Patents

Literature

356results about How to "Improve sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

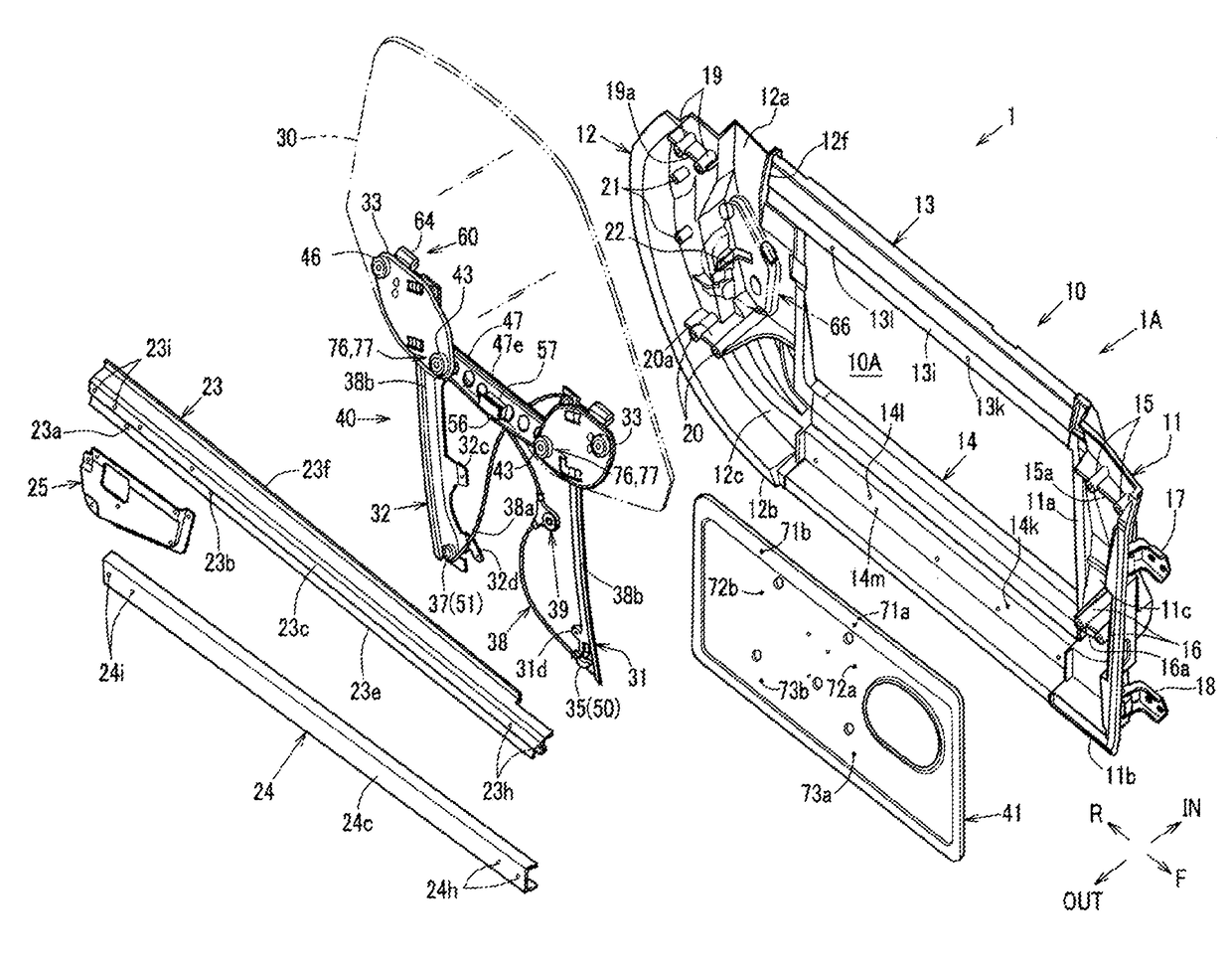

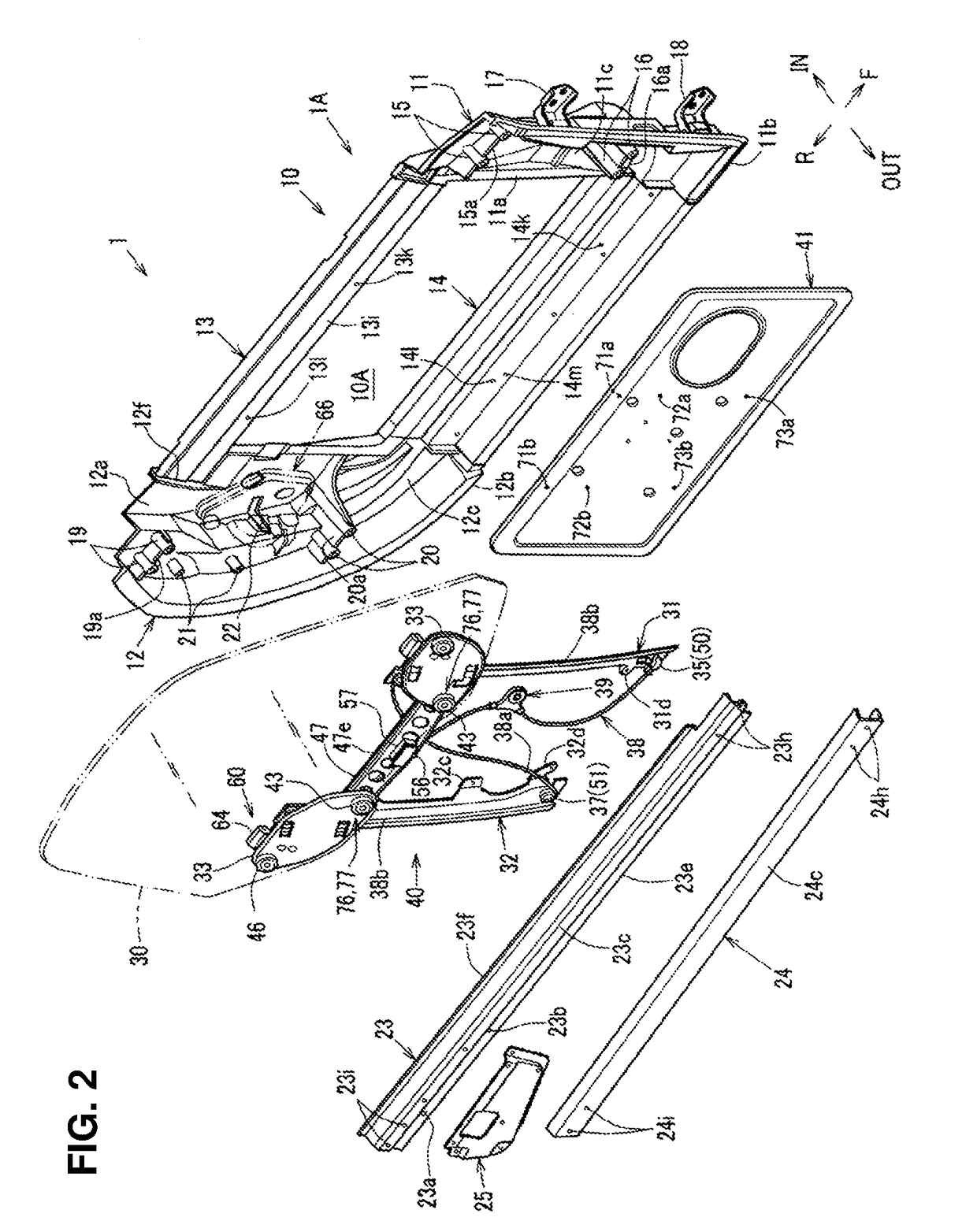

Door structure of automotive vehicle and assembly method of the same

ActiveUS20170240031A1Improve AssemblabilityImprove sealing performanceMan-operated mechanismPower-operated mechanismMechanical engineeringEngineering

Guide rails with which a window regulator is provided are respectively fixed to a module plate. The guide rails are fixed, together with the module plate, to an edge of an opening portion provided at inward frames from an outward side in a vehicle width direction. Attachment portions which are capable of afterward attaching outward frames to the inward frames are provided, and attachment portions which are capable of afterward attaching a door outer panel to a door frame comprising the inward frames and the outward frames are provided.

Owner:MAZDA MOTOR CORP

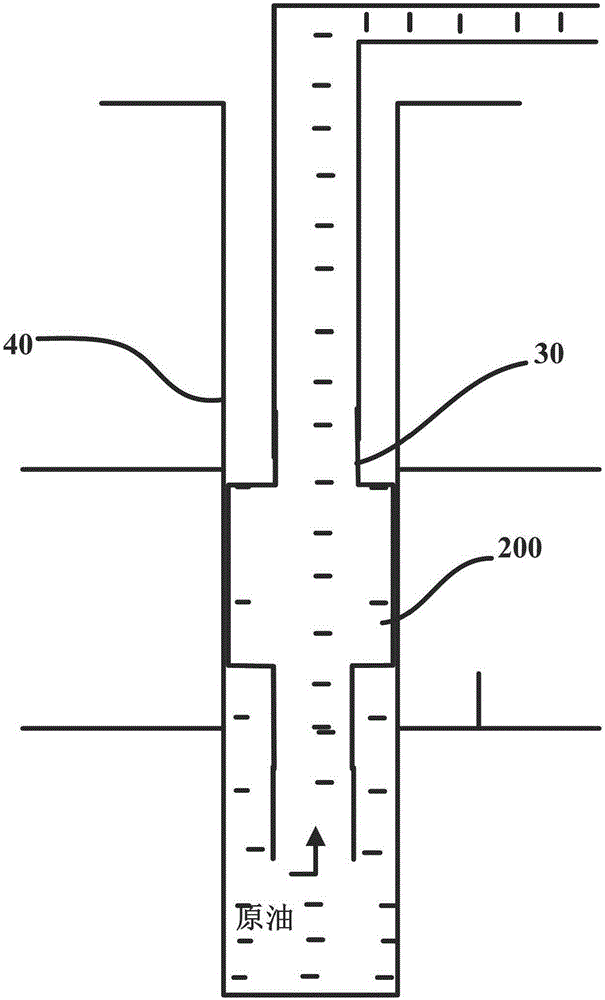

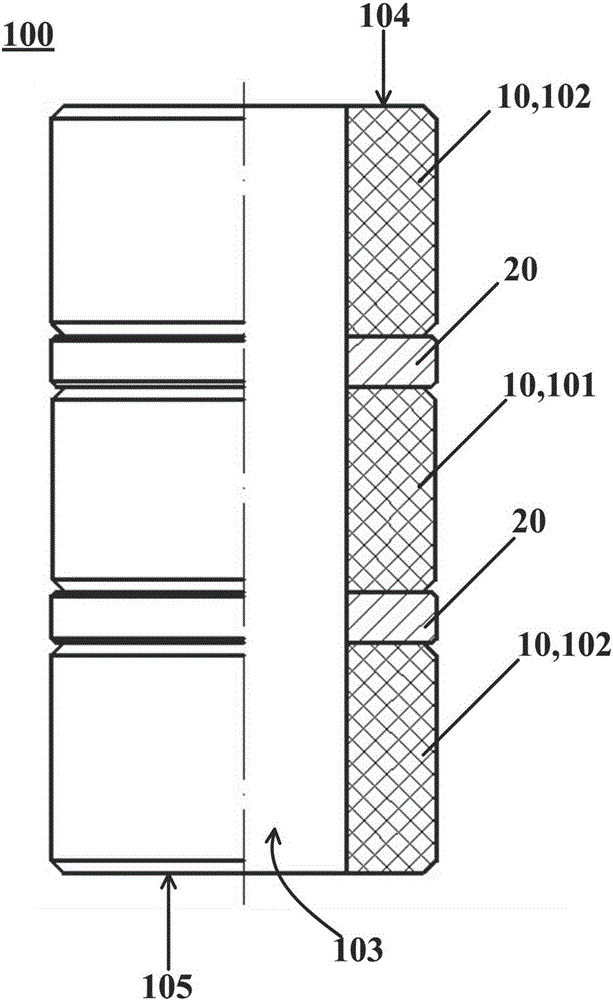

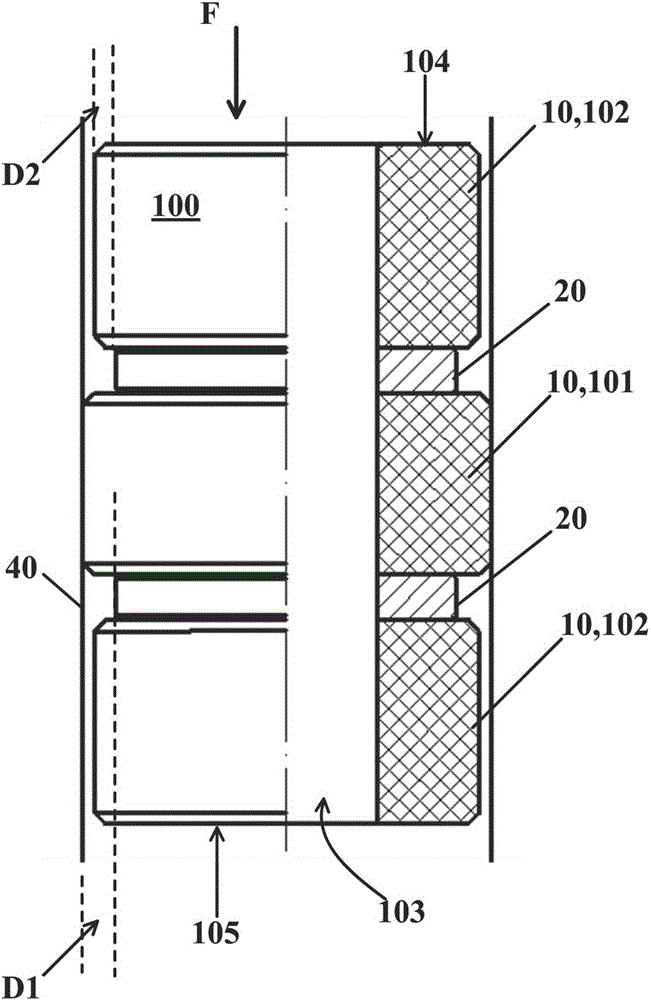

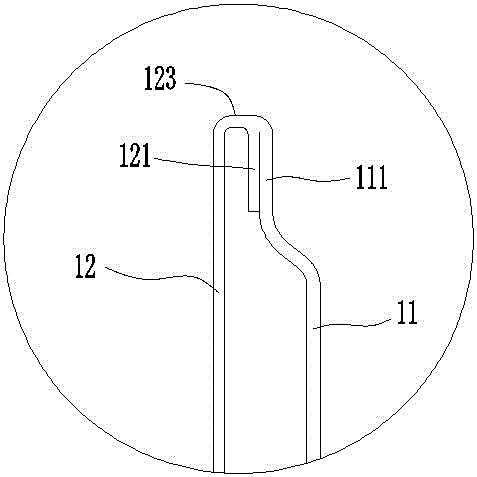

Rubber barrel capable of resisting high-temperature steam, compressed type packer and sealing method

ActiveCN105298434AImprove sealing performanceAvoid direct contactSealing/packingEngineeringMechanical engineering

The invention relates to the field of sealing, in particular to a rubber barrel capable of resisting high-temperature steam, a compressed type packer with the rubber barrel and a sealing method. The rubber barrel comprises a sealing body, wherein the sealing body is provided with a first sealing section and second sealing sections; the first sealing section is easier to compress than the second sealing sections; when axially compressed, the first sealing section seals a first bulge in the radial direction, and the second sealing sections are not enough to seal a second bulge in the radial direction; the second sealing sections are close to steam holes for jetting the high-temperature steam, so that when the steam holes jet the high-temperature steam, the second sealing sections continuous to seal a third bulge in the radial direction under the action of the high-temperature steam to prevent direct contact between the high-temperature steam and the first sealing section or shorten the time for the high-temperature steam to contact with the first sealing section. The rubber barrel disclosed by the invention can realize low-temperature sealing and high-temperature sealing, and can both achieve a sealing effect and resist the high-temperature steam.

Owner:TIANDING SEALING TECH BEIJING CO LTD

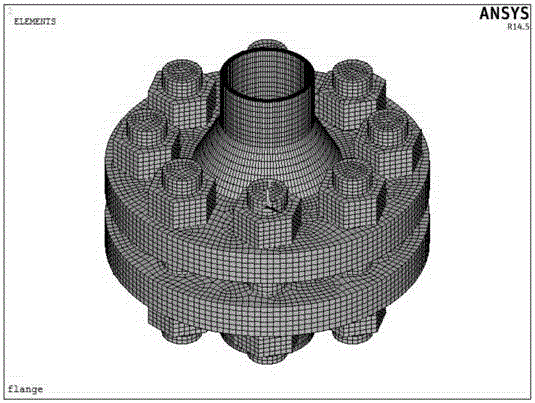

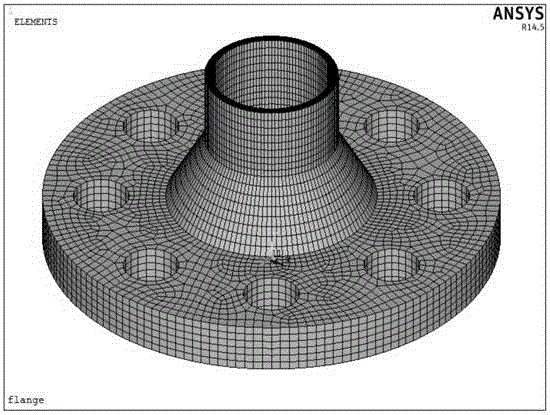

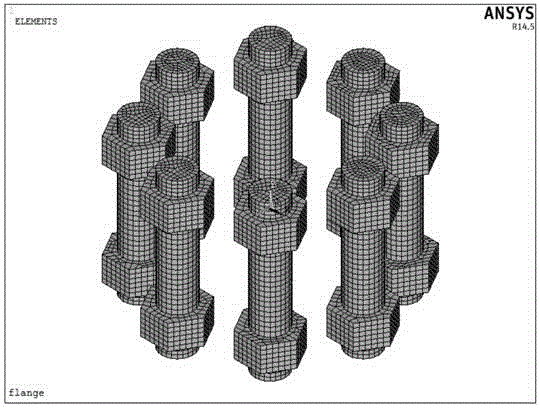

Pre-tightening optimization method of bolt connecting component

InactiveCN106446459AImprove sealing performanceImprove sealingDesign optimisation/simulationSpecial data processing applicationsGraphiteMetal

The invention provides a pre-tightening optimization method of a bolt connecting component. The bolt connecting component comprises two connecting pieces, the two connecting pieces are fixedly connected with each other through a bolt component, a flexible graphite metal wave gear composite gasket is arranged between the contact surfaces of the two connecting pieces, wherein the pre-tightening force of a bolt affected by negative elastic interaction is corrected by a correction factor in the process of tightening the connecting pieces through the bolt. According to the pre-tightening optimization method disclosed by the invention, the bolt force obtained by the bolt after every round of loading is finished is close to the target bolt force and is in concentrated distribution, and the inner side and the outer side of the gasket can obtain uniform contact stress.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

