Patents

Literature

196results about How to "Excellent anti-scaling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-free corrosion and scale inhibitor

InactiveCN101607763AReduce dosagePlay a role in corrosion inhibitionTreatment using complexing/solubilising chemicalsChelationPrecipitation types

The invention relates to a phosphorus-free corrosion and scale inhibitor, which is prepared from sodium molybdate, zinc salt, citrate, triethanolamine, benzotriazole (BTA), polyaspartic acid (PASP), polyepoxysuccinic acid (PESA), AA / AMPS terpolymer, solid alkali and water. The phosphorus-free corrosion and scale inhibitor inhibits corrosion of metals by forming oxidization type and precipitation type films on the surfaces of the metals, has the effect of inhibiting scale through chelation and dispersive action on salts causing scale in cooling water, is non-toxic and phosphorus-free, has easily biodegradable major organic compositions, does not cause environmental pollution and is not limited by phosphorus in emission.

Owner:SHANGHAI WEILAI ENTERPRISE

Non-phosphate, agglomerated laundry booster

InactiveUS6022843AGood lookingImprove performanceInorganic/elemental detergent compounding agentsSurface-active non-soap compounds and soap mixture detergentsPhosphateBleach

The invention is an improved, non-phosphate, non-bleach, agglomerated laundry booster which has a) a solids portion with i) at least 5% by weight of a first builder selected from the group consisting of alkali metal carbonate, alkali metal bicarbonate, alkali metal sesquicarbonate, and mixtures thereof; and ii) a second builder of at least 25% by weight alkali metal tetraborate pentahydrate; and b) i) a first liquid which comprises an anionic, acidic surfactant, in an amount no greater than about 10% by weight; and ii) a second liquid which comprises an agglomerating agent. The first liquid is neutralized by the first builder of a)i) to form a first set of particles, the second builder forms a second set of particles, and the second liquid co-agglomerates both the first and second sets of particles. The invention also provides a method for preparing this laundry booster.

Owner:THE CLOROX CO

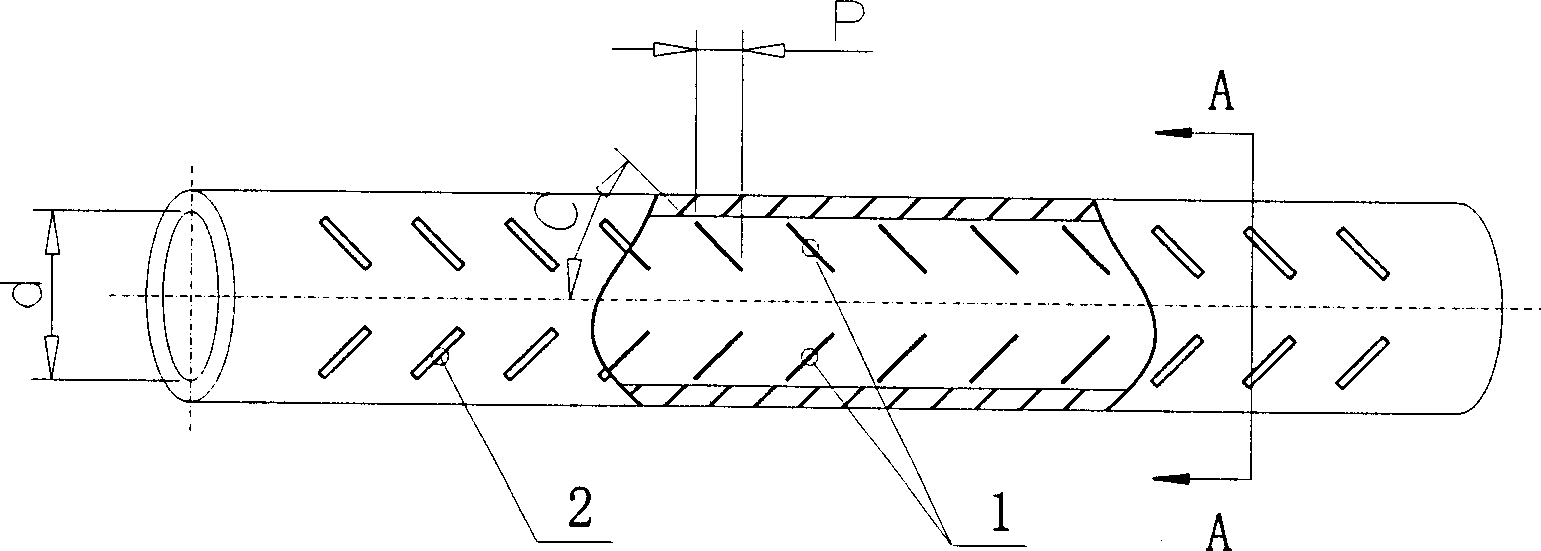

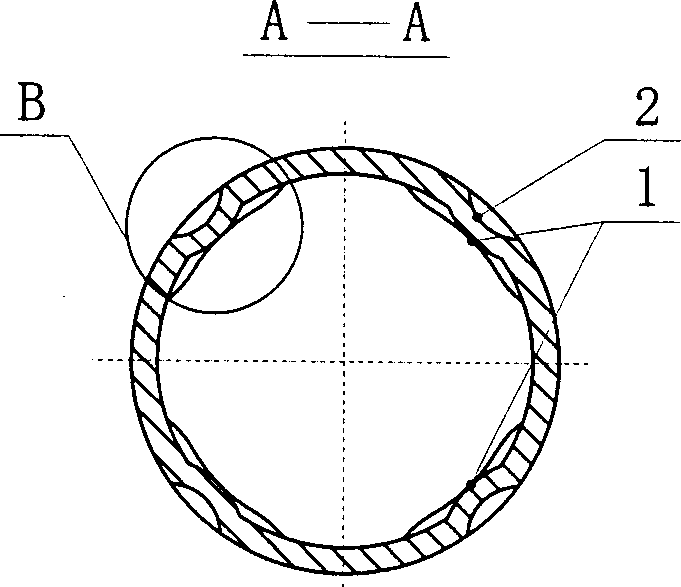

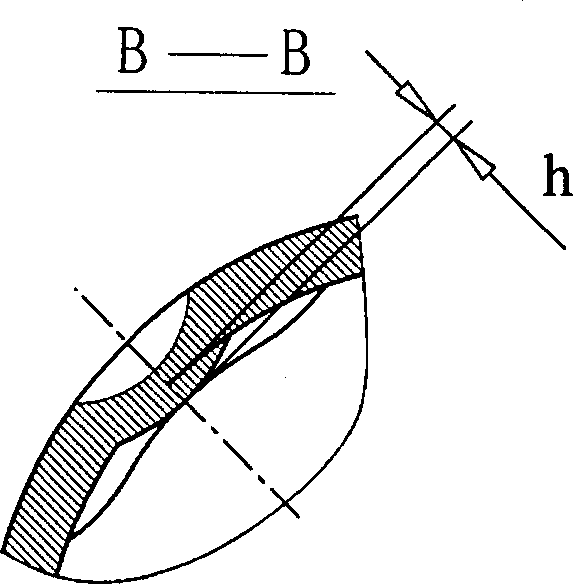

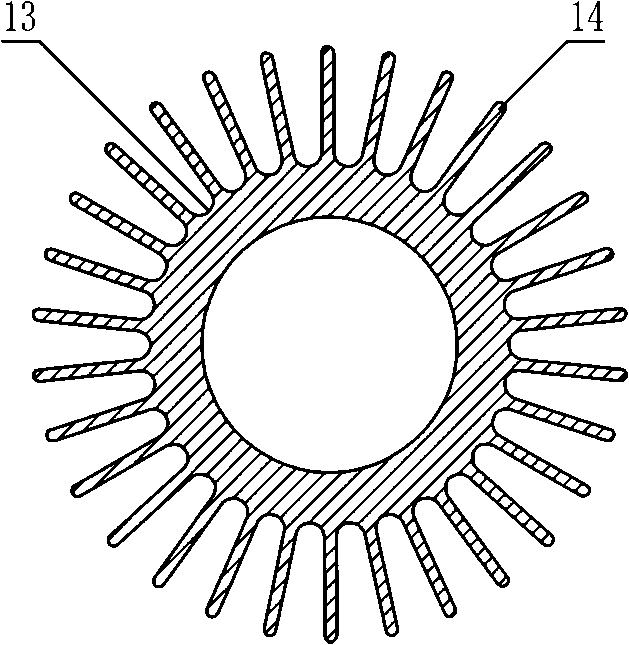

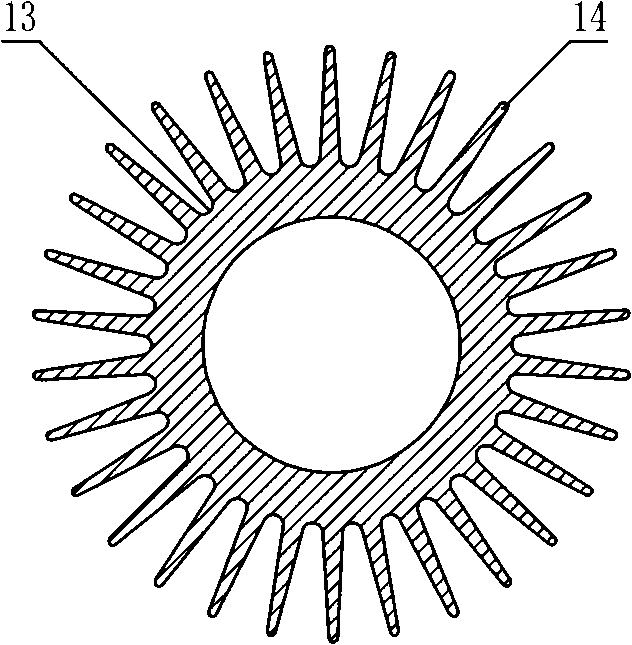

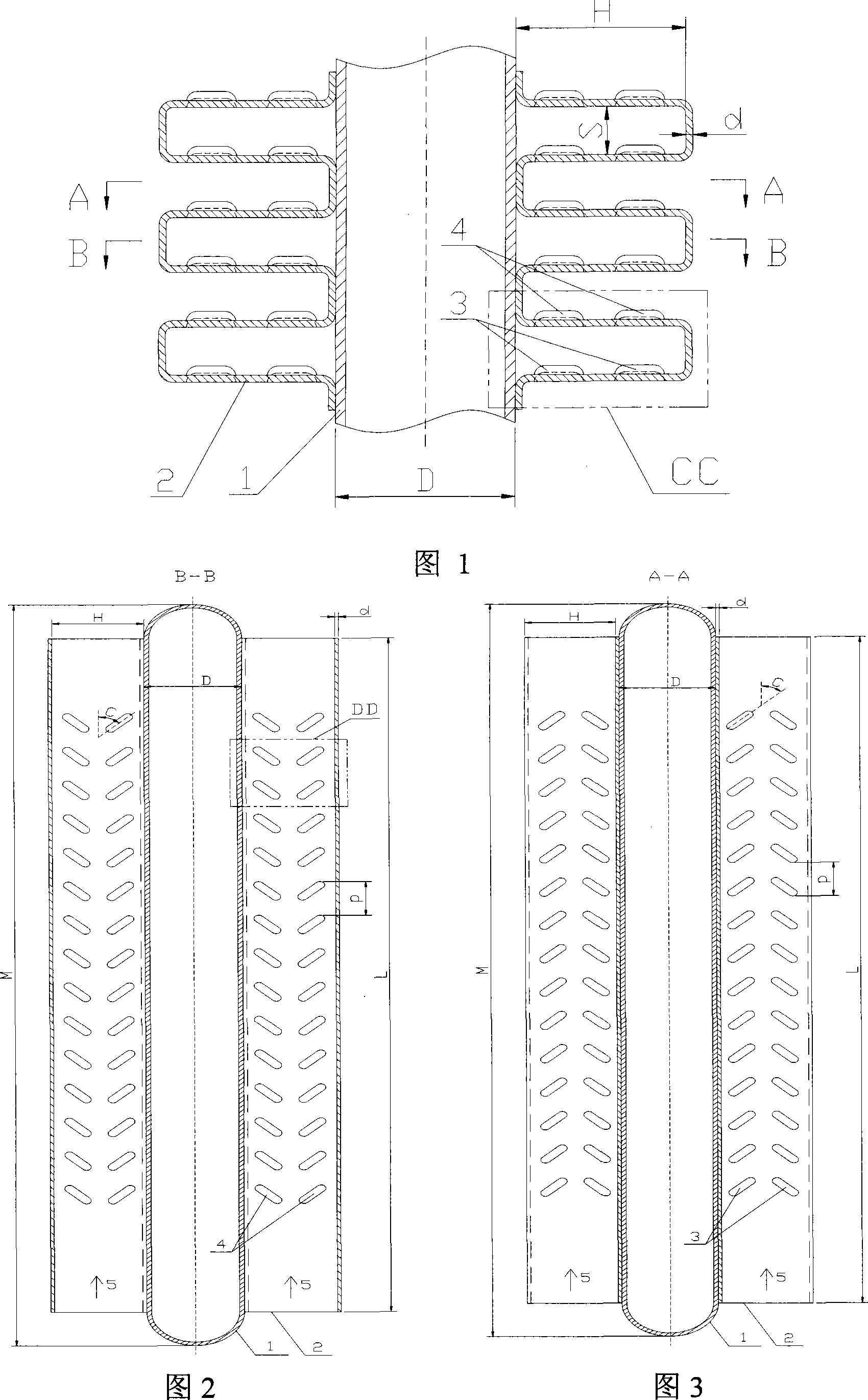

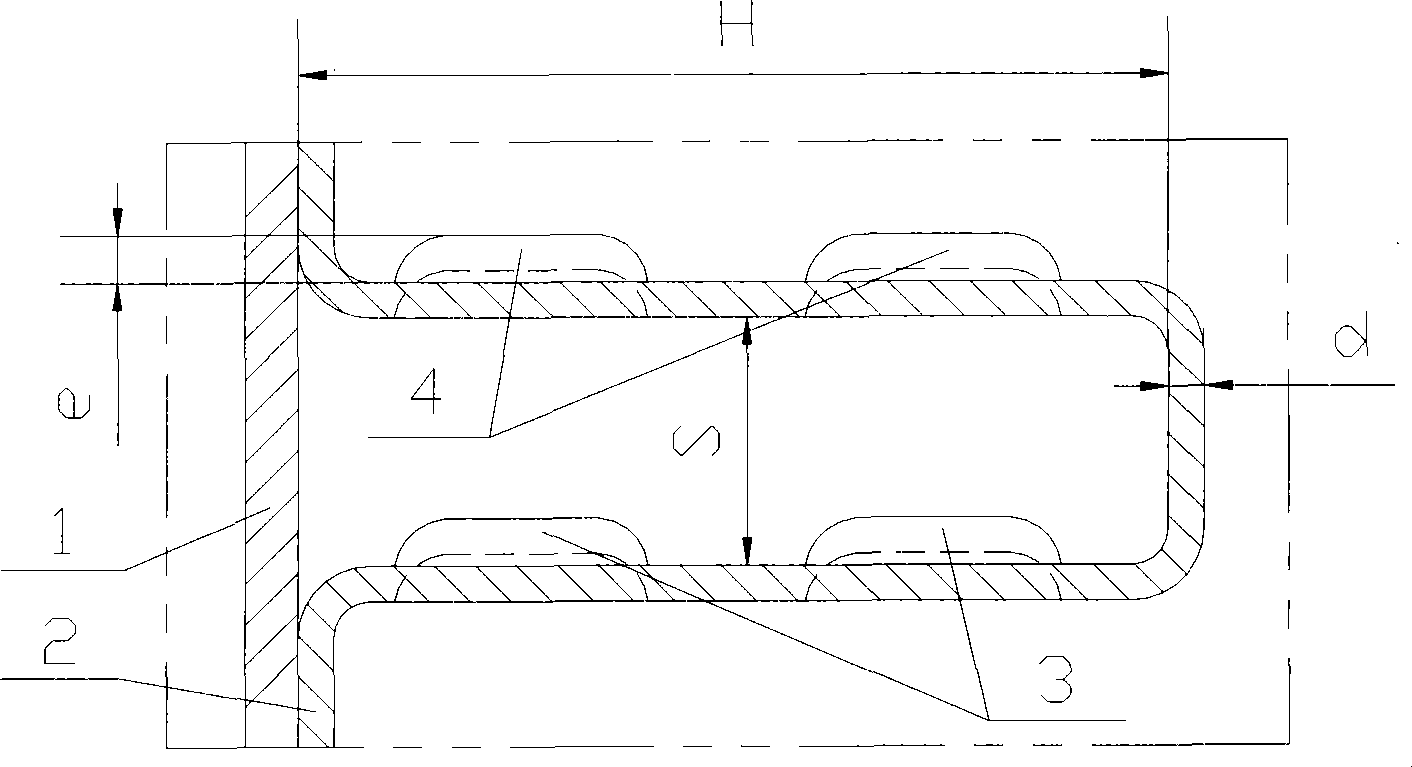

Non-continuous double diagonal internal rib reinforced heat exchange tube

InactiveCN1451937ASignificant effect of enhanced heat transferSmall flow resistanceHeat exchanger casingsTubular elementsEngineeringHigh heat

A heat exchanging tube is characterized by that on its inner surface there are discontinuous internal ribs which have a certain included angle (5-85 deg.) relative to axis of tube and are inclined intwo directions. Its advantages are high heat exchange efficiency, low flow resistance and not scaling.

