Patents

Literature

57results about How to "Effective spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

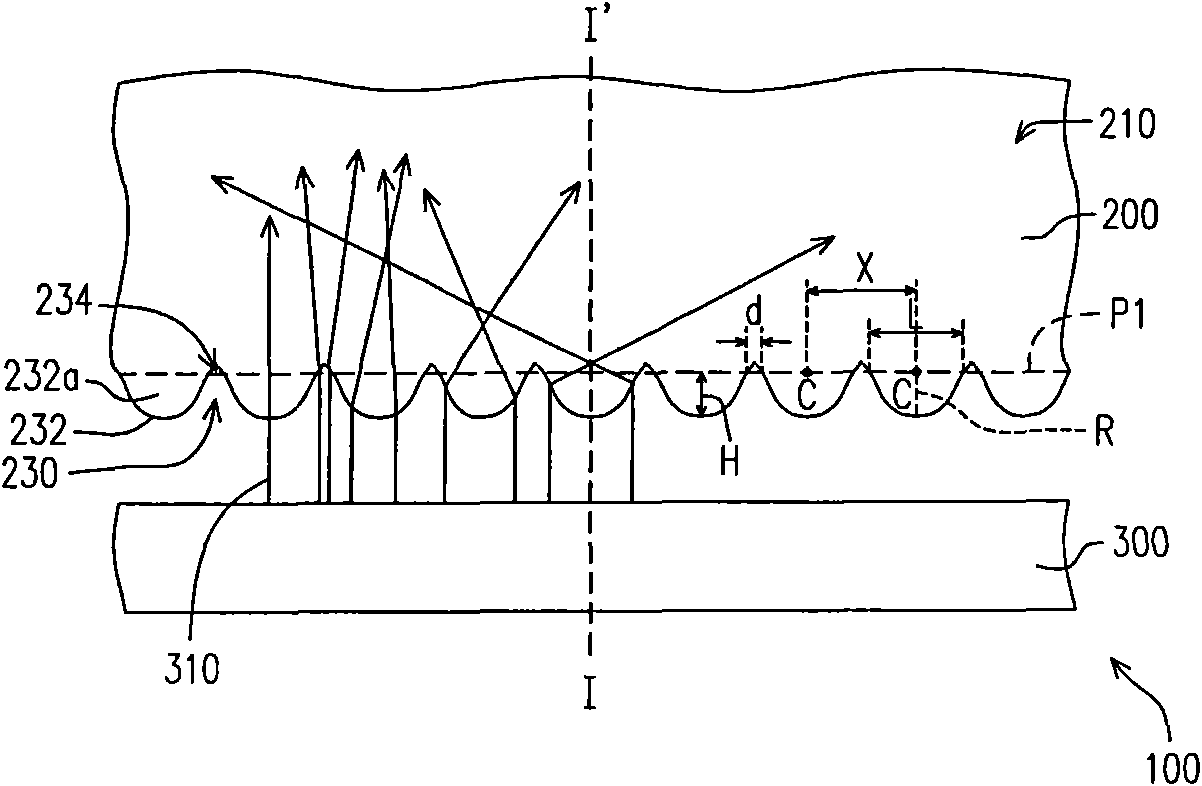

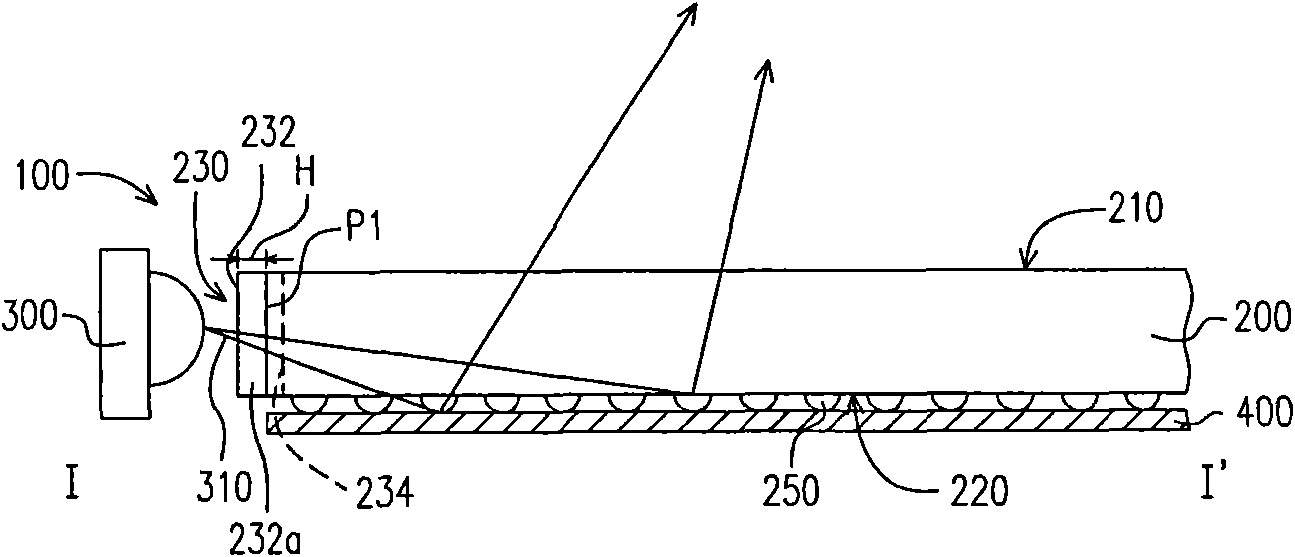

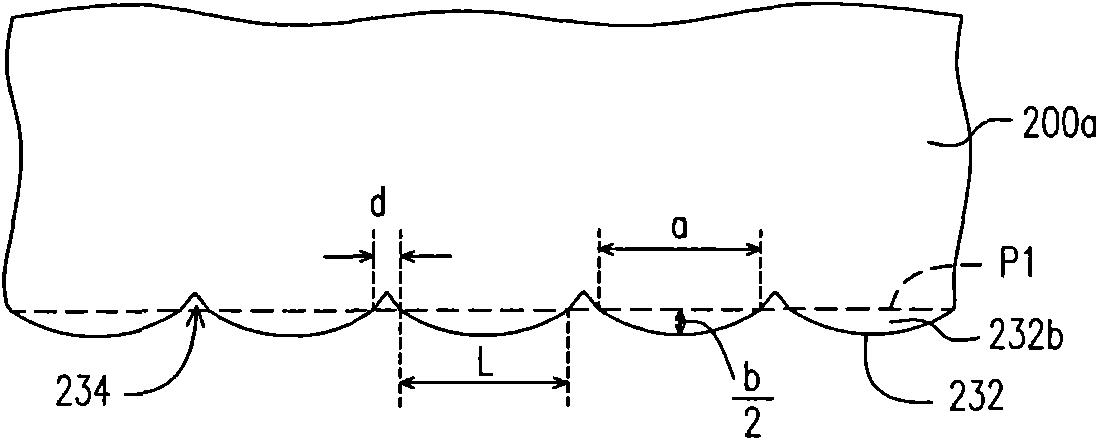

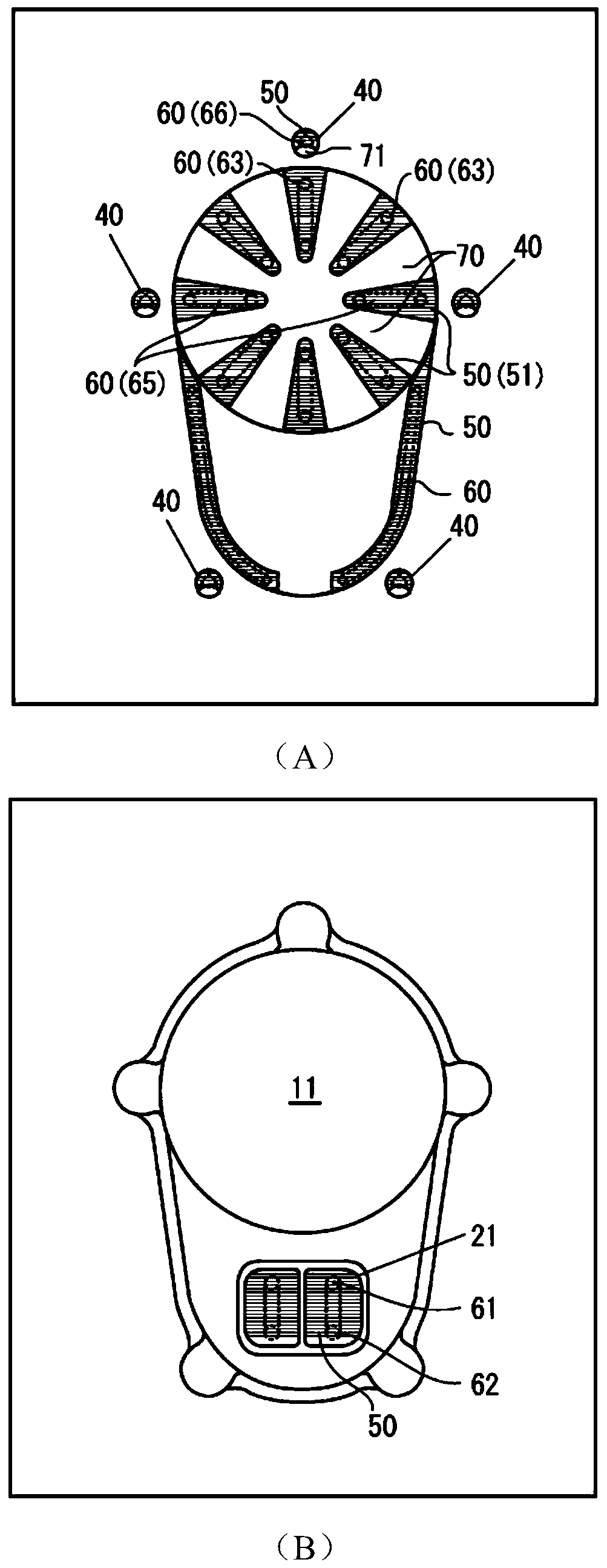

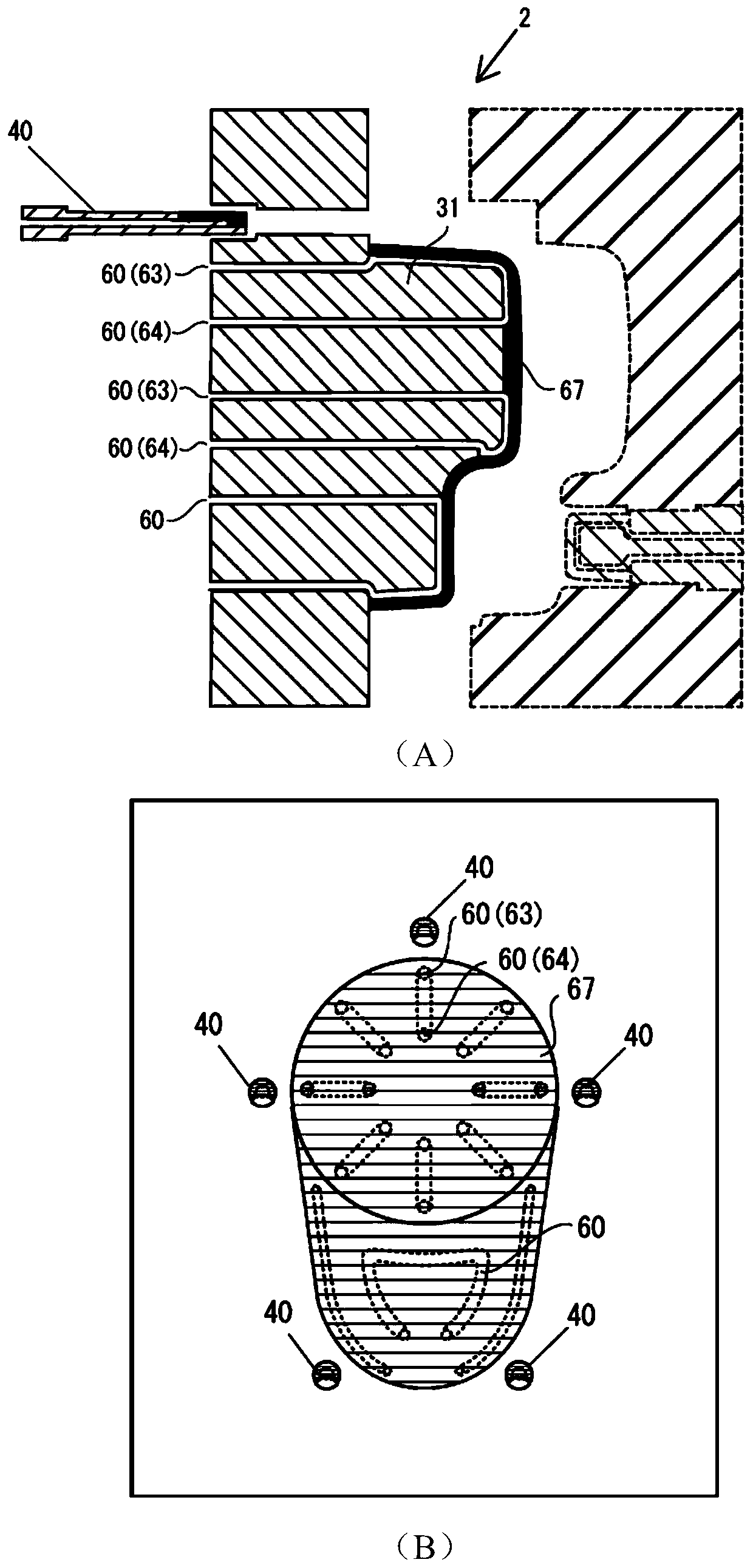

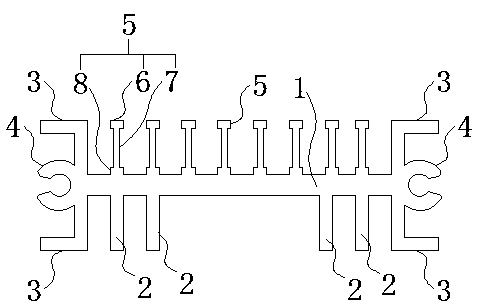

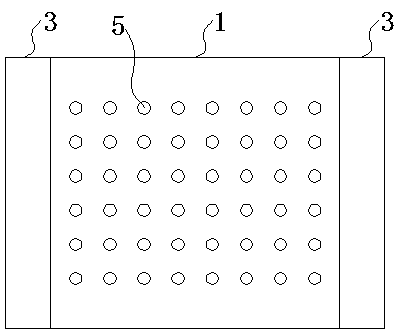

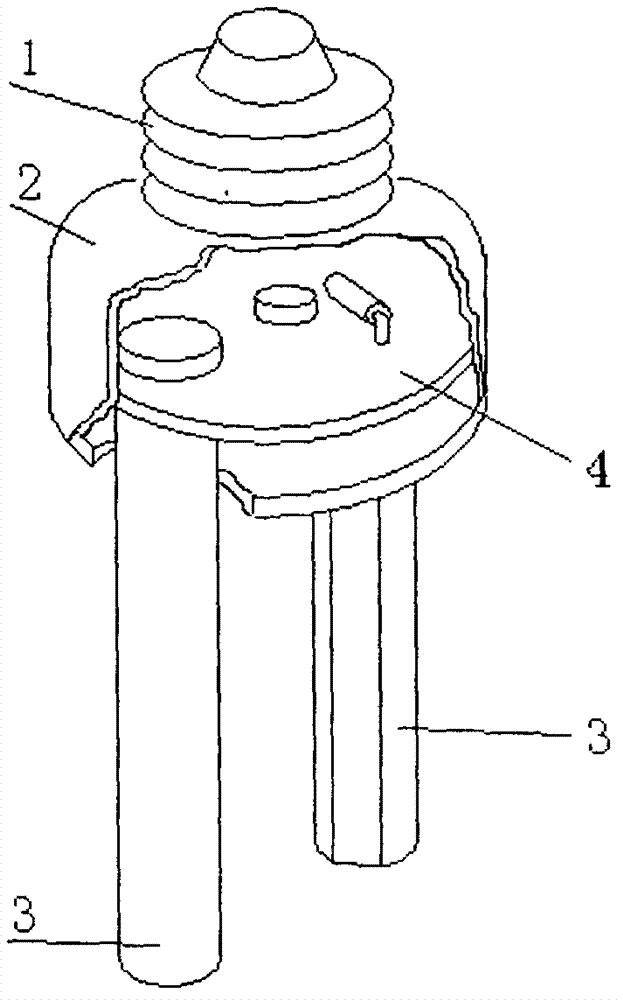

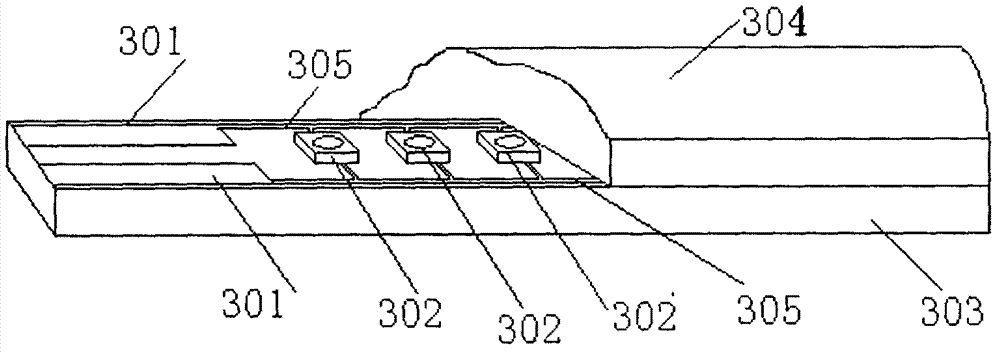

Light guide plate and backlight module

InactiveCN102168841AImprove light uniformityEffective spreadMechanical apparatusLighting device detailsVirtual surfaceOptoelectronics

The invention relates to a light guide plate and a backlight module. The light guide plate comprises a first surface, a second surface and an incident surface, wherein the second surface is opposite to the first surface; the incident surface is connected with the first surface and the second surface and is provided with a plurality of arc-shaped bulges and a plurality of V-shaped grooves; the V-shaped grooves and the arc-shaped bulges are formed alternately and are adjacent mutually; connecting lines of the V-shaped grooves and the arc-shaped bulges which are adjacent form a virtual surface; and the arc-shaped bulges and the V-shaped grooves are positioned on both sides of the virtual surface respectively. The invention also provides a backlight module using the light guide plate. By the light guide plate, the integral light-emitting uniformity of the backlight module can be improved.