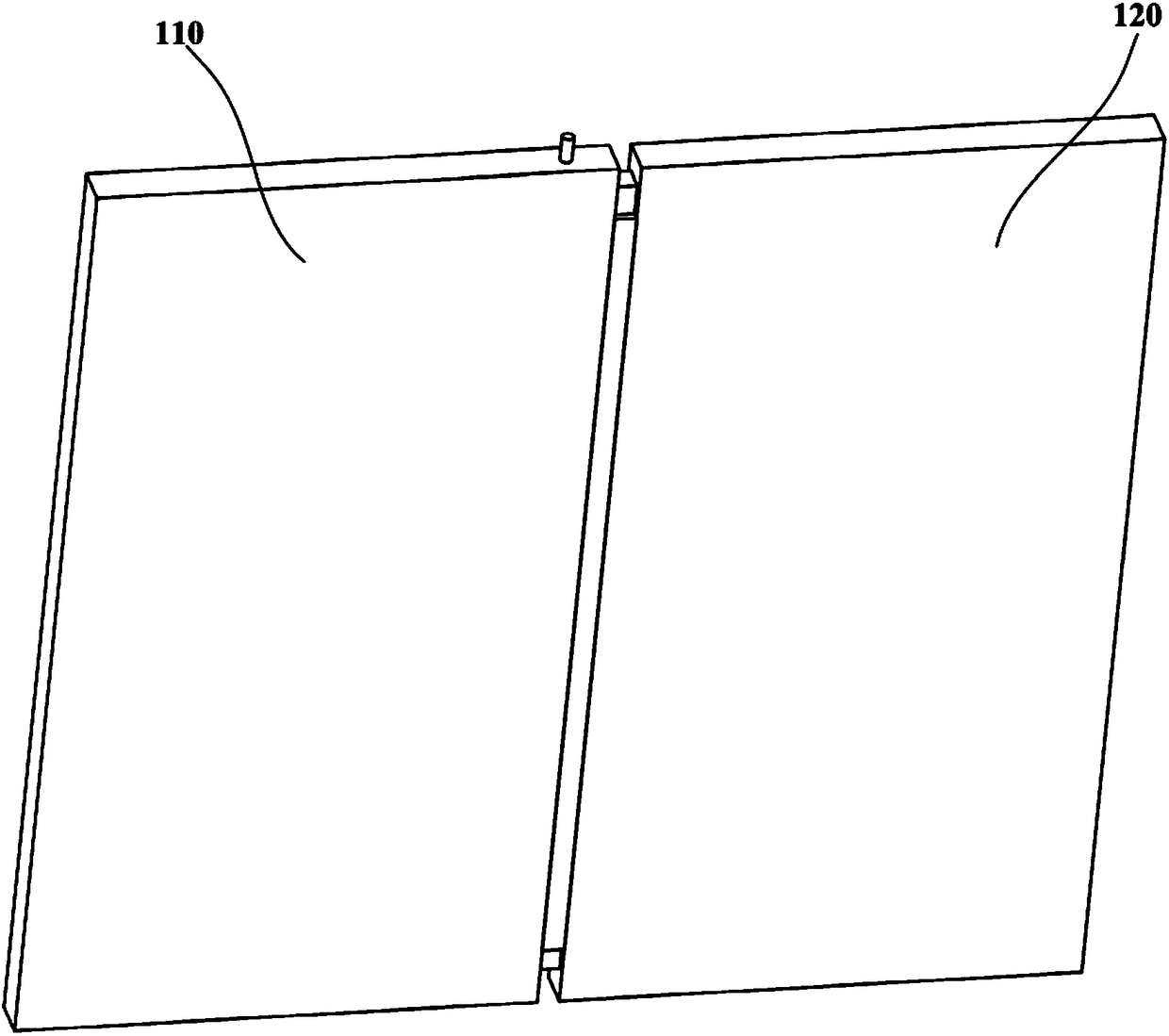

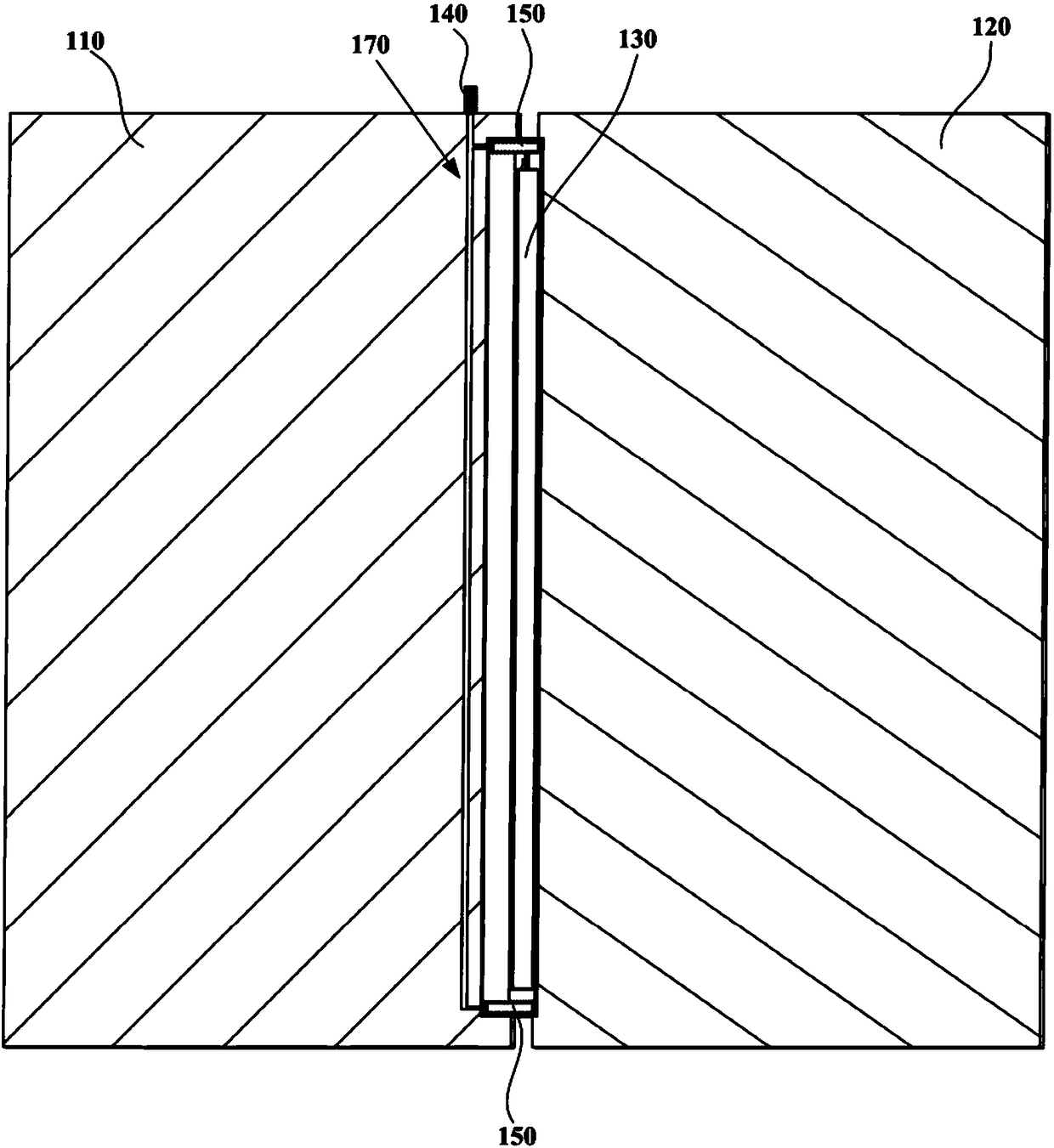

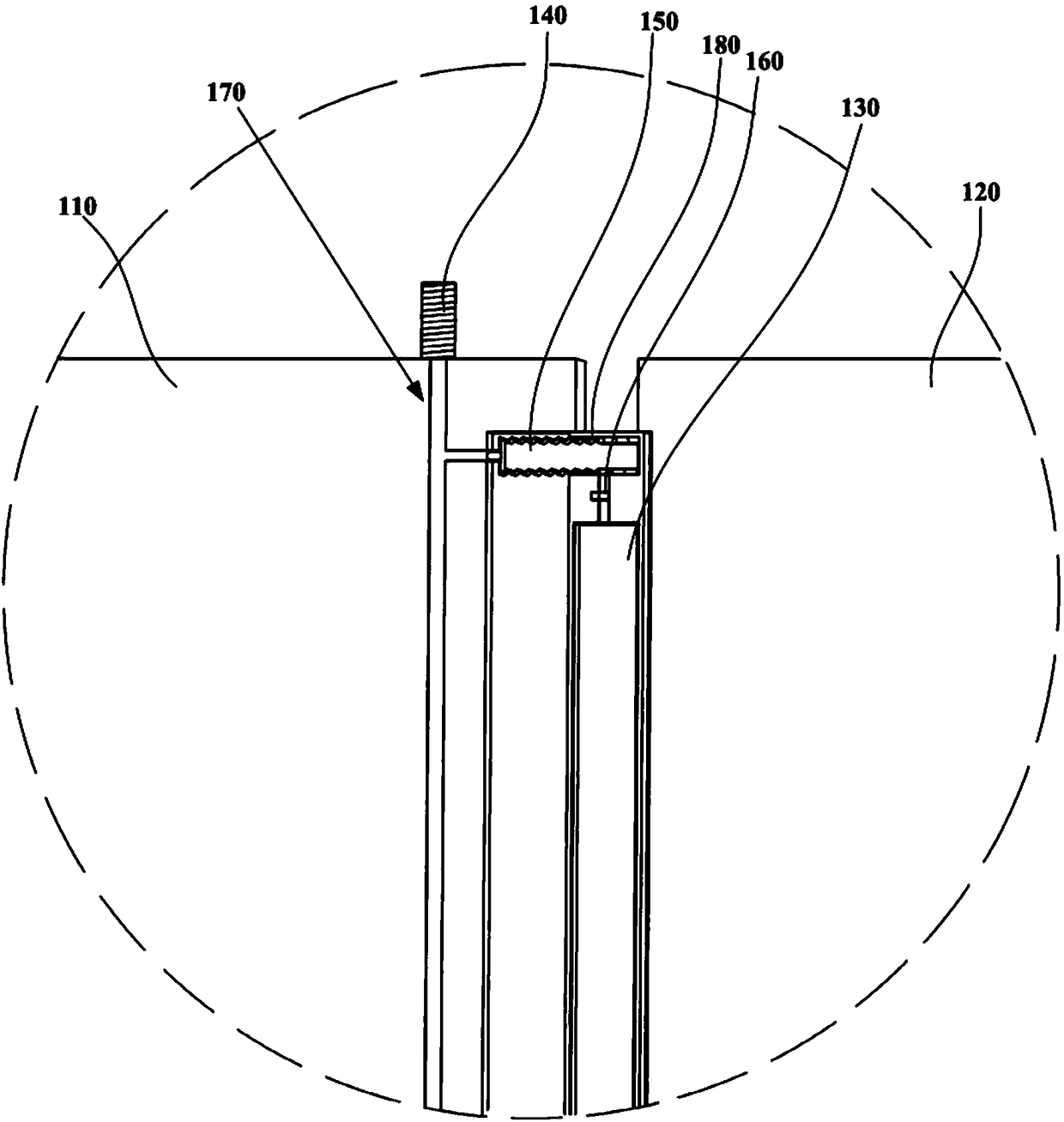

Split door body assembly and refrigerator

ActiveCN108426413AImprove insulation effectImprove insulation performanceLighting and heating apparatusCooling fluid circulationEngineeringElectrical and Electronics engineering

The invention provides a split door body assembly and a refrigerator. The split door body assembly comprises a group of split door bodies, a sealed air bag, an inflator, and at least one telescopic component. In the split door body assembly provided by the invention, when the door body is closed by a user, the telescopic component pushes the sealed air bag to move toward a second door body, and the inflator is started to fill a gas into an inflation passage, and the sealed air bag expands to seal a gap between the split doors. When the door body is opened, the telescopic component drives the sealed air bag to move away from the second door body, and the inflator deflates the sealed air bag. The sealed air bag is retracted into a first cavity. The sealed air bag is filled with the gas, so that the door body is sealed more firmly; meanwhile, the gap between the split doors is completely filled by the sealed air bag with high elasticity, thereby improving the sealing and heat insulation effects of the refrigerator.

Owner:CHONGQING HAIER REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

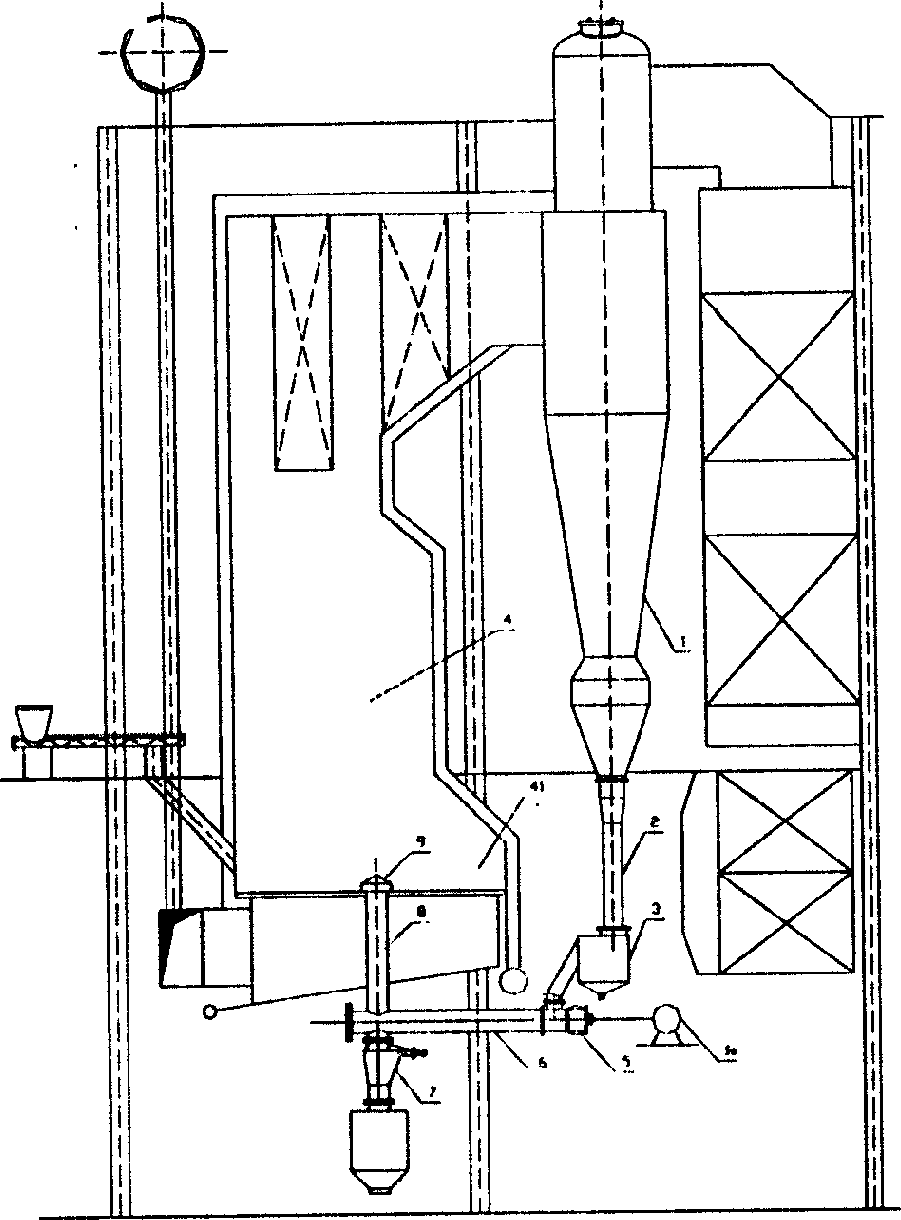

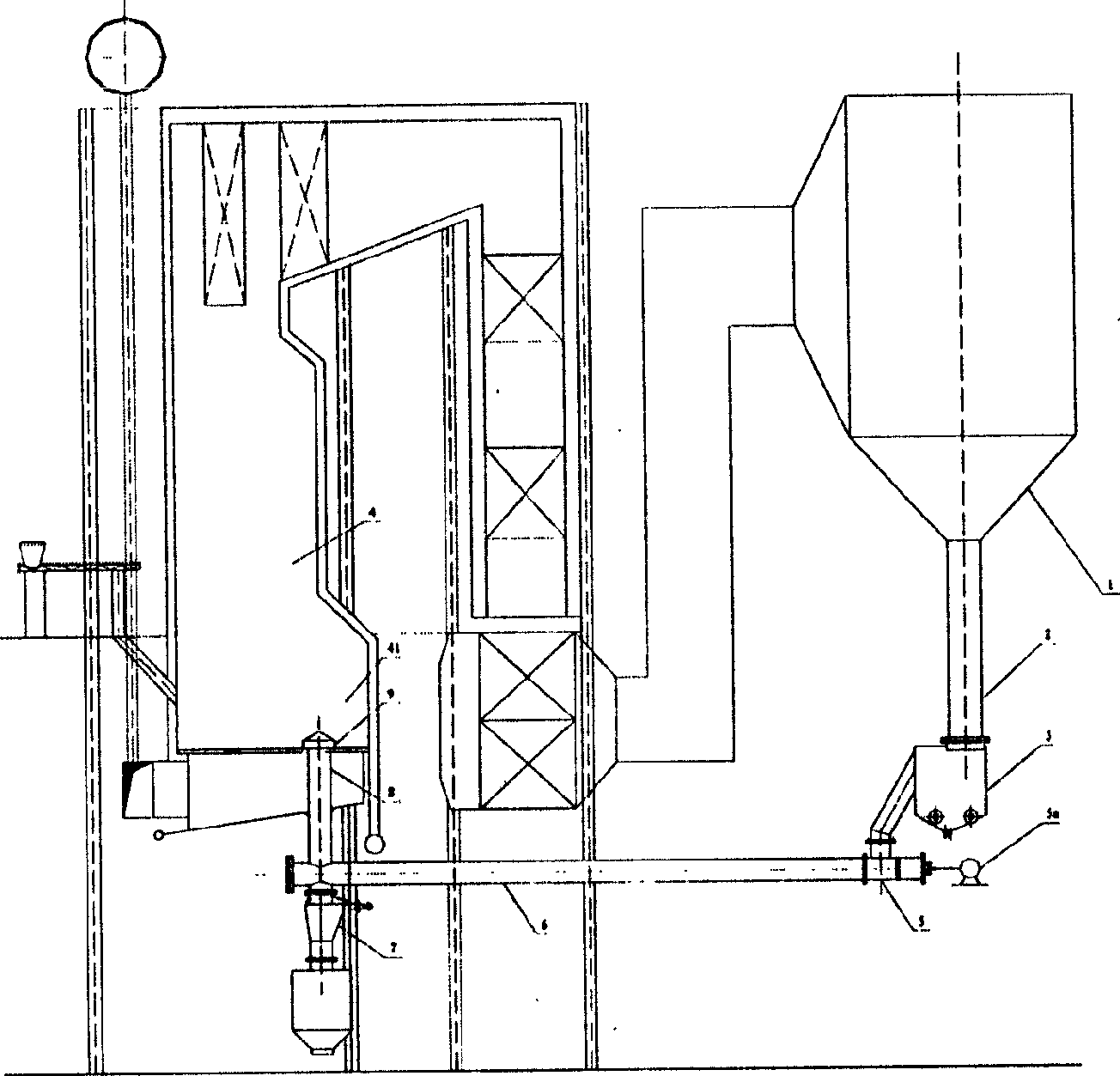

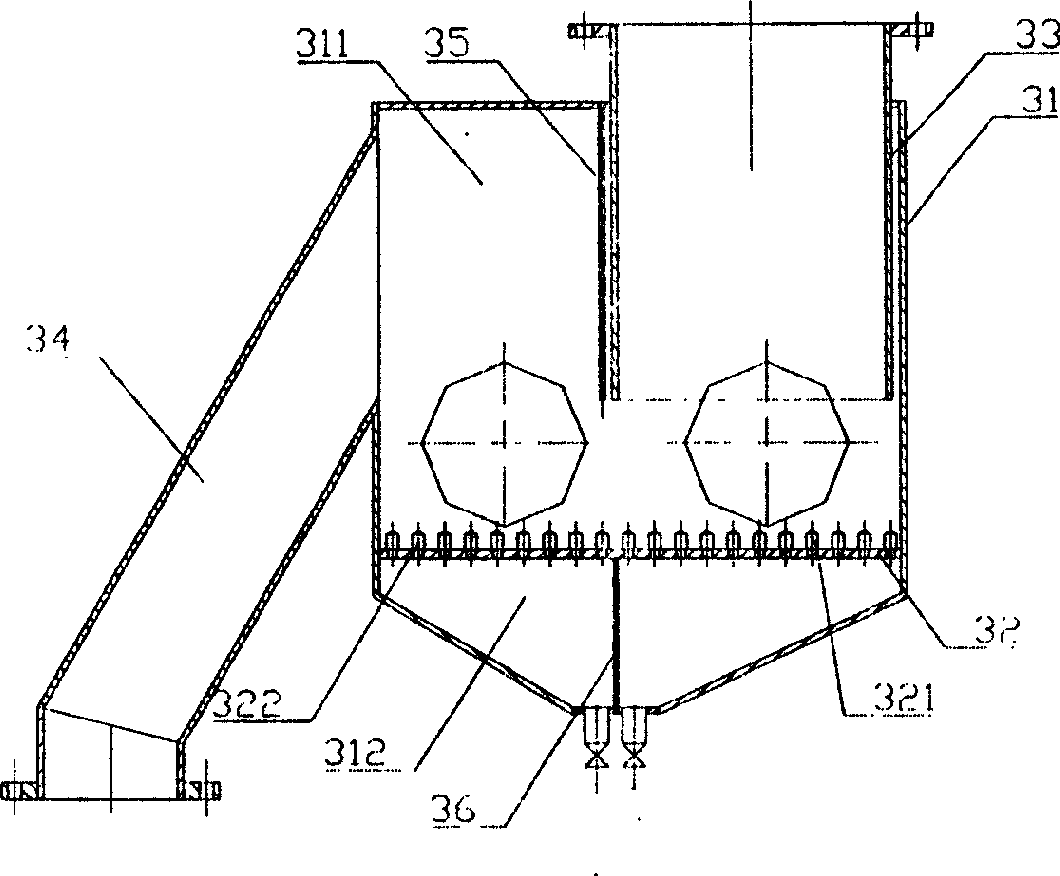

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

ActiveCN1529088AReduce leakageImprove sealing performanceFluidized bed combustionApparatus for fluidised bed combustionInjectorCorrosion

The invention provides a kind of fly ash bottom feeding circular fluidized-bed combustion method and the device, the method is: uses fly ash collector to collect the fly ash with high content in smoke, the fly ash are put into the back material controller through vertical pipe, then and they are carried to the return pipe through transmitting and ejector, and they are returned to the thick phase area of bed through bottom feeding spraying muzzle which is high temperature resisting and corrosion resisting. The device is: it is made up of fly ash collector, back material controller, gas transmitting ejector and the combustion furnace. The top of the combustion furnace connects with the inlet of fly ash collector, the fly ash through the fly ash collector outlet, are carried to the thick phase area of combustion furnace through the bottom feeding sprayer with gas transmitting ejector. The invention can enhance the combustion effect of the fly ash; it can save energy and protect the environment.

Owner:SOUTHEAST UNIV

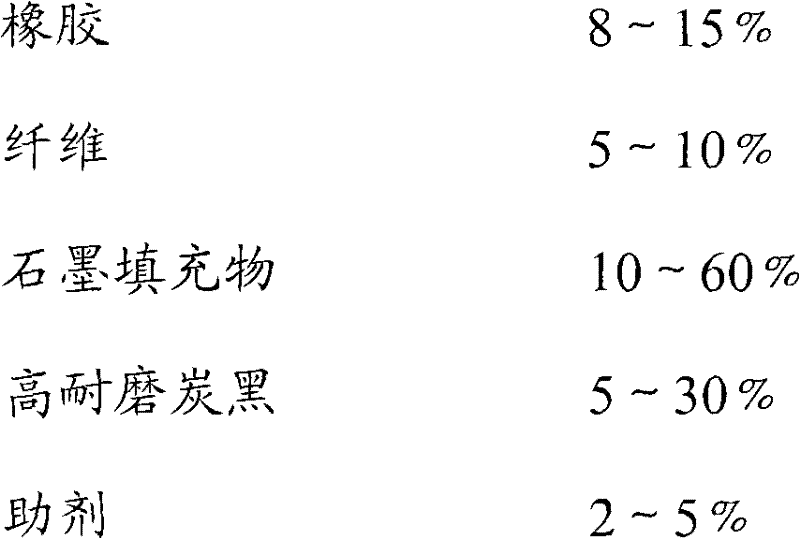

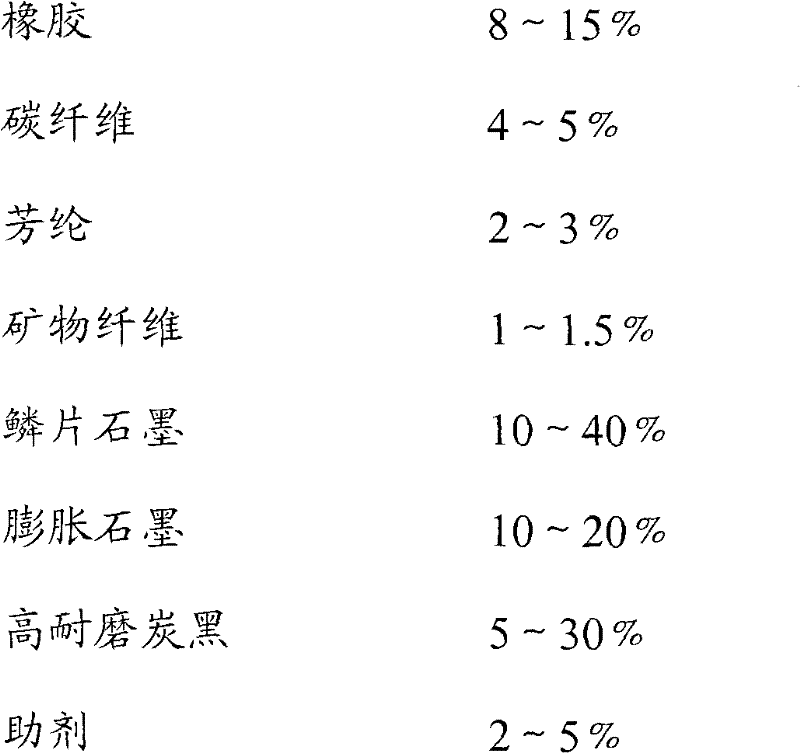

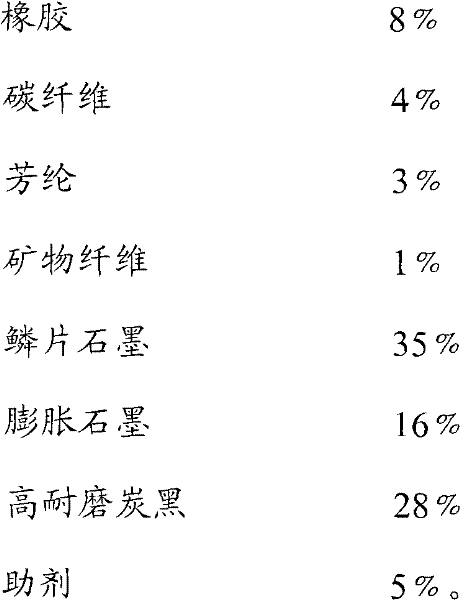

Low-leakage high-temperature resistant asbestos-free plate or cushion

The invention discloses an asbestos-free plate or an asbestos-free cushion and a preparation method thereof. The asbestos-free plate or the asbestos-free cushion comprises, by weight ratio, rubber 8-15%, fibers 5-10%, graphite fillers 10-60%, high abrasion resistant carbon black 5-30% and addition agent 2-5%. The asbestos-free plate and the asbestos-free cushion do not contain asbestos materials and adopt specific components and specific contents, thereby resolving the technical problem that materials do not adopt asbestos, having high-temperature resistant performance superior to the performance of the asbestos materials and higher sealing performance, achieving perfect substitution of corresponding asbestos products and enabling the sealing performance to be remarkably improved.

