Patents

Literature

90results about How to "Continuous and stable delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

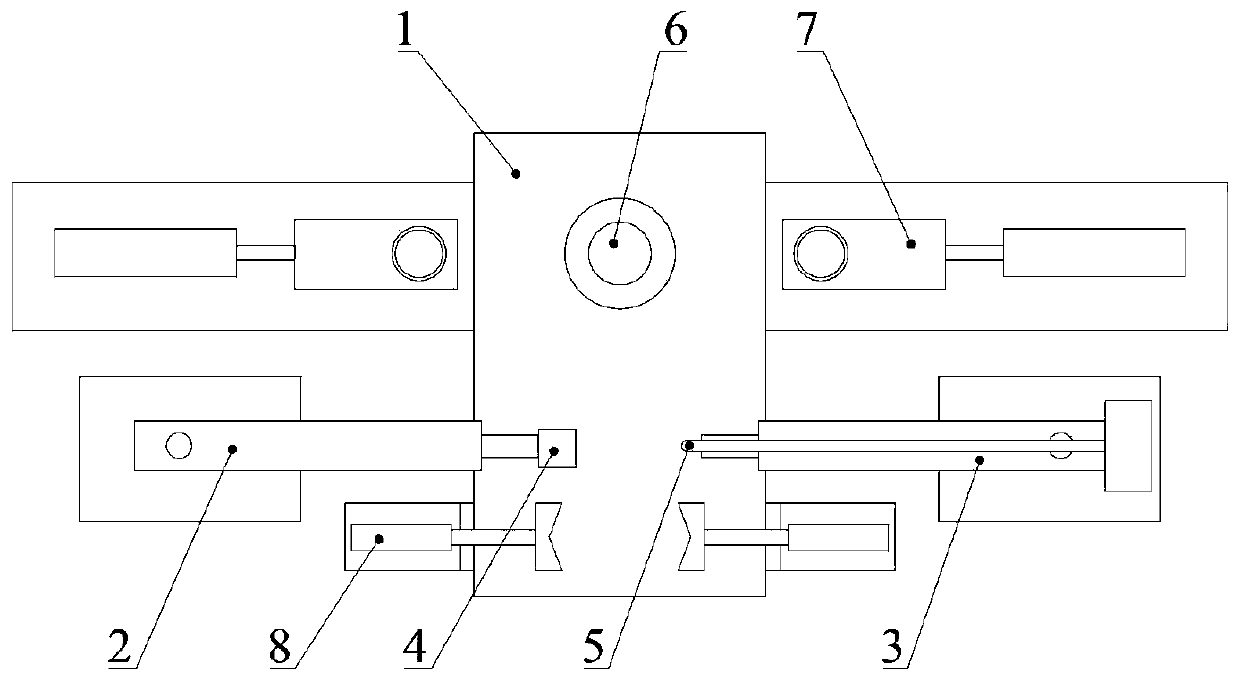

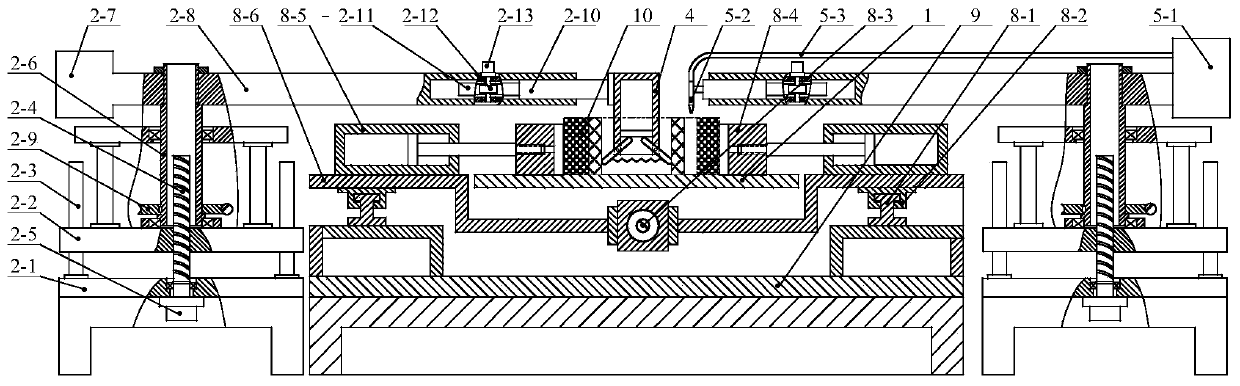

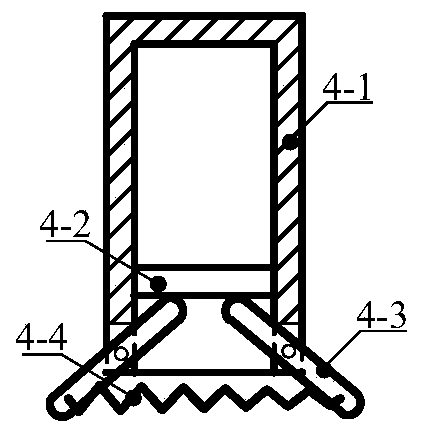

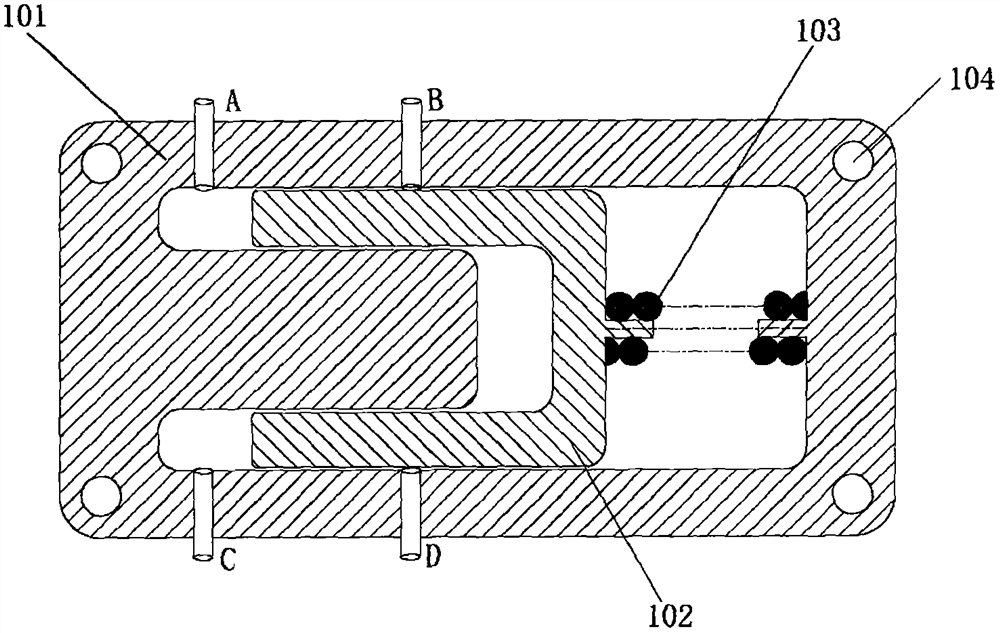

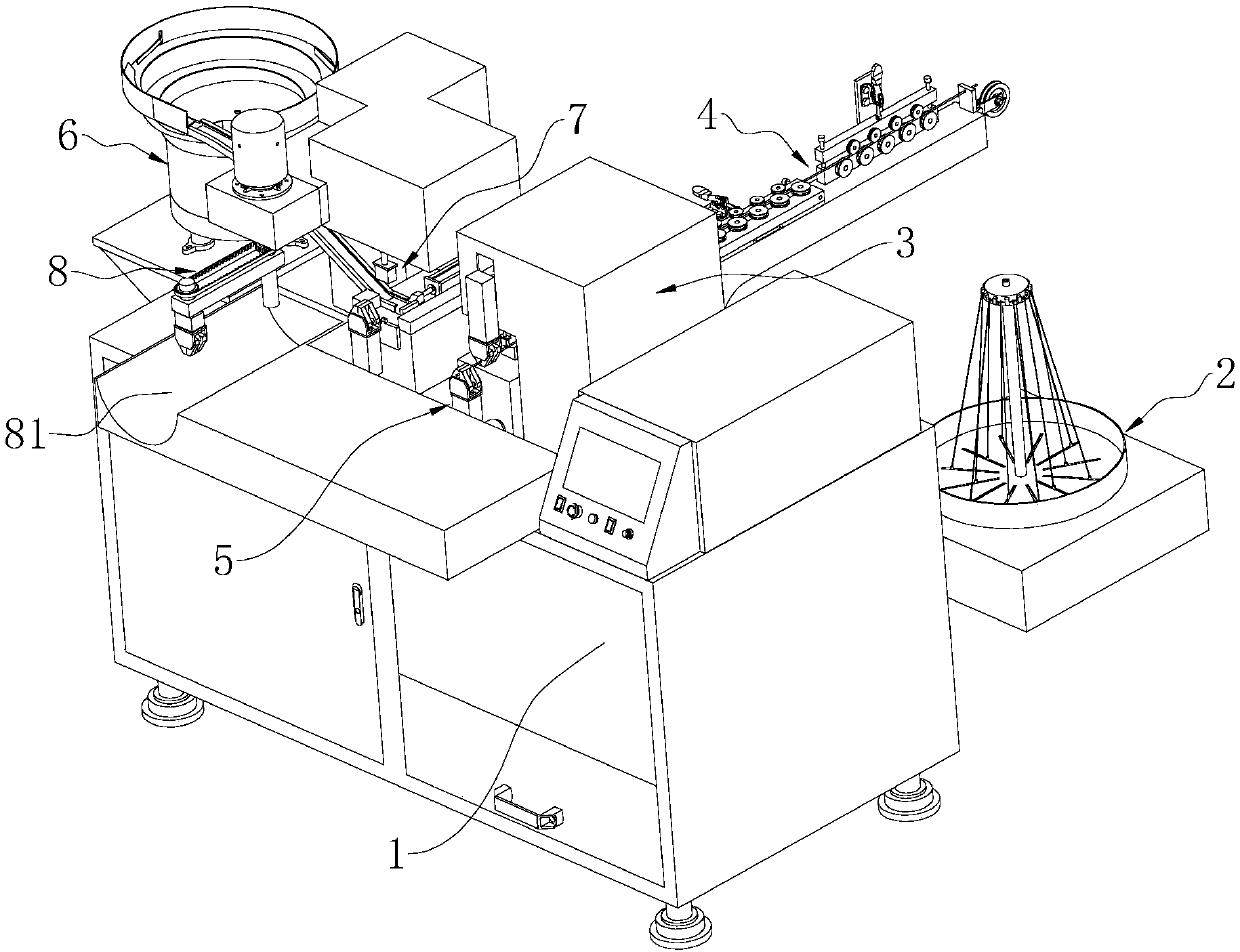

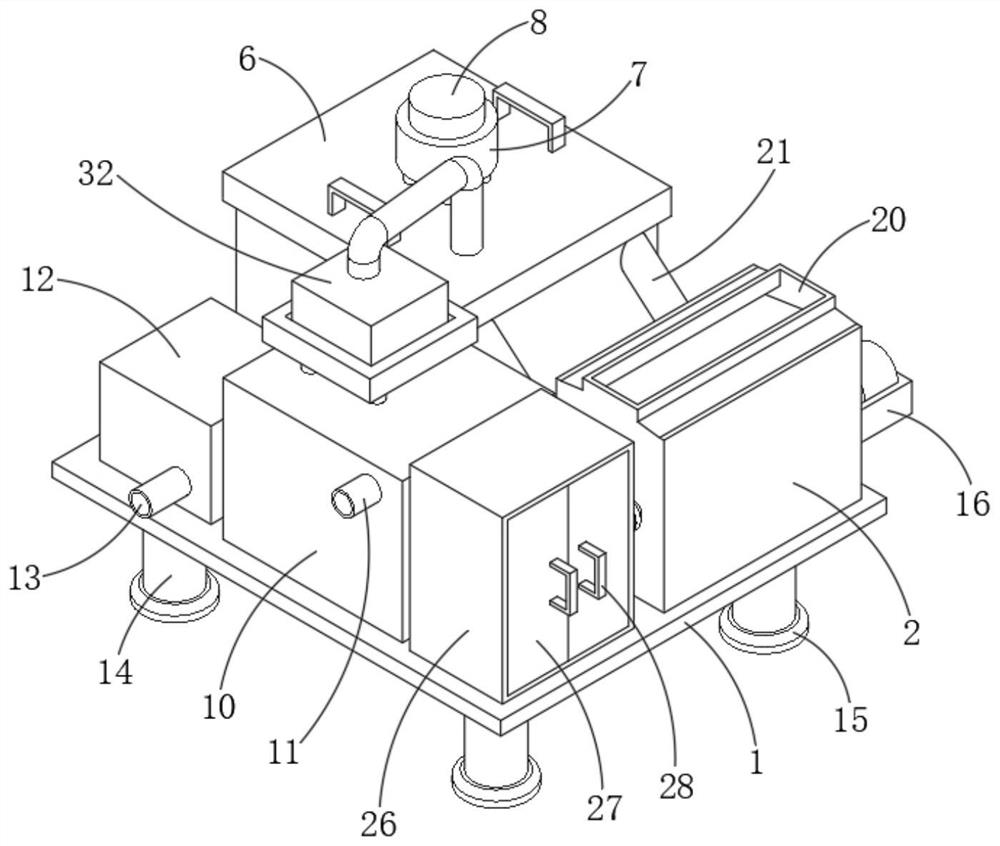

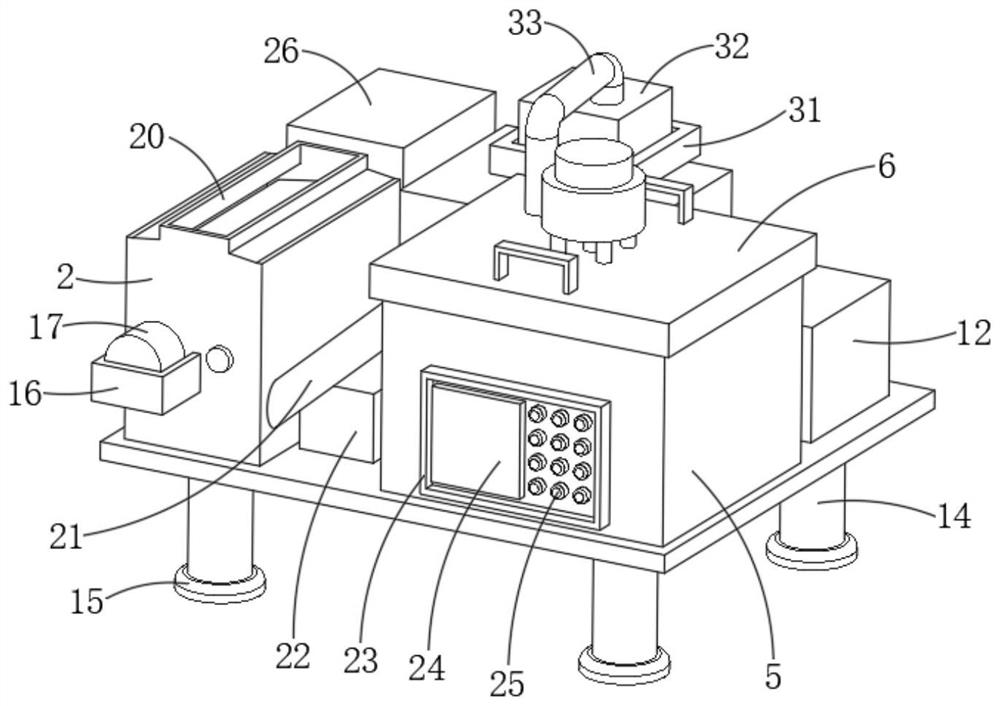

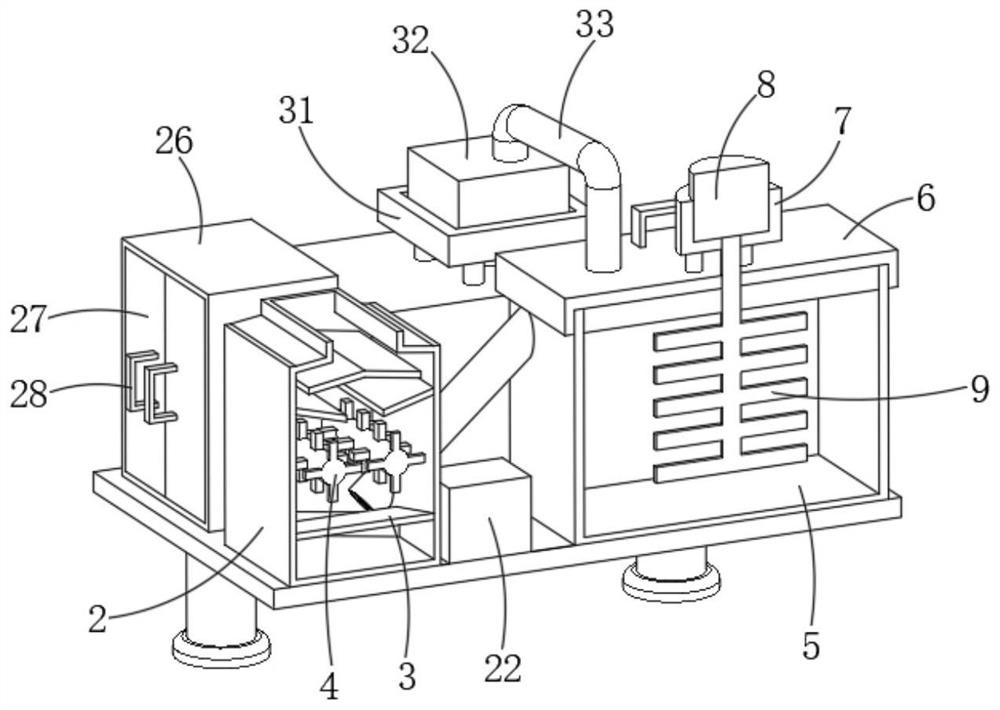

Bearing assembly all-in-one machine and assembly method thereof

ActiveCN110185711AGuaranteed precision and consistencySimple mechanical structureBearing componentsNozzleEngineering

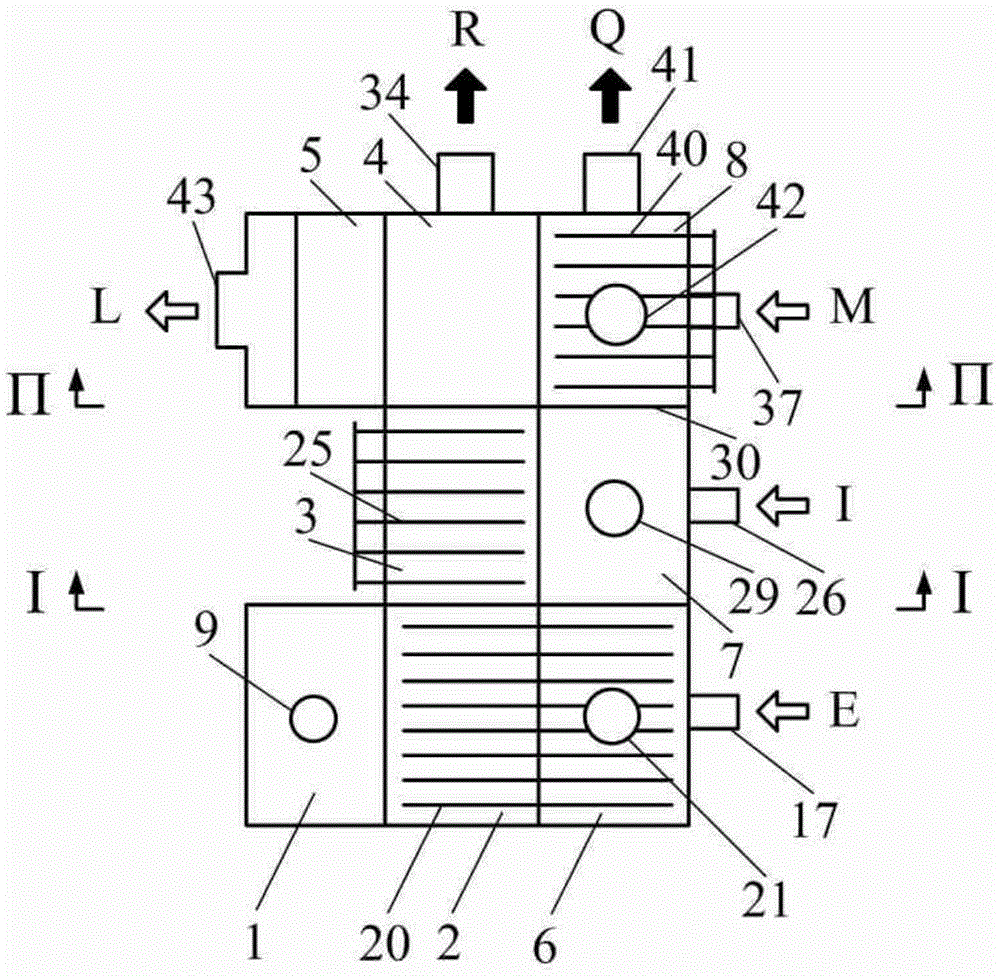

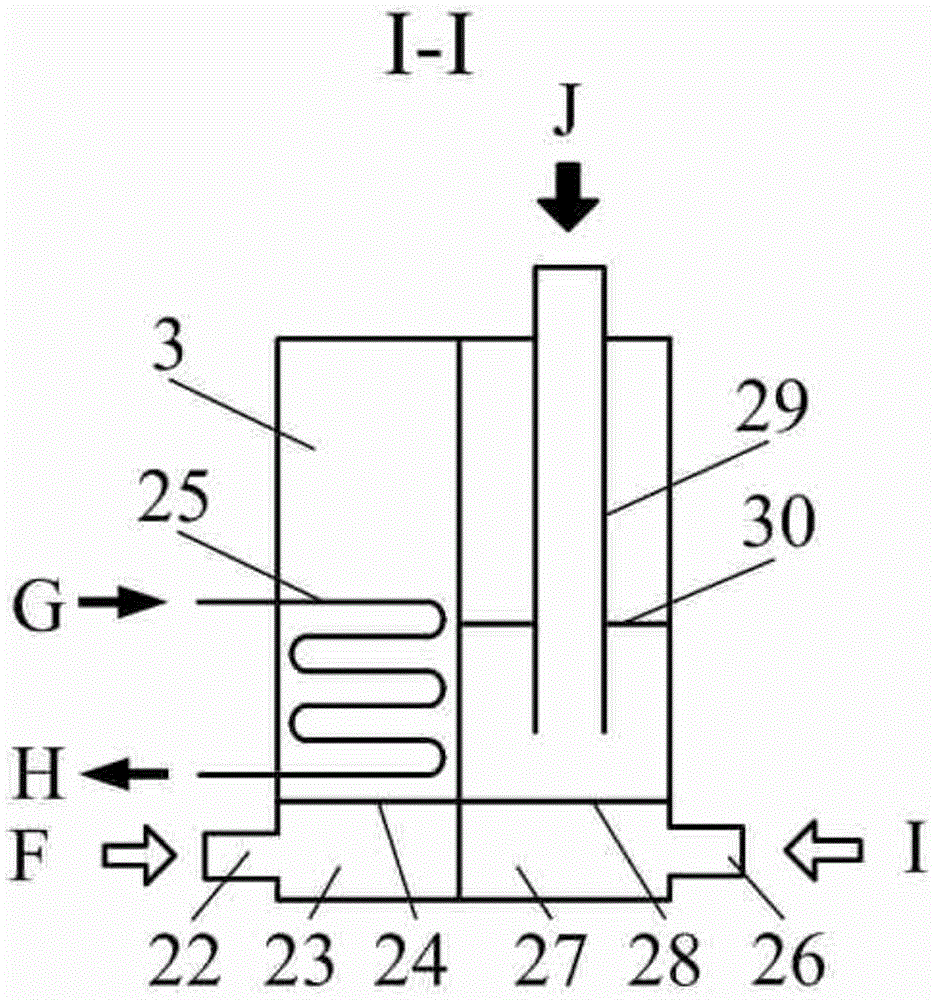

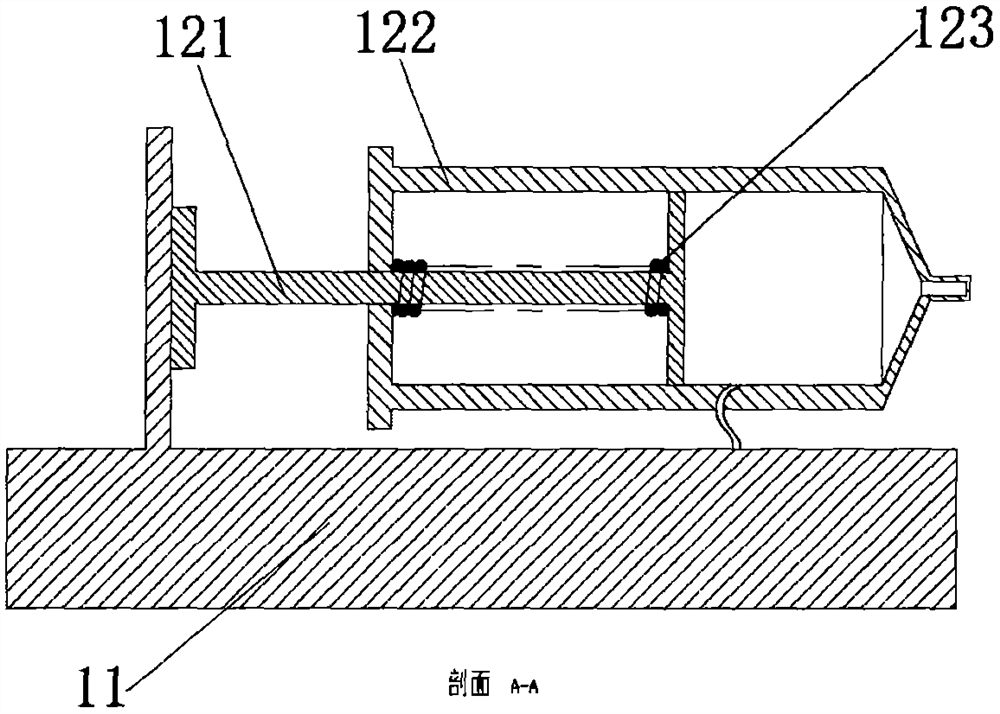

The invention discloses a bearing assembly all-in-one machine and an assembly method thereof. The assembling of bearing balls and press-fitting of a bearing retainer are important processes in the assembly of rolling bearings. The machine comprises an operating platen, a ball loading module, a retainer pressing-in module, a station switching mechanism and a base, wherein the ball loading module comprises an inner ring triaxial mechanical arm, a ball triaxial mechanical arm, an inner ring mounting chuck and a ball blowing mechanism; the retainer pressing-in module comprises a pressing-down mechanism and a retainer pushing mechanism; the ball blowing mechanism comprises an air pressure ball bin, an on-off valve, a nozzle and a ball conveying pipe; and the retainer pushing mechanism comprisesa feeding device seat, a feeding air cylinder, a return spring, a T-shaped locking pin, a feeding bottom plate, a feeding device, a feeding inclined rail and a retainer storage bin. By matching the station switching mechanism, the ball loading module and the retainer pressing-in module, the assembly of an inner ring, an outer ring, the balls and the retainer of the bearing can be completed fullyautomatically, and the assembly precision and uniformity of the bearing are effectively guaranteed.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

