Patents

Literature

30results about How to "Avoid secondary generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

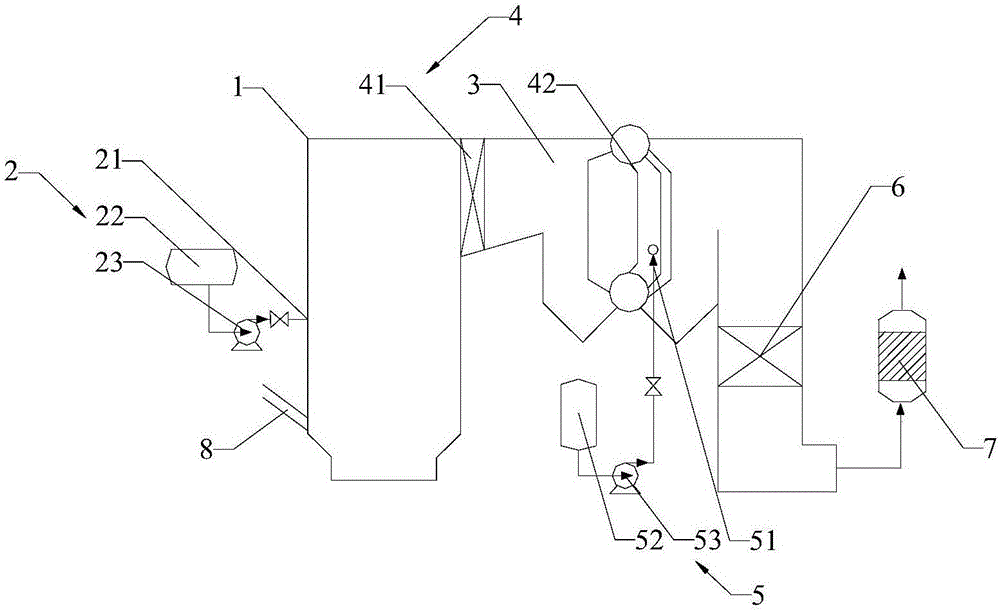

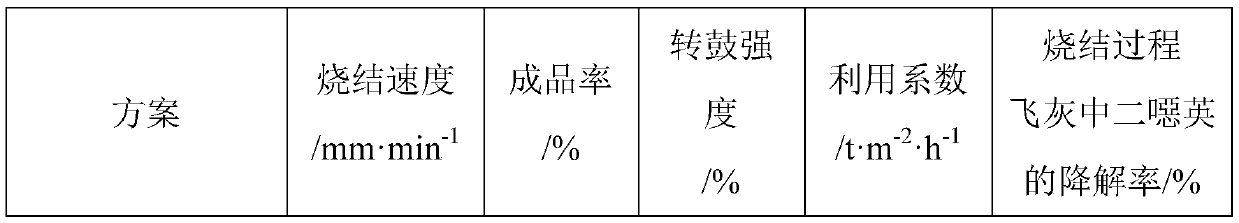

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

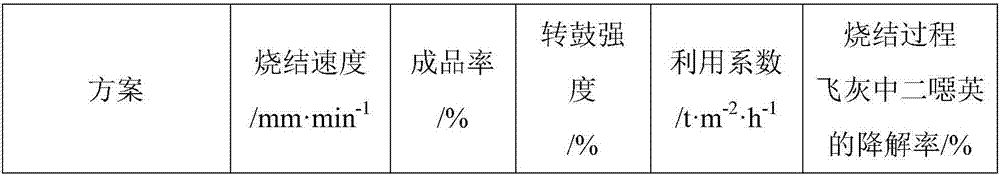

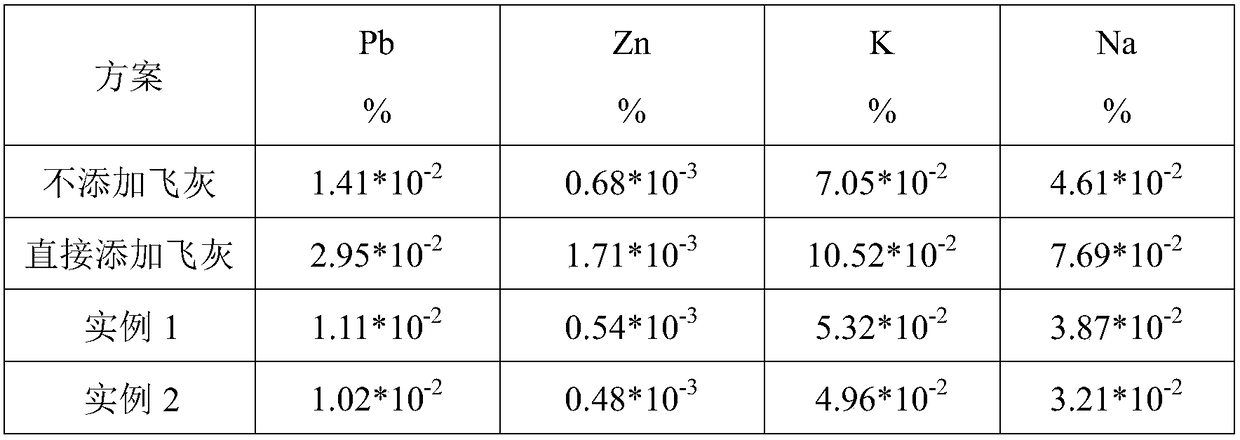

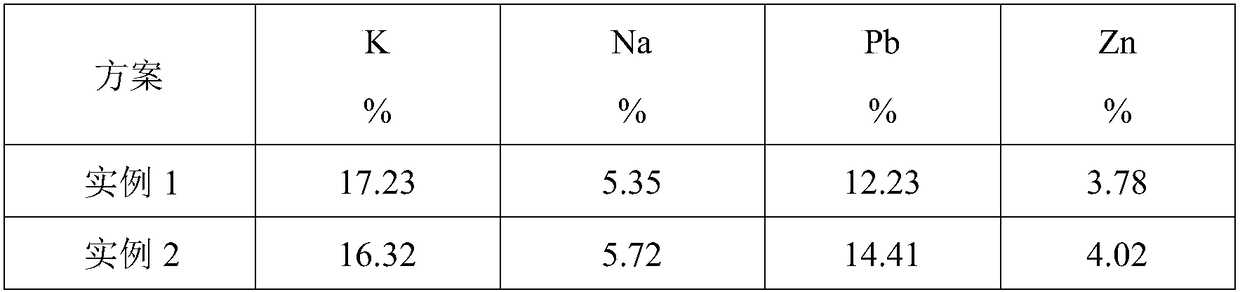

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

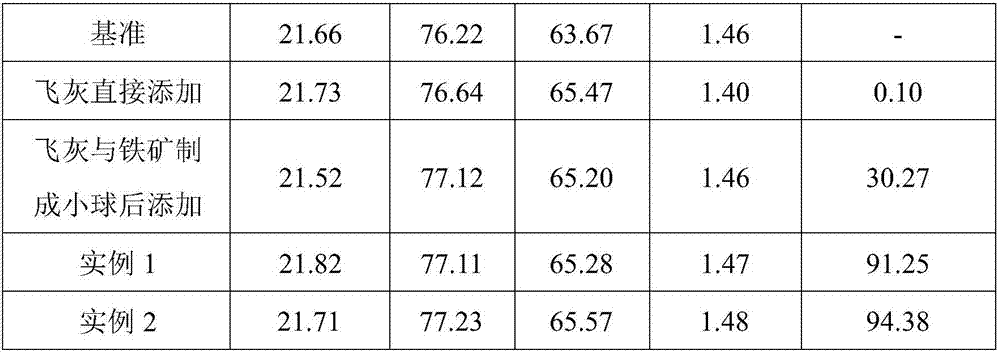

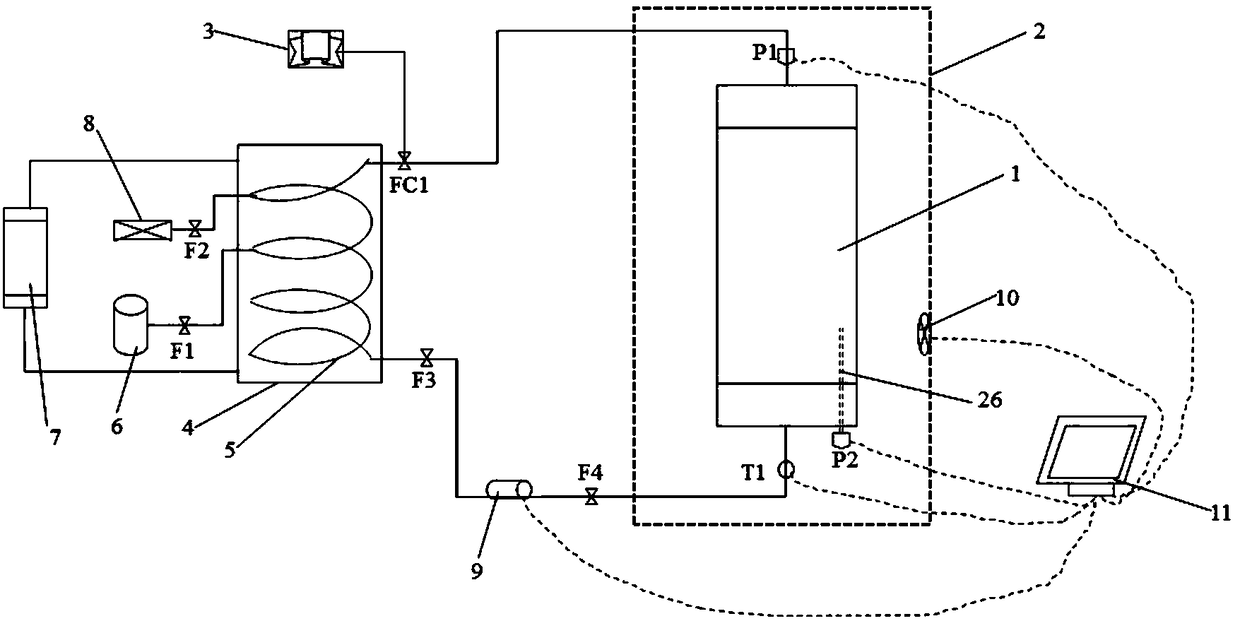

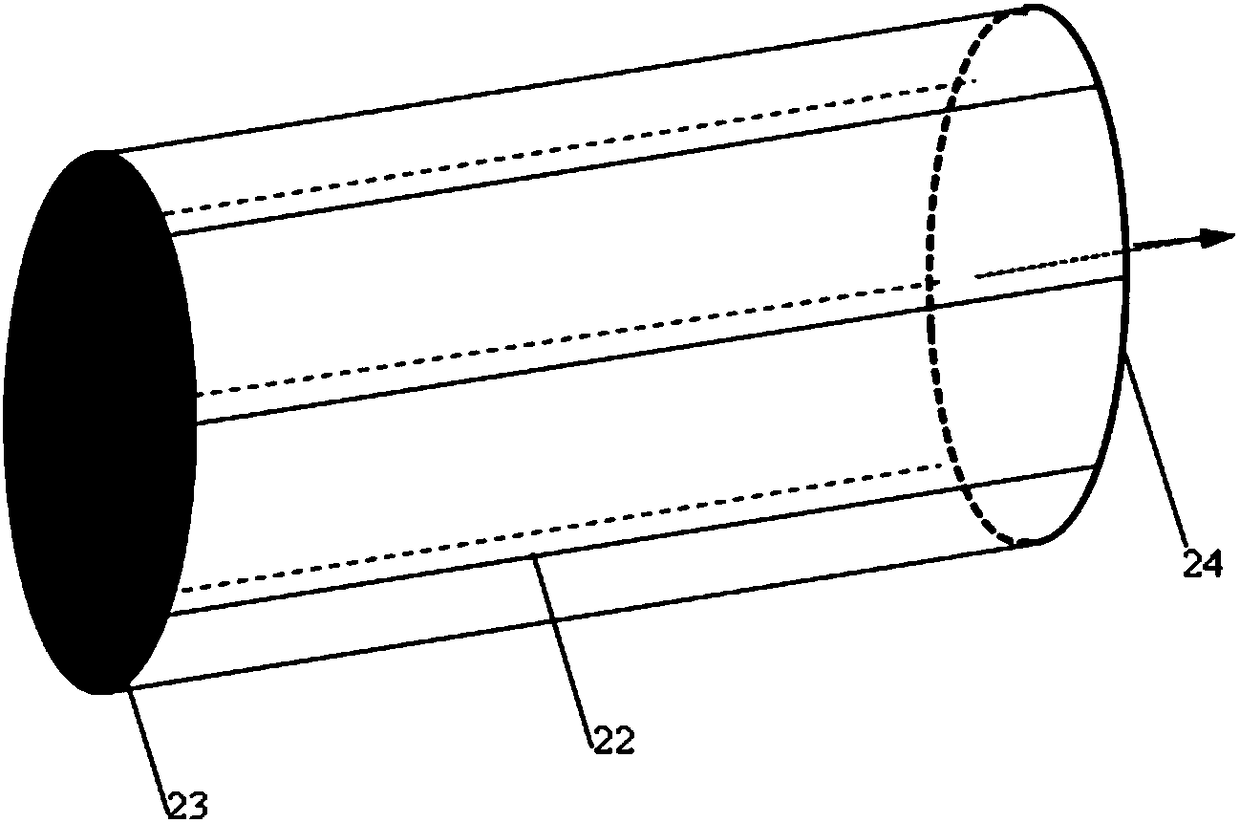

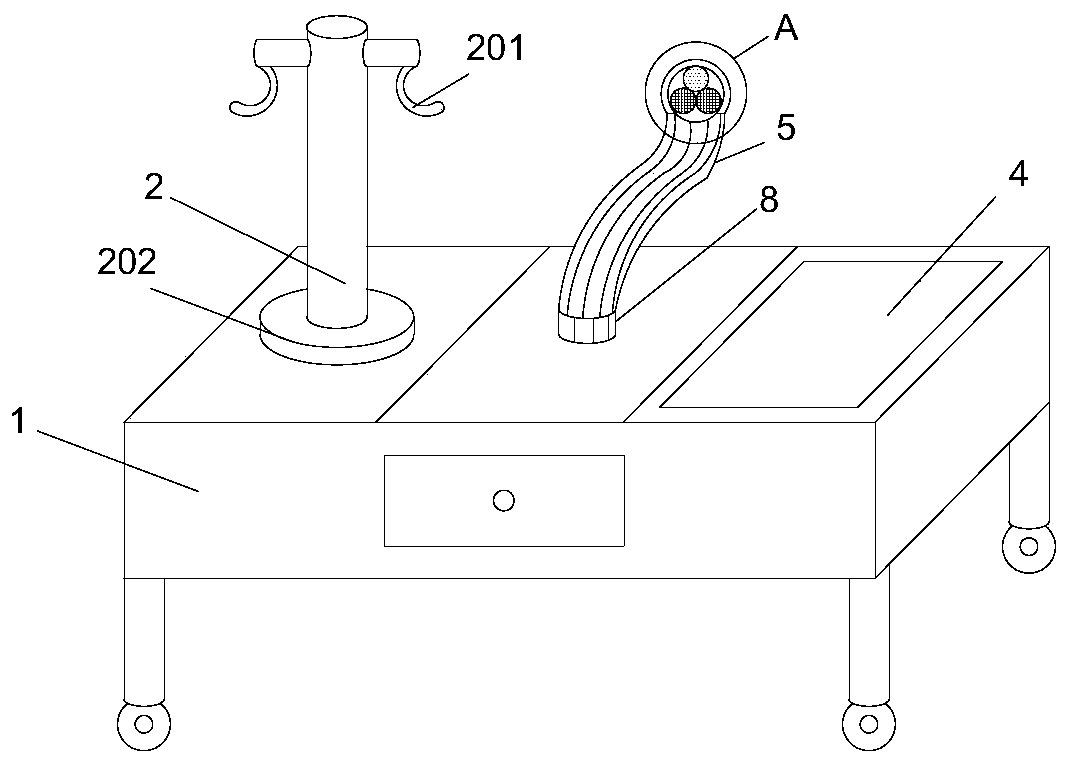

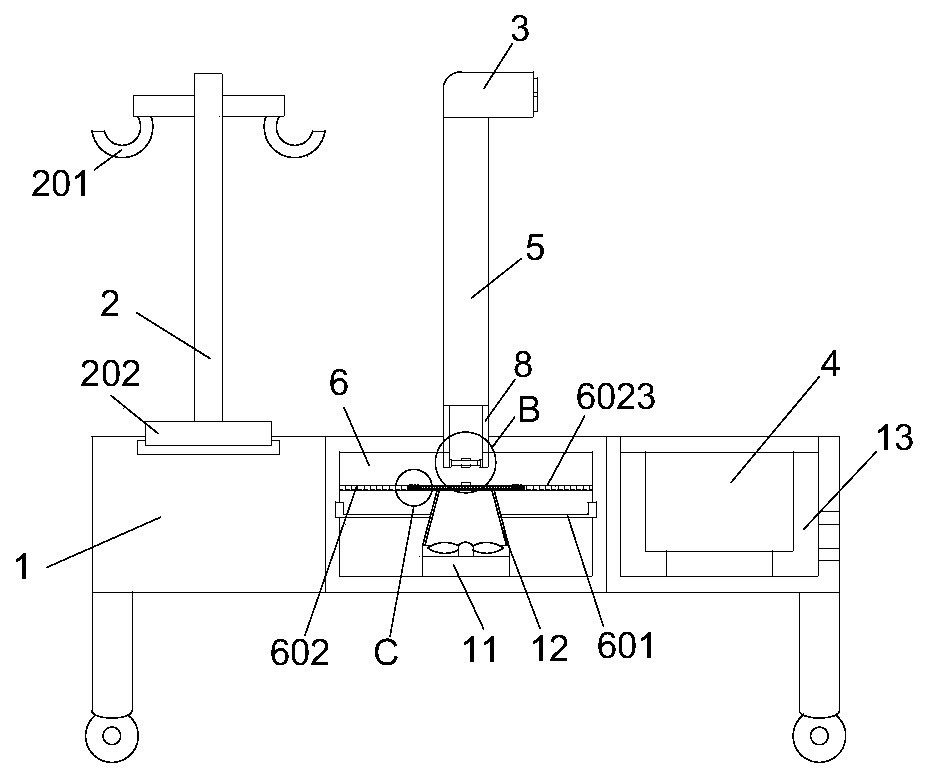

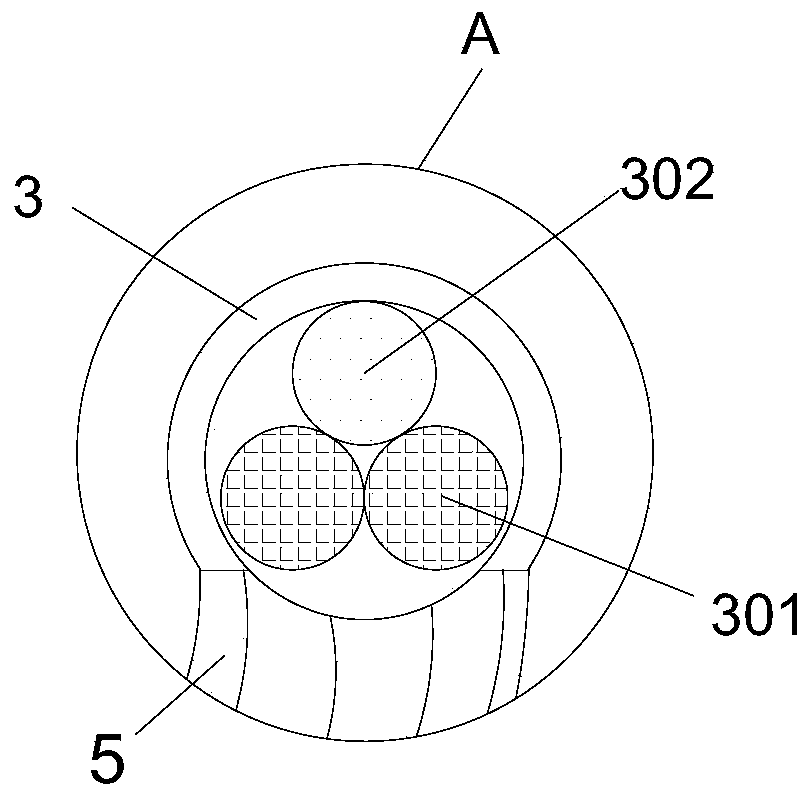

System and method for visually evaluating production and blockage law of hydrate in screen

ActiveCN108226162AAvoid secondary generationAvoiding the Difficulty of Borehole Pressure MeasurementInvestigating moving fluids/granular solidsTemperature controlSkin factor

The invention provides a system for visually evaluating a production and blockage law of hydrate in a screen and a testing method thereof. An experimental system for testing a secondary production, enrichment and blockage law of the hydrate in a screen mesh comprises a reaction kettle, a gas-liquid mixed conveying coil, a high-speed camera, a data acquisition and processing module and the like. The testing method is based on the system, and through adjustment of a cooling mode and control of a temperature and pressure condition and a gas-liquid ratio condition, a three-dimensional chart of thesecondary production and blockage of the hydrate in the screen mesh is simulated; the system can provide basic data for calculation of a well-bottom screen sand control additional skin factor and formulation of a precise pressure-reducing and temperature-controlling scheme under different well body structure conditions (a vertical well, a horizontal well or a multi-branch hole) of a natural gas hydrate production well, and provides a strong support for a sand production management system of the natural gas hydrate production well.