Owner:JIANGSU SEALSTARS SEALING TECH CO LTD

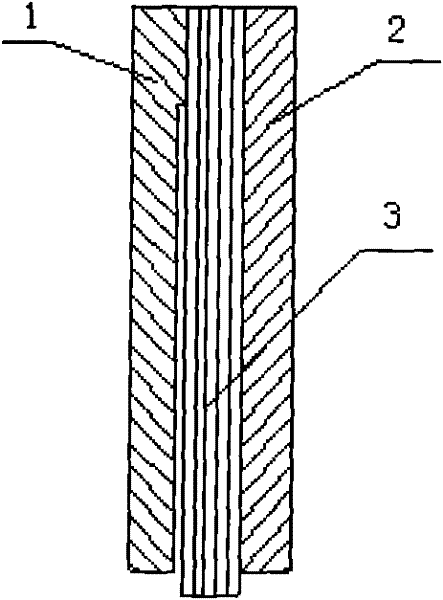

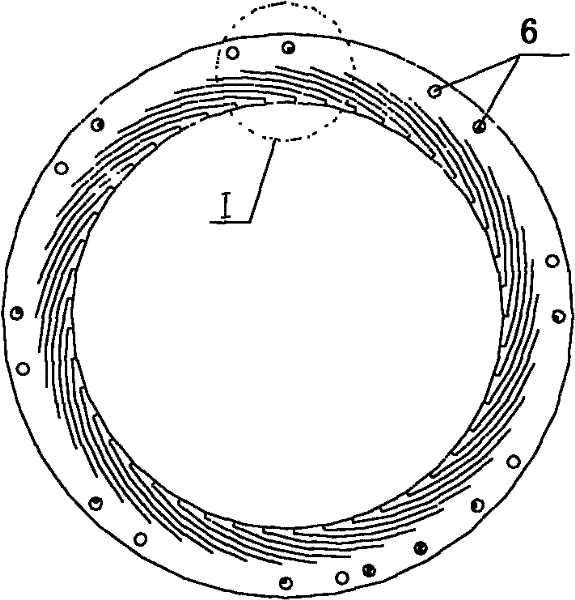

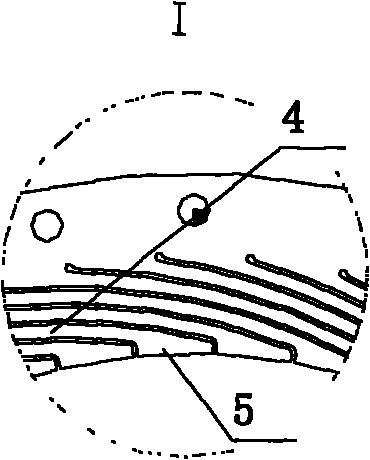

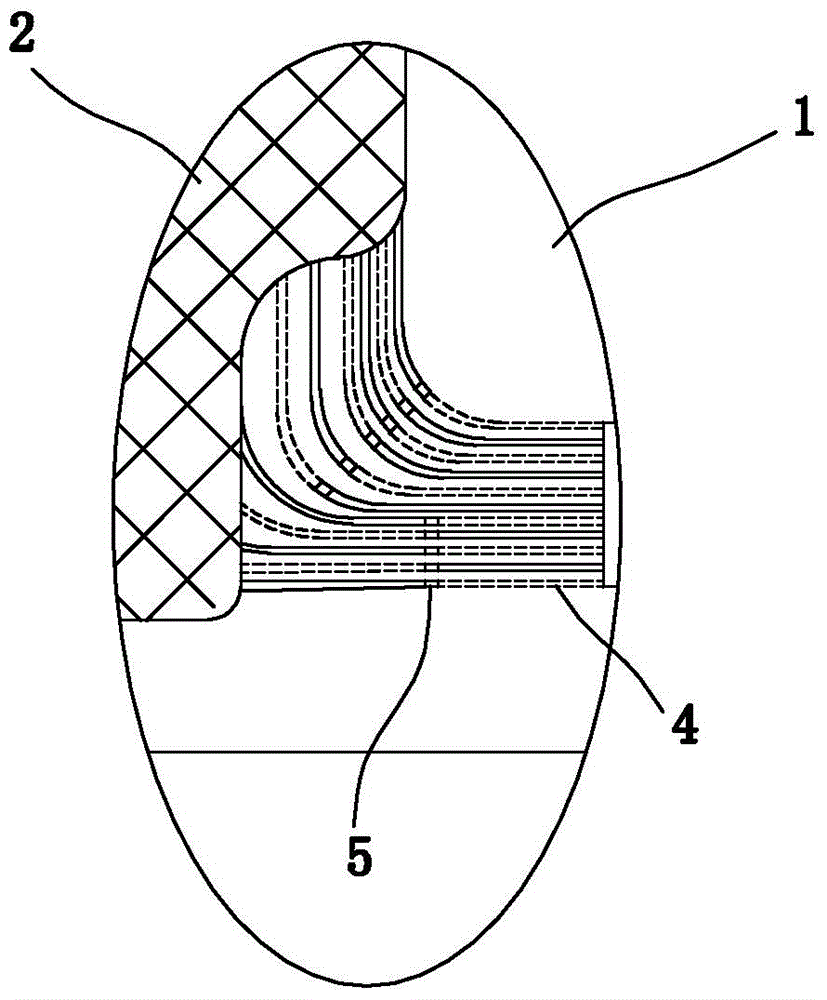

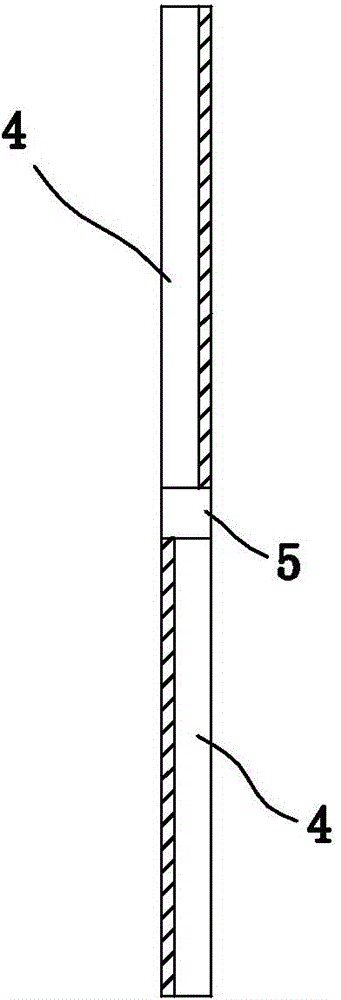

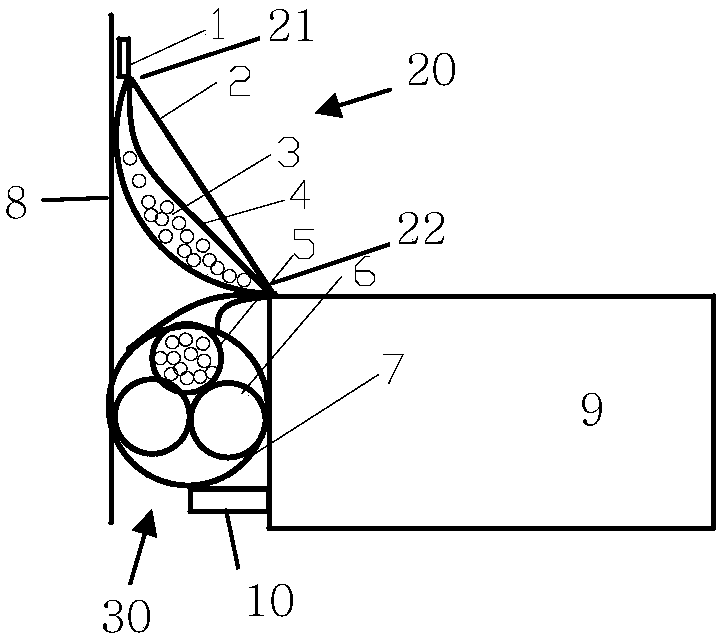

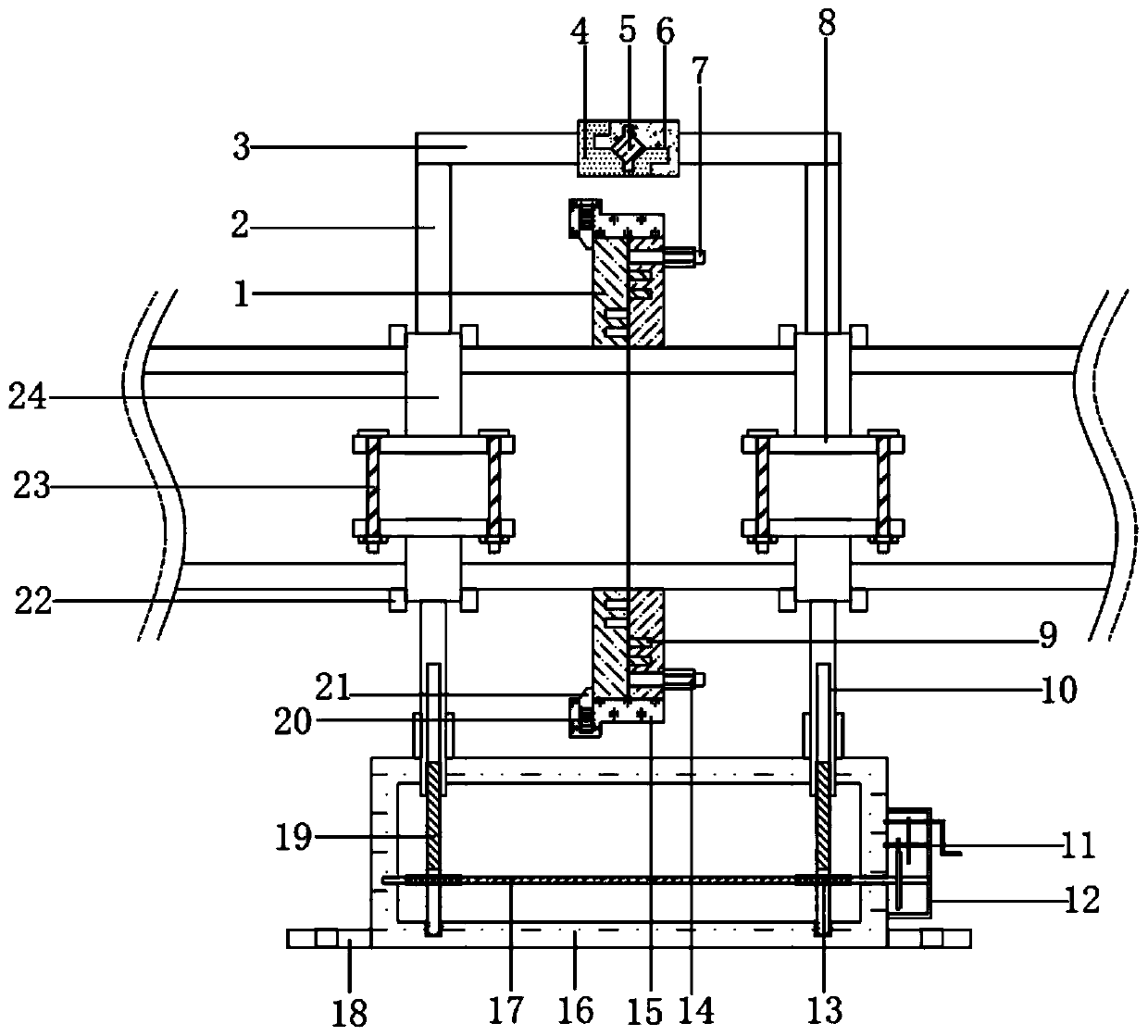

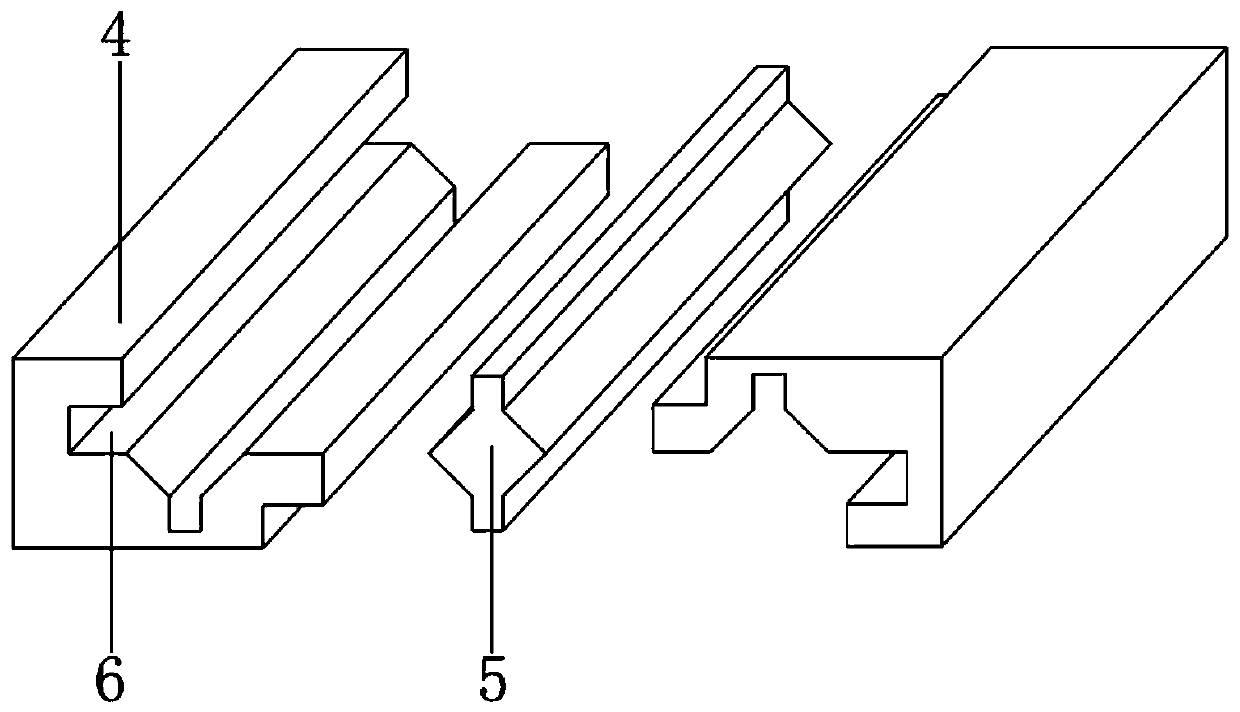

Involute-type fingertip sealing structure

InactiveCN101749055AImprove sealing performanceReduce leakageEngine sealsLeakage preventionBatch productionEngineering

The invention relates to a sealing structure, in particular to a fingertip sealing structure used for controlling leakage of secondary flow in an engine. The involute-type fingertip sealing device comprises a front baffle plate (1), a back baffle plate (2) and a plurality of layers of fingertip chips (3) which are arranged between the front baffle plate and the back baffle plate; the characteristics are as follows: the internal diameter of the fingertip chip is provided with an involute-type finger body (4), and the free end of the finger body (4) forms a sealing boot (5), and the finger bodies (4) between the two adjacent fingertip chips (3) are mutually staggered. Through the design of the involute-type finger body, and combining the characteristics of the fingertip sealing and the fine-toothed comb sealing, the involute-type fingertip sealing structure provided by the invention has good sealing performance, can effectively decrease leakage. Meanwhile, the invention has simple structure, convenient processing, low cost, and is suitable for batch production, and has large actual application value.

Owner:CHINA GAS TURBINE ESTAB

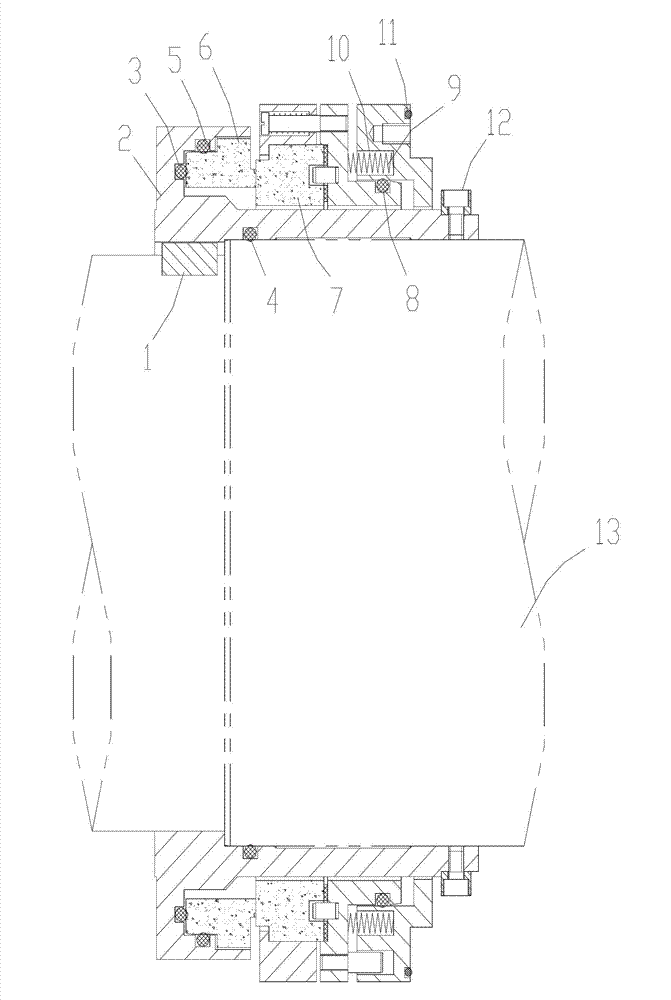

Leakage-proof pressure-bearing hydraulic cylinder

InactiveCN104613047AImprove sealing performancePrevent leakageEngine sealsFluid-pressure actuatorsPistonMechanical engineering

The invention relates to a leakage-proof pressure-bearing hydraulic cylinder which comprises a left cylinder cover, a right cylinder cover, a cylinder drum, a cylinder rod, a piston and pressure bearing pieces. The cylinder drum is coaxially and fixedly arranged between the left cylinder cover and the right cylinder cover. The piston slides in the cylinder drum coaxially. The pressure bearing pieces are symmetrically arranged on the front radial face and the rear radial face of the piston respectively. The pressure bearing pieces are coaxially and fixedly arranged on the piston through clamping rings. Seals are coaxially arranged between the pressure bearing pieces and the radial faces of the piston. The leakage-proof pressure-bearing hydraulic cylinder is characterized in that two identical sealing rings are embedded in the portions, between the piston and the inner walls of the cylinder drum, of the cylindrical surface of the piston respectively, the sealing rings are groove type sealing rings, and the opening portions of the two groove type sealing rings are communicated with oil cavities formed in two sides respectively through an oil duct. The groove type sealing rings are adopted by the axial sealing rings of the hydraulic cylinder, and the two groove type sealing rings are communicated with the left oil cavity and the right oil cavity respectively, so that the sealing rings are expanded along with the changes of pressure, and the sealing performance is improved.

Owner:TIANJIN XINHAOSHENG HYDRAULIC MACHINERY TECH

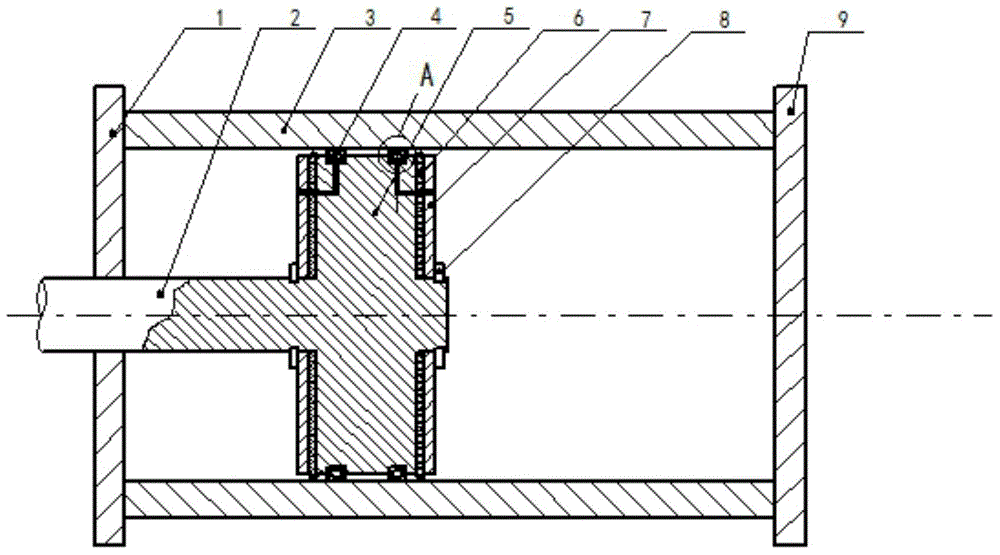

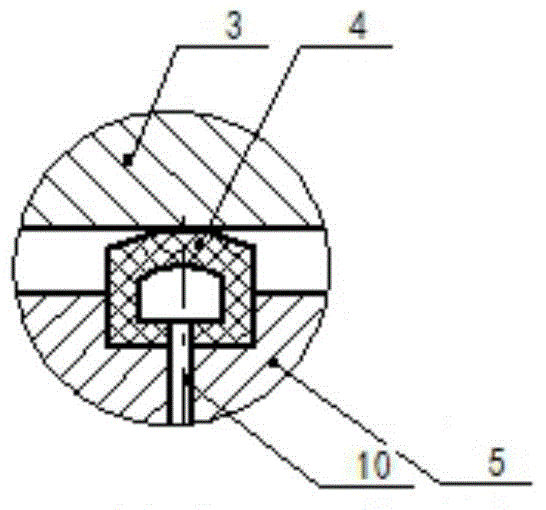

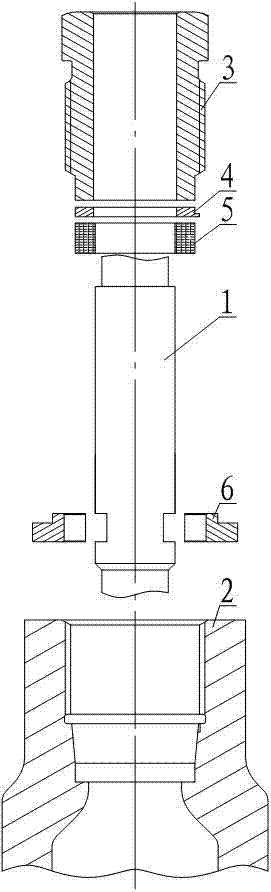

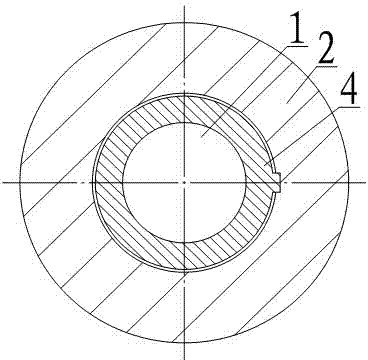

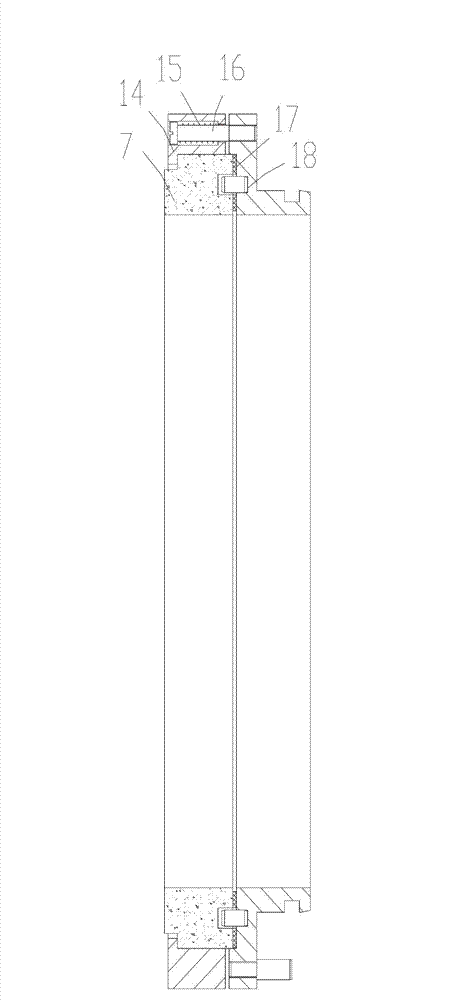

Self-tightening sealing structure for single detector

ActiveCN103400614AImprove the sealing effectImprove sealing performanceEngine sealsNuclear energy generationEngineering

The invention discloses a self-tightening sealing structure for a single detector. The self-tightening sealing structure comprises the detector, a tube base and a tubular connecting piece, wherein the tube base is provided with a fluid cavity and a detector introducing passage communicated with the fluid cavity; the lower end of the tubular connecting piece is arranged inside the detector introducing passage and connected with the tube base; the lower end of the detector is arranged inside the fluid cavity after passing through an inner bore of the tubular connecting piece and the detector introducing passage. An annular supporting platform is formed on the inner wall of the detector introducing passage; the detector is connected with a separation ring which is positioned below the tubular connecting piece and arranged on the annular supporting platform; a filling sealing member is arranged in an area between the tubular connecting piece and the separation ring. The self-tightening sealing structure is simple integrally, is convenient to install and disassemble, and has a reliable self-tightening sealing function to ensure a good sealing effect and improve the safety of the detector.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

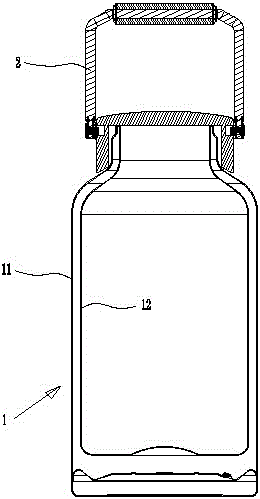

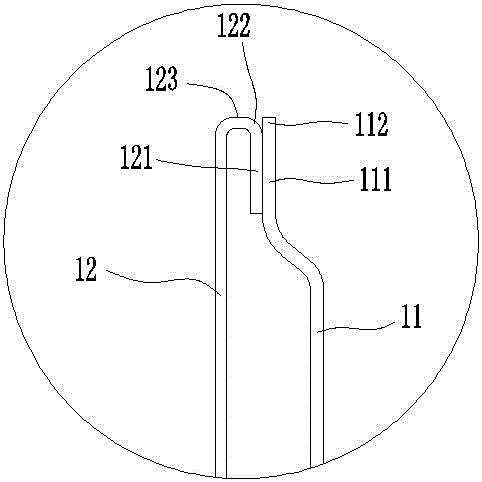

Seamless vacuum cup and machining method thereof

InactiveCN106136769AUniform mouth thicknessImprove sealing performanceDrinking vesselsArc weldingMaterials science

