Patents

Literature

174results about How to "Less dosage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

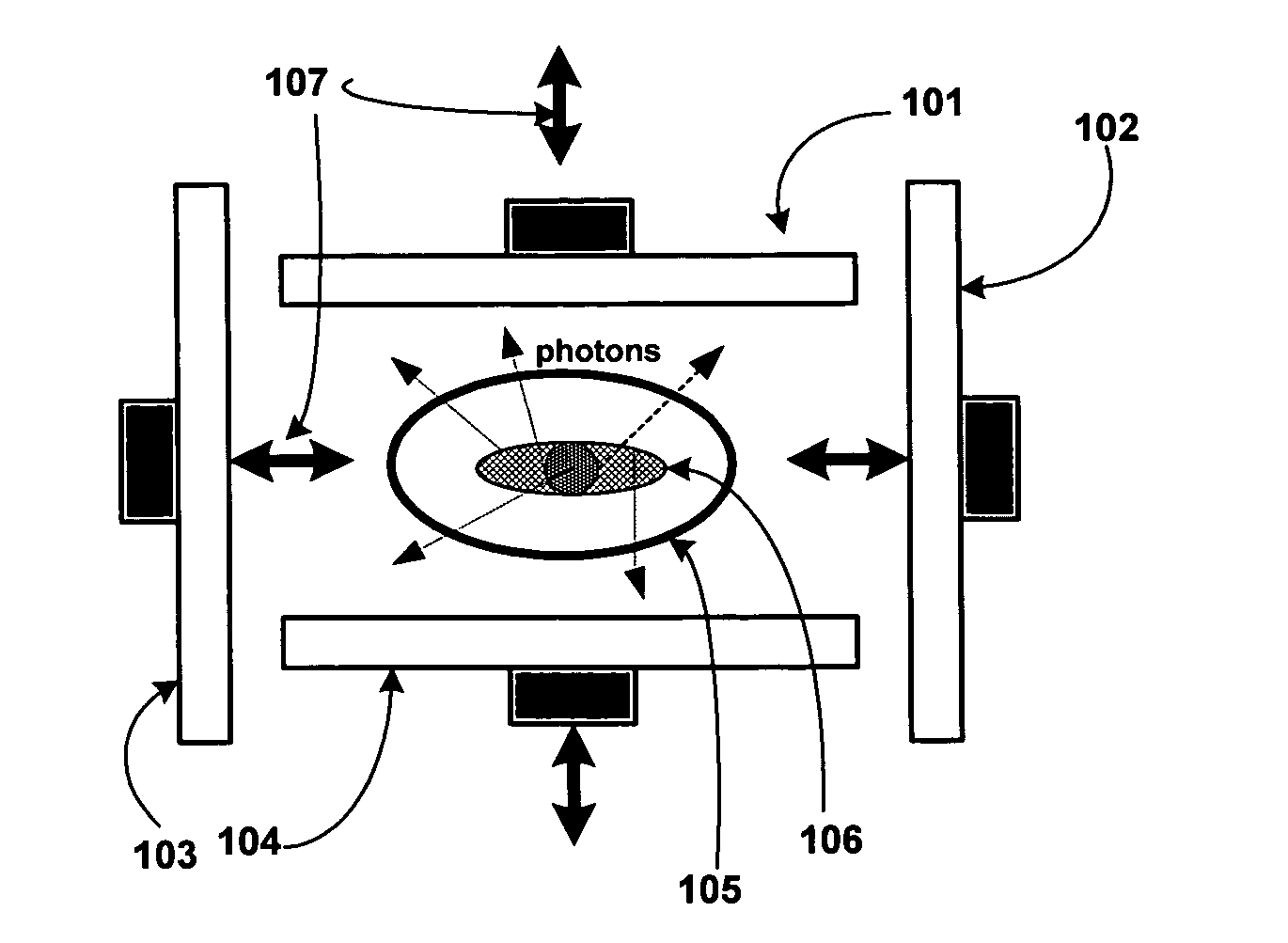

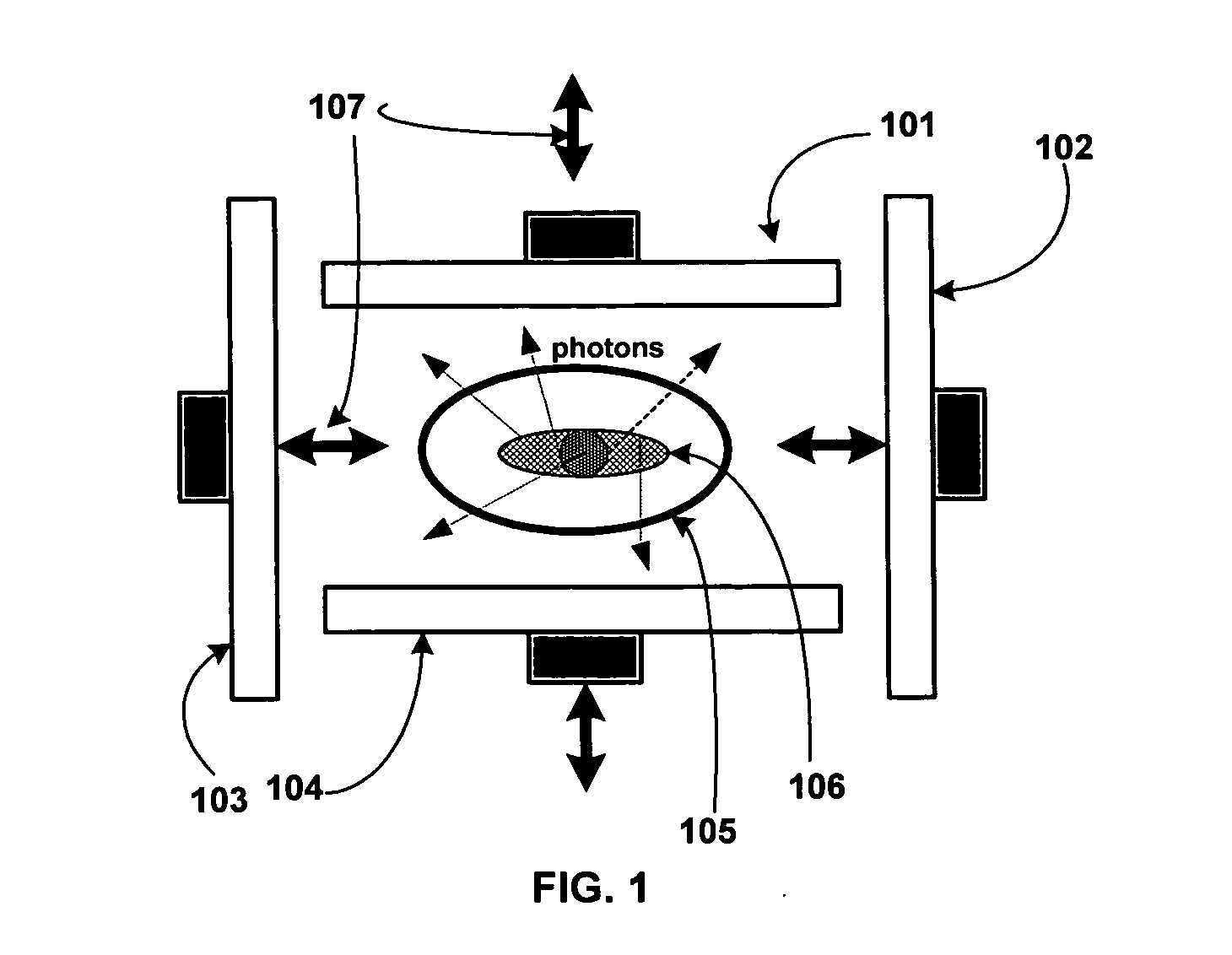

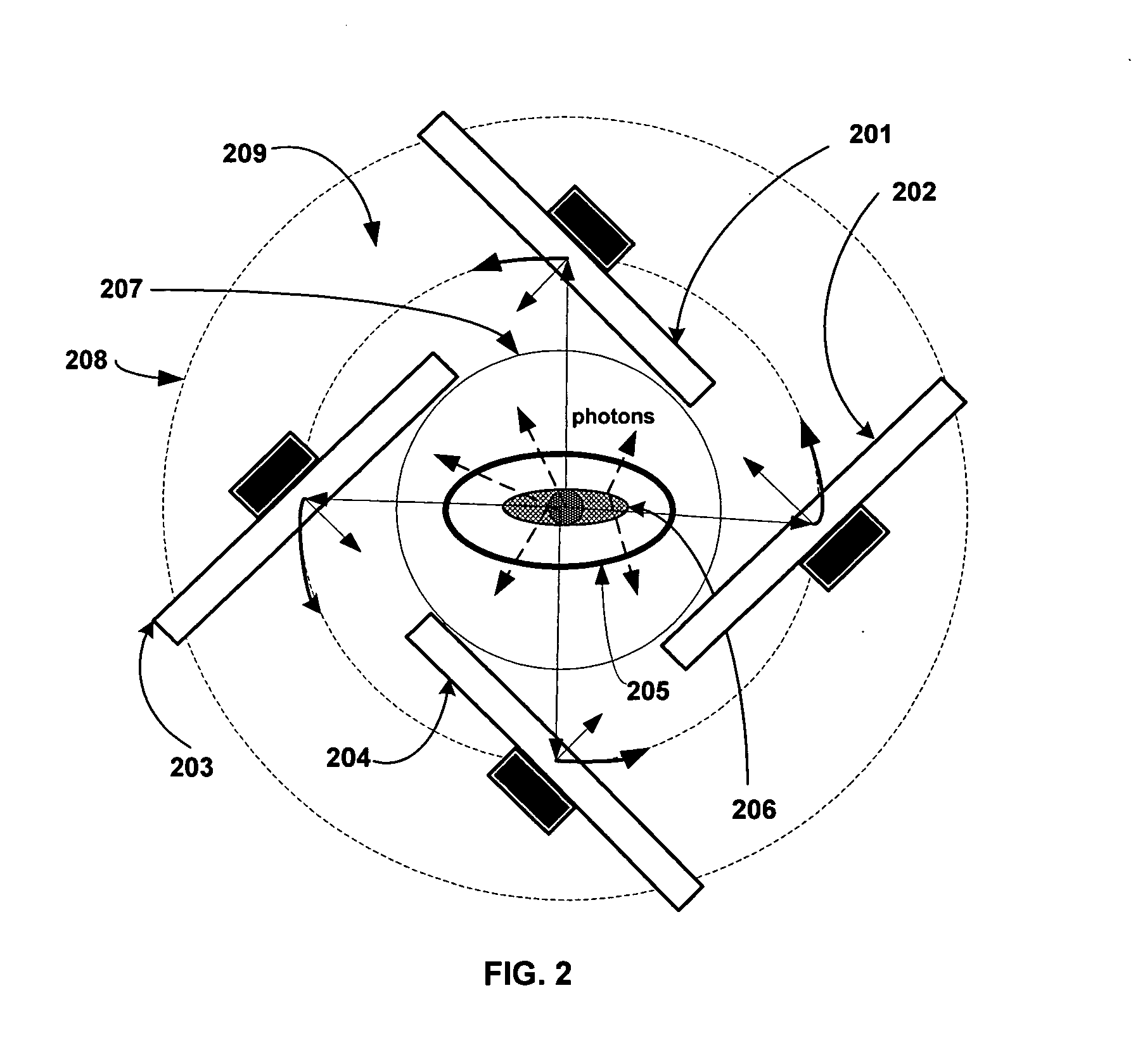

Method and apparatus for high-sensitivity Single-Photon Emission Computed Tomography

ActiveUS20110073763A1Facilitates higher qualityAccurate clinical diagnosisMaterial analysis using wave/particle radiationRadiation/particle handlingPhoton emissionSystem matrix

A method and apparatus are disclosed for high-sensitivity Single-Photon Emission Computed Tomography (SPECT), and Positron Emission Tomography (PET). The apparatus includes a two-dimensional (2D) gamma detector array that, unlike a conventional SPECT machine, moves to different positions in a three-dimensional (3D) volume space near an emission source and records a data vector g which is a measure of gamma emission field. In particular, the 3D volume space in which emission data g is measured extends substantially along a radial direction r pointing away from the emission source, and unlike a conventional SPECT machine, each photon detector element in the 2D gamma detector array is provided with a very large collimator aperture. Data g is related to the 3D spatial density distribution f of the emission source, noise vector n, and a system matrix H of the SPECT / PET apparatus through the linear system of equations g=Hf+n. This equation is solved for f by a method that reduces the effect of noise.

Owner:SUBBARAO MURALIDHARA

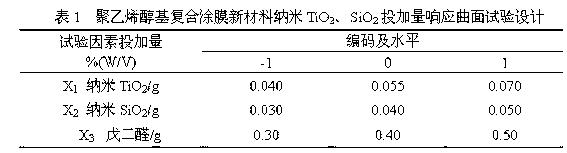

Polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method

ActiveCN103031026AImprove antibacterial and fresh-keeping functionChange hydrophilicityCoatingsPolyvinyl alcoholMoisture permeability

The invention relates to a polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method, which comprises the following steps: adding nano TiO2 and SiO2 into a polyvinyl alcohol aqueous solution and stirring; carrying out ultrasonic mixing on a mixed liquor; placing the mixed solution in a reaction kettle after ultrasonic; heating, stirring and reacting at constant temperature; adding stearic acid-alcohol mixed solution and glutaraldehyde with the same temperature and stirring; and carrying out cross-linking reaction at a constant temperature; stirring and cooling to a room temperature after reaction, so as to prepare into a nano composite coating new material. With the adoption of the polyvinyl alcohol radical composite coating fresh keeping packaging material nano TiO2 functional modification method, the nano TiO2 is adopted to modify a polyvinyl alcohol radical composite coating fresh keeping packaging material; the new material film formation moisture permeability is obviously reduced, and anti-bacteria fresh keeping performance of the packaging material is obviously improved.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +1

