Paranitrotoluene conveying device and device for preparing trinitrotoluene through nitrification of paranitrotoluene

A technology of p-nitrotoluene and conveying equipment, which is applied in the preparation of nitro compounds, organic chemistry, mechanical equipment, etc., can solve the problems of affecting production efficiency, high consumption quota of raw materials, and small space for reduction, so as to reduce power consumption cost, Improved productivity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

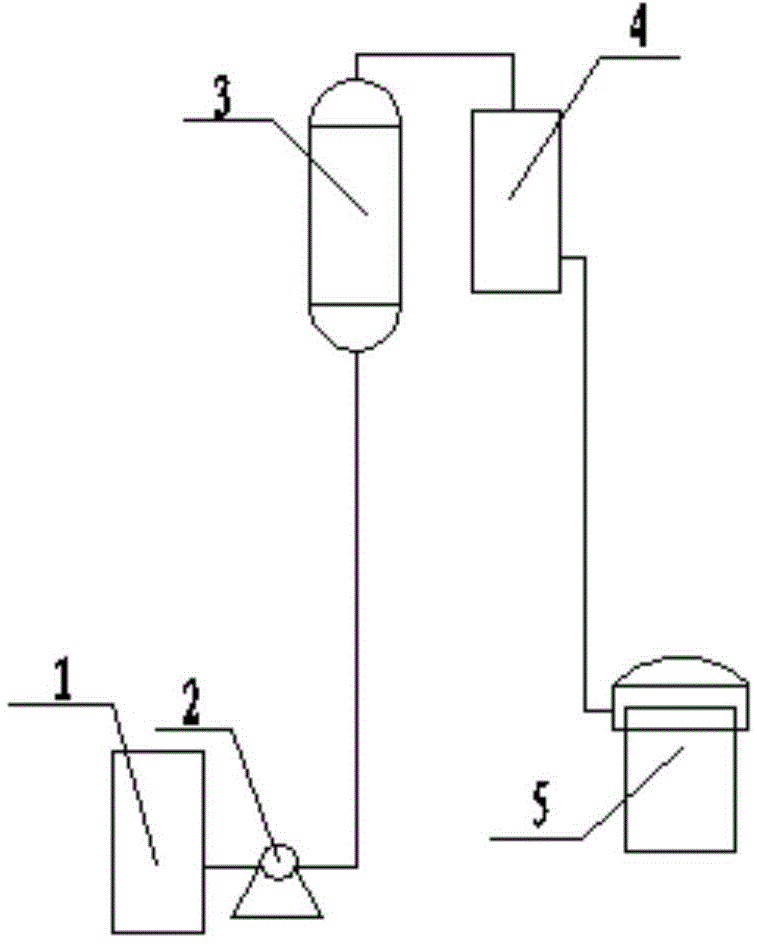

[0027] The p-nitrotoluene delivery device protected by the present invention, such as figure 1 As shown, the p-nitrotoluene finished product tank 1, the centrifugal pump 2, the p-nitrotoluene cooler 3, the p-nitrotoluene high-level tank 4, and the second-stage nitration machine 5 are connected in sequence by insulation pipelines. That is, the material outlet of the p-nitrotoluene finished product tank 1 is connected to the material inlet of the centrifugal pump 2 through the insulation pipeline, and the material outlet of the centrifugal pump 2 is connected to the material inlet of the p-nitrotoluene cooler 3 through the insulation pipeline, and the p-nitrotoluene cooler 3 The material outlet of the p-nitrotoluene high level tank 4 is connected to the material inlet of the p-nitrotoluene high level tank 4 through the insulation pipeline, and the material outlet of the p-nitrotoluene high level tank 4 is connected to the material inlet of the second stage nitration machine 5 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com