Patents

Literature

152results about How to "Improve wind pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

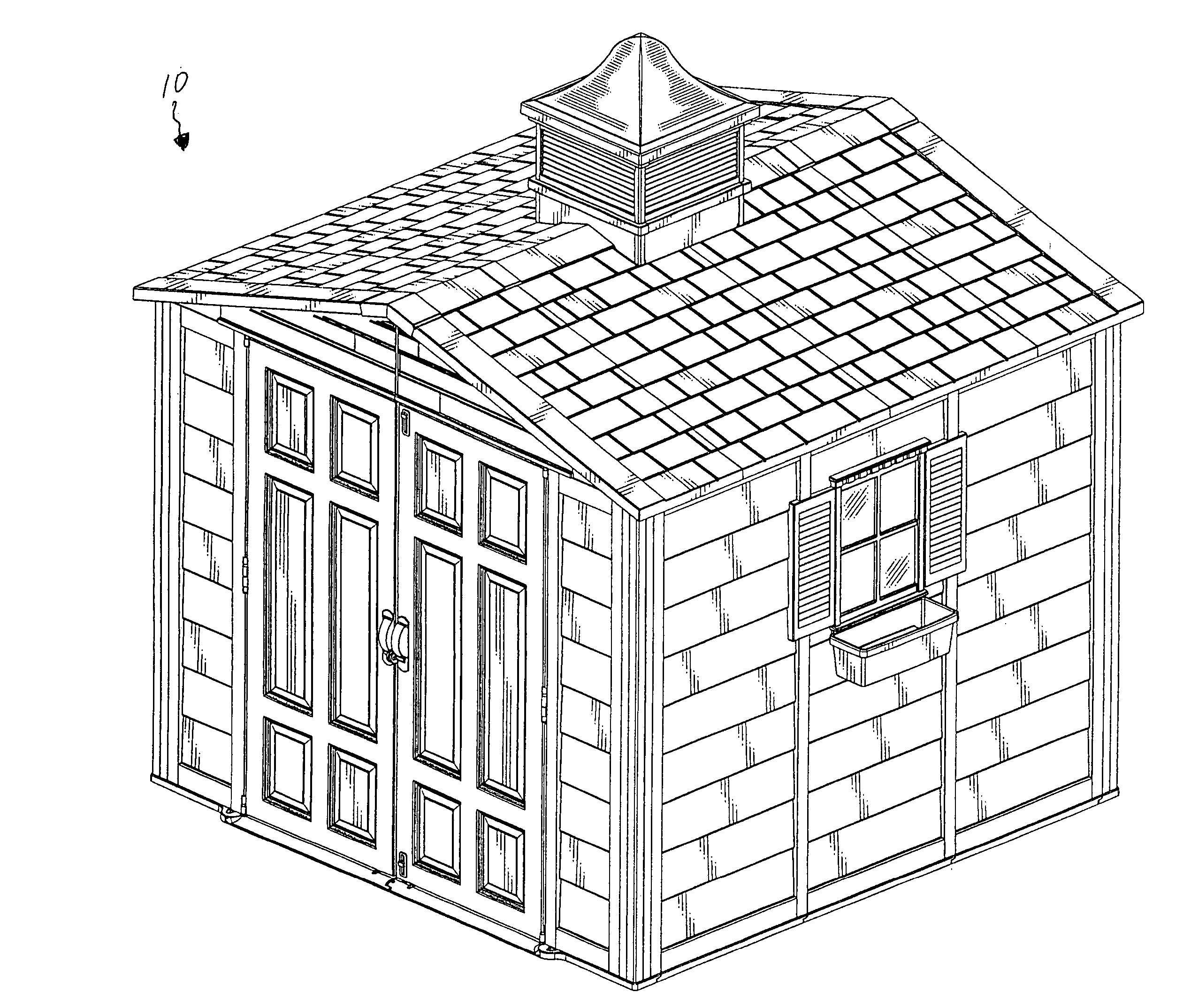

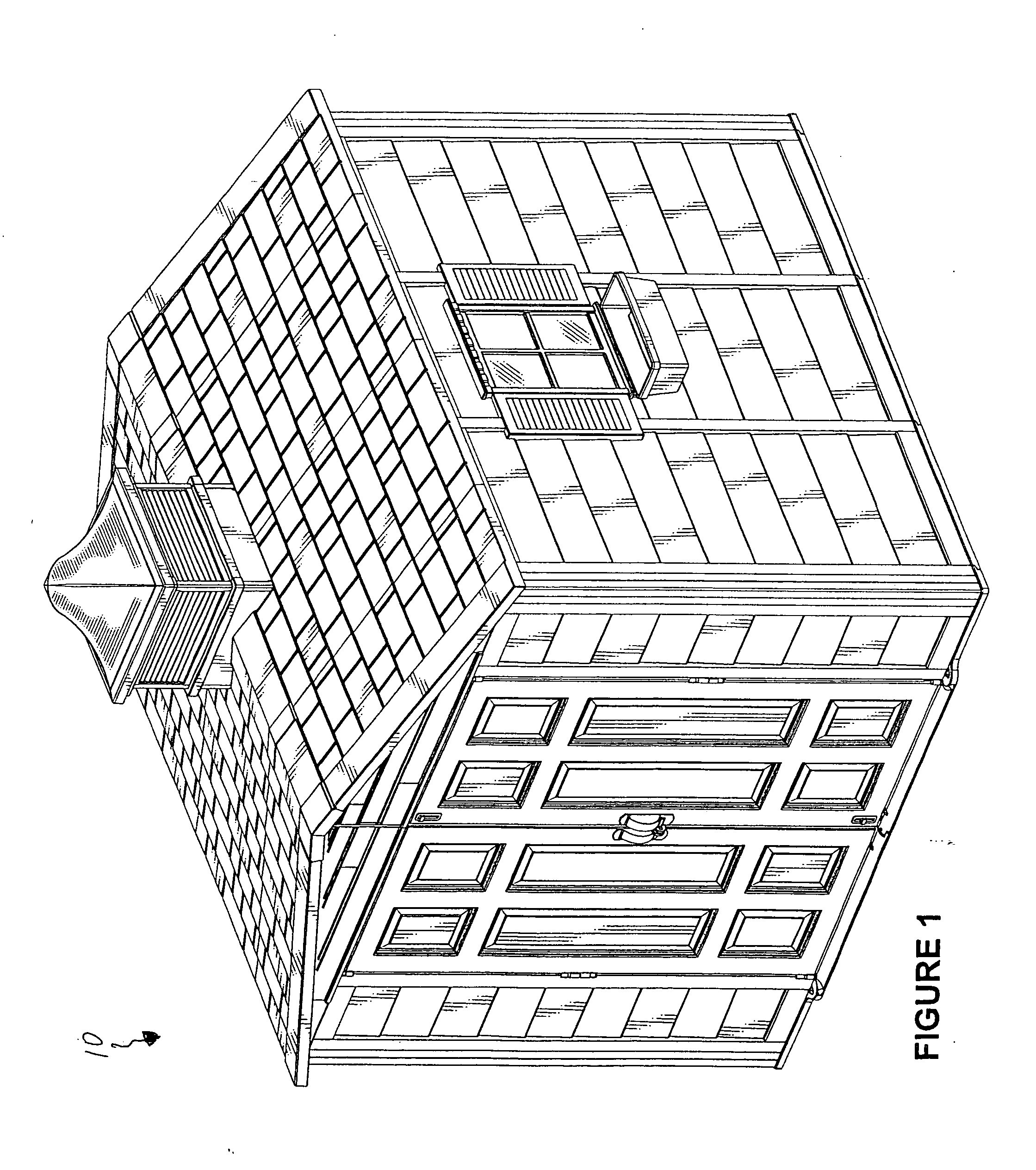

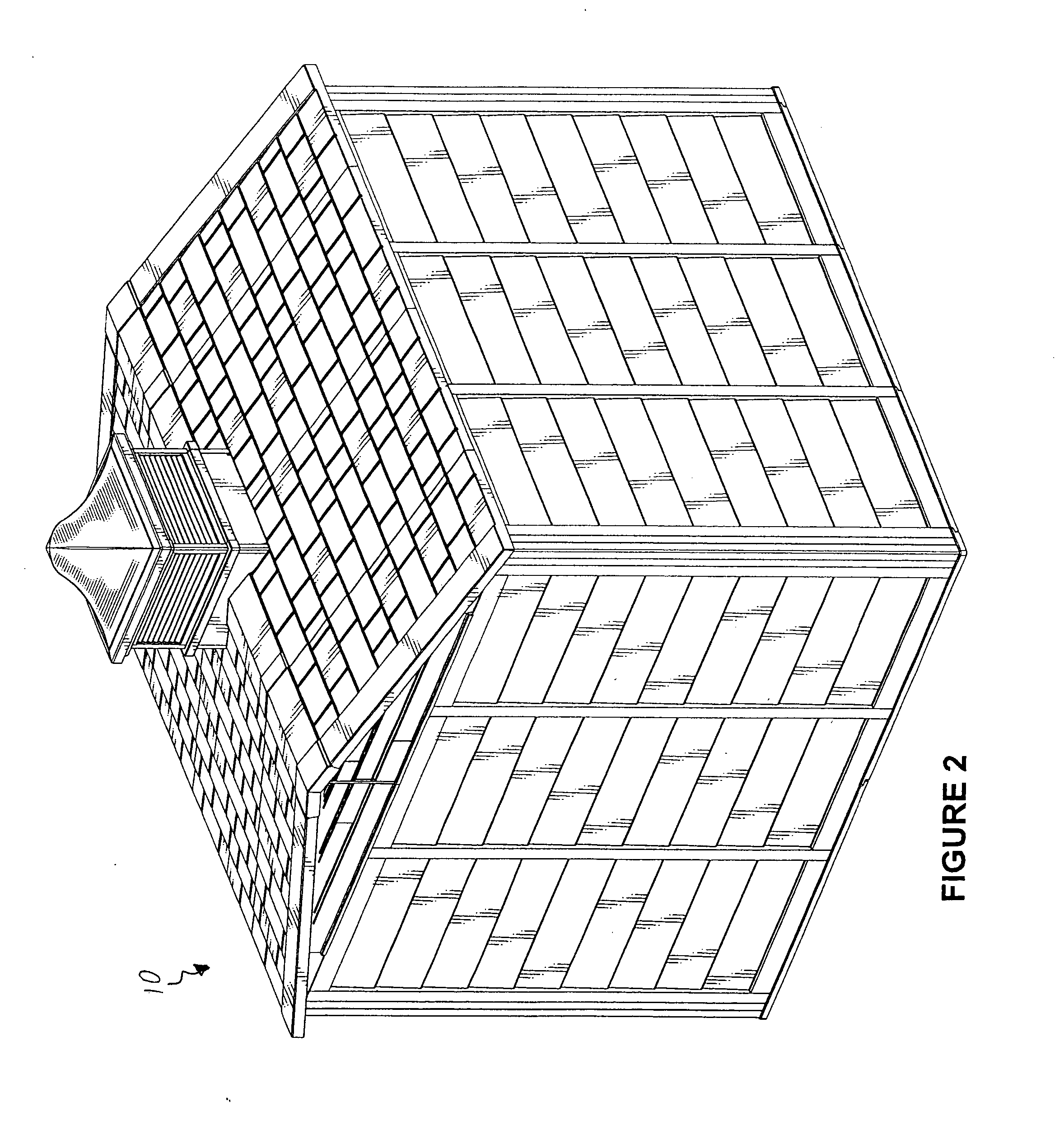

Plastic expandable utility shed

InactiveUS20070044391A1Improves Structural IntegrityIncrease shell rigidityBuilding roofsStrutsEngineeringInjection moulding

The present invention provides a system, or kit, of injection molded panels having integrated connectors which combine to form an enclosure, commonly in the form of a utility shed. The panels are formed of injection molded plastic to interlock with one another without the need for separate I-beam connectors. The ends of the wall panels have cavities to accept both roof and floor outwardly projecting locking bosses for interlocking cooperative engagement which serve to rigidly connect the components together. The symmetry of the wall, roof, floor and door components also minimizes component shapes and simplifies enclosure construction.

Owner:SUNCAST

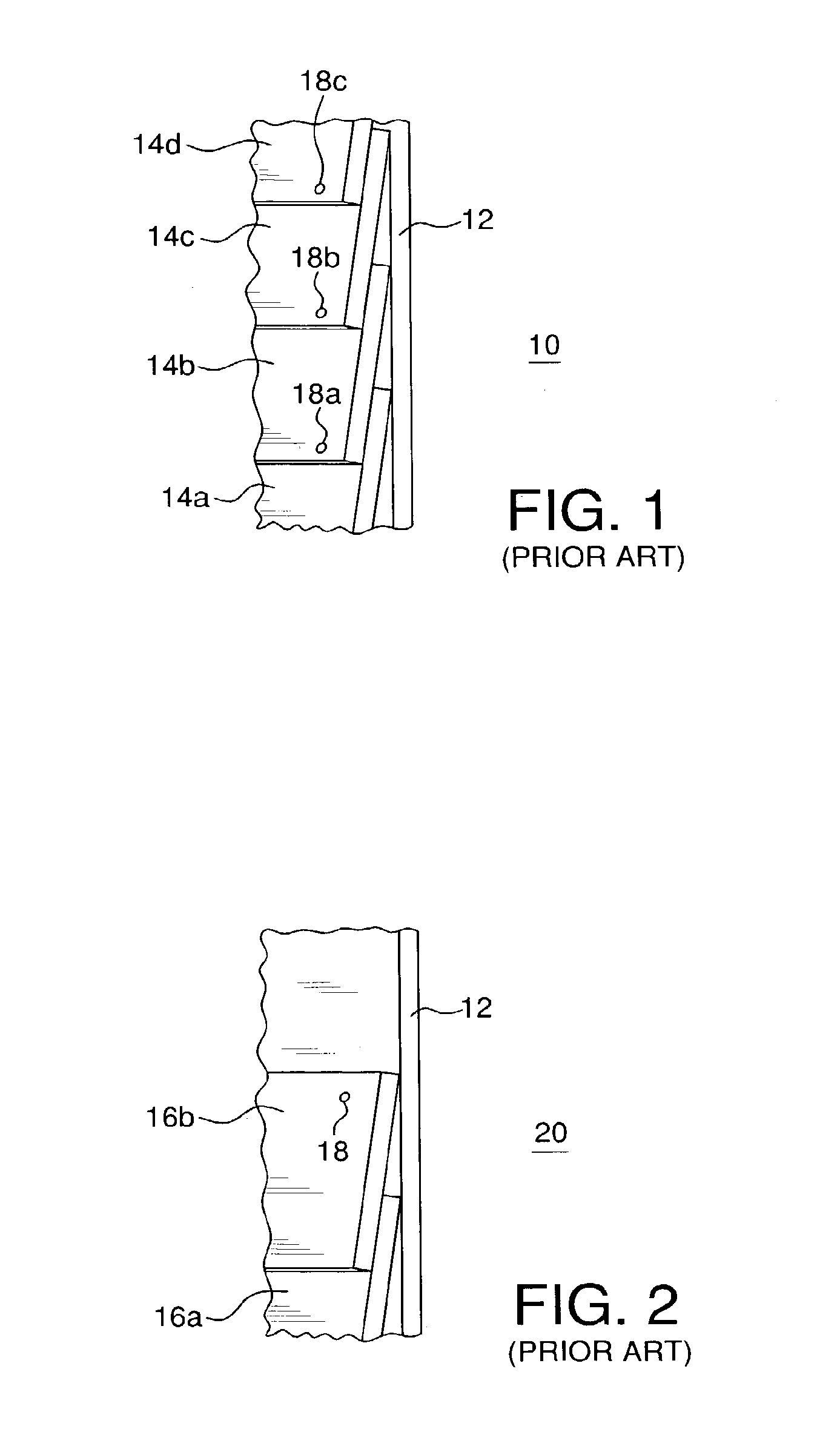

Clapboard siding installation clip and method of installing clapboard siding

ActiveUS7441382B2Simplify the installation processIncreased durabilityConstruction materialRoof covering using tiles/slatesEngineeringMechanical engineering

Owner:CERTAINTEED CORP

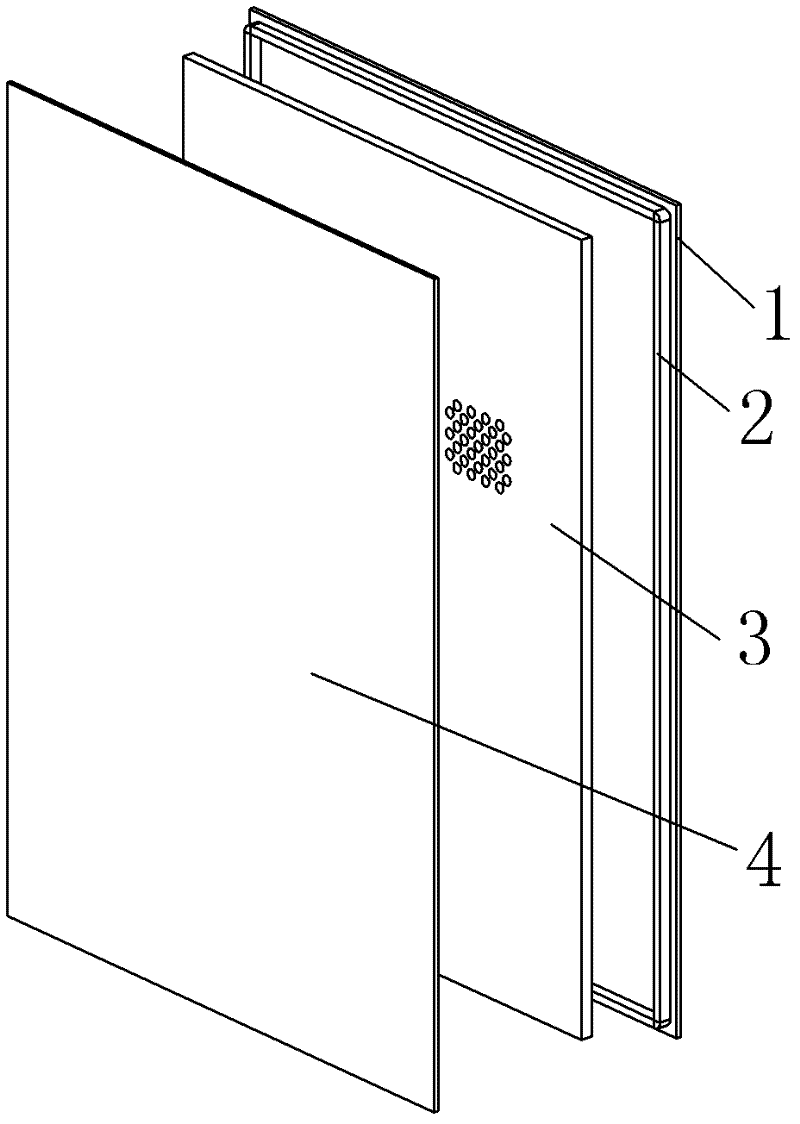

Coated hollow composite glass and manufacturing method thereof

ActiveCN102536061AIsolated irradiationPrevent agingClimate change adaptationWindows/door improvementThermal insulationPre treatment

Disclosed are coated hollow composite glass and a manufacturing method thereof. The coated hollow composite glass comprises an upper glass substrate, a lower glass substrate, a spacer frame and hollow filling, wherein the spacer frame is respectively and peripherally adhered to the upper glass substrate and the lower glass substrate and gaps among the spacer frame, the upper glass substrate and the lower glass substrate are sealed via sealant, a hollow cavity is enclosed by the upper glass substrate, the lower glass substrate and the spacer frame, the hollow filling is filled into the hollow cavity, the hollow filling is a honeycombed board, and aerogel is filled into cells of the honeycombed board. The manufacturing method includes steps of pretreating the upper glass substrate and the lower glass substrate, preparing the middle filling, attaching the spacer frame, filling with the hollow filling and attaching the lower glass substrate. The coated hollow composite glass and the manufacturing method can meet the construction requirement and the energy-saving requirement of public buildings, and the coated hollow composite glass has good thermal insulation property.

Owner:天津南玻节能玻璃有限公司

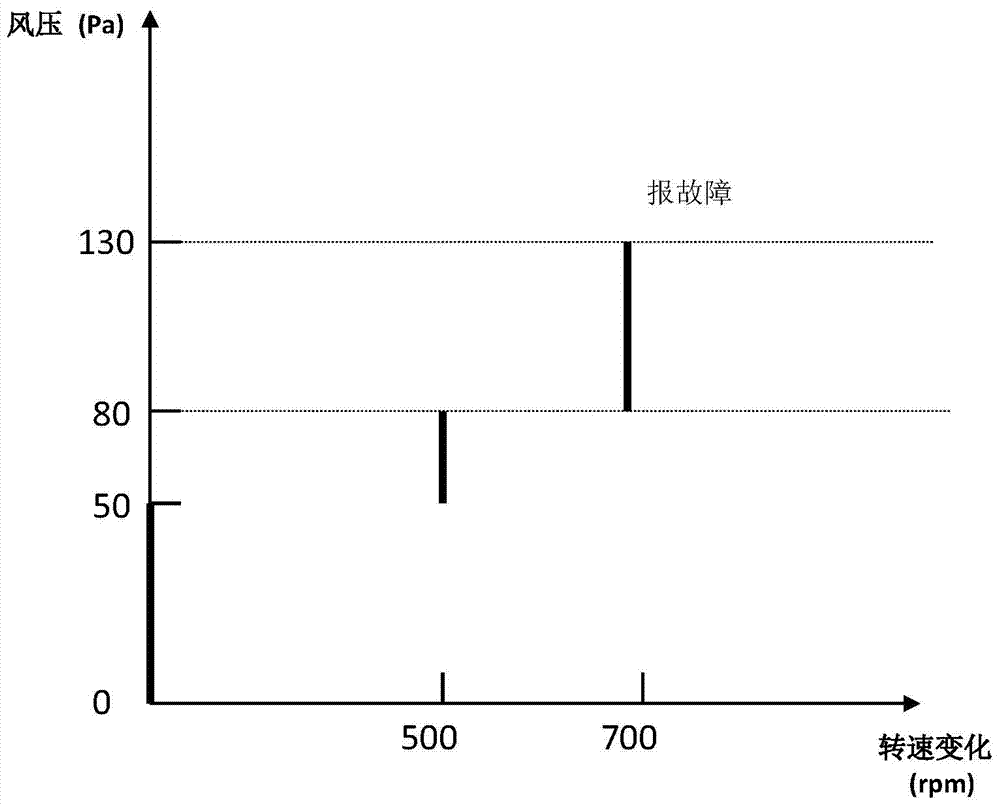

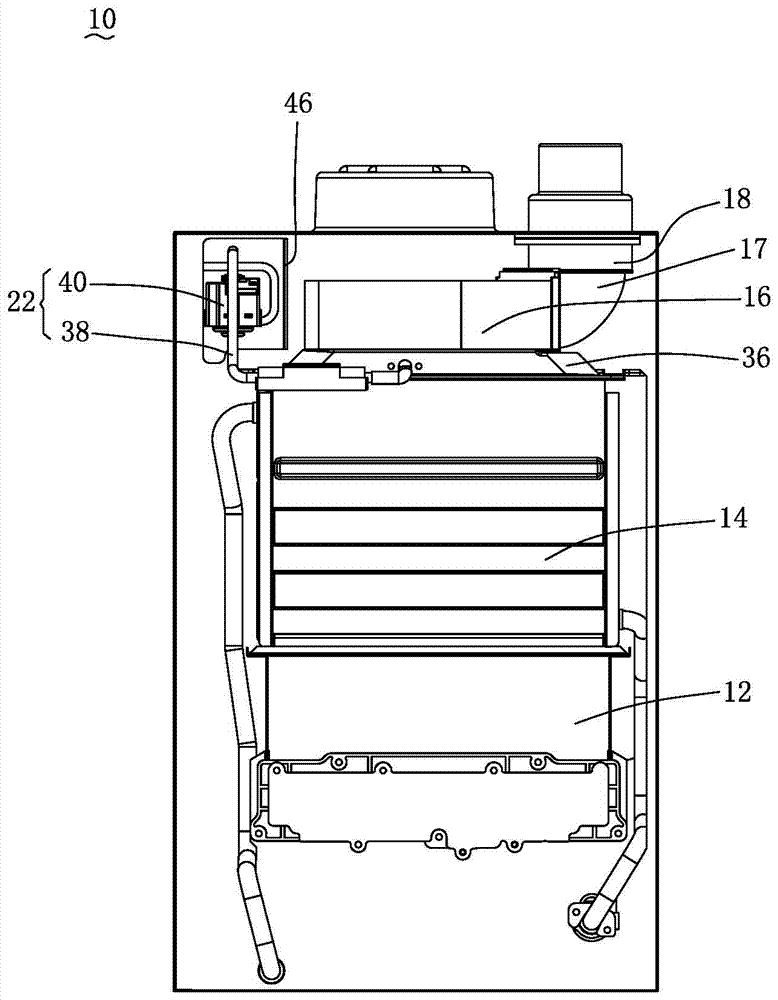

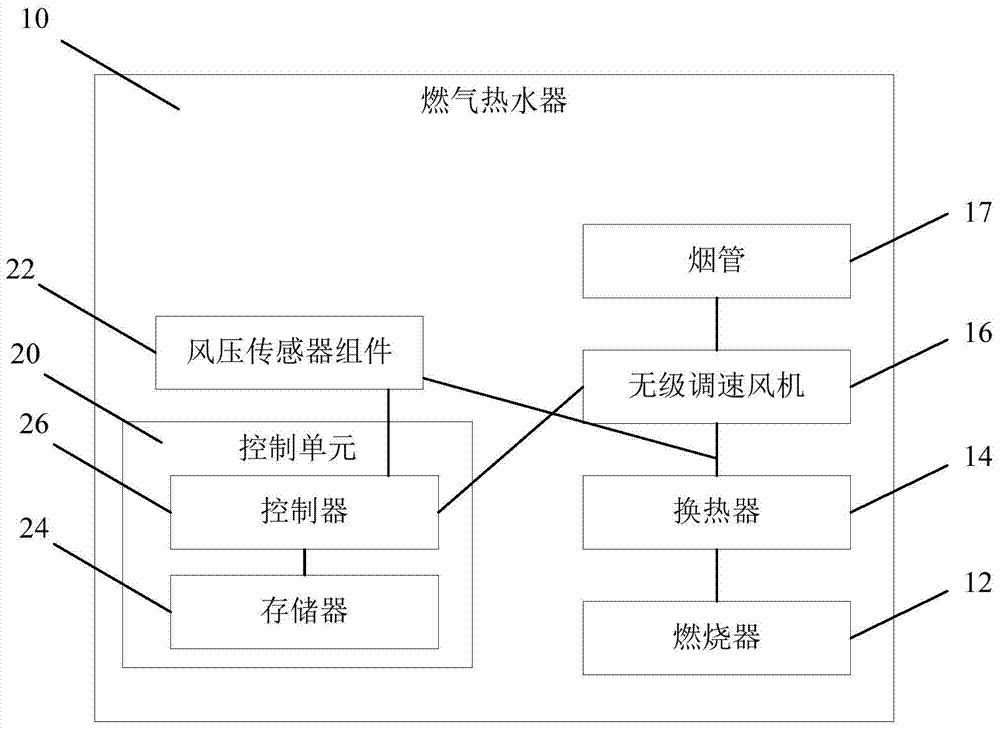

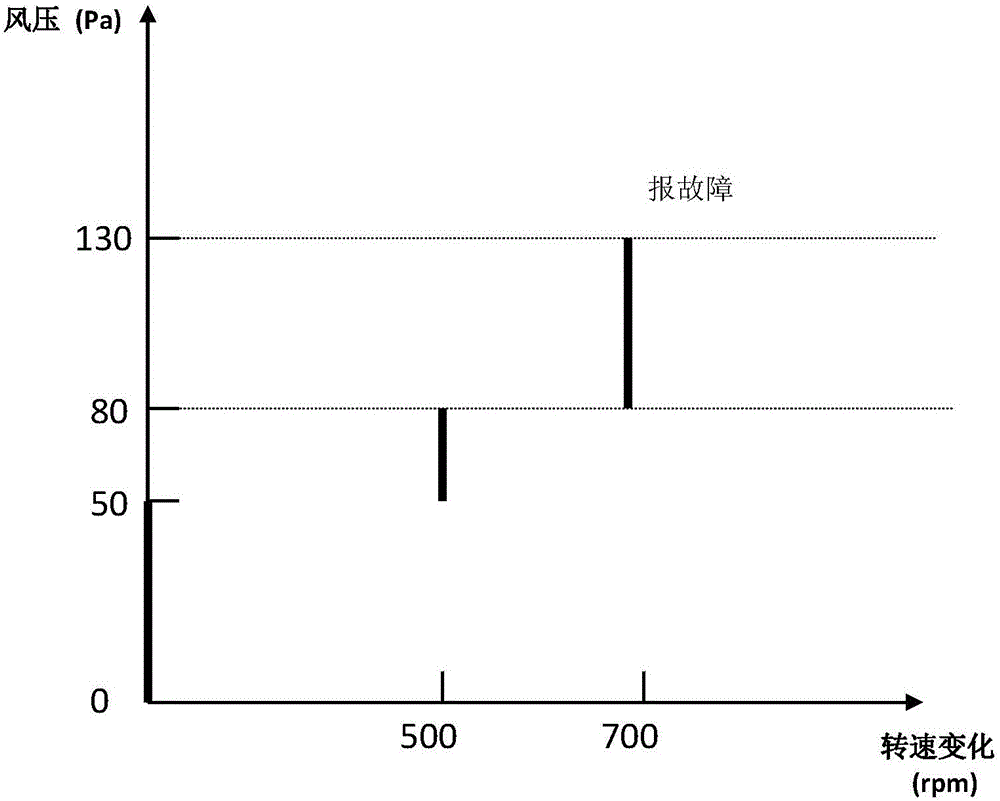

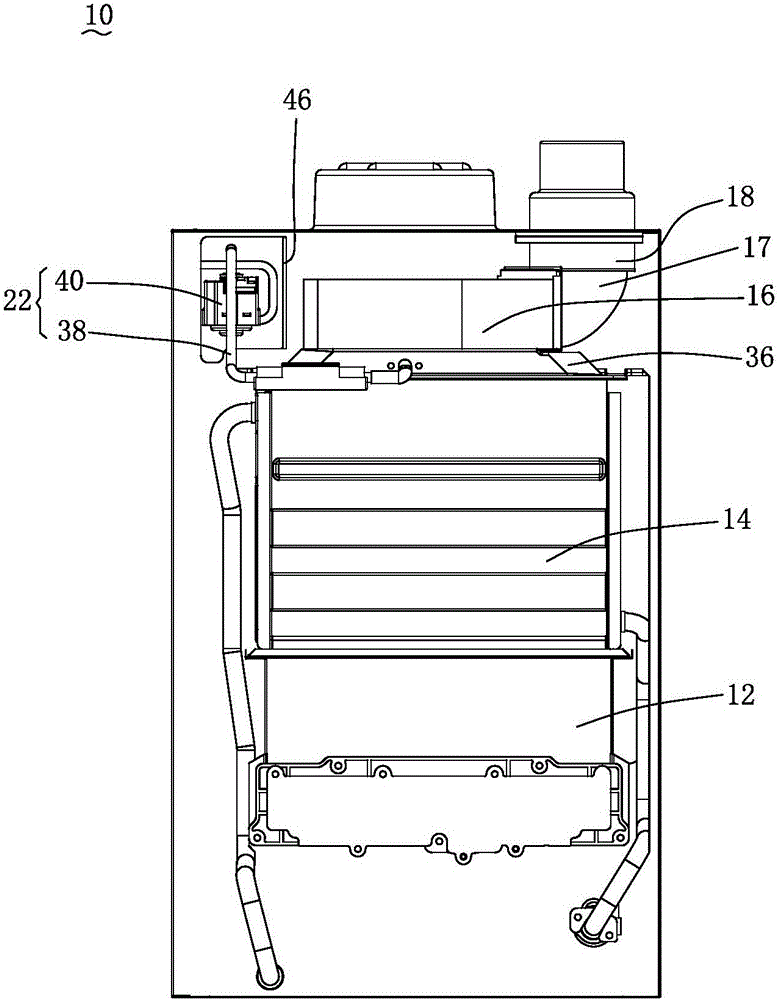

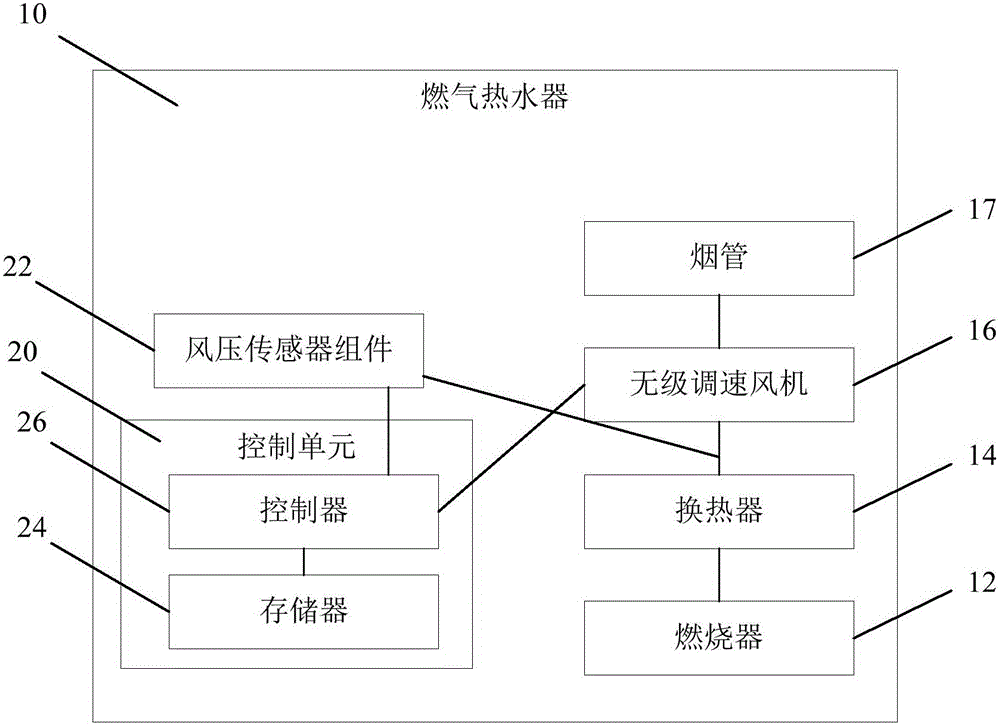

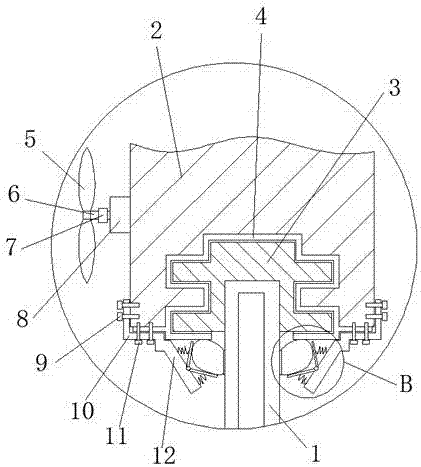

Combustion control system for gas water heater or wall-hanging stove and control method thereof