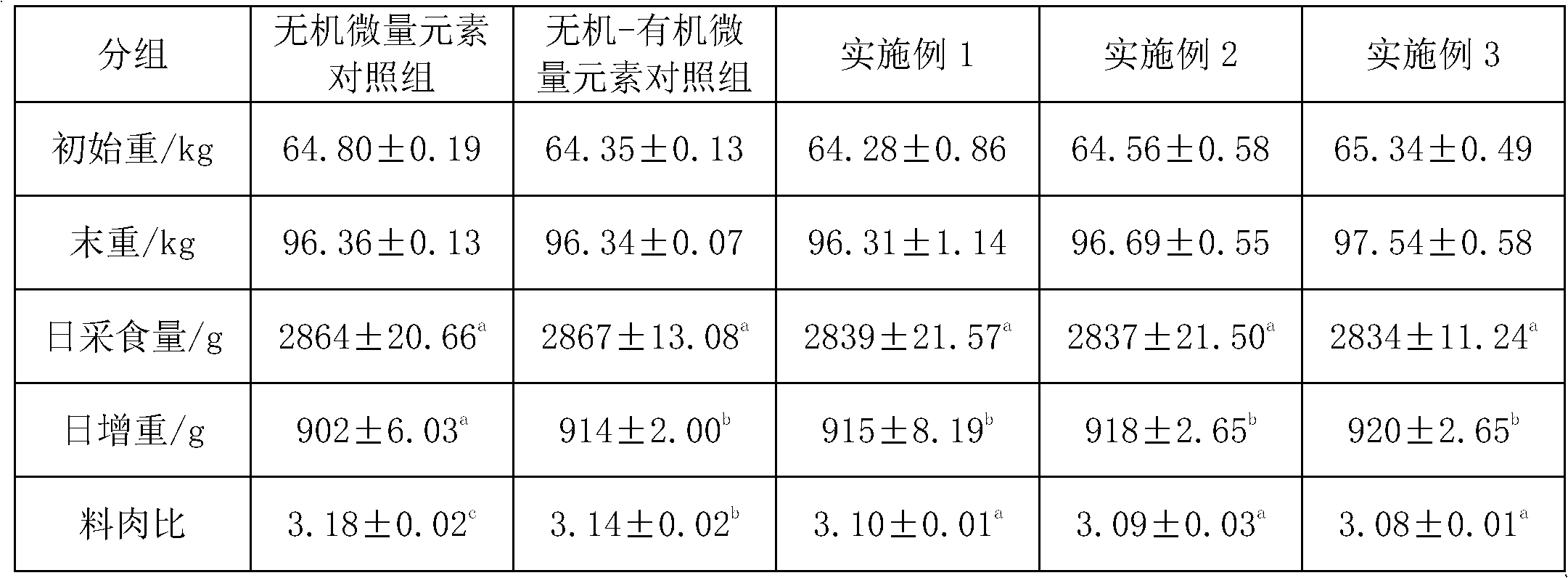

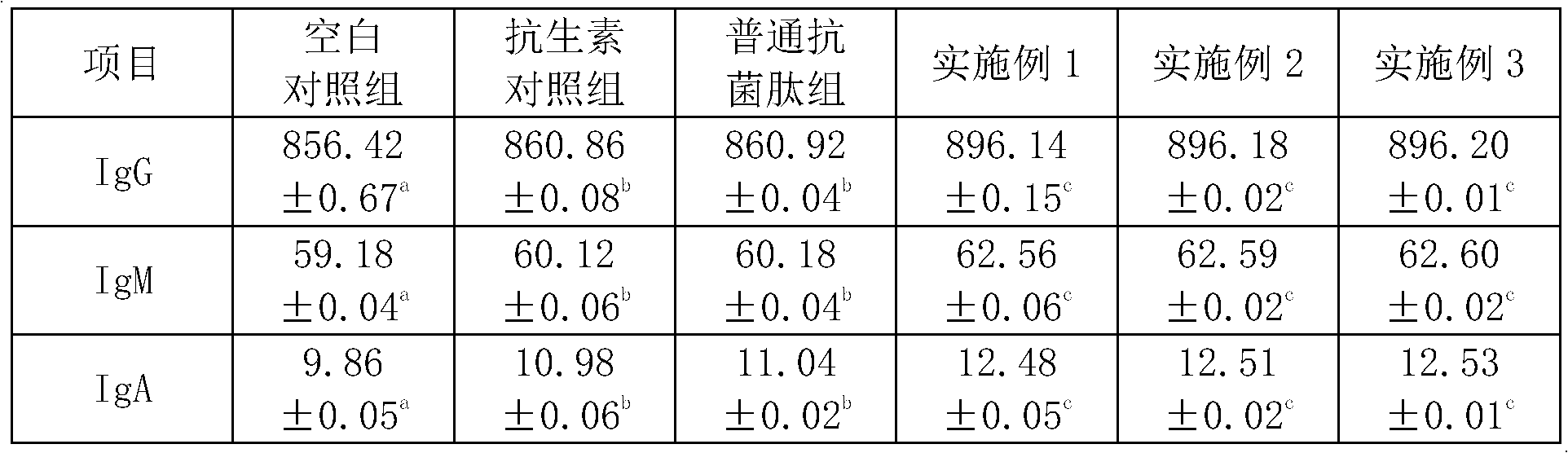

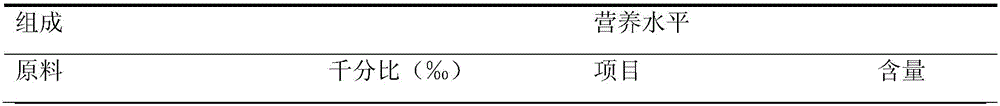

Composite premix for pigs

ActiveCN102726618AImprove immunityImprove survival rateAnimal feeding stuffPig farmsEcological environment

The invention discloses a composite premix for pigs and belongs to the technical field of feeds. The composite premix for pigs comprises a carrier, mineral matters, composite vitamin, amino acid, an anti-oxidant, phytase, antibacterial peptide and phytosterol. The mineral matters comprise trace element mineral matter and constant element mineral matter. The composite premix for pigs contains no antibiotic but antibacterial peptide and phytosterol. The trace elements adopted in the invention are mainly organic trace elements. Weighed according to a ratio, components of the composite premix forpigs can perform a synergistic effect, so as to avoid the antagonistic effect, raise utilization rate of additives such as trace elements for live pigs, save limited resources of inorganic mineral feeds, substantially improve the ecological environment around a pig farm, simultaneously reduce deposition of the trace elements in pigs, raise the quality of pork and guarantee the health of consumers.

Owner:CHENGDU CENTURY INVESTMENT

Flotation separation method of antimony sulfide gold minerals

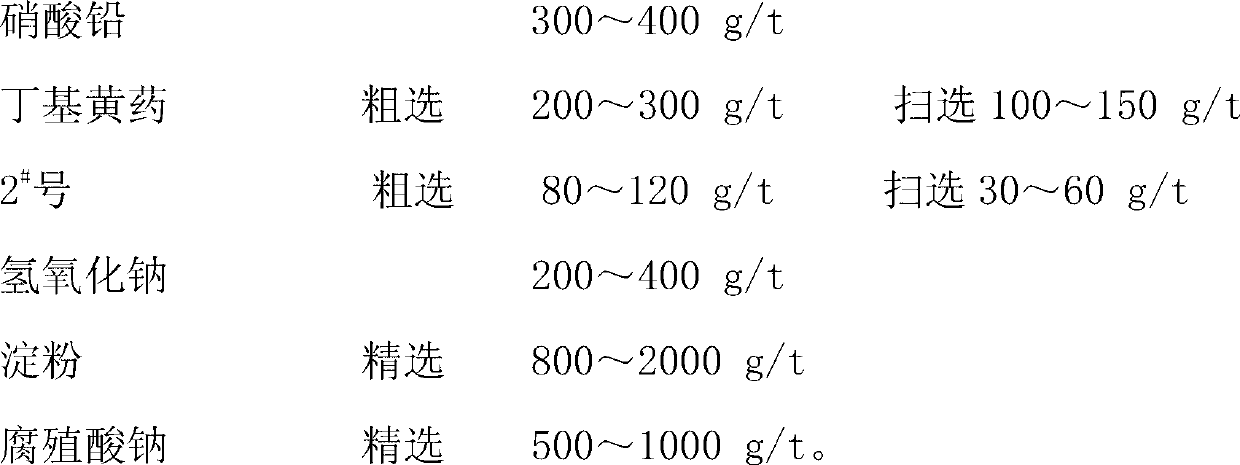

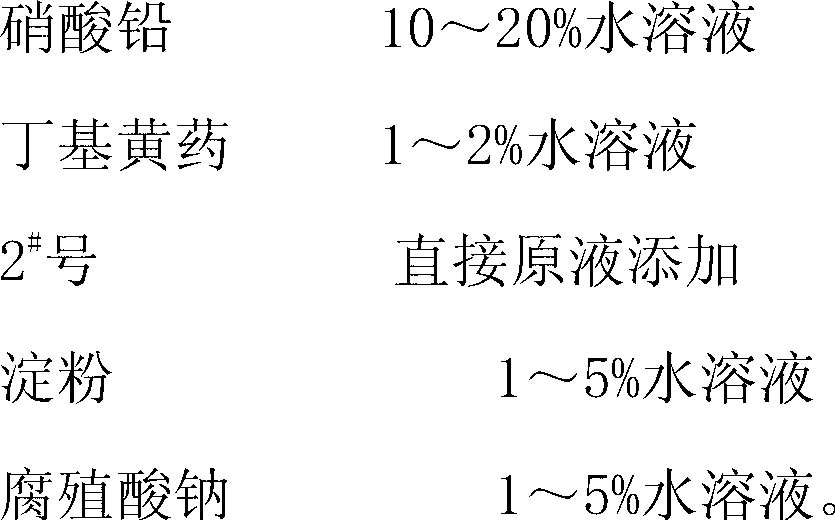

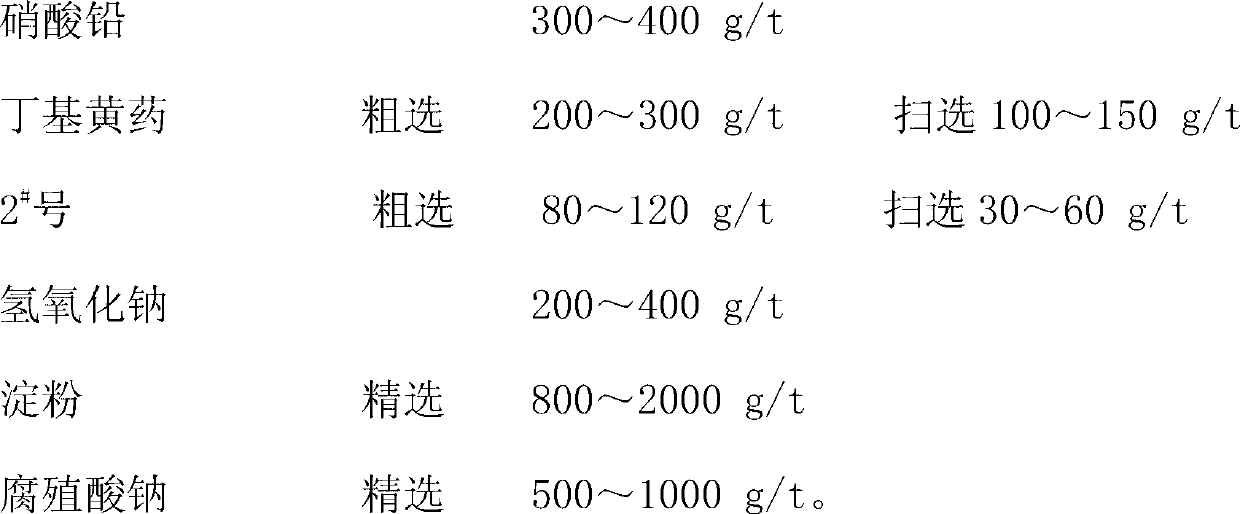

A flotation separation method of antimony sulfide gold minerals comprises the steps of performing bulk flotation to obtain antimony-gold mixed concentrate firstly and then separating the antimony-gold mixed concentrate to obtain antimony concentrate and gold concentrate, wherein in the bulk flotation, lead nitrate is taken as an activator for the antimony gold minerals, while sodium n-butylxanthate is used as a collecting agent and 2# oil is taken as a foaming agent; and in the flotation separation process, active carbon is used for reagent removal, while sodium hydroxide is used for adjusting the pH value to be 8.5-9.5, sodium humate and starch are used as a gold-containing mineral inhibitor and N, N-sodium diethyldithiocarbamate is used as the antimony mineral collecting agent. According to the flotation separation method, the antimony sulfide minerals can be effectively separated from the gold-carrying minerals through flotation, so that the antimony concentrate having the antimony grade of 33.82%-37.28% and the recovery rate of 87.21%-91.62% is obtained, and simultaneously, the gold concentrate having the grade of 40.27-45.81g / ton and the recovery rate of 85.64%-92.16% is obtained, through bulk flotation and further separation under the conditions that the feeding antimony grade is 0.37%-0.87% and the gold grade is 1.86-3.26 g / ton.