Owner:QINGDAO INST OF MARINE GEOLOGY +1

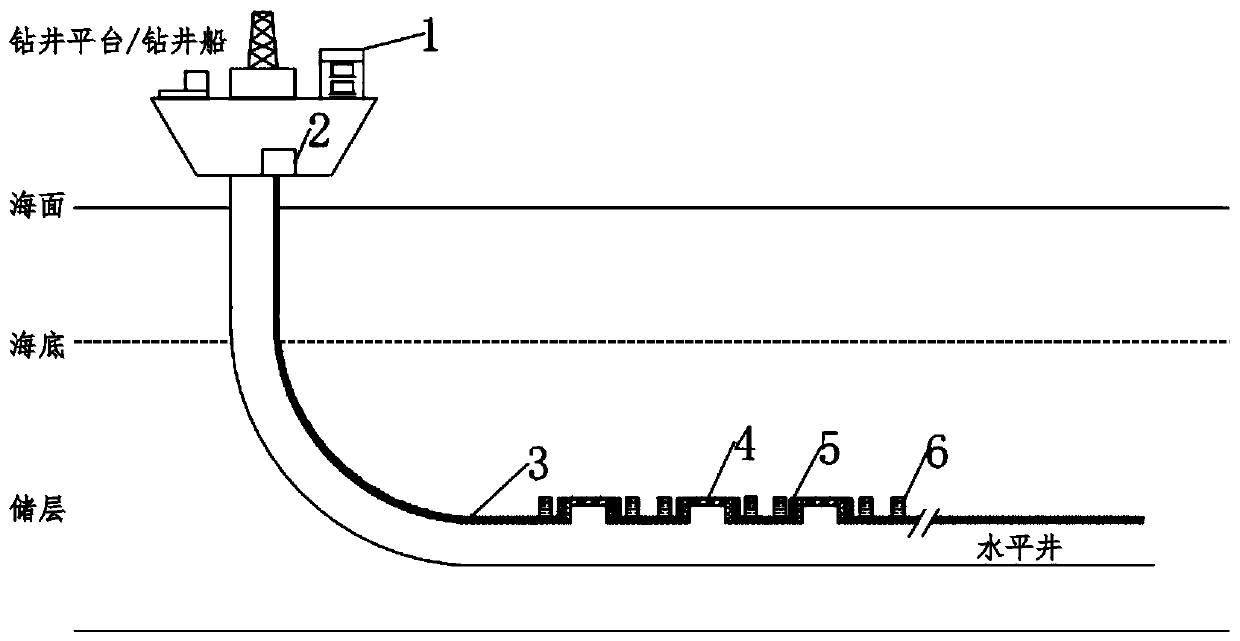

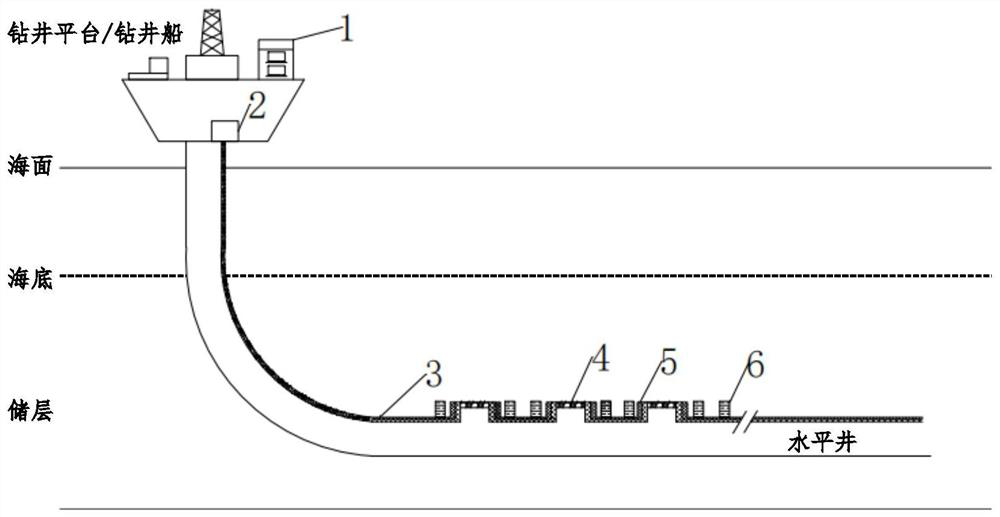

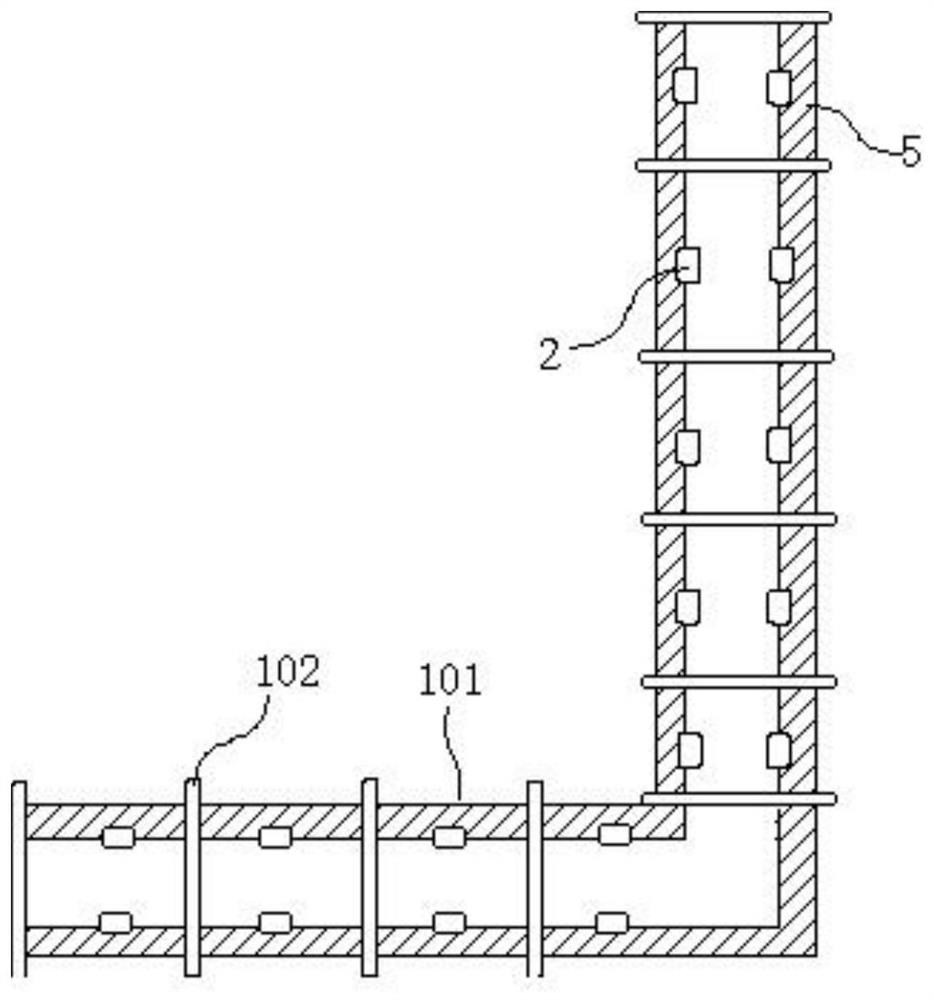

Combined mining method with decompression and heating in multi-branched horizontal wells for marine hydrate

ActiveCN109763794BEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingMining engineeringHorizontal wells

Owner:QINGDAO INST OF MARINE GEOLOGY

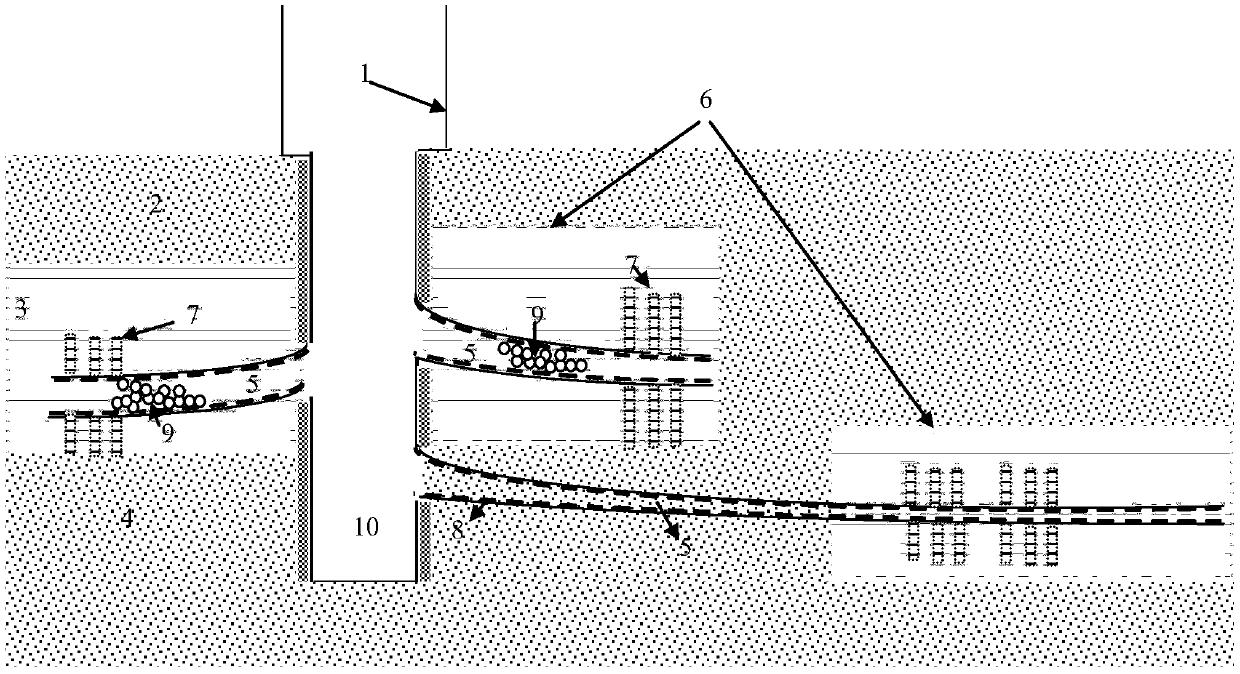

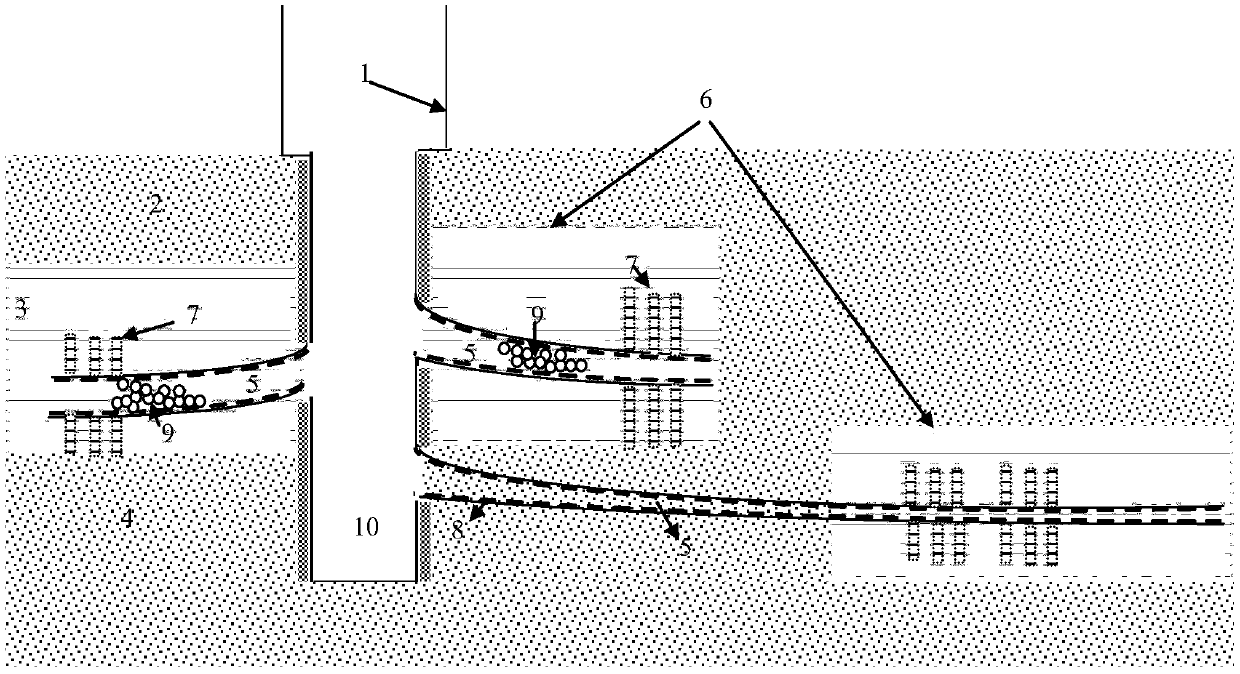

Multi-branch horizontal well depressurization and heating united mining method for marine hydrates

ActiveCN109763794AEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingSoil scienceHorizontal wells

The invention discloses a multi-branch horizontal well depressurization and heating united mining method for marine hydrates. For the 'congenital' defects that the marine hydrates are distributed in ascattered manner and cannot self flow and get together, based on well type structure improvement of a 'main borehole + a multi-branch horizontal well', an ore body reservoir is hydraulically cut by avertical hydrate layer to improve the hydrate decomposition efficiency and achieve the design objectives of connecting three-dimensional scattered ore bodies and relieving the problems of a large amount of sand, instability of the reservoir and blockage formed by secondary hydrates. The united mining method comprises the following steps: (1) forming a well by a main borehole; (2) drilling a multi-branch horizontal well: forming a plurality of multi-branch horizontal wells, which form a certain included angle and are distributed in a fixed direction, around the main borehole, and arranging thehorizontal wells in the middle region of a hydrate reservoir, wherein joints between the multi-branch horizontal wells and between the multi-branch horizontal wells and the main borehole are all of sleeve and conventional sand control sieve tube structures; (3) performing limited sand control and reservoir supporting; (4) transforming the reservoir by hydraulic jetting; (5) performing heating toprevent blockage.