ActiveCN104729101AExact matchImprove wind pressure resistanceAir supply regulationWater heatersCombustorControl system

The invention discloses a combustion control system for a gas water heater or a wall-hanging stove and a control method thereof. The system comprises a flue gas channel composed of a combustor, a heat exchanger, a stepless variable speed fan and a smoke pipe which are sequentially connected, a control unit connected with the signal input end of the stepless variable speed fan and an air pressure sensor assembly for detecting pressure signals of the upstream of the stepless variable speed fan, and the signal output end of the air pressure sensor assembly is connected with the control unit. The control unit comprises a storage and a controller, the storage is used for storing the corresponding relation between the pressure signals of the upstream of the stepless variable speed fan and heating loads of the combustor, and the controller is used for controlling operation of the stepless variable speed fan according to the corresponding relation. By detecting the pressure signals of the upstream of the stepless variable speed fan, the rotating speed of the upstream of the stepless variable speed fan is further adjusted, and the combustion control system has high wind-resistant performance.

Owner:A O SMITH CHINA WATER HEATER CO LTD

Production process of building vacuum glass plate

InactiveCN1861534AHigh strengthIncrease stiffnessGlass reforming apparatusScreen printingEngineering

A process for preparing vacuum glass plate for building features that the silk screen print is used to print peripheral sealing band and the welding glass material on internal supporting dots, and the glass sealing and the generation of vacuum cavity is performed by high-temp vacuum sealing.

Owner:王世忠

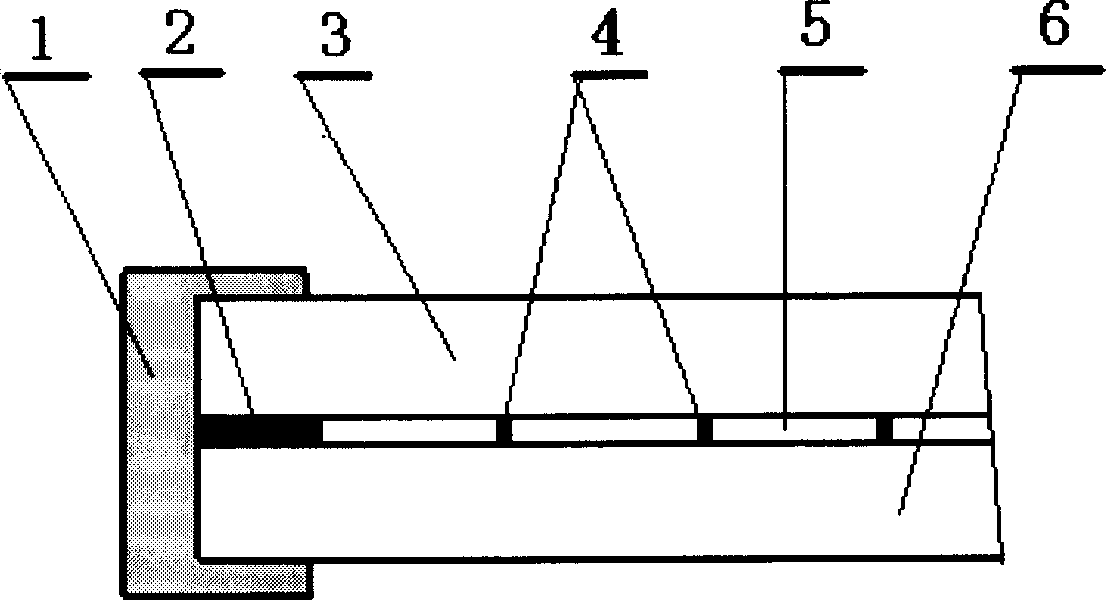

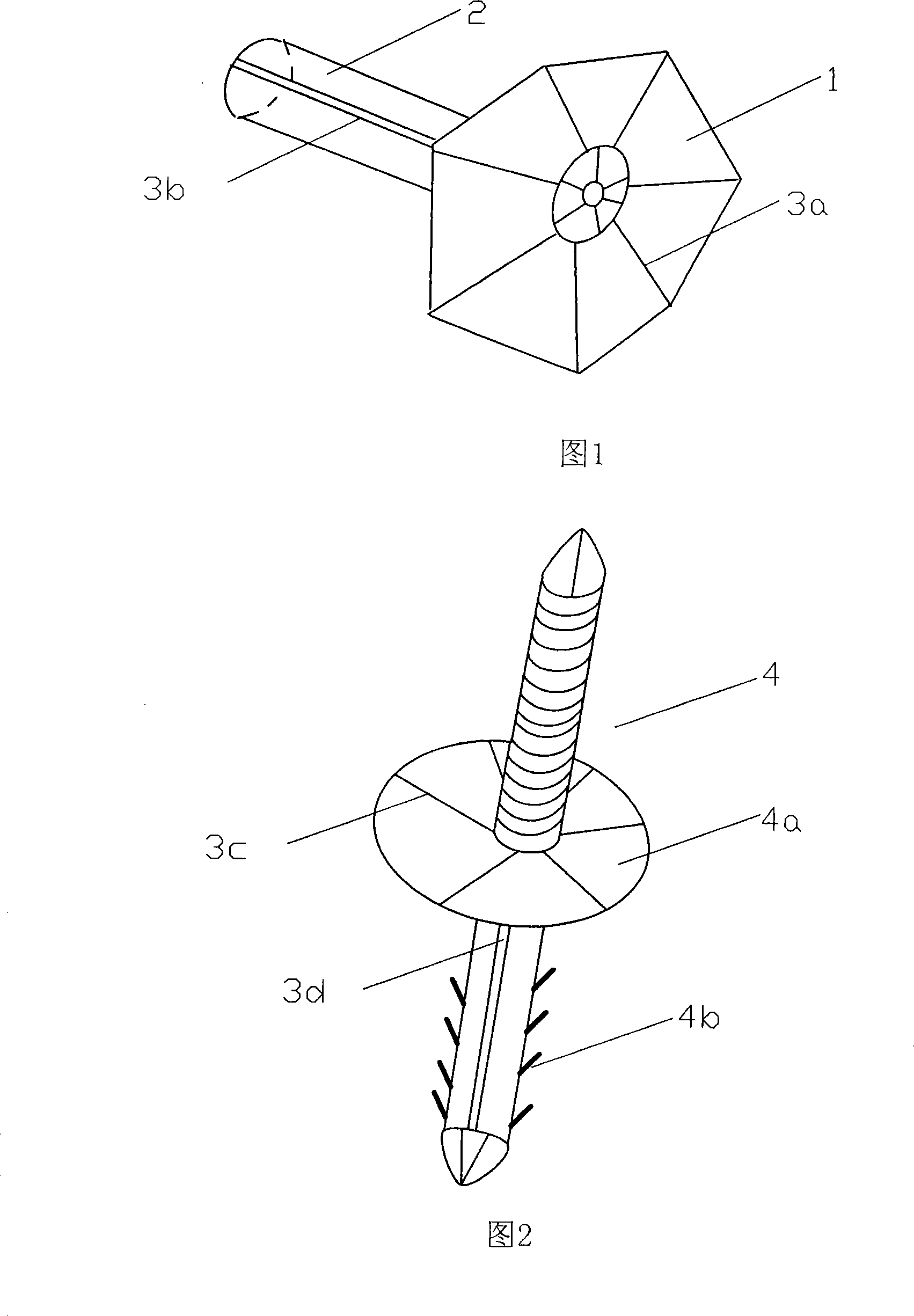

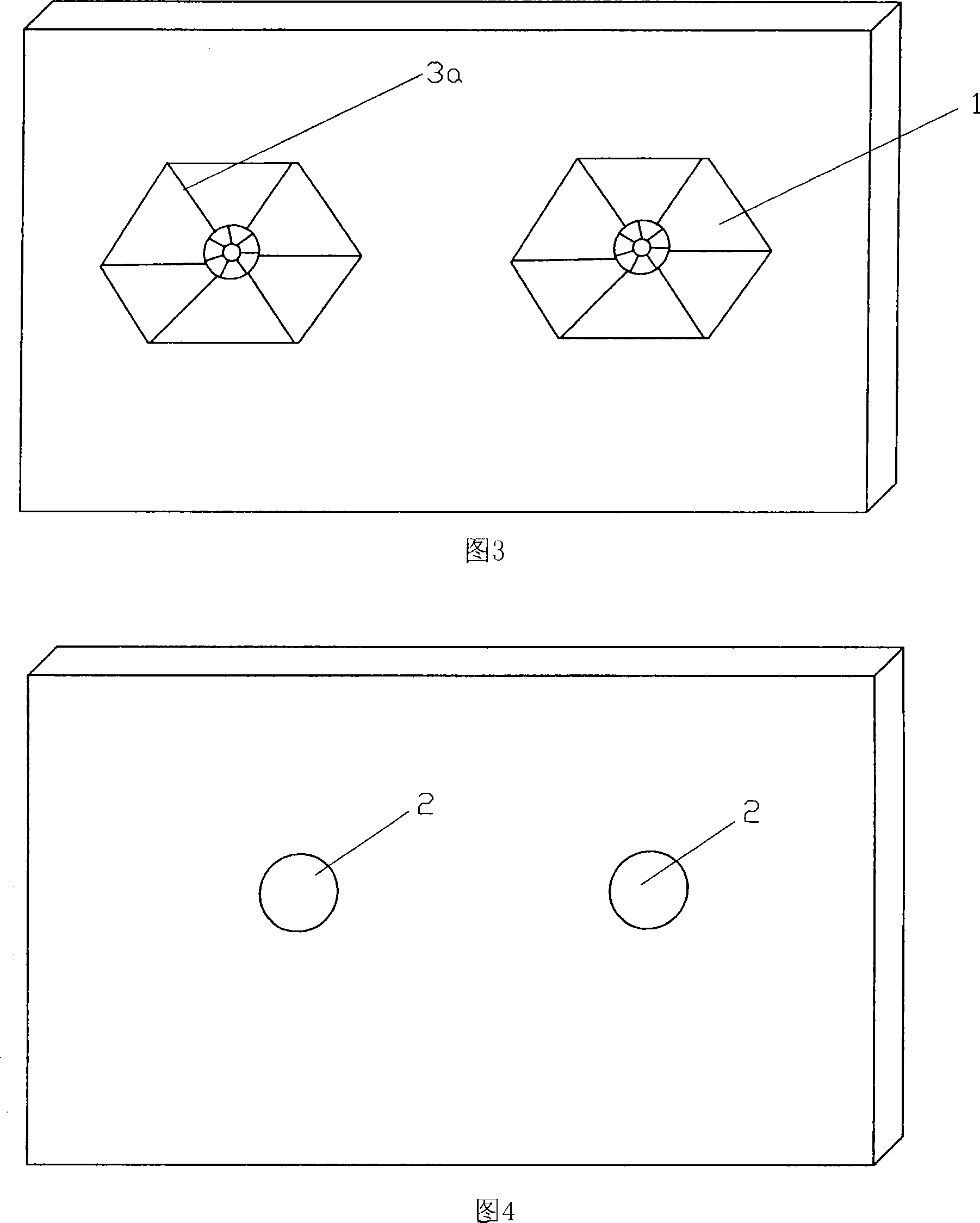

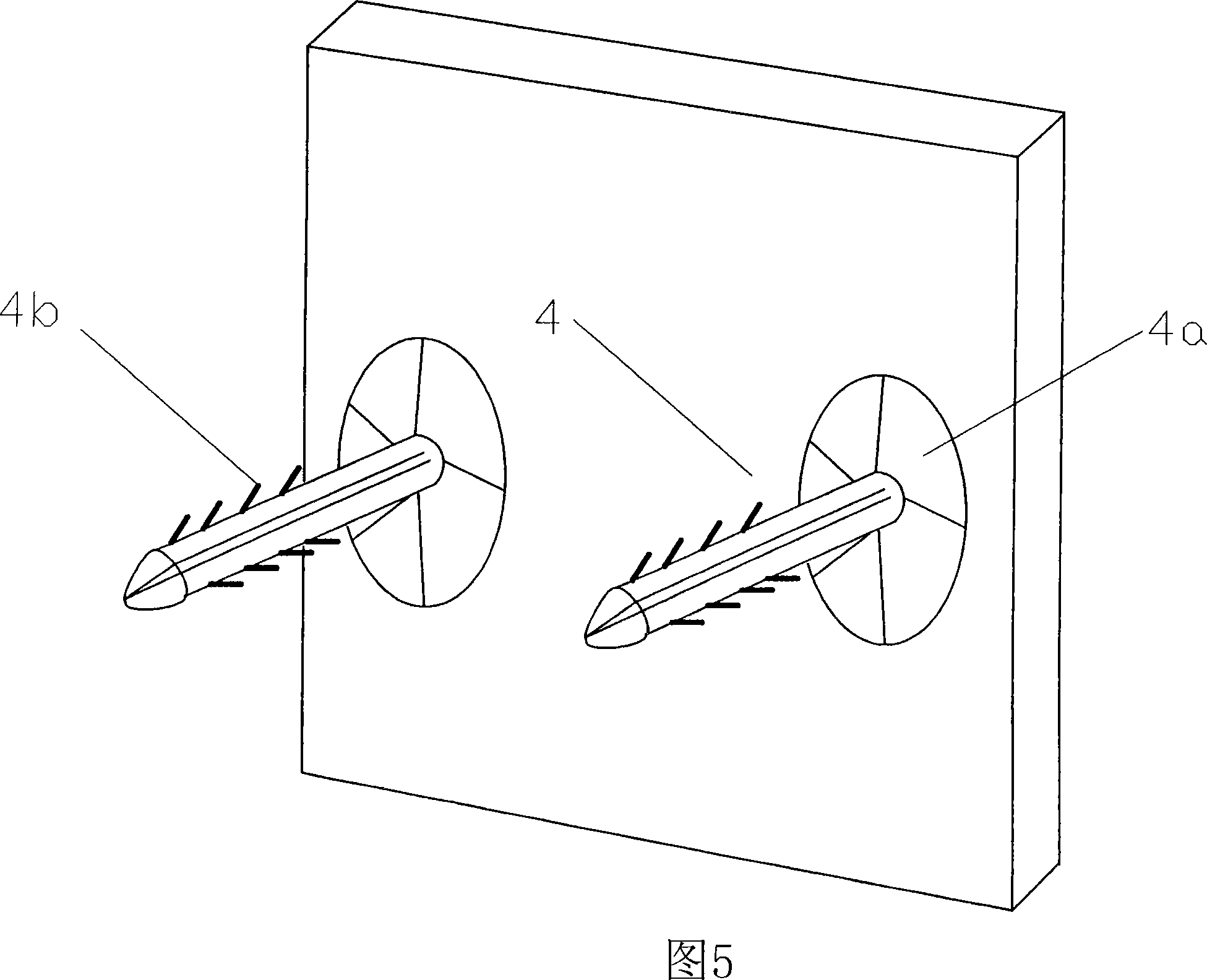

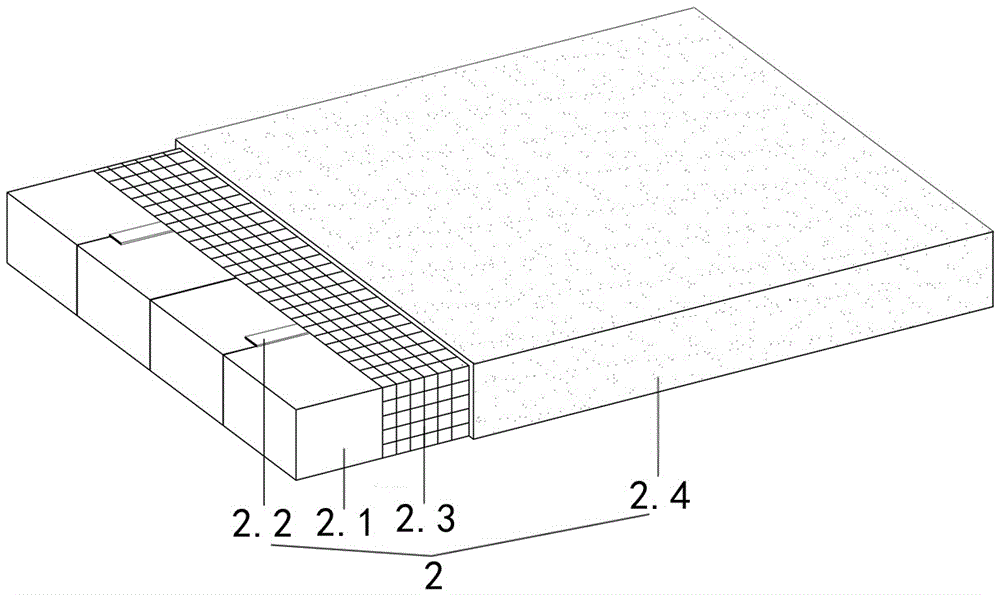

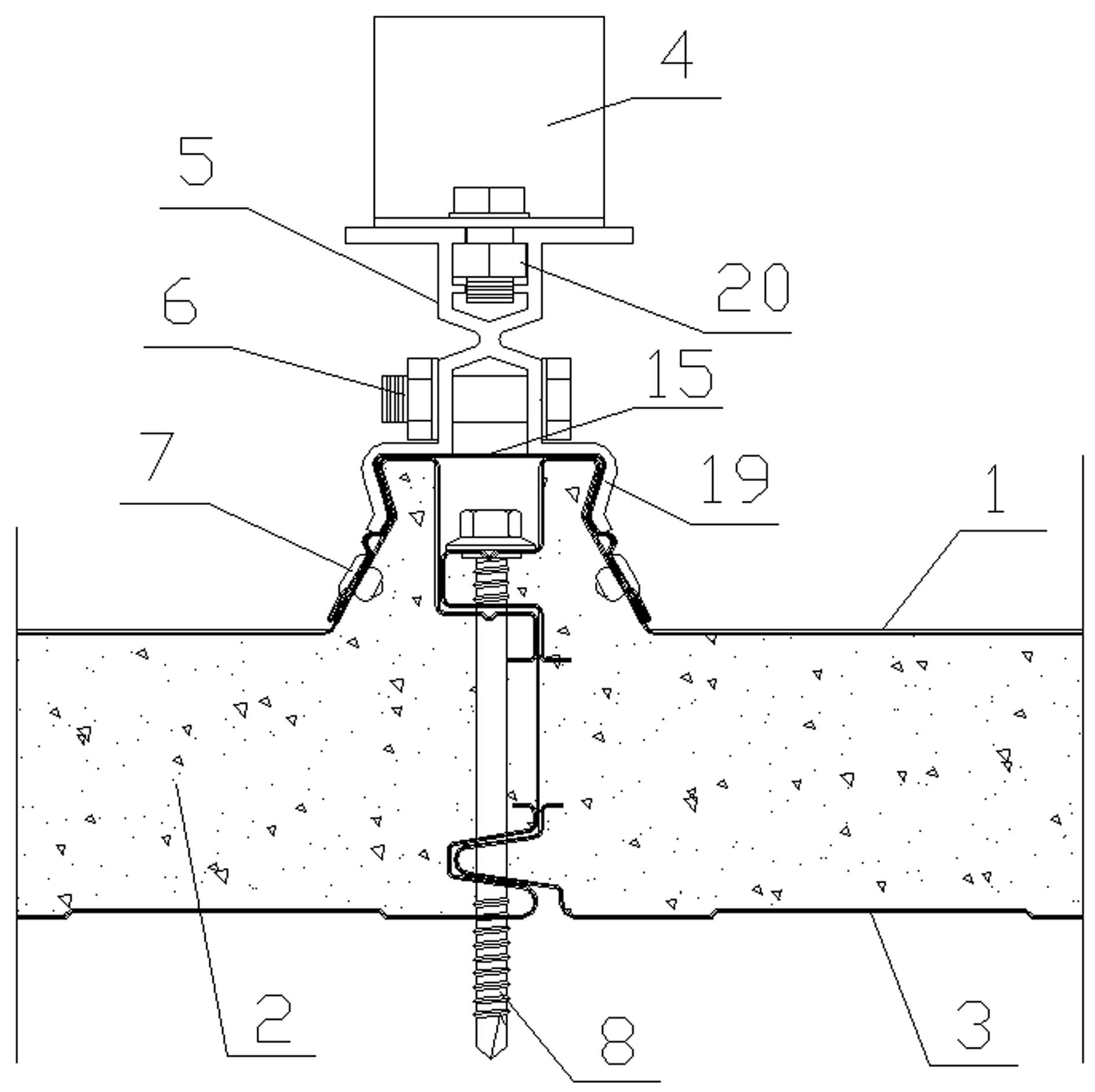

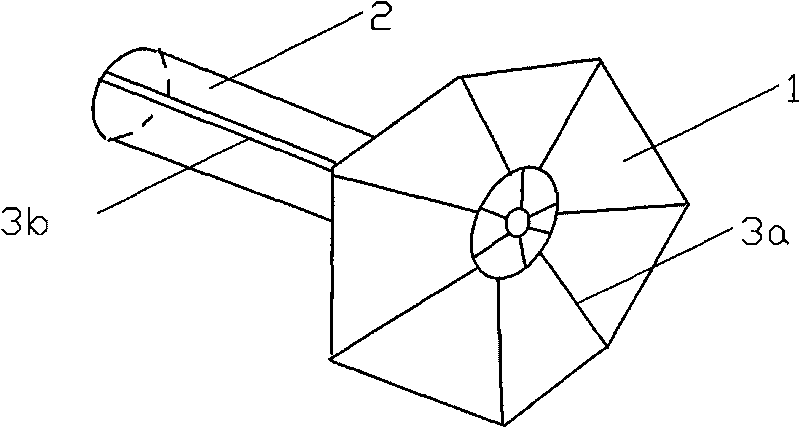

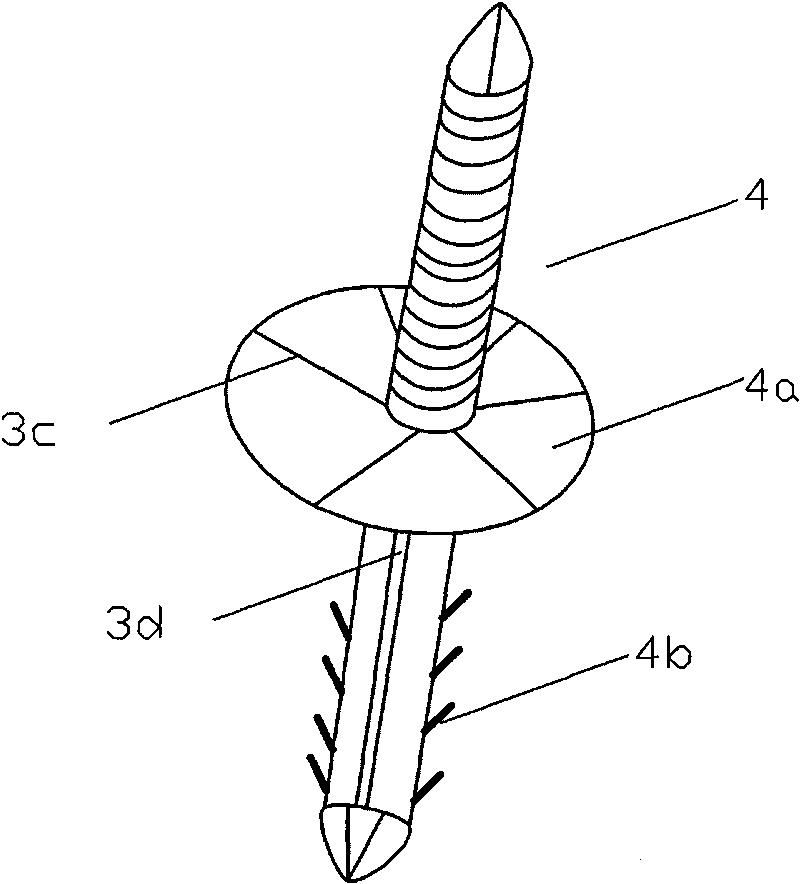

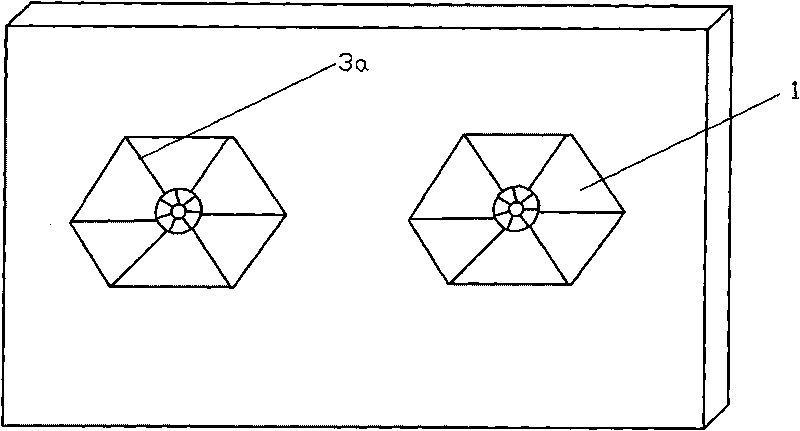

External wall heat insulation decorative board concealed anchor bolt and integral quick-mounting board for external wall heat insulation and decoration

The invention discloses an invisible anchor bolt of an external wall insulating decoration plate and an external wall insulating decoration integration packaged plate. The invisible anchor bolt comprises an inner tabletting with a column-shaped presser foot and a fastener, and the inner tabletting is embedded and inserted in a heat-insulating board, the pressure foot is an inner screw thread, one end of the fastener with an outer screw thread is connected with the pressure foot, and the outer wall of the other end is provided with a barb which is inserted in a mounting hole of the wall body, and the waist portion is provided with an outer tabletting which is vertical with the fastener, when the fastener is tightly screwed on the pressure foot, the outer tabletting is tightly clung on the surface of the packaged plate. The external wall insulating decoration integration packaged plate comprises a heated board whose inner surface is tightly clung on the wall body, and an alkali-fast break fiber web checked cloth layer and a decoration layer which are adhered on the outer surface of the plate one by one, the inner tabletting with the pressure foot are embedded into the heated board, and the surface of the pressure foot and the inner tabletting are all fell into the heated board, and the pressure foot is provided with an inner screw thread which is connected with the fastener. The invention has the advantages of simple structure, beauty and firmness, convenient transporting, and fast assemblage, which achieves a possibility of the industrialized production of external wall insulating decoration packaged plate.