Owner:CORETRONIC

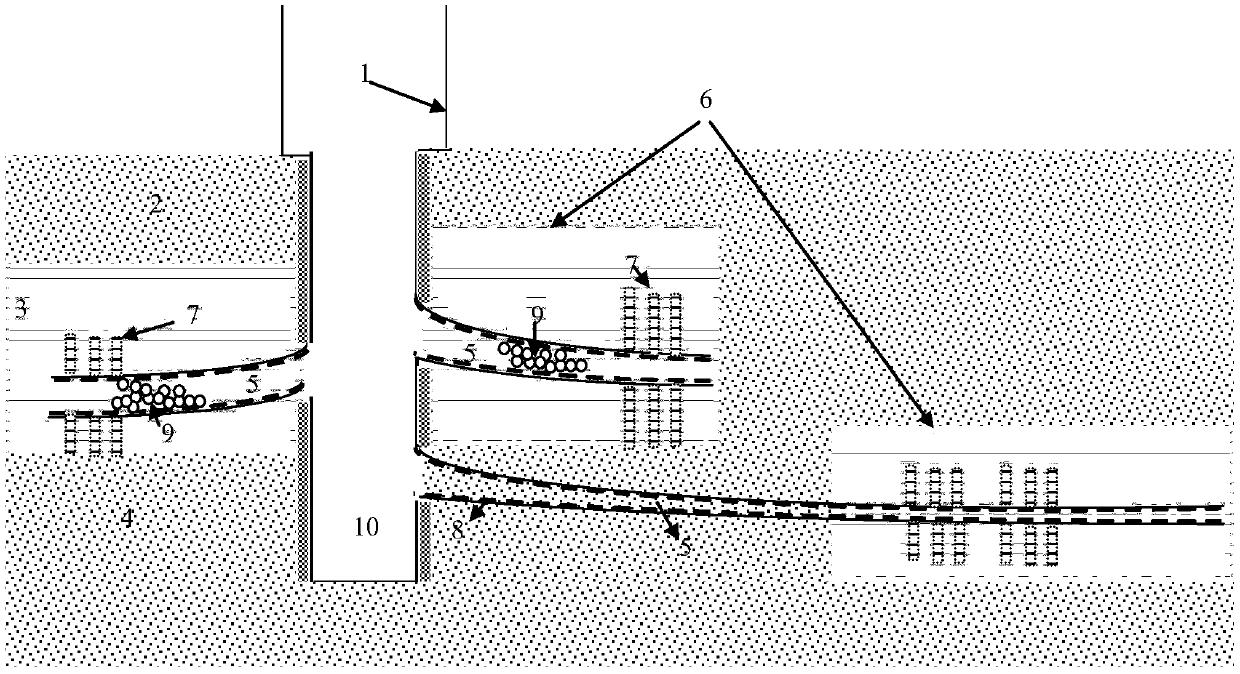

Combined mining method with decompression and heating in multi-branched horizontal wells for marine hydrate

ActiveCN109763794BEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingMining engineeringHorizontal wells

Owner:QINGDAO INST OF MARINE GEOLOGY

Self-flow type large-area batching mix for revolving furnace and methods for preparing and using self-flow type large-area mix

The invention discloses a self-flow type large-area batching mix for a revolving furnace and methods for preparing and using the self-flow type large-area batching mix. The batching mix consists of the following components in part by weight: 50 to 70 parts of aggregate, 20 to 30 parts of fine powder, 10 to 20 parts of micro powder, 1 to 10 parts of binding agent, 2 to 20 parts of burning promoter, 0.1 to 0.5 part of detonation inhibitor and 0.1 to 4 parts of thickening agent, and the sum of the parts of the aggregate, fine powder, micro powder and binding agent is 100; the aggregate and the fine powder are one or both of the medium-grade magnesia with the MgO content of more than or equal to 95 percent and the first-grade magnesia with the MgO content of more than or equal to 92 percent, and the grain sizes are more than 0.088mm and less than or equal to 5mm and less than or equal to 0.088mm respectively; and the micro powder is the mixture of SiO2 micro powder and active alpha-Al2O3 micro powder. The preparation method comprises the following steps of adding the aggregate, fine powder, micro powder and binding agent in a forced mixer, stirring for 5 to 8 minutes, adding the burning promoter, detonation inhibitor and thickening agent, and stirring the mixture for 3 to 5 minutes. The using method comprises the following steps of putting the batching mix in a mixer, performing dry mixing on the batching mix for 2 to 3 minutes, adding water in an amount which is 8 to 15 percent of the weight of the batching mix, uniformly stirring the mixture for 4 to 5 minutes, discharging, and adding the batching mix into the revolving furnace within one hour. The batching mix is low in cost, high in sintering property, long in service life and long in standing time.

Owner:武钢集团有限公司

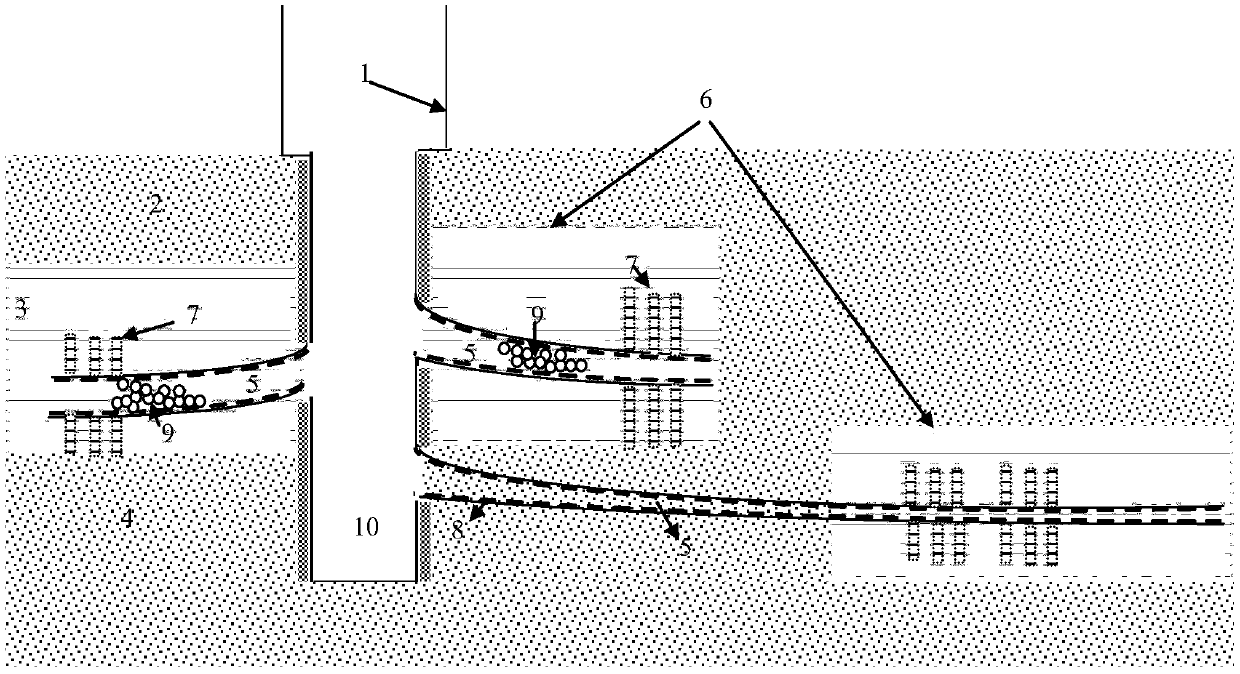

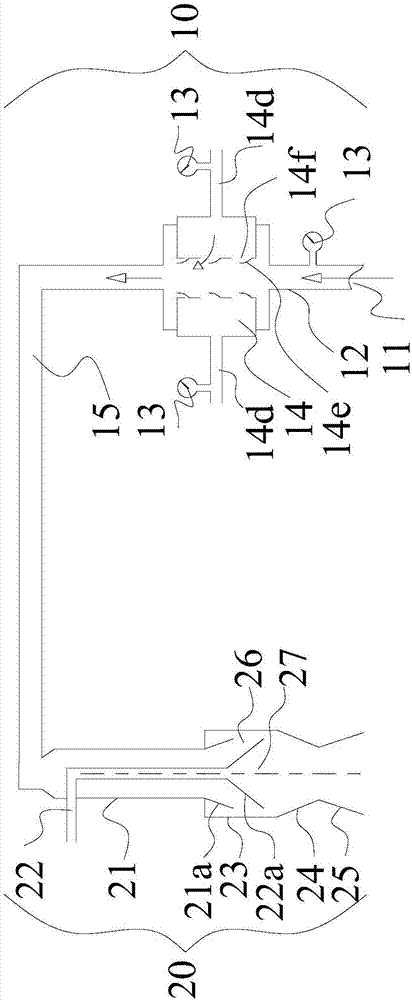

Multi-branch horizontal well depressurization and heating united mining method for marine hydrates

ActiveCN109763794AEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingSoil scienceHorizontal wells

The invention discloses a multi-branch horizontal well depressurization and heating united mining method for marine hydrates. For the 'congenital' defects that the marine hydrates are distributed in ascattered manner and cannot self flow and get together, based on well type structure improvement of a 'main borehole + a multi-branch horizontal well', an ore body reservoir is hydraulically cut by avertical hydrate layer to improve the hydrate decomposition efficiency and achieve the design objectives of connecting three-dimensional scattered ore bodies and relieving the problems of a large amount of sand, instability of the reservoir and blockage formed by secondary hydrates. The united mining method comprises the following steps: (1) forming a well by a main borehole; (2) drilling a multi-branch horizontal well: forming a plurality of multi-branch horizontal wells, which form a certain included angle and are distributed in a fixed direction, around the main borehole, and arranging thehorizontal wells in the middle region of a hydrate reservoir, wherein joints between the multi-branch horizontal wells and between the multi-branch horizontal wells and the main borehole are all of sleeve and conventional sand control sieve tube structures; (3) performing limited sand control and reservoir supporting; (4) transforming the reservoir by hydraulic jetting; (5) performing heating toprevent blockage.

Owner:QINGDAO INST OF MARINE GEOLOGY

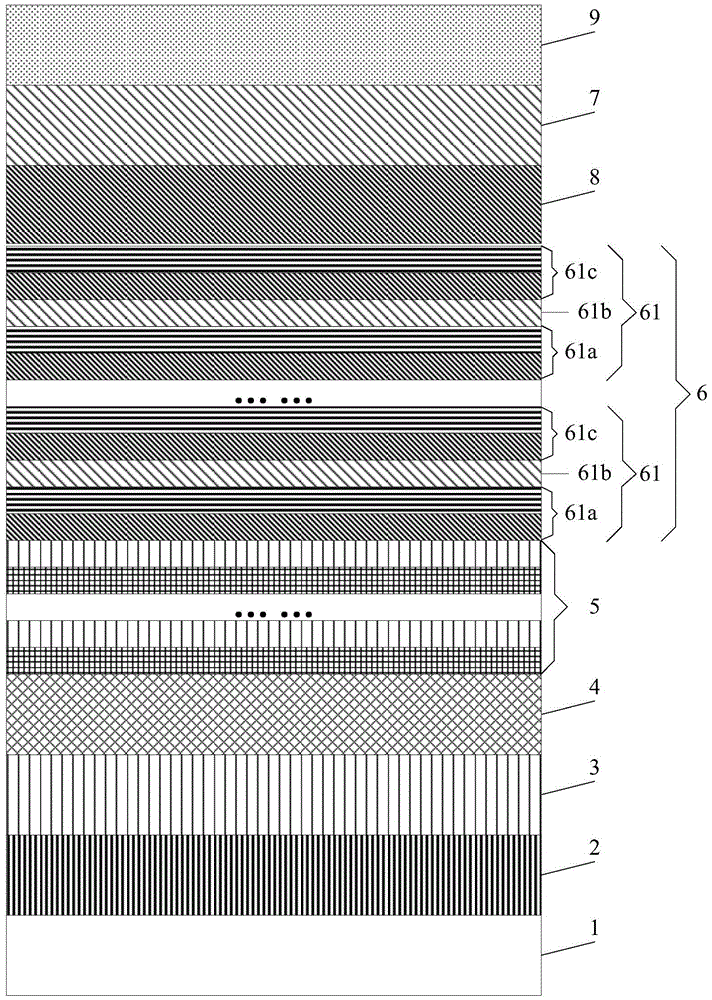

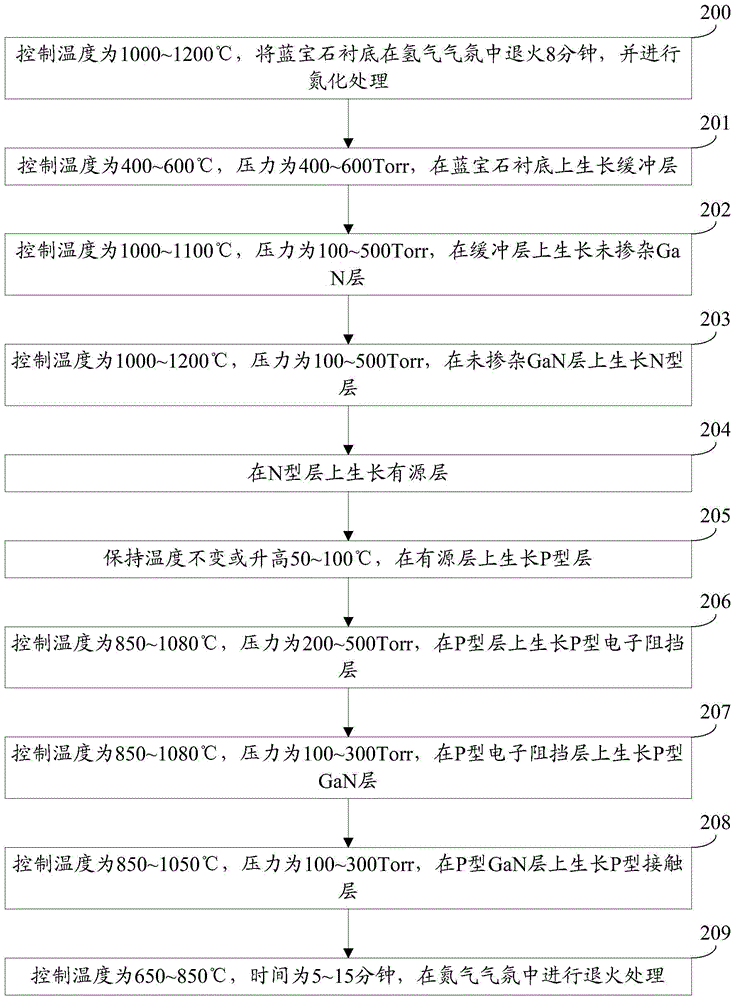

Gallium nitride-based light-emitting diode and manufacturing method thereof

ActiveCN105679900AImprove injection efficiencyImprove luminous efficiencyNanotechnologySemiconductor devicesLattice mismatchGallium nitride

The invention discloses a gallium nitride-based light-emitting diode and a manufacturing method thereof, and belongs to the technical field of semiconductors. The gallium nitride-based light-emitting diode comprises a sapphire substrate, a buffer layer, an undoped GaN layer, an N-type layer, an active layer and a P-type layer, wherein the buffer layer, the undoped GaN layer, the N-type layer, the active layer and the P-type layer are sequentially laminated on the sapphire substrate; the P-type layer comprises a plurality of P-type sub-layers; each P-type sub-layer comprises a hole low-barrier layer, a hole supply layer and a hole high-barrier layer; each of the hole low-barrier layer and the hole high-barrier layer comprises an AlGaN layer and an InGaN layer; and each hole supply layer comprises a P-type GaN layer. The AlGaN layers and the InGaN layers with relatively large lattice mismatches are adopted by the hole low-barrier layers and the hole high-barrier layers; a hole two-dimensional gas capable of effectively spreading charges is generated on the interfaces of the AlGaN layers and the InGaN layers due to relatively high polarization stress; certain drive force is provided for injection of an active layer in holes; and the injection efficiency of the holes is improved, so that the luminous efficiency is improved.

