Patents

Literature

238results about How to "Reduce pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

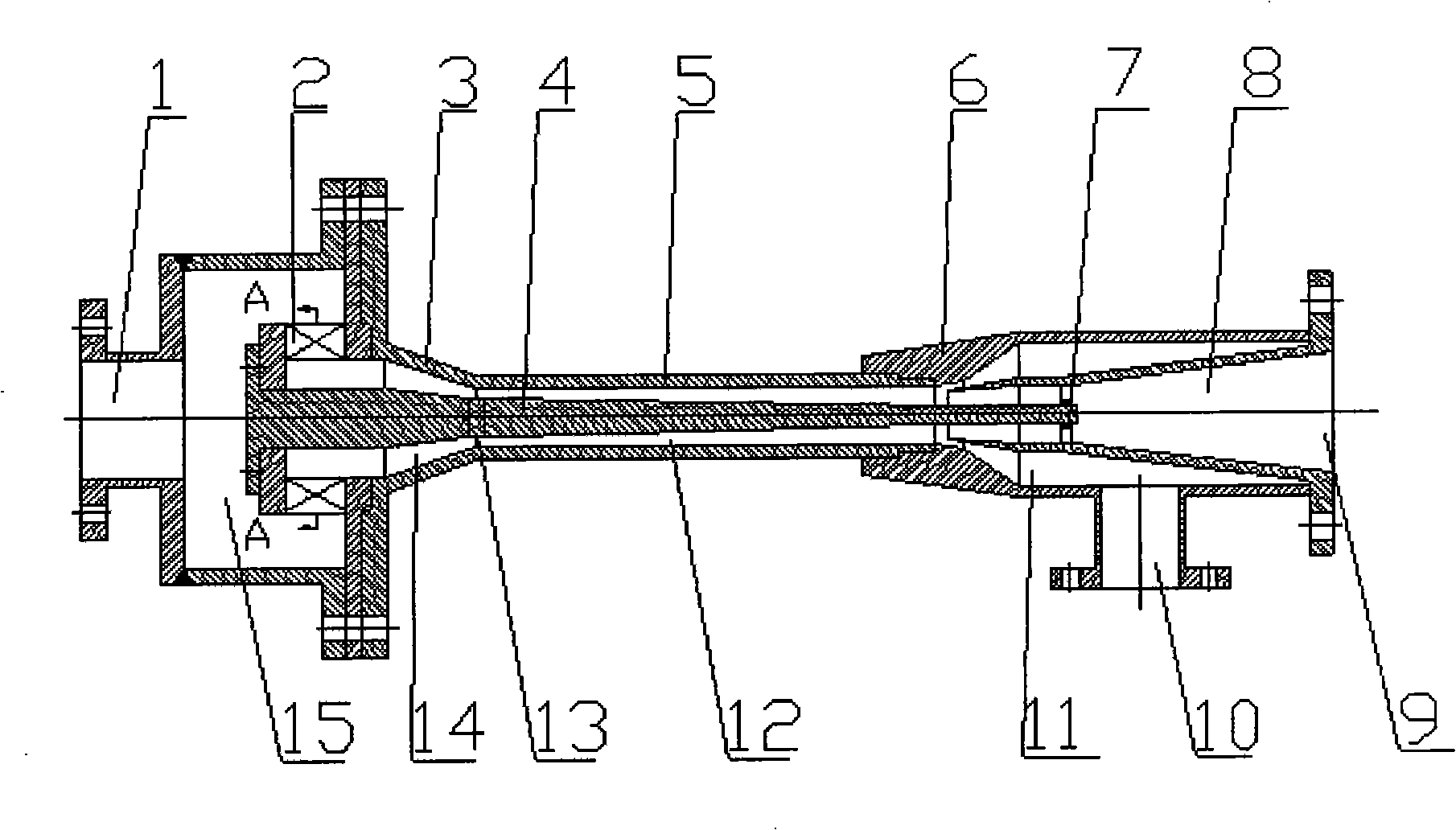

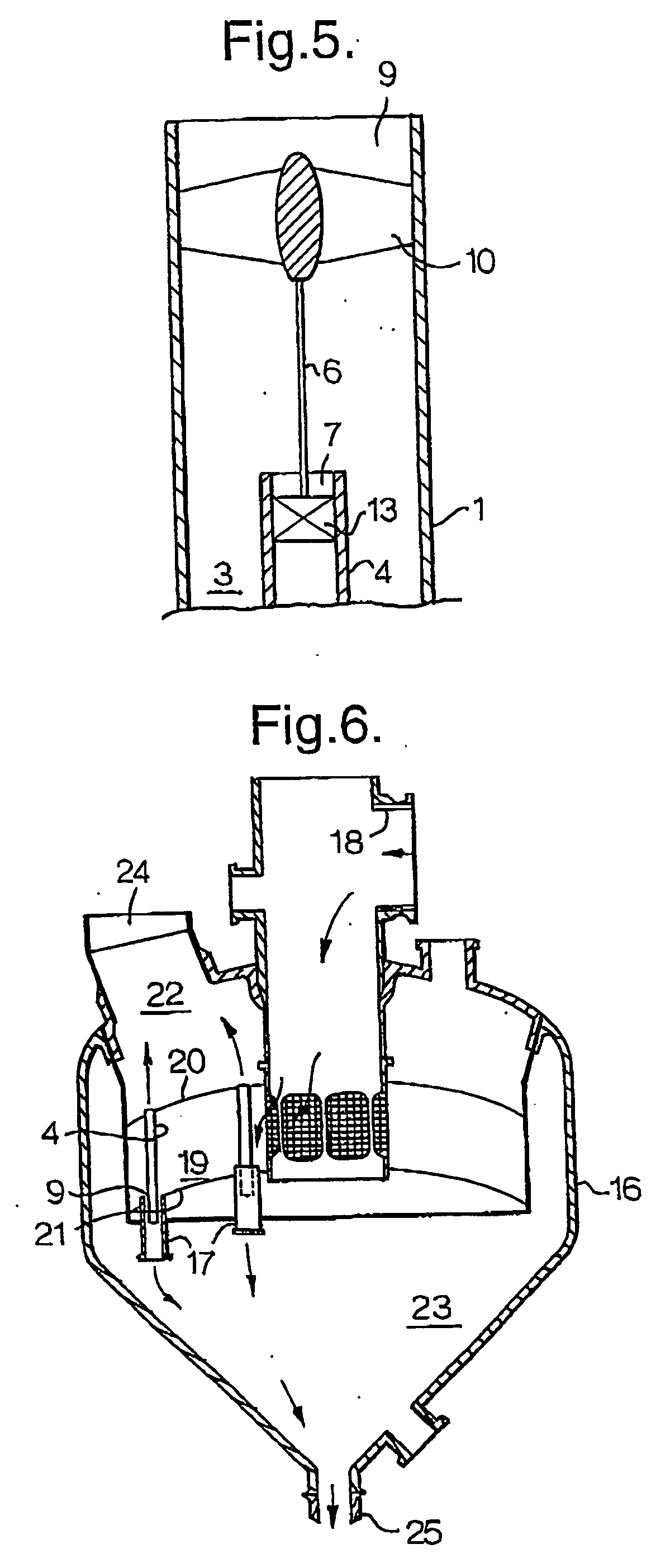

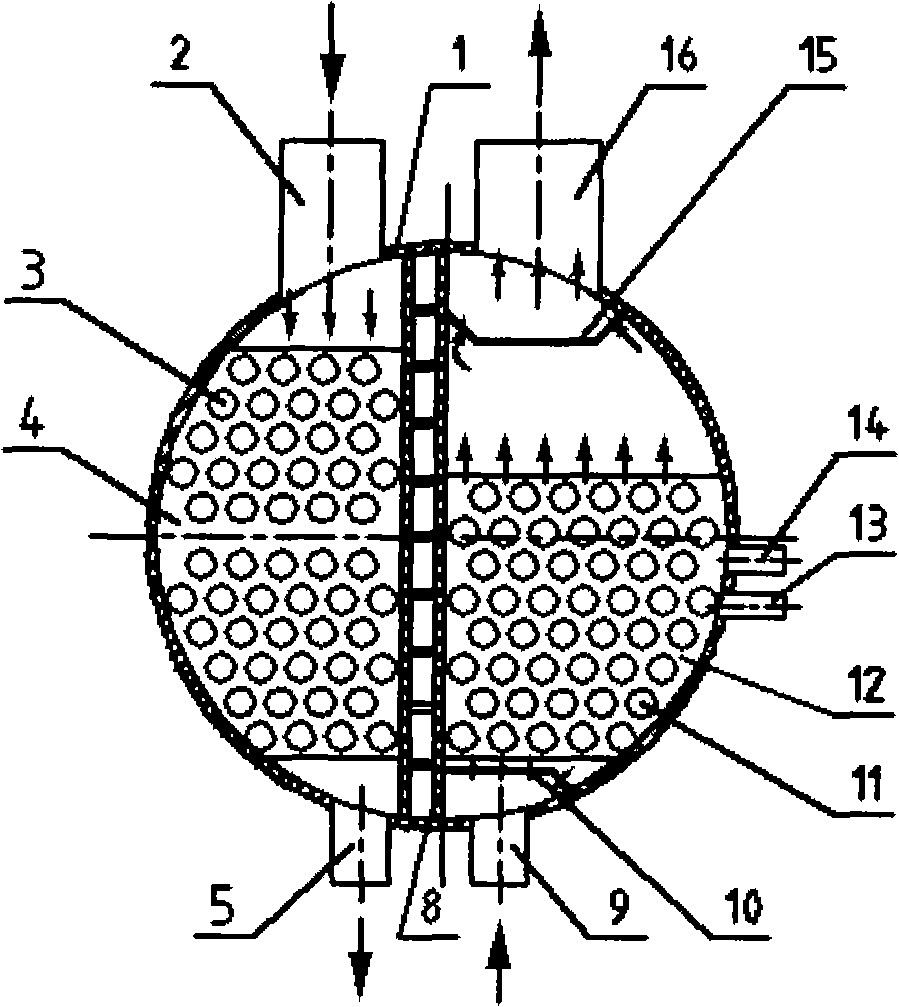

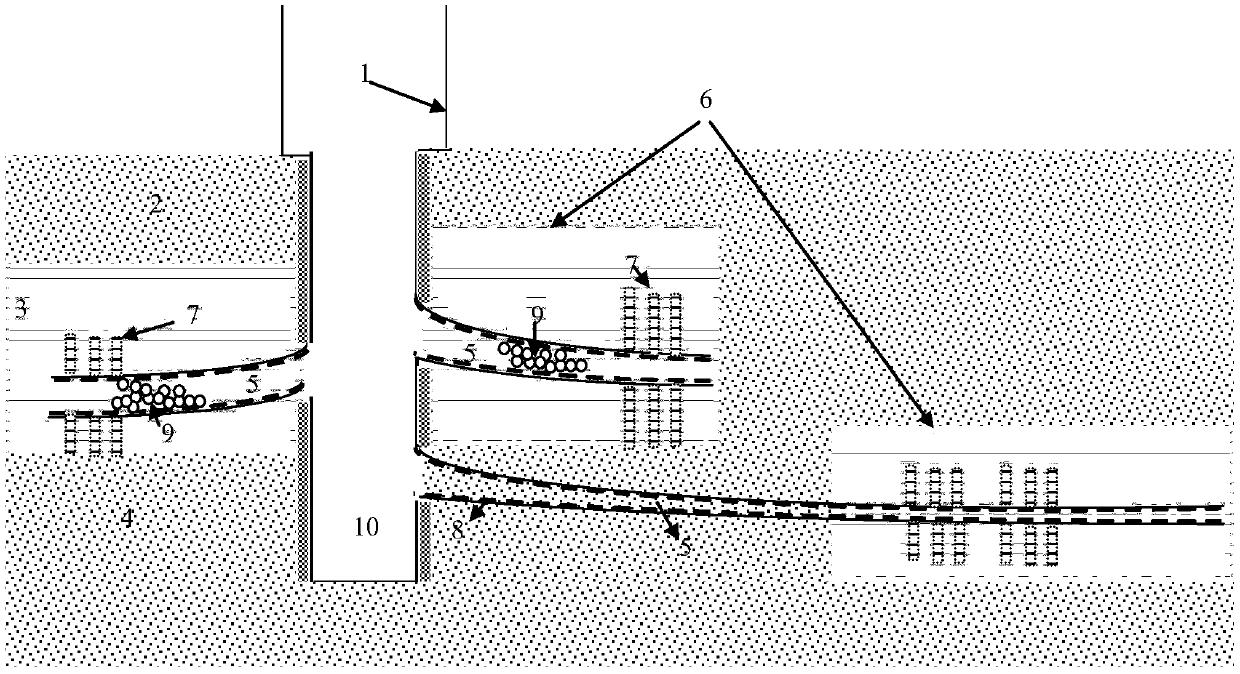

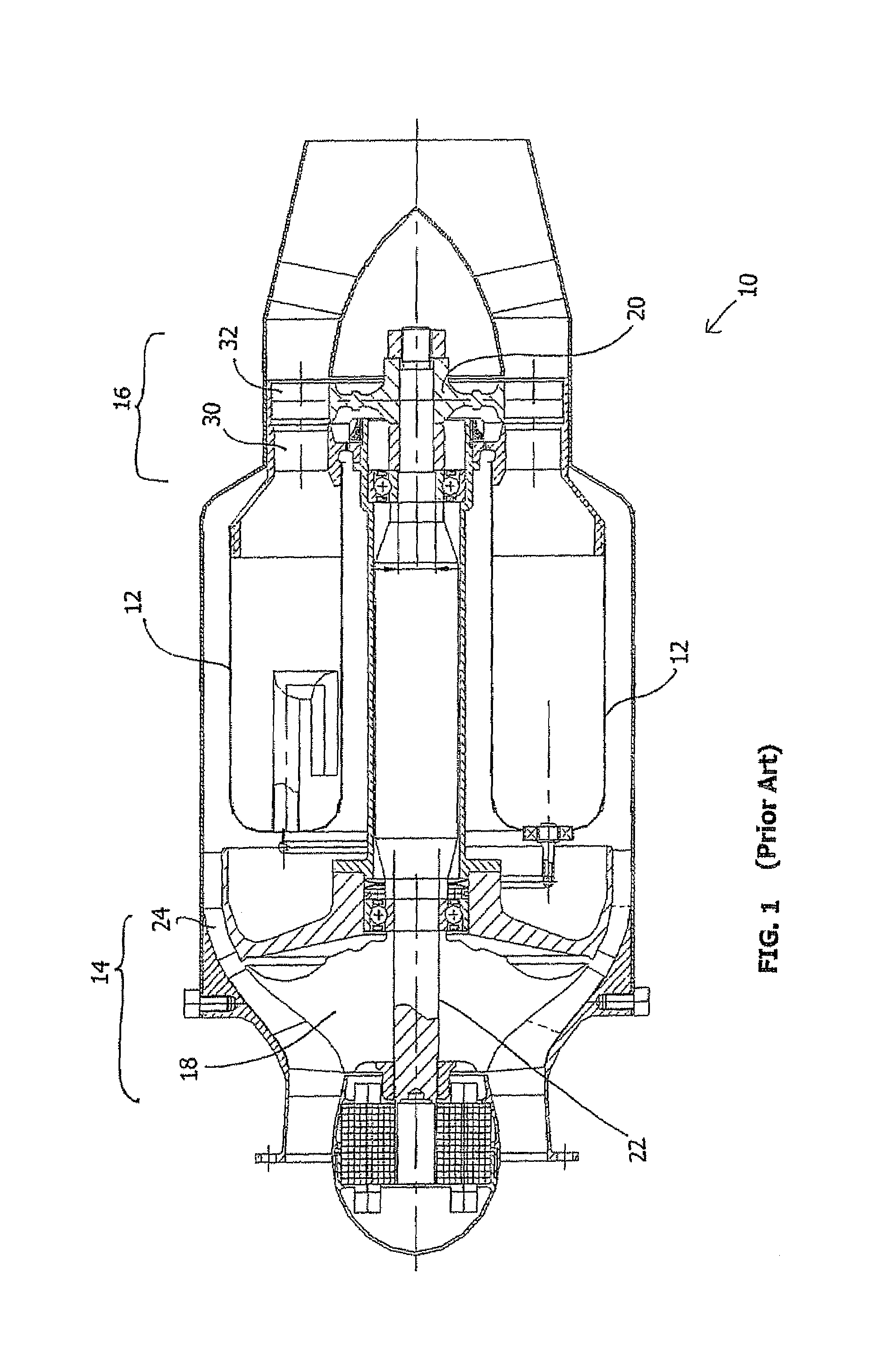

Conical core type supersonic condensing cyclone separator

ActiveCN101264470AHigh precisionEasy to separateDispersed particle separationVapor condensationCycloneSeparation technology

The invention relates to a taper core type supersonic condensation cyclone separator, belonging to the technical field of expansion refrigeration and condensation separation of pressure gas. The taper core is inserted in a passage, and the diameter of the taper core is changed at different places, so as to form the passage with a gradually decreased section part, a constant throat part and a gradually increased section part; therefore, a constant diameter inner hole can be adopted to avoid gradually increased small taper pipe passage which is difficult to be machined, so that the spin strength is not weakened due to the diameter increase. The taper core type supersonic condensation cyclone separator enables low-temperature working condition by means of pressure expansion and cooling of the gas, and reinforces spin by means of diameter decrease to generate strong centrifugal force field. The pressure can be increased after separation. The taper core type supersonic condensation cyclone separator has the advantages of no moving pieces, no need of external drive, energy saving, compact size, low cost, stable and reliable operation, and applicability to condensation separation of mixed gas with high pressure and low flow rate and separation of heavy components of natural gas and petroleum gas, in particular to offshore platform and other occasions with limited space due to compact size.