The invention discloses a seamless vacuum cup and a machining method thereof. The machining method comprises the following steps: bending the upper end of an opening part of a stainless steel liner to the outer side to form a folding part; feeding the stainless steel liner into a stainless steel shell and sleeving the outer side of a drooping edge of the folding part on the upper end part of the opening part of the stainless steel shell; fusing and welding the end of the upper end part and a bent corner of the upper end of the drooping edge to form a whole body by argon-arc welding; and a polishing treatment step: carrying out polishing treatment on the outer surface of a welding part. The seamless vacuum cup machined by the method comprises a cup body and a cup cover, wherein the folding part which is bent toward the outer side is formed at the upper end part of the opening part of the stainless steel liner and the drooping edge of the folding part sleeves the upper end part of the opening part of the stainless steel shell; and the end of the upper end part and the bent corner of the upper end of the drooping edge are welded through the argon-arc welding to form an integrated structure. With the adoption of the seamless vacuum cup and the machining method thereof, the technical difficulty of seamless connection of the shell and the liner of the vacuum cup is solved, the sealing property and the whole intensity of the vacuum cup are improved, and the welding is more convenient and efficient.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

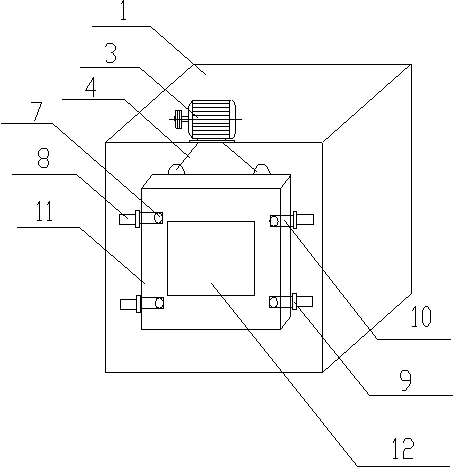

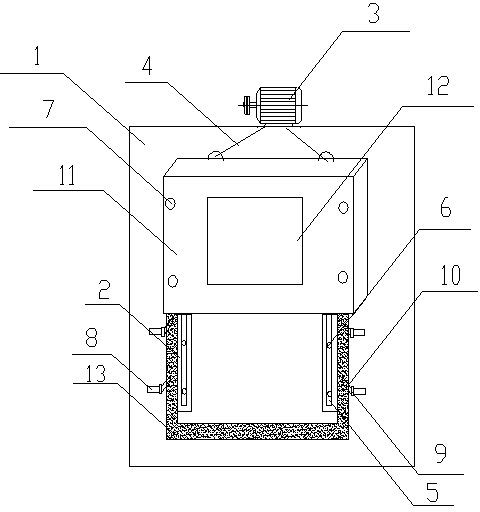

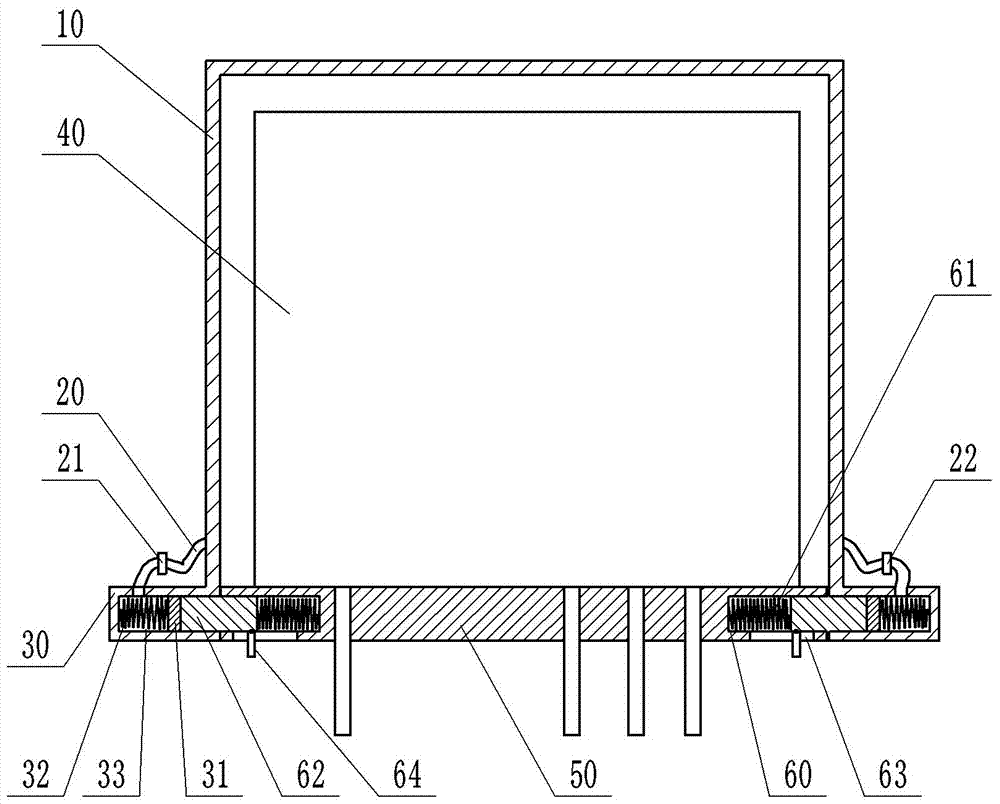

Drying-box door

InactiveCN103452444AGood sealing effectGood thermal insulation and sealing effectDoor/window applicationsSealing arrangementsPulleyDry box

The invention relates to a drying-box door, which comprises a door frame and a rolling track, wherein the door frame is arranged in a box-body opening, the rolling track is installed on the door frame, a box door is fixedly arranged on the rolling track through a pulley, a lifting iron chain is installed at the upper end of the box door and is connected with a minor crane, the minor crane is installed at the upper part of the box body, heat-preserving cotton beyond the edge of the box body is arranged on the inner wall of the box body, compacting devices are installed on the box body at the periphery of the box door, and lugs are positioned at positions where the framework of the box door and the compacting devices are buckled, and are positioned on the box door. Differing from a traditional drying-box door, an up-down stretching-type structure and the compacting device are adopted by the drying-box door disclosed by the invention; compared with a traditional door opening-closing type drying-box door, better sealing and heat-preserving effects are achieved. The heat-preserving cotton is adopted on a sealing surface, so that the sealing effect can not be influenced due to stretching for many times. Since the structure that the box door is stretched through the crane is adopted, manpower is saved, so that the design is applicable to large and small drying boxes.

Owner:JIANGSU GAOHAO IND FURNACE

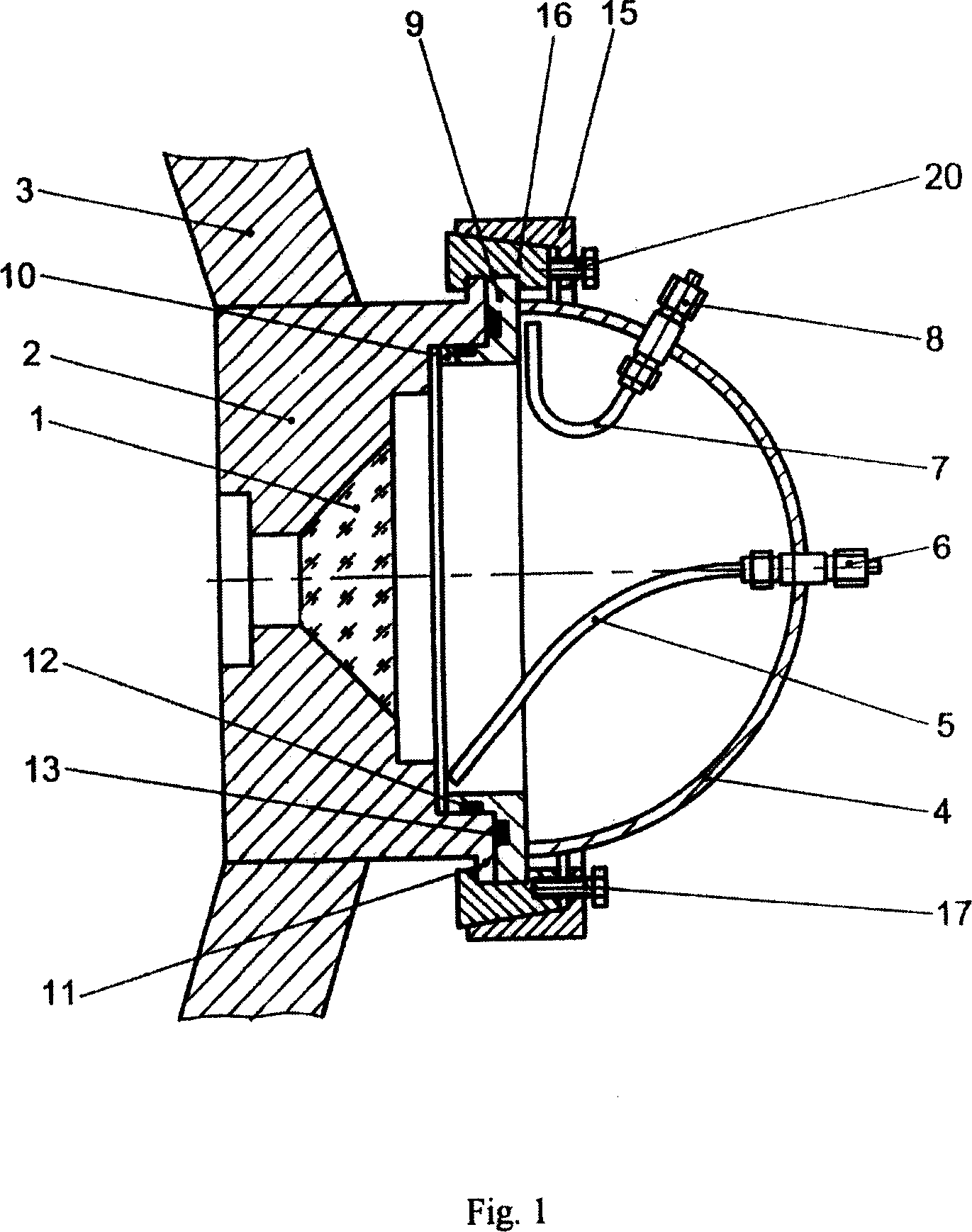

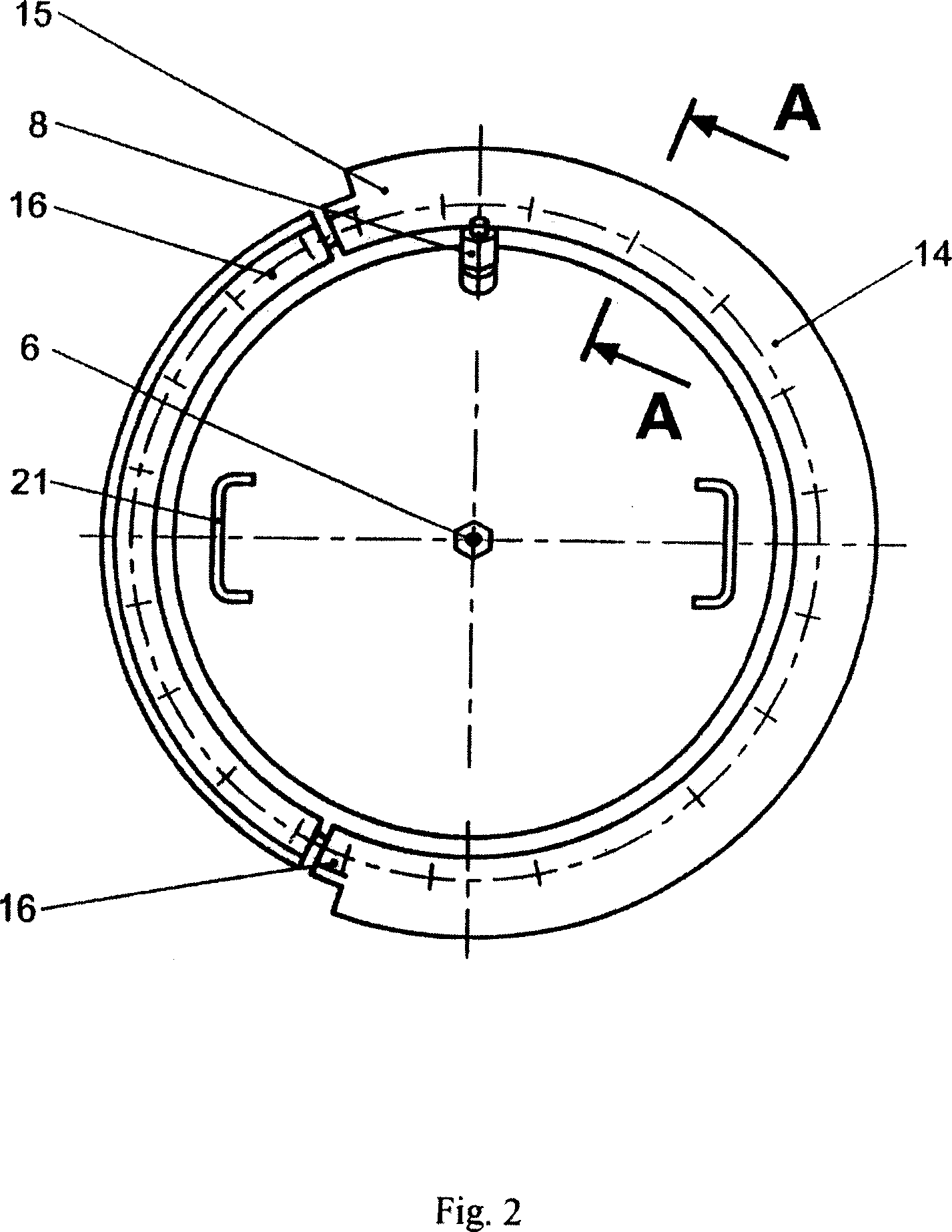

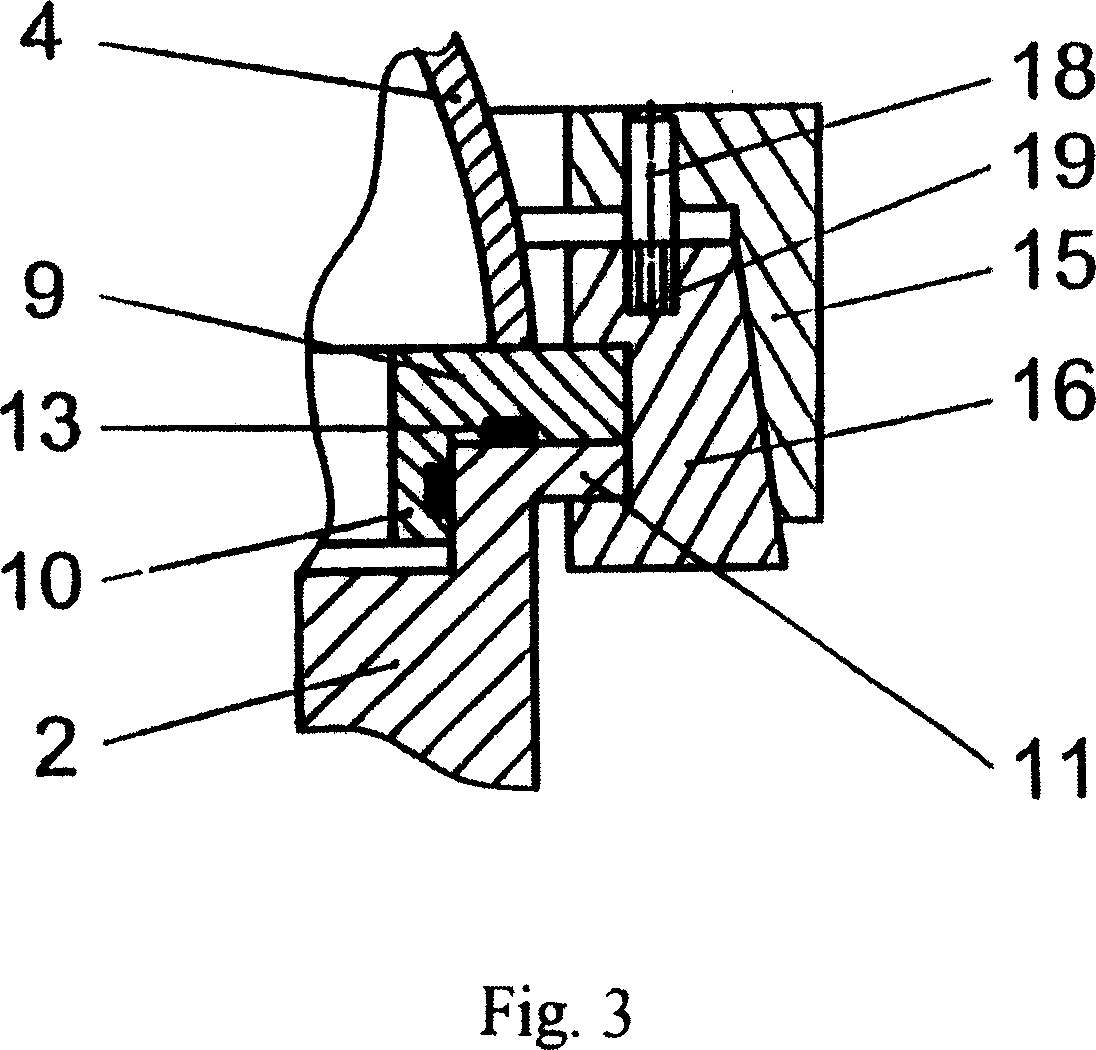

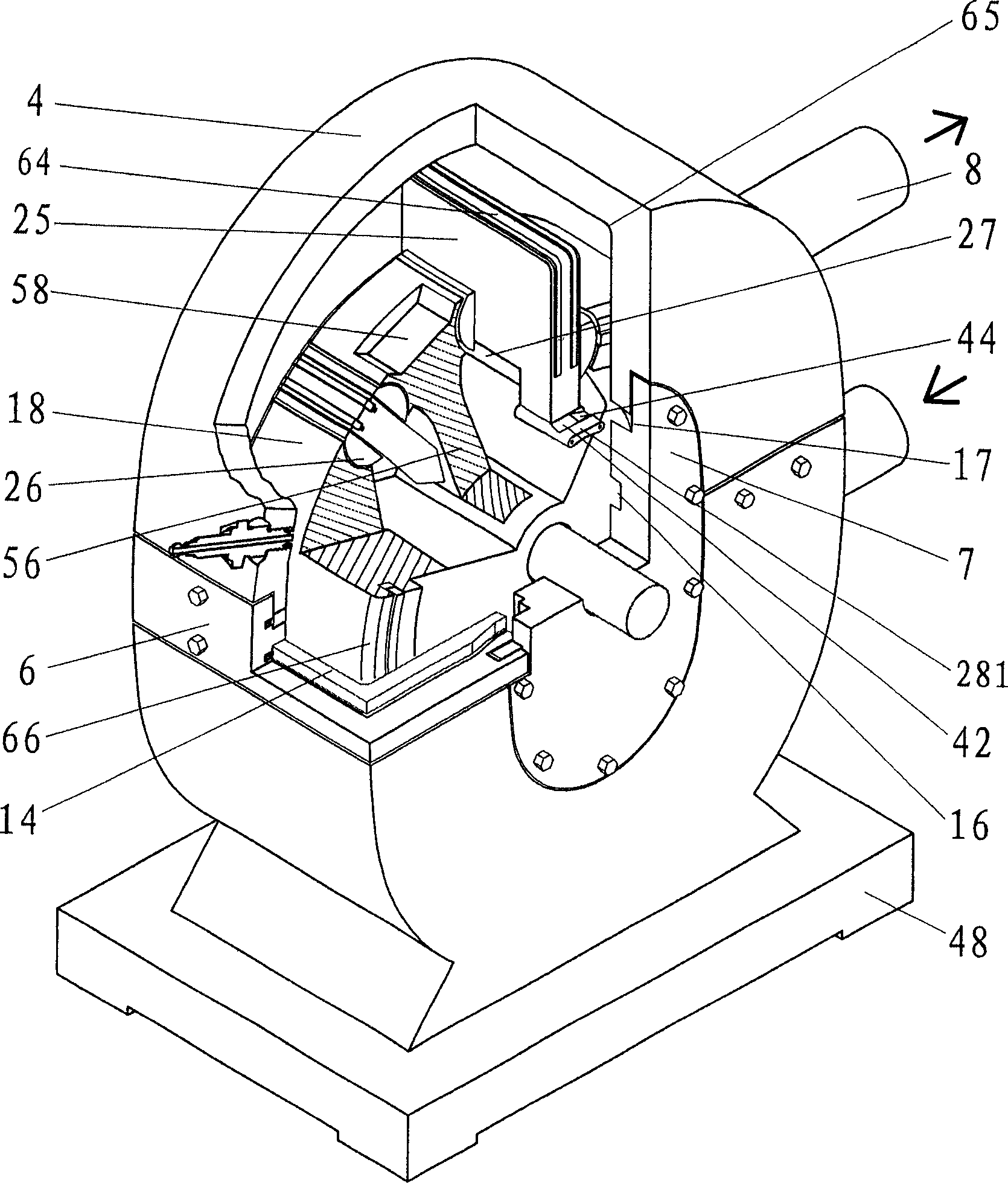

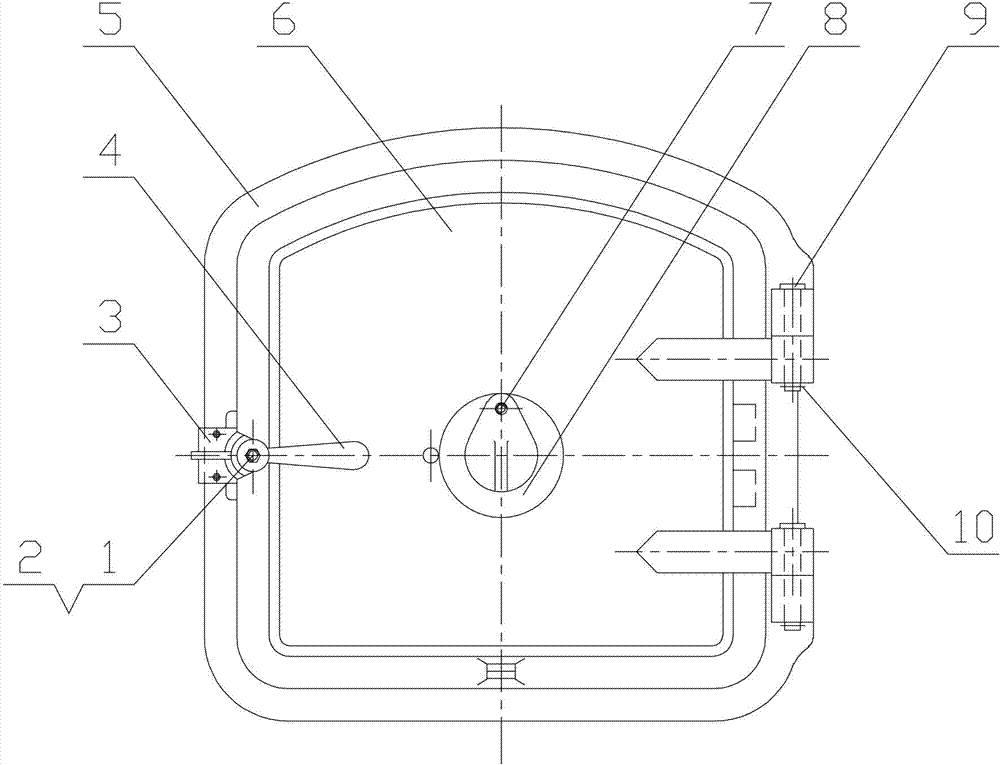

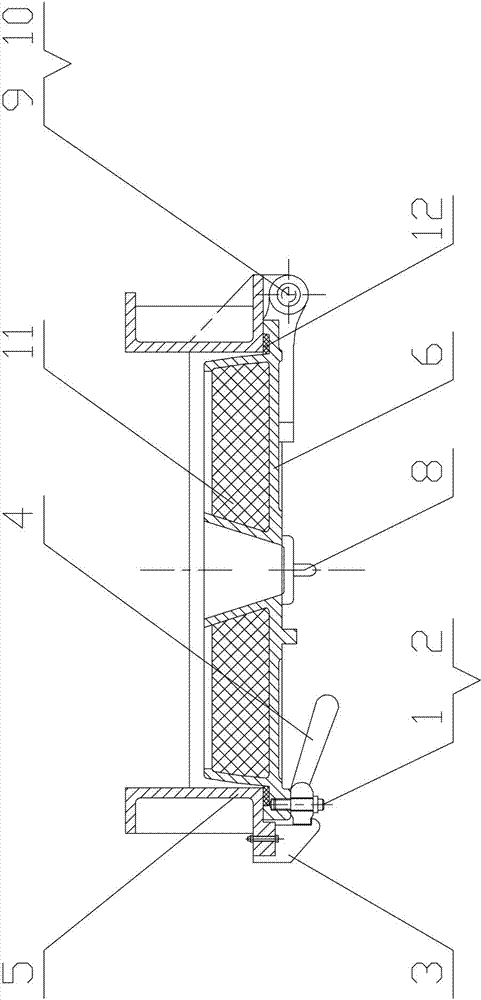

Connectable chamber for porthole testing

InactiveCN1960907AImprove sealing performanceEliminate leakageMeasurement of fluid loss/gain rateShip windowsTight junctionLeakage test

The invention relates to shipbuilding and can be used for strength and leakage tests of the portholes of low-volume submersible vehicles. A connectable chamber is used for increased external pressure testing of the submersible vehicle portholes (1) which are arranged in a cylindrical body (socket welded connection) (2) provided with a supporting flange (11). The body of a chamber (4) is embodied at least partially in the form of a spherical surface and comprises a joining flange (9) which is provided with an internal annular collar (10) embodied in such a way that it encompasses the porthole (1). A device (14) for pressing the body (4) against the socket welded connection (2) is embodied in the form of a banding ring (15) provided with a sectional annular insert (16) arranged thereinside the contact surfaces of the ring and insert being embodied in the form of the surface a truncated cone. The annular insert (16) is provided with an annular slot for simultaneously embracing the supporting (11) and joining (9) flanges. The ring (15) is tightened by bolts (17), whereby the perfect junction thereof to the annular insert (16) and the tight crimping of the spherical body of the chamber (4) through a sealing ring are maintained. A working medium is supplied inside the body (4) by an internal pressure source. The inventive device reduces the test duration, increases the reliability thereof and can be used directly during the submersible vehicle operation.