Owner:QINGDAO INST OF MARINE GEOLOGY

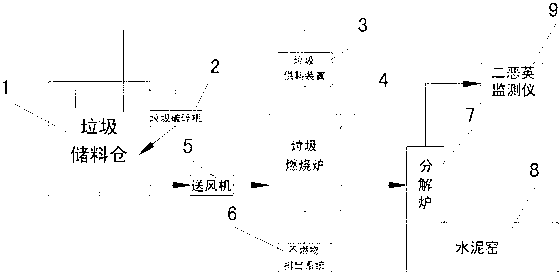

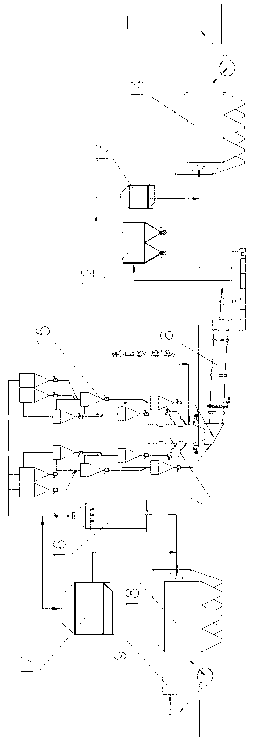

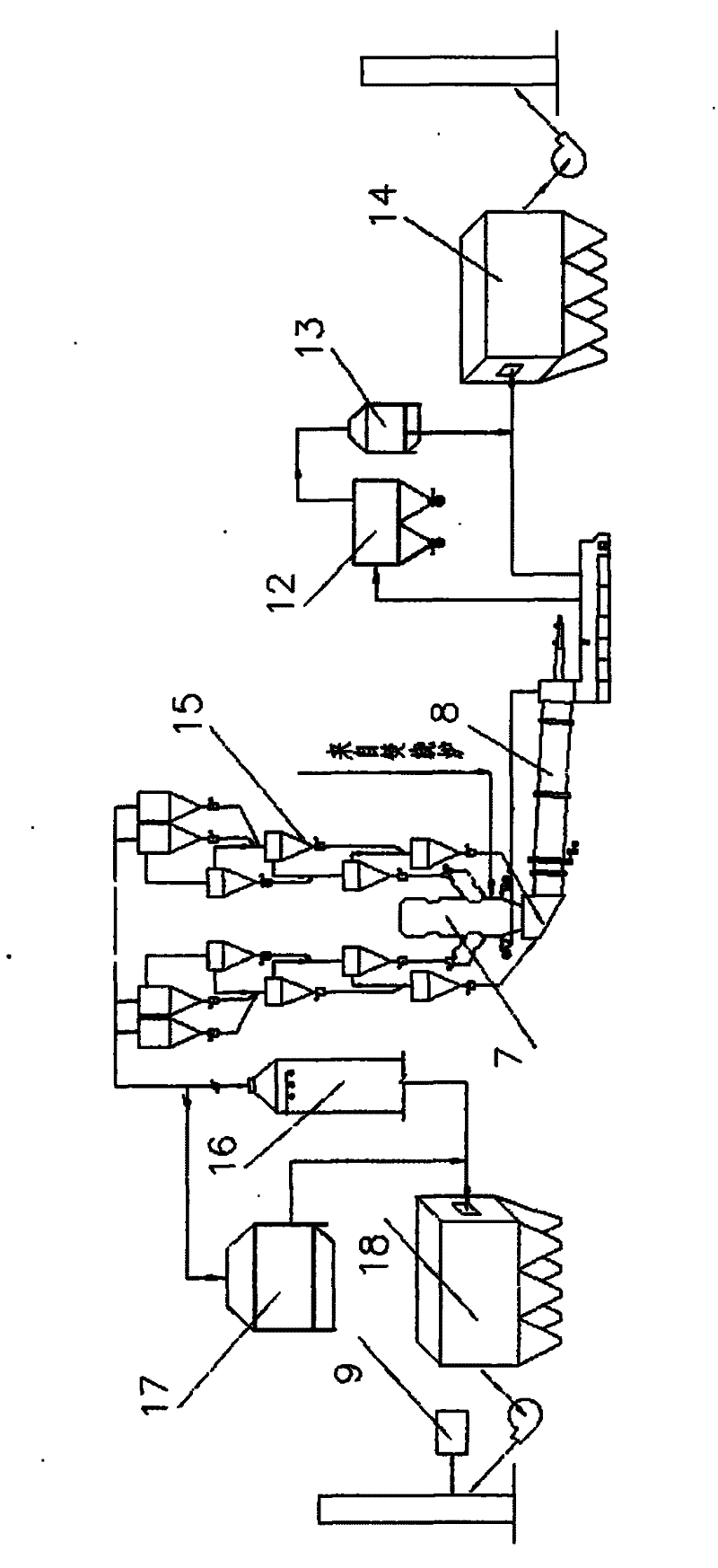

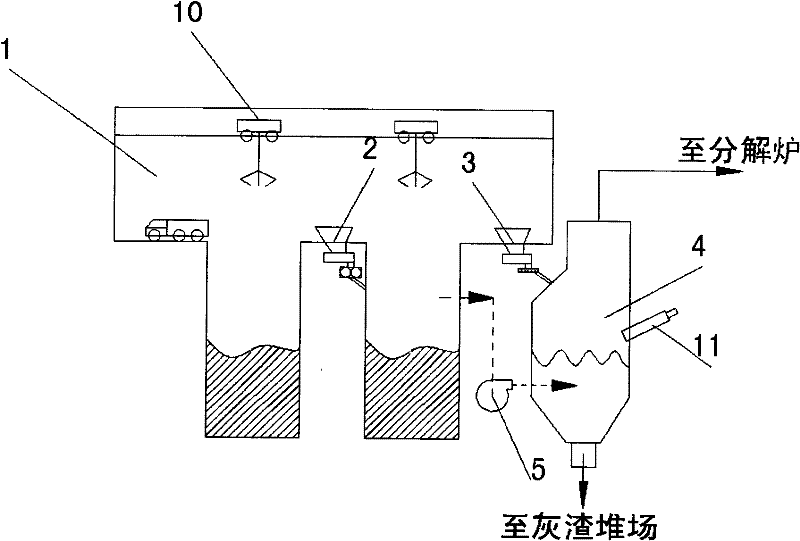

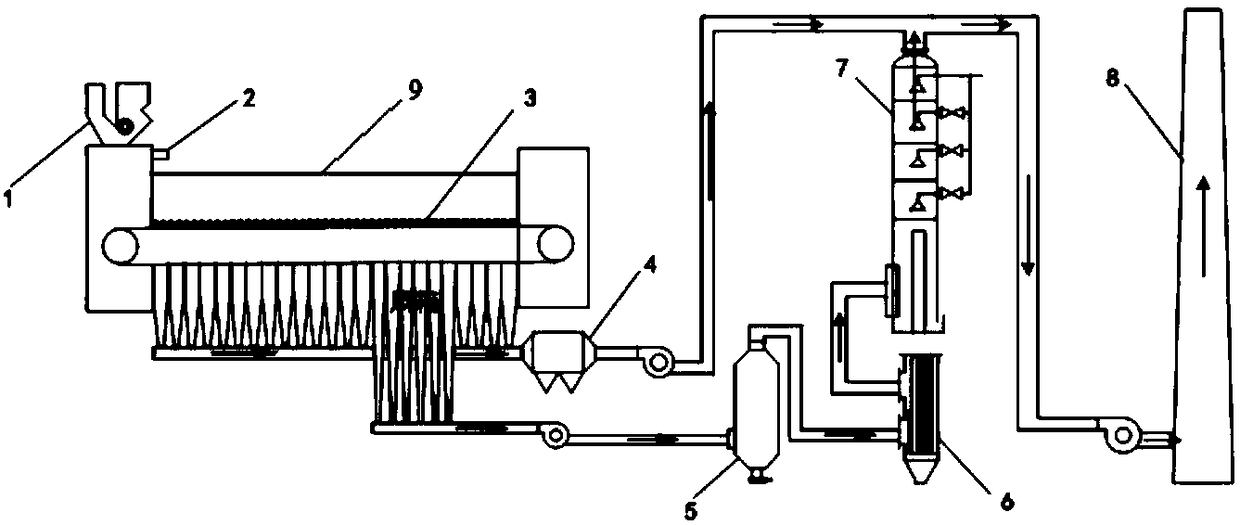

Garbage incinerating exhaust gas using environment-friendly and energy-saving device

InactiveCN102980193AAvoid secondary generationPromote absorptionClinker productionIncinerator apparatusCement kilnPollution

A garbage incinerating exhaust gas using environment-friendly and energy-saving device comprises a garbage storage silo, a garbage breaker, a garbage feeder, a garbage incinerator, a decomposing furnace, a rotary cement kiln and a dioxin detector. The decomposing furnace, the rotary cement kiln and the dioxin detector are used for cement dry method production. The garbage feeder is communicated with a garbage inlet of the garbage incinerator. An exhaust port of the garbage incinerator is communicated with the decomposing furnace through pipelines. A material outlet of the decomposing furnace is communicated with a feeding port of the rotary cement kiln. The garbage incinerator and the rotary cement kiln are combined, high-temperature gas generated by garbage incineration is sent to the decomposing furnace and the rotary cement kiln, heat is provided for the decomposing furnace, meanwhile standing time of the self exhaust gas under a high-temperature condition in the decomposing furnace is over 4 seconds, combustion process is sufficient, incineration under the high-temperature condition is complete, and particularly the dioxin is prevented from being generated, and therefore pollution to environment is reduced, recycling of resources and sustainable development of economy are beneficial for being achieved, and an energy-saving and environment-friendly aim is achieved.

Owner:娄卡奔新能源科技发展(上海)有限公司

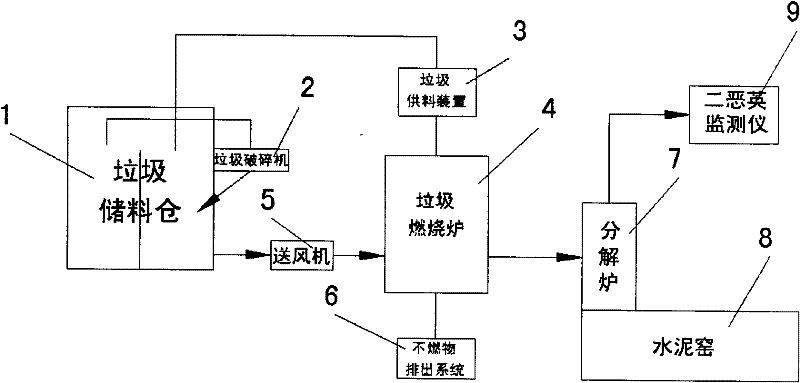

Environmental-protection and energy-saving garbage incineration and waste gas utilization device

InactiveCN102344259AAvoid secondary generationPromote absorptionClinker productionRetention timeCrusher

The invention relates to an environmental-protection and energy-saving garbage incineration and waste gas utilization device, which comprises a garbage storage silo, a garbage crusher, a garbage feed device, a garbage incinerator, a decomposing furnace, a rotary cement kiln and a Dioxin detector, wherein the decomposing furnace, the rotary cement kiln and the Dioxin detector are used for dry-process cement production; the garbage feed device is communicated with the garbage inlet of the garbage incinerator; the exhaust port of the garbage incinerator is communicated with the decomposing furnace through a pipeline; and the material outlet of the decomposing furnace is communicated with the feed port of the cement kiln. Garbage incineration and the rotary cement kiln are combined with each other, so that high-temperature gas generated by garbage incineration is delivered to the cement kiln and the decomposing furnace again, and when heat is provided for the decomposing furnace, the retention time of the waste gas generated by the garbage incineration reaches as long as 4 seconds or above under the high-temperature condition in the decomposing furnace; the combustion process is full; the incineration at high temperature is thorough; and especially, Dioxin is prevented from being generated, and the environmental pollution is reduced, thereby being beneficial to realize the resource recycling and the sustainable development of the economy, and achieving the goals of energy saving and environmental protection.