Owner:DALIAN UNIV OF TECH

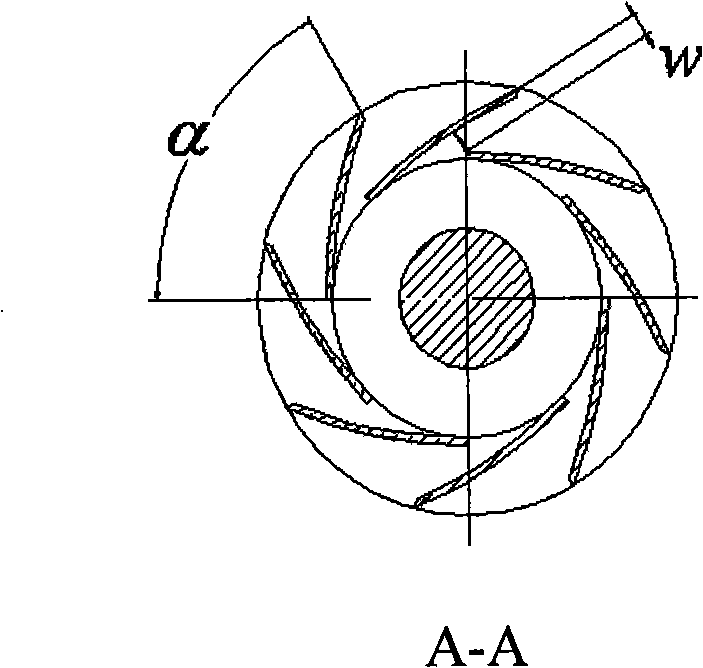

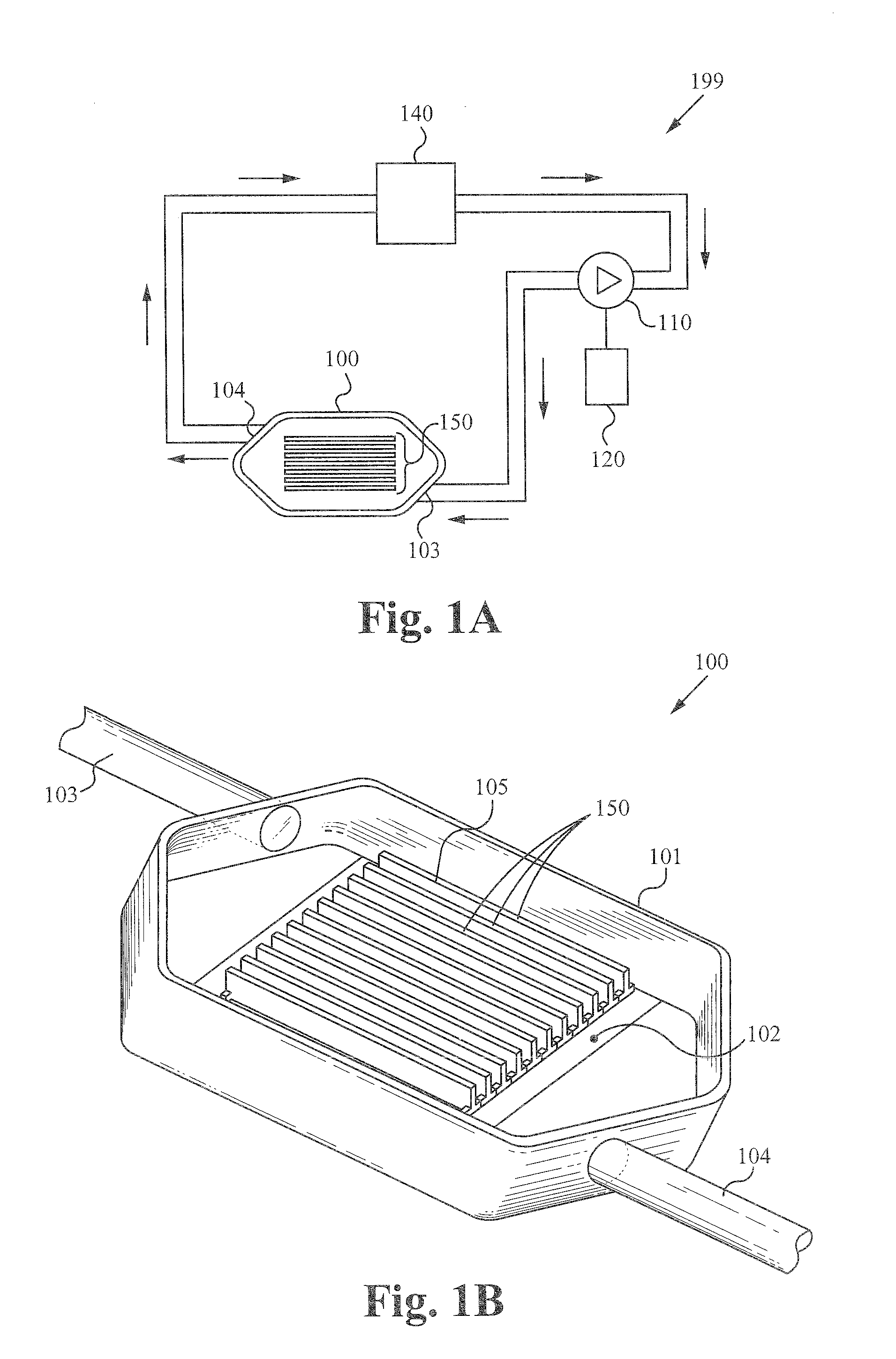

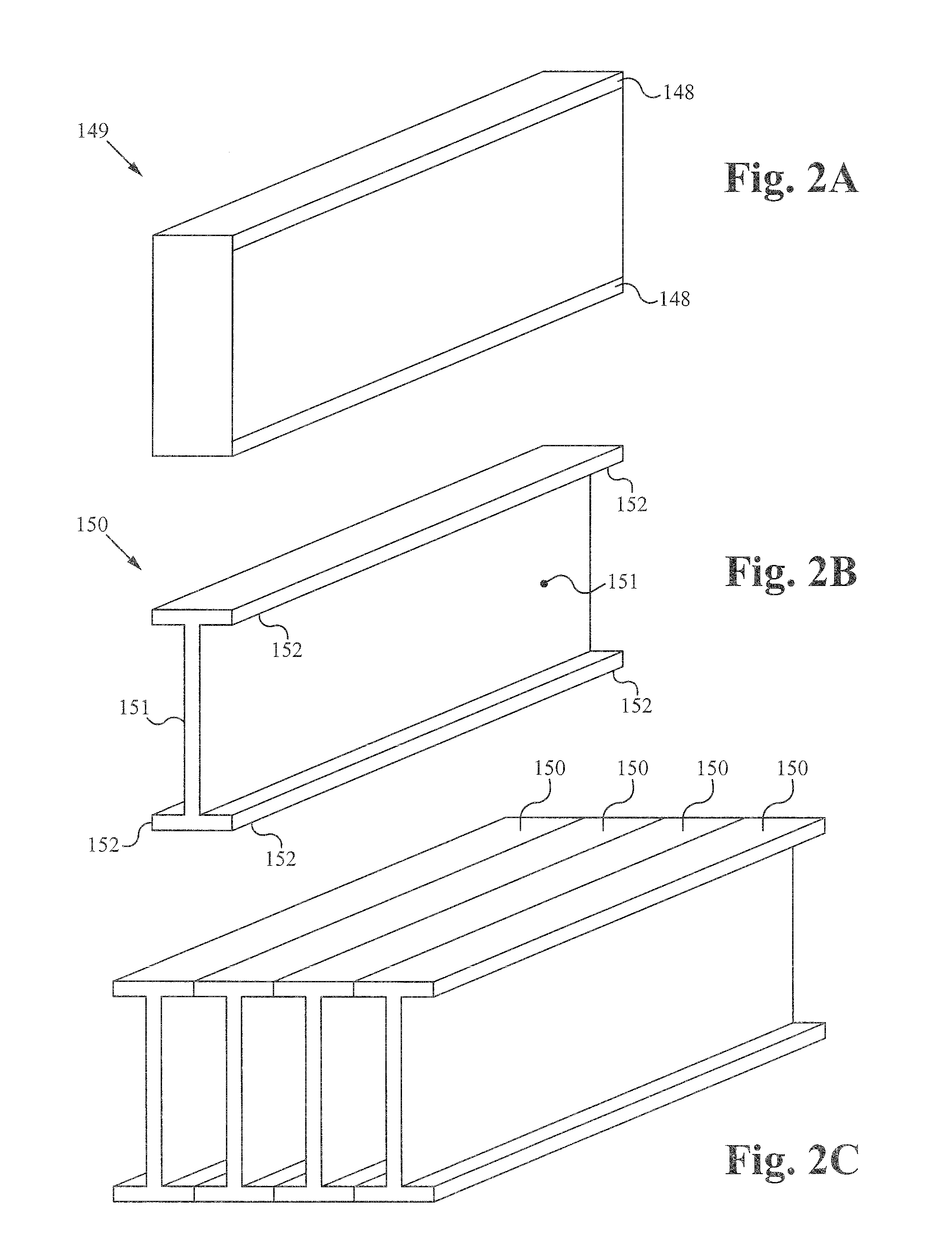

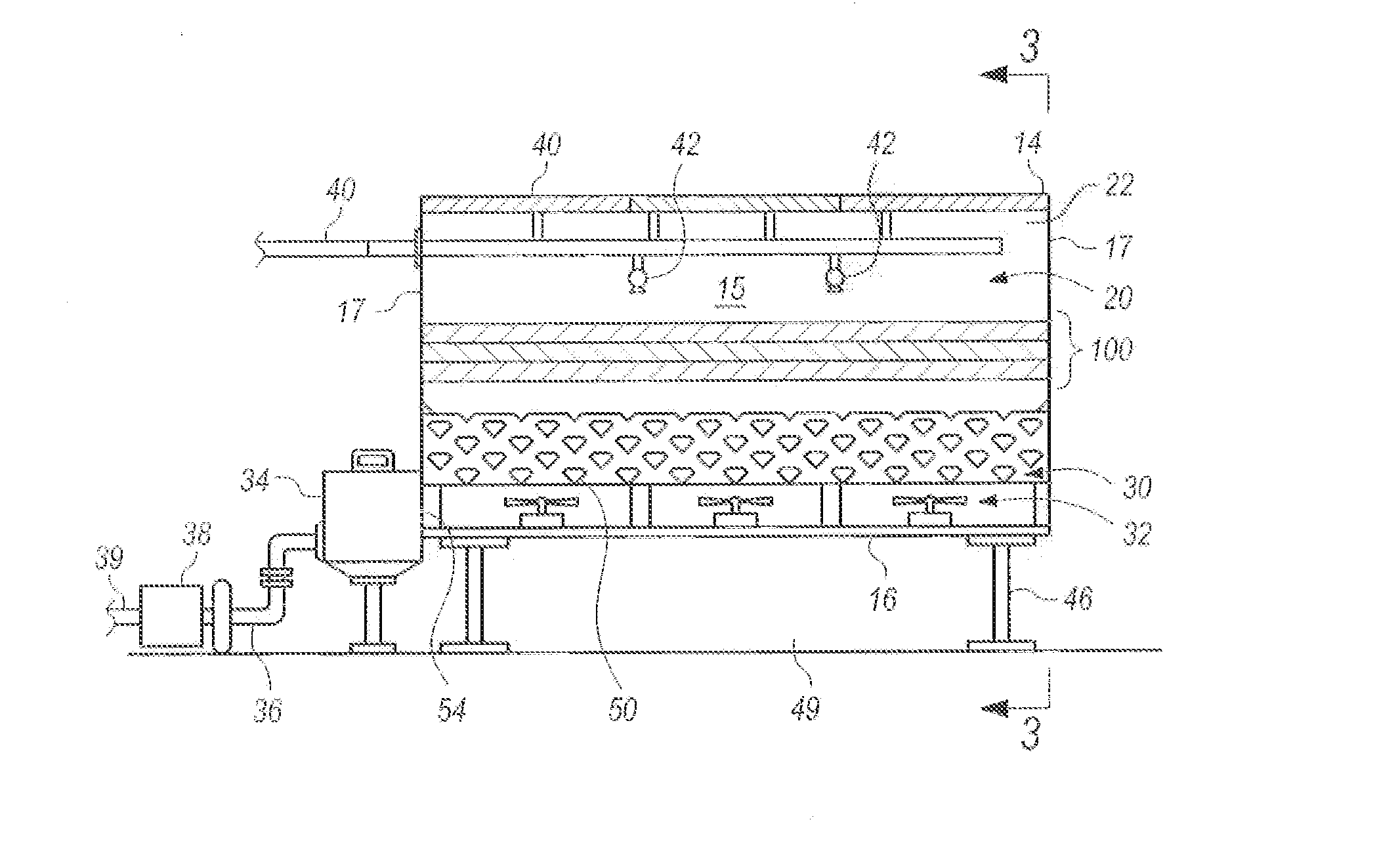

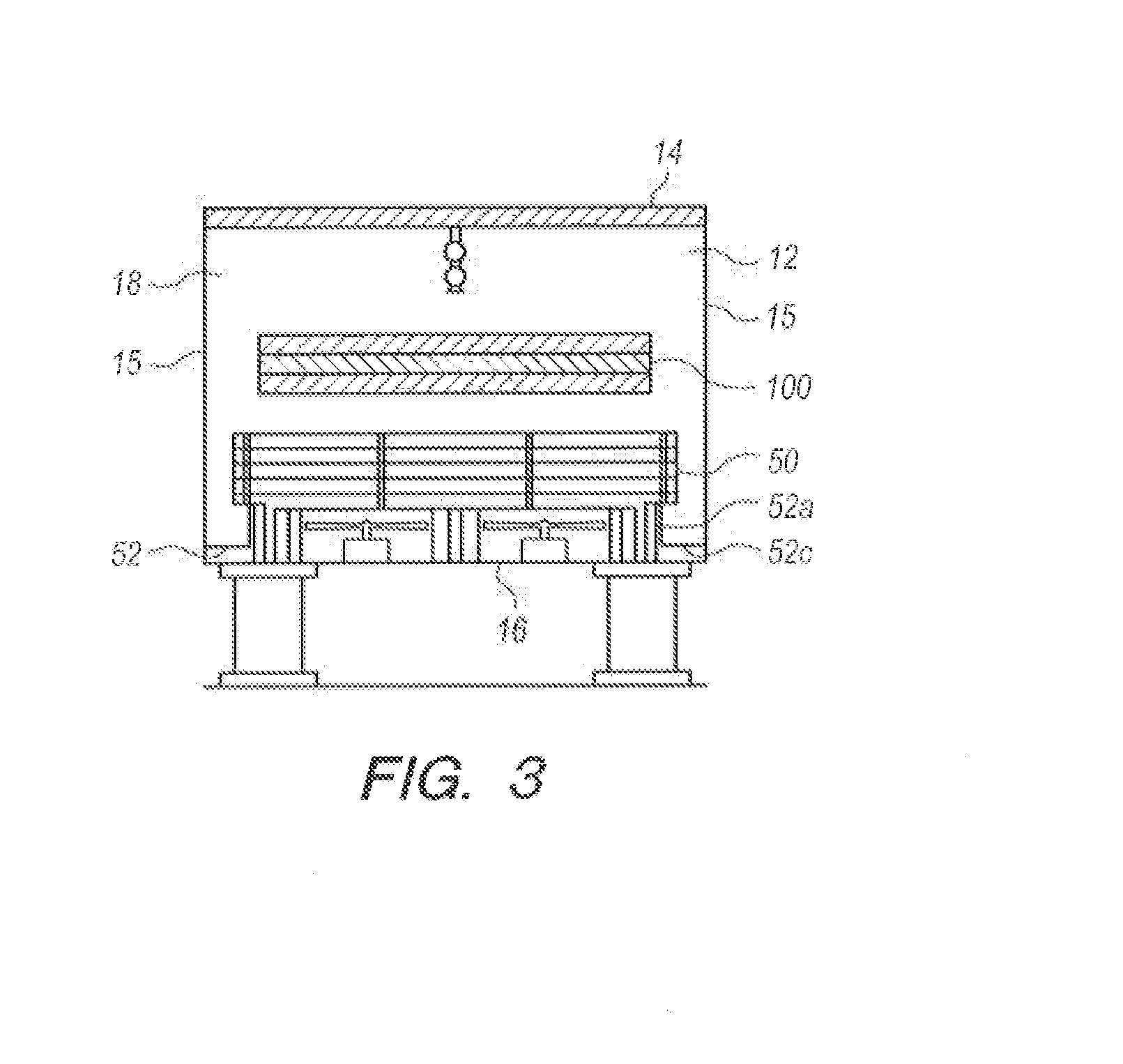

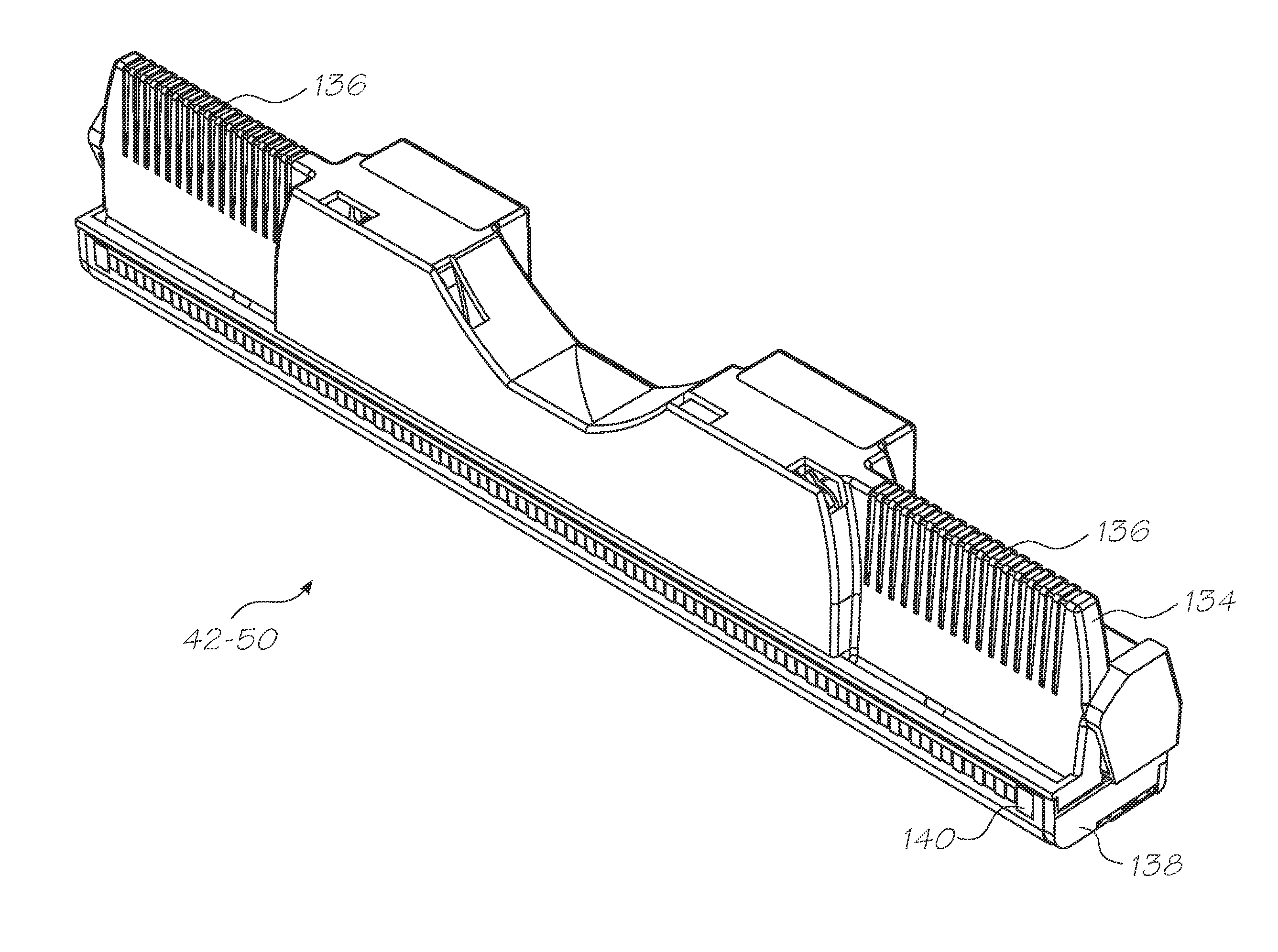

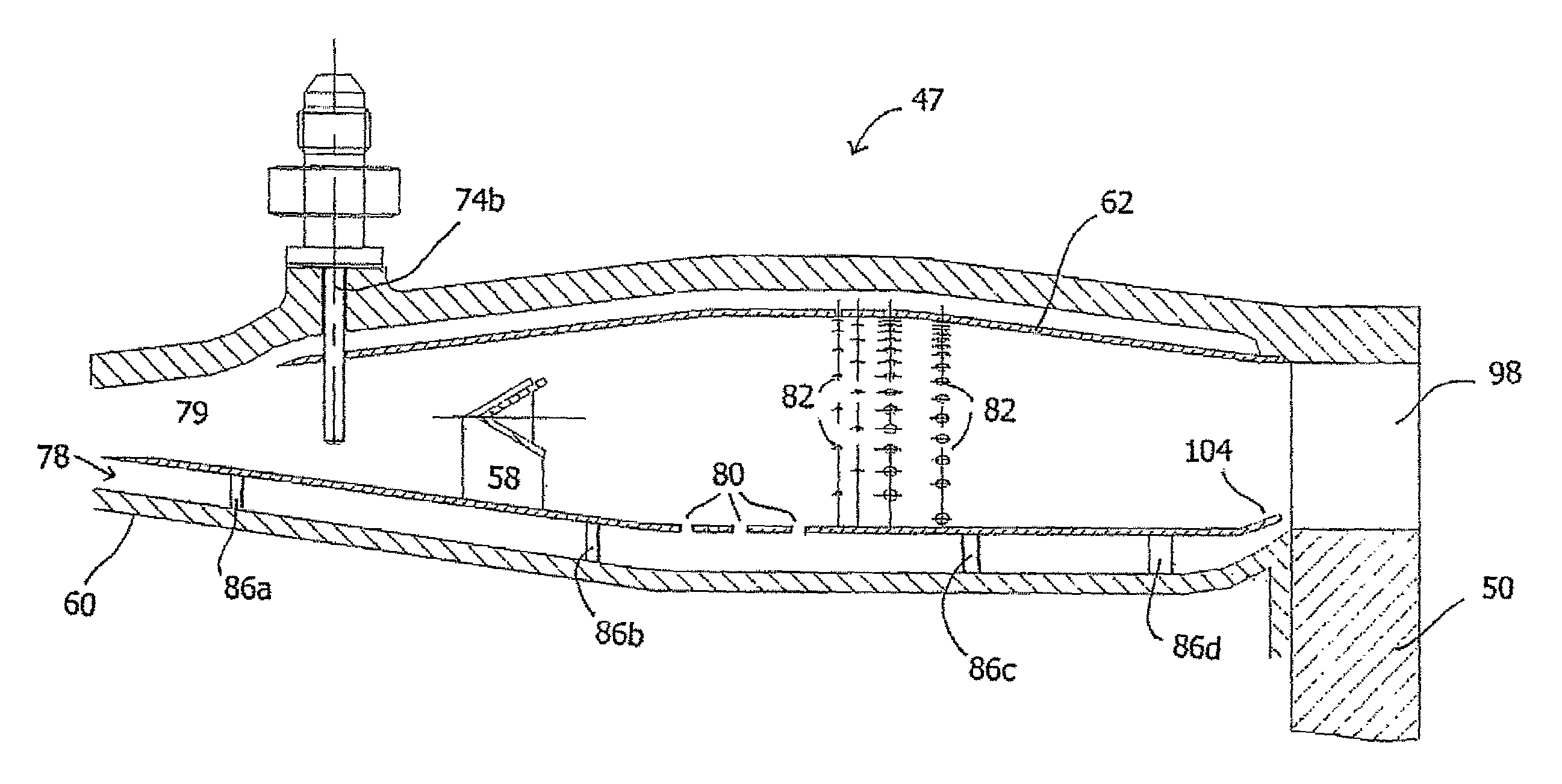

Fabrication of high surface area, high aspect ratio mini-channels and their application in liquid cooling systems

InactiveUS20110073292A1High aspect ratioSimple structureSemiconductor/solid-state device detailsSolid-state devicesLiquid cooling systemEngineering

The present invention provides methods and apparatuses which achieve high heat transfer in a fluid cooling system, and which do so with a small pressure drop across the system. The present invention teaches the use of wall features on the fins of a heat exchanger to cool fluid in a fluid cooling system. The present invention also discloses high aspect ratio, high surface area structures applicable in micro-heat exchangers for fluid cooling systems and cost effective methods for manufacturing the same.

Owner:BRIDGESTONE CORP +1

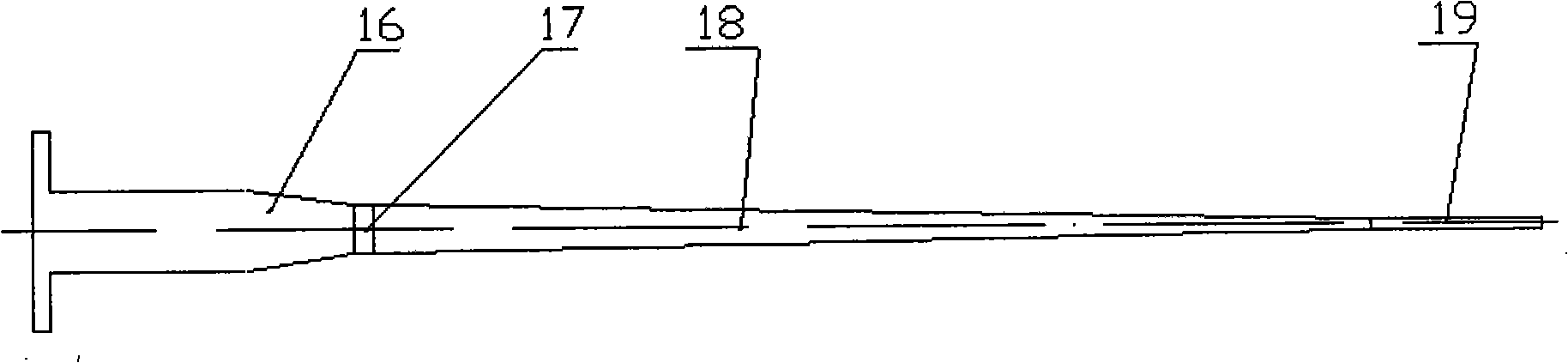

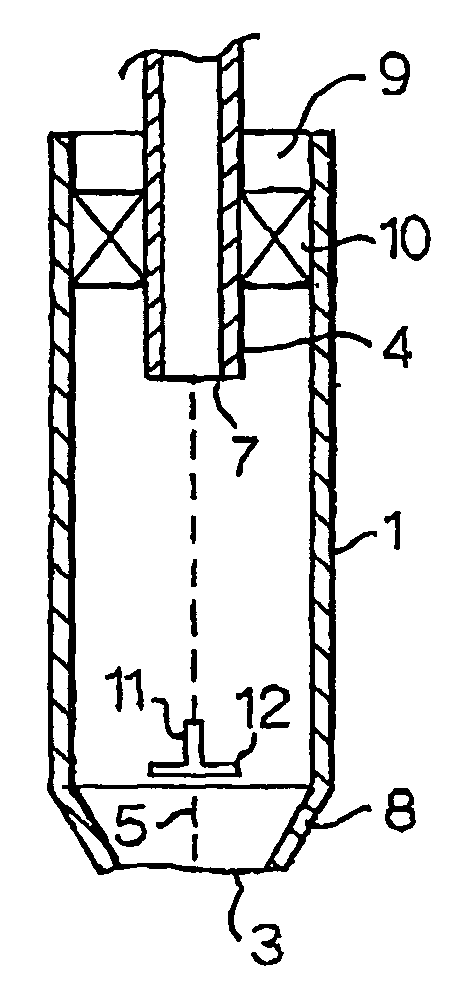

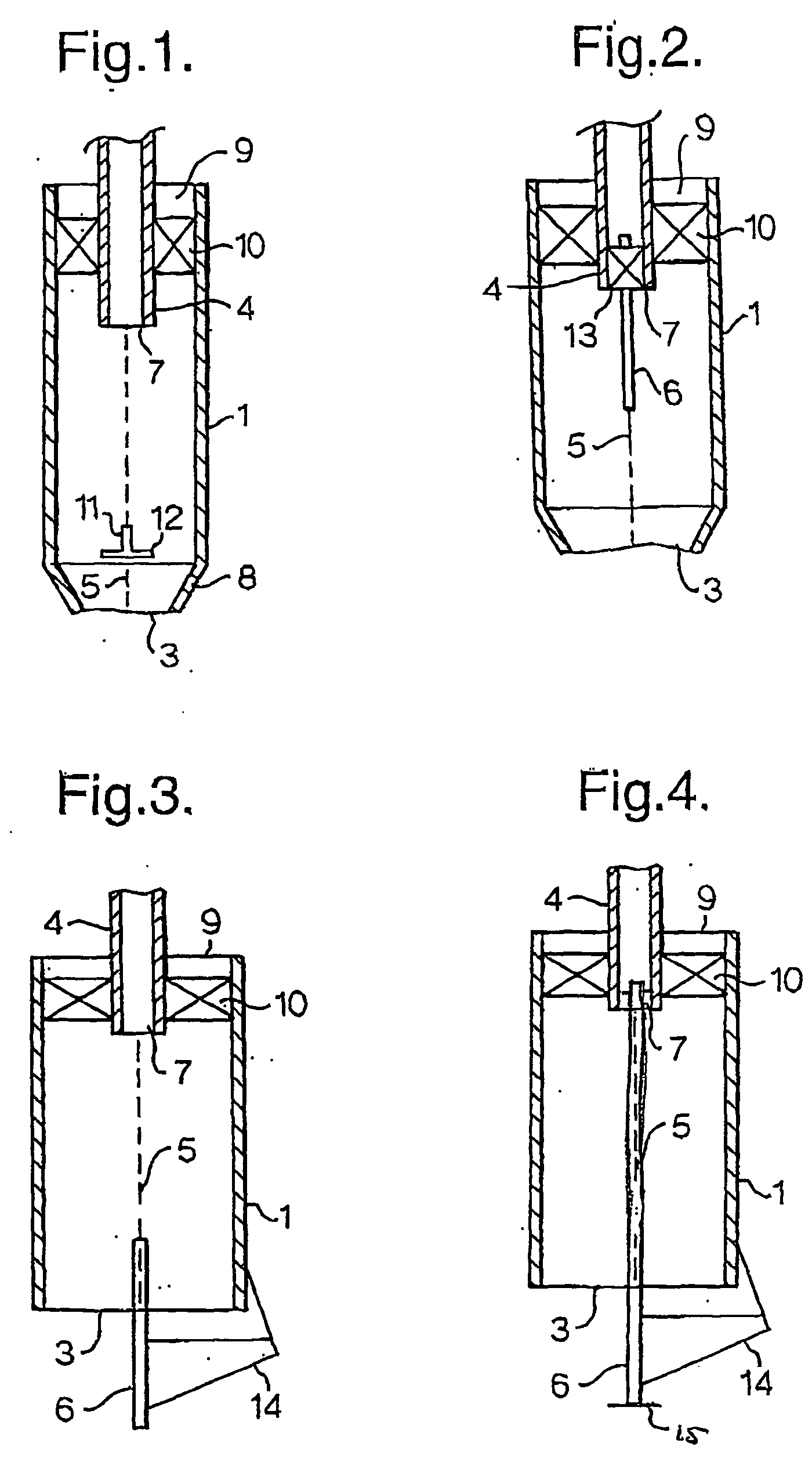

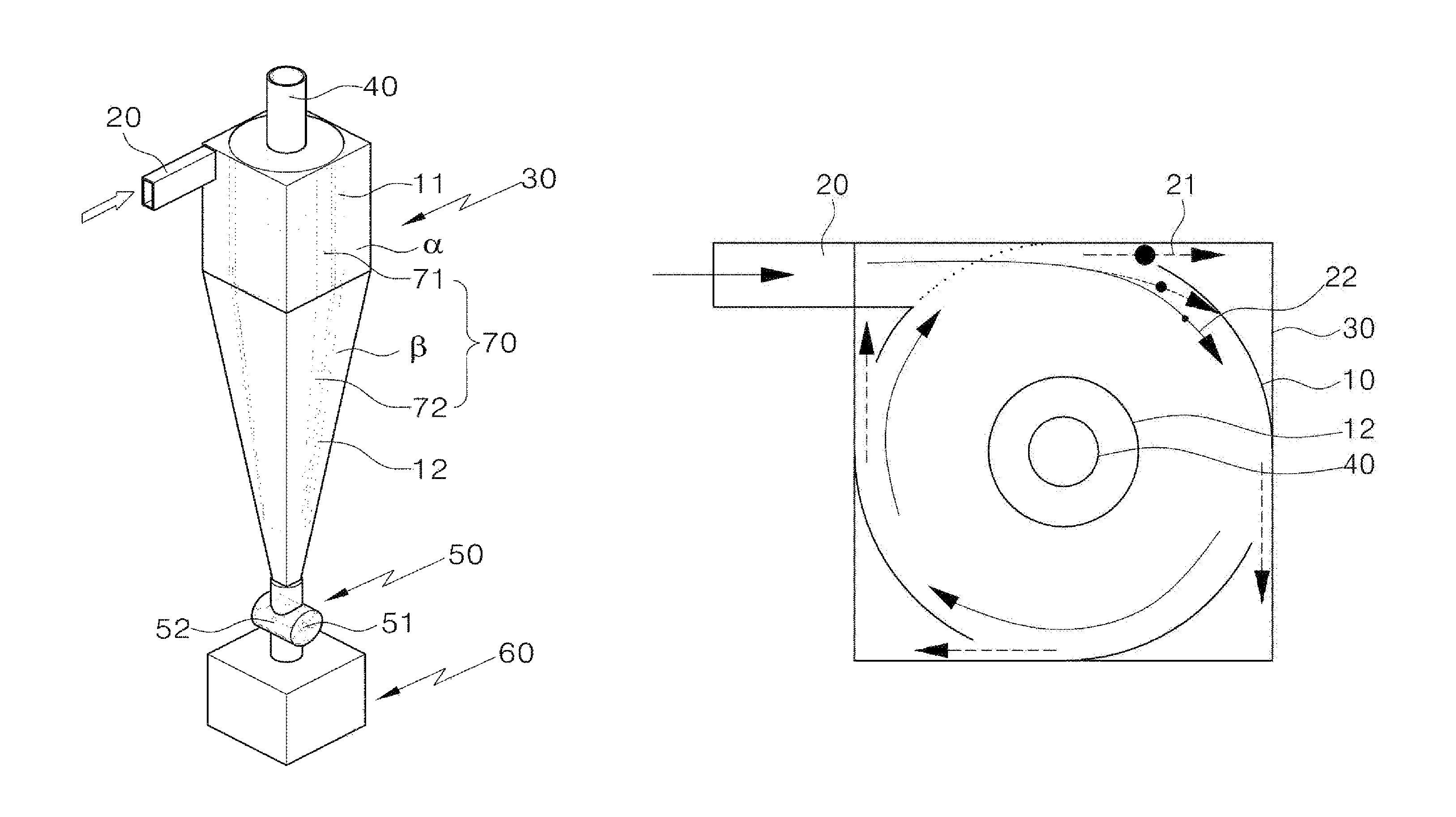

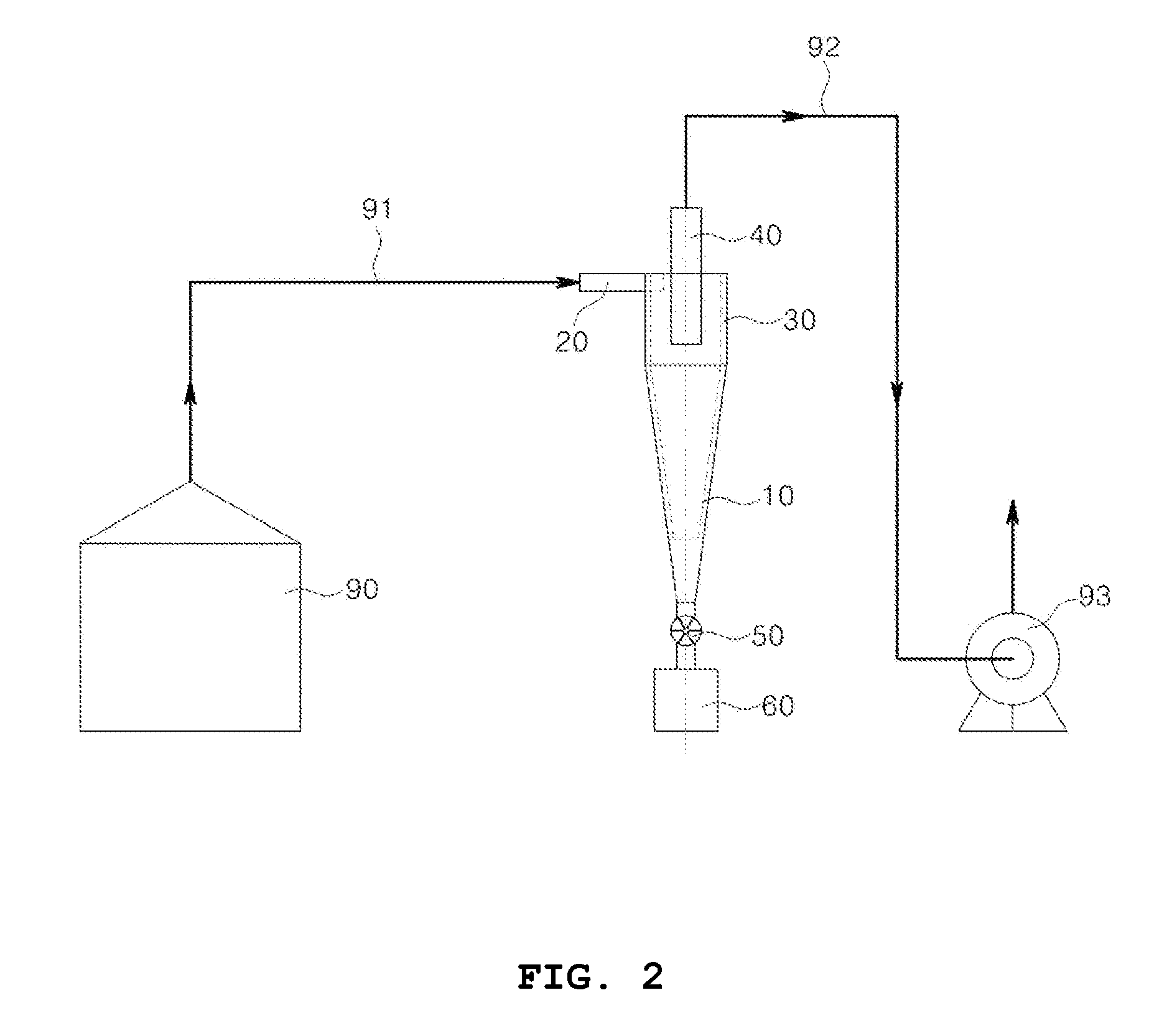

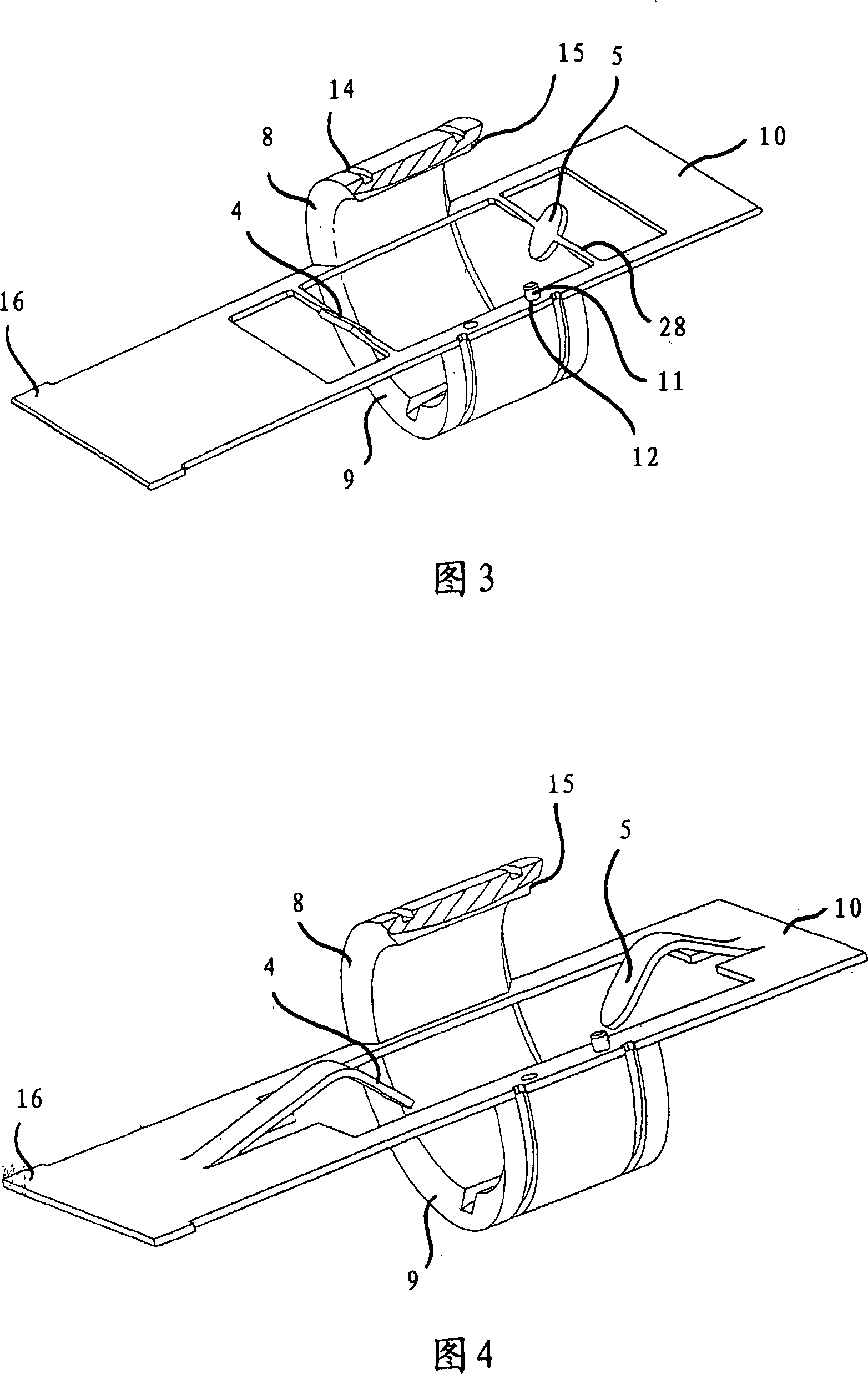

Swirl tube separator

InactiveUS20060070362A1Easy to separateGuaranteed uptimeCombination devicesLiquid degasificationEngineeringGas solid

Swirl tube separator for separating solids from a gas-solid containing feed comprising a tubular housing, an inlet for introducing a gas-solids mixture at one end of said housing, a solids outlet opening at the opposite end of said housing, and a co-axial positioned tubular gas outlet conduit placed at an end of said housing, wherein along the axis of the tubular housing a vortex extender pin is present.

Owner:SHELL OIL CO

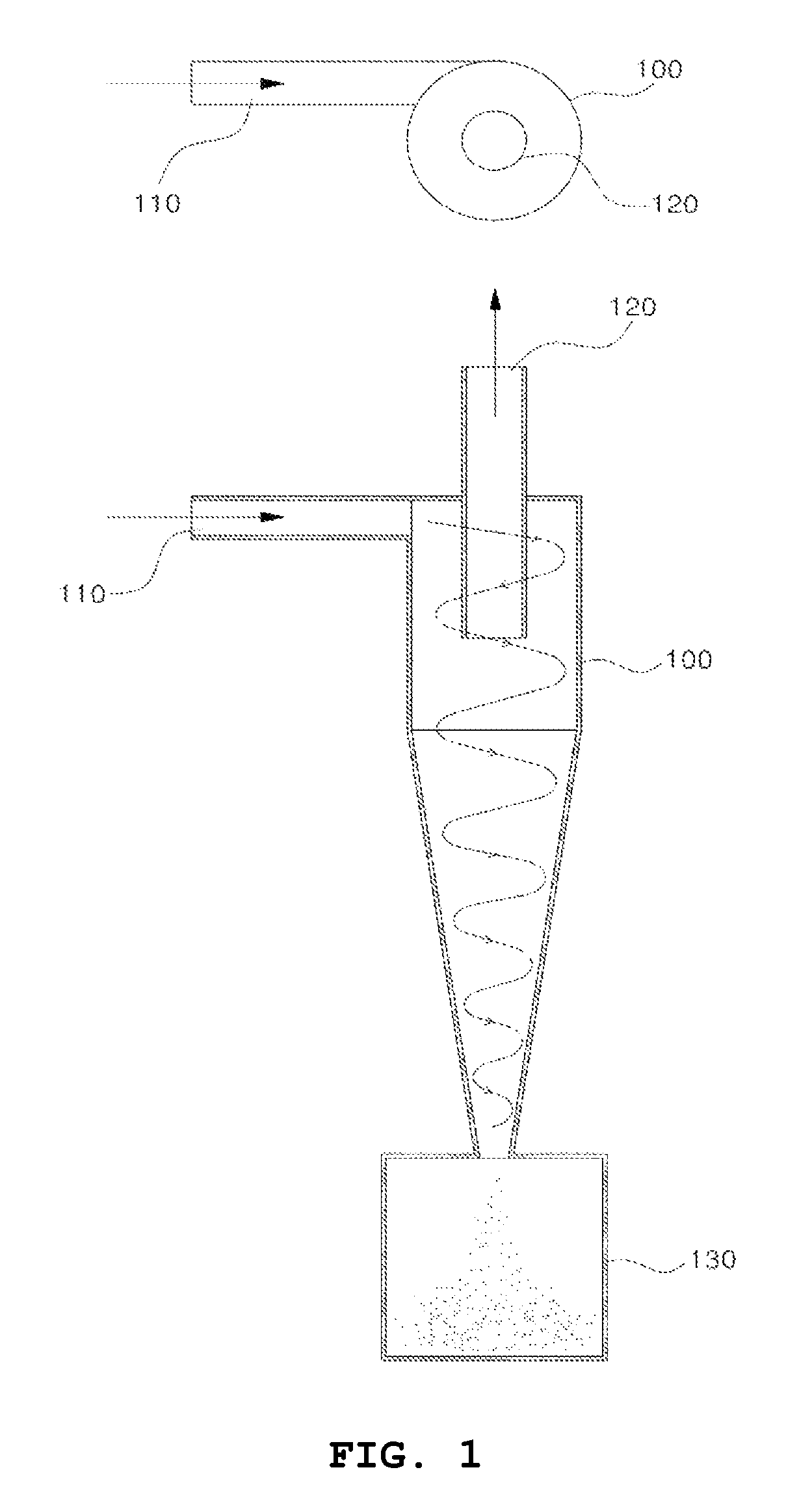

Multi-branch-hole finite sand control exploitation method for marine silty reservoir gas hydrates

ActiveCN106761587AIncrease the decomposition surfaceReduce pressure dropConstructionsFluid removalResource developmentSouth china

The invention belongs to the technical field of marine gas hydrate resource development engineering, and particularly relates to a multi-branch-hole finite sand control exploitation method for marine silty reservoir gas hydrates. The method comprises the following steps that (1) a main borehole is drilled, and a casing pipe with reserved branch holes is adopted for well completion; (2), multi-branch holes are drilled, wherein the multi-branch holes are distributed around the main borehole evenly and arranged directionally and have a certain included angle with the main borehole; (3), the periphery of the casing pipe of the main borehole and the multi-branch holes are filled with gravel layers for finite sand control; 4, well back-flushing is carried out, the well is put into production, and a step-by-step pressure reducing state starts. By means of the method, the inherent defect that a shallow hydrate reservoir is not suitable for fracturing reformation is overcome, and the problems that the permeability of a natural gas hydrate reservoir in the South China Sea is low, the comprehensive strength of the formation is low, and sand outflow is serious are solved; the method has great reference significance for increasing the duration of hydrate trial exploitation, and can promote the development of the hydrate commercial exploitation technology.