Owner:白银金锑矿业科技有限公司

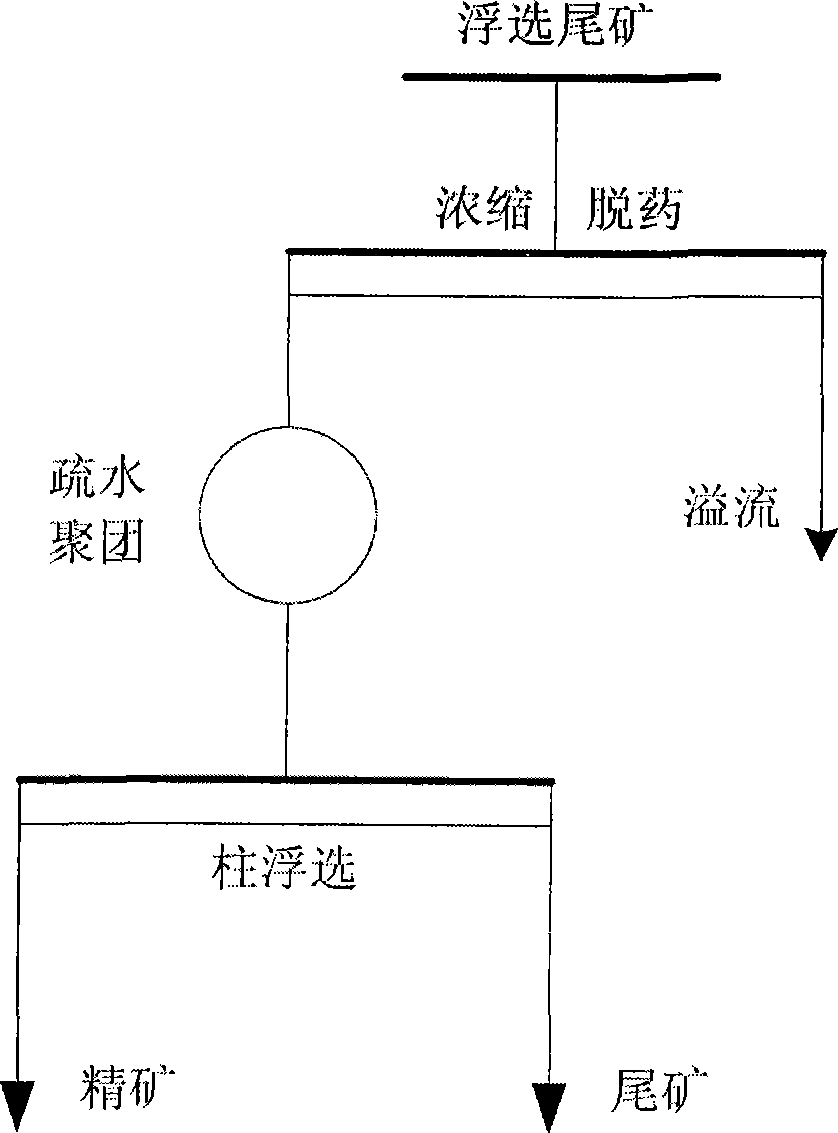

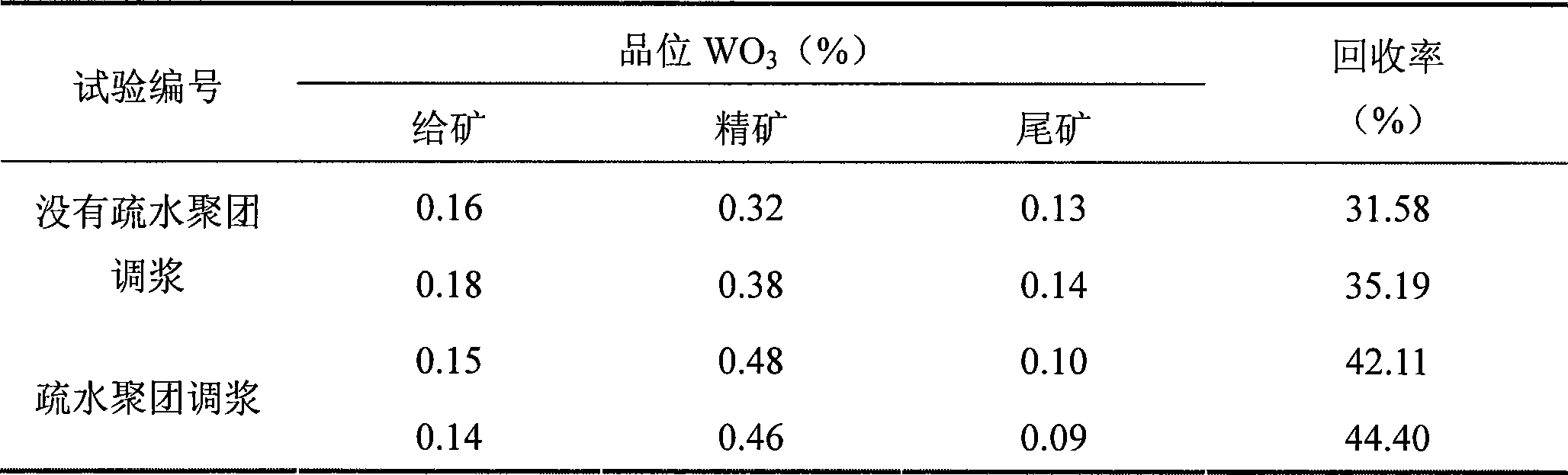

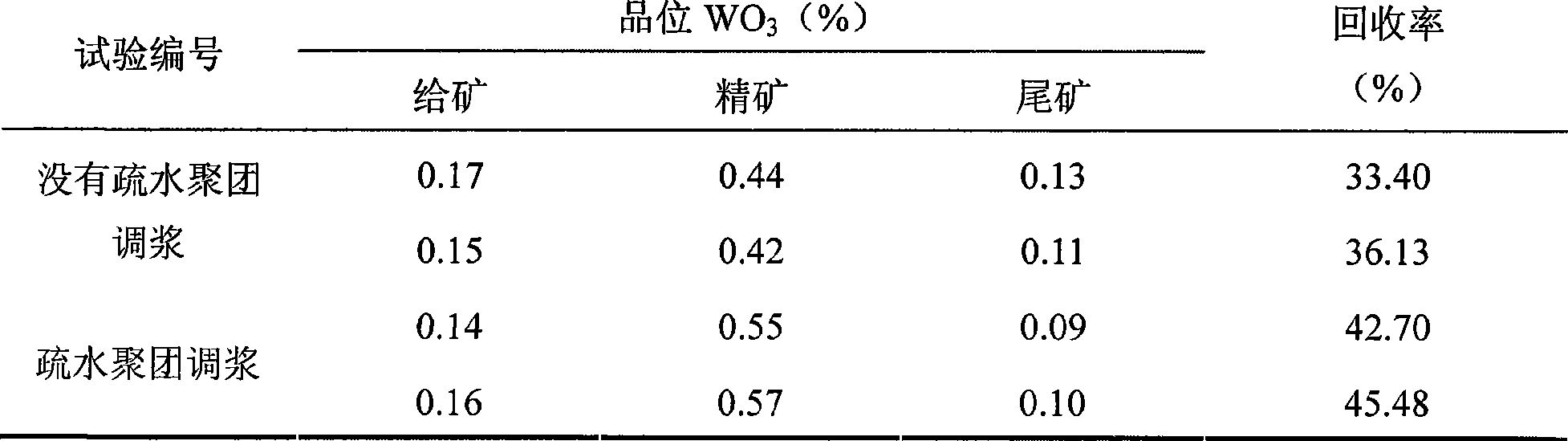

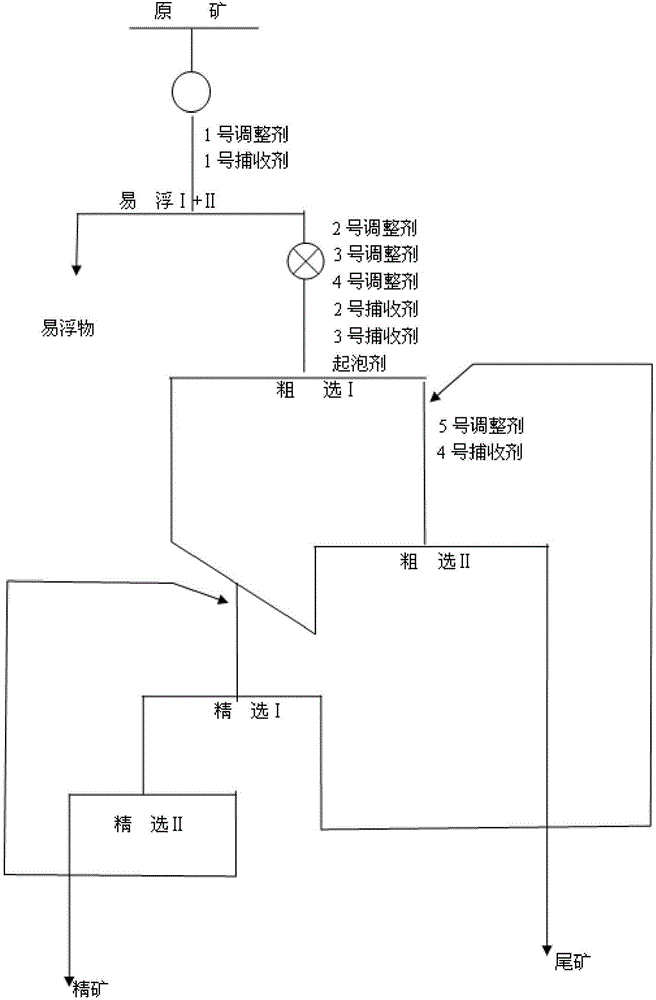

Mineral separation process capable of recovering micro scheelite from scheelite flotation tailings

The invention discloses a method for recovering scheelite in microfine size fraction(-19mu m) from scheelite flotation ore tailings. The method comprises that: firstly, the ore tailings are pre-treated to eliminate the influence of remained agents and slime; secondly, the size mixing is reinforced by using hydrophobic groups which adopts the combination of oleic acid or saponified oleic acid, oxidized paraffin wax soap 731 or 733 and kerosene or diesel oil, the rotary speed of impellers is between 1,600 and 3,000rev / min during size mixing, and the size mixing time is between 10 and 20 minutes; and thirdly, by using the static column floatation equipment, the scheelite in microfine size fraction are recovered from the ore tailings. Small-scale tests show that by the combination of the sizing mixing by the hydrophobic groups and the column separation technique, the scheelite in microfine size fraction can be effectively recovered from the flotation ore tailings. The method has the advantages of short flow and low cost, and can realize the effective recovery of the microfine mineral grains((-19mu m) by the combination of the sizing mixing by the hydrophobic groups and the column floatation.

Owner:CENT SOUTH UNIV

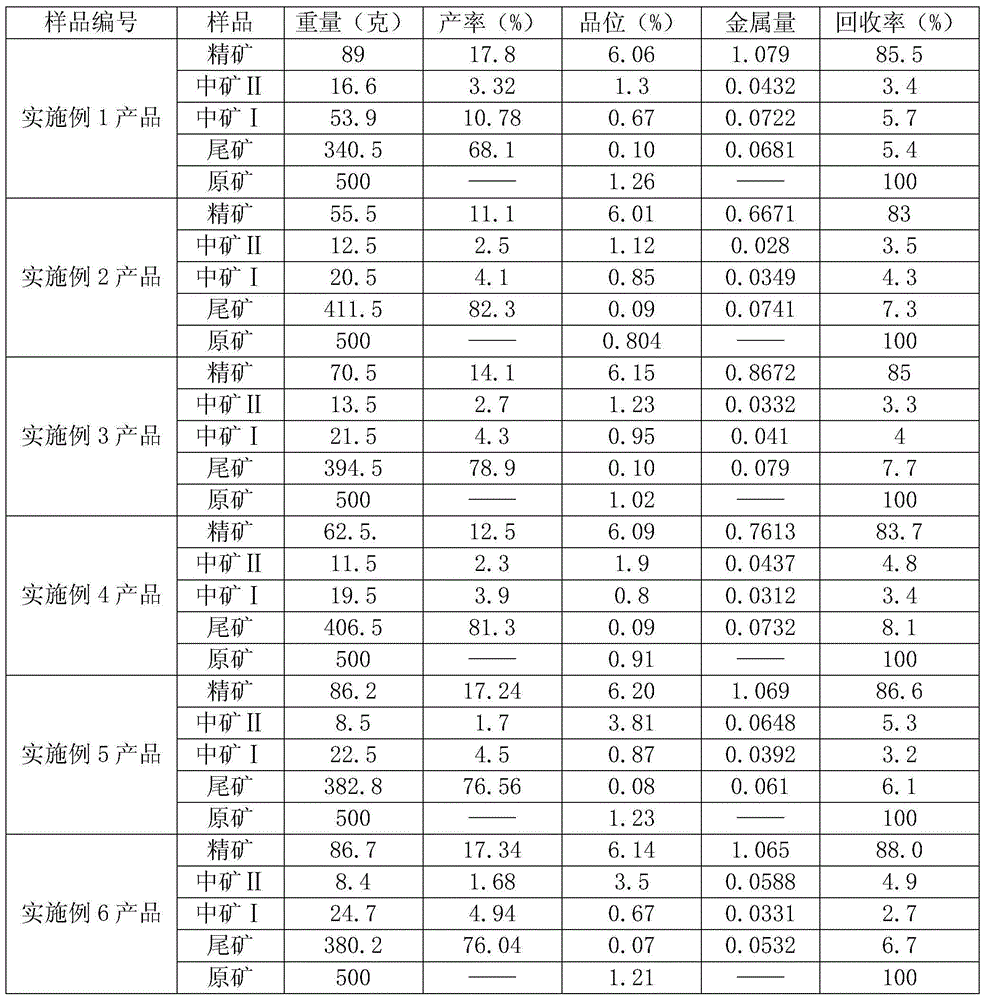

Spodumene ore processing method

The invention relates to a spodumene ore processing method and belongs to the field of ore production. The spodumene ore processing method aims at solving the technical problem of providing an ore processing method for spodumene ore. The spodumene ore processing method is formed by steps of ore grinding, roughing for two times, scavenging and selecting for two times and finally the spodumene concentrate is obtained. The spodumene ore processing method has the advantages of being simple in technological process, good in used medicament selectivity, strong in collecting capability and low in medicament amount, greatly reducing processing costs and enabling obtained spodumene concentrate level to be more than 6 % and the recovery rate to be more than 85 %.

Owner:SICHUAN TIANQI LITHIUM IND INC

Stainless steel pickling waste water resource recycling method

ActiveCN105060599AReduce dosageImprove recycling efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodEvaporation

The invention discloses a stainless steel pickling waste water resource recycling method. The method includes the steps of firstly, conducting reduced pressure evaporation on mixed acid of hydrofluoric acid and nitric acid so that acid recycling can be achieved; secondly, separating out and recycling iron in the solution; thirdly, gathering diluted acid, nickel and chromium in a circulating mode; fourthly, recycling diluted acid through a film method; fifthly, conducting neutralization and iron recycling; sixthly, separating nickel and chromium and recycling nickel; seventhly recycling chromium. By means of the method, efficient recycling of valuable metal resources such as nitric acid, hydrofluoric acid, iron, chromium and nickel is achieved, purified water can stably reach the standard, and the method is remarkable in economic benefit.

Owner:CENT SOUTH UNIV

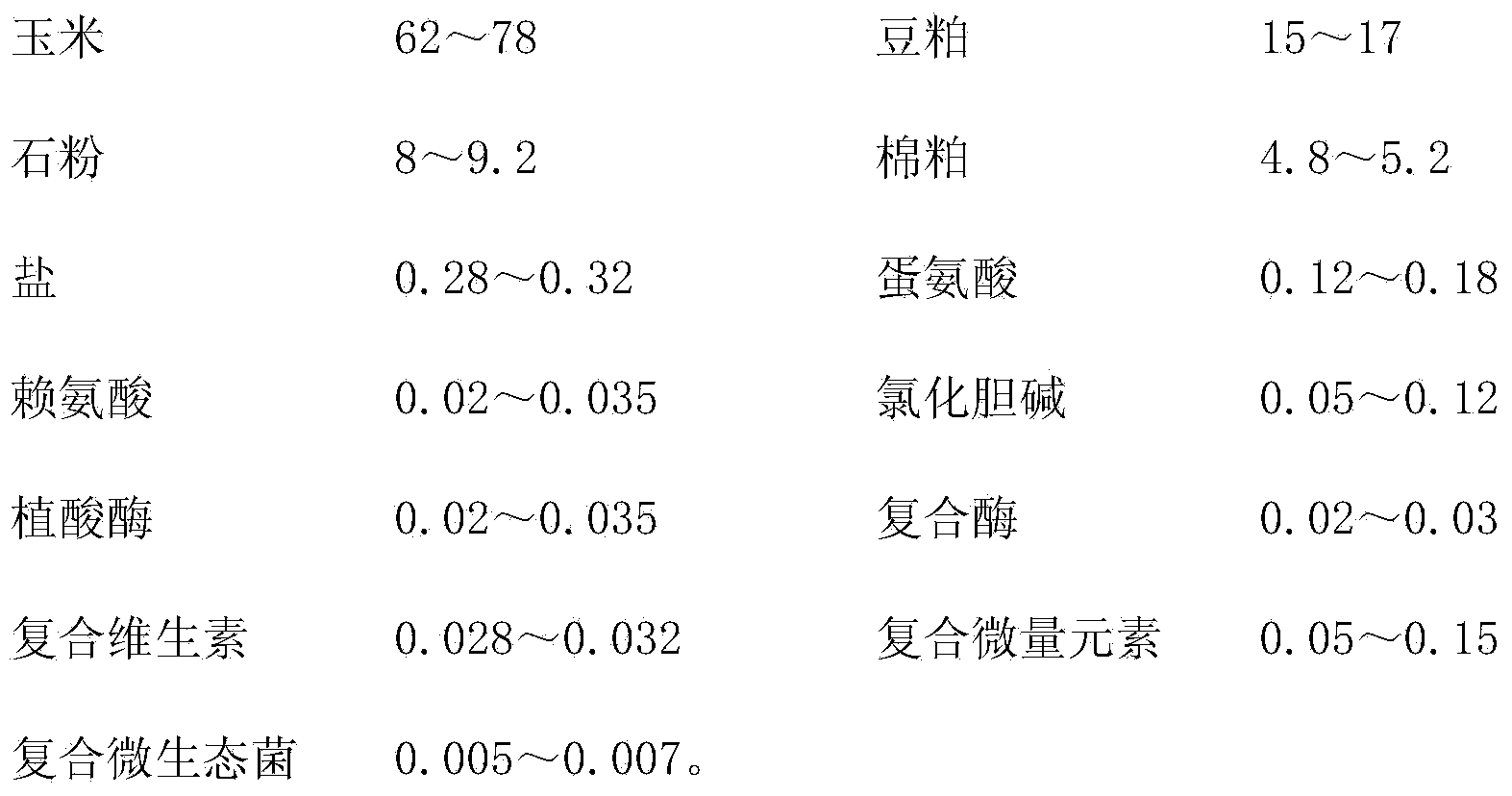

Titanium beneficiation method from titaniferous blast furnace slag

The invention relates to a titanium beneficiation method from titaniferous blast furnace slag and belongs to the field of metallurgy waste residue comprehensive utilization technology. The method comprises the following steps: adding B2O3 with quantity of slag of 1.5-2.5% or solid H3BO3 additive with quantity of slag of 2.7-4.4% to titaniferous blast furnace slag with the titaniferous quantity of 22.5%, performing fusion, cooling and heat preservation treatment under the reducing condition, and performing quenching on the furnace slag in ice water. Through the adoption of the beneficiation method, more than 20% of titanium dispersed and distributed in the furnace slag is transferred to titanium-containing kainotype anosovite for beneficiation and seed out, and separation and extraction of titanium from titaniferous blast furnace slag are facilitated. The beneficiation method is simple in technology and low in cost; in addition, the titanium beneficiation phase has higher titaniferous content and can be directly used for extracting titanium, so that the titanium beneficiation method from titaniferous blast furnace slag has significant social and economic benefits.