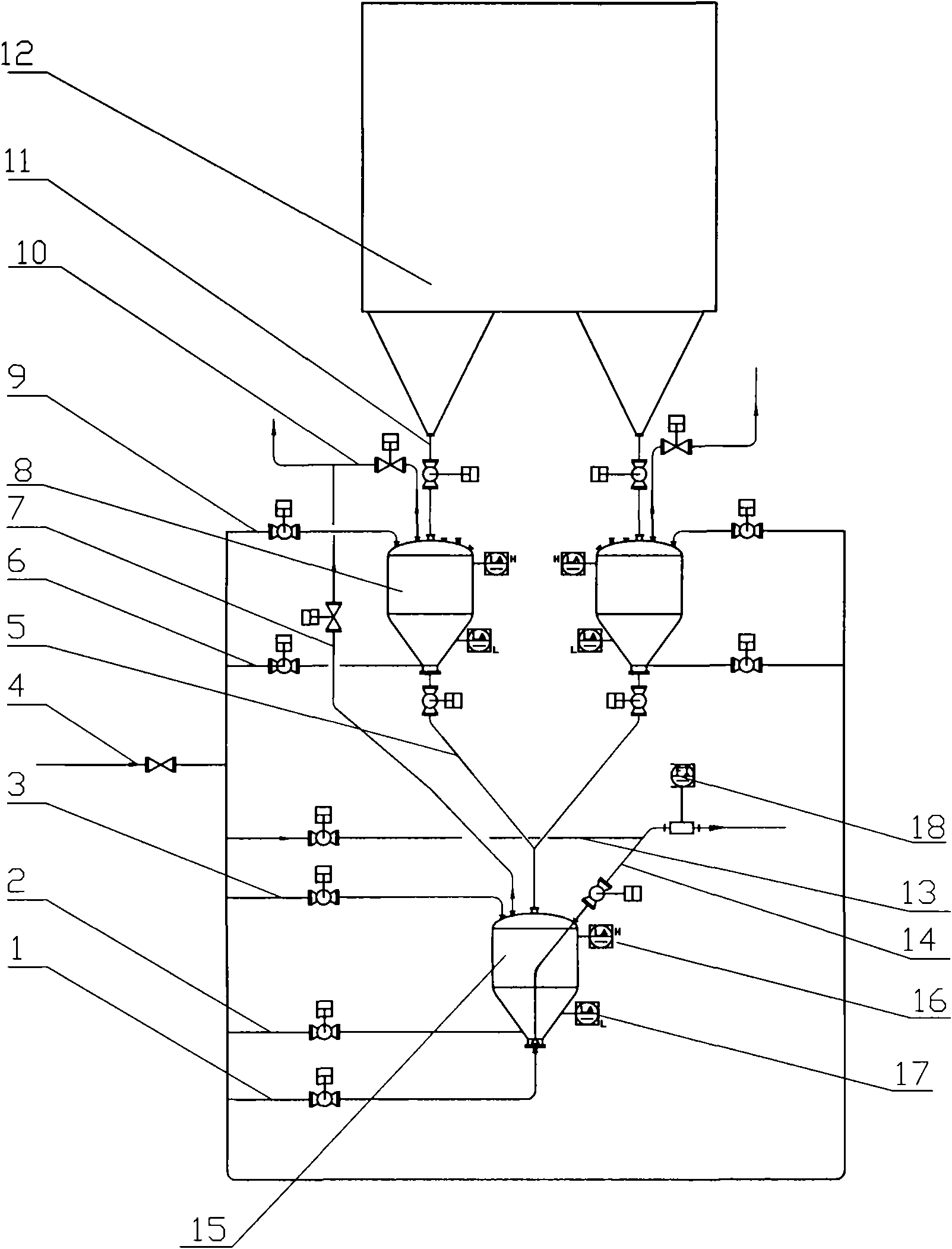

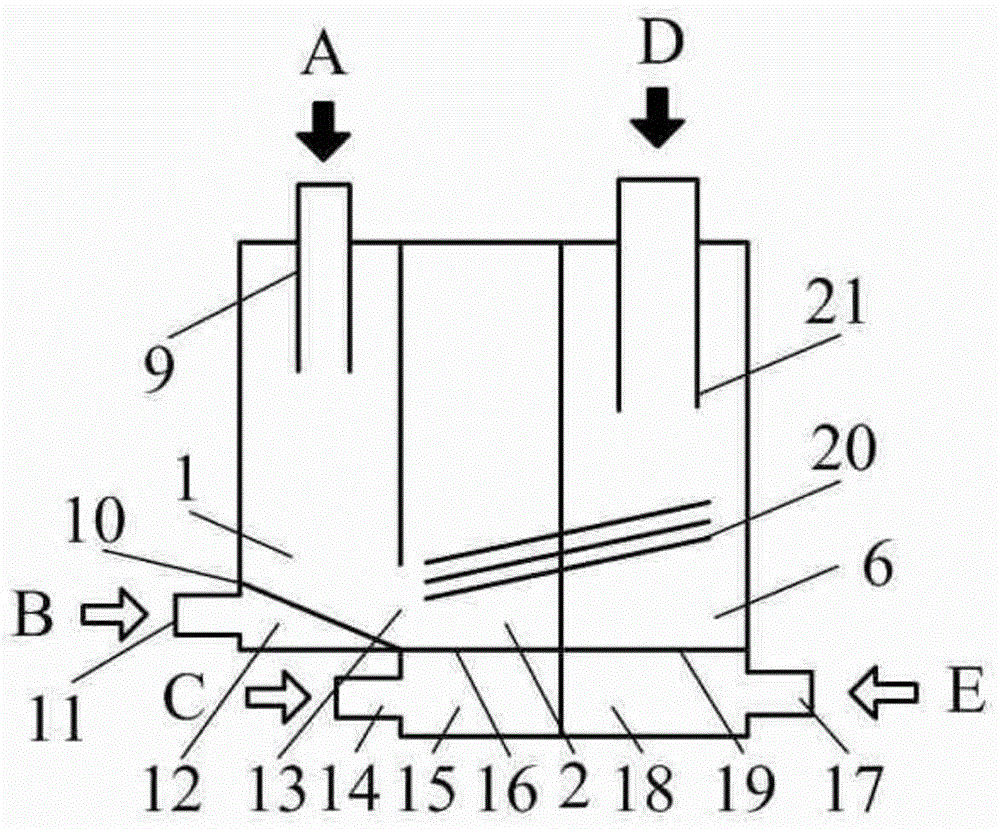

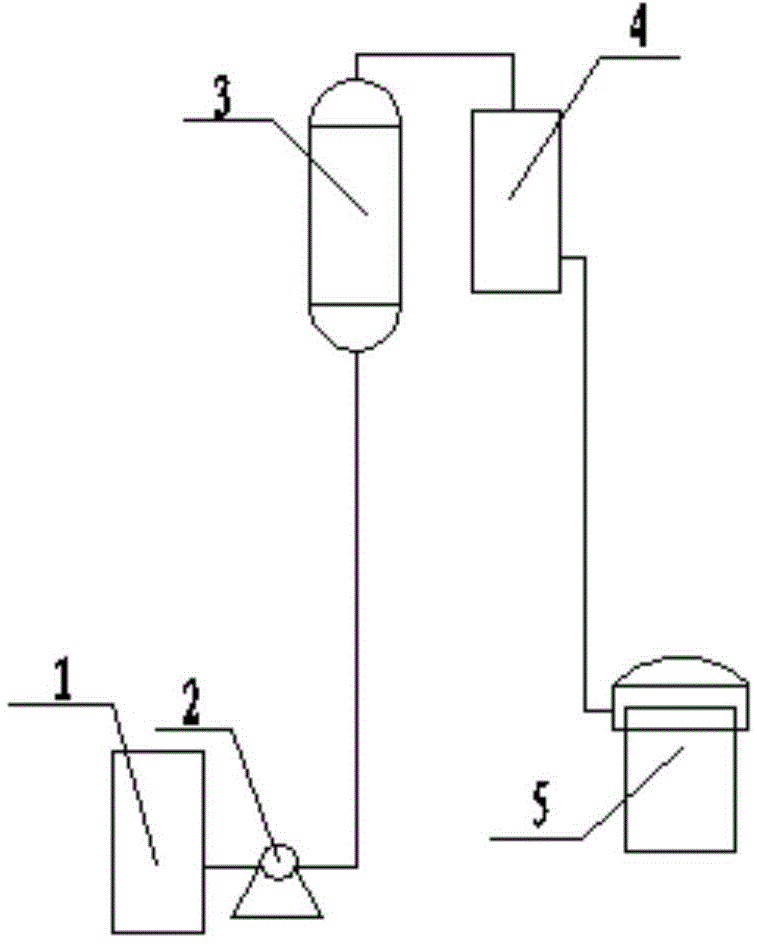

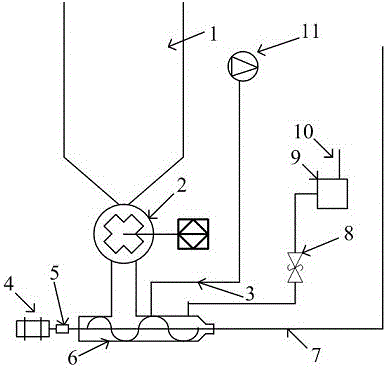

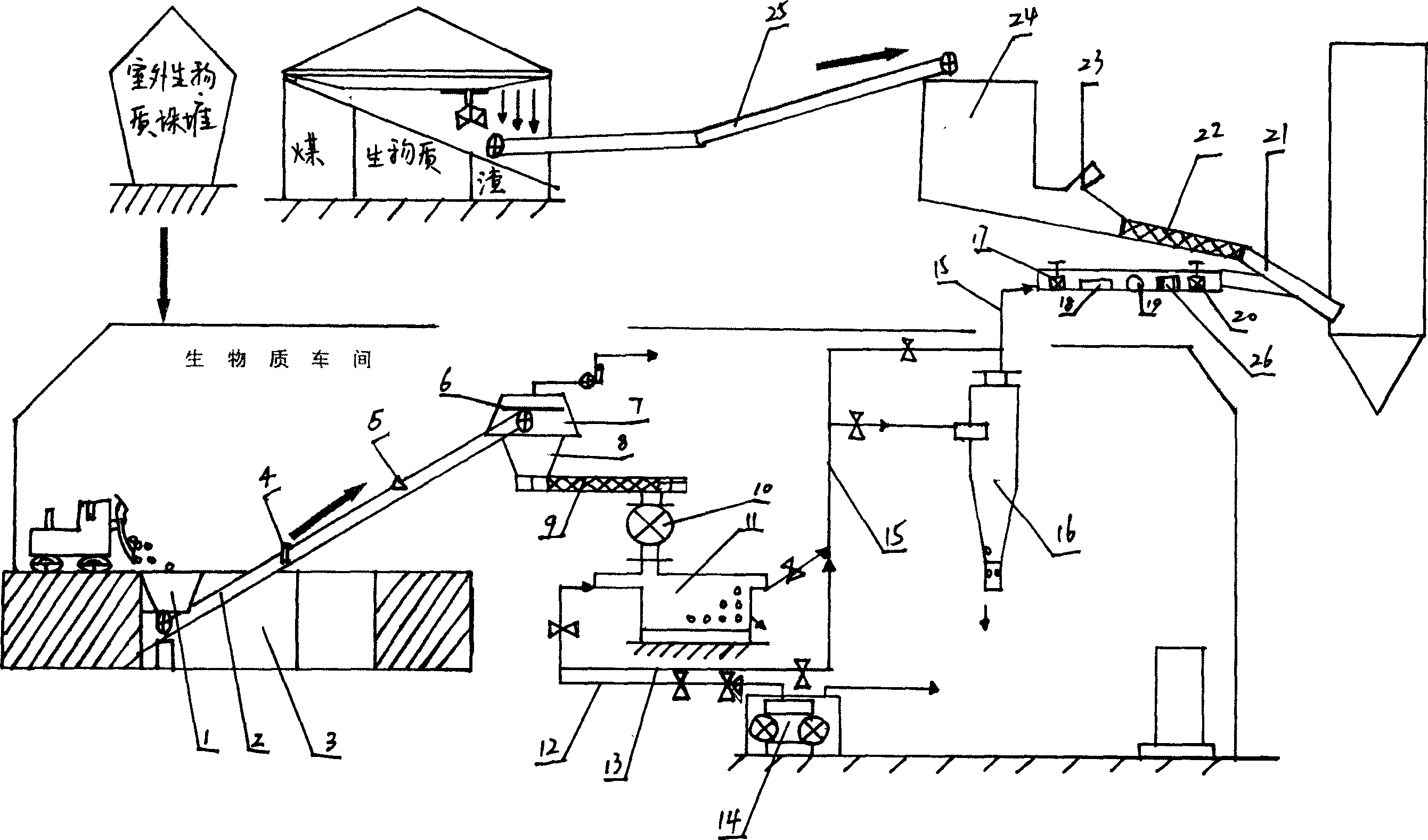

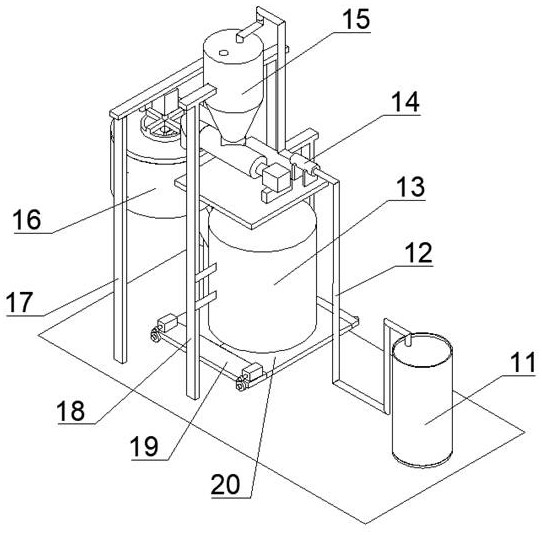

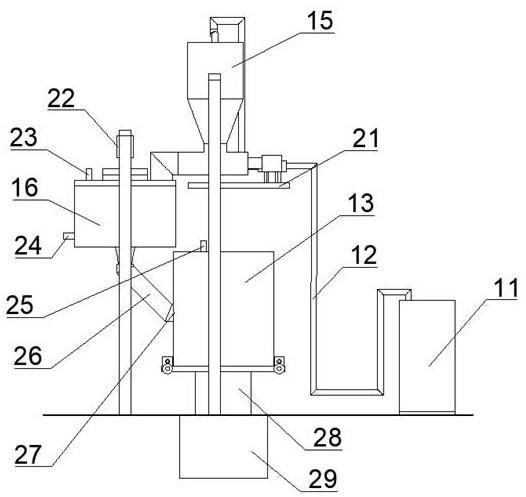

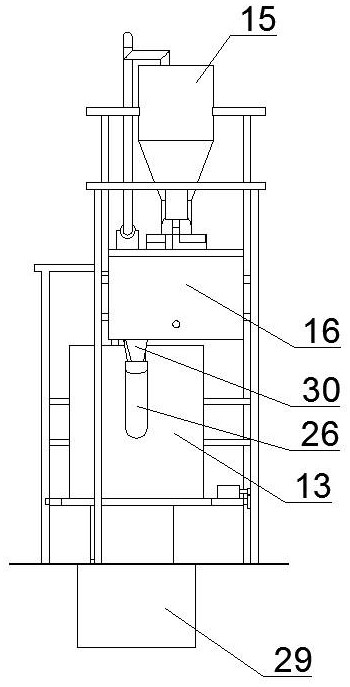

High-pressure continuous dense-phase biomass powder conveying device with height of delivery outlet adjustable

InactiveCN101863383AContinuous and stable deliveryConvey evenlyBulk conveyorsCombustionProcess engineering

The invention discloses a high-pressure continuous dense-phase biomass powder conveying device with the height of a delivery outlet adjustable, which comprises a storage silo, at least two feeding silos and a delivery silo. The principle is that the two transitional feeding silos are arranged between the storage silo and the delivery silo, are respectively provided different air ducts communicated with a main air pipeline and can control the interactive and continual feeding to the delivery silo according to the time sequence through changing the pressure difference between the two feeding silos, so that the level in the delivery silo is maintained no lower than the low level, thereby realizing the continuous and stable conveying of biomass powder to gasification equipment. The device is mainly applied in the biomass powder pressurization and gasification plant and the continuous combustion device of the biomass powder, no blockage can occur to the conveying process, and the biomass powder is conveyed continuously, smoothly and uniformly with low pulsation. Therefore, the conveying device satisfies the requirements for pressurization and gasification of the biomass powder.

Owner:合肥天焱绿色能源开发有限公司

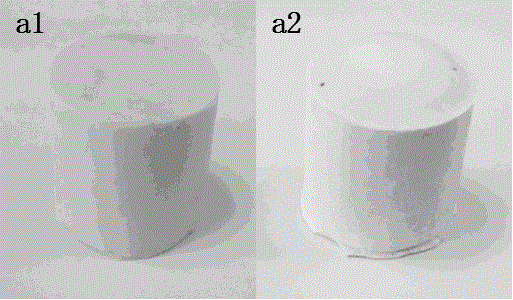

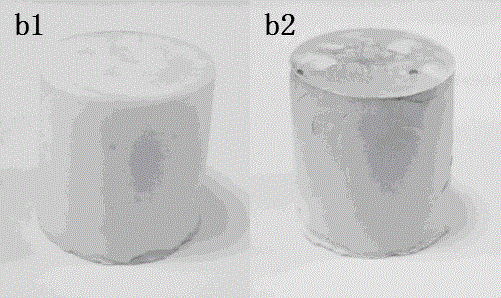

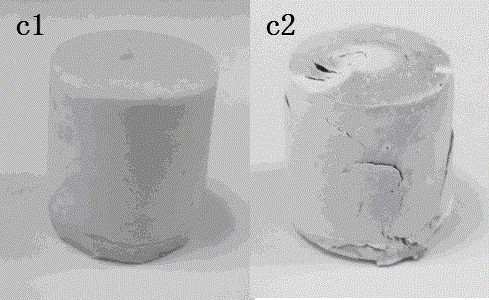

Preparation method of ceramic silicon rubber composite material used for fire-resistant insulated cable

InactiveCN105647190ASimple production processLow costRubber insulatorsPlastic/resin/waxes insulatorsLow smoke zero halogenFiber

The invention relates to a preparation method of a ceramic silicon rubber composite material used for a fire-resistant insulated cable and belongs to the technical field of functional materials. According to the formula, the ceramic silicon rubber composite material used for the fire-resistant insulated cable is prepared from, by mass, 100 parts of methyl vinyl silicone rubber, 5-30 parts of inorganic fiber filling, 10-40 parts of ceramic powder and 0.1-1 part of anti-aging agent. The ceramic silicon rubber composite material used for the fire-resistant insulated cable has excellent fire resistance and outstanding shape-keeping capacity, can be ablated into a hard ceramic shell under continuous combustion of flames, protects the burnt object from damage, achieves a good fire-resistant effect and meanwhile will be free of large size deformation, shrinkage and cracking under a high-temperature condition. The ceramic silicon rubber composite material has the advantages of being low in cost, simple in production technology, free of toxin and environmentally friendly and achieving the effect of low smoke zero halogen.

Owner:SHANGHAI UNIV

Air curtain and water mist linkage dust settling method for full mechanized workface

The invention provides an air curtain and water mist linkage dust settling method for a full mechanized workface, which is applicable to dust control in a full mechanized workface in an underground coal mine. According to the invention, an air curtain generator arranged in a no man's zone located between a head-on workface and a driver of a heading machine is started to form an air curtain, and an enclosed area is formed between the head-on workface and the air curtain, which prevents dust from spreading outwards; simultaneously, water mist is injected into the formed enclosed area, and the water mist rapidly disperses in the enclosed area to capture dust in a moistened settling enclosed zone, thereby realizing air curtain and water mist linkage dust settling for the full mechanized workface. The method has the advantages of a simple process, convenient operation, small water consumption, low utilization cost and high dust settling efficiency; the water mist injected into the enclosed area can wet the surface of coal rock mass in head-on full mechanized workface, which enables gas and dust explosion induced by sparks generated in cutting of coal rocks to be avoided; the invention has wide practicality.

