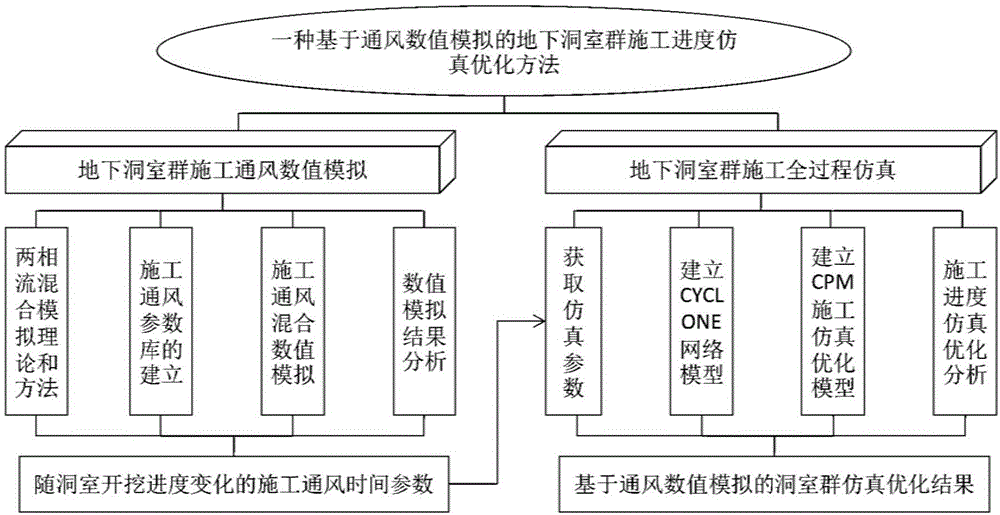

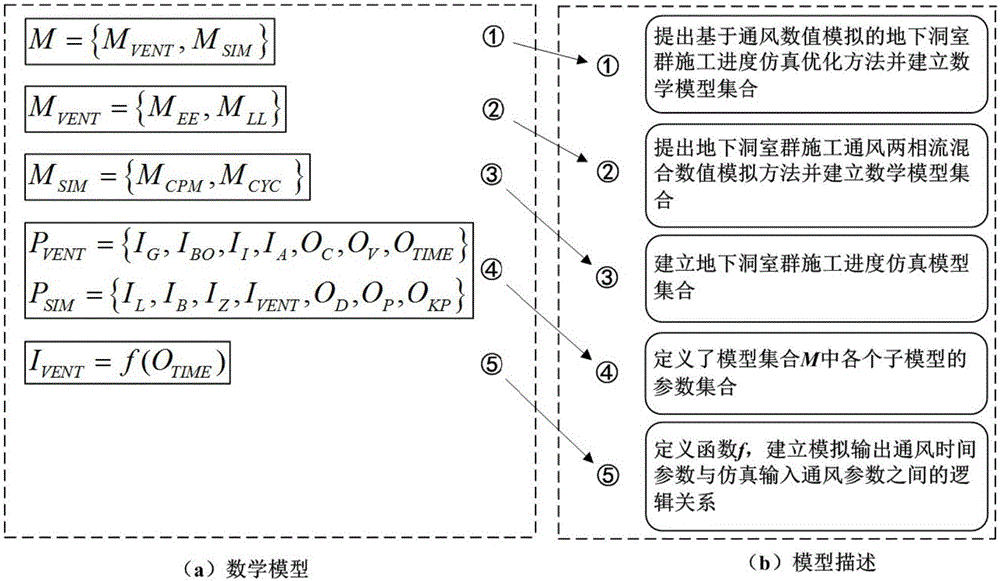

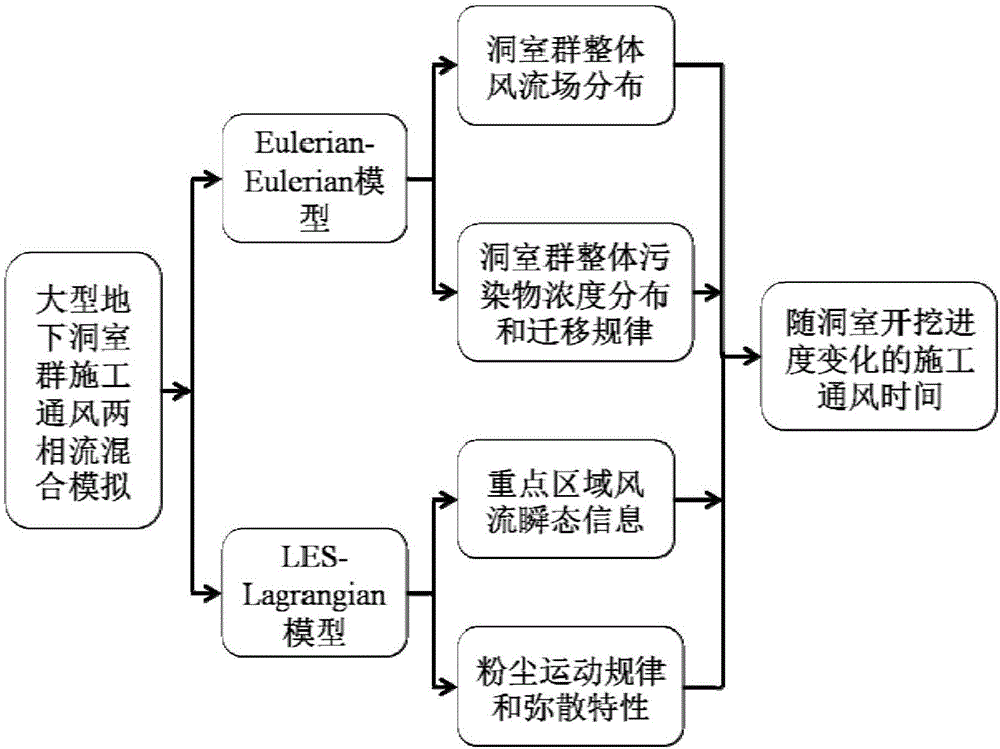

Underground-cavern-group-construction-schedule simulating optimization method based on ventilation numerical simulation

ActiveCN106777823AOptimization of construction resource intensityImprove construction progressGeometric CADDesign optimisation/simulationUnderground cavernMathematical model

The invention discloses an underground-cavern-group-construction-schedule simulating optimization method based on ventilation numerical simulation. The underground-cavern-group-construction-schedule simulating optimization method includes the following steps that (1) ventilation numerical simulation and the underground-cavern-group construction schedule are combined, and an underground-cavern-group-construction-schedule simulating optimization mathematical model based on ventilation numerical simulation is established; (2) an underground-cavern-group-construction-ventilation two-phase-flow hybrid simulation theoretical method is provided; (3) an underground-cavern-group-construction-ventilation numerical simulation parameter base is established; (4) an underground-cavern-group-construction-ventilation three-dimensional fine physical model is established, and grids are divided; (5) underground-cavern-group-construction-ventilation two-phase-flow hybrid simulation under different excavation schedules is achieved; (6) simulating optimization analysis of underground-cavern-group-construction whole process is carried out in cooperation with the ventilation numerical simulation result. According to the underground-cavern-group-construction-schedule simulating optimization method based on ventilation numerical simulation, the whole wind flow structure, pollutant space distribution and the dynamic variation rule in cavern groups are solved, and wind-flow-field transient pulsation information and the dust particle dispersion mechanism of ventilation difficulty areas can also be obtained.