Owner:合肥乐千年涂料有限公司

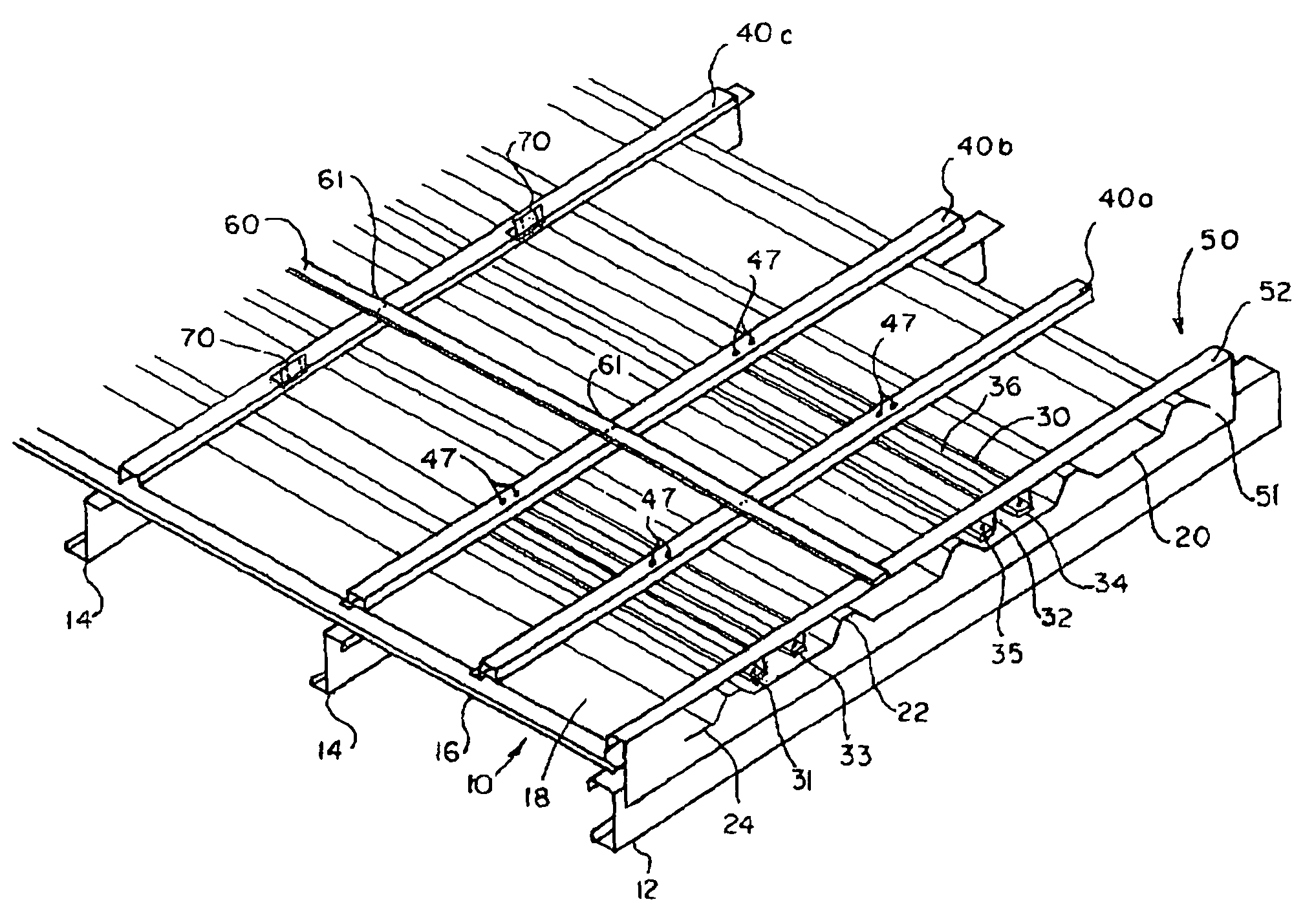

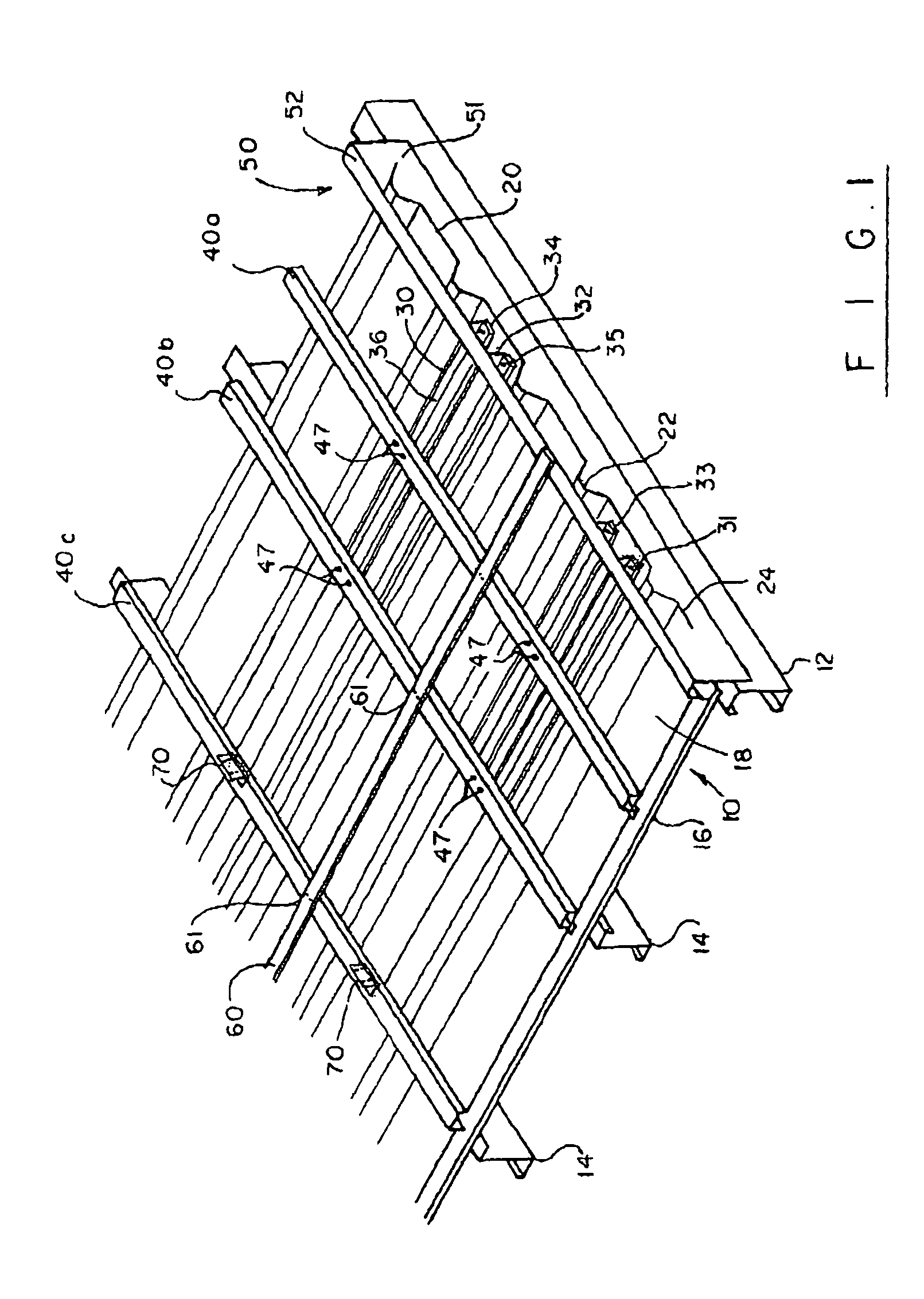

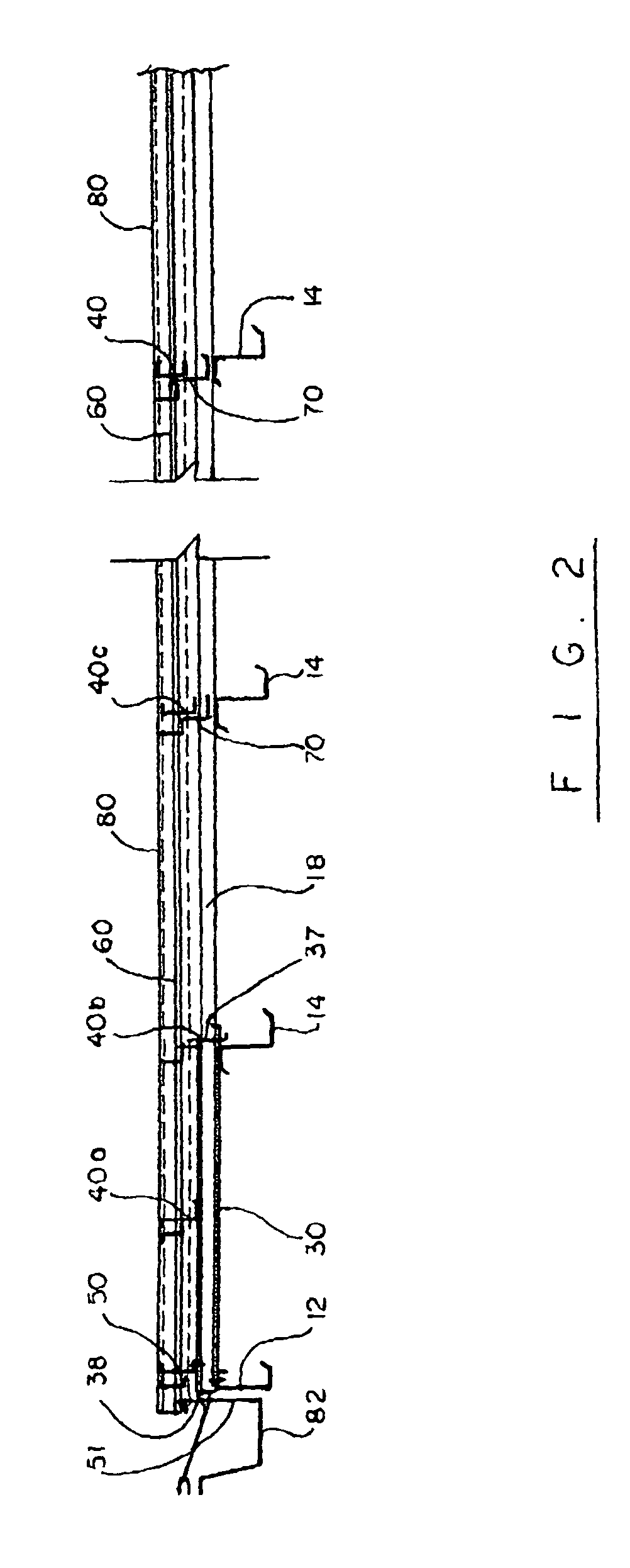

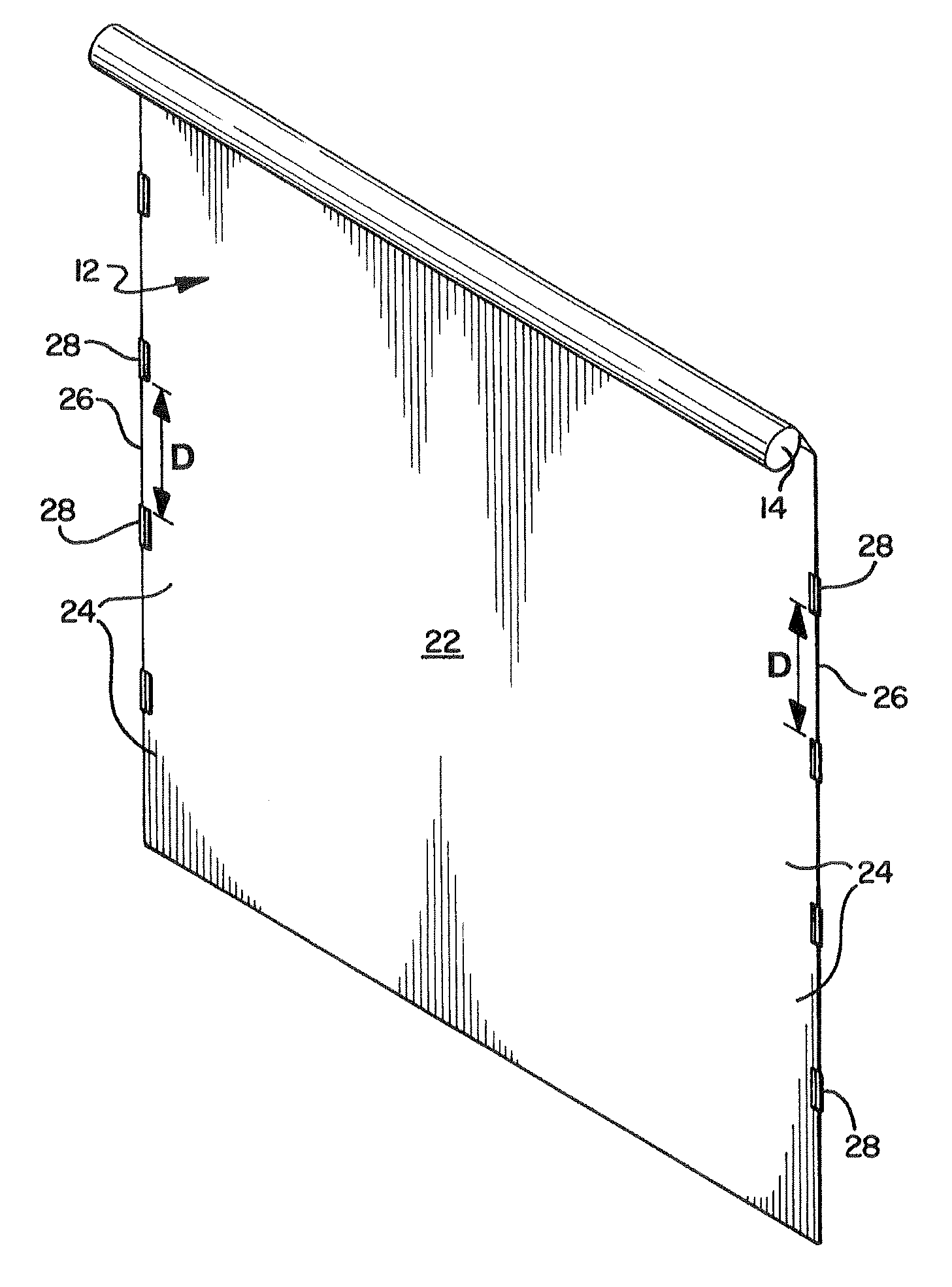

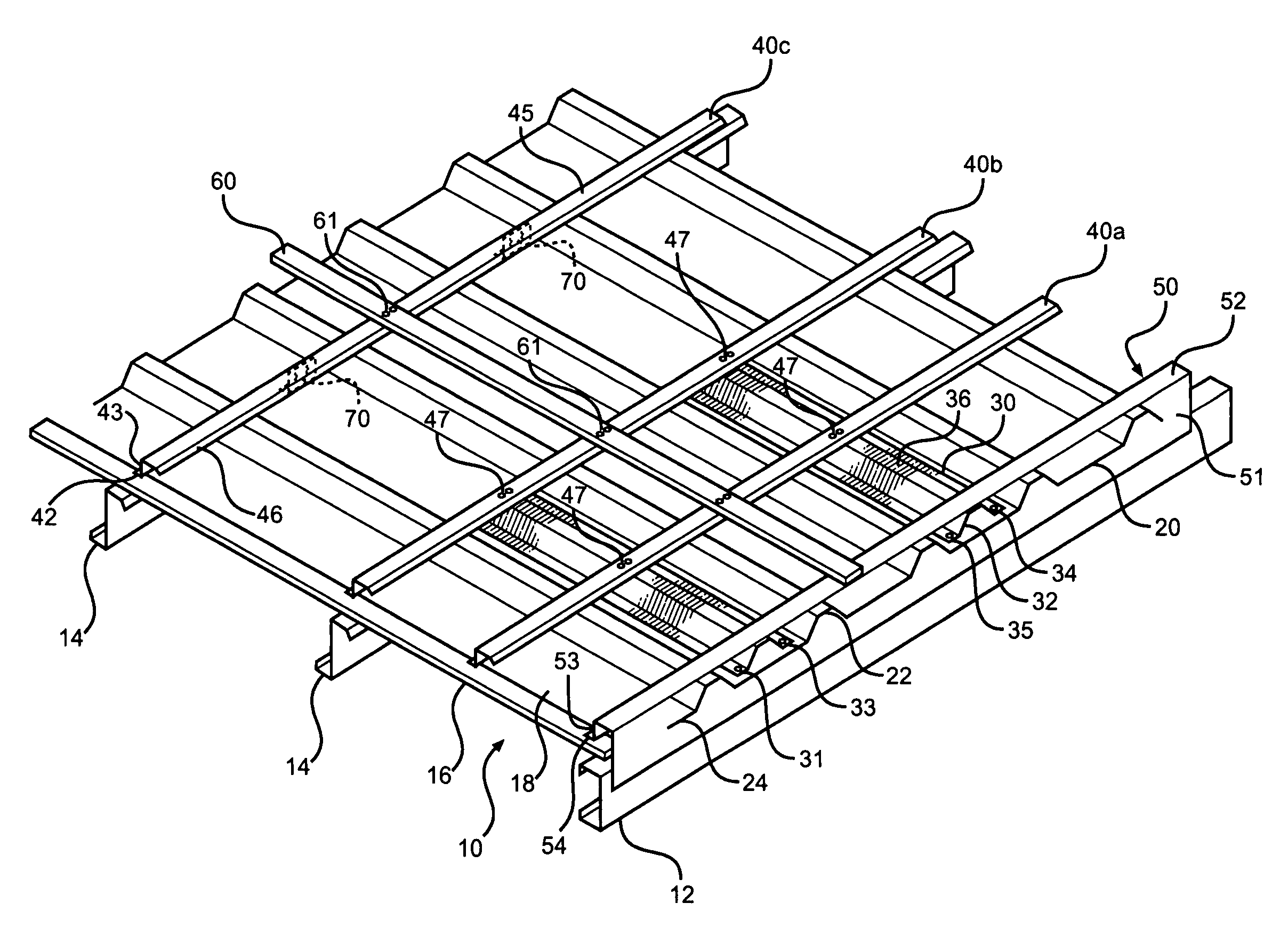

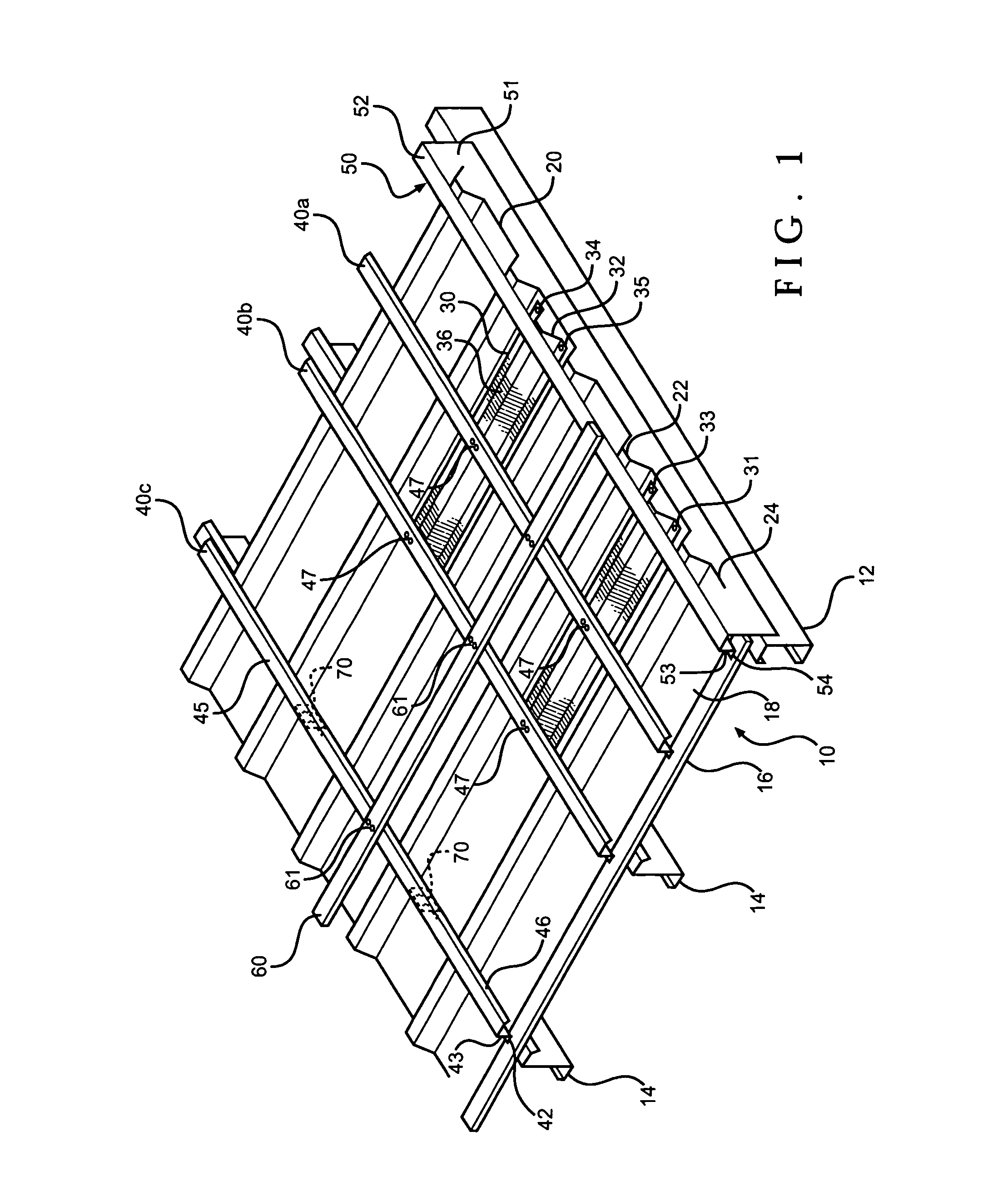

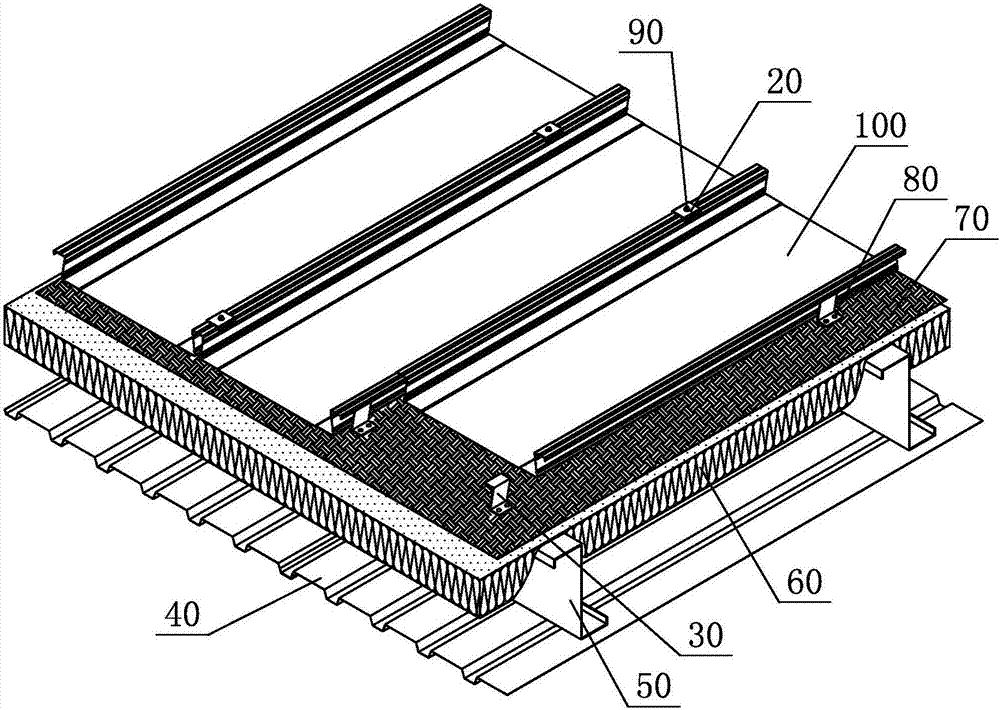

Retrofit framing system for metal roof

ActiveUS8061087B2Improve wind resistanceIncrease the number ofRoof covering using slabs/sheetsBuilding roofsEngineeringMechanical engineering

A support assembly for supporting a retrofit roof to be installed above an existing roof made of preformed panels. Elongated support assembly members are positioned along the roof line to provide additional points of attachment for the new roof, while at the same time forming a substantially even plane for new rood panels. Some of the support members fit in the channels between the ridges of the preformed panels, which can be R-panels or standing seam panels. Transverse top members secure the channel-mounted members in place, while strapping members positioned atop the top members form additional lateral support for the new roof.

Owner:RAY GINO

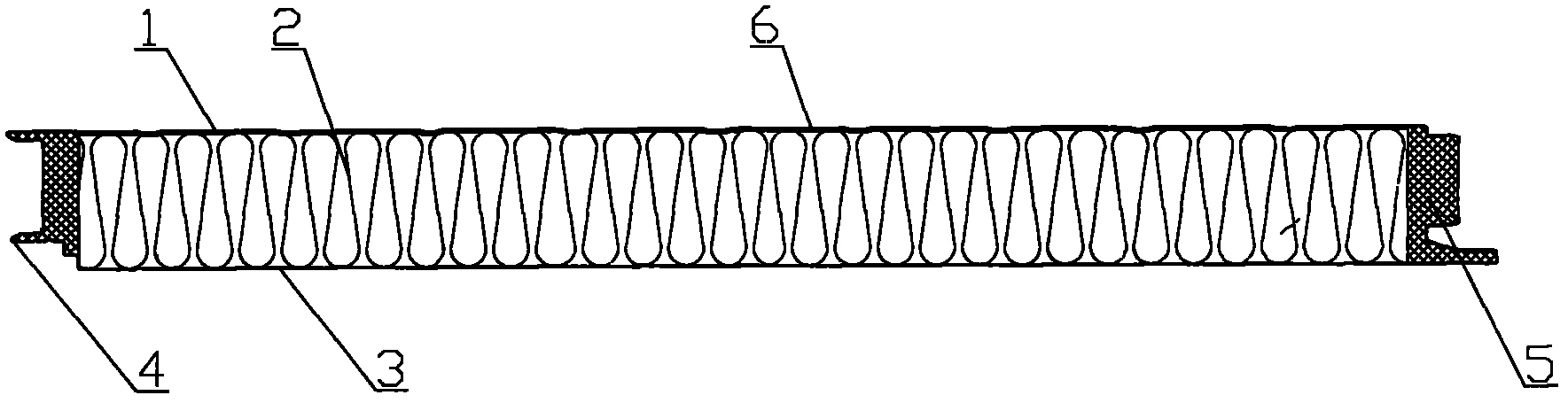

Compound sound insulation-absorption barrier board

ActiveCN101982613AGood hydrophobicityAvoid CapillarityNoise reduction constructionMicrometerAverage diameter

The invention discloses a compound sound insulation-absorption barrier board, comprising a front panel, a rear panel and a core material fixed between the front panel and the rear panel in a bonding manner, wherein, the core material is arranged in a strip shape, and the fiber direction of the core material is vertical to the front panel and the rear panel; multi-tongue rabbets are arranged at the two sides of the compound sound insulation-absorption barrier board at the joint of the front panel and the rear panel and can be spliced mutually; the front panel is a perforating panel; micropores are distributed on the perforating panel, wherein, the perforated rate of the micropores is more than 3% to 30%; the porosity of the core material is 97-98.4%; the average diameter of the fiber is 5-6 micrometers; the fiber length is 150-200 micrometers; and the noise enters into the core material through the micropores and is absorbed along the fiber direction of the core material. The compound sound insulation-absorption barrier board disclosed in the invention has the advantages of absorbing the noise in the environment, simultaneously insulating the noise, and avoiding the influence of the noise to the surrounding environment.