Owner:QINGDAO INST OF MARINE GEOLOGY

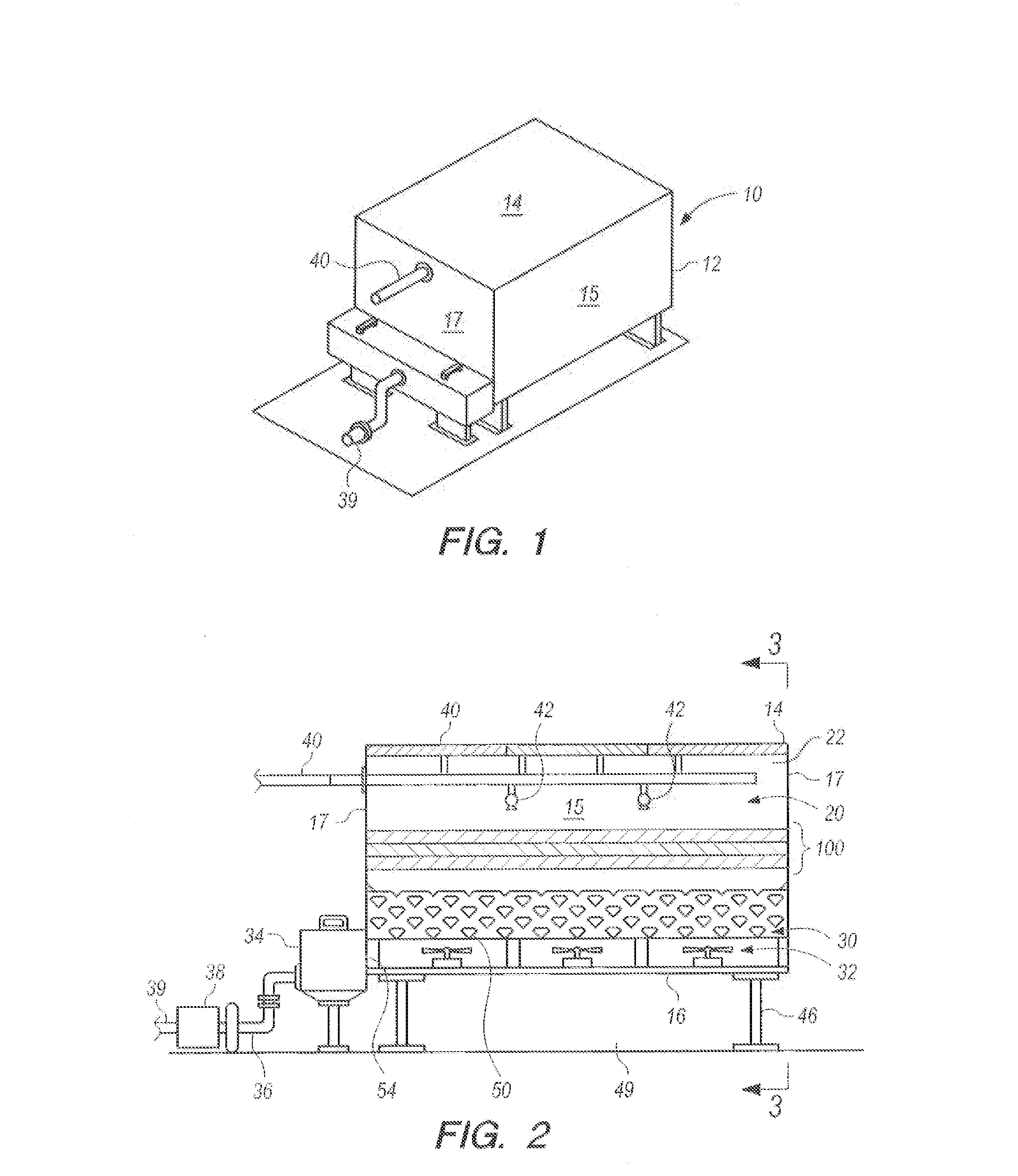

Direct Forced Draft Fluid Cooling Tower

InactiveUS20150330710A1Improve thermal performanceReduce pressure dropUsing liquid separation agentFree-cooling systemsWater collectionCooling tower

A cooling tower is provided with a housing containing a fan at the bottom of the tower, and a plurality of layers of water collection troughs or channels above the fan to capture water droplets sprayed downwardly from the top of the device through an evaporative cooling pad located above the collection troughs. The collection troughs extend from one side of the housing to the other in the form of a structural support for the housing and the equipment therein. The troughs have open ends which extend through the housing to discharge collected water to an adjacent vertical tank.

Owner:SYNTECH TOWERS L L C

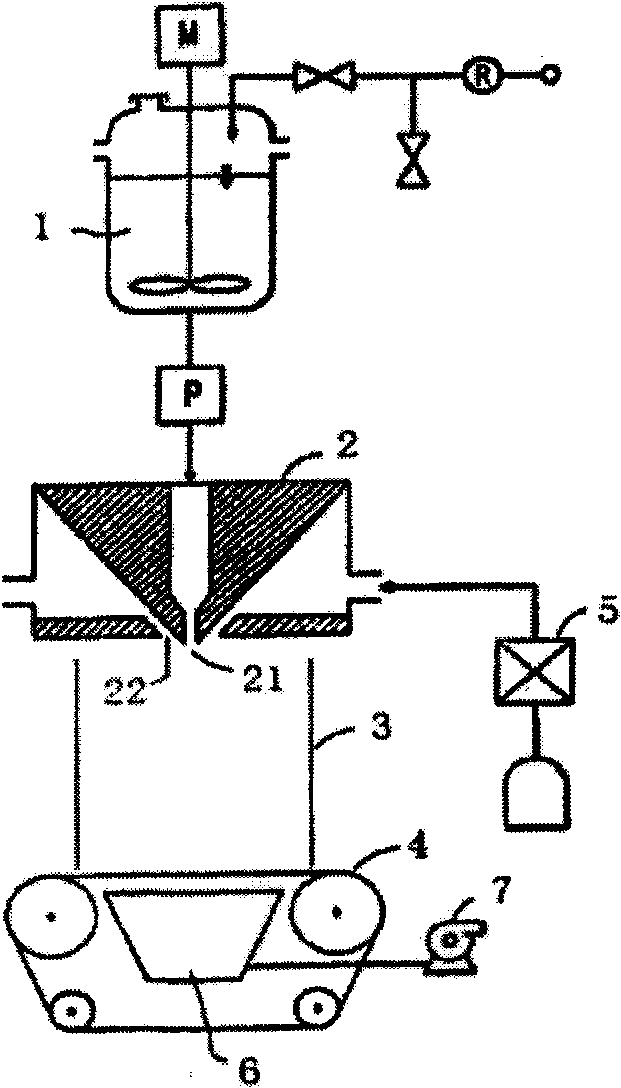

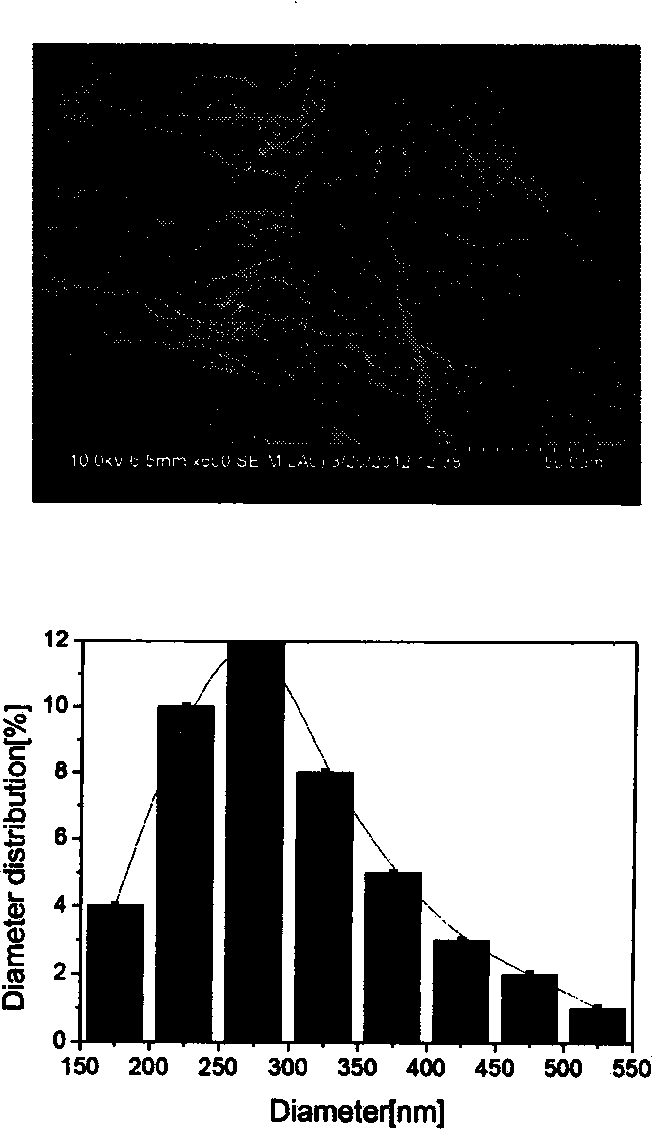

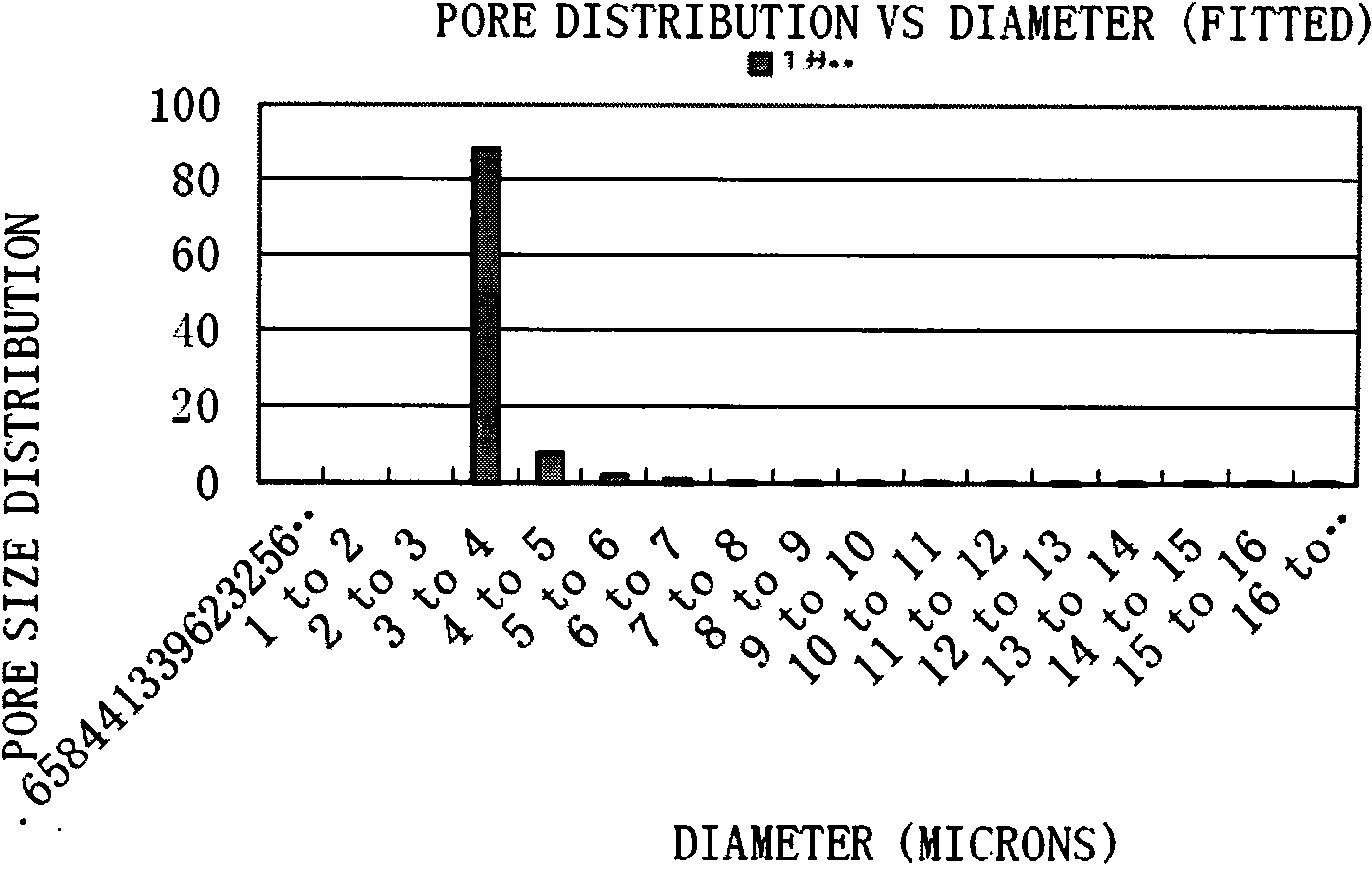

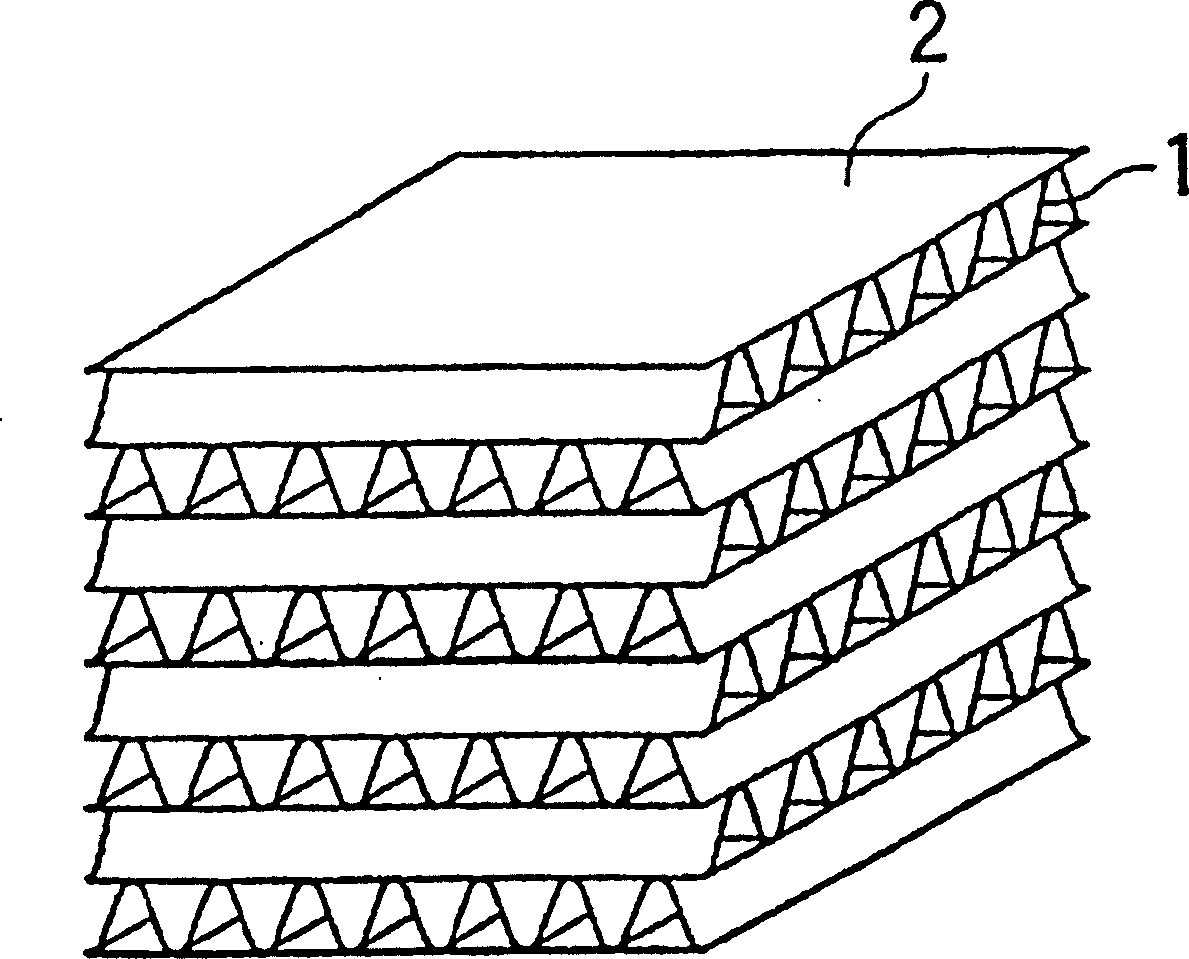

Nanofiber filter material

InactiveCN103505942AHigh yieldSimple processSynthetic resin layered productsFiltration separationPorosityPolymer science

The invention relates to a nanofiber filter material which comprises at least one porous nanofiber layer formed by continuous polymer fibers with a diameter less than 1000 nm. The nanofiber filter material is characterized in that the nanofibers are prepared by the solution jet spinning technology, the gram weight of each nano-layer is at least 1.5 g / m<2>; the nanofibers are in a three-dimensional curled state, the porosity of the fiber layer is more than 95%, and the proportion of the pores having an aperture of 1-10 micron in the fiber layer is more than 95%. When particles having a mean grain size of 0.3 micron are filtered at a surface speed of 5.33 cm / s, the filtration efficiency of the filter material nanofiber layer is at least 40%, the initial pressure drop is less than 8 mmH2O, and the filtration quality factor QF of the filter material is higher than 0.06 (1 / mmH2O). The nanofiber filter material provided by the invention has a filtering property with high efficiency and low resistance.

Owner:TIANJIN POLYTECHNIC UNIV

Fracturing technology for implementing ultrahigh flow conductivity

ActiveCN103306659ALow effective concentrationReduce the overall heightFluid removalMaterial PerforationOrder of magnitude

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Integral fuel gas buring catalyst and process for preparing the same

InactiveCN1504260AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic functionHigh activity

The invention discloses an integral style gas, combustion catalyst and method for the making same, wherein the base material of the catalyst is integral ceramic honeycomb body or metallic honeycomb body, the catalyst coating layer coated on the base material surface comprises catalytic functional components and coating layer aiding agents, the catalytic functional components are classified into compound catalytic functional components having at least three different catalytic functions, each of which is prepared through corresponding predecessor physical process. The catalyst by the invention has high activity, high stability, high heat efficiency and low contaminant discharge.

Owner:SICHUAN TIANJIAN CATALYTIC COMBUSTION

Cyclone dust collector

ActiveUS8657910B2Low pressure lossReduce flow rateCombination devicesSuction filtersCycloneCentrifugal force

Owner:KOREA INST OF ENERGY RES

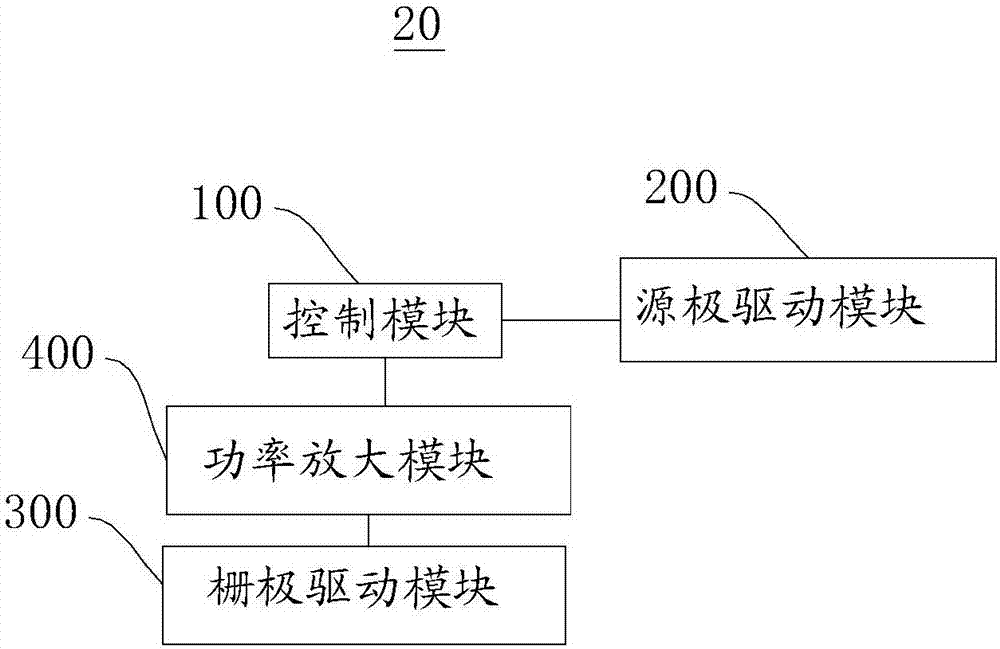

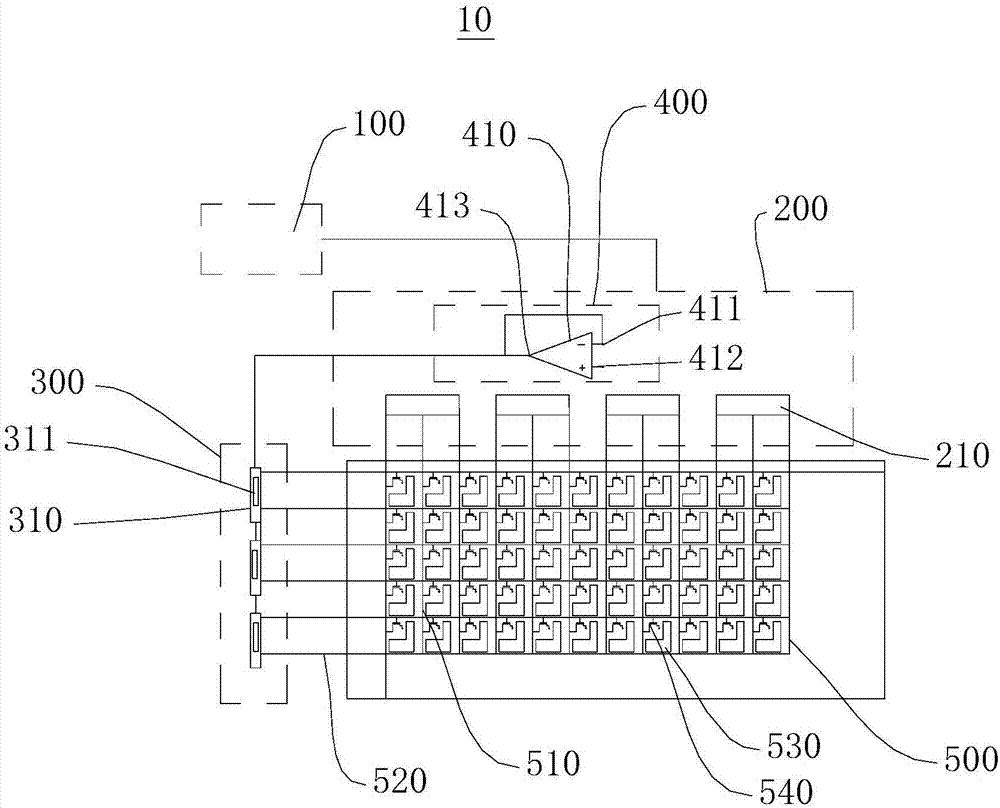

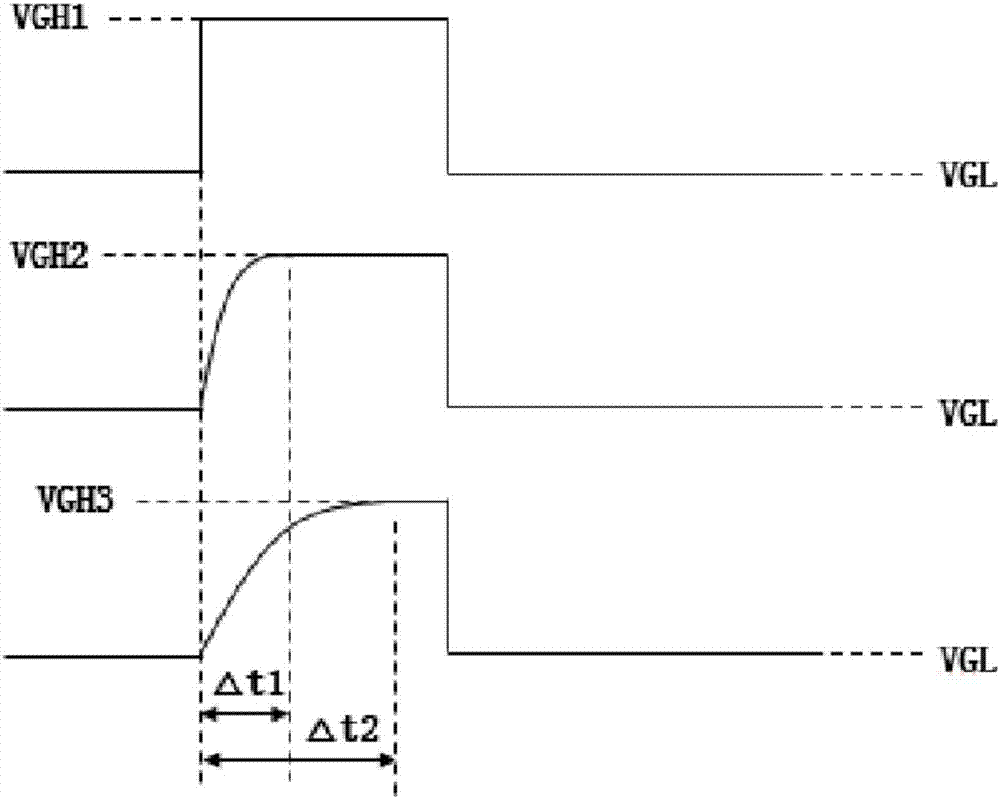

Display panel driving circuit, display device and display panel driving circuit's driving method

InactiveCN107146586AReduce pressure dropReduce latencyStatic indicating devicesPower flowData signal

The invention discloses a display panel driving circuit, a display device and a display panel driving circuit's driving method. The display panel driving circuit comprises a control module, a source electrode driving module and a gate electrode driving module in connection with the control module. The control module, through the gate electrode driving module and the source electrode driving module, outputs a scanning signal and a data signal respectively. Between the control module and the gate electrode driving module, a power amplification module is arranged. The power amplification module is connected with the control module and the gate electrode module. The scanning signal outputted from the control module is amplified by the power amplification module, and then enters the gate electrode driving module. The amplified scanning signal is capable of increasing the driving capability of the signal current on the line, and is able to quicken the responding time, reduce the signal deformation, solve the weakening problem and increase the power charging efficiency.