Owner:ГОСУДАРСТВЕННОЕ УЧРЕЖДЕНИЕ "ФЕДЕРАЛЬНОЕ АГЕНТСТВО ПО ПРАВОВОЙ ЗАЩИТЕ РЕЗУЛЬТАТОВ ИНТЕЛЛЕКТУАЛЬНОЙ ДЕЯТЕЛЬНОСТИ ВОЕННОГО +1

Environment-friendly building wall system

InactiveCN110241939AImprove sealing performanceReduce heat transferWallsHeat proofingC shapedAir layer

The invention relates to an environment-friendly building wall system, and belongs to the technical field of wall heat preservation. According to key points of the technical scheme, an environment-friendly constant-temperature building wall comprises a wall body; the wall body comprises a foundation wall, and two side walls directly facing each other; the foundation wall and the side walls are integrally poured to be formed and are in a C shape; a first isolation plate parallel to the foundation wall is arranged between the two side walls, and mounting grooves with openings which directly face each other are formed in the two side walls; the mounting grooves are vertically formed in the height direction of the side walls, and the mounting grooves are formed in a step shape; and first isolation sliding blocks which are in sliding fit with the mounting grooves are fixedly arranged on the two sides of the first isolation plate, the sides, deviating from the foundation wall, of the side walls are sequentially provided with a second isolation plate, a reinforced layer, a sound insulating layer and a heat insulating layer from inside to outside, and an air layer is arranged between the first isolation plate and the second isolation plate. The effect of improving the heat preservation capacity of the wall is achieved.

Owner:天津弘野建设集团有限公司

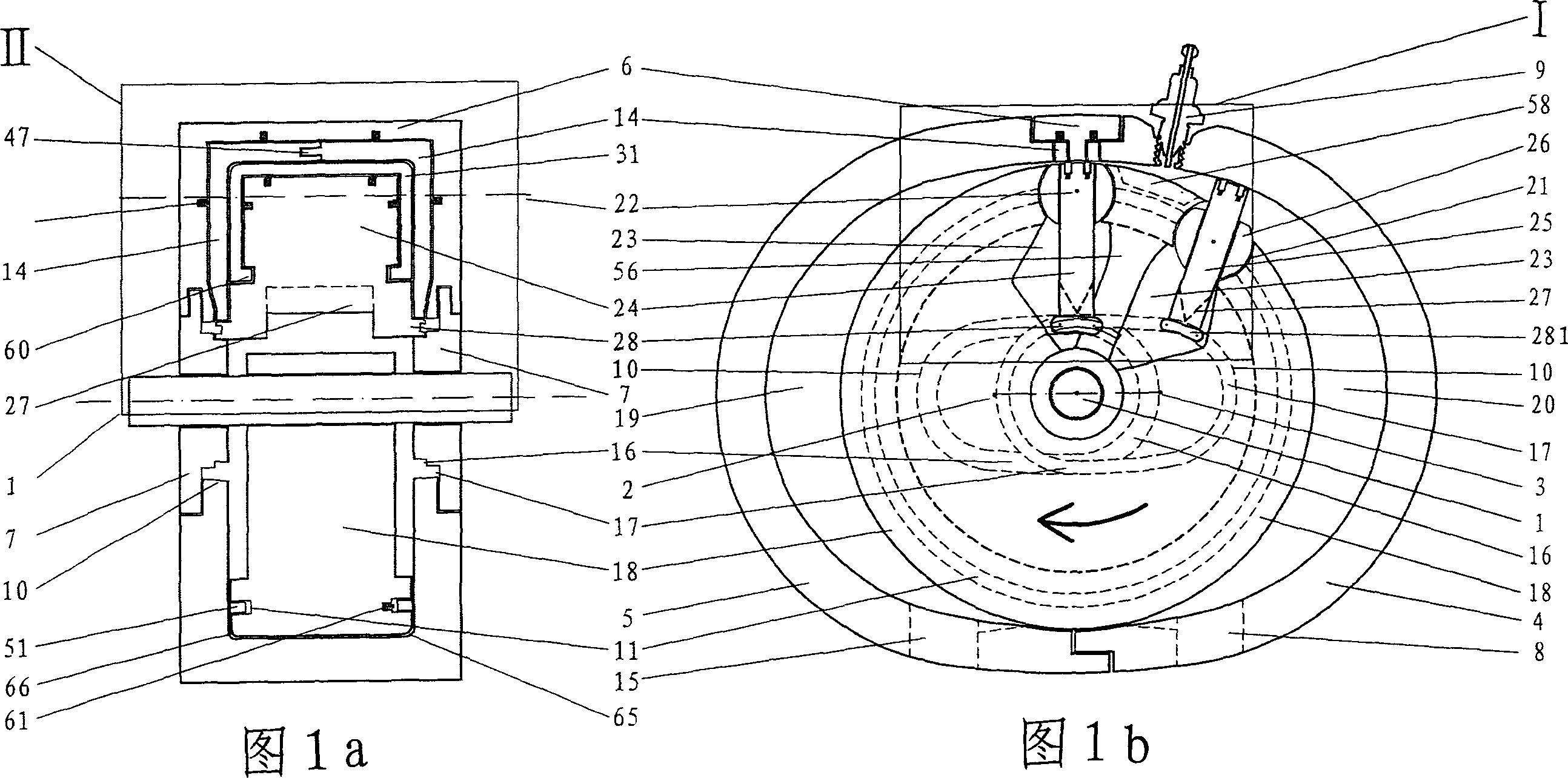

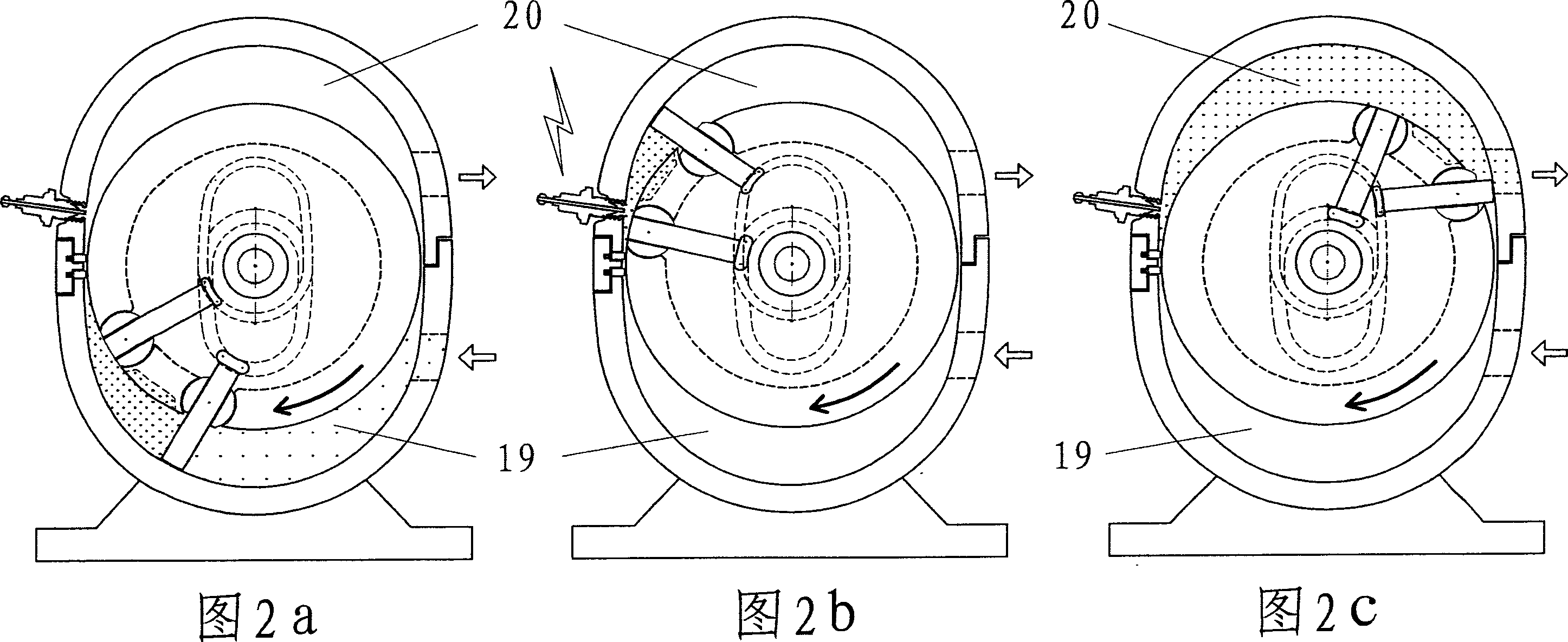

Changeable slide sheet circular centre type internal combustion engine

InactiveCN1900499AReduce inertial forces and wearImprove sealing performanceInternal combustion piston enginesRotary piston enginesEngineeringCylinder block

The disclosed engine includes cylinder body, end covers on two sides of the cylinder body, and rotor. The rotor divides inner cavity of cylinder into compression cavity and cavity of applying work. Compression sliding blade and exergonic sliding blade are setup in sliding blade slot of rotor alternately. Compression guiding slide way and exergonic slide way are setup on two sides of the cylinder body. Compression guiding slider of compression sliding blade are slid in sliding blade slot so as to drive the compression sliding blade to be protruded out of the compression cavity; and its revolving center of circle is changed in following change of circular arc center of circle in compression cavity. Thus, the compression sliding blade is retracted in cavity of applying work. Similarly, exergonic sliding blade is retracted in compression cavity, and is protruded out in cavity of applying work. The engine reduces inertia and abrasion, and cost, and raises tightness and work efficiency.

Owner:李东林

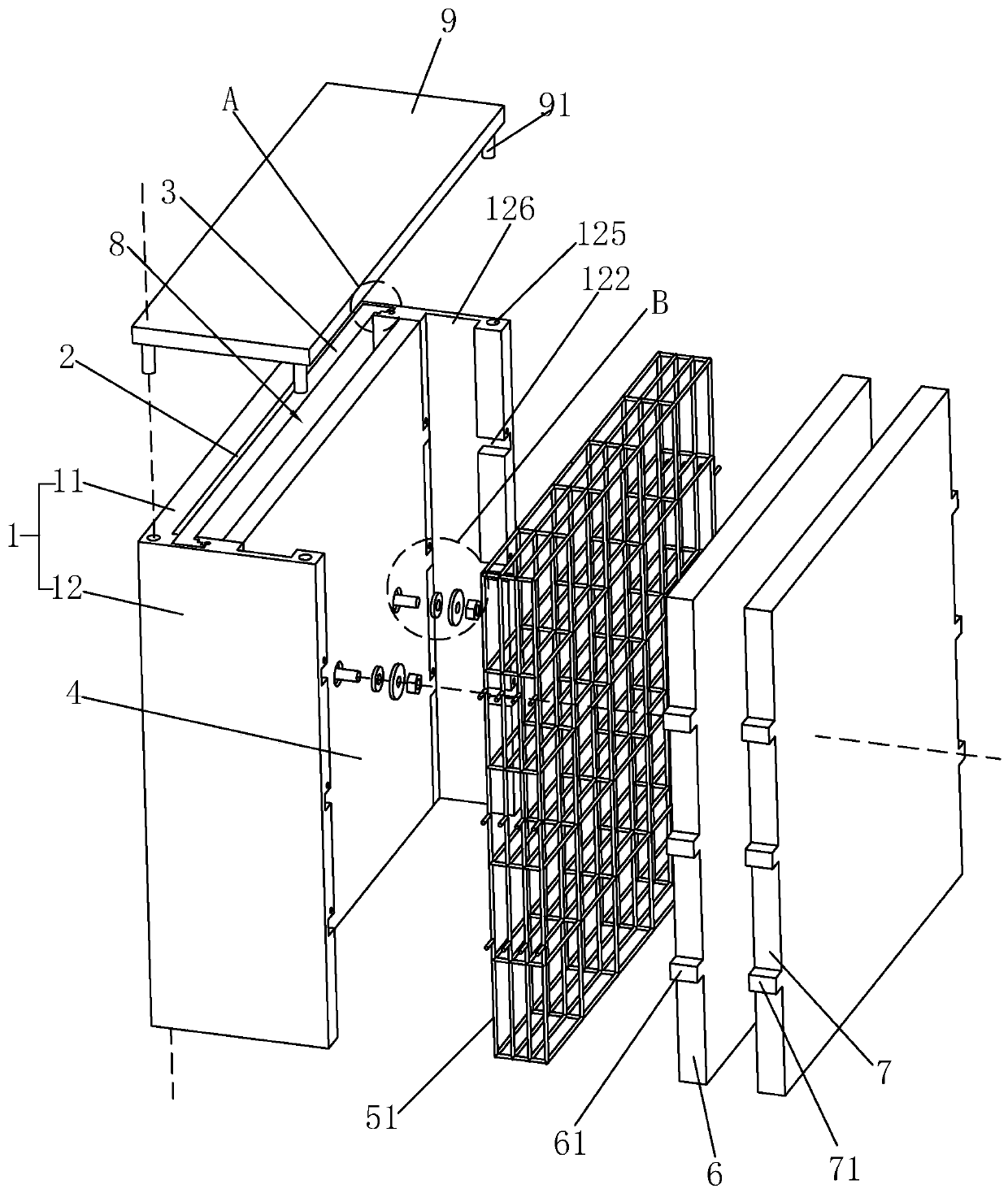

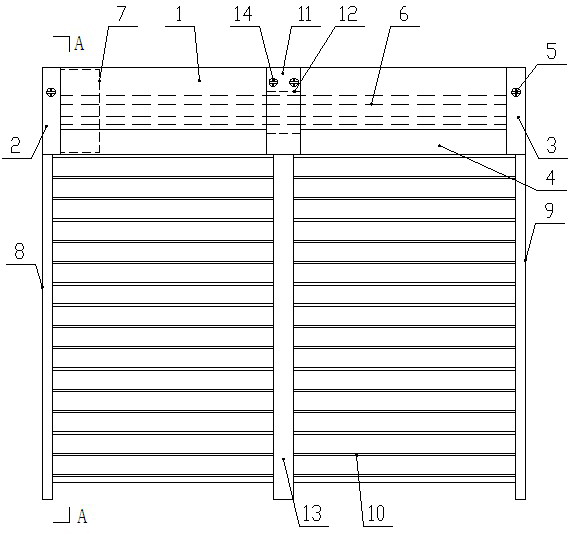

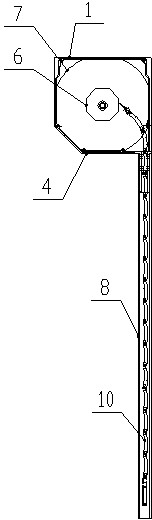

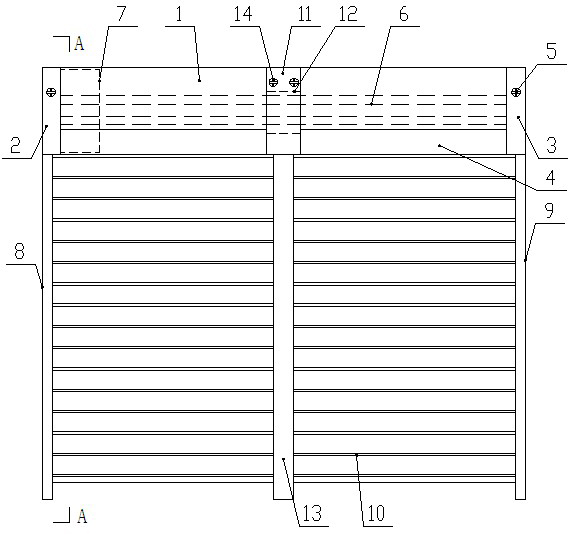

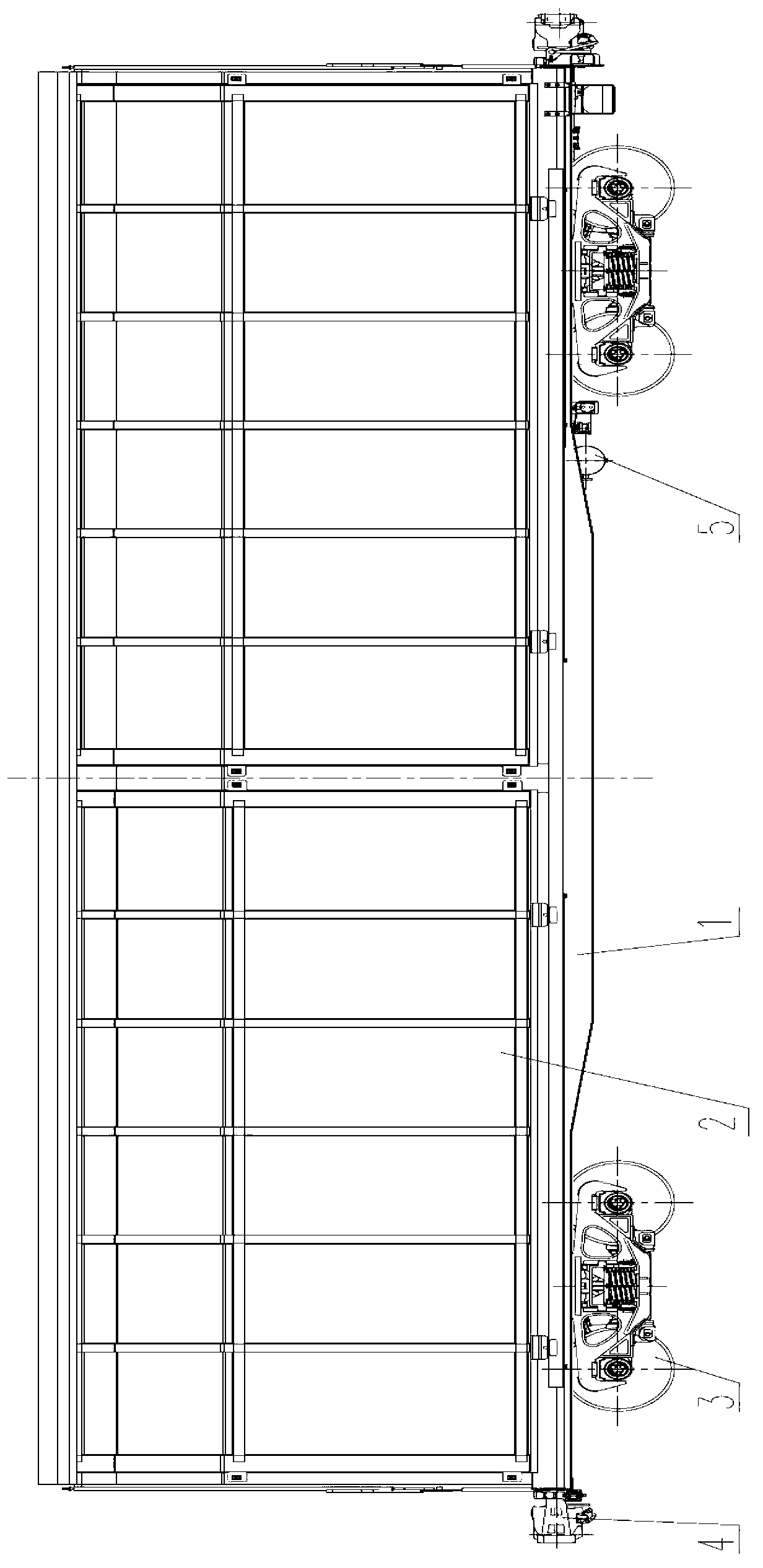

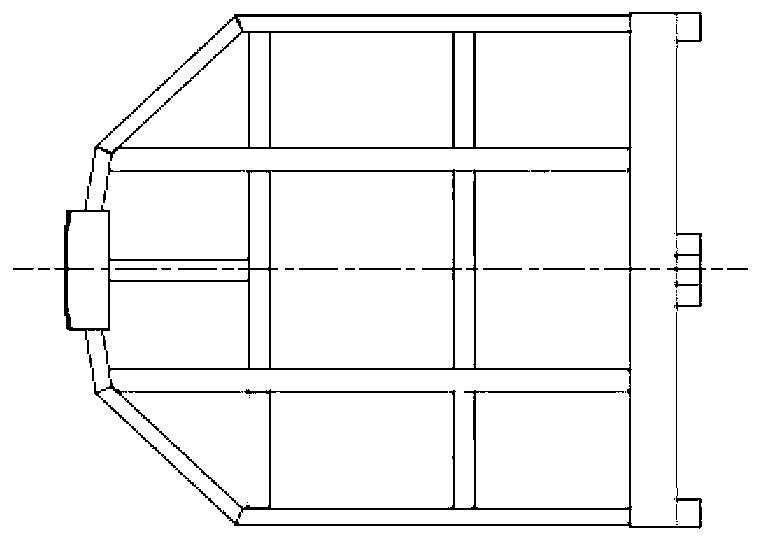

Single-motor window shutter for large window

InactiveCN102661117ALow failure rateGuaranteed mechanical propertiesShutters/ movable grillesFailure rateLoad resistance

A single-motor window shutter for a large window comprises a shutter box. An upper cover, a left end seat, a right end seat and a lower cover are connected by end screws to form the shutter box, a reel which is respectively rotationally connected with the left end seat and the right end seat is horizontally disposed on the shutter box, a tubular motor is arranged on the reel, a left guide track is vertically arranged at the lower end of the left end seat, a right guide track is vertically disposed at the lower end of the right end seat, two shutter hanging sheets are wound on the reel, a middle end seat is arranged in the middle of the shutter box, a through hole is disposed in the middle of the middle end seat, the reel penetrates through the through hole, and a middle guide track with double tracks is arranged at the lower end of the middle end seat. The single-motor window shutter for the large window has the advantages that production cost is sufficiently reduced while a mechanical performance is guaranteed and wind load resistance and an antitheft safety performance are improved, and failure rate of the electric window shutter is reduced; the problem that a gap is formed when a conventional window shutter is used and two shutter boxes of the conventional window shutter are spliced is avoided owing to the middle end seat, and sealing and heat-insulation performances are fine; and the shutter window is integrated, is more attractive and is installed more simply and easily.