Owner:TSINGHUA UNIV

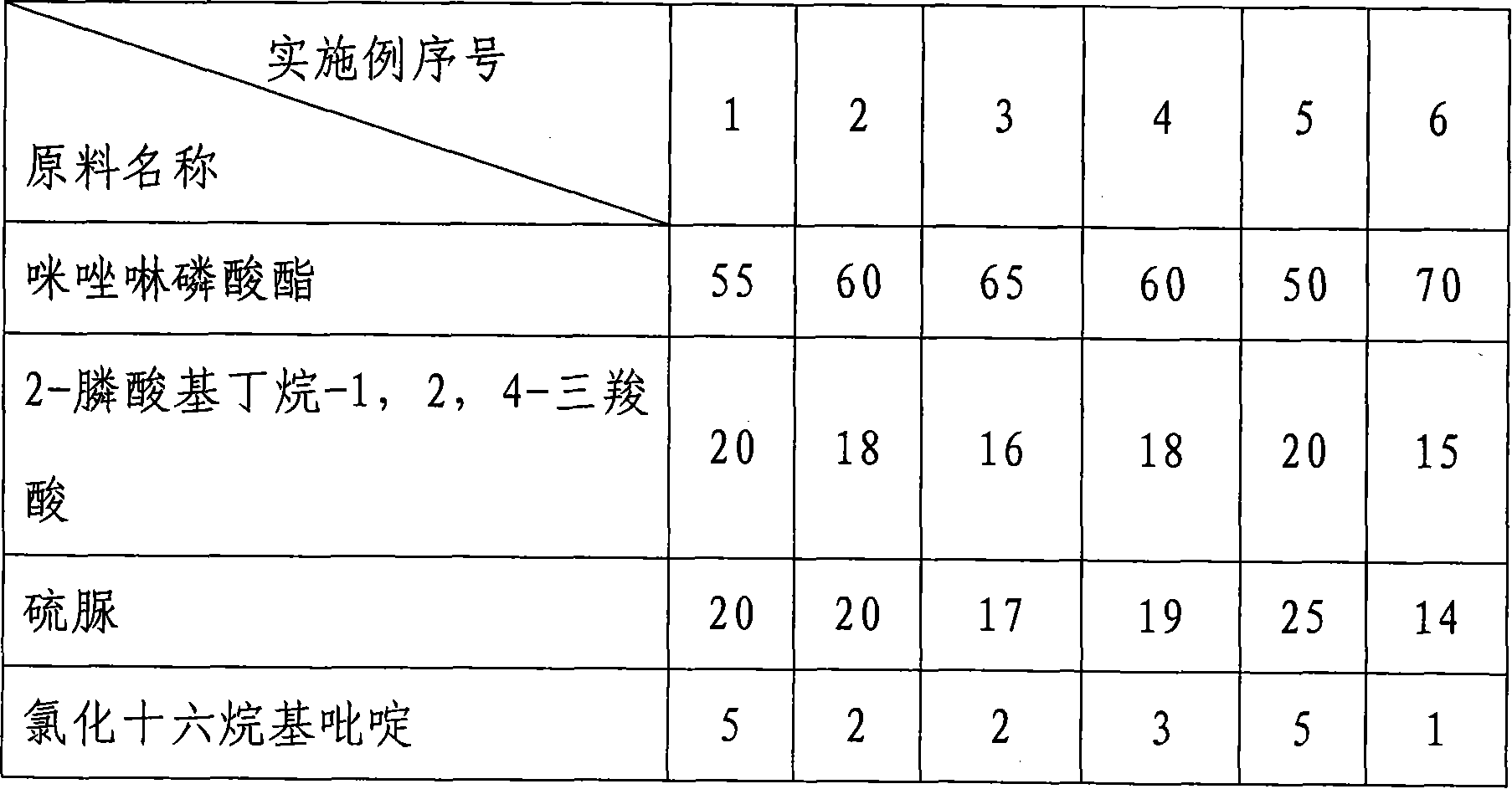

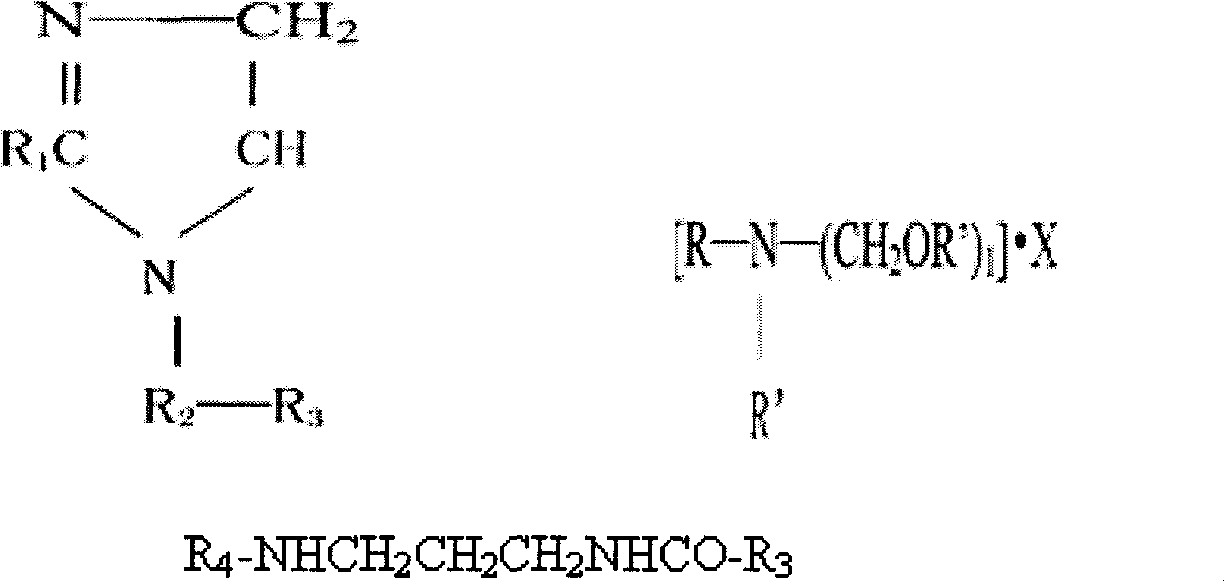

Compound inhibitor for exploitation of oil-gas field and preparation method thereof

ActiveCN101230260AGood corrosion inhibitionPrevents foulingBorehole/well accessoriesPhosphateThiourea

The invention discloses an oil gas field exploitation used compound inhibitor and the preparation method. The compound inhibitor contains imidazolinyl organic phosphate, 2 - N-acid butyrate -1, 2, 4-tricarboxylic acid, thiourea, cetylpyridinium chloride. The mixture proportions of all constituents by weight can meet the specified contents of all active substances. The preparation method is that the 2 - N-acid butyrate -1, 2, 4 - tricarboxylic acid is added into imidazolinyl organic phosphate; thiourea is added into and dissolved into water; the solutions obtained by sub-steps are mixed together and are added into the cetylpyridinium chloride; after evenly stirring for 50-90 minutes and keeping the temperature rang within 15-45 DEG C, the inhibitor of the invention is produced. The compound inhibitor uses multifold medicaments for synergia, can prevent scale formation, can kill bacteria or inhabit bacteria from growing with less usage, can be applied to wide range, and can perform excellent efficiency under complex water quality condition.

