Gas-collecting hood for gas water heater and gas water heater using gas-collecting hood

A technology of gas water heaters and gas collecting hoods, which is applied in the direction of fluid heaters, combustion methods, exhaust gas devices, etc., which can solve the problems of large exhaust resistance, the opening of the top of the valve plate, and the difficulty of exhausting smoke, so as to achieve enhanced anti-corrosion Wind pressure capacity, reduce exhaust resistance, and reduce the effect of force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] like Figure 1-7 Shown is a preferred embodiment of the present invention.

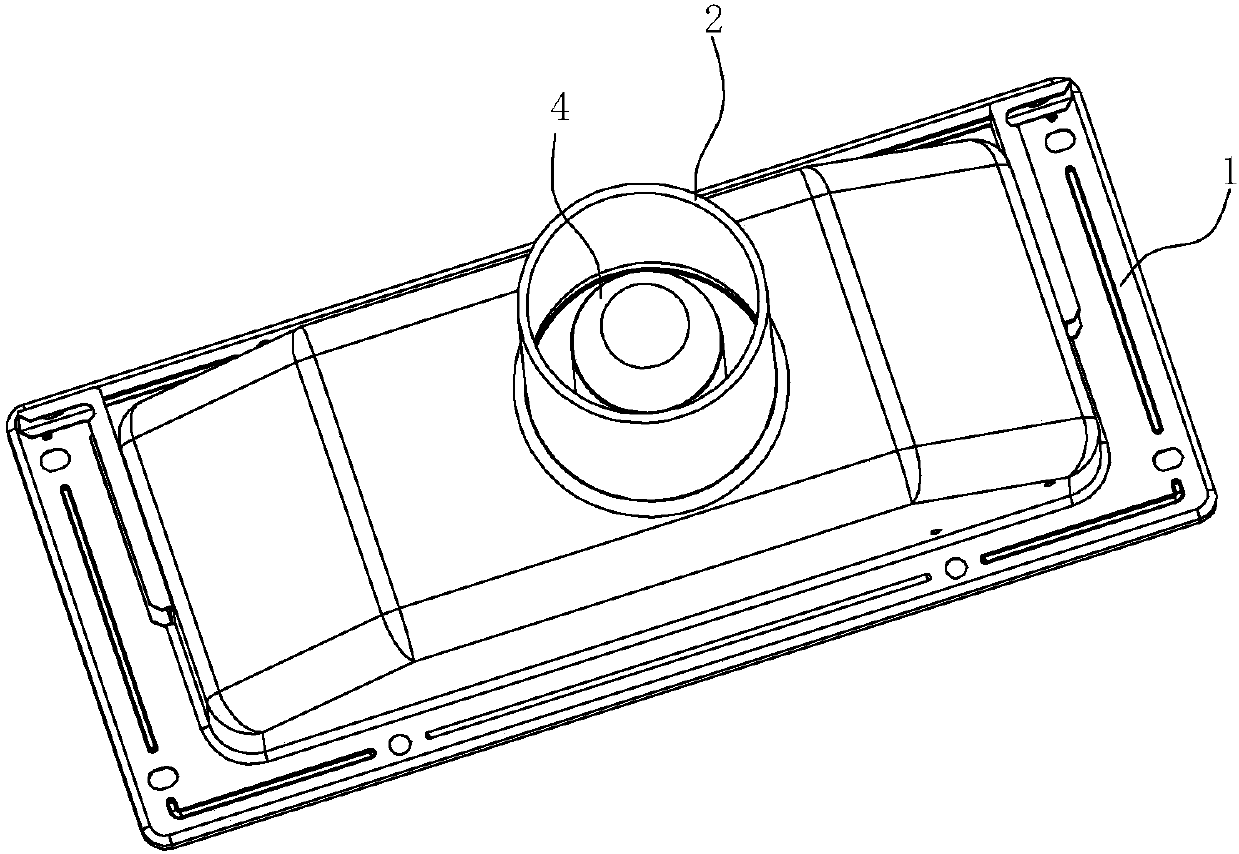

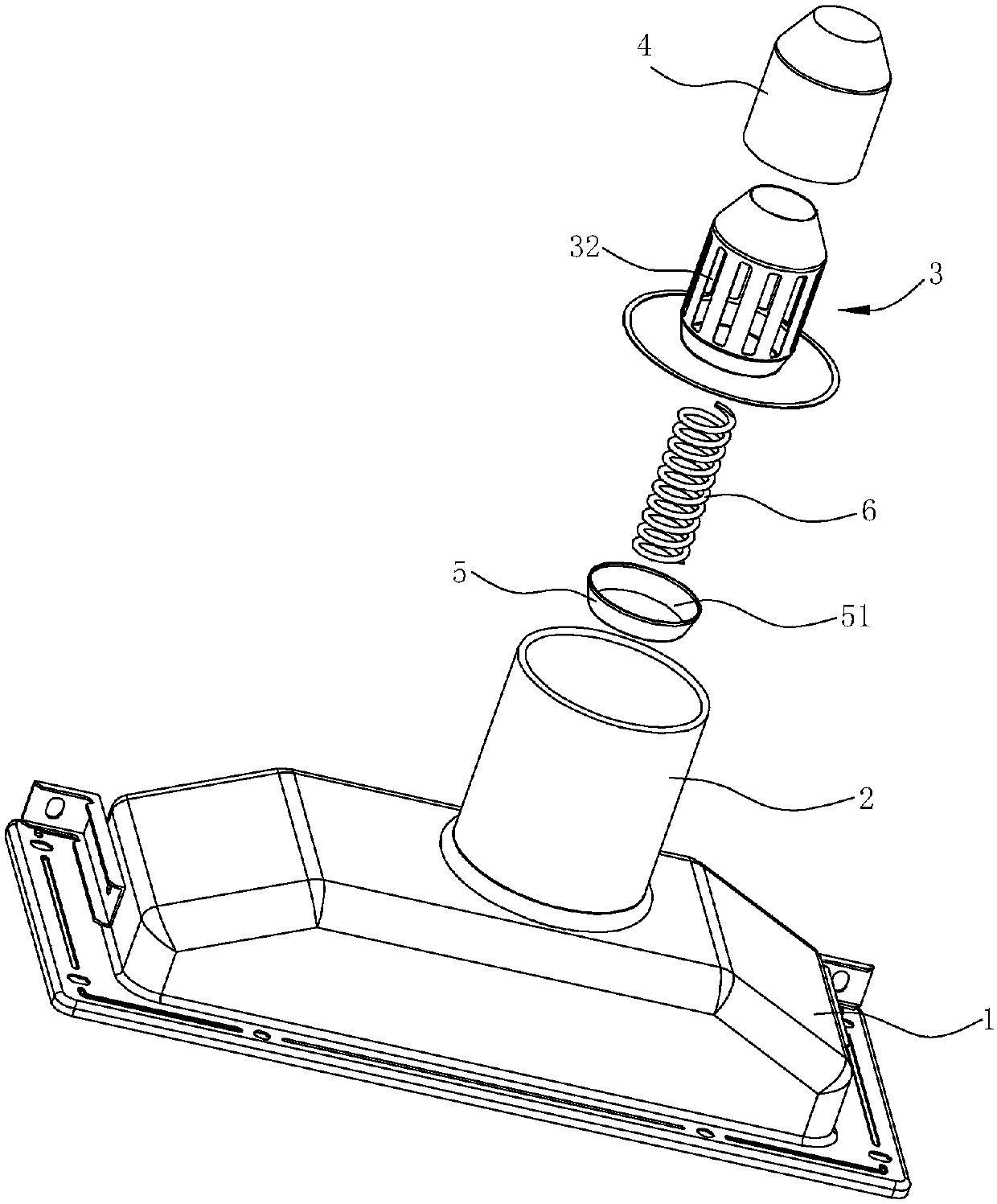

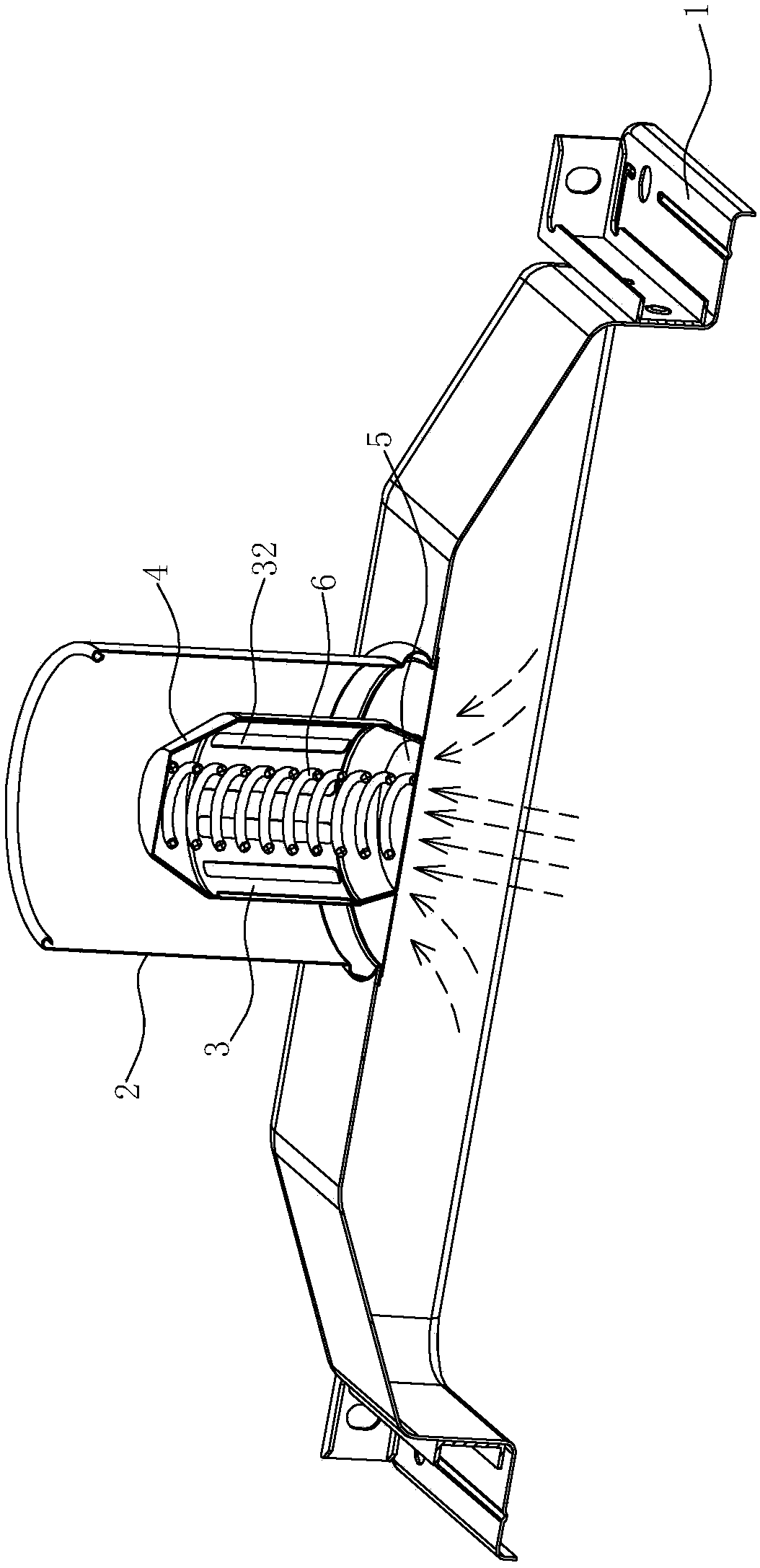

[0032] The gas collecting hood for a gas water heater includes a hood body 1 and a vertical exhaust pipe 2 arranged on the top of the hood body 1, and the exhaust pipe 2 is connected with a pipe leading to the outside to discharge smoke. Wherein the exhaust pipe 2 is provided with an air guide cylinder 3, the lower end air inlet 31 of the air guide cylinder 3 communicates with the inner cavity of the cover body 1, and the side peripheral wall of the air guide cylinder 3 is provided with at least two exhaust pipes at intervals in the upper direction. Hole 32 , the exhaust hole 32 extends axially along the side peripheral wall of the air guide tube 3 . A sleeve 4 with an open bottom and a closed top is provided outside the air guide tube 3, the sleeve 4 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com