Owner:CHINA UNIV OF MINING & TECH

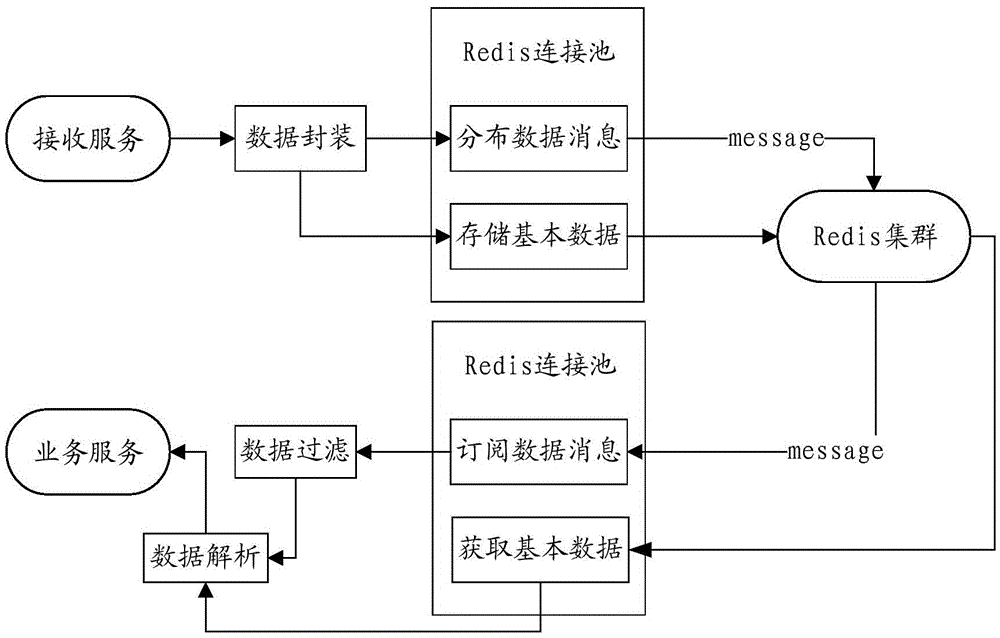

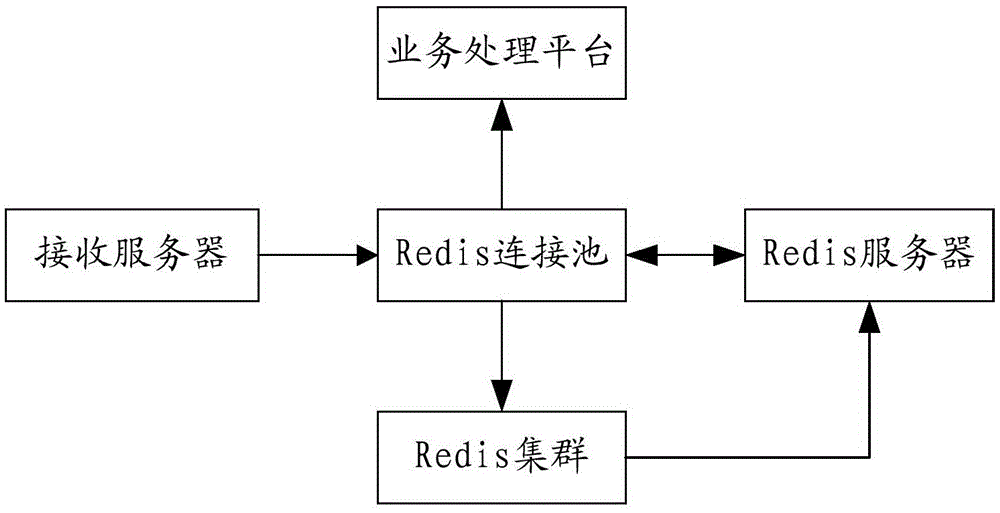

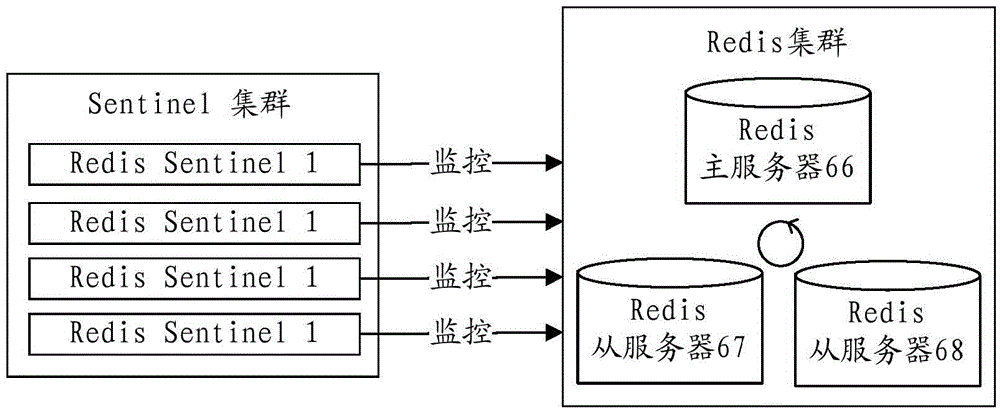

Redis pipeline communication-based message passing method and system

InactiveCN105630913AEfficient deliveryContinuous and stable deliveryInterprogram communicationDatabase distribution/replicationFailoverSoftware

The invention provides a Redis pipeline communication-based message passing method. The method comprises the following steps: 1, receiving data messages, reading basic data, packaging the basic data, calling an issue instruction, issuing the data messages into different channels of a Redis server according to the types of the data messages, and storing the packaged basic data in the Redis server; 2, calling a subscription instruction by a business processing platform to obtain the data messages in corresponding channels; 3, filtering the subscribed data messages by the business processing platform; 4, carrying out format conversion on the filtered data messages by the business processing platform through using a packaged interface, and analyzing the filtered data messages according to the packaged basic data messages; and 5, obtaining the analyzed data messages by the business processing platform, and transmitting the data messages to user software to display. The invention furthermore provides a Redis pipeline communication-based message passing system through which the messages can be rapidly and effectively transmitted and the failover can be carried out automatically.

Owner:FUJIAN XINGHAI COMM TECH

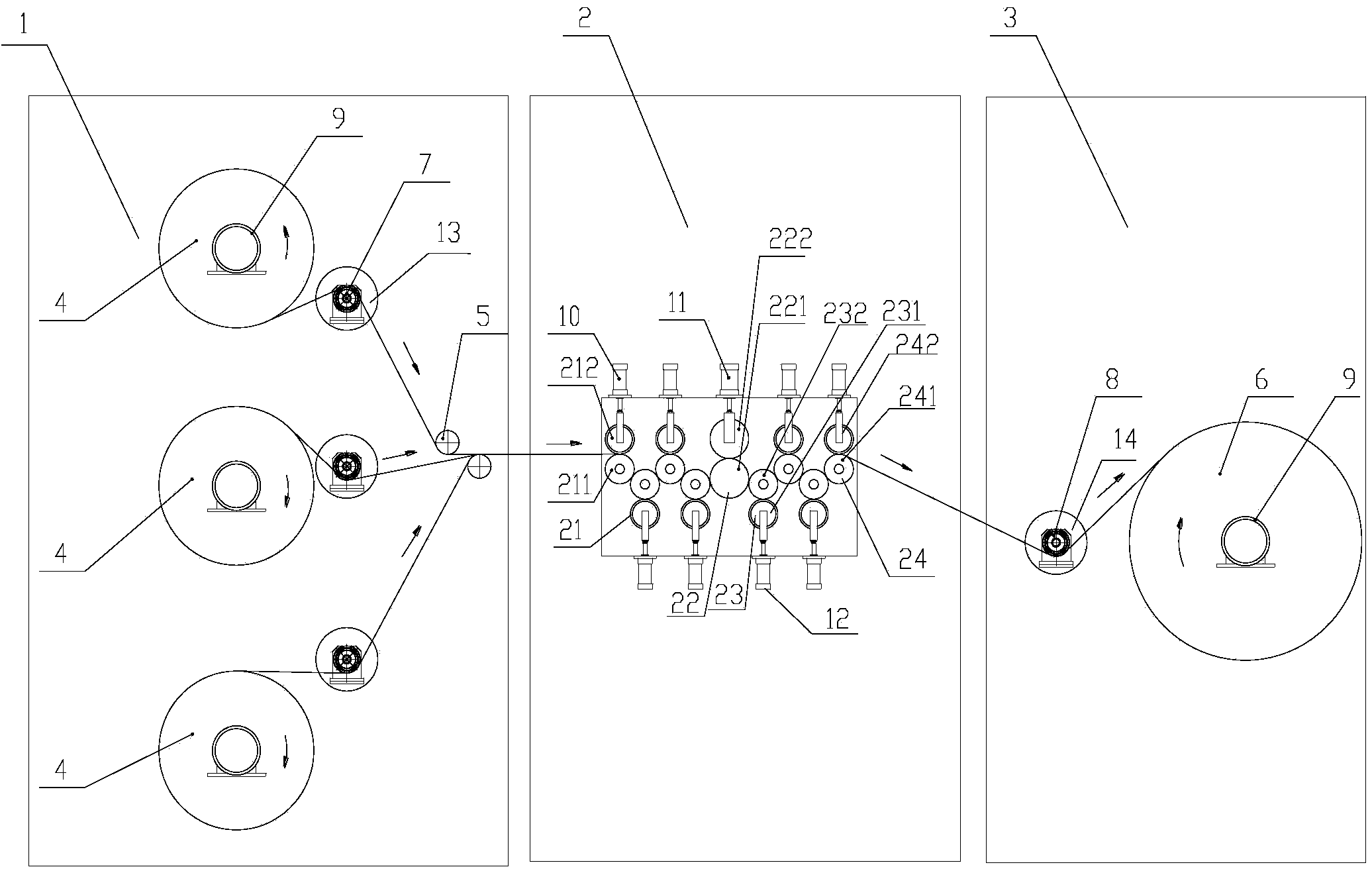

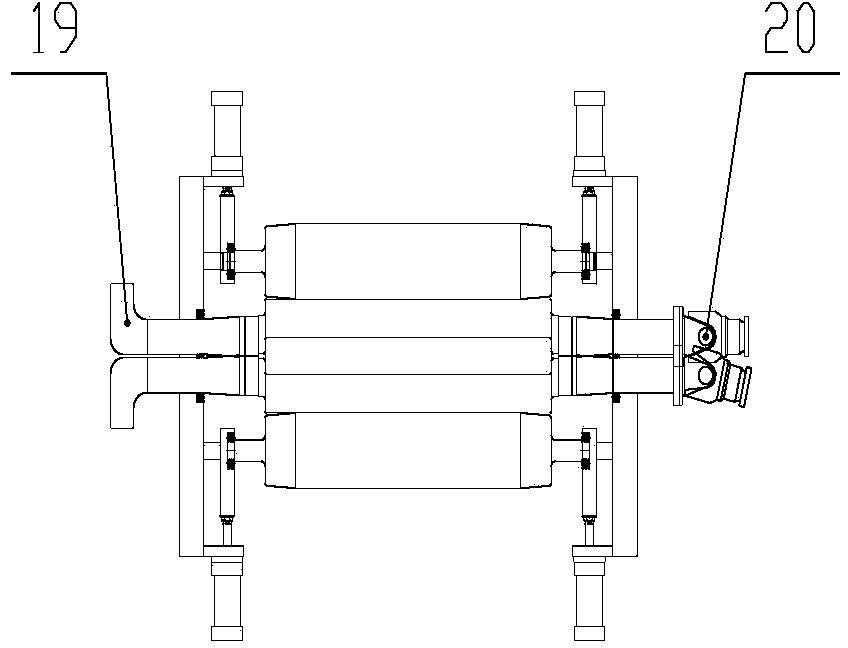

Lithium battery diaphragm compound device and compound method thereof

InactiveCN103753936AUniform Roll LaminationGood adhesionLaminationLamination apparatusPulp and paper industryLithium battery

The invention discloses a lithium battery diaphragm compound device and a compound method thereof. The device comprises an unwinding device, a rolling device and a winding device, wherein the unwinding device comprises at least two unwinding rollers, an unwinding guide roller and a direction guide roller; the unwinding guide roller is used for guiding a lithium battery diaphragm to the rolling device; the direction guide roller is used for changing the diaphragm guide direction; the rolling device comprises a preheating roller, a hot pressing roller, a heat setting roller and a cooling roller; the preheating roller, the hot pressing roller, the heat setting roller and the cooling roller are orderly arranged in parallel; the preheating roller, the hot pressing roller, the heat setting roller and the cooling roller are arranged inside the rolling device of the device, so that uniform rolling and compounding of a plurality of layers of films can be well achieved, the adhesion between the films can be enhanced, and the compound effect is better.

Owner:成都芝田高分子材料有限公司

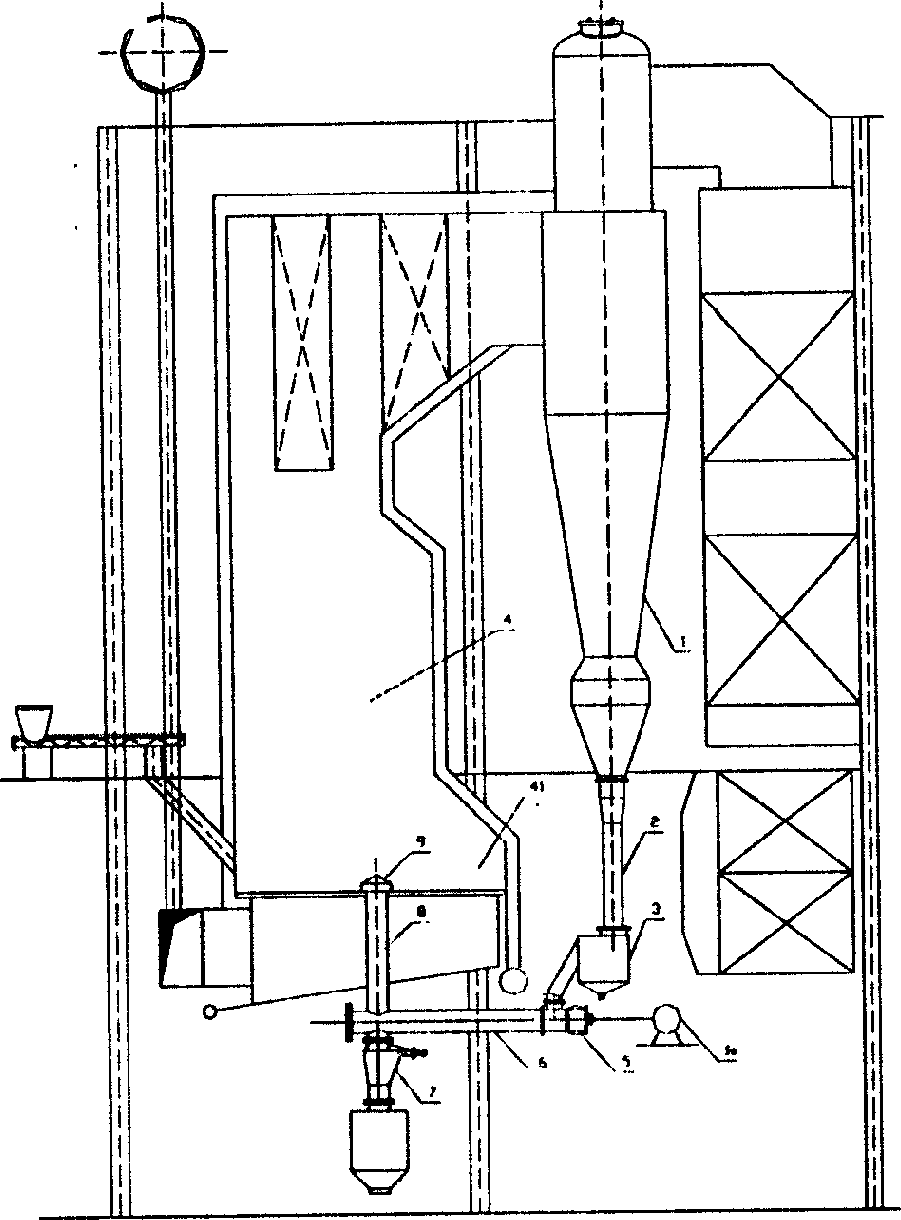

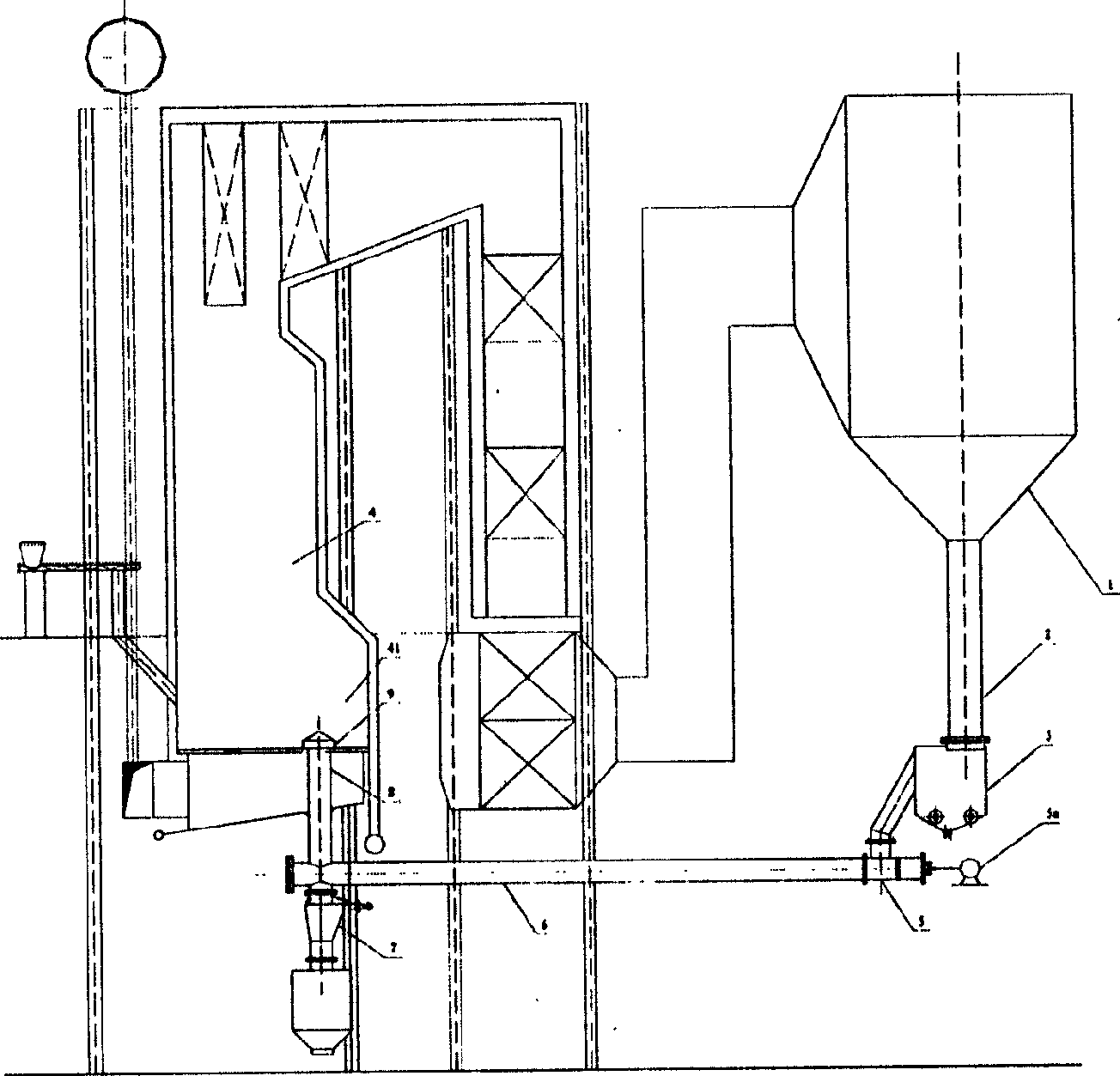

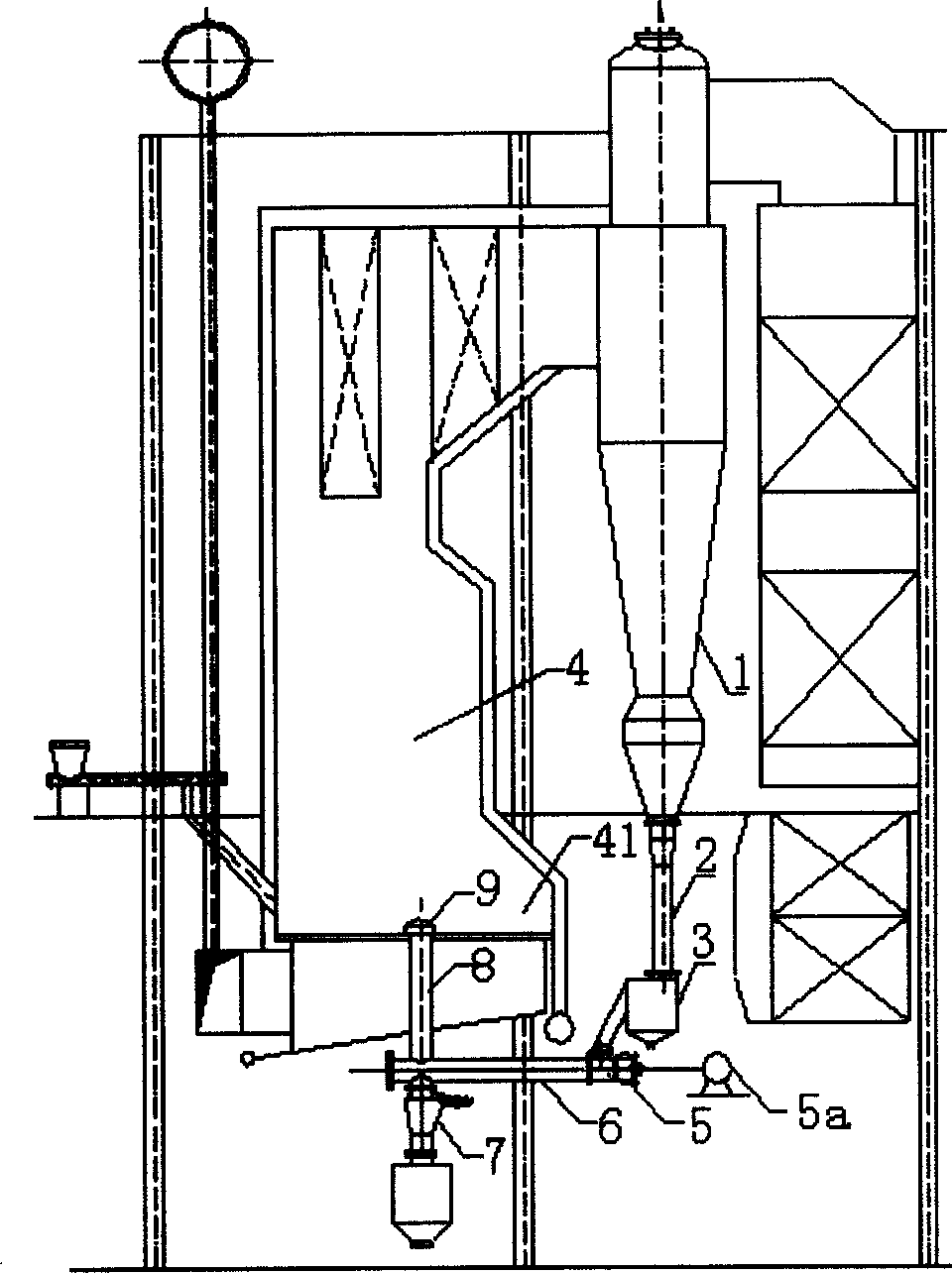

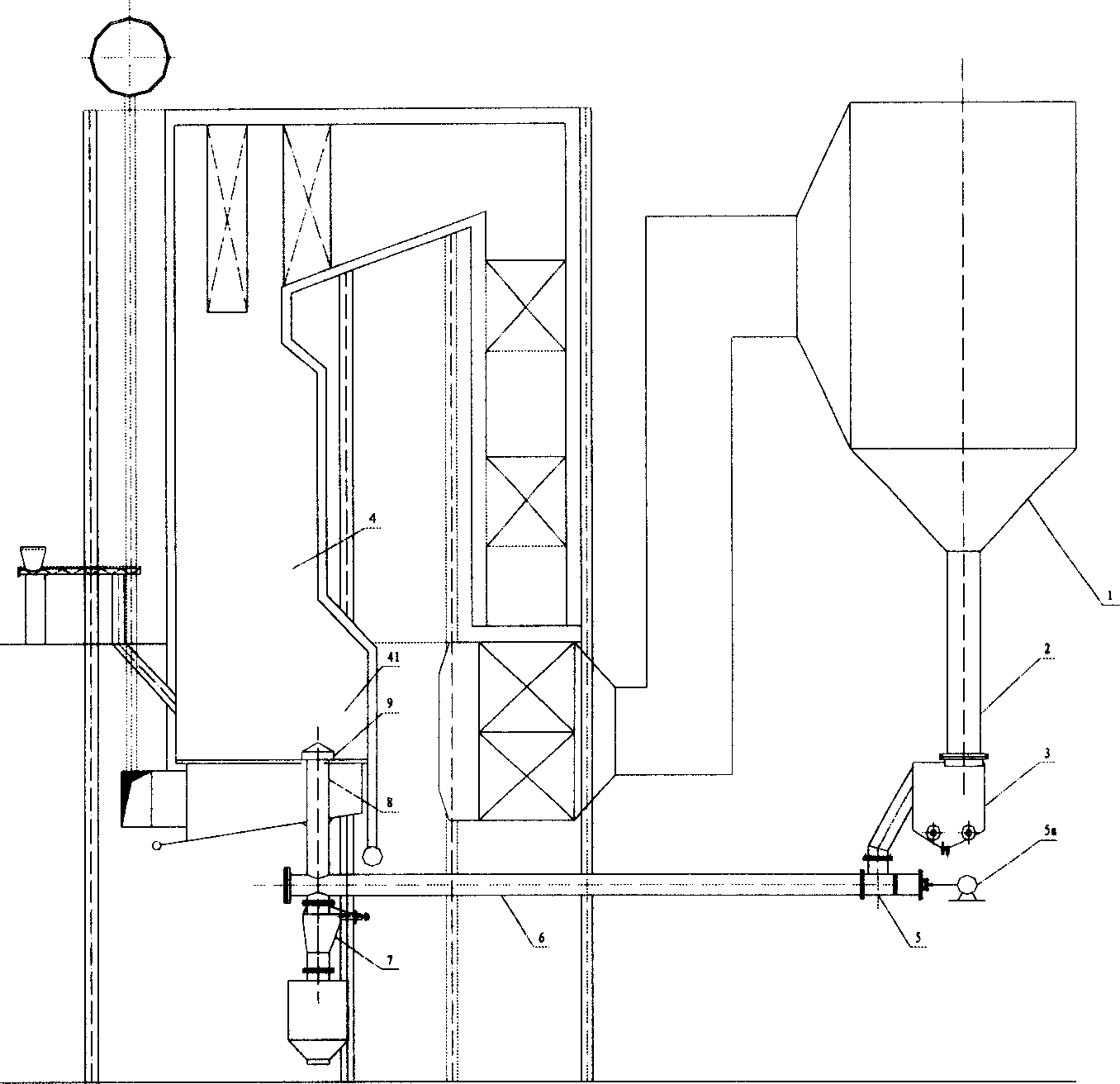

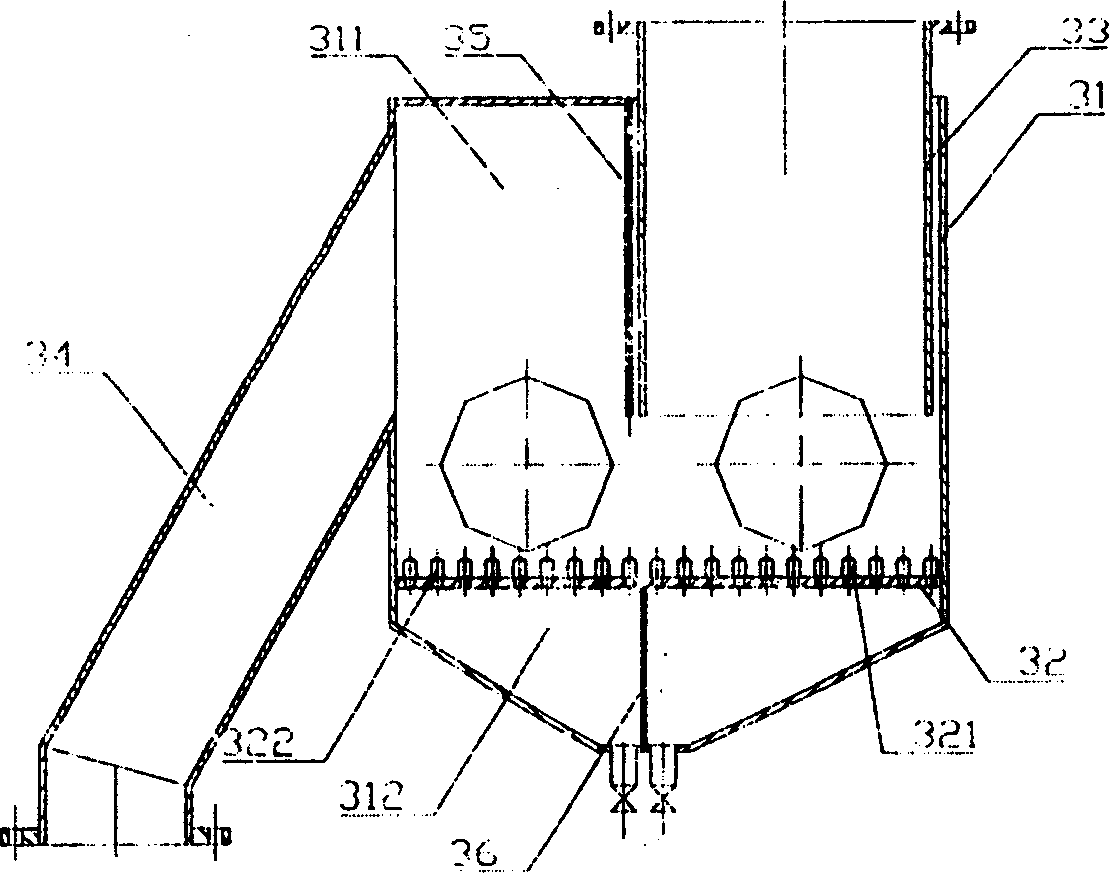

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

ActiveCN1529088AReduce leakageImprove sealing performanceFluidized bed combustionApparatus for fluidised bed combustionInjectorCorrosion

The invention provides a kind of fly ash bottom feeding circular fluidized-bed combustion method and the device, the method is: uses fly ash collector to collect the fly ash with high content in smoke, the fly ash are put into the back material controller through vertical pipe, then and they are carried to the return pipe through transmitting and ejector, and they are returned to the thick phase area of bed through bottom feeding spraying muzzle which is high temperature resisting and corrosion resisting. The device is: it is made up of fly ash collector, back material controller, gas transmitting ejector and the combustion furnace. The top of the combustion furnace connects with the inlet of fly ash collector, the fly ash through the fly ash collector outlet, are carried to the thick phase area of combustion furnace through the bottom feeding sprayer with gas transmitting ejector. The invention can enhance the combustion effect of the fly ash; it can save energy and protect the environment.