Owner:XINJIANG DELAND

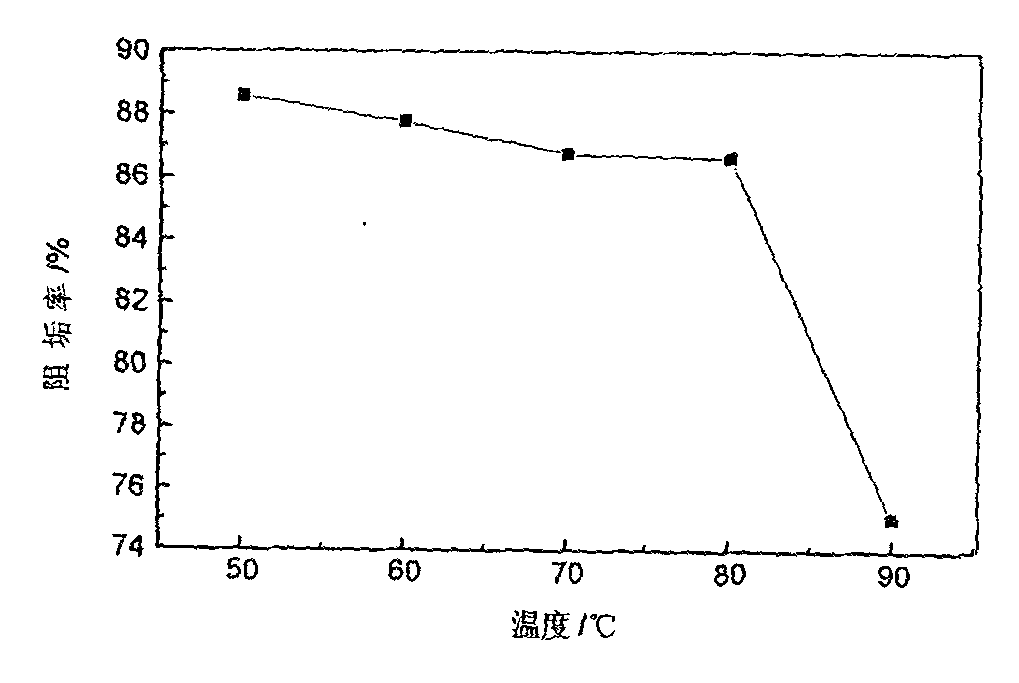

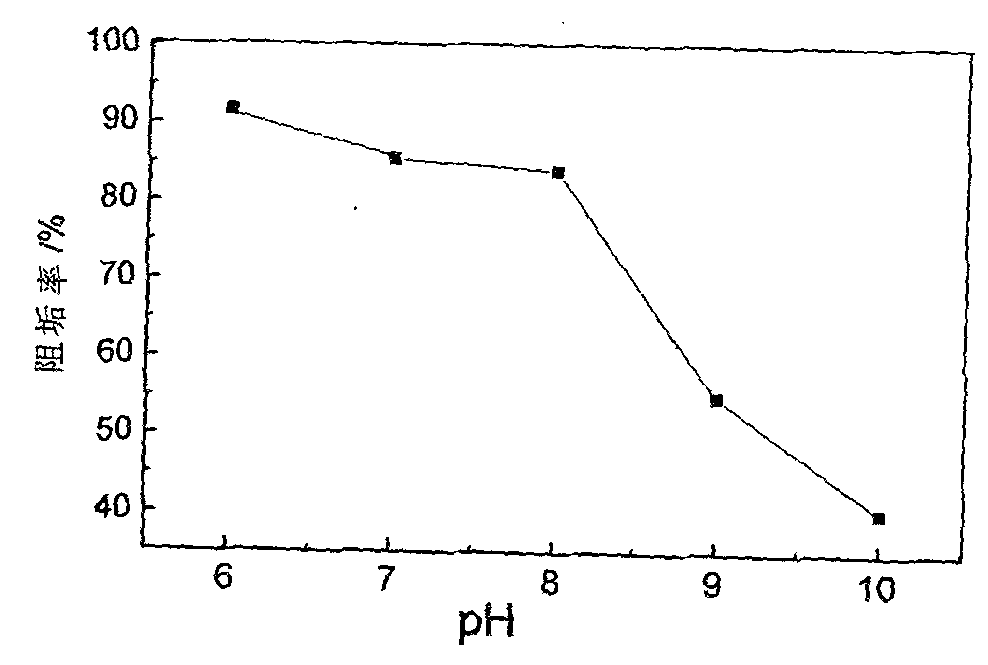

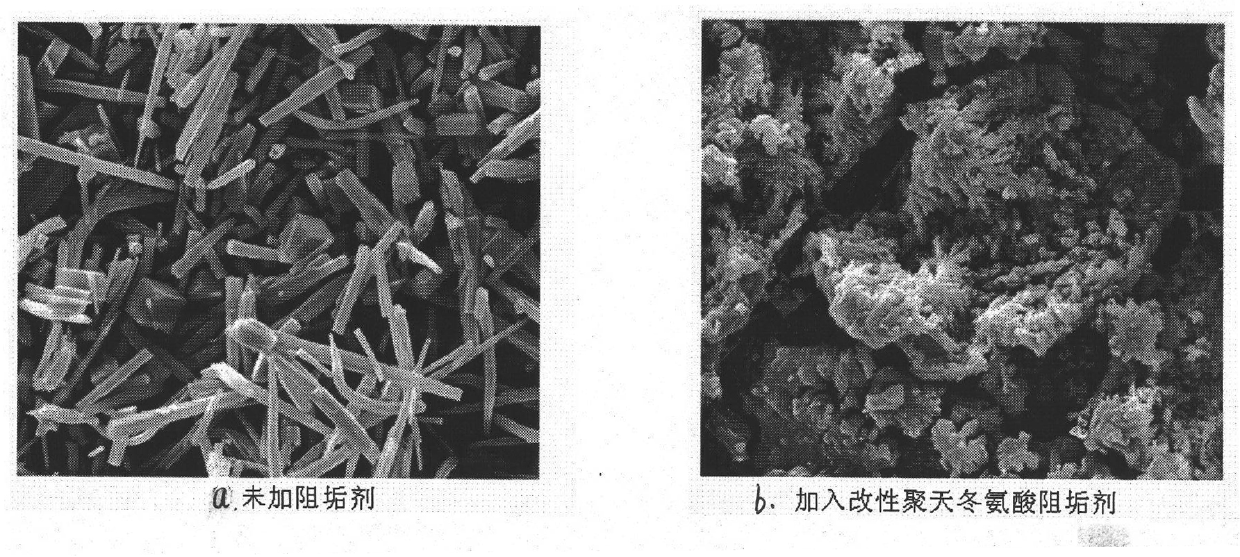

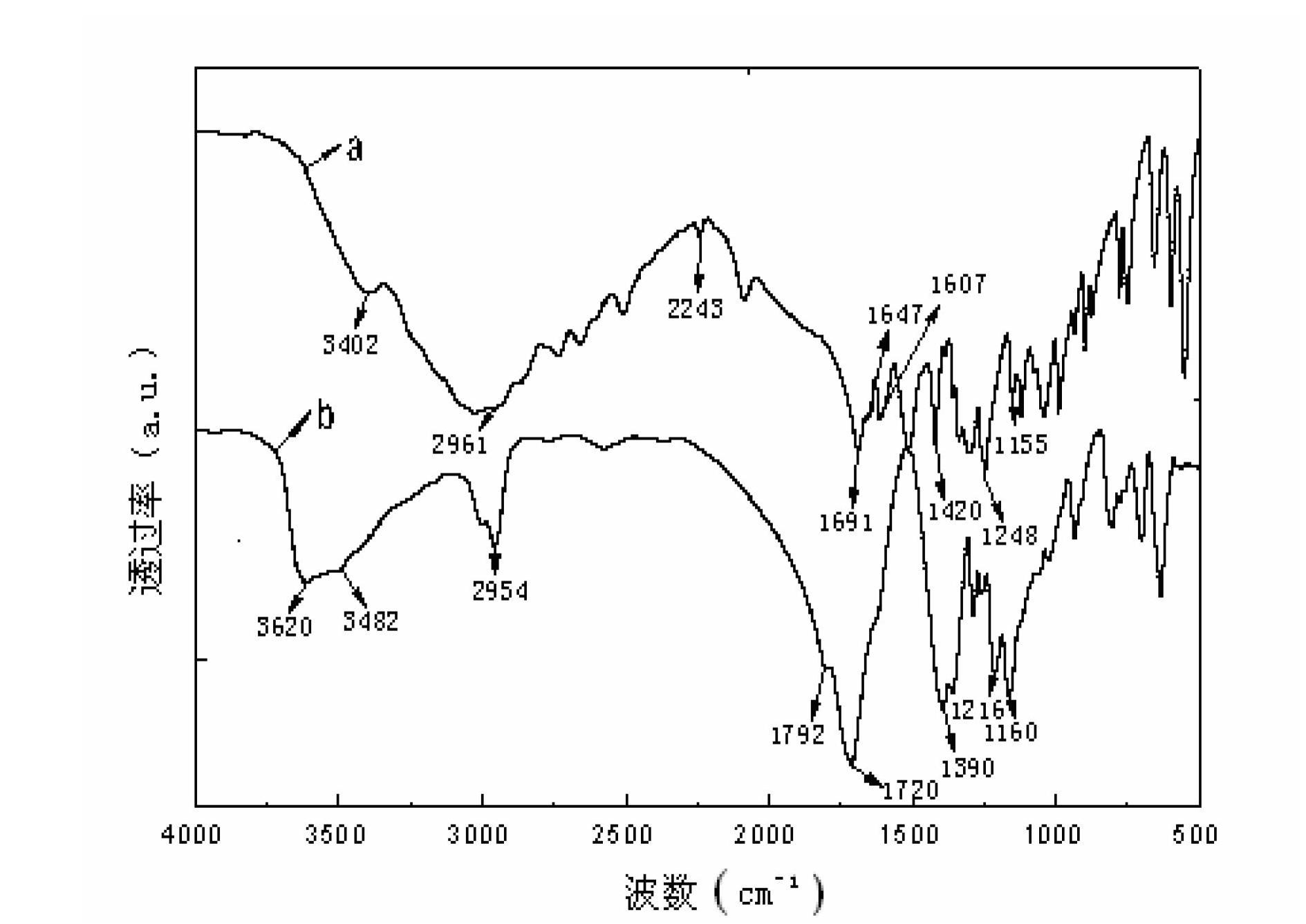

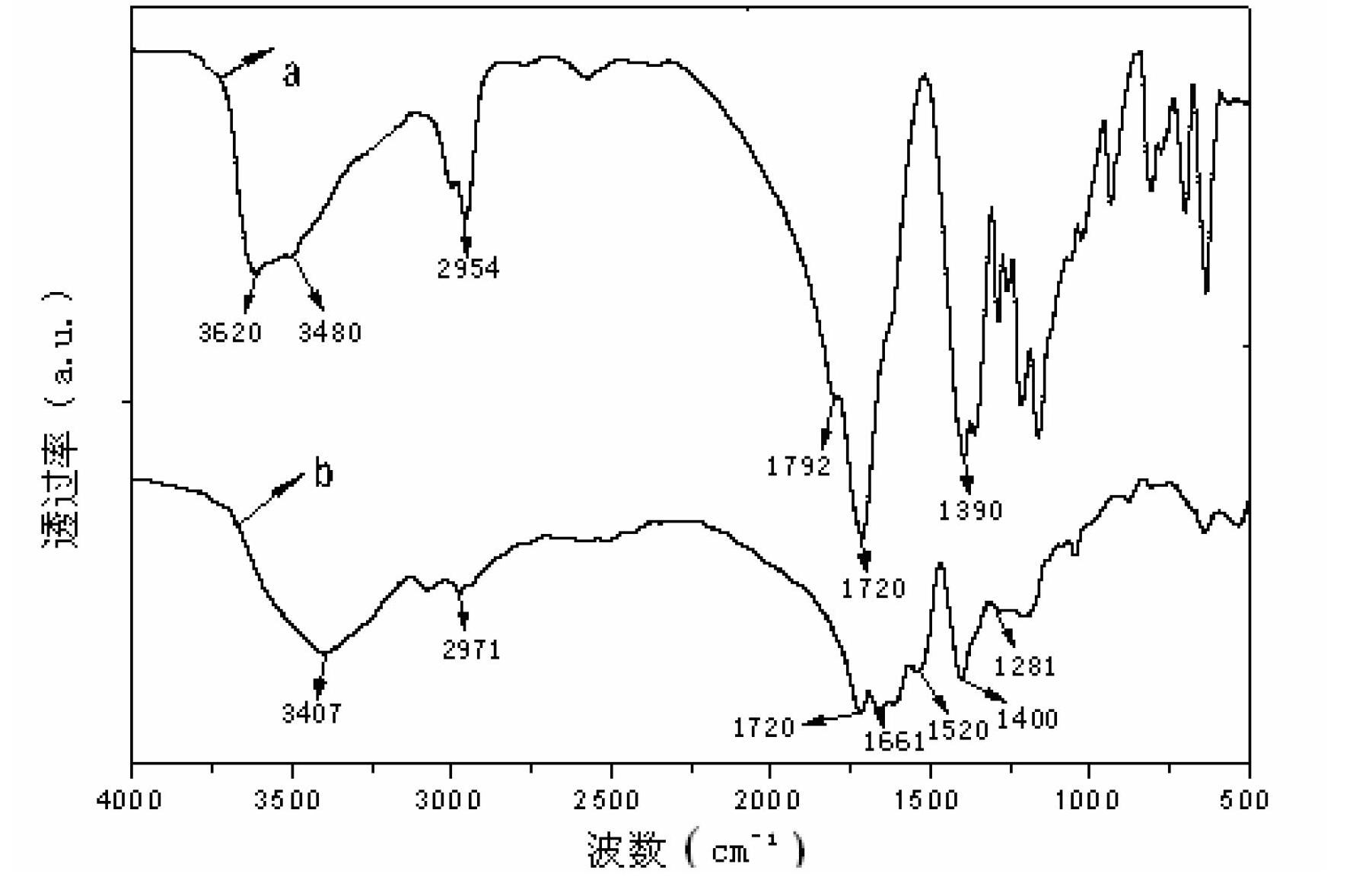

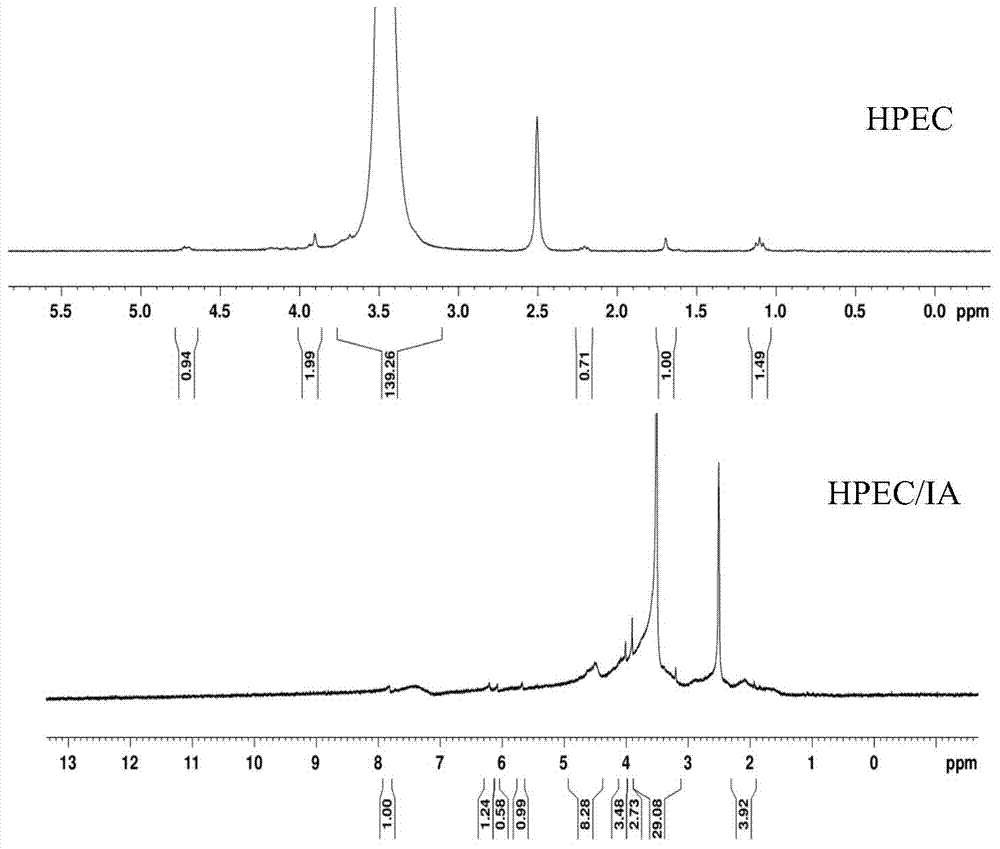

Methods for preparing and applying modified polyaspartic acid scale inhibitor

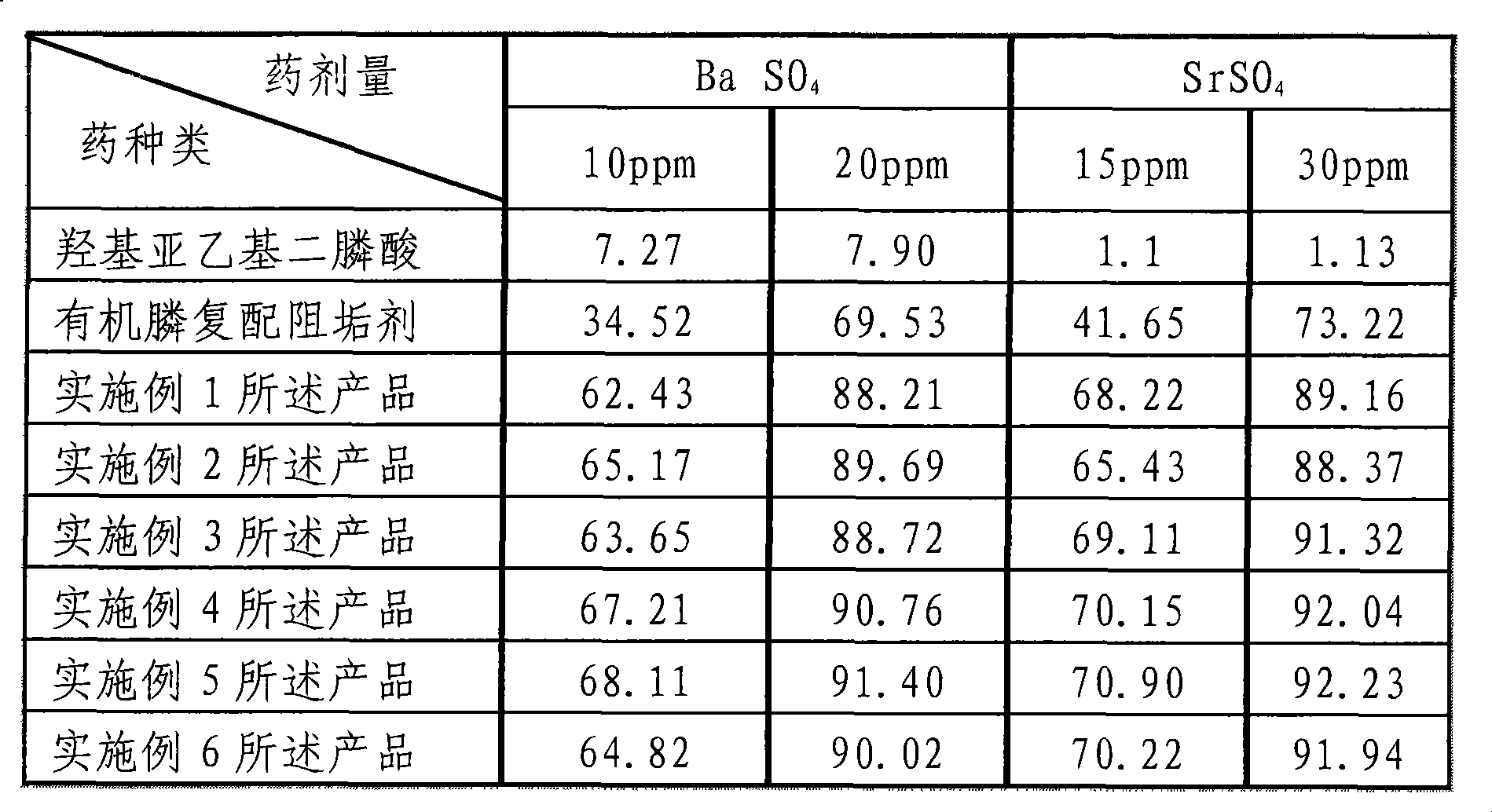

InactiveCN101792504AExcellent anti-scaling performancePromote degradationScale removal and water softeningImidePolyaspartic acid

The invention relates to methods for preparing and applying a modified polyaspartic acid scale inhibitor, which belong to the field of preparation and application of scale inhibitors. The method for preparing the modified polyaspartic acid scale inhibitor comprises the following step of: preparing polysuccinimide (PSI), polyaspartic acid (PASP) and modified polyaspartic acid (CSN-PASP). The scale inhibitor prepared by using the method has good adaptability at the temperature of 50-80 DEG C and the pH value ranging from 6.0 to 8.5. The modified polyaspartic acid scale inhibitor belongs to a polymer type scale inhibitor. A PASP molecule does not contain phosphorus, has no poison, does not destroy the ecological environment and has favorable biodegradability and water solubility, and the excellent scale inhibiting dispersion performance is particularly suitable for industrial water treatment. The aim for improving the scale inhibiting performance of the PASP is achieved by just adding a micromolecule substance in synthesis without changing other process conditions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Continuous crystallization process for monopotassium phosphate

InactiveCN103159194AReduce manufacturing costEasy to operatePhosphorus compoundsSmall footprintMonopotassium phosphate

The invention discloses a continuous crystallization process for monopotassium phosphate. The continuous crystallization process comprises the following specific steps of: introducing a feed liquid to be crystallized into a first-stage continuous flash crystallizer so as to be separated into a primary clear liquid, primary crystal mush and secondary steam; discharging the primary crystal mush from the first-stage continuous flash crystallizer and feeding the primary crystal mush into a second-stage continuous cooling crystallizer, wherein the second-stage continuous cooling crystallizer is composed of an Oslo crystallizer and an external cooler; separating the primary crystal mush into secondary crystal mush and a secondary clear liquid in the Oslo crystallizer; discharging the secondary crystal mush from the Oslo crystallizer, feeding the secondary crystal mush into a thickener and separating the secondary crystal mush into triple clear liquid and triple crystal mush; discharging the triple crystal mush from the thickener, feeding the triple crystal mush into a centrifugal machine, and separating the triple crystal mush into solid monopotassium phosphate and a centrifugal liquid; and discharging the solid monopotassium phosphate from the centrifugal machine. The continuous crystallization process is stable in operation, low in energy consumption and low in labor intensity; and by using the continuous crystallization process, the operation stability and the product quality are greatly improved, the on-site operation environment is improved, and the production cost of the monopotassium phosphate is reduced. A mating device for the process is small in floor area and high in capacity.

Owner:HEBEI NUODA CHEM EQUIP

Scale inhibitor for reverse osmosis membrane and preparation thereof

ActiveCN101497481AExcellent anti-scaling performanceImprove low limit scale inhibition performanceScale removal and water softeningBiopolymerPhosphate

The invention relates to a reverse osmosis water treatment agent, in particular to a scale inhibitor for reverse osmosis membrane. A formulation comprises organic poly-phosphate compound, phosphine carboxylic acid, crylic acid biopolymer, polymaleic acid compound and water; the compositions have the following weight mixture ratio: 1.0 to 6.0 percent of the organic poly-phosphate compound, 2 to 12 percent of the phosphine carboxylic acid, 10 to 40 percent of the crylic acid biopolymer, 0.2 to 2 percent of the polymaleic acid compound and the balance being water. The scale inhibitor for the reverse osmosis membrane utilizes synergism of each composition, improves the lower-limit scale inhibition performance of the scale inhibitor on reverse osmosis concentrated water (highly mineralized water), effectively controls large-scale formation on the reverse osmosis membrane of calcium, strontium, barium, magnesium, iron, copper, zinc and other salts, reduces the cleaning frequency of a reverse osmosis system and maintains normal water drainage and water supply pressure.

Owner:北京弘扬紫东环保科技有限公司

Ash water scale inhibiting and dispersing agent, and application thereof

The present invention discloses an ash water scale inhibiting and dispersing agent, and an application thereof. The ash water scale inhibiting and dispersing agent is prepared from the following raw materials, wherein the raw materials comprise, by weight, 60-65% of a multicomponent copolymer, 5-10% of a corrosion inhibitor, 7-10% of a phosphonate and 15-20% of water. According to the present invention, the ash water scale inhibiting and dispersing agent is applicable for treating the ash water from the texaco gasification process; the scaling problem of the ash water system in the texaco coal water slurry gasification process is effectively solved; the influence on the production due to the ash water scaling and the corrosion is effectively reduced; the operating cycle of the production equipment is prolonged; the sewage discharging can be reduced; the reuse efficiency of the ash water is improved, and the water resource is saved.

Owner:CHANGZHOU ZHONGNAN CHEM

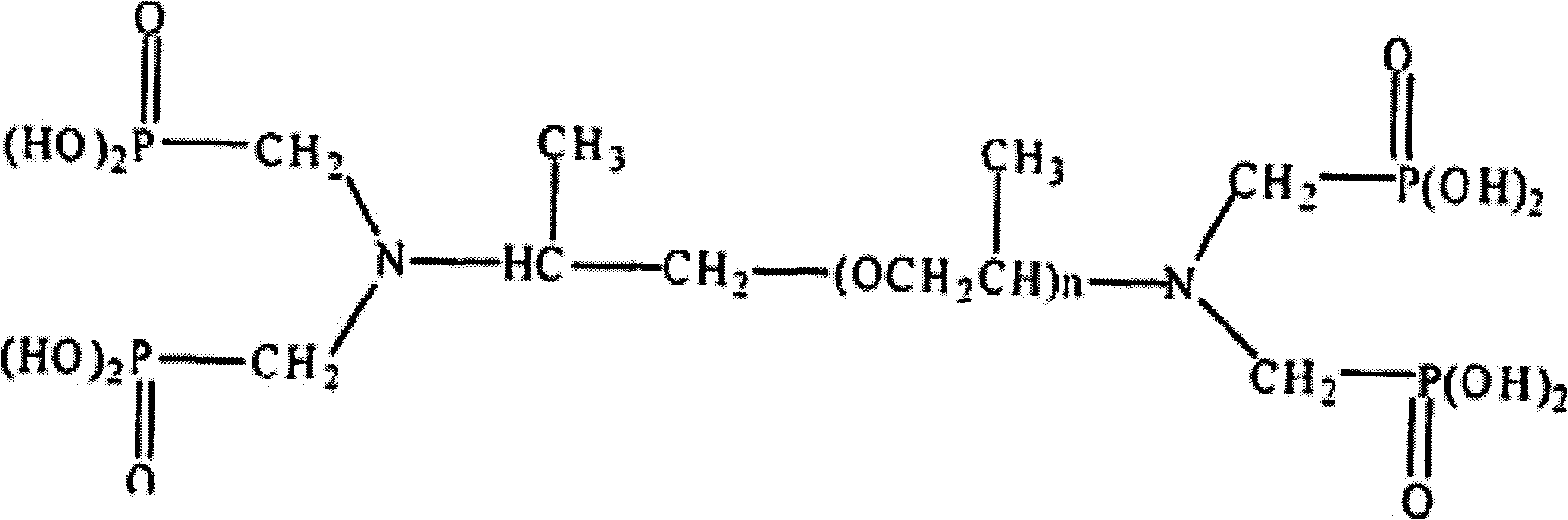

Chemical pressure-reducing injection-increasing agent for injection well and preparation and use thereof

ActiveCN102311728AHigh Chelating Dispersion PerformanceExcellent anti-scaling performanceFluid removalDrilling compositionInjection wellINCREASED EFFECT

The invention relates to a chemical pressure-reducing injection-increasing agent for an injection well and preparation and use thereof. The chemical pressure-reducing injection-increasing agent comprises the following components in percentage by weight: 0.03 to 0.3 percent of hexadecyl trimethyl ammonium bromide surfactant, 0.05 to 0.5 percent of MY / IMC-80BHH corrosion inhibitor, 0.1 to 0.3 percent of polyamino polyether methylene phosphonae, 0.01 to 0.03 percent of polyquaternium, 0.05 to 0.1 percent of citric acid, 0.1 to 0.5 percent of hydrochloric acid and the balance of water. The total amount of the injected water is 100 percent. The pressure-reducing injection-increasing agent is used in an amount which is 0.1 to 0.3 percent based on the weight of injected water. The pressure-reducing injection-increasing agent is added into a medicine adding device in a water injection station, uniformly mixed, pumped into a high-pressure pipe by a high-pressure pump and is injected into stratum with injected water to achieve a chemical pressure-reducing injection-increasing effect. The single-well pressure drop is about 15 percent.

Owner:PETROCHINA CO LTD

Copolymerization derivative of poly-asparagic acid and synthetic method

A modified polyasparagic acid is prepared through preparing intermediate from asparagic acid, a compound, catalyst and solvent by radiating at 50Hz or 2450+ / -50 Hz and 100-3000W for 1-40 min, and hydrolyzing.

