Spodumene ore processing method

A beneficiation method and spodumene ore technology, applied in flotation, solid separation and other directions, can solve the problems of low recovery rate, many steps, complicated process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

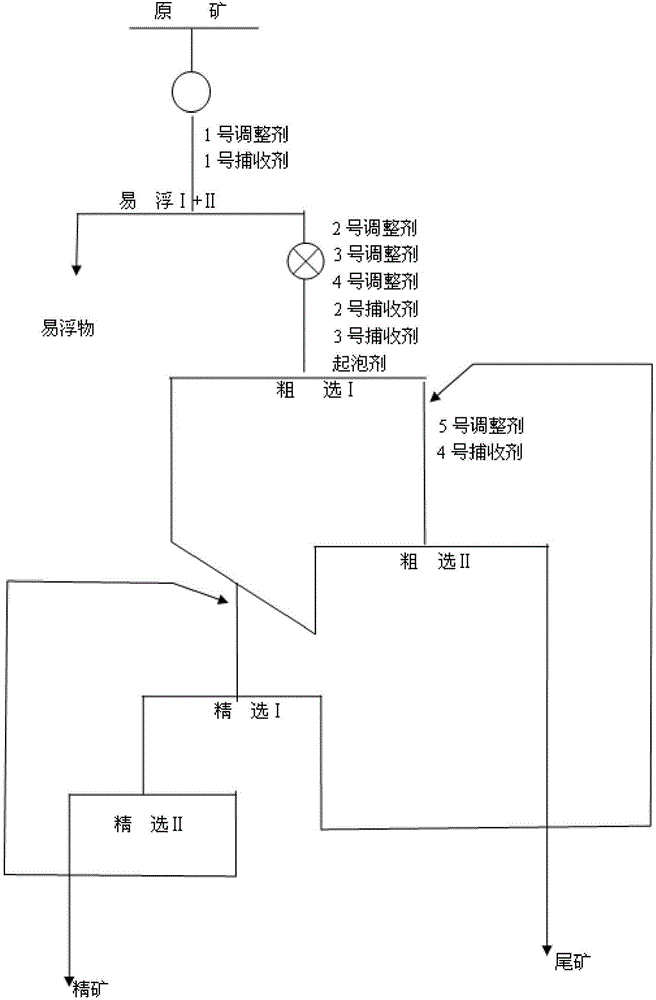

Method used

Image

Examples

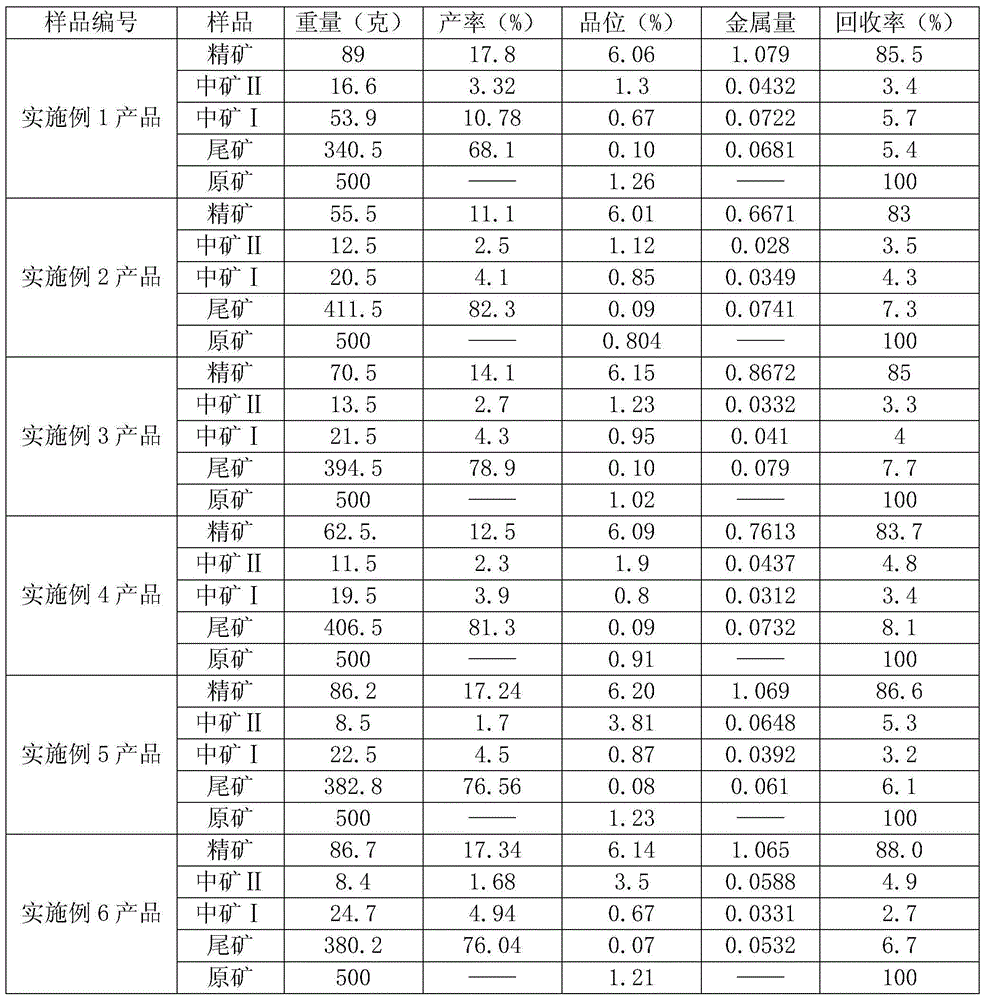

Embodiment 1

[0059] Carry out the beneficiation of spodumene ore according to the following steps:

[0060] a. Grinding: Take 500g of spodumene raw ore, add 350ml of water to grind the ore to obtain pulp I, the grinding fineness is -200 mesh, the content accounts for 72%, and the raw ore grade is 1.2%;

[0061] b, flotation: add regulator sodium carbonate 0.04g in pulp I, stir for 10 minutes, then add collector naphthenic acid soap 0.03g, stir for 3 minutes and carry out flotation, carry out the flotation of easy-floating ore, get Flotation and pulp II;

[0062] c. Rough separation Ⅰ: Add 0.15 g of modifiers sodium hydroxide and 0.05 g of sodium carbonate to pulp II and stir for 20 minutes, then add 0.08 g of regulator ferric chloride and stir for 10 minutes, then add collector 0.4 g of oleic acid and 0.05 g of benzohydroxamic acid was stirred for 5 minutes, and finally 0.05 g of foaming agent kerosene was added and stirred for 1 minute, and rough flotation was carried out to obtain rough...

Embodiment 2

[0066] Carry out the beneficiation of spodumene ore according to the following steps:

[0067] a. Grinding: take 500g of spodumene raw ore, add 350ml of water for grinding, and obtain pulp I, the grinding fineness is -200 mesh, the content accounts for 72%, and the raw ore grade is 0.8%;