Owner:TIANJIN UNIV

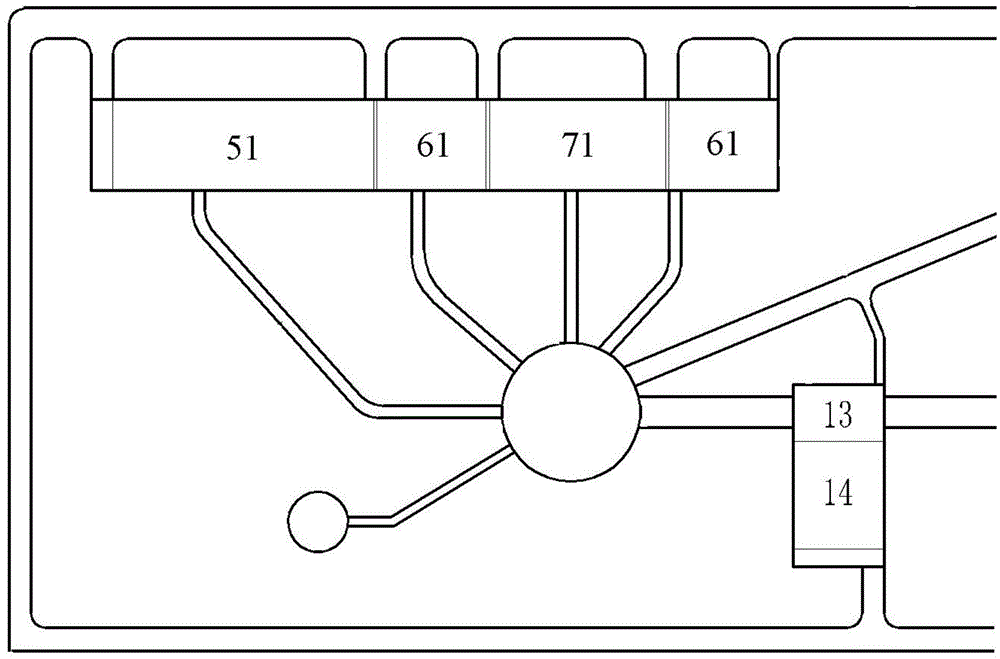

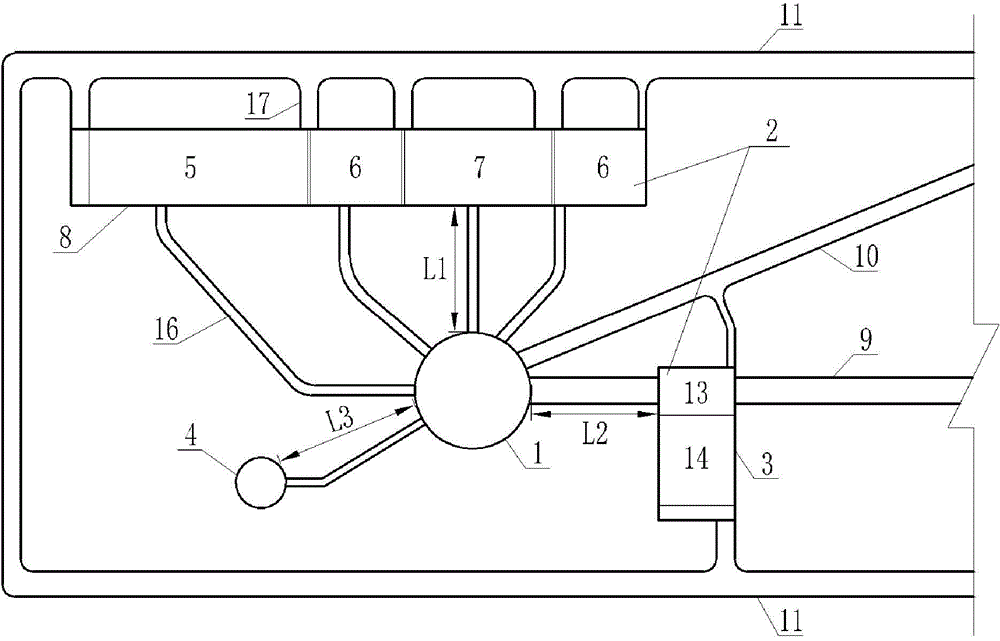

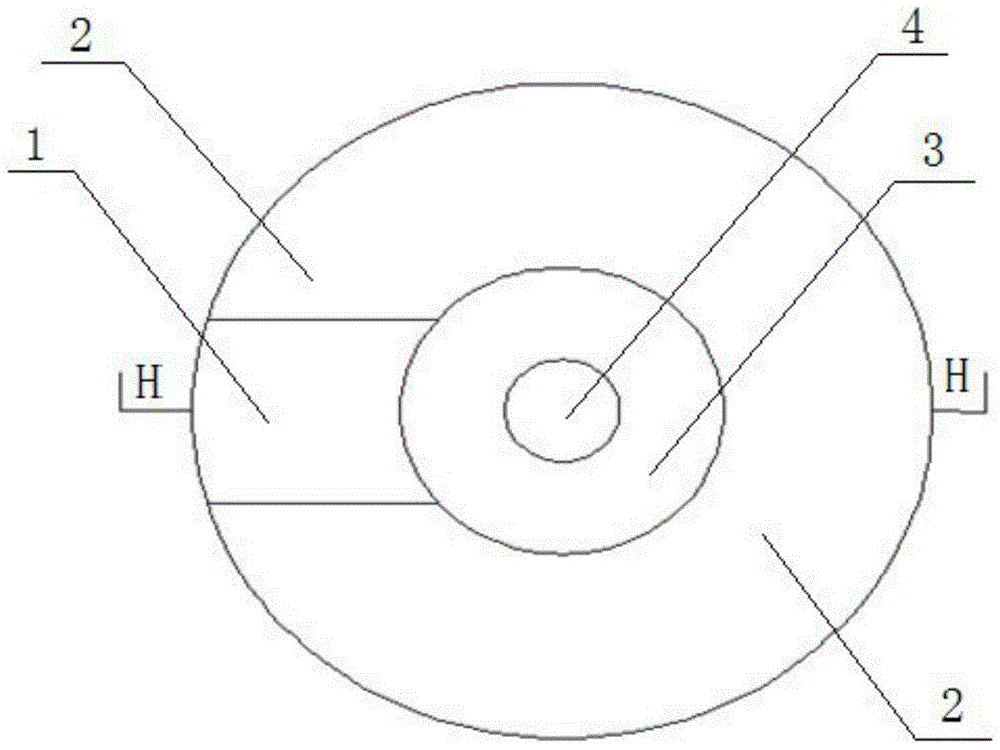

Underground cavern group layout method

ActiveCN103291331AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernTransformer

The invention discloses a large-scale underground cavern group layout method applied to water conservancy and hydropower engineering and underground storage cavern engineering. The underground cavern group layout method can give overall consideration to major factors having influences on underground cavern adjoining rock stability, particularly gives overall consideration to the crucial factor of the rock strength-stress ratio, enables a large-scale underground cavern group layout designing scheme to be scientific, and is overall in considered factors. The method includes the following steps: firstly, determining the positions of main caverns, then determining the axis directions of the main caverns, determining the thickness of a rock pillar between the main caverns, and finally determining cavern shapes of the main caverns. When the cavern shapes of the main caverns are determined, each main cavern is divided into an underground main power house, a main transformer chamber and a tail water surge chamber according to functions, the hole shape of each underground main power house and the hole shape of each main transformer chamber are in circular arch straight wall shapes or egg shapes, and each tail water surge chamber is in a cylinder shape or a gallery shape.

Owner:POWERCHINA CHENGDU ENG

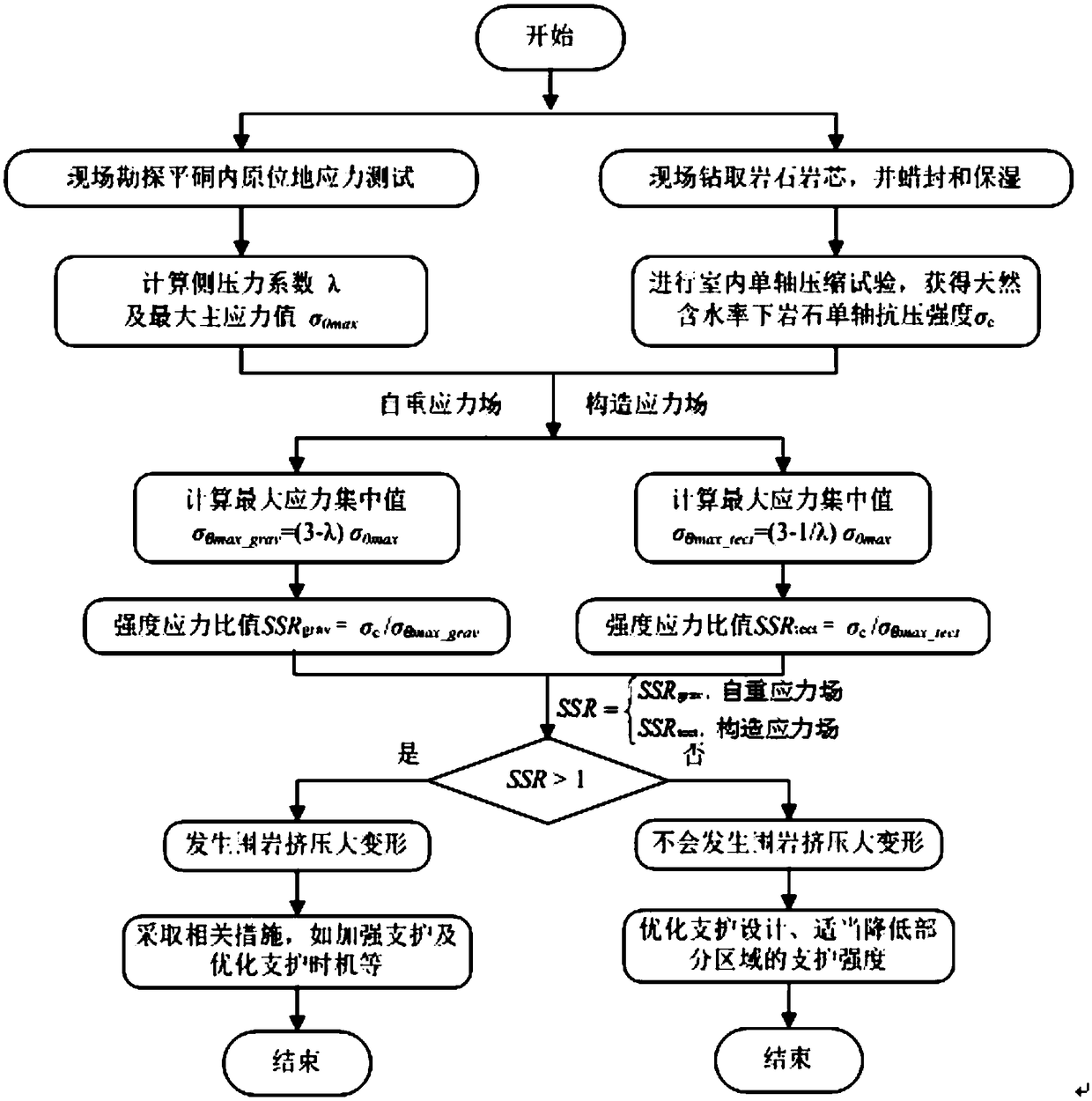

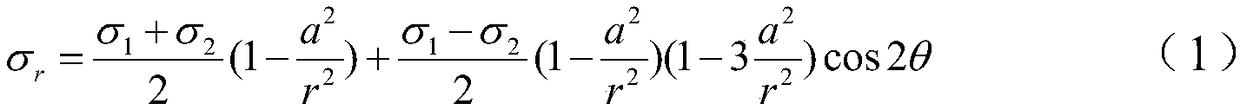

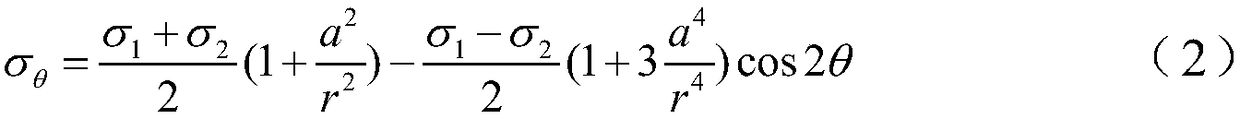

Large bury depth cavern extrusion surrounding rock large deformation discrimination method

ActiveCN108871262AAccurate and quick judgmentImprove stabilityMeasurement devicesPrincipal stressStress ratio

The invention discloses a large bury depth cavern extrusion surrounding rock large deformation discrimination method which can quickly and reliably predict large deformation of the calculation point of the deep buried cavern engineering surrounding rock. The method comprises the steps that the in-situ ground stress test is performed and the lateral pressure coefficient lambda and the maximum principal stress value sigma0max are acquired; the rock core is drilled and processed into the cylindrical rock sample; the uniaxial compression test is performed on the rock sample so as to acquire the rock uniaxial compressive strength sigmac under the natural water content; the self-weight stress field is calculated according to the stress environment of the underground cavern or the rock strength-to-stress ratio SSR under the stress field is constructed; and occurrence of surrounding rock extrusion large deformation is judged according to the acquired self-weight stress field or the rock strength-to-stress ratio SSR under the constructed stress field. The method is used for judgment and prediction of large bury depth cavern surrounding rock extrusion large deformation and can be used for stability evaluation of the bury depth cavern and optimization of the permanent support design.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