Owner:HC SEMITEK SUZHOU

A preparation method of large-area perovskite thin film and a battery module thereof

ActiveCN109103338AEfficient extractionReduce extractionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEngineering

The invention belongs to the field of perovskite solar cells, in particular to a preparation method of a large-area perovskite thin film and a battery module thereof. The preparation method comprisesthe following steps of: cleaning a transparent conductive substrate and drying for standby; depositing a tin oxide electron transport layer by chemical bath method; performing uniform coating and depositing of the perovskite precursor solution by slit extrusion-scraping method, and then obtaining the perovskite absorbing layer by a spin-coating moving droplet antisolvent method; using a green solvent to prepare a Spiro-OMeTAD solution, preparing the hole transport layer on the perovskite light-absorbing layer by a slit extrusion scraping method, and evaporating the metal electrode on the holetransport layer. As the precursor solution of the perovskite deposit is extruded and scraped by the slit, the perovskite solution can be spread effectively and the consumption is saved; the antisolvent can be uniformly dropped on the perovskite film by moving the antisolvent droplet, which can effectively widen the extraction area of perovskite film and save the use of antisolvent.

Owner:广东光晶能源科技有限公司

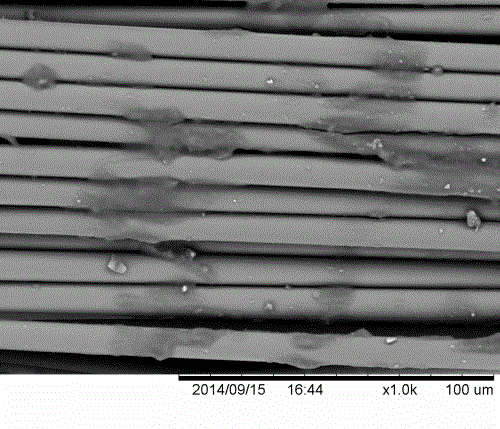

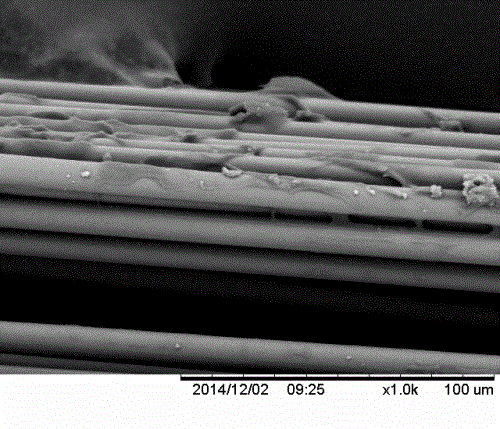

Preparation method of gelatin modified starch wetting agent

The invention relates to a preparation method of a gelatin modified starch wetting agent, which is characterized by comprising the following steps: (1) pretreatment: drying the raw material starch at 50 DEG C for 24 hours, passing through an 80-mesh screen, mixing 12-20 parts by mass of impurity-removed original starch, 1-3 parts by mass of gelatin and 400 parts by mass of water solution, and reacting at 90 DEG C for 1-3 hours to obtain a modified starch paste solution; (2) proportioning and mixing: sequentially and slowly adding 0.25 part by mass of 50% glutaraldehyde solution, 0.5 part by mass of glycerol, 0.25 part by mass of polyvinyl alcohol, 0.5 part by mass of sodium sulfate and 0.3 part by mass of Tween 60 into the modified starch paste solution to obtain a mixture; and (3) stirring the mixture at 90 DEG C for 1-5 hours to obtain a reaction mixture, cooling the reaction mixture to room temperature, standing for 6 hours, and degassing to obtain the gelatin modified starch wetting agent. The gelatin modified starch wetting agent can be directly used in glass fiber tank kiln wire drawing production and glass fiber textile processing; and the method is simple in preparation technique and easy to operate, has the advantages of environmental protection, low cost and high practicality, and is worthy of popularization.

Owner:通城县同力玻纤有限公司

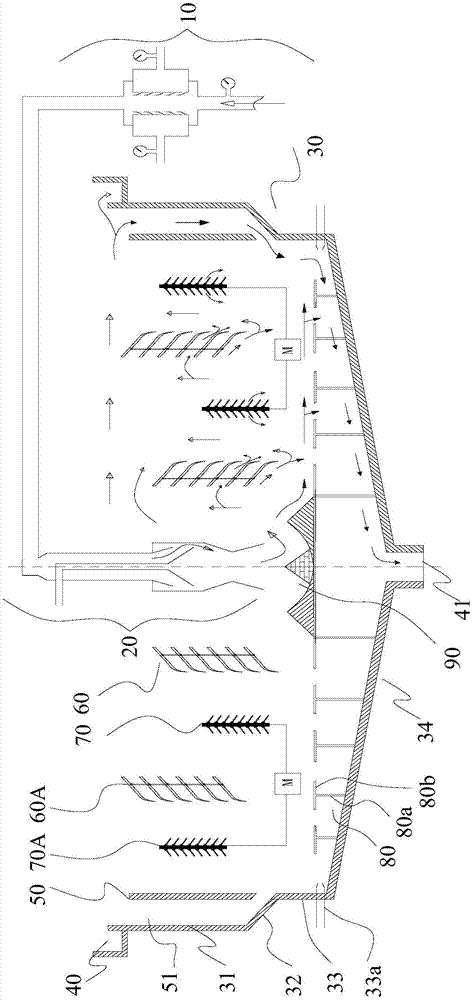

Parabolic grading concentration tank

ActiveCN106976944ATo achieve the graded effectRealize quantitative dosingWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLiquid mediumProcess engineering

The invention belongs to the technical field of slime water treatment and specifically relates to a parabolic grading concentration tank. The invention designs the grading principle according to the difference of parabolic tracks of coal slime particles in different shape, weight and size in a liquid medium. The parabolic grading concentration tank at least comprises a drug adding system, a feeding system, a concentration tank body, a first draining mud-lagging plate unit, a second draining mud-lagging plate unit, a first adjustable vibrating plate device and a second adjustable vibrating plate device; the quantitative addition of the drug can be realized in a manner of mixing the drug with the ore pulp once while passing by an annular drug disperser; the ore pulp after being mixed once can be added again according to the practical requirement by a secondary dosing pipe in the feeding system; a big horn-shaped drug dispersing port and a surrounding zigzag structure thereof can violently disperse the ore pulp flowing out of a small horn-shaped dispersing port; the slime water is deeply cleared by a free settling area formed by encircling of an annular separating plate in the concentration tank body. The parabolic grading concentration tank has the advantages of simple structure, low construction cost, low maintenance load, obvious effect, and the like.

Owner:ANHUI UNIV OF SCI & TECH

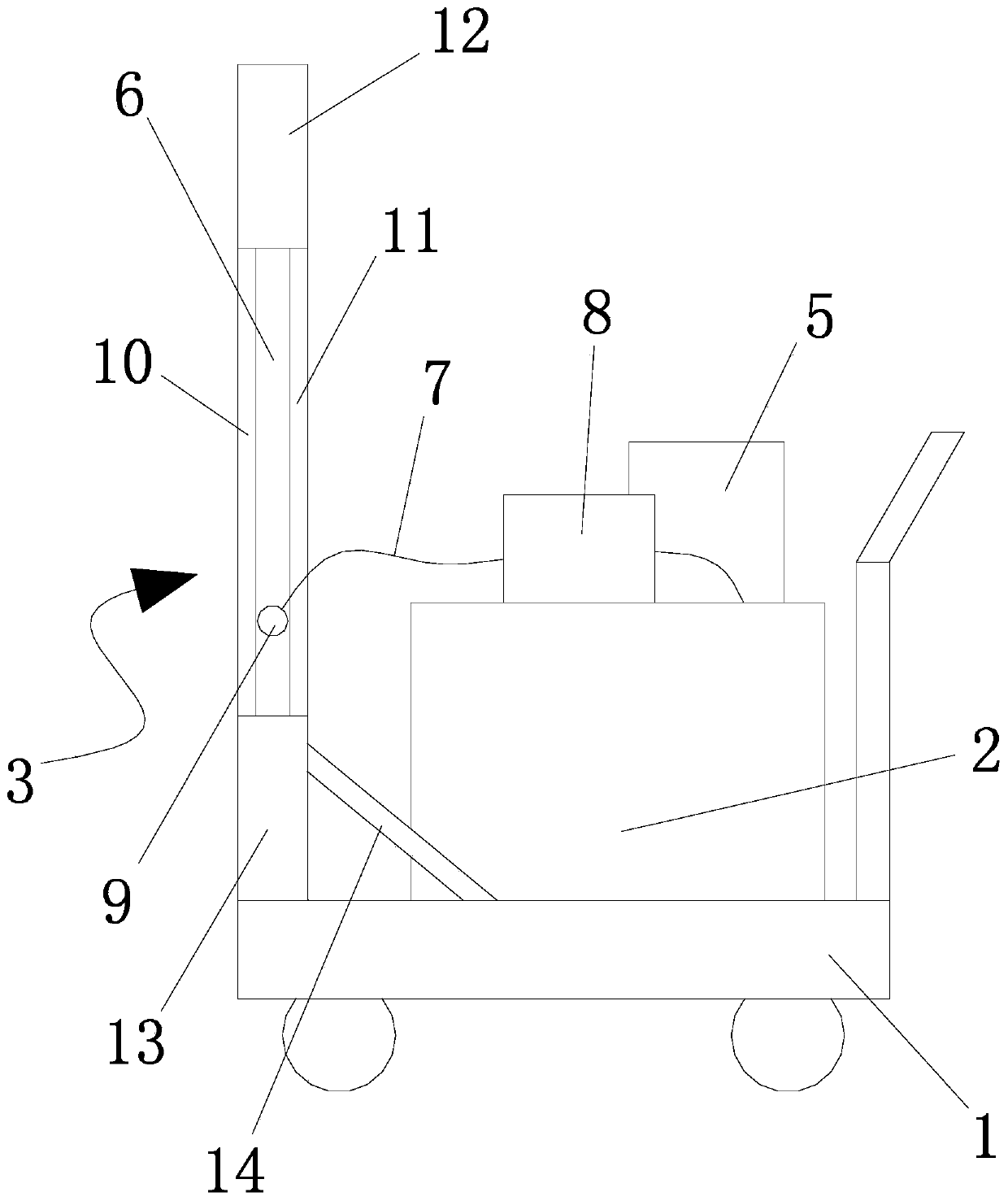

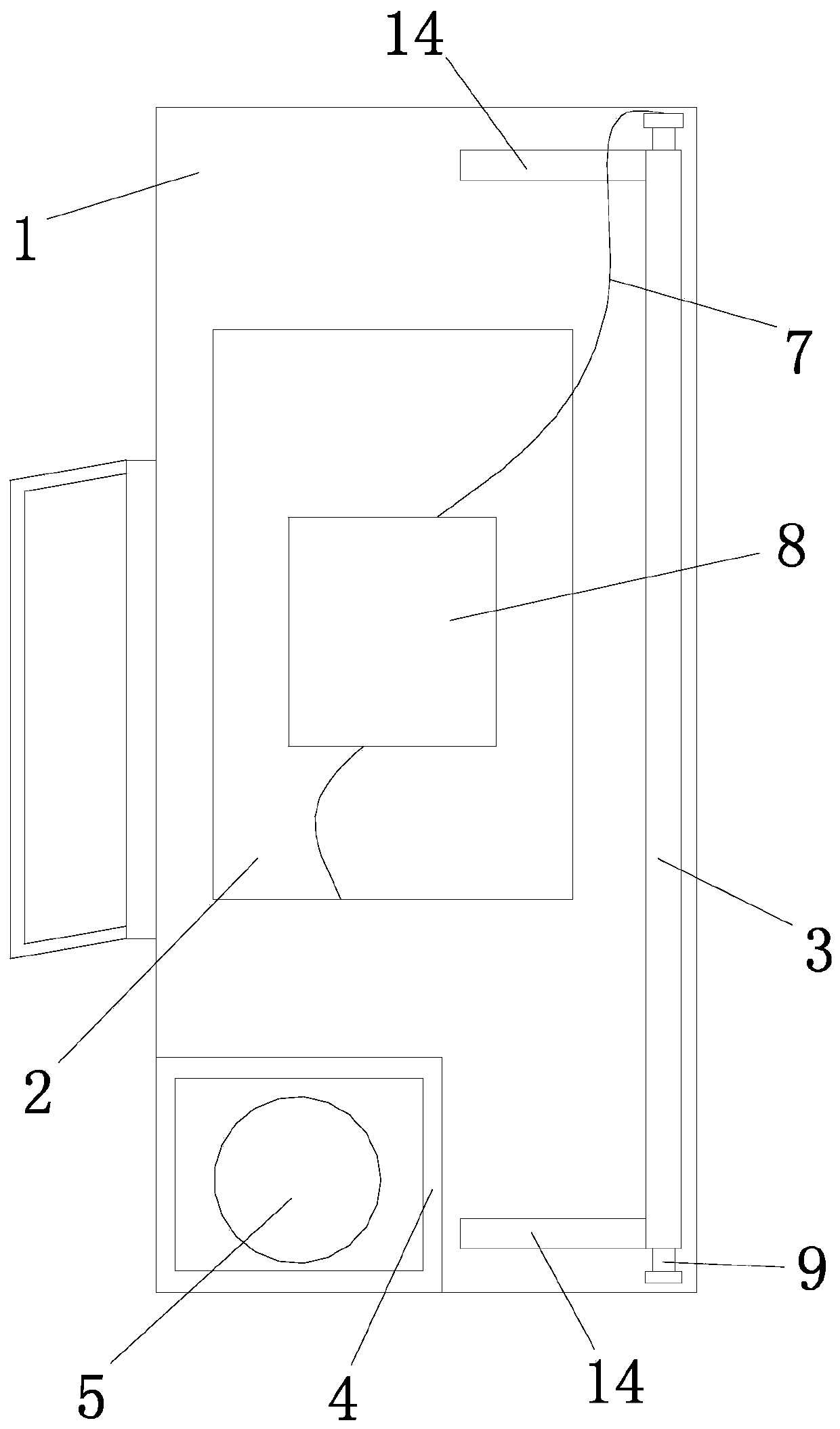

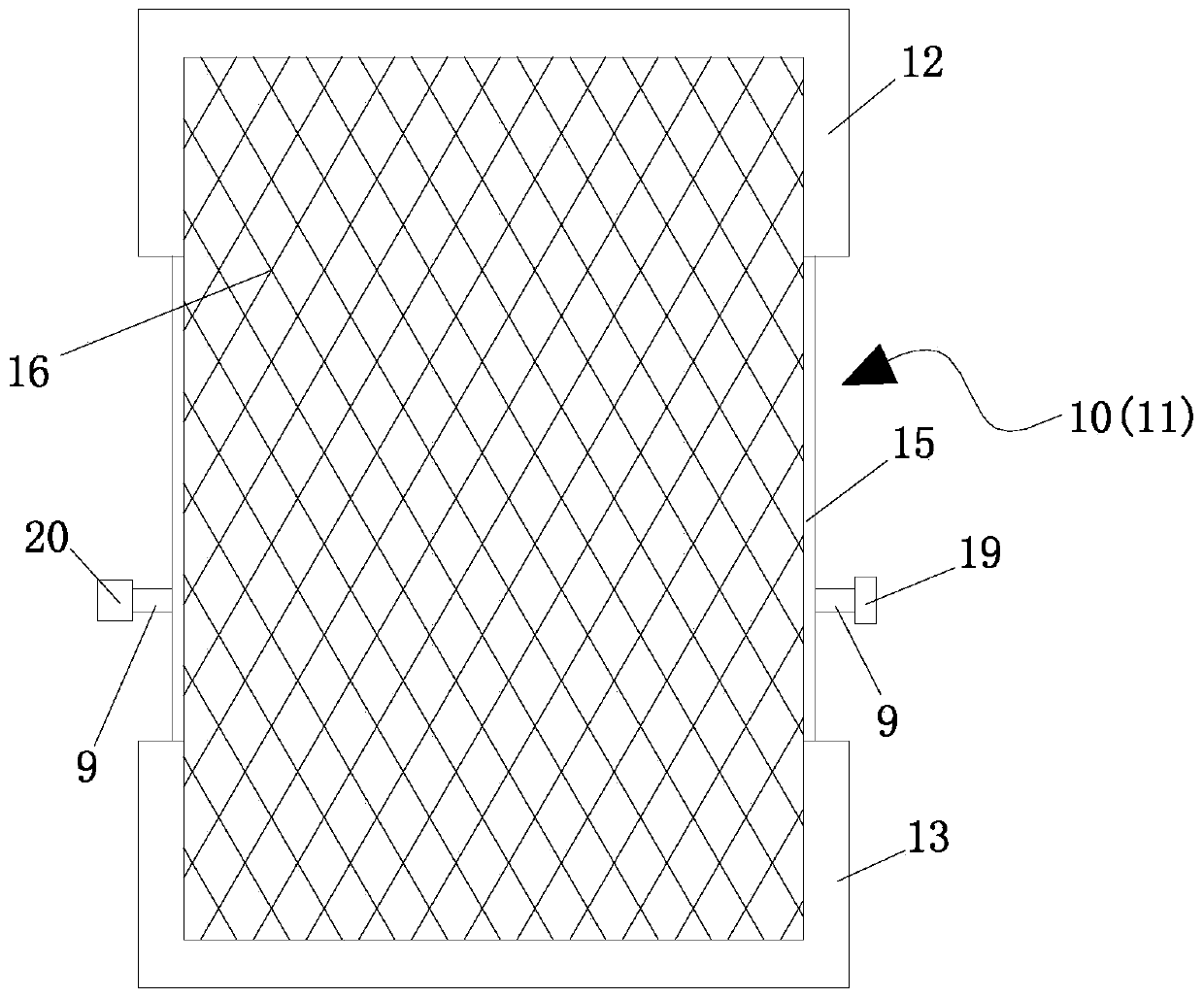

Portable heat flow insulating device for actual fire scenes

ActiveCN110152220ASimple structureScientific and reasonable designFire rescueBoring toolsHeat flowHeat resistance

The invention discloses a portable heat flow insulating device for actual fire scenes. The device solves the problem that firefighters and trapped persons in a fire scene have life risk in a high heatradiation environment. The device comprises a trolley, a water tank and a heat flow insulating mechanism, wherein the heat flow insulating mechanism comprises a steel wire net rack, a water conveyinghose, a water pump and a water spraying assembly, wherein the steel wire net rack is placed in the fire scenes to generate water curtains to reduce radiation heat flow, the water conveying hose is connected with the water tank, the water pump is arranged on the water conveying hose, and the water spraying assembly is arranged in the steel wire net rack, connected with the water conveying hose andused for spraying the sector-shaped water curtains onto the steel wire net rack; and the water pump is fixed at the top of the water tank, the water pump pumps clean water in the water tank to the water spraying assembly through the water conveying hose, and the water spraying assembly sprays the clean water conveyed by the water conveying hose onto the steel wire net rack in a sector shape and makes the steel wire net rack continuously generate uniform water curtains to reduce the radiation heat flow of the fire scenes. The device can be used in fire scene rescue equipment, and has the characteristics of heat flow insulation, light weight, movable performance, long fire resistance time, good heat resistance effect and the like.

