Process for cleaning surface of piston rod

A surface cleaning and piston rod technology, applied in metal material coating process, cleaning method and utensils, cleaning method using liquid, etc., can solve low production efficiency, impurity quality that cannot meet cleanliness requirements, and steel brush cleaning is not thorough and other problems to achieve the effect of preventing secondary generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

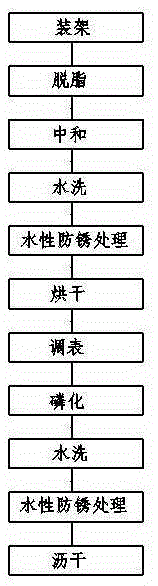

[0050] The technical process will be described in detail below in conjunction with the accompanying drawings and specific implementation methods: the length of the piston rod is between 200-500mm, so the cleaning tool is installed vertically, which has the advantage of reducing the tool adjustment time. The solvent used in the degreasing tank is LDS-004 solution, the proportioning concentration is 10%, and the operating temperature is 60±2°C. The solvent used in the neutralization tank is LPWC-001 solution, the proportioning concentration is 5%, and the operating temperature is 50-60°C. The anti-rust treatment tank adopts PWA-001 solution, the proportioning concentration is 10%, and the use temperature is 25-30°C. The drying process adopts hot air drying at 100°C to accelerate the formation of the anti-rust film on the surface.

[0051] The whole process uses ultrasonic equipment to provide ultrasonic waves. The technical parameters of the equipment are as follows:

[0052] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com