Polar mixed reagent for low-rank coal flotation and flotation process

A technology of mixed reagents and low-rank coal, which is applied in flotation, solid separation, etc., can solve the problems of hindering the adsorption and spreading of oil collector molecules, low degree of deterioration, and poor adsorption effect, and achieves significant production economic benefits, The effect of reducing pollution and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

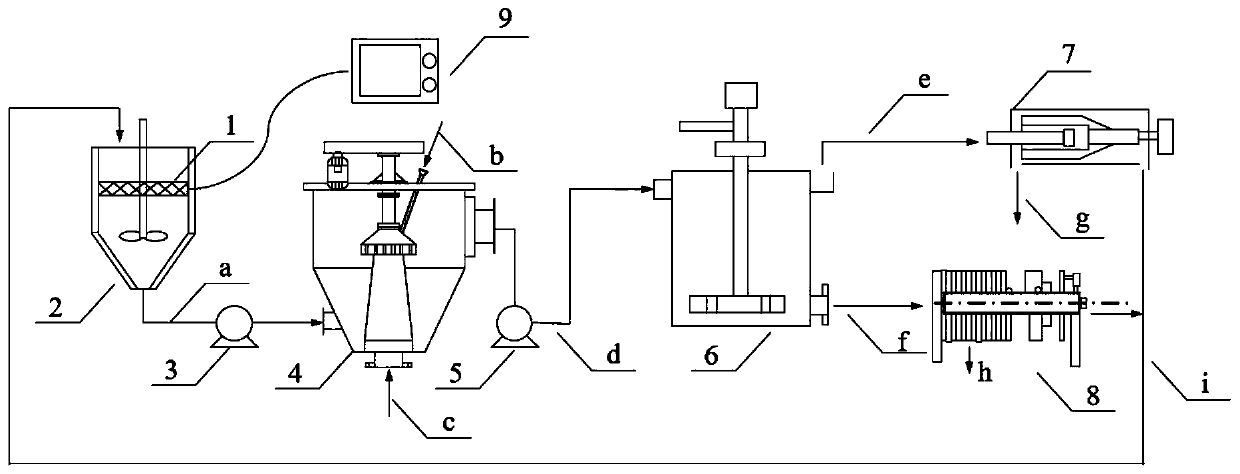

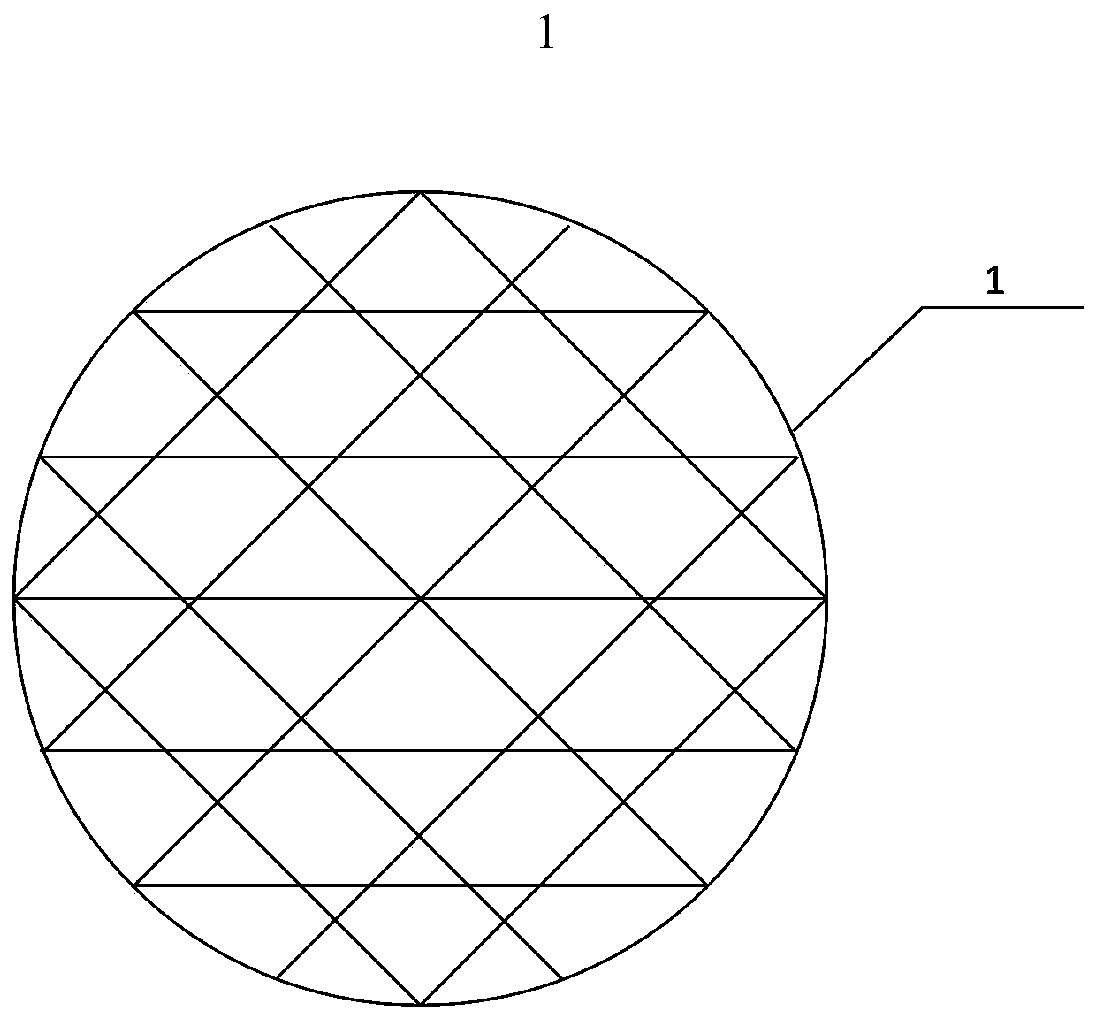

[0025] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as figure 1 As shown, the low-rank coal flotation of the present invention uses a polar mixed agent, and its raw material composition is calculated in parts by