Owner:叶金辉

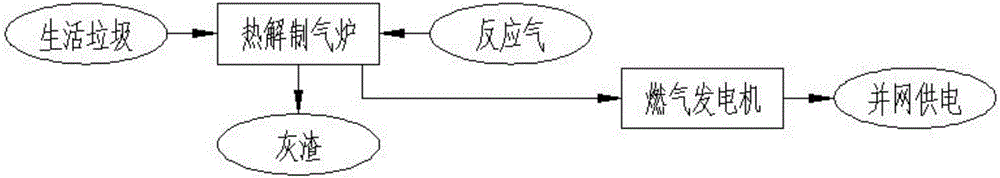

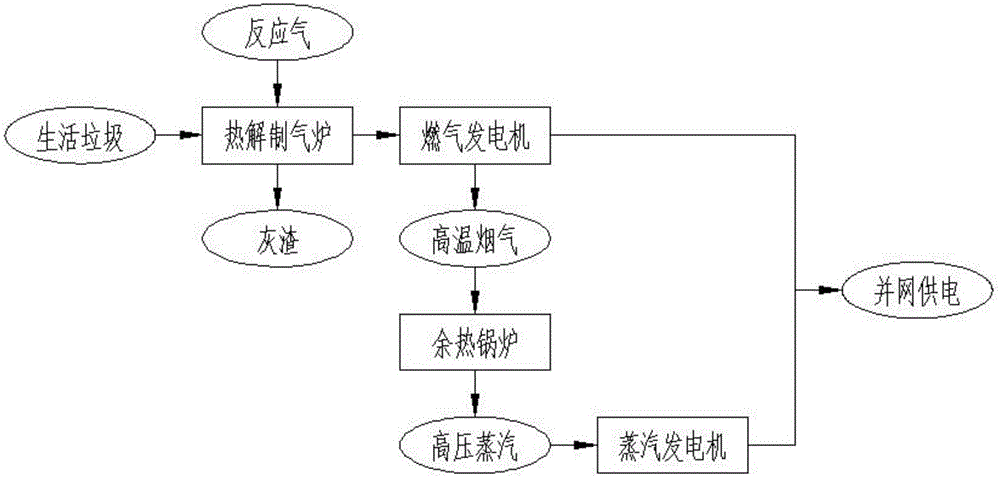

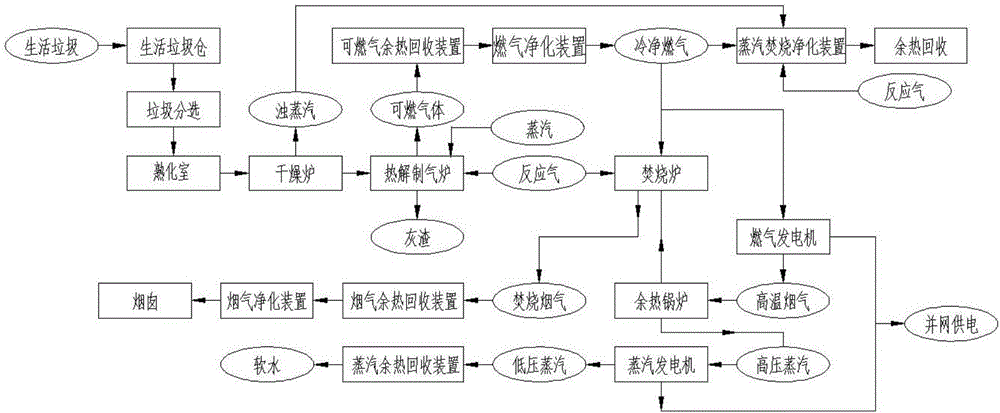

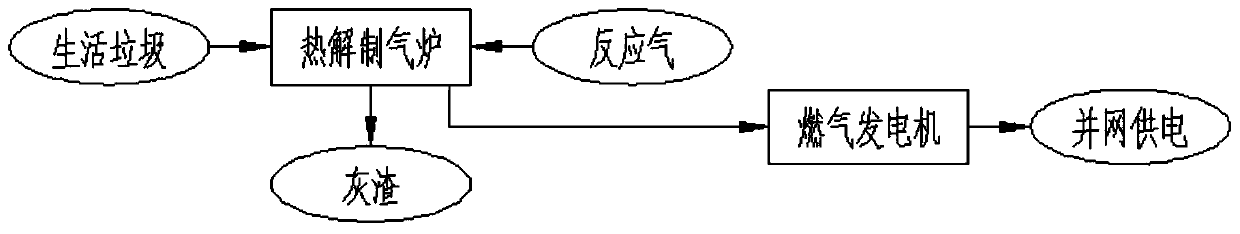

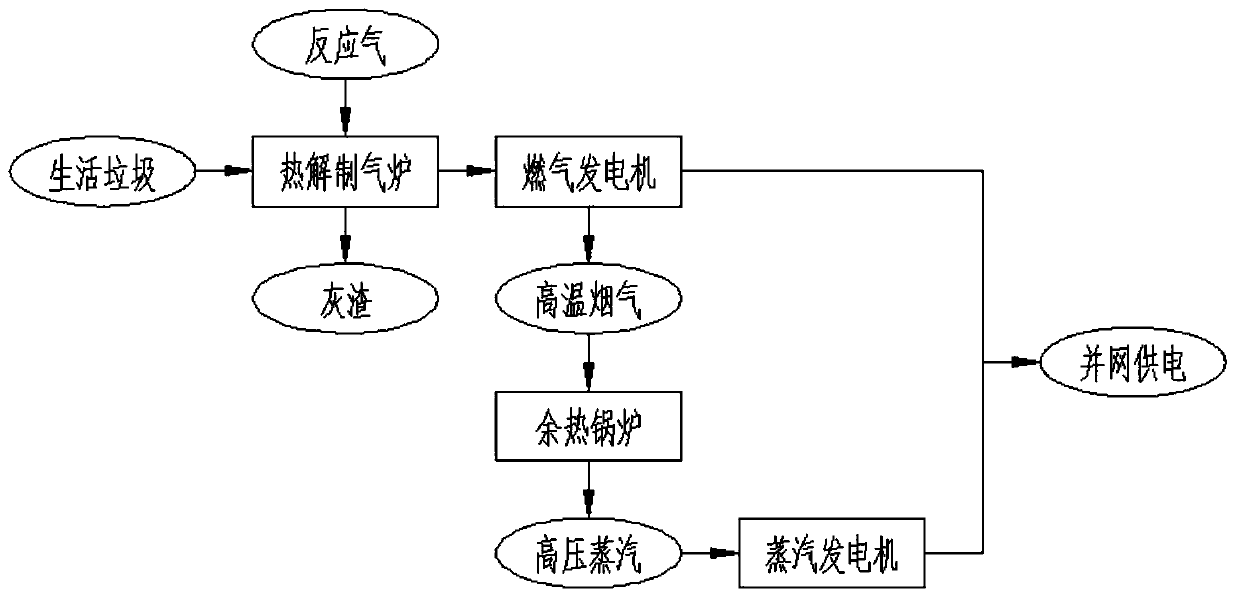

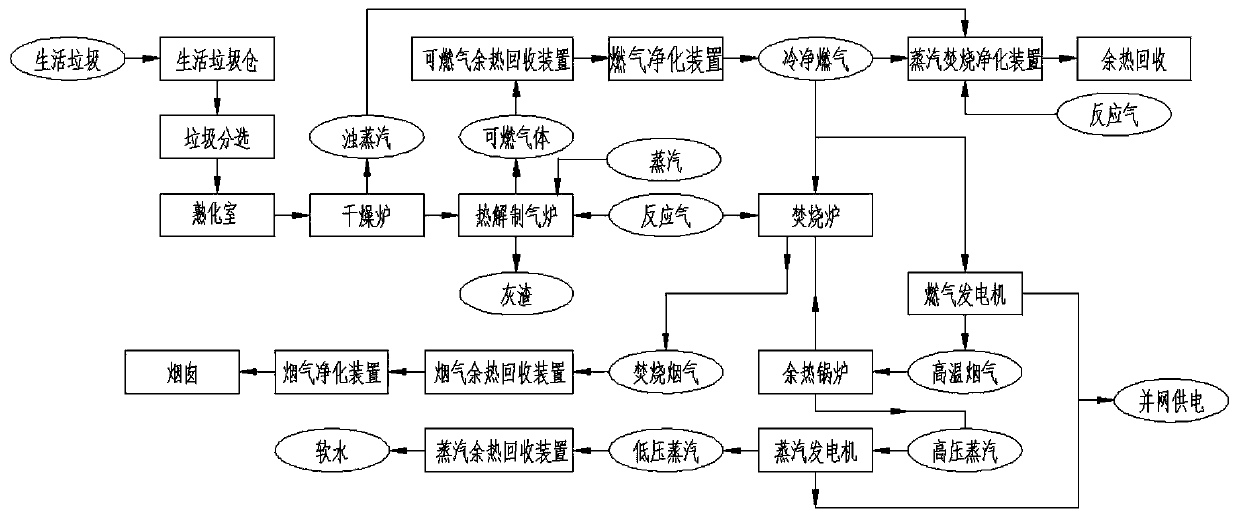

Household garbage pyrolytic electricity generation method

ActiveCN106367117AIncrease power generationGood economic benefitsInternal combustion piston enginesEnergy inputProcess engineeringElectricity

The invention relates to the technical field of garbage disposal, in particular to a household garbage pyrolytic electricity generation method. The method comprises the following steps that S1, household garbage is conveyed into a pyrolytic gas making furnace for pyrolytic gasification, reaction gas is introduced into the pyrolytic gas making furnace, and a product which contains combustible gas is obtained, wherein the oxygen content in the reaction gas ranges from 30% to 93%; S2, the heat value of the generated combustible gas is detected, and the oxygen content in the reaction gas introduced into the pyrolytic gas making furnace is regulated in real time, so that the heat value of the obtained combustible gas is output stably; S3, the combustible gas obtained in S2 is conveyed into a gas electricity generator for electricity generation. The gas obtained through household garbage pyrolytic gasification can be directly used for gas electricity generation.

Owner:THERMONERGY HIGH TECH CO LTD

Burr trimming equipment used after cutting textile clothing cloth

ActiveCN110938959AAchieve absorptionAchieve vibrationMechanical cleaningPressure cleaningFan bladeKnife blades

The invention relates to the technical field of textile equipment, and discloses burr trimming equipment used after cutting textile clothing cloth. The burr trimming equipment comprises a table body;the top of the table body is provided with a clothes rail, a trimmer and a heating device in order from left to right; a dust collection bin is configured at the middle of the table body; and the heating device is arranged at the right side of the table body. According to the burr trimming equipment used after cutting the textile clothing cloth provided by the invention, through the work of a vacuum cleaner, the vacuum cleaner absorbs burrs and thread residues trimmed by a trimmer blade, and the burrs and the thread residues enter the filter screen layer; at the same time, the work of the vacuum cleaner enables a fan blade to rotate; the fan blade drives a second magnet to rotate to change the magnetic pole; when the second magnet and a first magnet have opposite magnetic poles, the firstmagnet is attracted to drive the filter screen layer to move to the upper side, so that the burrs and the thread residues falling on the top of the filter screen layer move towards dust outlet layerson the two sides, and finally enter a dust collection box, so that when clothes are trimmed, the thread residues and the burrs are absorbed while being trimmed.

Owner:青岛威达生物科技有限公司

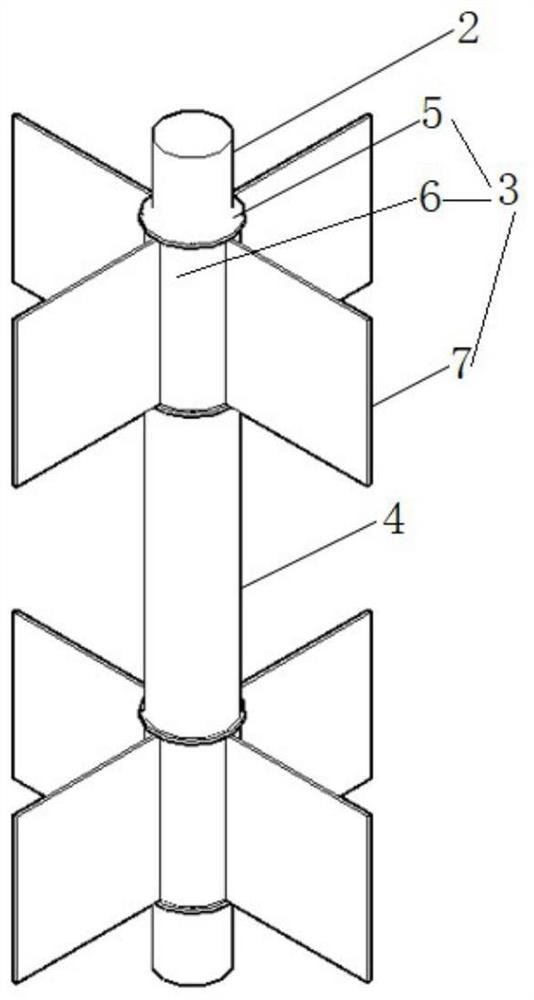

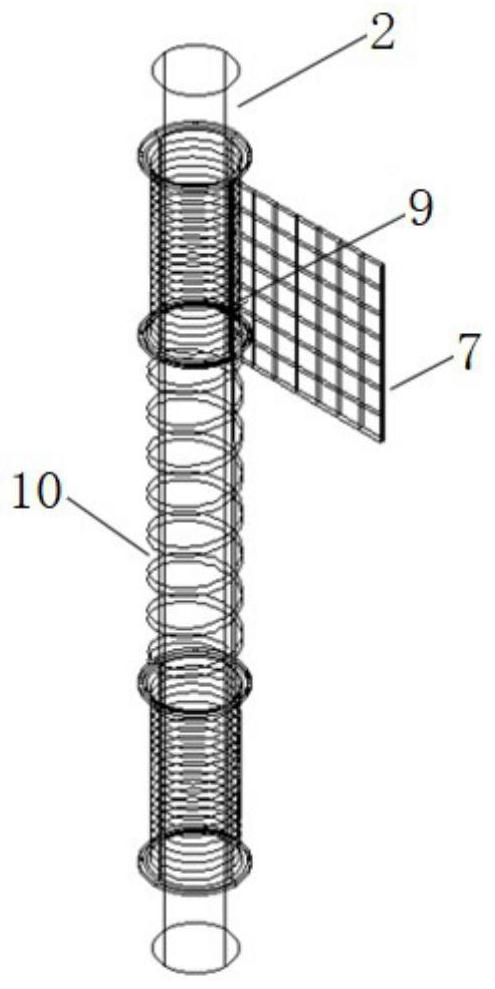

Efficient mining equipment and method of natural gas hydrate through horizontal well fracturing filling

The invention belongs to the field of energy and environment, and provides efficient mining equipment and method of natural gas hydrate through horizontal well fracturing filling. The equipment comprises a pressure monitoring system, a horizontal well fracturing filling system, a sand prevention system and an automatic control feedback system. The problem of difficulty in pressure transmission dueto the fact that low permeability of muddy sediment in the mining process of the natural gas hydrate causes the conditions of secondary generation and ice blockage of the hydrate are solved. Additionally, the pressure permeability range is effectively extended by utilizing the fracturing filling system, and a support agent is solidified in a fracturing area, so that the fracturing area and a gastransfer channel are stabilized, and the hydrate decomposition process is obviously intensified. A gas collecting port is effectively prevented from being blocked by fine sands in a fracturing processby the sand prevention system in a gas production process, and the sand prevention system is flushed by utilizing the fracturing system in the mining process of the natural gas hydrate, so that the problem of easiness in blockage of the sand prevention system is solved. According to the equipment and the method, the safe and efficient large-scale mining of the marine gas hydrate is promoted.

Owner:DALIAN UNIV OF TECH

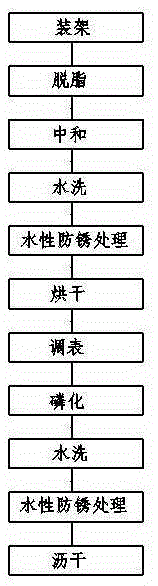

Process for cleaning surface of piston rod

ActiveCN105369261AEasy to cleanAvoid secondary generationMetallic material coating processesCleaning using liquidsWater basedBiochemical engineering

The invention discloses a process for cleaning the surface of a piston rod. The process comprises the following steps: 1. racking, 2. degreasing, 3. neutralization, 4. washing, 5. water-based anti-rust treatment, 6. drying, 7. surface conditioning, 8. phosphorization, 9. washing, 10. water-based anti-rust treatment, and 11. room-temperature draining. The process has the following advantages: in the degreasing procedure, the overall rust of the rod is cleaned, and an ultrasonic device is arranged around a groove body, for accelerating rust cleaning; in the neutralization procedure, the overall particle impurities of the rod are cleaned, and the residual solution in the previous procedure is subjected to neutralization treatment; in the washing procedure, the residual solution in the previous procedure is cleaned, and prevented from being brought in the next procedure; in the anti-rust treatment procedure, a layer of anti-rust film on the surface in an activated state, of the rod, is ensured; in the phosphorization procedure, the end surface of a piston is phosphorized, then medicine residues on the surface are cleaned through washing, then the anti-rust treatment is carried out, and the whole cleaning process is completed.

Owner:锦州万友机械部件有限公司

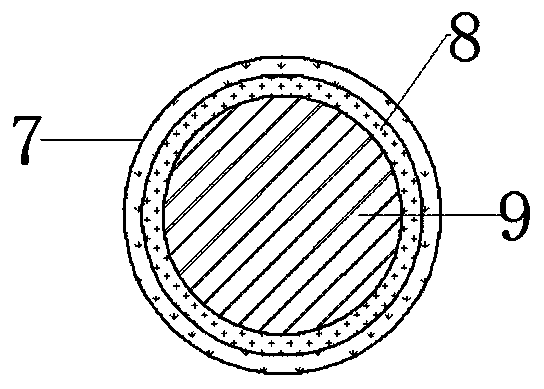

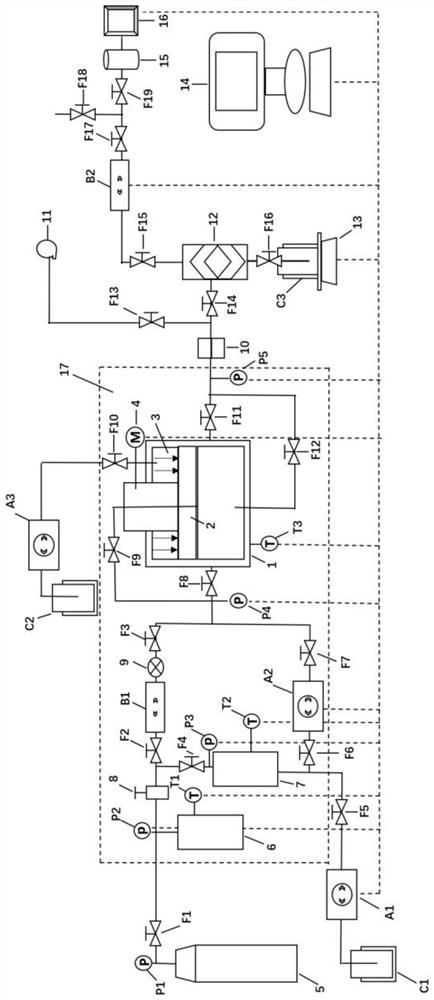

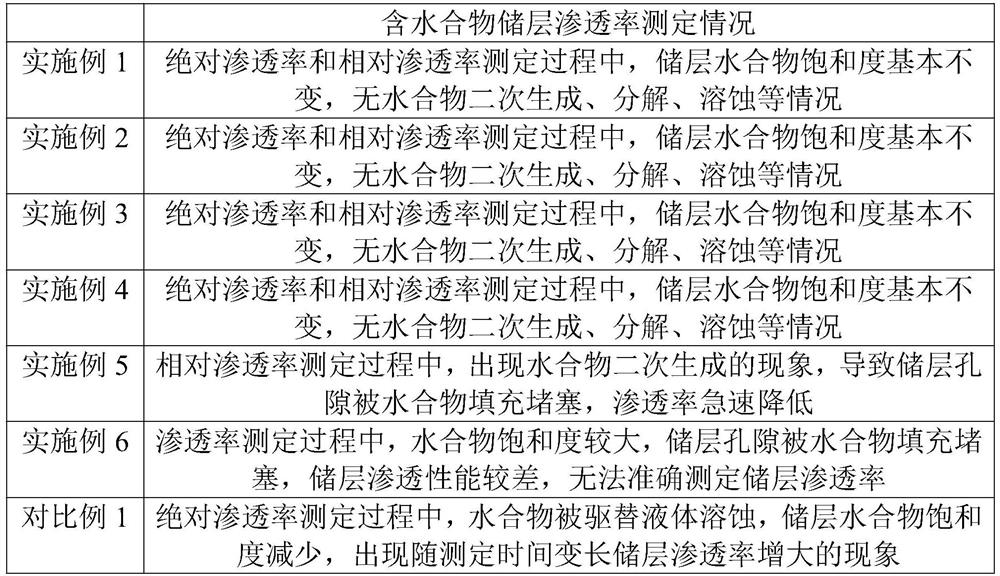

Determination method for permeability of hydrate-containing reservoir in hydrate phase change process

ActiveCN112816386AAvoid secondary generationReduce decompositionPermeability/surface area analysisThermodynamicsDecomposition

The invention relates to the field of determination of the permeability of a hydrate-containing reservoir in a hydrate phase change process, and discloses a determination method of the permeability of a hydrate-containing reservoir in the hydrate phase change process. The determination method comprises the following steps of: preparing a reference reservoir and a decomposition reservoir; preparing displacement gas and / or displacement liquid; injecting the displacing gas and / or displacing liquid the reference reservoir and the decomposition reservoir, and determining the horizontal absolute permeability or the vertical absolute permeability of the reference reservoir and the water-phase horizontal effective permeability or the vertical effective permeability of the decomposition reservoir in the bound gas state under different effective stresses; and determining the horizontal gas-water relative permeability or the vertical gas-water relative permeability of the reference reservoir and the decomposition reservoir by using a steady-state method or an unsteady-state method. According to the determination method, the gas-water seepage rule in the natural gas hydrate reservoir in the phase change process can be reflected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

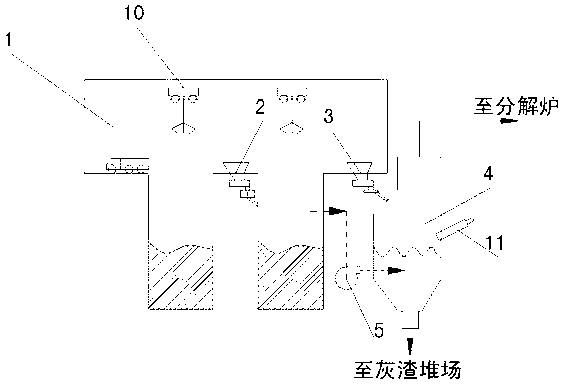

Fluidized bed incinerator for special waste

PendingCN106838934AReduce dwell timePrevent the production or secondary generation of dioxinsEmission preventionIncinerator apparatusFlueWater pipe

The invention relates to the technical field of harmless disposal of an industrial organic waste, in particular to a fluidized bed incinerator for a special waste. The fluidized bed incinerator for the special waste comprises a fluidized bed incinerator body, a heating device, a flue, a steam boiler and a rapid cooling device, wherein the heating device comprises an oil gun connected to a dilute-phase zone of the body; a temperature controller for controlling the heating device is arranged in the dilute-phase zone of the body; the rapid cooling device comprises a fluid atomizing spray gun mounted on the flue corresponding to the back section of the steam boiler; a gun head of the fluid atomizing spray gun is positioned inside the flue; the spray gun is connected with a water tank through a water pipe; a water pump is arranged on the water pipe. Through arrangement of the heating device in the dilute-phase zone of the incinerator, the temperature in the dilute-phase zone of the incinerator is controlled to be above 1100 DEG C, so that the special waste is completely incinerated in the dilute-phase zone of the fluidized bed incinerator; the rapid cooling device is mounted in the flue corresponding to the back section of the steam boiler, so that flue gas is rapidly cooled to be 200 DEG C, and thus the secondary environment pollution caused by dioxin production is prevented.