Owner:UNIV OF SCI & TECH BEIJING

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

Graphite paste spray material of anode steel claw and spraying method of graphite paste sprayer

InactiveCN103084315AReduce frequency of refillingImprove efficiencyLiquid surface applicatorsCoatingsKeroseneGraphite

The invention discloses a graphite paste spray material of an anode steel claw and a spraying method of the graphite paste spray material. The graphite paste spray material comprises, by mass, 5-24% of graphite and the balance kerosene. The spraying method includes: utilizing compressed air at 0.3-0.6 megapascal as a carrier to spray the kerosene on the surface of the anode steel claw via a spraying tool; and after 5-10 seconds, utilizing the compressed air at 0.3-0.6 megapascal as a carrier to spray graphite powder on the surface of the anode steel claw via the spraying tool. In the graphite paste spray material in the embodiment, graphite content is greatly reduced, cost is saved, particles are diminished, the graphite paste spray material are easy to attach on the surface of the anode steel claw, and stability is enhanced.

Owner:SNTO TECH GRP

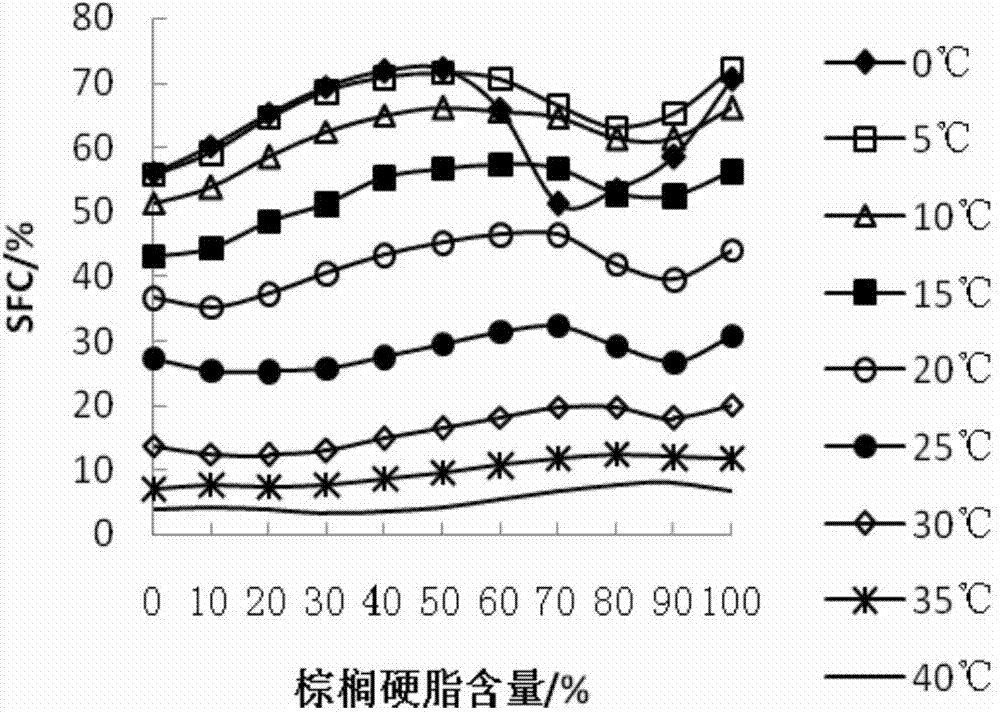

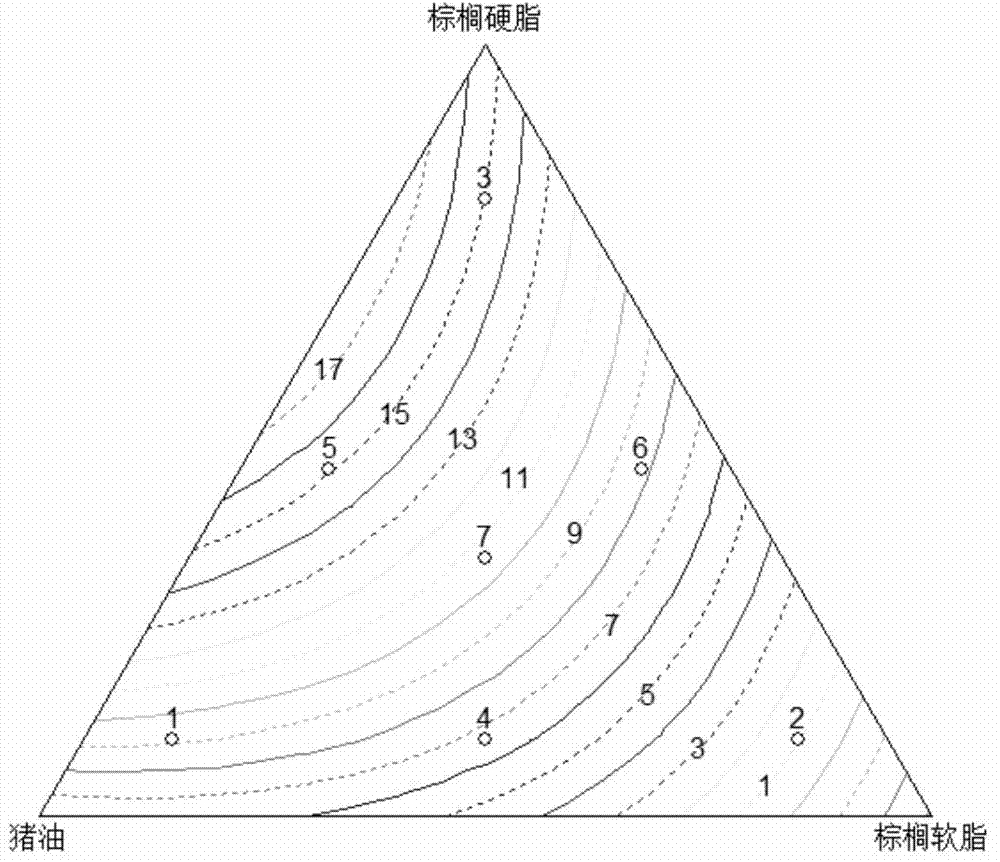

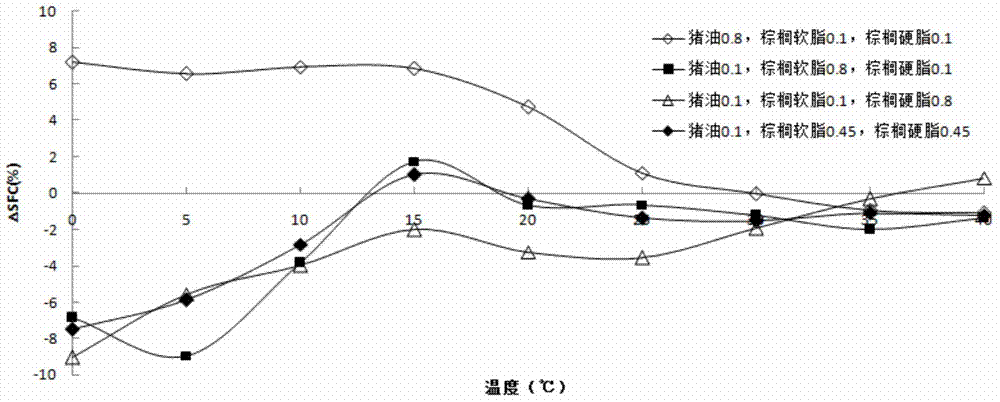

Special grease for refrigeration and prepared by mixing lard oil and palm oil and preparation method thereof

The invention discloses special grease for refrigeration and prepared by mixing lard oil and palm oil and a preparation method thereof. The preparation method of the special grease for refrigeration includes the steps of heating and melting the lard oil, the palm olein and palm stearin, adding a food-grade emulsifier and water into a totally melt oil phase, carrying out emulsification, then carrying out cooling and kneading, and finally curing to obtain the special grease for refrigeration. The special grease for refrigeration comprises, by weight, 8-12 parts of the lard oil, 10-80 parts of the palm olein, 10-80 parts of the palm stearin and 1-2.5 parts of the food-grade emulsifier. An obtained special grease product for refrigeration is in a beta crystal form, the SFC curve of the product is smooth, crystals are fine, the product has good processing characteristics and certain plasticity, compatibility of the grease is good at low temperature, and the oil separation phenomenon can be prevented from occurring.

Owner:JIANGNAN UNIV

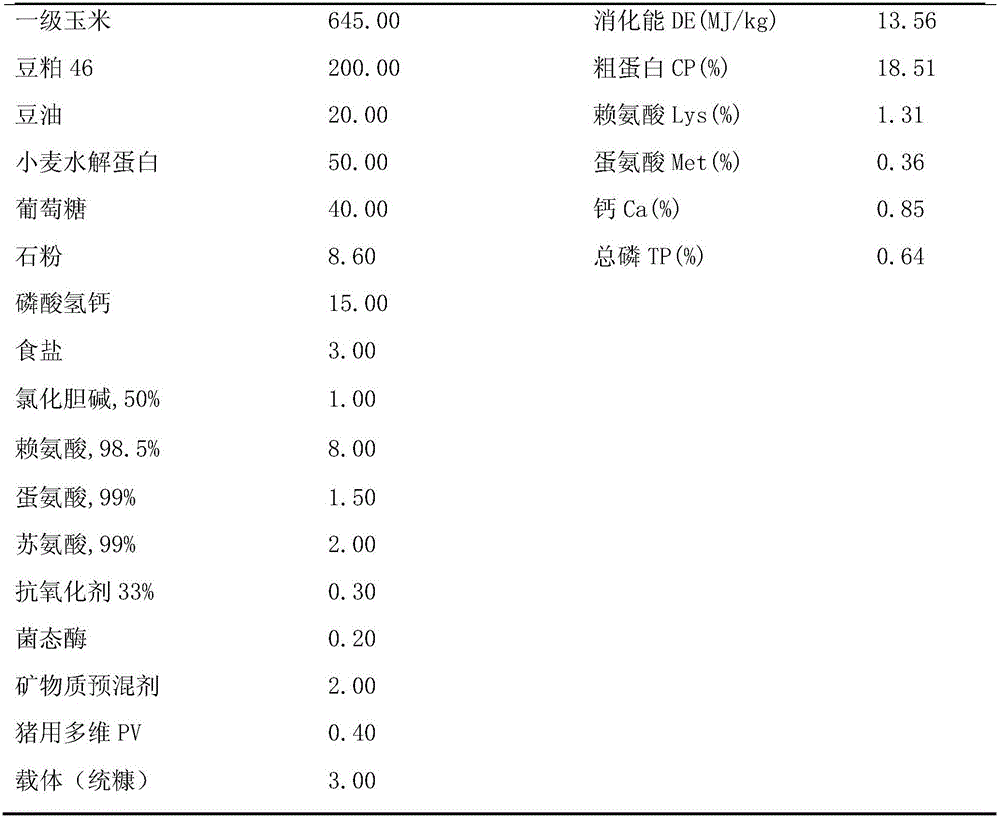

Application of nano-zinc oxide as animal feed additives

The invention proposes a new usage for nanometer zinc oxide as an animal fodder additive. As a feed zinc source, the nanometer zinc oxide has the advantages of high bioavailability, small additive dosage and stable quality and hard reaction with other components, etc. As the feed additive, the nanometer zinc oxide can effectively supplement the demand of the animals on zinc, promote the animals to healthily grow and enhance the feed use efficiency, can effectively lower the occurrence of the diarrhea of the piglets and avoid causing the drug residue in the livestock products by the use of the antibiotics. With low use dosage, the invention reduces the contamination of the environment caused by the animal excrement. The nanometer zinc oxide promotes the growth, enhances the feed efficiency, replaces the antibiotics as the growth promoters, eliminates the residue of the antibiotics in the animal products, reduces the environmental contamination and produces the pollution-free animal products.