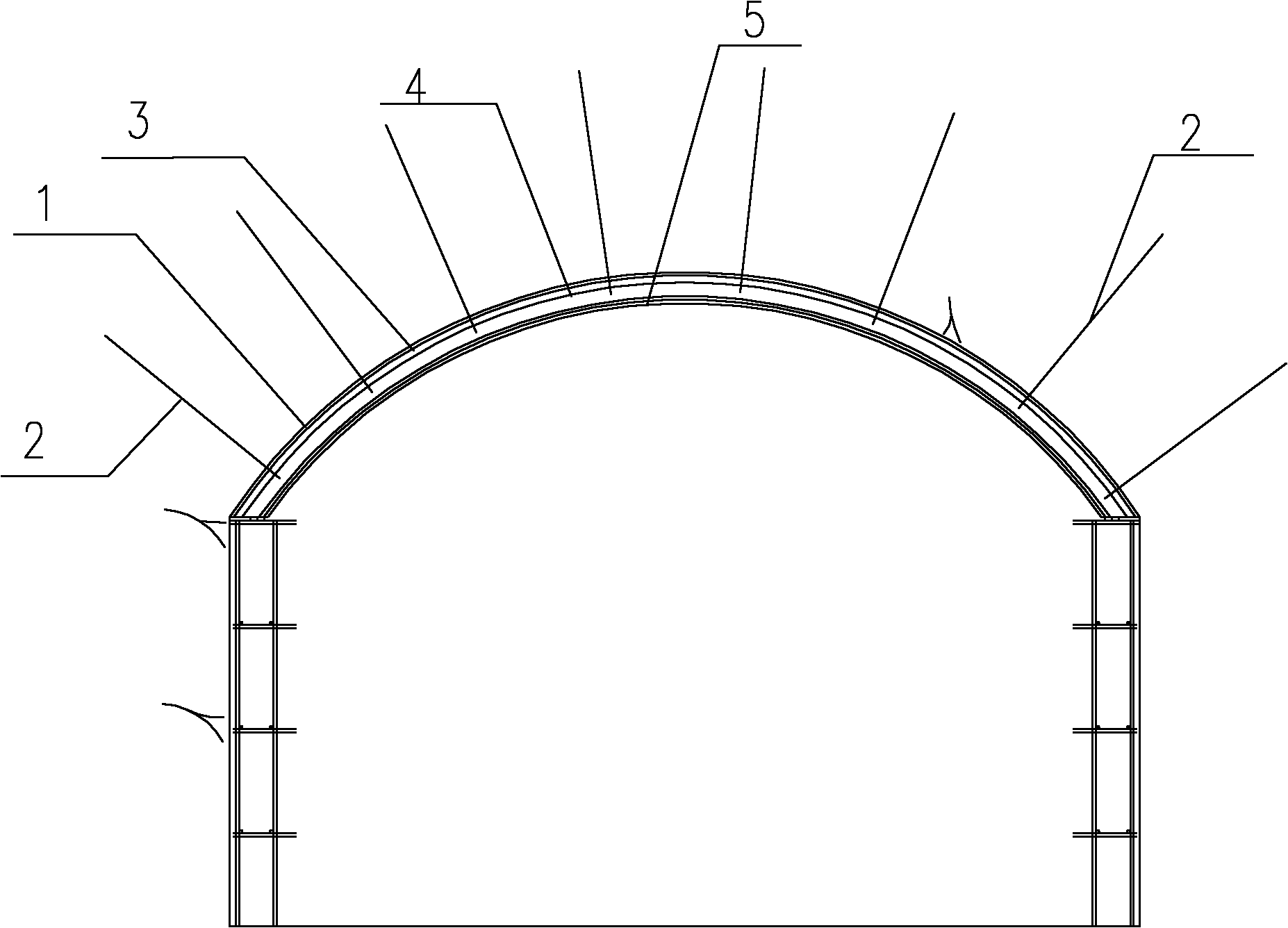

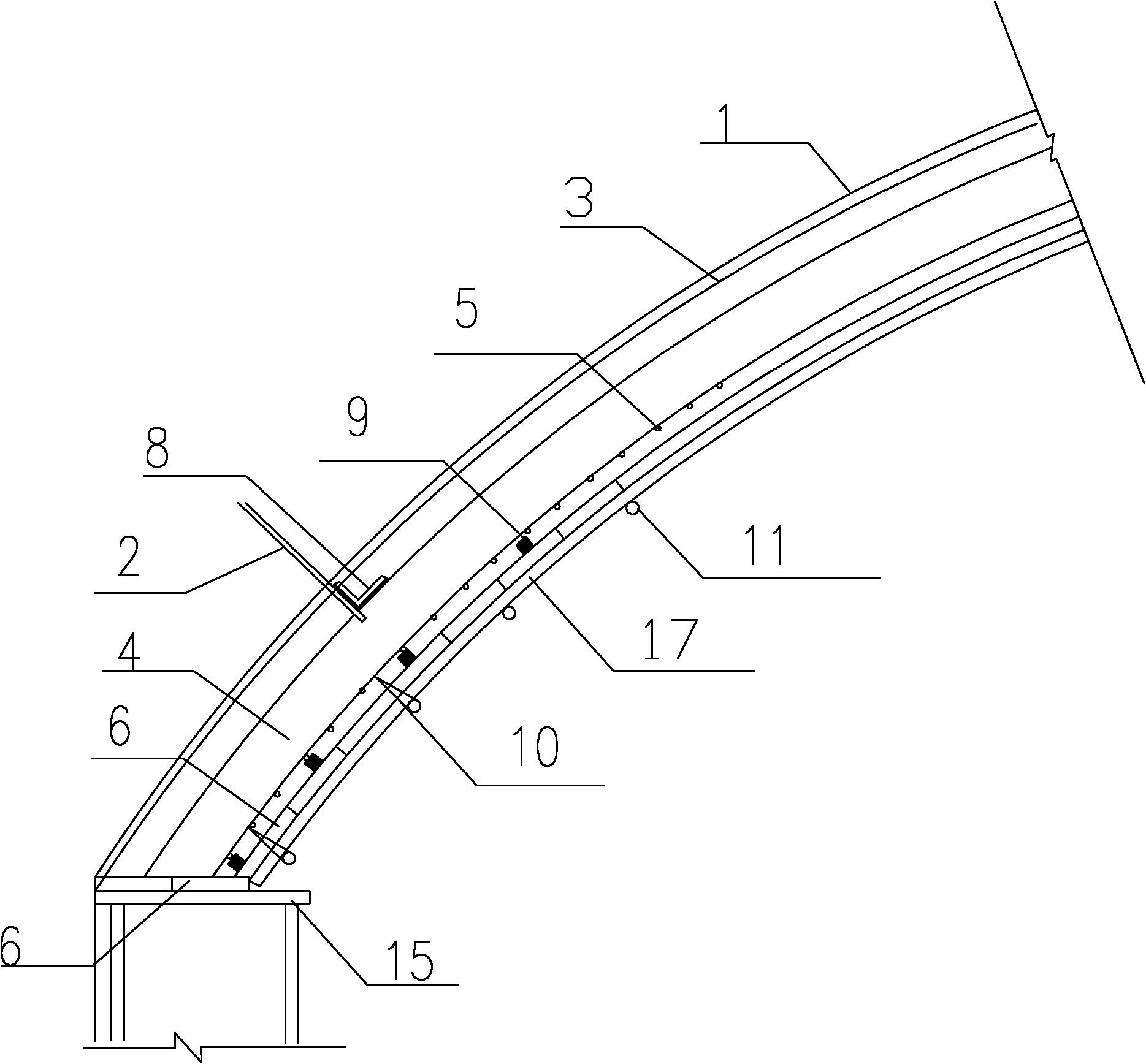

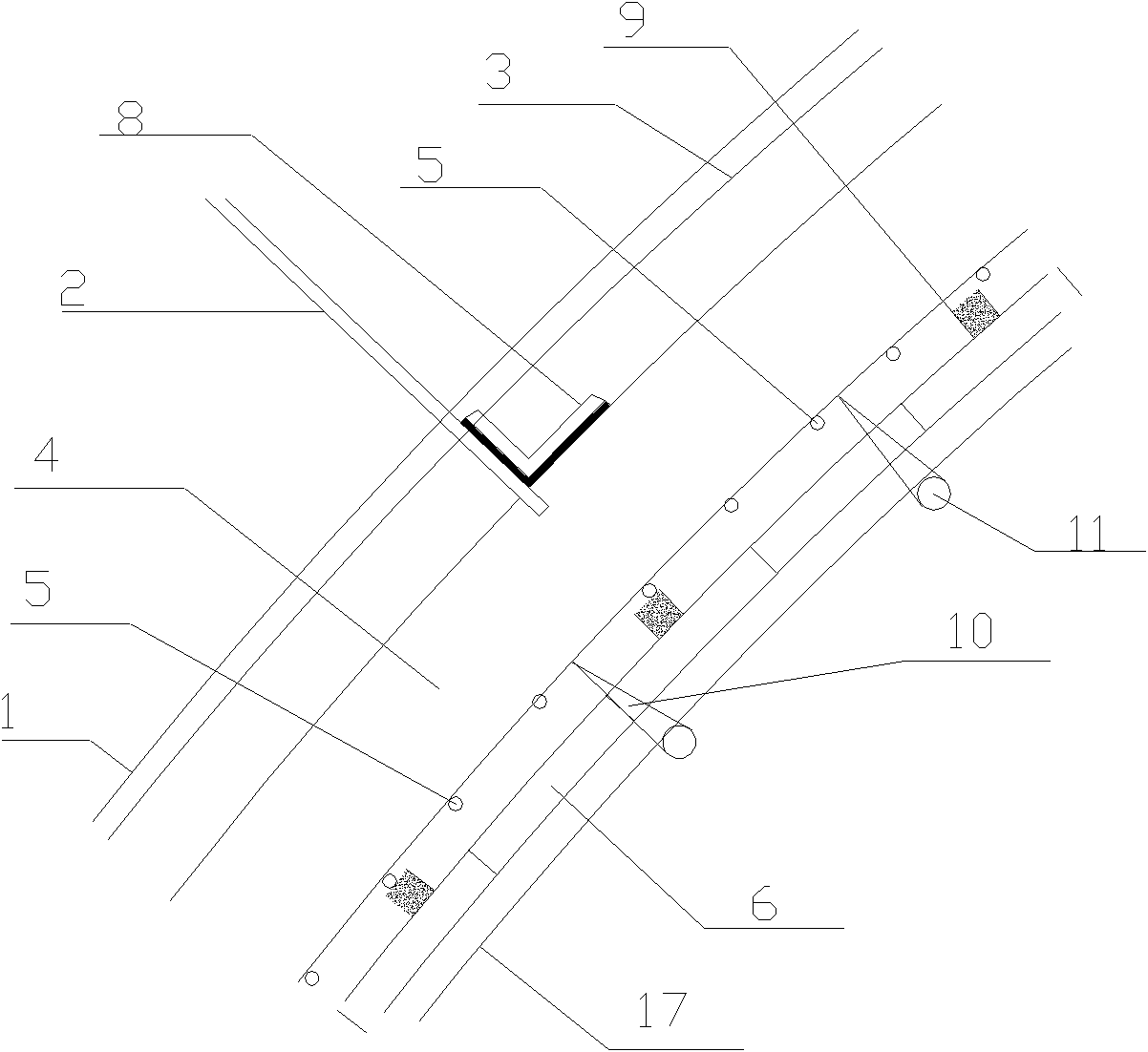

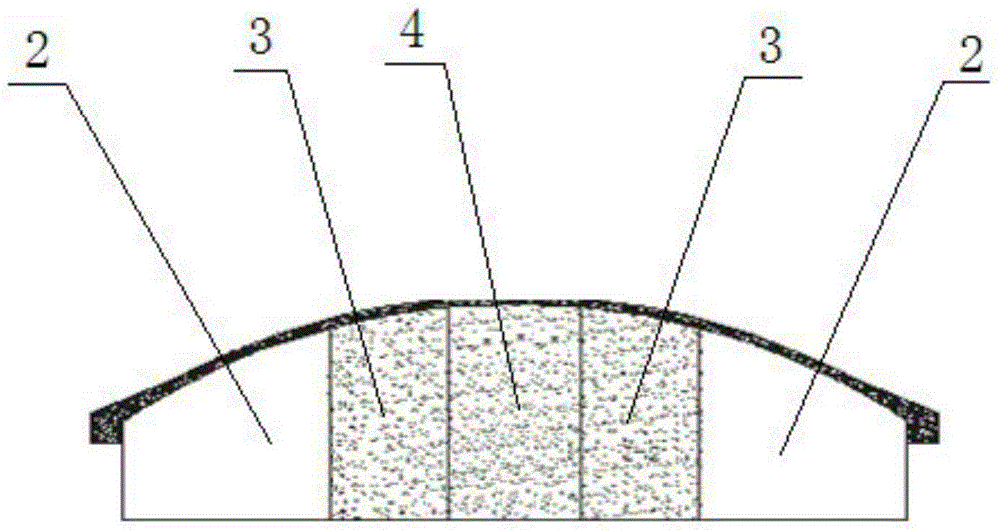

Cavern arch mould spraying concrete construction structure and process

ActiveCN101936170AEffectively closedShort construction periodUnderground chambersBuilding reinforcementsFalseworkUnderground cavern

The invention discloses a cavern arch mould spraying concrete construction structure and a cavern arch mould spraying concrete construction process. The structure comprises an anchor rod, a steel structure, concrete and a template, wherein the anchor rod is fixed in a bed rock; the steel structure is fixed through the anchor rod; the detachable template is suspended and fixed and forms a cavern arch pouring space with the bed rock together; and the concrete is sprayed into the pouring space through the template. The construction process comprises the following steps of: rock bed surface treatment, anchor rod construction, inner steel fabric installation, I iron installation, outer steel fabric installation, template installation, concrete spraying and the like. The construction needs no concrete delivery pump, does not need to build a full bearing scaffold and needs only a few constructors and spraying equipment. Therefore, construction materials are greatly saved; the construction period is short; arch lining concrete can be substituted by the mould spraying concrete of an underground cavern permanent structure; and the arch mould spraying concrete is more convenient to operate and the quality is assured.