Owner:福建省环境工程有限公司

Dioxin control method in iron ore sintering co-processing garbage fly ash process

ActiveCN107159678BRealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeIron ore sintering

The invention discloses a method for controlling dioxin in the process of iron ore sintering synergistic treatment of garbage fly ash. The method comprises mixing, granulating and drying the four components of garbage fly ash, milk of lime, flammable solid fuel and sludge. , to obtain pellets containing garbage fly ash; iron ore sintering raw materials are granulated and mixed with the pellets containing garbage fly ash, and then ignited and sintered after the cloth is placed; this method realizes The efficient degradation of dioxin contained in fly ash itself prevents the secondary formation of dioxin in the sintering process of garbage fly ash; this method not only makes the degradation rate of dioxin in garbage fly ash reach more than 90%, but also ensures the The effective consolidation of the fly ash achieves the purpose of cleaning the waste fly ash during the sintering process.

Owner:CENT SOUTH UNIV +1

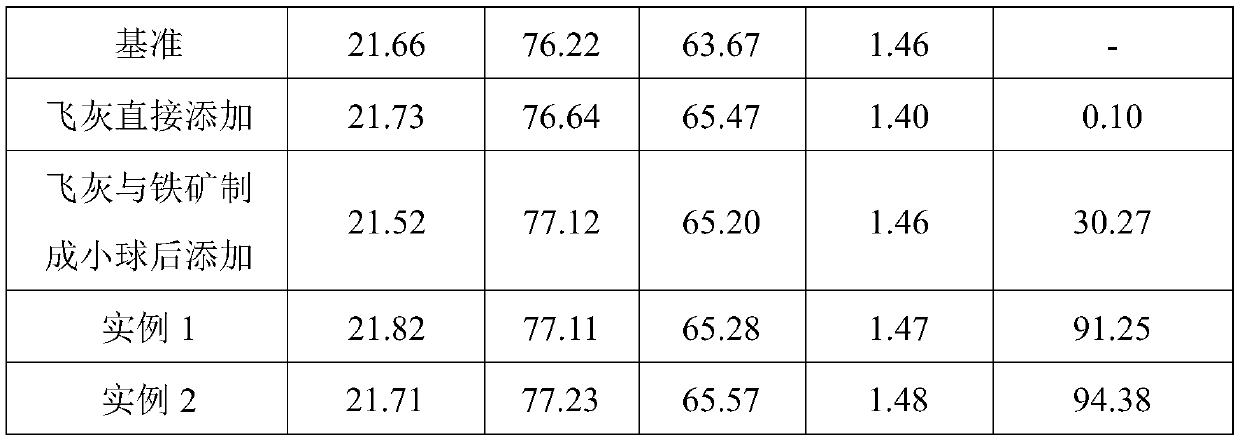

Wastewater treatment system

PendingCN107827248ALow costAvoid secondary generationGas treatmentAmmonium sulfides/polysulfidesExhaust gasTreatment effect

A wastewater treatment system comprises a wastewater tank, a degradation tank, absorption columns, a recycling tank and a crystallization unit and is technically characterized in that the wastewater tank is connected with the bottom intake end of the absorption column I, the top exhaust end of the absorption column I is communicated with the bottom intake end of the absorption column II, the top exhaust end of the absorption column II is communicated with the bottom intake end of the absorption column III, the top exhaust end of the absorption column III is communicated with the air, the bottom drain end of the absorption column I and the bottom drain end of the absorption column II are communicated with the recycling tank, the top exhaust end of the absorption column I is communicated with the bottom intake end of the recycling tank, the topo exhaust end of the absorption column II is communicated with the top intake end of the recycling tank, and the bottom drain end of the recyclingtank forms a crystallization cycle with the top inflow end of the recycling tank through the crystallization unit and pump block II. The wastewater treatment system has the advantages of simple compact structure, low setup cost, good convenience of use, high treatment efficiency, good treatment effect and the like.

Owner:SHENYANG PARAFFIN CHEM

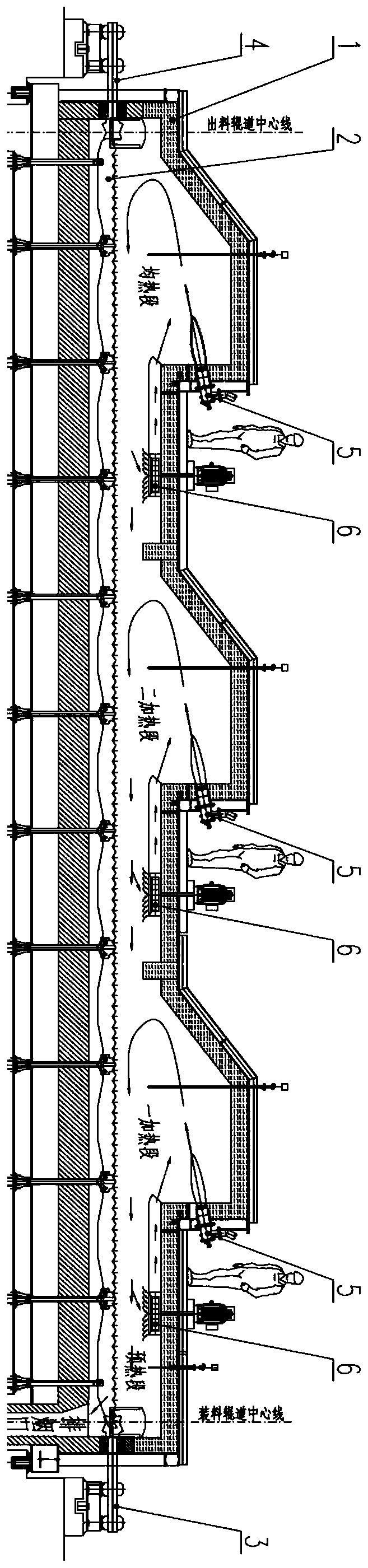

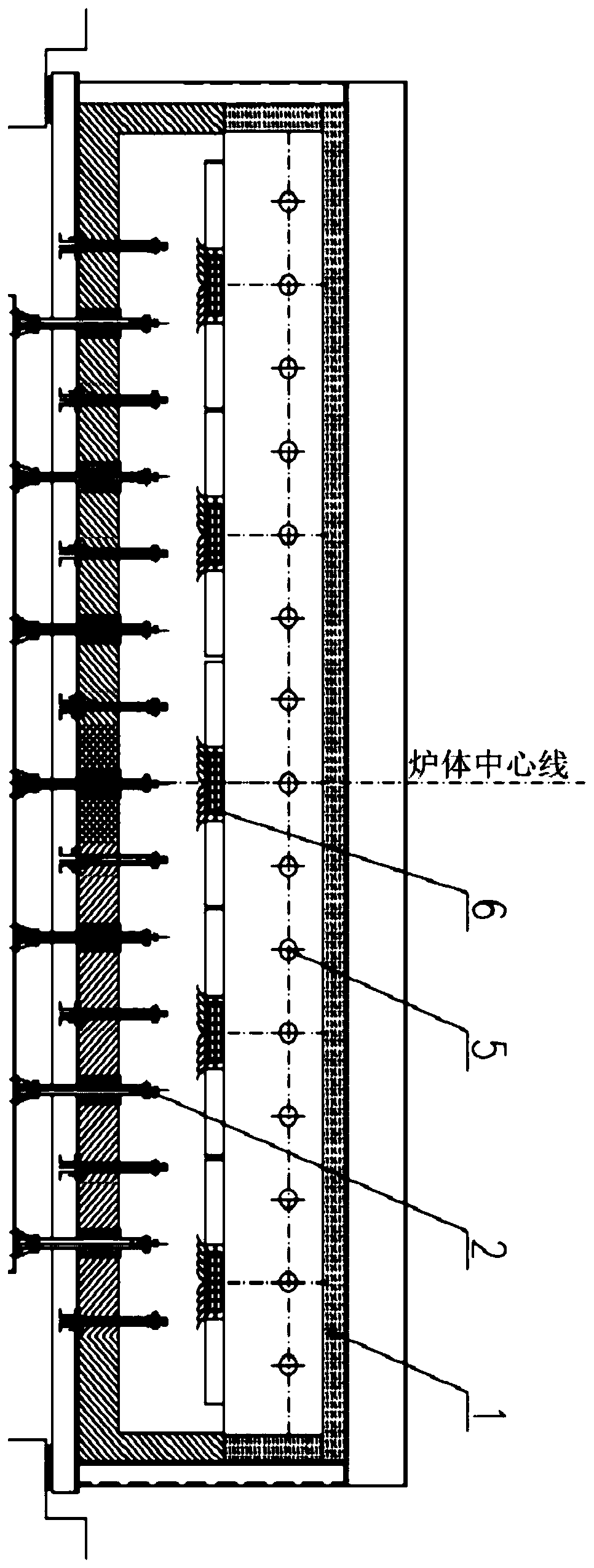

Medium-low temperature heat treatment furnace

PendingCN111394562AGuaranteed uniformityImprove balanceMaintainance of heating chambersFurnace typesFurnace temperatureFlue gas

The invention belongs to the field of industrial furnaces, and relates to a medium-low temperature heat treatment furnace. The medium-low temperature heat treatment furnace comprises a furnace body, wherein a workpiece conveying mechanism arranged in the extending direction of the furnace body is arranged in the furnace body, at least one heat supply section is arranged in the furnace body in theconveying direction of the workpiece conveying mechanism, each heat supply section comprises at least one burner arranged at the top of the furnace body and at least one in-furnace flue gas self-circulation system, and a smoke outlet is formed in the furnace body. According to the medium-low temperature heat treatment furnace, the transverse heat supply balance of a hearth can be guaranteed; the convection heat transfer effect in the furnace is enhanced; the furnace temperature uniformity, especially the temperature uniformity at medium and low temperatures, can be improved; when a in-furnaceflue gas circulation system fails, normal production can still be achieved; the furnace discharges smoke from the tail of the preheating section, the smoke discharge temperature is low, and the heat efficiency is high; and the in-furnace circulation system cannot increase the height of the hearth, and the furnace profile structure is simple and reliable.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

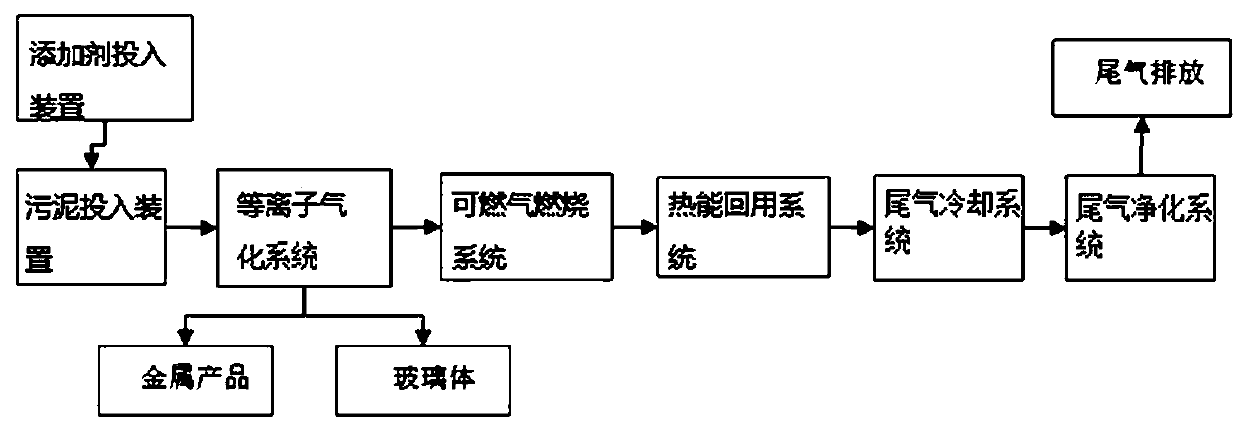

Process system and method for plasma gasification of industrial sludge

PendingCN108676572AAvoid harmPrevent respawnSludge treatmentSpecial form destructive distillationProcess systemsCombustion system

The invention discloses a process system and a method for plasma gasification of industrial sludge and belongs to the technical field of harmless disposal of industrial sludge. The process system comprises a sludge adding device, a plasma gasification system, a combustible gas combustion system and a tail gas treatment system which are sequentially connected; an additive adding device is connectedwith the sludge adding device; the plasma gasification system comprises a plasma gasifier; the combustible gas combustion system comprises a combustion tower with an oxygen supply pipeline; the tailgas treatment system comprises a tail gas cooling system and a tail gas purifying system.

