Multi-casing structure capable of facilitating bridge-pile construction in cavern development areas and construction method thereof

A construction method and protection tube technology, applied in sheet pile wall, infrastructure engineering, construction and other directions, can solve the problems of buried hammer head, loss of construction enterprises, increase of pier construction cost, etc., so as to ensure construction safety and speed up construction. , the effect of controlling project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

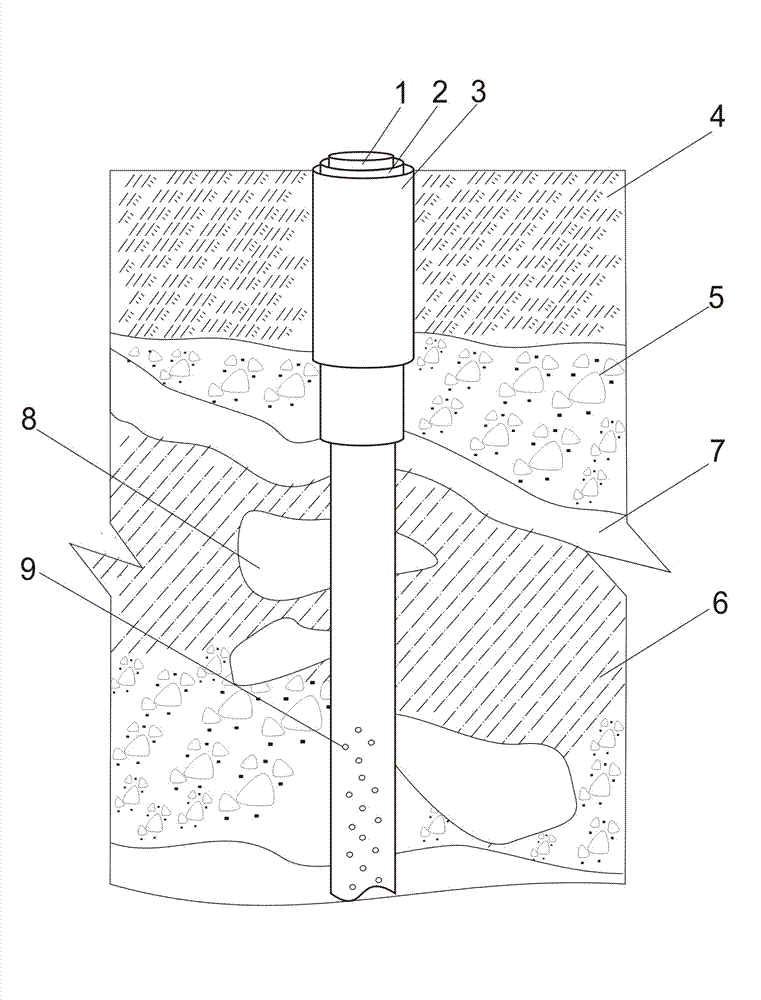

[0019] Example 1: Multiple casings and construction method for bridge pile construction in areas with developed karst caves

[0020] It is characterized by:

[0021] 1. Casing processing

[0022] The thickness of the steel plate of the casing needs to be calculated according to the forming of the drum and the application of vibration, combined with the groundwater level and the breakdown of the roof of the underground cave, and the pressure difference in the most unfavorable situation when the mud leaks out. Apply the formula of material mechanics to calculate the steel plate with a thickness of 12-20mm;

[0023] Casing length: According to the thickness of the required steel plate, select A3 standard steel plate with a width of 1.8m to be rolled and welded into a section of steel casing, and 5-8 sections of steel casing are spliced into a group of steel casings; the length of the inner casing 1 is determined by Multiple groups of steel casings are spliced to form the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com