Owner:HKC CORP LTD +1

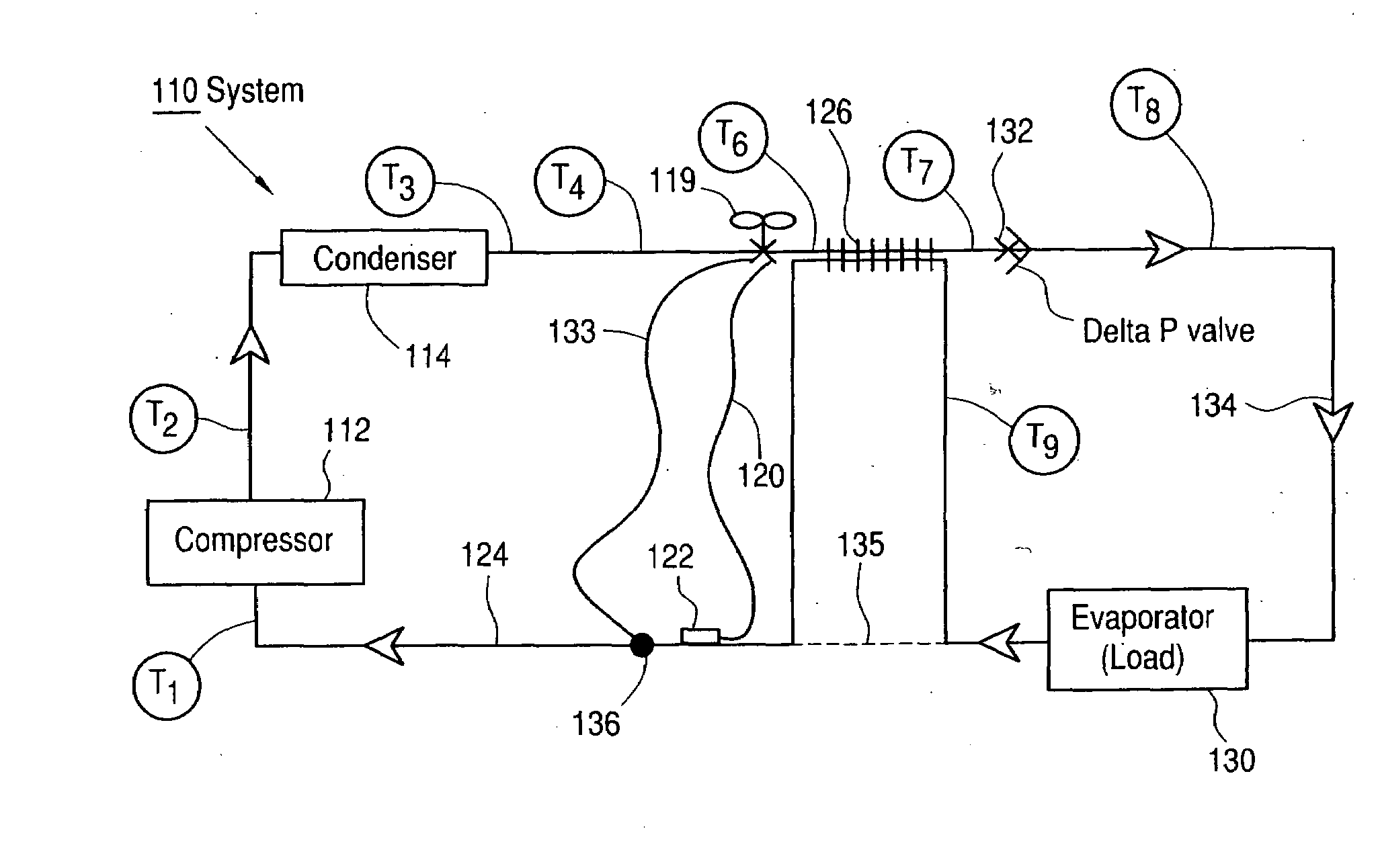

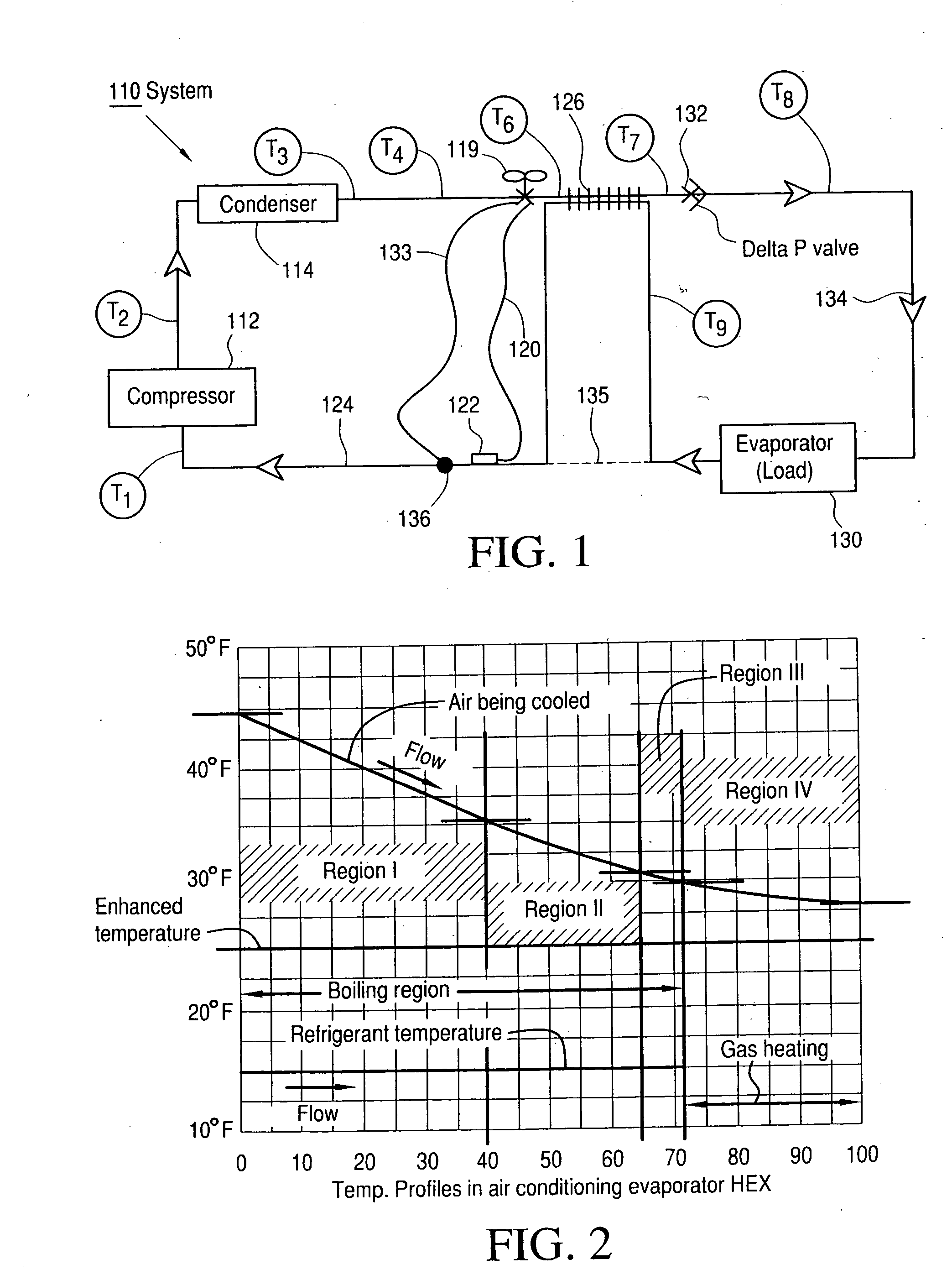

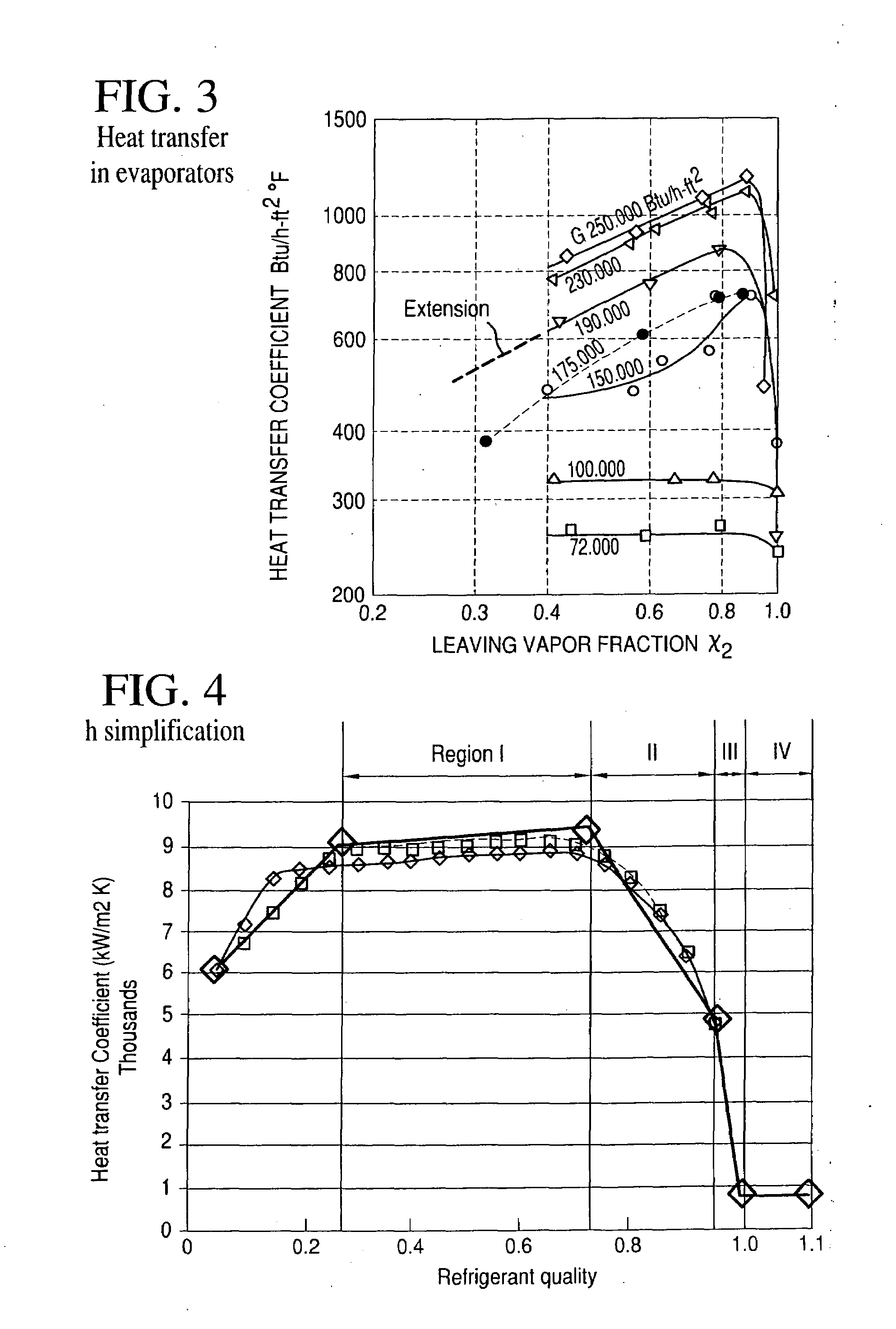

Thermal control system and method

ActiveUS20090105889A1Degradation in quality levelRaises effective heat transfer coefficient (h)Mechanical apparatusTemperatue controlEnergy transferThermal energy

A system for improving the thermal efficiency of a thermal control loop in which refrigerant after compression and condensation is applied to an evaporator employs a subsidiary counter-current heat exchange intercepting refrigerant flow to maintain the quality of the refrigerant by exchanging thermal energy between the input flow and the output flow from the evaporator. The same principle is effective, with particular advantage when small connections have to be made, in systems using mixed phase media and using the concept of direct energy transfer with saturated fluid.

Owner:BE AEROSPACE INCORPORATED

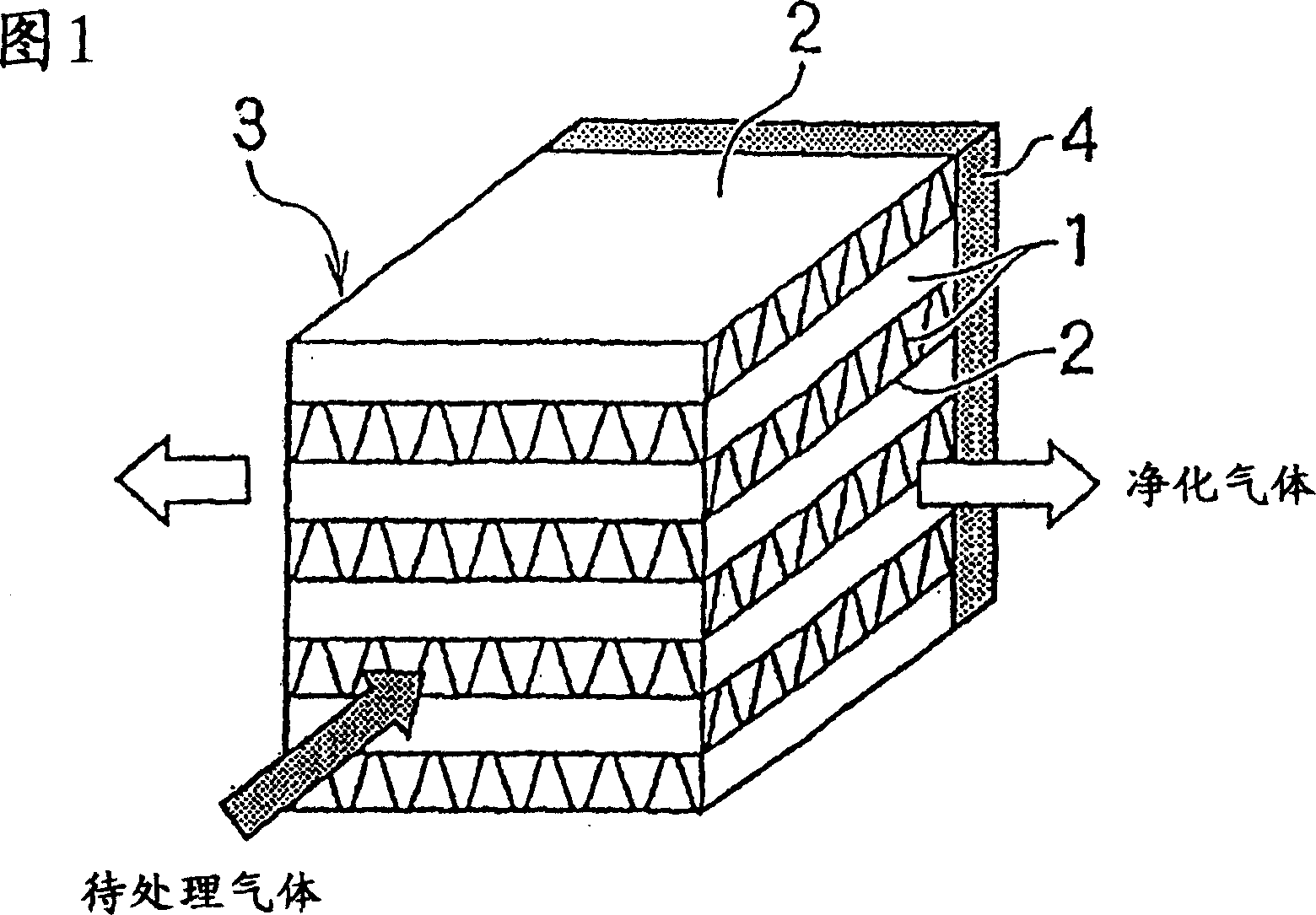

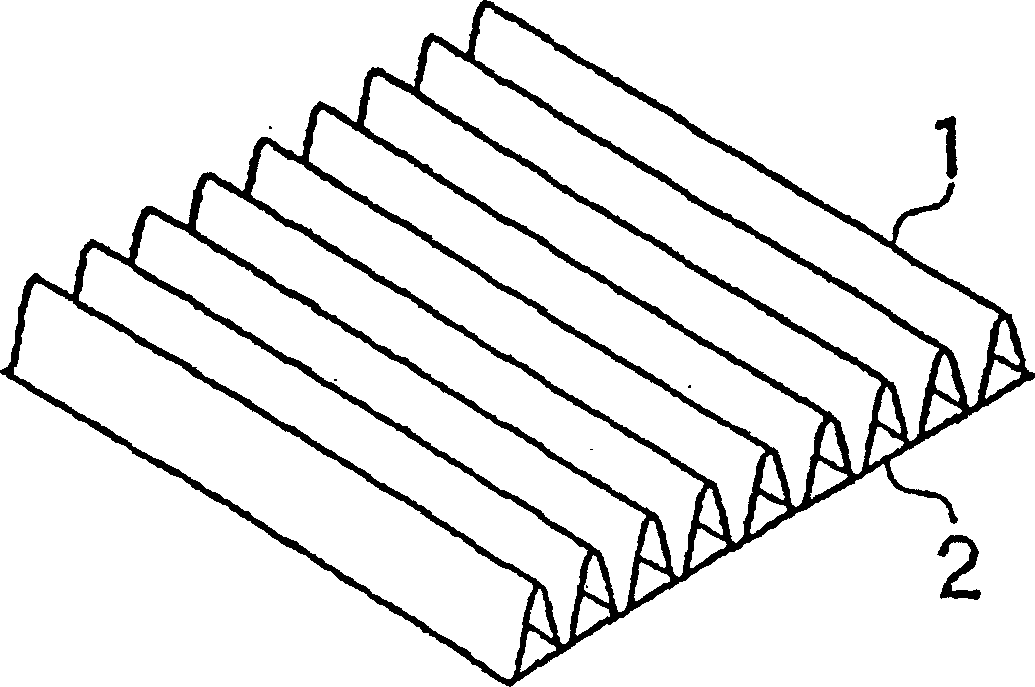

Particulate matter-containing exhaust emission controlling filter, exhaust emission controlling method and device

InactiveCN1902384AImprove performanceReduce pressure dropPhysical/chemical process catalystsExhaust apparatusExhaust gasExhaust fumes

A particulate matter-removing filter being resistant to clogging and ash blocking, requiring no special means such as back-washing and heating combustion, and being formed of inexpensive materials; and exhaust emission controlling method and device using this. (1) A particulate-matter-containing exhaust emission controlling filter which uses as a basic unit a pair of porous corrugated sheet and a porous flat sheet that support an exhaust emission controlling catalyst, has a molding formed by laminating the porous corrugated sheets so that their ridge lines alternately cross perpendicularly, has one of side surfaces, perpendicularly crossing the corrugated sheet ridge lines, of the molding or mutually-adjoining two surfaces that are the perpendicularly-crossing side surfaces sealed, and has exhaust gas in-flow passage and out-flow passage respectively formed between porous corrugated sheets via a porous flat sheet. (2) A filter having the exhaust emission controlling catalyst that is an oxidizing catalyst for oxidizing nitrogen monoxide in an exhaust gas.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

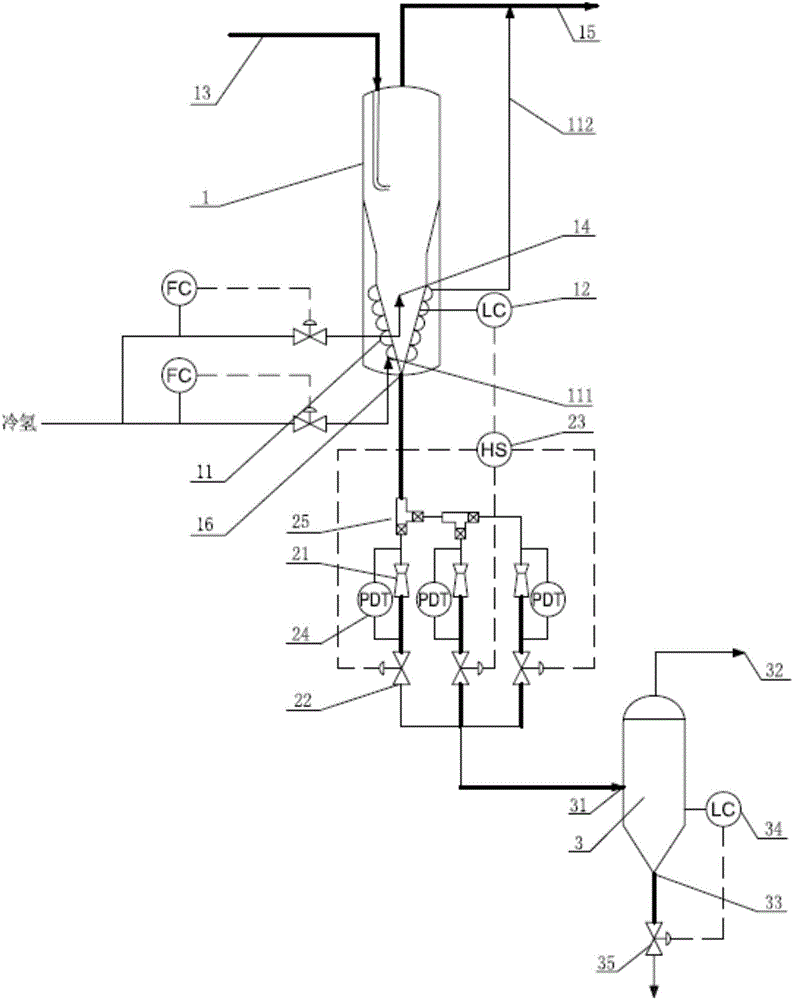

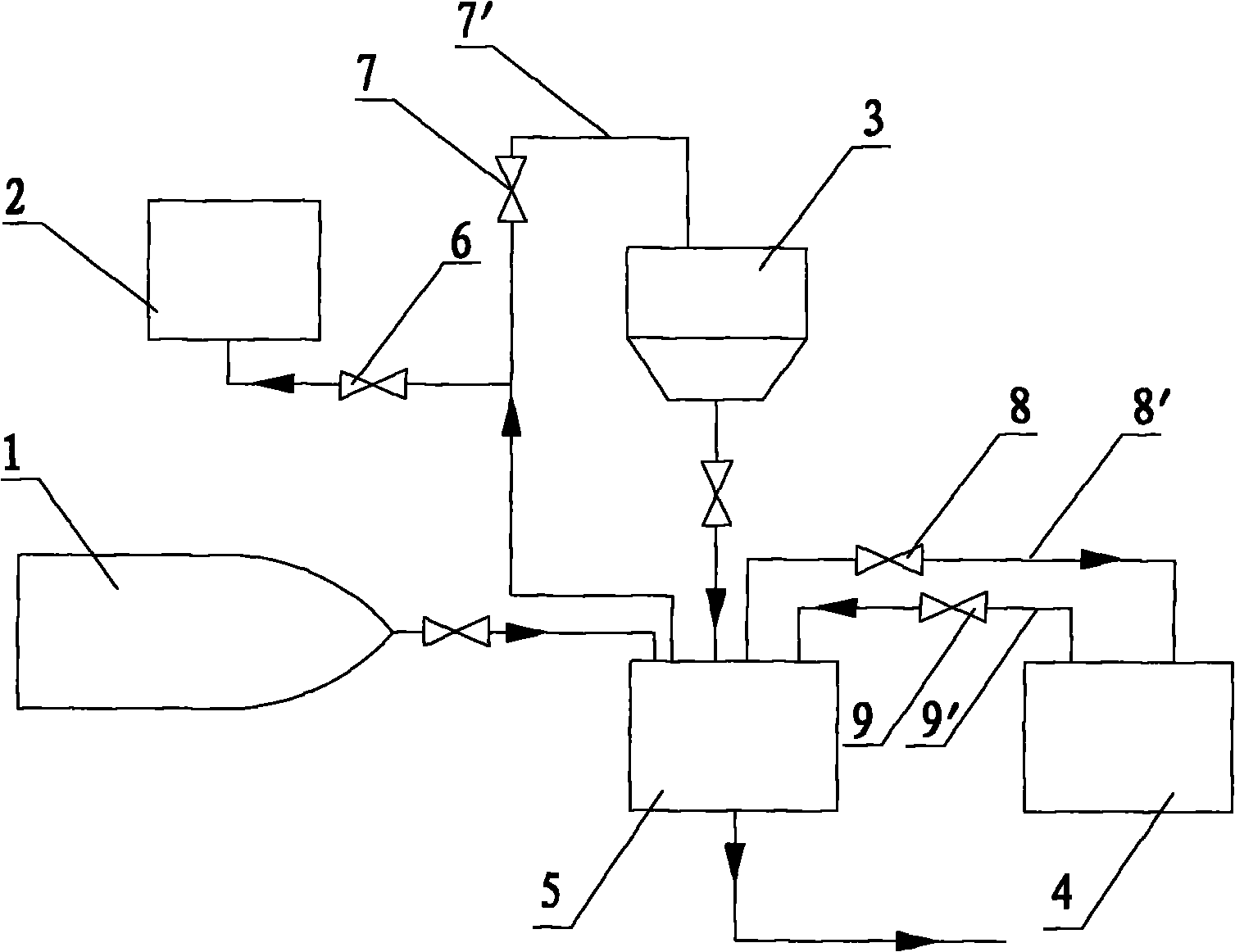

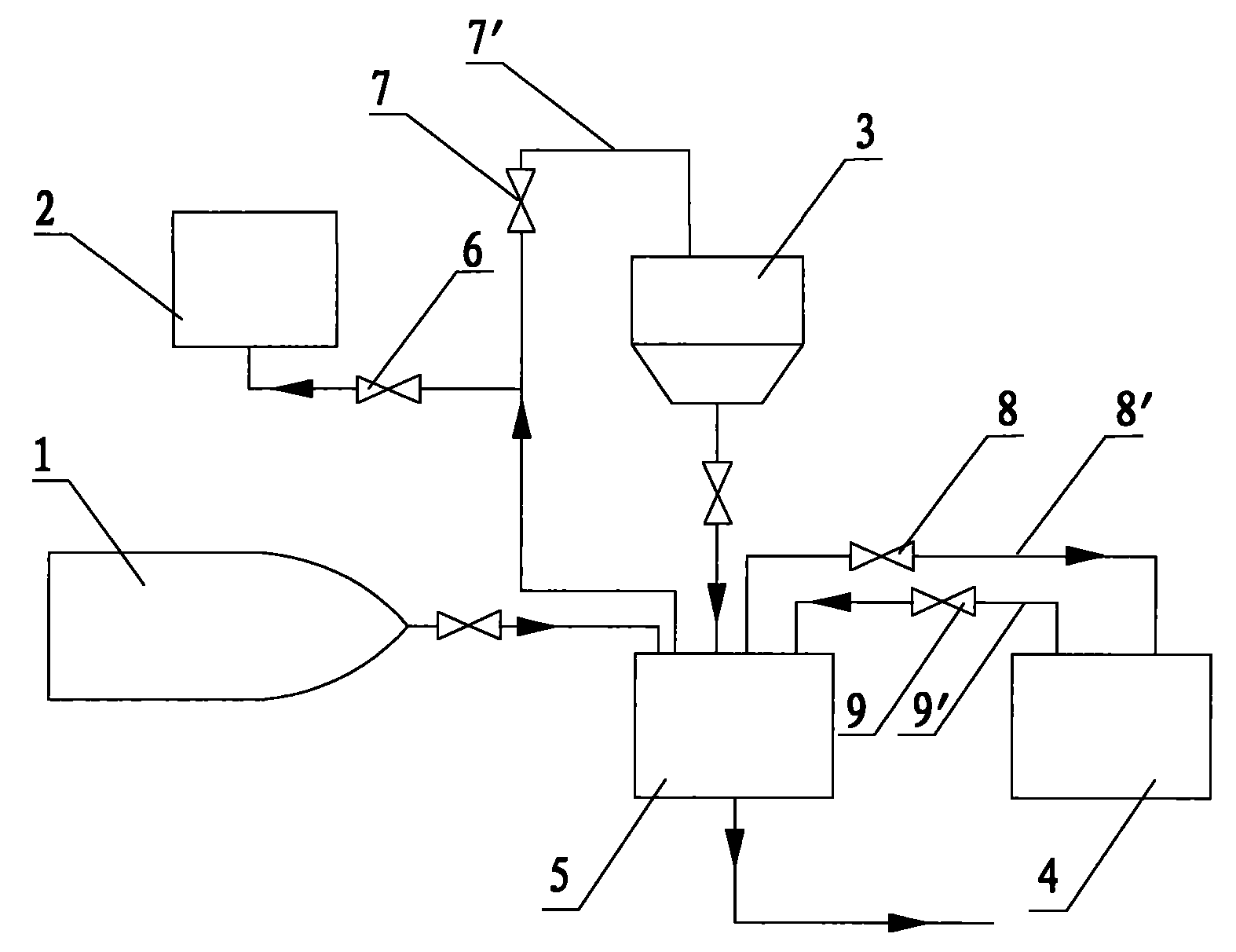

Separation and pressure reduction combining system for suspended bed hydrocracking reaction products

ActiveCN104449824AModerate operating conditionsAchieve separationTreatment with plural serial refining stagesHydrogenProcess engineering

The invention provides a separation and pressure reduction combining system for suspended bed hydrocracking reaction products. The system comprises a heat high-pressure separator, a pressure relief valve bank and a heat low-pressure separator, wherein a feeding hole for the suspended bed hydrocracking reaction products is formed in the upper part of the heat high-pressure separator; a cold hydrogen feeding hole is formed in the lower part of the heat high-pressure separator; a heat high-pressure separating gas outlet is formed in the top part of the heat high-pressure separator; a heat high-pressure separating liquid outlet is formed in the bottom of the heat high-pressure separator; the pressure relief valve bank comprises at least one set of valve bank; each set of valve bank comprises a venturi throttling element and an angle adjusting valve which are communicated with each other; a heat low-pressure feeding hole is formed in the upper part of the heat low-pressure separator; a heat low-pressure separating gas outlet is formed in the top of the heat low-pressure separator; a heat low-pressure separating liquid outlet is formed in the bottom of the heat low-pressure separator; the heat high-pressure separating liquid outlet is communicated with the venturi throttling element of the pressure relief valve bank; and the angle adjusting valve is communicated with the heat low-pressure feeding hole. The invention also provides a pressure reduction and separation method for the suspended bed hydrocracking reaction products by using the separation and pressure reduction combining system.