Owner:哈尔滨云水工大环保科技股份有限公司

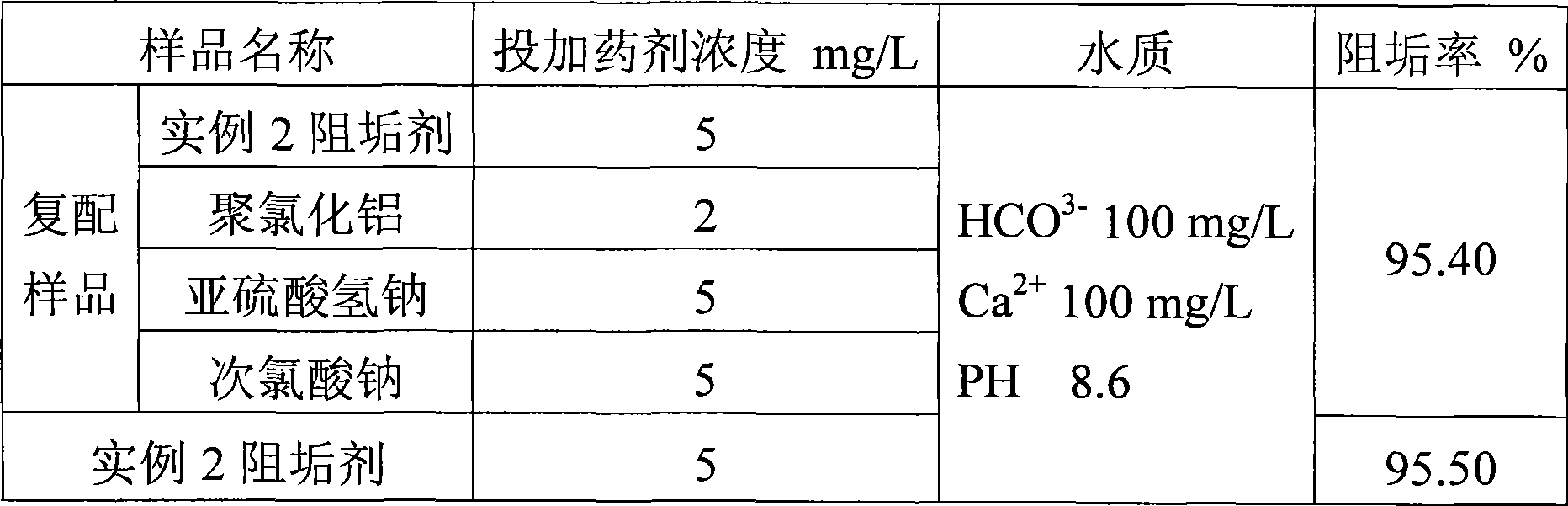

Preparation method of multielement composite scale inhibitor

InactiveCN102464409AExcellent anti-scaling performanceLow equipment investment costScale removal and water softeningReverse osmosisRoom temperature

The invention discloses a preparation method of a multielement composite scale inhibitor. The method is characterized by comprising the following steps: adding 1 part of melamine, 1-3 parts of 30-40% hydrolyzed maleic anhydride, 1-3 parts of ammonium chloride and 1-3 parts of formaldehyde into a container; stirring, dissolving and reacting at 80+ / -5 DEG C for 0.5-2 h; adding 1-3 parts of urea, 1-3 parts of ammonium chloride and 1-3 parts of formaldehyde, and reacting at 90 + / -5 DEG C for 2-4 h; adding 1-3 parts of 15-30% polyacrylic acid and 1-3 parts of 0.5-2% cation polyacrylamide, reacting at 70 + / -5 DEG C for 0.5-1 h; cooling to room temperature to obtain a finished product. The method reduces equipment investment and cost of a reverse osmosis system, and reverse osmosis scale inhibitor has high scale inhibition performance.

Owner:HUBEI ZHONGBI ENVIRONMENTAL PROTECTION TECHCO

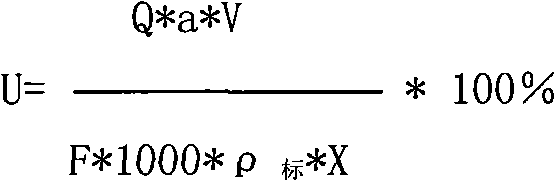

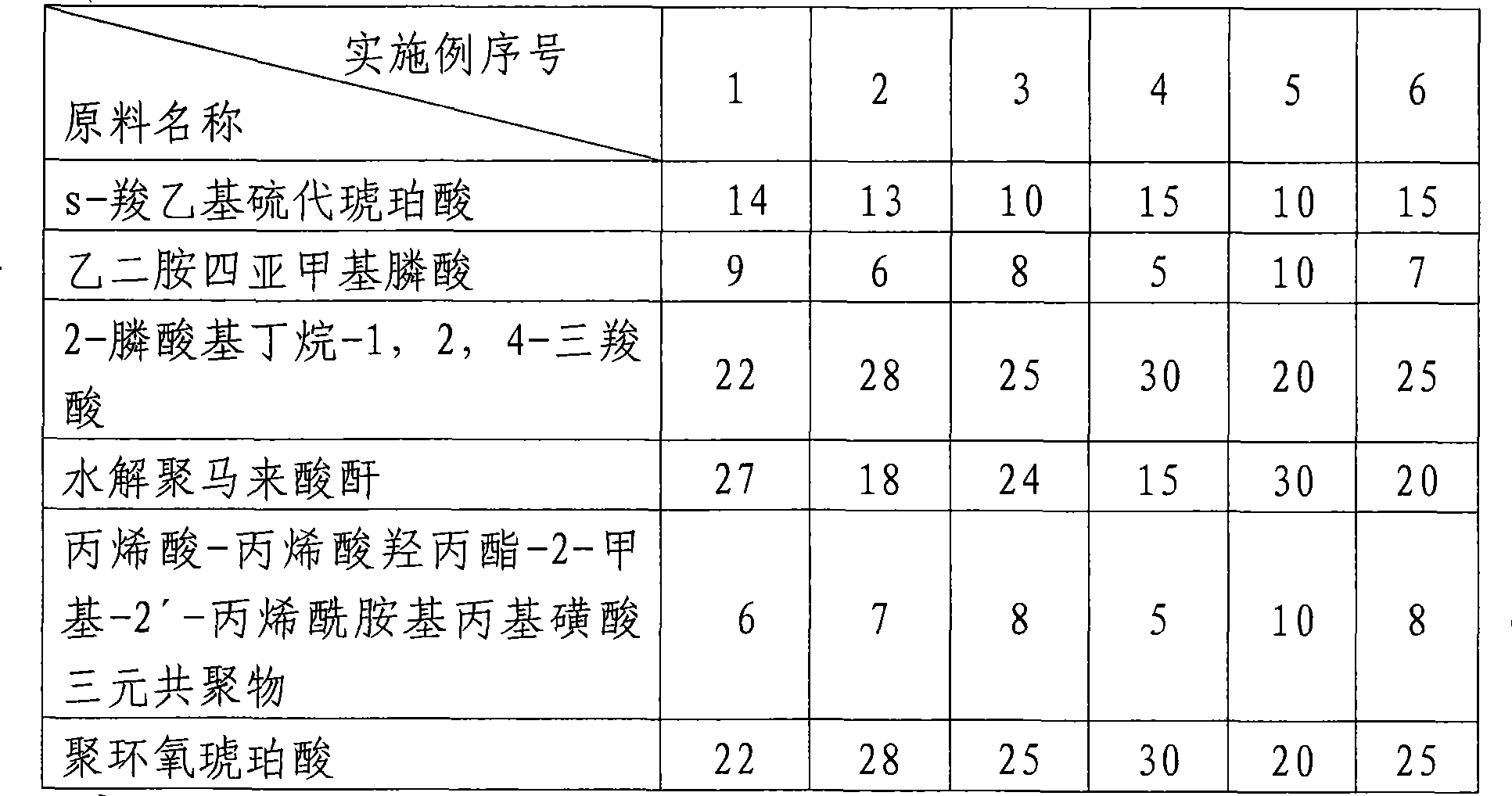

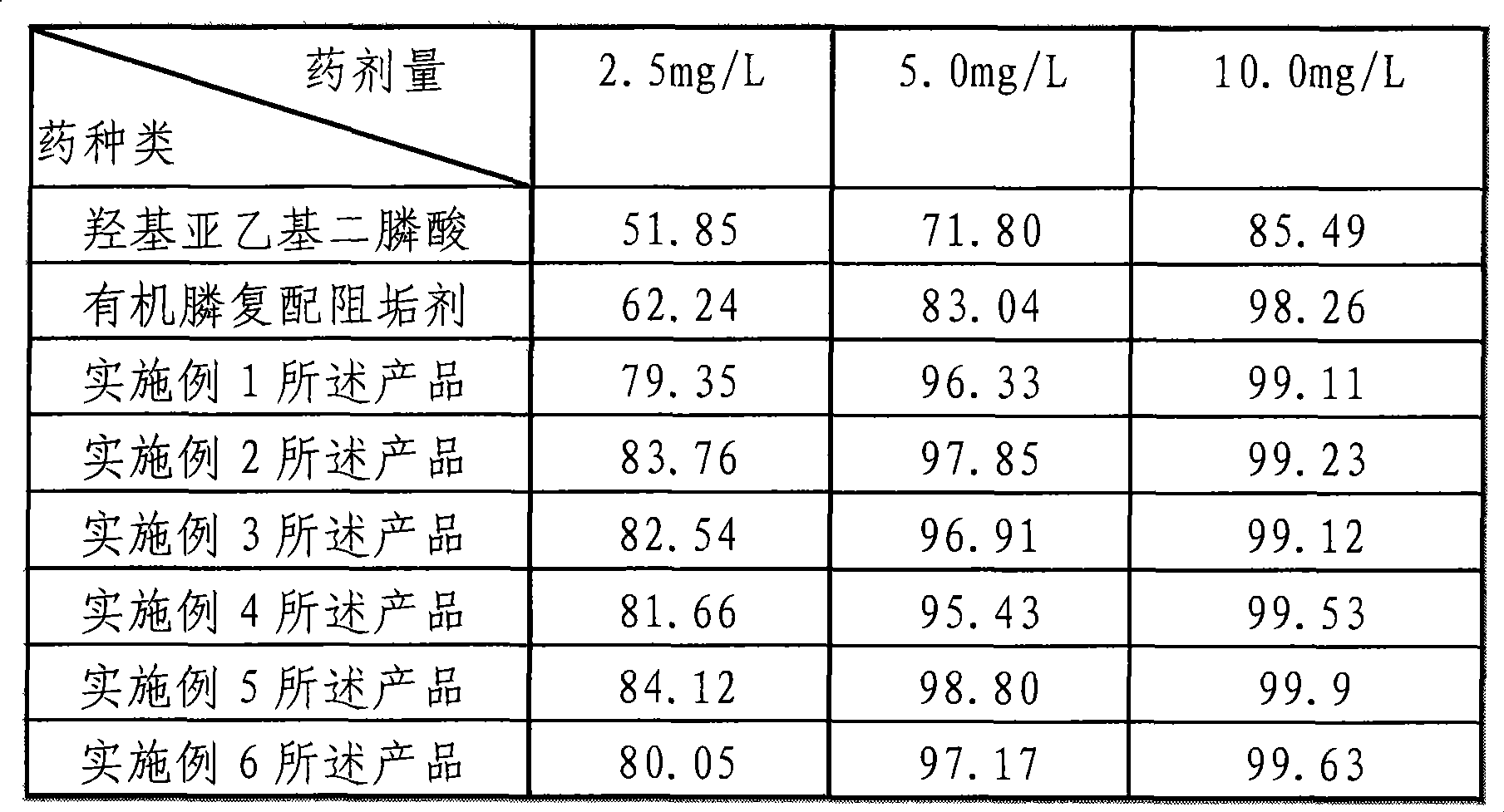

Composite multi-component scale inhibitor for treating oil-field water and preparation thereof

ActiveCN101412567ALattice distortionHas a critical effectScale removal and water softeningChemistryEthylenediaminetetra(methylenephosphonic)acid

The invention relates to a composite multi-component scale inhibitor for oil field water treatment and a preparation method thereof. The composite multi-component scale inhibitor comprises s-propyloic sulpho succinic acid, tetramethylenediamine phosphonic acid, 2-phosphonic butane-1, 2, 4-tricarboxylic acid, hydrolyzed polymaleic anhydride, propenoic-hydroxypropyl acrylate-2-methyl-2'-acrylamide propyl sulphonic acid terpolymer, and polyepoxy succinic acid, which are mixed in weight portion, wherein active substances must reach standardized contents of the experiment. The preparation method comprises the following steps: adding the polyepoxy succinic acid into the 2-phosphonic butane-1, 2, 4-tricarboxylic acid; adding the tetramethylenediamine phosphonic acid into the hydrolyzed polymaleic anhydride; and preparing solutions of the propenoic-hydroxypropyl acrylate-2- methyl-2' -acrylamide propyl sulphonic acid terpolymer and the s-propyloic sulpho succinic acid by steps and mixing the solutions, stirring the solution evenly for 50 to 90 minutes and keeping a temperature range from 12 to 48 DEG C, and obtaining the composite multi-component scale inhibitor for oil field water treatment which has little dosage, wide application range, and can play excellent efficiency under the conditions of high alkali, high hardness and high temperature.

Owner:XINJIANG DELAND

Reverse osmosis water treatment agent and preparation method thereof

InactiveCN101913714AExtended cycleExtended service lifeScale removal and water softeningReverse osmosisSodium salt

The invention discloses a reverse osmosis water treatment agent and a preparation method thereof, which belong to the field of polymer chemistry. The formula of the reverse osmosis water treatment agent consists of the following components in percentage by weight: 10 to 40 percent of the mixture of two organic phosphonic acid compounds, 1 to 10 percent of polyacrylic acid and / or sodium salt of the polyacrylic acid, 2 to 9 percent of hydrolyzed polymaleic anhydride, 2 to 20 percent of sulfonic acid copolymer, 0.1 to 3 percent of dodecyl dimethyl benzyl ammonium chloride and the balance of water. When used in a reverse osmosis water treatment system, the agent can prevent scales of CaCo3, CaSO4, Ca3(PO4)2, BaSO4, SrSO4 and the like and the deposition of iron hydroxide and zinc salt on a reverse osmosis membrane, so that the chemical cleaning period and the service life of the reverse osmosis membrane are prolonged.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

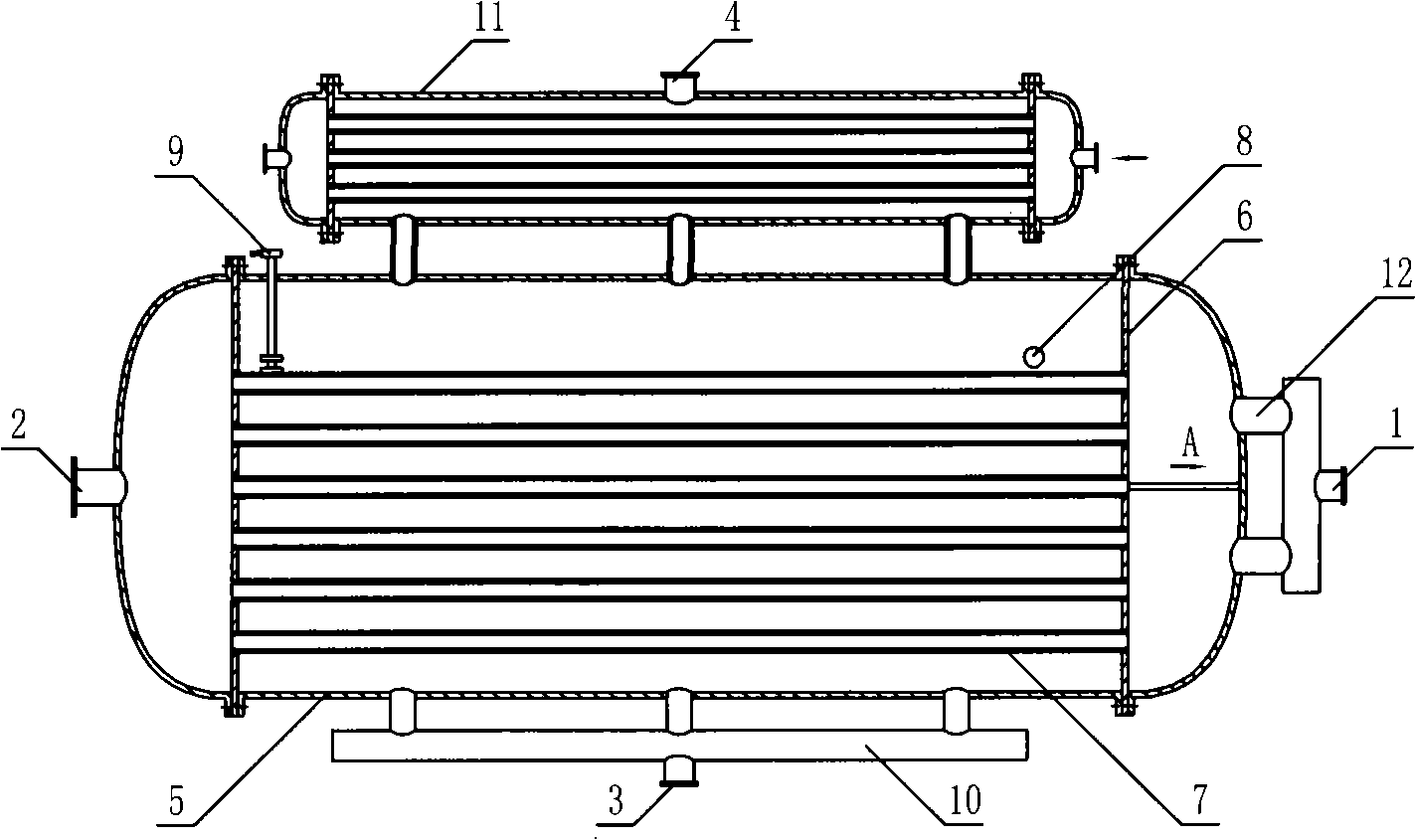

Low water temperature high-efficiency heat exchange tube full solution type evaporator

InactiveCN101275816AImprove heat transfer efficiencyPrevent freezingIndirect heat exchangersStraight tubeWater source

A low water temperature high-efficiency heat exchange tube flooded evaporator comprises a housing separated into water inlet and outlet chambers, and a refrigerant liquid storage chamber through a tube plate and the heat exchange tube; a return opening and a liquid level controller are installed corresponding to liquid level of the refrigerant; the heat exchange tube is composed of a parent tube integrated with axial rib which is in radiate uniform distribution along circumference at the outside surface of the parent tube and which has the height as 0.2 to 0.8 time of outside diameter of the parent tube; the housing of the heat exchange tube is allocated in straight tube single water path mode. The technical plan of the invention also comprises: a gas liquid heat exchanger arranged above the housing; an incoming liquid distributor arranged below the housing; and a water segregator arranged at the side of the water inlet chamber. The invention is provide with high rib coefficient heat exchange tube in straight single water path distribution, which enhances heat exchange efficiency of the evaporator greatly with reduced volume and reduced manufacturing cost, so as to meet requirement of water source heat bump using low temperature water from river, lake or sea as water source in winder.