Owner:SOUTHEAST UNIV

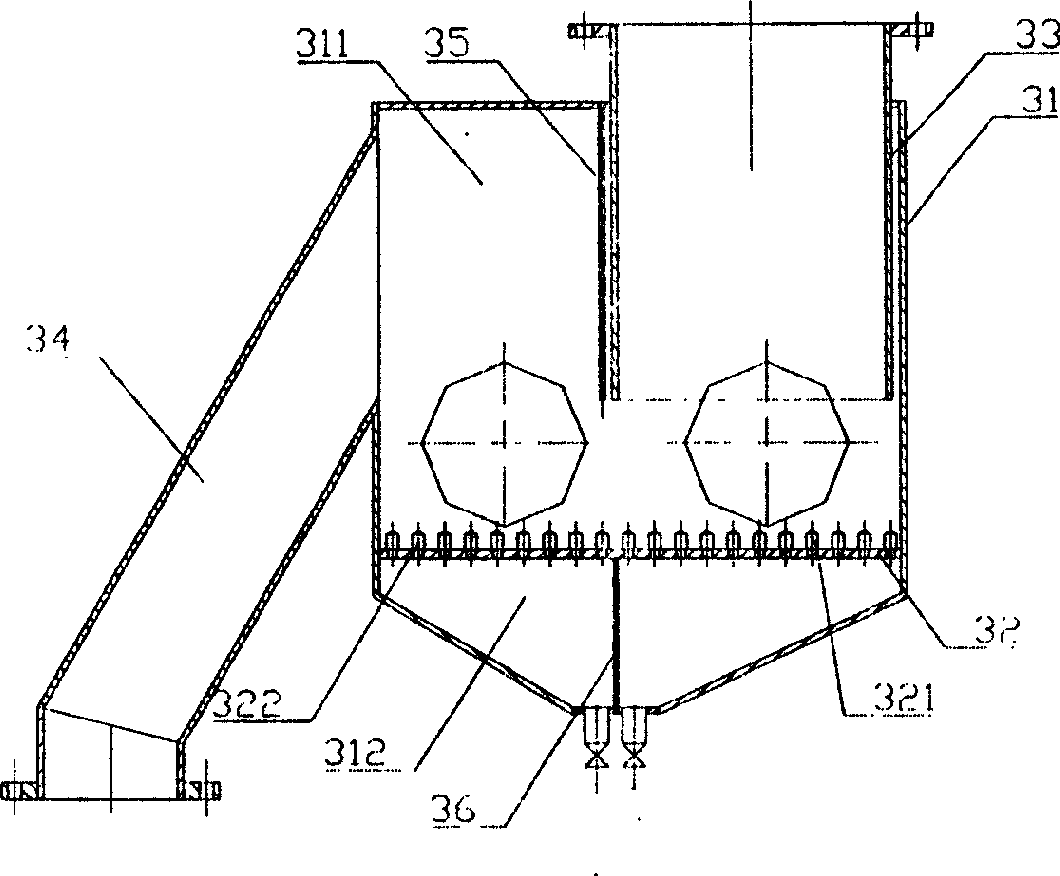

Ex-situ soil thermal desorption device

ActiveCN105382024AReduce usageIncrease fertilityContaminated soil reclamationHeat regenerationFertilizer

The invention discloses an ex-situ soil thermal desorption device. Soil to be repaired is preheated through heat of bottom residues of a biomass circulating fluidized bed boiler through a heat pipe heat exchange manner; then a direct heat exchange manner is used for desorbing pollutants in soil through heat of circulating ash of the biomass circulating fluidized bed boiler; and meanwhile fertility of the repaired soil is improved through active ingredients in the circulating ash, and gaseous pollutants generated through desorption are introduced into the boiler to be incinerated and decomposed. The device achieving the method comprises a slag conveying room, a first cold residue room, a second cold residue room, a third cold residue room, an inertia separating room, a preheating room, an analyzing room and a heat regeneration room. According to the ex-situ soil thermal desorption device, thermal desorption of the soil is achieved based on waste heat of the bottom residues of the boiler, meanwhile, fertilizer of the soil is improved by mixing active ingredients, volatile pollutants generated through desorption are sent into the boiler to be directly incinerated, and secondary pollution is avoided.

Owner:SOUTHEAST UNIV

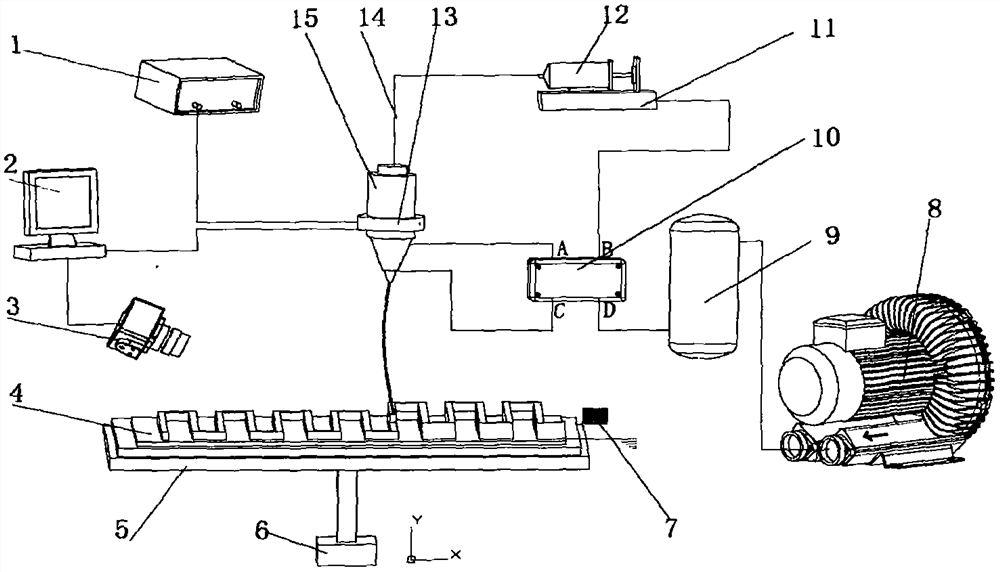

Electric jet printing device capable of dredging spray head through variable-pressure airflow

PendingCN113619108AOptimize micro-nano functional structureReduce equipment costsManufacturing platforms/substrates3D object support structuresPhysicsAdvanced manufacturing

The invention belongs to the technical field of advanced manufacturing, and relates to an electric jet printing device capable of dredging spray head through a variable-pressure airflow. The electric jet printing device comprises four parts, namely a jet printing module, a visual detection module, an adsorption module and an air pressure dredging spray head module, the jet flow jetted based on the electrohydrodynamic effect quickly realizes micro-nano functional structure jet printing under the coupling action of factors such as electric field force and viscous force. The electronic jet printing device adopts a mode of dredging the spray head through the variable-pressure airflow, when the spray head is blocked, accumulated ink in a spray head cavity is increased, unit pressure is increased, a core device, namely a two-position four-way valve acts, and the variable-pressure airflow applies reciprocating pressure and suction force to the blocked part, so that the spray head is dredged. Compared with a traditional method for dredging the spray head through mechanical vibration and physical heating, the electronic jet printing device has the advantages that the equipment cost is low, the machining period is short, disassembly is avoided, the spray head is automatically dredged, it is guaranteed that discontinuous, continuous and stable nanoscale fine jet flow is not generated in the jet printing process, a micro-nano functional structure is optimized, the use performance of a nano device is improved, and the service life of the nano device is prolonged.

Owner:NINGBO UNIV

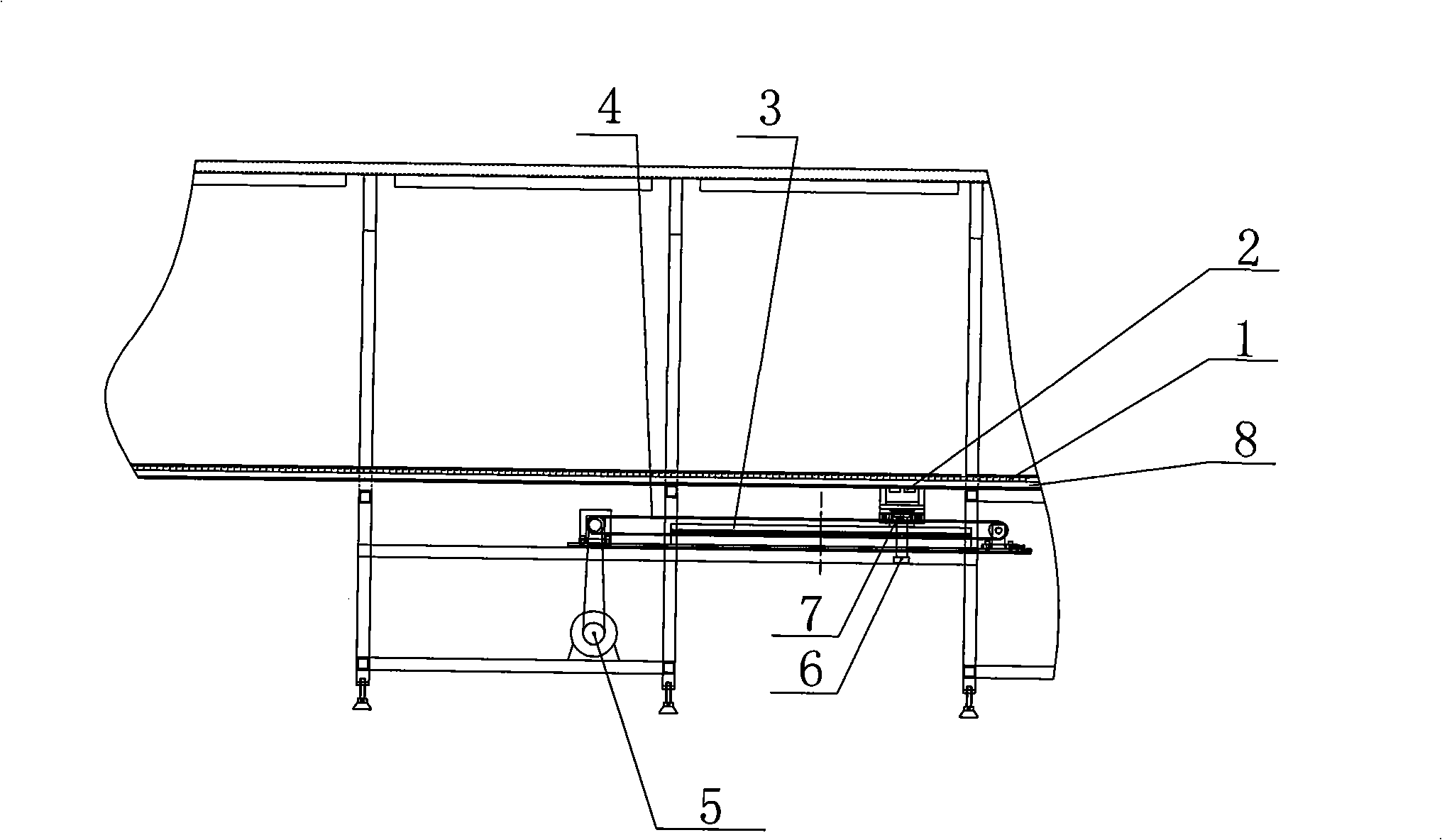

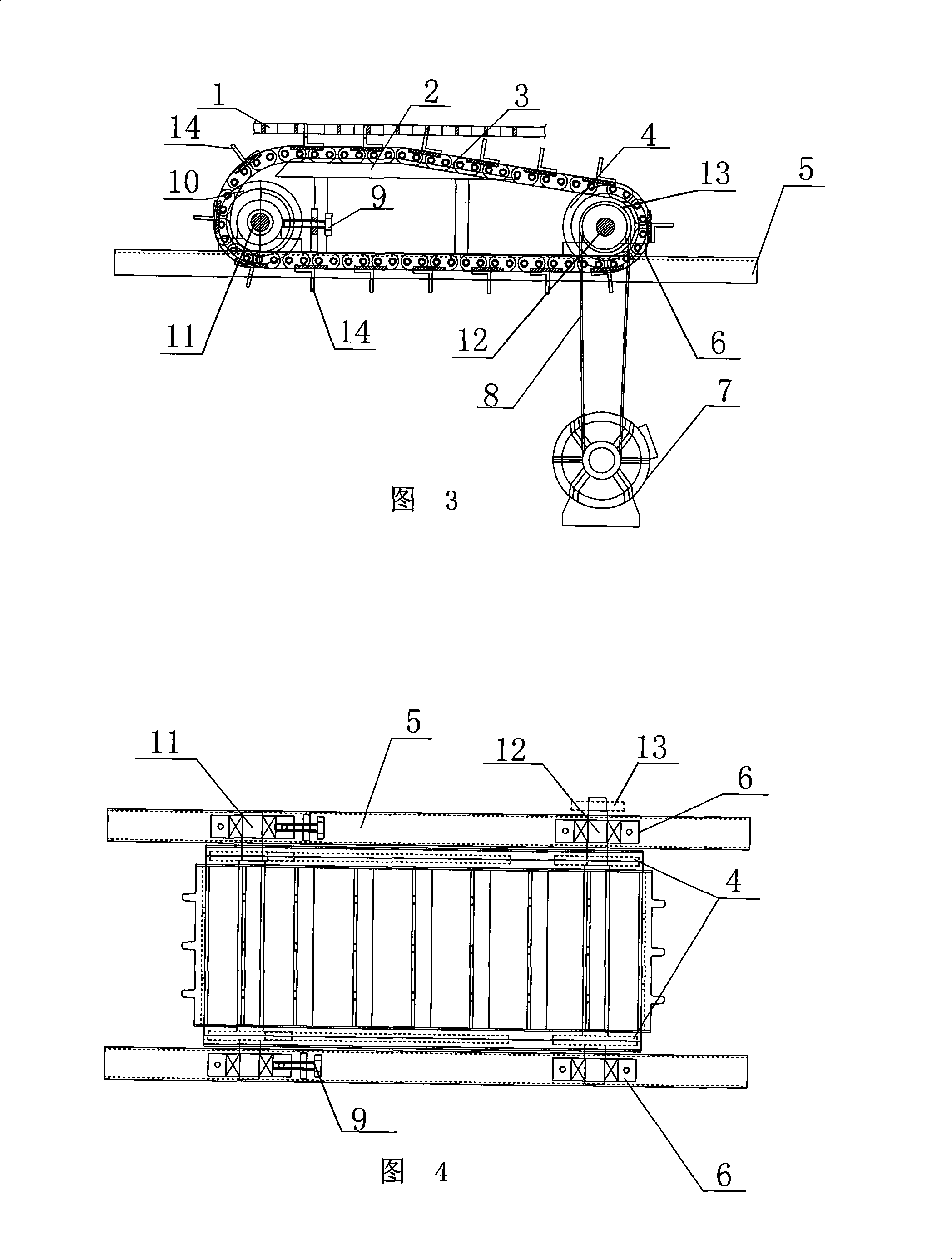

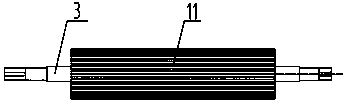

Transmission structure for conveyer belt for screen decorating machine

InactiveCN101402276AStable deliveryContinuous and stable deliveryConveyorsScreen printersScreen printingEngineering

The invention relates to a transmission structure for a conveyer belt for a silk screen printing machine, which has simple structure and continuous transmission, and ensures the stable transmission of the conveyer belt. The transmission structure comprises the conveyer belt, a conveyer chain and a driving structure, and is characterized in that the conveyer chain is meshed with the conveyer belt through a fastener connected with the outside of the conveyer chain, and two outside parts at the meshing part of the conveyer chain and the conveyer belt are in shapes of obtuse arc respectively.

