Single-motor window shutter for large window

A single-motor rolling shutter technology, applied in windows/doors, door/window protection devices, shutters/movable grilles, etc., can solve problems such as high failure rate, high motor cost, and poor thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

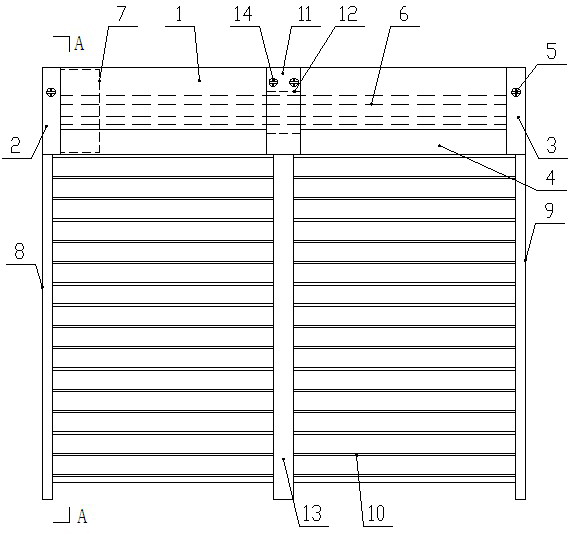

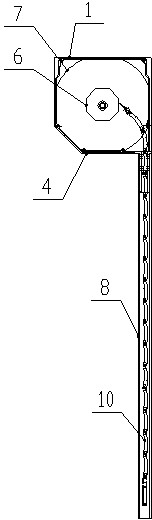

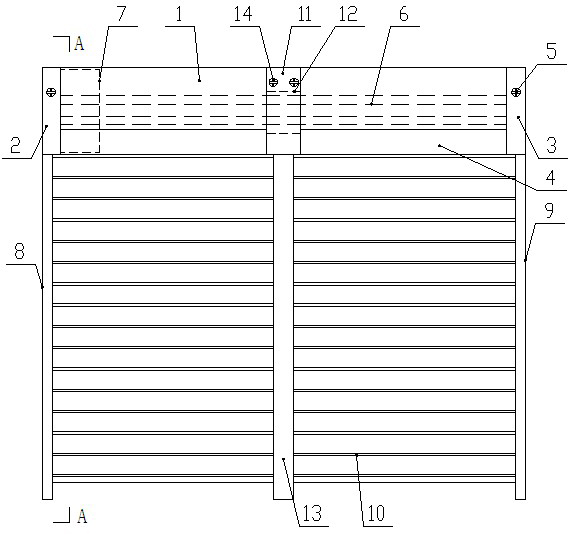

[0009] Such as figure 1 and figure 2 As shown, a single-motor roller shutter window for large windows of the present invention includes a roller shutter box composed of an upper case 1, a left end seat 2, a right end seat 3 and a lower case 4 connected by end screws 5, The rolling shutter box is horizontally provided with a reel 6 which is respectively connected to the left end seat 2 and the right end seat 3 in rotation. A right guide rail 9 is provided to the direction, and two hanging curtain sheets 10 are wound on the reel 6. The middle part of the shutter box is provided with a middle end seat 11, and the middle part of the middle end seat 11 is provided with a through hole 12 for passing the reel 6. The middle end seat The lower end of 11 is provided with a middle guide rail 13 with double tracks. When the motor 7 is running, the reel 6 drives the two hanging curtains 10 to run up and down at the same time. One of the hanging curtains 10 slides up and down along the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com