Owner:王全龄

Polymaleic acid boiler scale-inhibition corrosion inhibitor

ActiveCN101580311AExcellent anti-scaling performanceImprove thermal stabilityScale removal and water softeningSeawaterChemistry

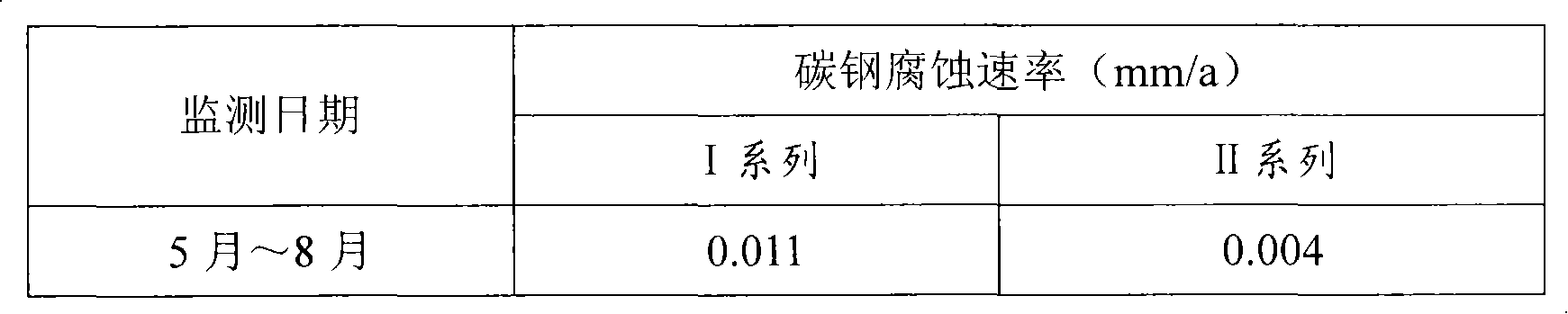

The invention relates to a polymaleic acid boiler scale-inhibition corrosion inhibitor, belonging to the technical field of chemical products, and aiming at providing a polymaleic acid boiler scale-inhibition corrosion inhibitor with high scale-inhibition rate and small corrosion rate. The average molecular weight of the polymaleic acid is larger than 5500, and the components and mass percentage thereof are as follows: 50 to 70 of aqueous solution with the content of polymaleic acid being 50 percent, 15 to 25 of aqueous solution with the content of polyepoxysuccinic acid being 50 percent, 2 to 4 of citric acid, and 10 to 14 of zinc salt. The preparation method comprises the following steps of: adding the polyepoxysuccinic acid into the aqueous solution of the polymaleic acid, and then adding the citric acid and the zinc salt, fully stirring the mixture until no precipitation exists, thus obtaining the final product. In the boiler scale-inhibition corrosion inhibitor, the scale-inhibition rate can reach more than 99 percent, and the corrosion rate is less than 0.011mm / a, thus not only being economical, practical and efficient, but also having significant economic and social benefits. The polymaleic acid boiler scale-inhibition corrosion inhibitor not only can be used for water treatment in the boiler, but also can be used for scale inhibition and corrosion inhibition in circulating cooling water in electrical power and petrochemical industries, seawater desalination, central air conditioner, water heater and the like.

Owner:安徽海瀚水处理科技有限公司

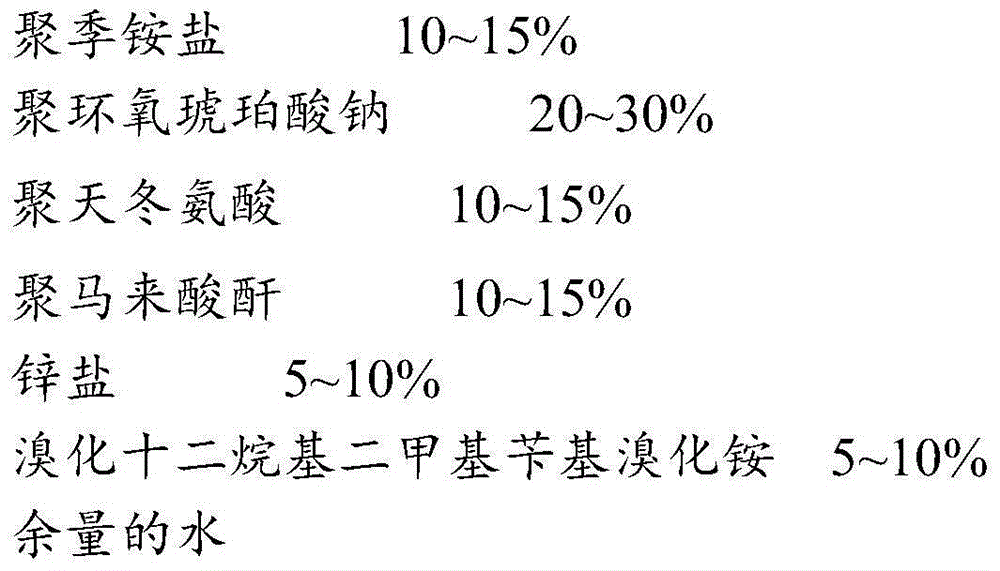

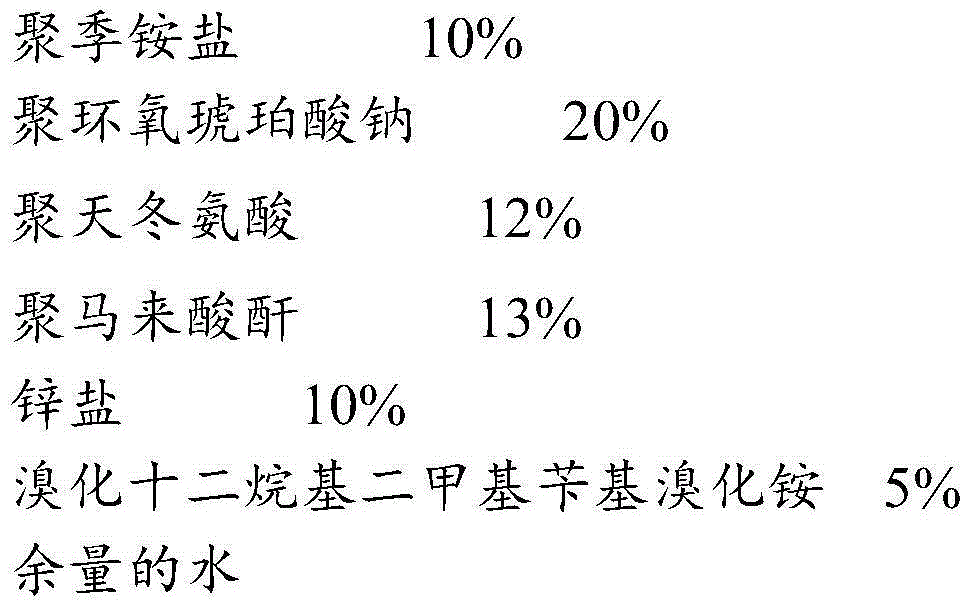

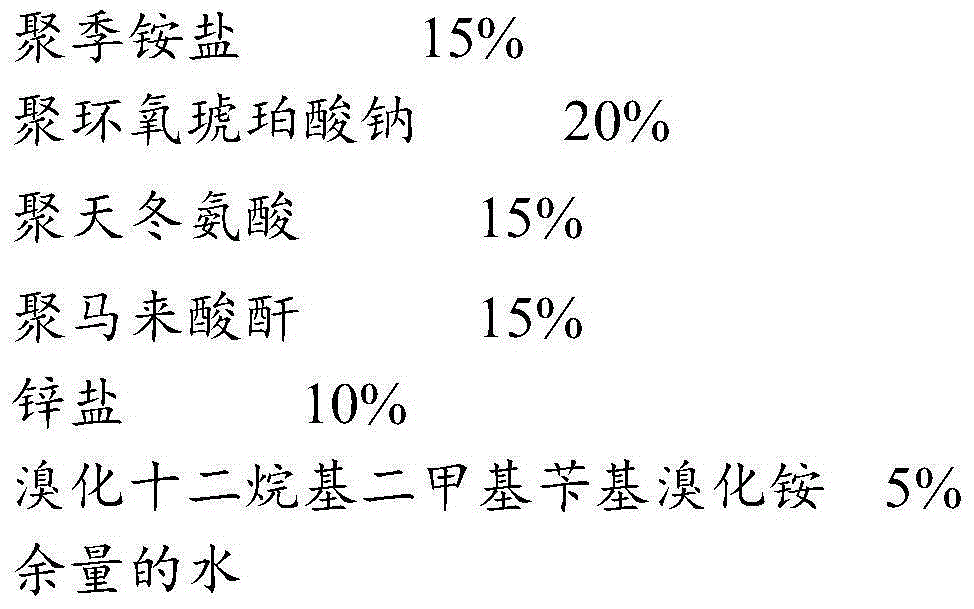

Bactericidal scale and corrosion inhibitor for seawater desalination

The invention provides a bactericidal scale and corrosion inhibitor for seawater desalination, and belongs to the technical field of chemical engineering. The bactericidal scale and corrosion inhibitor comprises, by weight, 10-15% of polyquaternary ammonium salt, 20-30% of sodium polyepoxysuccinate, 20-30% of polyaspartic acid-polymaleic anhydride, 5-10% of a zinc salt, 5-10% of dodecyl dimethyl benzyl ammonium bromide, and the balance of water. The bactericidal scale and corrosion inhibitor has scale inhibition, corrosion inhibition and sterilization functions, and all components of the bactericidal scale and corrosion inhibitor have very good intermiscibility, cooperativity and complementarity, so the bactericidal scale and corrosion inhibitor can substitute present single function scale and corrosion inhibitors and bactericides, and has comprehensive functions; and a formula and a preparation method of the bactericidal scale and corrosion inhibitor are green, compound raw materials adopted in the invention contain no phosphorus and cause no water eutrophication, discharged water causes no pollution to environment, and the preparation method is simple and feasible, is a clean technology, and has no emission of industrial three wastes.

Owner:安徽省蓝天能源环保科技有限公司

Method for synthesizing polyepoxysuecinic acid salt

InactiveCN101538362AReduce hydrolysis rateIncrease polymerization rateScale removal and water softeningCalcium hydroxideFiltration

The invention discloses a method for synthesizing a polyepoxysuecinic acid salt, which is characterized by comprising the following steps of: dissolving maleic anhydride in deionized water; adding a solution of sodium hydroxide at 30 to 60 DEG C with stirring; adding sodium tungstate and hydrogen peroxide when the temperature is controlled to be between 60 to 100 DEG C; adjusting the pH value to 5 to 7 for reaction for 2 to 100 hours; cooling the reaction solution to below 20 DEG C; adding a precipitator, mixing and stirring the precipitator and the solution; performing suction filtration, adding water into filtrate obtained after suction filtration; keeping the pH value between 6 and 7; heating the filtrate added with water to 70 to 100 DEG C to obtain an epoxysuecinic acid salt; preparing a 0.2 to 4.0 mol / L aqueous solution of the epoxysuecinic acid salt; adding calcium hydroxide and a polymerization promoter into the aqueous solution for performing polymerization reaction till liquid turns yellowish and pasty; and cooling the yellowish and pasty liquid to room temperature to obtain the polyepoxysuccinic acid salt. The method has the advantages of good product quality, low raw material cost and product scale inhibition performance advantageous over that of the prior art.

Owner:北京合创同盛科技有限公司

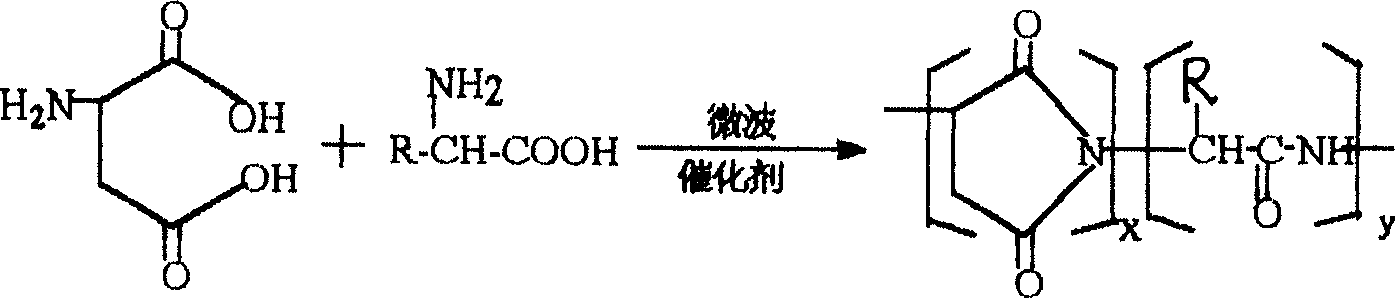

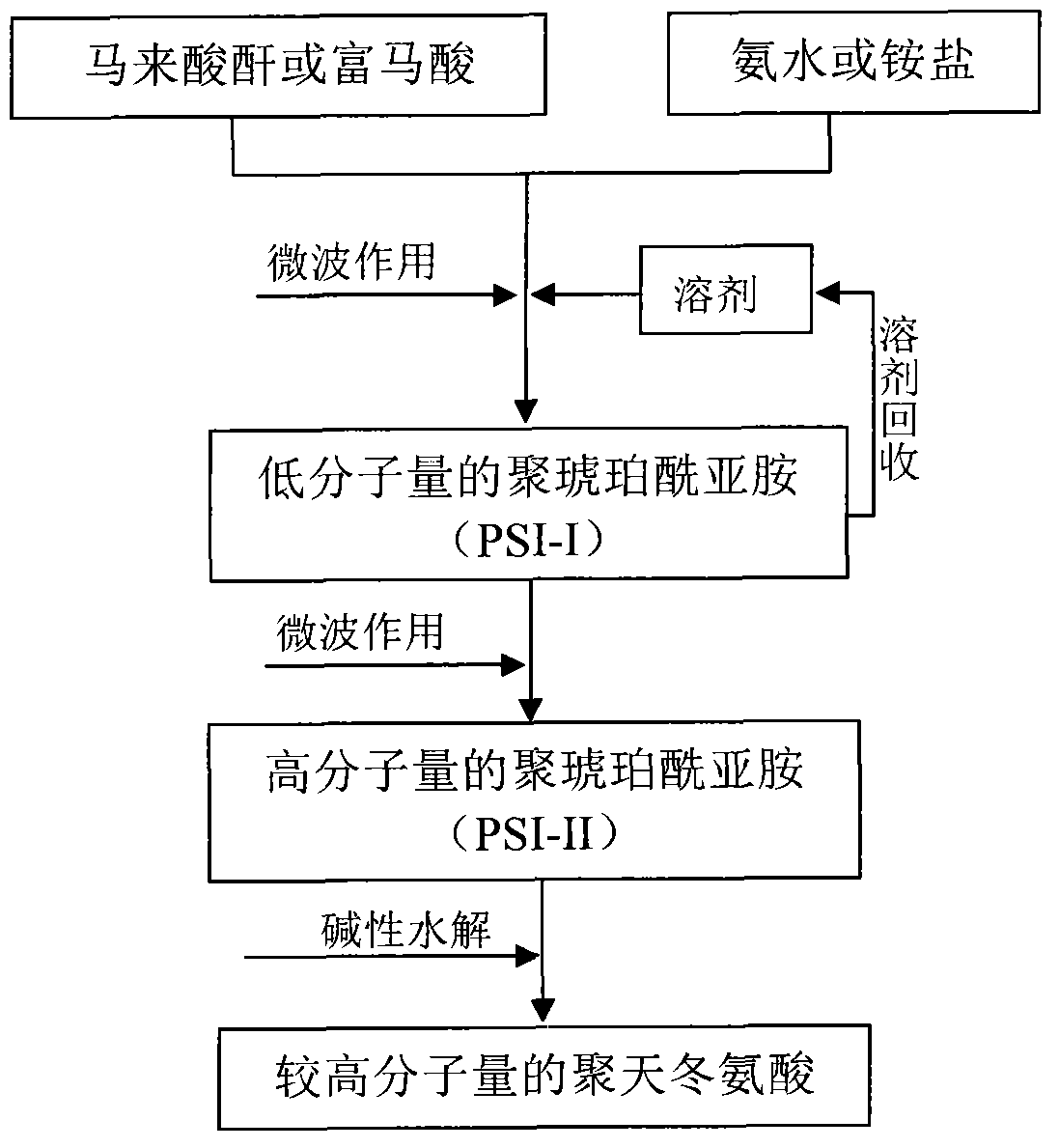

Polyaspartic acid synthesized by microwave half-solvent method

ActiveCN102796263AImprove performanceHigh molecular weightScale removal and water softeningFumaropimaric acidSynthesis methods

The invention relates to a synthesis method of a high-molecular-weight polyaspartic acid, particularly a polyaspartic acid synthesized by a microwave half-solvent method. The invention aims to overcome the defects of low molecular weight of the product, unstable antiprecipitation property, difficulty in solvent separation and the like in the existing microwave synthesis method. The synthetic process comprises the following two steps: 1. by using maleic anhydride or fumaric acid and ammonia water or ammonium salt as raw materials, adding a small amount of solvent, and radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 200-20000W, for 1-40 minutes to synthesize the low-molecular-weight polysuccinimide (PSI-I), wherein the solvent is recycled completely; and 2. by using the PSI-I as the raw material, radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 400-50000W, under the condition of no solvent for 1-30 minutes to synthesize the high-molecular-weight polysuccinimide (PSI-II), and hydrolyzing the PSI-II to obtain the high-molecular-weight polyaspartic acid. The invention has the advantages of simple technique, no need of solvent separation, obviously higher product molecular weight, obviously higher antiprecipitation property, high reaction speed, high yield, energy saving, low pollution and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