Owner:BEIJING HUAMU GREAT EXPLOIT SCI & TECH

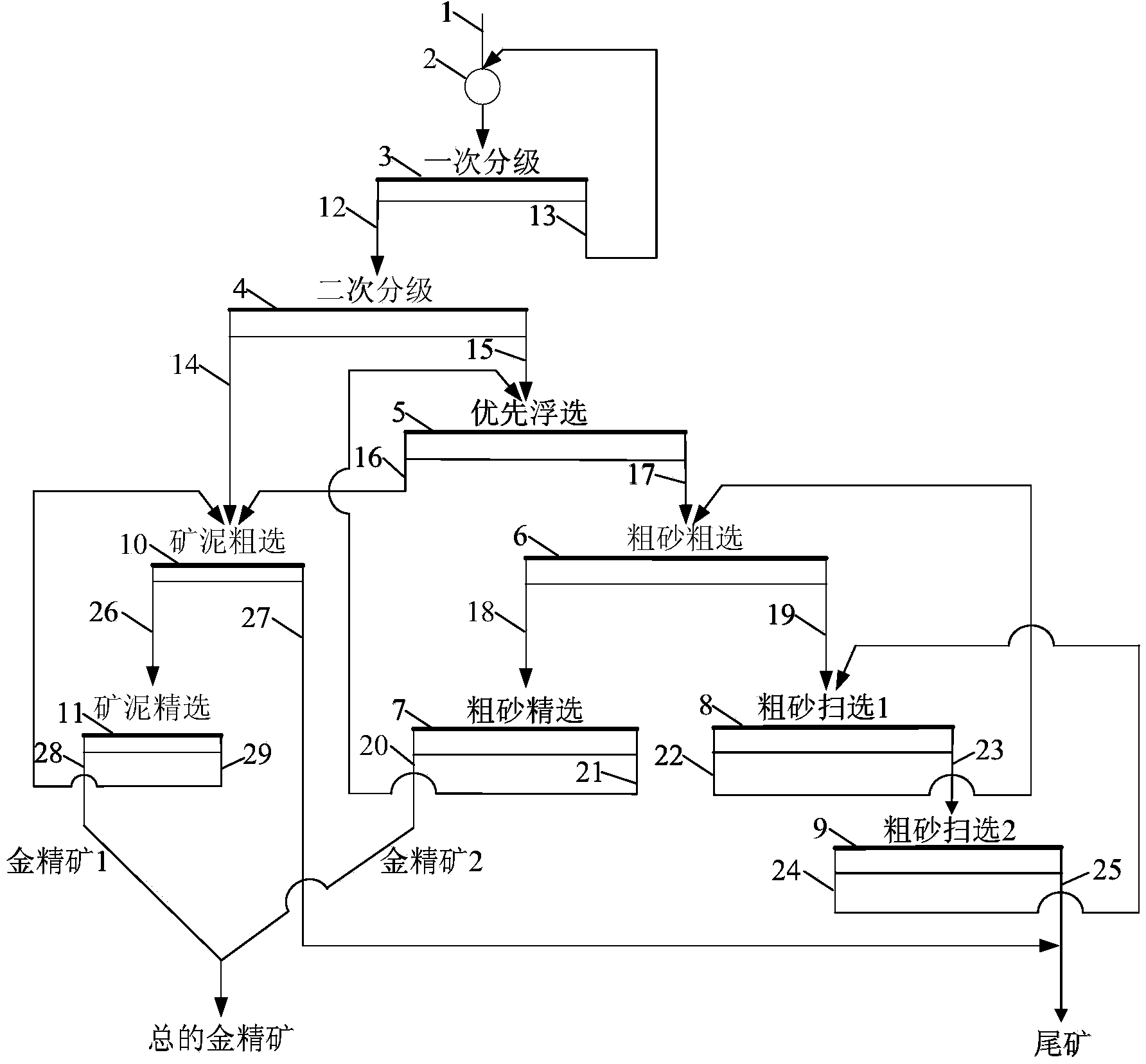

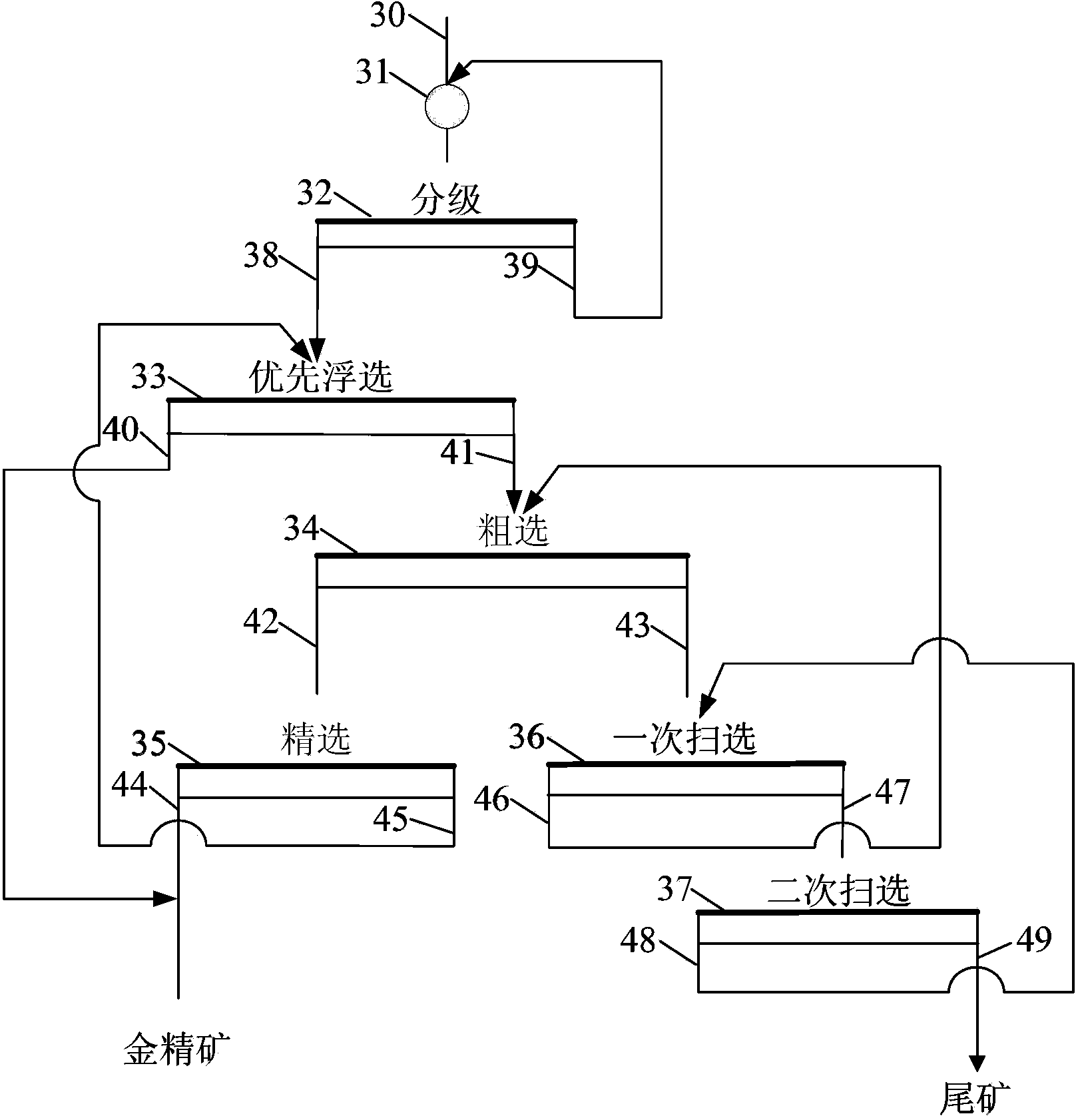

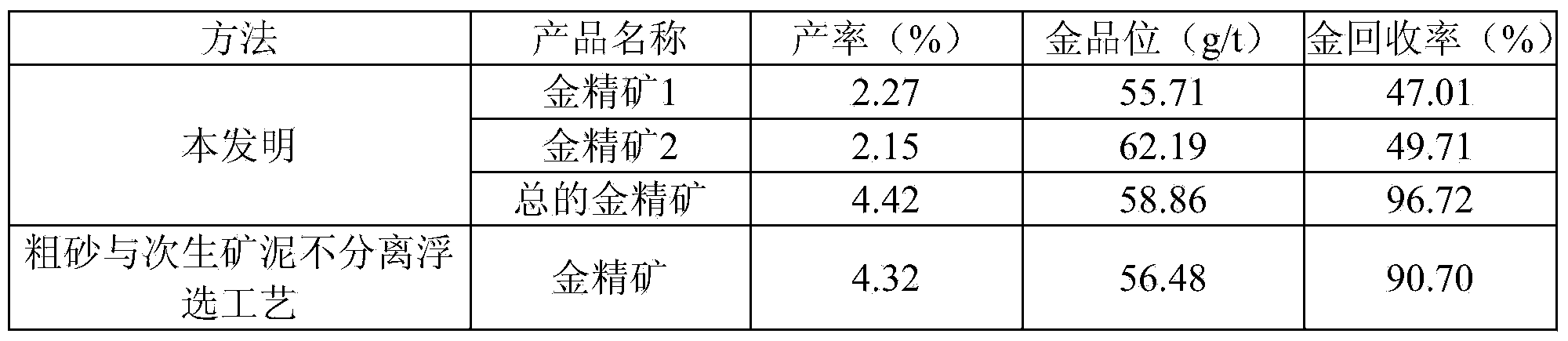

Separation-flotation technology of rough sand and secondary slime of vein gold ores

The invention relates to a separation-flotation technology of rough sand and secondary slime of vein gold ores. The separation-flotation technology is especially and mainly applied to ore dressing of the quartz vein type ores of gold-carrier ores, mainly iron pyrites. The separation-flotation technology includes the following steps of ore grinding grading operation, rough sand flotation operation, secondary slime flotation operation and combining forming operation of total gold ore concentrate. The recovery rate of gold of the obtained total gold ore concentrate is larger than or equal to 95.46%, the recovery rate of the gold is obviously improved, the use efficiency of resources is improved and the separation-flotation technology is small in use amount of medicaments and reduces environment pollution.

Owner:JIANGXI UNIV OF SCI & TECH

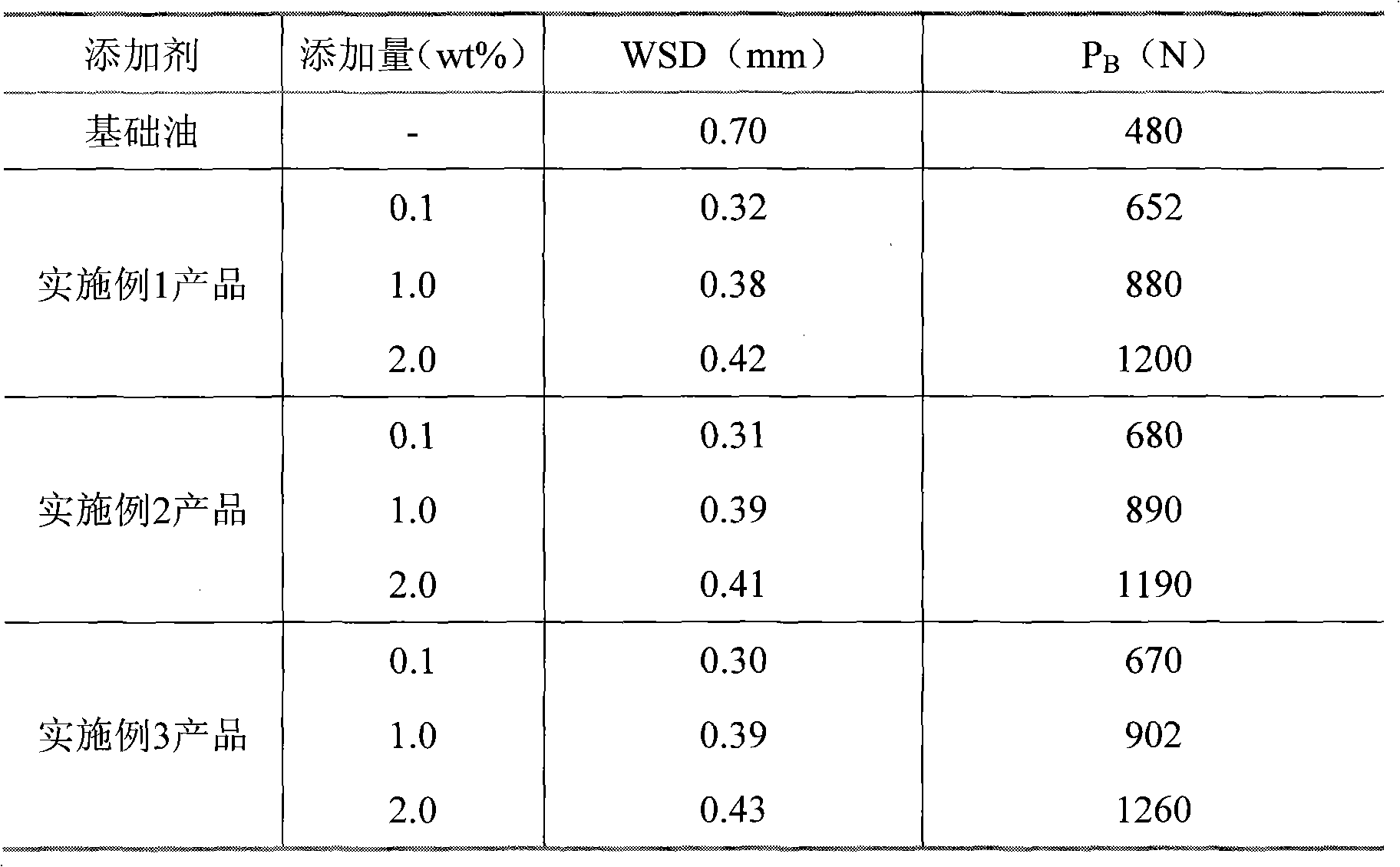

Additive for wear resistance of lubricating oil

ActiveCN101812354AExcellent extreme pressure anti-wear and anti-friction propertiesNot corrosiveAdditivesParaffin waxPolybutene

The invention discloses an additive for wear resistance of lubricating oil, which comprises the following components in part by weight: 15 to 35 parts of antiwear agent, 6 to 29 parts of detergent dispersant and 12 to 26 parts of antioxidant preservative, wherein the antiwear agent consists of boric acid tributylester, phosphonic acid dibutyl ester, copper isooctoxyborate and cupric cyclohexoxylborate; the detergent dispersant consists of polybutene amine, polyisobutene carbamic acid ester and 2-aminopyridine; and the antioxidant preservative is boronized butanimide. The additive has wide use range, can be used in paraffin, naphthene and intermediate base oil, and also can be used in synthetic and semi-synthetic base oil. The additive has the advantages of effectively improving the wear resistance of the lubricating oil, strengthening the bearing capacity of the lubricating oil, making the lubricating oil have long service life, and having small dosage in the lubricating oil and simple and convenient preparation process.

Owner:山东星火知识产权服务有限公司

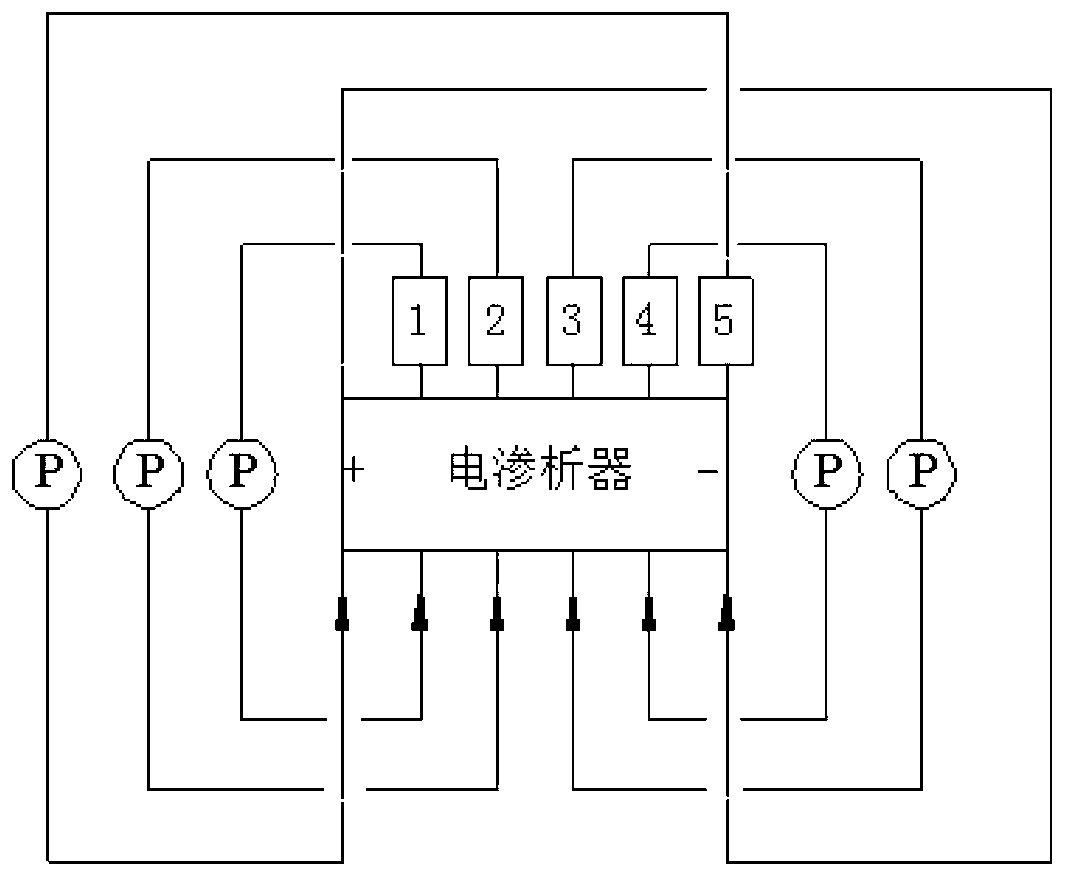

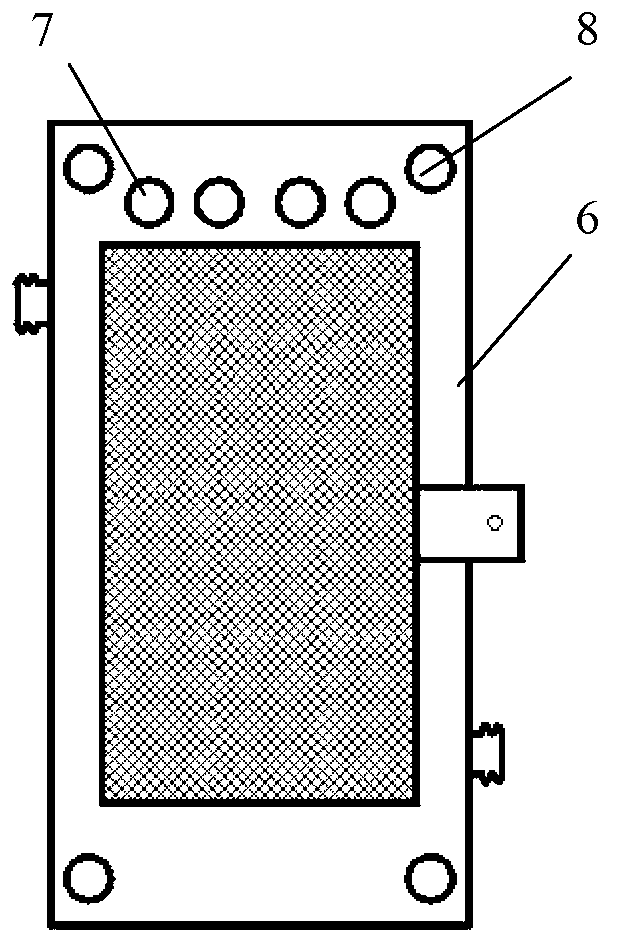

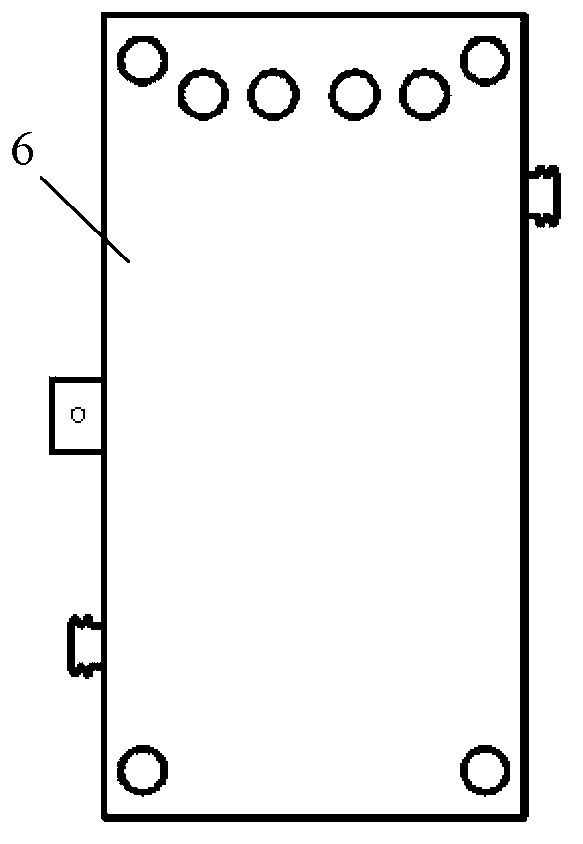

Preparation technology of hypophosphorous acid with five-room electrodialysis method