Owner:应急管理部四川消防研究所

Oxidation-resistant high energy density magnesium alloy for 500-600 degrees and process thereof

The invention discloses oxidation-resistant high energy density magnesium alloy for 500-600 degrees and a process thereof. The alloy comprises the following components by weight: Li: 2.0-3.0%, Al: 5.0-6.0%, In: 1.0-1.2%, Zn: 2.5-2.8%, B: 0.10.2%, Sn: 1.0-1.2%, Bi: 5.0-6.0%, Sb: 2.4-2.5% and the balance magnesium. A multi-element near-eutectic alloy solution for the oxidation-resistant high energydensity magnesium alloy for 500-600 degrees in the field of alloy energy storage is provided. Alloy melt has excellent oxidation resistance, thermal cycle performance and thermophysical performance. The alloy can effectively overcome the defect of innovation shortage of novel alloy materials in the field of energy storage, and is expected to obtain great market value while solving industrial problems.

Owner:GUANGZHOU YUZHI TECH CO LTD

Monolithic perovskite catalyst, and preparation method and application thereof

PendingCN111151257AHigh specific surface areaGood dispersionGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention discloses a monolithic perovskite catalyst, and a preparation method and an application thereof, and belongs to the technical field of preparation of catalysts. The structure of the catalyst is ABO3, the A position is Pr1-xCax, x is 0.1, 0.2 or 0.3, and the B position is one or two of Co, Mn, Fe and Cu. The preparation method comprises the following steps: firstly, selecting cordierite honeycomb ceramic as a carrier, and pretreating the cordierite honeycomb ceramic; weighing related raw materials according to a certain stoichiometric ratio, dissolving in a certain amount of deionized water, stirring, heating in a water bath for dissolving, adding a certain amount of citric acid, and stirring for dissolving to obtain a catalyst precursor solution; and finally, dipping the pretreated carrier in the catalyst precursor solution, taking out the carrier after dipping is completed, and drying and calcining the carrier to obtain the catalyst. The monolithic perovskite catalyst provided by the invention is low in preparation cost and low in energy consumption, and has high catalytic activity.