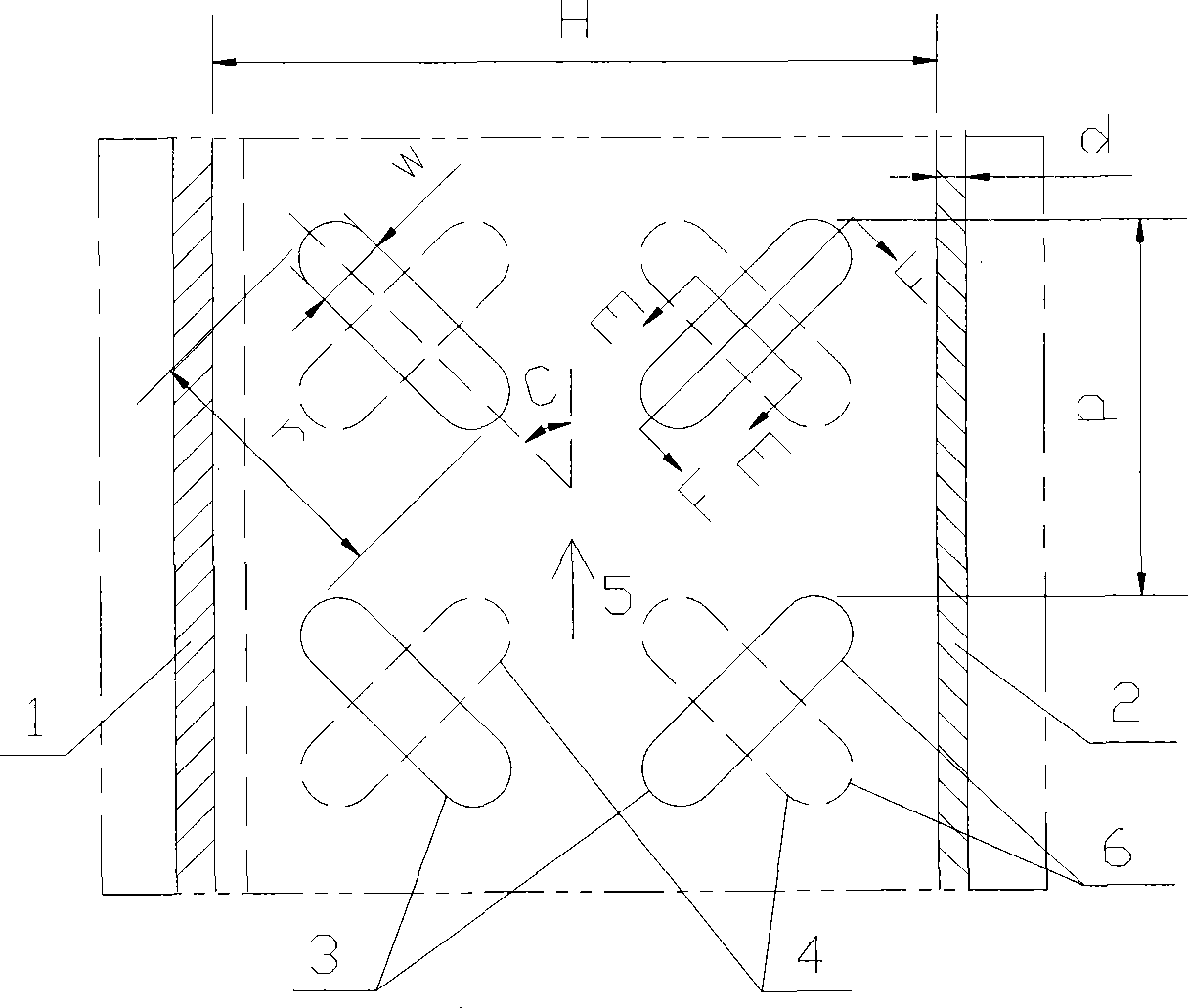

Discontinuous double oblique crossing rib strengthened heat exchange method between flat-plates

InactiveCN101424490ASignificant effect of enhanced heat transferSmall flow resistanceStationary plate conduit assembliesEngineeringFlat panel

The invention discloses a method for reinforcing heat convection between flat plates by incontinuous array diclinic diagonal ribs, which belongs to the technical field of heat convection between rib reinforced flat plates. The technical proposal of the method is that a series of incontinuous prismatic ribs which have certain included angles with the flow directions of fluid between the flat plates and inclines towards two directions are arranged on surfaces of the flat plates involved in the heat convection; protrusions and debosses are formed on two sides of the flat plate surface respectively; and the ribs on the adjacent flat plates are arranged crossly along the surfaces of the flat plates vertically, so as to form arrayed incontinous diclinic diagonal ribs. The method has the advantages of obvious function of reinforcing heat transfer, smaller flow resistance, and simple mould, and better scale resistance function; and compared with the prior art for reinforcing heat exchange fins / plates, the method also has the advantages of low processing and manufacturing cost, good applicability, and the like.

Owner:TSINGHUA UNIV

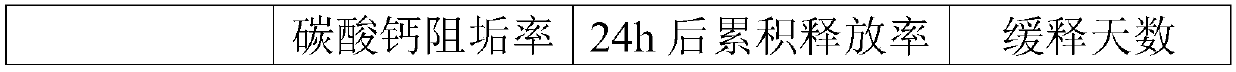

Scale inhibition particle as well as preparation method and application thereof

PendingCN111233176AGood sustained release effectAchieve long-term effectTreatment using complexing/solubilising chemicalsControl releasePhysical chemistry

The invention provides a scale inhibition particle as well as a preparation method and application thereof, the scale inhibition particle comprises scale inhibition powder, an adsorption material anda binder, and the binder is a combination of a water-soluble binder and a cured binder; the scale inhibition particle prepared by the invention has the advantages of strong descaling capability, longscale inhibition life, good water resistance, excellent water purification function, good slow release effect, controllable release rate, long action, simple preparation process and low cost, are usedfor water quality scale inhibition treatment, and are especially suitable for scale inhibition treatment of household water.

Owner:BEYCLEAN ENVIRONMENTAL PROTECTION TECH

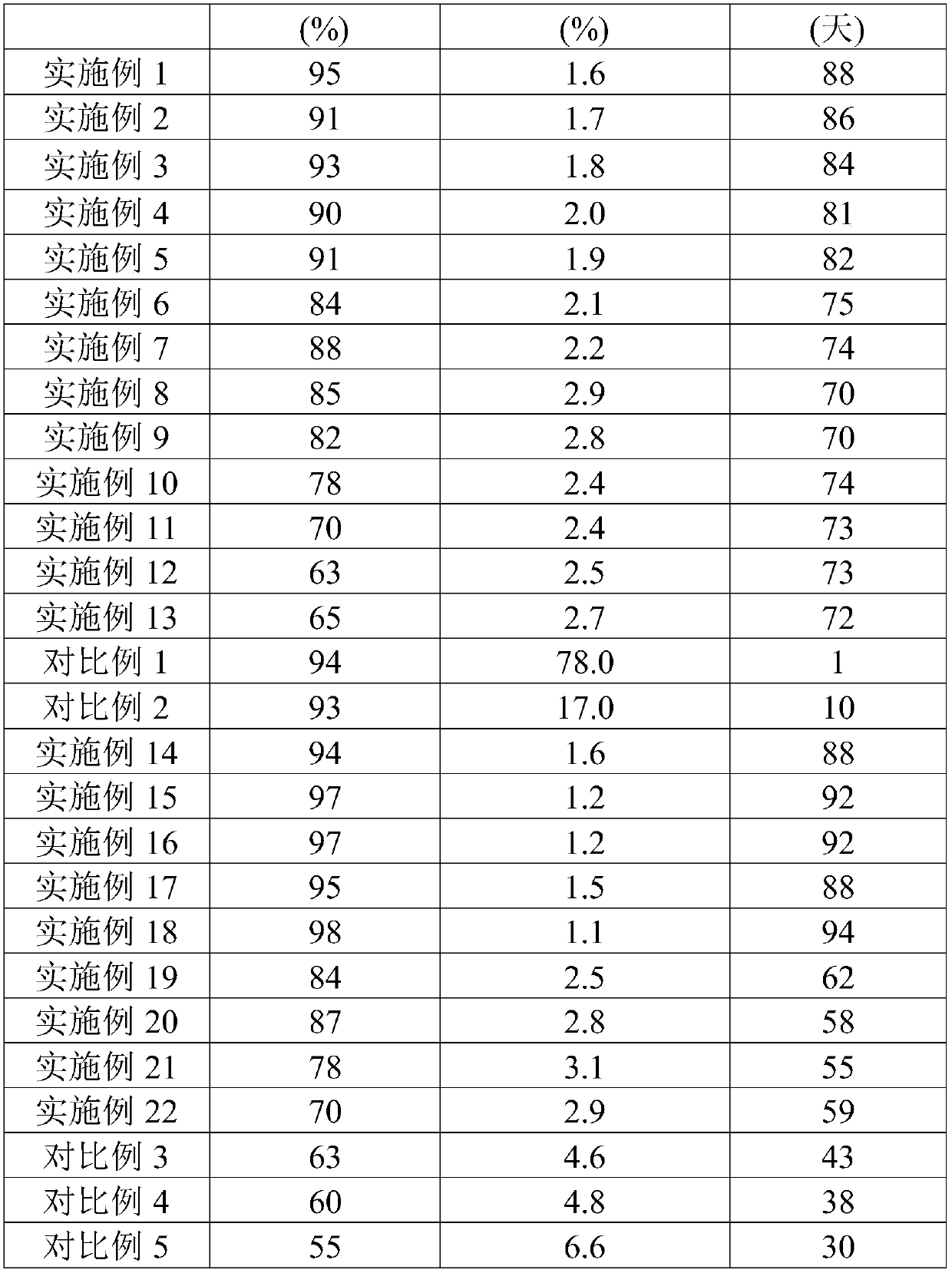

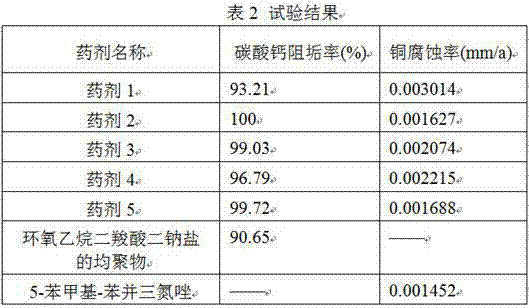

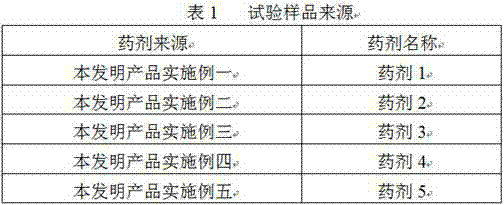

Long-acting sustained-release scale and corrosion inhibitor for circulating water

InactiveCN104743685AStrong scale inhibition and dispersibilityStrong anti-scaling and dispersing performance, strong corrosion inhibition performance on carbon steelSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsCelluloseEngineering

The invention aims to provide a long-acting sustained-release scale and corrosion inhibitor for circulating water. The long-acting sustained-release scale and corrosion inhibitor for circulating water is prepared from the following raw materials in percentage by weight: 30-52% of deionized water, 0.2-1% of guar gum, 4-6% of hydroxypropyl methylcellulose, 30-40% of an epoxy ethane-dicarboxylic acid-disodium salt homopolymer, 10-15% of a crylic acid- isopropenyl phosphonic acid copolymer, 4-6% of 5-benzyl-benzotriazole, 0.025-0.05% of 5-chloro-2-methyl-4-isothiazolin-3-one and 0.007-0.017% of 2-methyl-4-isothiazolin-3-one. The sustained-release scale and corrosion inhibitor prepared by the invention achieves a scale and corrosion inhibiting effect when being dissolved slowly, has a long acting time and achieves a good effect. In addition, the sustained-release scale and corrosion inhibitor is a solid agent and therefore the package and transportation cost is reduced.