The present invention provides a preparation technology of hypophosphorous acid with five-room electrodialysis method, which takes hypophosphite and mineral acid as raw materials, and titanium plate ruthenium plating as the electrode. The electric field effect of the five-room electrodialysis tank is used for ion exchange; 40-200g / L hypophosphite aqueous solution and 20-100g / L sulfuric acid aqueous solution are provided in two raw material rooms of the five-room electrodialysis tank; the mass ratio between the input raw material of sulfuric acid and hypophosphite crystal is (0.4-0.6): 1; sulfuric acid aqueous solution with the initial concentration of 5-10g / L is provided in an electrode chamber of the five-room electrodialysis tank; distilled water or purified water or deionized water is provided in two product chambers of the five-room electrodialysis tank. The preparation process provided by the present invention improves membrane electrolysis method and traditional electrodialysis method of preparation of hypophosphorous acid, which has simple technological process, low energy consumption, and low production cost with little environment pollution and high conversion efficiency, and is easy for industrial mass production. The electrodialysis device adopted by the invention can be easily operately with low energy consumption and low cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

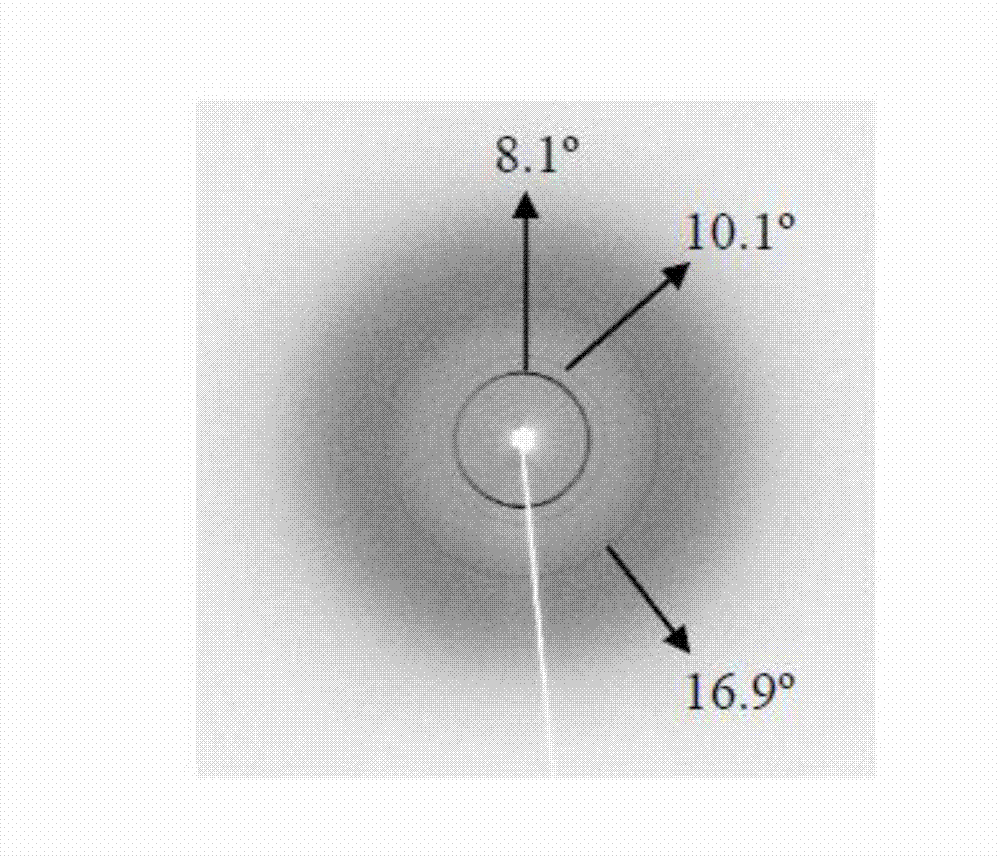

High-strength industrial polyester fiber and preparation method thereof

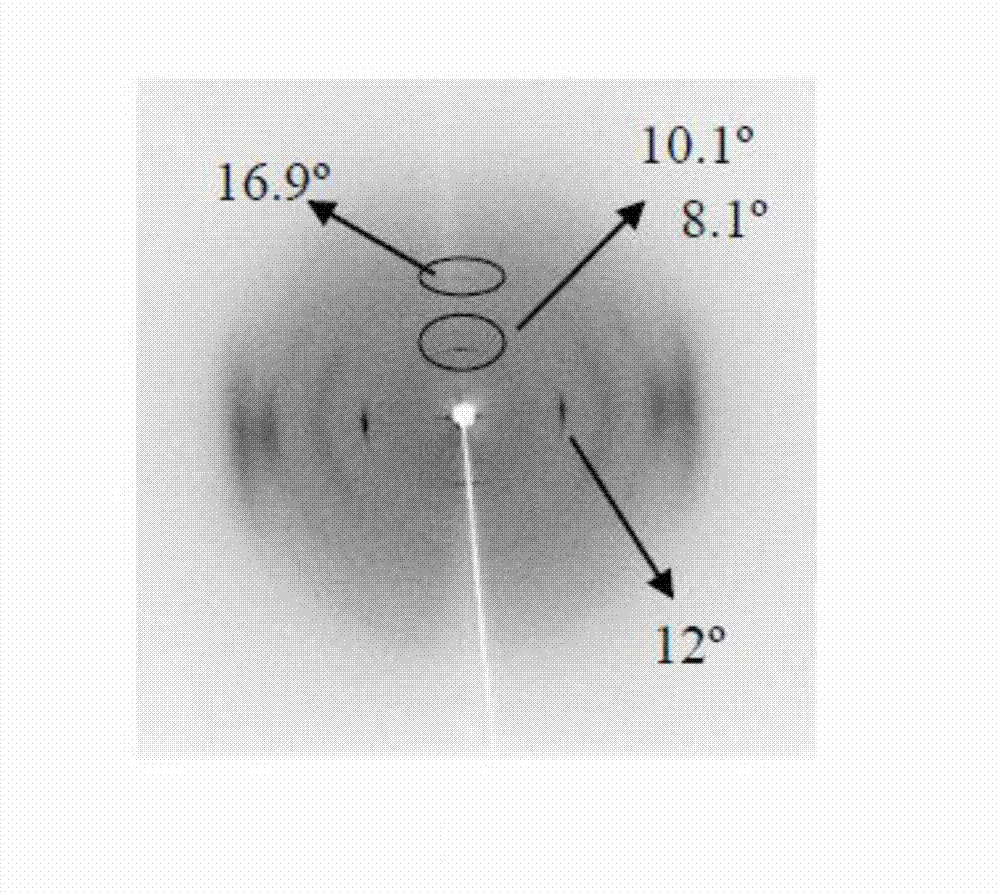

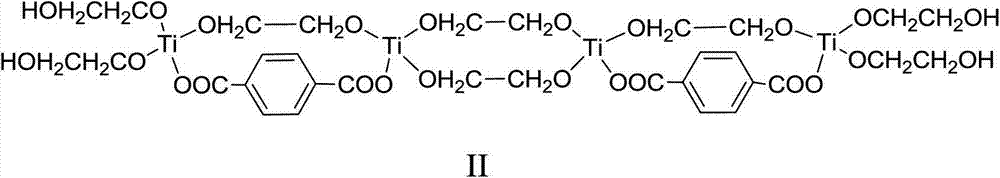

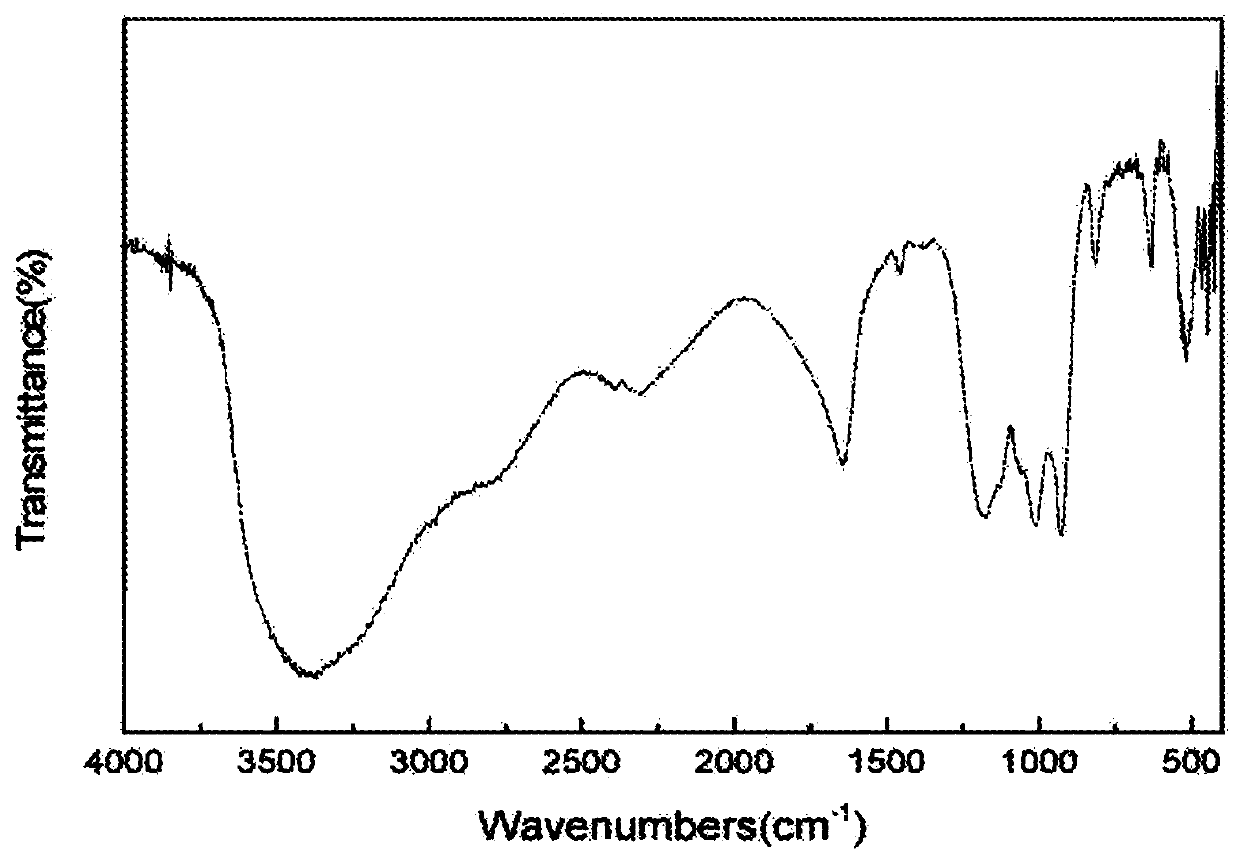

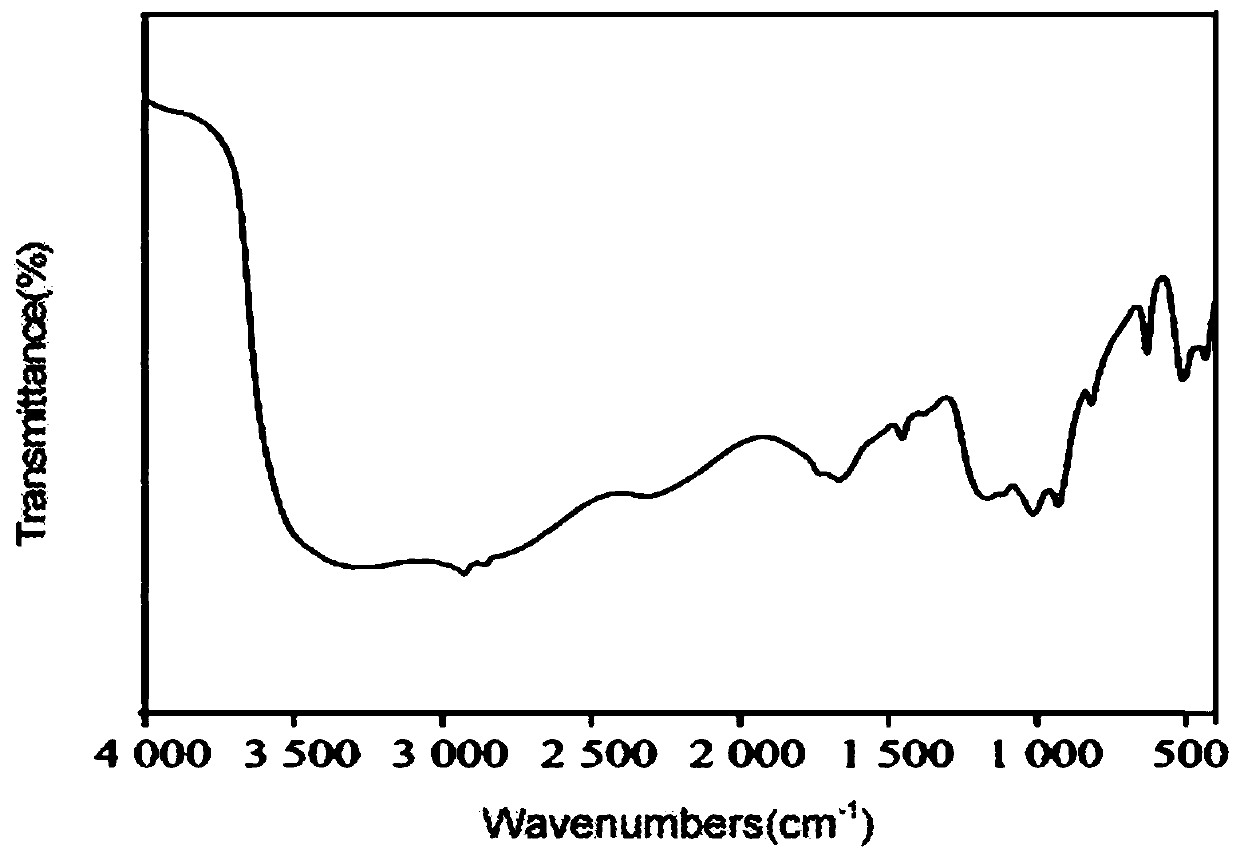

ActiveCN103088460AImprove mechanical propertiesLess dosageMonocomponent polyesters artificial filamentArtifical filament manufactureSolid phasesChemistry

The invention belongs to the field of polyester fiber, and particularly relates to a high-strength industrial polyester fiber and a preparation method thereof. The high-strength industrial polyester fiber comprises a PET (polyethylene terephthalate) matrix with the intrinsic viscosity of 0.8-1.2dl / g and a compound in a compound having a formula (I) dispersed in the PET matrix, wherein the general structural formula of the compound in the formula (I) is Tix(OR<1>O)y(OOC6H4COO)zH4. According to the preparation method of the high-strength industrial polyester fiber, composite resin is obtained by adopting a melt blending method, a melt blending-solid phase tackifying method or in-situ polymerization-solid phase tackifying method, and then the high-strength industrial polyester fiber is formed. According to the technical scheme, the orientation of the nanometer material with a laminated structure is introduced into the PET matrix in the production process, so as to induce the orientation of a PET molecule chain, so that the mechanical property can be improved, the amount of the additive added is less, the cost is low, and market prospects are wide.

