Butt joint device used for industrial gas pipeline installation

A technology of pipeline installation and docking device, which is applied in the direction of pipeline bracket, pipe/pipe joint/pipe fitting, sleeve/socket connection, etc., can solve the problems of general connection strength and single connection method of gas pipeline, save manpower and improve connection. Strength, the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

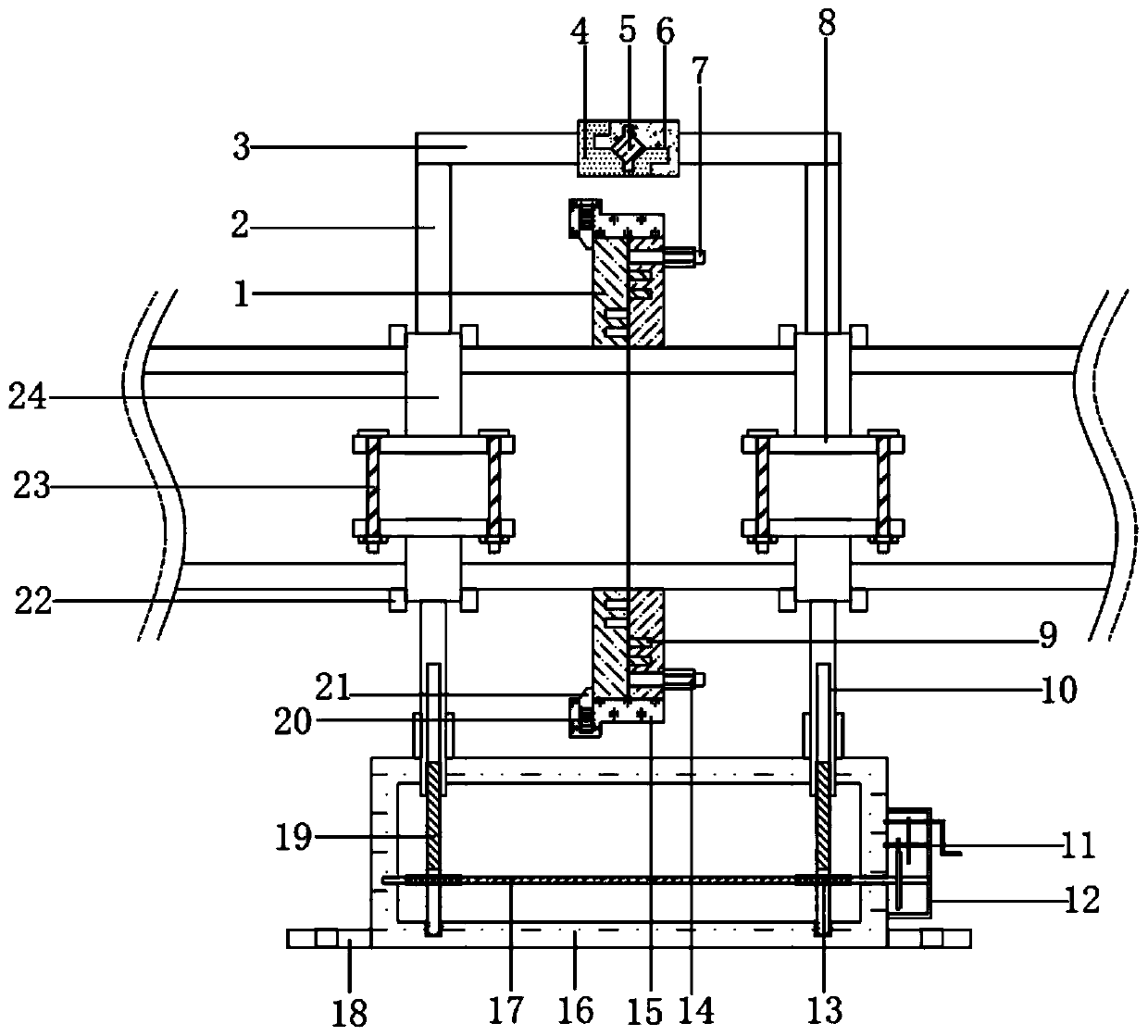

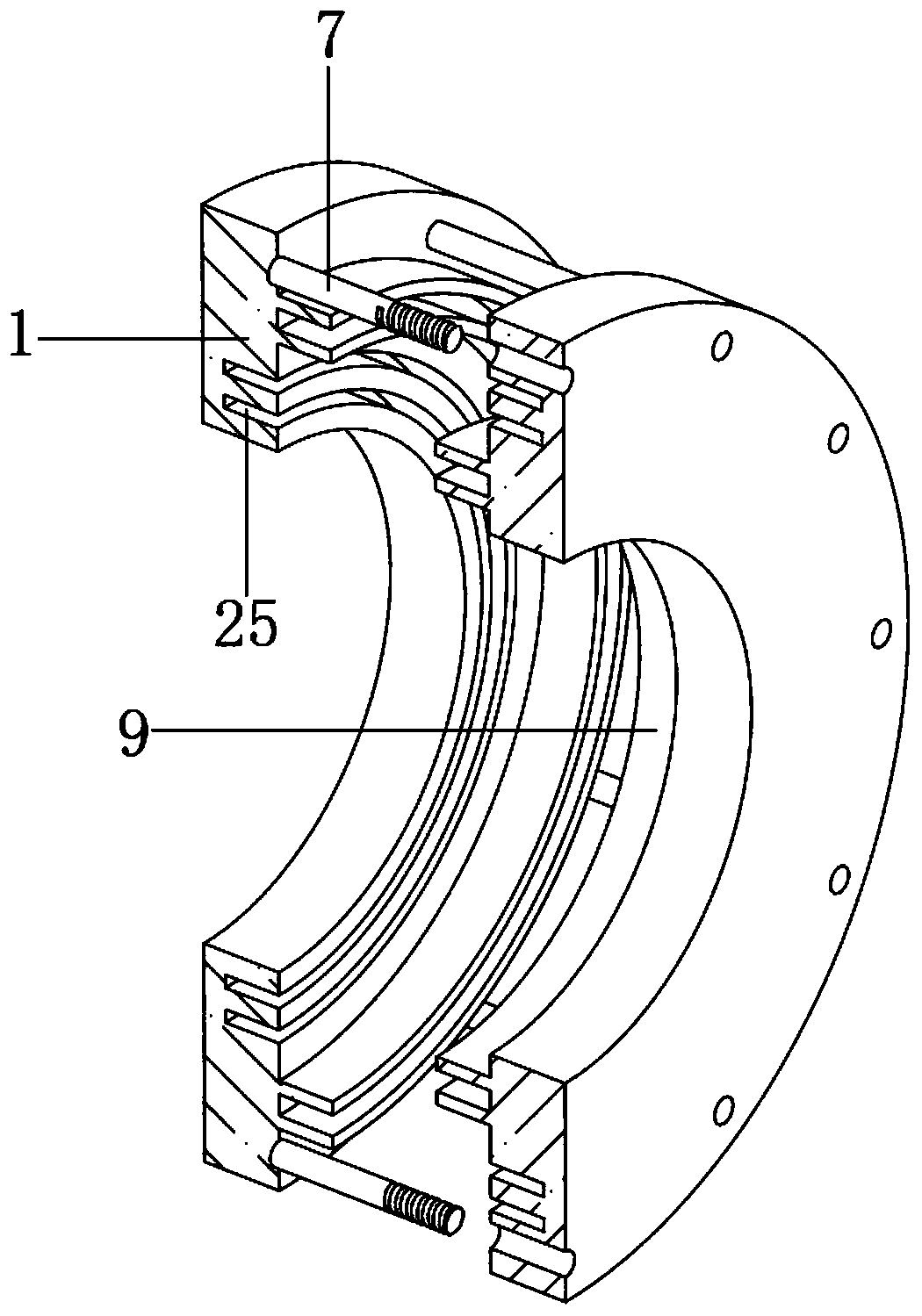

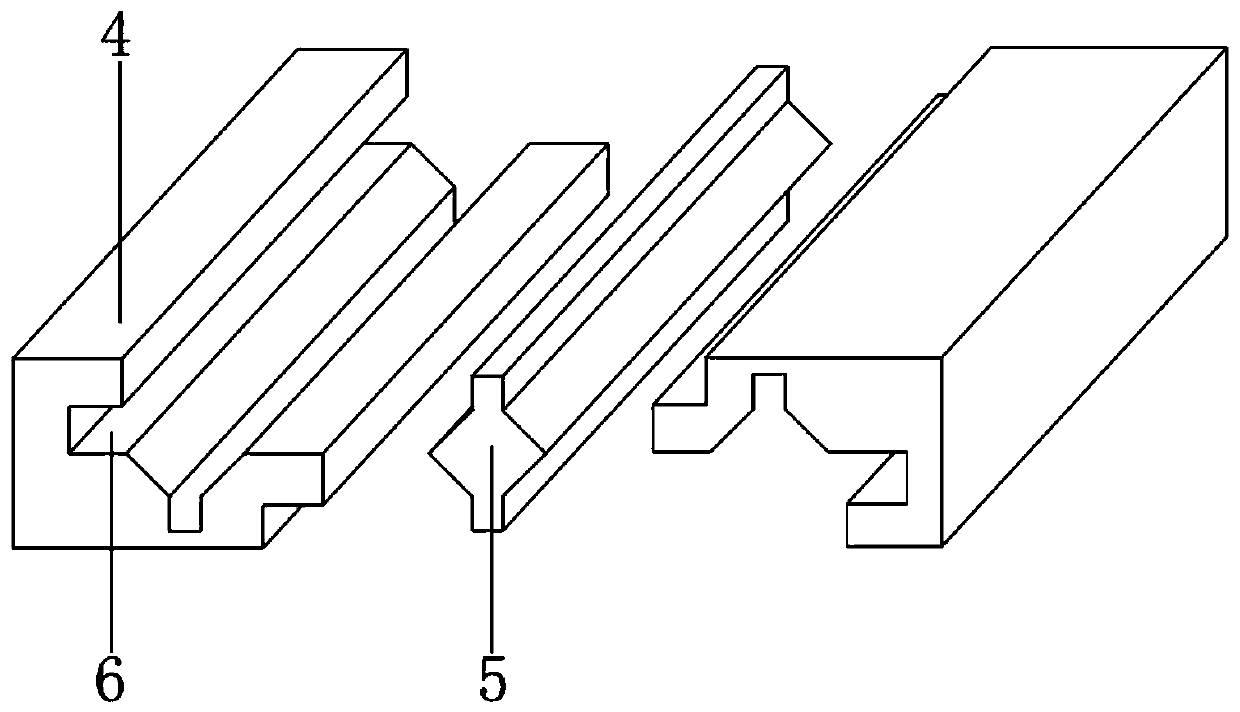

[0030] refer to figure 1 , figure 2 , image 3 with Figure 5 , a docking device for industrial gas pipeline installation, comprising a gas pipeline body, a supporting bracket 16, a butt ring 1 and a butt ring 2 welded to the opposite side of the gas pipeline body, and a butt ring 1 and a butt