Owner:HENAN WEISI ENERGY ENVIRONMENTAL PROTECTION TECH

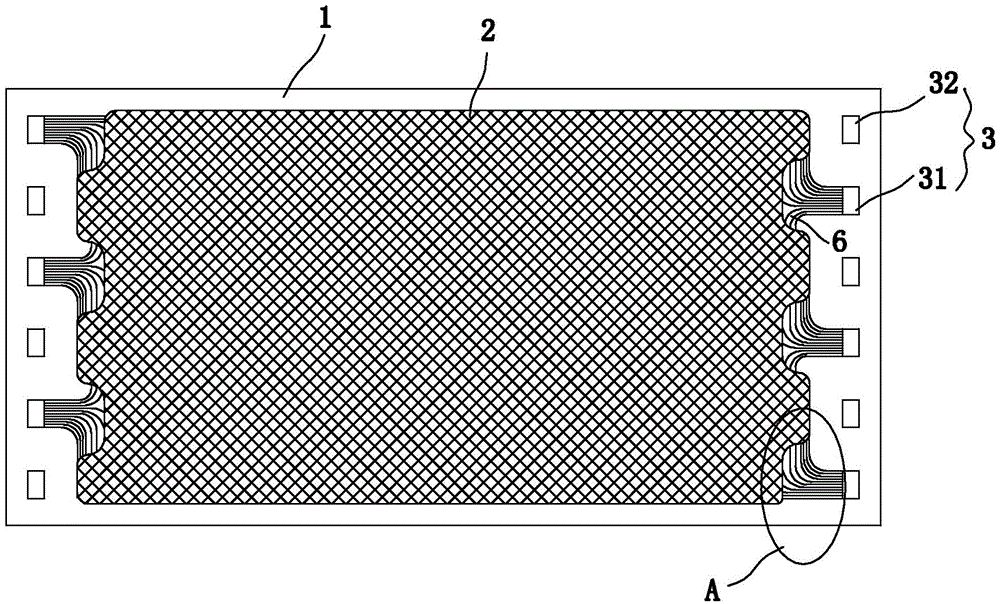

Electrodialysis partitioning plate

InactiveCN103816806ASparse distribution of water distribution channelsImprove sealing performanceDispersed particle separationElectrodialysisIon-exchange membranesElectricity

The invention discloses an electrodialysis partitioning plate which comprises a plate frame, wherein liquid guide holes and water distribution channels for communicating the liquid guide holes with a central cavity of the plate frame are formed in the plate frame; each water distribution channel is at least divided into two sections; multiple sections of the water distribution channels are arranged on two side surfaces of the plate frame in a cross manner; two adjacent sections of the water distribution channels are communicated through the through holes in the plate frame. As each water distribution channel is divided into multiple sections, and the sections are arranged on the two side surfaces in the cross manner, the sealing capability of an ion exchange film and the partitioning plate is improved under the condition that the same number of water distribution channels are formed.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

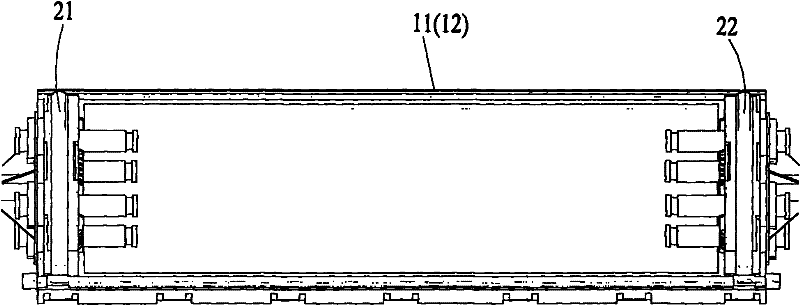

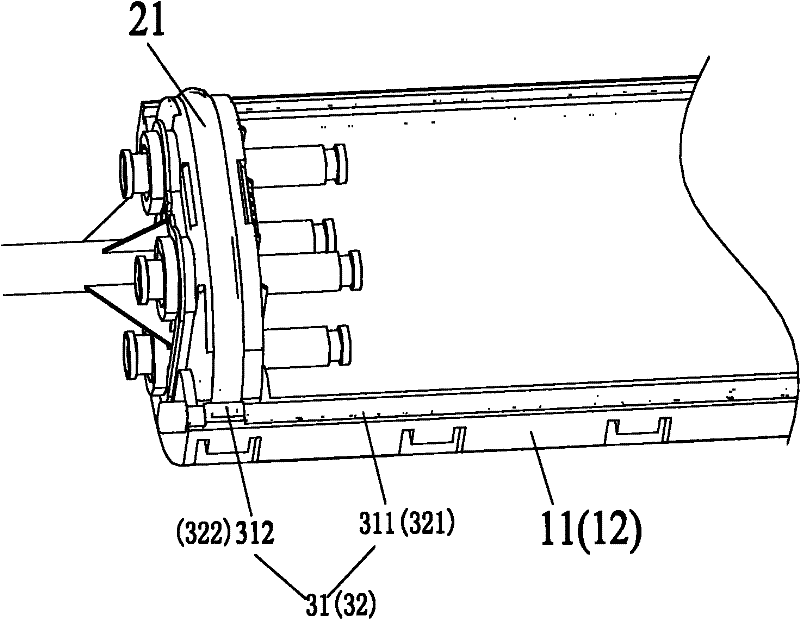

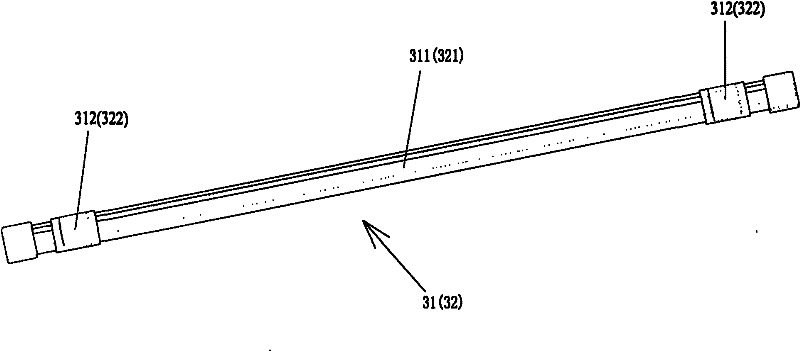

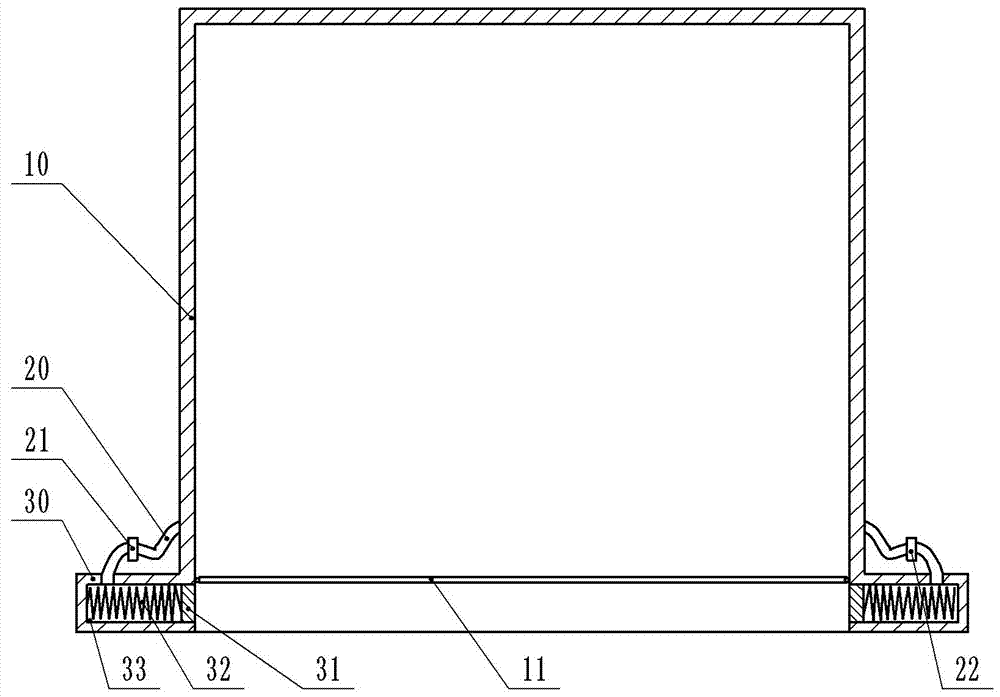

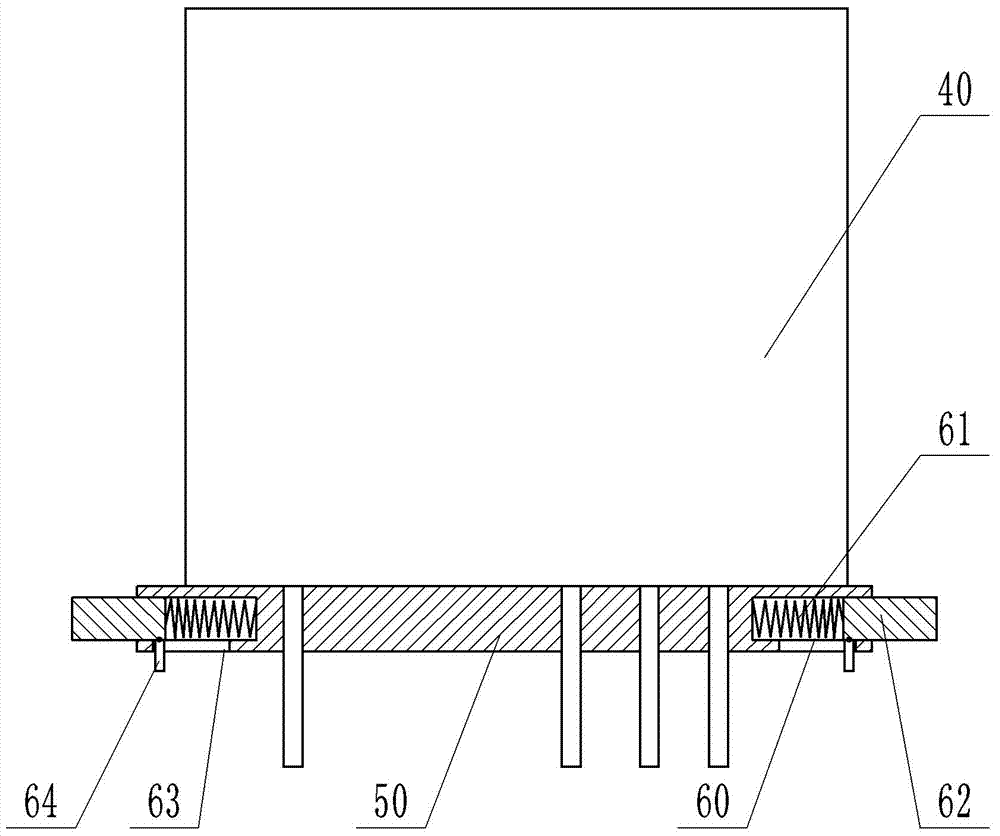

Sliding side wall covered wagon for railway transportation

InactiveCN103303325AImprove sealing performanceLarge openingAxle-box lubricationWagons/vansIn vehicleRail transportation

The invention discloses a sliding side wall covered wagon for railway transportation, which comprises a vehicle body steel structure and a sliding side wall, wherein the vehicle body steel structure comprises a center back and an underframe which are connected with each other. The sliding side wall covered wagon provided by the invention further comprises the sliding side wall, the center back and the underframe are welded with each other through end walls at the two ends of the vehicle and a side wall vertical column in the middle, the sliding side wall comprises two walls, an upper sliding rail assembly, a lower sliding assembly and a switching device, pulleys are arranged on the side walls, the upper sliding rail assembly is connected with the center back, the lower sliding rail assembly is connected with the under frame, the upper sliding rail assembly and the lower sliding rail assembly form two sliding rails arranged up and down as a support when the side walls are sliding, the switching device comprises an operating handle, a connecting rod and a locking device, wherein the operating handle is connected with the end wall at the end part of the vehicle body, and is connected with the locking device through the connecting rod, the locking device is connected with the underframe and the center back; and the sliding side wall covered wagon is good in sealing effect, high in mechanized handling efficiency and fast in vehicle running period, and the large size goods hoisting is satisfied through end part operation.