Owner:BEIJING PETROCHEM ENG

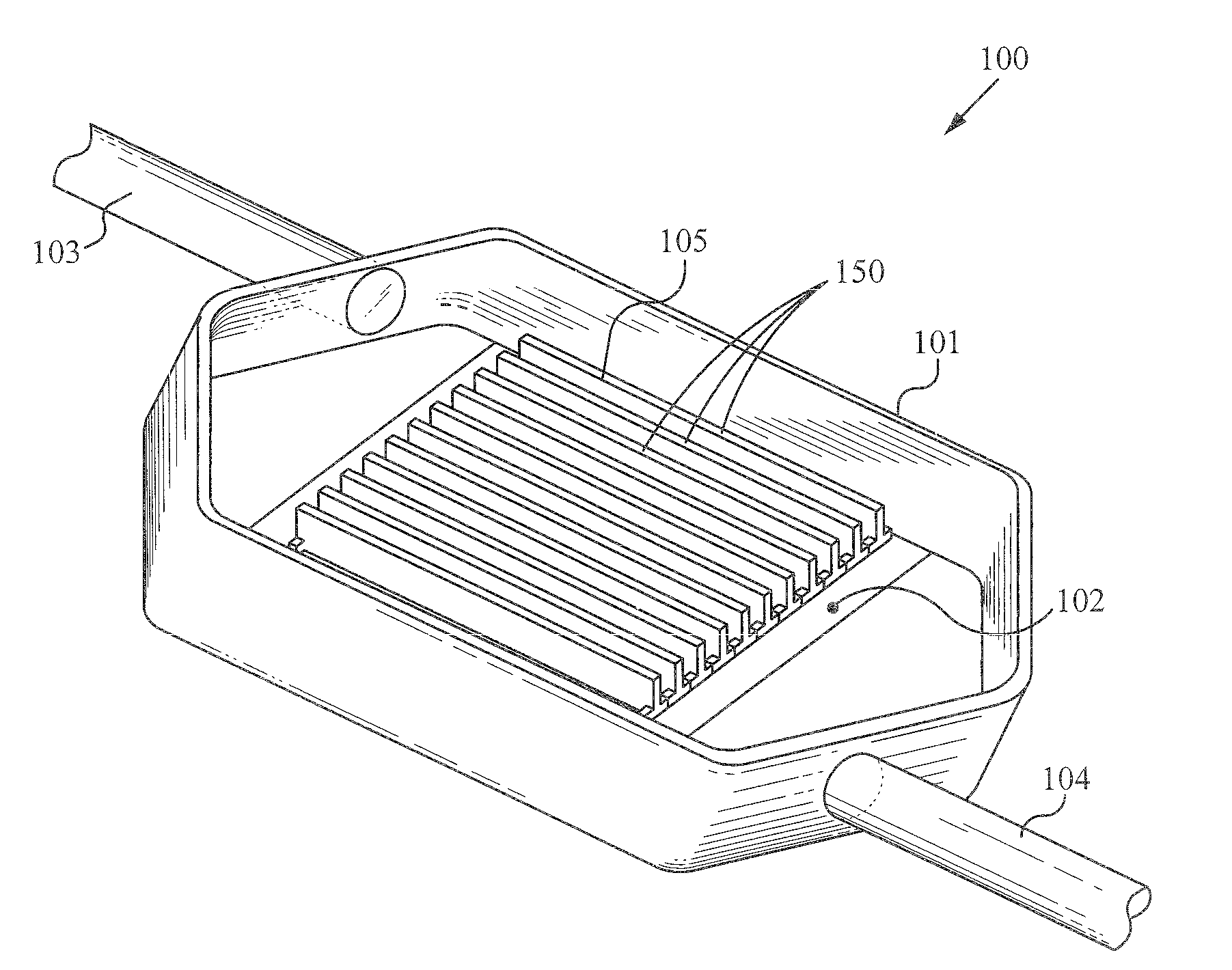

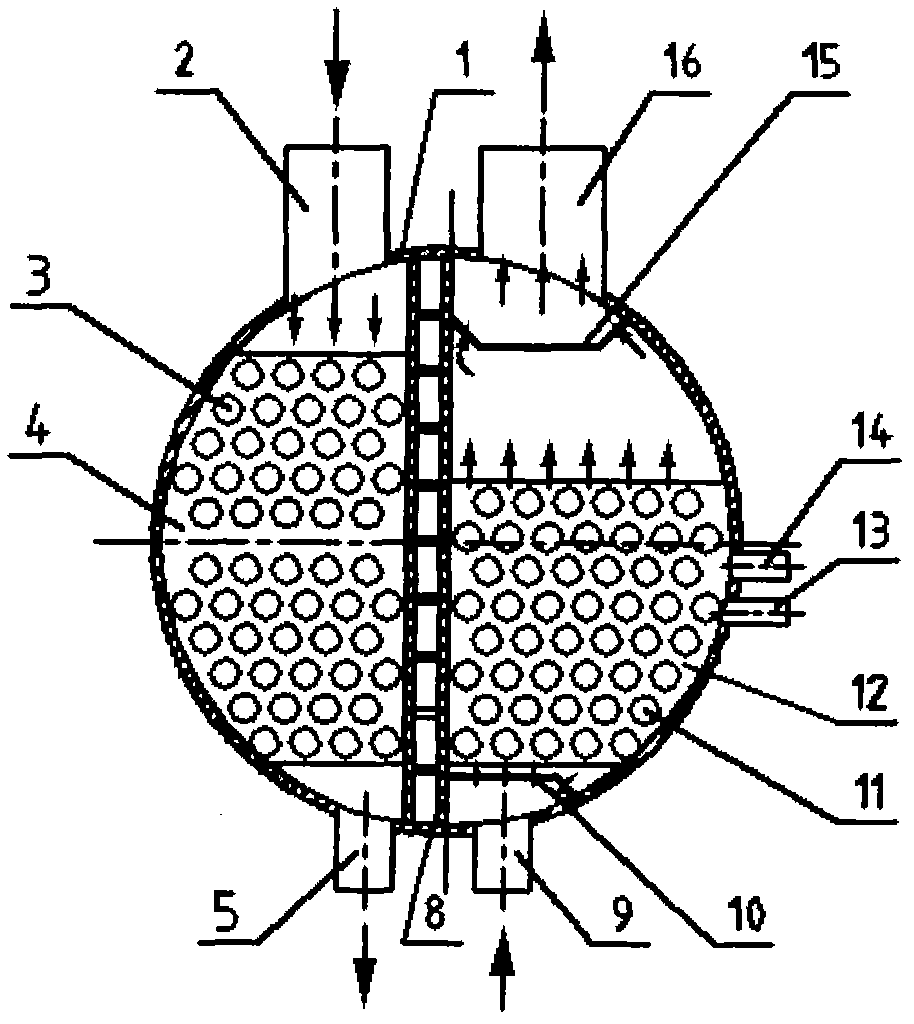

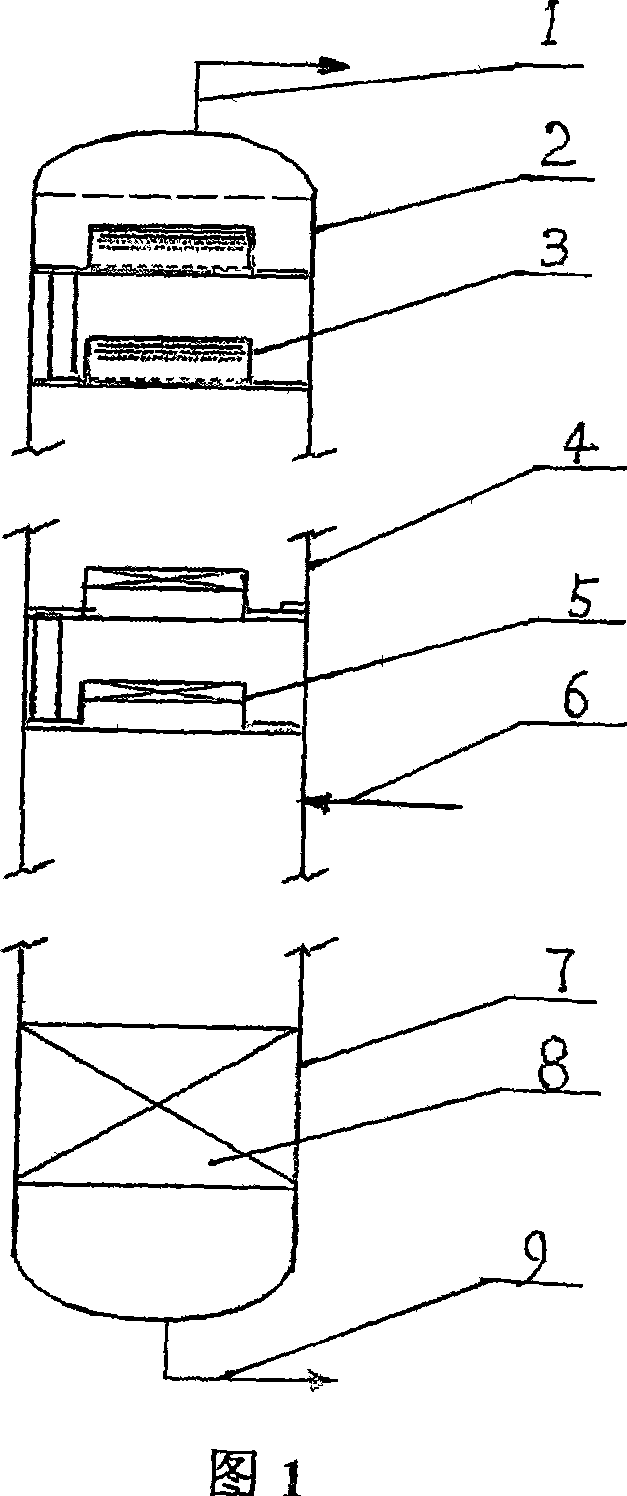

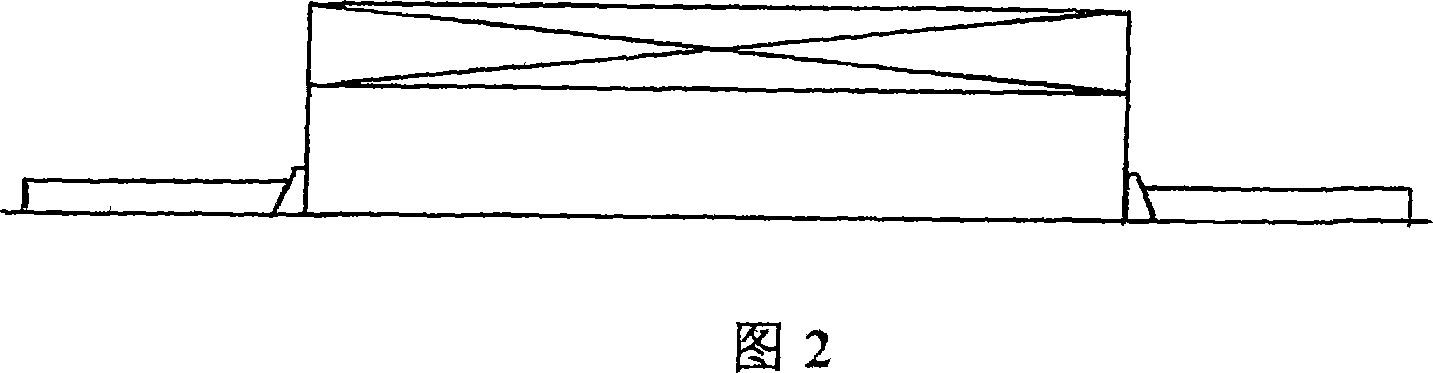

Integrated condensing flooded evaporator device and using method thereof

ActiveCN102052803ACompact structureReduce volumeEvaporators/condensersIndirect heat exchangersEngineeringDistributor

The invention relates to an integrated condensing flooded evaporator device and a using method thereof. A single condenser and a single flooded evaporator are adopted in the prior art, and the technical scheme is that: the condenser and the flooded evaporator are combined in the same cylinder. The device consists of a cylinder, an air inlet pipe, a condensing pipe bundle, a condensing side supporting plate, a refrigerant liquid outlet, a condensing side pipe plate, a condensing side secondary refrigerant inlet / outlet, a double-layer clapboard, a liquid inlet pipe, a dispenser, an evaporating pipe bundle, an evaporating side supporting plate, an oil return low interface, an oil return high interface, an air suction distributor, an air outlet pipe, an evaporating side secondary refrigerant inlet / outlet and an evaporating side pipe plate. The invention has the advantages that: two heat exchanger devices, namely the single condenser and the single flooded evaporator, are integrated in the same cylinder; and the device is compact in structure, saves pipelines, valves and raw materials by 20 percent, reduces pressure drop by 10 percent, reduces leakage points, wholly improves the energy efficiency by 8 to 10 percent, and is economic and energy-saving.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

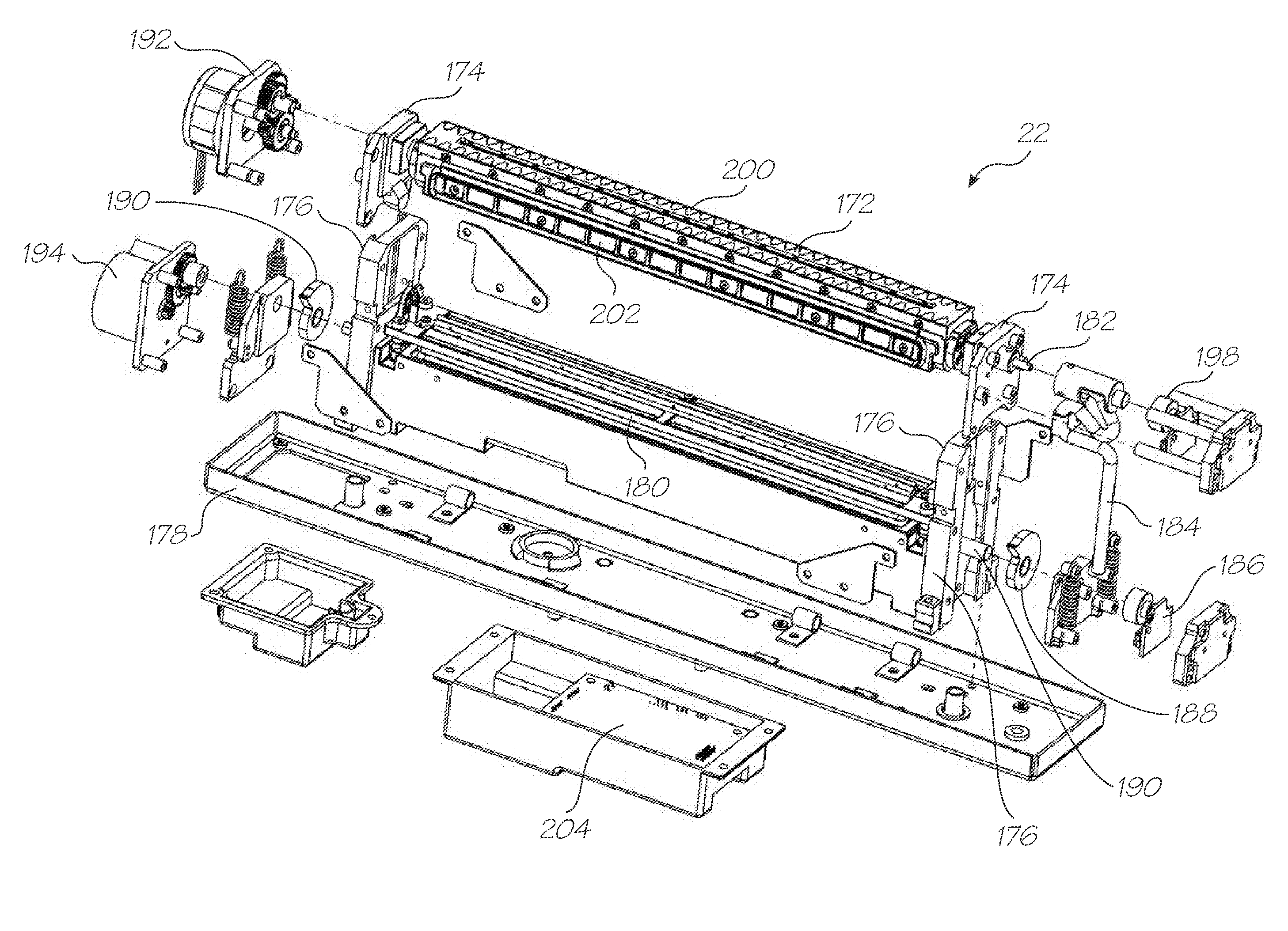

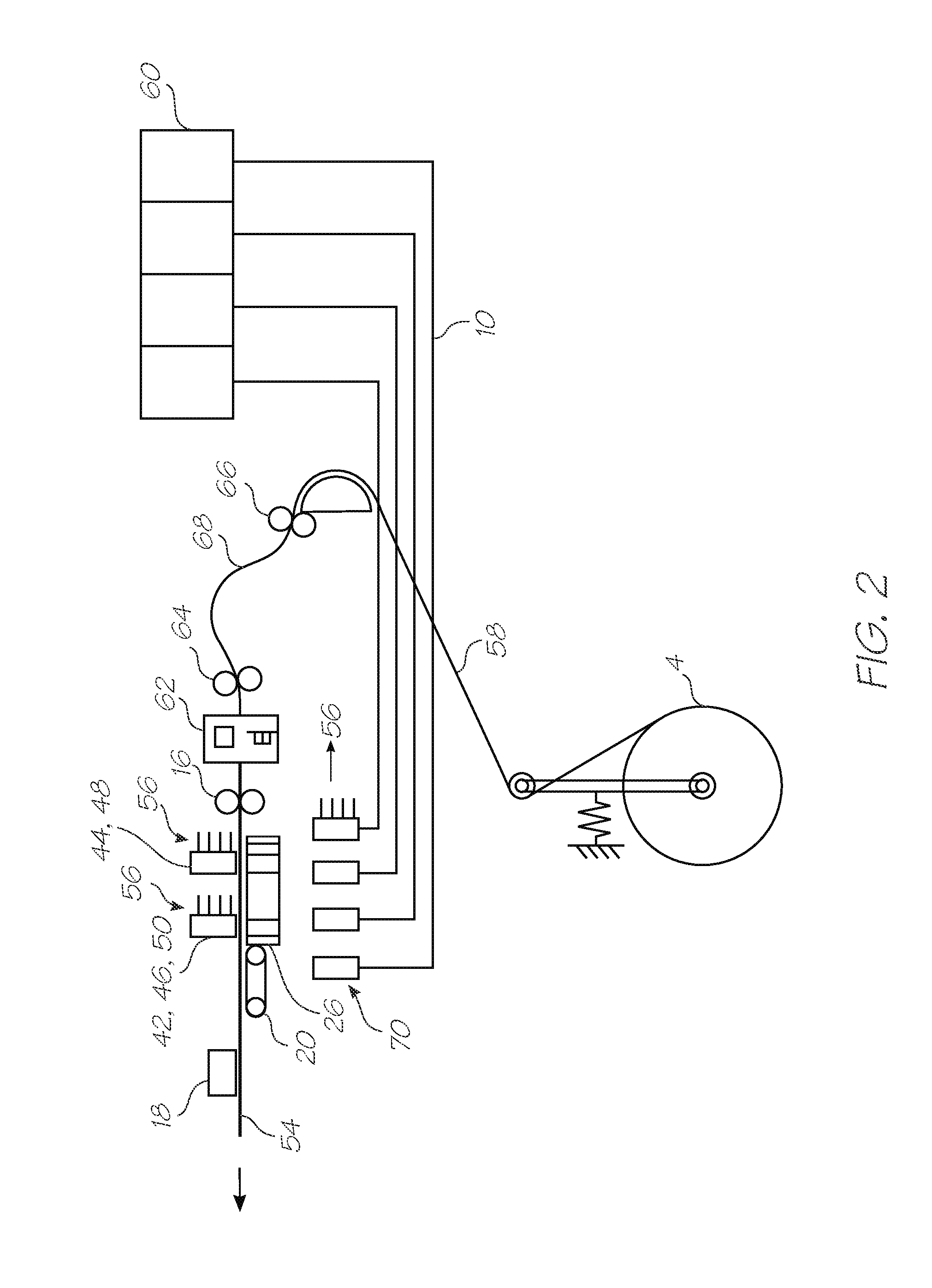

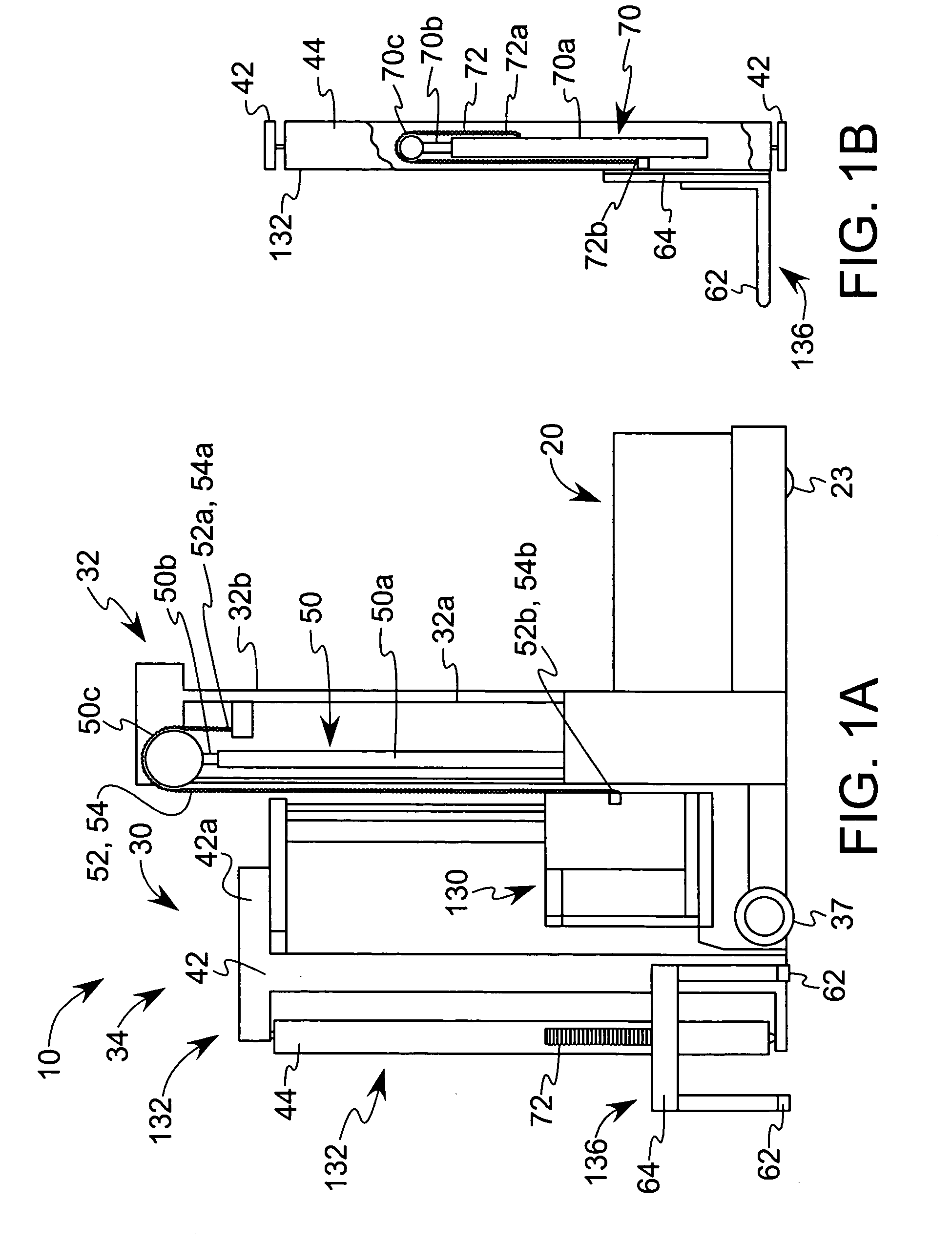

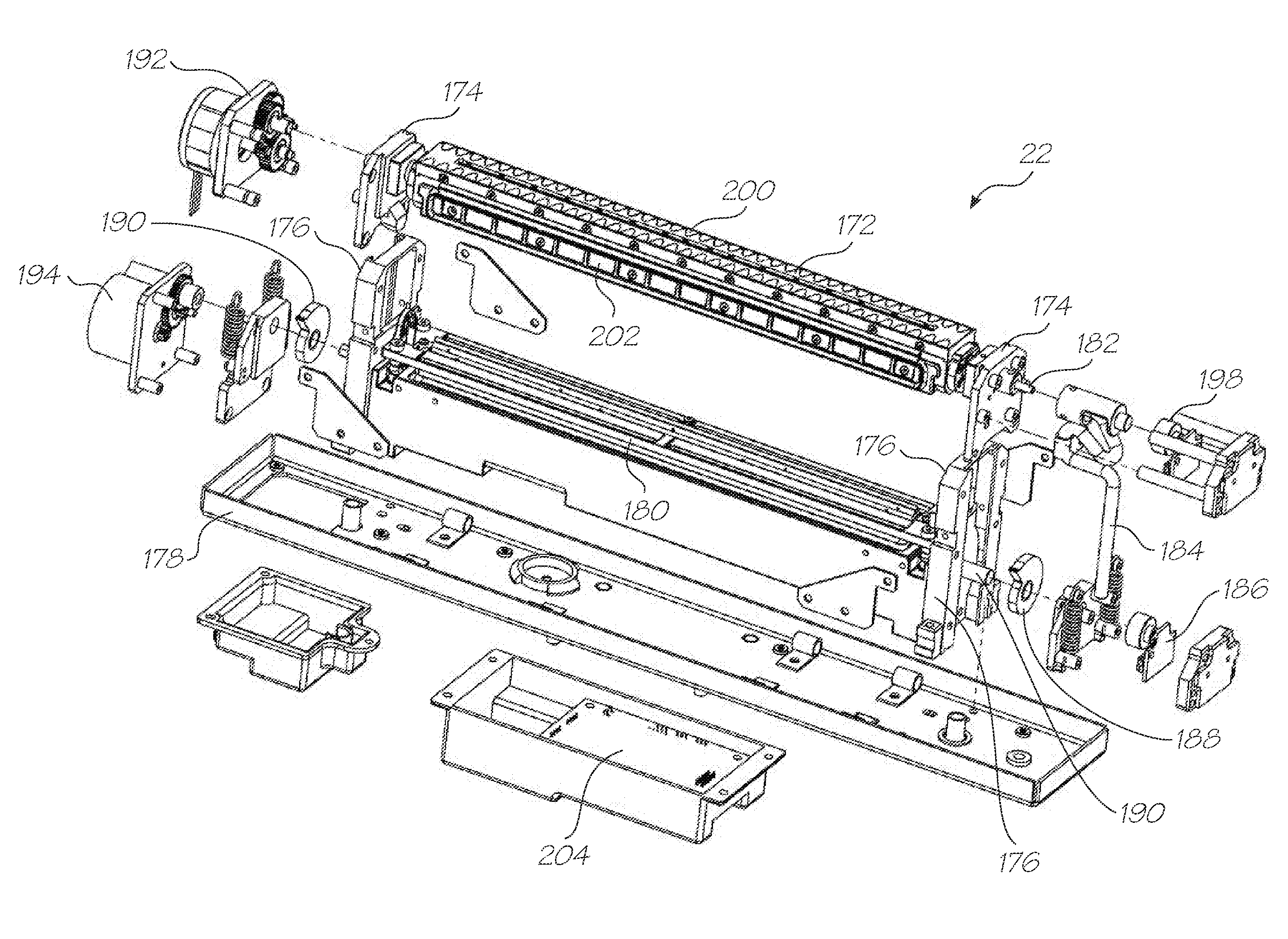

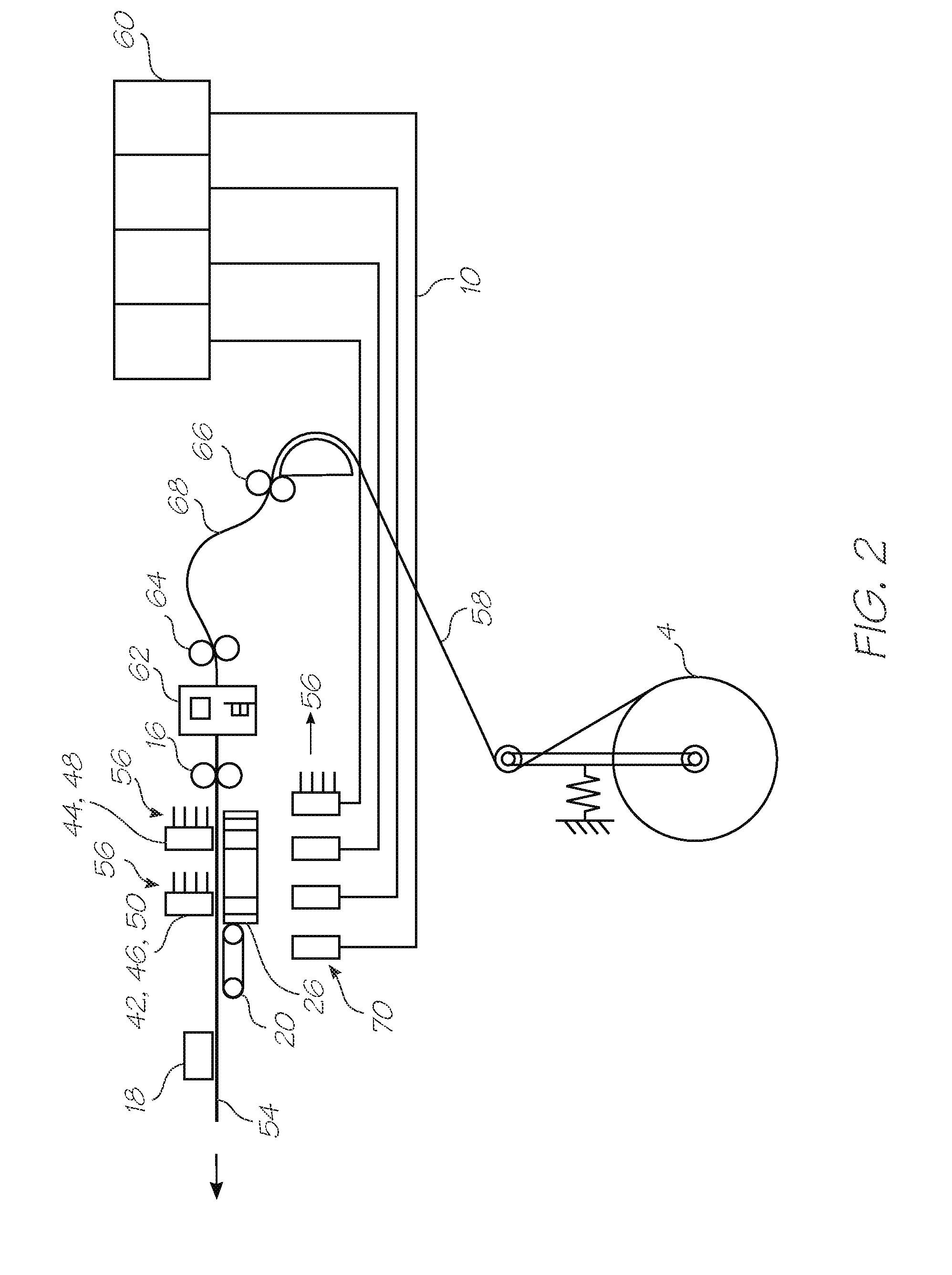

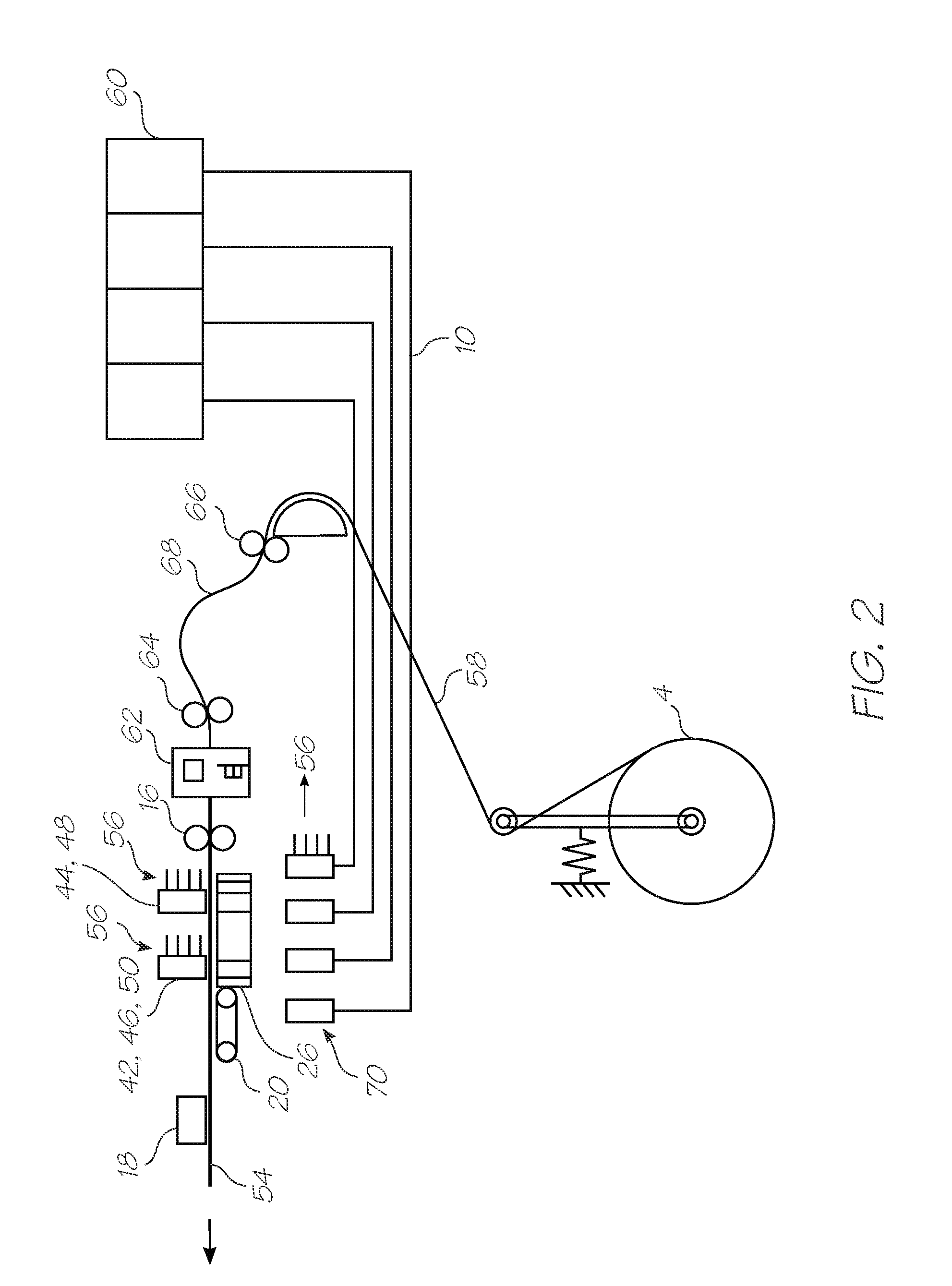

Wide format printer with adjustable aerosol collection

InactiveUS20110025766A1Practical and reliable hydrostatic pressure regulationControl range is also very narrowTypewritersOther printing apparatusCollection systemMechanical engineering

A wide format printer that has a drive roller for feeding different sizes of media along a media path at least 432 mm (17 inches) wide, an inkjet printhead assembly for printing the media and an ink aerosol collection system for removing ink aerosol from areas adjacent the media path. The ink aerosol collection system is configured to remove aerosol at a greater rate in response to an increase in the media size.