Owner:SHANDONG UNIV OF SCI & TECH

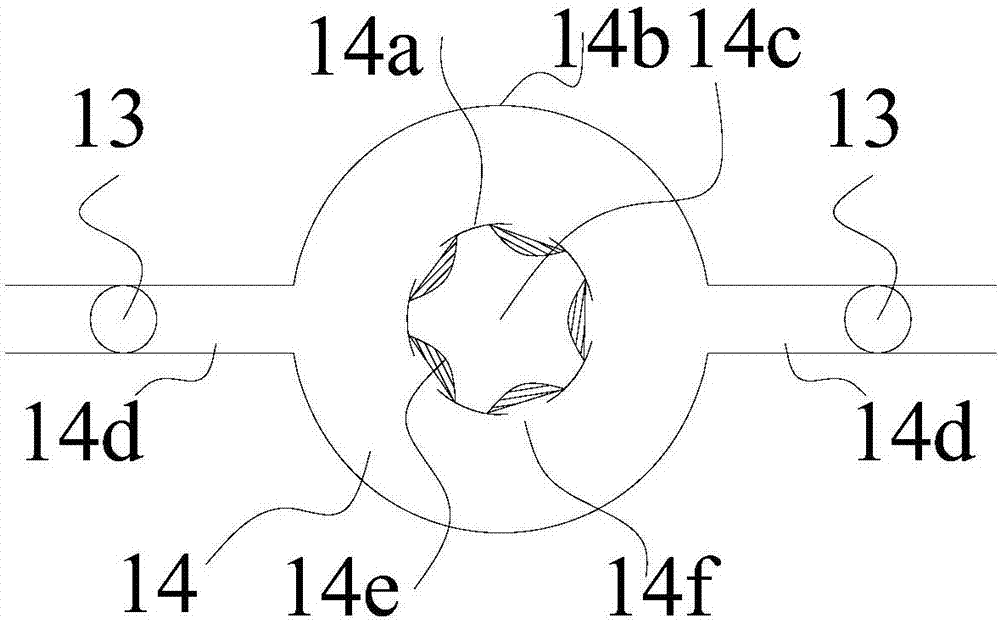

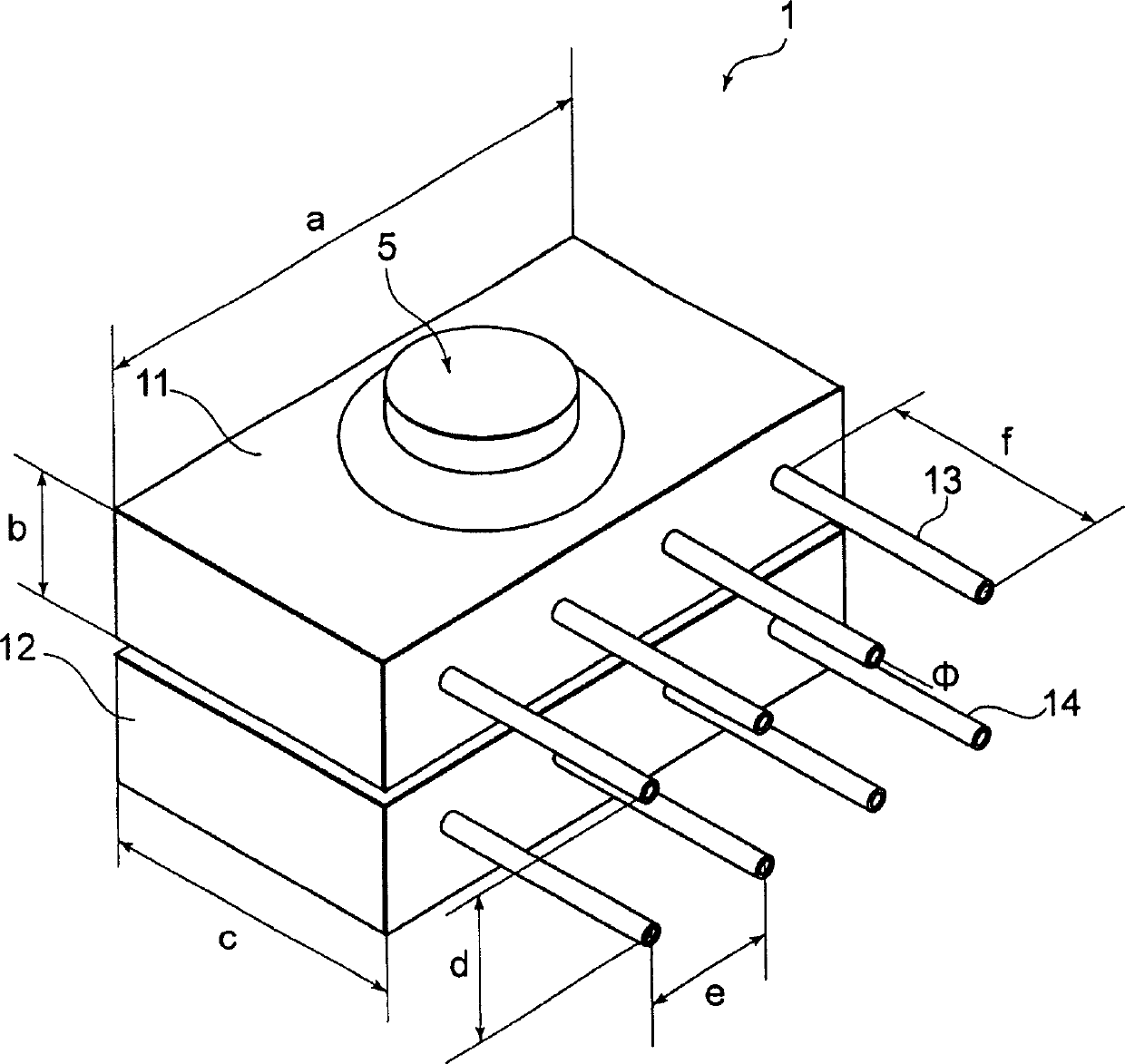

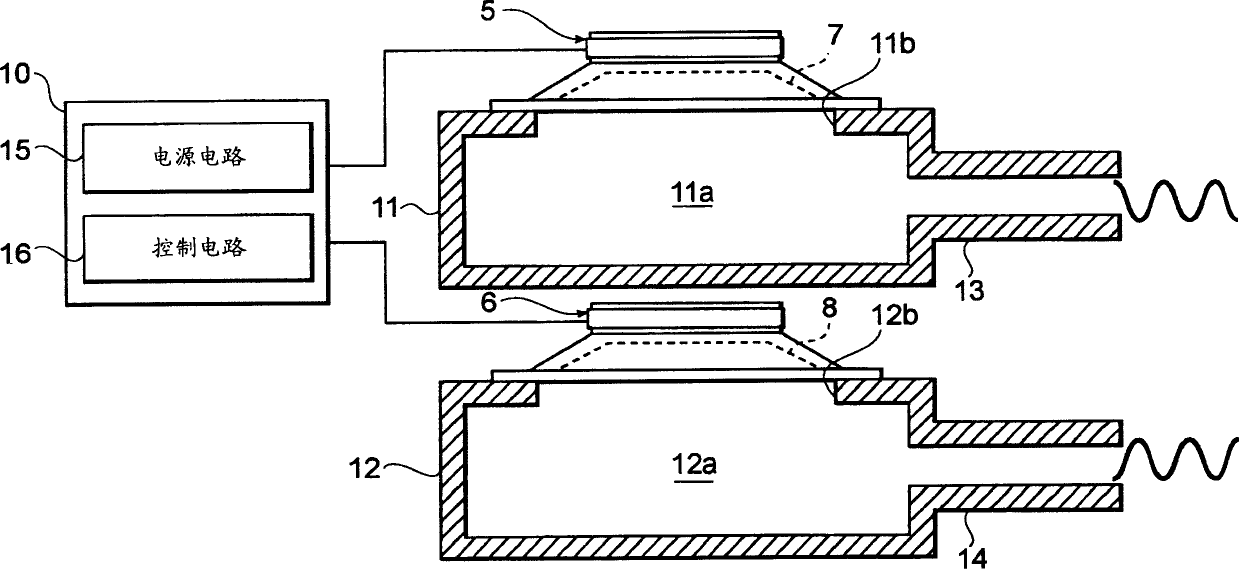

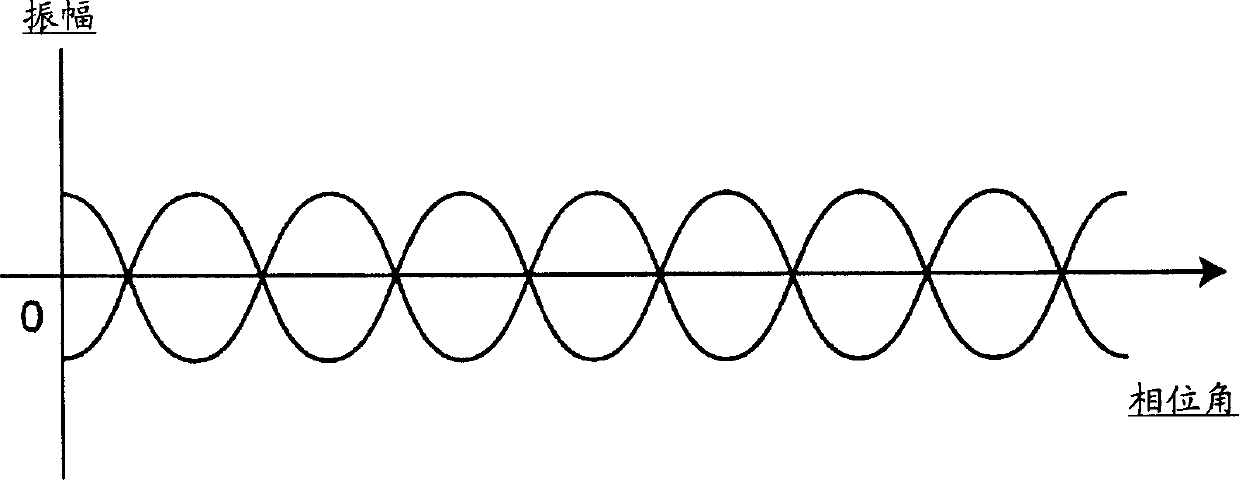

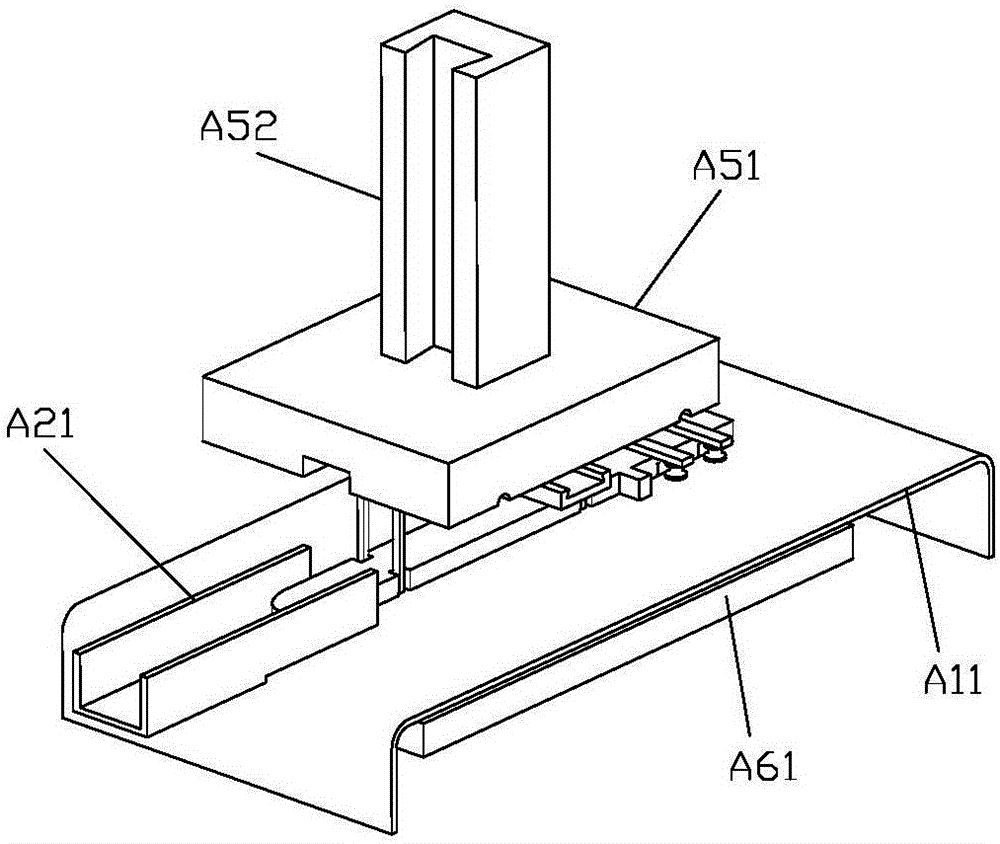

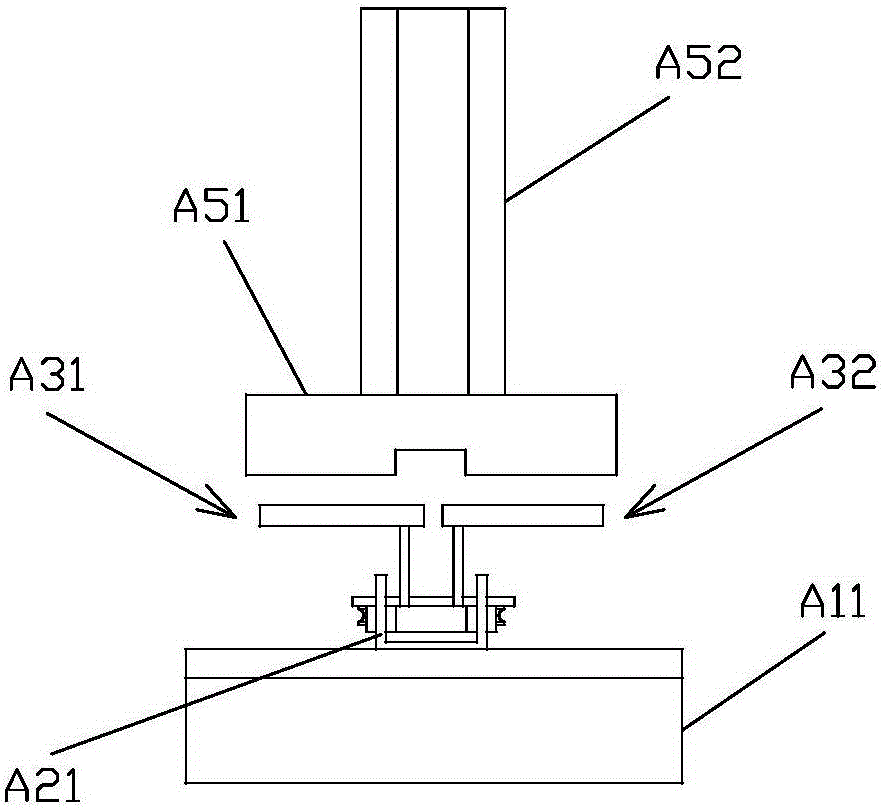

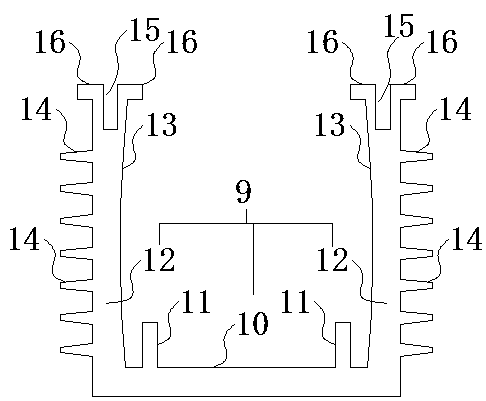

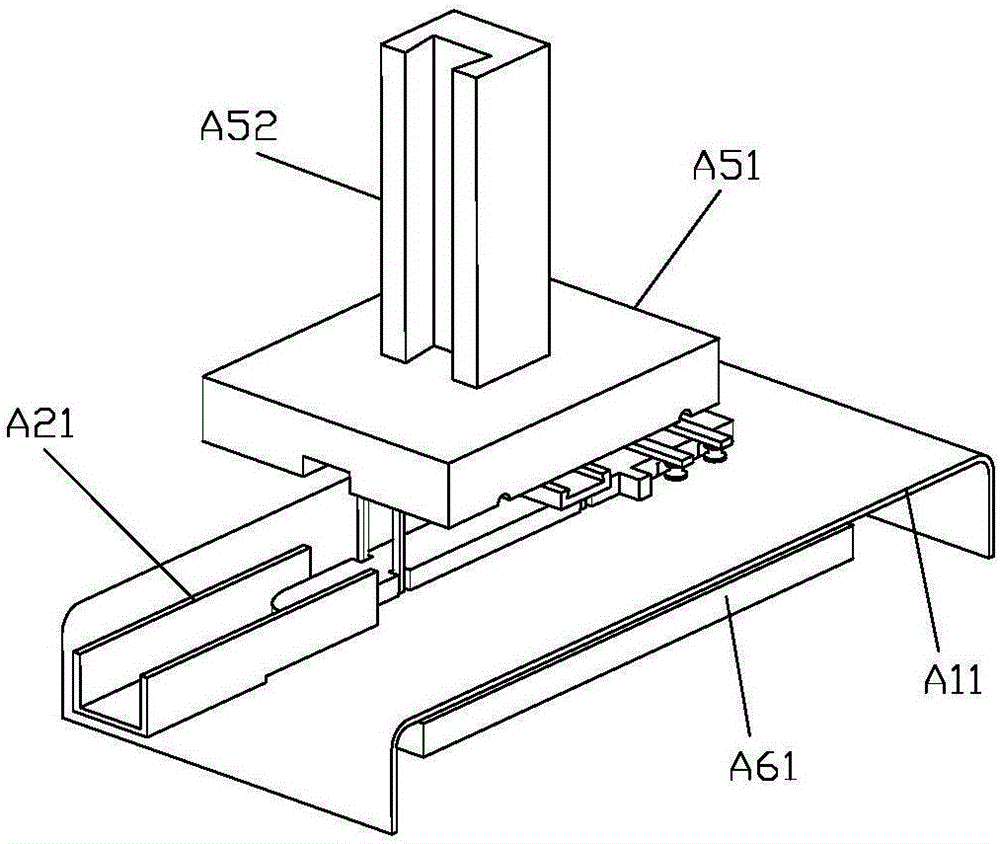

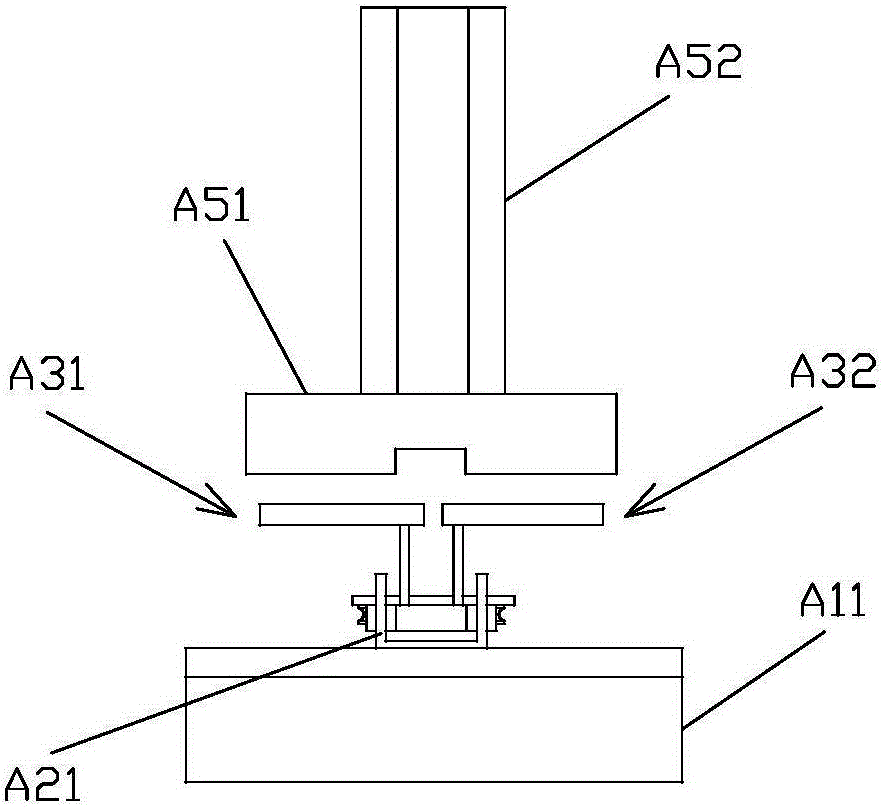

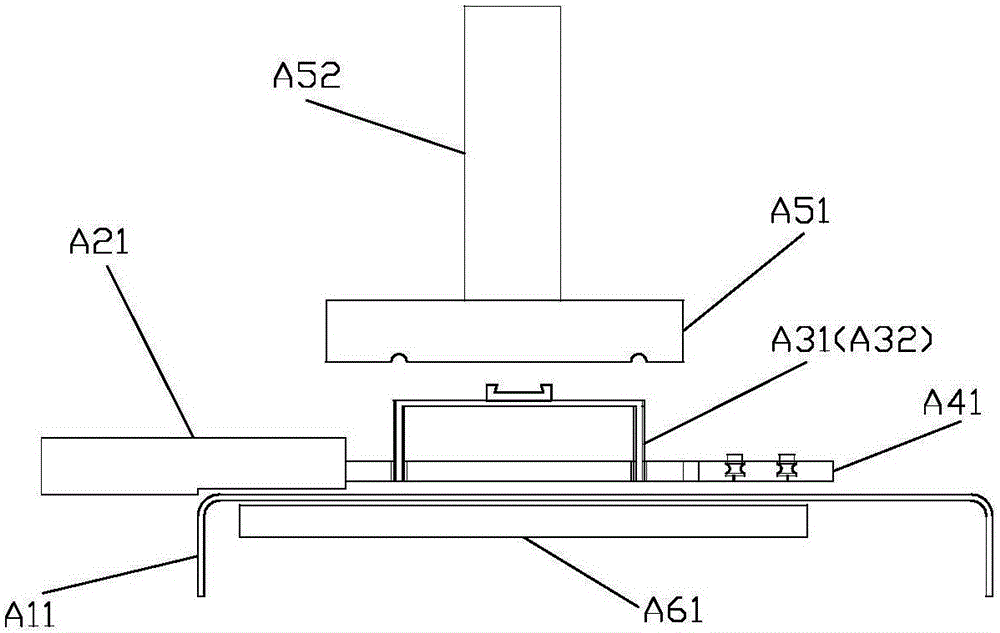

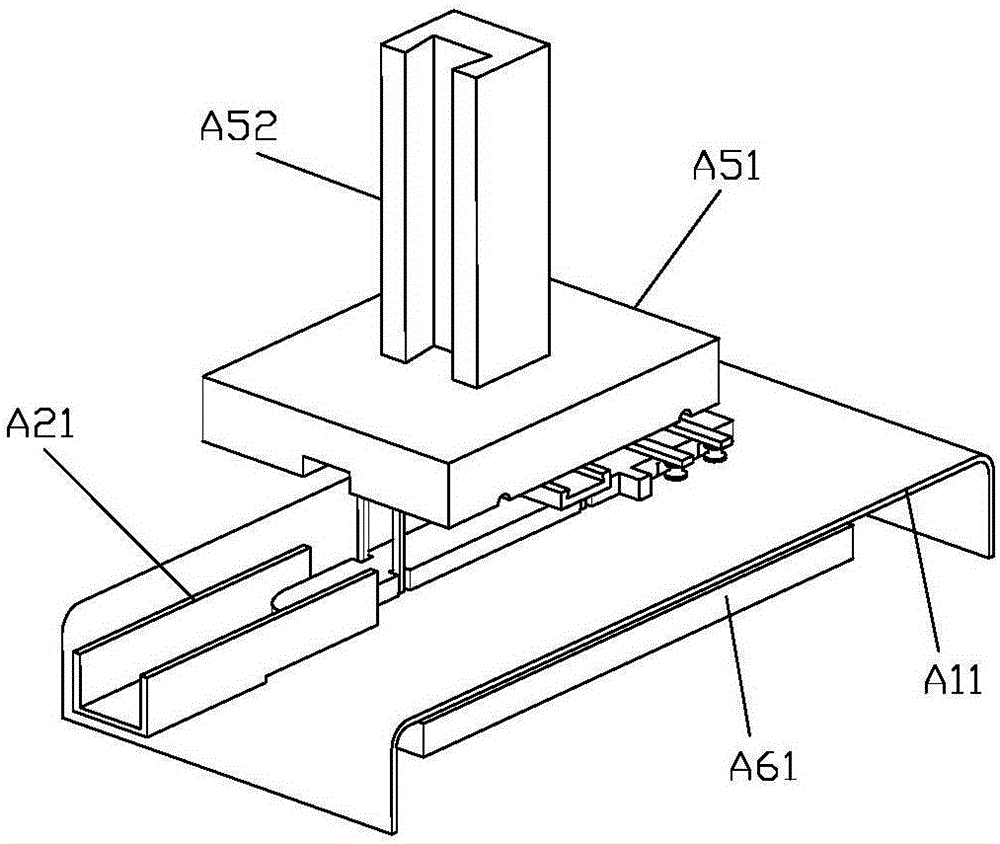

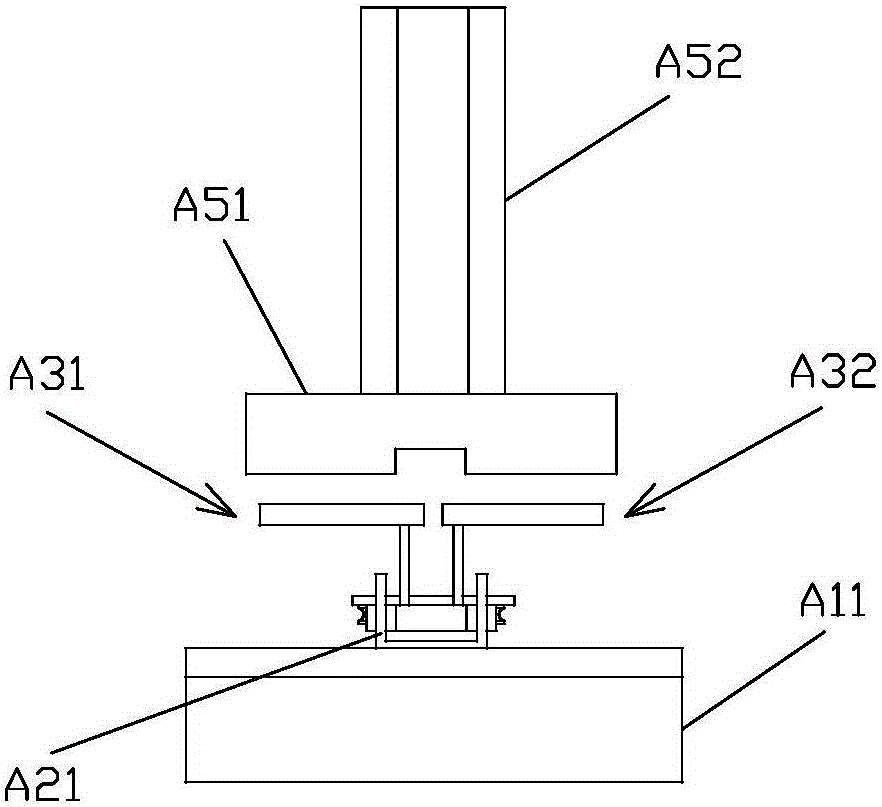

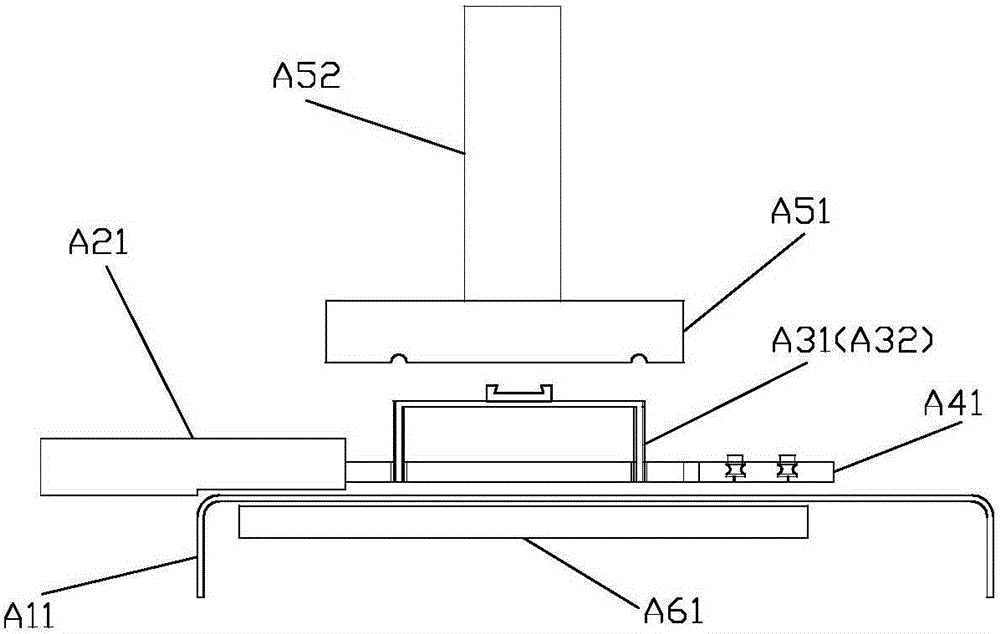

Jet flow generating apparatus, electronic apparatus, and jet flow generating method

InactiveCN1671279ASuppress noiseEffective spreadFlexible member pumpsIndirect heat exchangersJet flowEngineering

A jet flow generating apparatus that suppresses noise as much as possible and effectively radiates the heat generated by a heat generating member, an electronic device that is equipped with the jet flow generating apparatus, and a jet flow generating method are provided. According to the present invention, a jet flow generating apparatus comprises a plurality of chambers each having an opening and each containing a coolant, a vibrating mechanism for vibrating the coolant contained in each of the plurality of chambers so as to discharge the coolant as a pulsating flow through the openings, and a control unit for controlling the vibration of the vibrating mechanism so that the sound waves generated by the coolant discharged from the plurality of chambers weaken each other.