Owner:SINOHYDRO BUREAU 7 CO LTD

Underground nuclear plant with nuclear island cavern groups distributed in L shape

ActiveCN104064233AArrangement satisfiedReduce the difficulty of research and developmentNuclear energy generationNuclear plant auxillary equipmentNuclear plantUnderground cavern

The invention discloses an underground nuclear plant with nuclear island cavern groups distributed in an L shape. The underground nuclear plant comprises nuclear islands used for generating steam through nuclear fission energy and arranged in underground cavern groups, a reactor factory building cavern used for containing reactor factory buildings is arranged in the middle in the underground cavern groups, and auxiliary cavern groups used for containing auxiliary factory buildings are arranged around the reactor factory building cavern in an L shape. By means of the underground nuclear plant with the nuclear island cavern groups distributed in the L shape, an existing underground cavern digging technology meets the building requirement of the underground nuclear plant, the number of caverns contained in the auxiliary cavern groups is small, and stability of surrounding rock is facilitated.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

Layout design method of underground cavern group

ActiveCN103266902AReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersDesign planUnderground cavern

The invention discloses a layout design method of an underground cavern group applied to a water conservancy and hydropower project and an underground storage. According to the layout method, main factors influencing the stability of surrounding rock of the underground caverns, especially, the rock strength stress ratio which is the essential factor can be fully taken into consideration. The method comprises the following steps of: firstly determining the positions of main caverns, determining the axial line directions of the main caverns, determining the thicknesses of rock pillars among the main caverns, and finally determining the shapes of the main caverns, wherein in the process of determining the thicknesses of the rock pillars among the main caverns, the thicknesses of the rock pillars are 1.0-2.5-time mean than excavation span between two adjacent main caverns and are 0.5-0.8 times that of the height of the big one in the adjacent two main caverns. Compared with the layout design with a design plan provided by a using traditional layout method, the layout design with the layout method disclosed by the invention is more scientific; and especially, in a highland stress environment and in a condition with relatively low surrounding rock strength, the phenomena of the deformation and destruction of the surrounding rock after the surrounding rock of the underground cavern group is excavation-unloaded can be greatly reduced or the deformation and destruction degrees of the surrounding rock can be reduced.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Manufactured caverns in carbonate rock

Disclosed is a process for manufacturing underground caverns suitable in one embodiment for storage of large volumes of gaseous or liquid materials. The method is an acid dissolution process that can be utilized to form caverns in carbonate rock formations. The caverns can be used to store large quantities of materials near transportation facilities or destination markets. The caverns can be used for storage of materials including fossil fuels, such as natural gas, refined products formed from fossil fuels, or waste materials, such as hazardous waste materials. The caverns can also be utilized for applications involving human access such as recreation or research. The method can also be utilized to form calcium chloride as a by-product of the cavern formation process.

Owner:CLEMSON UNIVERSITY

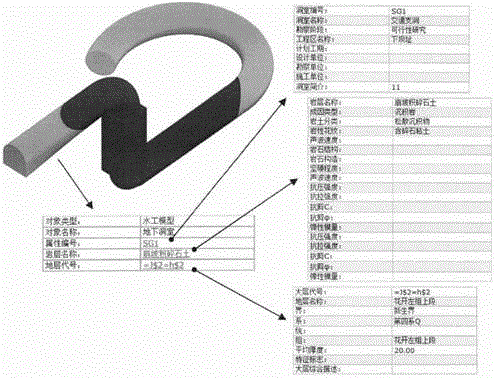

Underground cavern automatic modeling method based on geology information

InactiveCN103150428AImprove intelligenceEasy to checkSpecial data processing applicationsInteractive modelingUnderground cavern

The invention relates to an underground cavern automatic modeling method based on geology information, and solves the problems that underground cavities and exploration caverns are large in geology information, the multiple geometrical segmented modeling is complex, and the man-machine interactive modeling efficiency is low. The invention adopts the technical scheme that method comprises the following steps: 1, object classification and attribute definition A: the attribute fields are defined for the classified geological objects, and then are outputted in an object classification and attribute definition configuration E; 2, the geometrical parameter input B: a base line parameter definition B1 and a section parameter definition B2 are carried out on the special underground cavities and explosion caverns; and 3, multiple geometrical segmented data input C: according to E, an occurrence geological interface segment C1 and a non-occurrence geological interface segment C2 are carried out according to different classifies of geologic bodies disclosed by the underground cavities and the exploration caverns; and 4, automatic modeling parameterization D. The method is suitable for water conservancy and hydropower, traffic and other engineering practices.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

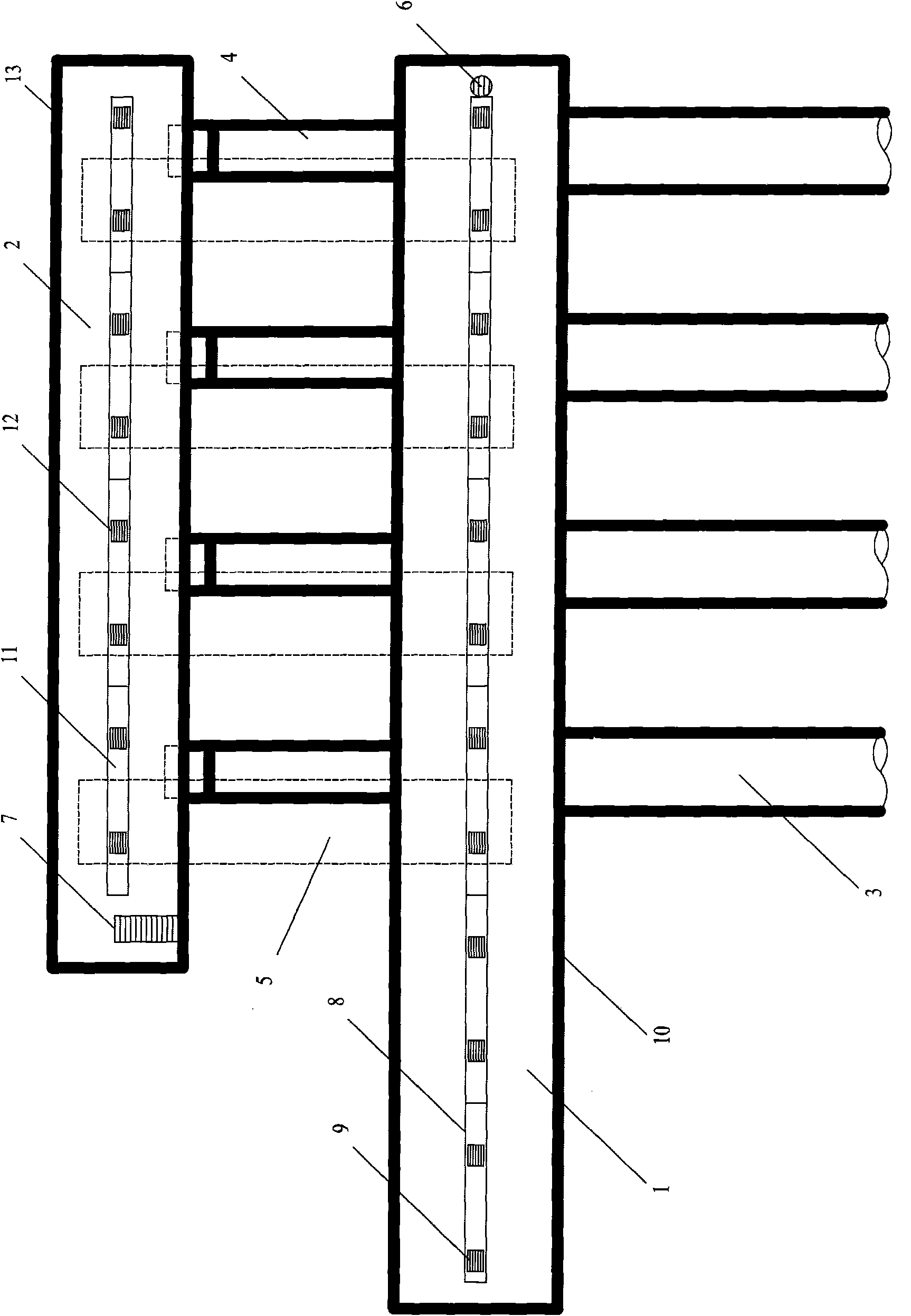

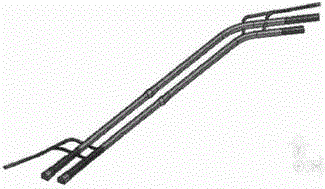

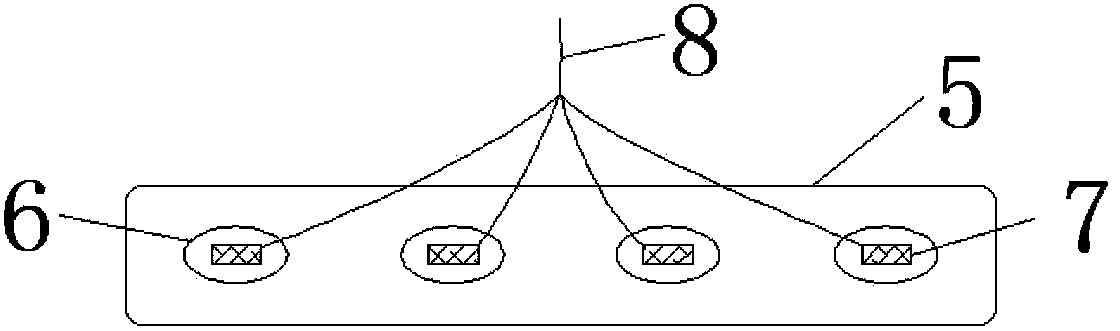

Flexible transmission type built-in miniature multi-point displacement test system used for model experiment

InactiveCN101344382AHigh precisionImprove real-time performanceForce measurementUsing optical meansUnderground cavernData acquisition

The invention discloses a flexible transfer type built-in micro-multi-point displacement measurement system used for a model test, the structure thereof comprises a bench, a raster ruler, a steel wire rope, a signal conversion system and a data acquisition system, wherein, the steel wire rope penetrates the raster ruler which is fixed on the bench after being led out from a measurement fixed end and is finally connected with a heavy hammer, the raster ruler is connected with the signal conversion system by a guide wire, and the signal conversion system is connected with the data acquisition system by the guide wire. The micro-multi-point displacement measurement system used for a geomechanics model test has the advantages of high precision (precision is 1Mu), real-time property, the capability of testing the horizontal or the vertical model deep micro-displacement and the capability of being turned in the model for testing the displacement, etc. The micro-multi-point displacement measurement system can be widely applied in the displacement tests of deep underground cavern model tests of civil engineering, utility, transportation, energy, mining, national defense and such fields.