Owner:CENT INT GROUP

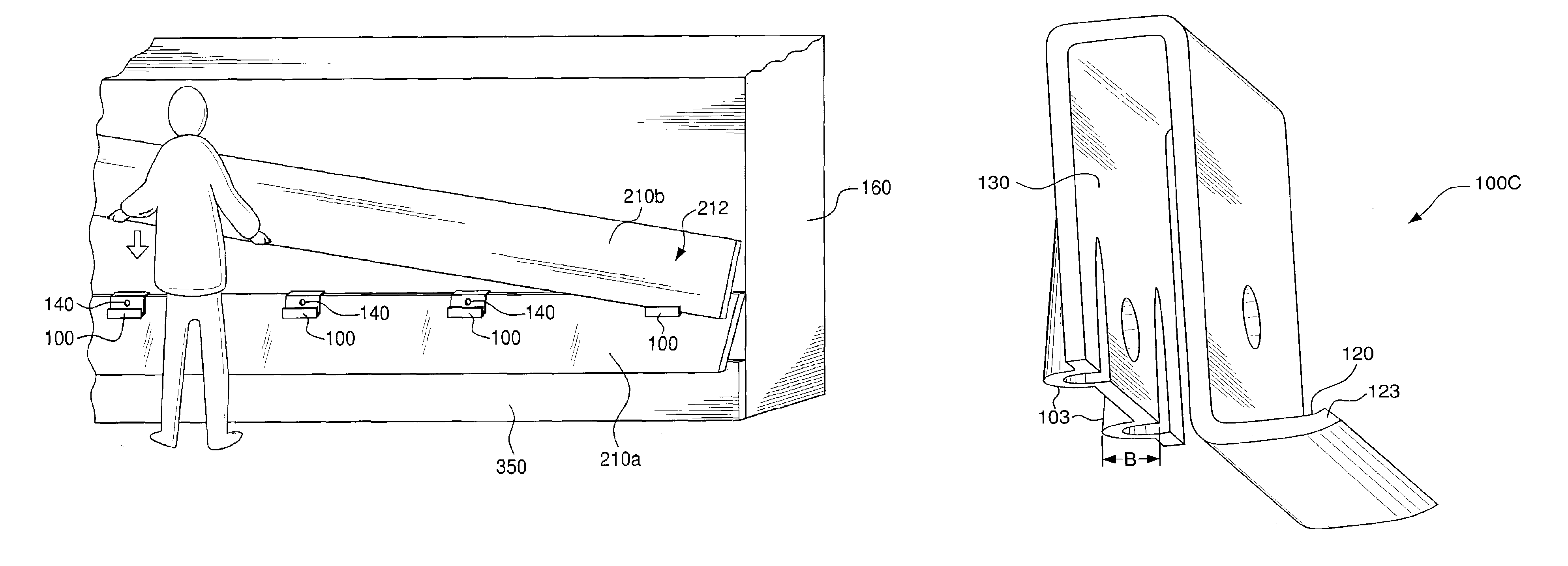

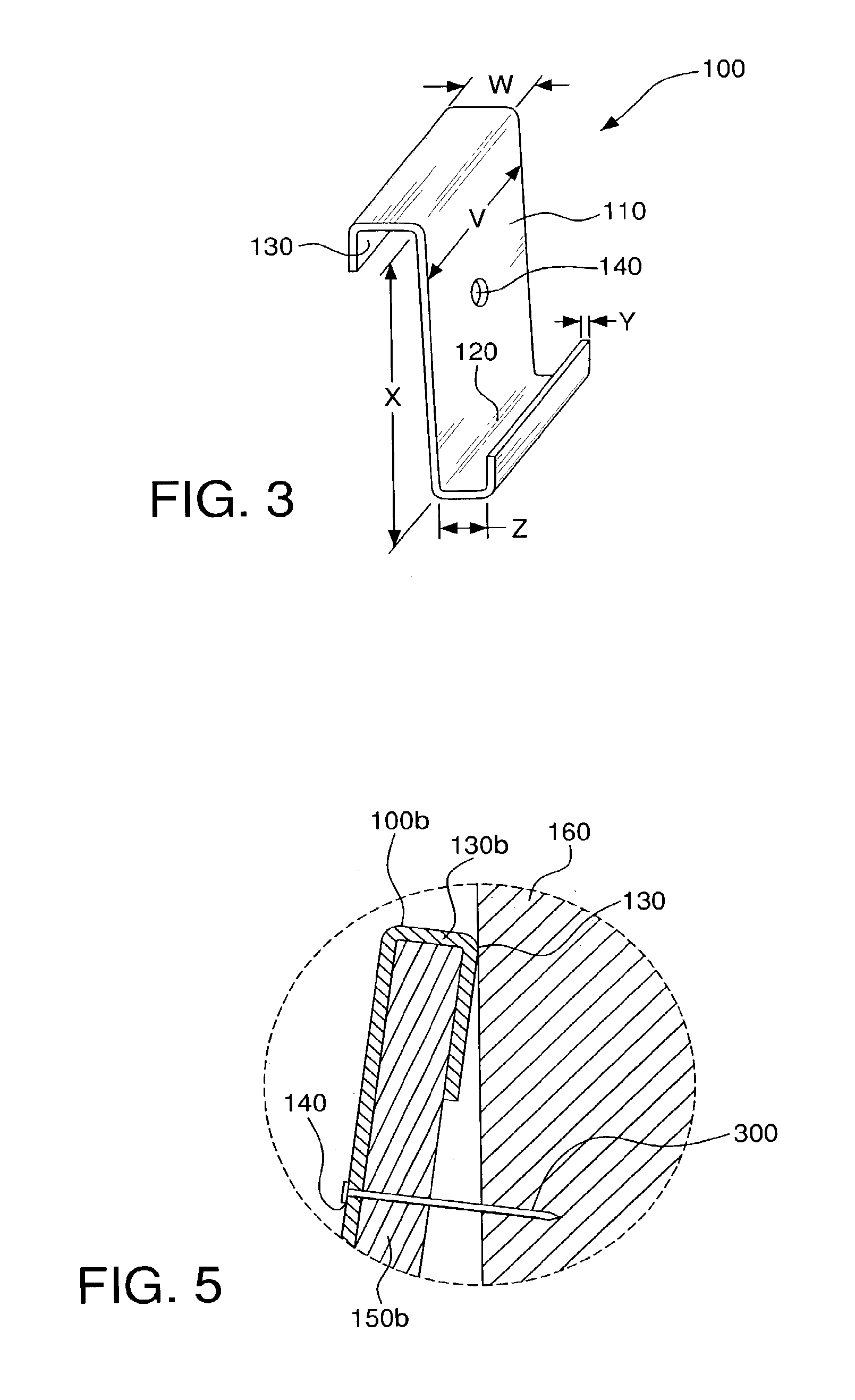

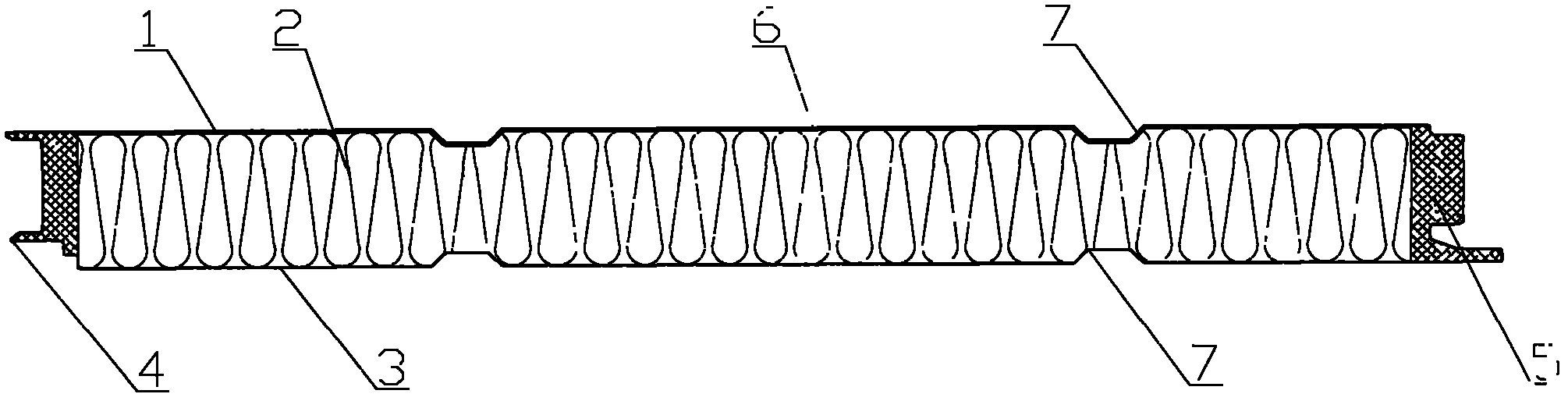

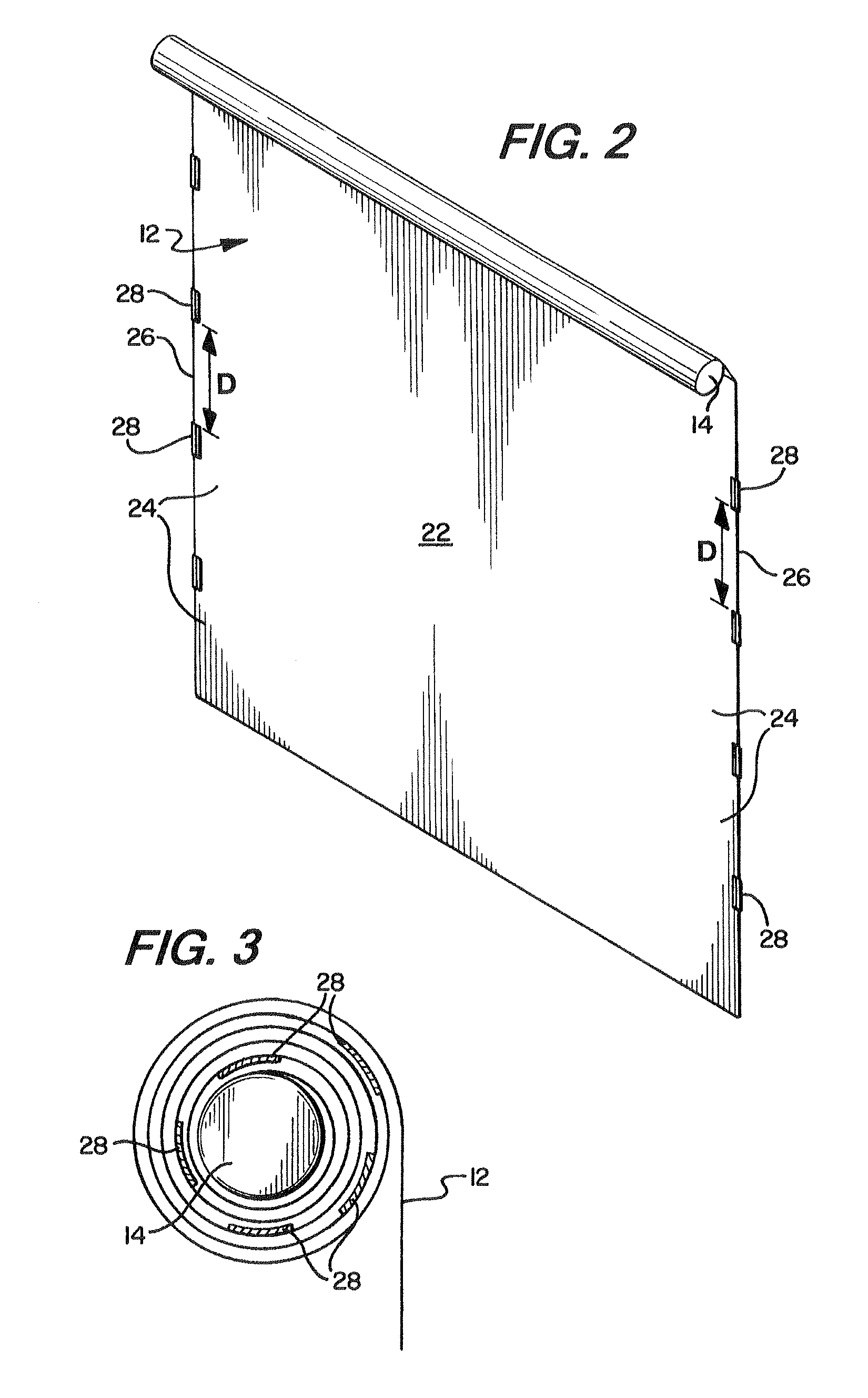

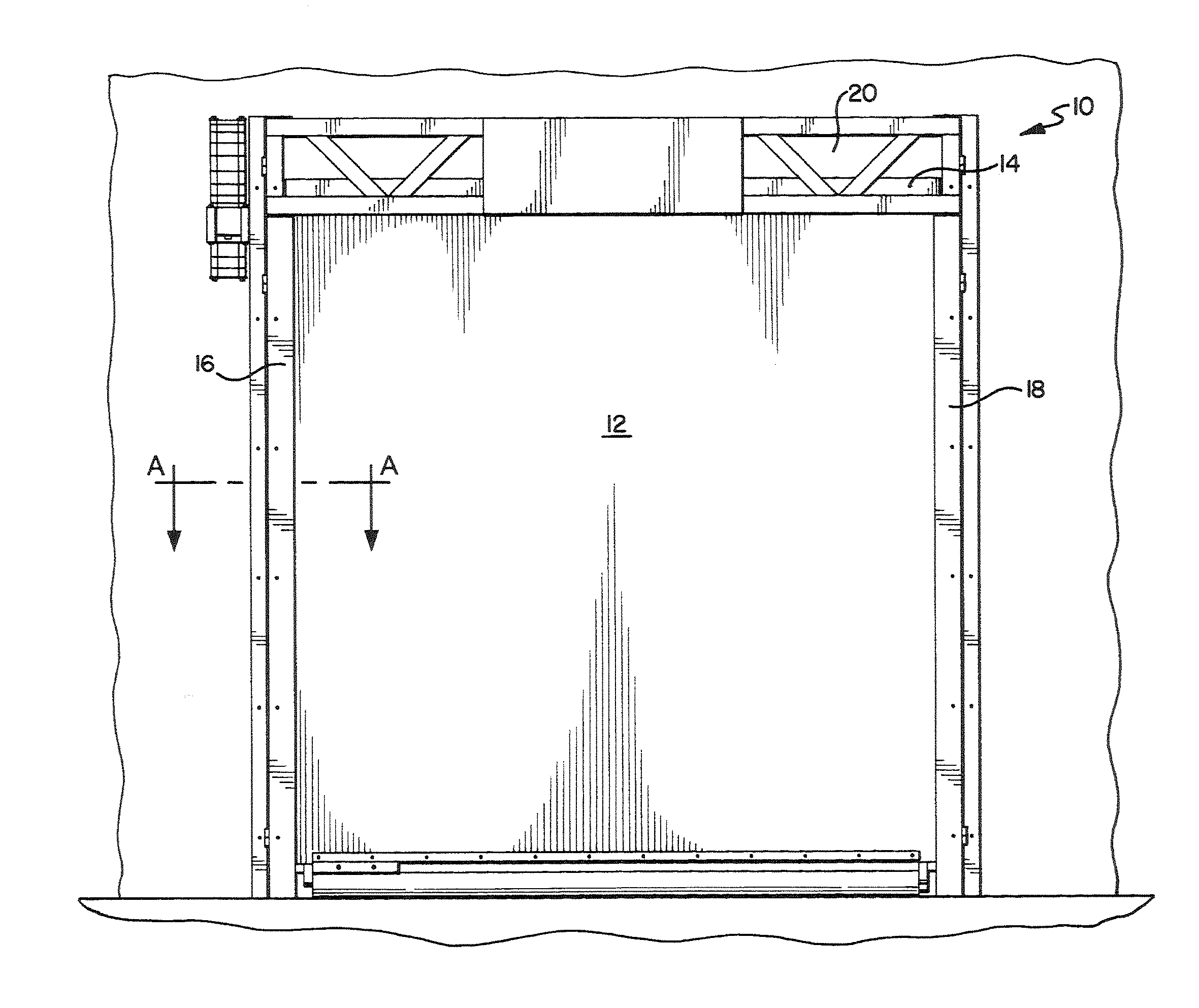

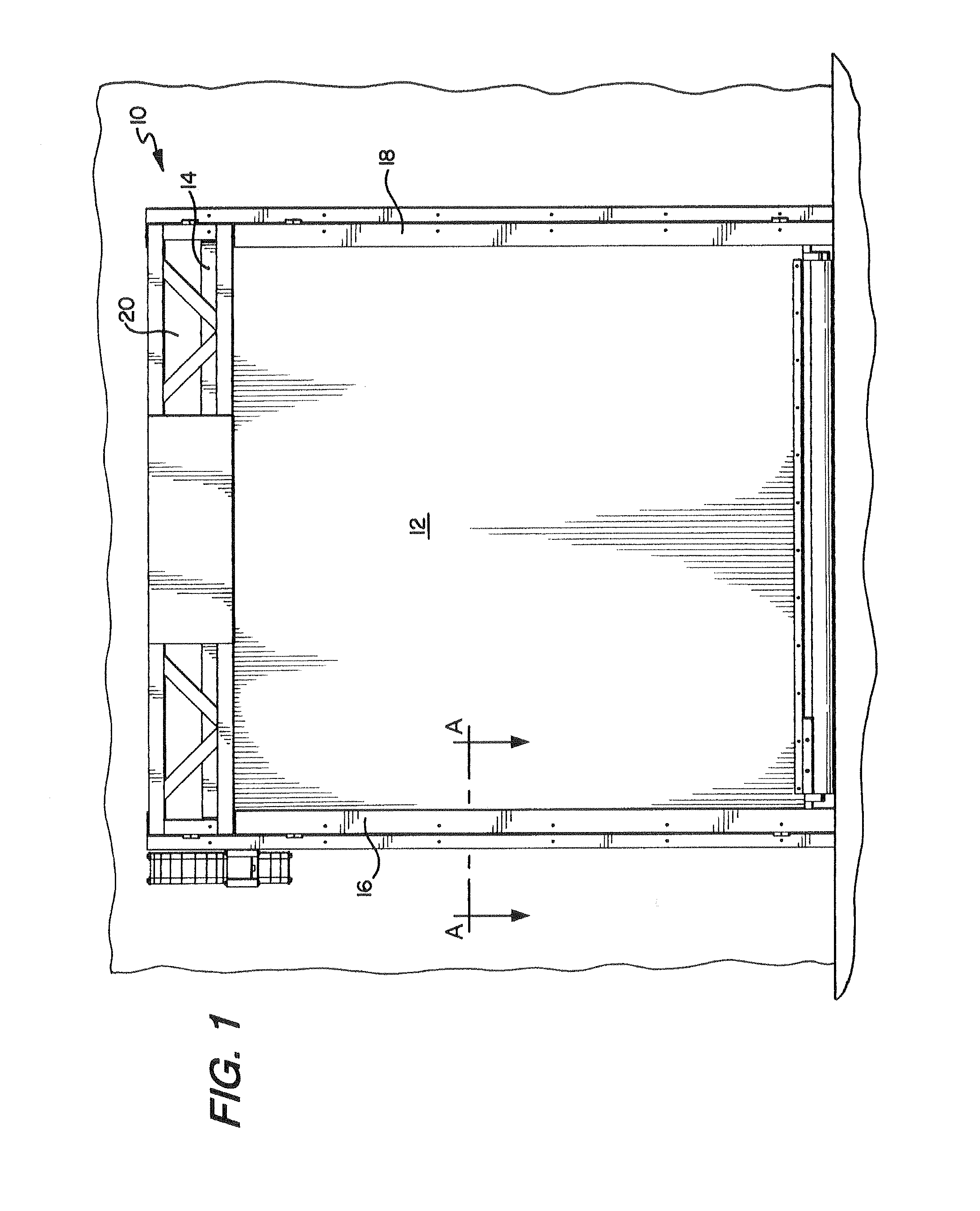

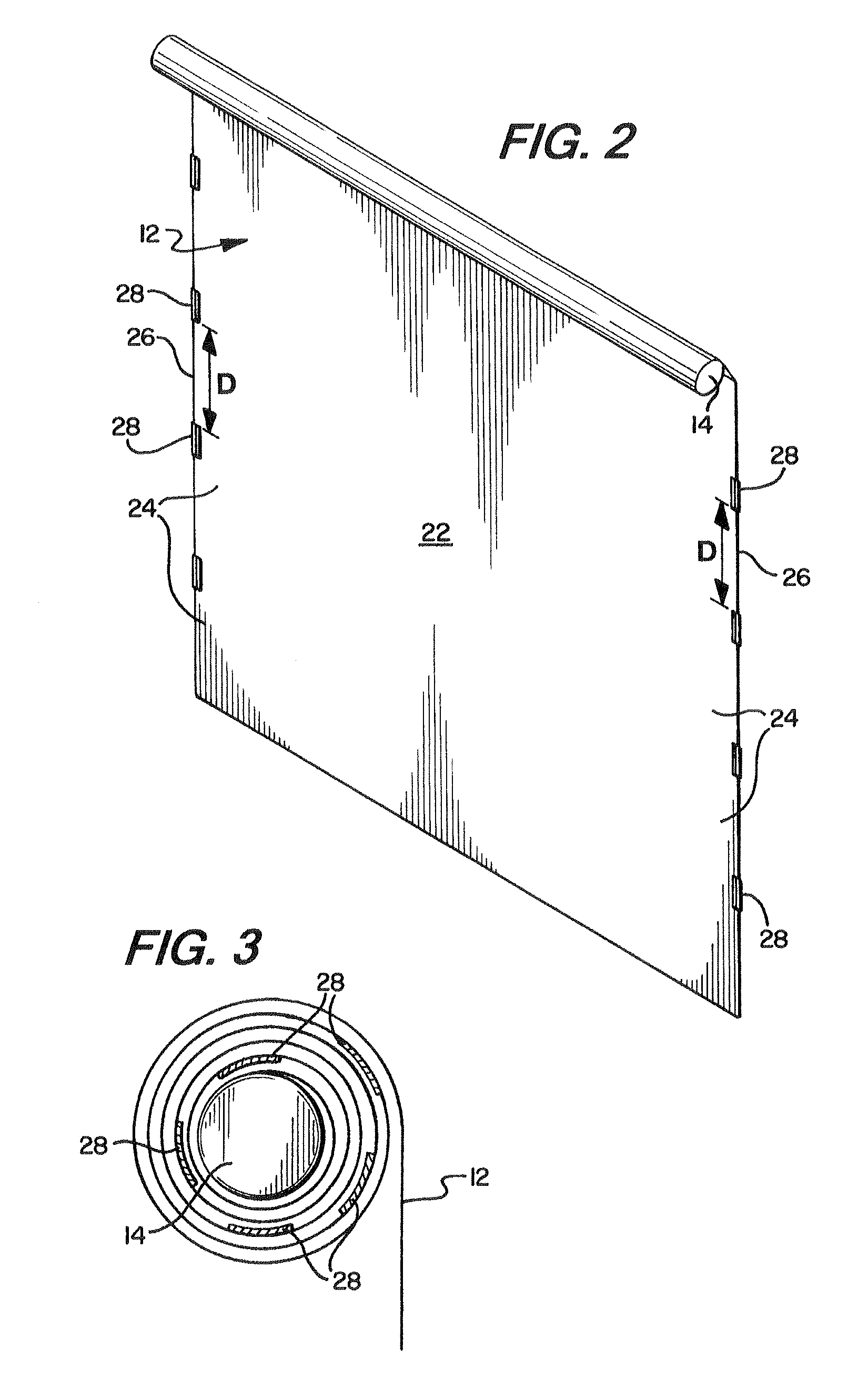

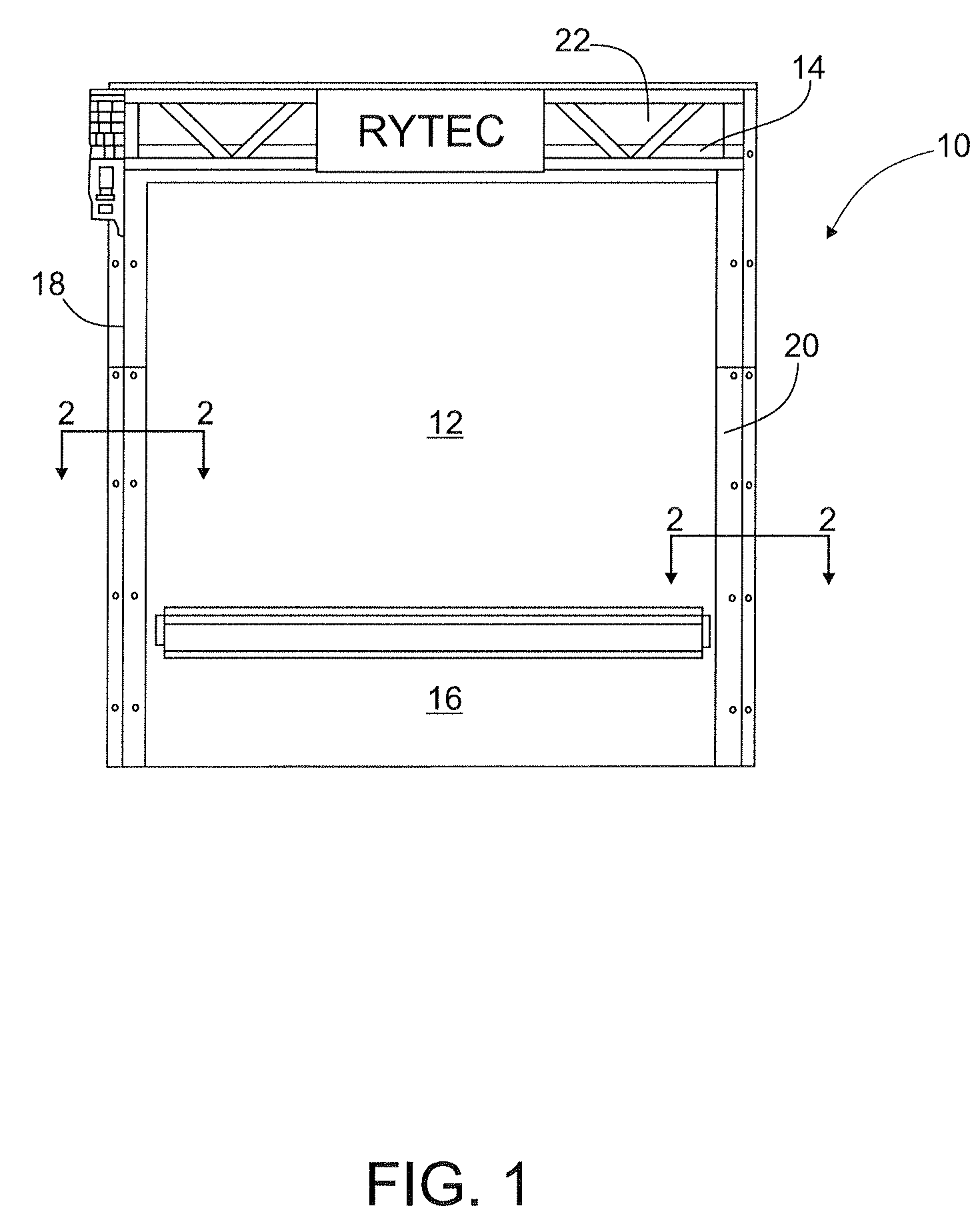

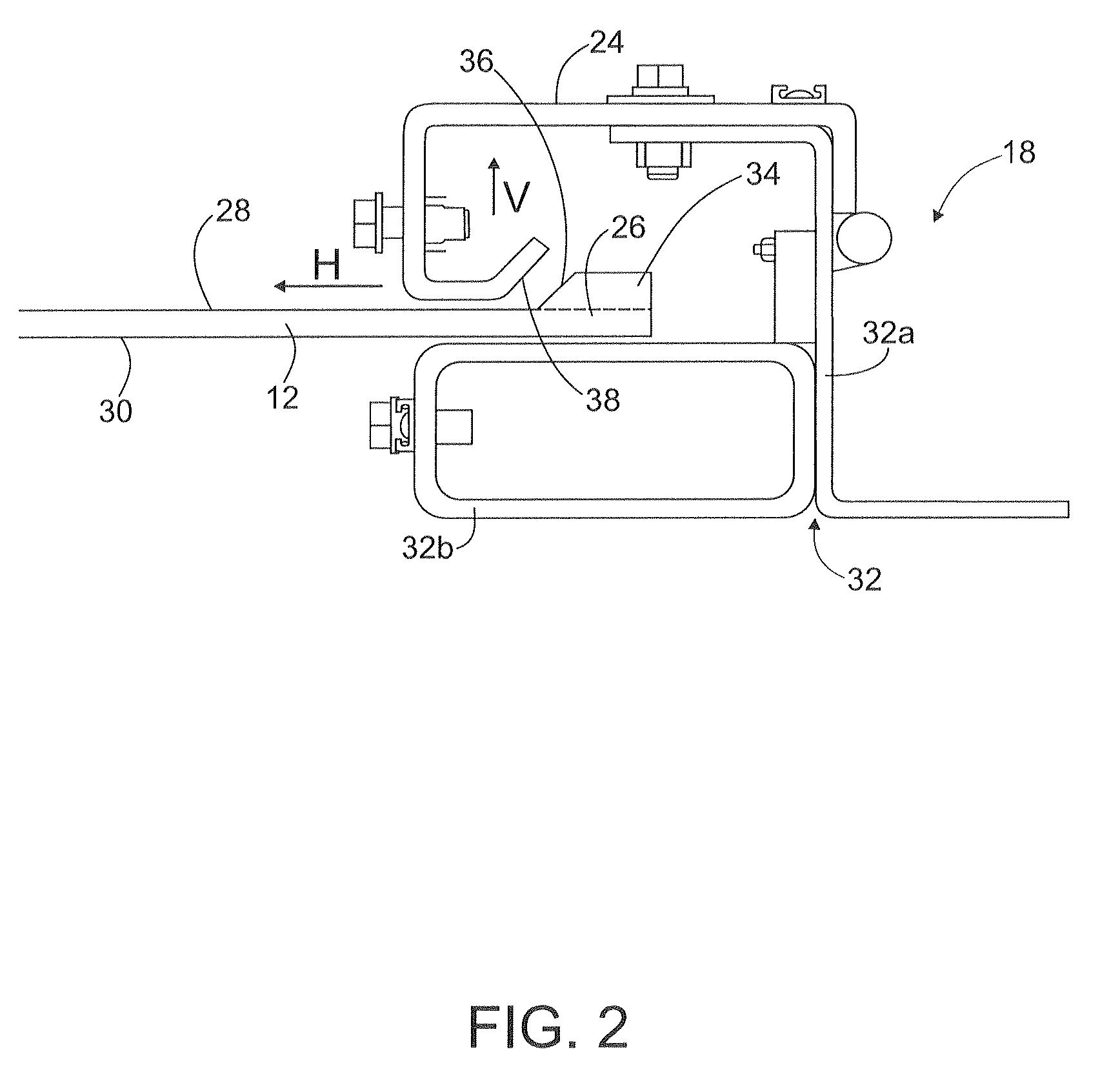

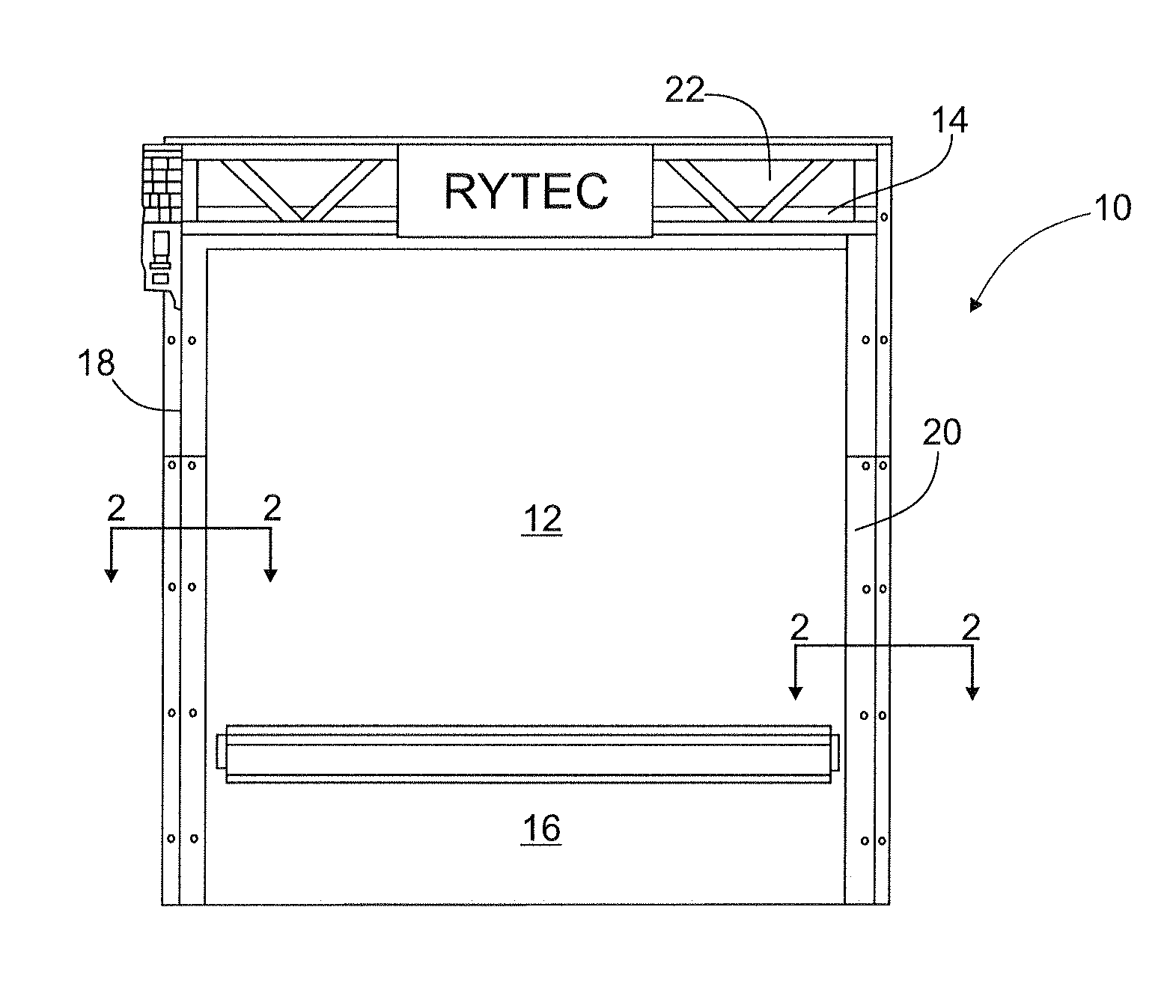

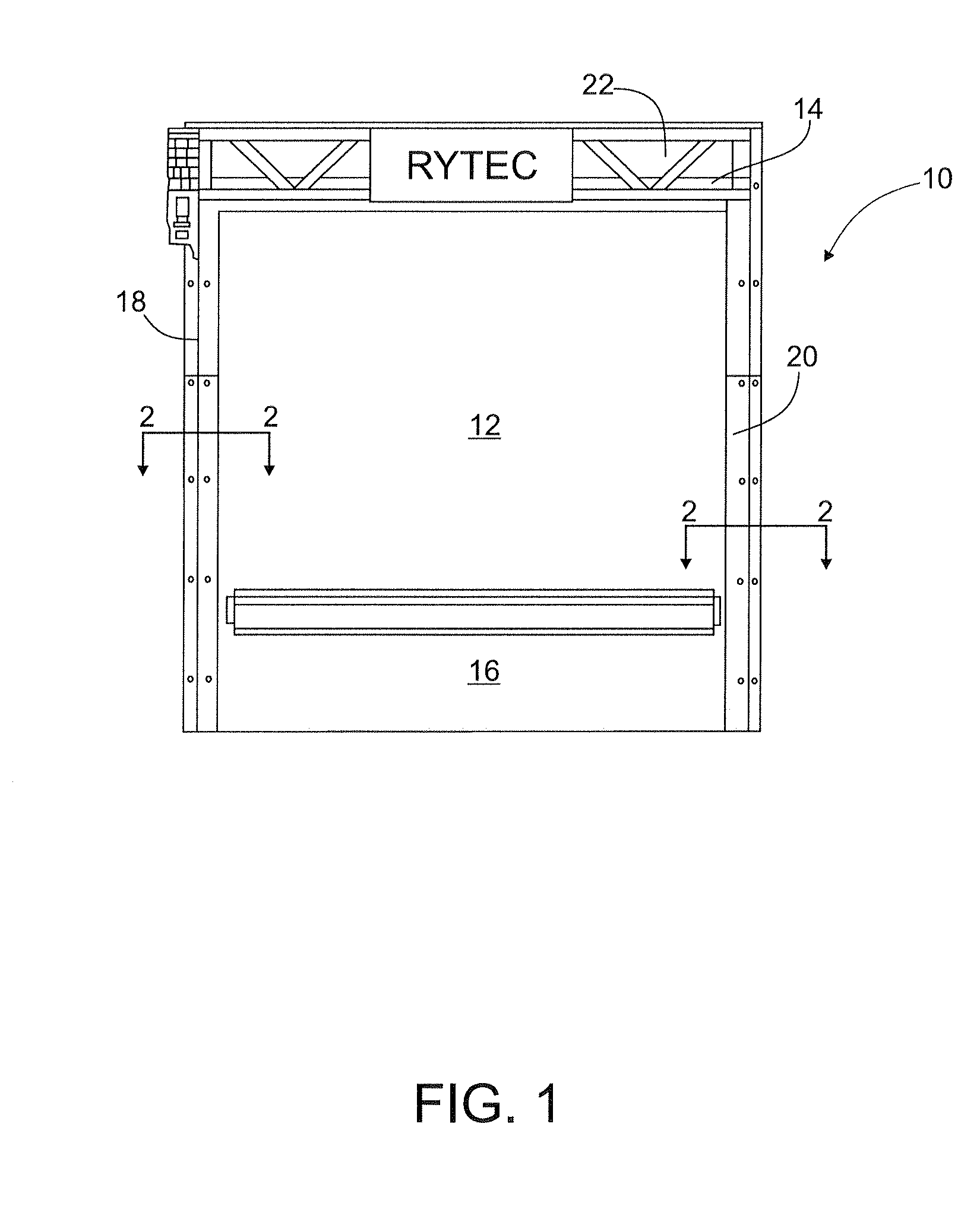

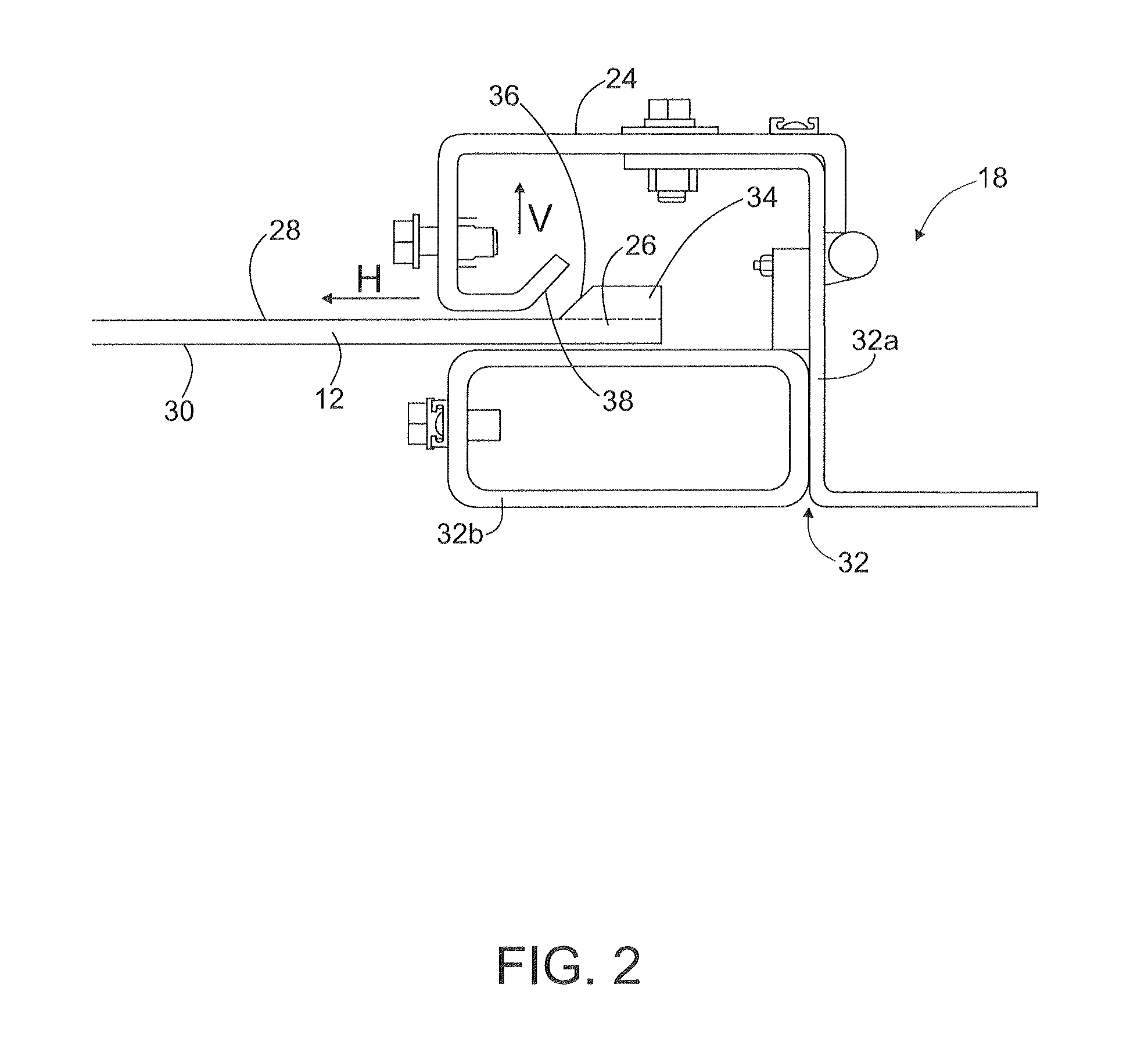

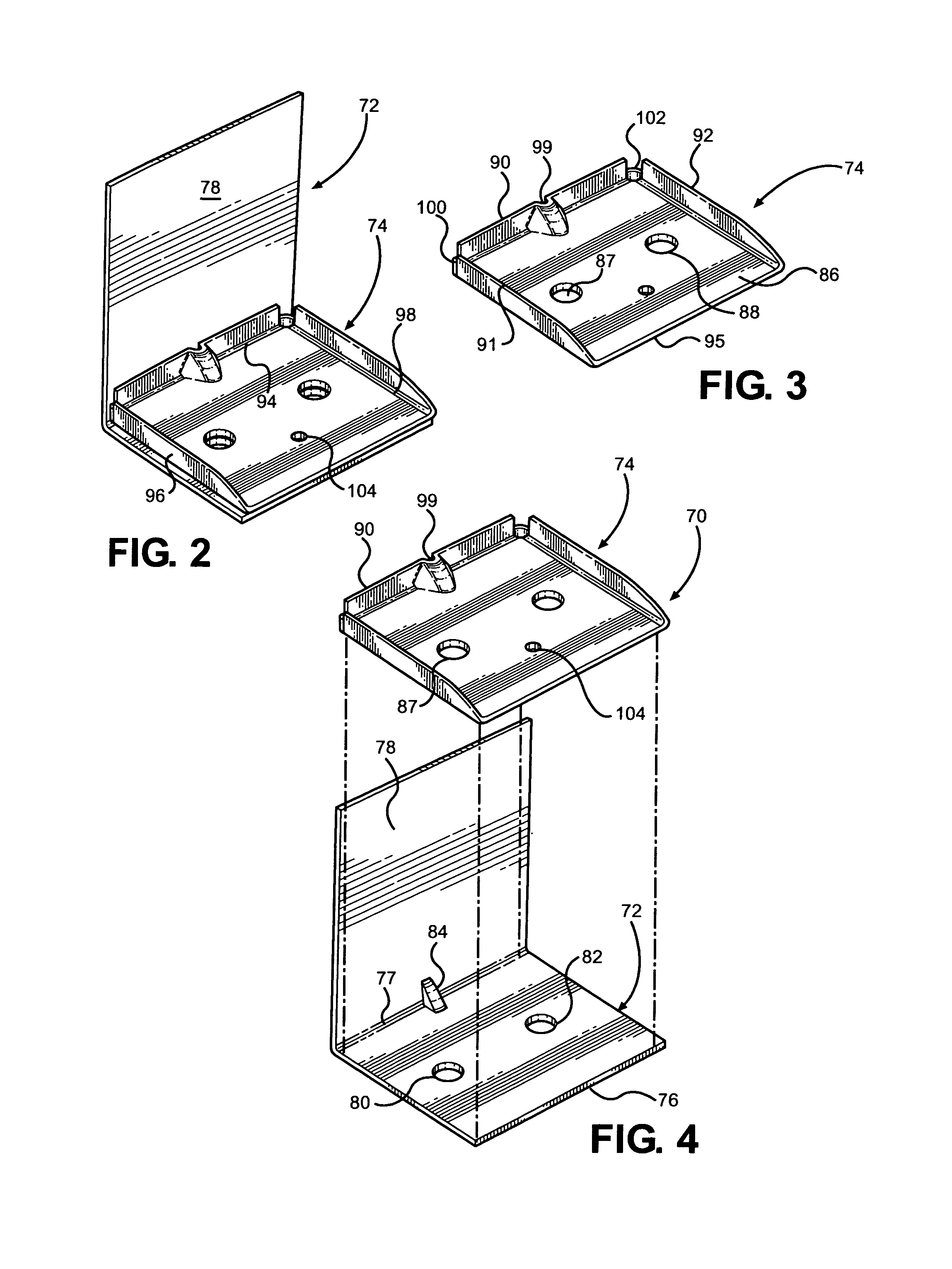

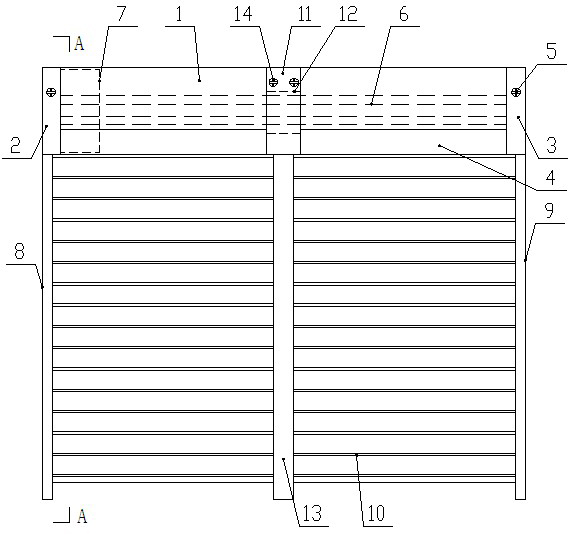

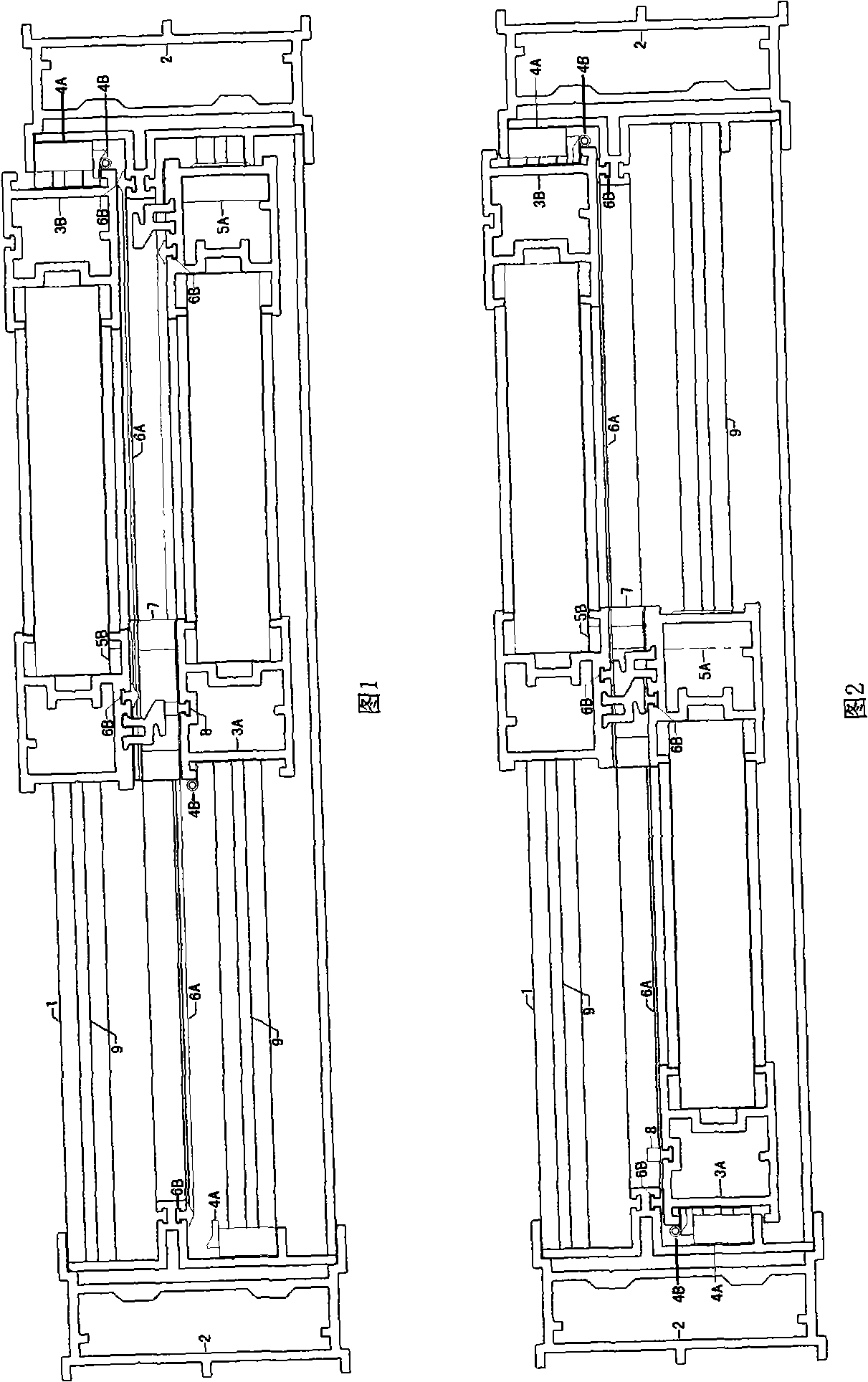

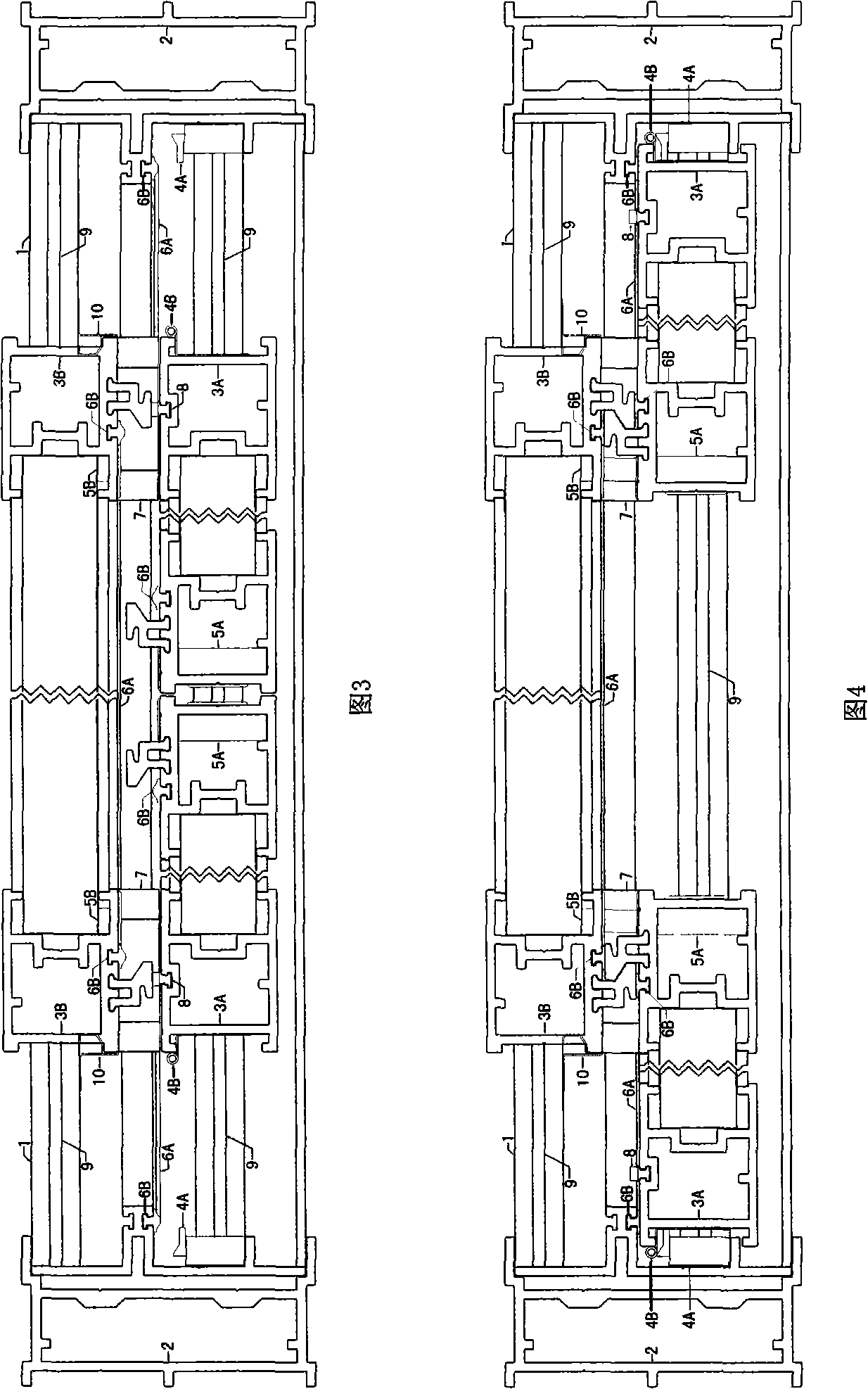

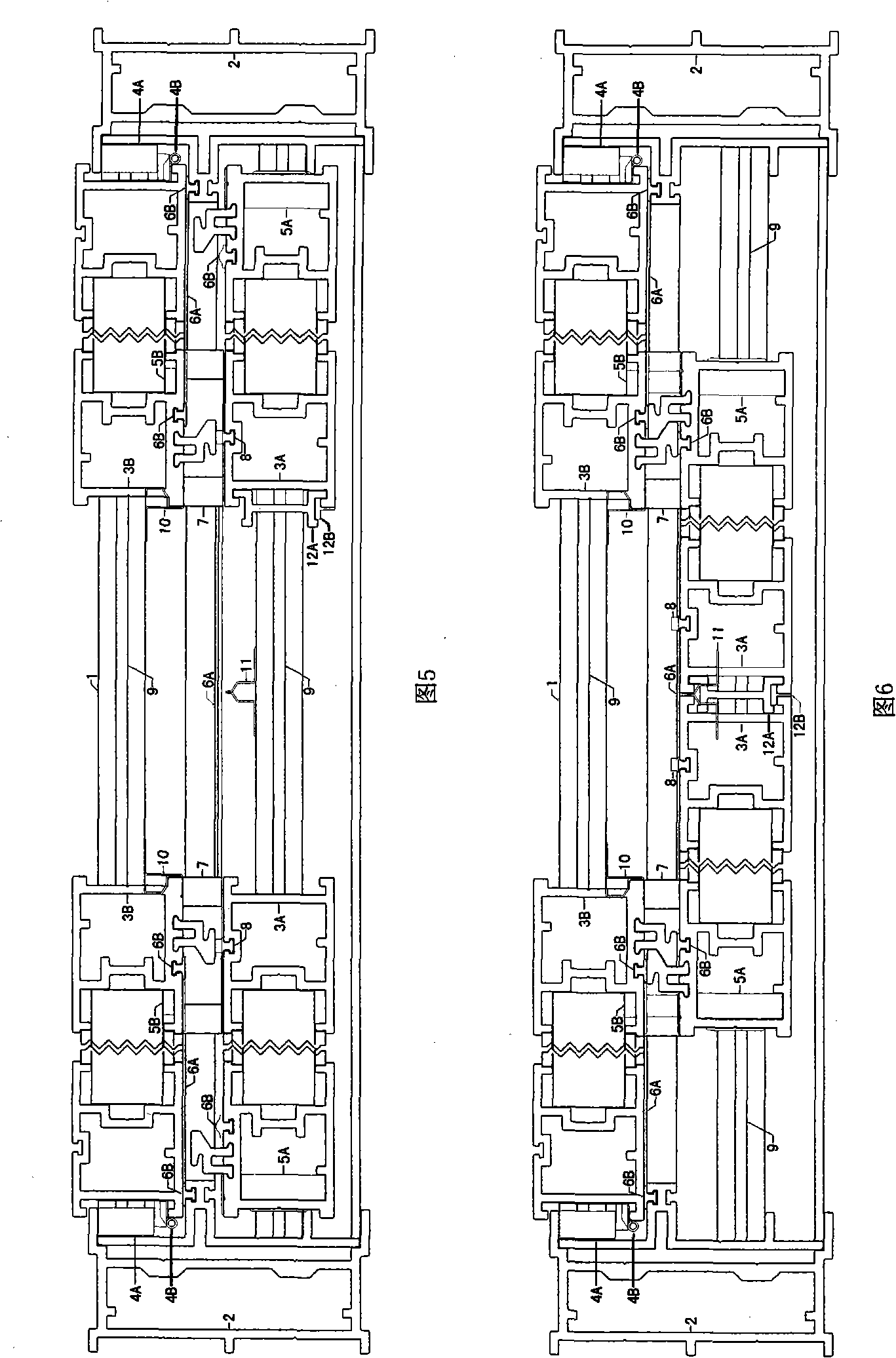

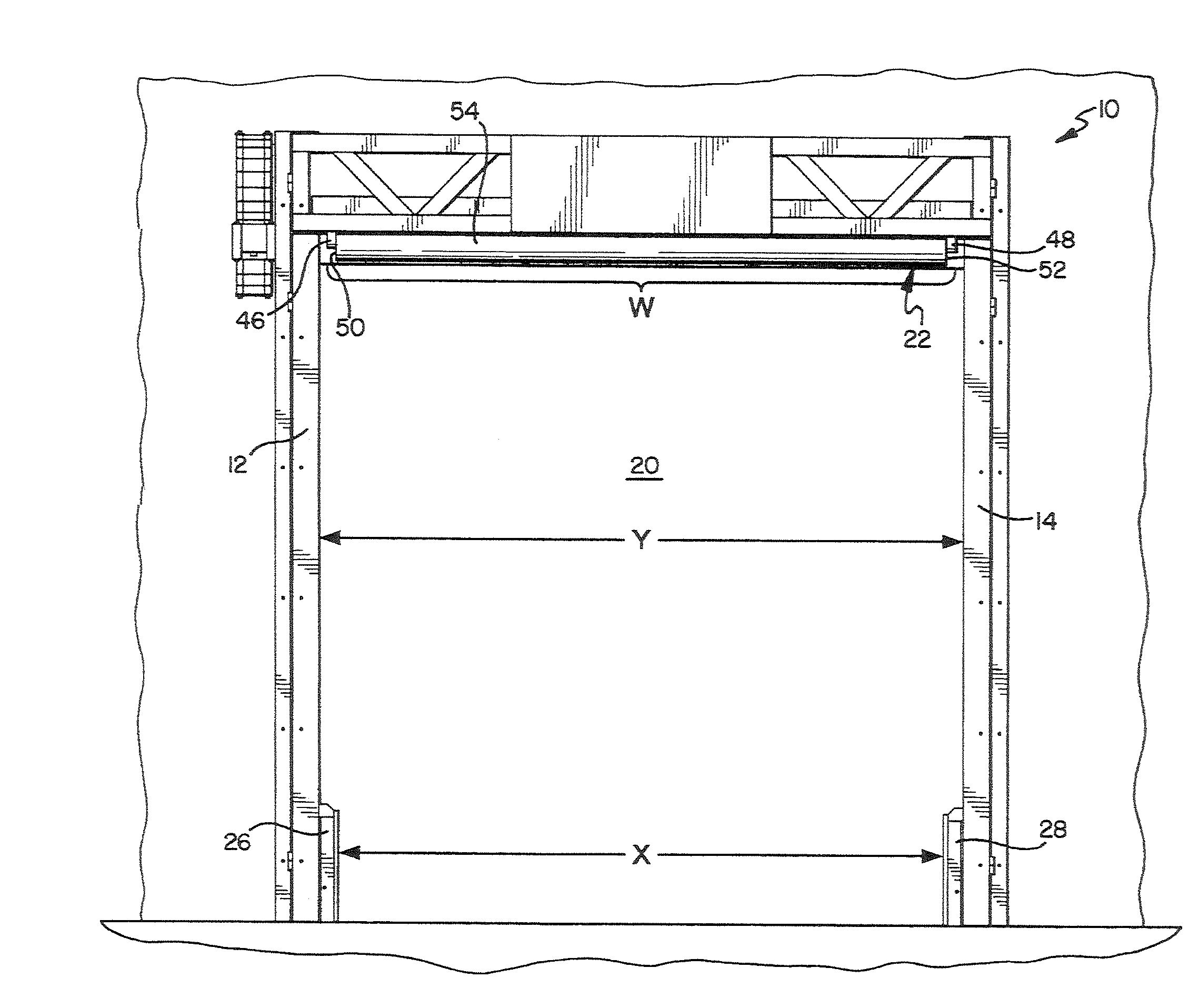

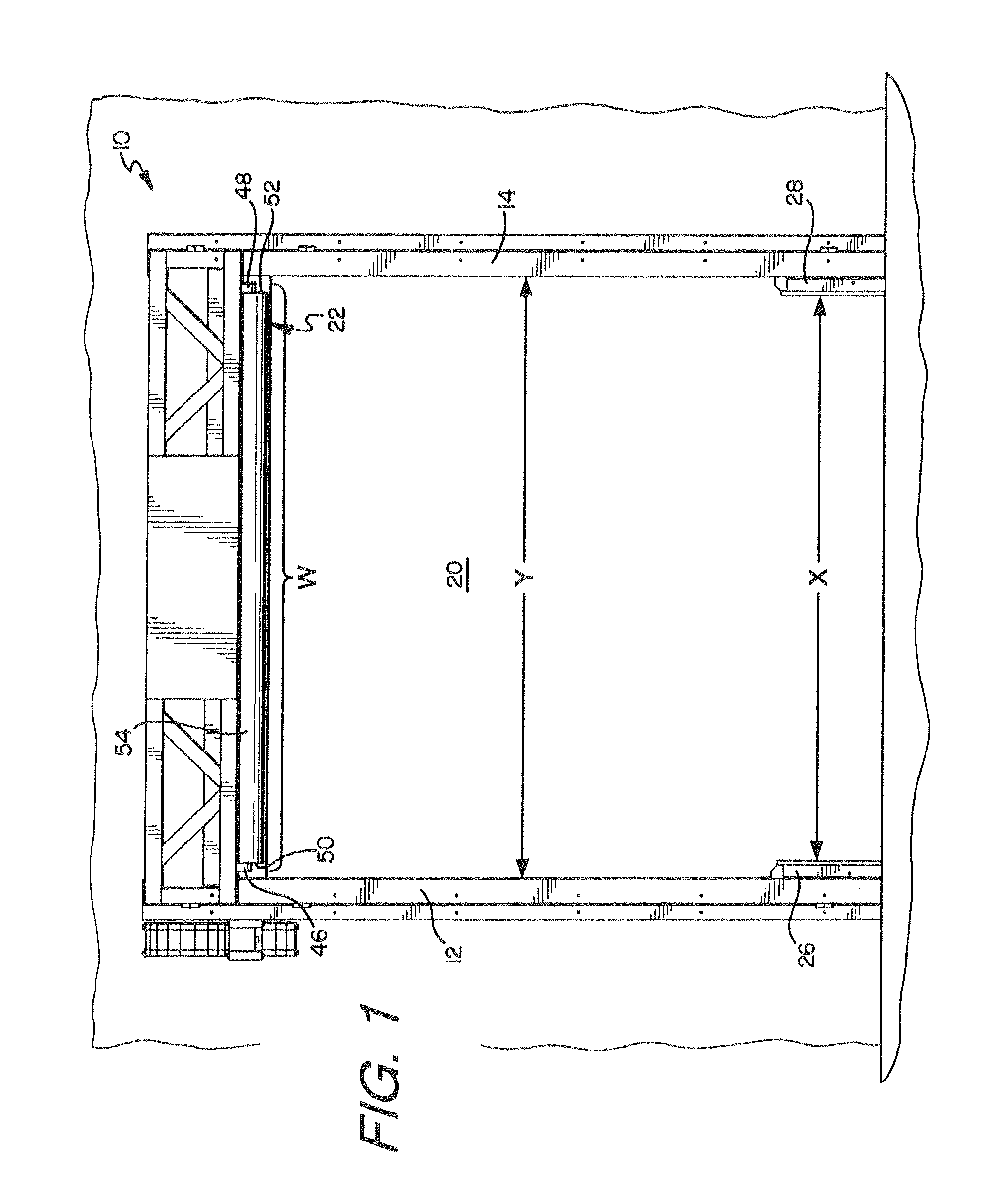

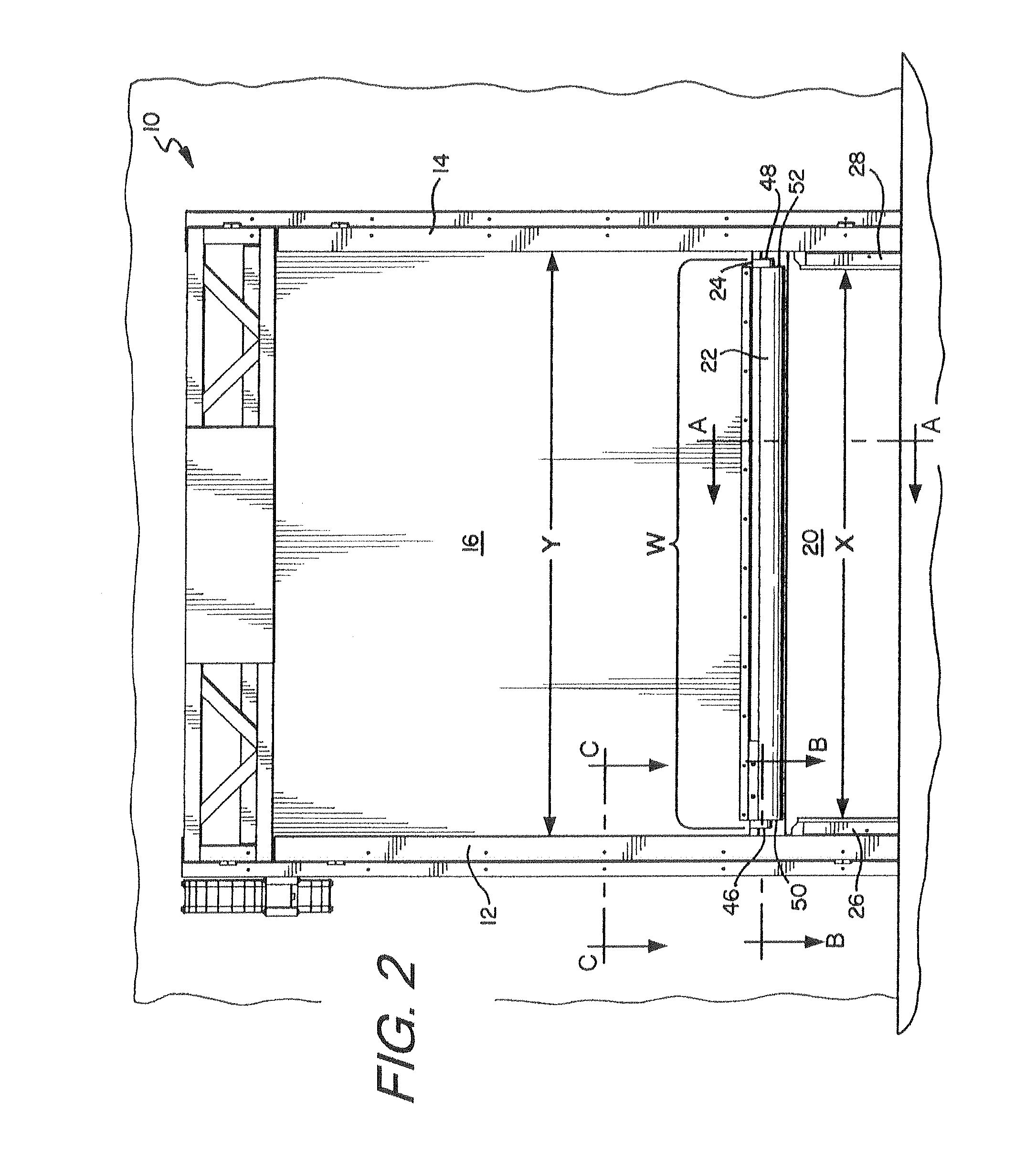

Segmented wind lock configuration for overhead roll-up doors and method of constructing the same

ActiveUS8851147B2Improve wind pressure resistanceIncreasing the thicknessScreensShutters/ movable grillesEngineeringMechanical engineering

An overhead roll-up door assembly for a vertically moving door to permit and prohibit access to an opening, the door assembly having a door panel with two faces and opposing marginal and lateral edges, and at least two wind locks attached proximate each marginal edge. The at least two wind locks extend away from one face of the door panel in a direction substantially perpendicular thereto, and are spaced apart vertically along each respective side edge of the door panel. The assembly further includes a drum for winding and unwinding the door panel to permit and prohibit access to the opening, and, a pair of opposing parallel side columns aligned and spaced apart such that each of the opposing side edges engage one of the side columns in a manner in which at least a portion of the side columns guide vertical movement of the door panel.