Owner:SONY CORP

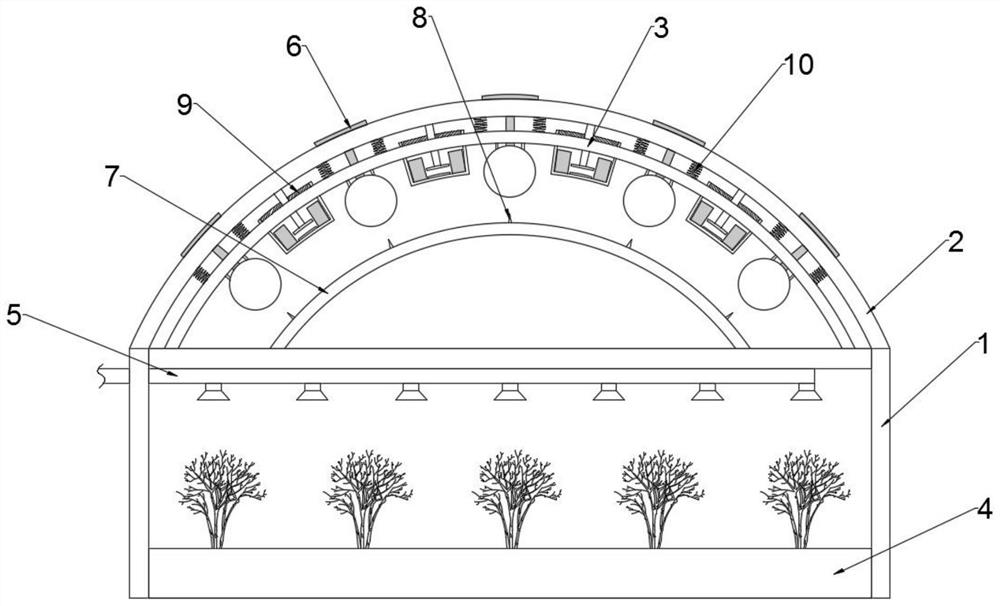

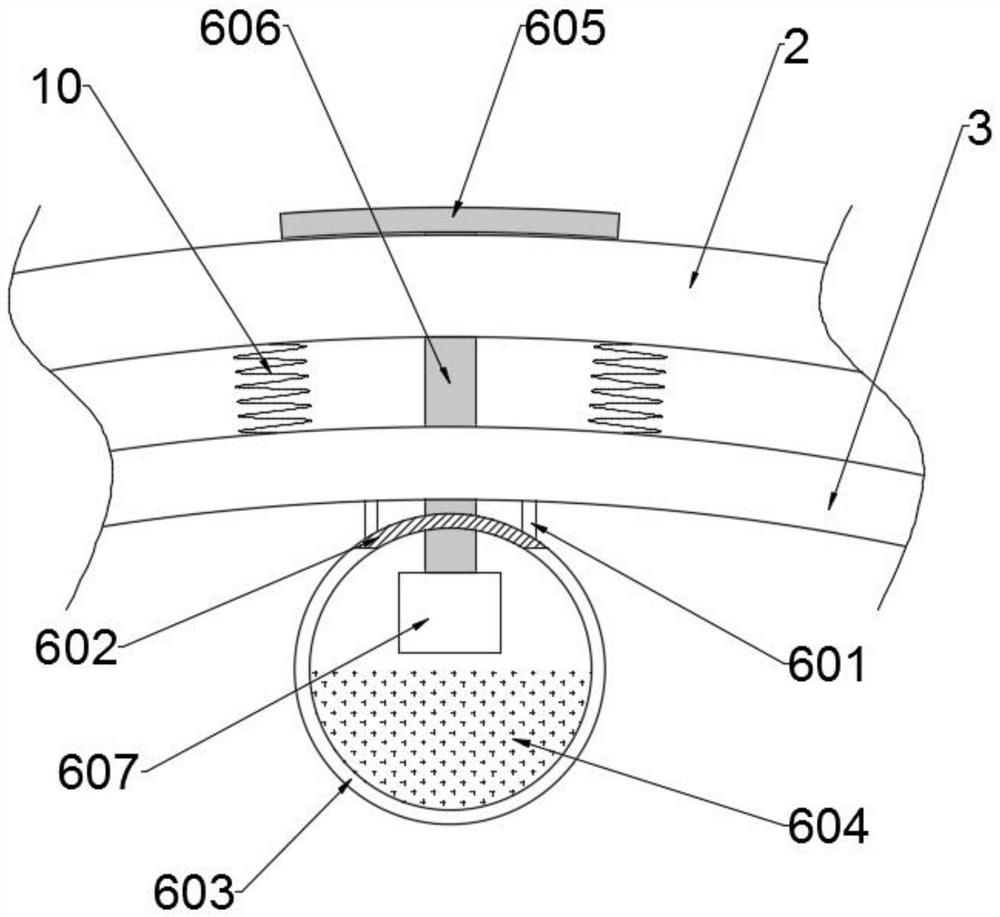

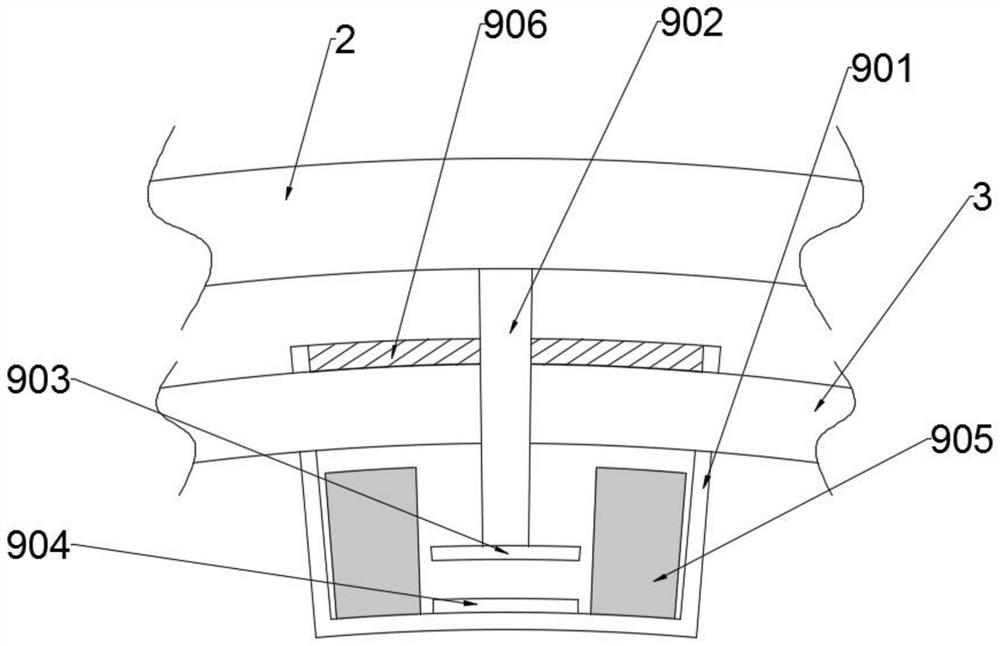

Self-adjusting greenhouse with automatic snow removing function

InactiveCN112655429AImprove thermal conductivityImprove fertilityClimate change adaptationFertiliser distributersSnowpackSnow removal

The invention discloses a self-adjusting greenhouse with an automatic snow removing function and belongs to the technical field of planting greenhouses. The self-adjusting greenhouse with an automatic snow removing function comprises a greenhouse body and a greenhouse roof fixed on an upper side of the greenhouse body, a planting groove is formed in an inner bottom of the greenhouse body, a supporting cross beam is fixed on a side wall of a top part of the greenhouse body, a surface of the greenhouse roof is covered with a PE film, the greenhouse roof is a flexible framework, a plurality of greenhouse roof supporting frameworks are fixed to the supporting cross beam in a length direction of the greenhouse body, a plurality of compression springs are connected between the greenhouse roof and the greenhouse roof supporting frameworks, a plurality of snow melting devices which are evenly distributed are arranged on each greenhouse roof supporting framework, and an auxiliary snow melting device is further arranged at a position, between every two adjacent snow melting devices, of the roof supporting framework. The double snow removing device can fully remove snow, avoids a phenomenon of snow accumulated on a roof, a nitrogen fertilizer beneficial to plant growth adjustment and carbon dioxide promoting plant photosynthesis can be sprayed in a snow removing process, and plant growth is effectively promoted.

Owner:倪丽华

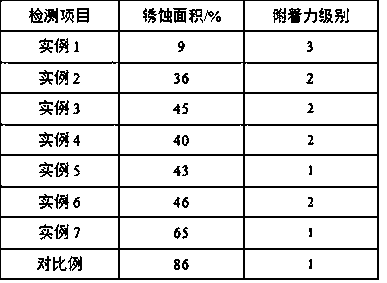

Water-based antirust liquid for metal

The invention discloses water-based antirust liquid for metal and belongs to the technical field of metal protection. The water-based antirust liquid comprises a polyvinyl alcohol solution, chitosan enzymatic hydrolysate, terephthalaldehyde, polyamide modified hydrogenated castor oil, chromium salt, organic acid, organic amine and an emulsifier. A preparation method of the water-based antirust liquid includes: stirring and mixing the polyvinyl alcohol solution and the chitosan enzymatic hydrolysate, sequentially adding the organic acid, the organic amine, the emulsifier, the polyamide modifiedhydrogenated castor oil and the chromium salt, stirring and mixing, adding the terephthalaldehyde, performing heating and stirring reaction, and discharging to obtain the water-based antirust liquid.The prepared water-based antirust liquid is lasting in antirust effect, good in adhesion, excellent in antirust effect and promising in application prospect in the development of metal protection industry.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Oxidization-resisting magnesium-containing aluminum alloy with working temperature of 400 to 500 DEG C for storing energy

The invention discloses an oxidization-resisting magnesium-containing aluminum alloy with working temperature of 400 to 500 DEG C for storing energy. The alloy is prepared from the following components in percentage by weight: 8.0 to 9.0 weight percent of Sn, 29.0 to 30.0 weight percent of Mg, 14.0 to 15.0 weight percent of Si, 0.5 to 0.8 weight percent of In, 0.1 to 0.2 weight percent of P, 1.0 to 1.2 weight percent of Mn and the balance of aluminum. The material provided by the invention provides a magnesium-containing multi-element near-eutectic alloy solution for the field of energy storage of alloys; an alloy melt has excellent oxidization-resisting performance, thermal cycling performance and thermophysical performance. The current situation that the related performance of current Al-Mg binary eutectic alloys is not enough at present can be effectively overcome, and extremely great market value can be obtained while industrial problems in the field of heat storage are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

A method for preparing large-area perovskite thin films and battery components thereof

ActiveCN109103338BEfficient extractionReduce extractionSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionMetallic electrode

The present invention is the field of perovskite solar cells, which involves a preparation method for a large -scale perovskite film and its battery components.The method of preparation includes: cleaning the transparent conductive substrate and drying for later use; the chemical bath method sedimentation tin oxide electronic transmission layer; the slits are squeezed out of the scraping method evenly coated with the ingot osteotomy front drive body solution, and then use the rotary coating to move the drip drip.Anti -solvent method treatment obtains perovskite absorption layer; uses green solvents to prepare SPIRO‑Oometad solution, use slits to extract the scratch coating method on the osteotic lighting layer to prepare the empty acupoint transmission layer, and finally steamed on the cave transmission layer.Metal electrode.The present invention uses a slit to squeeze out and scratch the oscope oremine anterior drive body solution, which can effectively spread the perovskite solution and save dosage; further use the mobile dripping solvent method to evenly move the anti -solvents on the perxonic film, which can be effectively moved to effectiveThe extraction area of the perovskin film is widened, and the amount of anti -solvent is saved.

Owner:广东光晶能源科技有限公司

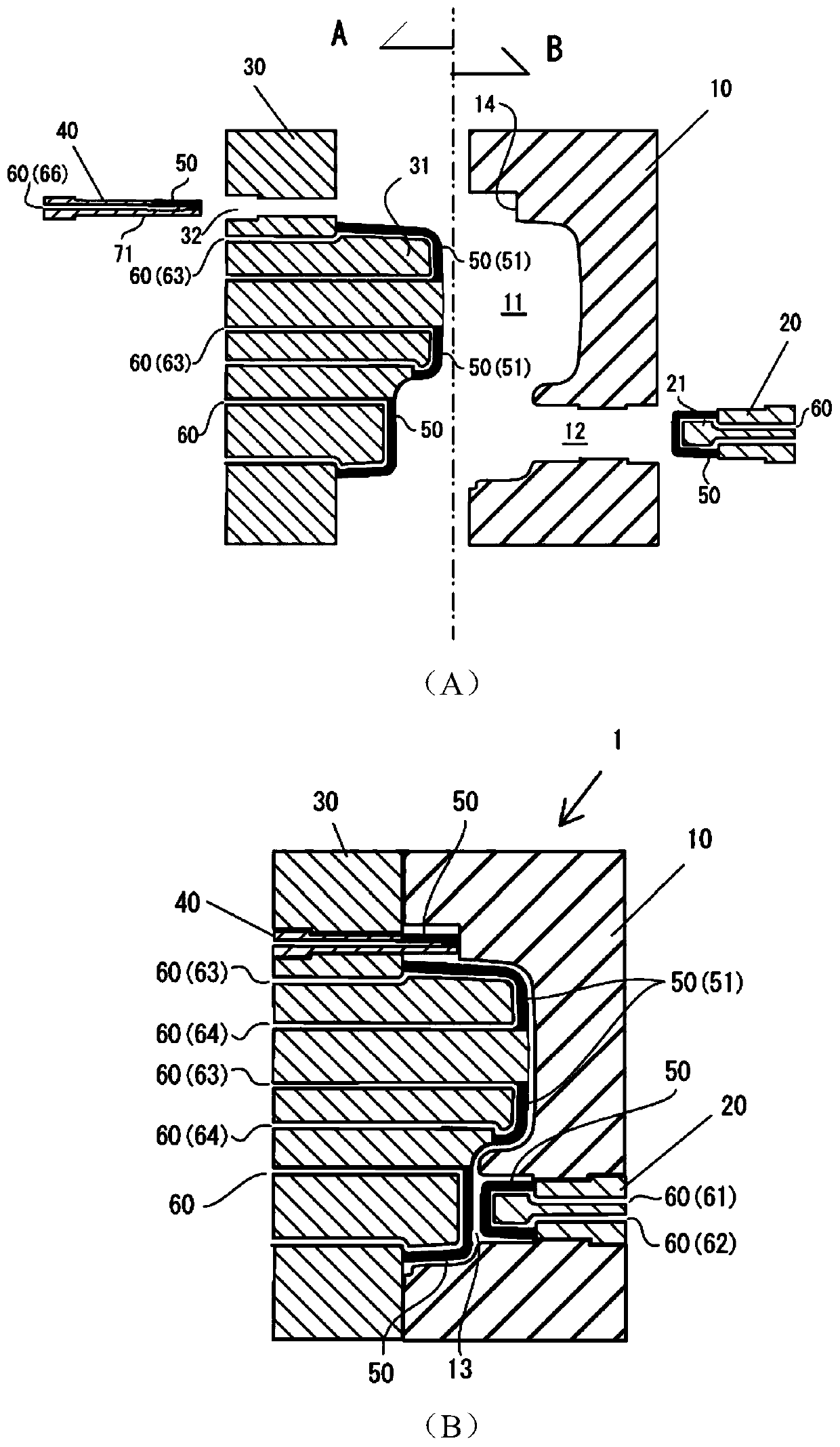

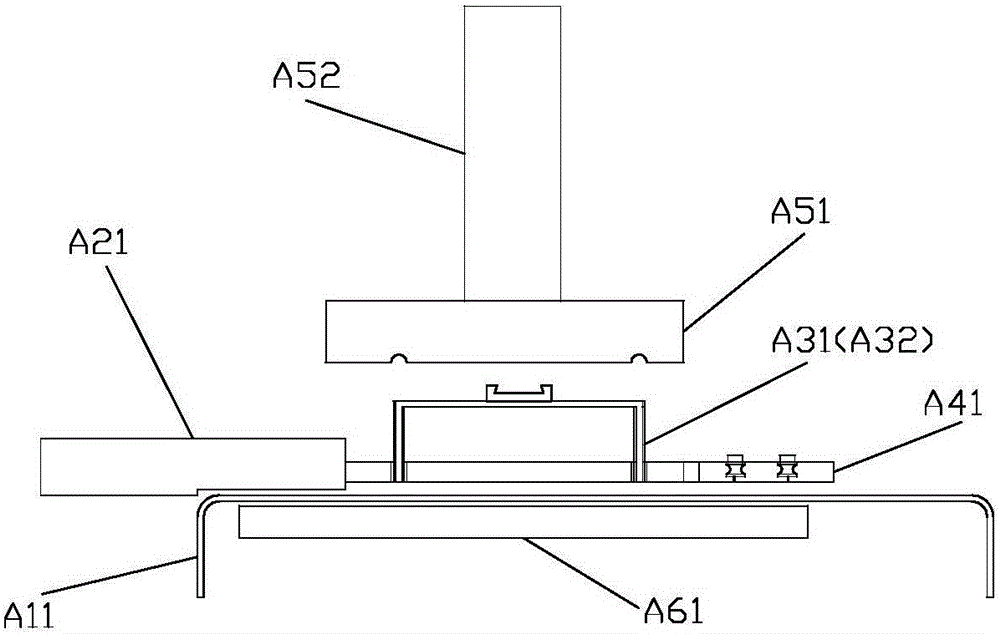

Mold and molding system

Owner:SHIPPO KANAGATA INDS

Processing device for environment-friendly gift box production raw materials

InactiveCN106003294AEffective spreadReliable supportWood treatment detailsCane mechanical workingEngineeringRaw material

The invention relates to a processing device for environment-friendly gift box production raw materials. A liquid removal device for removing cooking liquor on cooked bamboo shells is arranged on the side of a cooking device. The liquid removal device comprises an inner cylinder and an outer cylinder. The inner cylinder is rotationally fixed in the outer cylinder. A drive mechanism G drives the inner cylinder to rotate. Meshes are evenly formed in the barrel wall of the inner cylinder. The diameter of the inner cylinder is matched with the outer diameter of a frame body. By means of the above technical scheme, the bamboo shells can be effectively spread and unfolded, and reliable support is provided for processing and utilizing of the bamboo shells.