Owner:ZAMTEC

Method for producing phenol adsorbent resin

InactiveCN102229710ALarge particlesImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPhenol adsorptionGranularity

The invention provides a preparation method of phenol adsorbent resin. The preparation method comprises the following steps of: with small-granularity waste polymerization white spheres of macroporous ion exchange resin within the granularity range of 45-60 meshes adopted, extracting to obtain a porogenic agent, stoving, carrying out chloromethylation according to a macroporous anion resin standard process until chloride content is 15-25%, washing chloride spheres with water until no chloride ion exist after reaction is finished, stoving, then carrying out Friedel-Crafts reaction and then crosslinking, and then carrying out surface fluorination to generate the adsorbent resin with high specific surface area. The phenol adsorbent resin obtained by the preparation method provided by the invention has high adsorption capacity, the phenol adsorption capacity is more than 100mg per ml of the resin, and the phenol adsorbent resin has high strength, is difficult to break and has short regeneration time.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

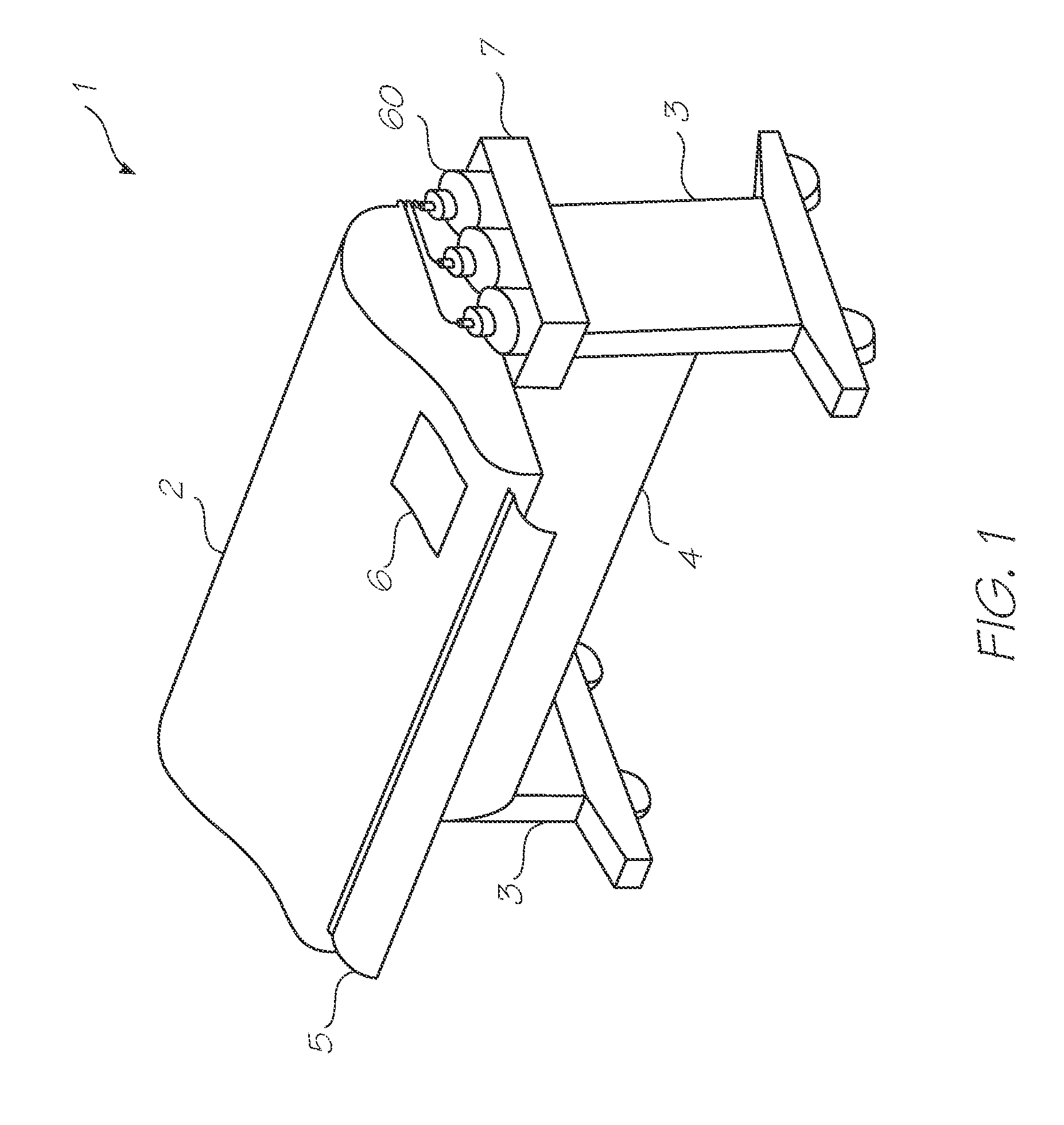

Wide format printer with printhead carriage connected to ink supply from a single side

ActiveUS20110025739A1Practical and reliable hydrostatic pressure regulationControl range is also very narrowTypewritersOther printing apparatusEngineeringMechanical engineering

A wide format printer that has a print zone, a media path more than 432 mm (17 inches) wide and extending through the print zone along a paper axis, a printhead carriage with a plurality of printhead mounting sites for mounting a plurality of printhead modules adjacent the print zone such that the printhead modules collectively span the media path, the printhead carriage having a long side extending transverse to the paper axis, the long side having access formations for ink conduits and a plurality of interfaces for connection to the ink conduits to supply ink to each of the printhead modules respectively. All ink for the plurality of printhead modules is supplied by ink conduits extending through the access formations on the long side of the printhead carriage.

Owner:MEMJET TECH LTD

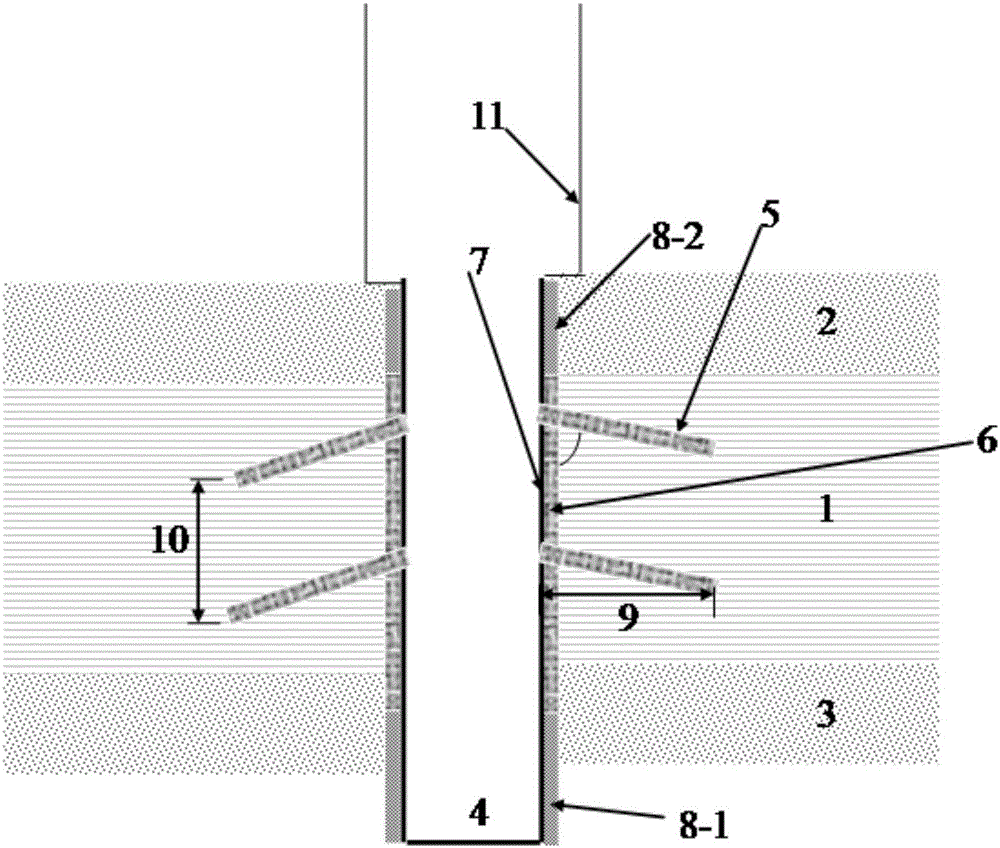

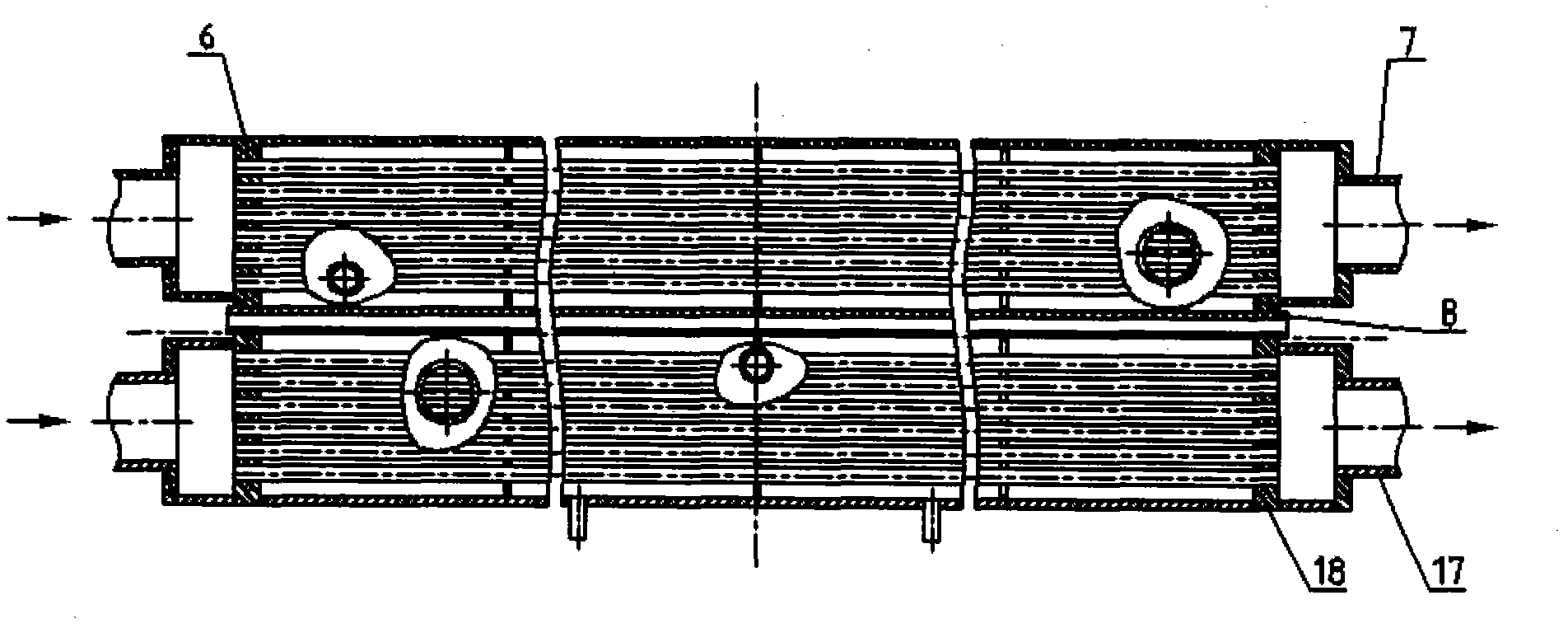

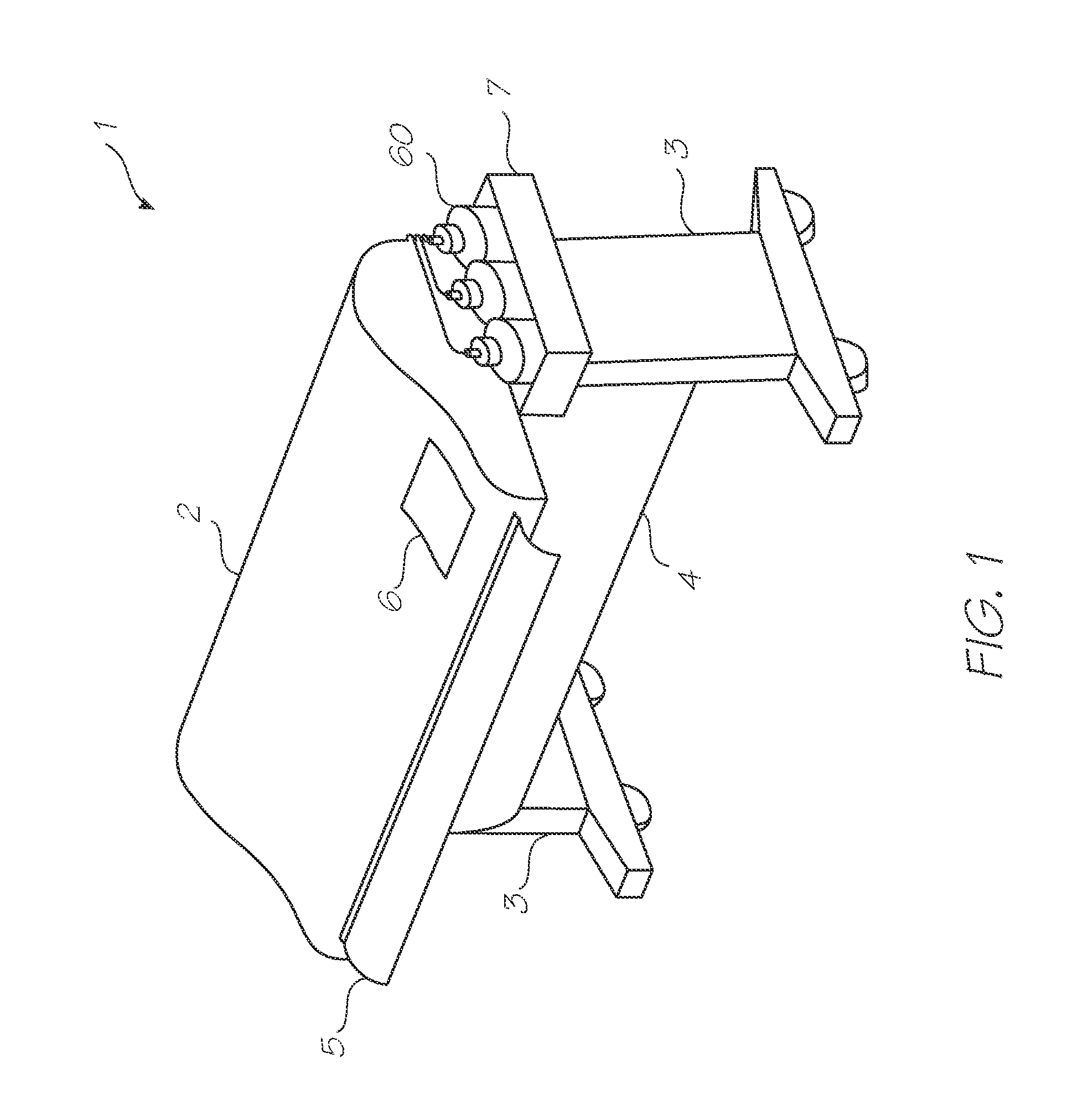

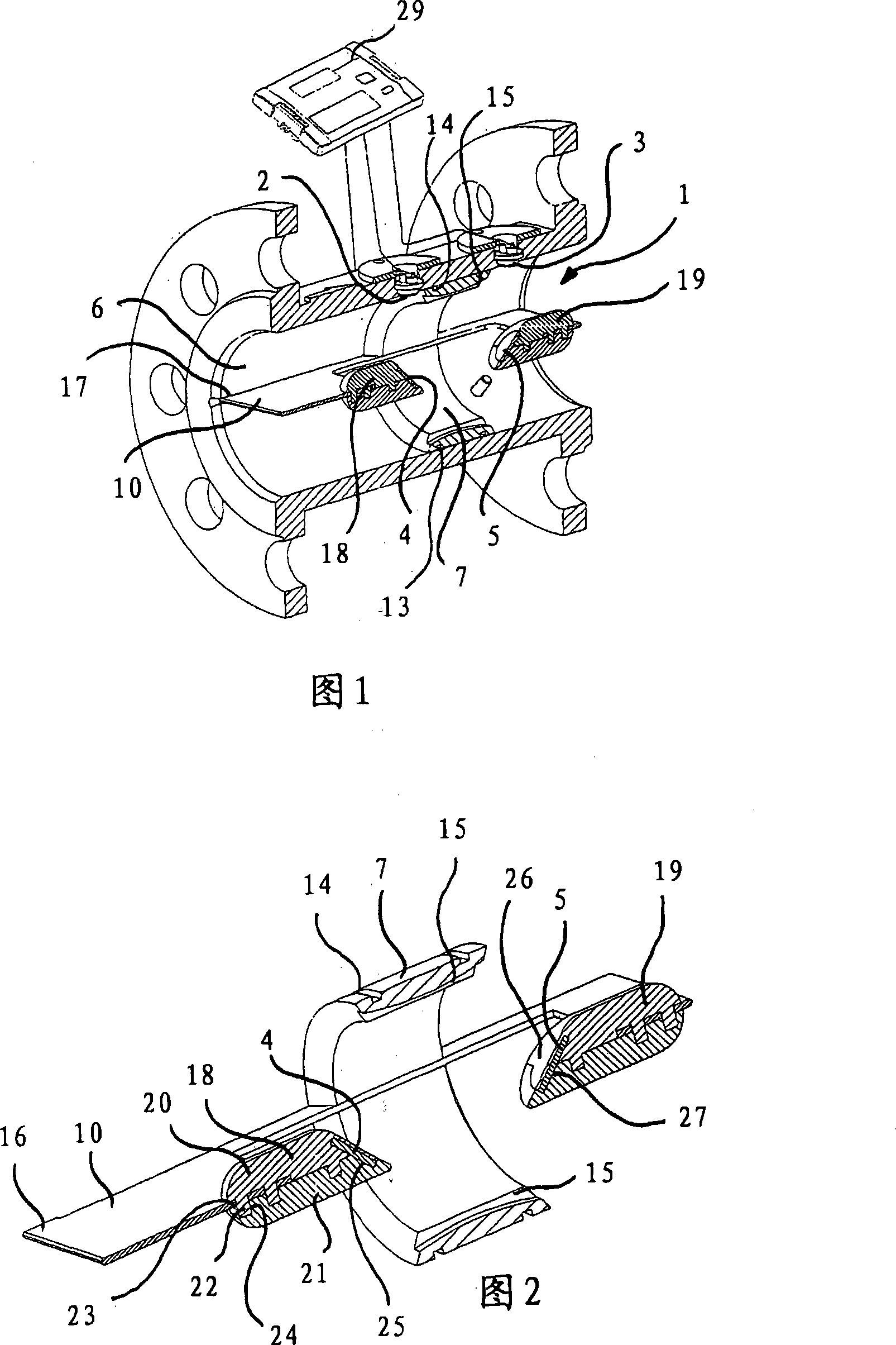

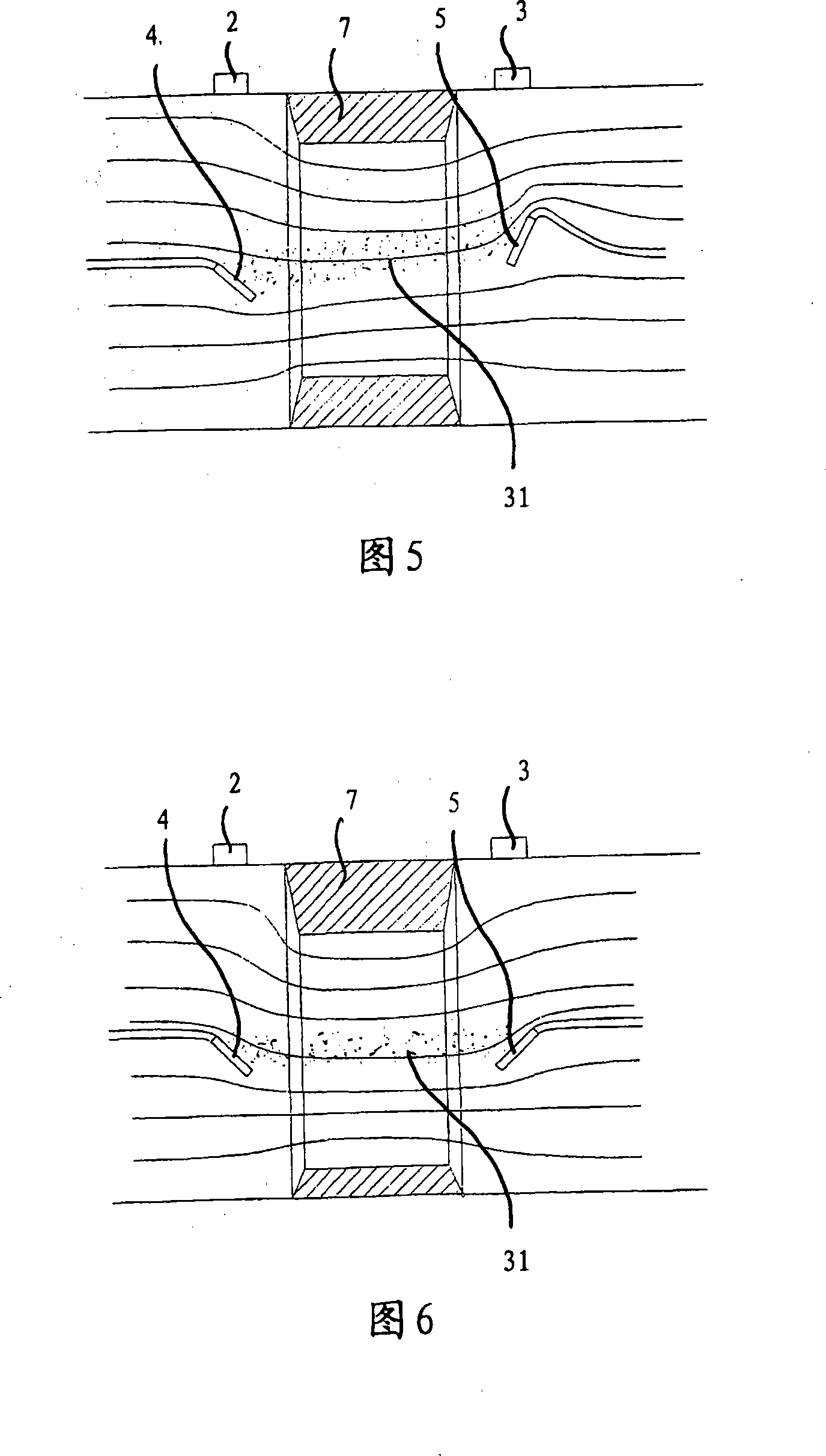

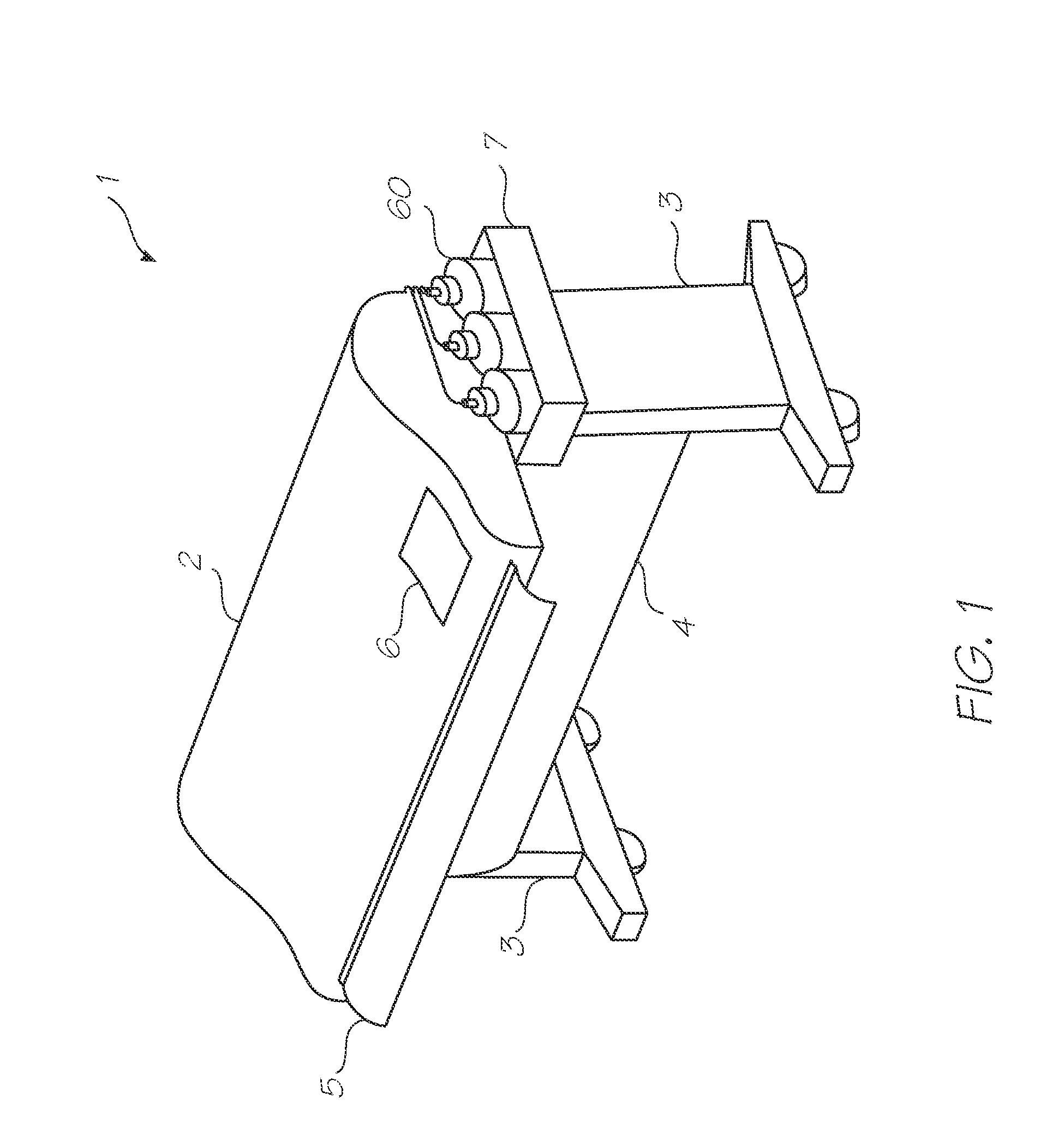

Ultrasound flow meter

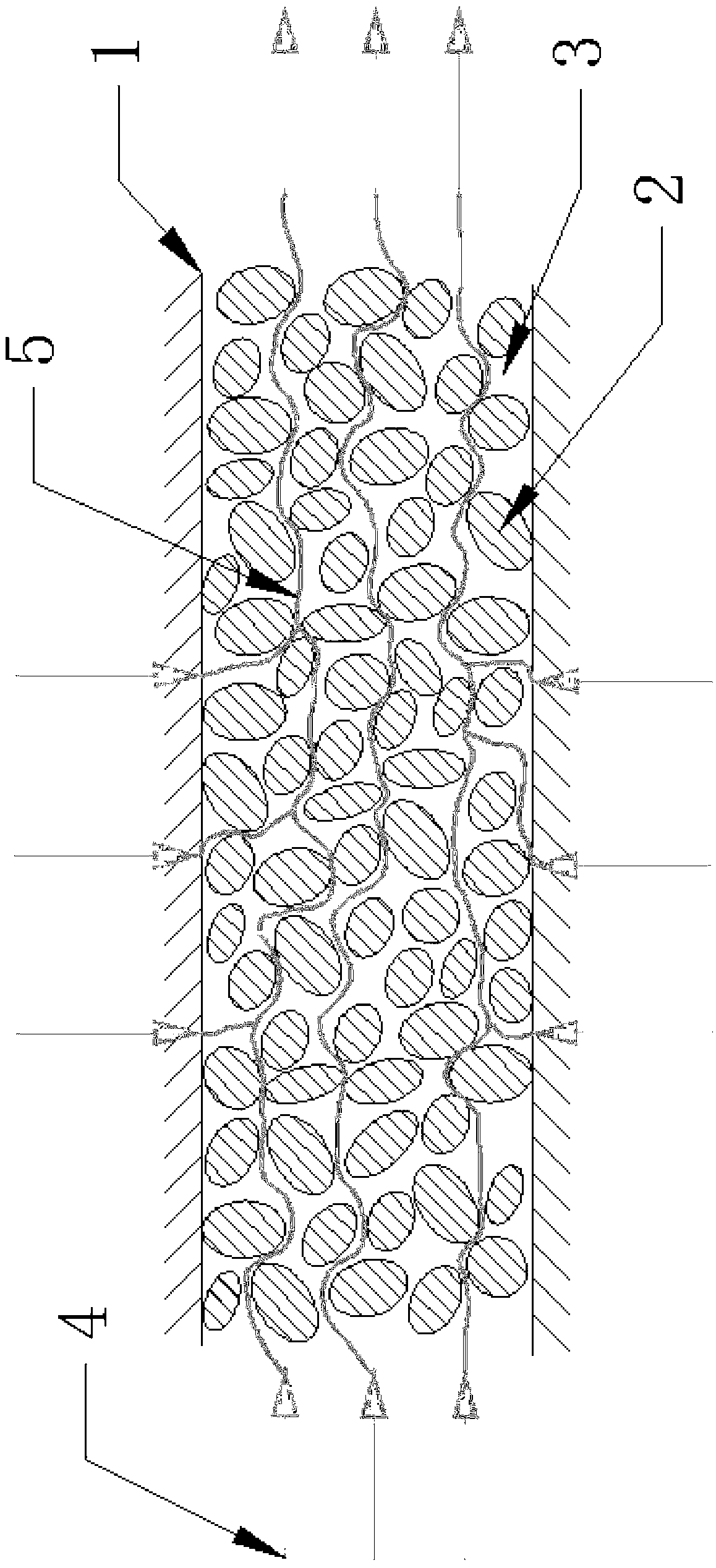

InactiveCN101149280AHigh measurement accuracyReduce asymmetric flow sectionVolume/mass flow measurementFluid speed measurementTransducerEngineering

The invention relates to a flow meter used in liquid or gas medium, which includes one measuring channel (1) flowed through medium, at least one inlet passage, at least one exit passage and at least one ultrasonic wave transducer couple pairs (2, 3), wherein, at least one reflector couple pairs (4, 5) is disposed in the measuring channel (1) for transporting one ultrasonic wave signal from one ultrasonic wave transducer (2 or 3) to another ultrasonic wave transducer (2 or 3). The diameter of the measuring channel (1) is decreased partly by one reduction part (7) to guide through flow, wherein, the reduction part (7) is comprised of insert of measuring channel disposed or combined on the inner wall (6) of the measuring channel, meanwhile the reduction part is keeper or stationary object for using in other functional parts. Furthermore, the invention also relates to a flow meter, wherein, one flow guide plate as fixed plate of reflector couple pairs extends upwards on the measuring channel. In another implementing case, at least two measuring sections are disposed, which includes at least one reflector couple pairs and one ultrasonic wave transducer couple pairs respectively.