Owner:DONGHUA UNIV

Polylactic acid flexibilizer and preparation method thereof and modified polylactic acid and preparation method thereof

The invention provides a polylactic acid flexibilizer and a preparation method thereof and a modified polylactic acid and a preparation method thereof. The preparation method of the polylactic acid flexibilizer includes the steps: firstly, adding methyl acrylate and methyl methacrylate into a first emulsifier to obtain a first mixture; secondly, adding a first initiator into the first mixture for initiation reaction, and removing aggregate generated in the reaction to obtain a second mixture; thirdly, adding a second emulsifier into the second mixture and adding a third mixture to continue reacting to obtain emulsion, wherein the third mixture is composed of methyl acrylate, dispersing agent, the second emulsifier, a second initiator and water; and fourthly, diluting the emulsion, adding demulsifying agent, heating for coagulation, and drying precipitates to obtain the polylactic acid flexibilizer. The preparation method is simple, the obtained polylactic acid flexibilizer is well compatible to polylactic acid, additives used by modified polylactic acid prepared from the polylactic acid flexibilizer are reduced, and utilization rate of polylactic acid is increased.

Owner:CHERY AUTOMOBILE CO LTD

High-sulfur bauxite flotation and desulphurization method

ActiveCN103272701AReduce sulfur contentEfficient flotation desulfurization processFlotationFoaming agentHydrogen

The invention relates to a high-sulfur bauxite flotation and desulphurization method. The high-sulfur bauxite flotation and desulphurization method comprises the following steps of adding lime in the raw ore grinding process, controlling potential of hydrogen (pH) of ore pulp to be in a range of 6-8 and sequentially adding an activating agent, a collecting agent and a foaming agent in the ore pulp to perform flotation. By adopting the high-sulfur bauxite flotation and desulphurization method, the sulfur content of aluminum copper concentrate can be reduced to be below 0.3%under the condition of low collecting agent using amount. Compared with existing high-sulfur bauxite flotation and desulphurization technologies, the high-sulfur bauxite flotation and desulphurization method is low in agent using amount and good in desulphurization effect, corrosion of an acid environment formed by the ore pulp to devices is eliminated, and the high-sulfur bauxite flotation and desulphurization process is efficient and stable.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

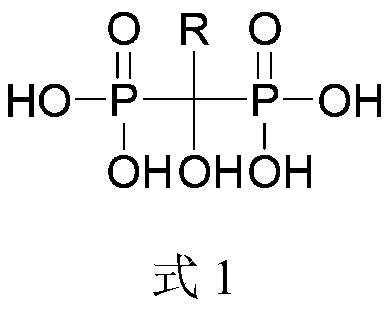

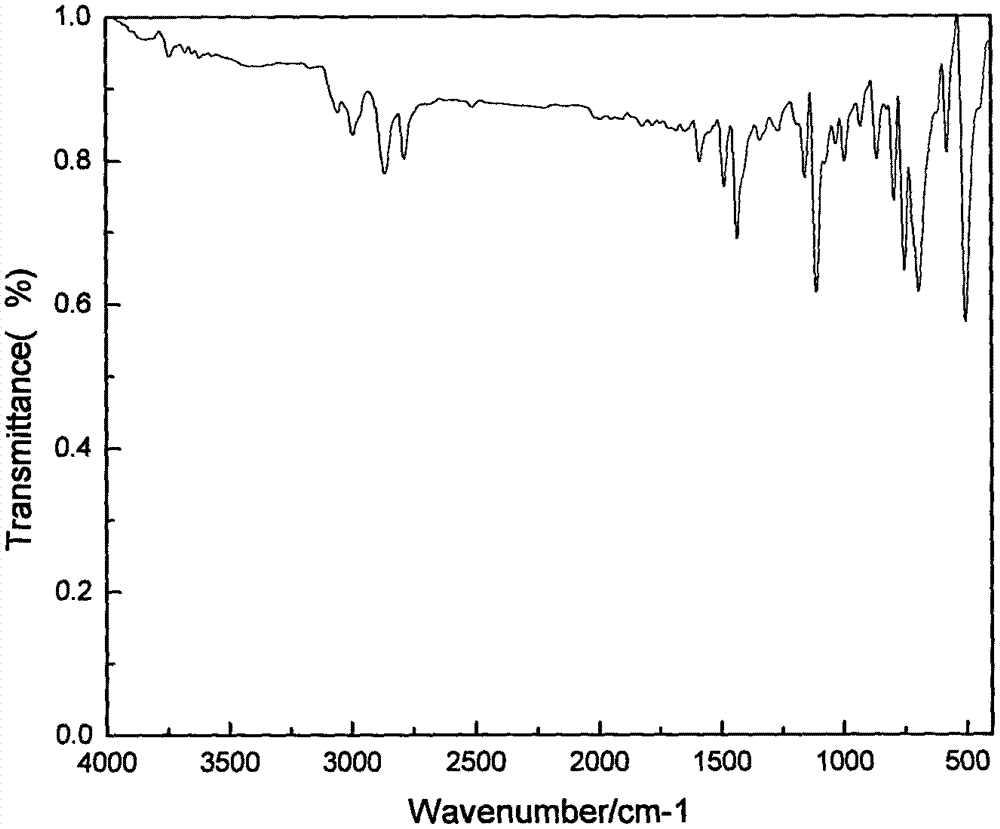

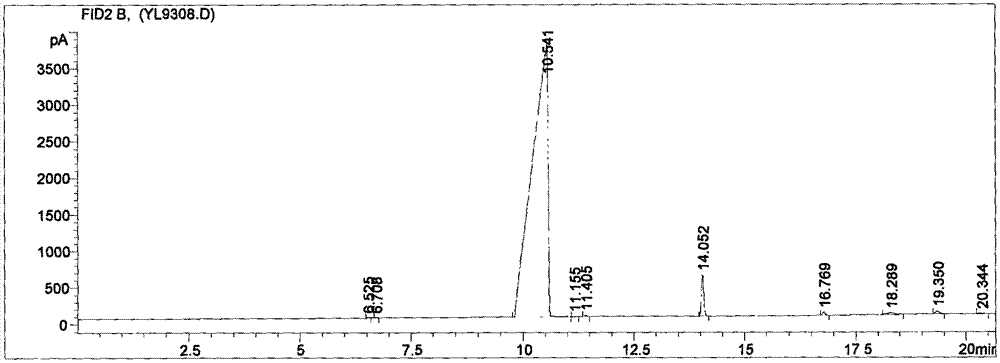

Organic phosphoric acid compound, synthesis method of compound and application of compound as chalcopyrite collector

ActiveCN109776606AThe synthesis method is simpleEnvironmental advantages are obviousGroup 5/15 element organic compoundsFlotationPhosphorous acidChalcopyrite

The invention discloses an organic phosphoric acid compound, a synthesis method of the compound and application of the compound as a chalcopyrite collector. The synthesis method of the organic phosphoric acid compound comprises the steps that an organic carboxylic acid compound and phosphorous acid are subjected to a condensation reaction under the function of phosphorus pentoxide, and a product of the condensation reaction is hydrolyzed by water vapor, separated and purified to obtain the compound. The organic phosphoric acid compound is used for the flotation of chalcopyrite, the selectivityof the compound is high, the agent use amount is small, the cost is low, flotation indexes are stable, and efficient flotation separation can be carried out on chalcopyrite and pyrite.

Owner:CENT SOUTH UNIV

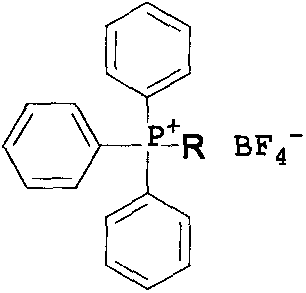

One alkyl triphenyl substituted group based phosphonium salt preparation method and application

InactiveCN107129511AImprove bindingHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphonium saltSodium tetrafluoroborate

The invention discloses a one alkyl triphenyl substituted group based phosphonium salt preparation method and application. The preparation method includes that a one alkyl triphenyl phosphonium salt halide I is obtained through reaction of several alkyl halides and triphenylphosphine in a DMF (dimethyl formamide) solvent through nucleophilic substitution, and an aqueous solution of a compound I and a sodium tetrafluoroborate aqueous solution are subjected to ion exchange to prepare the phosphonium salt through high yield of recrystallization. The phosphonium salt preparation method and application has the advantages of low cost and easy obtaining of raw materials and low cost, one alkyl triphenyl substituted group containing phosphonium salt II serving as a phase transfer catalyst has the advantages of high catalytic activity, less required dose, long activity time, high thermal stability and low toxicity, high reaction recovery and the like in catalytic fluorine chlorine exchange reaction, and wide commercial application prospect is achieved.

Owner:WUHAN UNIV OF SCI & TECH

Low-phosphorous grain-saving environmentally friendly type laying hen feedstuff

InactiveCN104304831AImprove the utilization rate of total phosphorusLow costAnimal feeding stuffPhytaseAntibiotic Y

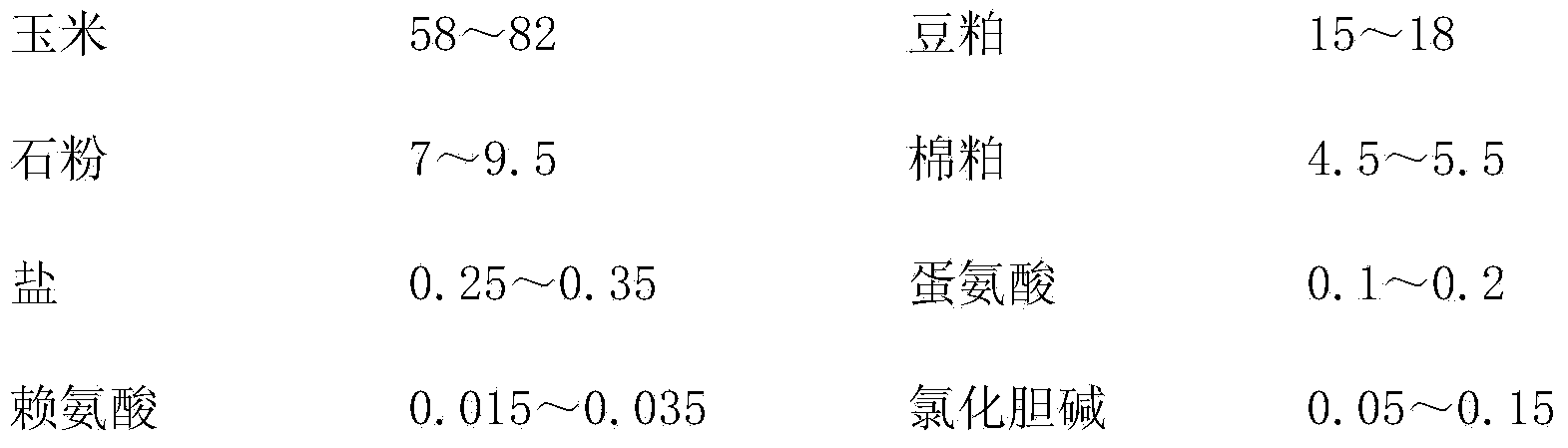

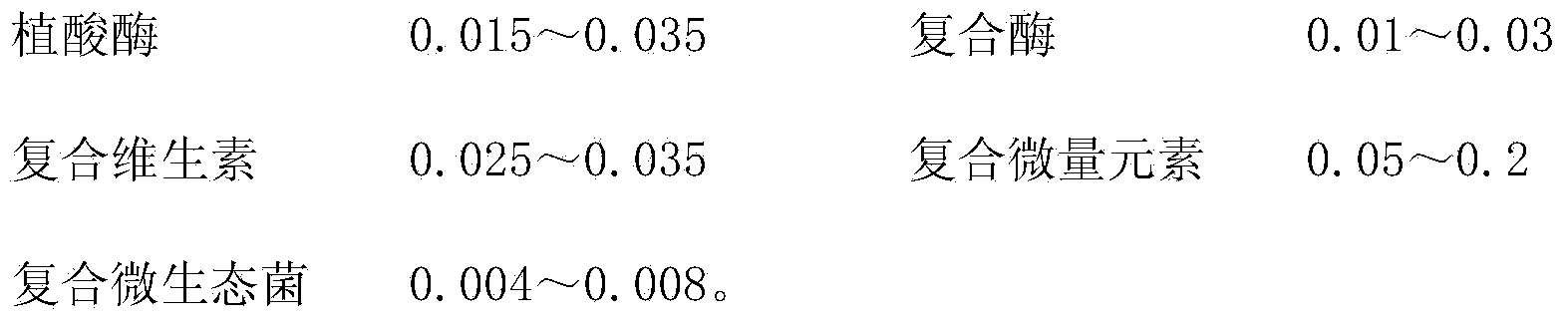

The invention relates to the technical field of livestock animal nutrition and feedstuff, in particular to a low-phosphorous grain-saving environmentally friendly type laying hen feedstuff. The feedstuff is composed of, by weight, 58-82 parts of corn, 15-18 parts of bean pulp, 7-9.5 parts of stone powder, 4.5-5.5 parts of cottonseed meal, 0.25-0.35 part of salt, 0.1-0.2 part of methionine, 0.05-0.15 part of choline chloride, 0.015-0.035 part of lysine, 0.015-0.035 part of phytase, 0.01-0.03 part of compound enzyme, 0.05-0.2 part of compound microelement, 0.025-0.035 part of compound vitamin and 0.004-0.008 part of compound micro-ecology fungus. The laying hen feedstuff is scientific and reasonable in formula, no inorganic phosphorus, antibiotics and hormone are added into the feedstuff, great contributions are made to ecological balance protection and human health, through adding the compound microorganism enzyme and the compound microorganism fungus into the feedstuff, the conversion utilization rate of the feedstuff is greatly increased, the disease-resistant ability of laying hens is greatly improved, the cost of the feedstuff is lowered, and high economical benefits and social benefits are achieved.

Owner:浠水县四方饲料有限公司

Preparation method for in-situ modified expansion type fire retardant

The invention discloses a preparation method for an in-situ modified expansion type fire retardant. The method comprises the following steps: (a) preparing acidic phosphate ester; (b) preparing hydroxymethylated melamine; (c) cladding ammonium polyphosphate; (d) based on the amount of solid in step c, adding an in-situ modifier with a mass percent of 0.2 to 6% and carrying out uniform dispersion;(e) carrying out filtration, drying a product obtained after filtration and roasting the product into powder so as to obtain a finished product of in-situ modified microcapsule cladded ammonium polyphosphate. According to the invention, the in-situ modifier has a synergistic flame retardant effect is uniformly dispersed in the whole system of the fire retardant in a form of a stable compound, which enables the problems that a preparation system is acidic and a trace amount of the in-situ modifier is difficult to disperse uniformly to be effectively overcome and flame retardant efficiency of the fire retardant to be substantially improved.