Owner:SHANDONG UNIV

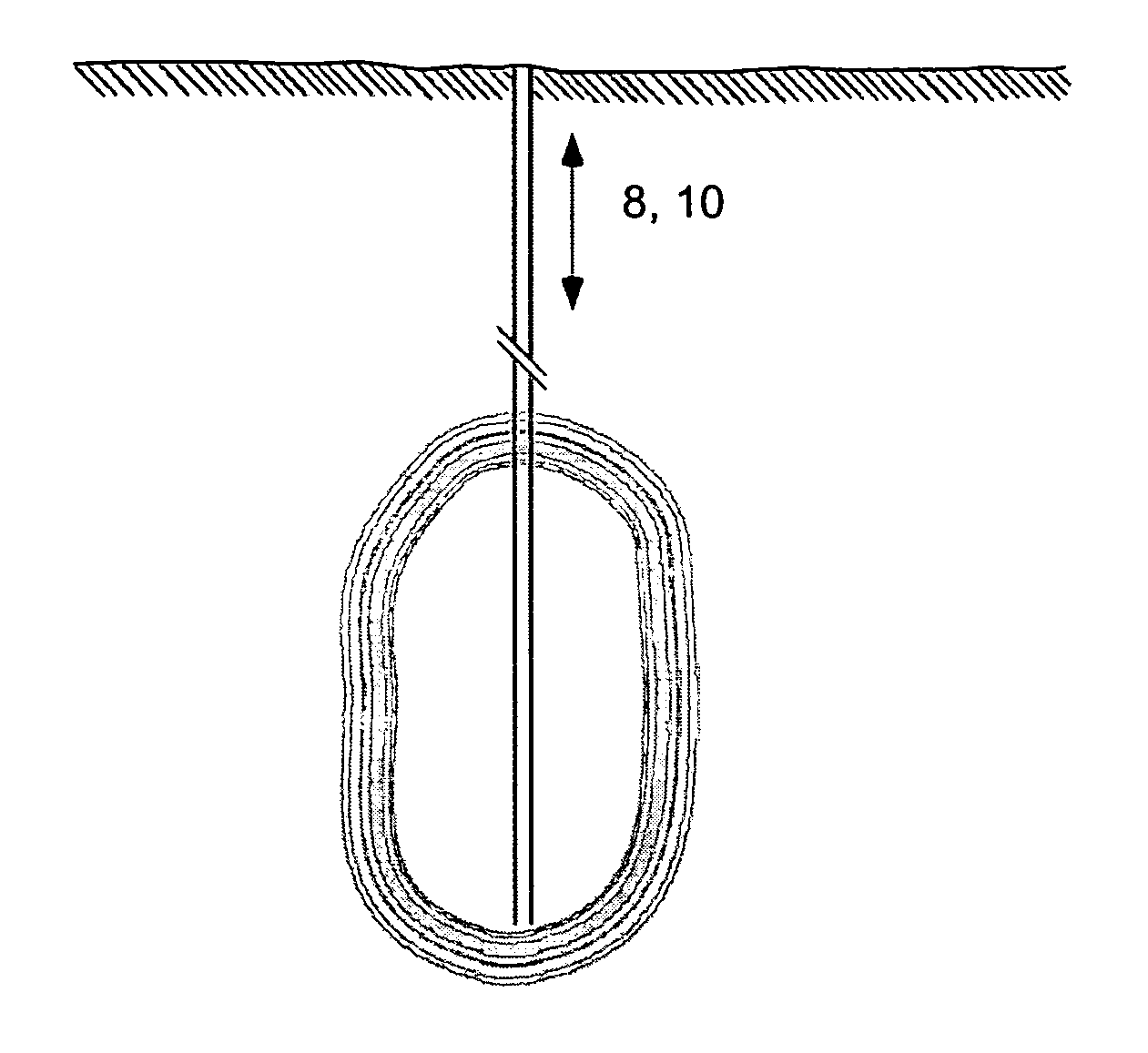

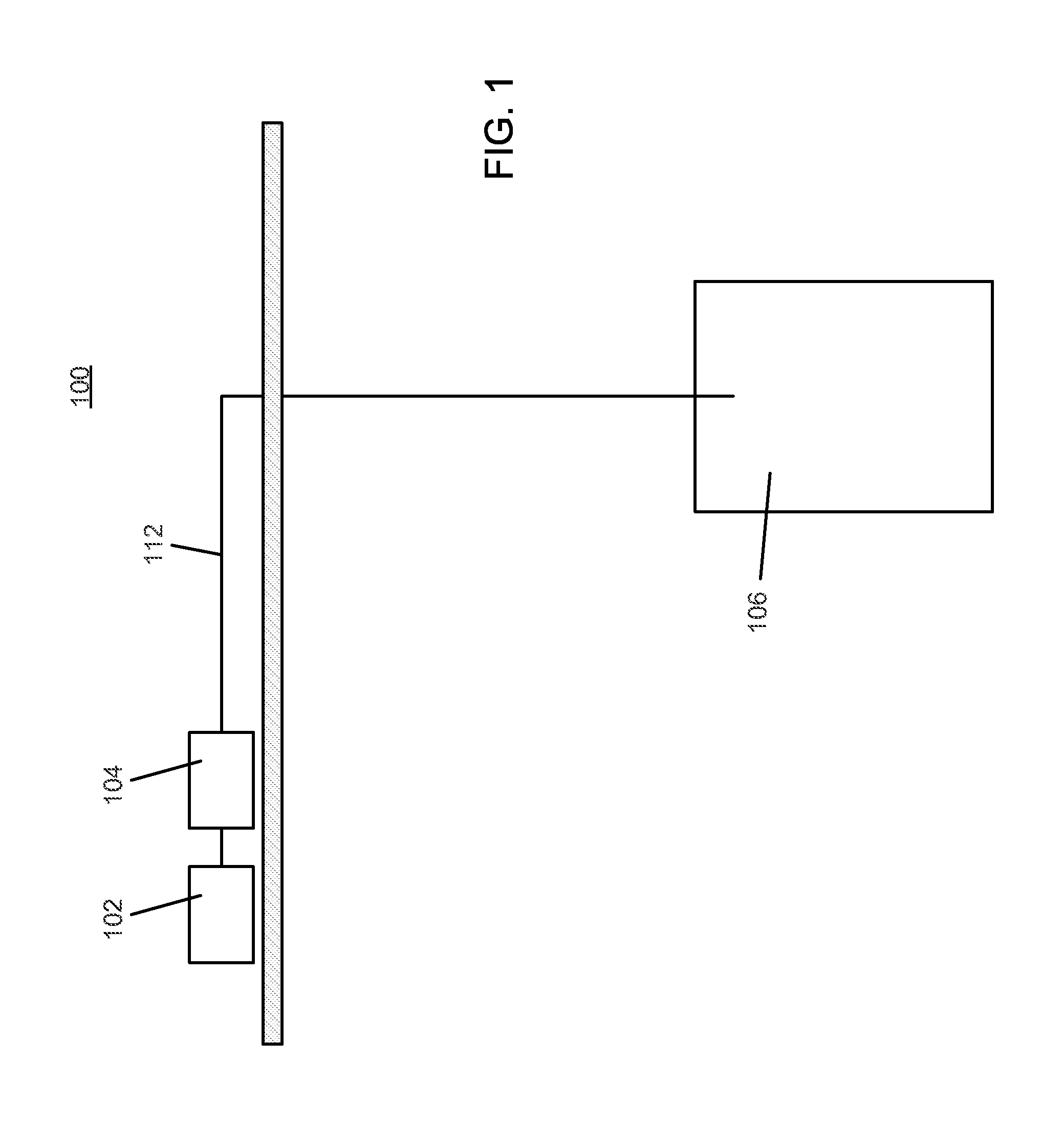

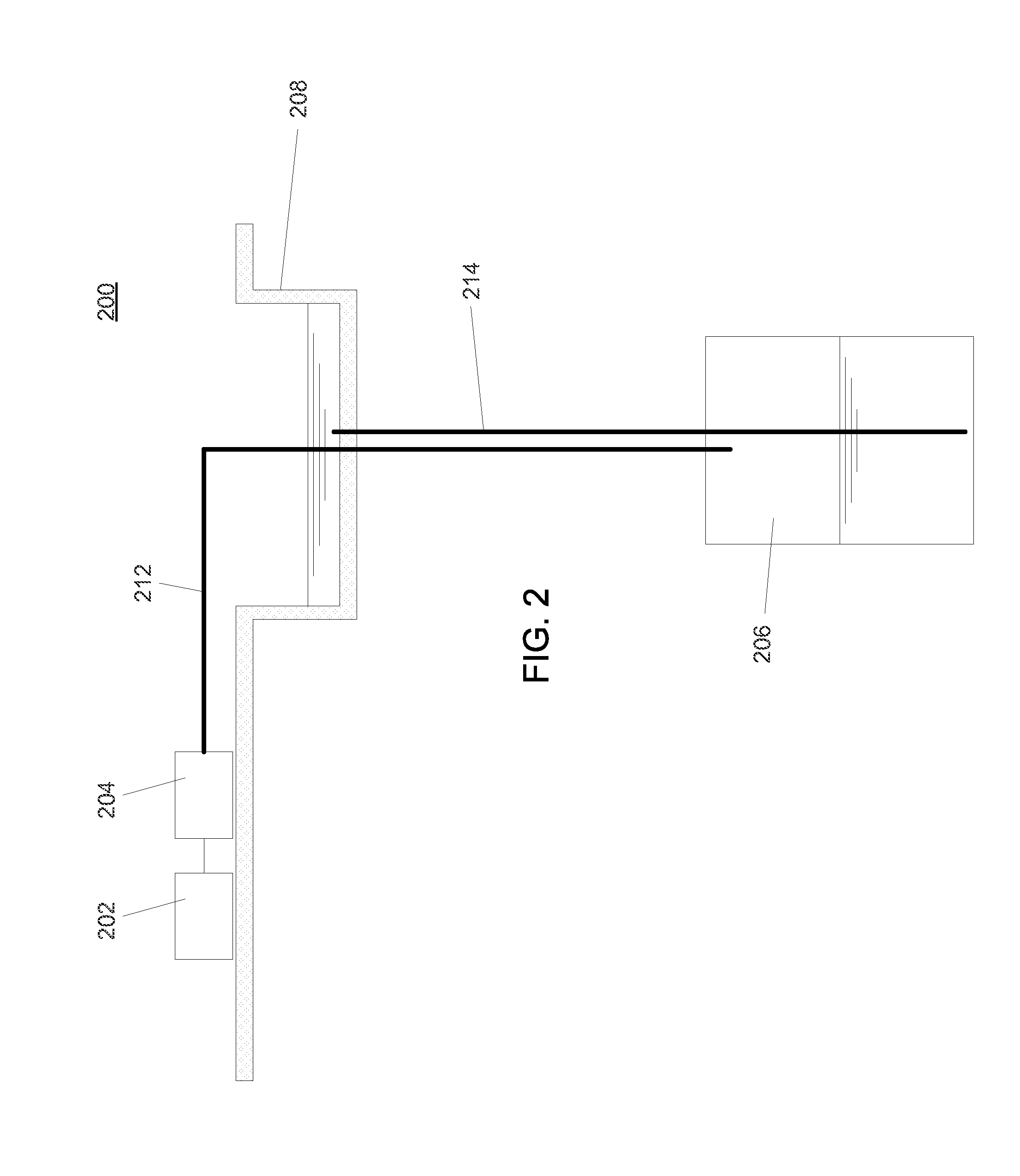

Excavated underground caverns for fluid storage

InactiveUS20150125210A1Maximizes storage volumeMinimize overall surface areaMining devicesGas turbine plantsElectricityUnderground cavern

An underground fluid storage structures formed by mechanical excavation of a subsurface formation in a controlled fashion. The structure comprises vertical holes (260, 270) and transversal caverns (256) of circular section and preferably in spiral arrangement. Storage caverns as described herein may further employ hydraulic pressure compensation to prevent wide pressure variations in the storage caverns, and to provide relatively constant injection and discharge pressures when introducing or releasing stored fluids. The preferred application is compressed air energy storage (CAES) systems for storing energy in the form of compressed air in order to generate electricity.

Owner:GENERAL COMPRESSION

Large-scale underground cavern group arrangement design method

ActiveCN103291316AReduce deformation and damageReduce the cost of reinforcement supportTunnelsUnderground cavernPrincipal stress

The invention discloses a large-scale underground cavern group arrangement design method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement design method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the orientation of the axis of the main cave is determined, the trend of a rock mass main structural surface on a construction site and the orientation of the maximum principal stress are measured at first, the orientation of the axis of the main cave is determined according to an included angle between the axis of the main cave and the trend of the rock mass main structural surface and an included angle between the axis of the main cave and the orientation of the maximum principal stress, the included angle between the axis of the main cave and the trend of the rock mass main structural surface is not less than 40 degrees, and the included angle between the axis of the main cave and the orientation of the maximum principal stress is 0-40 degrees.

Owner:POWERCHINA CHENGDU ENG

Large-sized underground cavern group arrangement designing method

ActiveCN104005777AEasy to operateHigh degree of quantificationUnderground chambersUnderground cavernStress ratio

The invention relates to the underground cavern designing method and discloses a large-sized underground cavern group arrangement designing method which is applied to water resources and hydropower engineering and underground storage cavern engineering to scientifically and reasonably confirm positions of the underground cavern group. According to the large-sized underground cavern group arrangement designing method, the rock strength stress ratio, site area crustal stress field characters, the cavern group effect, the main cavern size and the like key factors which influence arrangement of the underground cavern group are considered comprehensively according to the basis that the main cavern group longitudinal axis direction, the main cavern shape and size and the cavern distance are confirmed and the main cavern group valley wall slope rock mass thickness and the overlaying rock mass thickness are further confirmed. The valley slope crustal stress character quantitative analysis method, the valley slope side rock mass thickness computational formula and the cavern group overlaying rock mass thickness confirming method are scientific and reasonable, high in quantization degree, strong in operability, convenient for designer application and applicable to large-sized underground cavern group arrangement and design under various crustal stress levels and complete geological conditions.