Owner:RYTEC CORP

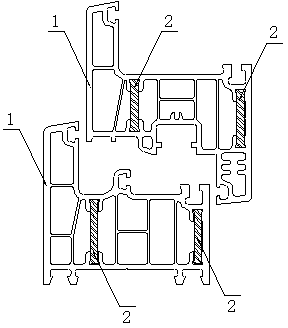

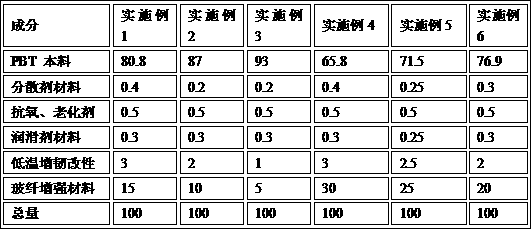

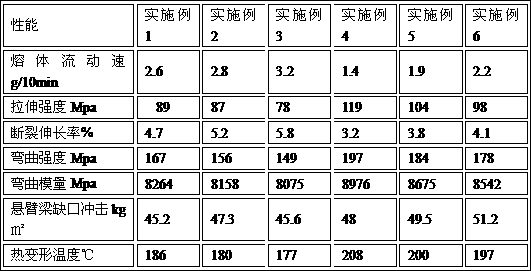

Preparation method for PVC (Polyvinyl Chloride)/modified PBT (Polybutylece Terephthalate) lining material composite section

ActiveCN103075071AMaintain fatigue resistanceSmall creepWindow/door framesWing framesGlass fiberPolymer science

The invention discloses a PVC (Polyvinyl Chloride) / modified PBT (Polybutylece Terephthalate) lining material composite section and a preparation method. The PVC / modified PBT lining material composite section is characterized in that PBT is reinforced and modified, is extruded with a PVC section in a cavity together and is compositely formed to substitute a reinforced section. Compounding with the PVC section can be realized through a co-extrusion process, so that mounting steps of a metal lining are simplified, the effect is improved, and the production cost is greatly reduced. A modified material comprises the following components in parts by weight: 75-84 parts of PBT resin, 15-30 parts of glass fiber reinforcing agent, 0.1-0.3 part of lubricating agent, 1.0-1.4 parts of dispersant, 0.5-1 part of processing flow modifier (AMS), 0.5-0.7 part of anti-aging agent and 1-3 parts of low-temperature modified toughening agent.

Owner:HARBIN ZHONGDA PROFILE TECH

Polyphenyl board composite thermal insulative wall and constructing process

InactiveCN1584236AImprove stabilityImprove insulation effectHeat proofingInsulation layerMechanical engineering

The present invention relates to a polypenyl plate composite heat-insulating wall body and its construction process. Said wall body has base layer wall body, boundary surface mortar layer, adhesive coating, polyphenyl plate, anticrack mortar layer and finishing coat from interior to exterior successively. Its polyphenyl plate is adhered and fixed on the base layer wall body by means of heat-insulating mortar, on the polyphenyl plate there are some air-permeable plug-holes, if necessary, the polyphenyl plate can be strengthened and fixed by using plastic expanding anchor, and according to the requirements it can be leveled by using heat-insulating mortar. Said invention can raise heat-insulating effect and construction speed.

Owner:黄振利

Segmented wind lock configuration for overhead roll-up doors and method of constructing the same

ActiveUS20120241110A1Improve wind pressure resistanceIncreasing the thicknessScreensShutters/ movable grillesEngineeringMechanical engineering

An overhead roll-up door assembly for a vertically moving door to permit and prohibit access to an opening, the door assembly having a door panel with two faces and opposing marginal and lateral edges, and at least two wind locks attached proximate each marginal edge. The at least two wind locks extend away from one face of the door panel in a direction substantially perpendicular thereto, and are spaced apart vertically along each respective side edge of the door panel. The assembly further includes a drum for winding and unwinding the door panel to permit and prohibit access to the opening, and, a pair of opposing parallel side columns aligned and spaced apart such that each of the opposing side edges engage one of the side columns in a manner in which at least a portion of the side columns guide vertical movement of the door panel.

Owner:RYTEC CORP

High weather resistance PVC profile for doors and windows and production technology

The invention discloses a high weather resistance PVC profile for doors and windows. The PVC profile is prepared from, by weight, 420 parts of PVC resin, 13-14 parts of ACR processing aids, 25 parts of stabilizer, 50-55 parts of chlorinated polyethylene, 32 parts of CaCO3, 20 parts of superfine CaCO3, 36-38 parts of titanium dioxide, 2-2.5 parts of antioxidants, 1.4-2 parts of ultraviolet light absorbents and 2.5-3 parts of ultramarine. The stabilizer is one or more of calaium strarate, calcium ricinoleate, zinc stearate and zinc diricinoleate. The invention further discloses a production technology of the PVC profile. According to the high weather resistance PVC profile for the doors and the windows and the production technology of the PVC profile, the PVC profile has higher rigidity, wind load resistance and low temperature enhancement by means of optimizing of profile raw materials and the preparation technology.

Owner:LIAONING CHENGWEI PLASTIC PROFILE

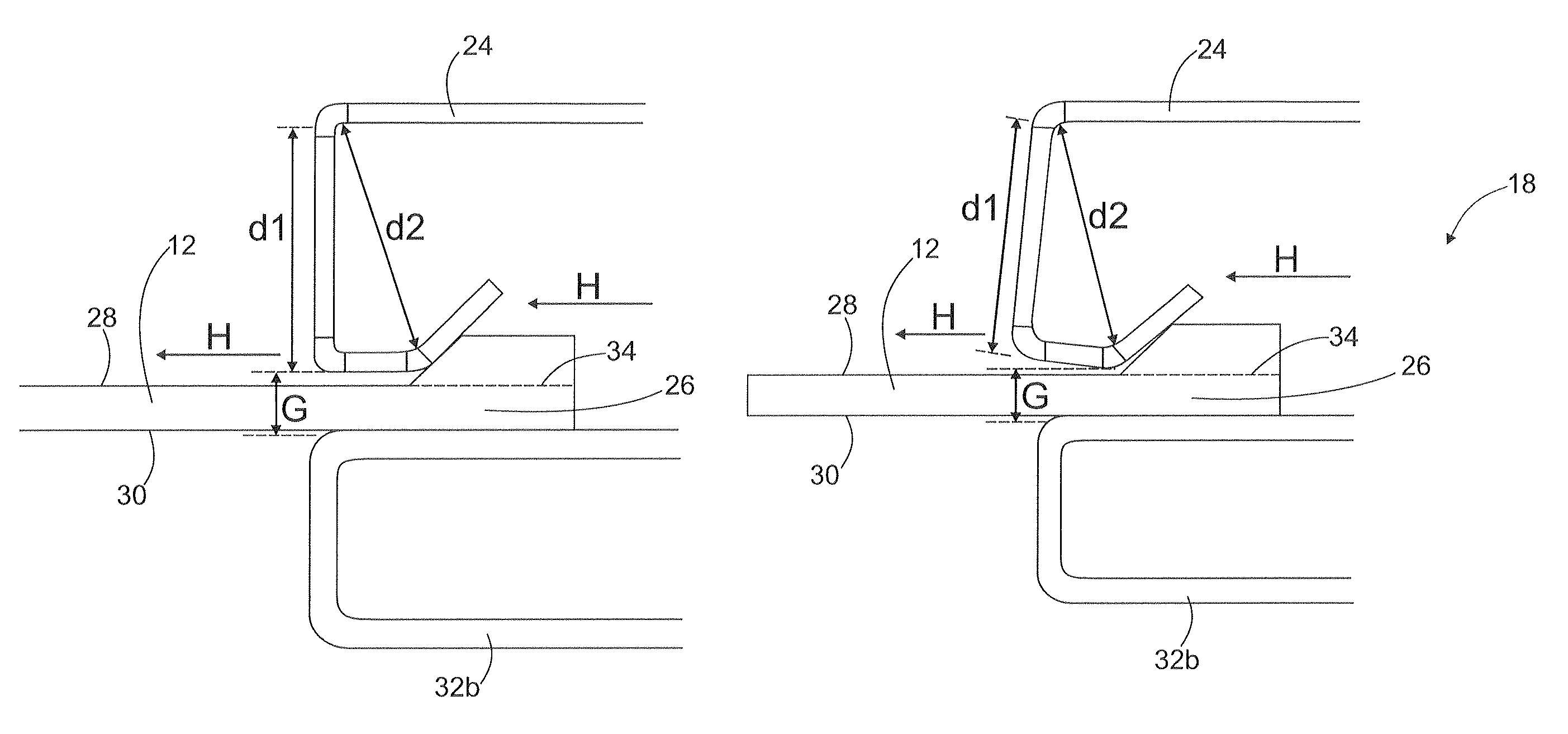

Side column configuration for overhead roll-up door assemblies

ActiveUS9187953B2Small sizeImprove wind pressure resistanceShutters/ movable grillesWindow/door framesEngineeringMechanical engineering

Owner:RYTEC CORP

Side column configuration for overhead roll-up door assemblies

ActiveUS20120241105A1Small sizeImprove wind pressure resistanceShutters/ movable grillesDoor/window applicationsEngineeringMechanical engineering

An overhead roll-up door assembly for a vertically moving door to permit and prohibit access to an opening in a wall, the door assembly having a flexible door panel and side columns located proximate opposite sides of the opening. The side columns each include an arm configured to engage the door panel as the door panel moves vertically, the arms being configured to move in a first direction in response to a first threshold moment being applied to the arms by the door panel wherein movement of each arm in the first direction prevents the door panel from escaping the side columns. The arms may be further configured to move in a second direction in response to a second threshold moment being applied on the arms by the door panel in a substantially vertical direction perpendicular to and away from the door panel.

Owner:RYTEC CORP

System and method for controlling combustion of gas water heater or wall-hanging stove

ActiveCN105042871AExact matchImprove wind pressure resistanceAir supply regulationWater heatersImpellerCombustor

The invention discloses a combustion control system for a gas water heater or a wall-hanging stove and a control method thereof. The system comprises a flue gas channel composed of a combustor, a heat exchanger, a stepless variable speed fan and a smoke pipe which are sequentially connected, a control unit connected with the signal input end of the stepless variable speed fan and an air pressure sensor assembly for detecting pressure signals of the upstream of the stepless variable speed fan, and the signal output end of the air pressure sensor assembly is connected with the control unit. The control unit comprises a storage and a controller, the storage is used for storing the corresponding relation between the pressure signals of the upstream of the stepless variable speed fan and heating loads of the combustor, and the controller is used for controlling operation of the stepless variable speed fan according to the corresponding relation. By detecting the pressure signals of the upstream of the stepless variable speed fan, the rotating speed of the upstream of the stepless variable speed fan is further adjusted, and the combustion control system has high wind-resistant performance.

Owner:A O SMITH (CHINA) WATER HEATER CO LTD

Energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance

ActiveCN107989515APlay a role in corrosion resistanceEffective shock absorptionClimate change adaptationWindow/door framesAdhesiveCorrosion resistant

The invention discloses an energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance and belongs to the field of energy-saving aluminum alloy doors and windows. The energy-saving aluminum alloy door and window with high compression resistance and corrosion resistance comprises a vacuum window body, wherein the vacuum window body is connected to a wall,the periphery of the vacuum window body is fixedly connected with connecting profiles, and connecting slots corresponding to the connecting profiles are formed in the wall. Corrosion-resistant rubbergaskets can play a corrosion-resistant role and effectively realize buffering and shock absorption to improve the wind pressure resistance, every two rotating buffer plates are connected with on oblique buffer plate through buffer springs, effective buffering and shock absorption can be realized, the wind pressure resistance effect can be improved, an inflatable buffer air bag is arranged betweenevery two rotating buffer plates and sealed and fixedly connected to the vacuum window body and the corresponding corrosion-resistant rubber gasket respectively through an adhesive, a sealed space canbe formed to surround the connecting profiles, corrosion of the connecting profiles can be effectively prevented, effective buffering and shock absorption can be realized, and the wind pressure resistance capacity of the aluminum alloy door and window can be guaranteed.