Owner:HEBEI UNIVERSITY

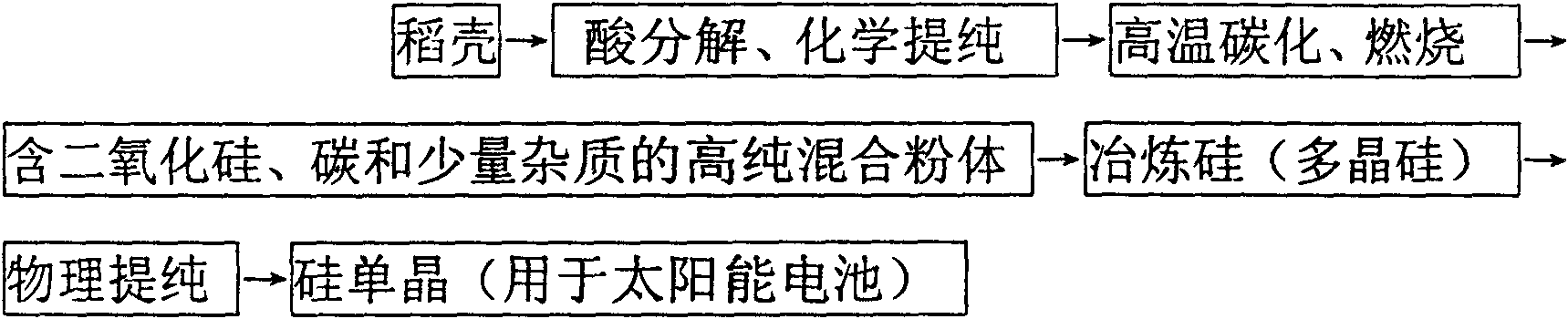

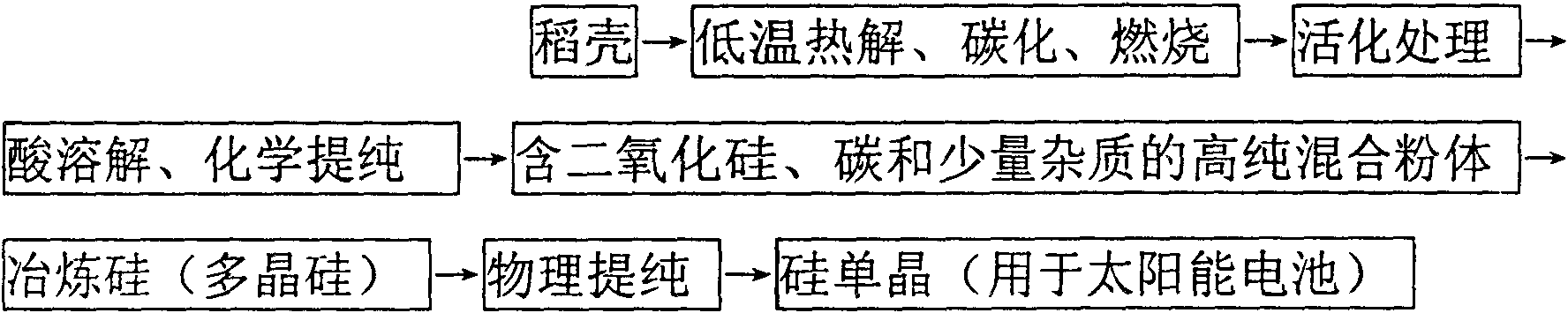

Method for preparing solar cell polysilicon raw material from rice hulls

InactiveCN101673781ALess dosageReduce pollutionSilicaFinal product manufactureElectric arc furnaceSingle crystal

The invention relates to a method for preparing a solar cell polysilicon raw material from rice hulls. The method comprises the following steps: heat treatment, activation treatment and chemical purification treatment of rice hulls. The method has the advantages of small drug dose, less pollution discharging and low production cost. The grain size of finally prepared mixed powder of SiO2 and C isin a nano range, and when the mixed powder is applied to an arc furnace for reducing and smelting silicon, the mixed powder presents higher reactivity and lower specific energy consumption. The mixedpowder prepared from SiO2 and C comprises boron less than 0.8ppm and phosphorus less than 0.5ppm, the total impurity content is less than 100ppm, and high-purity (99.99 percent) polysilicon products containing low boron and phosphorus for solar cells can be smelted and produced by using the mixed powder (or pills) as a raw material. If a universal wet hydrogen boron removal type suspension zone smelting method continues to be used for physical purification, solar-grade polysilicon can be finally manufactured. The solar-grade polysilicon is then processed and drawn into single crystal ingots, and the single crystal ingots are cut into silicon chips which can be used for producing solar panel products.

Owner:邵振亚

Composite nano-zinc oxide additive and preparation method and application thereof

ActiveCN105901356AKeep healthyPrevent diarrheaAccessory food factorsWorking-up animal fodderAdditive ingredientNano zinc oxide

The invention belongs to the field of feed additives and specifically relates to a composite nano-zinc oxide additive and its preparation method and application. In allusion to problems such as low bioavailability and instable using effect of nano-zinc oxide, the invention provides a composite nano-zinc oxide additive and its preparation method and application. The composite nano-zinc oxide additive comprises the following ingredients (by weight): 70-80% of nano-zinc oxide, 5-15% of plant essential oil and 2-10% of oligosaccharide. By cooperation of plant essential oil and oligosaccharide and nao-zinc oxide, the anti-diarrhea effect of naon-zinc oxide is enhanced through compatibility of other synergistic substances on one hand; and on the other hand, damage of gastric acid to nano-zinc oxide passing through stomach is reduced such that effective dose of nano-zinc oxide which succeeds in reaching the intestinal tract is increased so as to enhance the anti-diarrhea effect of piglets.

Owner:德阳定芯丸生物科技有限公司

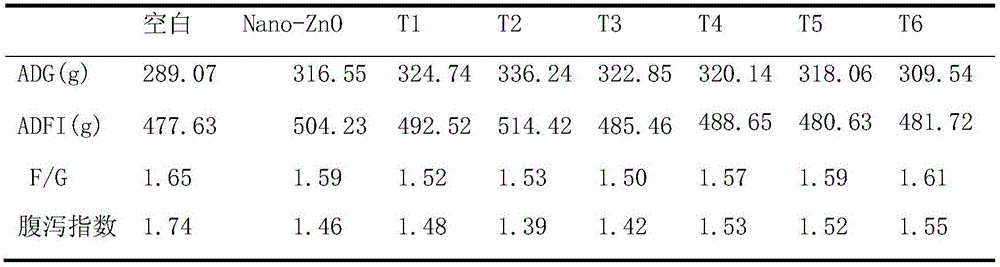

Vehicle methanol fuel corrosion-inhibitor for various metals

The invention belongs to the field of substituting an automobile alcohol ether for a fuel additive, and in particular relates to a vehicle methanol fuel corrosion-inhibitor for various metals. The methanol fuel corrosion-inhibitor for various metals is composed of 30-40wt% of imidazoline derivatives, 5-10wt% of dimer acids, 3-7wt% of polyaspartic acid, 3-10wt% of benzoxazole, 1-5wt% of organic amine, 2-6wt% of nitrogen heterocyclic ring-containing compounds, 0.05-0.1wt% of metal ion passivator and the balance of dispersant. The vehicle methanol fuel corrosion-inhibitor is suitable for anti-corrosion and corrosion inhibition of various metals, such as red copper, brass, 45# steel disc, stainless steel, alumium, zinc and tin. Besides, the vehicle methanol fuel corrosion-inhibitor for various metals is low in the addition amount of additives, nontoxic and pollution-free, and belongs to an environment-friendly corrosion inhibitor.

Owner:中油延长石油销售股份有限公司

Pure Chinese medicinal composition for improving egg yolk color and preparation method thereof

InactiveCN102579681ANo pollution in the processNo drug residueDrug compositionsPlant ingredientsYolkPharmacy medicine

The invention relates to a pure Chinese medicinal composition for improving egg yolk color, which is prepared by mixing the following components in parts by weight: 15 to 35 parts of red pepper, 20 to 60 parts of pine needle, 15 to 35 parts of kelp, 15 to 35 parts of clover, 10 to 25 parts of calendula officinalis, and 10 to 25 parts of marigold. The pure Chinese medicinal composition has the beneficial effects of reasonable prescription, simpleness in preparation, no pollution, no toxic or side effect and no medicine residues; an advanced superfine grinding technology is adopted in the preparation process, so that effective components of the medicaments can be quickly and sufficiently released, the bioavailability of effective components is greatly improved, and the adding dosage is low with only 0.01 percent which is far lower than that of a common Chinese medicinal product. Clinical application proves that: the pure Chinese medicinal composition has special effect in improving the egg yolk color, and has wide application prospect.

Owner:QINGDAO LVMAN BIOLOGICAL ENG

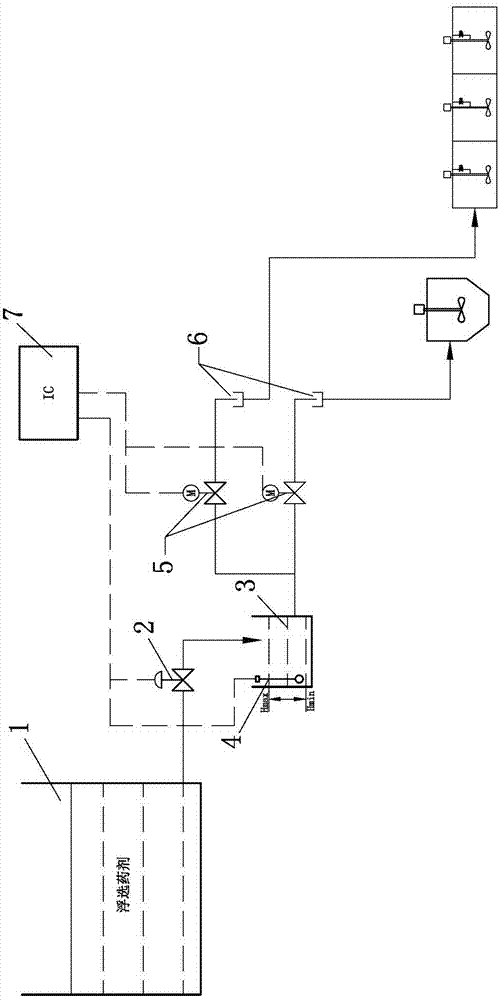

Intelligent flotation medicine quantitative adding system

InactiveCN105446401APrecise control of drug dosageLess dosageSimultaneous control of multiple variablesManual medicineBiomedical engineering

The invention provides an intelligent flotation medicine quantitative adding system. The system comprises a high-position medicine box, a solenoid valve, a low-position medicine box, a liquid level meter, an electric adjusting valve, a medicine buffer and an intelligent controller, wherein the high-position medicine box communicates with a pipeline to the low-position medicine box through the solenoid valve, the liquid level meter is arranged in the low-position medicine box for detecting high and low liquid level restrictions of floatation medicine, the bottom of the low-position medicine box communicates with the medicine buffer downstream through the electric adjusting valve and the pipeline, the medicine buffer communicates with a pulp pretreatment and flotation system through the pipeline, and the solenoid valve, the liquid level meter and the electric adjusting valve are connected with the intelligent controller through a wired mode. The intelligent flotation medicine quantitative adding system has the advantages of automatic real-time addition of the medicine in a flotation process, accurate dosage control and smaller medicine amount, at the same time, effectively solves the defects of poor accuracy, lagged reaction and the like of a conventional manual medicine adding mechanism, and guarantees qualified floatation product indexes.

Owner:TIANJIN MEITENG TECH CO LTD

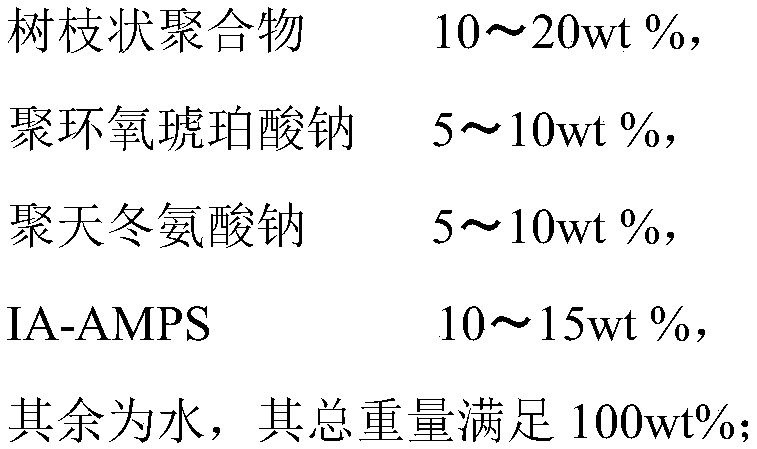

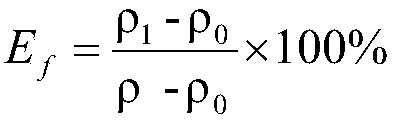

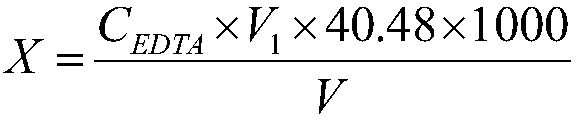

Composite non-phosphorus scale inhibitor

ActiveCN109133389ALess dosageExcellent anti-scaling performanceSpecific water treatment objectivesScale removal and water softeningSodium succinateItaconic acid

The invention belongs to the field of water treatment chemicals and in particular relates to a composite non-phosphorus scale inhibitor which consists of a dendritic polymer, polyepoxy sodium succinate, sodium polyaspartate, IA-AMPS (Itaconic Acid-2-Acrylamide Amino-2-Propanesulfonic Acid) and water, wherein the dendritic polymer is a polyamide-amine dendritic polymer EDA-PAMAM (Ethylenediamine-Polyamidoaminedendrimer) with ethylenediamine as a core and amino as an end group; IA-AMPS is a copolymer of itaconic acid and 2-acrylamide amino-2-propanesulfonic acid as monomers through free radicalpolymerization reactions. The composite non-phosphorus scale inhibitor is free of phosphorus, the components have synergistic effects, mutual coagulation and polymerization of SiO2-PAMAM are prevented, coagulate precipitate can be reduced, the scale inhibition performance is greatly improved, and excellent scale inhibition performance can be achieved for CaCO3, CaSO4 and CaSiO3.

Owner:SHANDONG UNIV OF TECH

Breeding method of antibiotics and hormones-free selenium-enriched chicken

InactiveCN105941304ANo side effectsImprove absorption rateFood processingAnimal feeding stuffAnimal scienceSide effect

The invention discloses a breeding method of antibiotics and hormones-free selenium-enriched chicken. The method comprises following steps: (1) selenium-enriched forage grass selecting: diluting water-soluble protein selenium to obtain water-soluble protein selenium solution and spreading the solution on forage grass inside a farm once a week, and collecting and storing the selenium-enriched forage grass after four months for free feeding of chicken; (2) fodder selecting: natural grain and the selenium-enriched forage grass collected in step (1) are used as breeding fodder; (3) drinking water preparing: water-soluble protein selenium is added to drinking water for chicken according to prescribed ratio; (4) breeding environment: free-ranging covers the whole breeding process and no antibiotic and medicinal component is used. The bred chicken has no side effect and is non-toxic; the chicken has high selenium content, good taste, and meets the dual requirement of health and delicacy.

Owner:OMEGA BIOTECH LUAN CO LTD

Method for preparing zinc oxide ore collecting agent

ActiveCN106238217AGood selectivity and low temperature resistanceLess dosageFlotationChemistryOleic Acid Triglyceride

The invention provides a method for preparing a zinc oxide ore collecting agent. The method comprises the following steps: firstly, mixing oleic acid methyl ester with carbinolamine according to a molar ratio of (1-2):(1-3) to obtain a solution 1, adding sodium hydroxide with mass percentage concentration of 25-30% in the solution 1 according to a mass ratio of (1-2):(2-3), stirring for 2-2.5 h at a temperature of 120-125 DEG C to prepare a solution 2, adding phosphorus pentoxide in the solution at 90 DEG C according to a mass ratio of (1-2):(1.5-4), stirring for 3-3.5 h, and finally adding sodium hydroxide with mass percentage concentration of 20-25% for neutralization, and carrying out drying at a temperature of 40-50 DEG C to obtain the zinc oxide ore collecting agent.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com