mass: short-chain ester: 30-44 parts, n-octanoic acid: 30-44 parts, sec-octanol: 3 parts, Fatty acid polyoxyethylene ether: 7 parts, Tween 40: 5 parts, Span 80: 4 parts, CuSO 4 : 7 servings.

[0027] Specifically, the weight ratio of the polar mixed agent used for low-rank coal flotation includes:

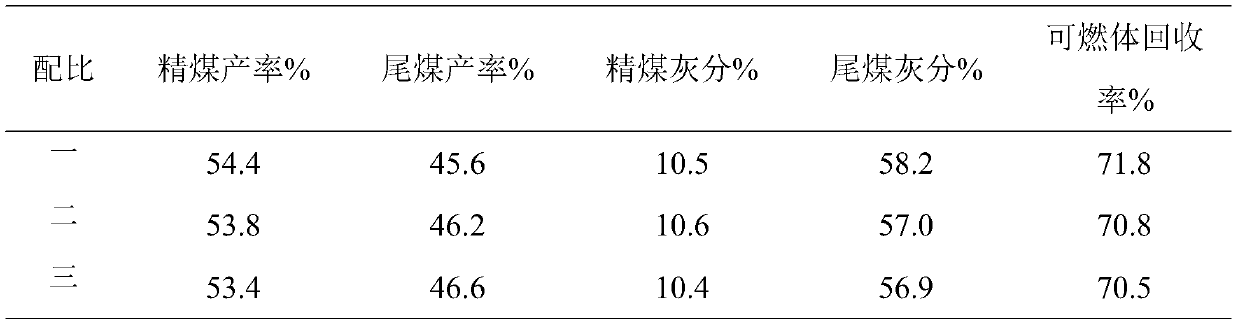

[0028] 1. Short-chain ester: 30 parts, n-octanoic acid: 44 parts, 2-octanol: 3 parts, fatty acid polyoxyethylene ether: 7 parts, Tween 40: 5 parts, Siban 80: 4 parts, CuSO 4 : 7 servings.

[0029] 2. Short-chain ester: 44 parts, n-octanoic acid: 30 parts, secondary octanol: 3 parts, fatty acid polyoxyethylene ether: 7 parts, Tween 40: 5 parts, Sipan 80: 4 parts, CuSO 4 : 7 servings.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com