Multipurpose stainless steel filter

A stainless steel and filter technology, applied in the field of multi-purpose stainless steel filters, can solve the problems of increasing production costs, energy consumption of products, increasing labor intensity, inconvenient operation, etc., and achieve simplified structure, reliable operation, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

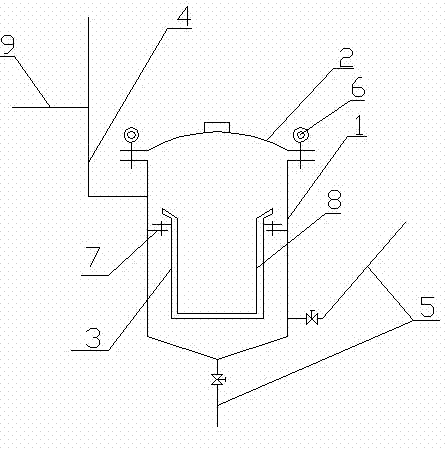

[0010] A multi-purpose stainless steel filter as shown in the accompanying drawings, including a stainless steel barrel body 1, a barrel cover 2, a stainless steel mechanical filter 3, a feed pipe 4 and a discharge pipe 5, the stainless steel barrel body 1 and the barrel cover 2 pass through the hanging Ear bolts 6 are connected, and a mechanical filter seat 7 is fixedly installed on the inner wall of the stainless steel barrel body 1 for installing a stainless steel mechanical filter 3. A screen 8 is installed on the inner side of the stainless steel mechanical filter 3, and the upper side wall of the stainless steel barrel body 1 is connected There is a feed pipeline 4, and a gas pipeline 9 is also opened on the feed pipeline 4. The gas pipeline 9 is connected to the external air pressure system. A discharge pipeline 5 is provided at the bottom and side wall of the stainless steel barrel body 1. The stainless steel barrel The edge contact portion between the body 1 and the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com