Owner:CHENGDU YUANYONG TECH DEV

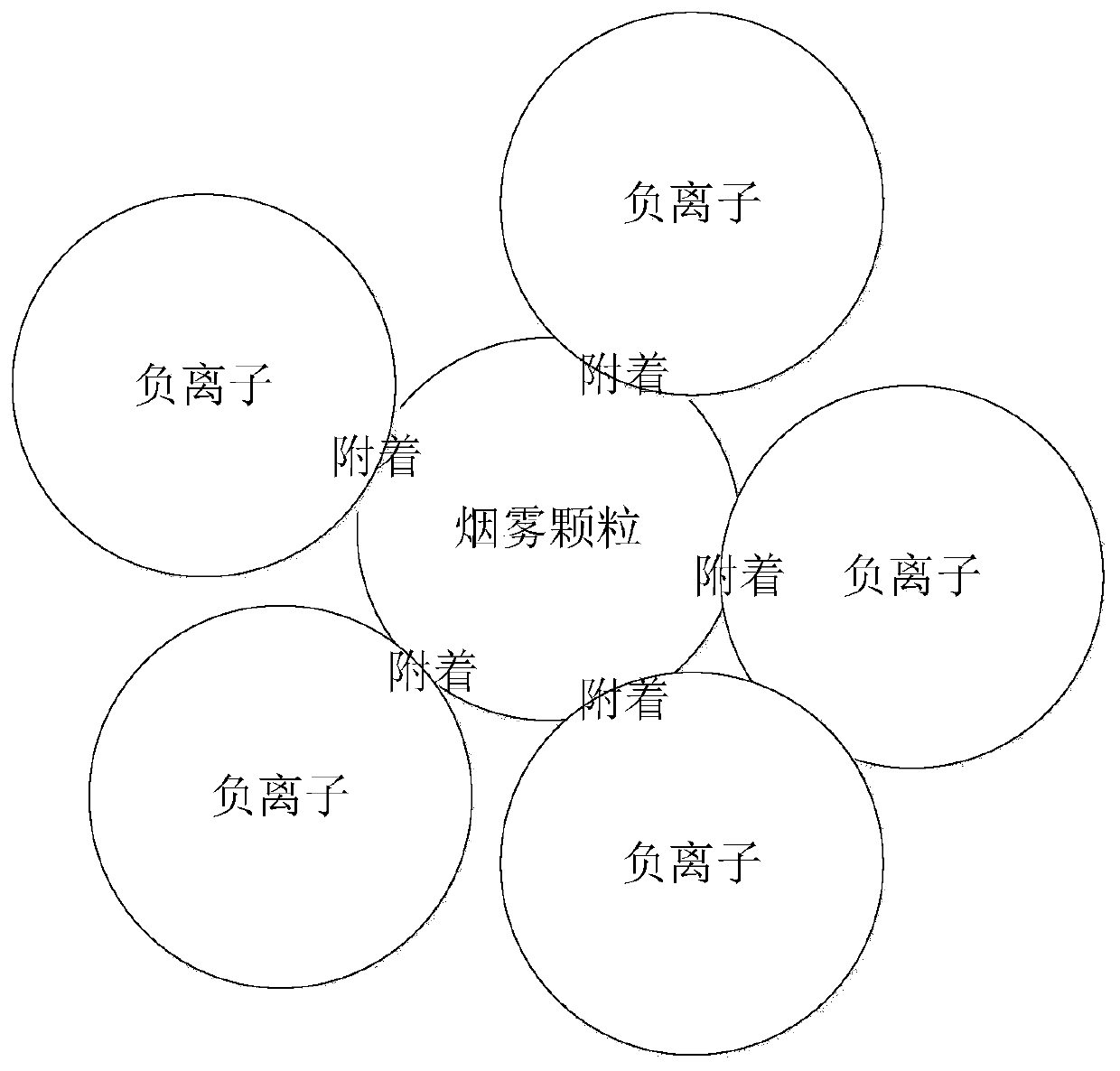

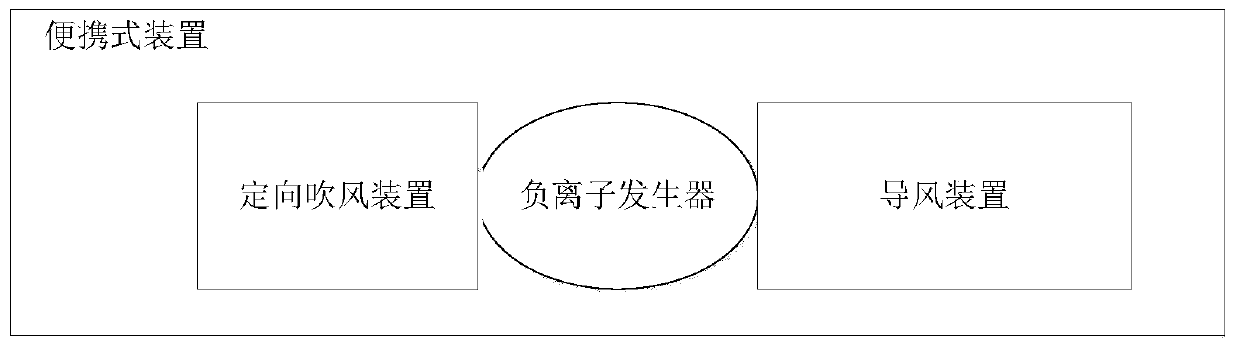

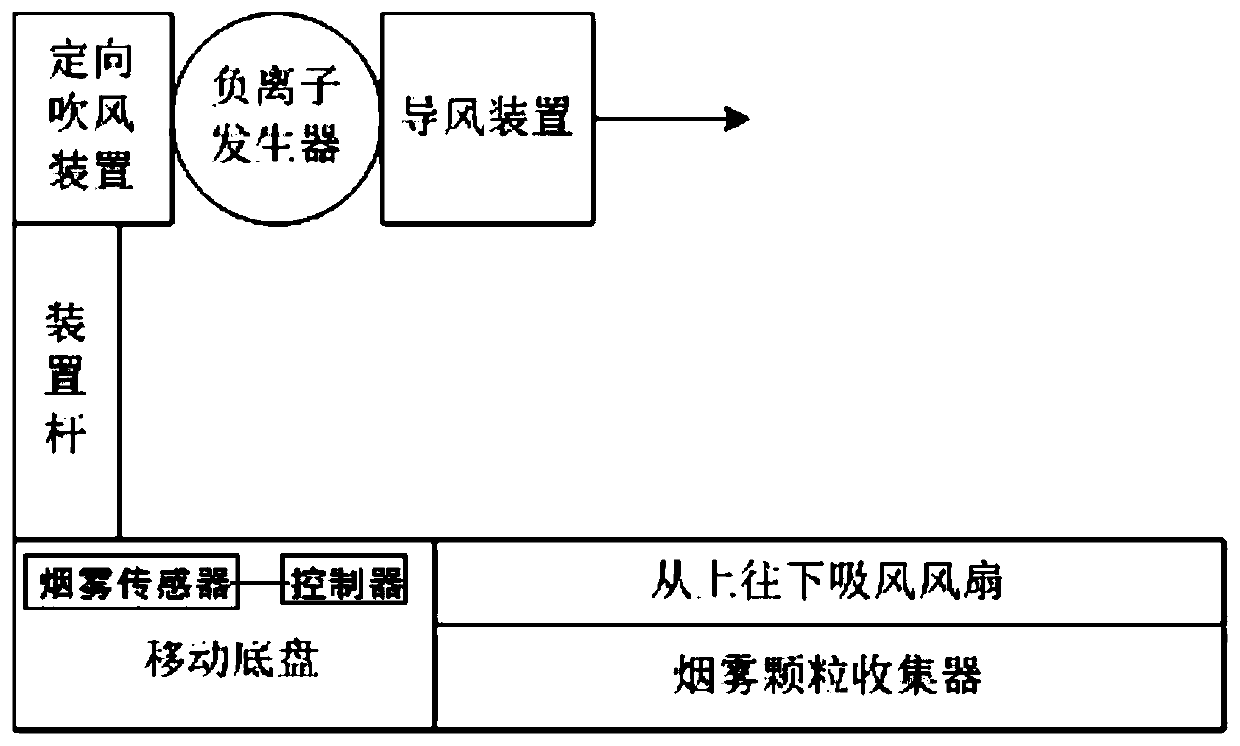

Fire-fighting and smoke removing method and device

PendingCN109945380AImprove the effect of fire and smoke removalImprove convenienceMechanical apparatusSpace heating and ventilation safety systemsEngineeringFire fighter

The invention relates to a fire-fighting facility, in particular to a fire-fighting and smoke removing method and device. The fire-fighting and smoke removing device comprises a directional air blowing device, an anion generator and an air guide device which are sequentially connected with one another. The fire-fighting and smoke removing device can be a portable device and can also be of an air guide structure for supporting, moving and guiding air at the same time; meanwhile, the tail end of the air guide structure is provided with an air suction fan capable of sucking air from top to bottom; and the lower part of the air suction fan is provided with a smoke particle collector. By adopting the fire-fighting and smoke removing device, the effect of fire-fighting and smoke removal is remarkably improved; by means of a wearing type, a throwing type and a robot automatic walking manner, the convenience, the rapidness and the effectiveness of fire-fighting and smoke removal are improved;and the life safety of firefighters is guaranteed, and the fire-fighting ability of the firefighters is improved.

Owner:SHANGHAI FIRE RES INST OF MEM +1

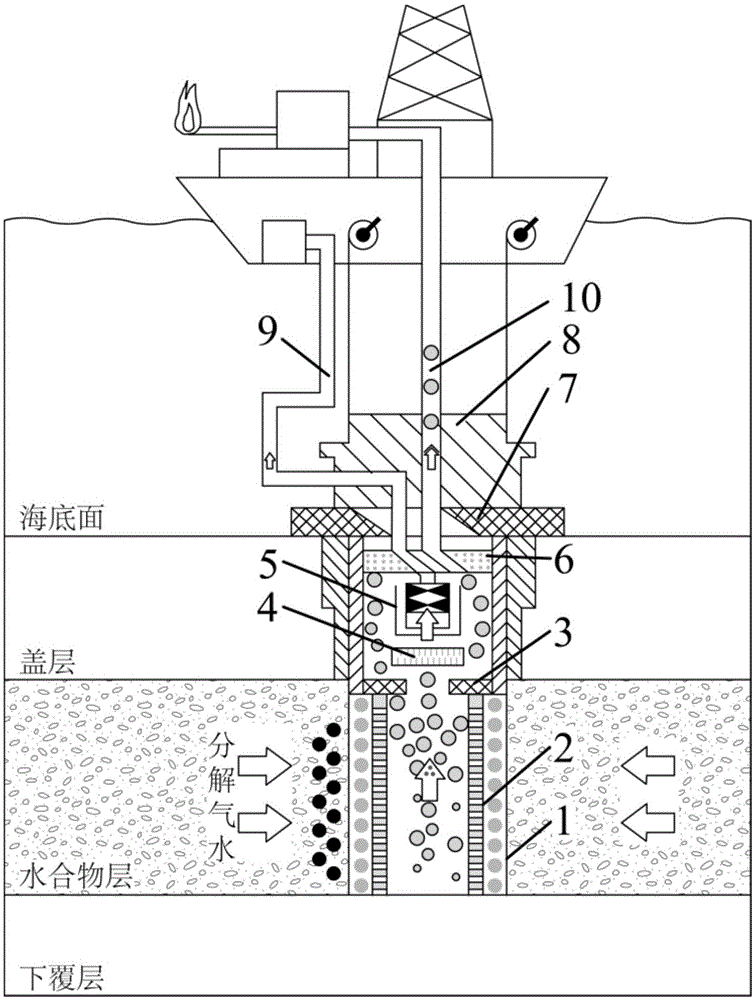

A safe and efficient marine natural gas hydrate decompression and decomposition production device and method

ActiveCN103867165BAvoid enteringAvoid secondary generationFluid removalSealing/packingDecompositionHydrate decomposition

A safe and efficient marine natural gas hydrate depressurization decomposition production device and method, the device includes a sand production prevention device, a gas-water separation device and a safety protection device, and can also be provided with a hydrate secondary generation prevention device. The method for decomposing and exploiting marine natural gas hydrate by using the device includes the following steps: the decomposed gas, water and sand flow to the wellbore, the mud and sand in the sedimentary layer are blocked, and the gas and water enter the wellbore; the gas and water go upward along the wellbore under the extraction action of the water pump The flow is separated into the respective pipelines, and finally lifted to the production platform or ship; the well pressure is detected in real time, and once an abnormality occurs, the gas and water pipelines are disconnected and the gas production is suspended. The invention can well prevent quicksand formed by hydrate decomposition from entering the wellbore, realize gas-water separation in the wellbore, prevent secondary generation of hydrate in the wellbore, etc., and realize safe and efficient exploitation of marine natural gas hydrate.