Owner:WEIHAI XIANGYU TECH

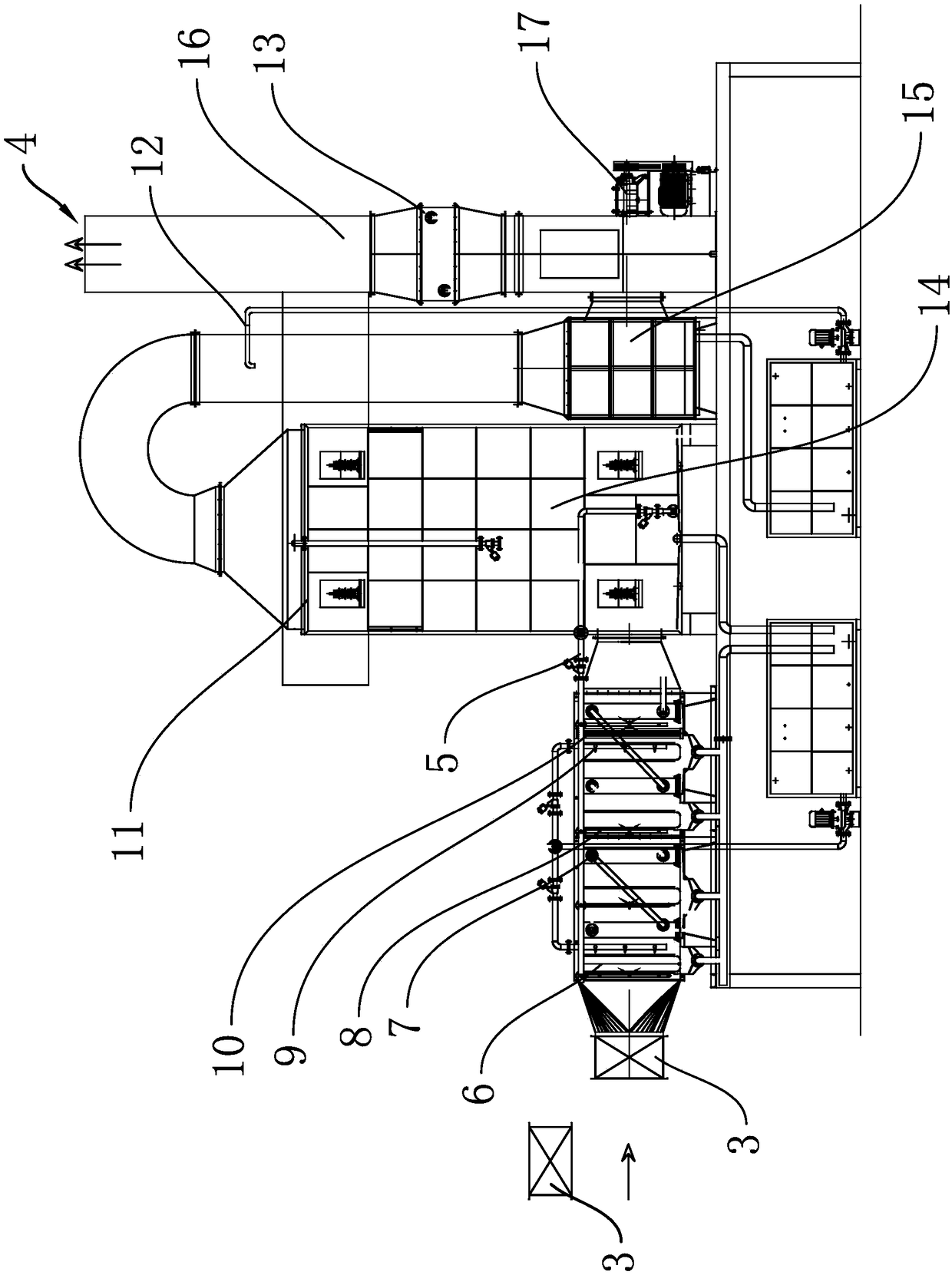

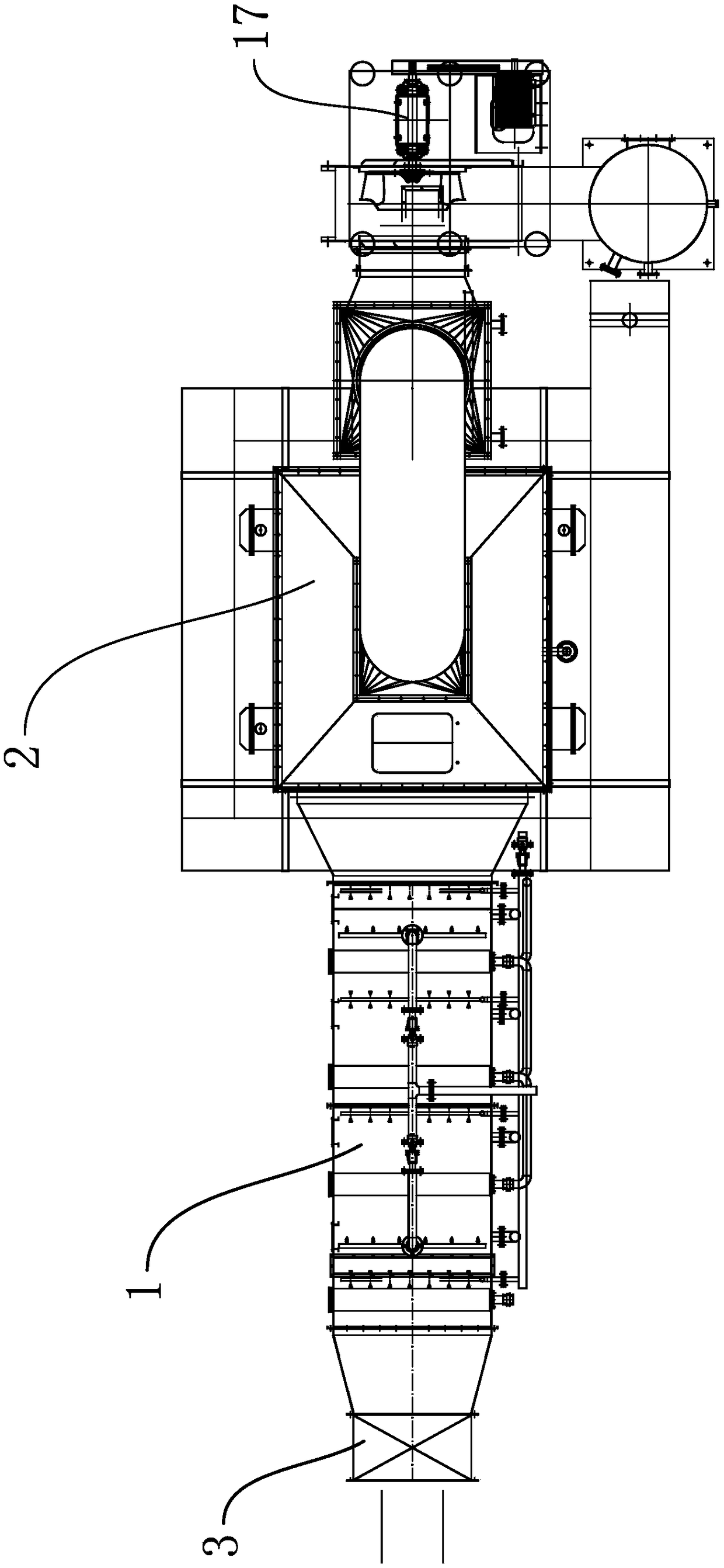

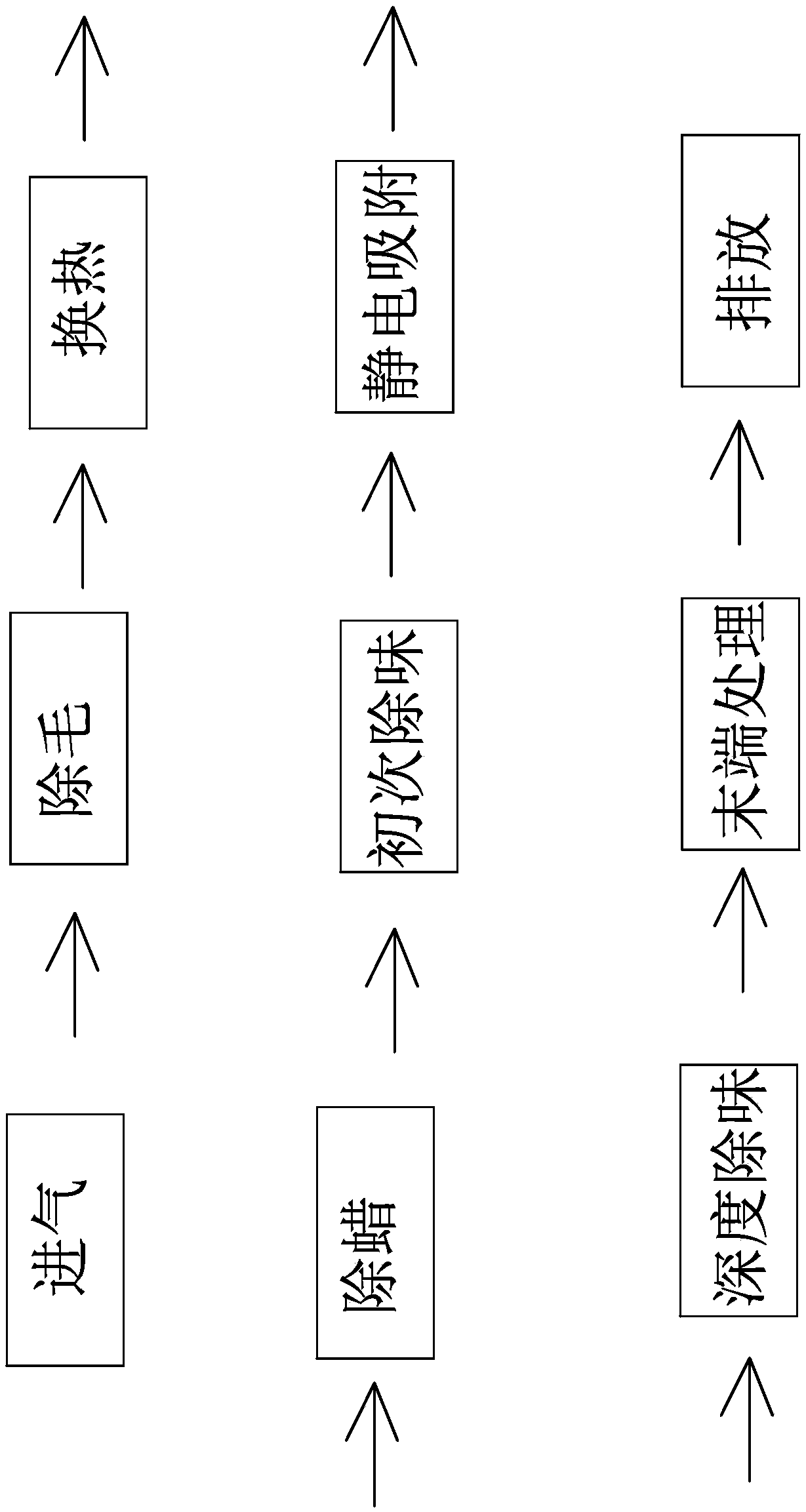

Atmospheric pollutant treatment technology

InactiveCN109225633AImplement automatic filteringGuaranteed uptimeElectrostatic separationMicro nanoParticulates

The invention relates to an atmospheric pollutant treatment technology which comprises the steps: A) gas feeding: inflating waste gas to be treated into a waste gas pretreatment device; B) flock removal: making the waste gas pass through an automatic flock removing mechanism to remove flocks in the waste gas; C) heat exchange: making the flock removed waste gas pass through a gas-liquid heat exchange mechanism to exchange heat with the gas-liquid heat exchange mechanism to reduce the temperature of the waste gas; D) wax removal: making the heat exchanged waste gas pass through a wax and impurity removing mechanism to remove wax in the waste gas; E) primary deodorization: making the wax removed waste gas pass through a primary microbubble deodorizing mechanism to primarily deodorize the waste gas; F) electrostatic adsorption: inflating the primarily-deodorized waste gas into a purifying tower from bottom to top and removing lamp black and particles in the waste gas through an electrostatic adsorption device; G) deep deodorization: making the electrostatically-adsorbed waste gas pass through a micro-nano bubble deep deodorizing mechanism from top to bottom to achieve deep deodorization; H) terminal treatment: making the deep-deodorized waste gas pass through a terminal white steam removing mechanism from bottom to top to remove white steam; I) discharge.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

Method for synthetizing polyaspartic acid by microwaves in ionic liquid

InactiveCN102643425ARapid responseEvenly heatedScale removal and water softeningSynthesis methodsReaction rate

The invention discloses a method for synthetizing polyaspartic acid by microwaves in ionic liquid and relates to a method for synthetizing the polyaspartic acid. The invention aims to solve the problems that the scale inhibition effect of a synthetic product is not good in the synthesis method of the polyaspartic acid in traditional ionic liquid. The method for synthetizing the polyaspartic acid by the microwaves in the ionic liquid comprises the following steps of: I-, preparing the ionic liquid; II-, polymerizing; III-, performing hydrolysis reaction; and IV-, performing precipitation drying. The invention provides a novel method for synthetizing the polyaspartic acid, which is high in reaction rate and short in reaction time. The scale inhibition efficiency on CaCO3 reaches 96.77 percent. Compared with a traditional liquid polymerization process, the scale inhibition efficiency is increased by 8 percent. The method for synthetizing the polyaspartic acid by the microwaves in the ionic liquid can be used for the field of cooling by using circulating water and boiler heating.

Owner:HEILONGJIANG UNIV

Scale corrosion inhibitor for poly-maleic anhydride boiler

InactiveCN101269887AExcellent anti-scaling performanceImprove thermal stabilityScale removal and water softeningCentral air conditioningMaleic anhydride

The invention provides an antisludging inhibiter of a polymaleic anhydride boiler, which belongs to the chemical product technical field, and aims at providing an antisludging inhibiter of the polymaleic anhydride boiler, which has high ansludging ratio and small corrosion rate. The antisludging inhibiter has the material components and the mass percents thereof that: water solution with the content of polymaleic acid being 50 percent is 60-70, water solution with the content of polyepoxysuccinic acid being 50 percent is 15-25, citric acid is 2-4, and zinc salt is 10-14. The polyepoxysuccinic acid is added into the water solution of polymaleic acid, and the citric acid and the zinc salt are added, and the full mixing is performed to obtain the antisludging inhibiter. The antisludging ratio of the antisludging inhibiter of the invention can reach up to more than 99 percent, and the corrosion rate is less than 0.011 mm / a, so the antisludging inhibiter is not only economic and practical, but also has good effect, and has very marked economic and social benefits, is used for the water treatment in the boiler, and also can be applied to the scale prevention and the scale boiling of central air conditioning systems and water heaters, etc.

Owner:邢献军

Environment-friendly high-efficiency compound corrosion and scale inhibitor

InactiveCN104402125AExcellent anti-scaling performanceEnvironmental protection is goodTreatment using complexing/solubilising chemicalsSodium polyacrylateChemistry

The invention discloses an environment-friendly high-efficiency compound corrosion and scale inhibitor. The environment-friendly high-efficiency compound corrosion and scale inhibitor comprises the following raw materials in parts by weight: 20 to 40 parts of polyepoxysuccinic acid, 15 to 30 parts of lignosulfonic acid, 10 to 15 parts of sodium polyacrylate, 8 to 12 parts of sodium gluconate, 5 to 10 parts of sulfite, 3 to 8 parts of nitrite, 1 to 5 parts of azole derivatives, 1 to 3 parts of a dispersant, 3 to 8 parts of a synergist, and 0.2 to 1 part of a surfactant. The environment-friendly high-efficiency compound corrosion and scale inhibitor has excellent scale inhibition performance, has high environment friendliness, has a very good effect on inhibiting the production of calcium carbonate scale, and has a certain effect on inhibiting the growth of bacteria, and can avoid an eutrophication problem of water quality caused by the emission of phosphorus; the environment pollution is lightened; the multiplication of microbes is reduced.