Owner:HYDROMETER GMBH

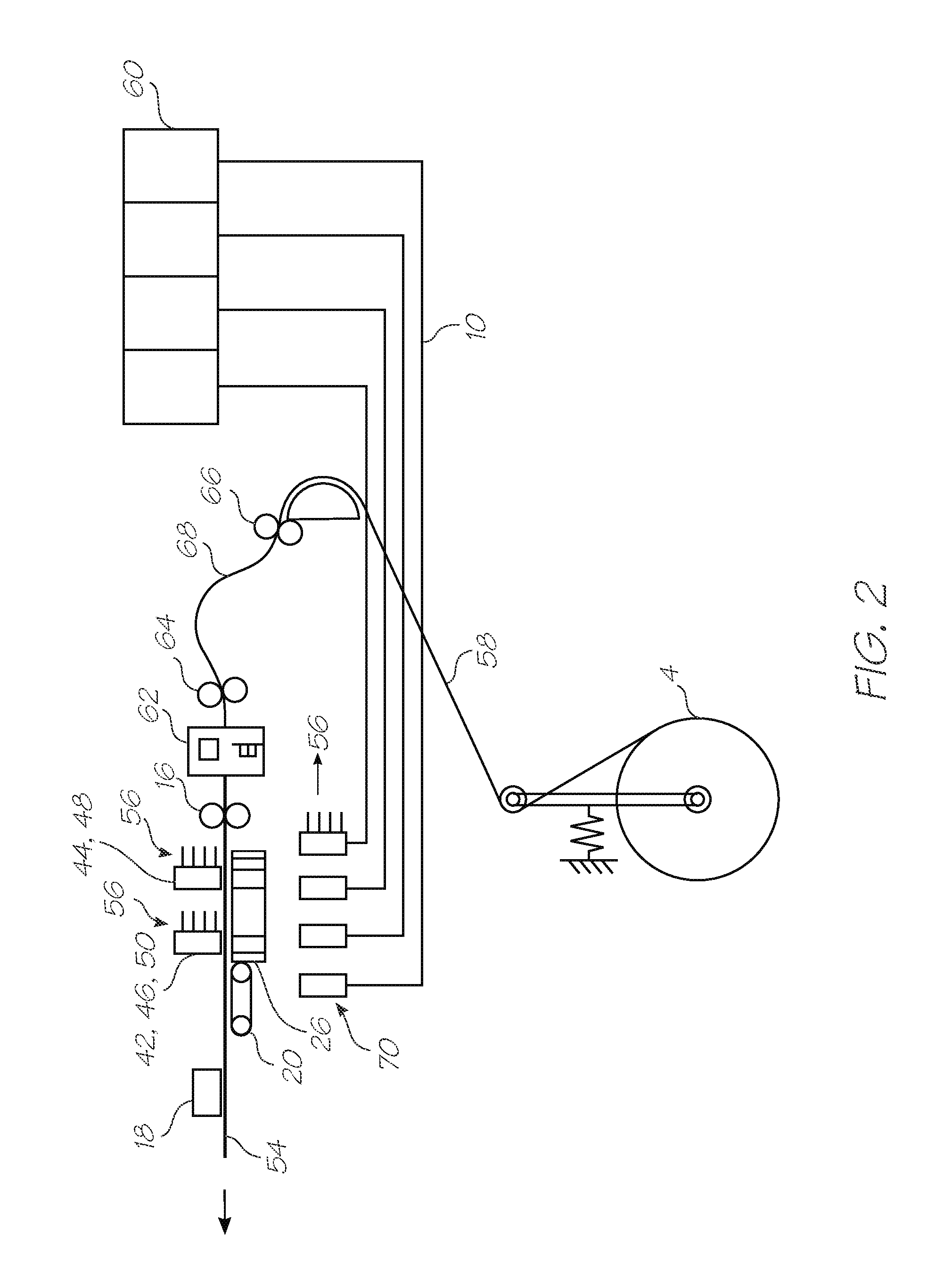

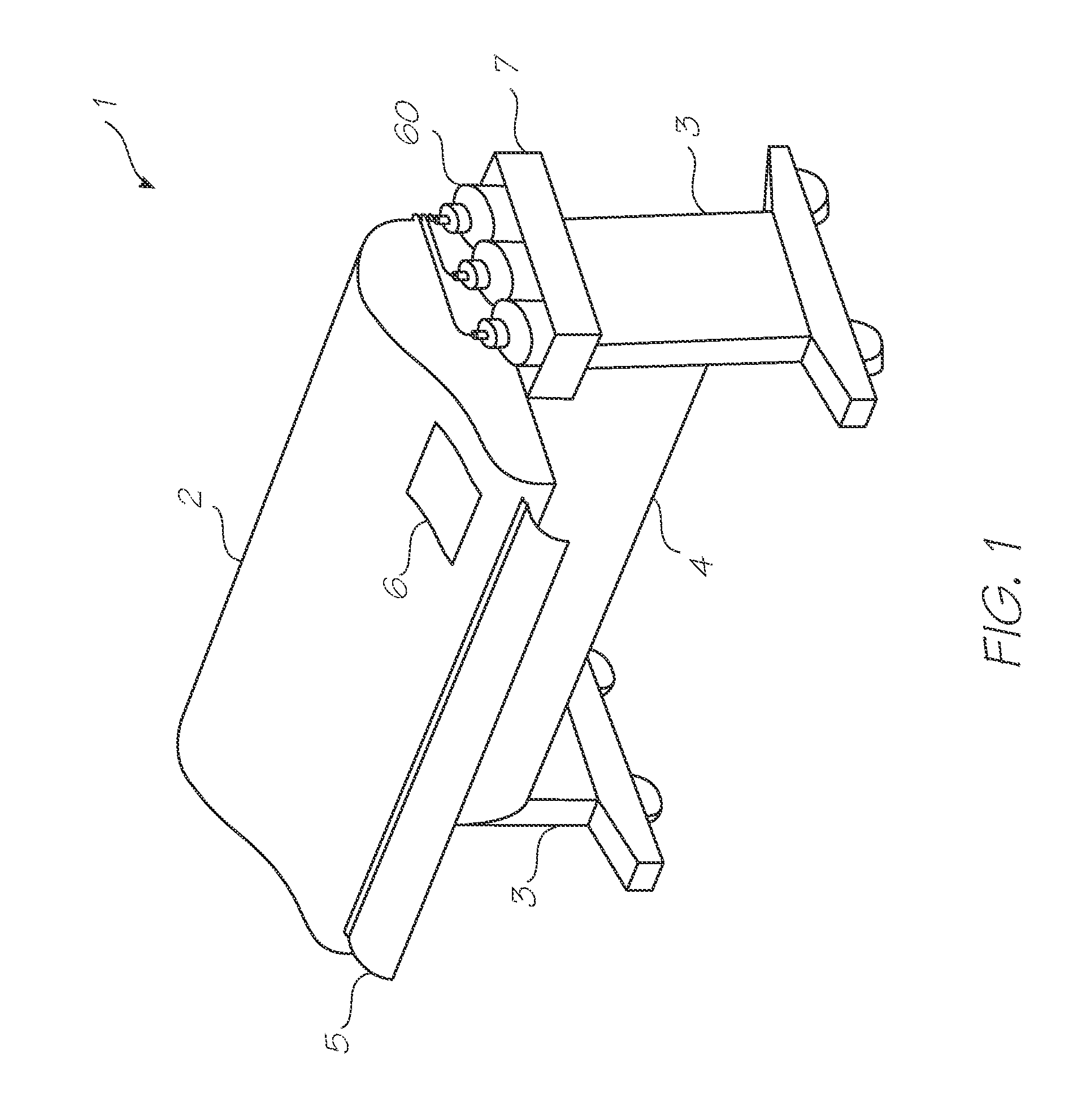

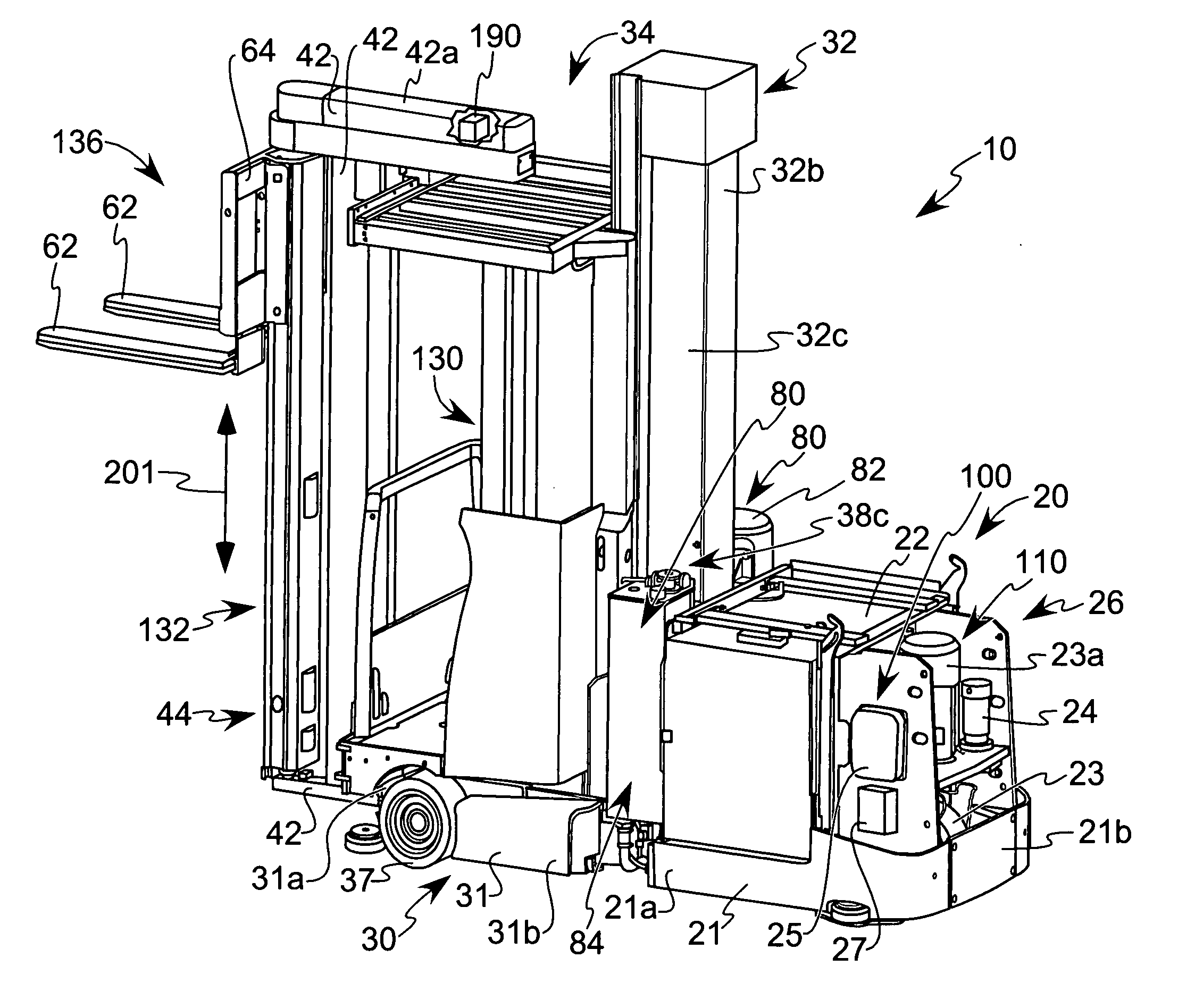

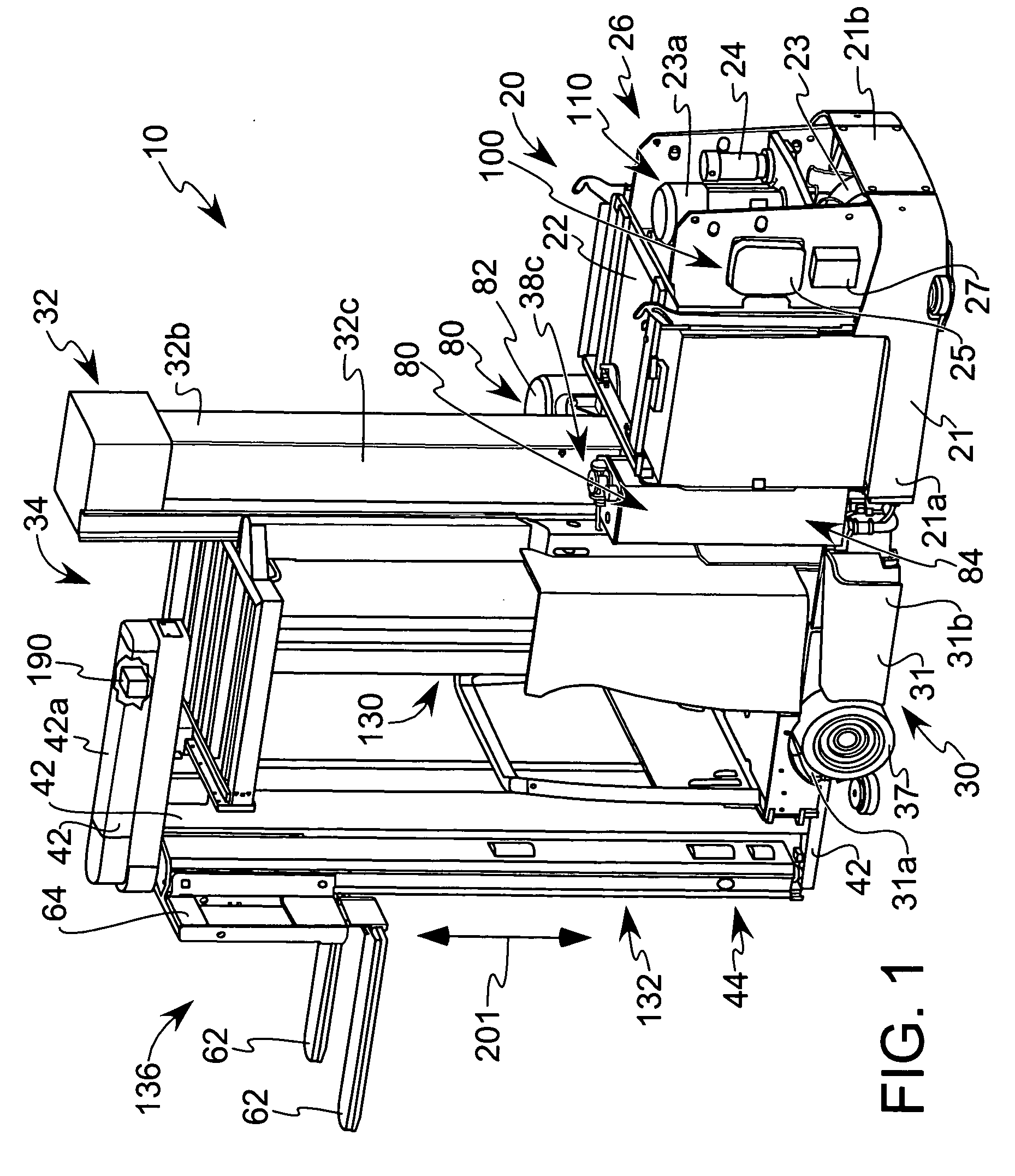

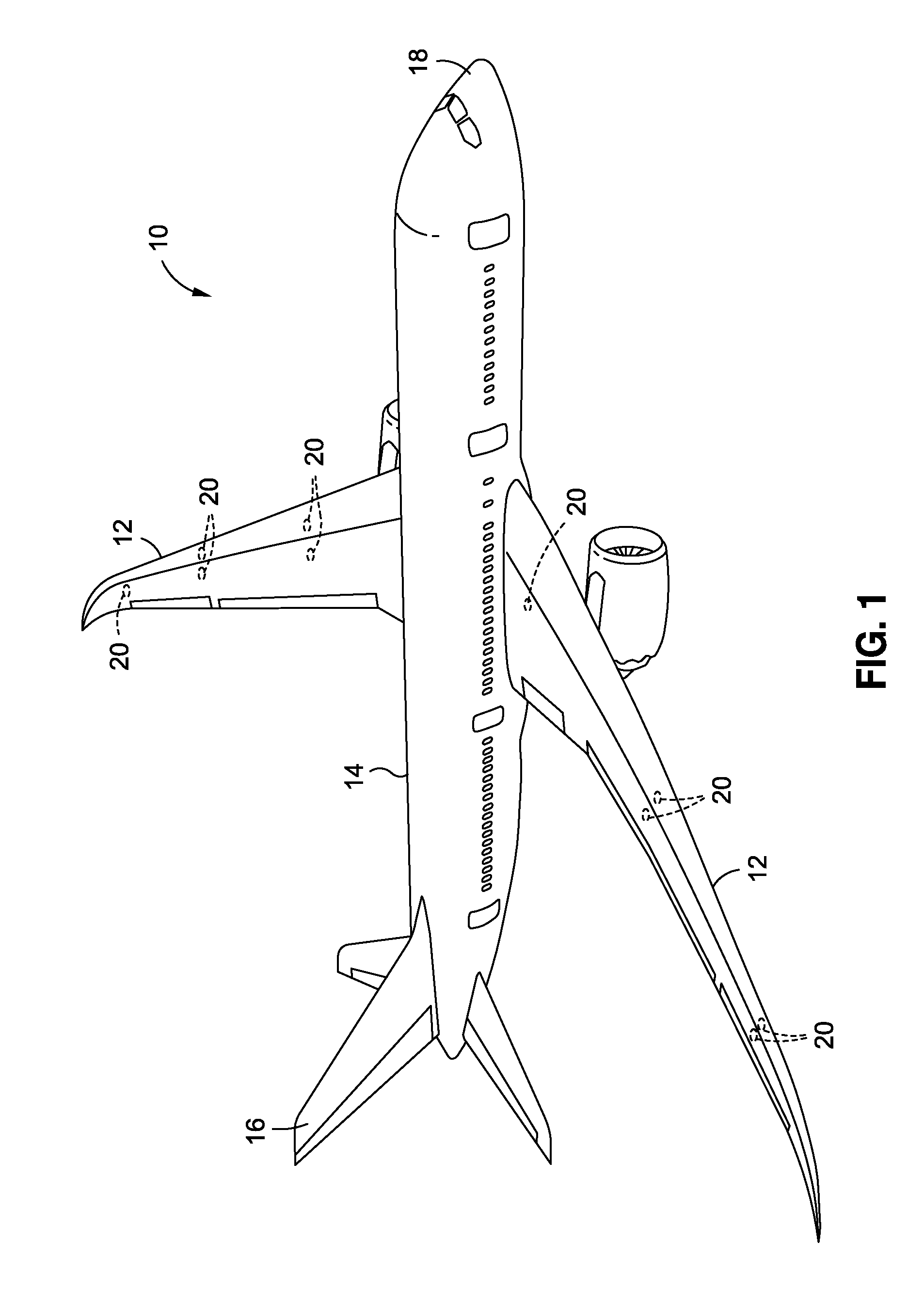

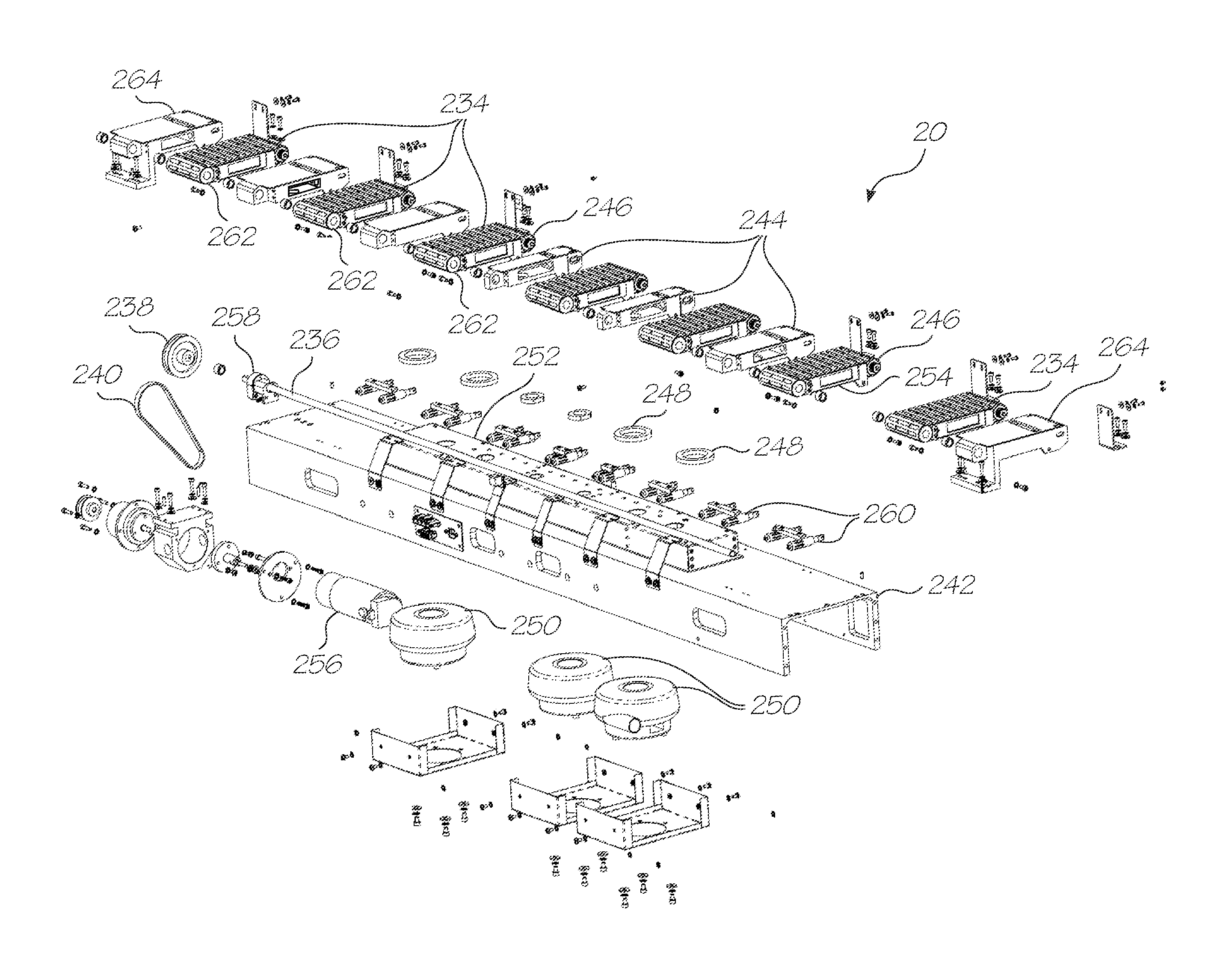

Materials handling vehicle having substantially all hydraulic components mounted on a main frame assembly

ActiveUS20060151249A1Low costReduce pressure dropElectric propulsion mountingLifting devicesEngineeringTruck

A lift truck is provided comprising: a power unit assembly comprising a power unit base, a wheel coupled to the base, and a system for driving the wheel; and a main frame assembly detachably connected to the power unit assembly. The main frame assembly comprises a main frame base, a mast assembly coupled to the main frame base, a carriage assembly coupled to the mast assembly, and hydraulic drive apparatus coupled to the mast assembly. Preferably, substantially the entirety of the hydraulic drive apparatus is provided on the main frame assembly such that the main frame assembly is detachable from the power unit assembly without requiring disconnecting hydraulic connections to the power unit assembly.

Owner:CROWN EQUIP CORP

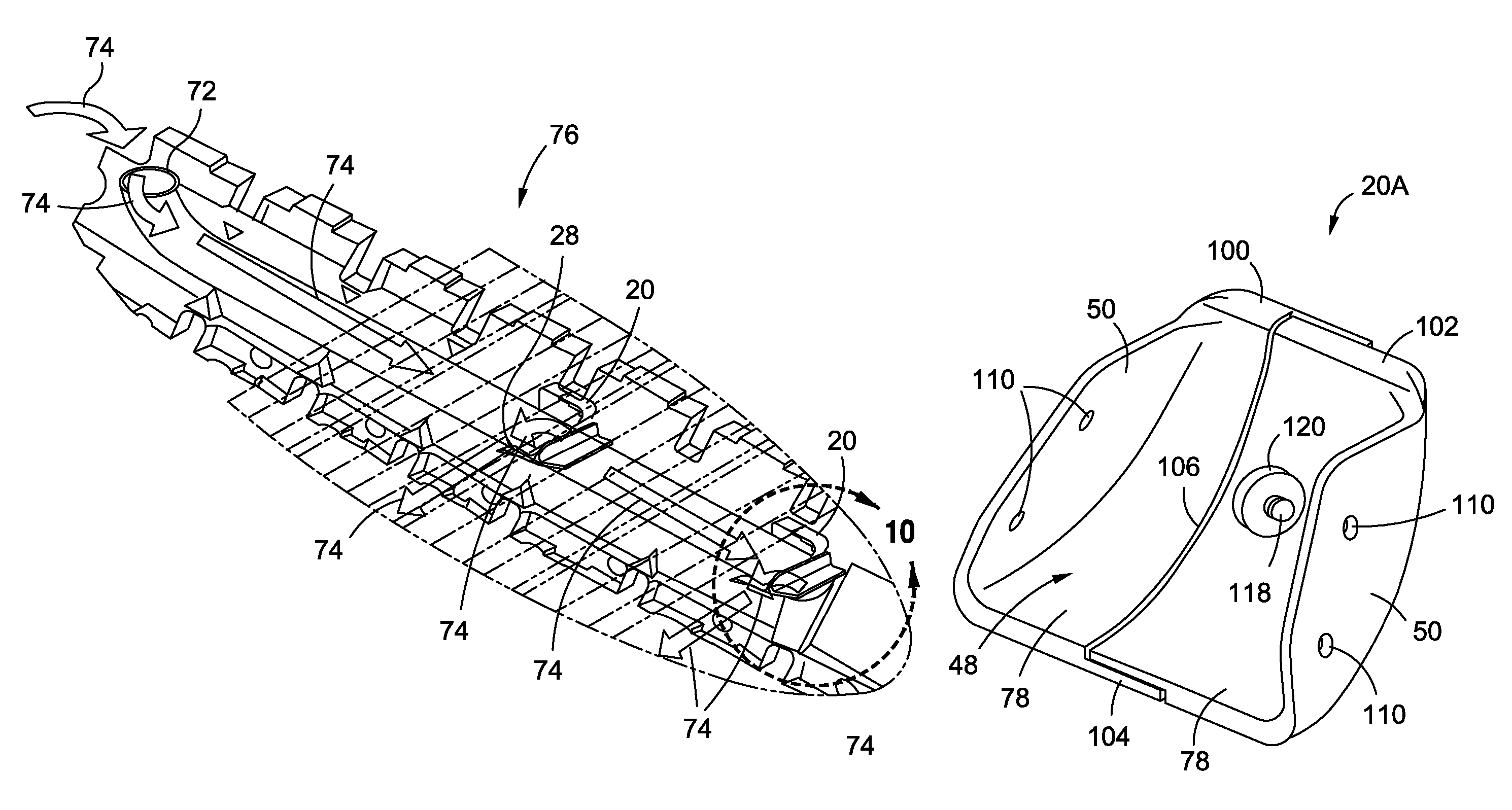

Fluid dynamic vent dam

ActiveUS9010689B1Efficiently and smoothly directingImprove fluid flowPower plant fuel tanksFuel tank safety measuresEngineeringFlange

The disclosure provides in one embodiment for a vent dam for use in a vent stringer in a fuel vent system. The vent dam comprises a contoured guiding surface for guiding fluid flow in a vent stringer. The vent dam further comprises one or more side flanges extending from the contoured guiding surface for providing attachment of the vent dam within the vent stringer.

Owner:THE BOEING CO

Blast-furnace coal powder injection method and system thereof

The invention discloses a blast-furnace coal powder injection method and a system thereof. The method comprises the following steps: A, arranging coal powder stored in a coal powder bin in an injecting tank of an injecting tank group; B, pressurizing the injecting tank by using the high pressure gas obtained from a factory-supplied gas system, and injecting the coal powder into a blast furnace; and C, depressurizing the high pressure gas in the injecting tank, and then directly discharging into the coal powder bin, wherein a step C' needs to be done before the step C, and a step B' needs to be done before the step B. The step C' comprises the following steps: communicating the injecting tank with a gas container, and depressurizing the gas container by using the injecting tank. The step B' comprises the following steps: communicating the injecting tank with the gas container, and pressurizing the injecting tank by using the gas container. The invention can realize the effective recycle of the gas depressurized by the injecting tank, reduce the gas consumption of the powder making and injecting system, save the production cost, reduce the depressurized pressure difference of the depressurization system, decrease the maximum instant depressurized gas flow, reduce the impact on pipelines in the depressurization process, improve the operation stability of the system, and achieve high gas recovery rate.

Owner:CISDI ENG CO LTD

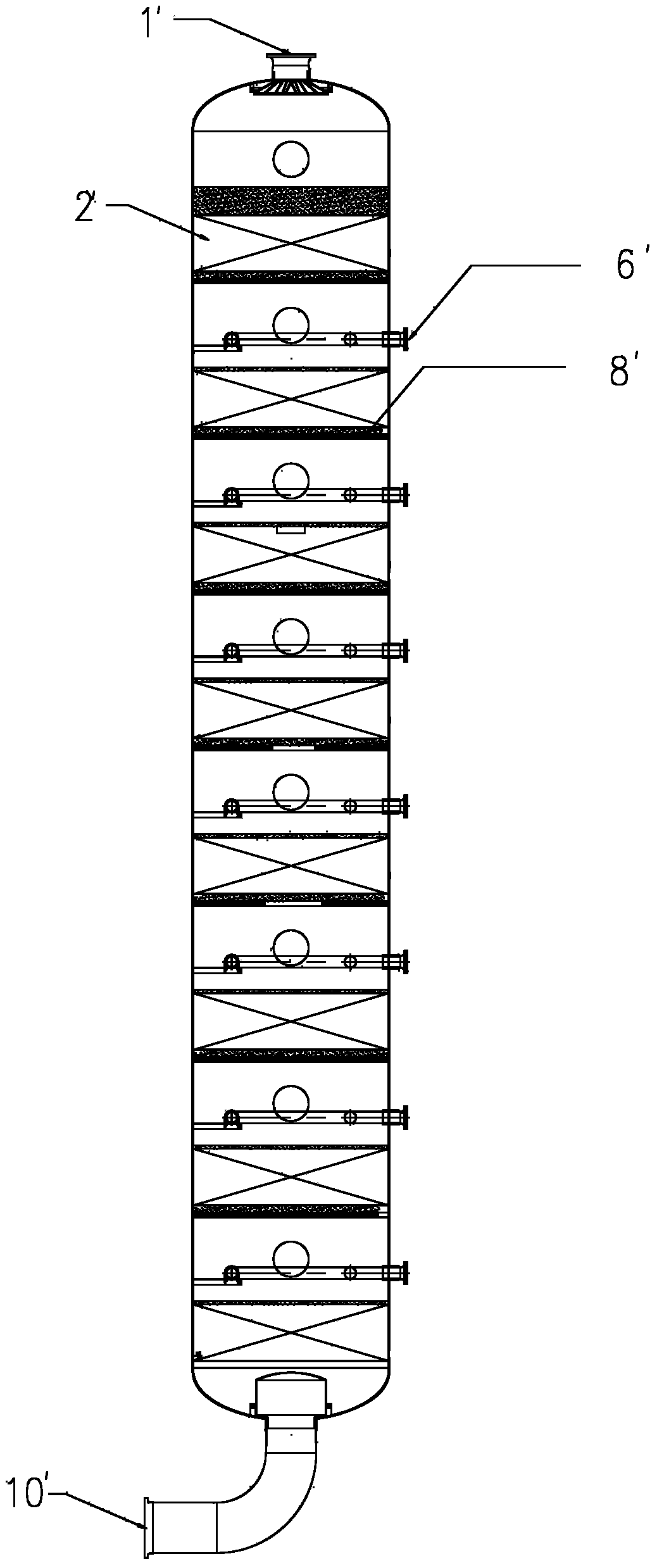

Fractionating tower for separating acrylic aldehyde from 3-hydroxypropionaldehyde solution

ActiveCN101033180AEasy to cleanSpeed up contactCarbonyl compound separation/purificationEngineeringTower

This invention provides a rectifying tower for separating and hydrate acrolein to prepare non-reacted acrolein in a 3-lactic aldehyde reacted product, the top of the tower applies a new vertical seeve plate and the lower part applies a parallel flow jet filling tower plate and the rectifying section applies structured packing, which can increase the separation ability of towers to reduce pressure drop of the tower and operation temperature, reduce aggregation trend and reduction and aggregation trend of 3-hydroxide propaldehyde so as to reduce the loss of acrolein in the top tower.

Owner:SHANGHAI HUAYI NEW MATERIAL

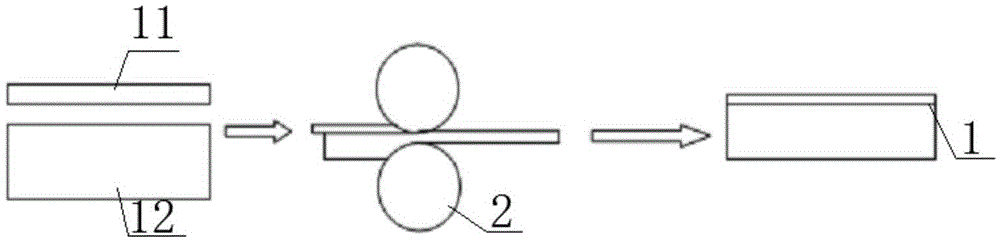

Aluminum steel compound board and compounding method thereof

The invention relates to an aluminum steel compound board. The aluminum steel compound board comprises a substrate steel plate and a composite aluminum alloy plate, wherein the compound board is formed by different temperature rolling and compounding to a steel plate heated to the temperature of 100 degrees and 120 degrees and a normal temperature aluminum alloy plate. The invention further relates to a compounding method of the aluminum steel compound board, and the compounding method comprises the following steps: preparing and compounding the required steel plate and the composite aluminum alloy plate; heating the steel plate to reach a temperature of 100 to 120 DEG C; stacking up the heated steel plate and the normal temperature aluminum alloy plate; and rolling and compounding the stacked up steel plate and the aluminum alloy plate. Due to the adoption of the technical scheme provided by the invention, the compound board is processed through a different temperature rolling and compounding method, the compounding and processing rolling reduction is reduced, requirements to rolling equipment are met, moreover, energy consumption is lowered, and the compounding and rolling cost is reduced.