Owner:POWERCHINA CHENGDU ENG

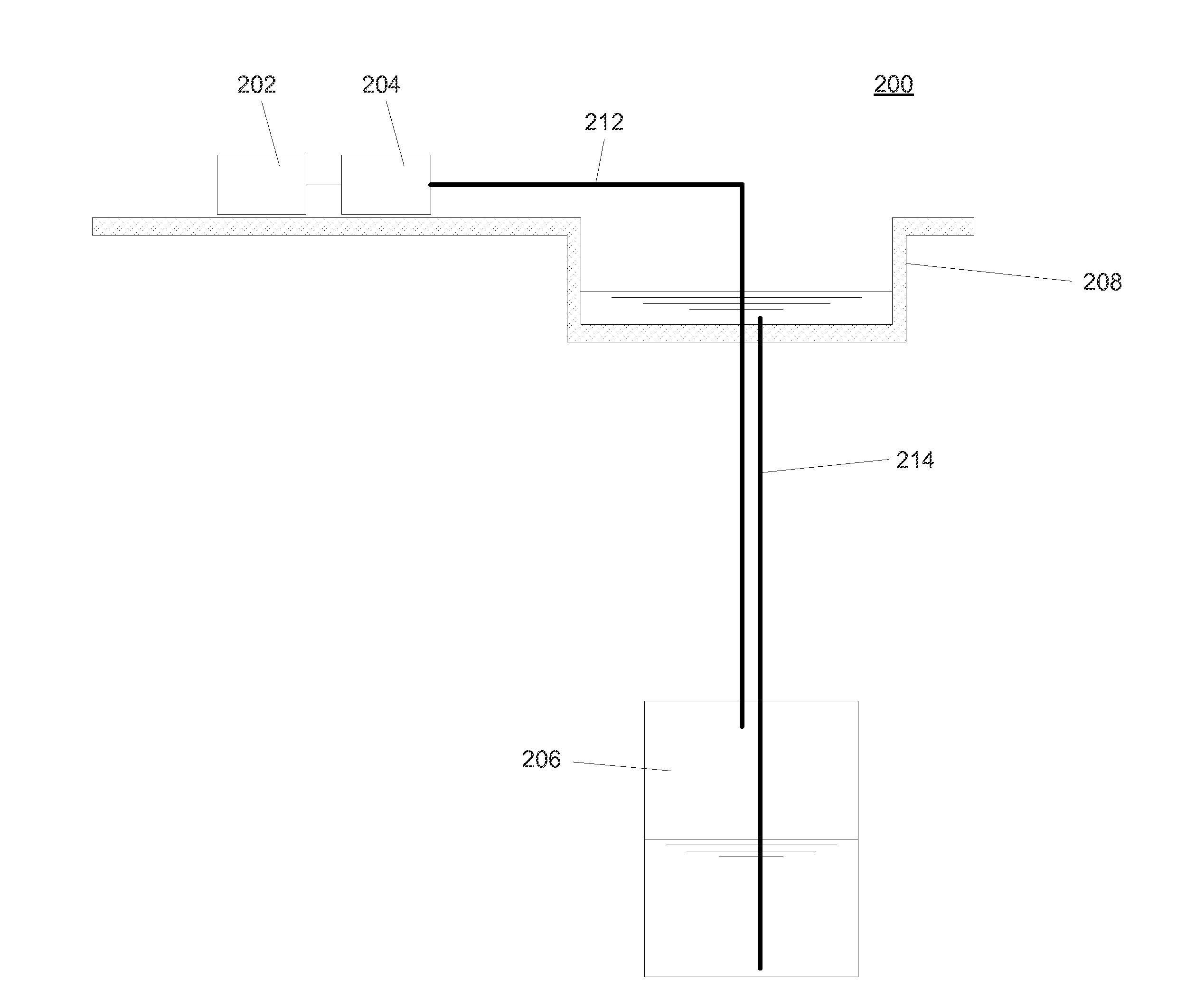

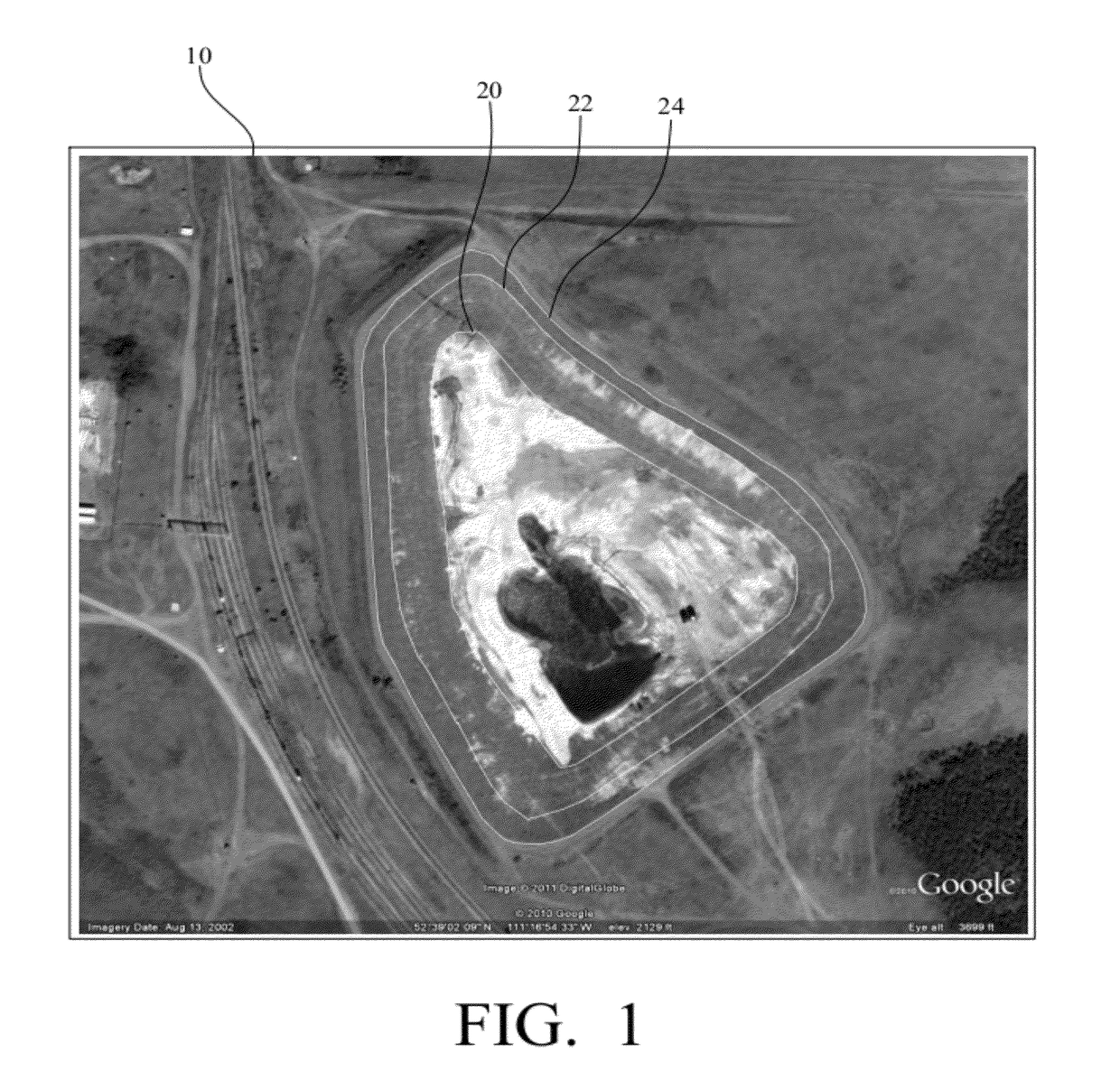

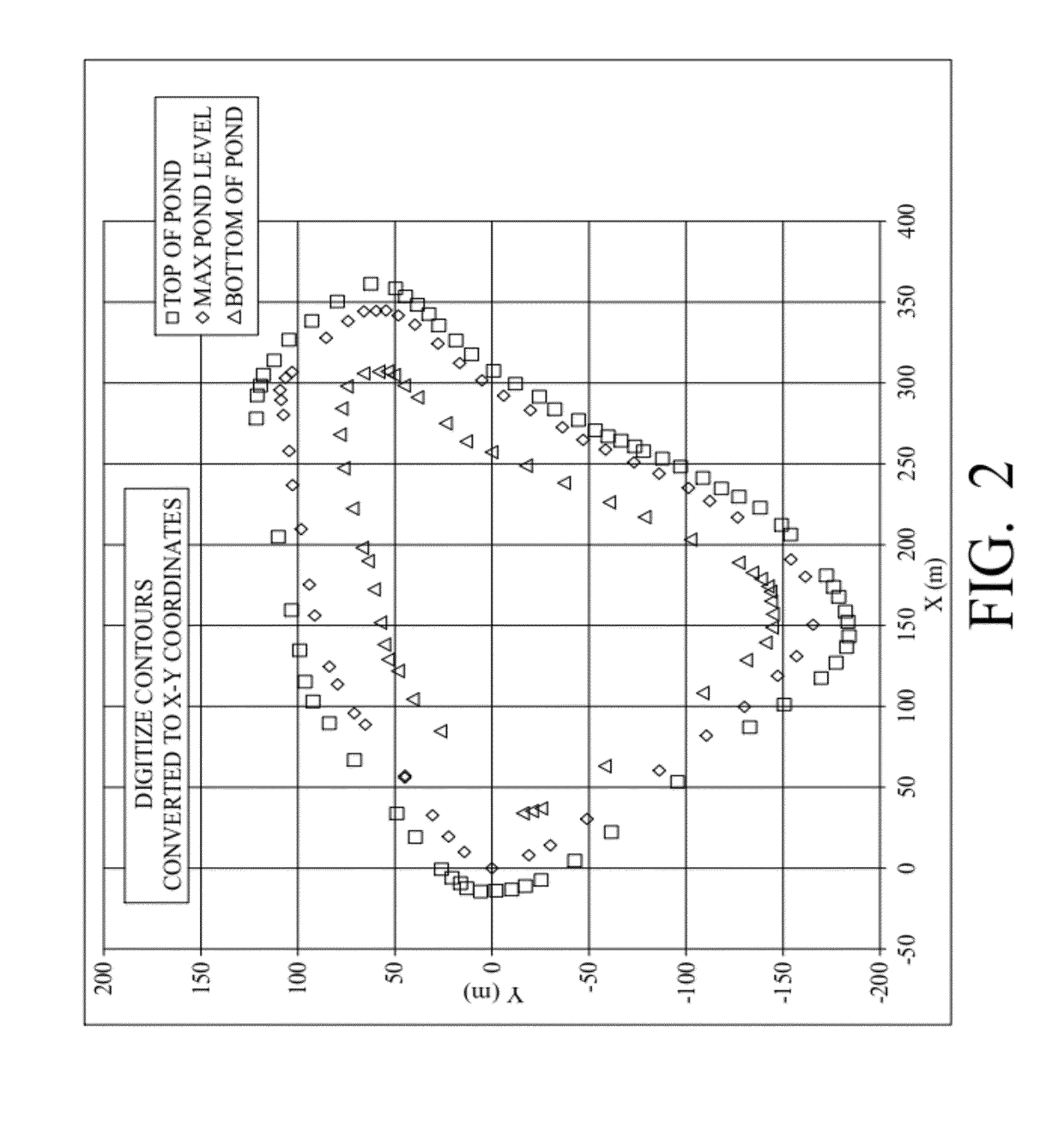

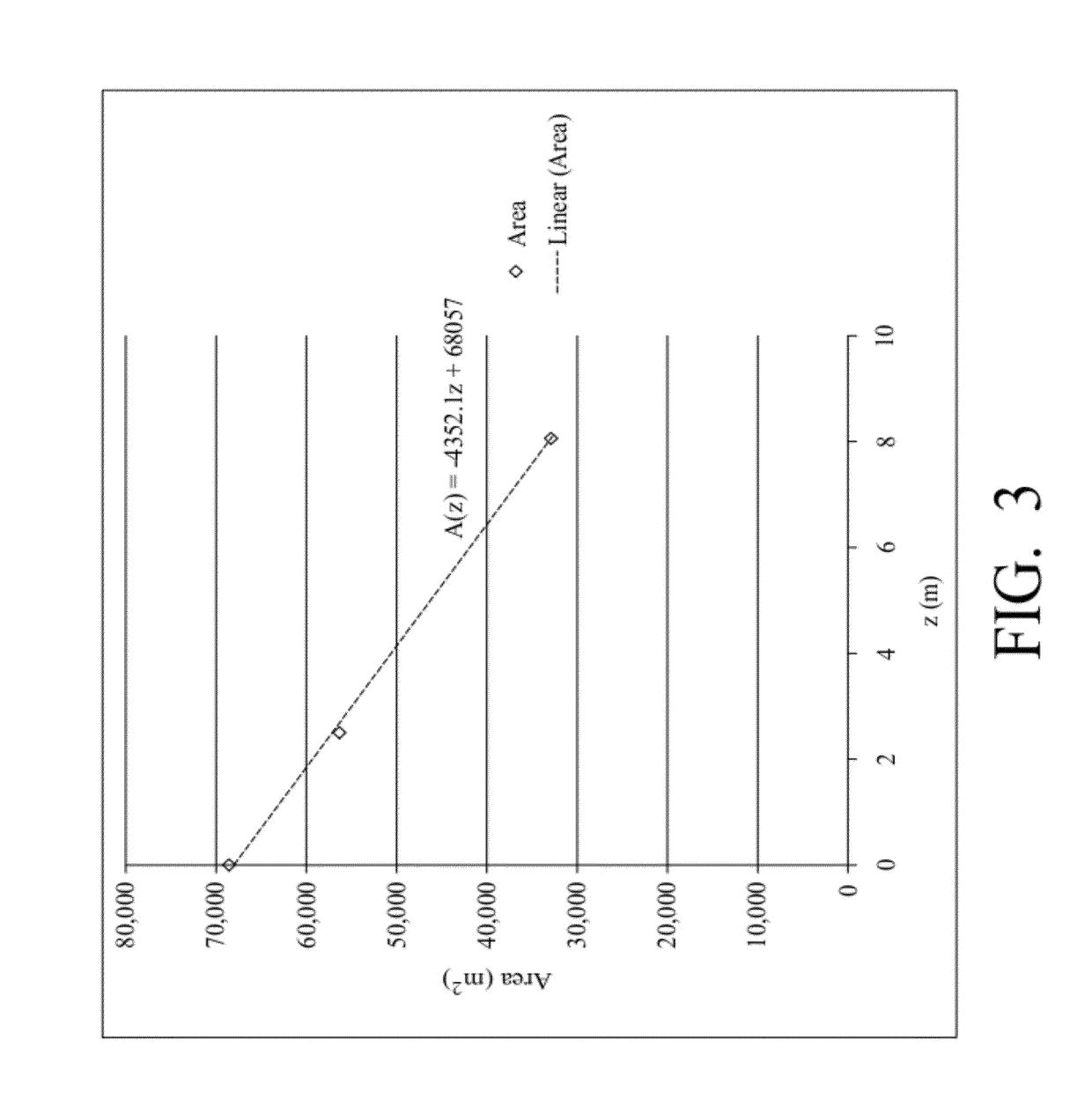

Method and system for determining an amount of a liquid energy commodity in storage in an underground cavern

A method for determining an amount of a liquid energy commodity in storage in an underground cavern generally comprises the steps of: establishing a volume function for a brine pond associated with the underground cavern; acquiring an image of the brine pond; transmitting the acquired image to a central processing facility; analyzing the acquired image to calculate a depth of the brine in the brine pond; estimating the volume of the brine in the brine pond based on the calculated depth and using the volume function; determining the amount of the liquid energy commodity in storage in the underground cavern associated with the brine pond based on the estimated volume of the brine in the brine pond; and communicating information about the amount of the liquid energy commodity in storage to a third-party market participant.

Owner:GENSCAPE

Large-scale underground cavern group arrangement method

ActiveCN103291332AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernStress ratio

The invention discloses a large-scale underground cavern group arrangement method applied to hydraulic and hydroelectric engineering and underground storage cavern engineering. According to the arrangement method, principal factors, especially the essential factor of the rock strength-stress ratio, influencing underground cavern surrounding rock stability can be comprehensively taken into account, the designing scheme for large-scale underground cavern group arrangement can be more scientific, and considered factors are more comprehensive. The position of a main cave is determined at first, the orientation of an axis of the main cave is determined, then the thickness of a rock pillar in the main cave is determined, and at last the shape of the main cave is determined. When the position of the main cave is determined, the rock strength-stress ratio on a construction site is firstly measured, and when the rock strength-stress ratio is 2.0-4.0, the thickness from the outer edge of the main cave to a rock of a valley slope surface should be larger than 400m; when the rock strength-stress ratio is 4.0-7.0, the thickness from the outer edge of the main cave to the rock of the valley slope surface is 200-400m; when the rock strength-stress ratio is larger than 7.0, the thickness from the outer edge of the main cave to a rock of the valley slope surface is 150-200m.

Owner:POWERCHINA CHENGDU ENG

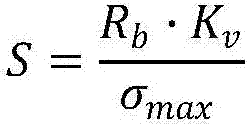

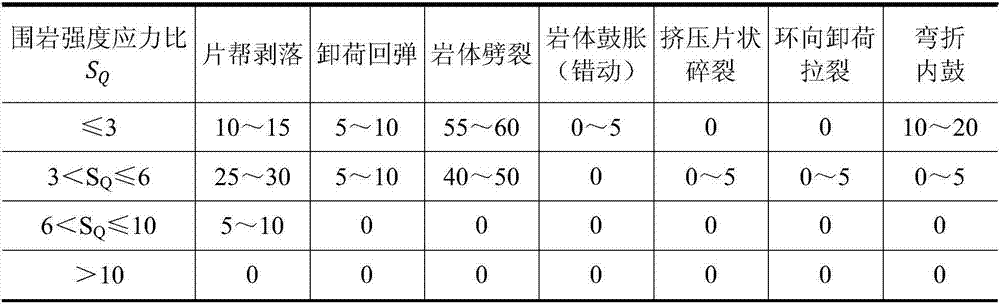

Method for predicting stratified rock mass underground cavern surrounding rock failure type in high ground stress region

The invention discloses a method for predicting the stratified rock mass underground cavern surrounding rock failure type in a high ground stress region, and relates to the field of rock-soil and water conservancy and hydropower engineering. The technical scheme adopted by the invention comprises the steps of A, performing geological survey, and carrying out engineering geological rock division by combining engineering significance and scale; B, selecting representative rocks, and performing a saturated uniaxial compression strength test on the selected rocks respectively, carrying out generalization on each engineering geological rock group according to the representative rocks, calculating the content of each representative rock in each engineering geological rock group, and then calculating the comprehensive compression strength Rbz of each engineering geological rock group by taking the content as a weight; C, conducting a three-dimensional space stress test, and acquiring the maximum principal stress [sigma]max; D, respectively calculating a strength-stress ratio SQ of each part of the cavern surrounding rock; and E, judging the failure type and occurrence probability of each part of the cavern surrounding rock. The method disclosed by the invention has important engineering significance for guiding a large underground cavern excavating and supporting method, parameter selection, supporting strength and engineering economic comparison and selection and the like.