Owner:CRRC SHANDONG CO LTD

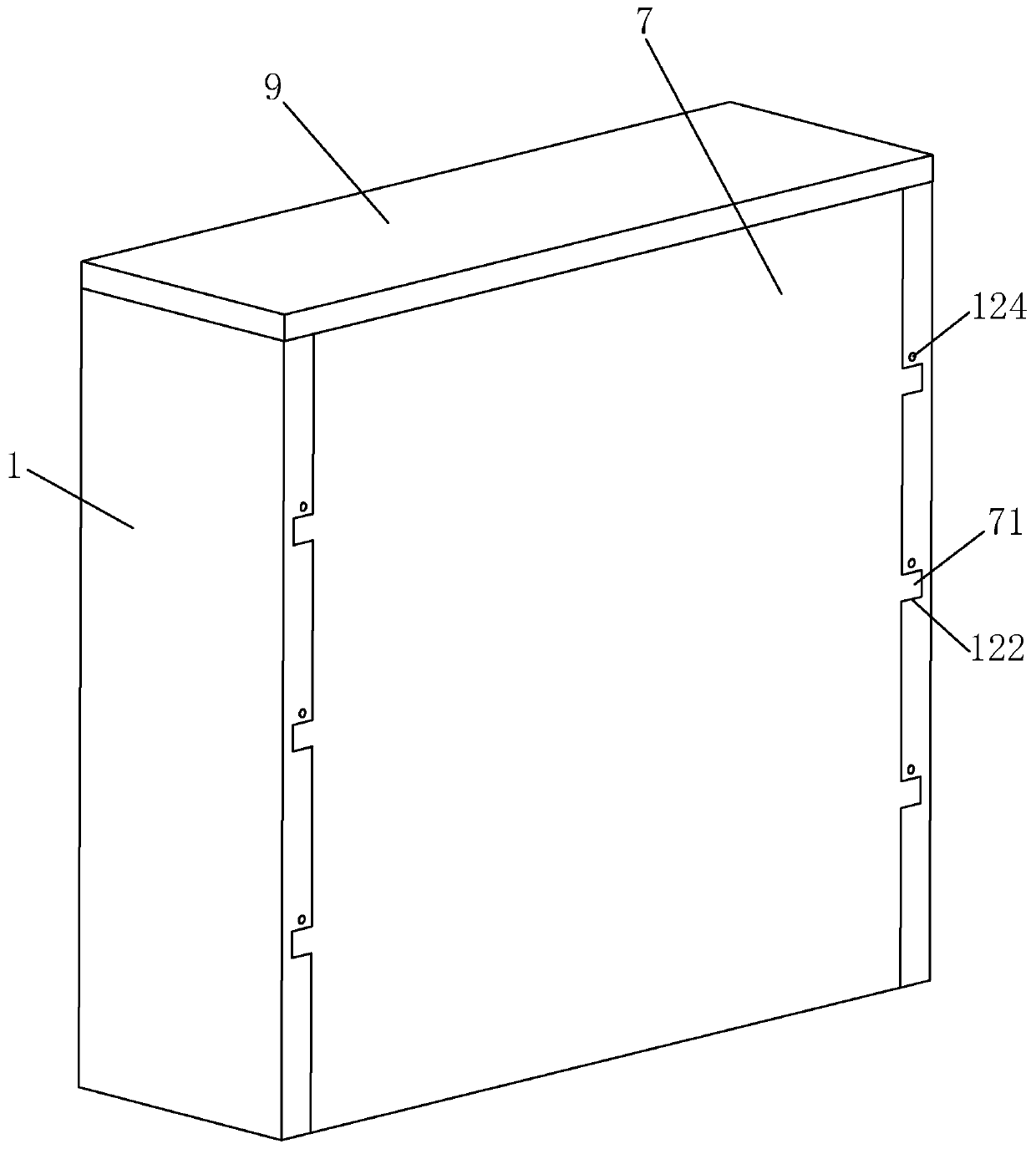

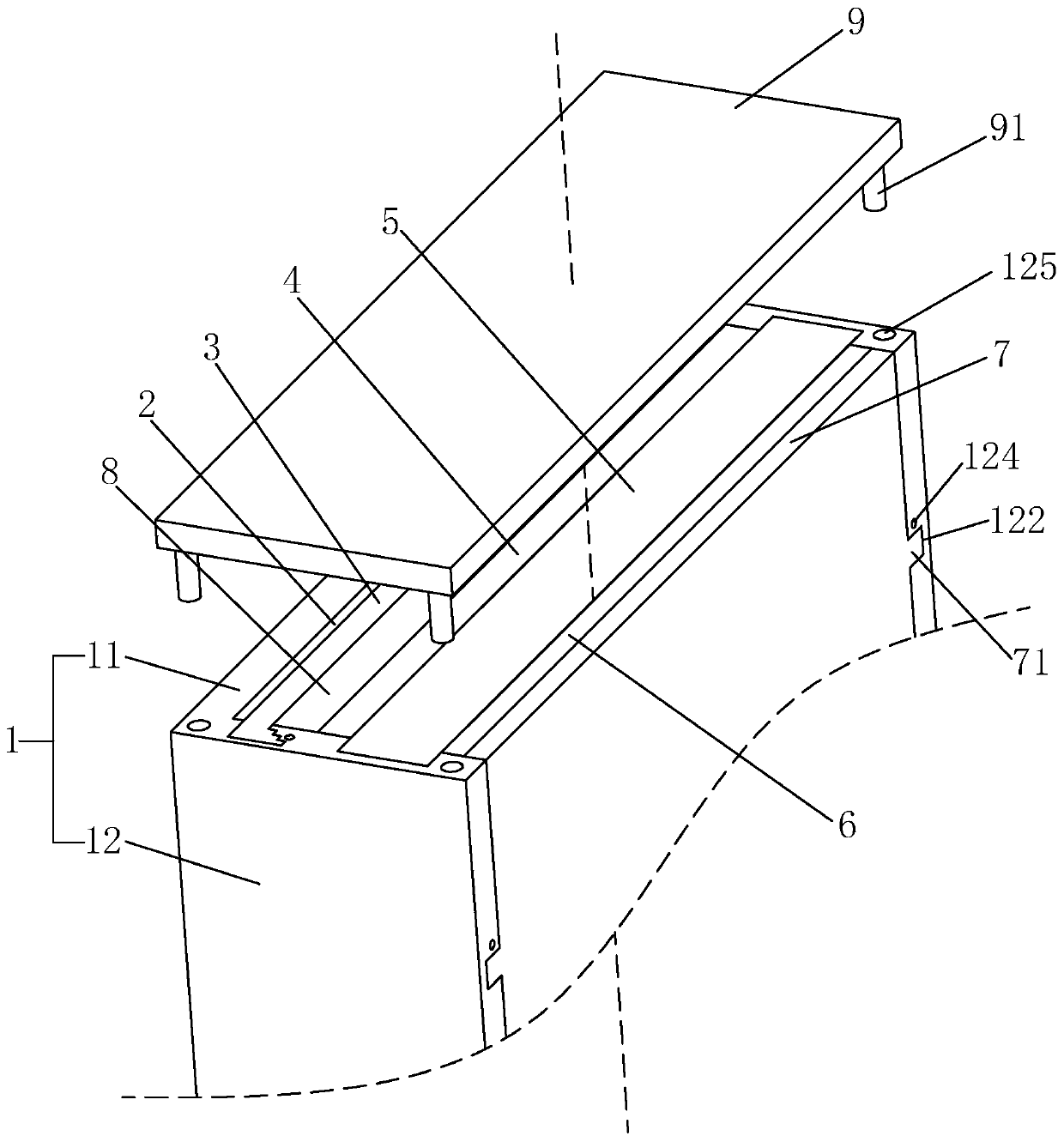

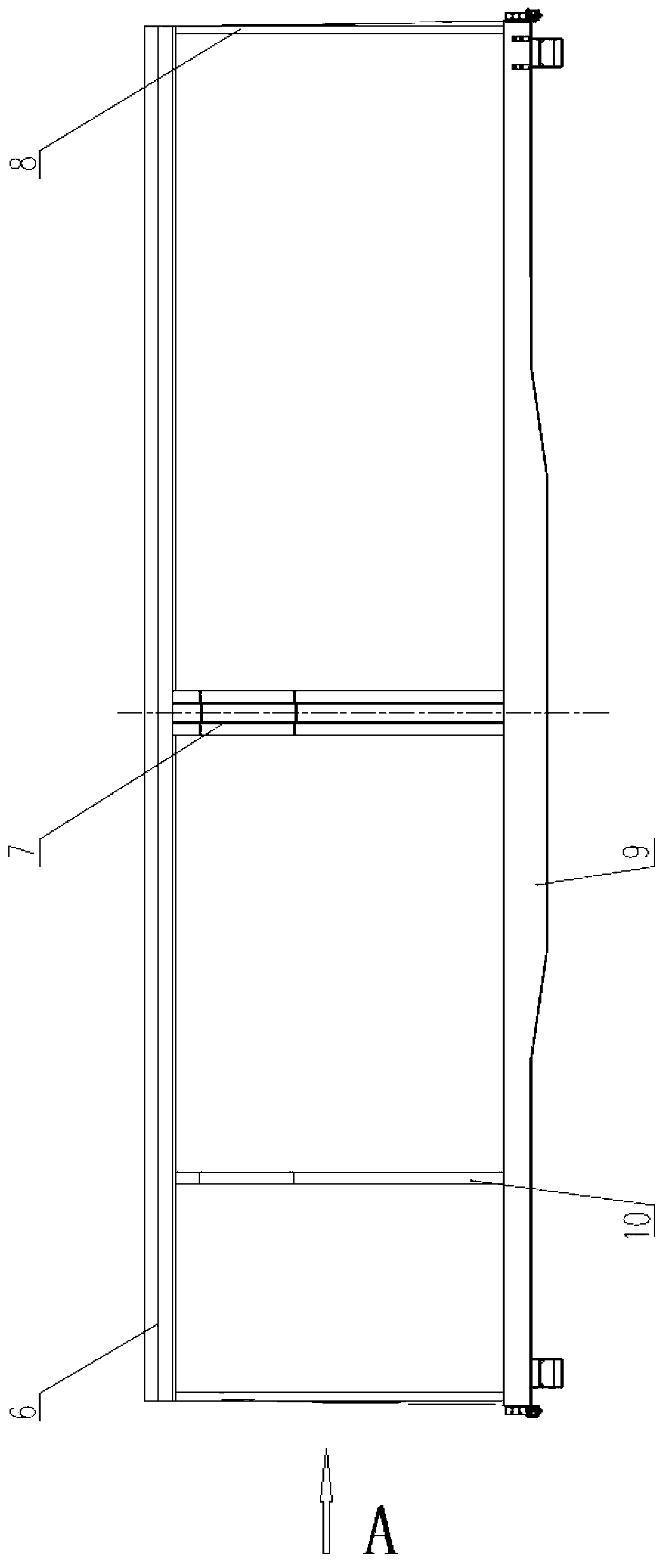

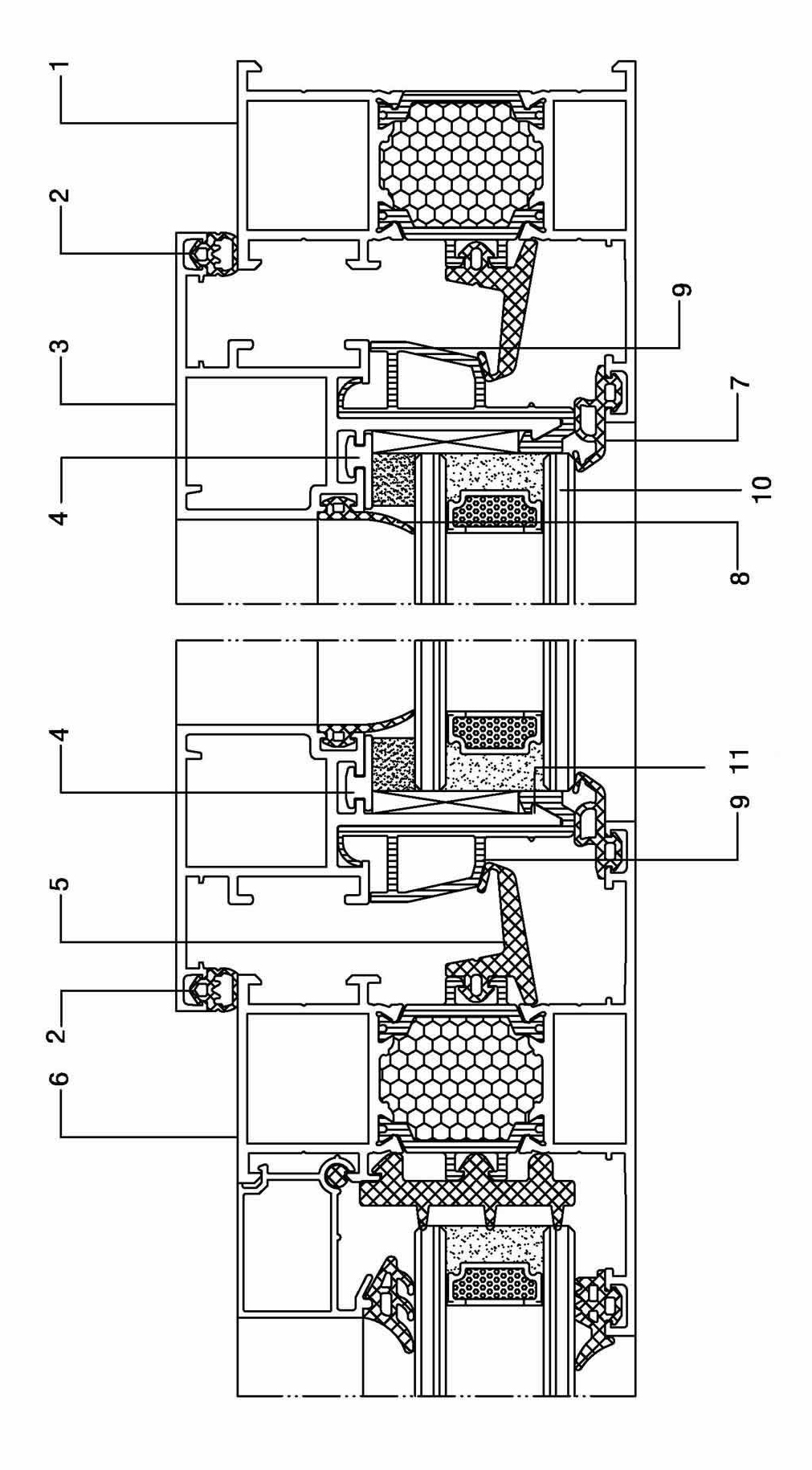

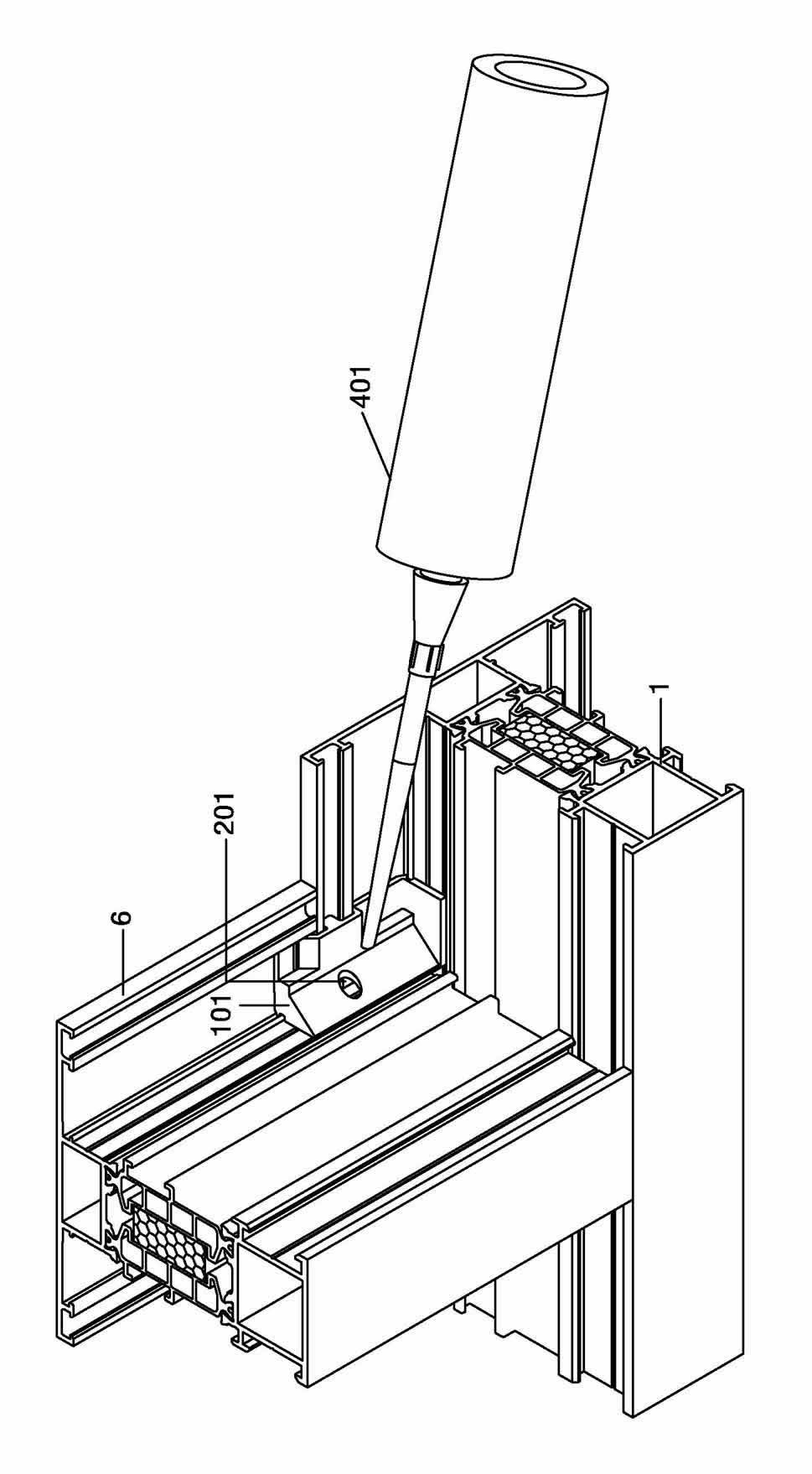

Energy-saving environment-friendly door/window system

ActiveCN102409925ASatisfy the requirement of dissipated energy indexImprove sealing performanceSills/thresholdSealing arrangementsSash windowArchitectural engineering

The invention belongs to the field of building door / window curtain walls, and particularly relates to an energy-saving environment-friendly door / window system. The system comprises a border (1), a mullion (6) and a leaf-hidden window sash (3) arranged therein, wherein an outdoor sealing rubber strip (7) is fixed between the border (1) and the leaf-hidden window sash (3) on the border (1); an indoor sealing rubber strip (2) is fixed between the leaf-hidden window sash (3) and the the border (1) on the leaf-hidden window sash (3); a T-shaped connection glue injection sheet is fixed at the joint between the mullion (6) and the border (1); the T-shaped connection glue injection sheet is clamped and fixed with a notch of the mullion (6); and a glue injection port is formed on the T-shaped connection glue injection sheet. The energy-saving environment-friendly door / window system provided by the invention has good sealing and heat insulation performance, a firm structure and high generality, and can effectively meet the requirements on the lost energy index of the building door / window.

Owner:LIAONING JOYDON ALUMINUM BUILDING SYST

Expansion flat gate valve

The invention relates to an expansion flat gate valve which comprises a valve body, valve seats, a valve rod and gates, wherein the gates comprise a main gate and a slave gate; the upper end of the main gate is fixedly connected with the valve rod; a V-shaped matching inclined plane is arranged between the contact surfaces of the main gate and the slave gate; a lever lock mechanism is arranged on the side planes of the main gate and the slave gate; and guide plates are symmetrically installed on the outer walls of the two valve seats on the left and right of the valve body. When the valve is in a fully closed or fully open state, the gates and the valve seats are in the hermetic matching state, and a middle cavity of the valve body is isolated from the medium pressure of a passage, thereby improving the sealing property of the valve cap and the valve rod communicated with the middle cavity of the valve body and preventing leakage. In the process of opening and closing the valve, the gates and the valve seats are in a disengaged state all the time, thereby reducing the friction of a sealing pair, and having the advantages of small wear, good sealing property and the like. The expansion flat gate valve is especially suitable for a flat gate valve of a large-diameter pipeline.

Owner:BOTELI VALVE GROUP

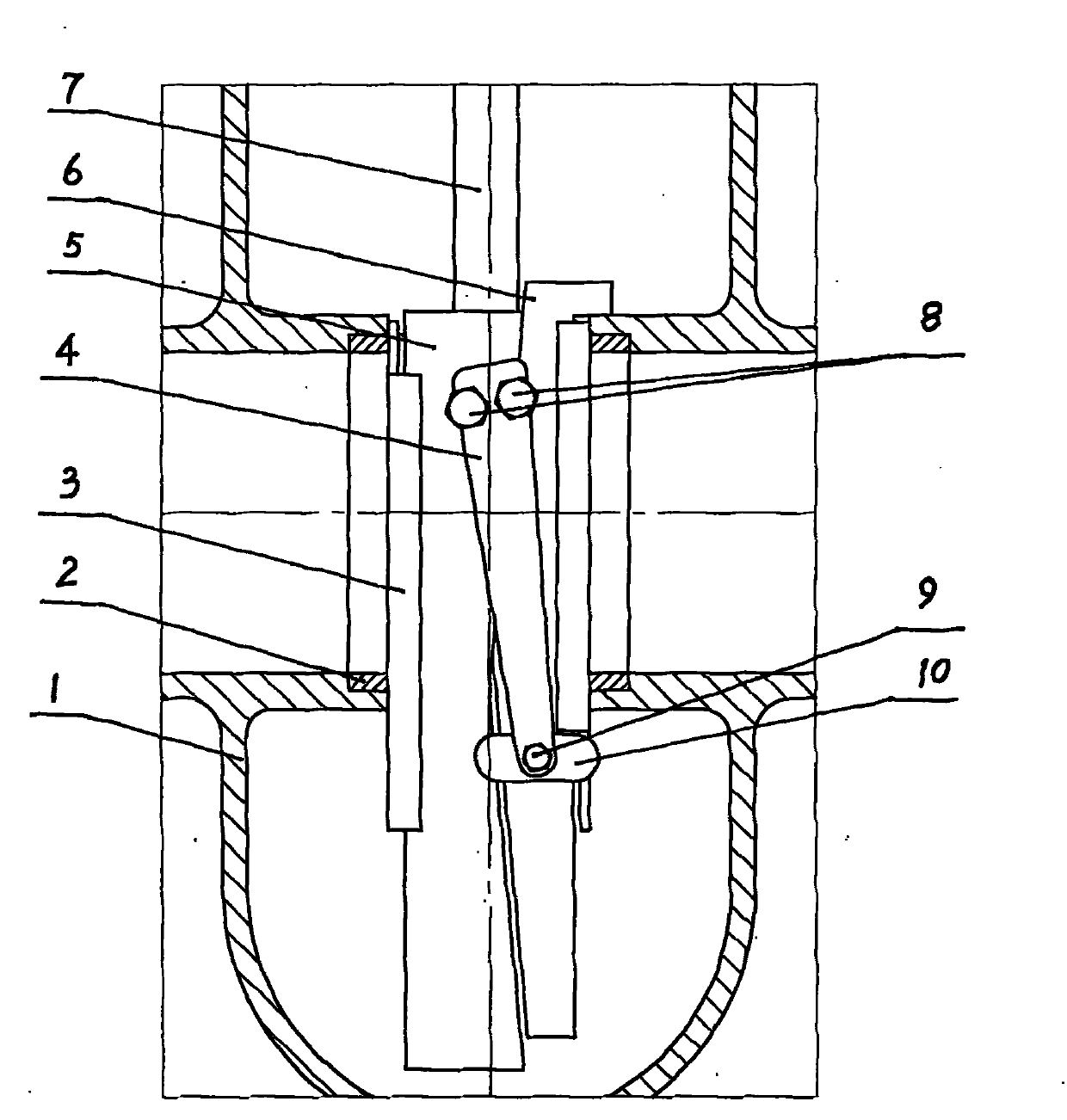

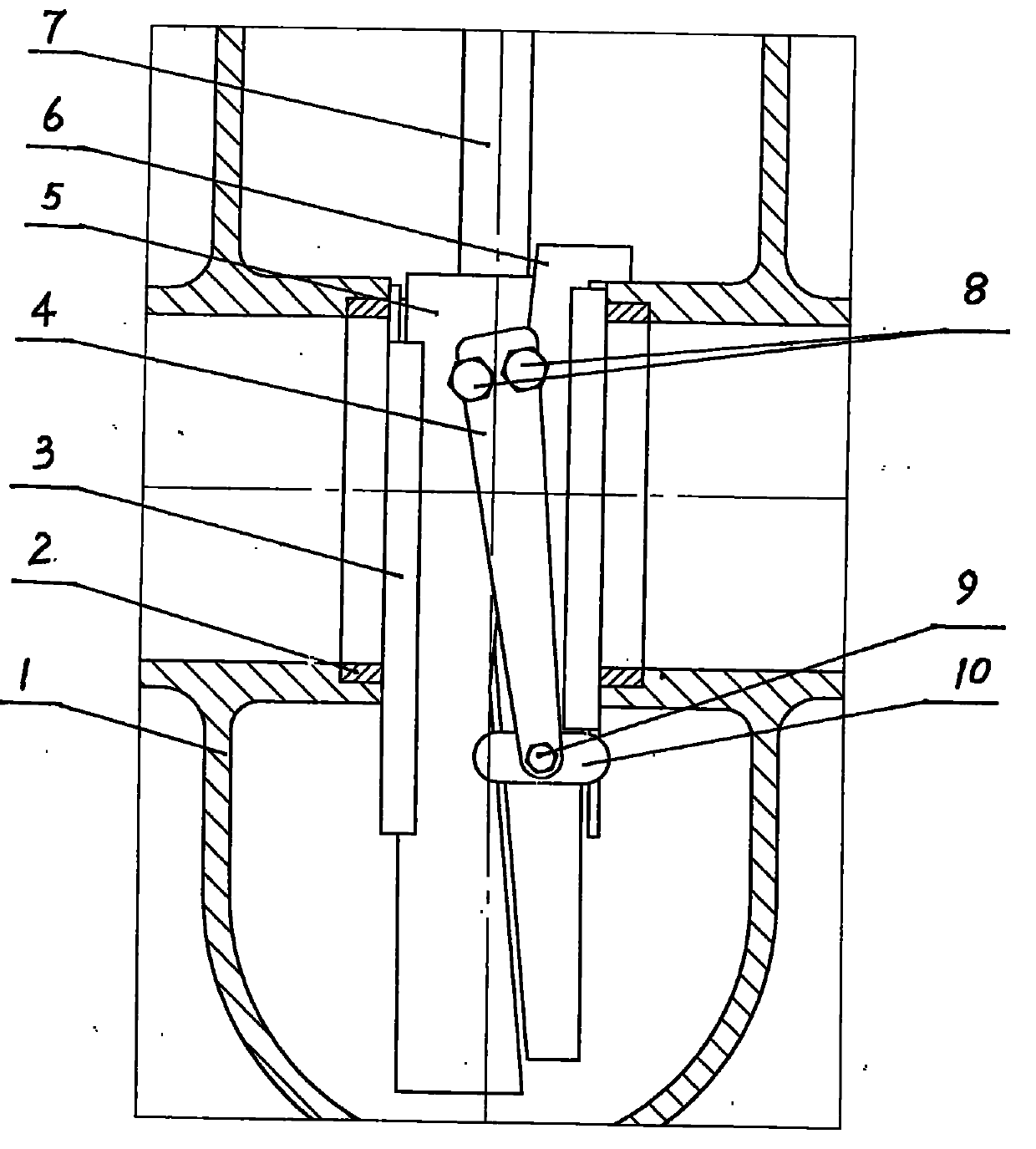

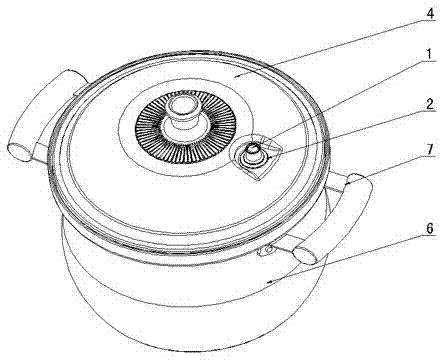

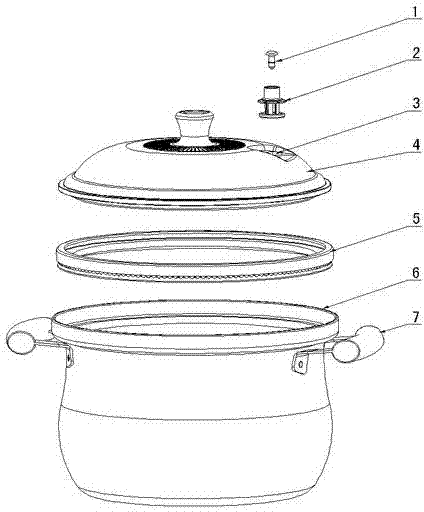

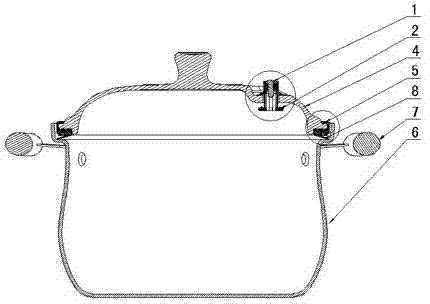

Micropressure pot

InactiveCN102397001AImprove sealing performanceReduce cooking time for stews or soupsCooking vesselsEngineeringMechanical engineering

Owner:ZHEJIANG COOKER KING COOKER

Sealing cover sealing device of storage tank

ActiveCN108202934AImprove sealing performanceIncrease occlusionLarge containersEngineeringMechanical engineering

The invention provides a sealing cover sealing device of a storage tank. The device comprises a first sealing component arranged between a tank wall of the storage tank and a sealing cover, and the first sealing assembly comprises a sealing bag connected with the sealing cover and a flexible sealing ring contained in the sealing bag; an extrusion function exists between the flexible sealing ring and the tank wall and between the flexible sealing ring and the sealing cover. According to a preferred embodiment, the sealing device further comprises a second sealing component, the second sealing component comprises an annular rigid body and a filling bag, wherein the lower edge of the annular rigid body is connected with the sealing cover, the upper edge of the annular rigid body is attached to the tank wall of the storage tank, and the filling bag which is connected to the inner side face of the rigid body and contains the flame-retardant particles. The invention particularly provides a floating disc sealing device of the floating roof storage tank. The sealing device has the advantages that the sealing performance is improved, and the automatic fire extinguishing function can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hot-blast stove door device

InactiveCN104729090AImprove fire resistanceImprove sealing performanceFluid heatersChamber doorsHot blastEngineering

The invention discloses a hot-blast stove door device comprising a door frame installed on a stove. The door frame comprises a door cover, one end of the door cover is hinged to the door frame through a sliding shaft and an opened shaft, the other end of the door cover is provided with a handle, the handle is rotatably connected to the door cover through a bolt and a nut and is connected to a clamping plate of the door frame in a buckled manner. The device is characterized in that the back of the door cover is provided with fire-resistant plastic, and an asbestos sealing pad is arranged between the door cover and the door frame. Since the fire-resistant plastic and the asbestos sealing pad are adopted, the tightness of the door cover and door frame is improved, the service life of the stove door is prolonged greatly, and the device is mainly adaptive to the hot-blast stove door.

Owner:陈煌

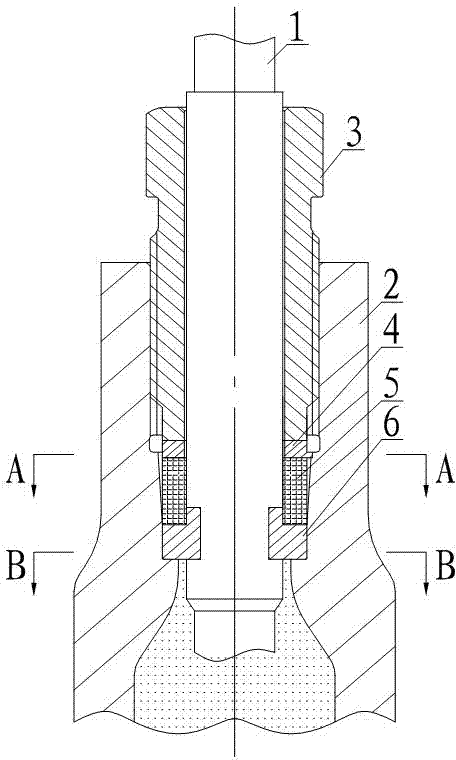

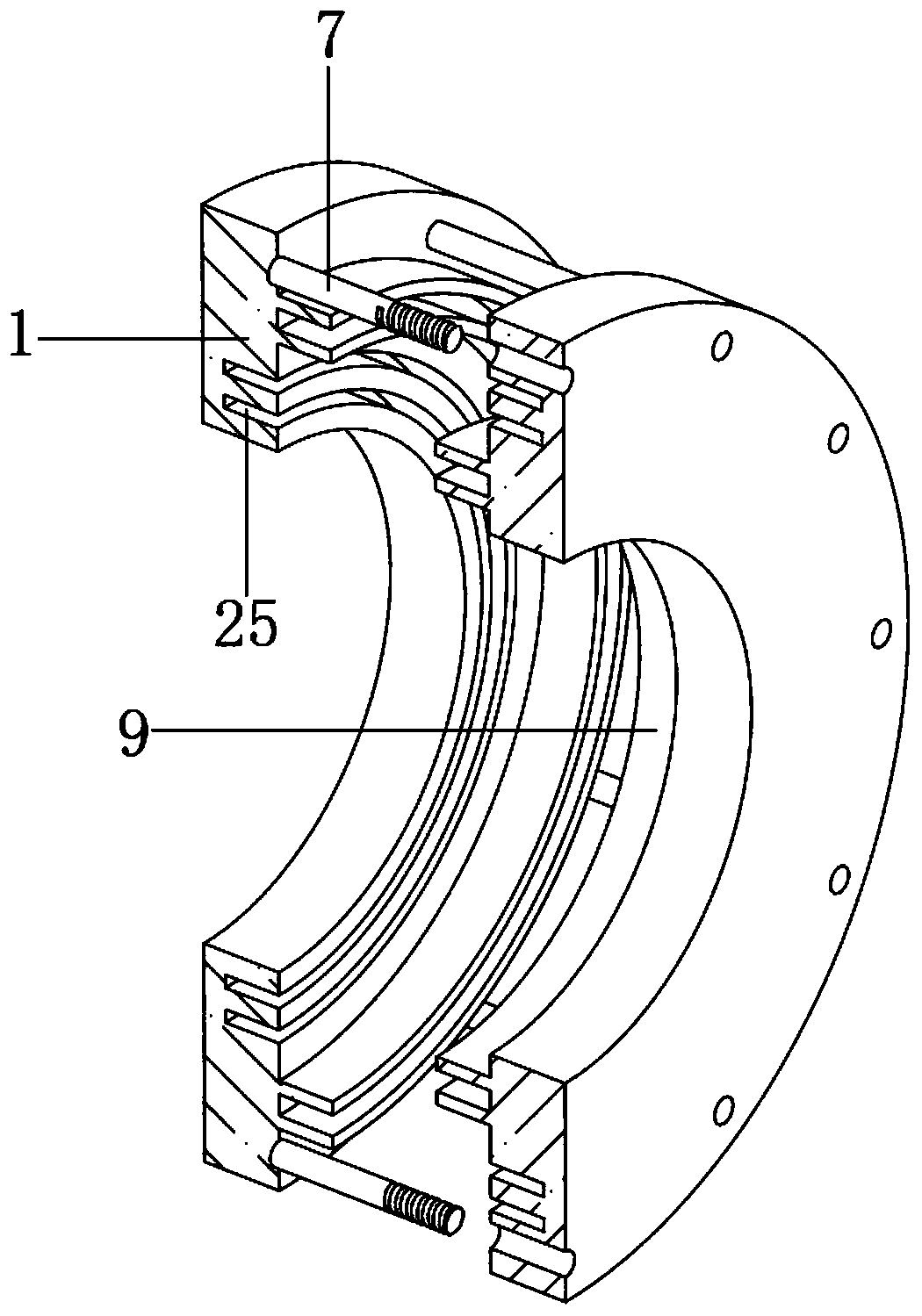

Double-floating integrated mechanical seal with large shaft diameter

InactiveCN102927286AImprove sealing performanceReduce stress deformationEngine sealsMechanical engineeringWaterline

The invention discloses a double-floating integrated mechanical seal with large shaft diameter, and relates to the technical field of mechanical seals. The double-floating integrated mechanical seal comprises a dynamic ring assembly and a static ring assembly, wherein the dynamic ring assembly comprises a dynamic ring which is connected with a rotary shaft by a shaft sleeve; a shaft sleeve O-shaped sealing ring is arranged between the shaft sleeve and the rotary shaft; a movable O-shaped sealing ring is arranged between the movable ring and the shaft sleeve; the static ring assembly comprises a static ring base and a static ring arranged on the static ring base; the end surface of the static ring is adhered with the end surface of the dynamic ring; a spring base is arranged on one side of the static ring base; a spring is arranged between the spring base and the static ring base; the double-floating integrated mechanical seal is characterized in that a floating O-shaped sealing ring is arranged at the bottom of the dynamic ring; a sealing cushion is arranged between the static ring and the static ring base; and waterlines are turned at the bottom of the static ring and the upper part of the static ring base, namely two planes contacting with the sealing cushion. According to the double-floating integrated mechanical seal disclosed by the invention, the floating O-shaped sealing ring is additionally arranged at the bottom of the dynamic ring, so that the sealing performance of the dynamic ring auxiliary seal is increased, and stress deformation generated by contacting can be reduced at the same time.

