Multi-branch horizontal well depressurization and heating united mining method for marine hydrates

A horizontal well and multi-branch technology, which is applied in the direction of underwater drilling, fluid extraction, earthwork drilling, etc., to achieve the effects of slowing down the degree of sand production, promoting decomposition, and prolonging the duration of test production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

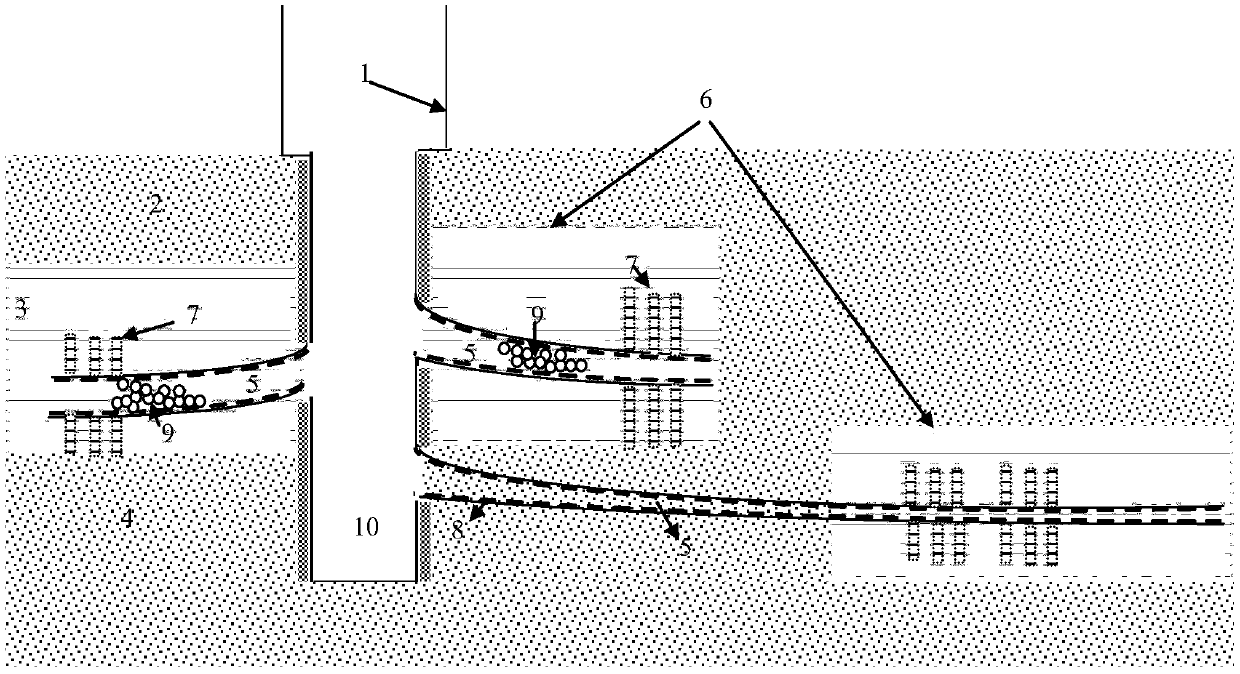

[0047] Example 1, such as figure 1 As shown, the method for depressurization and heating combined production of marine hydrate multi-branch horizontal wells is based on the well-type structure of the main wellbore and multi-branch horizontal wells, using hydraulic slitting and heating control means to connect three-dimensional scattered ore bodies To adapt to the hydrate depressurization mining in silty reservoirs.

[0048] Specifically, it includes the following implementation steps:

[0049] (1) The main borehole is completed

[0050] The main borehole drilling method is to drill the upper layer of the hydrate reservoir and cement the well, then drill to form a 16” main borehole. The main borehole penetrates the reservoir and leaves sedimentation at the bottom of the well below the bottom of the reservoir. pocket;

[0051] The completion mode of the main wellbore is casing completion, and the casing has reserved holes for docking with multi-branch horizontal wells; cement is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com