Owner:王寿南

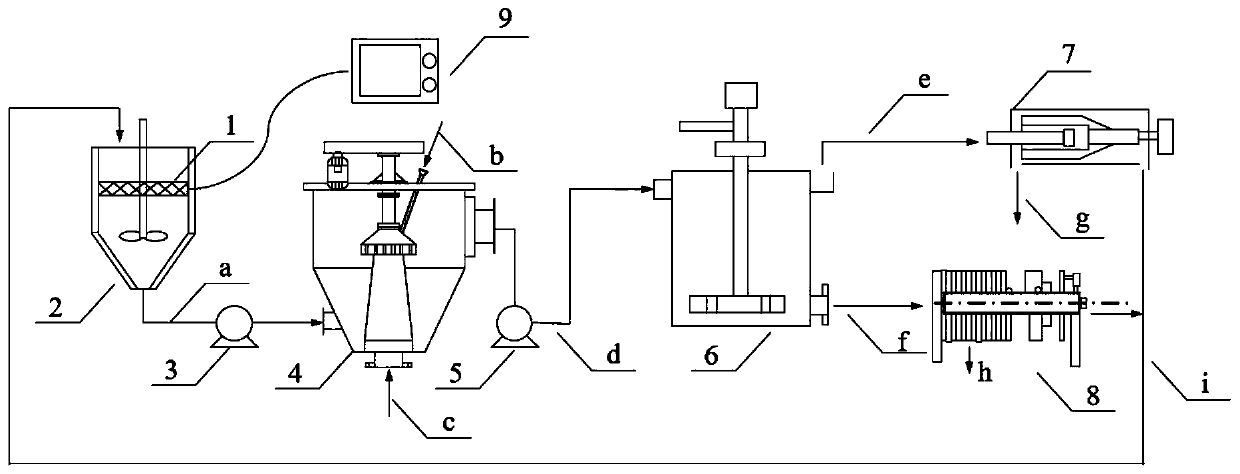

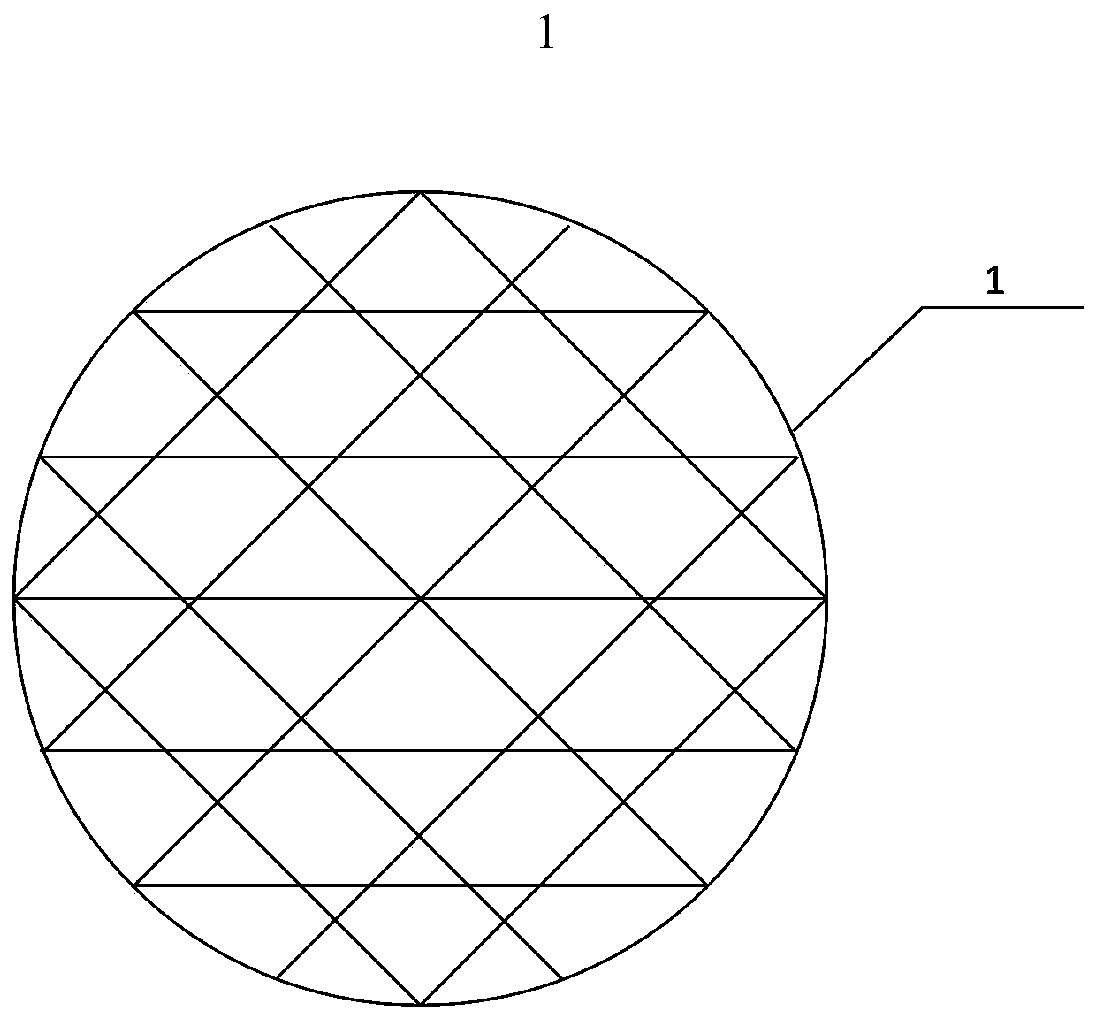

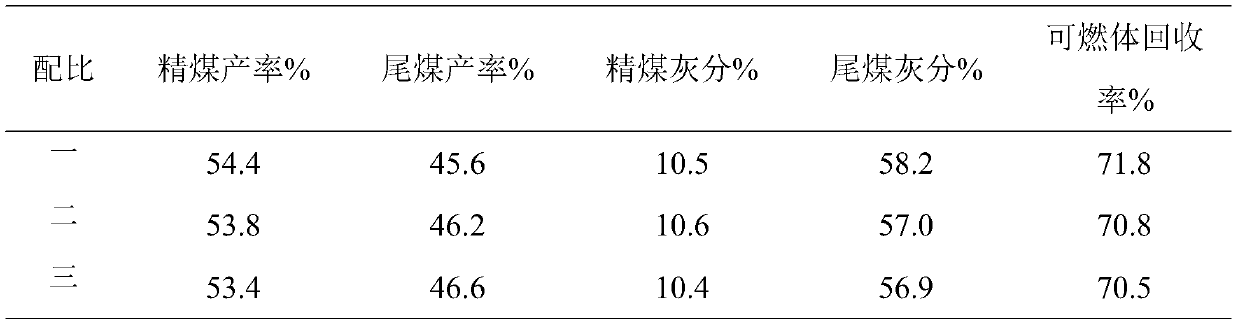

Polar mixed reagent for low-rank coal flotation and flotation process

A polar mixed reagent for low-rank coal flotation and a flotation process are suitable for the technical field of low-rank coal mining. The polar mixed reagent is prepared from the following raw materials in parts by mass: 30-44 parts of short-chain ester, 30-44 parts of n-caprylic acid, 3 parts of sec-octyl alcohol, 7 parts of fatty acid polyoxyethylene ether, 5 parts of Tween 40, 4 parts of span80 and 7 parts of CuSO4. During use, the reagent is fully and uniformly mixed in an aqueous solution in advance by using a stirring barrel and ultrasonic waves emitted by an ultrasonic plate. The reagent consumption is low, the flotation recovery rate is increased, different types of reagent molecules are fully dispersed into an ore pulp solution, the size of collecting agent oil drops is reduced, the reagent can be more efficiently and effectively spread on the surfaces of coal particles, the action efficiency of the reagent is greatly improved, the recovery rate of clean coal is increased,and pollution to the coal-series environment is reduced.

Owner:CHINA UNIV OF MINING & TECH +2

High-performance aluminum section radiator

PendingCN108684194AImprove cooling efficiencyImprove cooling effectModifications by conduction heat transferFlangingTroffer

Owner:江苏英杰铝业有限公司

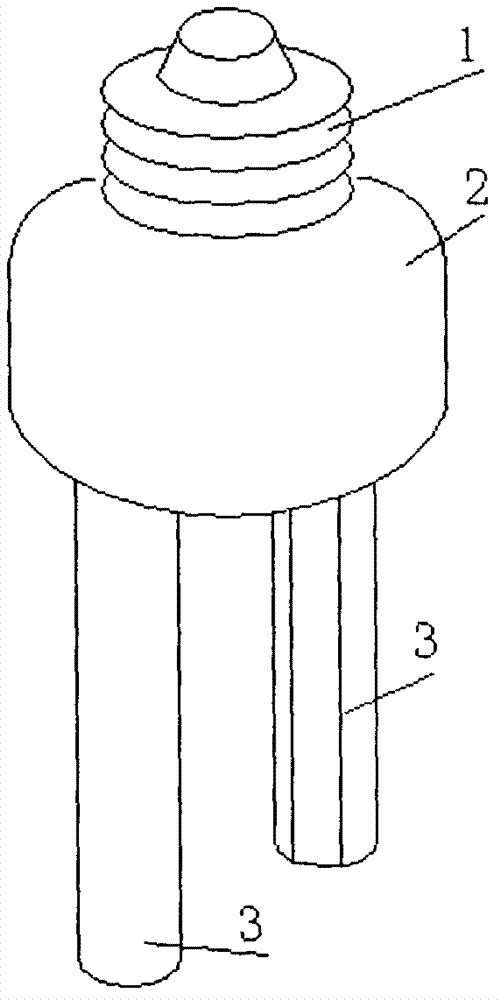

Socket-type LED (light-emitting diode) illuminating lamp

InactiveCN102853294AEffective spreadDoes not affect lifespanPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight fixture

The invention discloses a socket-type LED (light-emitting diode) illuminating lamp which adopts an LED lamp strip to assemble. The lamp adopts an LED lamp bead heat dissipation structure composed of the LED lamp strip with a heat dissipation function and a metal connecting plate with good heat dissipation, the heat generated by an LED lamp bead is effectively dispersed, and the socket-type LED illuminating lamp can not influence service life because of the heating problem. Meanwhile, the socket-type LED illuminating lamp and the traditional socket type lamp are completely same in structure, the structure is simple, the cost is low, and the socket-type LED illuminating lamp is suitable for popularizing and using.

Owner:陈林

Oxidization-resisting strontium-containing aluminum alloy with working temperature of 300 to 400 DEG C for storing energy

InactiveCN109234589AInhibition of internal diffusionImprove heat transfer performanceStrontiumWorking temperature

The invention discloses an oxidization-resisting strontium-containing aluminum alloy with working temperature of 300 to 400 DEG C for storing energy. The alloy is prepared from the following components in percentage by weight: 18.0 to 19.0 weight percent of Zn, 0.8 to 1.2 weight percent of Sr, 4.0 to 5.0 weight percent of Ge, 0.4 to 0.6 weight percent of In, 0.1 to 0.2 weight percent of S, 1.4 to1.6 weight percent of Co and the balance of aluminum. The material provided by the invention provides a strontium-containing multi-element near-eutectic alloy solution for the field of energy storageof alloys; an alloy melt has excellent oxidization-resisting performance, thermal cycling performance and thermophysical performance. The current situation that the related performance of current Al-Zn binary eutectic alloys is not enough at present can be effectively overcome, and extremely great market value can be obtained while industrial problems in the field of heat storage are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Digestible special laying-hen fodder capable of effectively enhancing immunity

InactiveCN106360081AAchieve protectionAchieve sustained releaseFood processingAnimal feeding stuffEmbryoFructooligosaccharide

The invention discloses digestible special laying-hen fodder capable of effectively enhancing immunity. The digestible special laying-hen fodder includes, by weight, 15-25 parts of cotton seed meal, 25-45 parts of soybean powder, 10-20 parts of milled rice with embryos, 10-15 parts of corn, 10-20 parts of shrimp meal, 15-25 parts of wheat protein powder, 3-7 parts of sodium carboxymethylcellulose, 3-7 parts of soybean oil, 1-2 parts of ginger, 1-2 parts of malic acid, 0.8-1.2 parts of choline chloride, 1.5-2.5 parts of soybean oligosaccharides, 0.5-1 part of fructooligosaccharide, 5-15 parts of enveloped vitamin E, 2-5 parts of gravel and 3-6 parts of soybean straw. The digestible special laying-hen fodder has the advantages of high disease resistance, uniformity in nutrition, digestibility and non-environment pollution.

Owner:全椒县金凤凰禽业养殖专业合作社

Laying hen feed with balanced nutrition and strong disease resistance

InactiveCN106376767AOvercome peptide chain cross-linking and bad flavorImprove solubilityAnimal feeding stuffAccessory food factorsXyloseDigestion

The invention discloses a laying hen feed with balanced nutrition and strong disease resistance. The laying hen feed comprises the following raw materials in parts by weight: 20-40 parts of sorghum powder, 10-20 parts of corn flour, 5-15 parts of cabbage caterpillar powder, 7-13 parts of earthworm, 12-24 parts of wheat, 5-15 parts of oatmeal, 1-4 parts of gravel, 1-3 parts of clay, 2-10 parts of coating vitamin E, 1-5 parts of carboxymethylcellulose sodium, 1-5 parts of corn oil, 0.5-1.2 parts of ginger, 0.5-1.5 parts of malic acid, 0.2-0.8 parts of xylo oligosaccharide, 1-2 parts of isomaltose oligosaccharide, and 0.2-0.6 parts of choline chloride. The laying hen feed has the advantages of strong disease resistance, balanced nutrition, easy digestion, and non environmental pollution.

Owner:全椒县金凤凰禽业养殖专业合作社

Traditional Chinese medicine for treating peptic ulcers in internal medicine department of traditional Chinese medicine

InactiveCN108355104AAchieve the purpose of healingWon't repelHeavy metal active ingredientsDispersion deliveryDiseasePeptic ulcer

The invention discloses a traditional Chinese medicine for treating peptic ulcers in an internal medicine department of traditional Chinese medicines. The traditional Chinese medicine comprises the following raw materials in part by weight: 5-8 parts of black alum, 5-6 parts of pinellia ternata, 3-5 parts of walnut kernels, 3-5 parts of inula flower, 4-7 parts of cuttle bone, 3-8 parts of fructusamomi, 10-20 parts of mangnolia officinalis, 15-20 parts of rhizoma sparganii, 1-5 parts of pangolin, 5-10 parts of medicated leaven, 5-10 parts of malt, 10-15 parts of honey, 2-5 parts of bear gall powder and 10-20 parts of lignum aquilariae sinensis from Hainan. The traditional Chinese medicine for treating the peptic ulcers, prepared by the invention, can treat multiple diseases, is suitable for all ages, cannot be rejected by bodies, effectively disperses and lowers cold and heat accumulated in spleens and stomachs, plays soothing and defecating roles and further can repair mucosa on innerwalls of the spleens and the stomachs, thereby effectively gradually restoring the functions of the spleens and the stomachs and achieving the purpose of healing the ulcer surface.