Owner:ANHUI PROVINCE JINPENG ENERGY SAVING TECH CO LTD

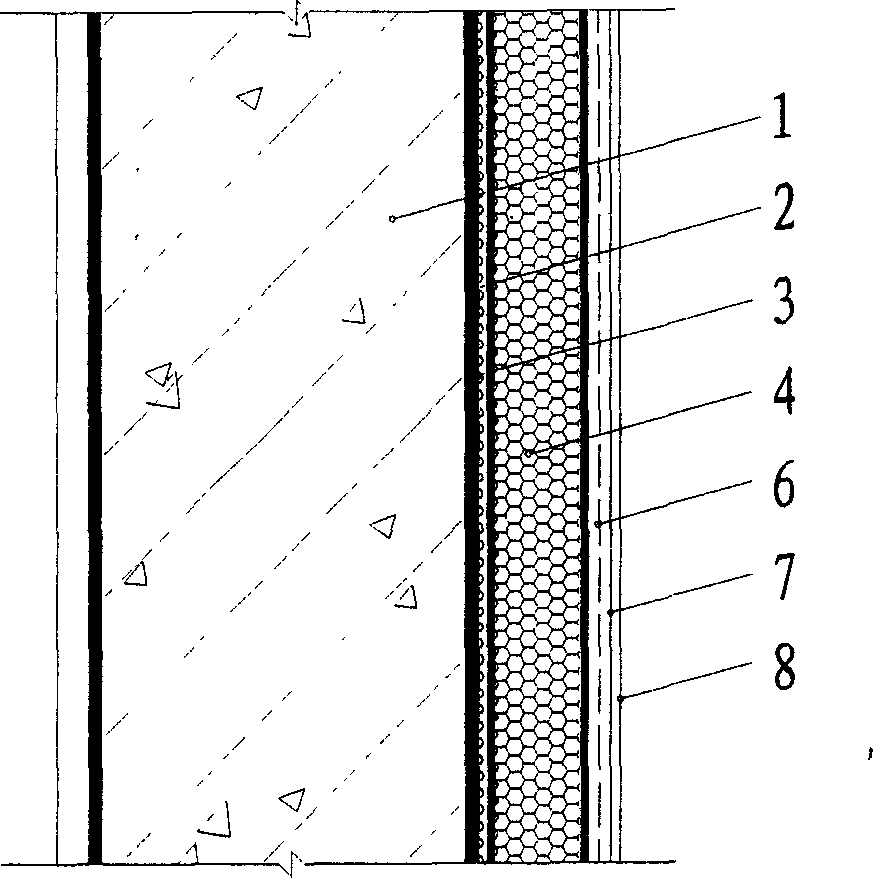

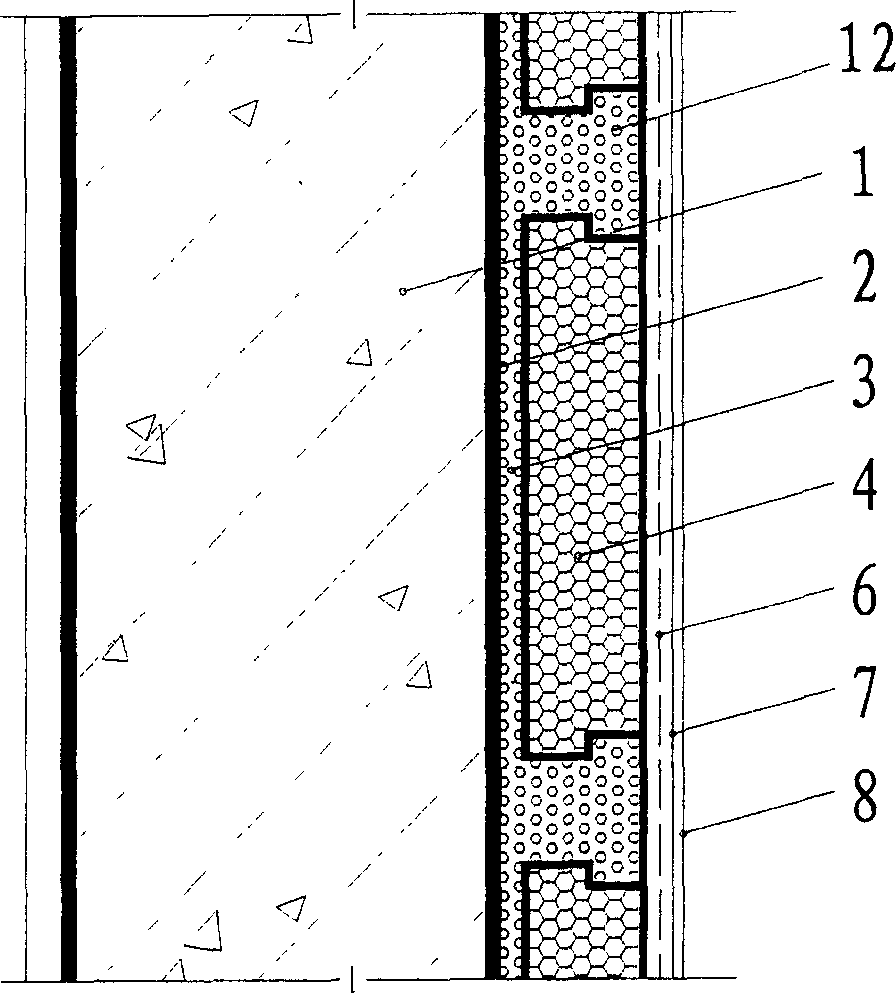

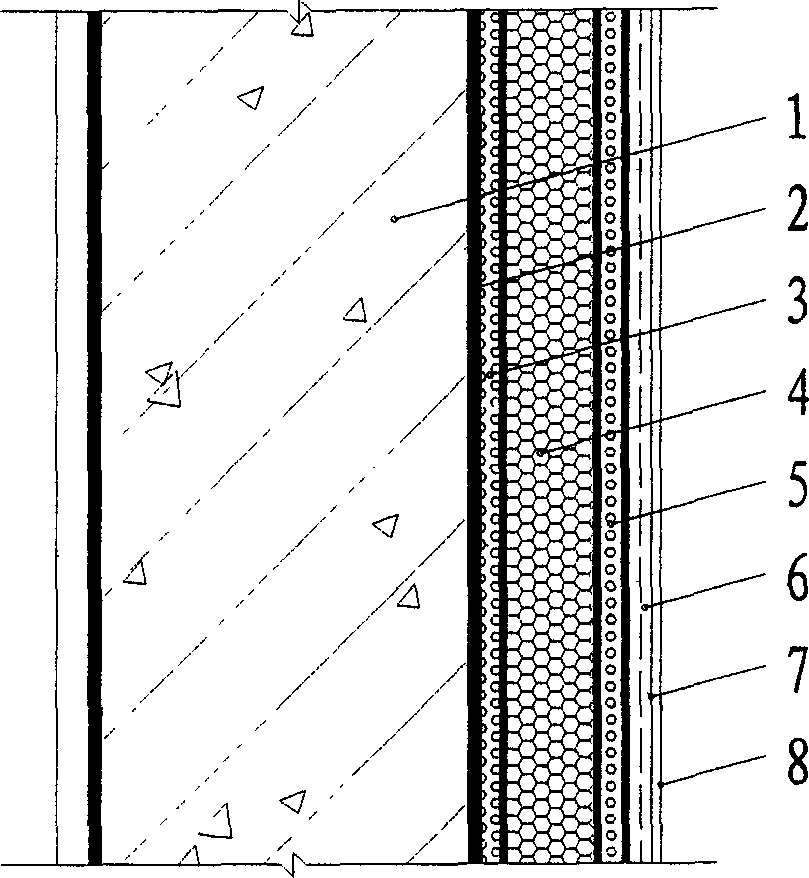

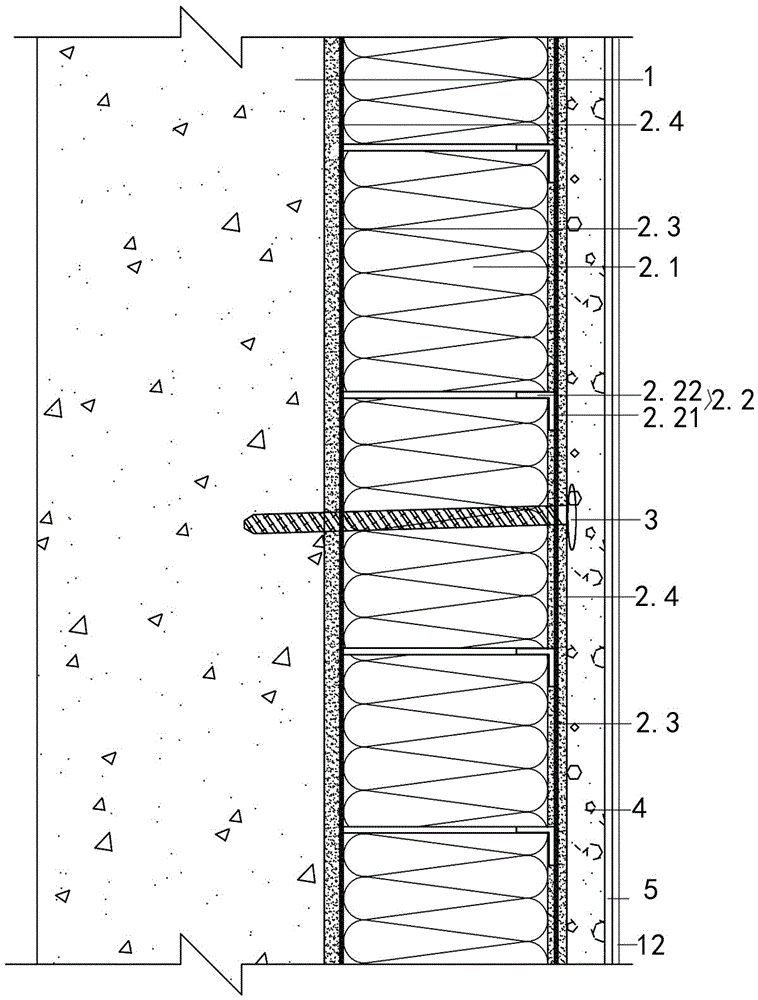

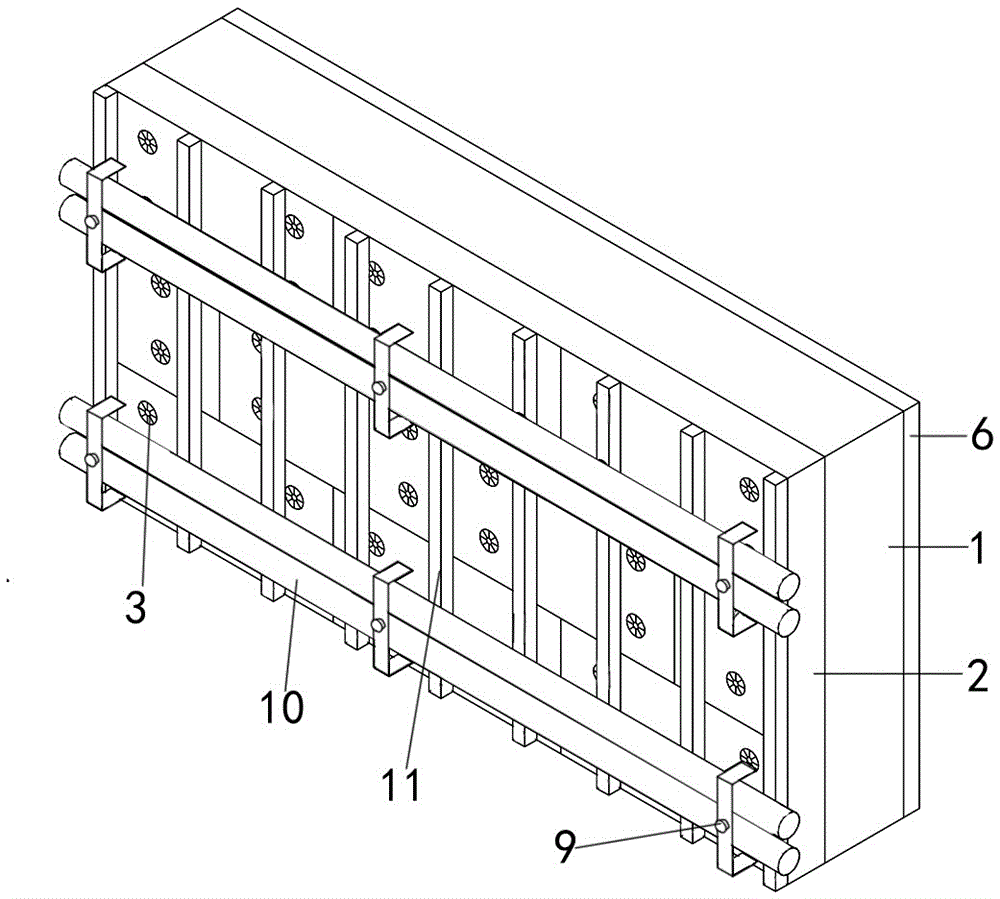

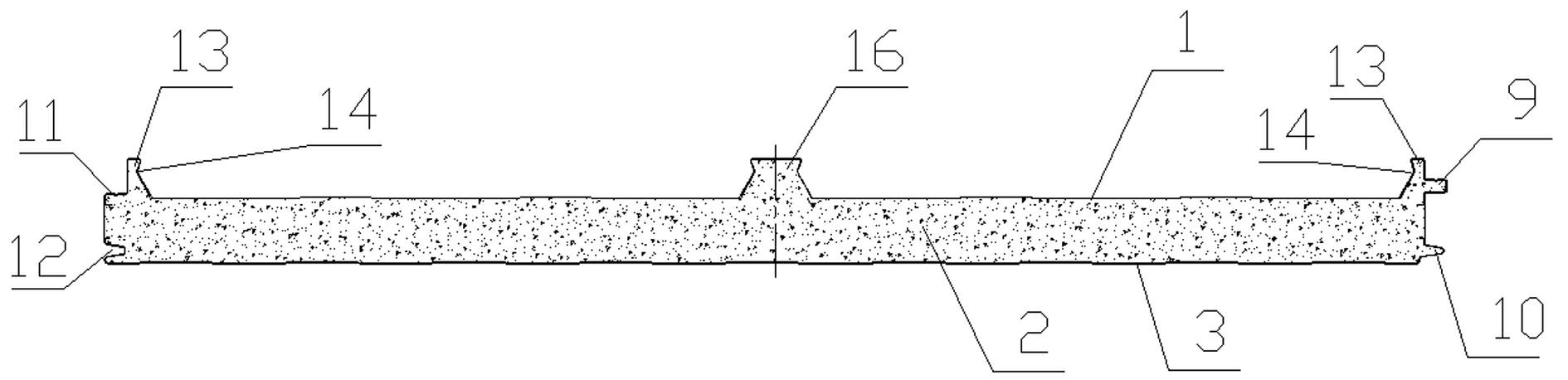

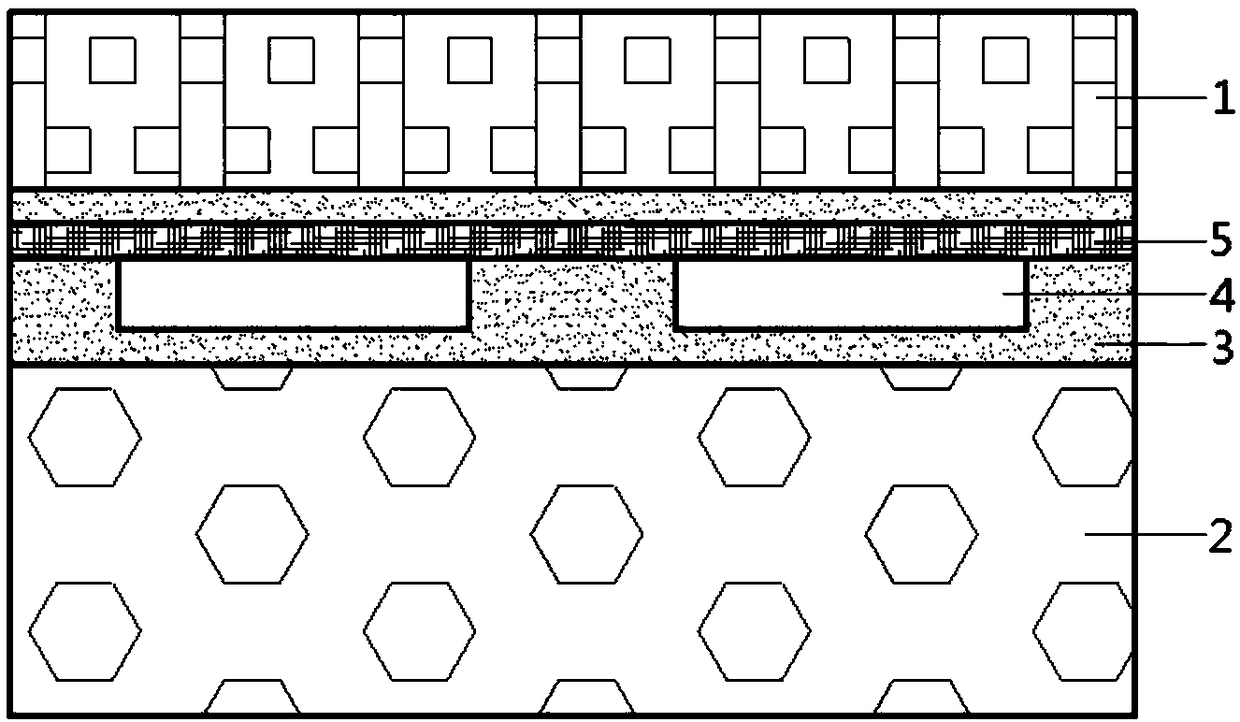

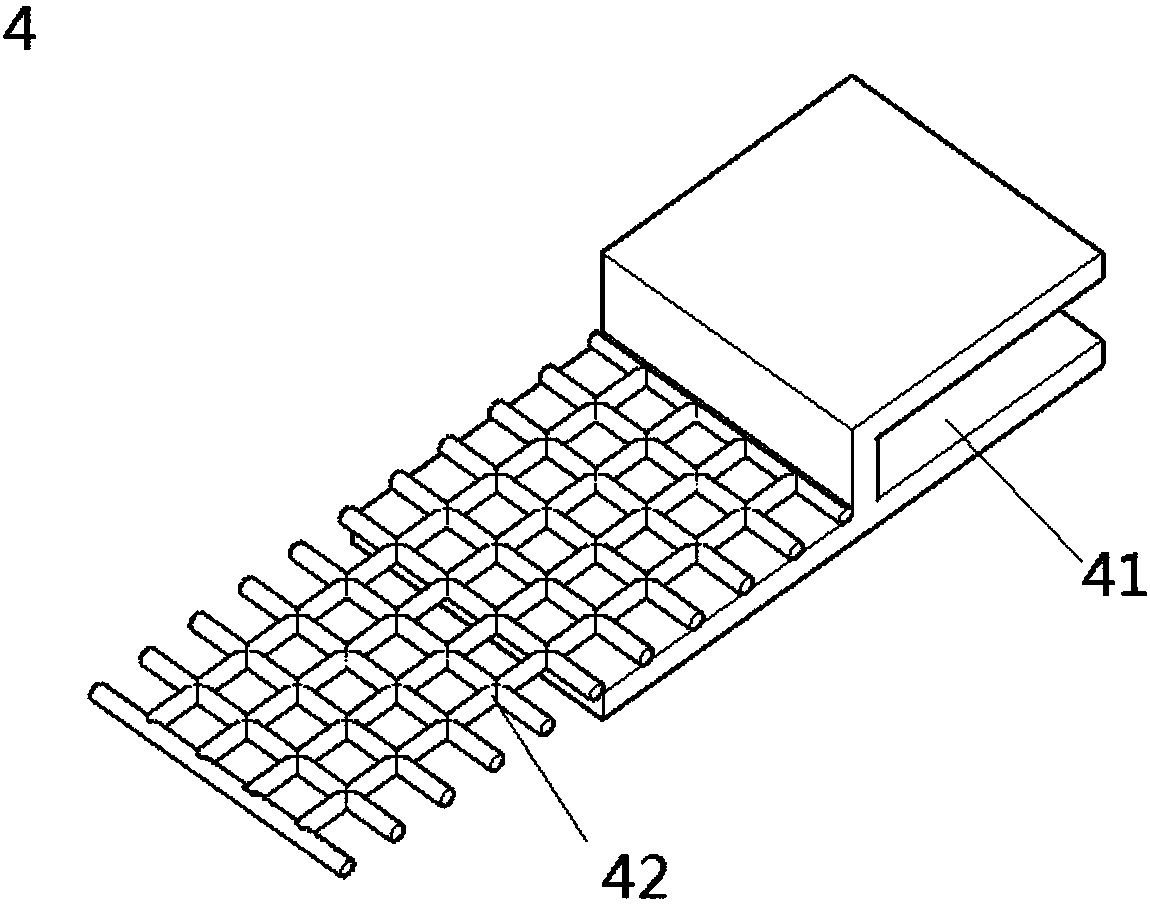

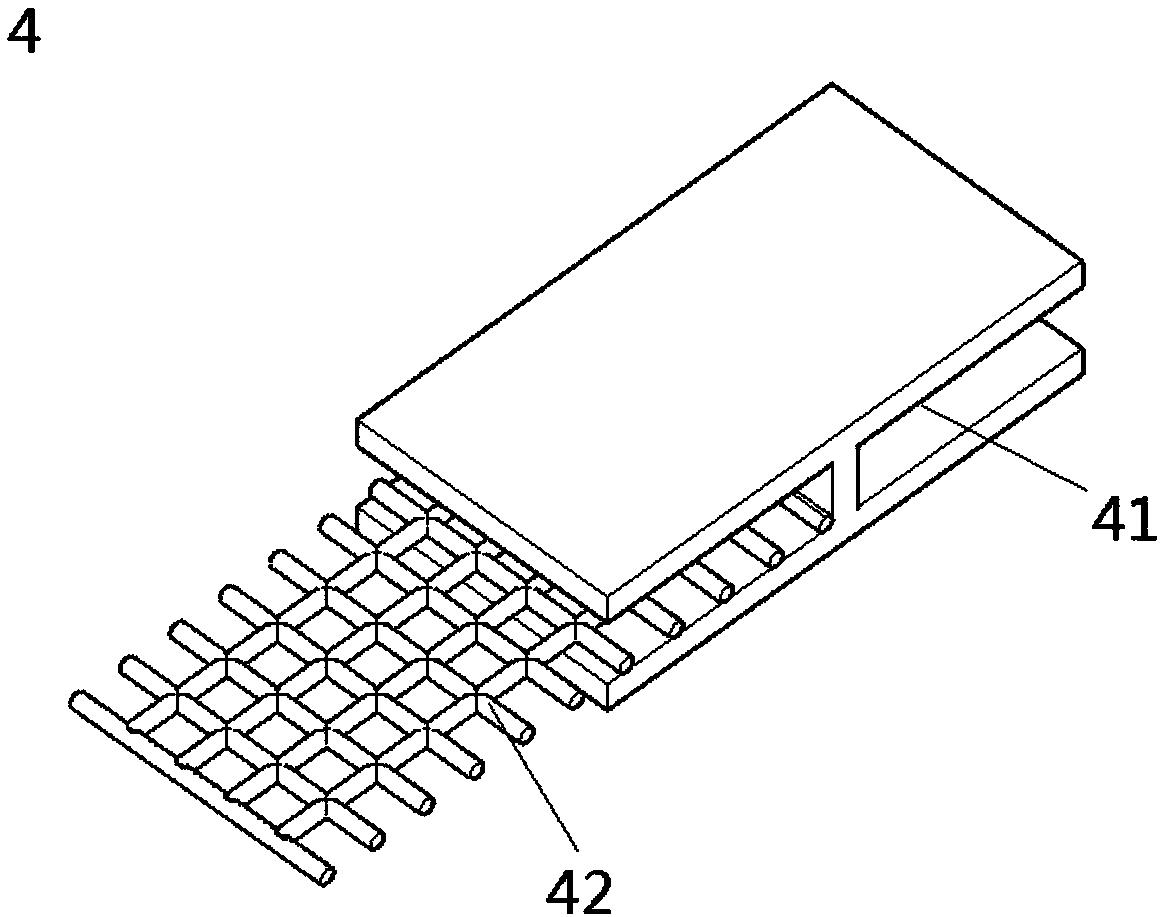

Ribbed rock wool cast-in-place concrete thermal insulation wall and construction method thereof

ActiveCN106836567AImprove wind pressure resistanceShorten the construction periodWallsClimate change adaptationRebarThermal insulation

The invention discloses a ribbed rock wool cast-in-place concrete thermal insulation wall and a construction method thereof. The ribbed rock wool cast-in-place concrete thermal insulation wall comprises a cast-in-place reinforced concrete wall base layer, a non-dismantling outer formwork insulation board fixedly connected to the outer surface of the cast-in-place reinforced concrete wall base layer, a leveling layer composited on the outer surface of the non-dismantling outer formwork insulation board, an anti-cracking protection layer composited on the outer surface of the leveling layer, and a veneer layer composited on the outer surface of the anti-cracking protection layer. The non-dismantling outer formwork insulation board comprises a vertical filament rock wool core, reinforcing ribs, a reinforced fiber layer with four faces annularly wrapping and binding the outer sides of the vertical filament rock wool core and the reinforcing ribs, and an inorganic thermal insulation mortar protection layer integrally poured to wholly cover the reinforced fiber layer. The ribbed rock wool cast-in-place concrete thermal insulation wall is firm in connection, good in fireproof performance and thermal insulation effect, long in service life and convenient to construct, integrates the advantages of thermal insulation, fire protection, shock resistance, environment protection, short construction period, low manufacturing cost and the like, and is suitable for various types of housing construction of cities and towns and good in social and economic benefit.

Owner:山东振利节能环保科技股份有限公司

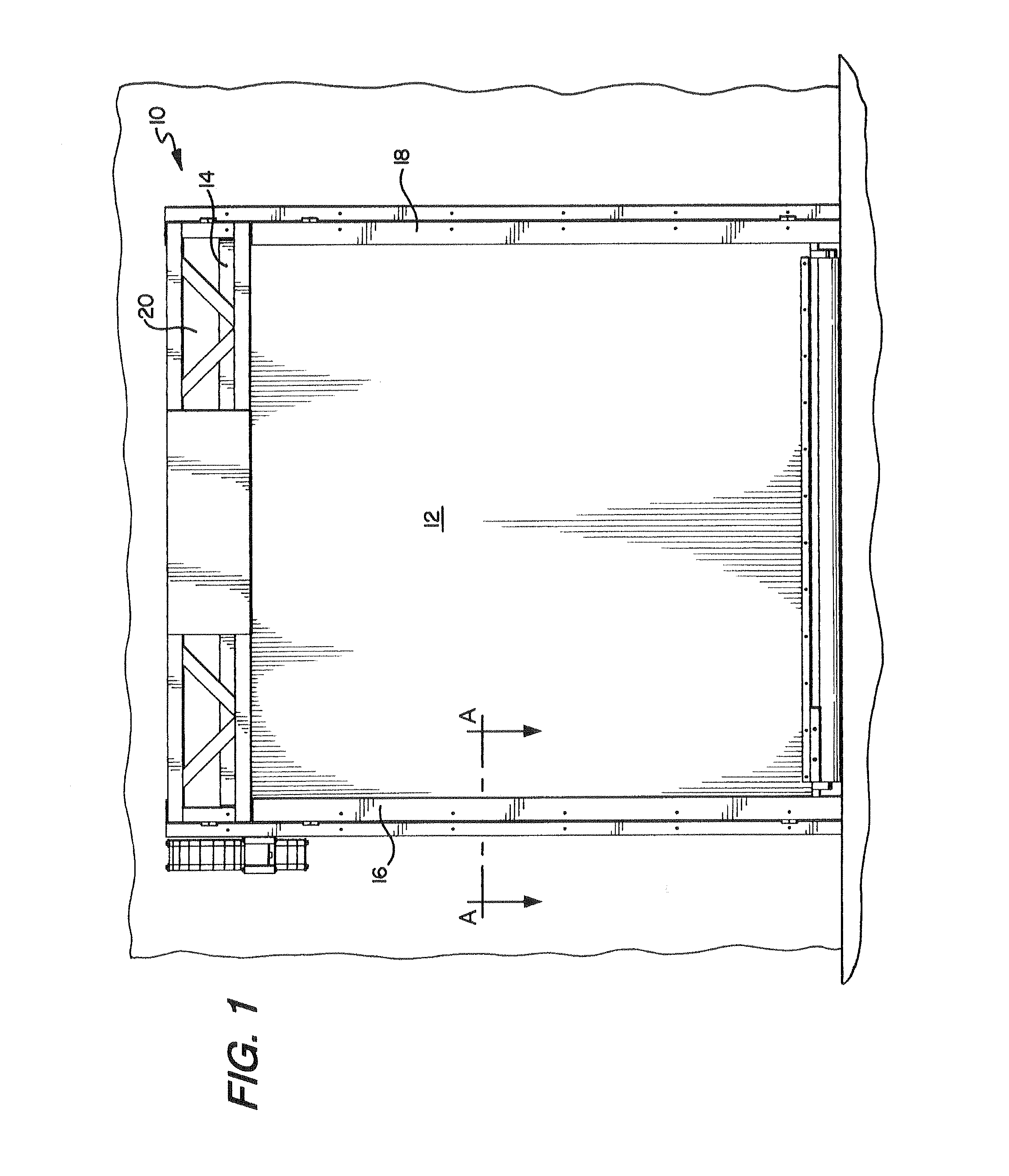

Roofing system support assembly

InactiveUS8327590B2Improve wind resistanceImprove the immunityBuilding roofsRoof covering using slabs/sheetsEngineeringMechanical engineering

Owner:RAY GINO

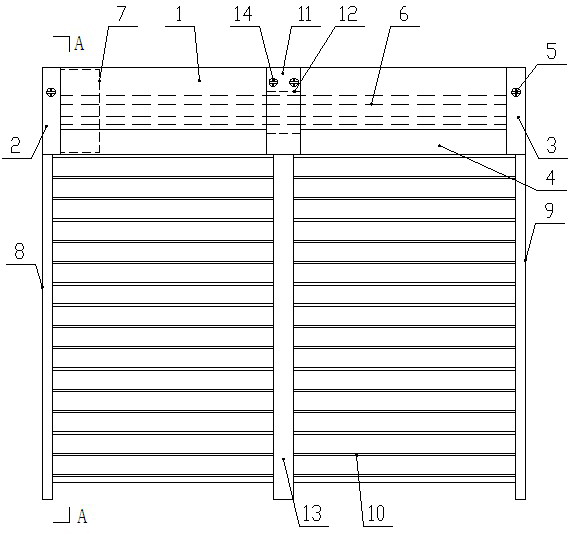

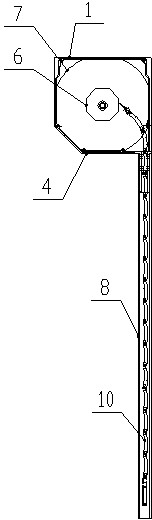

Single-motor window shutter for large window

InactiveCN102661117ALow failure rateGuaranteed mechanical propertiesShutters/ movable grillesFailure rateLoad resistance

A single-motor window shutter for a large window comprises a shutter box. An upper cover, a left end seat, a right end seat and a lower cover are connected by end screws to form the shutter box, a reel which is respectively rotationally connected with the left end seat and the right end seat is horizontally disposed on the shutter box, a tubular motor is arranged on the reel, a left guide track is vertically arranged at the lower end of the left end seat, a right guide track is vertically disposed at the lower end of the right end seat, two shutter hanging sheets are wound on the reel, a middle end seat is arranged in the middle of the shutter box, a through hole is disposed in the middle of the middle end seat, the reel penetrates through the through hole, and a middle guide track with double tracks is arranged at the lower end of the middle end seat. The single-motor window shutter for the large window has the advantages that production cost is sufficiently reduced while a mechanical performance is guaranteed and wind load resistance and an antitheft safety performance are improved, and failure rate of the electric window shutter is reduced; the problem that a gap is formed when a conventional window shutter is used and two shutter boxes of the conventional window shutter are spliced is avoided owing to the middle end seat, and sealing and heat-insulation performances are fine; and the shutter window is integrated, is more attractive and is installed more simply and easily.

Owner:HENAN WEISI ENERGY ENVIRONMENTAL PROTECTION TECH

Enclosed type sliding window

InactiveCN101492991AImprove wind pressure resistanceImprove airtightnessWing arrangementsSash windowSlide window

Owner:项瑞元

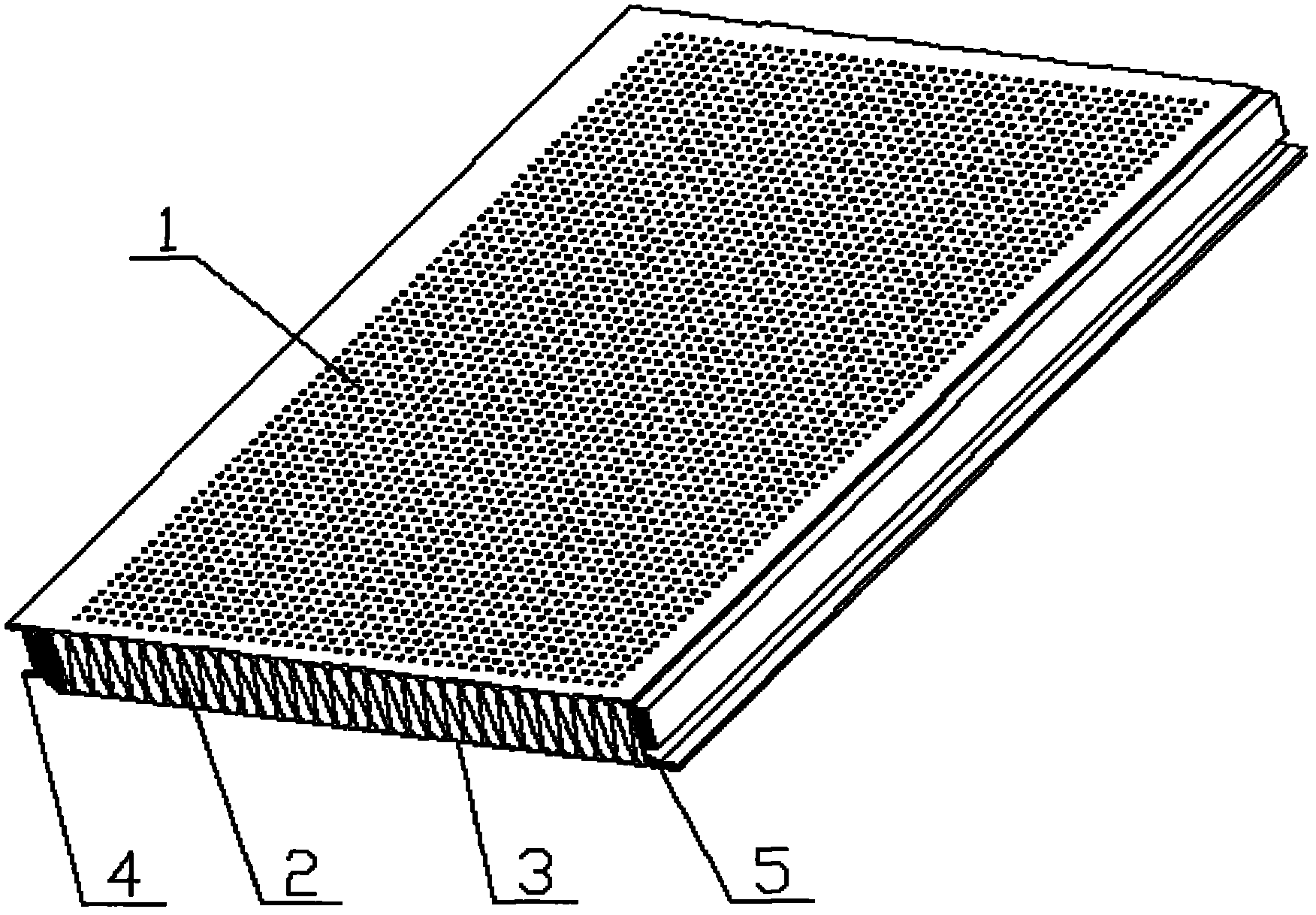

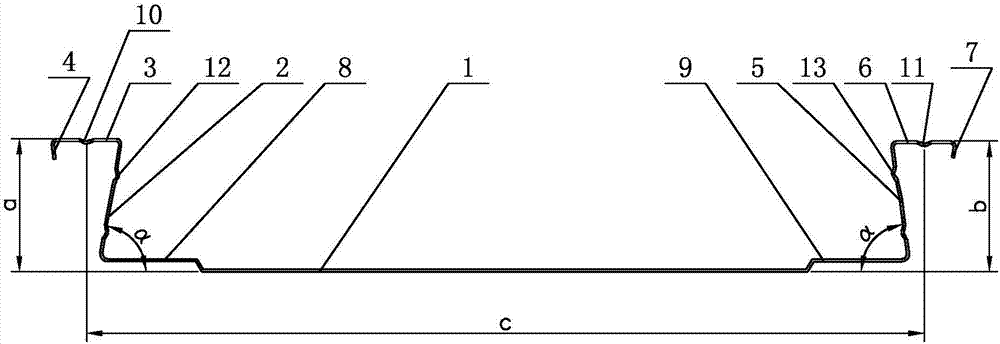

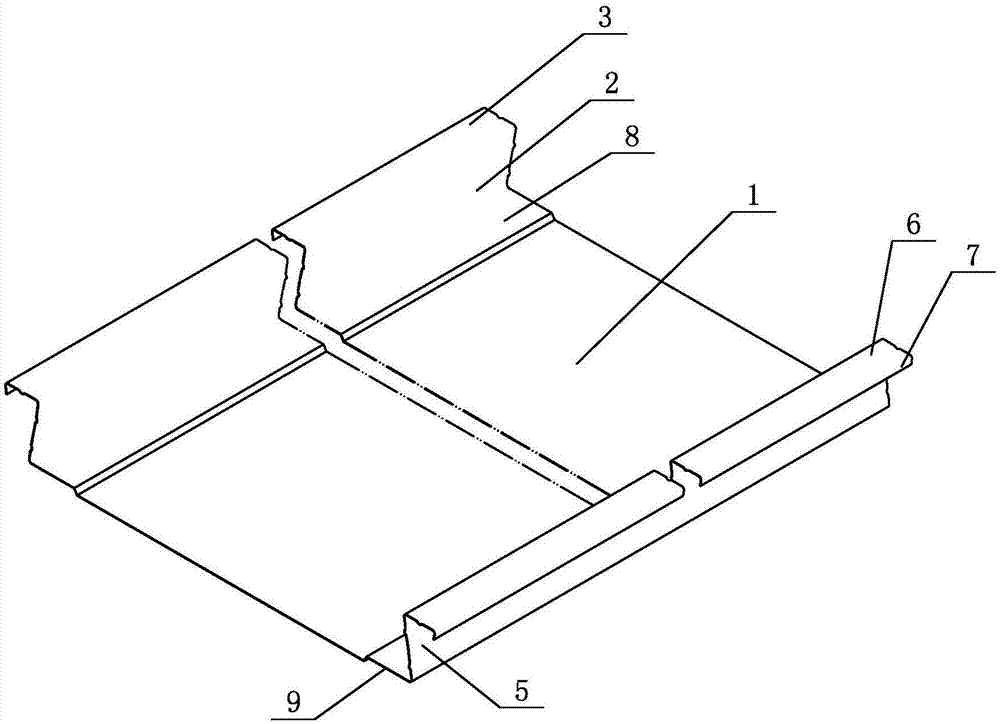

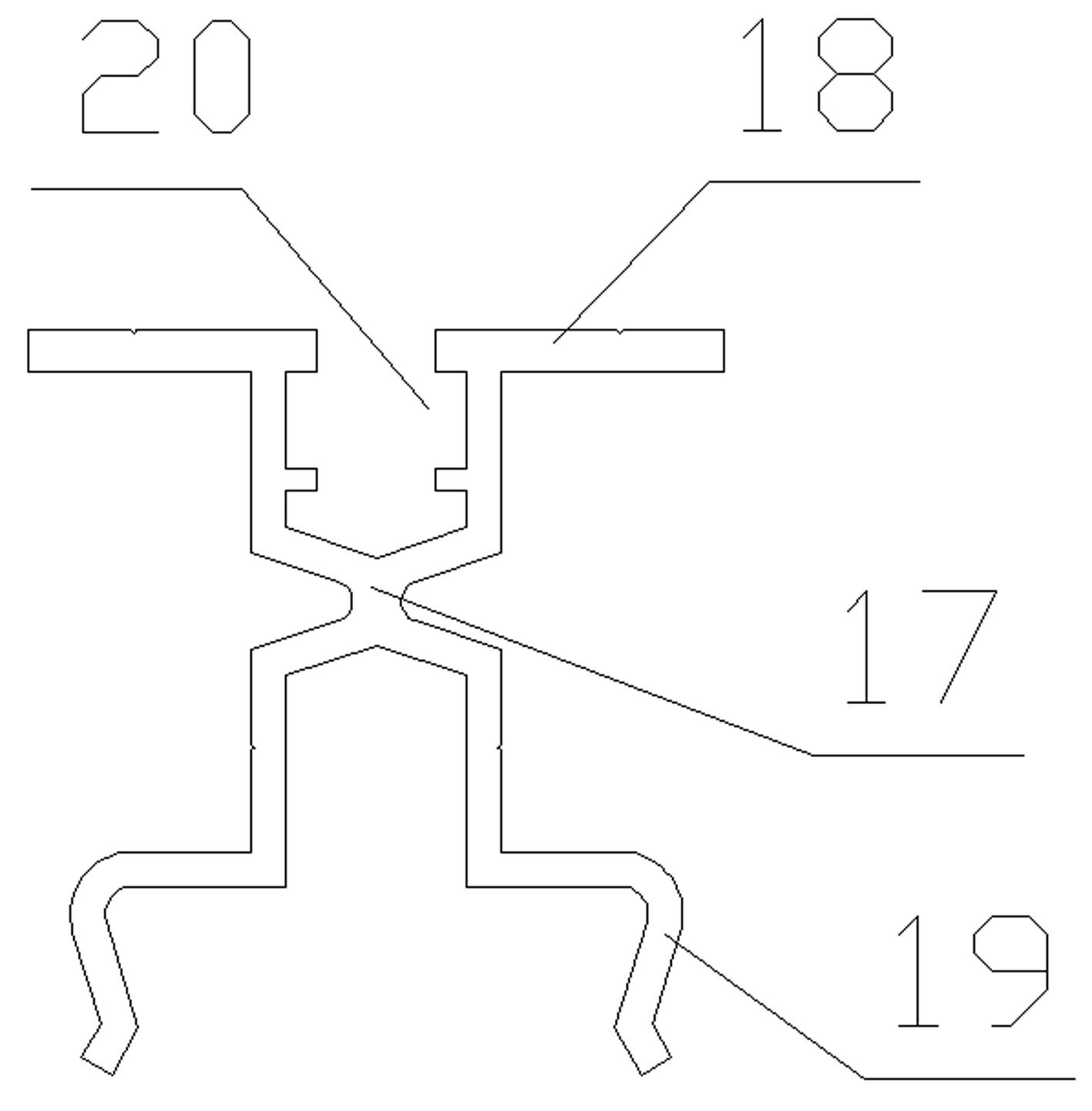

Metal roof boards and metal roof system

InactiveCN107989276AThe connection is tight and firmImprove wind pressure resistanceRoof covering using slabs/sheetsBuilding roofsTransverse planeEngineering

The invention discloses metal roof boards and a metal roof system which have high wind pressure resistant and deformation resistant capacity and excellent waterproof performance. The metal roof systemcomprises the metal roof boards, fixed seats (30) and clamping covers (20). Each metal roof board comprises a bottom plate (1), a left vertical rib and a right vertical rib; each left vertical rib comprises a left vertical plate (2), a left transverse plate (3) and a left folding edge (4), and each right vertical rib comprises a right vertical plate (5), a right transverse plate (6) and a right folding edge (7); the left vertical ribs and the right vertical ribs of the adjacent metal roof boards are connected in a matched mode; the fixed seats (30) are fixedly connected with purlines (50) andmatched with the left vertical ribs and the right vertical ribs in shape; the left vertical ribs are buckled on the fixed seats (30) in an overlapping mode, the right vertical ribs are buckled on theleft vertical ribs in an overlapping mode, and the multiple clamping covers (20) are buckled on the tops of the right vertical ribs and the left vertical ribs; and clamping cover fixing screws (90) penetrate through the clamping covers (20), the right transverse plates (6) and the left transverse plates (3) to fixedly connect the clamping covers (20) with the right vertical ribs and the left vertical ribs into a whole and fixedly connect the metal roof boards (100) with the fixed seats (30) and the purlines (50) into a whole.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

