Construction Method of Multiple Casings for Bridge Pile in Areas Facilitated by Karst Cave Development

A technology for protecting cylinders and karst caves, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as loss of construction enterprises, burial of hammer heads, and collapse of orifices, so as to ensure project quality, ensure construction safety, and speed up construction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

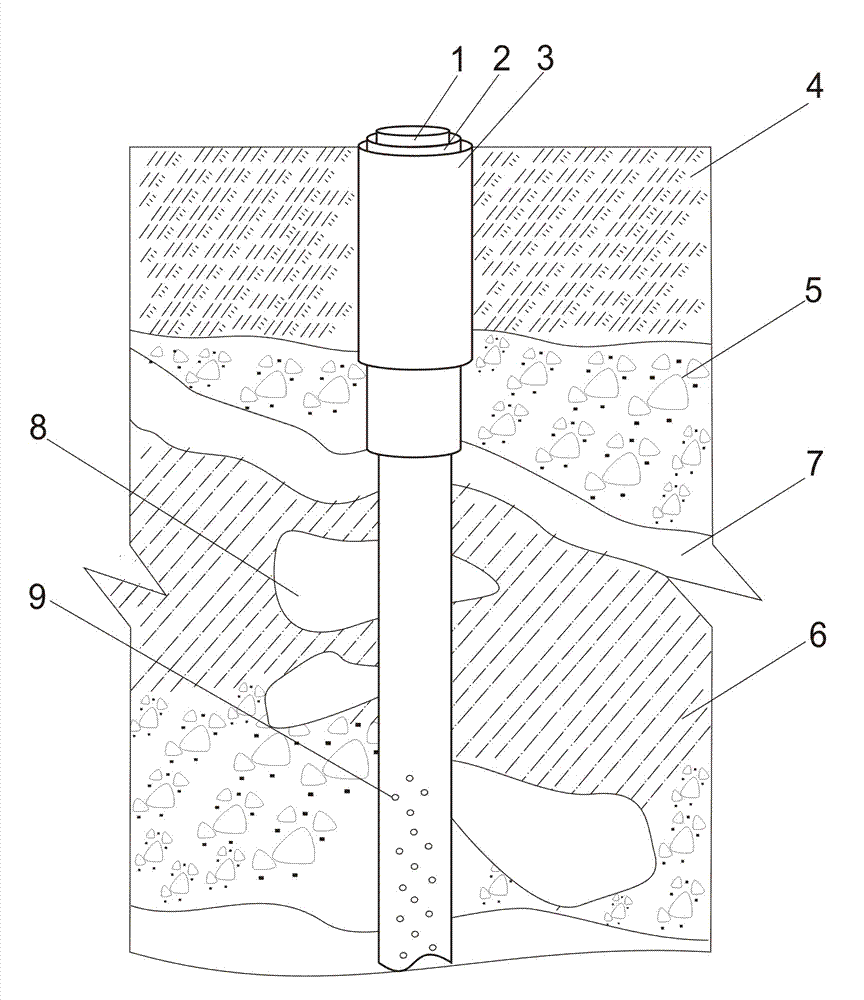

[0019] Example 1: The method of using multiple casings for bridge piles in areas where karst caves are developed

[0020] It is characterized by:

[0021] 1. Casing processing

[0022] Thickness of the steel casing of the steel casing: It needs to be determined according to the forming of the drum and the application of vibration combined with the groundwater level. When the roof of the underground karst cave breaks down and the mud leaks out, the pressure difference on the steel casing around the pile hole is the largest, which is the most unfavorable for construction. The thickness of the steel casing steel plate is calculated according to the working conditions of the steel casing; according to the working conditions of different pile holes, the steel plate reel with a thickness of 12-20mm is used for forming;

[0023] Steel casing length: According to the required steel plate thickness, choose 1.8m wide A3 standard steel plate to be rolled and welded into a section of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com