Owner:陆新田

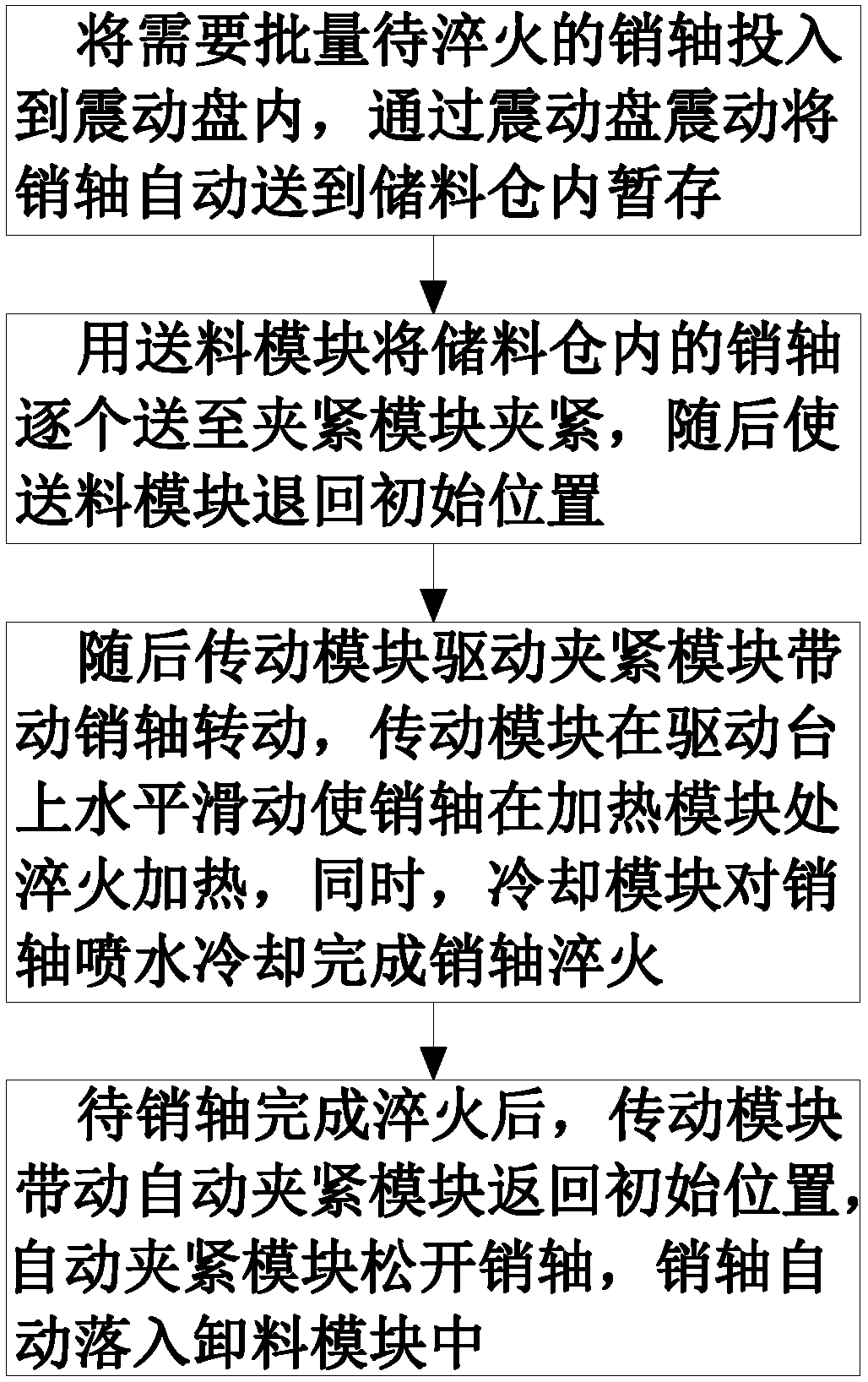

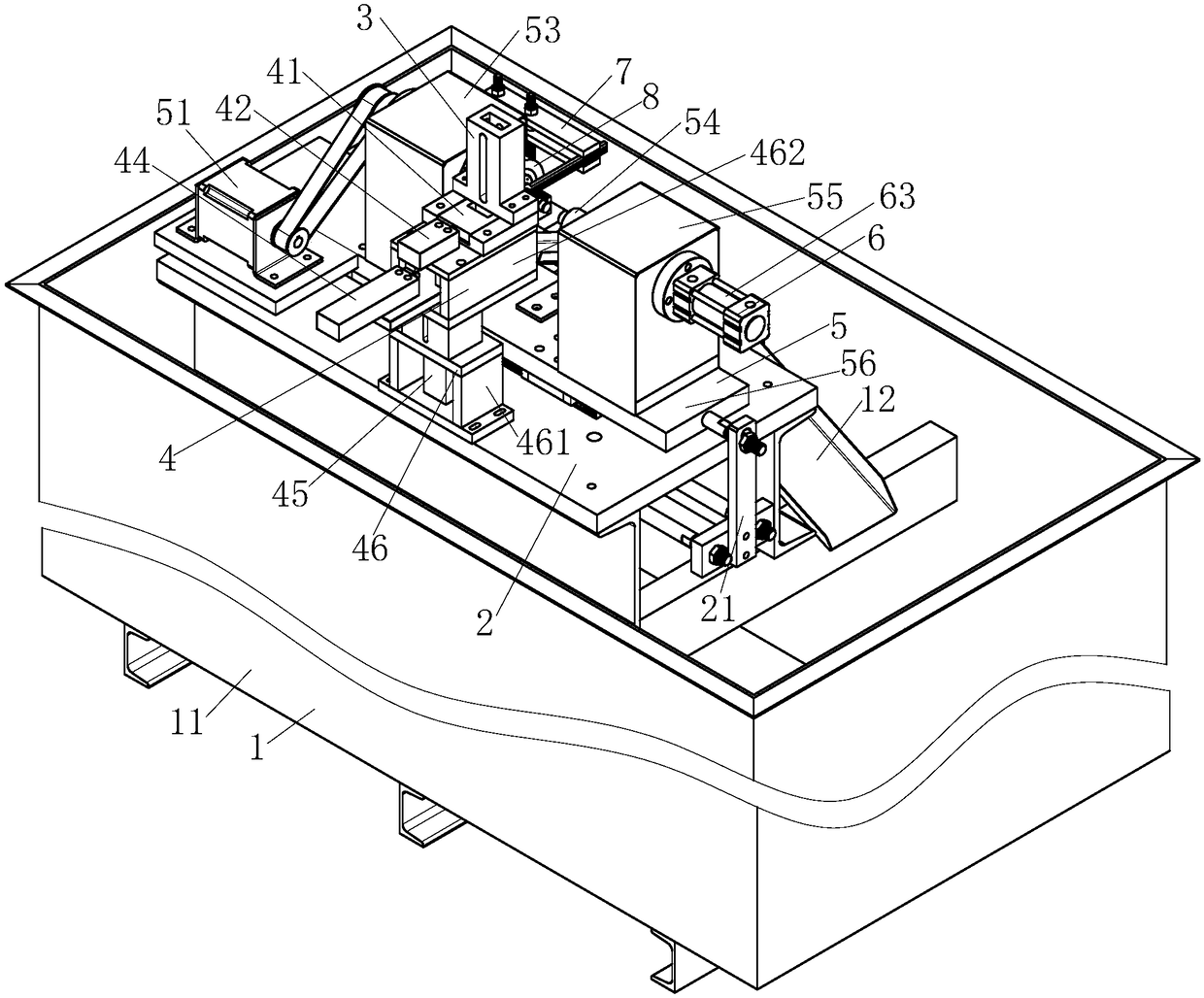

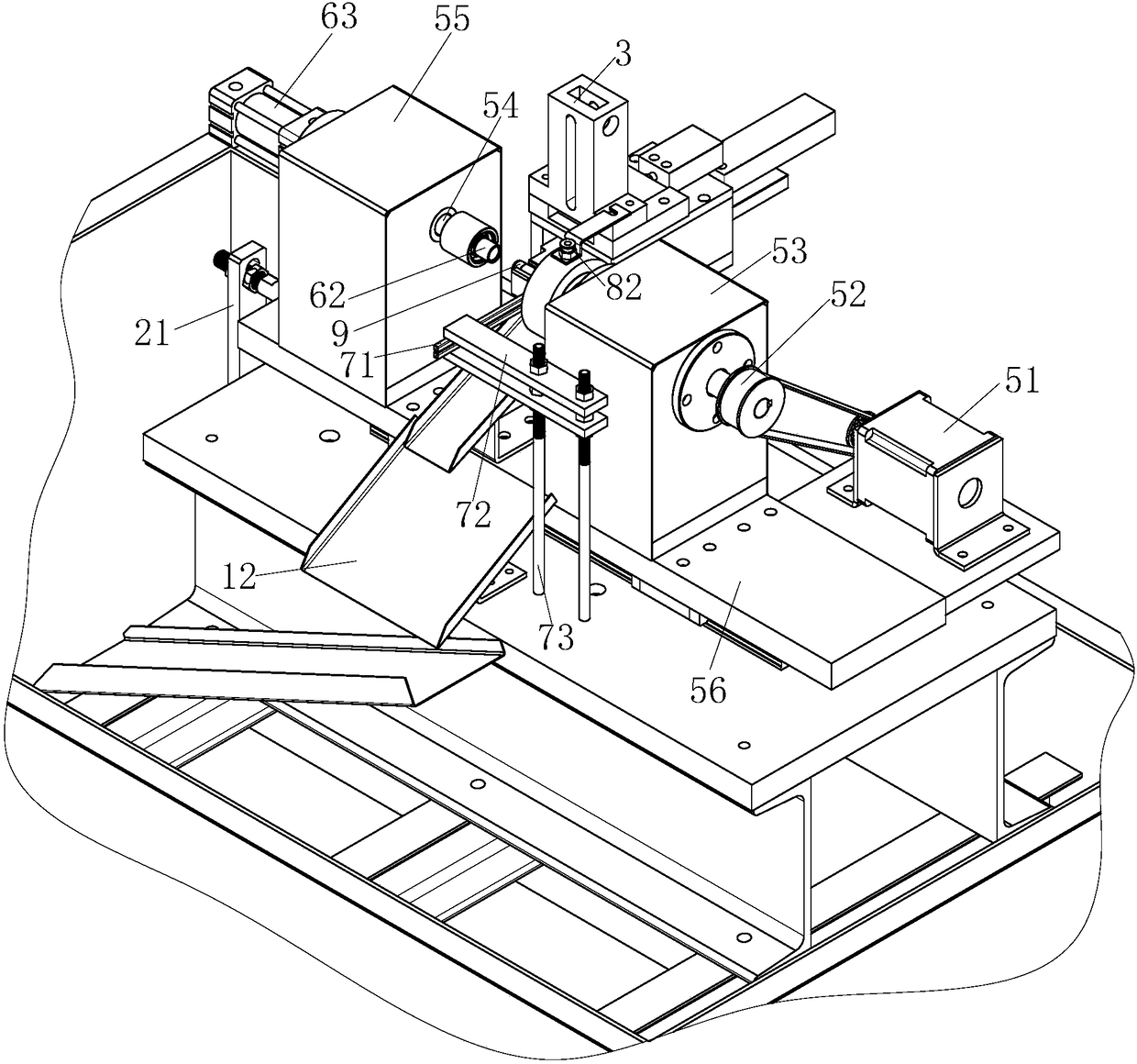

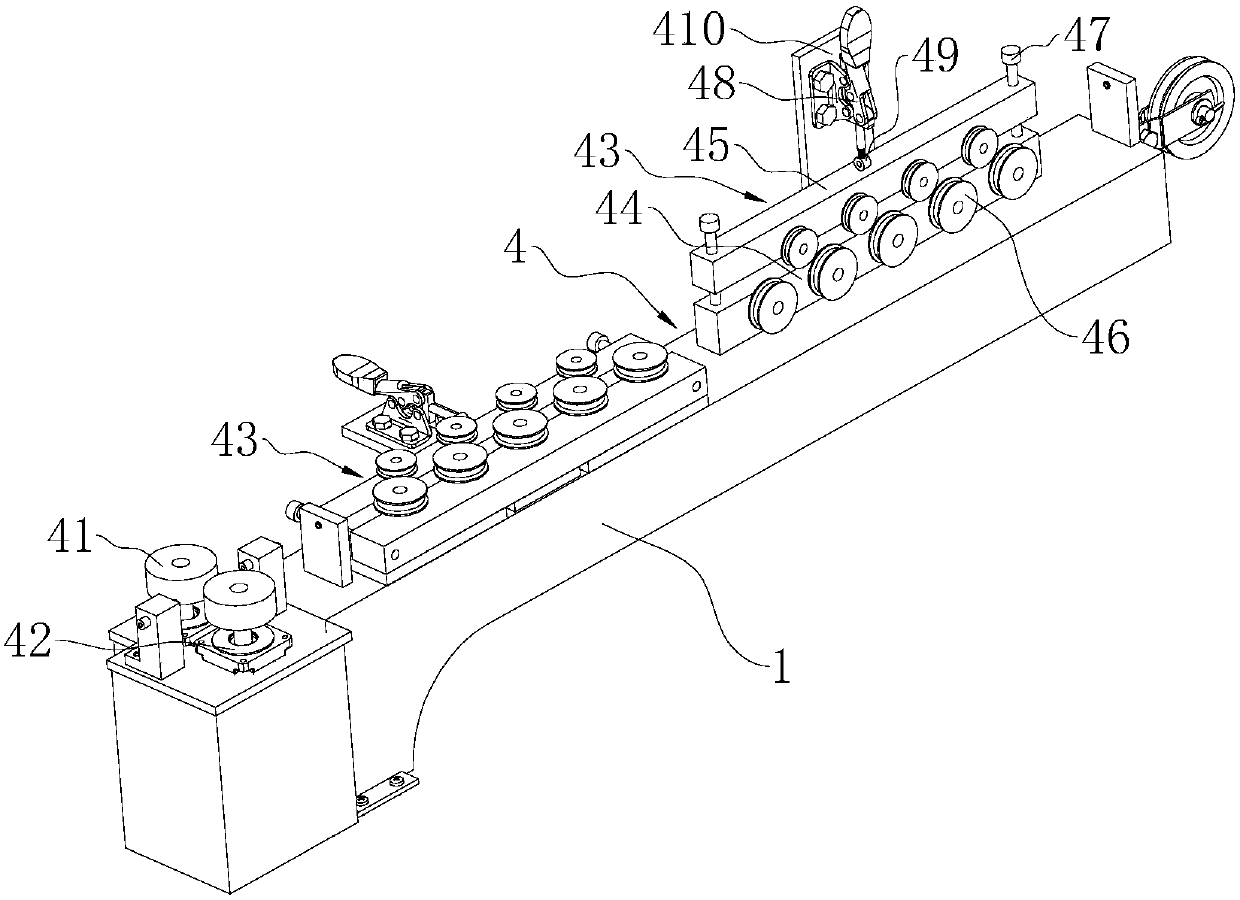

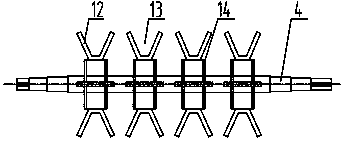

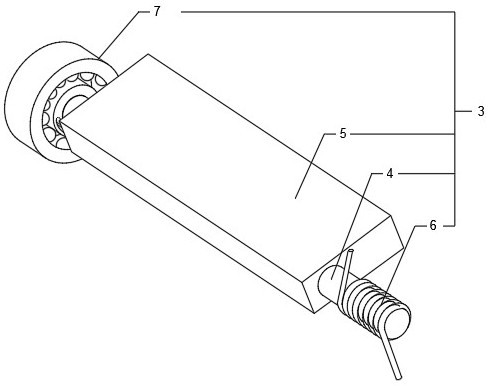

Pin shaft quenching method

ActiveCN108531704AImprove quenching efficiencyContinuous and stable deliveryIncreasing energy efficiencyFurnace typesQuenchingHeat treated

The invention relates to the technical field of pin shaft heat treatment, in particular to a pin shaft quenching method. The pin shaft quenching method comprises the following steps that to-be-quenched pin shafts are put into a storage bin to be temporarily stored, the pin shafts in the storage bin are fed to a clamping module to be clamped one by one through a feeding module, and then the feedingmodule returns back to the initial position; and a transmission module drives the clamping module to drive the pin shafts to rotate, the transmission module horizontally slides on a driving platformto enable the pin shafts to be quenched and heated at a heating module, at the same time, a cooling module sprays water to cool the pin shafts, pin shaft quenching is completed, the transmission module drives the automatic clamping module to return to the initial position, the automatic clamping module loosens the pin shafts, and the pin shafts automatically fall into a discharging module. According to the pin shaft quenching method, the pin shaft quenching method is improved through an automatic induction pin shaft quenching machine, therefore, full automation is achieved in the pin shaft quenching process, manual operation is not needed, and the pin shaft quenching efficiency and the pin shaft overall quality are improved.

Owner:ANHUI JIXI HUISHAN CHAIN TRANSMISSION

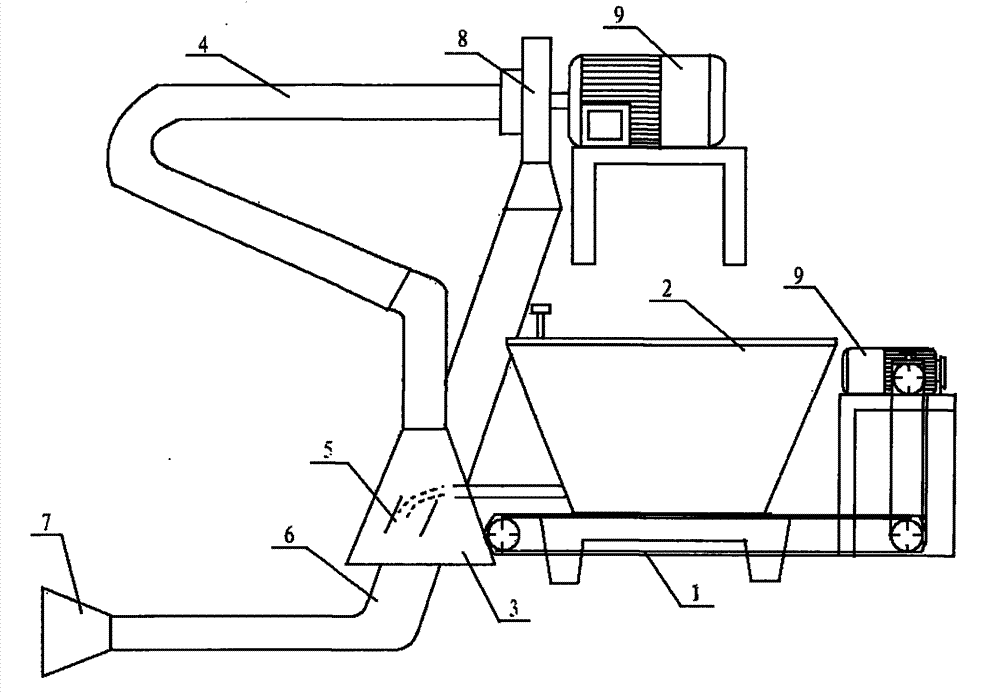

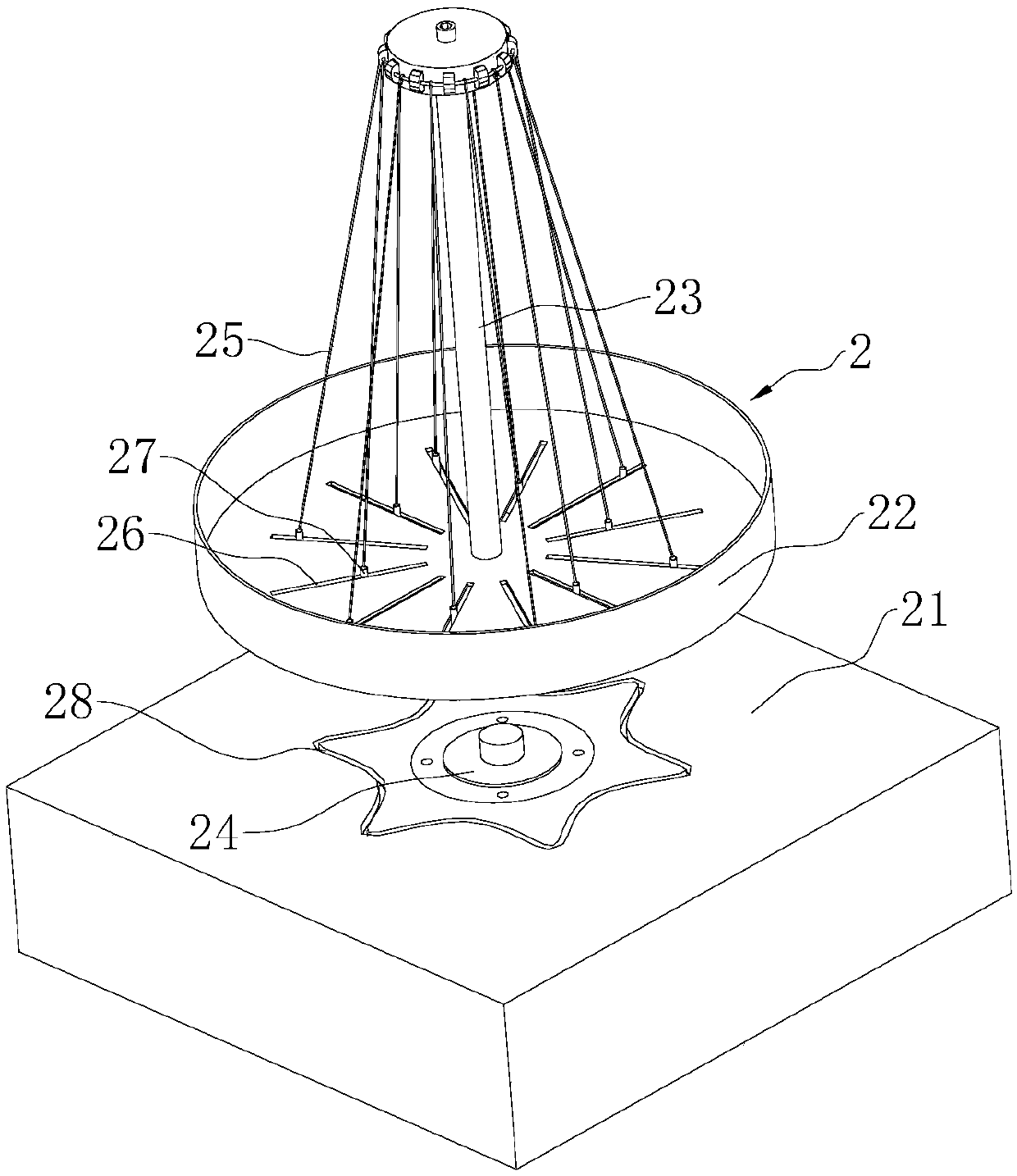

Biomass fuel conveying deivce

InactiveCN103196150AContinuous and stable deliveryExtended service lifeLump/pulverulent fuel feeder/distributionImpellerEngineering

The invention relates to a biomass fuel conveying deivce, in particular to a conveying deivce of powder biomass fuels. The biomass fuel conveying deivce comprises a conveying belt, a shuffling funnel, a feed hopper, a fan and a motor and is characterized by further comprising a floating dust pipe, a speed regulation plate, a conveying pipe and a material outlet. A chain speed reducer is arranged at one end of the conveying belt, the shuffling funnel is fixedly arranged above the conveying belt, and a side port, an upper port and a lower port are respectively arranged on the feed hopper. The conveying belt guides materials into the feed hopper form the side port, the upper port is connected with the floating dust pipe, and the lower port is connected with a fan port. Two ends of the floating dust pipe are connected with the upper port of the feed hopper and an air inlet of the fan respectively, and floating dust is sucked into an impeller of the fan under the negative pressure effect of the fan and is sent into a hearth through secondary conveying. A fan outlet and the speed regulation plate keep a certain distance, the conveying pipe enters a boiler through a boiler back door until to the middle of the hearth, and the conveying pipe is up with a certain inclination. A baffle is arranged at the front end of the material outlet so that fuels can be evenly jetted into the high temperature position in the boiler hearth.

Owner:邱保东

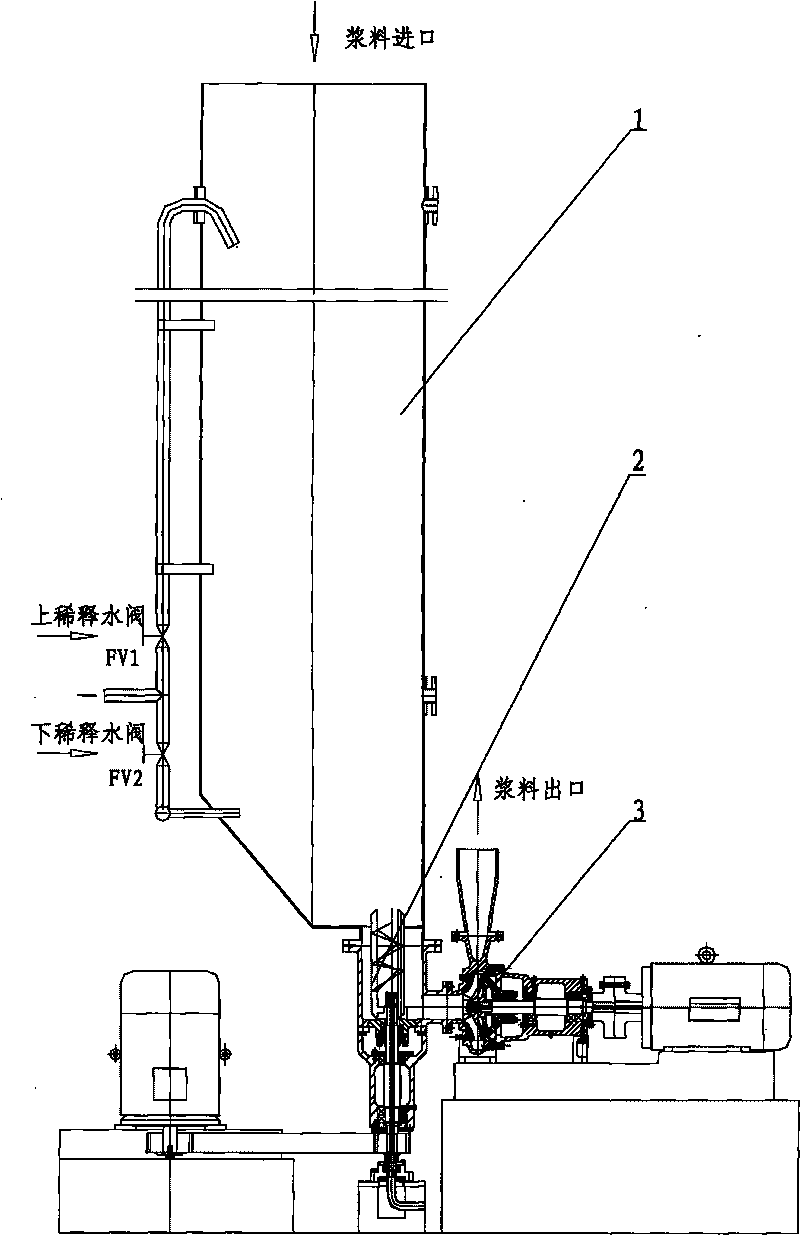

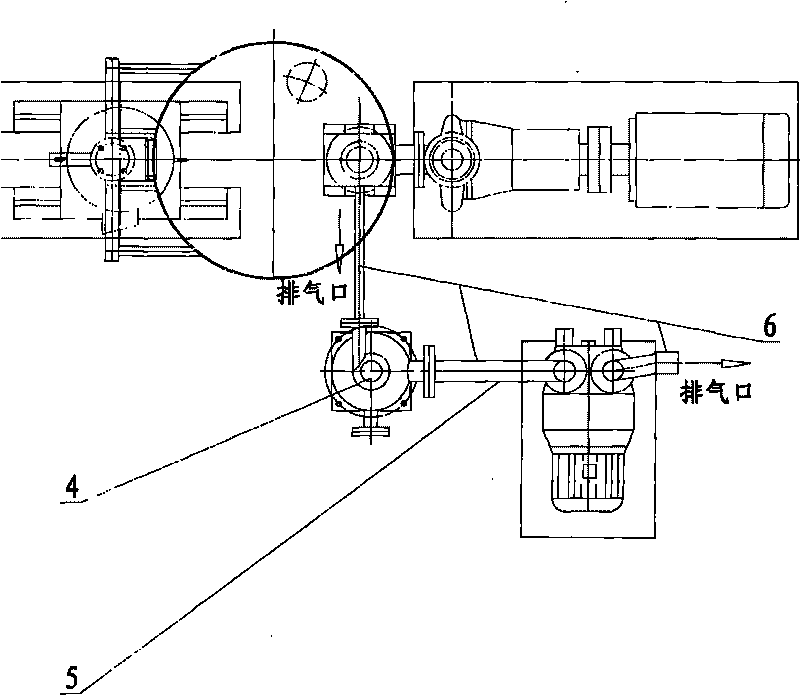

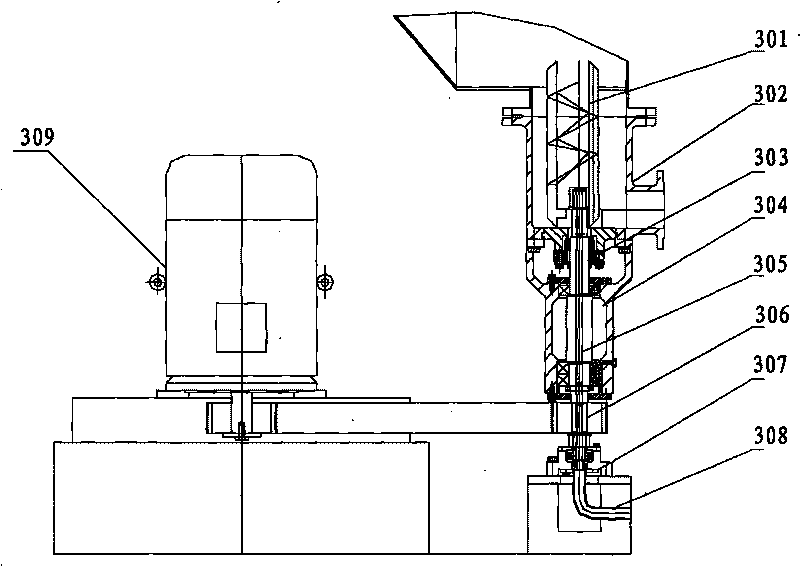

Method for conveying medium-concentration stuff and medium-concentration stuff pump system device for implementing same

InactiveCN101734600AEfficient separationContinuous and stable deliveryLiquid flow controllersMachine wet endThree-phasePulp and paper industry

The invention provides a method for conveying medium-concentration stuff and a medium-concentration stuff pump system device for implementing the method. The method comprises the following steps that: mounting the medium-concentration stuff pump system device below a concentrator in a process flow of cleaning and bleaching medium-concentration paper stuff; and conveying the medium-concentration paper stuff into a bleaching tower device according to certain flow and pressure to perform bleaching by the medium-concentration stuff pump system device. The medium-concentration stuff pump system device comprises a medium-concentration standpipe, a turbulent flow generator, a centrifugal medium-concentration stuff pump, a three-phase separator, a vacuum pump and a connecting pipeline, wherein the turbulent flow generator is fixed at the bottom of the medium-concentration standpipe through an inlet flange; an output of the turbulent flow generator is connected with an inlet flange of the centrifugal medium-concentration stuff pump; a supporting base of the turbulent flow generator is connected with an air inlet pipe of the three-phase separator through a vacuum exhaust pipeline; and an exhaust pipe of the three-phase separator is connected with the vacuum pump. The method and the medium-concentration stuff pump system device can realize effective separation of a three-phase flow including stuff, air and water for the disassembly of a fiber network of the medium-concentration stuff and the fluidization of the medium-concentration stuff in favor of the continuous stable conveyance of the medium-concentration stuff pump.