ring 2 opposite to each other There are interlaced protruding rings 9 welded on the sides respectively, and the opposite sides of the docking ring 1 and the docking ring 2 are provided with ring grooves 25 suitable for the protruding ring 9, and the outer wall of one side of the butt ring 1 is welded with equidistant Annularly distributed threaded alignment rods 7, and the ends of the threaded alignment rods 7 are all threadedly connected with lock nuts 14, and one end of the gas pipeline body is welded with snap rings 22, and the upper and lower ends of the snap rings 22 are all provided with There is a collar 24, the top outer wall of the collar 24 at the top is welded with a verti...

Embodiment 2

[0039] refer to figure 1 with Figure 4 , a docking device for industrial gas pipeline installation. Compared with Embodiment 1, this embodiment also includes a reduction transmission mechanism 11 installed on one side of the support bracket 16, and the reduction transmission mechanism 11 includes a bolt fixed to the support bracket 16 The transmission case 12 of one side outer wall.

[0040] In the present invention, one end of the worm 17 is rotatably connected to the transmission box 12, and the top of the transmission box 12 is rotatably connected to a rocker 27 and a transmission rod 29 through bearings, and one end of the worm 17 and the rocker 27 is keyed to a driven gear respectively. 30 and drive gear 26.

[0041] Wherein, the outer walls of both ends of the transmission rod 29 are respectively keyed with a transmission tooth 1 31 meshing with the driving gear 26 and a transmission tooth 2 28 meshing with the driven gear 30 .

[0042] When the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com