Owner:李雪

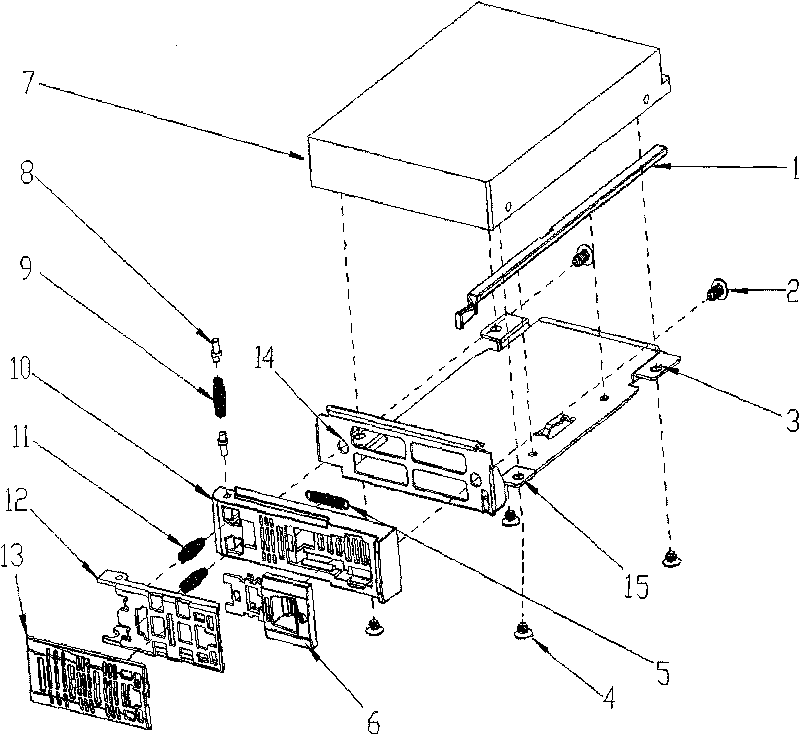

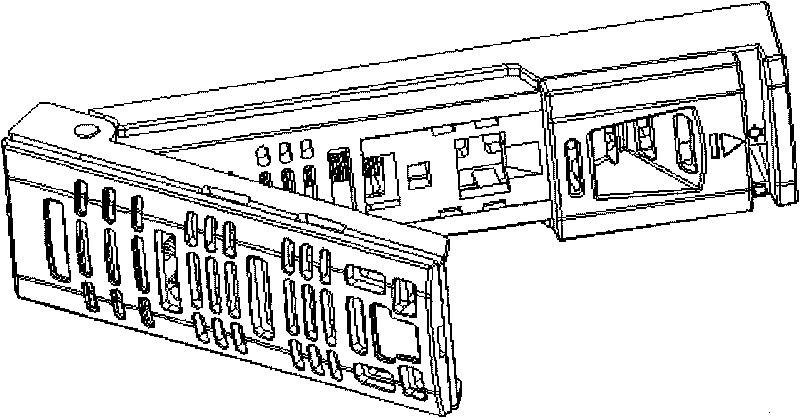

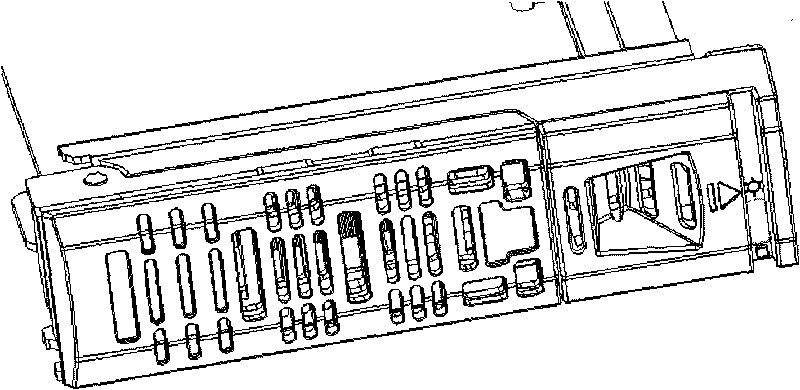

Hot plug device for 2.5 inch hard disc

InactiveCN101692345AReduce volumeEasy to assembleCarrier constructional parts dispositionRecord information storageServer roomFront panel

The invention discloses a hot plug device for 2.5 inch hard disc, comprising a hard disc tray, a front panel assembling device and a 2.5 inch hard disc, and belonging to the technical field of computer external equipment. The invention is characterized in that: one end of the hard disc tray is provided with a front panel locating rack, the front panel assembling device is fixed and mounted by the front panel locating rack, and the 2.5 inch hard disc fixed and mounted on the hard disc tray. The inventive hot plug device utilizes a simple buckling structure to mount the hard disc, thus reducing hard disc mounting time; the inventive hot plug device has a smaller volume, thus realizing mounting more hard discs in 1U PC server or 2U PC server room, e.g. 12 groups of hot plug devices for 2.5 inch hard disc can be mounted in 1U room in a structure of an upper layer and a lower layer with six groups in each layer, thus saving sever room; storage capacity is increased in the same room, thus meeting requirements of people. The invention has good commonality, and is suitable for 2.5 inch hard discs of various specifications.

Owner:昆山力盟机械工业有限公司

Equipment for treating packing box production raw materials

InactiveCN106003292AEffective spreadReliable supportWood compressionWood treatment detailsUniversal jointEngineering

The invention relates to a device for processing raw materials for packaging box production. A dehydration rack for removing the cooking liquid from the cooked bamboo shells is arranged on the side of the cooking device, and a cooking liquid collecting tank is arranged on the lower side of the dehydration rack. , the dehydration frame includes a dehydration support platform and a base for supporting the fence frame, support rods are respectively arranged around the dehydration support platform, and an installation sleeve is provided on the upper end of the support rod, and the installation sleeve is installed on the upper end of the support rod through the empty sleeve of the installation component , the inner diameter of the installation sleeve is larger than the outer diameter of the top of the support rod, the surroundings of the dehydration support table are fixedly connected with the installation sleeve respectively, the lower end of the support rod is connected with the base through a universal joint, and the dehydration support table is connected to the drive for reciprocating swing Body F is connected. The above technical scheme can effectively spread the bamboo shells, and provide reliable support for the processing and utilization of the bamboo shells.

Owner:胡刘满

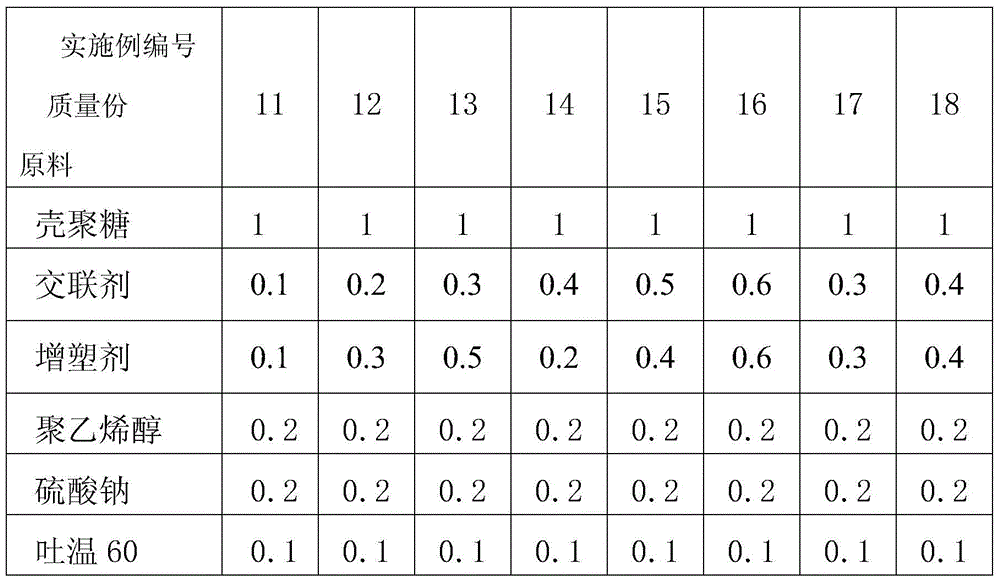

A kind of preparation method of chitosan modified starch type sizing agent

Owner:SOUTHWEAT UNIV OF SCI & TECH

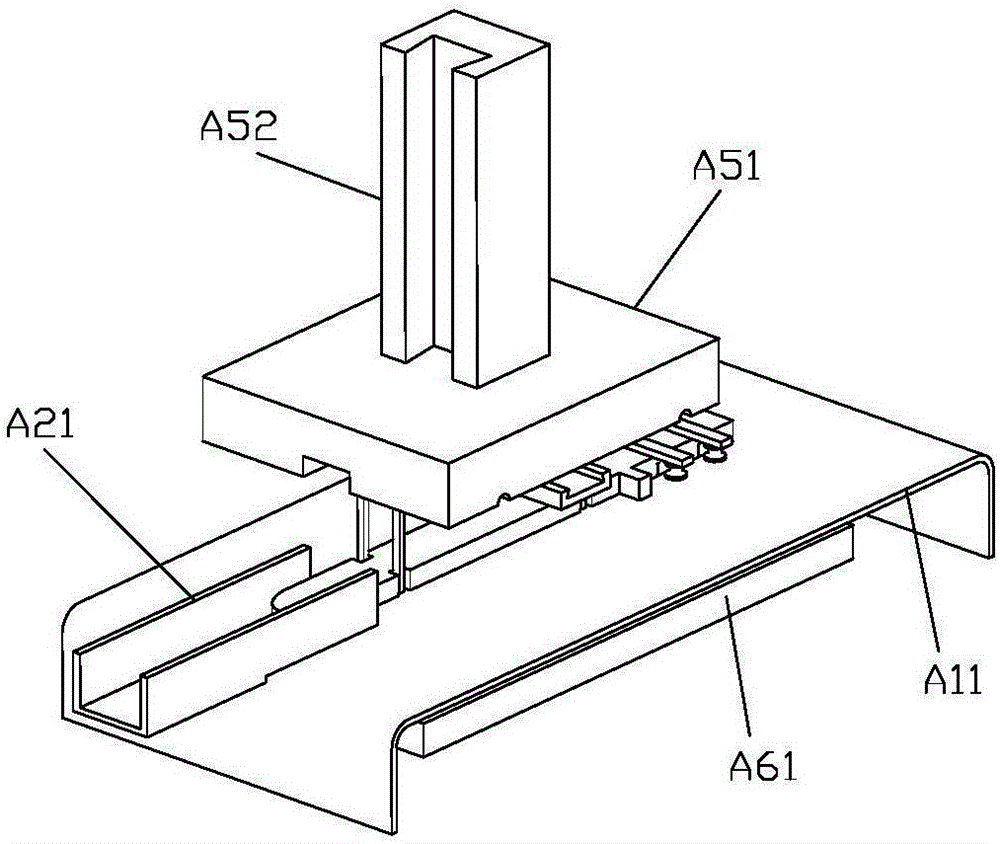

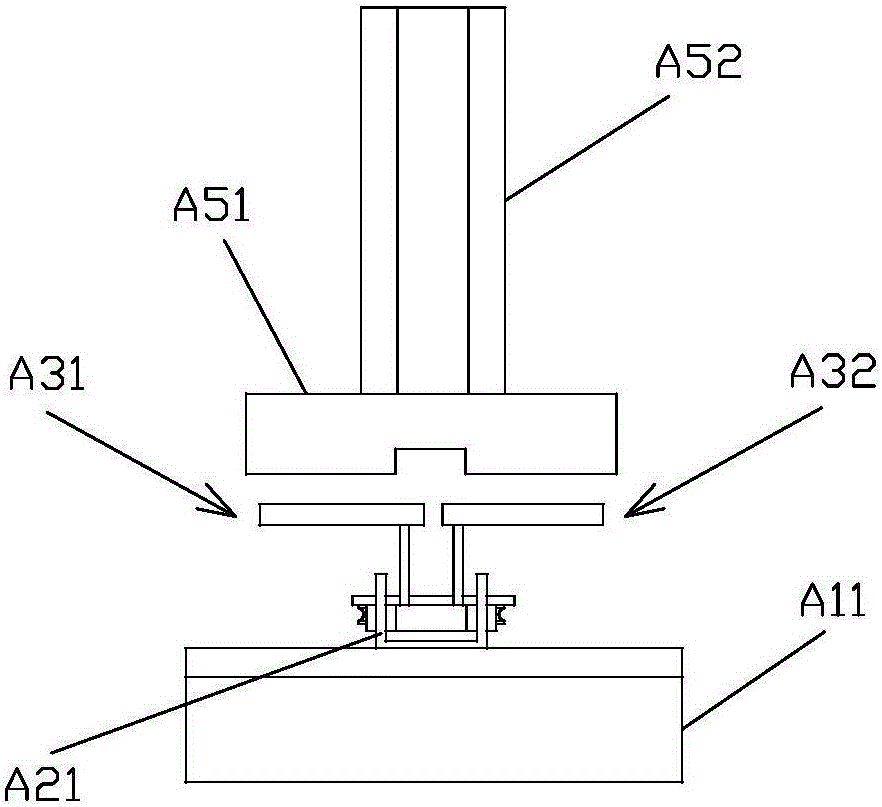

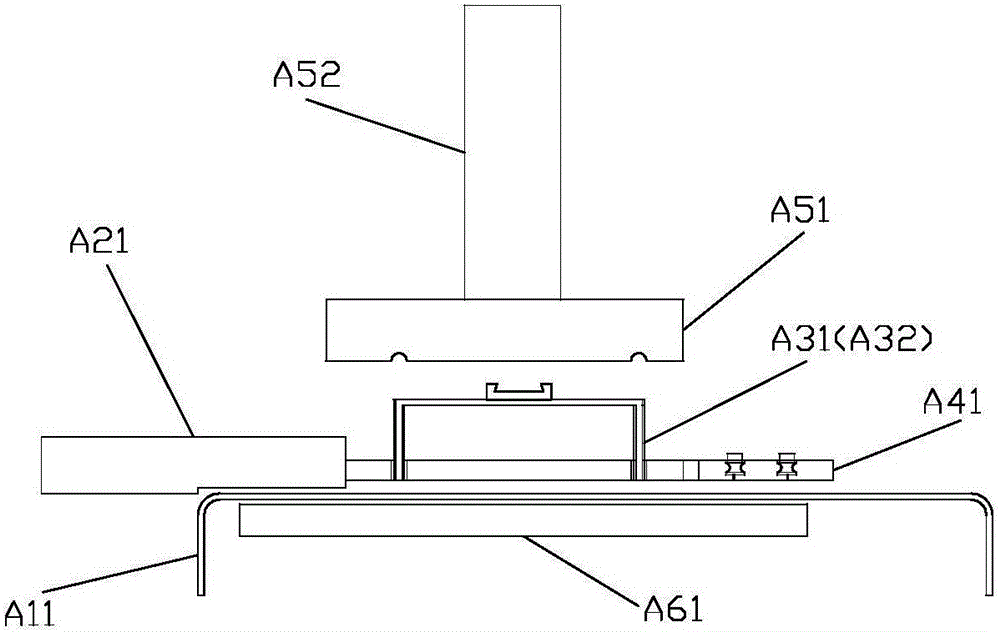

Unfolding machine

The invention relates to a spreading machine, which is used for spreading bamboo shells, including a frame A and a feeding mechanism set on the frame A, the feeding mechanism includes a bamboo shell conveyor belt for transporting bamboo shells, bamboo shells The shell conveyor belt is connected with the driving mechanism A, and the feeding end of the bamboo shell conveyor belt is provided with a bamboo shell feeding trough for pushing bamboo shells to the bamboo shell conveyor belt, and the length direction of the bamboo shell feeding trough is consistent with the conveying of the bamboo shell conveyor belt. The direction is the same, the inner surface of the bottom of the bamboo shell feeding trough is flush with the conveying surface of the upper layer of the bamboo shell conveyor belt, and the two groove walls of the bamboo shell feeding chute are extended to the inside of the bamboo shell conveyor belt. A spreading mechanism for spreading the bamboo shells and a hot pressing mechanism for hot pressing and shaping the bamboo shells after spreading are arranged above the bamboo shell conveyor belt. The above technical scheme can effectively spread the bamboo shells, and provide reliable support for the processing and utilization of the bamboo shells.

Owner:胡刘满

Preprocessing method for packaging box raw material

InactiveCN105922396AEffective spreadReliable supportWood treatment detailsCane mechanical workingPretreatment methodRemoving hair

The invention relates to a preprocessing method for a packaging box raw material. Hair removal in the step S1 is conducted in a hair removal device. The air removal device comprises a machine frame B and a hair removal drum obliquely arranged on the machine frame B. A feed port and a discharge port are formed in the two ends of the hair removal drum. Protruding ribs are arranged on the inner wall face of the hair removal drum. The length direction of the protruding ribs is consistent with the length direction of the hair removal drum. The protruding ribs are arranged on the inner wall of the hair removal drum in the length direction of the hair removal drum in a layered manner. The protruding ribs of every two adjacent layers are arranged at intervals in a staggered manner. The hair removal drum is connected with a drive mechanism E. The inclination angle of the hair removal drum ranges from 2 degrees to 5 degrees. By means of the technical scheme, bamboo shells can be effectively spread, and reliable support is provided for machining and utilizing of the bamboo shells.

Owner:胡刘满

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com