Owner:YINBANG CLAD MATERIAL

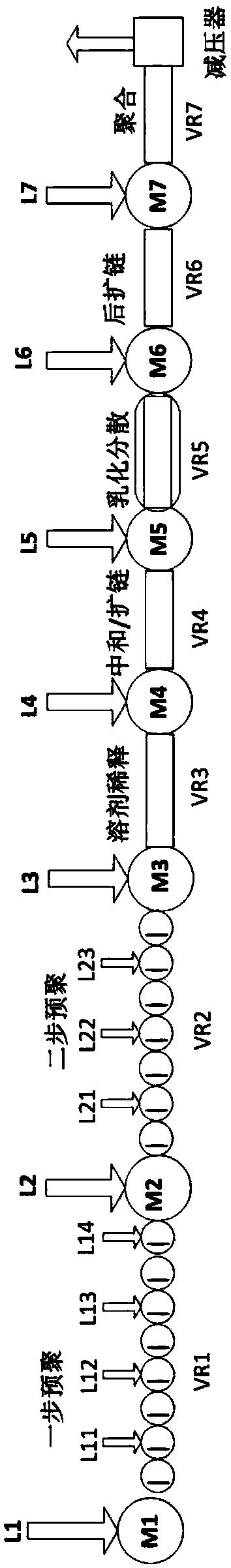

Continuous production system for preparing aqueous polyurethane dispersion, continuous production process of aqueous polyurethane dispersion and application of aqueous polyurethane dispersion

ActiveCN108097194AEfficient mixing abilityMultiple production typesFlow mixersRotary stirring mixersPolyurethane dispersionOligomer

The invention belongs to the technical field of continuous production of aqueous polyurethane dispersion and provides a continuous production system for preparing aqueous polyurethane dispersion, a continuous production process of the aqueous polyurethane dispersion and application of the aqueous polyurethane dispersion. The continuous production process comprises the following steps: (1) reactingpolyisocyanate with oligomer polyol in a first tubular reactor VR1 to obtain a prepolymer I, wherein the oligomer polyol is divided into four parts when the oligomer polyol is added into the VR1; (2)reacting the prepolymer I with a non-ionic hydrophilic compound in a second tubular reactor VR2 to obtain a prepolymer II, wherein the non-ionic hydrophilic compound is divided into three parts whenthe non-ionic hydrophilic compound is added into the VR2; (3) diluting the prepolymer II and a solvent in a VR3; (4) reacting the diluted prepolymer II with hydrophilic chain extending agent and smallmolecule diamine in a VR4; and (5) emulsifying and dispersing in a VR5. The process is capable of achieving rapid, efficient and continuous production of the aqueous polyurethane dispersion.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Printing system with pump to prime printheads

InactiveUS20110025762A1Practical and reliable hydrostatic pressure regulationControl range is also very narrowTypewritersOther printing apparatusIndustrial engineeringEngineering

A printing system that has an ink supply, a feed line coupled to the ink supply, a return line coupled to the ink supply, a plurality of printheads each coupled to the feed line and the return line and a pumping system configured to generate fluid flow from the feed line to the return line via the printheads to prime the printheads.

Owner:ZAMTEC

Combined mining method with decompression and heating in multi-branched horizontal wells for marine hydrate

ActiveCN109763794BEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingMining engineeringHorizontal wells

Owner:QINGDAO INST OF MARINE GEOLOGY

Wide format printer with media encoder in the platen

ActiveUS20110025804A1Practical and reliable hydrostatic pressure regulationControl range is also very narrowTypewritersOther printing apparatusPulp and paper industryEncoder

A wide format printer that has a vacuum platen assembly, a printhead assembly spaced from the vacuum platen assembly, a media path extending between the vacuum platen assembly and the printhead assembly and a media encoder embedded within the vacuum platen assembly wherein, the media path is greater than 432 mm (17 inches) wide.

Owner:MEMJET TECH LTD

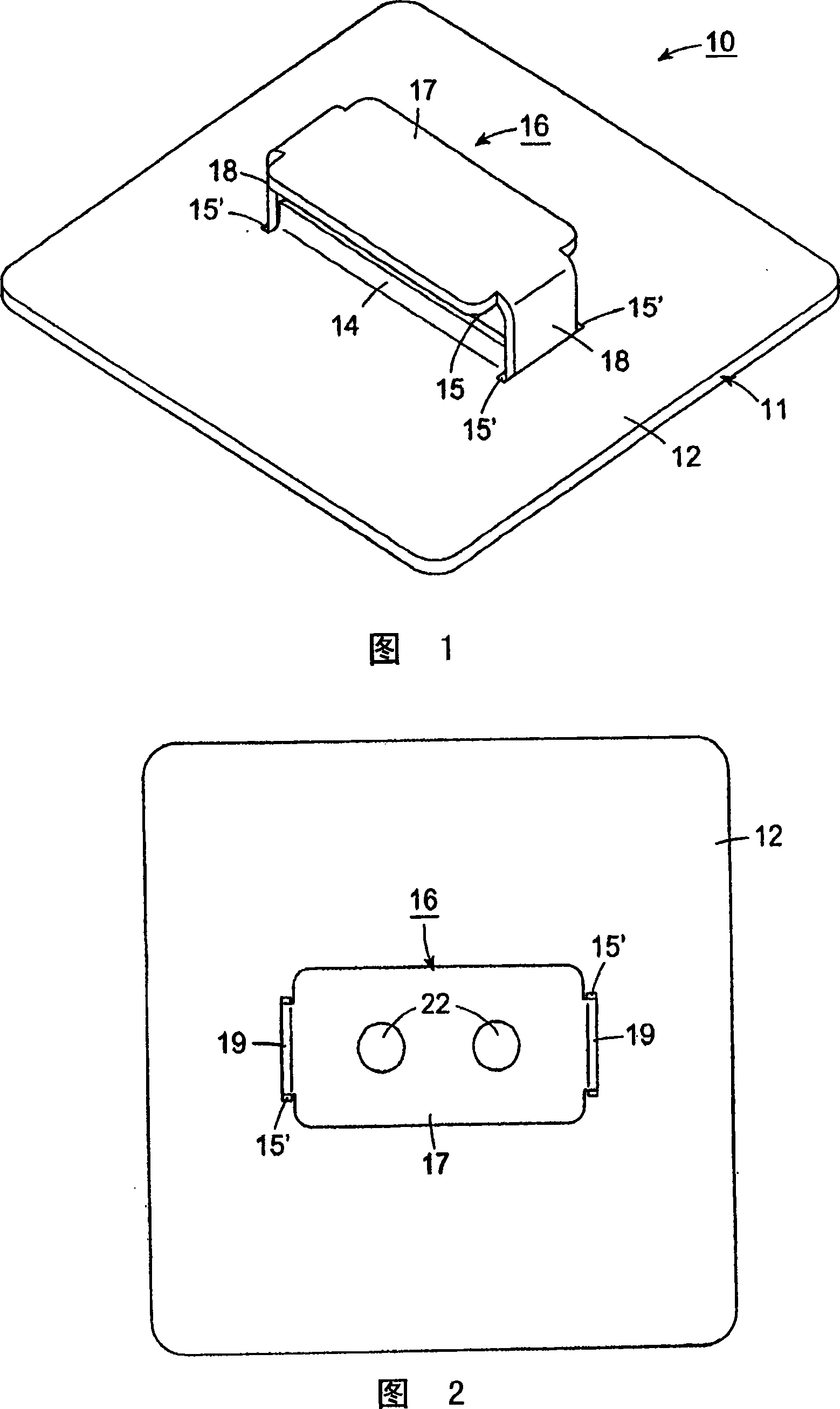

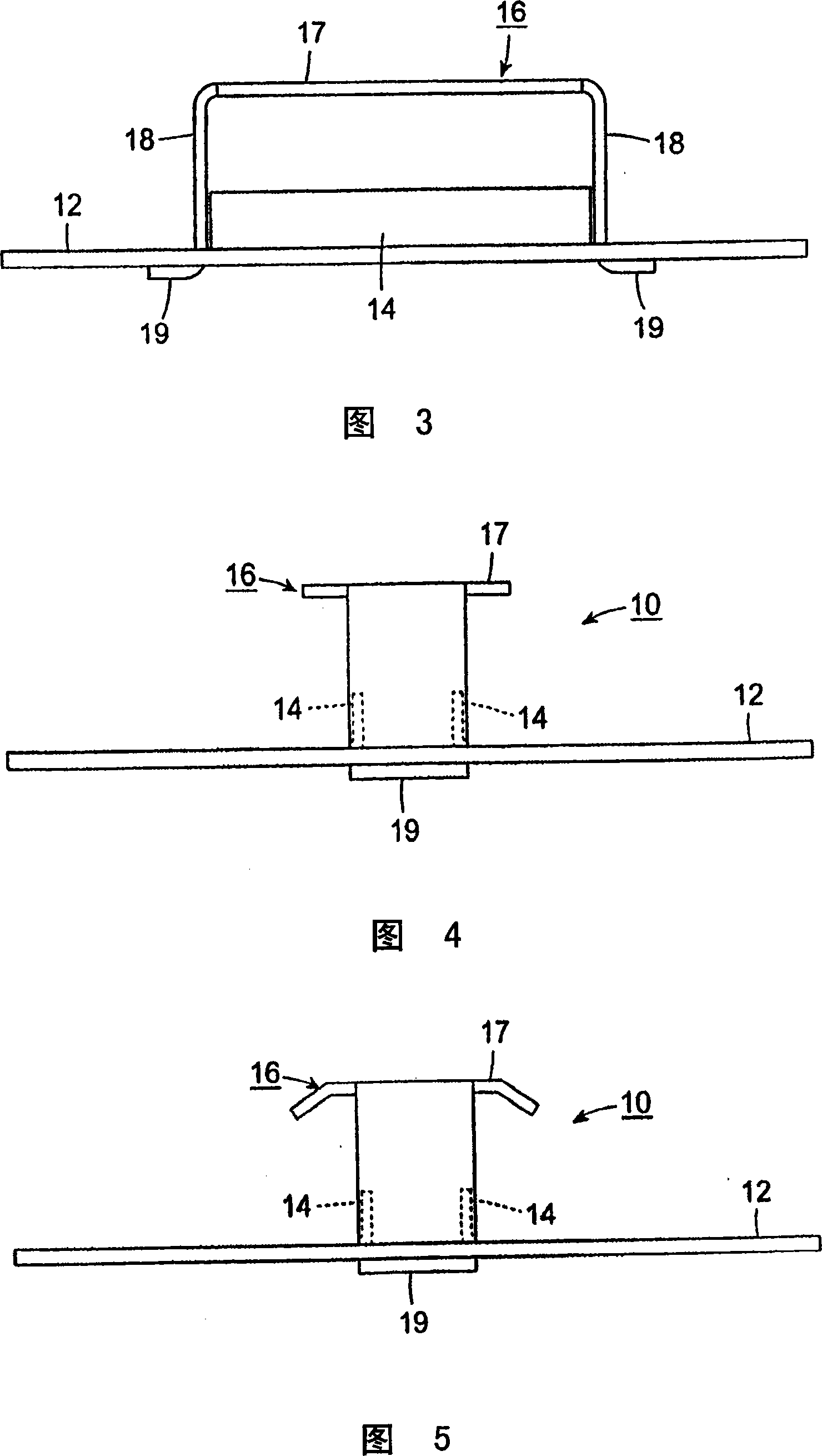

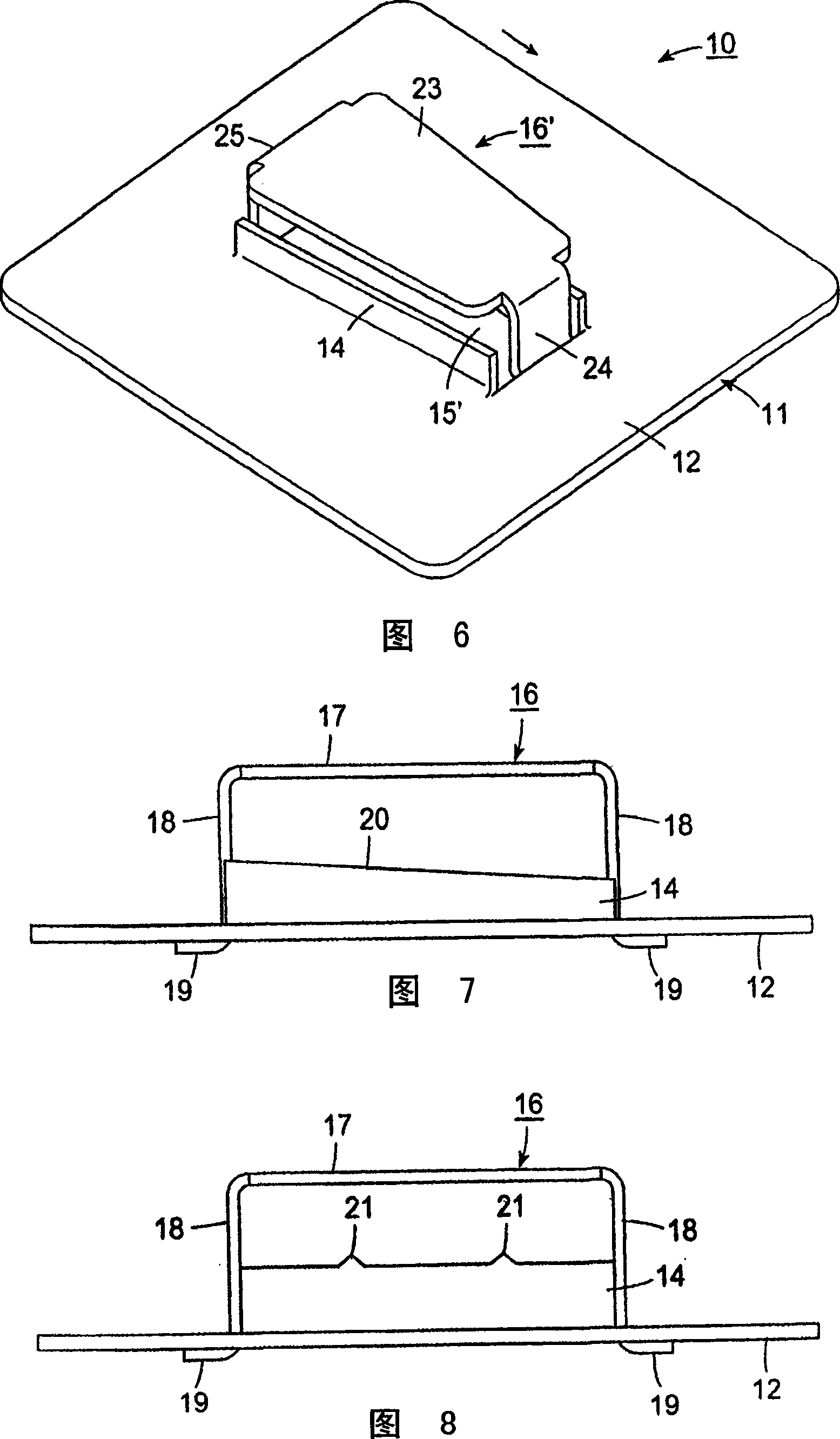

Valve for a contact tray

InactiveCN101138685AReduce loadIncrease capacityDistillation separationEngineeringMechanical engineering

The valve for a contract tray employs an aperture in a deck that is of rectangular or trapezoidal shape with upstanding walls at the sides of the aperture. The valve body is disposed in the aperture with a cover above the aperture and legs that extend downwardly to interfit with at least the upstream end of the walls to block the liquid flow. The valve body may be fixed or movable. In the movableembodiment, the valve body is seated on the walls about the aperture to close the aperture. The ascending vapor lifts the valve to allow bubbling of the vapor in the liquid on the deck.

Owner:SULZER CHEMTECH AG

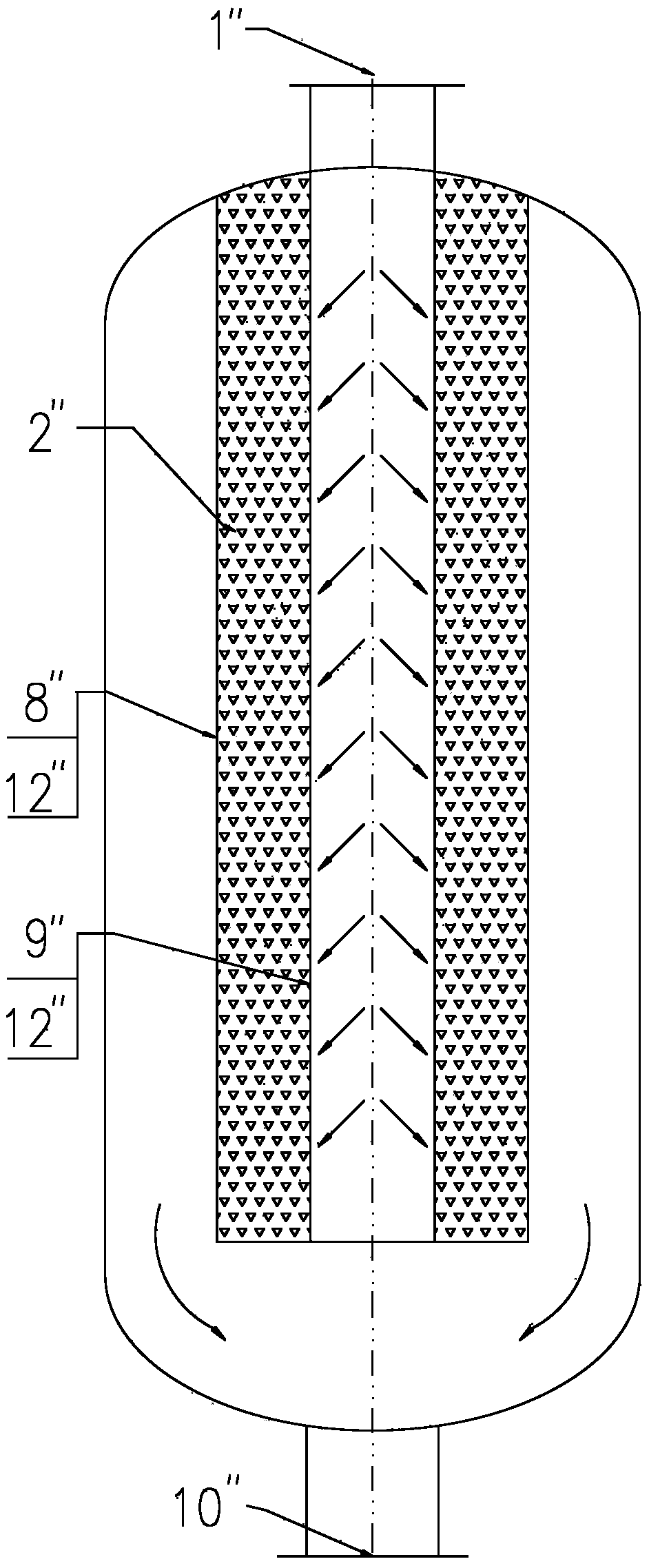

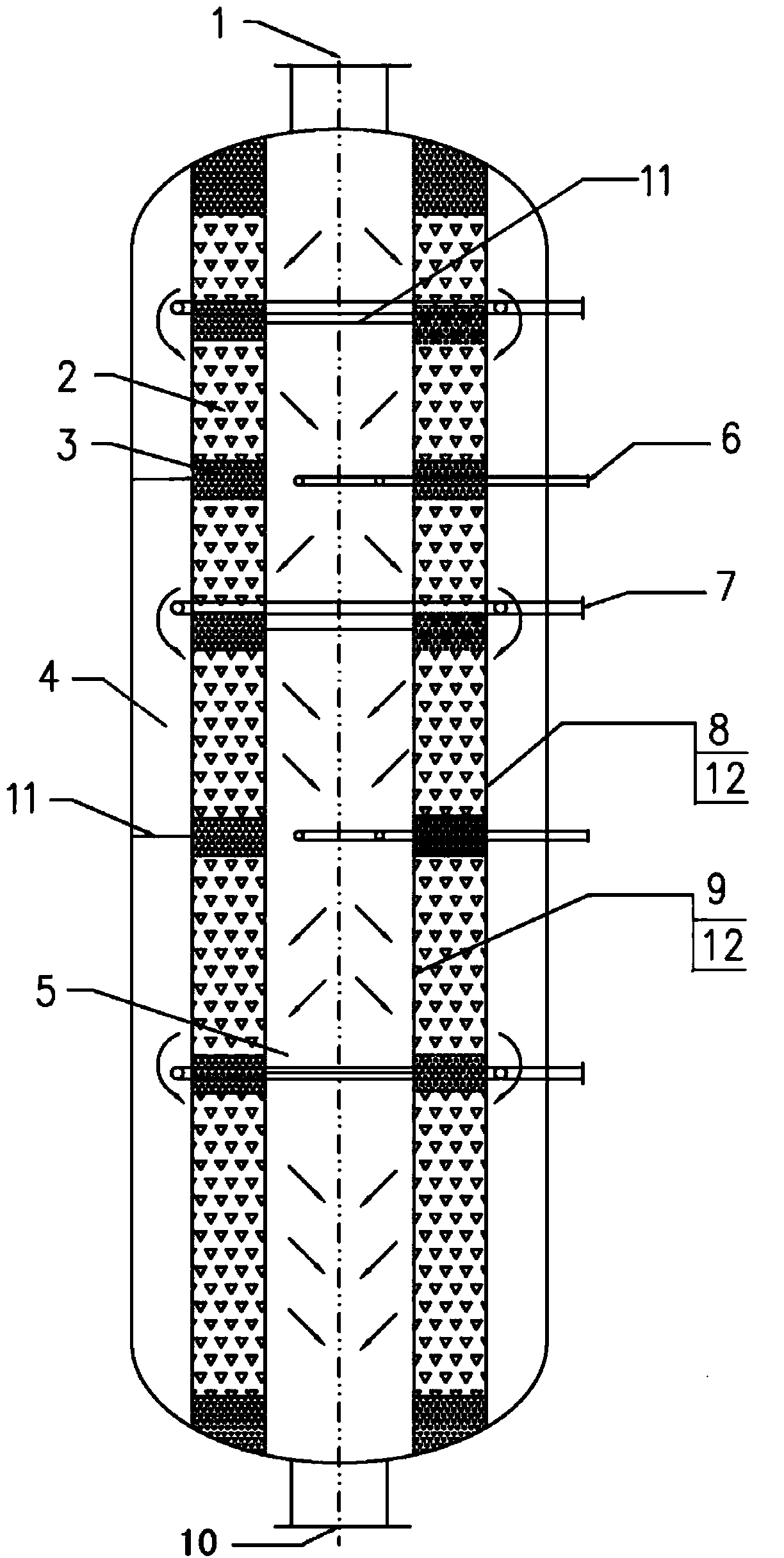

Novel multi-bed radial fixed bed reactor

InactiveCN103846061ASmall pressure dropRealize segmented feedingChemical/physical processesHigh densityFixed bed

The invention relates to a novel multi-bed radial fixed bed reactor which is distributed in a barrel shape. The novel multi-bed radial fixed bed reactor comprises a raw material inlet, catalyst beds, high-density porcelain balls, a ring-shaped channel, a center channel, a center channel distributor, a ring-shaped channel distributor, outer side grids, inner side grids, a reactant outlet and baffles, wherein the raw material inlet is formed in the top of the reactor, and the reactant outlet is formed in the bottom end of the reactor; the catalyst beds are distributed in the reactor along the radial direction in a ring barrel shape; the center channel is arranged in the center of the reactor, and the ring-shaped channel is arranged around the outer ring of the catalyst beds; the center channel and the ring-shaped channel are respectively provided with the baffles; the high-density porcelain balls are arranged on the baffles; the outer side grids are arranged at the outer sides of the catalyst beds, and the inner side grids are arranged at the inner sides of the catalyst beds. The novel multi-bed radial fixed bed reactor has the advantages that the sectional feeding proportion can be flexibly adjusted, and the bed pressure drop is effectively reduced.

Owner:LUOYANG ZHIDA PETROCHEM ENG

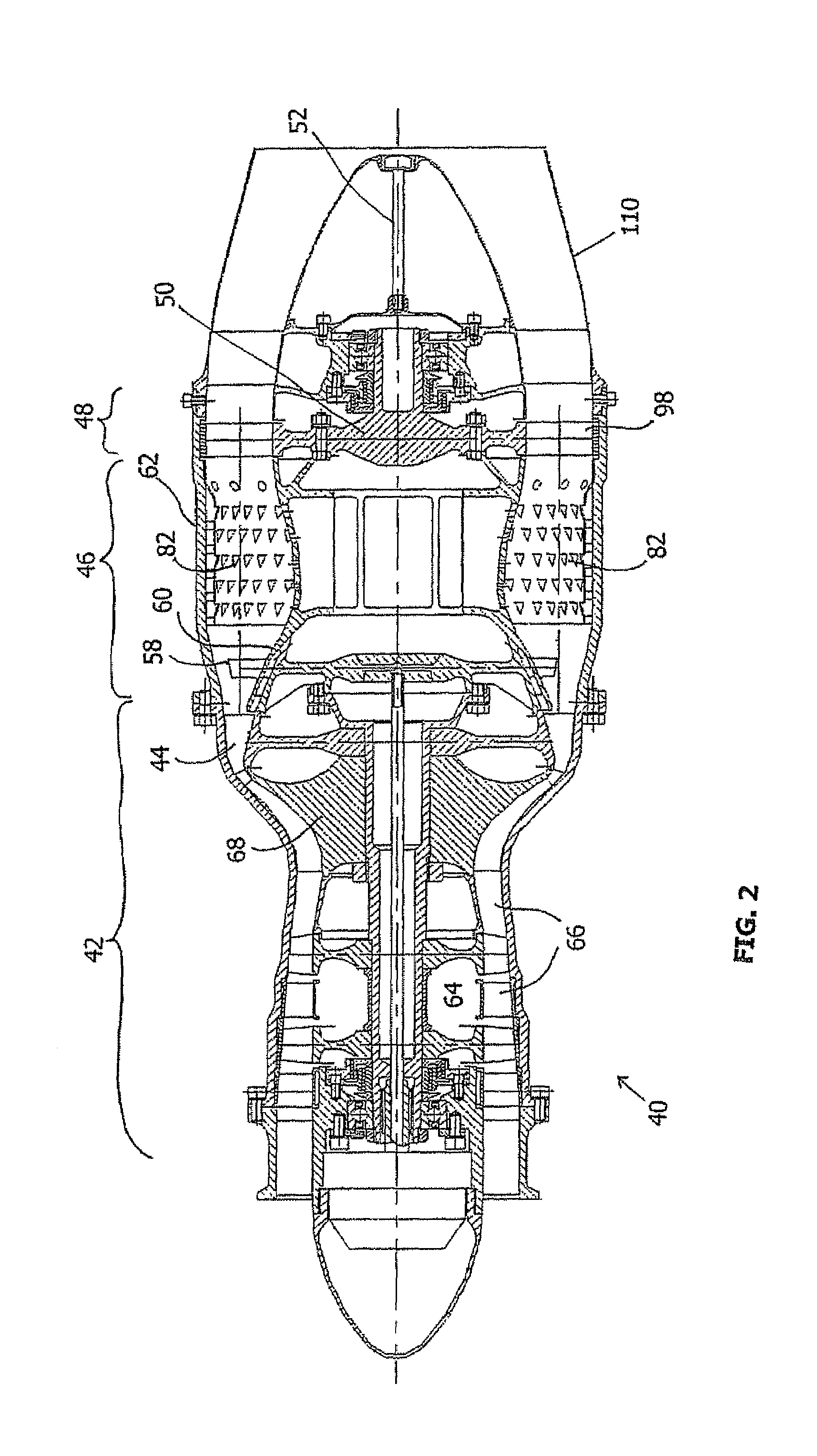

Orbiting combustion nozzle engine

InactiveUS7404286B2Lower overall pressure dropReduce pressureContinuous combustion chamberTurbine/propulsion engine coolingImpellerTurbine wheel

An orbiting combustor nozzle (OCN) engine, having a rotating assembly comprising a co-rotating compressor and nozzle wheel enclosed within a non-rotating outer casing, defining a rotating combustion chamber, is disclosed. Combustion occurs in the combustion chamber in a vortex of gas that rotates at the same angular velocity as the rotating assembly. Also disclosed, is a method of cooling a blade of a rotating wheel, such as a turbine wheel or nozzle wheel, by projecting cool air at the base of the vane form a nozzle corotating with the blade. Such cooling is easily implemented in an OCN engine with use of an innovative annular combustor. Also disclosed is a method of countering axial backflow by use of a combustion chamber compressor.

Owner:R JET ENG

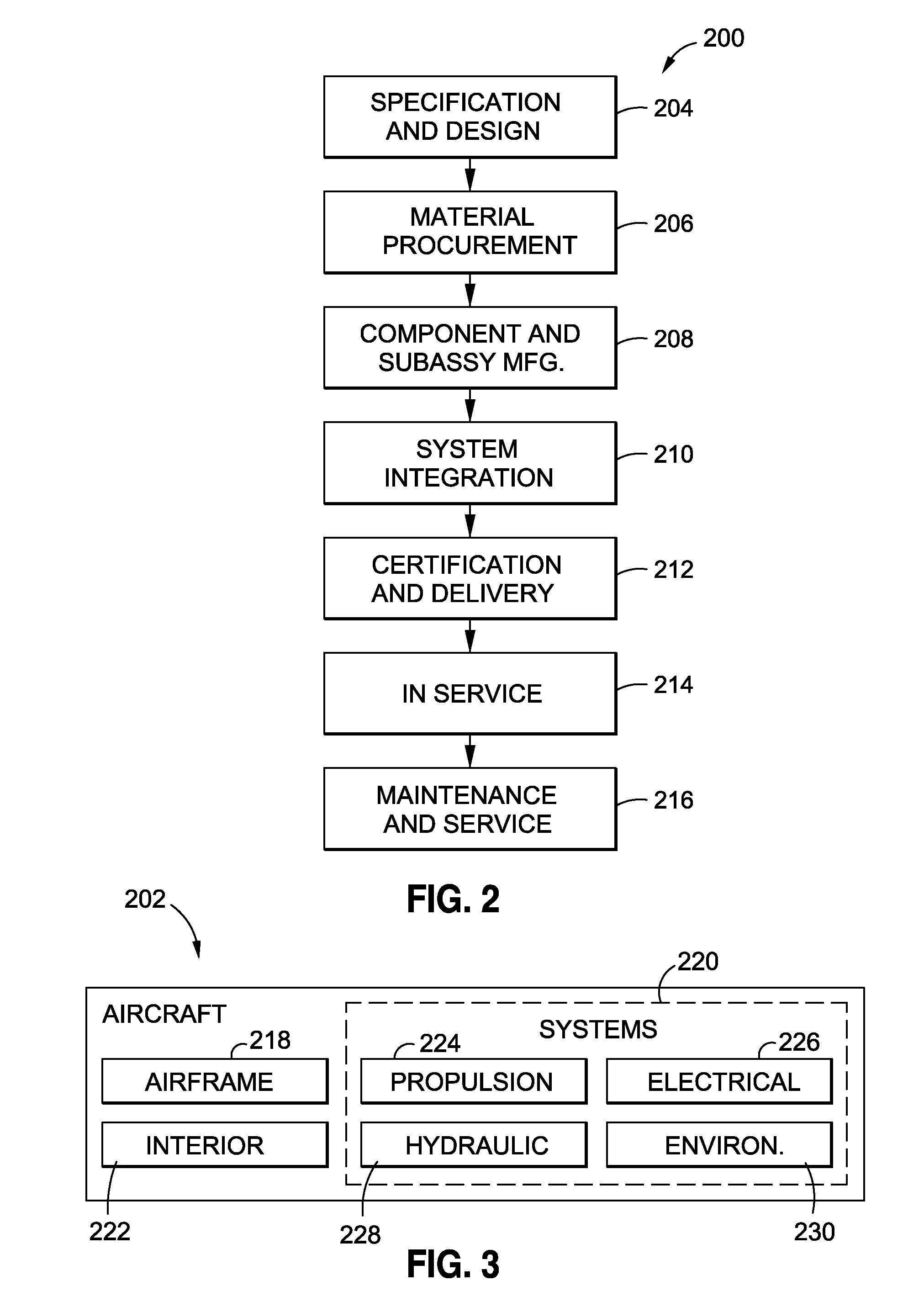

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com