Aluminum steel compound board and compounding method thereof

A composite plate and aluminum alloy plate technology, applied in metal rolling and other directions, can solve problems such as difficult coiling at the head and tail, high energy consumption, and severe work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

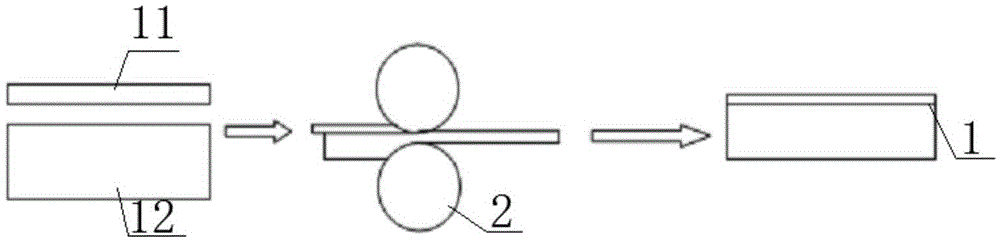

[0034] In this embodiment, a low-carbon steel material with a thickness of 2.6 mm and a 1060 aluminum alloy material with a thickness of 0.12 mm are respectively selected as the base material 12 and the composite material 11 of the composite plate 1 .

[0035] The head of the low-carbon steel material after the surface grinding treatment first passes through the rollers 2 of the compound rolling mill for a certain distance. It should be noted that the temperature of the steel strip can rise to 100-120°C after surface grinding to remove rust spots and oxides. There is no need to lower the temperature before the steel strip is compounded, and it can directly enter the rolling mill to carry out different temperature rolling and compounding with the aluminum alloy strip.

[0036] The aluminum alloy strip is coiled on an uncoiler. The head of the thin strip of aluminum alloy material at room temperature is fed into the roll entrance of the rolling mill in parallel with the steel p...

no. 2 example

[0041] In this embodiment, a low-carbon steel material with a thickness of 2.8 mm and a 1060 aluminum alloy material with a thickness of 0.15 mm are respectively selected as the base material 12 and the composite material 11 of the composite plate 1 .

[0042] According to the same method as the first embodiment, the above-mentioned base material and composite material were subjected to different temperature rolling and compounding, and finally an aluminum / steel composite material 1 with a thickness of 1.58 mm was obtained.

[0043]After inspection by relevant inspection equipment, the rolled steel plate and aluminum alloy are well composited together, and there is no aluminum layer falling off, no bubbles, and the thickness of the composite layer is uniform. It has been verified by practice that the aluminum layer will not be perforated and peeled off during subsequent annealing, leveling and other processes. And through the tensile and tearing test of special mold, the bondi...

no. 3 example

[0046] In this embodiment, a low-carbon steel material with a thickness of 3.0 mm and a 1060 aluminum alloy material with a thickness of 0.17 mm are respectively selected as the base material 12 and the composite material 11 of the composite plate 1 .

[0047] According to the same method as the first embodiment, the above-mentioned base material and composite material were subjected to different temperature rolling and compounding, and finally an aluminum / steel composite material 1 with a thickness of 1.62 mm was obtained.

[0048] After inspection by relevant inspection equipment, the rolled steel plate and aluminum alloy are well composited together, and there is no aluminum layer falling off, no bubbles, and the thickness of the composite layer is uniform. It has been verified by practice that the aluminum layer will not be perforated and peeled off during subsequent annealing, leveling and other processes. And through the tensile and tearing test of special mold, the bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com