Owner:DALIAN UNIV OF TECH

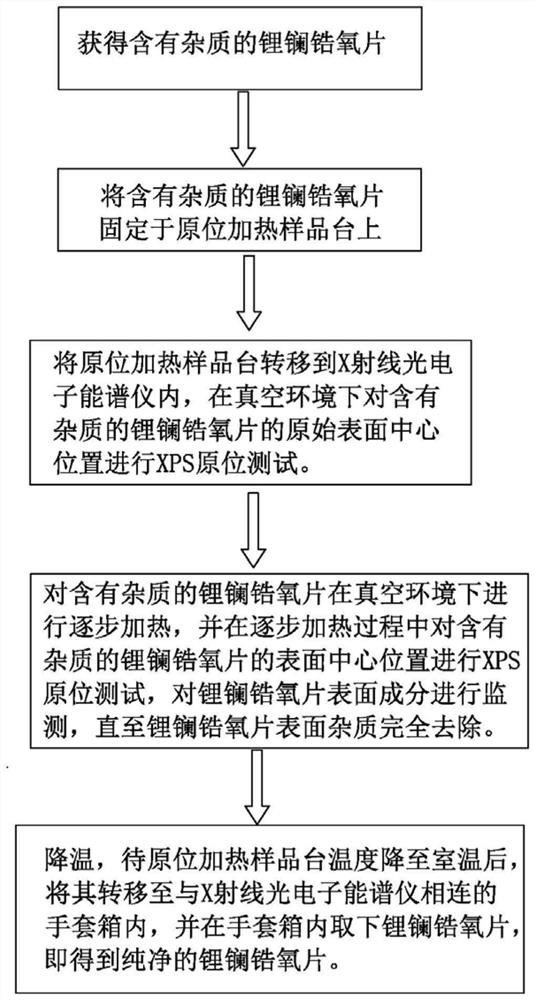

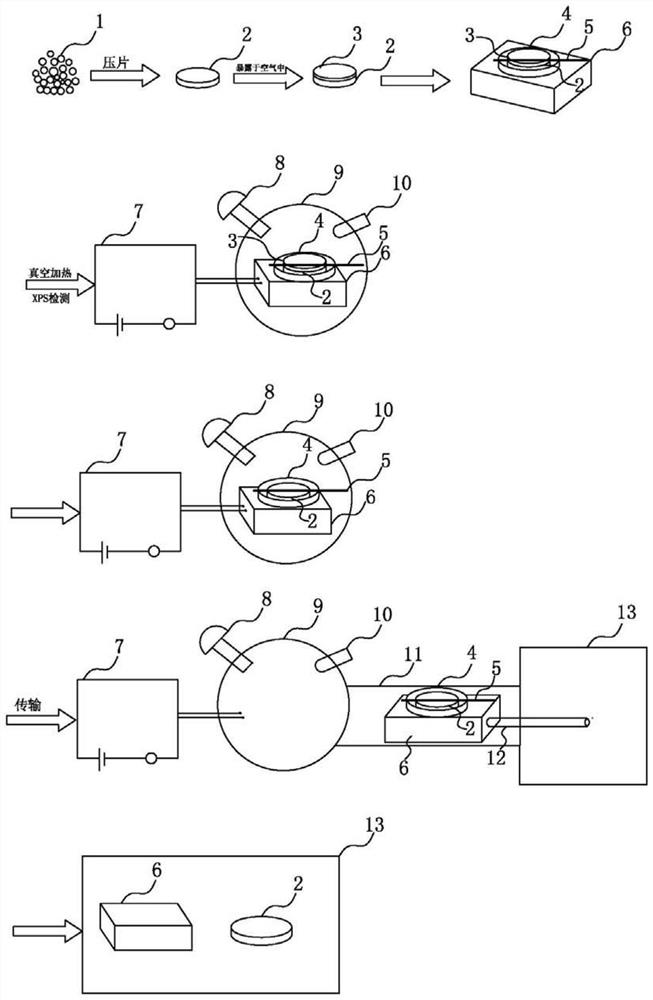

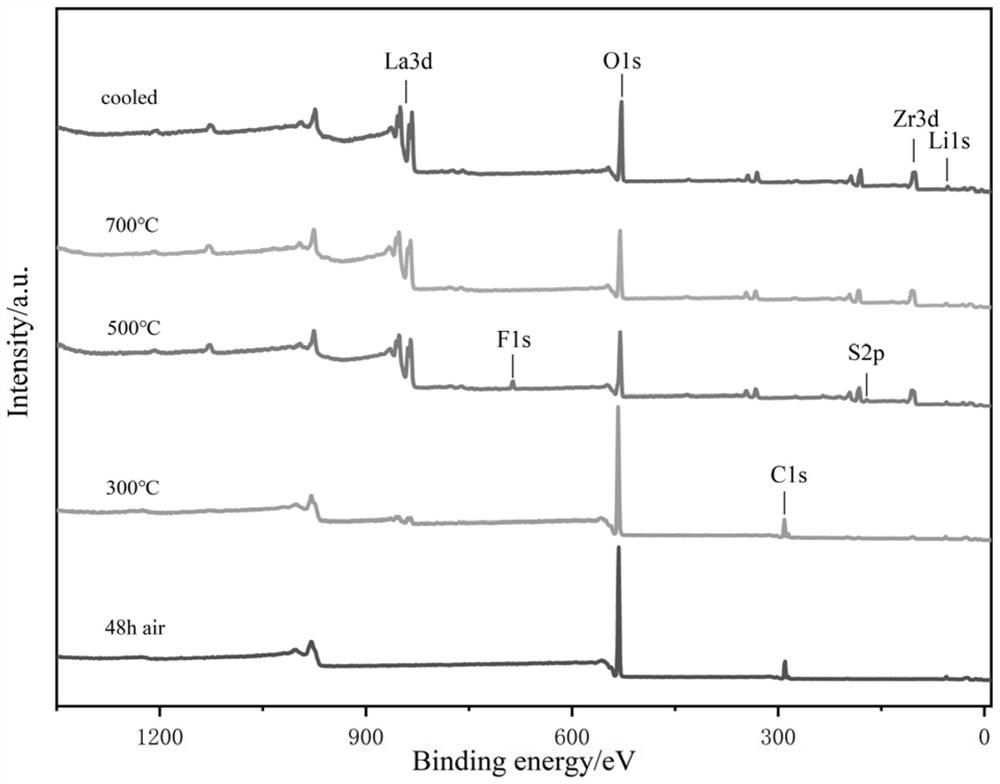

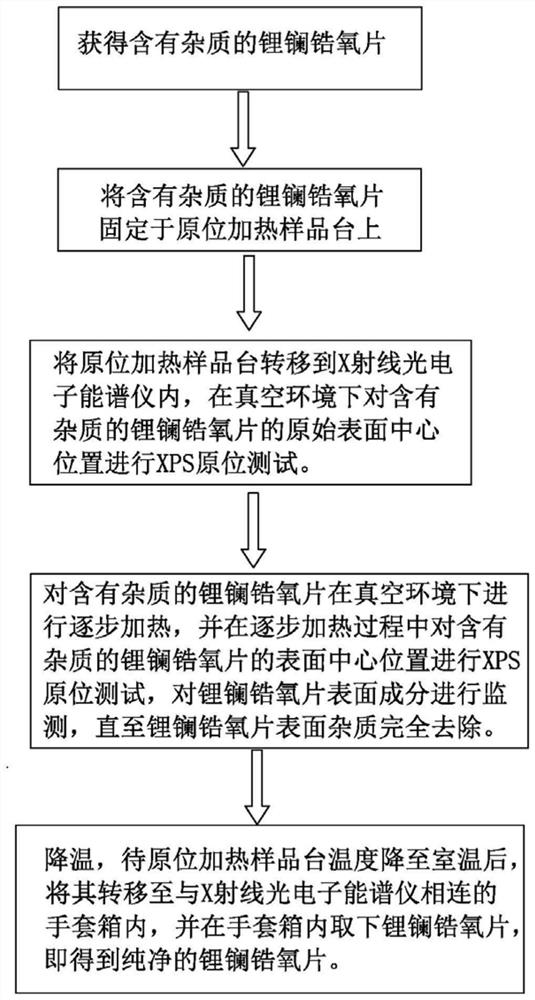

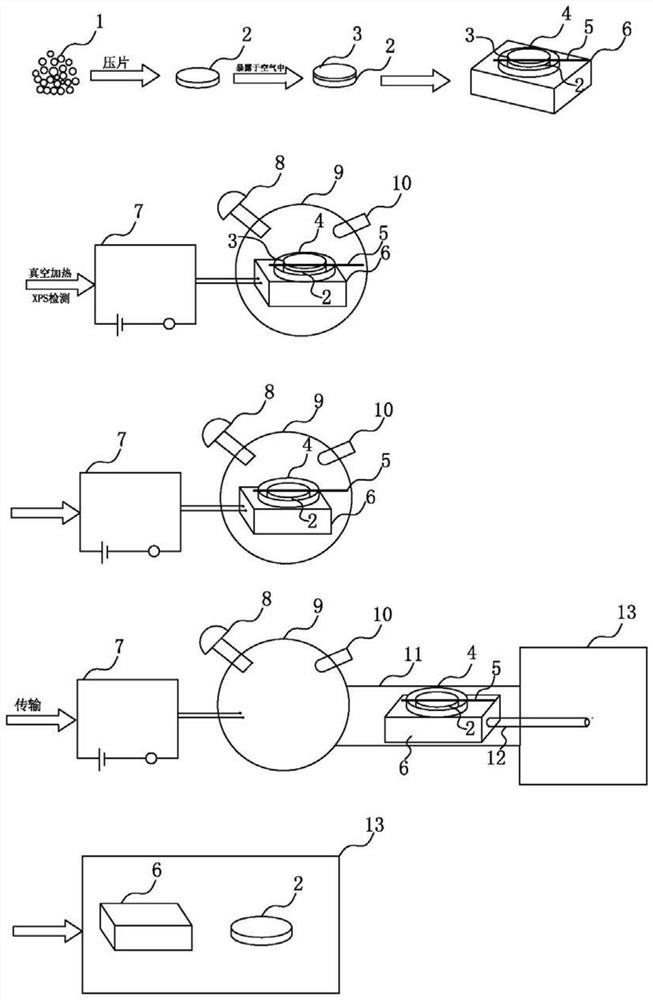

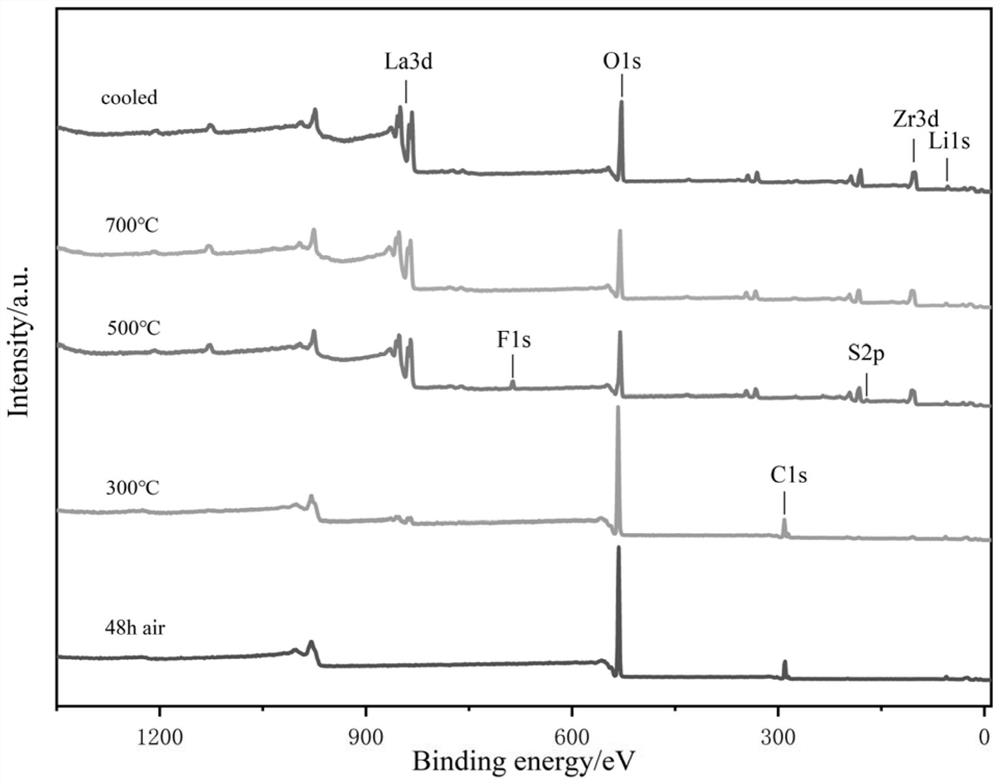

Method for removing impurities on surface of lithium-lanthanum-zirconium-oxygen electrolyte of solid-state lithium battery

ActiveCN113105271ACause damageDoes not change the structureSecondary cellsPhysical chemistryElectrolyte

The invention relates to the field of oxide solid electrolytes, in particular to a method for removing impurities on the surface of a lithium-lanthanum-zirconium-oxygen electrolyte of a solid-state lithium battery. The method comprises the following steps of: transferring a lithium-lanthanum-zirconium-oxygen sheet containing impurities into an analysis chamber of an X-ray photoelectron spectrometer, and gradually heating in a vacuum environment to remove the impurities on the surface of the lithium-lanthanum-zirconium-oxygen sheet; carrying out in-situ XPS testing on the surface of the lithium-lanthanum-zirconium-oxide sheet in the step-by-step heating process; after impurities on the surface of the lithium-lanthanum-zirconium-oxide sheet are removed, cooling the in-situ heating sample table to the room temperature and then transferring the in-situ heating sample table into a glove box connected with the X-ray photoelectron spectrometer, and taking down the lithium-lanthanum-zirconium-oxide sheet from the in-situ heating sample table to obtain the pure lithium-lanthanum-zirconium-oxide sheet. According to the method, vacuum annealing and in-situ XPS testing are used, removal of the impurity layer on the surface of the lithium-lanthanum-zirconium-oxide sheet is combined with surface component monitoring, and high-precision removal of impurities on the surface of the lithium-lanthanum-zirconium-oxide sheet is achieved.

Owner:SUN YAT SEN UNIV

A kind of method that utilizes metallurgy and municipal solid waste to prepare sintered NOx inhibitor

ActiveCN109365490BRealize resource utilizationPromote environmental protectionSolid waste disposalMunicipal solid wasteRaw material

The invention discloses a method for preparing sintered NOx inhibitor by using metallurgical and municipal solid waste. The sintered NOx inhibitor is obtained in the manner that metallurgical solid waste and municipal solid waste raw materials are subjected to pelletizing and roasting. In the sintering process of iron ore, the sintered NOx inhibitor is added on the surface of a fuel layer and plays a role of inhibiting the generation of NOx in the sintering process, the emission of the NOx can be reduced, and meanwhile the grade of iron ore sintered ore is not affected. The method provides a new way for clean resource utilization of the metallurgical and municipal solid waste.

Owner:CENT SOUTH UNIV +1

A method for power generation by pyrolysis of domestic waste

ActiveCN106367117BLow calorific valueHigh calorific valueInternal combustion piston enginesEnergy inputThermodynamicsCombustible gas

The invention relates to the technical field of garbage disposal, in particular to a household garbage pyrolytic electricity generation method. The method comprises the following steps that S1, household garbage is conveyed into a pyrolytic gas making furnace for pyrolytic gasification, reaction gas is introduced into the pyrolytic gas making furnace, and a product which contains combustible gas is obtained, wherein the oxygen content in the reaction gas ranges from 30% to 93%; S2, the heat value of the generated combustible gas is detected, and the oxygen content in the reaction gas introduced into the pyrolytic gas making furnace is regulated in real time, so that the heat value of the obtained combustible gas is output stably; S3, the combustible gas obtained in S2 is conveyed into a gas electricity generator for electricity generation. The gas obtained through household garbage pyrolytic gasification can be directly used for gas electricity generation.

Owner:THERMONERGY HIGH TECH CO LTD

A horizontal well fracturing filling natural gas hydrate efficiency-enhancing production equipment and method

The invention belongs to the field of energy and environment, and provides a horizontal well fracturing filling natural gas hydrate efficiency-enhancing exploitation equipment and method. The equipment includes pressure monitoring system, horizontal well fracturing and filling system, sand control system and automatic control feedback system. It solves the problem of difficult pressure transmission caused by the muddy low permeability characteristics of sediments during the production of natural gas hydrates, which in turn leads to the secondary generation of hydrates and freezing blockages. At the same time, the fracturing filling system is used to effectively increase the pressure penetration range, and through the solidification of the proppant in the fracturing area, the stability of the fracturing area and the gas migration channel is realized, and the hydrate decomposition process is significantly strengthened. During the gas production process, the sand control system is used to effectively prevent the fine sand from clogging the gas gathering port during the fracturing process, and the fracturing system is used to flush the sand control system during the natural gas hydrate production process, which solves the problem of easy blockage of the sand control system. The set of equipment and method promotes safe, efficient and large-scale exploitation of marine natural gas hydrate.

Owner:DALIAN UNIV OF TECH

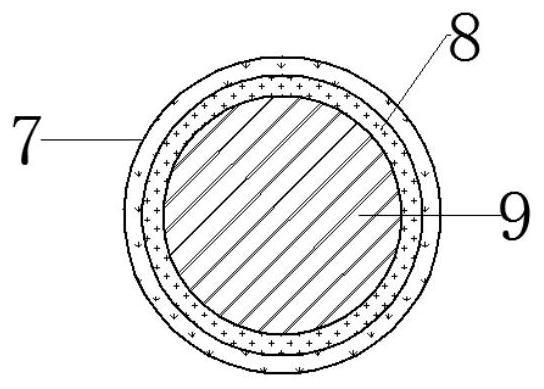

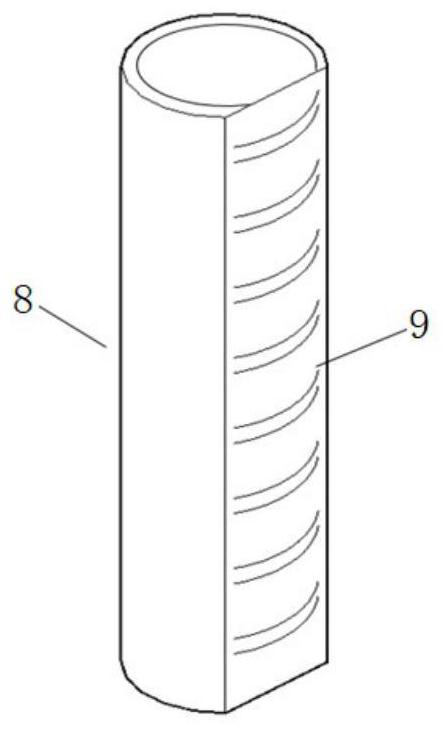

Heating device and method for deep sea hydrate production pipe column

ActiveCN114320233AAvoid secondary formationEfficient captureInsulationFluid removalThermodynamicsEnergy development

The invention belongs to the technical field of energy development, and relates to a heating device and method for a deep sea hydrate production pipe column, the heating device comprises a sleeve, at least two power generation modules and a heating module, the sleeve is used for fixing the power generation modules and the heating module with the hydrate production pipe column; the power generation modules and the heating module are arranged on the sleeve in a sleeving mode, the heating module is arranged between the two power generation modules, and the power generation modules are connected with the heating module through power transmission lines and supply power to the heating module. By arranging the heating module, secondary formation of hydrates in the mining process is avoided, by arranging the multiple layers of power generation modules with the blades, undulating wave energy can be effectively captured, and stable electric energy is provided for the device.

Owner:CHINA NAT OFFSHORE OIL CORP +1

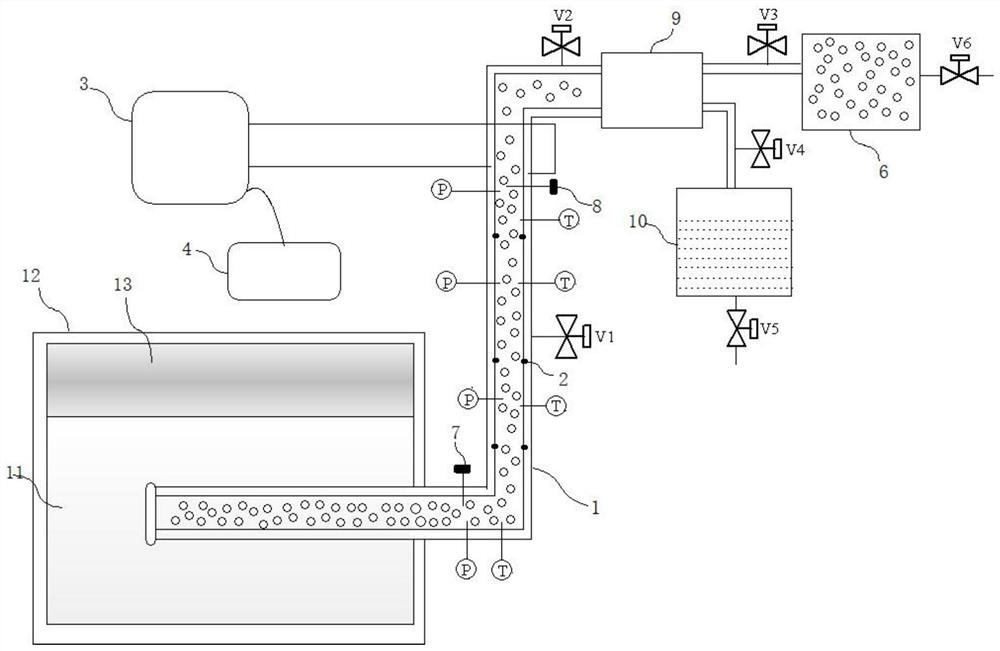

A system to monitor and avoid secondary formation during hydrate decomposition

ActiveCN111076094BMonitoring Secondary GenerationAvoid secondary generationPipeline systemsThermodynamicsCollection analysis

The invention discloses a system for monitoring and avoiding secondary generation in the process of hydrate decomposition, which includes a decomposition casing pipeline, a resistivity detection probe, an external power supply heating device, and a data collection and analysis interconnection device; wherein, the decomposition The casing pipeline adopts a rigid casing structure, and the inner and outer sides of the pipe wall are made of rigid structural materials. A heating element is arranged inside the casing, and the heating element is connected to the external power heating device; the resistivity detection probes are distributed at intervals In the unsleeving pipeline; the data acquisition and analysis interconnection device is used to analyze the received resistivity detection probe signal, and determine whether to issue a control command to start the external power heating device through the heating element according to the analysis result. Disassemble the casing line for heating. This system can effectively monitor and avoid the secondary generation of hydrate during the process of hydrate decomposition, and prevent the phenomenon of pipeline blockage.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A method for removing impurities on the surface of lithium lanthanum zirconium oxygen electrolyte for solid lithium batteries

ActiveCN113105271BCause damageDoes not change the structureSecondary cellsPhysical chemistryElectrolyte

Owner:SUN YAT SEN UNIV

A method for recycling waste fly ash in iron ore sintering process

ActiveCN107099658BReduce remaining amountHigh removal rateProcess efficiency improvementLitterFlue gas

The invention discloses a method for recycling fly ash from garbage during sintering of iron ore. The method comprises the following steps: uniformly mixing fly ash from garbage, biocarbon and a part of an iron-containing raw material from sintering raw materials and with high valuable metal content, preparing sphere kernels in advance, then wrapping the surfaces of the sphere kernels with fine-granule magnetite so as to form core-shell-structured spheres, subjecting the spheres to low-temperature drying and dehydrating and spreading the spheres on the ground floor of a sintering machine to replace a conventional finished-agglomerate grate-layer material; and subjecting other sintering raw materials to granulation, then spreading the granulated sintering raw materials on the spheres, and carrying out ignition and sintering. The method provided by the invention allows fly ash from garbage to be effectively solidified during sintering of iron ore, and dioxins in the fly ash are efficiently degraded; valuable metals in the core-shell-structured spheres are volatilized into flue gas in a heating section and effectively recovered through capturing in the procedure of flue gas dedusting; and thus, the purpose of recycling of the fly ash from garbage during sintering of iron ore is achieved.