Owner:SOUTH CHINA UNIV OF TECH

Riveting machine

ActiveCN107946868ASave human resourcesImprove work efficiencyConnection formation by deformationEngineeringRiveting machines

The invention relates to electric wire processing equipment, discloses a riveting machine, and solves the problems of waste of a large amount of human resources and low working efficiency in the conventional mode. The riveting machine comprises a rack; the rack is provided with a wire-placement mechanism used for placing volumed electric wires, a wire stripping mechanism used for cutting the electric wires and stripping one parts of plastic sheaths at one ends of the electric wires to expose metal lines, a first conveying mechanism used for conveying the volumed electric wires in the wire-placement mechanism to the wire stripping mechanism to be cut, a laminating mechanism used for fixing terminals on the electric wires, a second conveying mechanism used for conveying the stripped electricwires to the laminating mechanism, a third conveying mechanism used for conveying the terminals to the laminating mechanism to be connected with one ends of the electric wires, and a wire-collectingmechanism used for collecting the laminated electric wires. The riveting machine has the advantages of automatic production and capabilities of saving human resource and improving working efficiency.

Owner:杭州余杭电缆有限公司

Paranitrotoluene conveying device and device for preparing trinitrotoluene through nitrification of paranitrotoluene

InactiveCN104930350AStable deliveryContinuous and stable deliveryPipeline systemsNitro compound preparationEngineeringToluene

The invention discloses a paranitrotoluene conveying device. The paranitrotoluene conveying device is characterized by comprising a paranitrotoluene product channel, a centrifugal pump, a paranitrotoluene cooler, a paranitrotoluene high-position channel and a paranitrotoluene feeding pipe. The paranitrotoluene product channel, the centrifugal pump, the paranitrotoluene cooler and the paranitrotoluene high-position channel are sequentially connected through a heat preservation pipeline; and a material outlet of the paranitrotoluene high-position channel is connected with the paranitrotoluene feeding pipe. According to the paranitrotoluene conveying device, the paranitrotoluene conveying process is smooth, continuous and stable; and according to a device for preparing trinitrotoluene through nitrification of paranitrotoluene, the production process of the trinitrotoluene is continuous and stable, and the product yield is high.

Owner:HUBEI DONGFANG CHEM IND

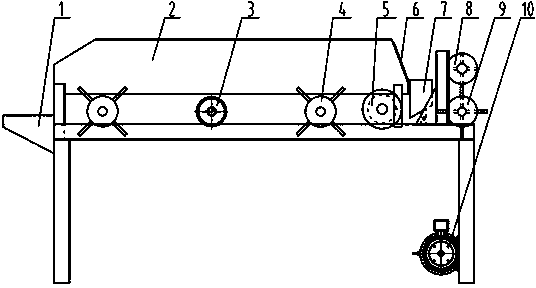

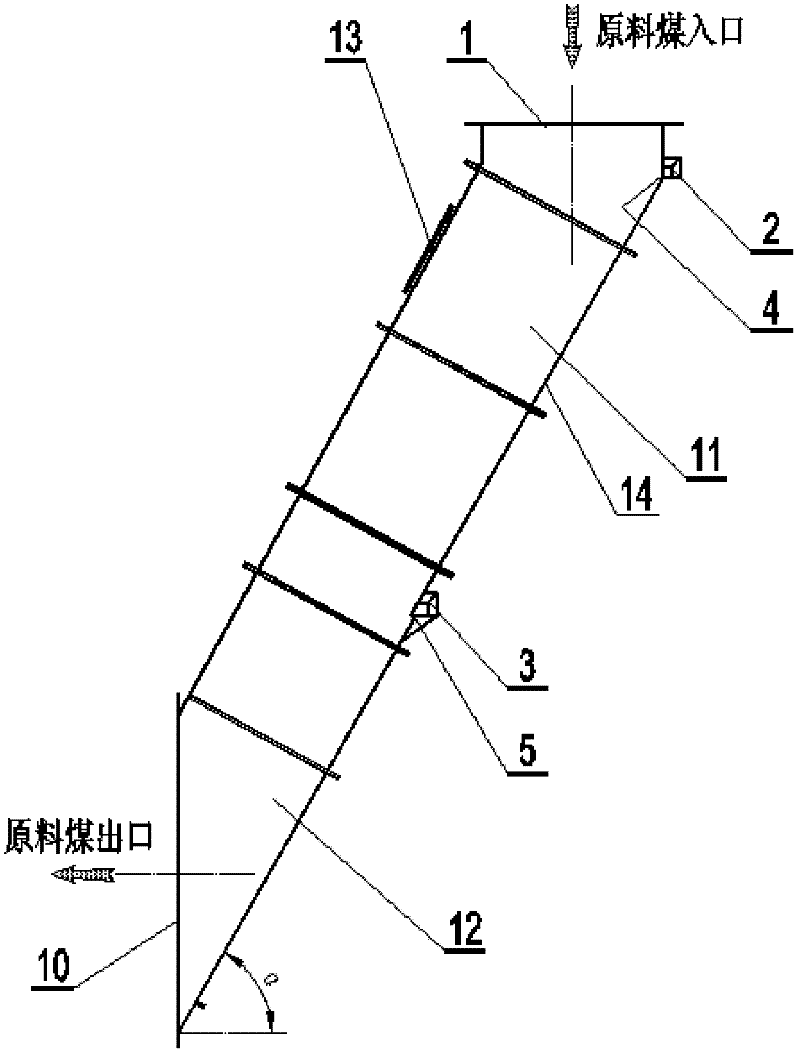

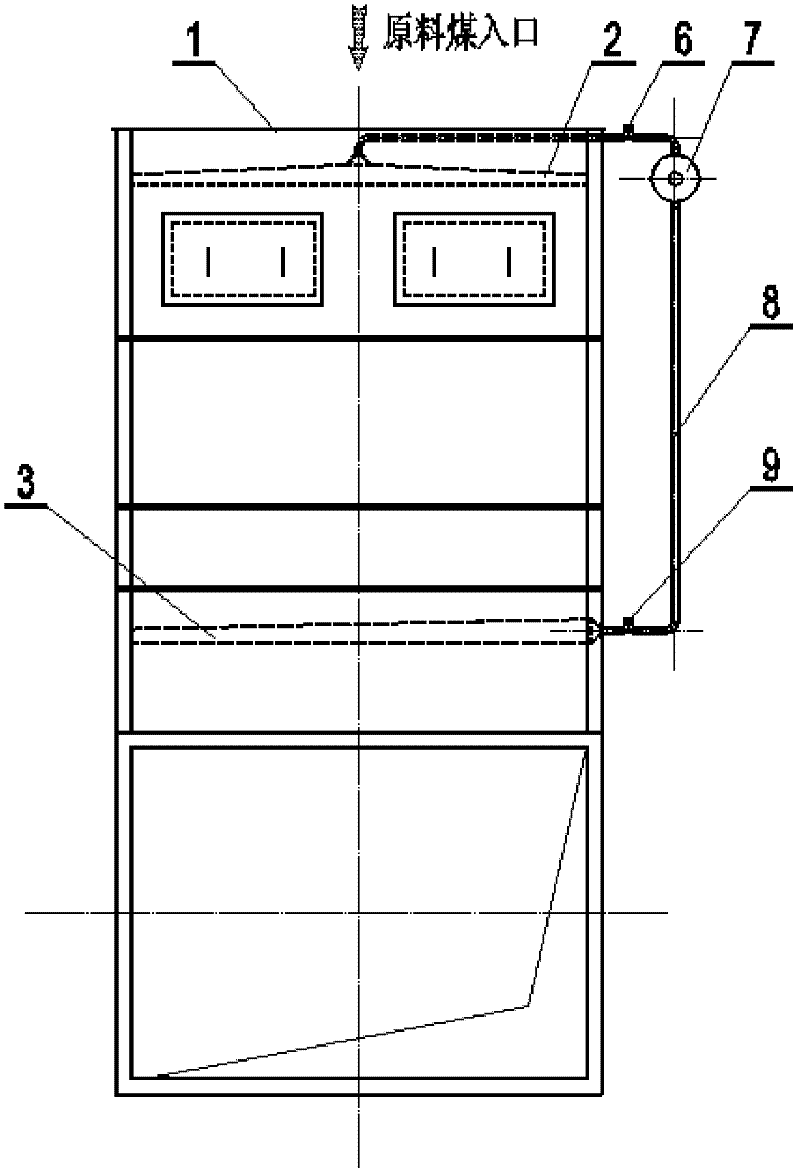

Split quantitative feeding device for corn stalk husk-stuff separator

The invention discloses a split quantitative feeding device for a corn stalk husk-stuff separator. The split quantitative feeding device is characterized in that a frame is sequentially provided with a feeding table (1), conveying mechanisms in transmission connection with a power mechanism (10), a dividing plate (2) uniformly arranged and vertical to the conveying mechanisms, a slopping baffle (6) connected to the tail end of the dividing plate (2), a feeding guide plate (7), and an output mechanism in the transmission connection with the power mechanism (10). The quantitative feeding device can be used for performing split quantitative feeding operation specially aiming at corn stalks, and has the characteristics of being simple in structure, high in working efficiency, low in power consumption, safe and reliable to use, little in operation fault and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

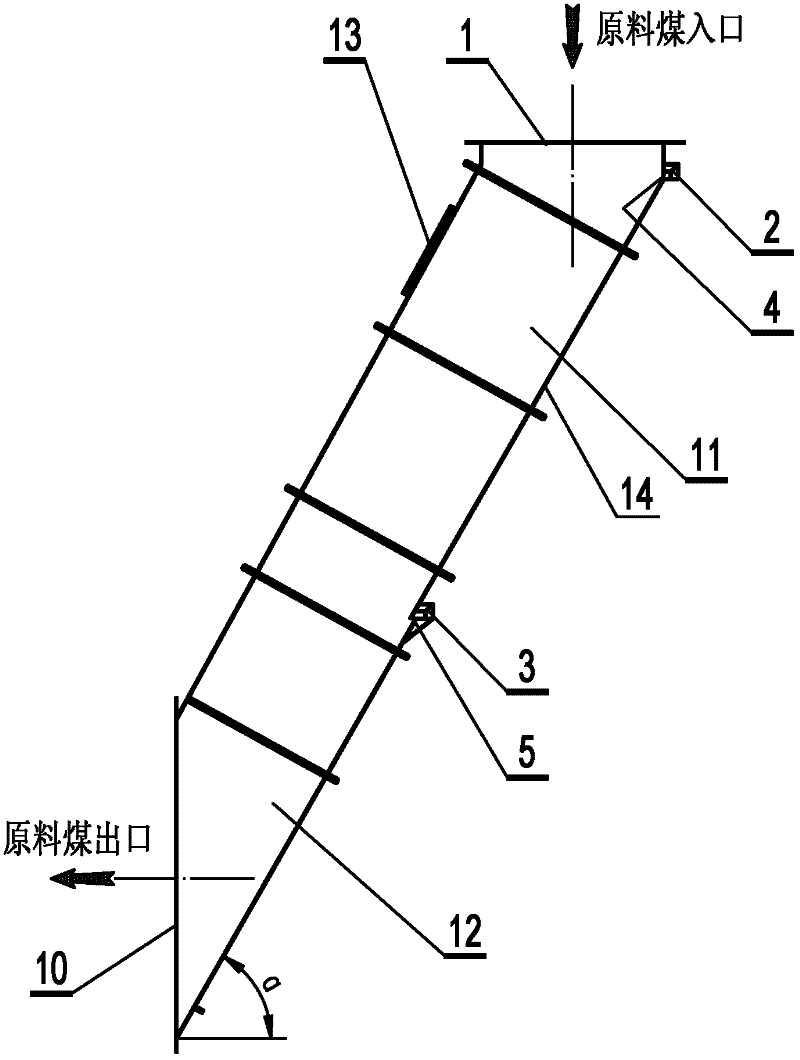

Air-vibrating type jet-boosted discharging device

The invention relates to an air-vibrating type jet-boosted discharging device. The device comprises multiple stages of jet material conveying sections and jet pulse generators; a feed coal inlet section is arranged at the top of the first-stage jet material conveying section, and a feed coal outlet section is arranged at the bottom of the last-stage jet material conveying section; and each stage of jet material conveying section is provided with a jet pulse generator, the jet pulse generator generates a pulse airflow instantaneously through programmed control, then an airflow shovel is formed on the bottom surface of each stage of feed-coal conveying section, so that wet coal materials adhered to the bottom surface of each stage of conveying section are completely shoveled and discharged from a feed coal outlet. The device disclosed by the invention has the advantages that: by using the device, the smooth conveying of materials under airtight conditions can be realized, and an effect of no vibration and shock on equipment can be achieved in the process of conveying high-viscosity and high-moisture-content materials, thereby ensuring the operating reliability of conveying equipment.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +2

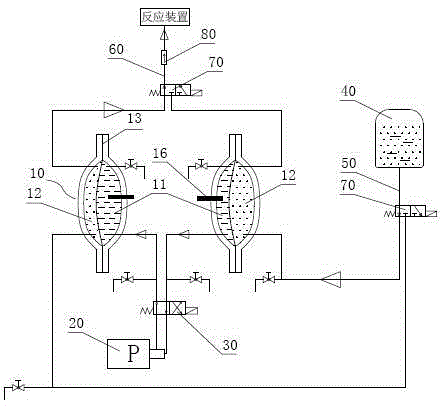

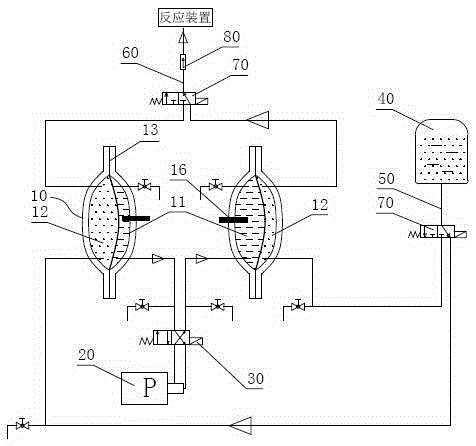

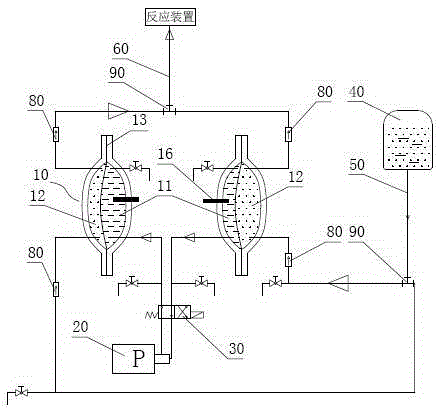

Multi-medium non-contact type continuous conveying device

InactiveCN105604921AGood monitoringSimple controlFlexible member pumpsPump controlControl modeEngineering

The invention discloses a multi-medium non-contact type continuous conveying device, which comprises two isolation conveying chambers, wherein a diaphragm is arranged inside each isolation conveying chamber; the inside space of each isolation conveying chamber is separated into a power transmission cavity and a medium conveying cavity by the corresponding diaphragm; each power transmission cavity and the corresponding medium conveying cavity are sealed; the sizes of the power transmission cavity and the medium conveying cavity are influenced when the diaphragm deforms; the medium conveying cavity is provided with a liquid inlet and a liquid outlet extending to the outside of the isolation conveying chamber; the two power transmission cavities are communicated through a pipeline; a reversing valve and a pump used for driving fluid to flow between the two power transmission cavities are arranged on a pipeline arranged between the two power transmission cavities. According to the structure, the medium conveying link realizes complete static sealing; the media are not in contact with the pump; the fluid which cannot damage a pump head is used as power fluid; the system reliability is improved; the long-time stable conveyance of the media can be realized; the conveying pressure and the conveying flow rate can be precisely controlled; the control mode is simple.

Owner:HANGZHOU PUPU SCI TECH

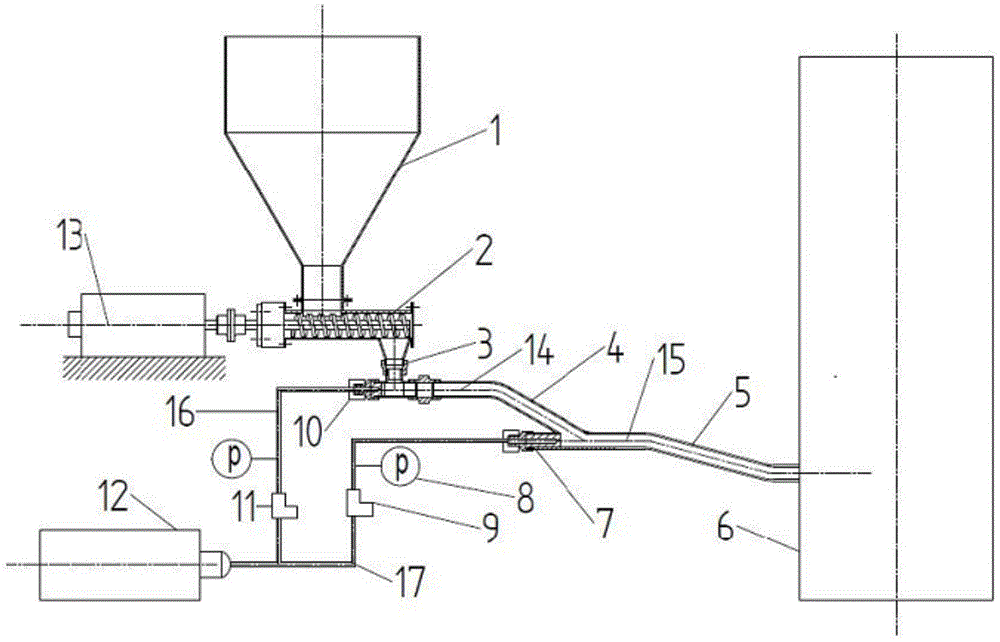

Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

InactiveCN104877694AAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveGas cylinder

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

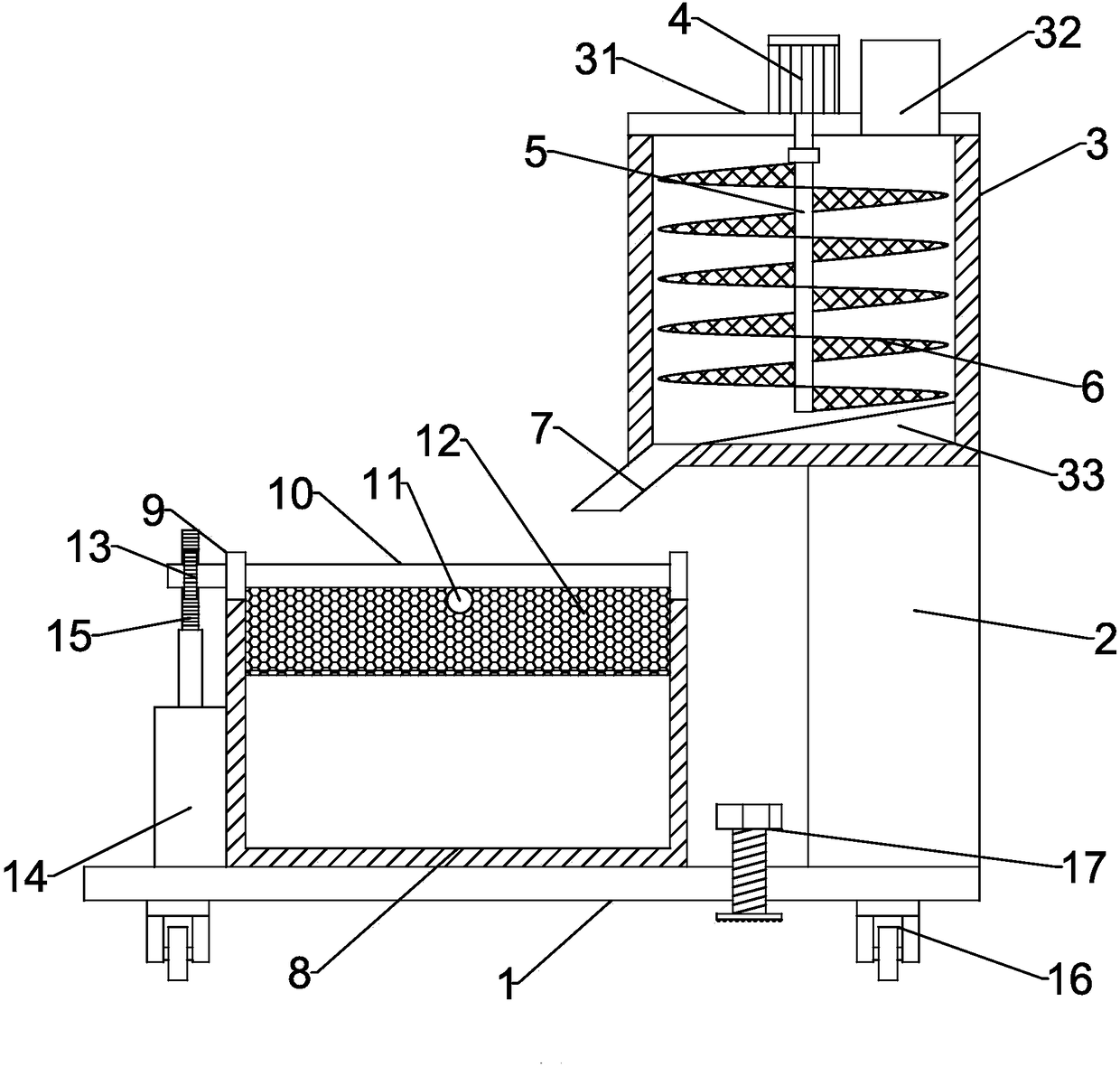

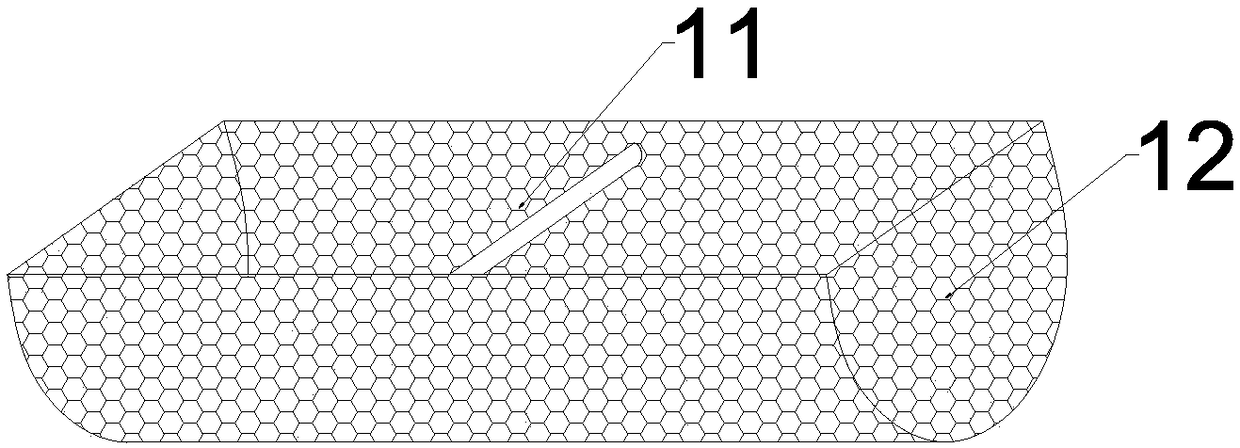

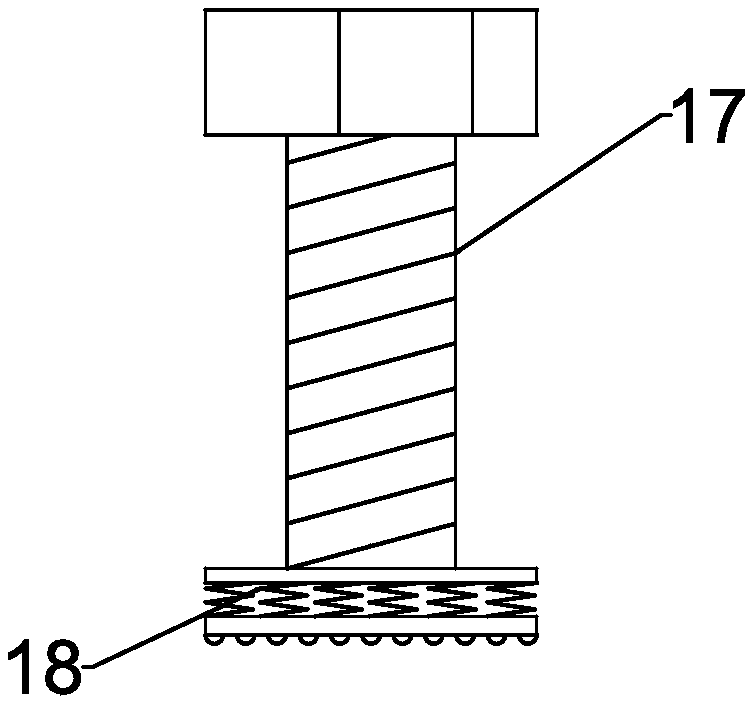

Shaking-type screening and impurity filtering device for building sand

InactiveCN108273737AContinuous and stable deliveryImprove subsequent processing efficiencySievingScreeningGear wheelMetal impurities