Owner:昆山瑞昱化工有限公司

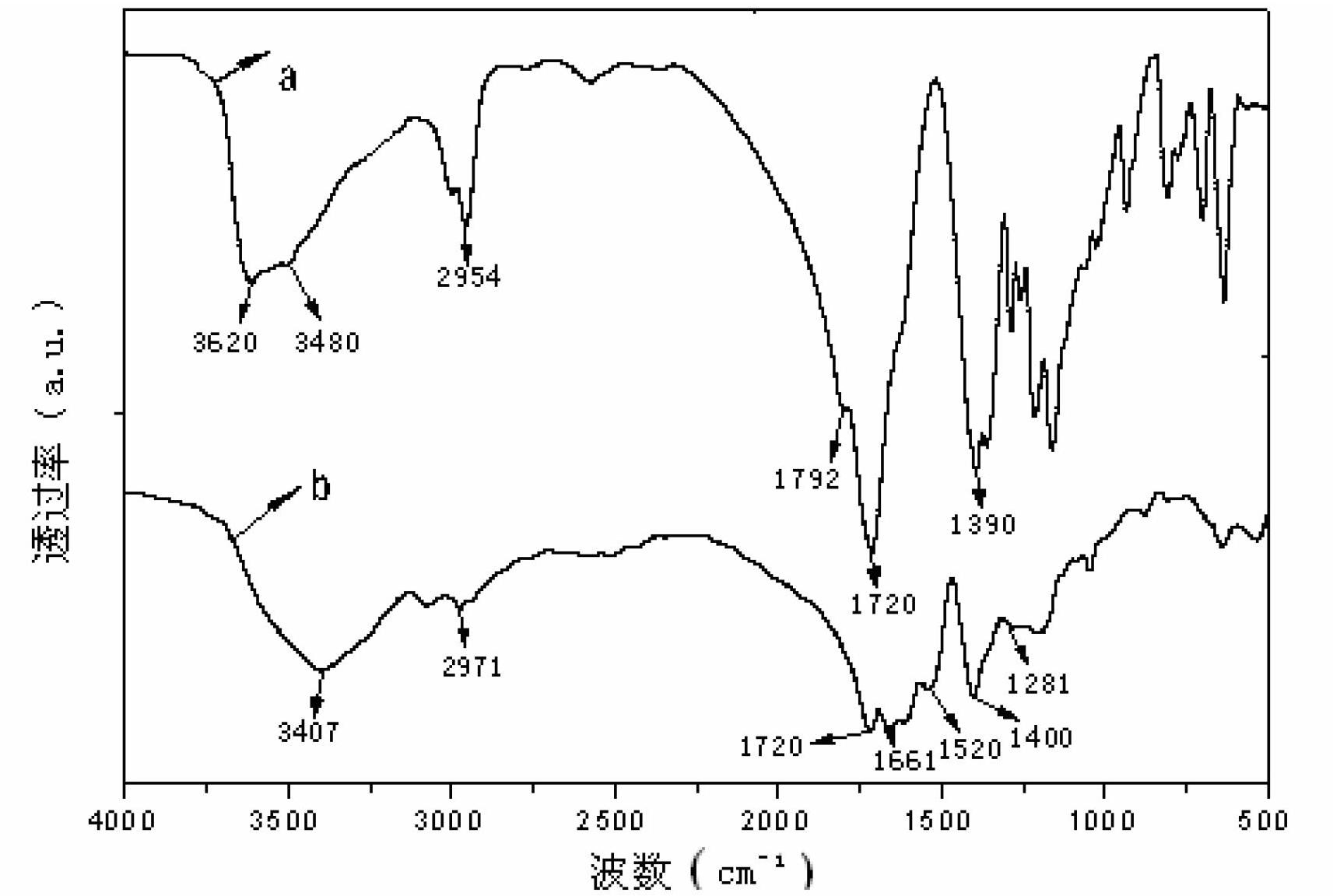

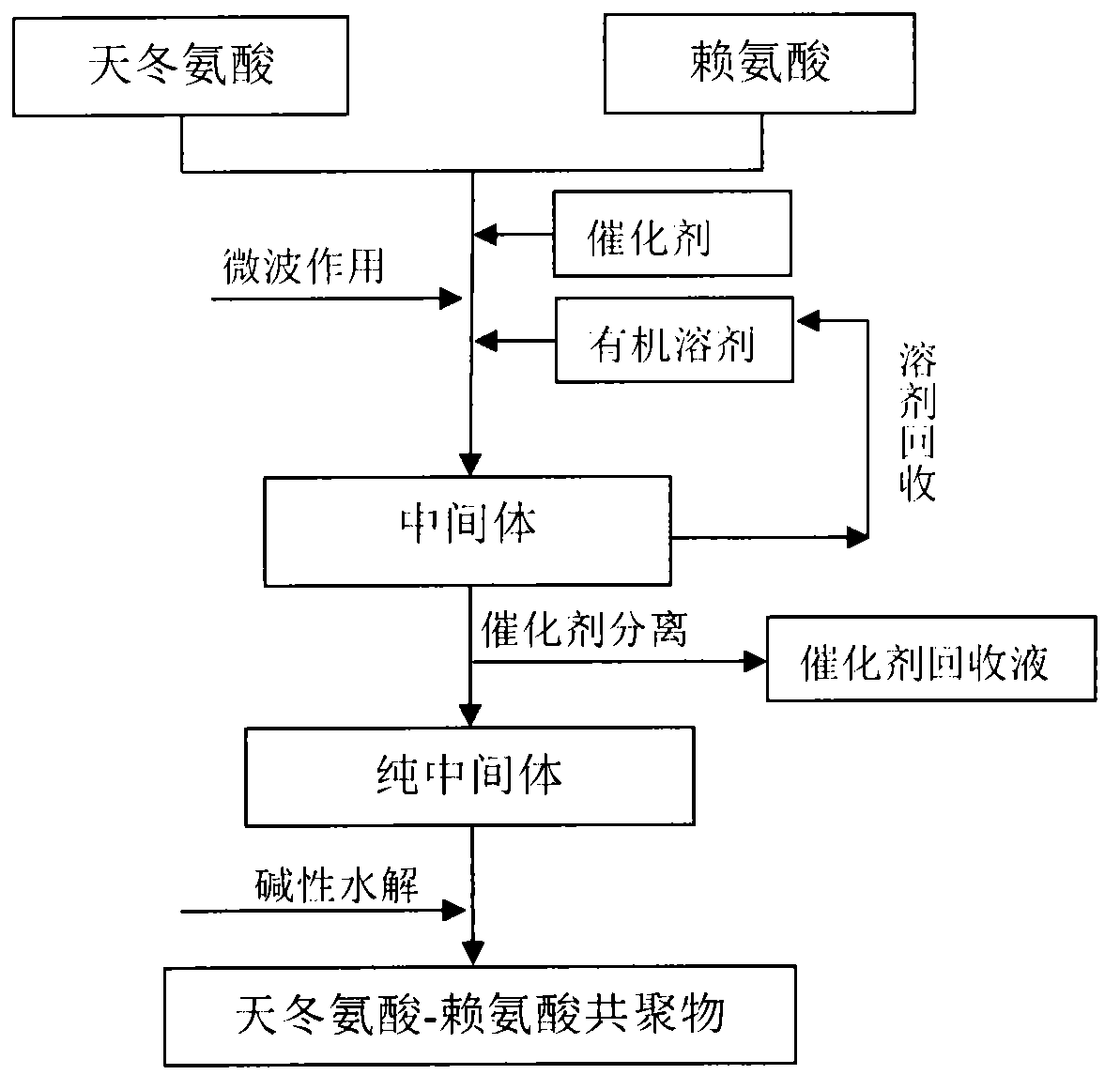

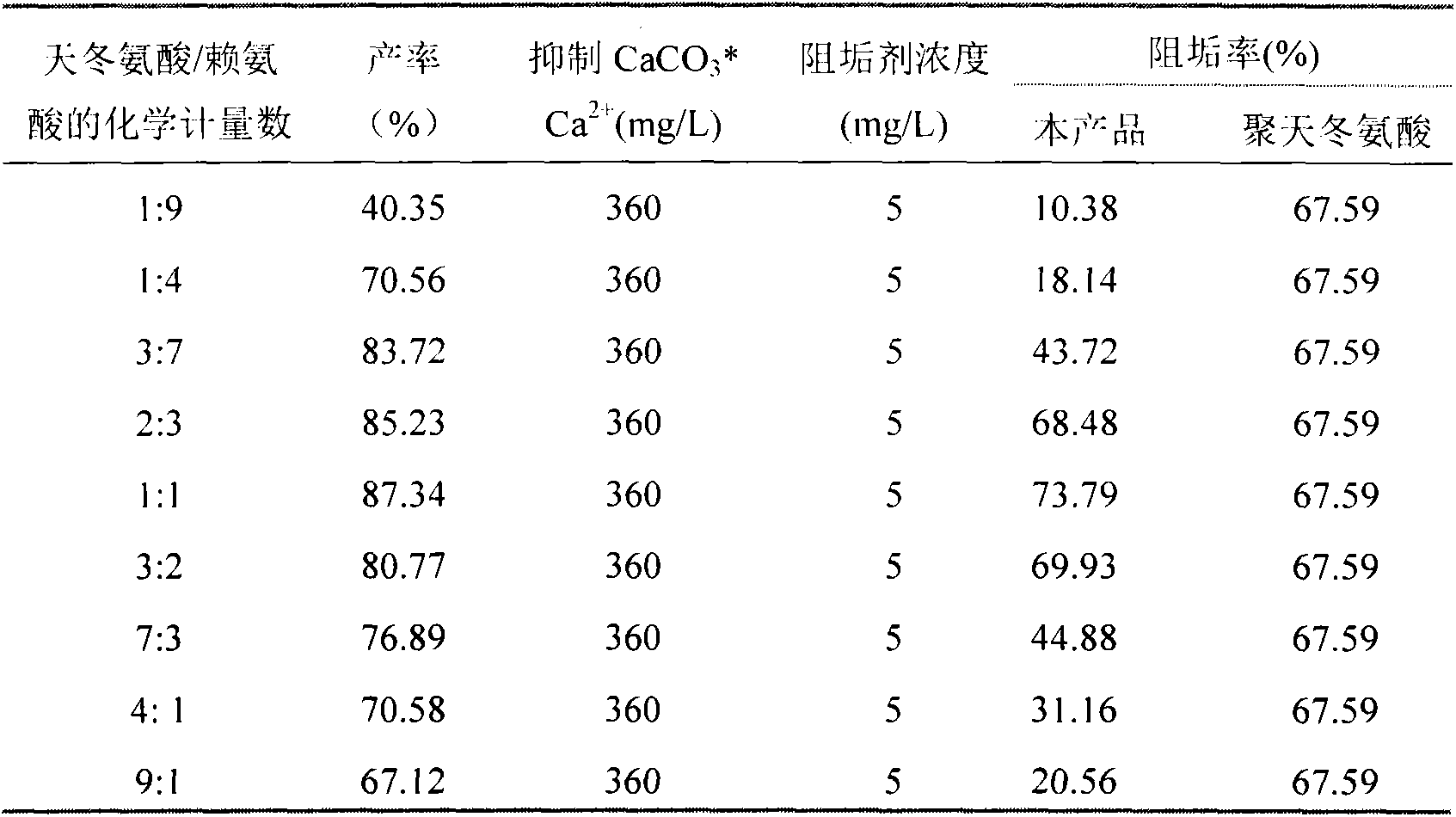

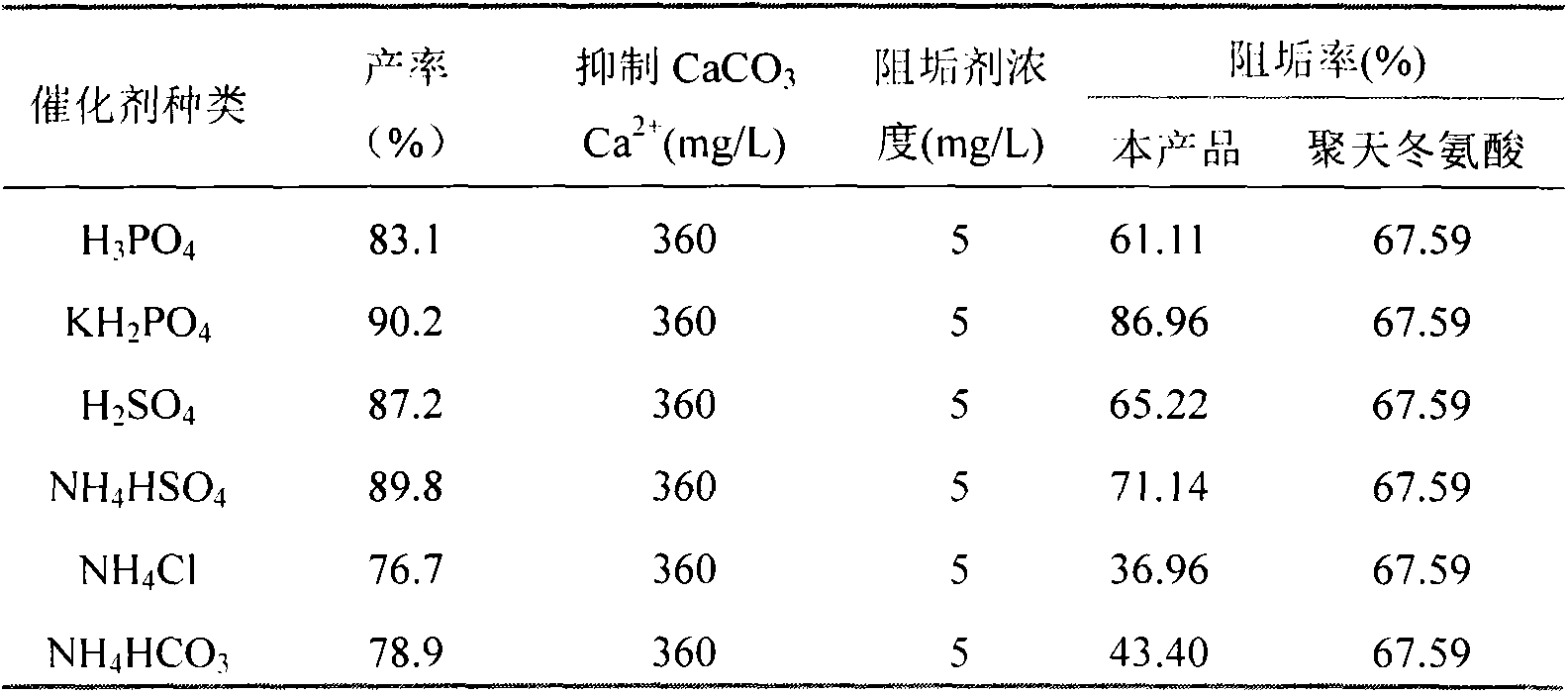

Aspartic acid-lysine copolymer and synthetic method thereof

ActiveCN104387585AImprove performanceExcellent anti-scaling performanceScale removal and water softeningStructural formulaCopolymer

The invention relates to modified polyaspartic acid and a synthetic method thereof, in particular to an aspartic acid-lysine copolymer and a synthetic method thereof and aims to solve the problems that the conventional polyaspartic acid modified product has the disadvantages of complex synthetic process, low reaction speed, unstable product performance and low CaCO3 scale inhibition rate. The structural formula of the aspartic acid-lysine copolymer is shown in the specification, and the synthetic process comprises the following steps: aspartic acid and lysine are used as the raw material, a small amount of a catalyst and an appropriate amount of an organic solvent are added under the microwave condition of 865-965 MHz or 2400-2500 MHz and 400-10000 W, and radiation is carried out for 1-30 min, so that a midbody is synthesized, the organic solvent is recovered in the form of gas, and pure water drip washing, separation of a catalyst and basic hydrolysis are sequentially performed on the midbody so as to obtain the aspartic acid-lysine copolymer. The aspartic acid-lysine copolymer and the synthetic method thereof have the advantages of simple process, high reaction speed, high yield, energy conservation, less pollution and obvious improvement of product performance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

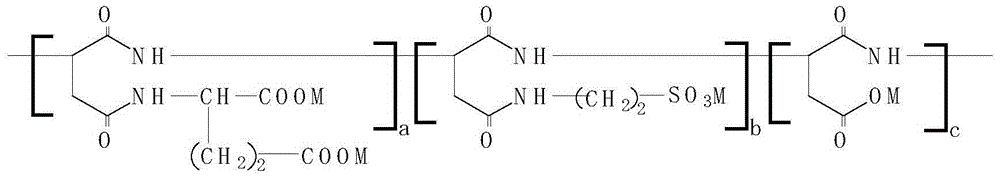

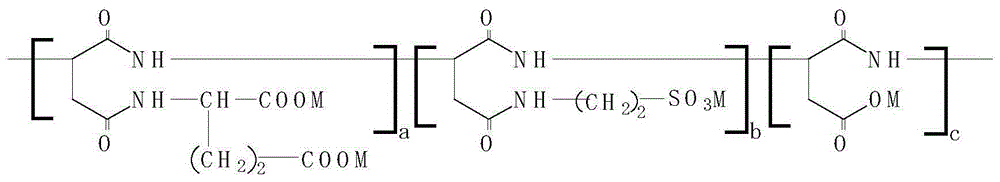

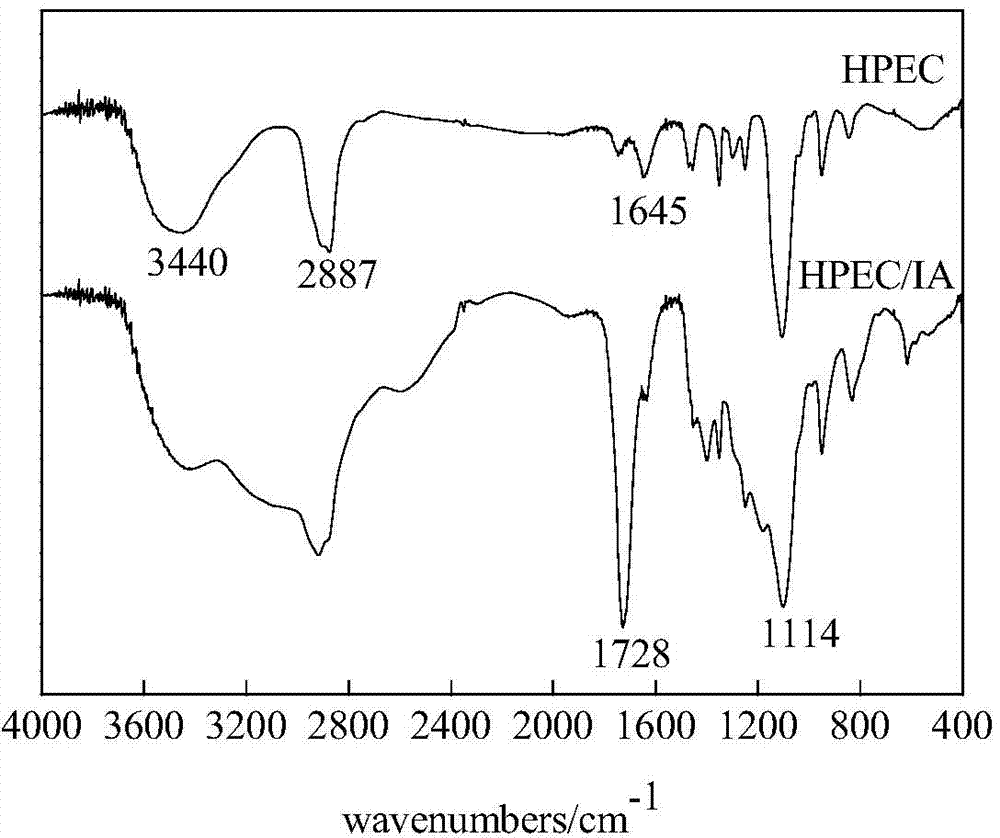

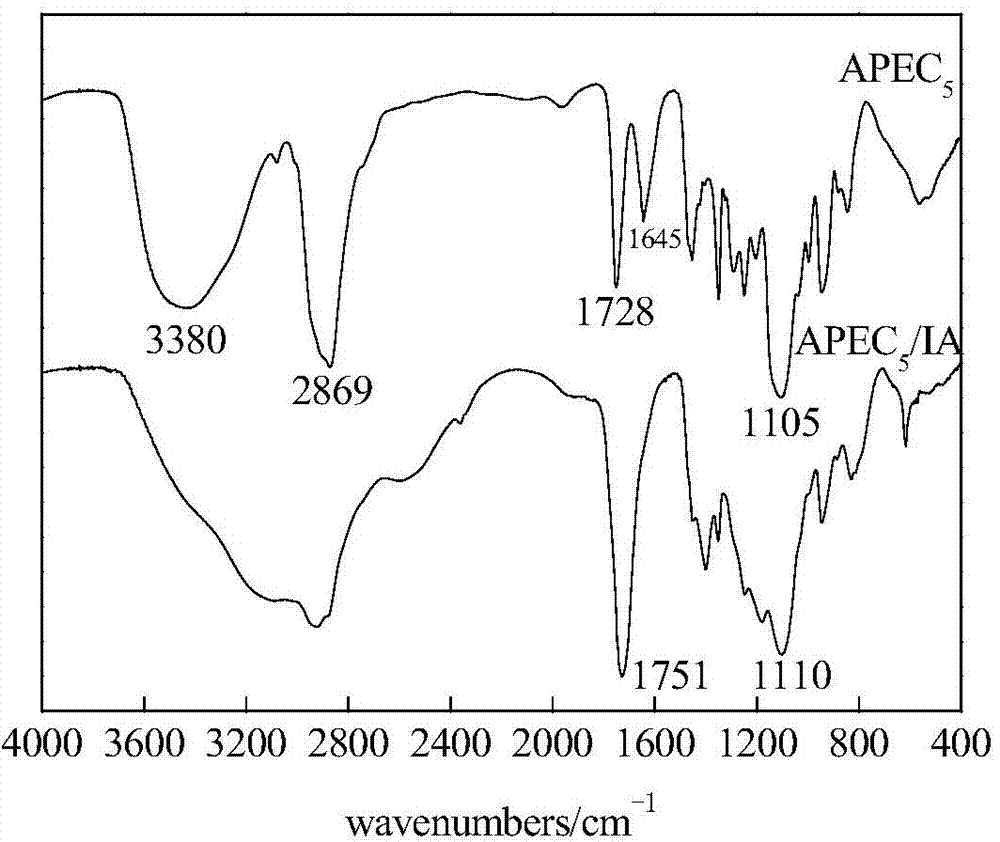

Preparation method of modified polyaspartic acid copolymer

InactiveCN104530428AOvercome the shortcomings of a single, simple structureExcellent anti-scaling performanceScale removal and water softeningSide chainCarboxylic acid

The invention discloses a preparation method of a modified polyaspartic acid copolymer. The preparation method is characterized in that maleic anhydride and urea are used as raw materials, a sulfonic acid group and a carboxy group are introduced to a side chain of polyaspartic acid by adopting polymerization and co-polymerization methods, and the defects that the polyaspartic acid is single in functional group, single in structure, poor in effect for resisting the scale of calcium phosphate, poor in scale-resistant effect and poor in dispersion capacity can be overcome. The product has a good scale-resistant effect for the calcium phosphate scale and calcium sulfate scale; moreover, the dispersion capacity also can be improved, and the zinc stabilizing effect is good. In addition, the product is non-toxic, pollution-free, easy to biologically degrade and capable of meeting the environmental protection requirement; moreover, the preparation process is environment-friendly and efficient, the raw material cost is low, and the economical benefit can be realized. The industrialized production can be facilitated.

Owner:ANHUI UNIVERSITY

Preparation method of olefin ether and unsaturated carboxylic acid copolymer anti-sludging agent

InactiveCN103570145AInitiation efficiency is highPromote polymerizationScale removal and water softeningSolubilityCopolymer

The invention belongs to the technical field of water treatment and provides a preparation method of an olefin ether and unsaturated carboxylic acid copolymer anti-sludging agent. The anti-sludging agent is synthesized through the following steps: (1) adding halogenated acid into a reaction system after the olefin ether is alkalized, raising the temperature to react, filtering, distilling, and drying in vacuum to obtain a carboxylic acid reaction monomer of the olefin ether; (2) raising the temperature and enabling the carboxylic acid reaction monomer of the olefin ether and the unsaturated carboxylic acid to react under the action of an initiator system, and cooling to the room temperature to obtain the olefin ether and unsaturated carboxylic acid copolymer anti-sludging agent. The anti-sludging agent contains a super-hydrophilic polyether structure and a large number of carboxyl, is good in water solubility, reacts easily with calcium ions in a circulating water system, and has an excellent anti-sludging property for calcium carbonate, calcium sulfate and calcium phosphate.

Owner:CHANGZHOU UNIV

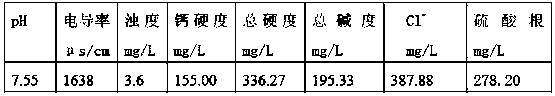

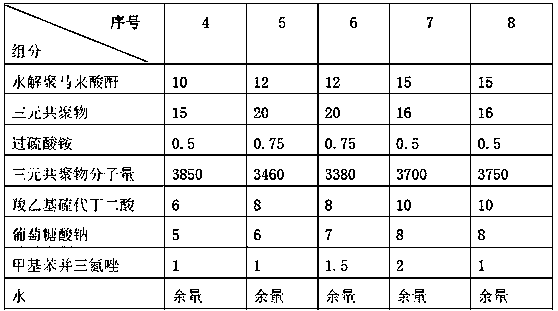

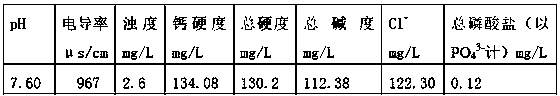

Environmentally-friendly scale and corrosion inhibitor and preparation method thereof

PendingCN109052675AGood scale and corrosion inhibitionGood anti-scaling and dispersing effectSpecific water treatment objectivesScale removal and water softeningGluconic acidTert butyl

The invention discloses an environmentally-friendly scale and corrosion inhibitor and a preparation method thereof. The environmentally-friendly scale and corrosion inhibitor comprises the following ingredients in parts by weight relative to the total mass of scale and corrosion inhibitor: 10-15% of hydrolytic polymaleic anhydride, 14-20% of acrylic acid / 2-acrylamide-2-methyl propanesulfonic acid / n-tert-butyl acrylamide terpolymer, 0.5-1% of ammonium persulfate, 5-10% of carboxyalkylthiosuccinic acid, 5-8% of sodium gluconate, 1-2% of methylbenzotriazole and the balance of deionized water. The scale and corrosion inhibitor has the advantages of no phosphorus or zinc, environment protection and excellent scale and corrosion inhibition effect.

Owner:CHANGZHOU KEWEI TIANSHI ENVIRONMENTAL TECH

Scale inhibitor for circulating water

ActiveCN101412568BGood anti-scaling effectAdaptableScale removal and water softeningPolyaspartic acidMethylphosphinic acid

The invention relates to a circulating water scale inhibitor, which comprises the following components by weight portion: 2. 5 to 2.8 portions of PASP (polyaspartic acid), 1 to 1.2 portions of ATMP (amino trimethylene phosphonic acid), 2.4 to 2.6 portions of HPMA (hydrolyzed polymaleic anhydride), 1.2 to 1.4 portions of AA / AMPS (acrylic acid and 2-acrylamide-2-methyl propane sulfonic acid copolymer), 1.1 to 1.3 portions of PAA (polyacrylic acid), and 0.7 to 1.8 portions of water. The scale inhibitor prepared by the formulation is environment-friendly, has the characteristics of safety and reliability, easy preparation, convenient use and the like, and is suitable to be used as medicaments for preventing scale on circulating water systems in the fields of electric power, chemical engineering, medicine, petroleum, and the like.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com