Owner:CENT SOUTH UNIV

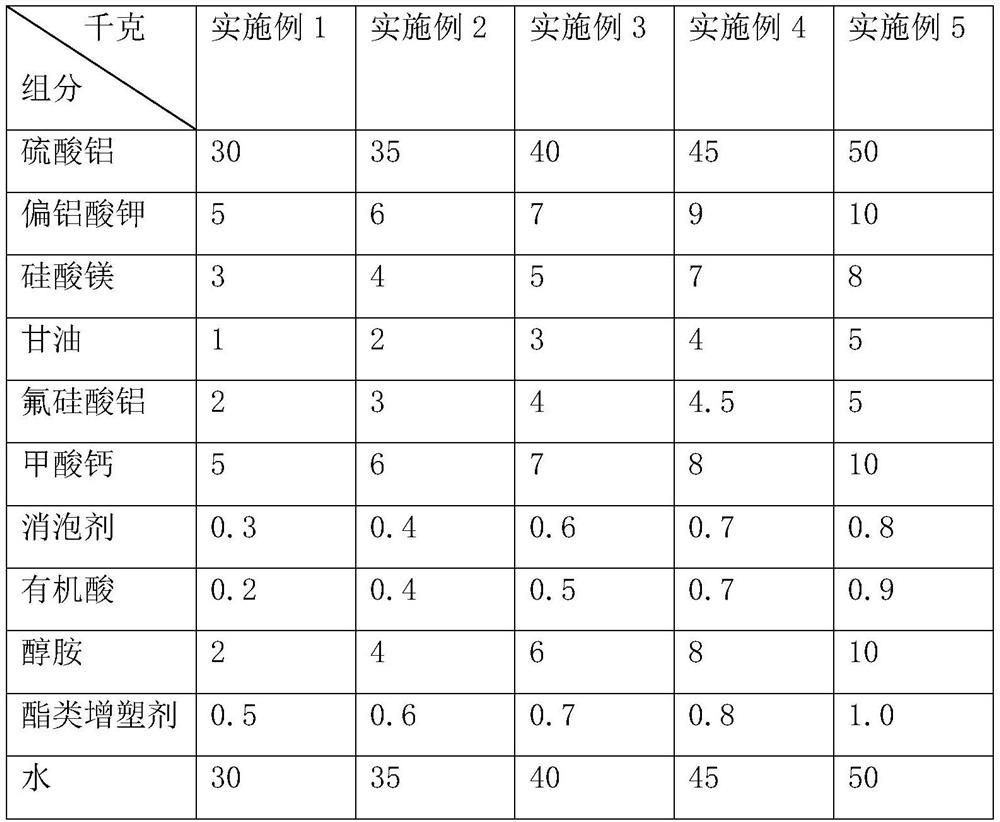

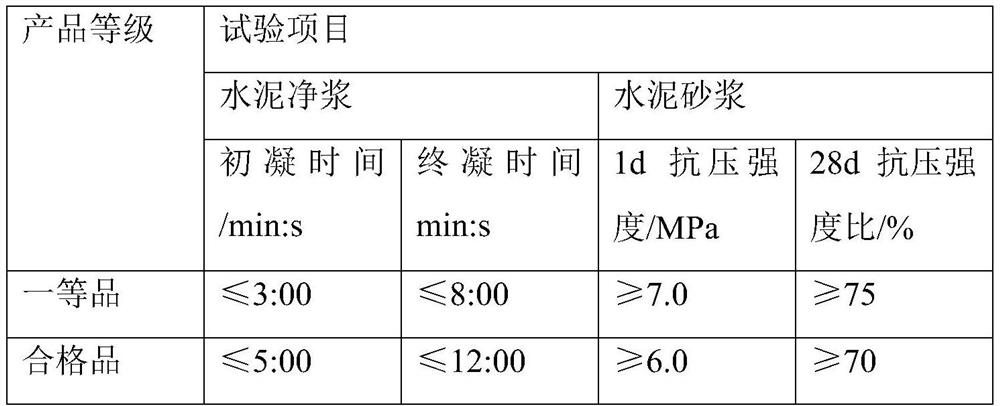

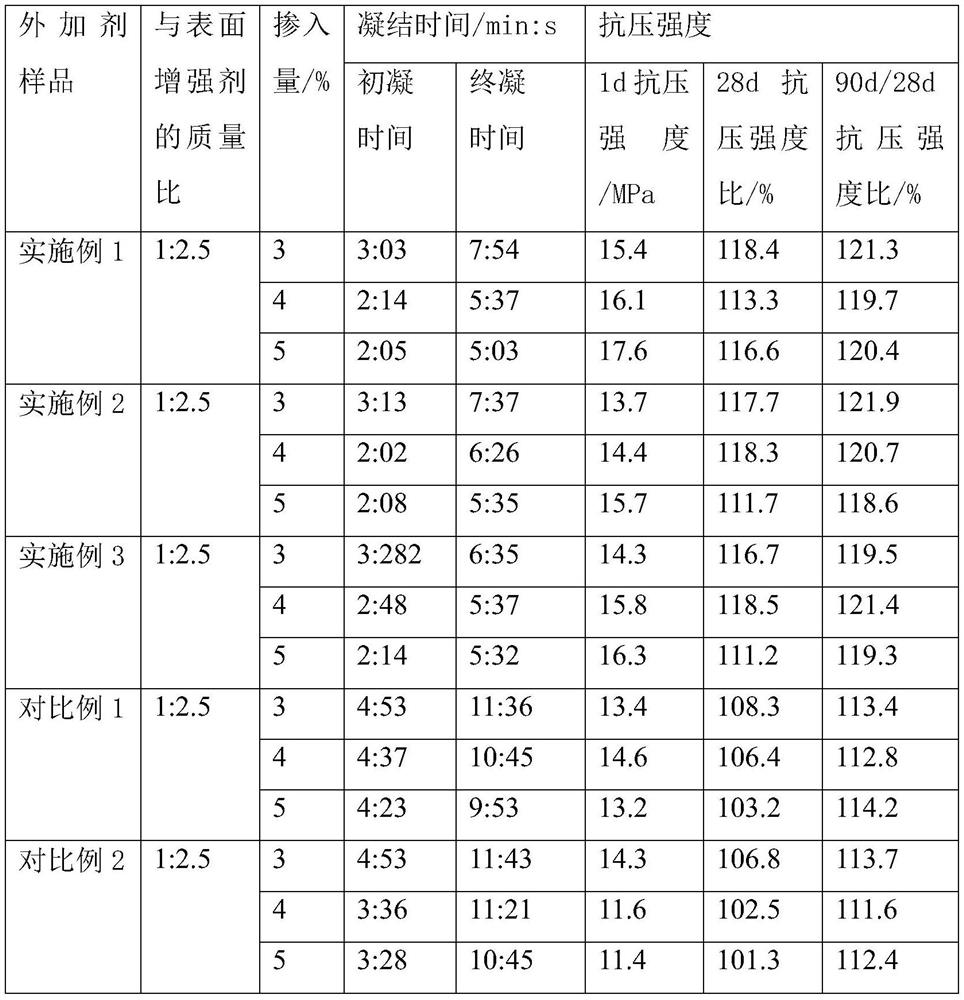

A kind of concrete admixture and its preparation method and application method

The invention discloses a concrete admixture, a preparation method and an application method thereof. The concrete admixture comprises the following components by weight: 30-50 parts of aluminum sulfate, 5-10 parts of potassium metaaluminate, 3-8 parts of magnesium silicate, 1-5 parts of glycerin, 2-5 parts of aluminum fluorosilicate, 5-10 parts of calcium formate, 0.3-0.8 parts of defoamer, 0.2-0.9 parts of organic acid, 2-10 parts of alcohol amine, 0.5-1 part of ester plasticizer, 30-50 parts of water. The dosage of the concrete admixture of the present invention is 3-5% of the cement mass. The application method of the concrete admixture of the present invention: the concrete admixture and the concrete surface enhancer are mixed according to the mass ratio of 1:2-3 and then added to the sprayed concrete at the nozzle, and the amount of the concrete admixture is calculated as 3 based on the cement weight. -5%. The concrete admixture of the invention has the advantages of no alkali metal ion, no corrosion, fast setting speed of concrete, and little strength loss in the later stage.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

Method for preparing sintered NOx inhibitor by using metallurgical and municipal solid waste

ActiveCN109365490ARealize resource utilizationPromote environmental protectionSolid waste disposalResource utilizationMunicipal solid waste

The invention discloses a method for preparing sintered NOx inhibitor by using metallurgical and municipal solid waste. The sintered NOx inhibitor is obtained in the manner that metallurgical solid waste and municipal solid waste raw materials are subjected to pelletizing and roasting. In the sintering process of iron ore, the sintered NOx inhibitor is added on the surface of a fuel layer and plays a role of inhibiting the generation of NOx in the sintering process, the emission of the NOx can be reduced, and meanwhile the grade of iron ore sintered ore is not affected. The method provides a new way for clean resource utilization of the metallurgical and municipal solid waste.

Owner:CENT SOUTH UNIV +1

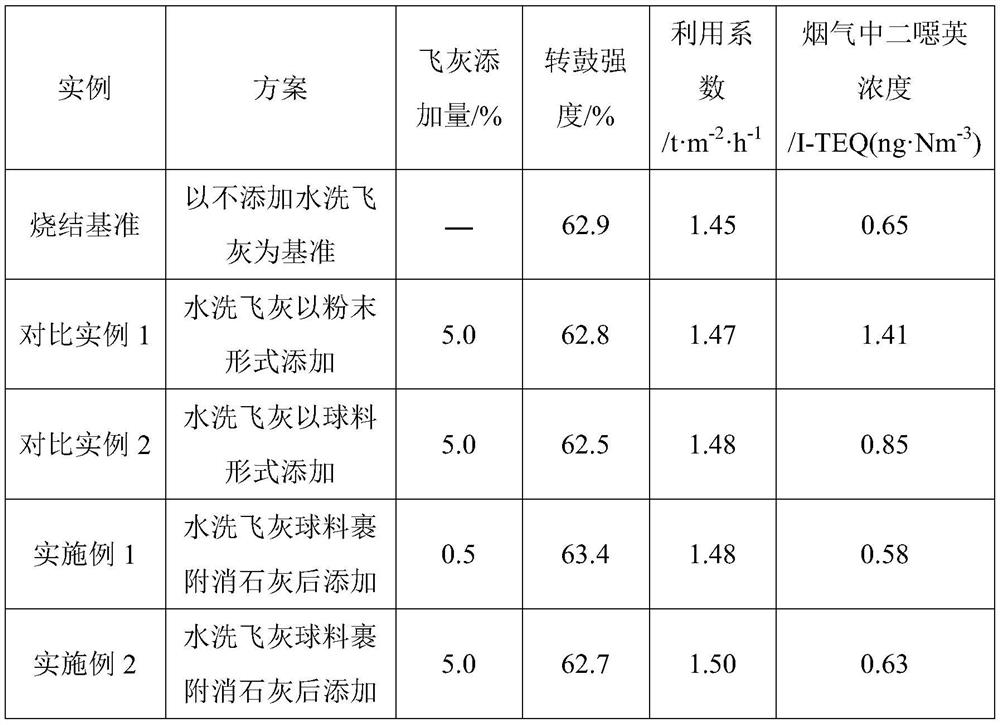

Method for controlling dioxin in fly ash washing process through sintering treatment

PendingCN113649393AReduce secondary generationAvoid secondary generationSolid waste disposalProcess efficiency improvementIncinerationIron ore

The invention discloses a method for controlling dioxin in a fly ash washing process through sintering treatment, which comprises the following steps: carrying out washing dechlorination treatment on waste incineration fly ash, performing pelletizing, coating the surfaces of pellets with a slaked lime layer, and carrying out drying to obtain washed fly ash pellets; and mixing the washed fly ash pellets into the iron ore sintered granules to be uniformly mixed, distributing the mixture to the middle lower part of a sintered material layer through segregation, and performing igniting and sintering. According to the method, the waste incineration fly ash is subjected to washing dechlorination, secondary generation of dioxin in the sintering process can be greatly reduced, meanwhile, the surfaces of the washing fly ash pellets are coated with slaked lime, chlorine volatilized by the washing fly ash ball material and surrounding sintering materials can be adsorbed, and by optimizing the distribution and sintering technology, the dioxin in the fly ash is effectively degraded, and secondary generation of the dioxin in the sintering process is inhibited. According to the method, secondary generation of the dioxin can be effectively inhibited under the condition that the quality of the sintered ore is not affected, and clean resource utilization of the waste incineration fly ash is promoted.

Owner:CENT SOUTH UNIV +1

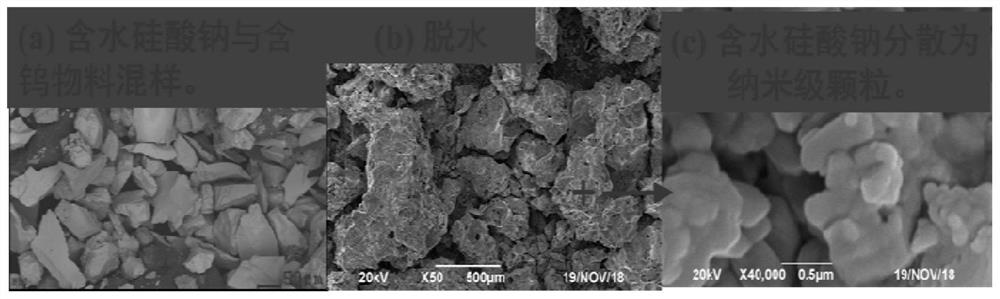

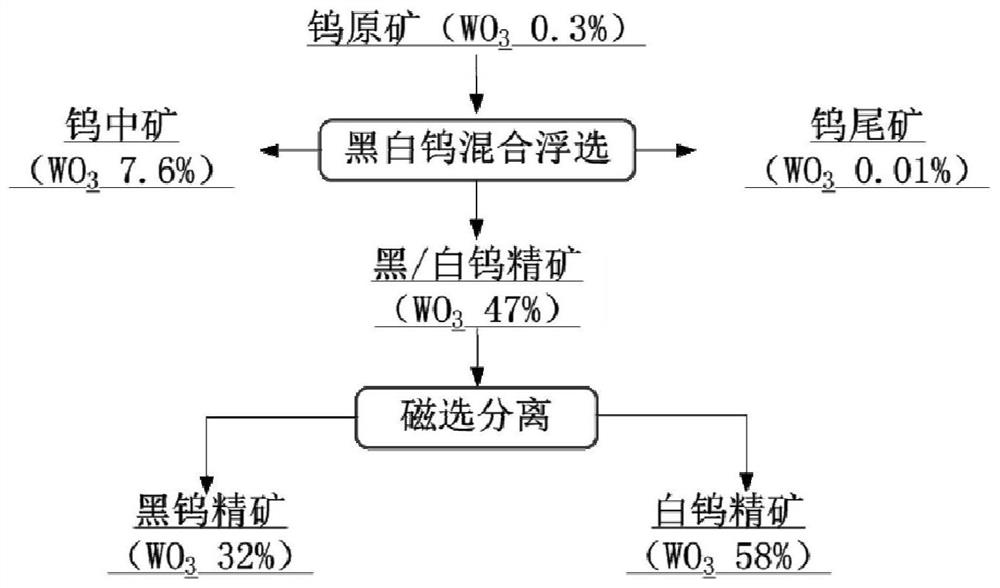

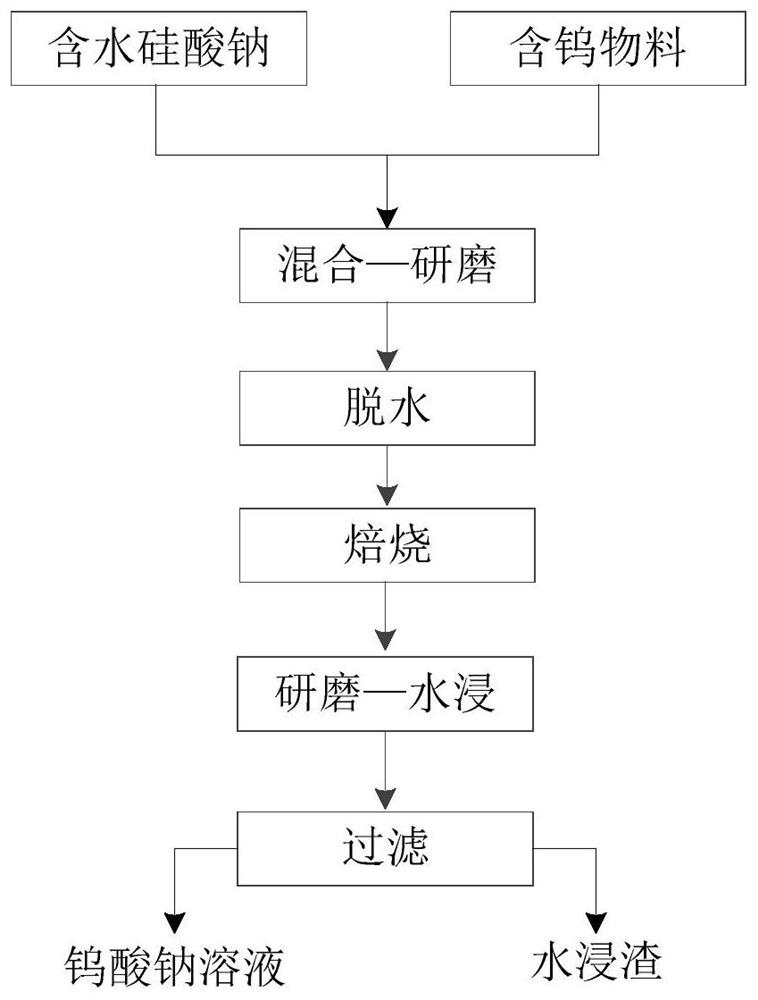

A method for extracting tungsten from tungsten-containing raw materials by using hydrous sodium silicate

ActiveCN112593098BEfficient recyclingAvoid secondary generationProcess efficiency improvementPtru catalystSlag

The invention discloses a method for extracting tungsten from tungsten-containing raw materials by using hydrous sodium silicate. After mixing and grinding the tungsten-containing material and hydrous sodium silicate, first roasting and dehydrating is carried out, and then high-temperature sintering is carried out, and the obtained sintered material is leached by water. , to obtain sodium tungstate solution. This method requires extremely low tungsten content in tungsten-containing raw materials, WO 3 High-efficiency decomposition and extraction can still be accomplished with a grade as low as 0.5%, and it can process low-grade black / scheelite concentrate, tungsten smelting slag, tungsten-containing catalyst, tungsten-containing waste alloy, etc., which greatly reduces the traditional tungsten extraction method. High requirements for tungsten content in tungsten-containing materials.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com