The invention discloses a shaking-type screening and impurity filtering device for building sand. The shaking-type screening and impurity filtering device comprises a baseplate, a material accommodating cavity, a collecting box, a rotating shaft I, a rotating shaft II, a filtering mesh bag and an electric push rod, wherein a bracket is arranged at the upper end of the baseplate; the material accommodating cavity is arranged at the upper end of the bracket; an upper cover, a feeding pipe, a material guiding baseplate, a motor, a stirring shaft, a stirring blade and a material guiding pipe are arranged on the material accommodating cavity; the collecting box is arranged at the upper end of the baseplate; rotating support plates are arranged on the collecting box; the rotating shaft I is arranged in the rotating support plates; the rotating shaft II and the filtering mesh bag are arranged at the lower end of the rotating shaft I; a transmission gear is arranged on the periphery of the rotating shaft I; the electric push rod and a toothed plate are arranged at the upper end of the baseplate; universal wheels are arranged below the baseplate; a threaded rod is arranged on the baseplate;and a non-slip mat is arranged at the lower end of the threaded rod. By adoption of the shaking-type screening and impurity filtering device disclosed by the invention, metal impurities in yellow sand can be filtered out; the uniform and stable discharging operation can be achieved; and besides, the yellow sand can be stably and efficiently screened in a shaking manner.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

Cable traction device

InactiveCN113173454AContinuous and stable deliverySteady deliveryFilament handlingClassical mechanicsStructural engineering

Owner:湖南天剑海洋工程设备有限公司

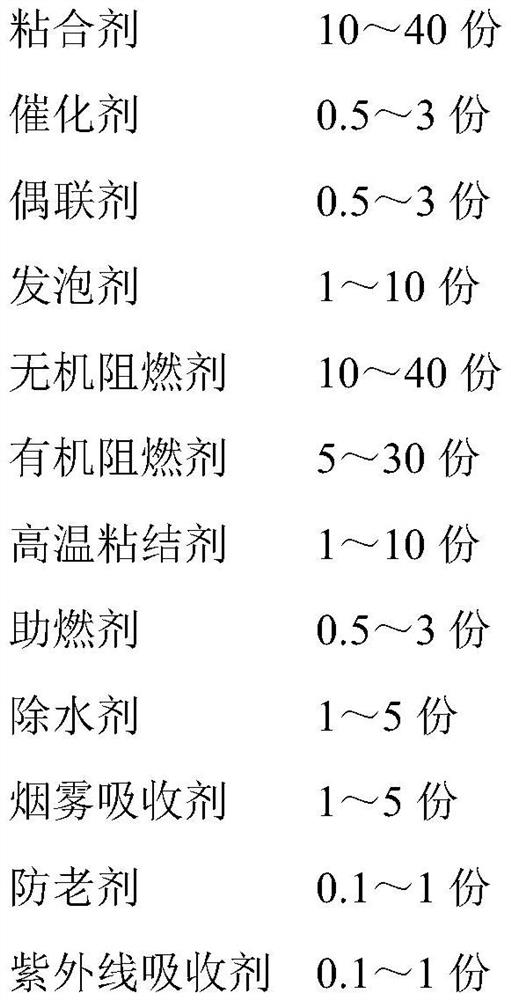

Intumescent flame-retardant heat-insulating fireproof coating and preparation method thereof

ActiveCN113122124ADelayed ignitionQuick releaseFireproof paintsAnti-corrosive paintsPtru catalystAdhesive

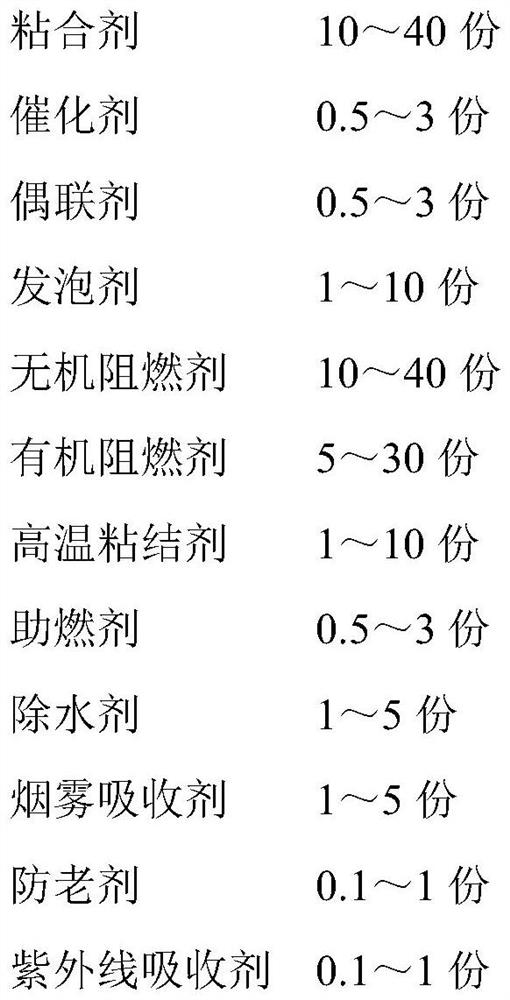

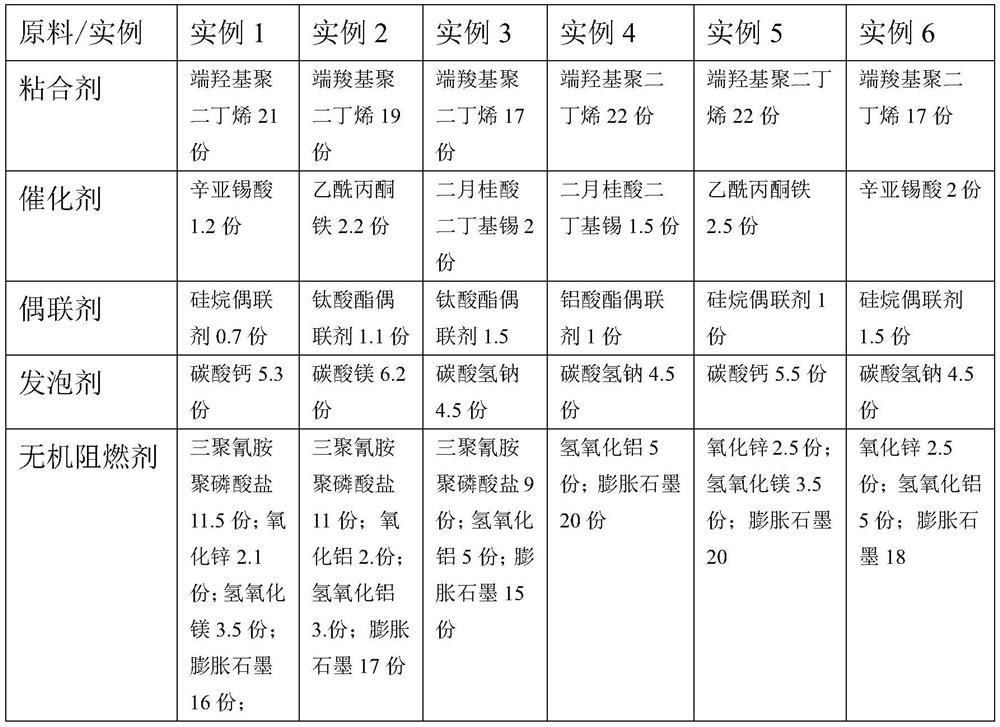

The invention relates to an intumescent flame-retardant heat-insulating fireproof coating and a preparation method thereof, the intumescent flame-retardant heat-insulating fireproof coating is formed by mixing a component A, a component B and an auxiliary agent, the component A comprises an adhesive, a catalyst, a coupling agent, a foaming agent, an inorganic flame retardant, an organic flame retardant, a high-temperature adhesive, a combustion improver, a water removal agent, a smoke absorbent, an anti-aging agent and an ultraviolet absorbent; the component B comprises a curing agent, a plasticizer and a chain extender; and the auxiliary agent is a diluent. The intumescent flame-retardant heat-insulating fireproof coating has the advantages that the intumescent flame-retardant heat-insulating fireproof coating is suitable for protection of various indoor and outdoor materials, particularly suitable for occasions with high fireproof performance requirements, such as electric power, information and petrochemical industries, can delay object ignition or reduce the combustion speed of a protected base material, can quickly release heat after the surface temperature of the intumescent flame-retardant heat-insulating fireproof coating exceeds 290 DEG C, a carbon flocculent isolation layer is formed through expansion, and conduction of the heat effect is isolated.

Owner:宋成镇

Limiting type conveying device for food packaging bags

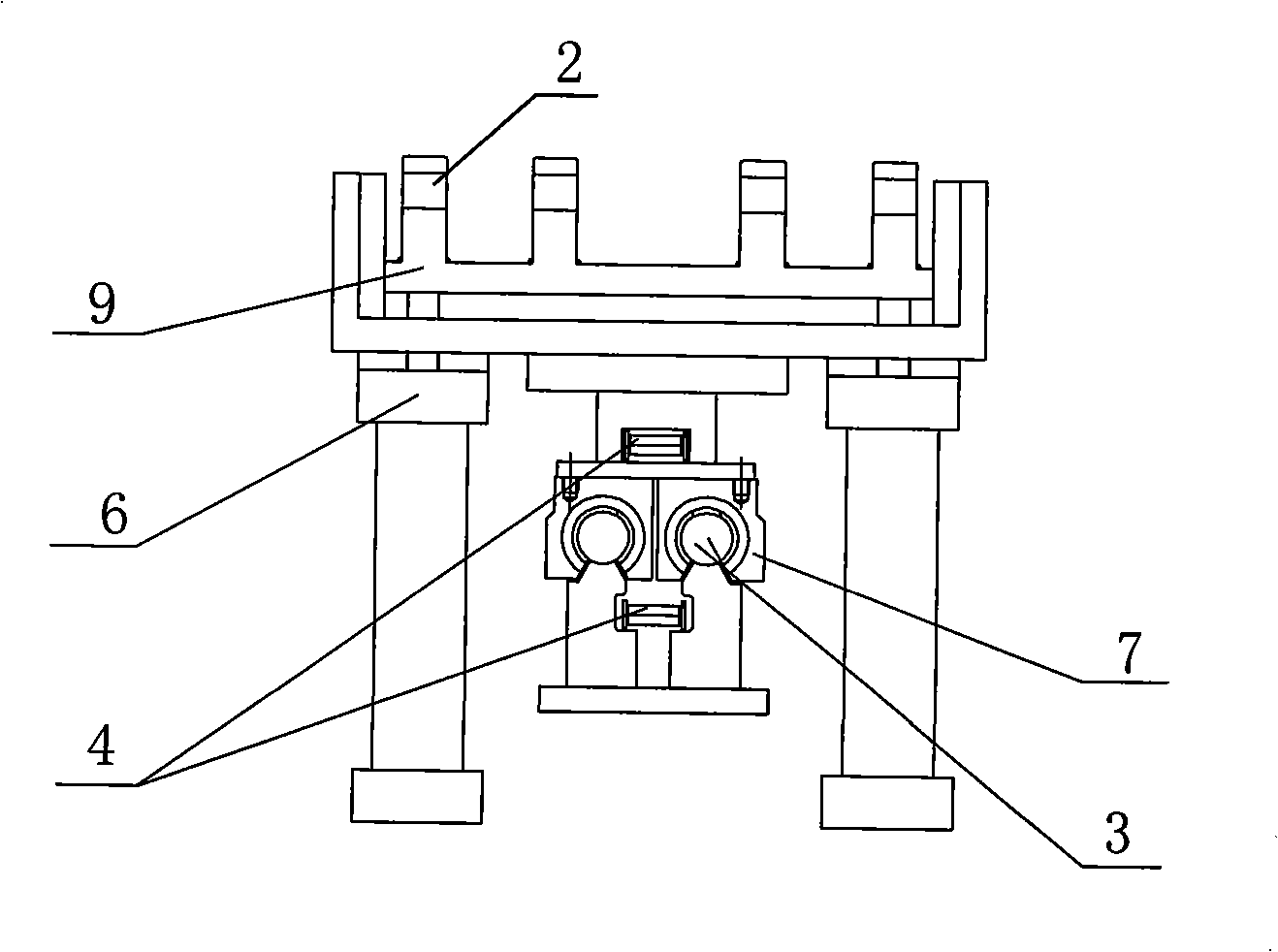

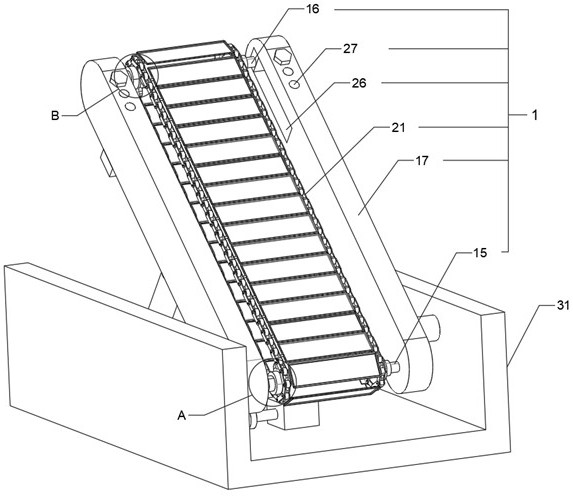

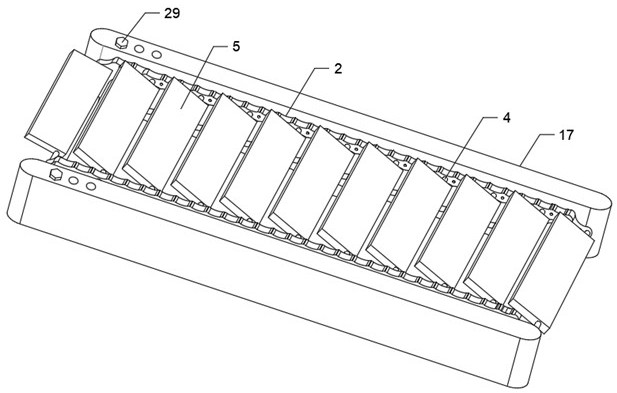

ActiveCN113911766AImprove loading efficiencyContinuous and stable deliveryConveyorsSupporting framesFood packagingAcute angle

The invention discloses a limiting type conveying device for food packaging bags. The limiting type conveying device for the food packaging bags comprises an obliquely-arranged chain type conveying mechanism, the chain type conveying mechanism comprises two chain transmission mechanisms arranged in parallel, a plurality of rotary supporting devices are arranged between the two chain transmission mechanisms, the plurality of rotary supporting devices are evenly arranged in the conveying direction of the chain transmission mechanisms, each rotary supporting device comprises a supporting shaft and a supporting plate, one end of each supporting shaft is connected with one chain transmission mechanism through a torsional spring, the other end of each supporting shaft is connected with the other chain transmission mechanism through a limiting rotating piece, the supporting shafts are fixedly sleeved with the supporting plates, the supporting plates and the conveying direction of the chain transmission mechanisms form acute angles, and the limiting rotating piece is used for enabling the multiple supporting plates supporting the packaging bags to be rotationally connected into a supporting plane in the conveying direction of the chain transmission mechanisms and limiting sliding of the packaging bags through the supporting plates located below the packaging bags. The limiting type conveying device is used for solving the problem that the packaging bags are prone to slipping off due to the fact that an existing conveying device conveys the packaging bags from low to high.