Owner:POWERCHINA CHENGDU ENG

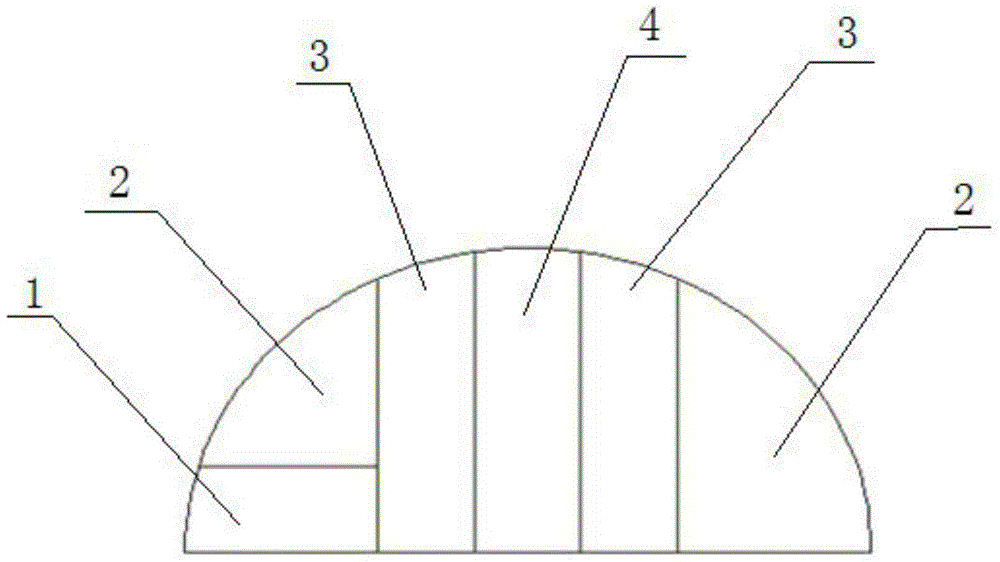

Ring excavation construction method for underground large-span spherical-cap-shaped dome under weak surrounding rock

ActiveCN105201532AImprove construction efficiencyImprove construction progressUnderground chambersTunnel liningFalseworkUnderground cavern

The invention discloses a ring excavation construction method for an underground large-span spherical-cap-shaped dome under weak surrounding rock and belongs to the technical field of excavation construction of underground caverns. The method comprises the following six steps: determining the rise-span ratio of the spherical-cap-shaped dome; directly entering the spherical-cap-shaped bottom from an up-leading cavity for forming of a section A; performing first ring excavation support of the spherical-cap-shaped dome; performing next ring excavation support of the spherical-cap-shaped dome; finishing excavation support of a section D in the center of the dome; performing off-wall coating of the spherical-cap-shaped dome. The method is applicable to various surrounding rock geological conditions, has wider application range and a few construction procedures; the scaffold input quantity for coating construction of the spherical-cap-shaped dome is reduced, the construction efficacy is improved, the construction progress is accelerated, the construction cost is saved, the difficult problem about excavation of the underground large-span spherical-cap-shaped dome under complex geological conditions of the weak surrounding rock is solved, personnel and equipment safety during construction operation is guaranteed, disturbance on the peripheral surrounding rock is reduced, and the forming quality of the spherical-cap-shaped dome can be controlled very well.

Owner:CHINA RAILWAY NO 9 GRP 2ND ENG

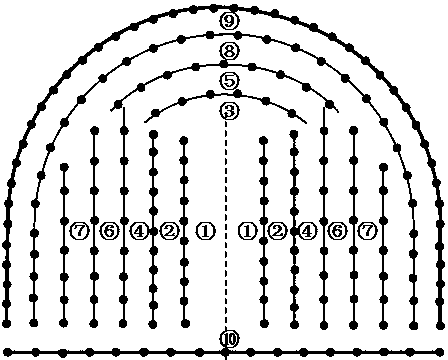

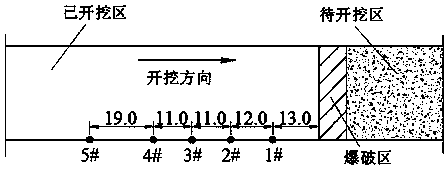

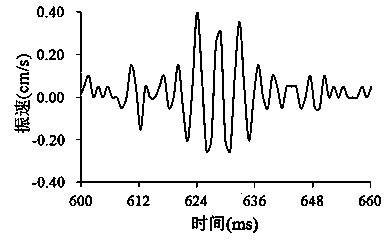

Method for forecasting transient unloading induced vibrations based on strain energy of rock masses

The invention discloses a method for forecasting transient unloading induced vibrations based on the strain energy of rock masses, which comprises the following steps: establishing a function relation between the strain energy Sa released by excavated rock masses and a peak vibration velocity v of a transient unloading induced vibration based on dimension analysis; and actually measuring a vibration waveform of surrounding rocks and calculating the strain energy of the excavated rock masses, and based on the function relation between the strain energy Sa released by excavated rock masses and a peak vibration velocity v of a transient unloading induced vibration, obtaining a transient unloading induced vibration forecasting formula by using a nonlinear fitting method, thereby carrying out forecasting on the transient unloading induced vibration of the excavation of a deep underground cavern. The method disclosed by the invention improves the forecasting accuracy of the transient unloading induced vibration of the blasting excavation of deep rock masses, and can be widely applied to the forecasting of the transient unloading induced vibration of the blasting excavation of deep underground engineering such as water & electricity, transportation, mines, and the like.