Owner:安徽亚兰密封件股份有限公司

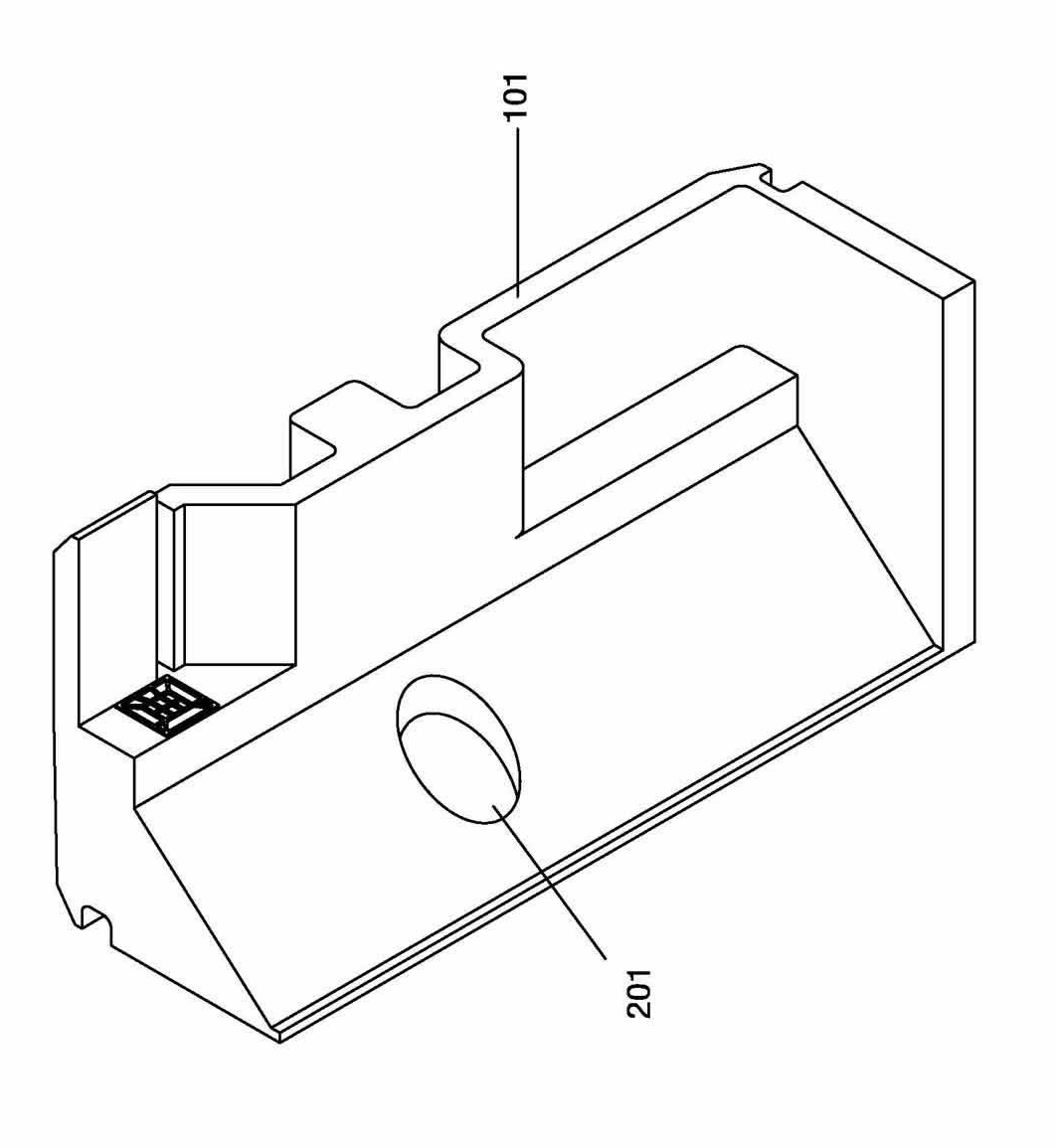

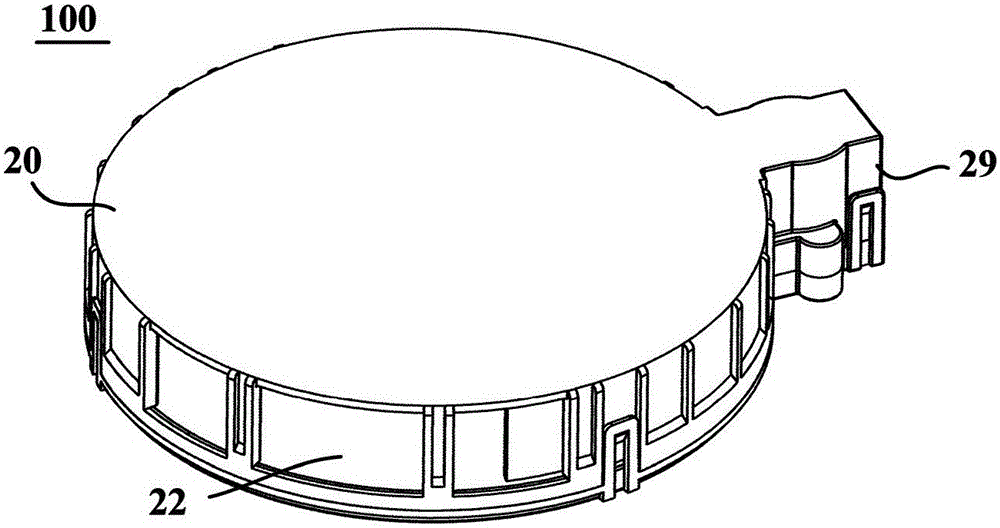

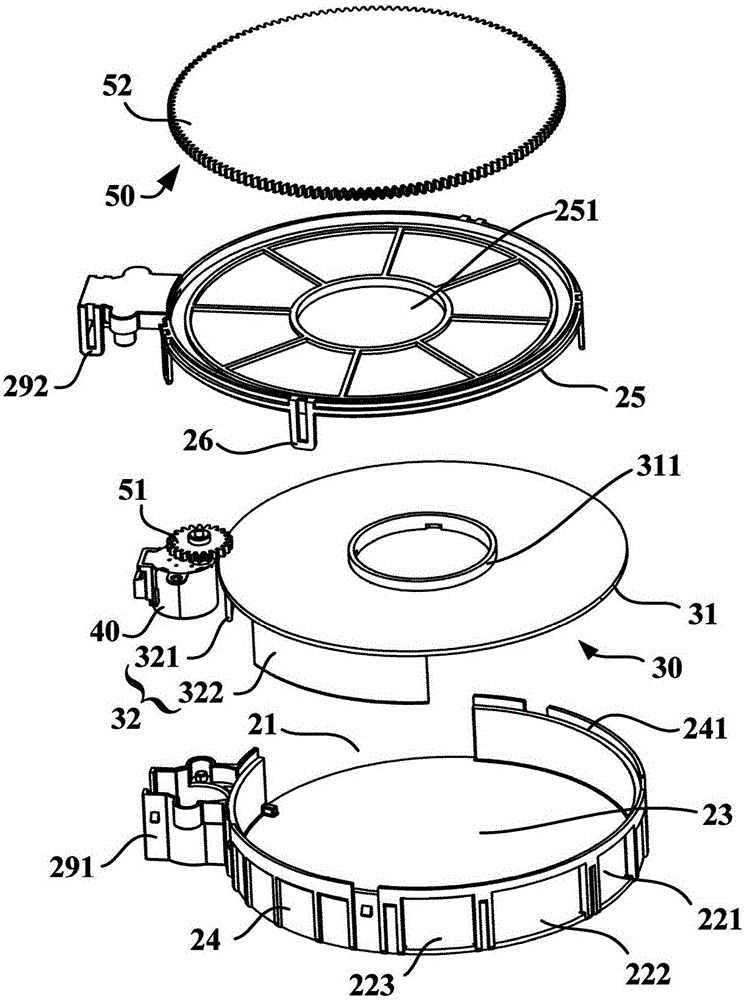

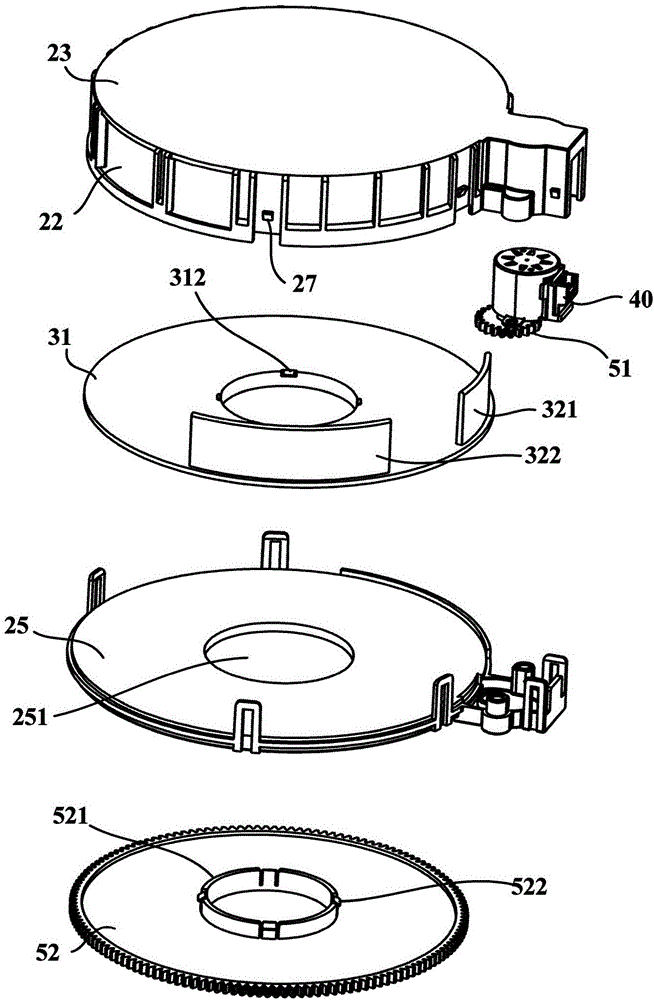

Branching air supply device and refrigerator comprising same

ActiveCN106196832AEnhance freshness retention and operational efficiencyImprove sealing performanceLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention relates to a branching air supply device and a refrigerator comprising the same. The provided branching air supply device used for the refrigerator comprises a shell body, an adjusting piece, a driven wheel disc and a driving mechanism, wherein the shell body is provided with at least one air inlet and a plurality of air outlets; the adjusting piece is provided with a rotary disc part and is rotationally arranged in the shell body so that each air outlet can be completely or partially covered or completely exposed, and accordingly the air outlet area of each air outlet is adjusted; the driven wheel disc and the rotary disc part are coaxially fixed to the rotary disc part, and the driven wheel disc is located outside the shell body; and the driving mechanism is arranged to drive the driven wheel disc to rotate. In addition, the invention further provides the refrigerator comprising the branching air supply device. According to the branching air supply device and the refrigerator comprising the same, the driven wheel disc is installed outside the shell body, matching holes which are large and used for enabling the driving mechanism to be matched with the adjusting piece can be decreased, accordingly, the sealing performance of the shell body can be improved, and cold air entering the shell body is prevented from flowing out from the matching holes.

Owner:HAIER SMART HOME CO LTD

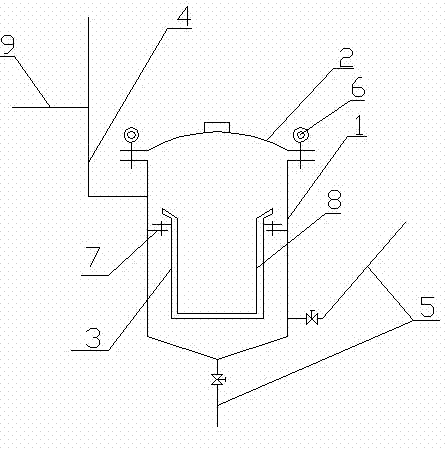

Multipurpose stainless steel filter

InactiveCN102728122AImprove sealing performanceReduce manufacturing costPolyureas/polyurethane adhesivesStationary filtering element filtersMetallurgyMechanical filter

The invention discloses a multipurpose stainless steel filter. The multipurpose stainless steel filter comprises a stainless steel barrel body, a barrel cover, a stainless steel mechanical filter, a feed pipe and discharging pipes, wherein the barrel body and the barrel cover are connected through a lug bolt; a mechanical filter seat is fixedly installed on an inside wall of the stainless steel barrel body and is used for installation of the stainless steel mechanical filter; a screen mesh is installed at an inner side of the stainless steel mechanical filter; the feed pipe is connected at an upper part of a side wall of the stainless steel barrel body; and both a bottom part of the stainless steel barrel body and a lower part of the side wall of the stainless steel barrel body are provided with a discharging pipe. The invention assists in solving problems existing in the prior art. By using the multipurpose stainless steel filter provided by the invention, production cost is reduced; structure is simplified; operation is reliable; no leakage occurs; and social energy saving and environmental protection requirements are satisfied.

Owner:南通恒隆化工有限公司

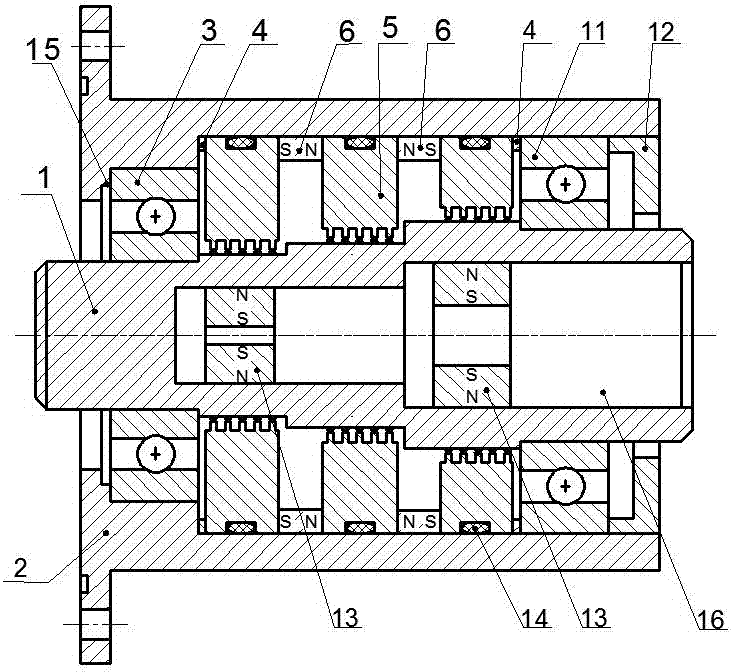

Magnetofluid sealing structure

ActiveCN107956880AIncrease the magnetic field strengthImprove sealing performanceEngine sealsEngineeringMagnetic circuit

The invention discloses a magnetofluid sealing structure. The magnetofluid sealing structure comprises a hollow shell and a rotating shaft; the rotating shaft and the shell are connected through a bearing in an assembled mode, multistage of steps are arranged on the outer surface of the rotating shaft, and at least one second permanent magnet is arranged in the radial direction between the outer surface of the rotating shaft and the inner wall of the shell; pole shoes are arranged on the two sides of each second permanent magnet, and each pole shoe is arranged to directly face one of the steps; gaps exist between the pole shoes and the outer surface of the rotating shaft, and magnetofluid is injected to the gaps; the rotating shaft is provided with a cavity, first permanent magnets are mounted in the cavity, and each first permanent magnet is correspondingly arranged in a magnetic circuit formed by the corresponding second permanent magnet and the pole shoes on the two sides of the corresponding second permanent magnet; and the field directions of the first permanent magnets are the same as that of the magnetic circuits where the first permanent magnets are located. According to the magnetofluid sealing structure, by additionally provided with the first permanent magnets, sealing performance of the magnetofluid is improved, the anti-pressure capability of magnetofluid sealing is increased, and the rotating shaft is designed by adopting a stepped shaft form, so that loss of the magnetofluid during sealing failure is reduced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Cable connector box

InactiveCN102221735AImprove sealing performanceCombined with reliableFibre mechanical structuresEngineeringMechanical engineering

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Relay convenient for disassembling

ActiveCN107230583AEasy to disassembleImprove sealing performanceElectromagnetic relay detailsEngineeringRelay

The invention belongs to the technical field of electronic control device, and specifically discloses a relay convenient for disassembling. The relay comprises a shell, a bottom plate, and a relay main body structure fixed on the surface of the bottom plate; the shell is buckled on the top of the bottom plate, wherein sliding chutes are opened on the left and right sides of the side wall of the bottom plate; a clamping strip is glidingly connected in the sliding chute; a first spring is connected between the clamping strip and the sliding chute; a pull rod is connected on the lower supper of the clamping strip; a through groove for moving the pull rod is opened on the bottom plate; bumps are arranged on the left and right sides of the lower part of the shell; a cavity clamped with the clamping strip is opened on the bump; a sliding block is glidingly connected in the cavity; a second spring is connected between the sliding block and the cavity; the contact part of the shell and the bottom plate is provided with an air bag; and an air pipe is connected between the air bag and the cavity. By adoption of the replay provided by the invention, the shell and the bottom plate can be rapidly disassembled; and thus, the relay is convenient to be maintained.

Owner:山东翰辰石油科技有限公司

Butt joint device used for industrial gas pipeline installation

ActiveCN111550622AImprove sealing performanceHigh strengthSleeve/socket jointsPipe supportsGas pipelineLocknut

The invention belongs to the technical field of gas pipeline installation and particularly relates to a butt joint device used for industrial gas pipeline installation. Specific to the problems that atraditional gas pipeline butt joint manner is relatively simple and common in connecting strength, the following scheme is now put forwards. According to the scheme, the butt joint device comprises agas pipeline body, a supporting bracket box, a first butt joint ring and a second butt joint ring, wherein the first butt joint ring and the second butt joint ring are welded to the opposite sides ofthe gas pipeline body. Protruding rings which are staggered are welded to the opposite sides of the first butt joint ring and the second butt joint ring correspondingly, and ring grooves matched withthe protruding rings are formed in the opposite sides of the first butt joint ring and the second butt joint ring correspondingly. Threaded alignment rods which are distributed in a ring shape at equal intervals are welded to the outer wall of one side of the first butt joint ring, and the end portions of the threaded alignment rods are connected with lock nuts through threads. By means of the butt joint device used for industrial gas pipeline installation, an arranged locking clamping rod can be matched with bar-shaped grooves with Y-shaped cross sections to conduct effective connection treatment on the two butt joint plates, and therefore the butt joint strength of the gas pipeline body can be effectively improved.

Owner:潮州深能燃气有限公司

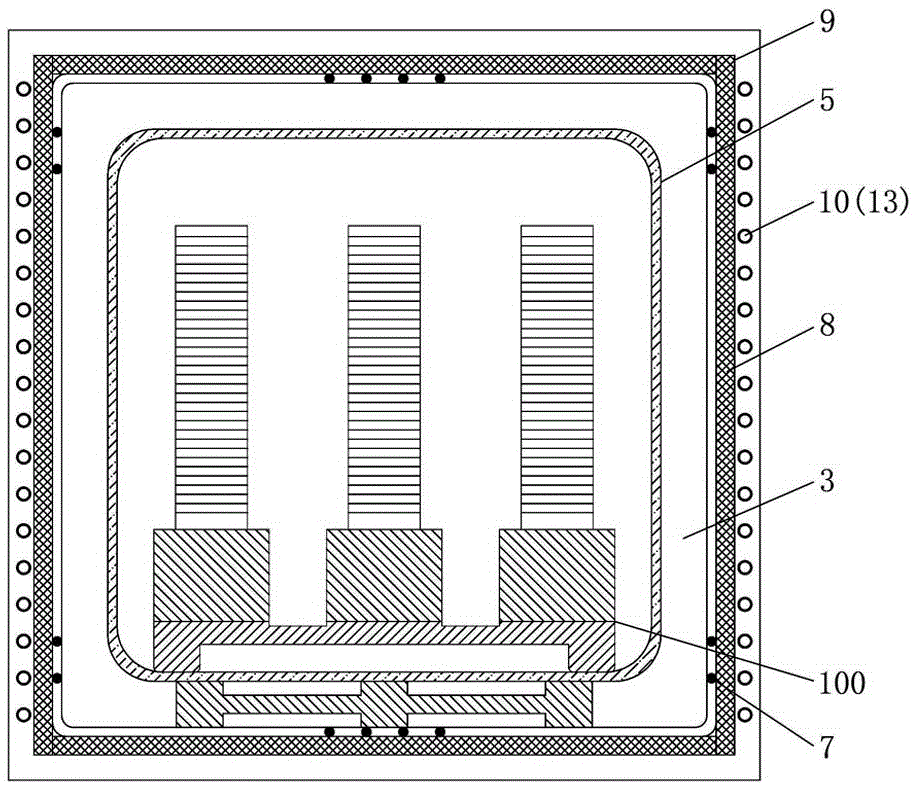

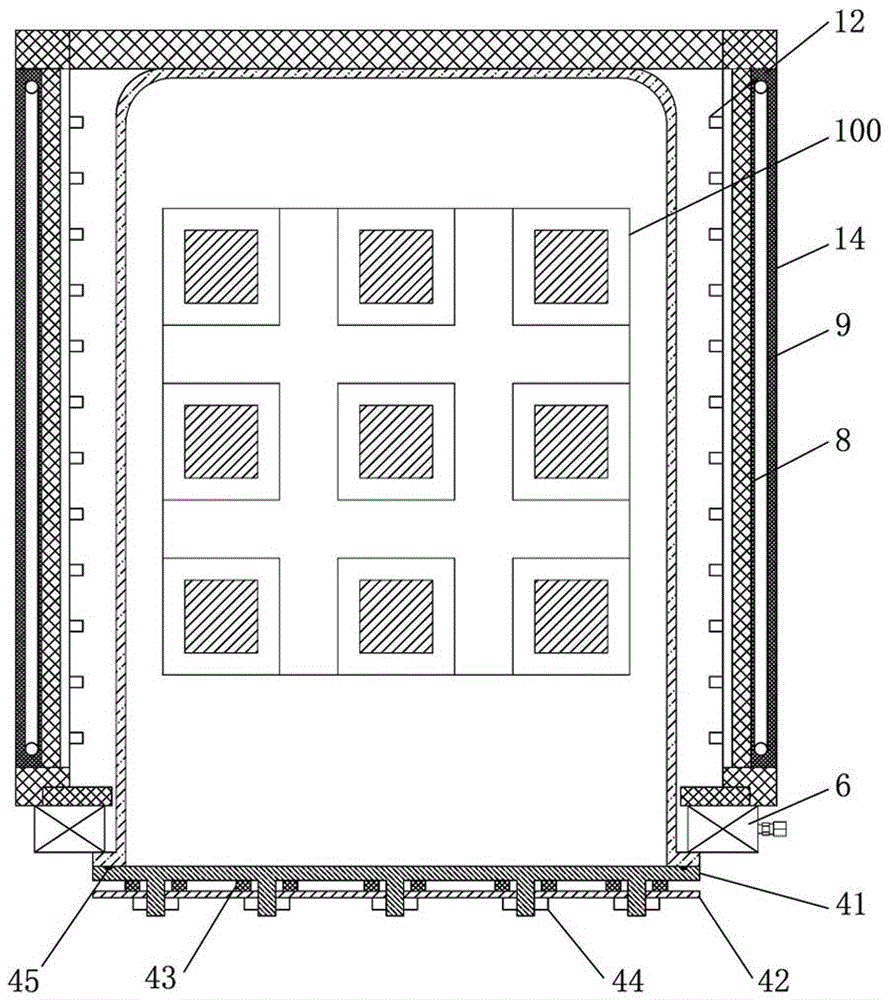

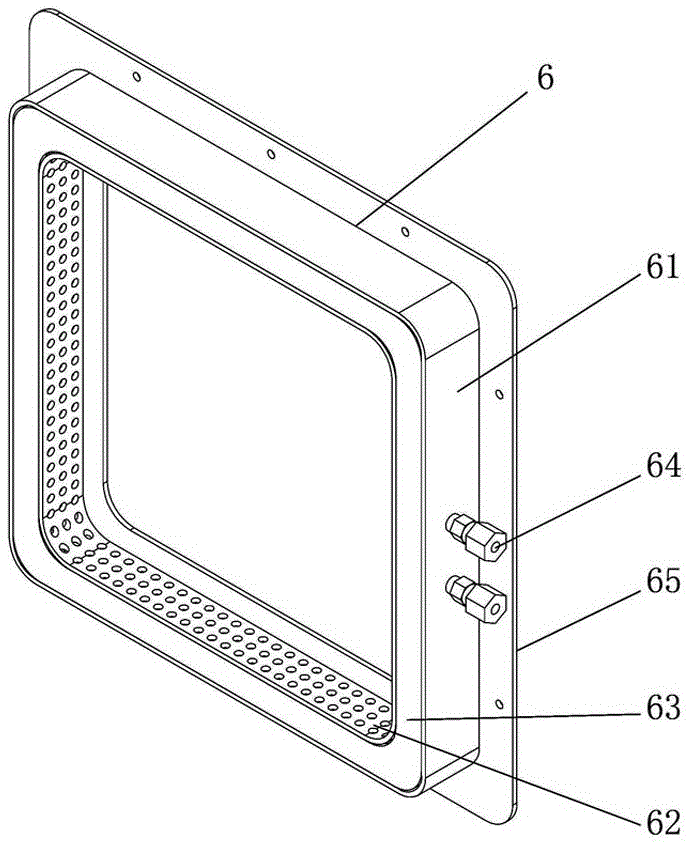

Depressurizing diffusion furnace and carrier plate bearing device

ActiveCN105552000AImprove sealing performanceGood sealingSemiconductor/solid-state device manufacturingFurnace typesEngineeringCold air

The invention discloses a depressurizing diffusion furnace and a carrier plate bearing device. The depressurizing diffusion furnace comprises a box type resistance furnace body, a furnace door assembly and a quartz reaction chamber; the quartz reaction chamber is arranged in the box type resistance furnace body and is sealed through the furnace door assembly; the inner side of the furnace door assembly is provided with an annular sealing ring which is closely attached to an end surface of the quartz reaction chamber; and an end portion of the quartz reaction chamber, which is adjacent to the annular sealing ring, is sleeved with a cold air cooling device. The depressurizing diffusion furnace of the invention has the advantages of simple structure, high production capacity and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com