Owner:四川远方云天食品科技有限公司

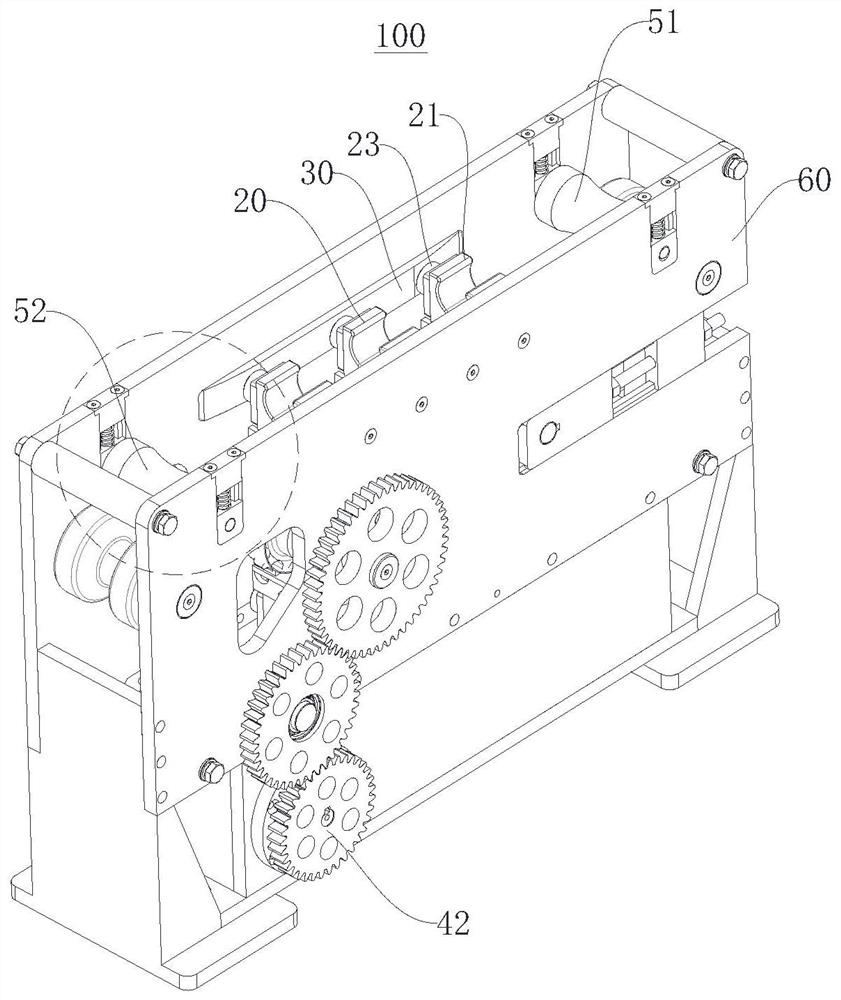

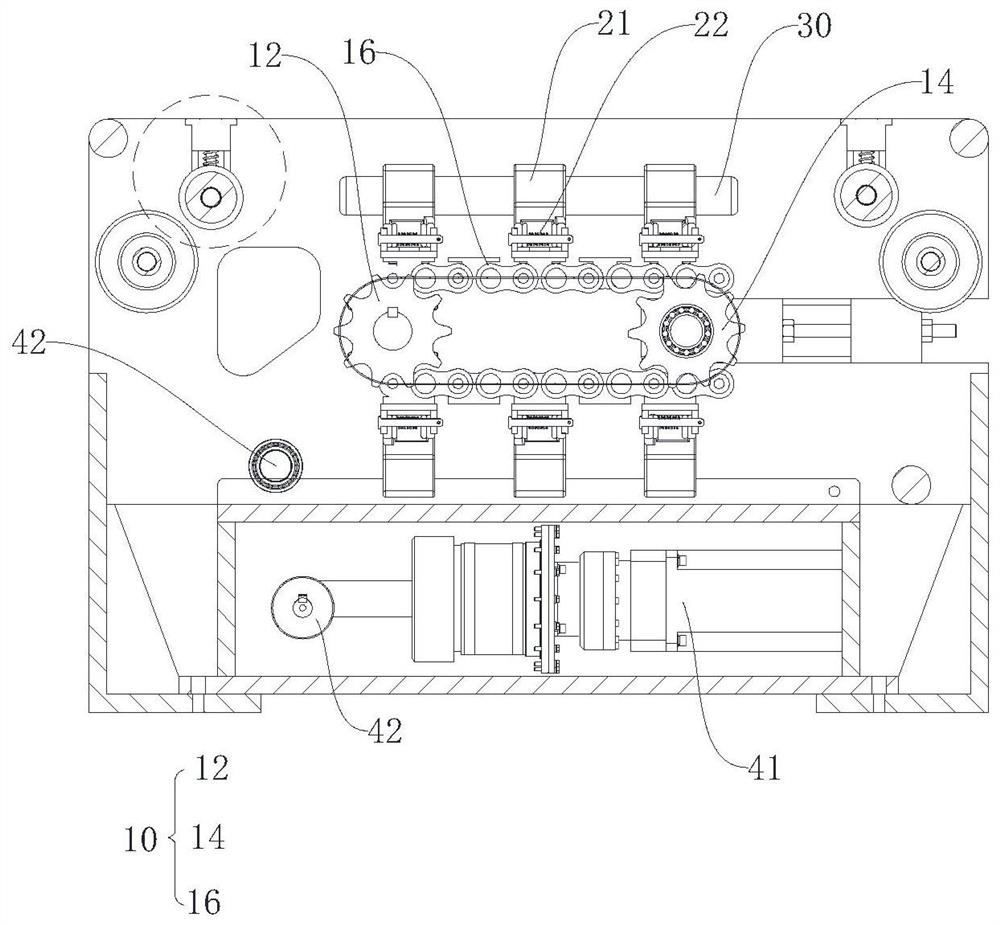

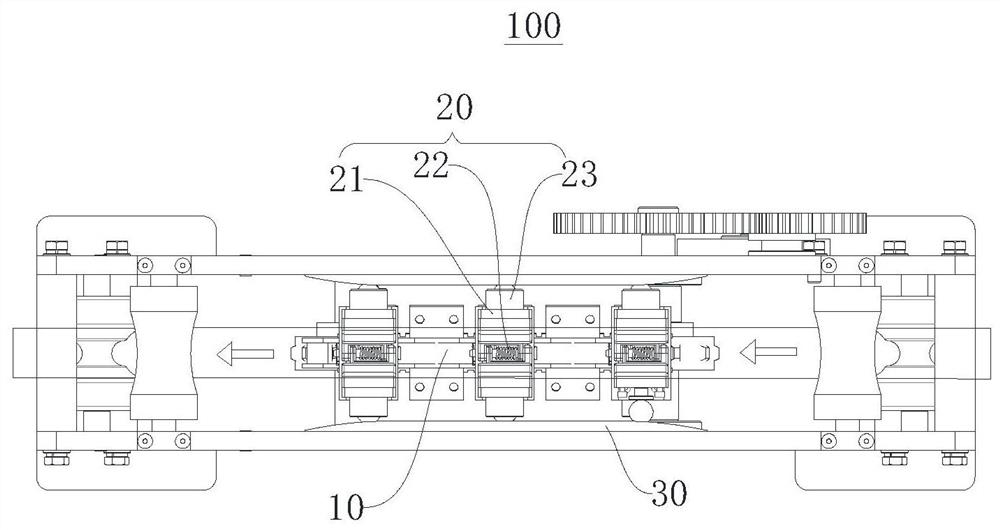

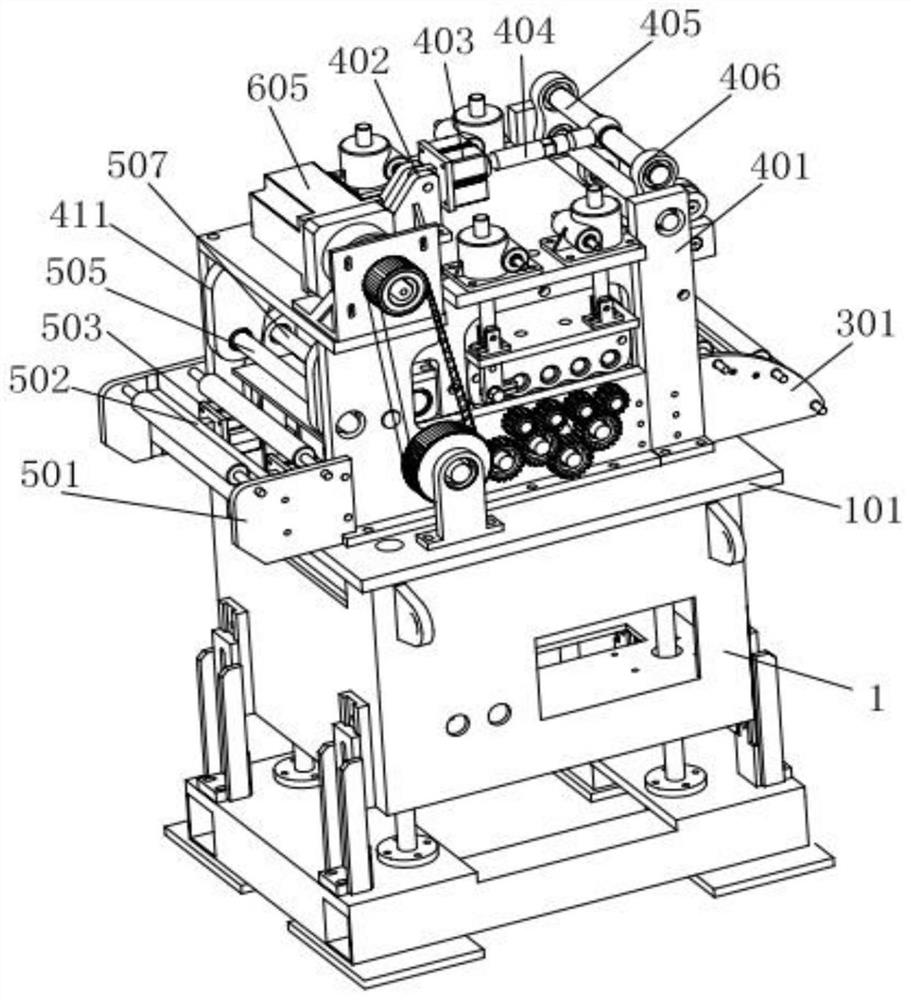

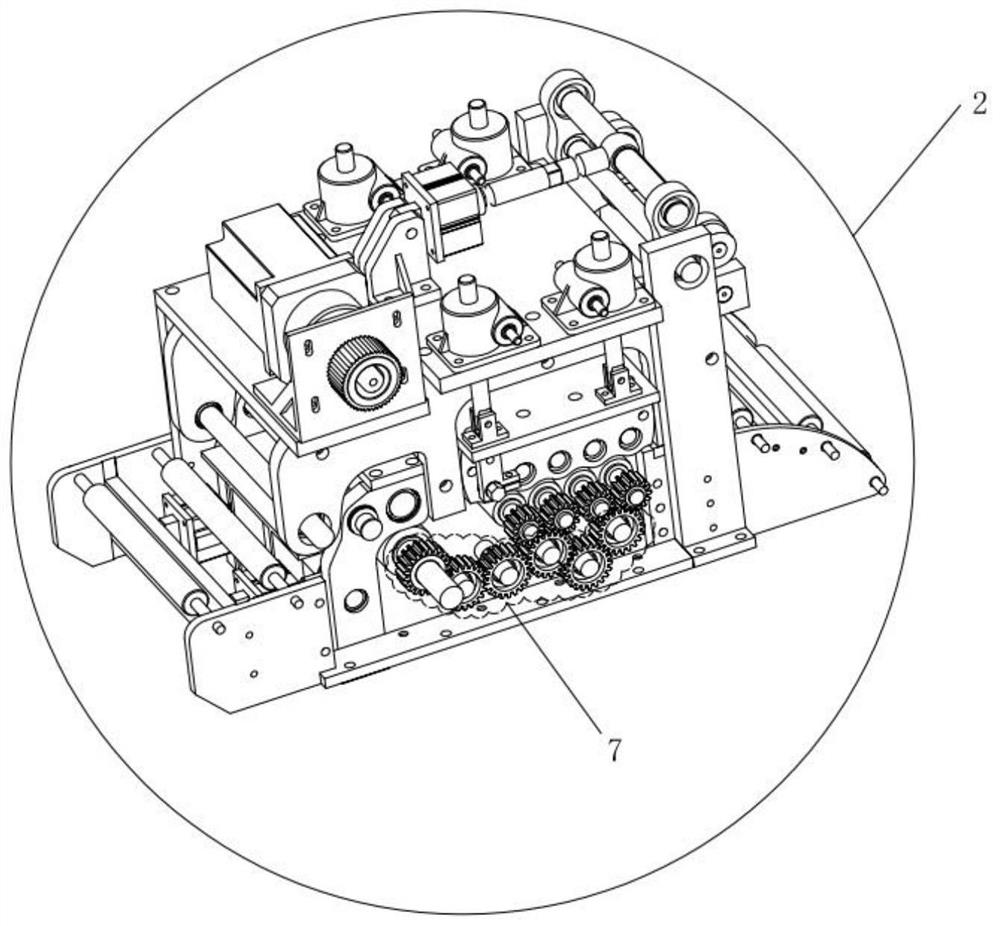

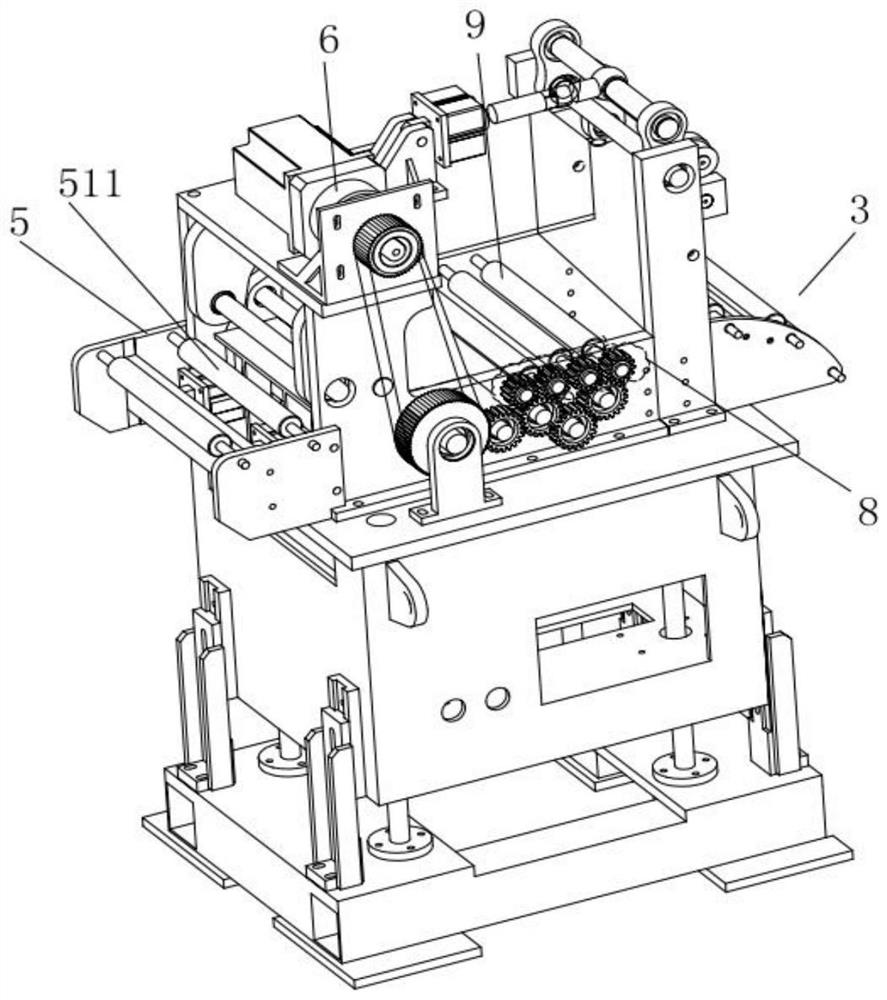

A New Type of Precision Leveling Feeder

ActiveCN110014055BGuaranteed parallelismEven by forceMetal-working feeding devicesPositioning devicesGear wheelDrive shaft

The invention discloses a novel precision leveling feeder. The novel precision leveling feeder comprises a machine frame and a machine head. The machine head is mounted on the machine frame. The machine head comprises a feeding mechanism, a leveling mechanism, a discharging mechanism and a power mechanism. The power mechanism comprises a servo motor, a first transmission wheel, a transmission belt, a second transmission wheel, a power transmission gear set and a leveling gear set. The servo motor is mounted and arranged on a bracket at the top of the machine head. The bracket is mounted on a support plate at the tops of large side vertical plates. The novel precision leveling feeder is more reasonable in structure, convenient in manufacturing and high in precision, and the transmission mechanism is high in power and stable in movement; and meanwhile, the power source, namely the servo motor of the novel precision leveling feeder is arranged at the top, the parallelism of a servo motorshaft and a gear shaft is effectively guaranteed, vibration generated during mechanical movement is slight, a gear, a bearing and a transmission shaft are slightly abraded, and the service life is long. In addition, the discharging mechanism of the novel precision leveling feeder is continuous and stable in action and uniformly applies force to metal sheets, and feeding is stable and accurate.

Owner:苏州炬烁精密机械有限公司

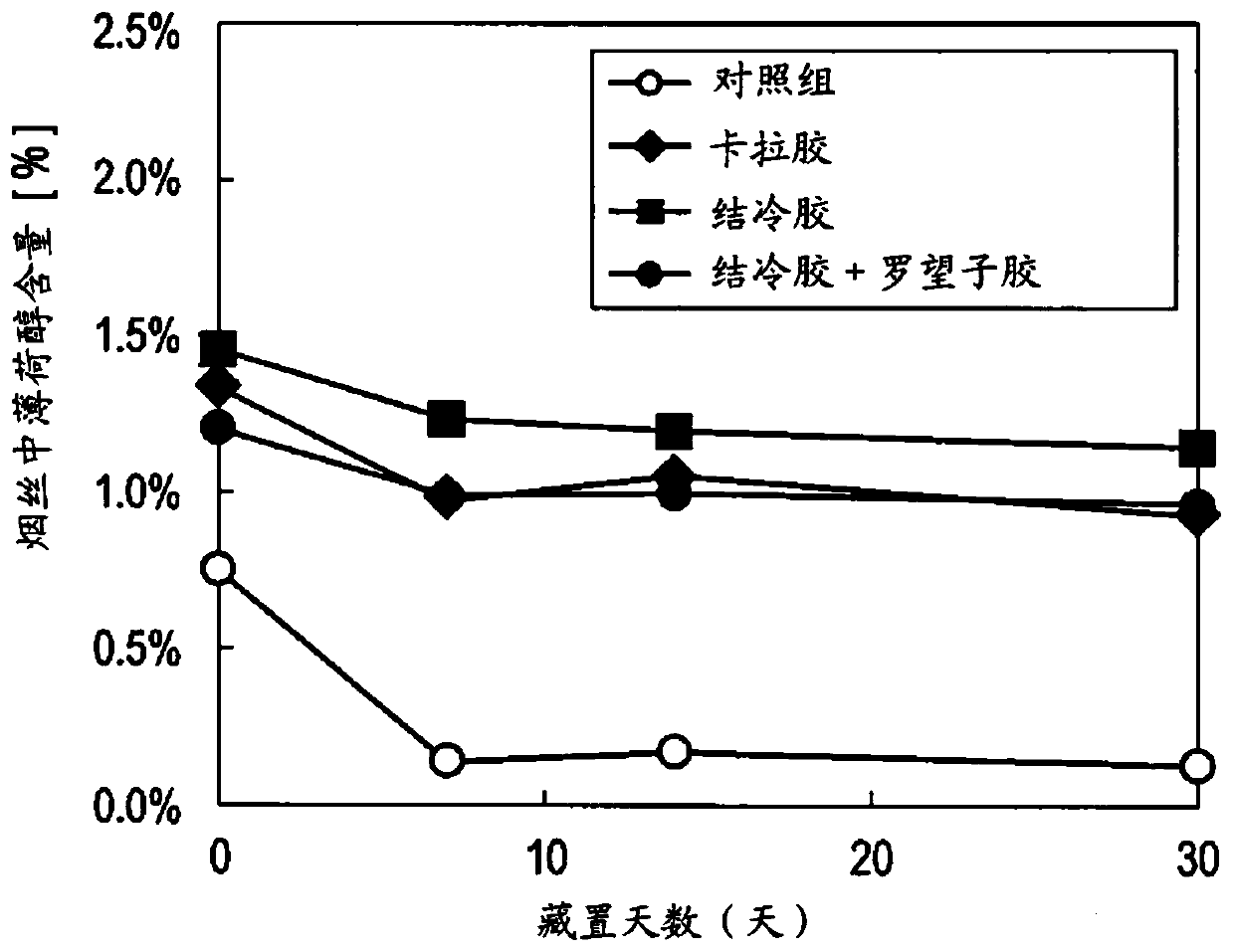

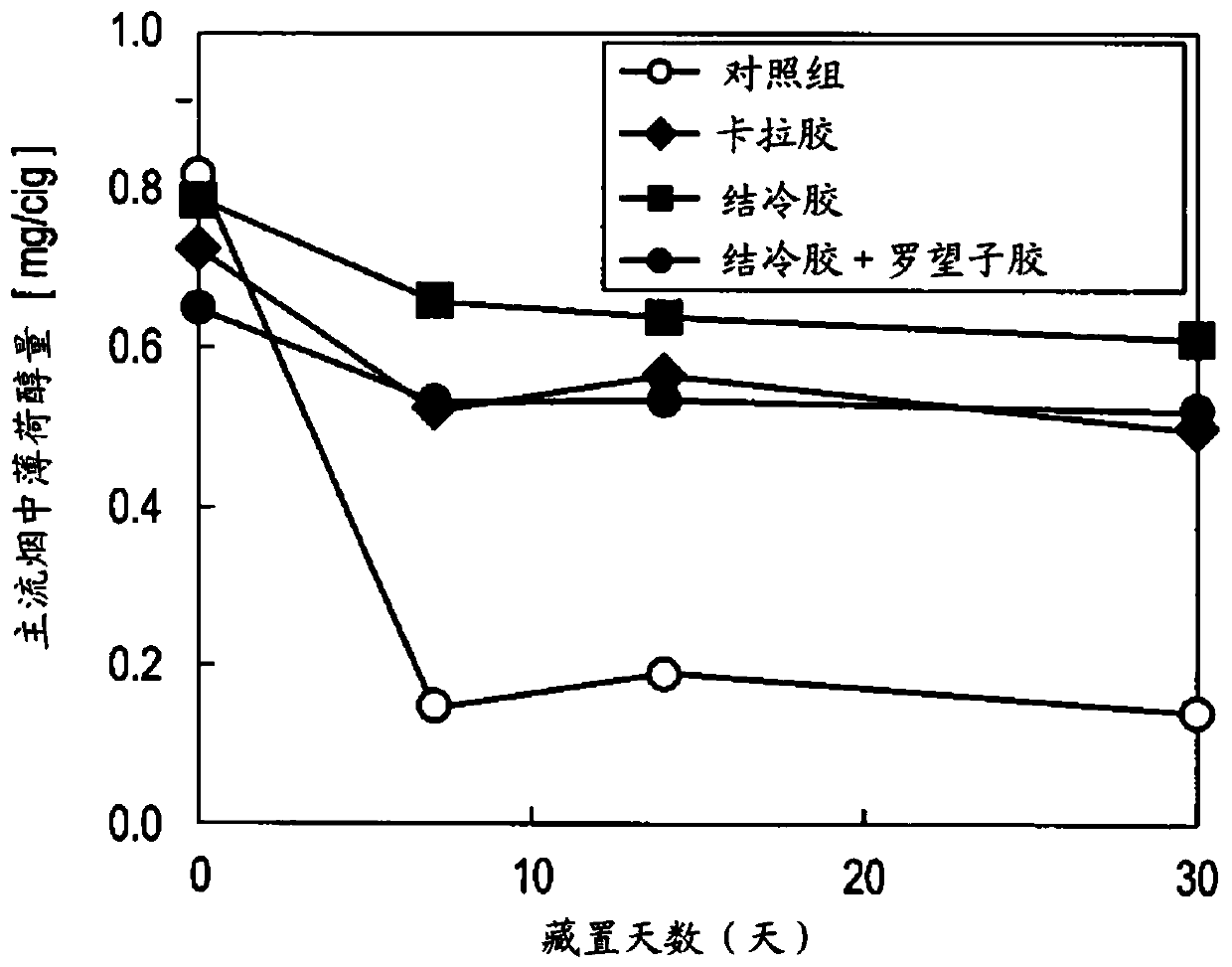

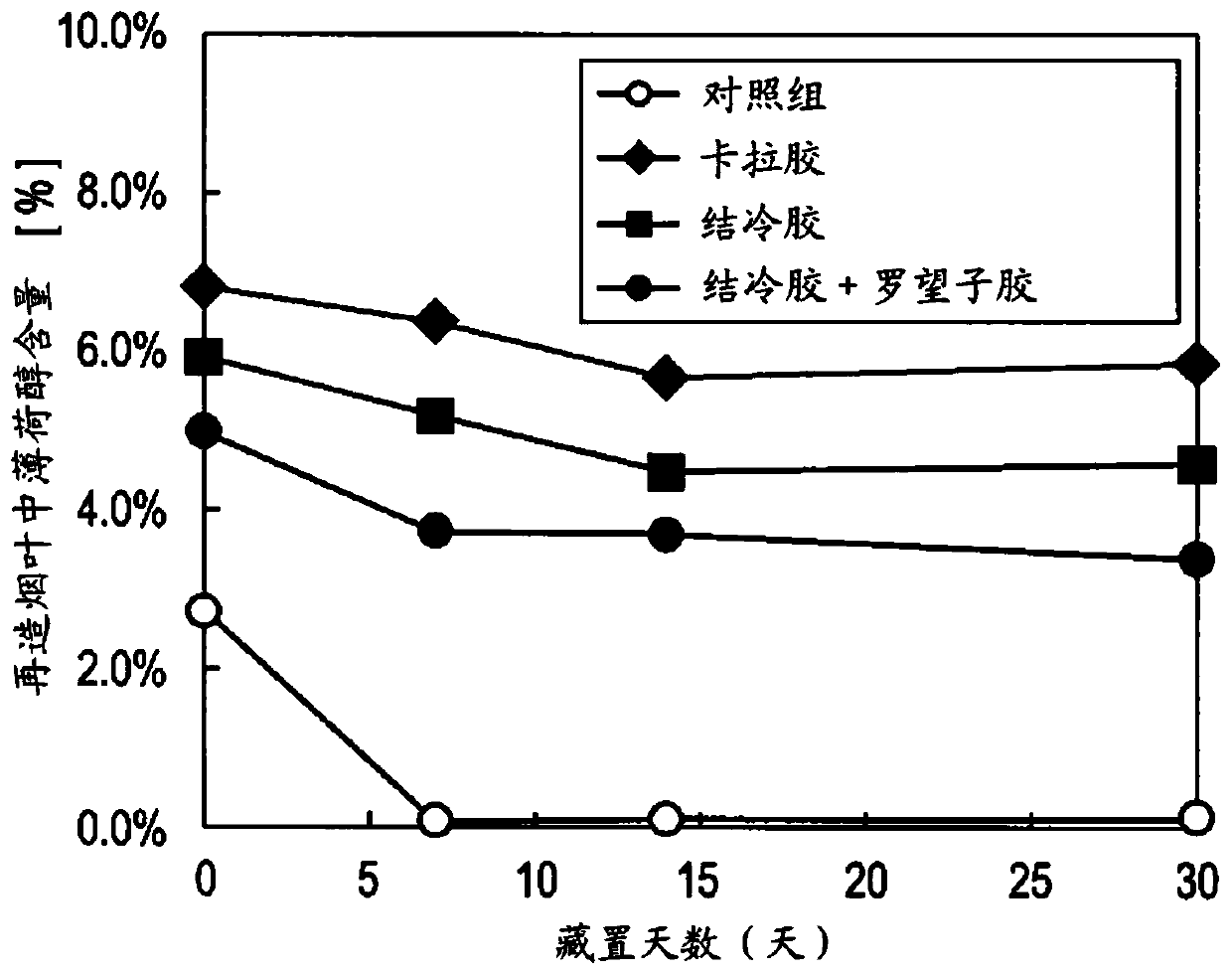

Fragrance-carrying cigarette constituent member and cigarette containing the same

ActiveCN110279140AUneven distribution of inhibitionContinuous and stable deliveryTobacco preparationTobacco treatmentBiotechnologyGellan gum

A fragrance-carrying cigarette constituent member characterized in being obtained by: applying a fragrance composition in a sol state to the surface of a cigarette constituent member, the fragrance composition containing a fragrance, water, and a polysaccharide selected from the group consisting carrageenan, gellan gum, and a combination of gellan gum and tamarind gum; then cooling the cigarette constituent member to which the fragrance-carrying composition has been applied to 0 to 40DC to gel the fragrance composition; and thereafter heating and drying the cigarette constituent member to which the fragrance composition has been applied.

Owner:JAPAN TOBACCO INC

Coal ash gas delivery system

PendingCN106829483AContinuous and stable deliverySolve the problem of easy silting at the discharge portBulk conveyorsControl systemProcess engineering

The invention relates to a coal ash gas delivery system. The system comprises an ash bucket, a star discharger, a feeding screw device and a control system. The feeding screw device is mounted at the bottom of the star discharger which is mounted at the bottom of the ash bucket, a compressed air inlet pipeline is mounted in the middle of the feeding screw device, and a pressure release valve and a dust collection device are mounted on a pressure release pipeline which is mounted in the rear of the feeding screw device. A power device and a delivery pipeline are mounted on the head portion and the tail portion of the feeding screw device respectively, and the control system controls the power device and the star discharger. The coal ash gas delivery system is high in automation degree, and the problem of stagnation of a discharging port is solved by the star discharger at the bottom of the ash bucket; by adoption of the compressed air inlet pipeline, the whole device is capable of operating continuously to realize continuous and stable delivery of materials; since the pressure release valve and the dust collection device are arranged on the pressure release pipeline, environment pollution and material waste are avoided, and safety and environmental friendliness are realized.

Owner:CHIPING XINFA HUAYU ALUMINA

Seedling water and fertilizer integrated irrigation device for sunflower cultivation

InactiveCN112913437APrevent leakageImprove the mixing effectWatering devicesPressurised distribution of liquid fertiliserAgricultural scienceAgricultural engineering

The invention provides a seedling water and fertilizer integrated irrigation device for sunflower cultivation, and belongs to the technical field of agricultural equipment. The seedling water and fertilizer integrated irrigation device for sunflower cultivation comprises a bottom plate, a water tank and a spiral pipeline, one side of the upper surface of the bottom plate is fixedly connected with a smashing box, the lower portion of the inner wall of the smashing box is fixedly connected with a material guide plate, and smashing rollers penetrate through the two sides of the inner wall of the smashing box through rotating shafts. According to the seedling water and fertilizer integrated irrigation device for sunflower cultivation, through the arrangement of the smashing box, a stepping motor, a feeding groove, a material shielding plate, the smashing rollers, a material guiding plate, the spiral pipeline, a motor box and a storage cabinet, when the device is used for irrigating sunflower seedlings, a handle is held by a hand to open a cabinet door of the storage cabinet, tools can be rapidly stored, convenience is provided for irrigation work, use is more convenient, fertilizer feeding through the feeding groove is simpler and more convenient, and meanwhile scattering and leakage of the fertilizer during smashing can be effectively avoided through the material shielding plate.

Owner:甘肃省农业科学院作物研究所

Device and system for feeding large bio-material to furnace for directly burning generating

InactiveCN1912468AAdaptableContinuous and stable deliveryLump/pulverulent fuel feeder/distributionMixed flowDirect combustion

A method for conveying large amount of raw material into furnace for directly burning to generate power includes cutting raw materials to be stubs then applying wind force to directly convey air and solid two-phase mixed flow formed by wind and raw material directly to internal phase zone of fluidized bed boiler through pipeline for burning to generate power, removing off sand and mud impurities while raw material is conveyed by wind force. The conveying system for realizing said method is also disclosed.

Owner:LIANYUNGANG XIEXIN ENVIRONMENT PROTECTION BIOLOGICAL THERMOELECTRIC

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

InactiveCN1257361CExtended stayIncrease burn shareFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

Owner:SOUTHEAST UNIV

Efficient sludge drying system for sewage treatment

ActiveCN114315086AFlexible position adjustmentAvoid deformationSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentProcess engineeringSewage treatment

The invention discloses an efficient sludge drying system for sewage treatment. The efficient sludge drying system comprises a temporary storage tank, a reaction kettle, a centrifugal tank and a forming tank, a tray is arranged at the bottom of the centrifugal tank, the tray is fixedly connected with the centrifugal tank, and a tank cover is detachably mounted at the top of the centrifugal tank; a circle of filter screen is arranged in the centrifugal tank, the filter screen is fixedly connected with the tray, a turntable is arranged in the middle of the filter screen, and the turntable is rotationally connected with the tray; sludge is conveyed to a reaction kettle from a temporary storage tank, a flocculating agent and the like are added, and the sludge enters a centrifugal tank and a forming tank in sequence after a certain time and is subjected to preliminary dehydration and drying forming respectively; wherein a scraping plate is arranged in the centrifugal tank, so that a large amount of sludge can be prevented from being solidified on the inner side of a filter screen, the elongation of the scraping plate is controllable, the position of the scraping plate can be flexibly adjusted according to the sludge dewatering time and the change of the water content, and the optimal dewatering effect can be achieved with the minimum energy consumption.

Owner:HUNAN ZHONGTUO ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com