Owner:WUHAN UNIV

Water-mist dust settling method implemented during blast excavation for large-scale underground project

InactiveCN103453809AReduce dust concentrationDust Concentration ControlUsing liquid separation agentBlastingUnderground cavernDetonation

The invention discloses a water-mist dust settling method implemented during blast excavation for a large-scale underground project. The water-mist dust settling method include steps of 1), forming main blast holes in a blast excavation area of an underground cavern, placing a row of elongated water bags made of polyethylene materials at positions close to a working plane or between a first row of the main blast holes and a second row of the main blast holes, and arranging emulsion explosive packages under the water bags; 2), connecting the emulsion explosive packages under the water bags into a detonation network; 3), completing preparation for blast work in the blast excavation area, enabling detonation conditions to be met, and then filling water into the water bags until the water is uniformly filled in the water bags; 4), detonating and forming water mist to absorb dust generated during blasting of rocks, and settling the dust under the effect of the gravity. The size of each water bag is 6-10X0.5-0.9X0.13-0.16, and the distance between each two adjacent water bags is 2-4m. In order to guarantee convenience in recycling the water bags after blasting and a good water-mist effect, the emulsion explosive packages under the water bags need to be equidistantly and uniformly arranged under the water bags, and simultaneous detonation of the emulsion explosive packages needs to be guaranteed to the greatest extent. When the emulsion explosive packages are connected into the network, the detonation time of the emulsion explosive packages is 25-50ms ahead of the detonation time of the corresponding main blast holes which are detonated at first.

Owner:中国人民武装警察部队水电三峡工程指挥部 +1

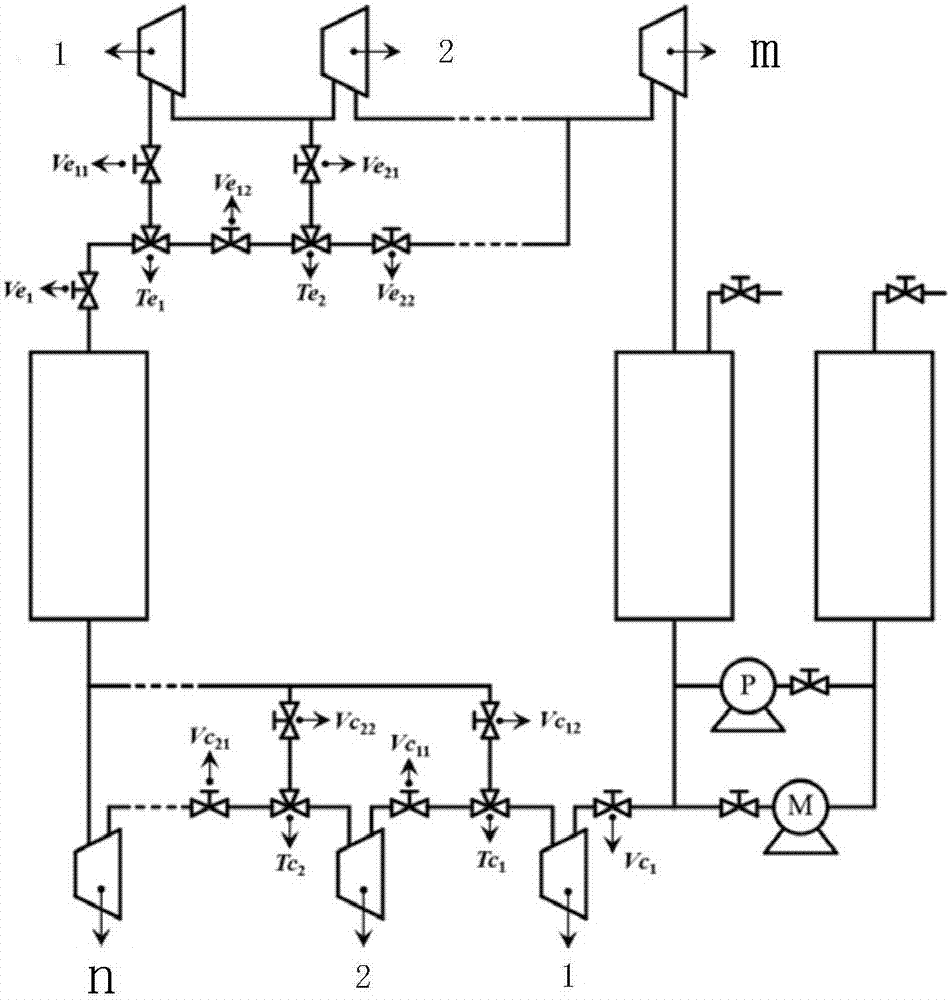

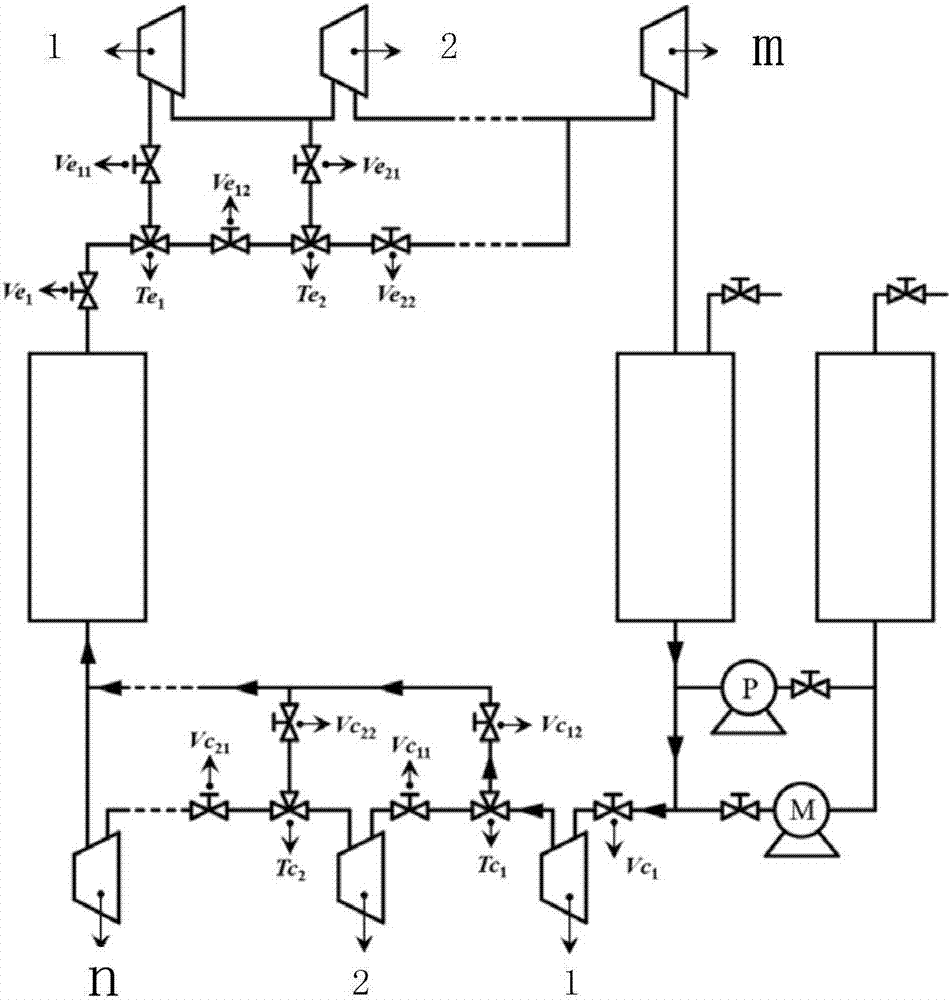

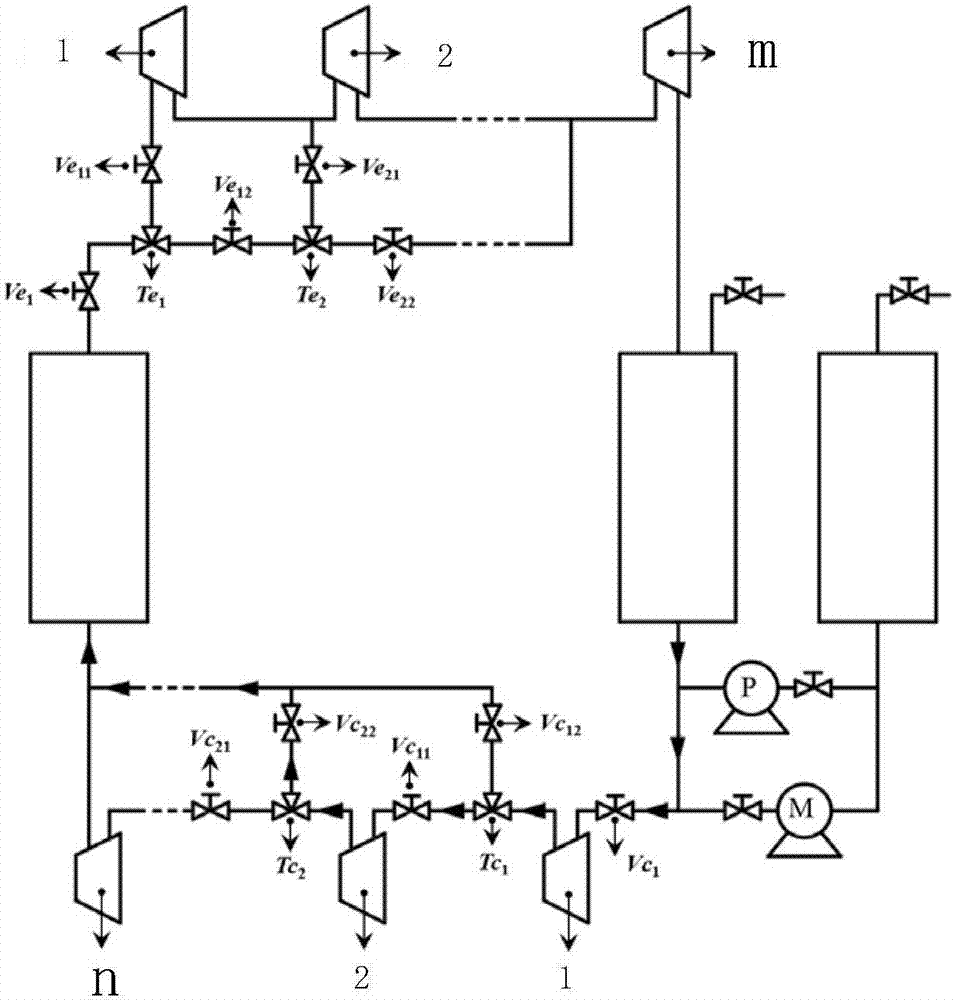

Compressed air water pumping energy storage system

PendingCN107489467AAvoiding Difficult Site Selection ProblemsEliminate dependenciesEngine componentsSteam engine plantsWater storage tankThermal energy storage

The invention discloses a compressed air water pumping energy storage system. The compressed air water pumping energy storage system comprises an air compression unit, an air expansion pressure stabilizing unit, a hydraulic turbine set, a pumping unit, a high-pressure air storage tank, a medium-pressure air storage tank, a high-pressure water storage tank and a normal-pressure water storage tank, wherein the medium-pressure air storage tank, the air compression unit and the high-pressure air storage tank are connected in sequence so as to form an energy storage channel; the high-pressure air storage tank, the air expansion pressure stabilizing unit, the high-pressure water storage tank, the hydraulic turbine set and the normal-pressure water storage tank are connected in sequence so as to form an energy releasing channel; and the normal-pressure water storage tank, the pumping unit and the high-pressure water storage tank are connected in sequence so as to form a water return channel. According to the compressed air water pumping energy storage system, the air storage tanks are used as air storage containers, so that the problem of difficulty in site selection of underground caverns of a traditional compressed air energy storage system is avoided, high-position water is replaced with high-pressure water, and the gravity head of water is replaced with the pressure head of water, so that the dependence of a traditional water pumping energy storage power station on the ground potential difference is eliminated.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com