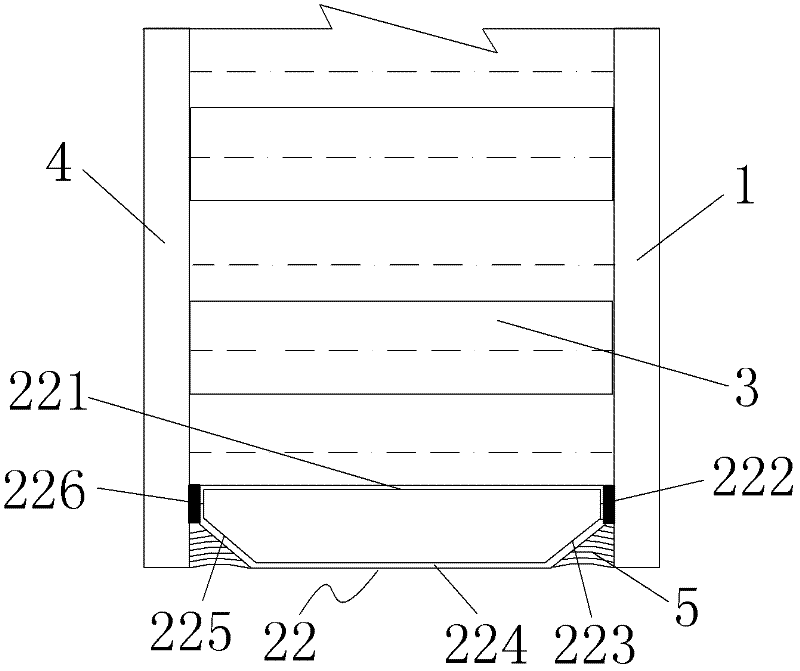

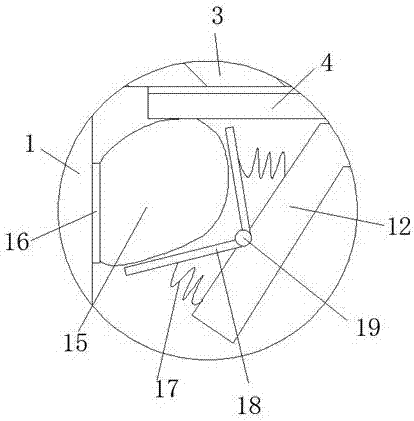

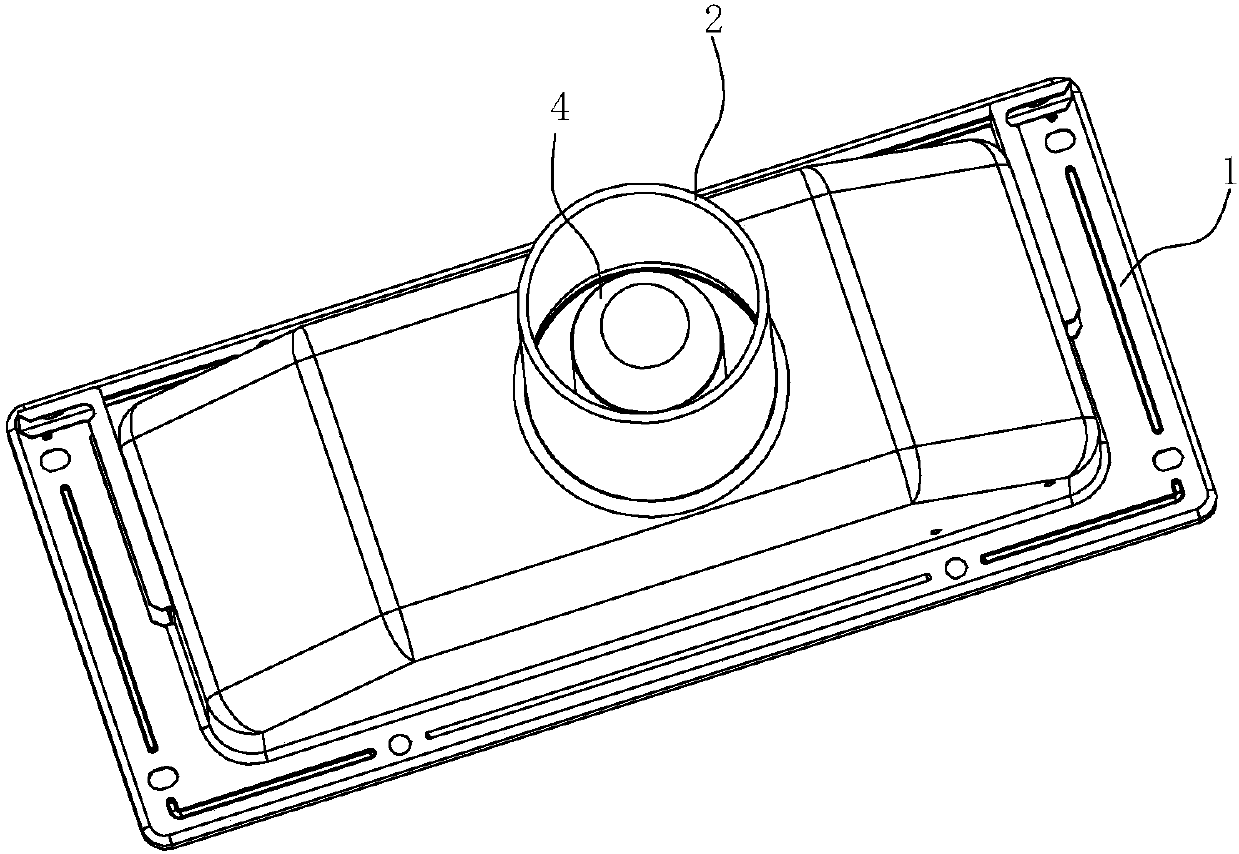

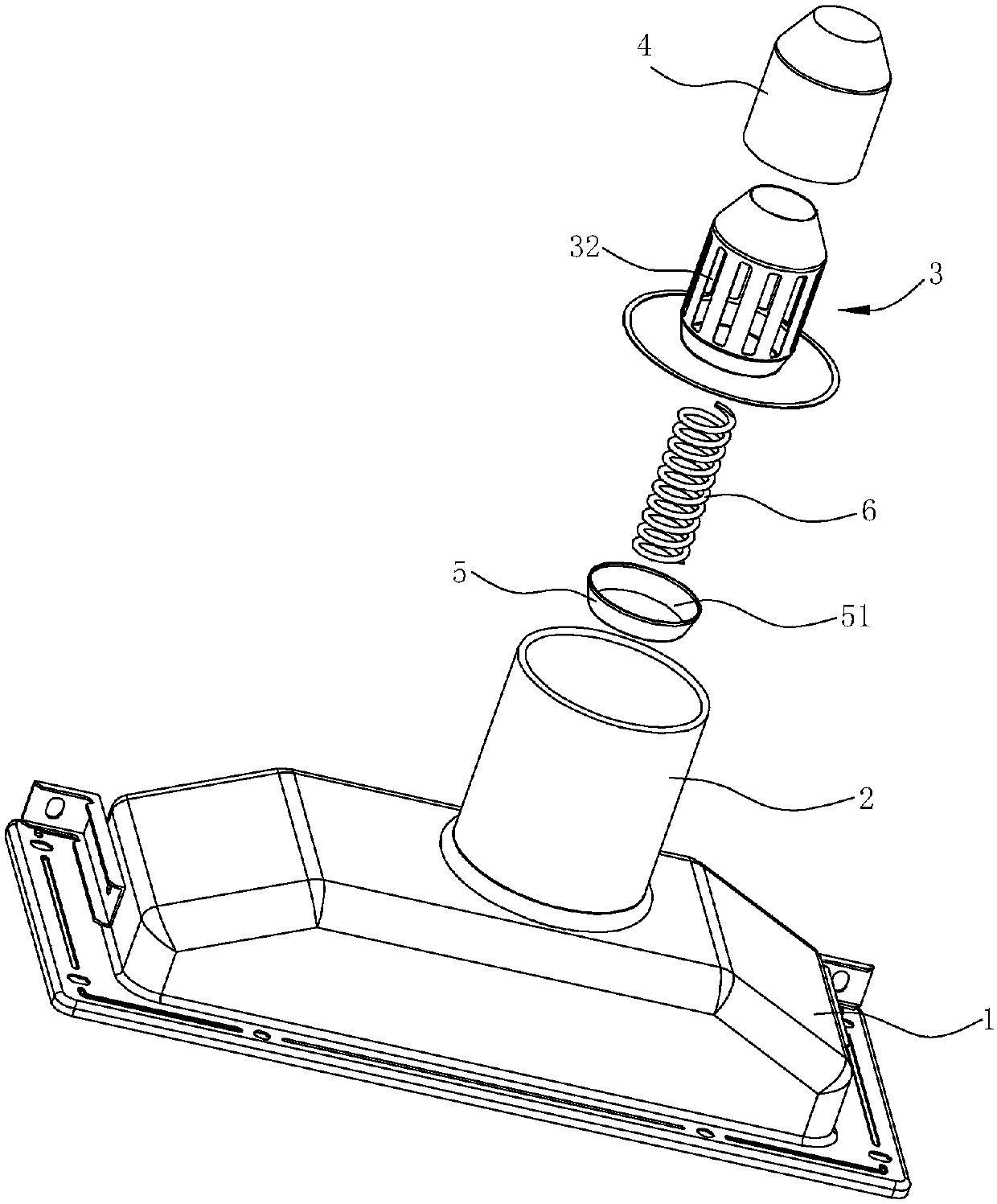

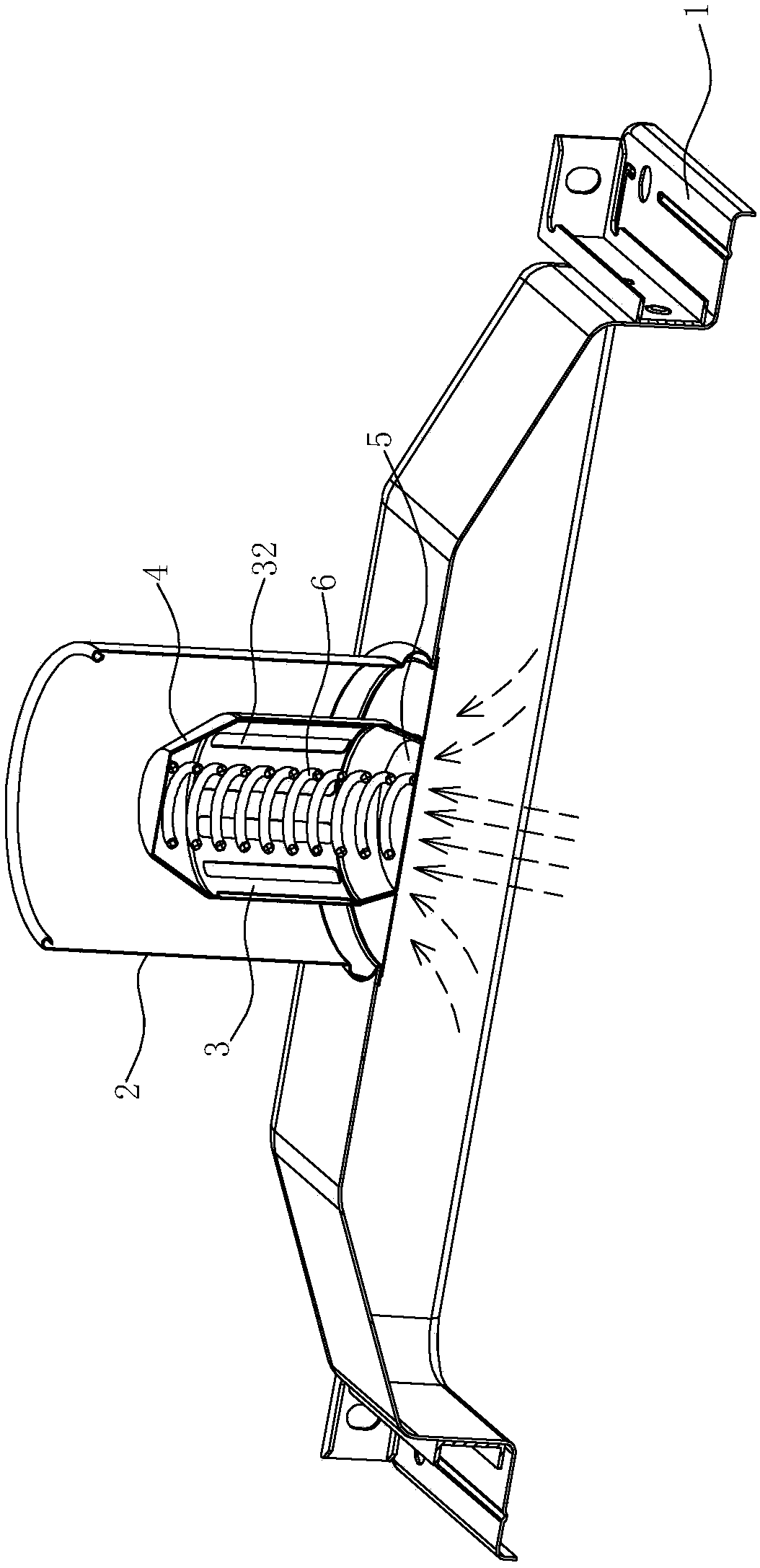

Gas-collecting hood for gas water heater and gas water heater using gas-collecting hood

The invention relates to a gas-collecting hood for a gas water heater. The gas-collecting hood comprises a hood body and a vertical gas-exhausting pipe arranged at the top of the hood body and is characterized in that: a gas guide drum is arranged in the gas-exhausting pipe; a gas inlet formed in the lower end of the gas guide drum is communicated with an inner chamber of the hood body; at least one gas-exhausting hole is formed in the side wall of the gas guide drum; a sleeve, of which the bottom is opened and the top is closed, is arranged on the outer side of the gas guide drum in a sleeving manner; and the sleeve can move up and down relative to the gas guide drum, and can move downward to fully cover the gas-exhausting hole and upward to expose at least part of the gas-exhausting hole. Compared with a manner of vertical fume exhausting, fume exhausting from the side wall of the gas guide drum can alleviate the impact of external wind force, reduces the resistance to the fume pressure, and allows fume to be exhausted easily.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Device and method for increasing the wind load resistance and disengage-ability of overhead roll-up doors

ActiveUS8607842B2Improve wind pressure resistanceImprove abilitiesScreensShutters/ movable grillesLeading edgeLoad resistance

A door assembly having a flexible door panel wound and unwound on a drum or the like to selectively block or permit access through an opening, the flexible door panel having a stiffness, a width, and a length. The door assembly further includes vertically extending side columns disposed on opposite sides of the opening, the side columns being configured to engage a marginal edge of the flexible panel to vertically guide the panel while opening or closing. Attached to a leading edge of the door panel is a bottom bar having a greater stiffness than the door panel and a narrower width than a distance between the vertical panel guide assemblies. Bottom bar guides are disposed proximate a lower portion of the opening and are configured to engage a portion of the bottom bar only when the bottom bar is located in at least a partially closed position.

Owner:RYTEC CORP

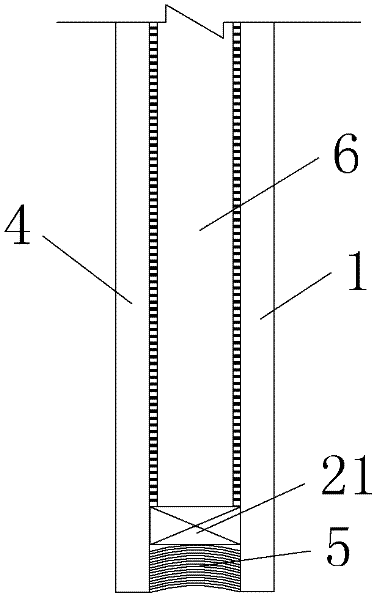

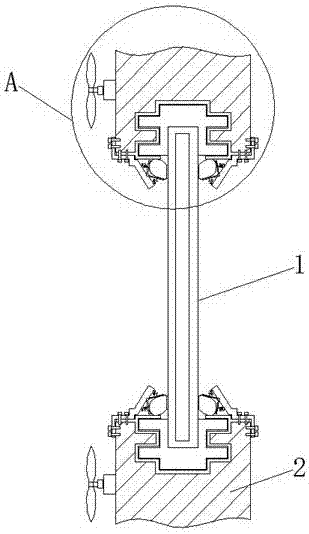

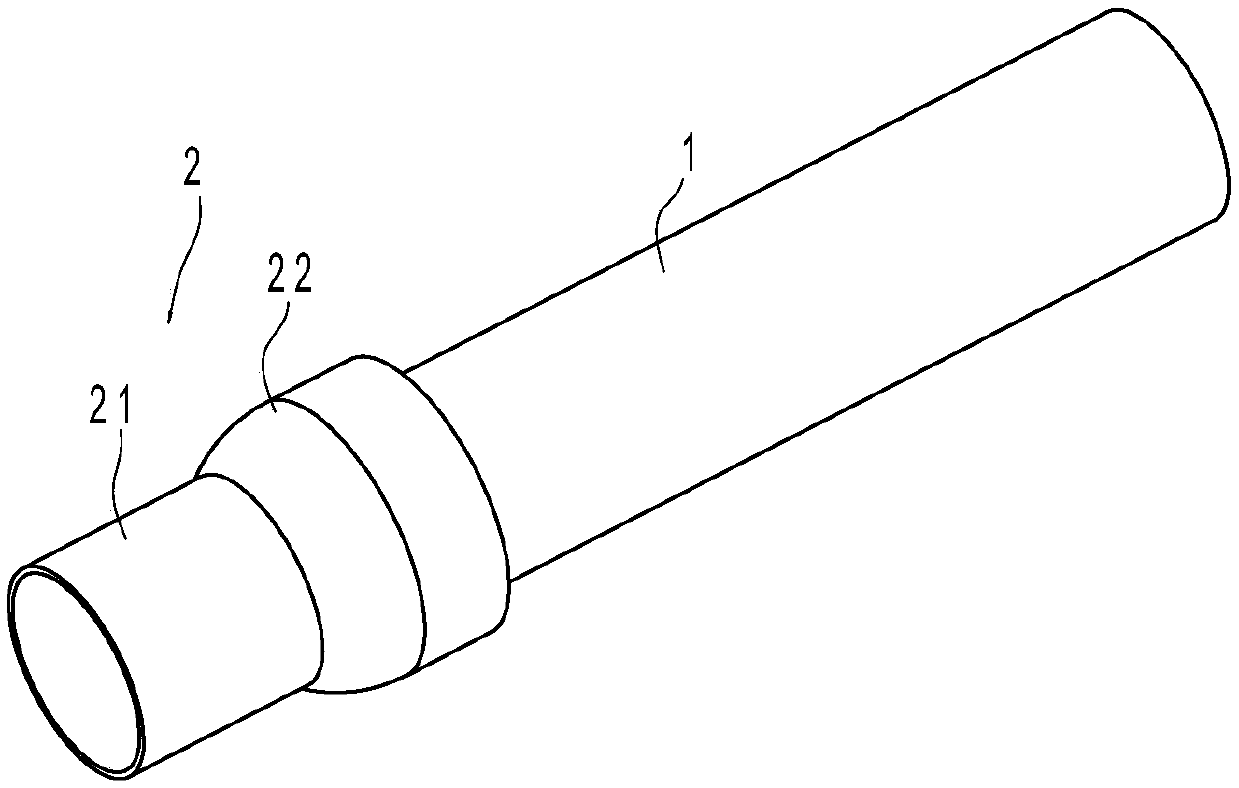

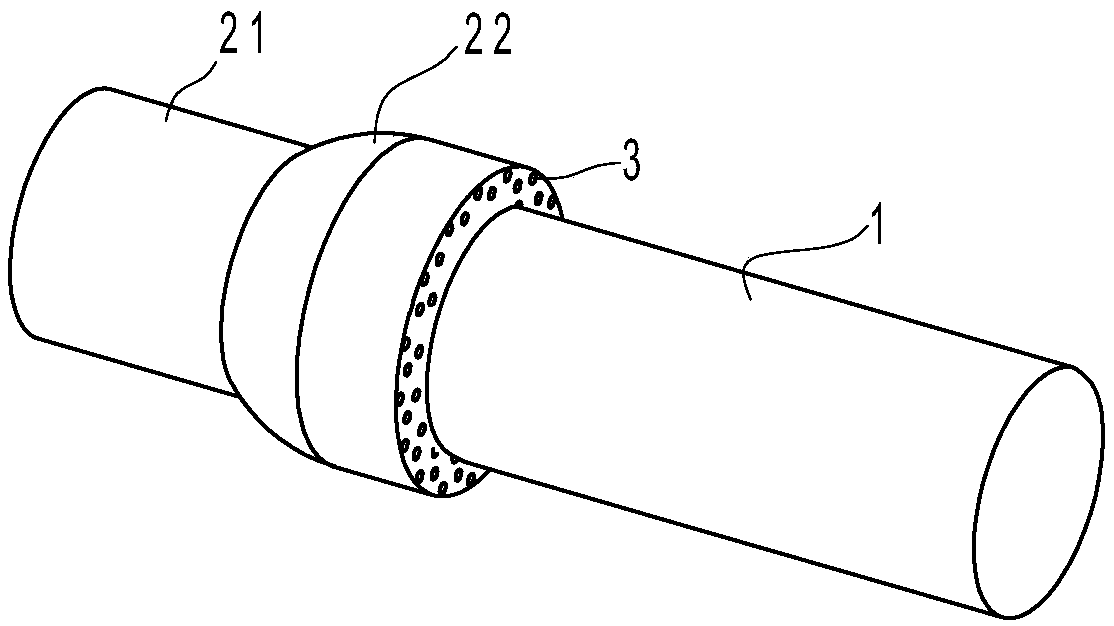

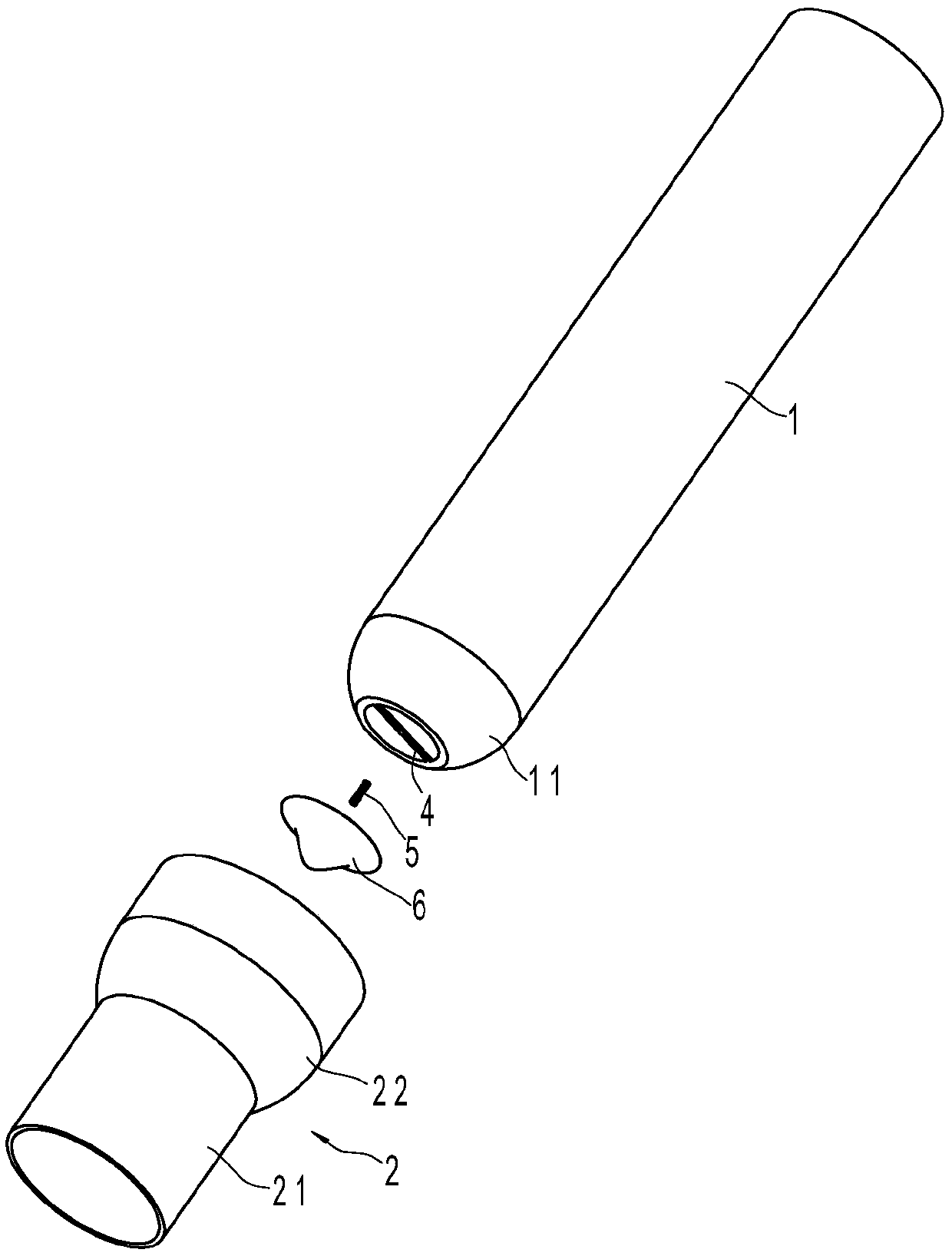

Anti-air-backflow smoke tube of gas water heater

PendingCN110608534AImprove wind pressure resistanceReduce entryFluid heatersChimneysEngineeringFuel gas

An anti-air-backflow smoke tube of a gas water heater is characterized by comprising a first smoke tube (1) and a second smoke tube (2), wherein the second smoke tube (2) comprises a straight section(21) and a flaring section (22) connected to the straight section (21); an annular exhaust channel (3) is formed between the outer wall of the first smoke tube (1) and the inner wall of flaring section (22); a diversion block (6) which can compress a smoke discharge hole in an air outlet end of the first smoke tube (1) when wind strength is high is disposed elastically at the air outlet end of thefirst smoke tube (1); and air which enters from the second smoke tube (2) can be led by the diversion block (6) into the exhaust channel (3). When a wind pressure is high, the anti-air-backflow smoketube of the gas water heater can effectively enhance a combustion state of fuel gas; fuel gas consumption can be reduced; and resources can be saved. In addition, occurrence of dangerous situations such as tempering and CO exceeding can be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Nondestructive roof board installation solar energy system

InactiveCN102619305AImproves mounting fit strengthImprove air tightnessRoof covering using slabs/sheetsAir tightnessPressure resistance

The invention discloses a nondestructive roof board installation solar energy system, which comprises a roof board and a fixing bracket, wherein the roof board is formed by splicing at least two roof board units; each roof board unit comprises a roof board front face, a roof board back face and polyurethane foam arranged between the roof board front face and the roof board back face; the roof board front face and the roof board back face are formed at certain intervals on an end face; adjacent roof board units are spliced together; projecting installation seats are pressed at the two ends of the roof board front face vertical to the roof board; the fixing bracket comprises a body; the lower part of the body is provided with a clamping groove structure; the clamping groove of the fixing bracket is clamped on the projecting installation seats of two adjacent roof board units; the clamping groove structure transversely passing through the body is provided with a bolt; the upper part of the body is provided with an installation platform; and a solar panel is arranged on the installation platform. The nondestructive roof board installation solar energy system can be arranged conveniently in a time-saving way, the air pressure resistance is enhanced, the solar panel can be arranged on the premise of not damaging the roof board, the production efficiency is increased, and the airtightness and heat-preserving property of the roof board are enhanced.

Owner:XUCHANG SUPERELEVATOR ELECTRICAL & MECHANICAL EQUIP

Outer wall thermal insulation decoration integrated quick-equipping plate

The invention discloses an outer wall thermal insulation decoration integrated quick-equipping plate. The quick-equipping plate comprises an insulation sheet of which inner surface sticks to the wall and an interface agent layer, an alkali resistance fiberglass mesh layer or a steel mesh layer, a crack resistance trowel finish layer and a facing layer which adhere to the surface of the thermal insulation board in turn; an internal pressure plate with a cylindrical presser foot is embedded in the thermal insulation board, the presser foot is provided with a thread which is connected with a fastening piece outside the thermal insulation board; the overall fastening piece is cylindrical, one end of the fastening piece is connected with the thread of the presser foot, the other end is inserted in an installing hole in the wall, and the waist part of the fastening piece is provided with an outer pressing sheet which is vertical to the fastening piece. The quick-equipping plate of the invention has simple structure, beautiful appearance, long service life and fast installation, thus the industrialized production of the outer wall thermal insulation finishing quick-equipping plate can be realized.

Owner:RES INST OF ENERGY SAVING BUILDING MATERIAL HEFEI LEQIANNIAN PAINT

A-level flame-retardance heat-preservation decoration integration plate and preparation method thereof

PendingCN108086614AImprove flame retardant performanceGood weather resistanceCovering/liningsSynthetic resin layered productsCalcium silicateAdhesive cement

The invention relates to an A-level flame-retardance heat-preservation decoration integration plate and a preparation method thereof. The plate comprises a facing layer, a heat preservation layer, a plastering layer, a reinforcement clamping groove and a grid cloth layer. The facing layer is compounded on the heat preservation layer through the plastering layer, the reinforcement clamping groove is formed in the plastering layer, and the grid cloth layer covers the upper portion of the reinforcement clamping groove. The A-level flame-retardance heat-preservation decoration integration plate has the advantages that the plate is compounded by multiple layers of A-level flame-retardance structure layers, composite flame-retardance fire-resistance adhesive cement five surfaces of a reinforcement belt mesh embedded part wrap the surface of the heat-preservation plate, prefabrication forming is conducted in a factory, the unit mass is low, the anchoring node is large, the structure is simple, and the demand of the A-level flame retardance is met; through five-surface sealing wrapping of the heat-preservation plate, the flame retardance of the heat-preservation plate is improved, the fireresistance of the integration plate is improved through multiple fireproof structures, and meanwhile the dangers of deformation and warping of a calcium silicate plate or a cement fiber plate and falling-off of the calcium silicate plate or the cement fiber plate during fire disasters are also avoided; through application of a belt-net-type built-in clamping groove, the anchoring connection forceof the integration plate and the wall is larger, and the safety and wind pressure resistance of a system are improved.

Owner:SHANGHAI APE STONE

Later-support vacuum glass manufacturing method

ActiveCN104591527APlay a supporting roleReduce cumbersomeGlass reforming apparatusGlass productionSolderingIrradiation

The invention discloses a later-support vacuum glass manufacturing method which comprises the following steps: cooling after high-temperature exhaustion; laying a soldering flux at a preset sealing area when the temperature is cooled to 150 DEG C; directly superposing two glass plates in parallel without set supports; raising the temperature to 200 DEG C, welding the soldering flux and sealing the edge; cooling to 150 DEG C and selecting points from one or two surfaces to carry out laser fixed-point irradiation after close welding to ensure that bulges are formed between the two glass plates at the irradiation points; and forming support between the two glass plates by bulges formed by one or more points. The later-support vacuum glass manufacturing method has the advantages of abandoning the complicated manner of previously laying a support, greatly improving the vacuum degree, simplifying the manufacturing process and improving the wind-resistant performance of the vacuum glass.

Owner:王磊

Transparent section and preparation process thereof

The invention relates to a transparent section and a preparation process thereof. At present, plastic profiles mainly have product structures such as white, white coextrusion, color coextrusion, whole color and spray color, the conventional products do not have transparency, the lighting effect is not optimal and the manufactured doors and windows do not achieve the maximum energy-saving effect. The preparation process for the transparent section comprises the following steps of: mixing vinyl chloride resin, an organic tin stabilizer, a polyol lubricant, an internal lubricant, ultramarine blue, a release agent and a toughening agent in a proportion at 110 DEG C; when hot mixing temperature of the materials reaches 110 DEG C, performing cold mixing in a cold pot to reduce the temperature to 45 DEG C, discharging, and putting into an extruder for extrusion, wherein the processing temperature range is 170 to 210 DEG C; and performing shaping, cooling and forming by using a mold, and performing cutting and packaging to obtain the finished product. The preparation method has a simple process; and the produced transparent section has transparent whole body, good transparency and clear visual effect, effectively improves the lighting effect of doors and windows, and improves the energy-saving effect.

Owner:西安中财型材有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com