[0068] b. Flotation: Add 0.05g of regulator potassium carbonate to pulp Ⅰ, stir for 9 minutes, then add 0.02g of collector 733 paraffin oxide soap, stir for 2 minutes, then carry out flotation, and carry out flotation of easy-floating ore , to obtain flotation material and pulp II;

[0069] c. Rough separation Ⅰ: Add 0.15 g of potassium hydroxide as a regulator and 0.05 g of potassium carbonate as a regulator to pulp II and stir for 13 minutes, then add 0.1 g of calcium chloride as a regulator and stir for 10 minutes, then add collector 733 Stir 0.04 g of paraffin wax soap and 0.5 g of sodium oleate for 4 minutes, finally add 0.02 g of foaming agent diesel oil and stir for 1 minute, and car...

Embodiment 3

[0074] Carry out the beneficiation of spodumene ore according to the following steps:

[0075] a. Grinding: Take 500g of spodumene raw ore, add 350ml of water to grind ore, and obtain pulp I, the grinding fineness is -200 mesh, the content accounts for 85%, and the raw ore grade is 1.02%;

[0076] b. Flotation: Add 0.03g of regulator sodium sulfide to pulp I, stir for 11 minutes, then add 0.05g of collector naphthenic acid soap, stir for 4 minutes, then carry out flotation, and carry out flotation of easy-floatable ore to obtain Flotation and pulp II;

[0077] c. Rough separation Ⅰ: Add 0.2 g of regulator potassium hydroxide and 0.06 g of regulator sodium carbonate to pulp II and stir for 13 minutes, add 0.12 g of regulator ferric chloride and stir for 10 minutes, then add collector naphthene Stir 0.3 g of acid soap and 0.07 g of 733 type oxidized paraffin wax soap for 6 minutes, finally add 0.02 g of foaming agent diesel oil and stir for 1 minute, and carry out rough flotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com